Page 1

Owner's Manual/Manual Del Propietario

II:RRFTSMRNI

1/2 HP

315MNz GARAGE DOOR OPENER

ABRIDOR DE PUERTA DE COCHERA DE 315MN=

For Residential Use Only/Solo para uso residencial

Model/Modelo • 139.53914D

Read and follow all safety rules

and operating instructions before

first use of this product.

Fasten the manual near the garage

door after installation.

Periodic checks of the opener are

required to ensure safe operation.

rlq

m

Leer y seguir todas las reglas de _,_

seguridad y las instrucciones de Z=

operacion antes de usar este 0

producto por primera vez. r--

Guardar este manual cerca de la

puerta de la cochera.

Se deben realizar revisiones

periodicas del abridor de puertas

para asegurar su operacion

segura.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

www.sears.com/craftsman

Page 2

TABLE OF CONTENTS

Introduction 2- 7

Safety symbol and signal word review ........................ 2

Preparing your garage door ........................................ 3

Tools needed ............................................................... 3

Planning .................................................................. 4-5

Carton inventory .......................................................... 6

Hardware inventory ..................................................... 7

Assembly 8.11

Assemble the rail and install the trolley ...................... 8

Fasten the rail to the motor unit and

Install the idler pulley ................................................... 9

Install the belt and attach the belt cap retainer ......... 10

Set the tension .......................................................... 11

Installation 11-26

Installation safety instructions .................................... 11

Determine the header bracket location ..................... 12

Install the header bracket .......................................... 13

Attach the rail to the header bracket ......................... 14

Position the opener ................................................... 15

Hang the opener ....................................................... 16

Install the door control ............................................... 17

Install the lights ......................................................... 18

Attach the emergency release rope and handle ....... 18

Electrical requirements .............................................. 19

Install The Protector System ®.............................. 20-22

Fasten the door bracket ....................................... 23-24

Connect the door arm to the trolley ..................... 25-26

Adjustment 27-29

Adjust the travel limits ............................................... 27

Adjust the force ......................................................... 28

Test the safety reversal system ................................. 29

Test The Protector System ®...................................... 29

Operation 30-34

Operation safety instructions ..................................... 30

Using your garage door opener ................................ 30

Using the wall-mounted Door Control ....................... 31

To open the door manually ........................................ 31

Care of your garage door opener .............................. 32

Having a problem? .................................................... 33

Diagnostic chart ......................................................... 34

Programming 35-36

To add or reprogram a hand-held remote control .....35

To erase all codes ..................................................... 35

3-Function Remotes .................................................. 35

To add, reprogram or change

a Keyless Entry PIN .................................................. 36

Repair Parts 37.38

Rail assembly parts ................................................... 37

Installation parts ........................................................ 37

Motor unit assembly parts ......................................... 38

Accessories 39

Warranty 39

Repair Parts & Service Back Cover

INTRODUCTION

Safety Symbol

and Signal Word Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated,

maintained and tested in strict accordance with the instructions and warnings contained in this manual.

When you see these Safety Symbols and Signal

Words on the following pages, they will alert you to

Mechanical

Electrical

the possibility of serious injury or death if you do

not comply with the warnings that accompany them.

The hazard may come from something mechanical

or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following

pages, it will alert you to the possibility of damage to

your garage door and/or the garage door opener if

you do not comply with the cautionary statements

that accompany it. Read them carefully.

Page 3

Preparing your garage door

Before you begin:

• Disable locks.

• Remove any ropes connected to garage door.

• Complete the following test to make sure your

garage door is balanced and is not sticking or

binding:

1. Lift the door about halfway as shown. Release

the door. If balanced, it should stay in place,

supported entirely by its springs.

2. Raise and lower the door to see if there is any

binding or sticking.

If your door binds, sticks, or is out of balance, call a

trained door systems technician.

To prevent possible SERIOUSINJURYor DEATH:

• ALWAYScall atrained door systems technician if

garage door binds, sticks, or is out of balance.An

unbalancedgarage door may not reverse when

required.

• NEVERtry to loosen,moveor adjust garage door,door

springs, cables, pulleys, brackets ortheir hardware,all

of which are under EXTREMEtension.

• Disable ALLlocks and removeALL ropes connectedto

garage door BEFOREinstalling and operating garage

door opener to avoid entanglement.

To prevent damageto garage door andopener:

• ALWAYSdisable locks BEFOREinstalling and operating

the opener

• ONLYoperategaragedoor opener at 120V,60 Hzto

avoid malfunction and damage

Sectional Door

One-Piece Door

Level (optional)

Drill

Tape Measure

3/16", 5/16'

and 5/32'

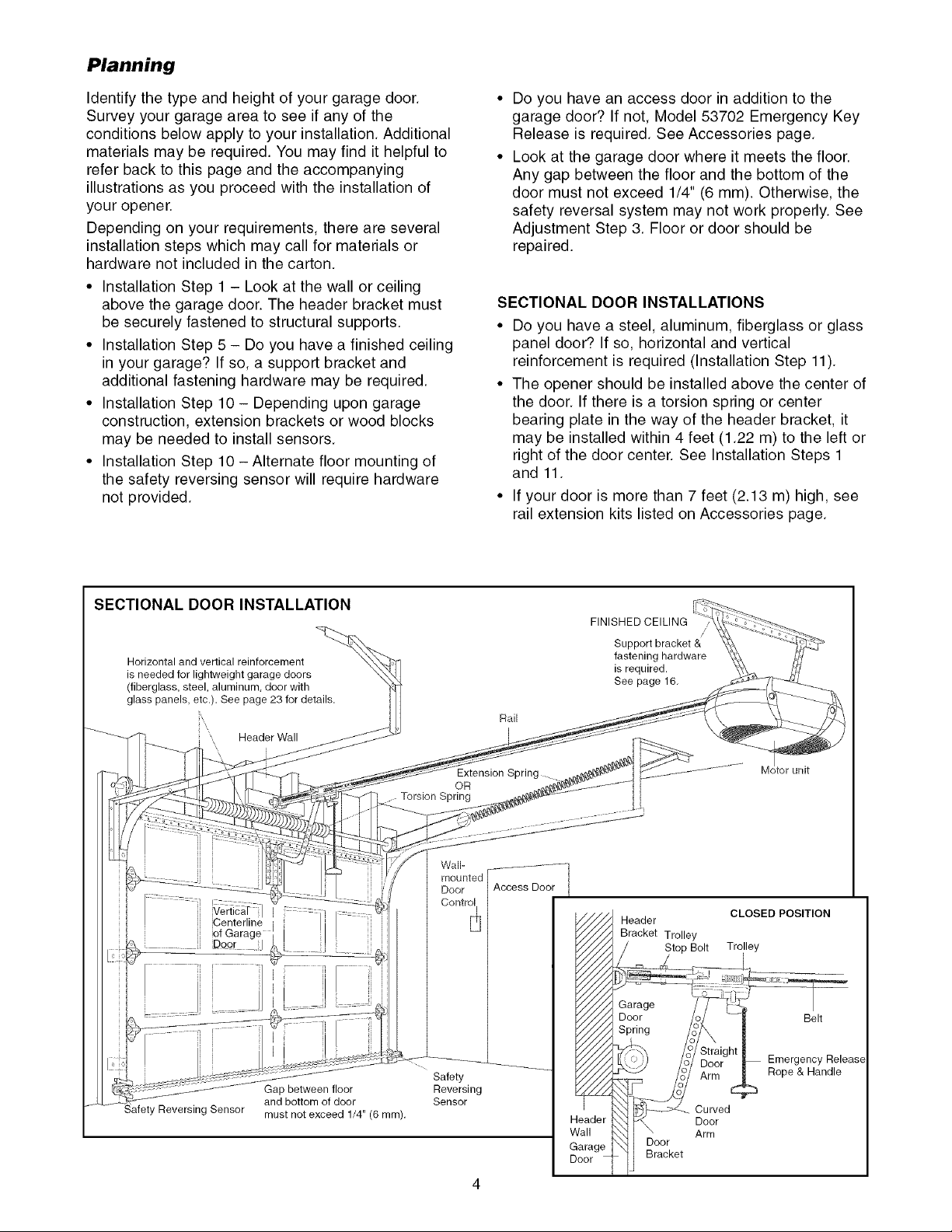

Tools needed

During assembly, installation and adjustment of the

opener, instructions will call for hand tools as

illustrated below.

Pencil

Hack Saw

Claw Hammer

Wire Cutters

Screwdriver

Stepladder

and 1/4"

Adjustable End Wrench

Page 4

Planning

Identify the type and height of your garage door.

Survey your garage area to see if any of the

conditions below apply to your installation. Additional

materials may be required. You may find it helpful to

refer back to this page and the accompanying

illustrations as you proceed with the installation of

your opener.

Depending on your requirements, there are several

installation steps which may call for materials or

hardware not included in the carton.

• Installation Step 1 - Look at the wall or ceiling

above the garage door. The header bracket must

be securely fastened to structural supports.

• Installation Step 5 - Do you have a finished ceiling

in your garage? If so, a support bracket and

additional fastening hardware may be required.

• Installation Step 10- Depending upon garage

construction, extension brackets or wood blocks

may be needed to install sensors.

• Installation Step 10 -Alternate floor mounting of

the safety reversing sensor will require hardware

not provided.

Do you have an access door in addition to the

garage door? If not, Model 53702 Emergency Key

Release is required. See Accessories page.

Look at the garage door where it meets the floor.

Any gap between the floor and the bottom of the

door must not exceed 1/4" (6 ram). Otherwise, the

safety reversal system may not work properly. See

Adjustment Step 3. Floor or door should be

repaired.

SECTIONAL DOOR INSTALLATIONS

• Do you have a steel, aluminum, fiberglass or glass

panel door? If so, horizontal and vertical

reinforcement is required (Installation Step 11).

• The opener should be installed above the center of

the door. If there is a torsion spring or center

bearing plate in the way of the header bracket, it

may be installed within 4 feet (1.22 m) to the left or

right of the door center. See Installation Steps 1

and 11.

• If your door is more than 7 feet (2.13 m) high, see

rail extension kits listed on Accessories page.

SECTIONAL DOOR INSTALLATION

Horizontal and vertical reinforcement

is needed for lightweight garage doors

(fiberglass, steel, aluminum, door with

glass panels, etc.). See page 23 for details.

\

' Header Wall

lCenterline i :: I...........

of Garage 'l I I

Door I_L_

Gap between floor

and bottom of door

must not exceed 1/4" (6 ram).

.... Torsion Spring

Wall-

mounted

Door

Control

Safety

Reversing

Sensor

Rail

Extension Spring

OR

Access Door

FINISHED CEILING

Support bracket &

fastening hardware

is required.

See page 16.

Header

Bracket Trolley

____Bolt Trolley

i _s_d

_/_ Garage /_7

F////A Door o/

_ Spring /_:

_////)_J /2/ D,

Header _ _ Door

Wall i\\_ F \ Arm

Garage HI Door

/

Straight !

Door_ _ Emergency Release

Arm _ Rope & Handle

Curved

Dooi_ ]l _a_t

unit

CLOSED POSITION

! Be,,

Page 5

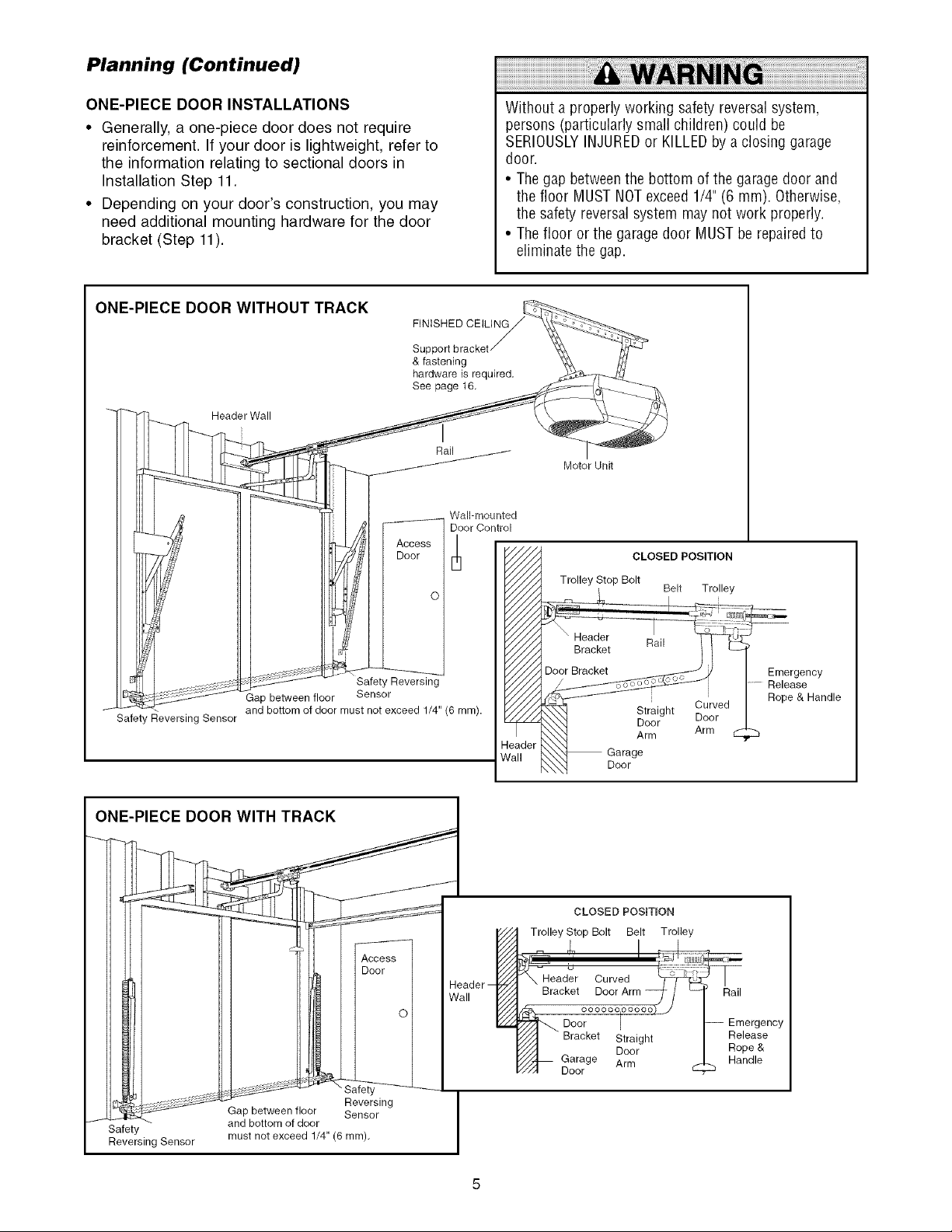

Planning (Continued)

ONE-PIECE DOOR INSTALLATIONS

• Generally, a one-piece door does not require

reinforcement. If your door is lightweight, refer to

the information relating to sectional doors in

Installation Step 11.

• Depending on your door's construction, you may

need additional mounting hardware for the door

bracket (Step 11).

ONE-PIECE DOOR WITHOUT TRACK

FINISHED

& fastening

hardware is required.

See page t6,

_-'_ HeaderWall

/

Access

Door

I

Rail

Wail-mounted

Door Control

Without a properly working safetyreversal system,

persons (particularly small children) could be

SERIOUSLYINJUREDor KILLEDby a closing garage

door.

• Thegap betweenthe bottom of the garage door and

the floor MUSTNOTexceed 1/4"(6 mm). Otherwise,

the safety reversal system maynot work properly.

• Thefloor or the garage door MUST be repairedto

eliminate the gap.

Motor Unit

CLOSED POSITION

Trolley Stop Bolt

Belt Trolley

drt1 I

Gap between floor

Safety Reversing Sensor

and bottom of door must not exceed 1/4" (6 mm).

