ForceTriad Energy PlatformForceTriad Energy Platform

Customer Support

Calibration Procedure

Troubleshooting

System Service

Periodic Safety Check

Customer SupportCustomer Support

Calibration ProcedureCalibration Procedure

TroubleshootingTroubleshooting

System ServiceSystem Service

Periodic Safety CheckPeriodic Safety Check

Covidien Customer Support ContactsCovidien Customer Support Contacts

Main Menu

Main Menu

Click anywhere on the map to access the Covidien technical support websiteClick anywhere on the map to access the Covidien technical support website

Covidien | December 7, 2011 | Confidential

Main Menu

The

different

calibration

levels

defined

below

are

the

by

d

i

d

Calibration Level 0

Utility Calibration

Main Menu

Calibration ProcedureCalibration Procedure

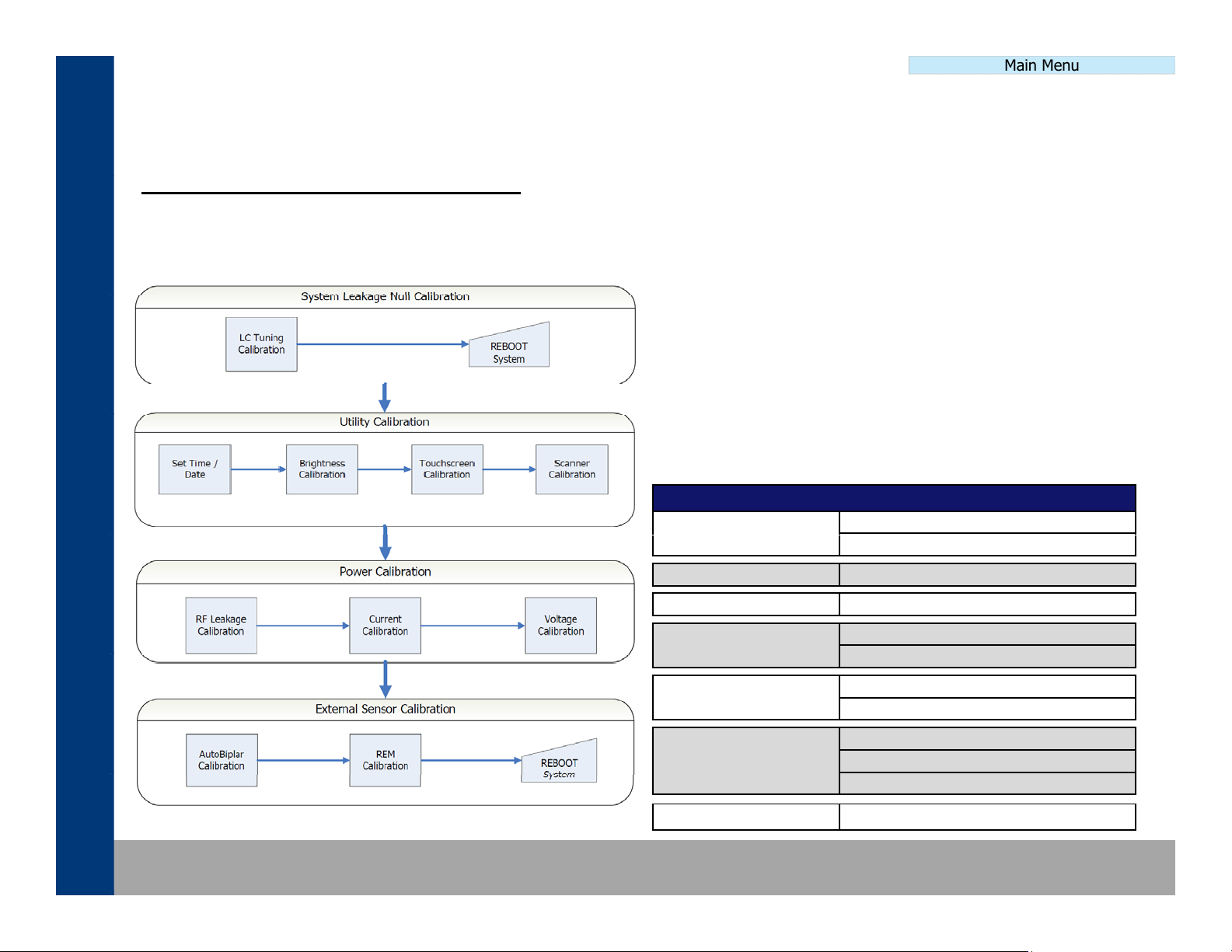

CALIBRATION PROCEDURE DEFINITION

The calibration procedure has been broken down into four different areas of calibration. The different calibration areas

segregate the full calibration procedure into smaller, more manageable calibration sections. These sections are then

selected based on the service performed. Additional information can be found by clicking on the flow chart below.

MINIMUM requirement of level of calibration to be

performed. Ultimately, a full, level 6 calibration is

preferred for all levels of service work completed.

The full calibration procedure definition, including a step-

-step procedure, canbefoun

Service Manual. The information found in the Calibration

Procedure section of this guide is for reference only.

CalibrationLevelDefinition