ONE-PIECE DOOR WITH TRACK

J Safety and bottom of door

Reversing Sensor must not exceed 1/4" (6 turn),

Gap between floor Sensor

Safety Reversing

Sensor

let

Reversing

Header

Wall

_eader

Vail

Trolley Stop Bolt Belt Trolley

J_-Head_r Curved

Bracket Door Arm _- /

idh,. °°°°°°l°°°°°)_

_////'_ Bracket Straight

"//A Door

///"_1_ Garage Arm

_/I Door

Garage

Door

CLOSED POSiTiON

Door I

Straight

Door Door

Arm Arm

I --

-- Emergency

Rail

Release

Rope &

Handle

Emergency

Release

Rope & Handle

Page 6

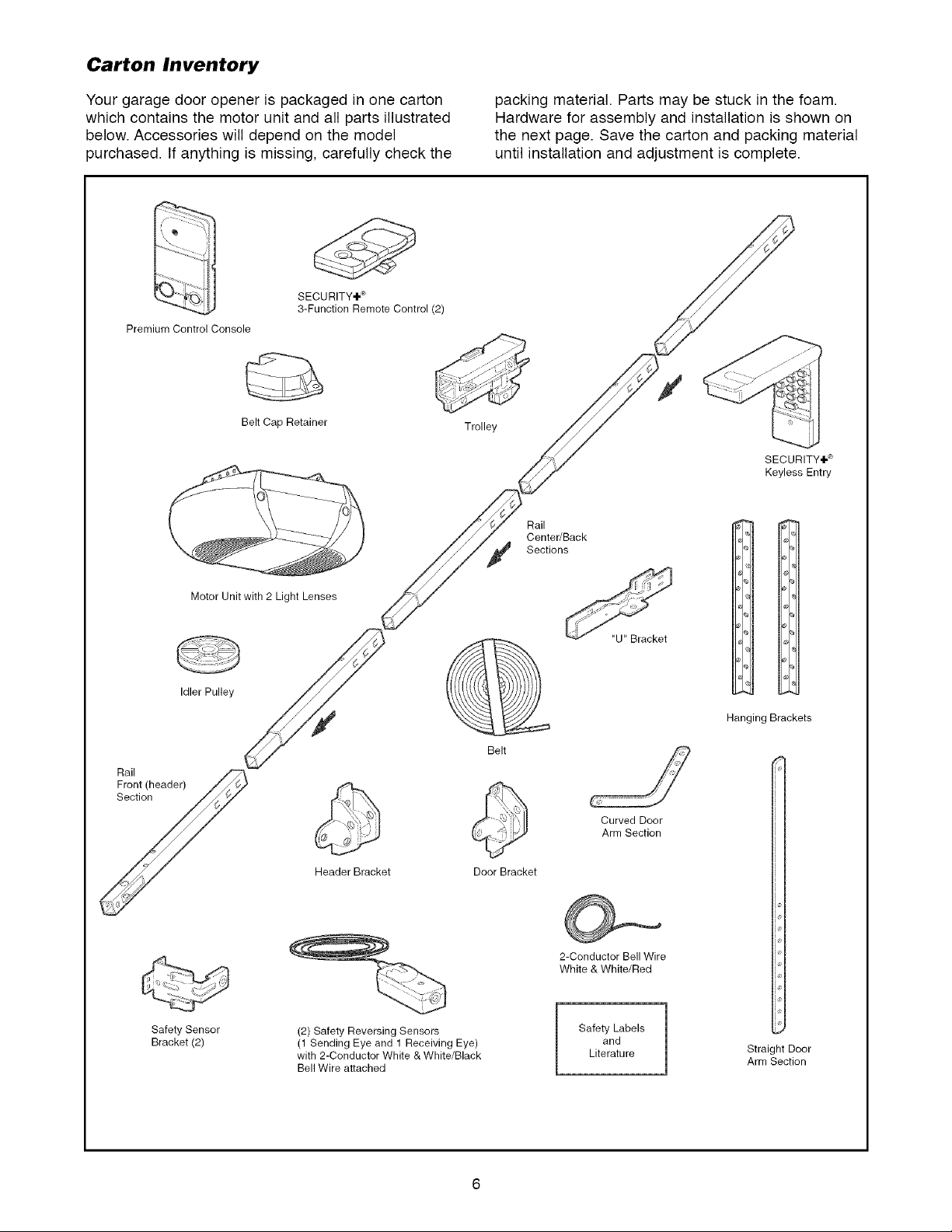

Carton Inventory

Your garage door opener is packaged in one carton

which contains the motor unit and all parts illustrated

below. Accessories will depend on the model

purchased. If anything is missing, carefully check the

SECURITY,l, _

3-Function Remote Control (2)

Premium Control Console

Belt Cap Retainer

packing material. Parts may be stuck in the foam.

Hardware for assembly and installation is shown on

the next page. Save the carton and packing material

until installation and adjustment is complete.

Trolley

SECURITY+ ®

Keyless Entry

Rail

Center/Back

Sections

Idler Pulley

Rail

Fron! (header) /_¢v/_

j

Safety Sensor

Bracket (2)

Motor Unit with 2 Light Lenses

Header Bracket

(2) Safety Reversing Sensors

(1 Sending Eye and 1 Receiving Eye)

with 2-Conductor White & White/Black

Bell Wire attached

Belt

Door Bracket

"U" Bracket

Curved Door

Arm Section

2-Conductor Bell Wire

White & White/Red

Safety Labels

and

Literature

Hanging Brackets

Straight Door

Arm Section

Page 7

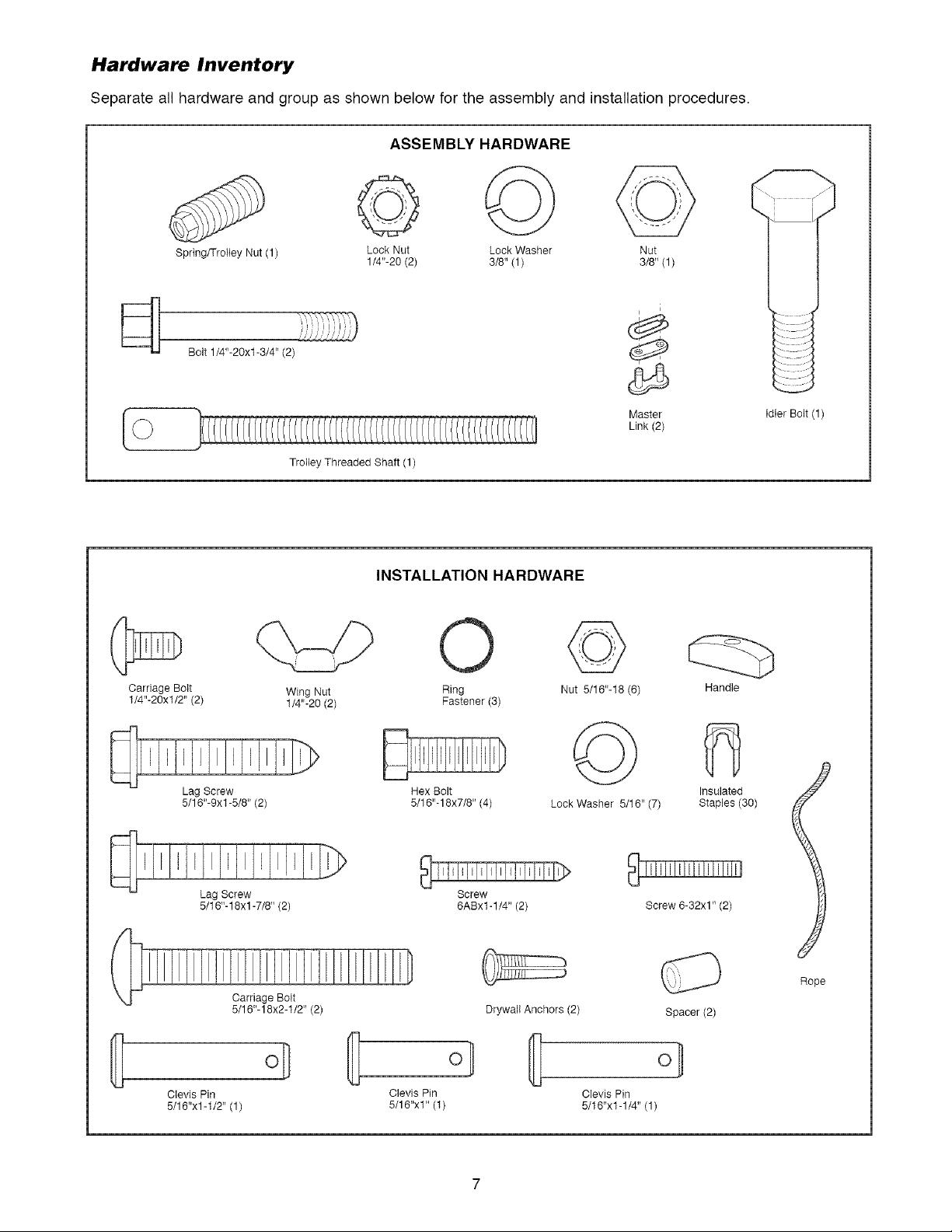

Hardware Inventory

Separate all hardware and group as shown below for the assembly and installation procedures.

ASSEMBLY HARDWARE

Spring/Trolley Nut (1)

Bolt 1/4"-20xl-3/4" (2)

Carriage Bolt

1/4"-20xl/2" (2)

Lock Nut Lock Washer Nut

1/4"-20 (2) 3/8" (1) 3/8" (1)

Trolley Threaded Shaft (1)

INSTALLATION HARDWARE

Wing Nut

1/4"-20 (2)

O

Ring

Fastener (3)

©

Nut 5/16"-18 (6)

Master

Link (2)

i

Idler Bolt (1)

Handle

Lag Screw

5/16"-9xt -5/8" (2)

Lag Screw

5/16"-18xl -7/8" (2)

Clevis Pin

5/16"xl -1/2" (1)

Carriage Bolt

5/16"-18x2-1/2" (2)

o]

©

Hex Bolt

5/16"- 18x7/8" (4)

Screw

6ABxl-1/4" (2)

Drywall Anchors (2)

Clevis Pin Clevis Pin

5/18"x1" (1) 5/16"x1-1/4" (1)

Lock Washer 5/16" (7)

Insulated

Staples (30)

Screw 6-32x1" (2)

Rope

Spacer (2)

Page 8

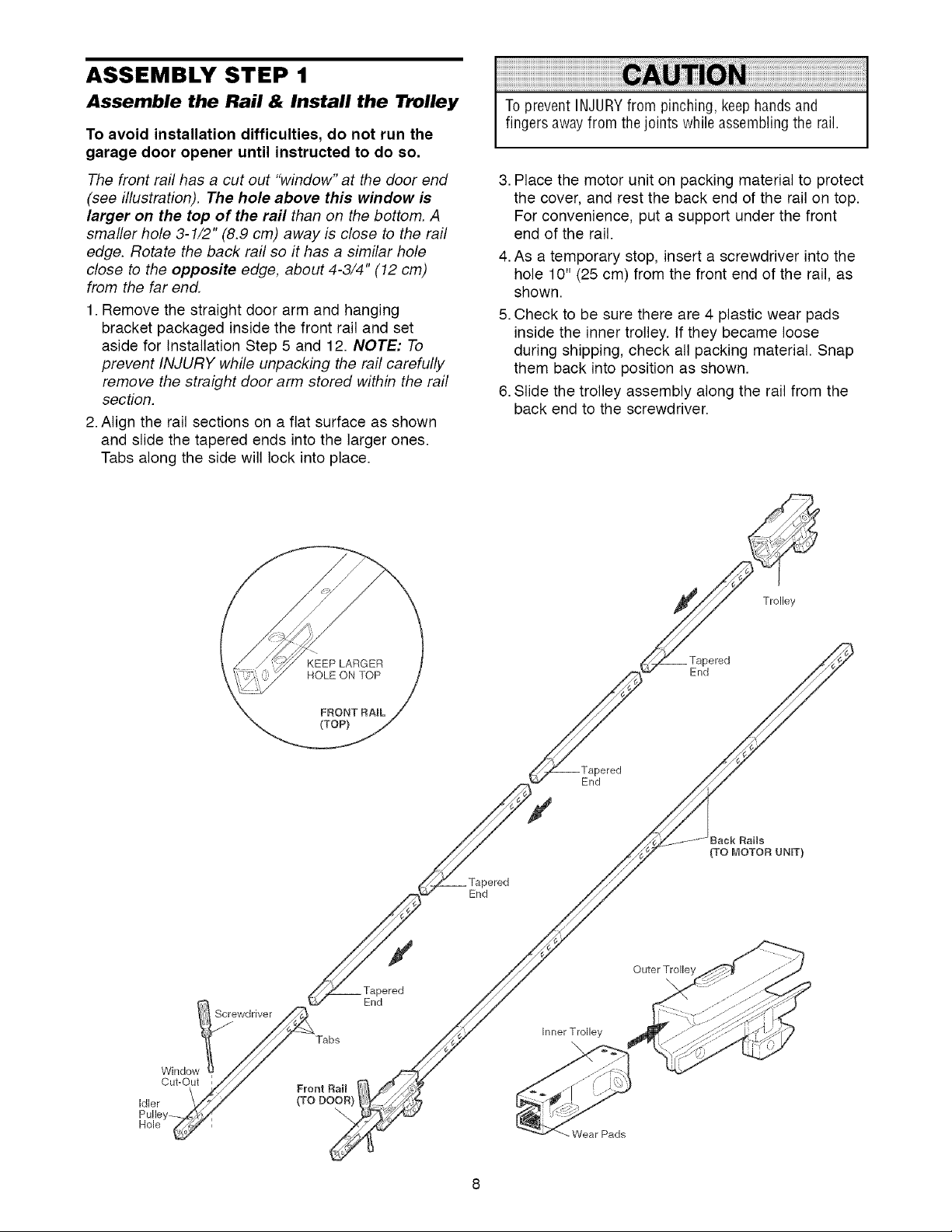

ASSEMBLY STEP 1

Assemble the Rail & Install the Trolley

To avoid installation difficulties, do not run the

garage door opener until instructed to do so.

The front rail has a cut out "window" at the door end

(see illustration). The hole above this window is

larger on the top of the rail than on the bottom. A

smaller hole 3-1/2" (8.9 cm) away is close to the rail

edge. Rotate the back rail so it has a similar hole

close to the opposite edge, about 4-3/4" (12 cm)

from the far end.

1. Remove the straight door arm and hanging

bracket packaged inside the front rail and set

aside for Installation Step 5 and 12. NOTE: To

prevent INJURY while unpacking the rail carefully

remove the straight door arm stored within the rail

section.

2. Align the rail sections on a flat surface as shown

and slide the tapered ends into the larger ones.

Tabs along the side will lock into place.

To prevent INJURYfrom pinching, keephandsand

fingers awayfrom the joints while assembling the rail.

3. Place the motor unit on packing material to protect

the cover, and rest the back end of the rail on top.

For convenience, put a support under the front

end of the rail.

4. As a temporary stop, insert a screwdriver into the

hole 10" (25 cm) from the front end of the rail, as

shown.

5. Check to be sure there are 4 plastic wear pads

inside the inner trolley. If they became loose

during shipping, check all packing material. Snap

them back into position as shown.

6. Slide the trolley assembly along the rail from the

back end to the screwdriver.

End

End

Trolley

_ered

End

End

ack Rails

(TO MOTOR UNIT)

)ered

Outer Trolley

Inner Trolley

\

Wear Pads

Page 9

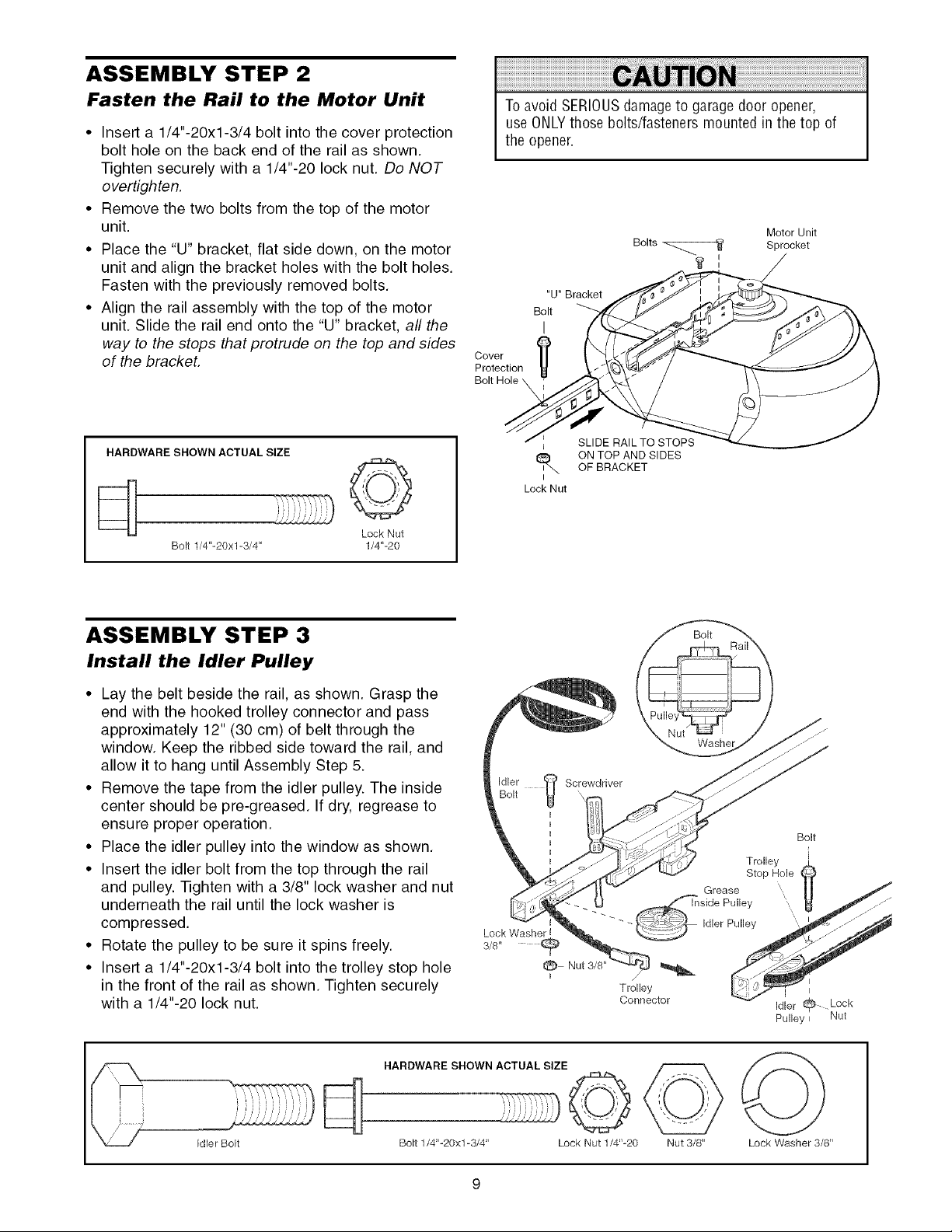

ASSEMBLY STEP 2

Fasten the Rail to the Motor Unit

• Insert a 1/4"-20xl-3/4 bolt into the cover protection

bolt hole on the back end of the rail as shown.

Tighten securely with a 1/4"-20 lock nut. Do NOT

overtighten.

• Remove the two bolts from the top of the motor

unit

• Place the "U" bracket flat side down, on the motor

unit and align the bracket holes with the bolt holes.

Fasten with the previously removed bolts.

• Align the rail assembly with the top of the motor

unit. Slide the rail end onto the "U" bracket, all the

way to the stops that protrude on the top and sides

of the bracket.

HARDWARE SHOWN ACTUAL SIZE

©

Bolt 1/4"-20xl-3/4" 1/4'L20

Lock Nut

To avoid SERIOUSdamageto garagedoor opener,

use ONLYthose bolts/fasteners mounted in the top of

the opener.

"U" Bracket

Bolt

I

Cover

Protection

Bolt Hole _

SLIDE RAIL TO STOPS

I

ON TOP AND SIDES

OF BRACKET

I

Lock Nut

Motor Unit

Sprocket

ASSEMBLY STEP 3

Install the Idler Pulley

• Lay the belt beside the rail, as shown. Grasp the

end with the hooked trolley connector and pass

approximately 12" (30 cm) of belt through the

window. Keep the ribbed side toward the rail, and

allow it to hang until Assembly Step 5.

• Remove the tape from the idler pulley. The inside

center should be pre-greased. If dry, regrease to

ensure proper operation.

• Place the idler pulley into the window as shown.

• Insert the idler bolt from the top through the rail

and pulley. -iqghten with a 3/8" lock washer and nut

underneath the rail until the lock washer is

compressed.

• Rotate the pulley to be sure it spins freely.

• Insert a 1/4"-20xl-3/4 bolt into the trolley stop hole

in the front of the rail as shown. Tighten securely

with a 1/4"-20 lock nut.

HARDWARE SHOWN ACTUAL SIZE

Connector

Bolt

Idler _ Lock

Pulley _ Nut

Idler Bolt

©

Bolt 1/4'L20x1-3/4" Lock Nut 1/4'L20 Nut 3/8" Lock Washer 3/8"

Page 10

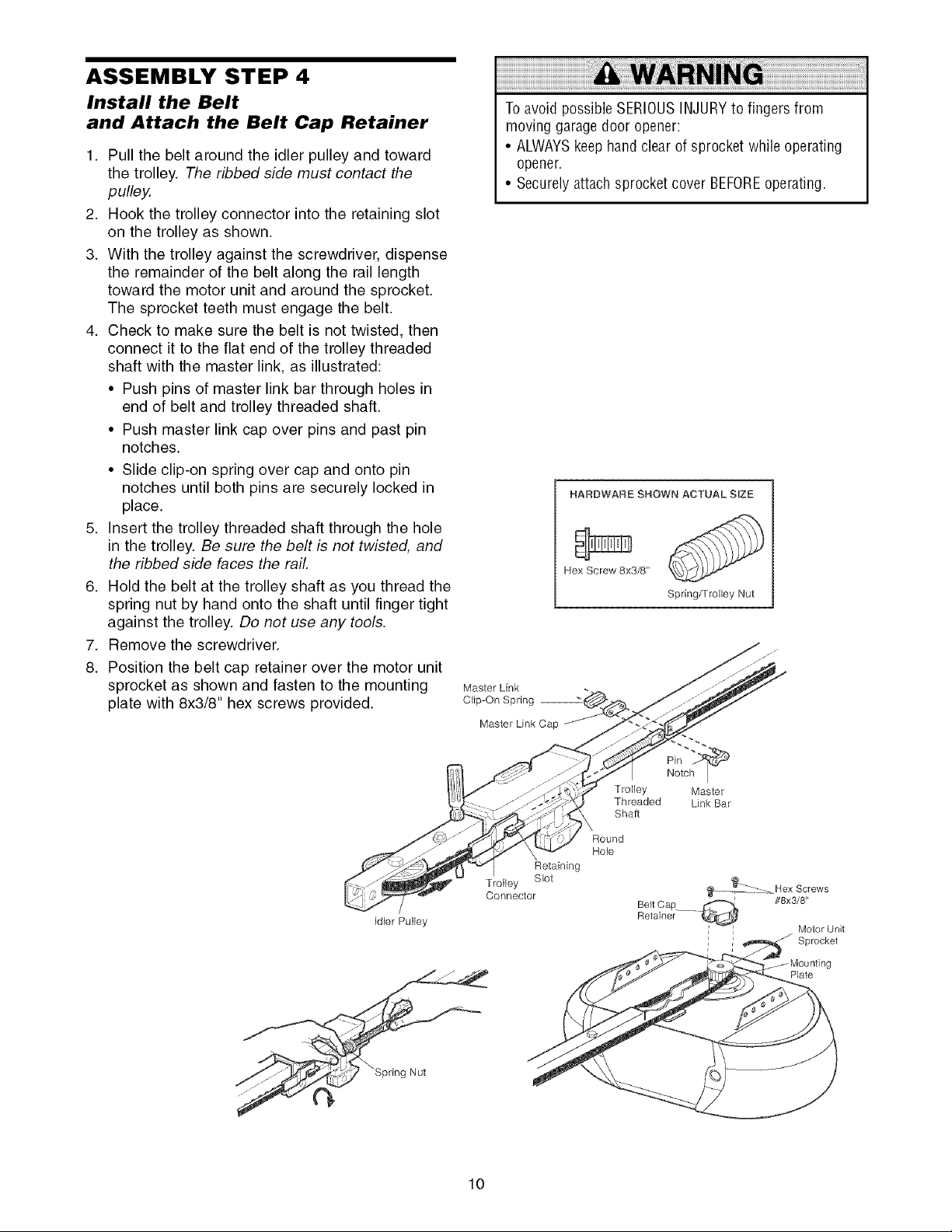

ASSEMBLY STEP 4

Install the Belt

and Attach the Belt Cap Retainer

1. Pull the belt around the idler pulley and toward

the trolley. The ribbed side must contact the

pulley.

2. Hook the trolley connector into the retaining slot

on the trolley as shown.

3. With the trolley against the screwdriver, dispense

the remainder of the belt along the rail length

toward the motor unit and around the sprocket.

The sprocket teeth must engage the belt.

4. Check to make sure the belt is not twisted, then

connect it to the flat end of the trolley threaded

shaft with the master link, as illustrated:

• Push pins of master link bar through holes in

end of belt and trolley threaded shaft.

• Push master link cap over pins and past pin

notches.

• Slide clip-on spring over cap and onto pin

notches until both pins are securely locked in

place.

5. Insert the trolley threaded shaft through the hole

in the trolley. Be sure the belt is not twisted, and

the ribbed side faces the rail.

6. Hold the belt at the trolley shaft as you thread the

spring nut by hand onto the shaft until finger tight

against the trolley. Do not use any tools.

7. Remove the screwdriver.

8. Position the belt cap retainer over the motor unit

sprocket as shown and fasten to the mounting

plate with 8x3/8" hex screws provided.

To avoid possible SERIOUSINJURYto fingers from

moving garage door opener:

• ALWAYSkeephand clear of sprocket while operating

opener.

• Securelyattach sprocket cover BEFOREoperating.

HARDWARE SHOWN ACTUAL SIZE

Hex Screw 8x3/8"

Spring/Trolley Nut

Master Link

Clip-On Spring

Master Link Cap

idler Pulley

Pin

Trolley Master

Threaded Link Bar

Shaft

Round

Hole

Retaining

Trolley Slot

Connector

///

Notc_

_- Hex Screws

Be_t Cap ___ #8x3/8

Retainer

i / Sprocket

Motor Unit

Plate

10

Page 11

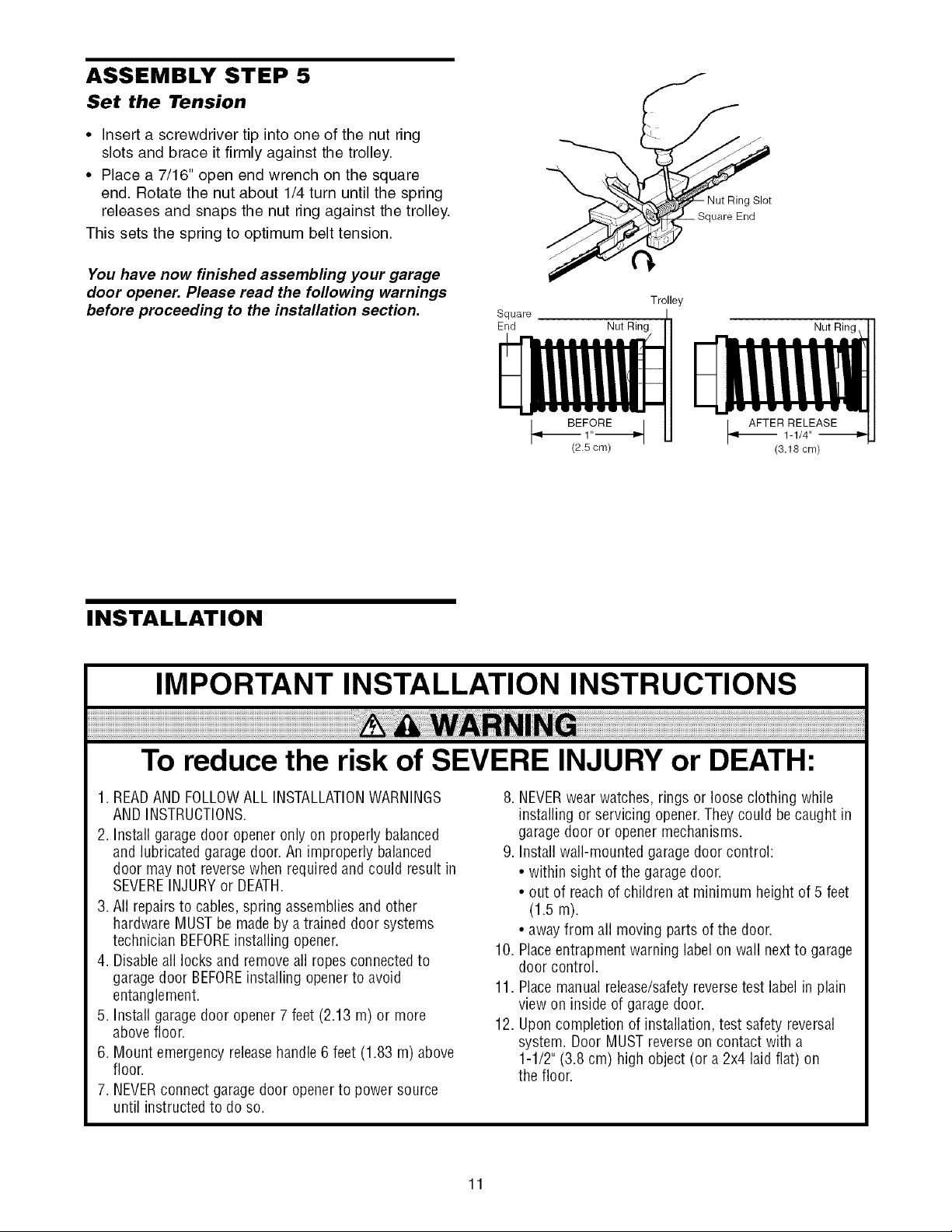

ASSEMBLY STEP 5

Set the Tension

• Insert a screwdriver tip into one of the nut ring

slots and brace it firmly against the trolley.

• Place a 7/16" open end wrench on the square

end. Rotate the nut about 1/4 turn until the spring

releases and snaps the nut ring against the trolley.

This sets the spring to optimum belt tension.

You have now finished assembling your garage

door opener. Please read the following warnings

before proceeding to the installation section.

Square

End

Trolley

Nut Ring Nut Rin(

INSTALLATION

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READAND FOLLOWALL INSTALLATIONWARNINGS

AND INSTRUCTIONS.

2. Install garage door openeronly on properly balanced

and lubricated garage door. An improperly balanced

door may not reversewhen required and could result in

SEVEREINJURYor DEATH.

3. All repairs to cables,spring assembliesand other

hardwareMUST be madeby atrained door systems

technician BEFOREinstalling opener.

4. Disableall locks and removeall ropesconnected to

garage door BEFOREinstalling opener to avoid

entanglement.

5. Install garage door opener7 feet (2.13 m) or more

above floor.

6. Mount emergency releasehandle 6 feet (1.83 m) above

floor.

7. NEVERconnect garage door openerto power source

until instructed to do so.

8. NEVERwearwatches, rings or loose clothing while

installing or servicing opener.They could be caught in

garage door or opener mechanisms.

9. Install wall-mounted garage door control:

• within sight of the garage door.

• out of reach of children at minimum height of 5 feet

(1.5 m).

• awayfrom all moving parts of the door.

10. Placeentrapment warning label on wall next to garage

door control.

11. Placemanual release/safetyreversetest label in plain

view on inside of garage door.

12. Uponcompletion of installation, test safety reversal

system. Door MUST reverseon contact with a

1-1/2" (3.8 cm) high object(or a 2x4 laid flat) on

the floor.

11

Page 12

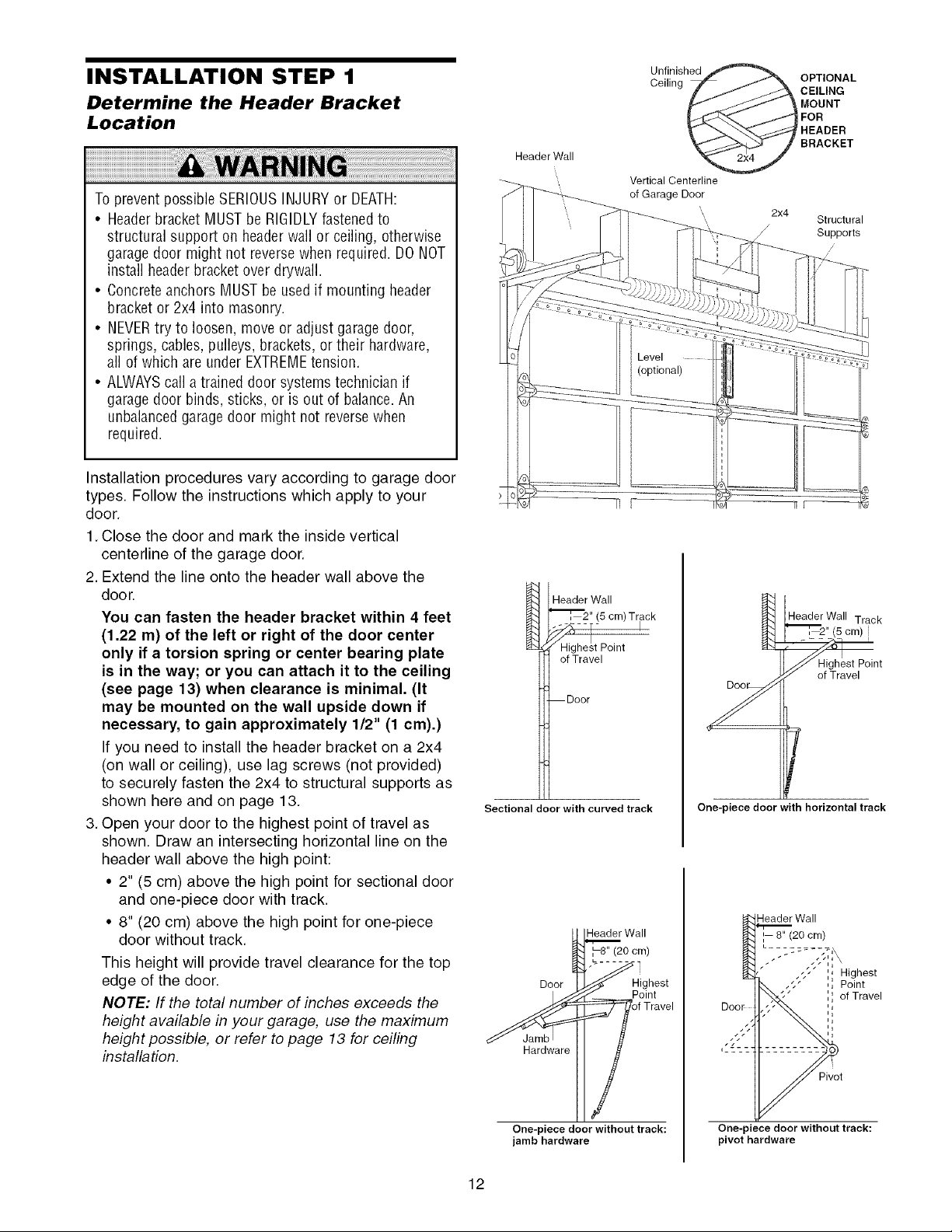

INSTALLATION STEP 1

Determine the Header Bracket

Location

Toprevent possible SERIOUSINJURYor DEATH:

• Headerbracket MUSTbe RIGIDLYfastenedto

structural support on headerwall or ceiling, otherwise

garagedoor might not reversewhen required. DONOT

install headerbracket over drywall.

• Concreteanchors MUST be usedif mounting header

bracket or 2x4 into masonry.

• NEVERtry to loosen, move or adjust garagedoor,

springs, cables, pulleys, brackets,or their hardware,

all of which are under EXTREMEtension.

• ALWAYScall a trained door systemstechnician if

garagedoor binds, sticks, or is out of balance.An

unbalancedgarage door might not reversewhen

required.

Installation procedures vary according to garage door

types. Follow the instructions which apply to your

door.

1. Close the door and mark the inside vertical

centerline of the garage door.

2. Extend the line onto the header wall above the

door.

You can fasten the header bracket within 4 feet

(1.22 m) of the left or right of the door center

only if a torsion spring or center bearing plate

is in the way; or you can attach it to the ceiling

(see page 13) when clearance is minimal. (It

may be mounted on the wall upside down if

necessary, to gain approximately 1/2" (1 cm).)

If you need to install the header bracket on a 2x4

(on wall or ceiling), use lag screws (not provided)

to securely fasten the 2x4 to structural supports as

shown here and on page 13.

3. Open your door to the highest point of travel as

shown. Draw an intersecting horizontal line on the

header wall above the high point:

• 2" (5 cm) above the high point for sectional door

and one-piece door with track.

• 8" (20 cm) above the high point for one-piece

door without track.

This height will provide travel clearance for the top

edge of the door.

NOTE: If the total number of inches exceeds the

height available in your garage, use the maximum

height possible, or refer to page 13 for ceiling

installation.

Header Wall

Vertical Centerline

of Garage Door

"_, 2" (5 cm) Track

---%--- I

Header Wall

Highest Point

of Travel

Door

Sectional door with curved track

_Wall

H ighest

Hardware

Ceiling _ CEILINGOPTIONALBRACKETHEADERFORMOUNT

Unfinished

2x4

/

Structural

Supports

/

/

"_[_, 2" (5 cm)

Header Wall Track

_Highest Point

_ of Travel

f

One-piece door with horizontal track

Header Wall

,, 8" (20 cm)

,;, ',, Highest

,, Point

Q

,, of Travel

__ PfOiTntave I

One-piece door without track:

jamb hardware

12

One-piece door without track:

pivot hardware

Page 13

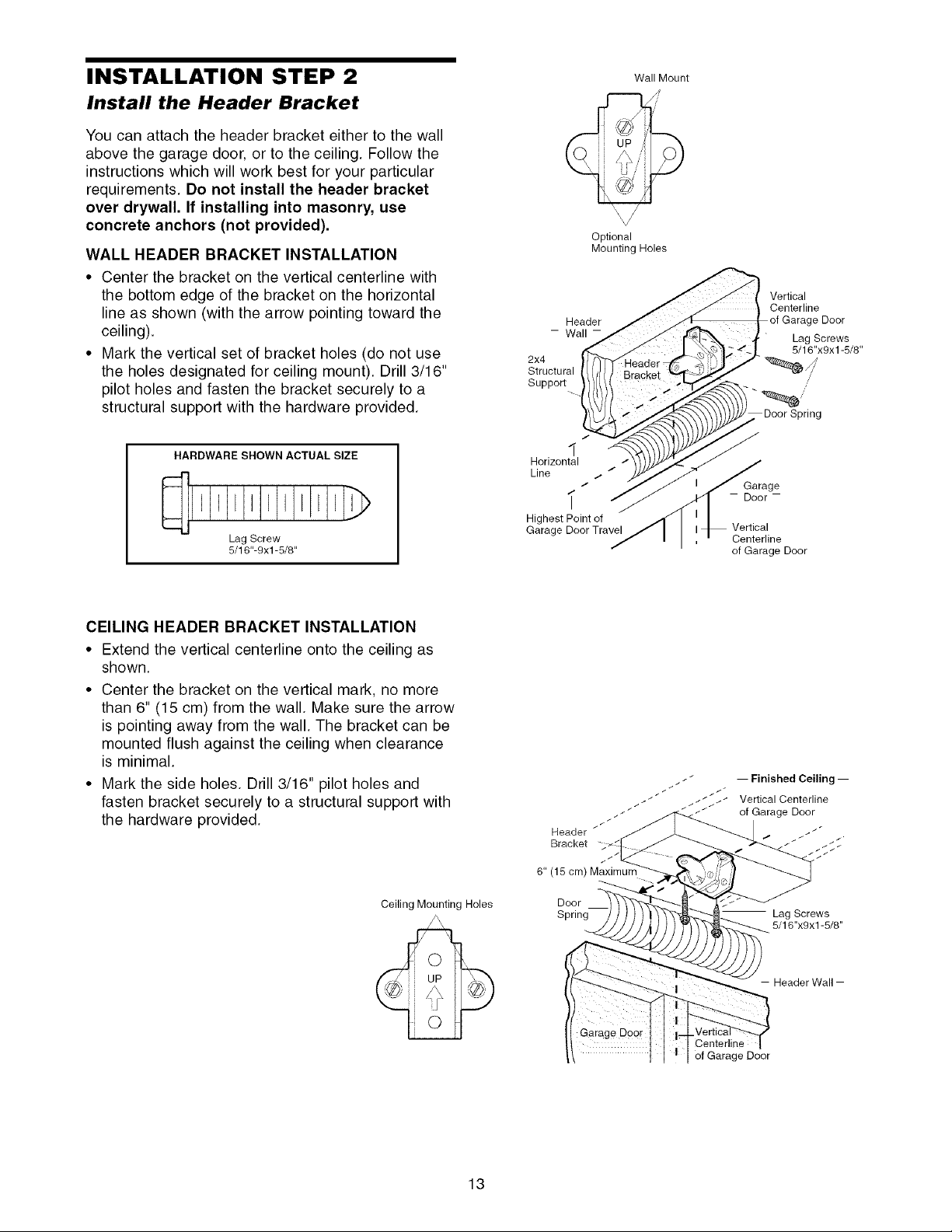

INSTALLATION STEP 2

Install the Header Bracket

You can attach the header bracket either to the wall

above the garage door, or to the ceiling. Follow the

instructions which will work best for your particular

requirements. Do not install the header bracket

over drywall. If installing into masonry, use

concrete anchors (not provided).

WALL HEADER BRACKET INSTALLATION

• Center the bracket on the vertical centerline with

the bottom edge of the bracket on the horizontal

line as shown (with the arrow pointing toward the

ceiling).

• Mark the vertical set of bracket holes (do not use

the holes designated for ceiling mount). Drill 3/16"

pilot holes and fasten the bracket securely to a

structural support with the hardware provided.

HARDWARE SHOWN ACTUAL SIZE

J EI I I EE 1,1

Lag Screw

5/16"-9xl -5/8"

Optional

Mounting Holes

Header

- Wall -

2x4

Structural

Support

I

1

Horizontal

Line / /

Highest Point of

Garage Door Travel

/

Wall Mount

\ /

Vertical

Centerline

Door Spring

Garage

- Door-

Vertical

Centerline

of Garage Door

÷ Door

Lag Screws

5/16"x9x1-5/8"

/

CEILING HEADER BRACKET INSTALLATION

• Extend the vertical centerline onto the ceiling as

shown.

• Center the bracket on the vertical mark, no more

than 6" (15 cm) from the wall. Make sure the arrow

is pointing away from the wall. The bracket can be

mounted flush against the ceiling when clearance

is minimal.

• Mark the side holes. Drill 3/16" pilot holes and

fasten bracket securely to a structural support with

the hardware provided.

Ceiling Mounting Holes

6" (15 cm) Maximum

Door

Spring

I Finished Ceiling I

Vertical Centerline

of Garage Door

Center]ine

of Garage Door

Lag Screws

5/16"x9x1-5/8"

-- Header Wall --

13

Page 14

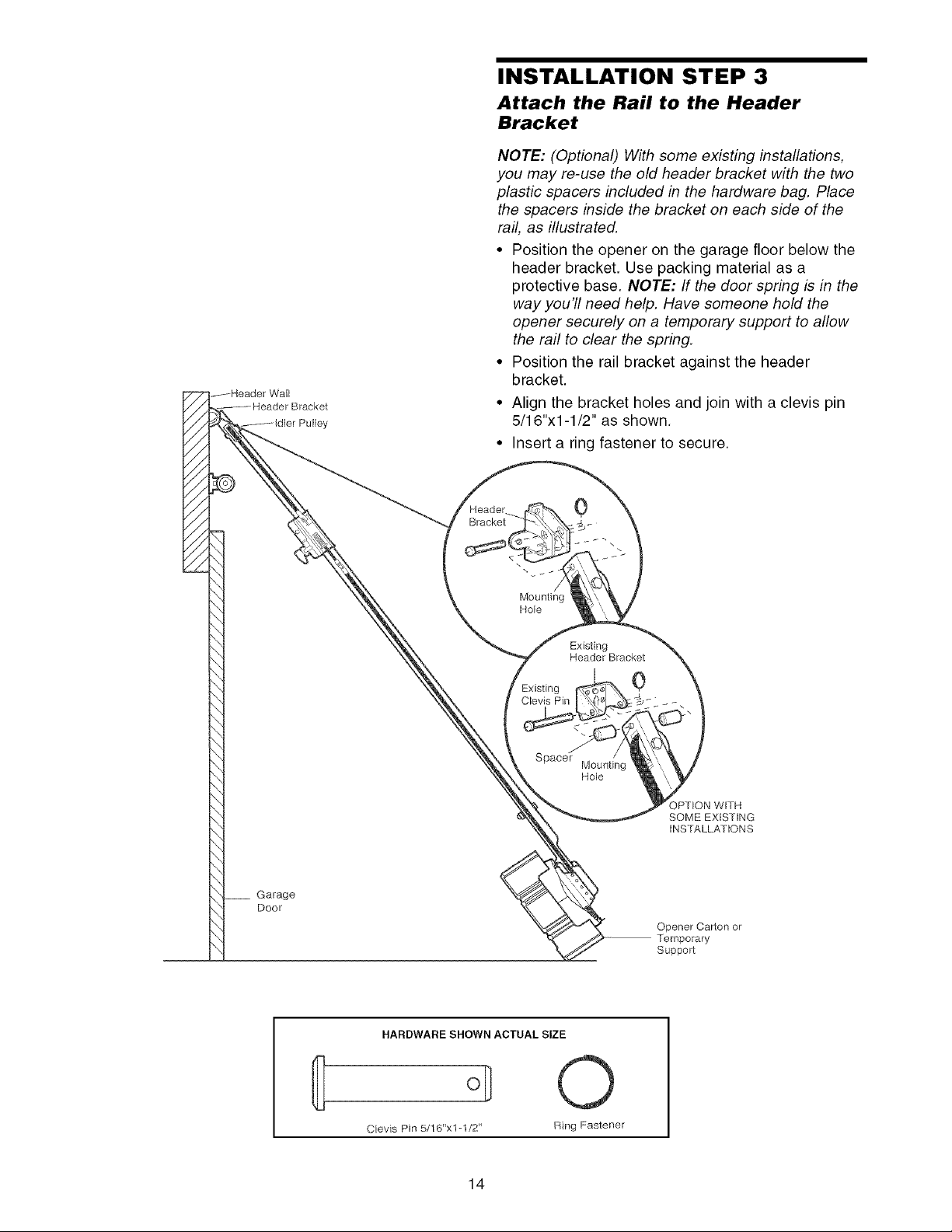

INSTALLATION STEP 3

Attach the Rail to the Header

Bracket

NOTE: (Optional) With some existing installations,

you may re-use the old header bracket with the two

plastic spacers included in the hardware bag. Place

the spacers inside the bracket on each side of the

rail, as illustrated.

• Position the opener on the garage floor below the

header bracket. Use packing material as a

protective base. NOTE: If the door spring is in the

way you'll need help. Have someone hold the

opener securely on a temporary support to allow

the rail to clear the spring.

• Position the rail bracket against the header

bracket.

//

//

//

//

//

• Align the bracket holes and join with a clevis pin

5/16"xl-1/2" as shown.

• Insert a ring fastener to secure.

Garage

Door

Bracket

\

\

Mounting

Hole

Clevis Pin

Spacer Mounting

0

\

Existing

Header Bracket

Hole

0

)PTION WITH

SOME EXISTING

iNSTALLATIONS

Opener Carton or

Temporary

Support

HARDWARE SHOWN ACTUAL SIZE

C{evis Pin 5/16"xl -1/2" Ring Fastener

14

Page 15

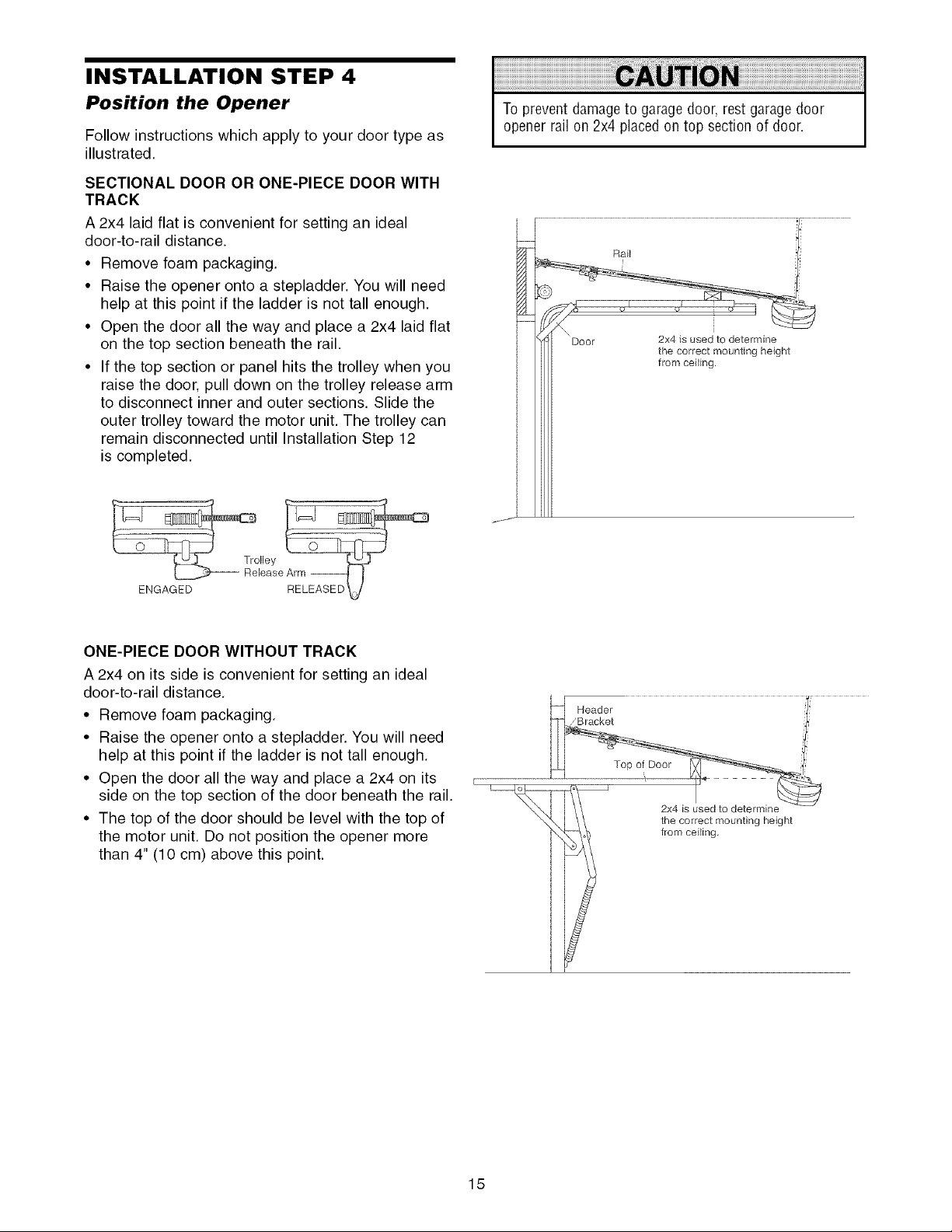

INSTALLATION STEP 4

Position the Opener

Follow instructions which apply to your door type as

illustrated.

SECTIONAL DOOR OR ONE-PIECE DOOR WITH

TRACK

A 2x4 laid flat is convenient for setting an ideal

door-to-rail distance.

• Remove foam packaging.

• Raise the opener onto a stepladder. You will need

help at this point if the ladder is not tall enough.

• Open the door all the way and place a 2x4 laid flat

on the top section beneath the rail.

• If the top section or panel hits the trolley when you

raise the door, pull down on the trolley release arm

to disconnect inner and outer sections. Slide the

outer trolley toward the motor unit. The trolley can

remain disconnected until Installation Step 12

is completed.

To prevent damageto garage door, rest garagedoor

opener rail on 2x4 placed on top section of door.

ENGAGED

ONE-PIECE DOOR WITHOUT TRACK

A 2x4 on its side is convenient for setting an ideal

door-to-rail distance.

• Remove foam packaging.

• Raise the opener onto a stepladder. You will need

help at this point if the ladder is not tall enough.

• Open the door all the way and place a 2x4 on its

side on the top section of the door beneath the rail.

• The top of the door should be level with the top of

the motor unit. Do not position the opener more

than 4" (10 cm) above this point.

i tfhemCOrr_ Ctgr_o u n t i ng height

15

Page 16

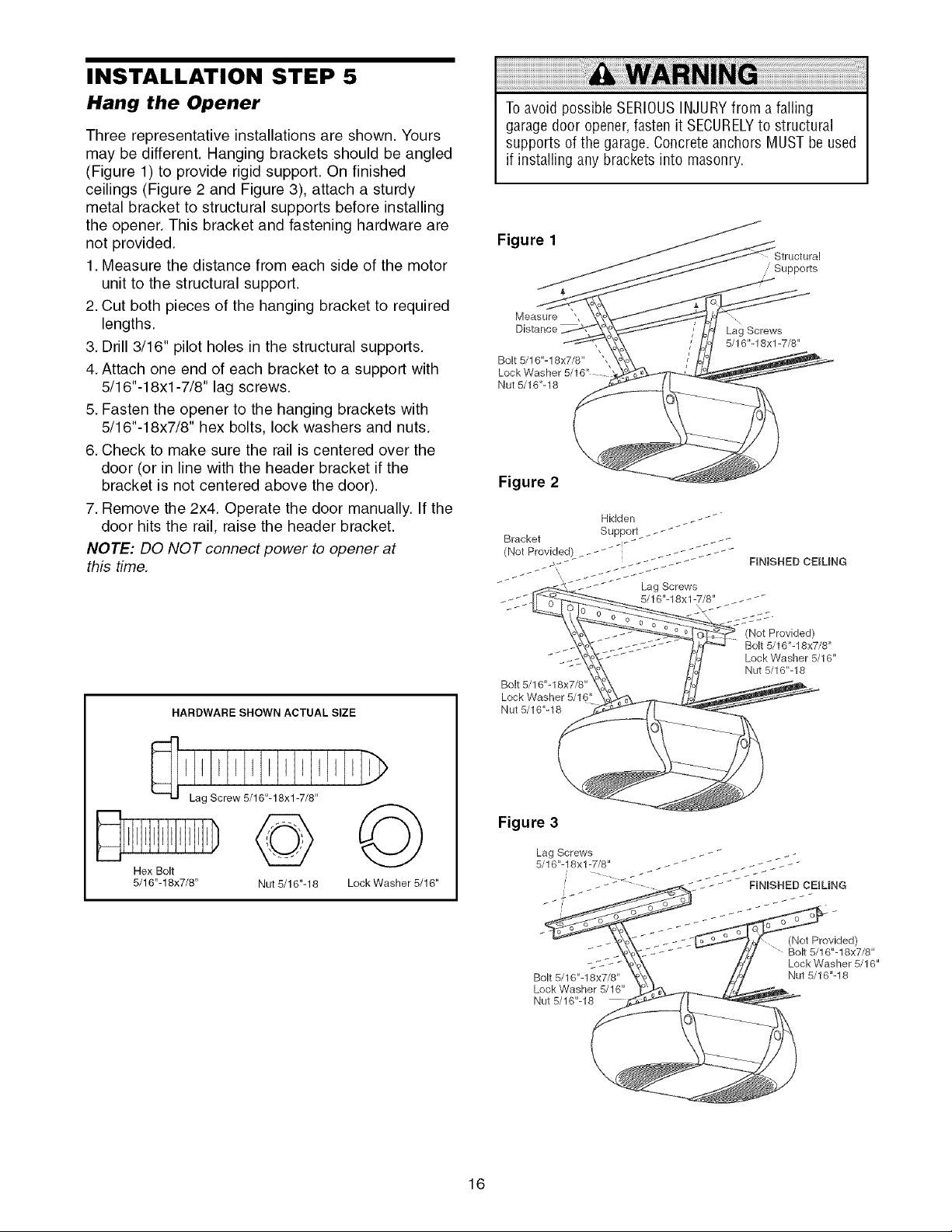

INSTALLATION STEP 5

Hang the Opener

Three representative installations are shown. Yours

may be different. Hanging brackets should be angled

(Figure 1) to provide rigid support. On finished

ceilings (Figure 2 and Figure 3), attach a sturdy

metal bracket to structural supports before installing

the opener. This bracket and fastening hardware are

not provided.

1. Measure the distance from each side of the motor

unit to the structural support.

2. Cut both pieces of the hanging bracket to required

lengths.

3. Drill 3/16" pilot holes in the structural supports.

4. Attach one end of each bracket to a support with

5/16"-18xl -7/8" lag screws.

5. Fasten the opener to the hanging brackets with

5/16"-18x7/8" hex bolts, lock washers and nuts.

6. Check to make sure the rail is centered over the

door (or in line with the header bracket if the

bracket is not centered above the door).

7. Remove the 2x4. Operate the door manually. If the

door hits the rail, raise the header bracket.

NOTE: DO NOT connect power to opener at

this time.

Toavoid possible SERIOUSINJURYfrom a falling

garage door opener,fasten it SECURELYto structural

supports of the garage.Concrete anchors MUSTbe used

if installing any brackets into masonry.

Figure 1

,,' Supports

Measure ',

Distance

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

'X

Lag Screws

5/16"-18xl -7/8"

Figure 2

FINISHED CEILING

Lag Screws

5/16"-18xl-7/8" -_-_

HARDWARE SHOWN ACTUAL SIZE

Hex Bolt

5/16"-18x7/8" Nut 5/16"-18 Lock Washer 5/16"

Bolt 5/16"-18x7/8

Lock Washer 5/16"

Nut 5/16"-18

Figure 3

Lag Screws

5/16"-18xl -7/8"

i'

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

(Not Provided)

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

(Not Provided)

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

16

Page 17

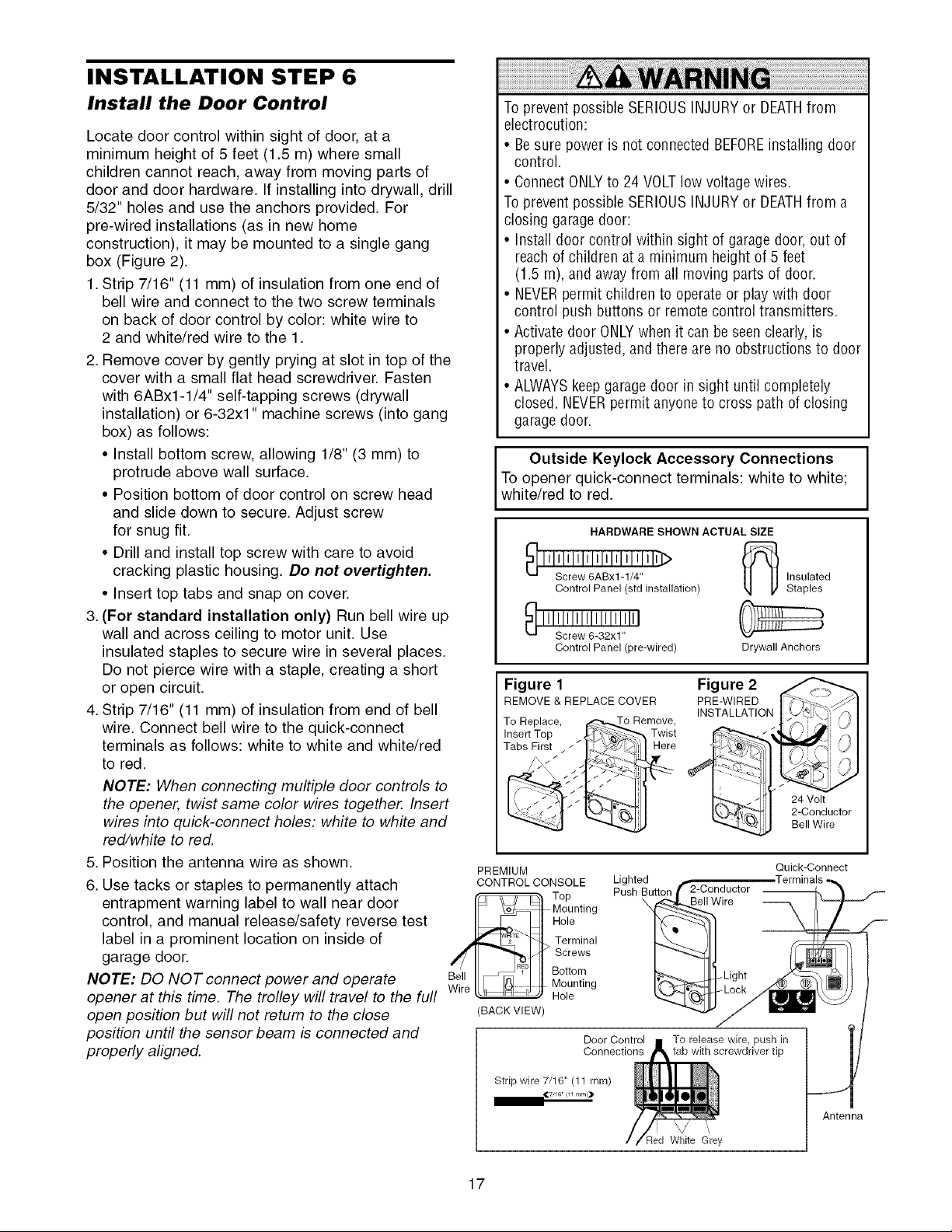

INSTALLATION STEP 6

Install the Door Control

Locate door control within sight of door, at a

minimum height of 5 feet (1.5 m) where small

children cannot reach, away from moving parts of

door and door hardware. If installing into drywall, drill

5/32" holes and use the anchors provided. For

pre-wired installations (as in new home

construction), it may be mounted to a single gang

box (Figure 2).

1.Strip 7/16" (11 mm) of insulation from one end of

bell wire and connect to the two screw terminals

on back of door control by color: white wire to

2 and white/red wire to the 1.

2. Remove cover by gently prying at slot in top of the

cover with a small flat head screwdriver. Fasten

with 6ABx1-1/4" self-tapping screws (drywall

installation) or 6-32xl" machine screws (into gang

box) as follows:

• Install bottom screw, allowing 1/8" (3 mm) to

protrude above wall surface.

• Position bottom of door control on screw head

and slide down to secure. Adjust screw

for snug fit.

• Drill and install top screw with care to avoid

cracking plastic housing. Do not overtighten.

• Insert top tabs and snap on cover.

3. (For standard installation only) Run bell wire up

wall and across ceiling to motor unit. Use

insulated staples to secure wire in several places.

Do not pierce wire with a staple, creating a short

or open circuit.

4. Strip 7/16" (11 mm) of insulation from end of bell

wire. Connect bell wire to the quick-connect

terminals as follows: white to white and white/red

to red.

NOTE: When connecting multiple door controls to

the opener, twist same color wires together. Insert

wires into quick-connect holes: white to white and

red/white to red.

5. Position the antenna wire as shown.

6. Use tacks or staples to permanently attach

entrapment warning label to wall near door

control, and manual release/safety reverse test

label in a prominent location on inside of

garage door.

NOTE: DO NOT connect power and operate

opener at this time. The trolley will travel to the full

open position but will not return to the close

position until the sensor beam is connected and

properly aligned.

Toprevent possible SERIOUSINJURYor DEATHfrom

electrocution:

• Besure power is not connected BEFOREinstalling door

control.

• ConnectONLYto 24VOLTlow voltagewires.

Toprevent possible SERIOUSINJURYor DEATHfrom a

closing garage door:

• Install door control within sight of garage door,out of

reachof children at a minimum height of 5 feet

(1.5 m), and awayfrom all moving parts of door.

• NEVERpermit children to operate or playwith door

control push buttons or remote control transmitters.

• Activate door ONLYwhen it can beseenclearly, is

properly adjusted,and there are no obstructions to door

travel.

• ALWAYSkeepgarage door in sight until completely

closed. NEVERpermit anyone to cross path of closing

garage door.

Outside Keylock Accessory Connections

To opener quick-connect terminals: white to white;

white/red to red.

Control Panel (std installation)

Control Panel (pre-wired)

Figure 1

REMOVE & REPLACE COVER

To Replace,

Insert Top Twist

Tabs First _ / _' Here

PREMIUM

CONTROL CONSOLE

Top

Mounting

Hole

Terminal

Screws

Bottom

..... _ Hole

(BACK VIEW)

Mounting

HARDWARE SHOWN ACTUAL SIZE

Drywall Anchors

Figure 2

PRE-WIRED

INSTALLATION

Lighted

Push Button

\

Door Control To release wire, push in

Connections tab with screwdriver tip

Bell Wire

Insulated

Staples

24 Volt

2-Conductor

Bell Wire

Quick-Connect

17

Antenna

Red White Grey

Page 18

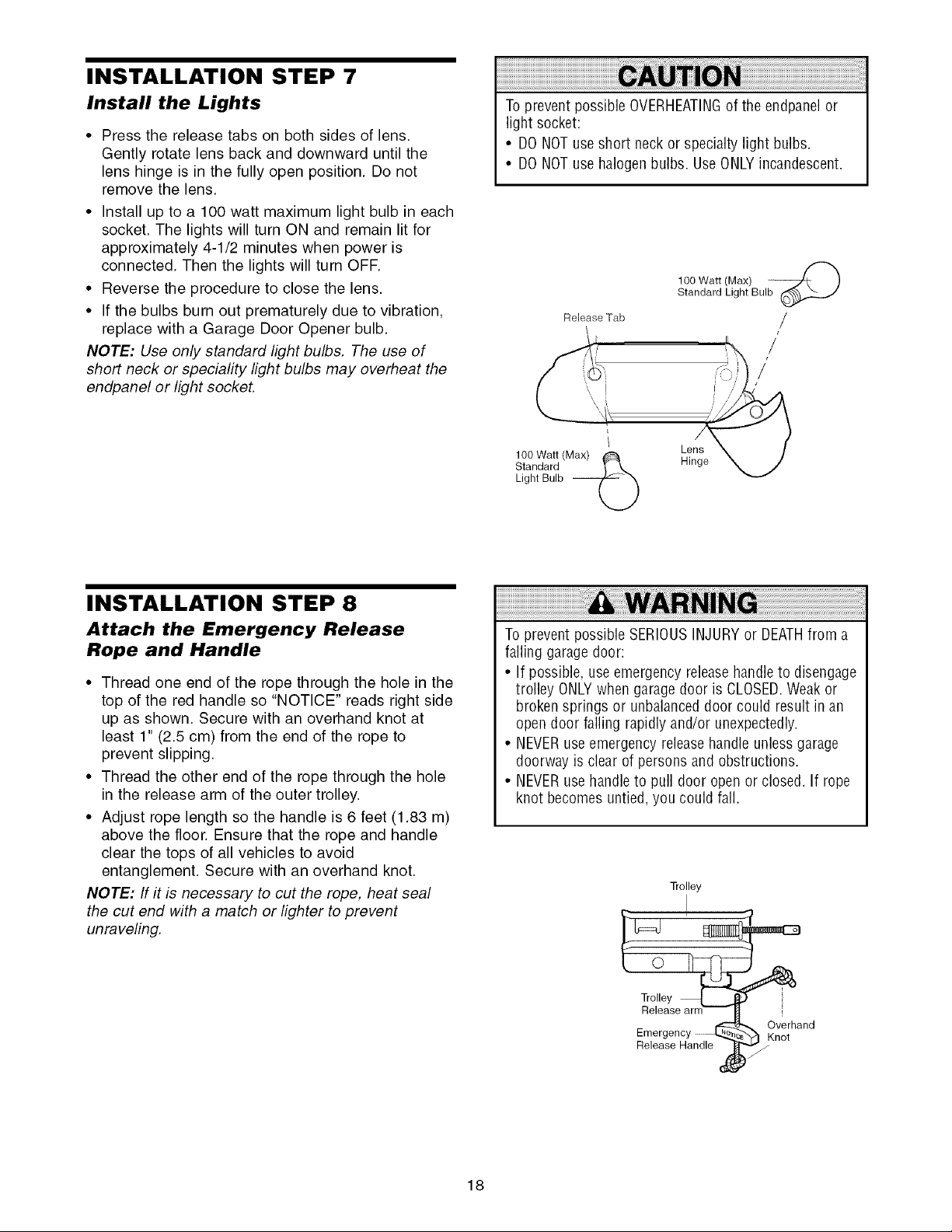

INSTALLATION STEP 7

Install the Lights

• Press the release tabs on both sides of lens.

Gently rotate lens back and downward until the

lens hinge is in the fully open position. Do not

remove the lens.

• Install up to a 100 watt maximum light bulb in each

socket. The lights will turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the lights will turn OFF.

• Reverse the procedure to close the lens.

• If the bulbs burn out prematurely due to vibration,

replace with a Garage Door Opener bulb.

NOTE: Use only standard light bulbs. The use of

short neck or speciafity light bulbs may overheat the

endpanel or light socket.

Toprevent possible OVERHEATINGof the endpanelor

light socket:

• DONOTuseshort neckor specialty light bulbs.

• DONOTuse halogenbulbs. UseONLYincandescent.

100 Watt (Max)

Standard Light Bulb

Release Tab

/

/

/

100 Watt (Max) _ Lens

Standard Hinge

Light Bulb --

©

INSTALLATION STEP 8

Attach the Emergency Release

Rope and Handle

• Thread one end of the rope through the hole in the

top of the red handle so "NOTICE" reads right side

up as shown. Secure with an overhand knot at

least 1" (2.5 cm) from the end of the rope to

prevent slipping.

• Thread the other end of the rope through the hole

in the release arm of the outer trolley.

• Adjust rope length so the handle is 6 feet (1.83 m)

above the floor. Ensure that the rope and handle

clear the tops of all vehicles to avoid

entanglement. Secure with an overhand knot.

NOTE: If it is necessary to cut the rope, heat seal

the cut end with a match or lighter to prevent

unraveling.

To prevent possible SERIOUSINJURYor DEATHfrom a

falling garage door:

• If possible, useemergency releasehandleto disengage

trolley ONLYwhen garage door is CLOSED.Weakor

brokensprings or unbalanced door could result in an

open door falling rapidly and/or unexpectedly.

• NEVERuseemergencyreleasehandle unless garage

doorway is clear of persons and obstructions.

• NEVERusehandleto pull door open orclosed. If rope

knot becomes untied, you could fall.

Trolley

Q

Emergency _ Overhand

Release Handle f

} Knot

18

Page 19

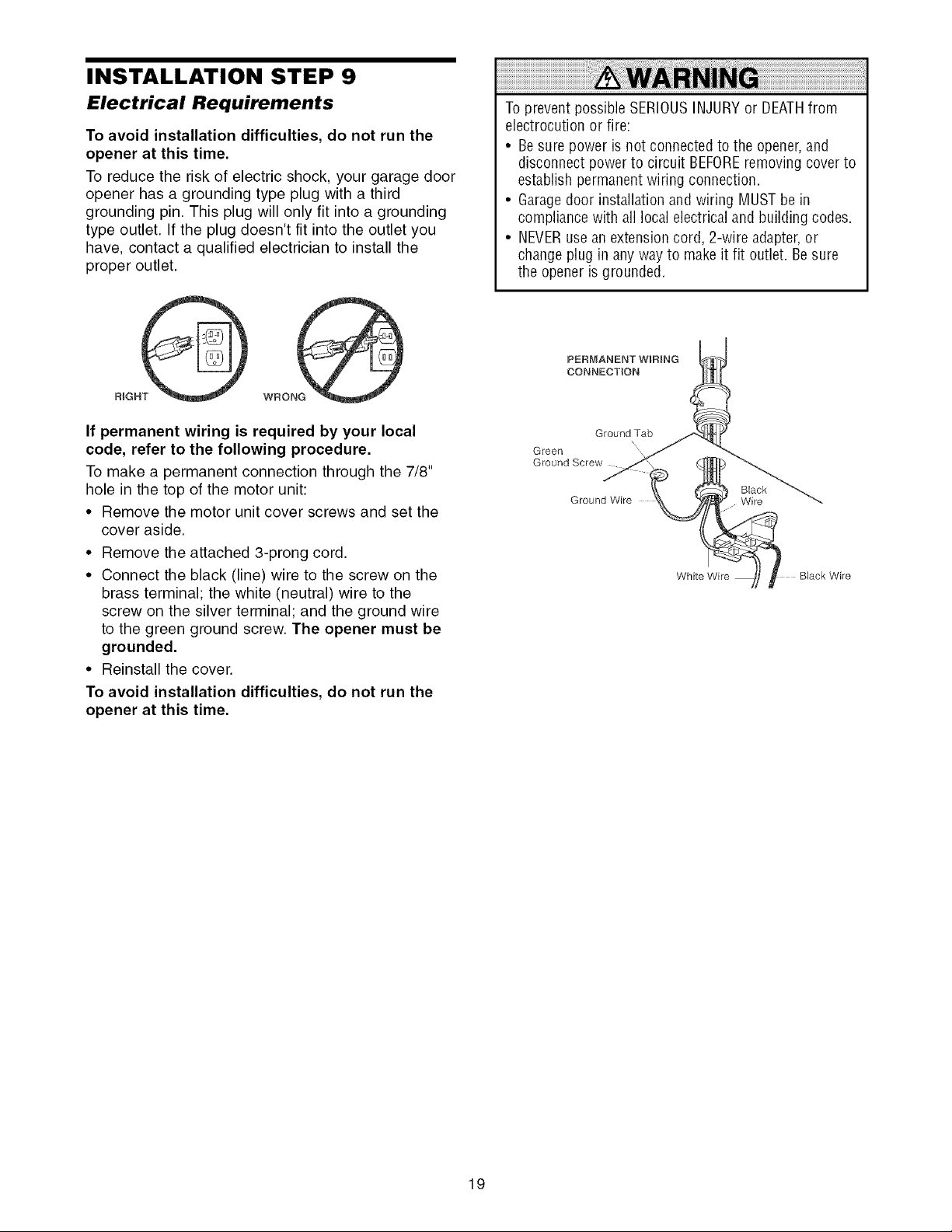

INSTALLATION STEP 9

Electrical Requirements

To avoid installation difficulties, do not run the

opener at this time.

To reduce the risk of electric shock, your garage door

opener has a grounding type plug with a third

grounding pin. This plug will only fit into a grounding

type outlet. If the plug doesn't fit into the outlet you

have, contact a qualified electrician to install the

proper outlet.

WRONG

If permanent wiring is required by your local

code, refer to the following procedure.

To make a permanent connection through the 7/8"

hole in the top of the motor unit:

• Remove the motor unit cover screws and set the

cover aside.

• Remove the attached 3-prong cord.

• Connect the black (line) wire to the screw on the

brass terminal; the white (neutral) wire to the

screw on the silver terminal; and the ground wire

to the green ground screw. The opener must be

grounded.

• Reinstall the cover.

To avoid installation difficulties, do not run the

opener at this time.

To prevent possible SERIOUSINJURYor DEATHfrom

electrocution or fire:

• Besure power is not connected to the opener,and

disconnect power to circuit BEFOREremoving cover to

establish permanentwiring connection.

• Garagedoor installation and wiring MUSTbe in

compliance with all localelectrical and building codes.

• NEVERusean extension cord, 2-wire adapter,or

changeplug in any way to makeit fit outlet. Besure

the opener is grounded.

PERMANENT WiRiNG

CONNECTION

Ground Tab

Green

Ground Screw

Ground Wire Wire

N\

Black

White Wire BJack Wire

19

Page 20

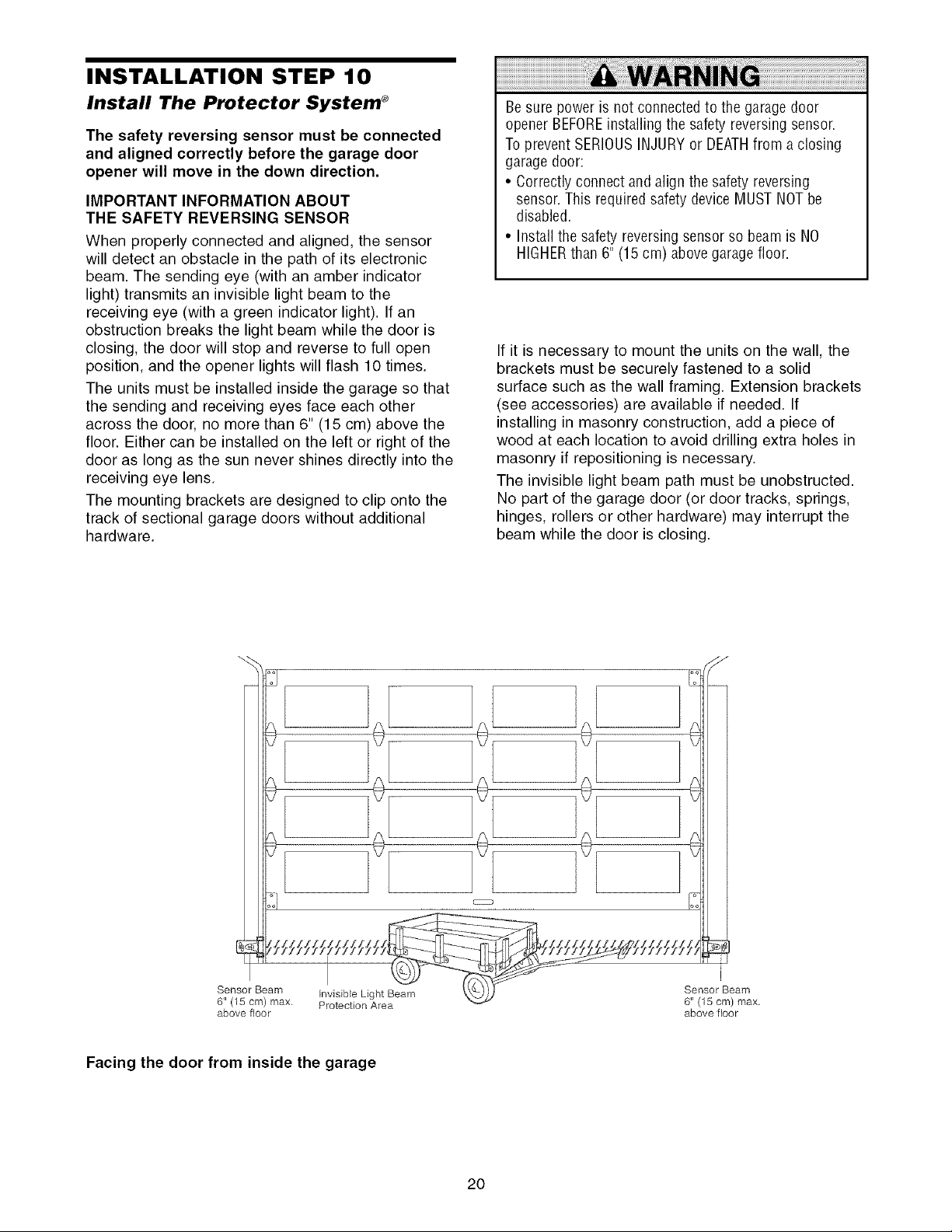

INSTALLATION STEP 10

Install The Protector System ®

The safety reversing sensor must be connected

and aligned correctly before the garage door

opener will move in the down direction.

IMPORTANT INFORMATION ABOUT

THE SAFETY REVERSING SENSOR

When properly connected and aligned, the sensor

will detect an obstacle in the path of its electronic

beam. The sending eye (with an amber indicator

light) transmits an invisible light beam to the

receiving eye (with a green indicator light). If an

obstruction breaks the light beam while the door is

closing, the door will stop and reverse to full open

position, and the opener lights will flash 10 times.

The units must be installed inside the garage so that

the sending and receiving eyes face each other

across the door, no more than 6" (15 cm) above the

floor. Either can be installed on the left or right of the

door as long as the sun never shines directly into the

receiving eye lens.

The mounting brackets are designed to clip onto the

track of sectional garage doors without additional

hardware.

Be sure power is not connectedto the garage door

opener BEFOREinstalling the safety reversingsensor.

To prevent SERIOUSINJURYor DEATHfrom a closing

garage door:

• Correctly connect andalign the safety reversing

sensor.This required safety device MUSTNOTbe

disabled.

• Install the safety reversingsensor so beam is NO

HIGHERthan 6" (15 cm) above garage floor.

If it is necessary to mount the units on the wall, the

brackets must be securely fastened to a solid

surface such as the wall framing. Extension brackets

(see accessories) are available if needed. If

installing in masonry construction, add a piece of

wood at each location to avoid drilling extra holes in

masonry if repositioning is necessary.

The invisible light beam path must be unobstructed.

No part of the garage door (or door tracks, springs,

hinges, rollers or other hardware) may interrupt the

beam while the door is closing.

Sensor Beam invisible Light Beam

6" (15 cm) max, Protection Area

above floor

Facing the door from inside the garage

2O

Sensor Beam

6" (15 cm) max,

above floor

Page 21

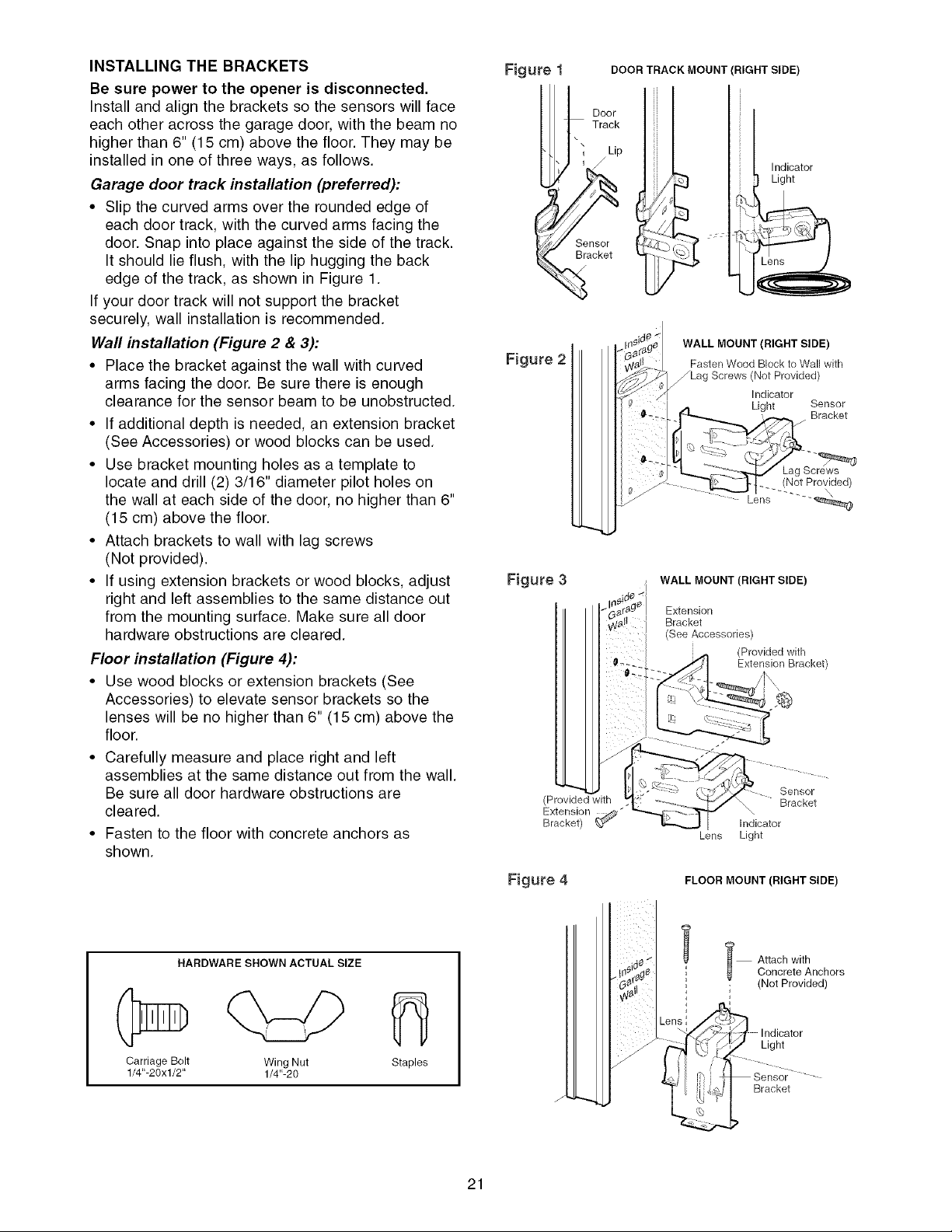

INSTALLING THE BRACKETS

Be sure power to the opener is disconnected.

Install and align the brackets so the sensors will face

each other across the garage door, with the beam no

higher than 6" (15 cm) above the floor. They may be

installed in one of three ways, as follows.

Garage door track installation (preferred):

• Slip the curved arms over the rounded edge of

each door track, with the curved arms facing the

door. Snap into place against the side of the track.

It should lie flush, with the lip hugging the back

edge of the track, as shown in Figure 1.

If your door track will not support the bracket

securely, wall installation is recommended.

Wall installation (Figure 2 & 3):

• Place the bracket against the wall with curved

arms facing the door. Be sure there is enough

clearance for the sensor beam to be unobstructed.

• If additional depth is needed, an extension bracket

(See Accessories) or wood blocks can be used.

• Use bracket mounting holes as a template to

locate and drill (2) 3/16" diameter pilot holes on

the wall at each side of the door, no higher than 6"

(15 cm) above the floor.

• Attach brackets to wall with lag screws

(Not provided).

• If using extension brackets or wood blocks, adjust

right and left assemblies to the same distance out

from the mounting surface. Make sure all door

hardware obstructions are cleared.

Floor installation (Figure 4):

• Use wood blocks or extension brackets (See

Accessories) to elevate sensor brackets so the

lenses will be no higher than 6" (15 cm) above the

floor.

• Carefully measure and place right and left

assemblies at the same distance out from the wall.

Be sure all door hardware obstructions are

cleared.

• Fasten to the floor with concrete anchors as

shown.

Figure DOOR TRACK MOUNT (RIGHT SIDE)

Door

Track

\

Indicator

Light

Sensor

Bracket

%

WALL MOUNT (RIGHT SIDE)

Figure 2

_.:_ _ L,_, Bracket

Figure 3 WALL MOUNT (RIGHT SIDE)

(Provided with

Extension

Bracket) _ ¢_"

Fasten Wood Block to Wall with

_Lag Screws (Not Provided)

Indicator

Light Sensor

Lens "--_

Extension

Bracket

(See Accessories)

(Provided with

Extension Bracket)

indicator

Lens

Light

Sensor

Bracket

HARDWARE SHOWN ACTUAL SIZE

Carriage Bolt Wing Nut

1/4"-20xl/2" 1/4"-20

Staples

Figure 4 FLOOR MOUNT (RIGHT SIDE)

I Attach with

i (Not Provided)

21

Concrete Anchors

Light

Bracket

Page 22

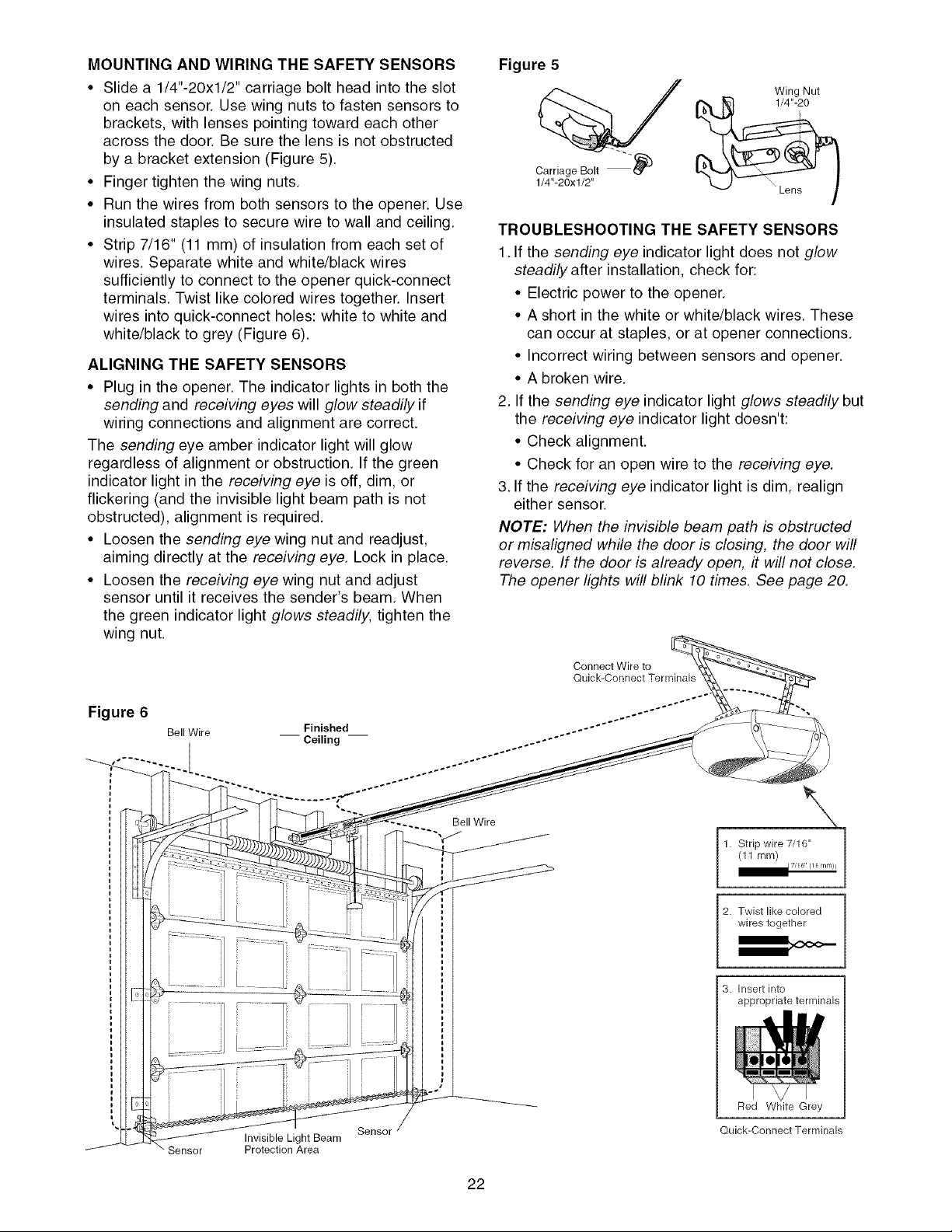

MOUNTING AND WIRING THE SAFETY SENSORS

• Slide a 1/4"-20xl/2" carriage bolt head into the slot

on each sensor. Use wing nuts to fasten sensors to

brackets with lenses pointing toward each other

across the door. Be sure the lens is not obstructed

by a bracket extension (Figure 5).

• Finger tighten the wing nuts.

• Run the wires from both sensors to the opener. Use

insulated staples to secure wire to wall and ceiling.

• Strip 7/16" (11 mm) of insulation from each set of

wires. Separate white and white/black wires

sufficiently to connect to the opener quick-connect

terminals. Twist like colored wires together. Insert

wires into quick-connect holes: white to white and

white/black to grey (Figure 6).

ALIGNING THE SAFETY SENSORS

• Plug in the opener. The indicator lights in both the

sending and receiving eyes will glow steadily if

wiring connections and alignment are correct.

The sending eye amber indicator light will glow

regardless of alignment or obstruction. If the green

indicator light in the receiving eye is off, dim, or

flickering (and the invisible light beam path is not

obstructed), alignment is required.

• Loosen the sending eye wing nut and readjust,

aiming directly at the receiving eye. Lock in place.

• Loosen the receiving eye wing nut and adjust

sensor until it receives the sender's beam. When

the green indicator light glows steadily, tighten the

wing nut.

Figure 5

Wing Nut

%

Carriage Bolt _)

1/4"-20xl/2"

TROUBLESHOOTING THE SAFETY SENSORS

1. If the sending eye indicator light does not glow

steadily after installation, check for:

• Electric power to the opener.

• A short in the white or white/black wires. These

can occur at staples, or at opener connections.

• Incorrect wiring between sensors and opener.

• A broken wire.

2. If the sending eye indicator light glows steadily but

the receiving eye indicator light doesn't:

• Check alignment.

• Check for an open wire to the receiving eye.

3. If the receiving eye indicator light is dim, realign

either sensor.

NOTE: When the invisible beam path is obstructed

or misaligned while the door is closing, the door will

reverse. If the door is already open, it will not close.

The opener lights will blink 10 times. See page 20.

Figure 6

Bell Wire

Sensor

Invisible Light Beam

Protection Area

Sensor

Bell Wire

1. Strip wire 7/16"

(11 ram)

2. Twist like colored

wires together

3. Insert into

appropriate terminals

Red White Grey

Quick-Connect Terminals

17/16" {11 mm)l

22

Page 23

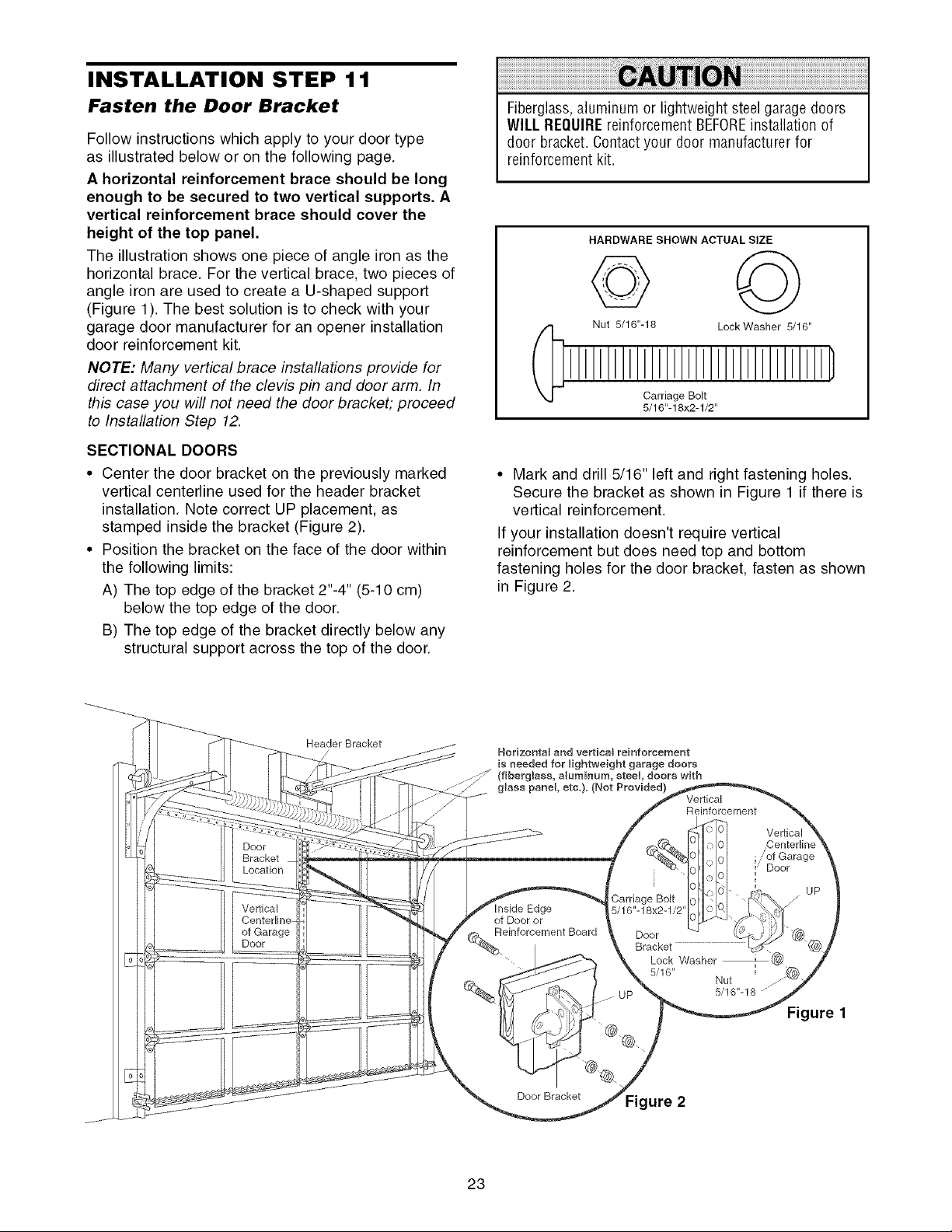

INSTALLATION STEP 11

Fasten the Door Bracket

Follow instructions which apply to your door type

as illustrated below or on the following page.

A horizontal reinforcement brace should be long

enough to be secured to two vertical supports. A

vertical reinforcement brace should cover the

height of the top panel.

The illustration shows one piece of angle iron as the

horizontal brace. For the vertical brace, two pieces of

angle iron are used to create a U-shaped support

(Figure 1). The best solution is to check with your

garage door manufacturer for an opener installation

door reinforcement kit.

NOTE: Many vertical brace installations provide for

direct attachment of the clevis pin and door arm. In

this case you will not need the door bracket; proceed

to Installation Step 12.

SECTIONAL DOORS

• Center the door bracket on the previously marked

vertical centerline used for the header bracket

installation. Note correct UP placement, as

stamped inside the bracket (Figure 2).

• Position the bracket on the face of the door within

the following limits:

A) The top edge of the bracket 2"-4" (5-10 cm)

below the top edge of the door.

B) The top edge of the bracket directly below any

structural support across the top of the door.

Fiberglass,aluminum or lightweight steel garage doors

WILL REQUIREreinforcement BEFOREinstallation of

door bracket. Contactyour door manufacturer for

reinforcement kit.

HARDWARE SHOWN ACTUAL SIZE

© ©

Nut 5/16"-18 Lock Washer 5/16"

Carriage Bolt

5/16"-18x2-1/2"

• Mark and drill 5/16" left and right fastening holes.

Secure the bracket as shown in Figure 1 if there is

vertical reinforcement.

If your installation doesn't require vertical

reinforcement but does need top and bottom

fastening holes for the door bracket, fasten as shown

in Figure 2.

Door

Bracket

Location

Vertical

of Garage

Door

Header Bracket

/

Horizontal and vertical reinforcement

is needed for lightweight garage doors

lass, aluminum, steel, doors with

glass panel, etc.}. (Not Provided)

Edge

of Door or

%Reinforcement Board

Door Bracket Figure 2

.Carriage Bolt

5/16"-18x2-1/2

23

Door

Bracket

Lock Washer

5/16"

Vertical

Reinforcement

Nut

5/16"-18 '''j

Vertical

.'of Garage

Door

Figure

UP

Page 24

ONE-PIECEDOORS

Please read and comply with the warnings and

reinforcement instructions on the previous page.

They apply to one-piece doors also.

• Center the door bracket on the top of the door, in

line with the header bracket as shown. Mark either

the left and right, or the top and bottom holes.

• Drill 5/16" pilot holes and fasten the bracket with

hardware supplied.

If the door has no exposed framing, drill 3/16" pilot

holes and fasten the bracket with 5/16"x1-1/2" lag

screws (not provided) to the top of the door.

NOTE: The door bracket may be installed on the top

edge of the door if required for your installation.

(Refer to the dotted line optional placement drawing.)

Drill 3/16" pilot holes and substitute 5/16"xl- 1/2" lag

screws (not provided) to fasten the bracket to the

door.

HARDWARE SHOWN ACTUAL SIZE

© ©

Nut 5/16"-16 Lock Washer 5/16"

Carriage Bolt

5/16"-18x2-1/2"

Header Wall

Header

Bracket

Optional

Placement

of Door

Bracket

2x4

Door

Bracket

Vertical

Centerline

of Garage

Door

HodzontaU and verticaU

reinforcement is needed for

(fiberglass, aUuminum, steel,

door with gUass panel etc.).

(Net Provided)

garage doors

JJJ_

5/16"-18

Door

Bracket

®

' 5/16"

i

i

i

Carriage Bolt

Lock

Washer

Top of Door

Top Edge

Optional

Placement

For a door with no exposed framing,

or for the optional installation, use

5/16"x1-1/2" lag screws (Not Provided)

to fasten door bracket.

24

5/16"-18x2-1/2"

Page 25

INSTALLATION STEP 12

Connect Door Arm to Trolley

Follow instructions which apply to your door type as

illustrated below and on the following page.

SECTIONAL DOORS ONLY

• Make sure garage door is fully closed. Pull the

emergency release handle to disconnect the outer

trolley from the inner trolley. Slide the outer trolley

back (away from the pulley) about 8" (20 cm) as

shown in Figures 1,2 and 3.

• Figure 1:

- Fasten straight door arm section to outer trolley

with the 5/16"x1" clevis pin. Secure the

connection with a ring fastener.

- Fasten curved section to the door bracket in the

same way, using the 5/16"x1-1/4" clevis pin.

• Figure 2:

- Bring arm sections together. Find two pairs of

holes that line up and join sections. Select holes

as far apart as possible to increase door arm

rigidity.

• Figure 3, Hole alignment alternative:

- If holes in curved arm are above holes in straight

arm, disconnect straight arm. Cut about 6"

(15 cm) from the solid end. Reconnect to trolley

with cut end down as shown.

- Bring arm sections together.

- Find two pairs of holes that line up and join with

bolts, lock washers and nuts.

• Pull the emergency release handle toward the

opener at a 45° angle so that the trolley release

arm is horizontal. Proceed to Adjustment Step 1,

page 27. Trolley will re-engage automatically when

opener is operated.

Figure 1

Door Bracket

Figure 2

©

Nut 5/16"-18

Clevis Pin

5/16"xl" (Trolley)

HARDWARE SHOWN ACTUAL SIZE

Lock Washer 5/16" Ring Fastener

o-1{ el

Clevis Pin Hex Bolt

5/16"x1-1/4" (Door Bracket) 5/16"-18x7/8"

25

Figure 3

Pulley

",, i i

"ie-_" (2ocm)_i_,.-..-)i

Trolley / / L

Lock /o/

Nuts 5/16" /o7

Washers/o-/

//

ot_ _ Cut this end

// I

Page 26

ALL ONE-PIECE DOORS

1.Assemble the door arm, Figure 4:

• Fasten the straight and curved door arm sections

together to the longest possible length (with a 2

or 3 hole overlap).

• With the door closed, connect the straight door

arm section to the door bracket with the

5/16"x1-1/4" clevis pin.

• Secure with a ring fastener.

2. Adjustment procedures, Figure 5:

• On one-piece doors, before connecting the door

arm to the trolley, the travel limits must be

adjusted. Limit adjustment screws are located on

the left side panel as shown on page 27. Follow

adjustment procedures below.

• Open door adjustment: decrease UP

travel limit

- Turn the UP limit adjustment screw

counter-clockwise 4 turns.

- Press the Door Control push button. The trolley

will travel to the fully open position.

- Manually raise the door to the open position

(parallel to the floor), and lift the door arm to the

trolley The arm should touch the trolley just in

back of the door arm connector hole. Refer to

the fully open trolley/door arm positions in the

illustration. If the arm does not extend far

enough, adjust the limit further. One full turn

equals 2" (5 cm) of trolley travel.

• Closed door adjustment: decrease DOWN

travel limit

- Turn the DOWN limit adjustment screw

clockwise 4 complete turns.

Figure 5

inner Trolley

Door

Bracket

Clevis Pin Straight

5/16"x1-1/4" Arm

Figure 4

Bolts

5/16"-18x7/8

Fastener

Lock

Washers

5/16"

Nuts

5/16"-18

Curved

Door Arm

- Press the Door Control push button. The trolley

will travel to the fully closed position.

- Manually close the door and lift the door arm to

the trolley. The arm should touch the trolley just

ahead of the door arm connector hole. Refer to

the fully closed trolley/door arm positions in the

illustration. If the arm is behind the connector

hole, adjust the limit further. One full turn equals

2" (5 cm) of trolley travel.

3. Connect the door arm to the trolley:

• Close the door and join the curved arm to the

connector hole in the trolley with the remaining

clevis pin It may be necessary to lift the door

slightly to make the connection.

• Secure with a ring fastener.

• Run the opener through a complete travel cycle.

If the door has a slight "backward" slant in full

open position as shown in the illustration,

decrease the UP limit until the door is parallel

to the floor.

NOTE: When setting the up limit on the following

page, the door should not have a "backward" slant

when fully open as illustrated below. A slight

backward slant will cause unnecessary bucking

and/or jerking operation as the door is being opened

or closed from the fully open position.

Release Handle

cy

Inner Trolley

Correct Angle _r _

Open Door (Incorrect)

26

Outer Trolley

Page 27

ADJUSTMENT STEP 1

Adjust the UP and DOWN Travel

Limits

Limit adjustment settings regulate the points at which

the door will stop when moving up or down.

To operate the opener, press the Door Control push

bar. Run the opener through a complete travel cycle.

• Does the door open and close completely?

• Does the door stay closed and not reverse

unintentionally when fully closed?

If your door passes both of these tests, no limit

adjustments are necessary unless the reversing test

fails (Adjustment Step 3, page 29).

Adjustment procedures are outlined below. Read the

procedures carefully before proceeding to

Adjustment Step 2. Use a screwdriver to make limit

adjustments. Run the opener through a complete

travel cycle after each adjustment.

NOTE: Repeated operation of the opener during

adjustment procedures may cause the motor to

overheat and shut off. Simply wait 15 minutes and

try again.

NOTE: If anything interferes with the door's upward

travel, it will stop. If anything interferes with the

door's downward travel (including binding or

unbalanced doors), it will reverse.

Without a properly installed safety reversalsystem,

persons (particularly small children) could be

SERIOUSLYINJUREDor KILLEDby a closing garage

door.

• Incorrect adjustment of garage doortravel limits will

interfere with proper operation of safety reversal

system.

• If onecontrol (force or travel limits) is adjusted, the

other control may also need adjustment.

• After ANYadjustments are made,the safety reversal

system MUSTbe tested. Door MUST reverse on

contact with 1-1/2" high (3.8 cm) object (or 2x4 laid

flat) on floor.

Toprevent damageto vehicles, be surefully open door

provides adequateclearance.

Cover Protection Bolt

LY

HOW AND WHEN TO ADJUST THE LIMITS

• If the door does not open completely but opens

at least five feet (1.5 m):

Increase up travel. Turn the UP limit adjustment

screw clockwise. One turn equals 2" (5 cm) of

travel.

NOTE: Toprevent the trolley from hitting the cover

protection bolt, keep a minimum distance of 2-4"

(5 cm - 10 cm) between the trolley and the bolt.

• If door does not open at least 5 feet (1.5 m):

Adjust the UP (open) force as explained in

Adjustment Step 2.

• If the door does not close completely:

Increase down travel. Turn the down limit

adjustment screw counterclockwise. One turn

equals 2" (5 cm) of travel.

If door still won't close completely and the trolley

bumps into the pulley bracket (page 4), try

lengthening the door arm (page 25) and

decreasing the down limit.

• If the opener reverses in fully closed position:

Decrease down travel. Turn the down limit

adjustment screw clockwise. One turn equals 2"

(5 cm) of travel.

Left Panel Limit Adjustment

ADJUSTMENT LABEL

If the door reverses when closing and there is

no visible interference to travel cycle:

If the opener lights are flashing, the Safety

Reversing Sensors are either not installed,

misaligned, or obstructed. See Troubleshooting,

page 22.

Test the door for binding: Pull the emergency

release handle. Manually open and close the door.

If the door is binding or unbalanced, call for a

trained door systems technician. If the door is

balanced and not binding, adjust the DOWN

(close) force. See Adjustment Step 2.

Screws

27

Page 28

ADJUSTMENT STEP 2

Adjust the Force

Force adjustment controls are located on the right

panel of the motor unit. Force adjustment settings

regulate the amount of power required to open and

close the door.

If the forces are set too light, door travel may be

interrupted by nuisance reversals in the down

direction and stops in the up direction. Weather

conditions can affect the door movement, so

occasional adjustment may be needed.

The maximum force adjustment range is about

3/4 of a complete turn. Do not force controls

beyond that point. Turn force adjustment controls

with a screwdriver.

NOTE: If anything interferes with the door's upward

travel, it will stop. If anything interferes with the

door's downward travel (including binding or

unbalanced doors), it will reverse.

Without a properly installed safety reversalsystem,

persons (particularly small children) could be

SERIOUSLYINJUREDor KILLEDby a closing garage

door.

• Too much force on garagedoor will interfere with

proper operation of safety reversalsystem.

• NEVERincreaseforce beyond minimum amount

requiredto close garage door.

• NEVERuseforce adjustments to compensate for a

binding or sticking garagedoor.

• If onecontrol (forceor travel limits) is adjusted,the

othercontrol may also need adjustment.

• After ANYadjustments are made,the safety reversal

system MUSTbetested. Door MUST reverseon

contact with 1-1/2" high (3.8 cm) object (or 2x4 laid

flat) on floor.

HOW AND WHEN TO ADJUST THE FORCES

1.Test the DOWN (close) force

• Grasp the door bottom when the door is about

halfway through DOWN (close) travel. The door

should reverse. Reversal halfway through down

travel does not guarantee reversal on a 1-1/2"

(3.8 cm) obstruction. See Adjustment Step 3,

page 29. If the door is hard to hold or doesn't

reverse, DECREASE the DOWN (close) force by

turning the control counterclockwise. Make small

adjustments until the door reverses normally.

After each adjustment, run the opener through a

complete cycle.

• If the door reverses during the down (close)

cycle and the opener lights aren't flashing,

INCREASE DOWN (close) force by turning the

control clockwise. Make small adjustments until

the door completes a close cycle. After each

adjustment, run the opener through a complete

travel cycle. Do not increase the force beyond the

minimum amount required to close the door.

2. Test the UP (open) force

• Grasp the door bottom when the door is about

halfway through UP (open) travel. The door

should stop. If the door is hard to hold or

doesn't stop, DECREASE UP (open) force by

turning the control counterclockwise. Make small

adjustments until the door stops easily and opens

fully. After each adjustment, run the opener

through a complete travel cycle.

• If the door doesn't open at least 5 feet (1.5 m),

INCREASE UP (open) force by turning the

control clockwise. Make small adjustments until

door opens completely. Readjust the UP limit if

necessary. After each adjustment, run the opener

through a complete travel cycle.

ADJUSTMENT LABEL

Open Force

Force Adjustment

Controls

Close Force

Antenna

28

Page 29

ADJUSTMENT STEP 3

Test the Safety Reversal System

TEST

• With the door fully open, place a 1-1/2" (3.8 cm)

board (or a 2x4 laid flat) on the floor, centered

under the garage door

• Operate the door in the down direction The door

must reverse on striking the obstruction

ADJUST

• If the door stops on the obstruction, it is not

traveling far enough in the down direction.

Increase the DOWN limit by turning the DOWN

limit adjustment screw counterclockwise 1/4 turn.

NOTE: On a sectional door, make sure limit

adjustments do not force the door arm beyond a

straight up and down position. See the illustration

on page 25.

• Repeat the test.

• When the door reverses on the 1-1/2" (3.8 cm)

board, remove the obstruction and run the opener

through 3 or 4 complete travel cycles to test

adjustment.

• If the unit continues to fail the Safety Reverse Test,

call for a trained door systems technician.

IMPORTANT SAFETY CHECK:

Test the Safety Reverse System after:

• Each adjustment of door arm length, limits, or

force controls.

• Any repair to or adjustment of the garage door

(including springs and hardware).

• Any repair to or buckling of the garage floor.

• Any repair to or adjustment of the opener.

Without a properly installed safety reversalsystem,

persons (particularly small children) could be

SERIOUSLYINJUREDor KILLEDby a closing garage

door.

• Safety reversalsystem MUST betested every month.

• If onecontrol (forceor travel limits) is adjusted,the

other control mayalso needadjustment.

• After ANYadjustments are made,the safety reversal

system MUSTbetested. Door MUST reverseon

contact with 1-1/2" high (3.8 cm) object (or 2x4 laid

flat) on the floor.

J .....

i

1/2 (3 8 cm) board

(or a 2x4 laid flat)

ADJUSTMENT STEP 4

Test The Protector System ®

• Press the remote control push button to open the

door.

• Place the opener carton in the path of the door.

• Press the remote control push button to close the

door. The door will not move more than an inch

(2.5 cm), and the opener lights will flash.

The garage door opener will not close from a remote

if the indicator light in either sensor is off (alerting

you to the fact that the sensor is misaligned or

obstructed).

If the opener closes the door when the safety

reversing sensor is obstructed (and the sensors

are no more than 6" (15 cm) above the floor), call

for a trained door systems technician.

Without a properly installed safety reversing sensor,

persons (particularly small children) could be

SERIOUSLYINJUREDor KILLEDby a closing garage

door.

Safety Reversing Sensor

29

Page 30

OPERATION

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READAND FOLLOWALL WARNINGSAND

INSTRUCTIONS.

2. ALWAYSkeep remote controls out of reach of children.

NEVERpermit children to operate or playwith garage

door control push buttons or remotecontrols.

3. ONLYactivategaragedoor when it can be seenclearly, it

is properly adjusted, and there are no obstructions to

door travel.

4. ALWAYSkeepgarage door in sight until completely

closed. NOONESHOULDCROSSTHEPATHOFTHE

MOVINGDOOR.

5. NOONESHOULDGOUNDERA STOPPED,PARTIALLY

OPENEDDOOR.

6. If possible, use emergency releasehandle to disengage

trolley ONLYwhen garage door is CLOSED.Weakor

brokensprings or unbalanced door could result in an

open door failing rapidly and/or unexpectedly.

7. NEVERuse emergencyreleasehandle unlessgarage

doorway is clear of persons and obstructions.

8. NEVERuse handleto pull garagedoor open or closed. If

rope knot becomes untied,you could fall.

Using Your Garage Door Opener

Your Security+ ®opener and hand-held remote

control have been factory-set to a matching code

which changes with each use, randomly accessing

over 100 billion new codes. Your opener will operate

with up to eight Security+ ®remote controls and one

Security+ ®Keyless Entry System. If you purchase a

new remote, or if you wish to deactivate any remote,

follow the instructions in the Programming section.

Activate your opener with any of the following:

• The hand-held Remote Control: Hold the large

push button down until the door starts to move.

• The wall-mounted Door Controh Hold the push

button or bar down until the door starts to move.

• The Keyless Entry (See Accessories): If provided

with your garage door opener, it must be

programmed before use. See Programming.

When the opener is activated (with the safety

reversing sensor correctly installed and aligned)

1. If open, the door will close. If closed, it will open.

2. If closing, the door will reverse.

3. If opening, the door will stop.

4. If the door has been stopped in a partially open

position, it will close.

5. If obstructed while closing, the door will reverse. If

the obstruction interrupts the sensor beam, the

opener lights will blink for five seconds.

9. If one control (force or travel limits) is adjusted, the

other control may also needadjustment.

10. After ANYadjustments are made,the safety reversal

system MUSTbe tested.

11. Safety reversalsystem MUSTbe tested every month.

Garagedoor must reverseon contact with 1-1/2" high

(3.8 cm) object (or a 2x4 laid flat) on the floor.

12. ALWAYSKEEPGARAGEDOORPROPERLYBALANCED

(see page3). An improperly balanceddoor may not

reversewhen required and could result in SEVERE

INJURYor DEATH.

13. All repairs to cables,spring assemblies and other

hardware, all of which are under EXTREMEtension,

MUSTbe madeby a trained door systemstechnician.

14. ALWAYSdisconnectelectric power to garage door

opener BEFOREmaking any repairs or removing

covers.

1sSAVETHESEINSTRUCTIONS.

6. If obstructed while opening, the door will stop.

7. If fully open, the door will not close when the beam

is broken. The sensor has no effect in the opening

cycle.

If the sensor is not installed, or is misaligned, the

door won't close from a hand-held remote. However,

you can close the door with the Door Control, the

Outdoor Key Switch, or Keyless Entry, if you activate

them until down travel is complete. If you release

them too soon, the door will reverse.

The opener lights will turn on under the following

conditions: when the opener is initially plugged in;

when power is restored after interruption; when the

opener is activated.

They will turn off automatically after 4-1/2 minutes or

provide constant light when the Light feature on the

Premium Control Console is activated. Bulb size is

1O0 watts maximum.

Security.I _ light feature: Lights will also turn on

when someone walks through the open garage door.

With a Premium Control Console, this feature may be

turned off as follows: With the opener lights off, press

and hold the light button for 10 seconds, until the

light goes on, then off again. To restore this feature,

start with the opener lights on, then press and hold

the light button for 10 seconds until the light goes off,

then on again.

30

Page 31

Using the Wall.Mounted To Open the Door Manually

Door Control

CONSOLE Push Button

THE PREMIUM CONTROL _Lighted

Press the lighted push button to L_ /_l

again to reverse the door during -Button

the closing cycle or to stop the Button

open or close the door. Press _Light

-Lock

door while it's opening.

Light feature

Press the Light button to turn the opener light on or

off. It will not control the opener lights when the door

is in motion. If you turn it on and then activate the

opener, the light will remain on for 4-1/2 minutes.

Press again to turn it off sooner. The 4-1/2 minute

interval can be changed to 1-1/2, 2-1/2, or 3-1/2

minutes as follows: Press and hold the Lock button

until the light blinks (about 10 seconds). A single blink

indicates that the timer is reset to 1-1/2 minutes.

Repeat the procedure and the light will blink twice,

resetting the timer to 2-1/2 minutes. Repeat again for

a 3-1/2 minute interval, etc., up to a maximum of four

blinks and 4-1/2 minutes.

Lock feature

Designed to prevent operation of the door from

hand-held remote controls. However, the door will

open and close from the Door Control, the Outdoor

Key Switch and the Keyless Entry Accessories.

To activate, press and hold the Lock button for 2

seconds. The push button light will flash as long as

the Lock feature is on.

To turn off, press and hold the Lock button again for

2 seconds. The push button light will stop flashing.

The Lock feature will also turn off whenever the

"learn" button on the motor unit panel is activated.

Additional feature when used with the 3-Function

hand-held remote

To control the opener lights:

In addition to operating the door,

you may program the remote to

operate the lights.

1.With the door closed, press and hold a small

remote button that you want to control the light.

2. Press and hold the Light button on the door

control.

3. While holding the Light button, press and hold the

Lock button on the door control.

4. After the opener lights flash, release all buttons.

Toprevent possible SERIOUSINJURYor DEATHfrom a

falling garagedoor:

• If possible, useemergencyrelease handleto

disengagetrolley ONLYwhen garage door is CLOSED.

Weakor broken springs or unbalanceddoor could

result in anopen door falling rapidlyand/or

unexpectedly.

• NEVERuseemergency releasehandle unless garage

doorway is clear of persons and obstructions.

• NEVERusehandle to pull door open or closed. If rope

knot becomes untied, you could fall.

DISCONNECT THE TROLLEY:

The door should be fully closed if possible. Pull down

on the emergency release

handle (so that the trolley

release arm snaps into a

vertical position) and lift the

door manually. The lockout

feature prevents the trolley

from reconnecting

automatically, and the door

can be raised and lowered

Trolley--- .L2:'

Release Arm /

(In Manual

Disconnect

Position)

manually as often as

necessary.

Lockout position

TO RE-CONNECT THE

TROLLEY:

Pull the emergency

release handle toward the

opener at an angle so that

the trolley release arm is

horizontal. The trolley will

reconnect on the next UP

or DOWN operation,

either manually or by

using the door control or

remote.

(Manual disconnect)

'L=J t

Emergency ""__

Release Handle _ _'_ ._

(Down and Back) "_ 2_'

To reconnect

Trolley

Trolley

_ARelm ease

%:

31

Page 32

CARE OF YOUR OPENER

LIMIT AND FORCE ADJUSTMENTS:

Weather conditions may FORCECONTROLS

cause some minor changes

in door operation requiring

some re-adjustments,

particularly during the first

year of operation.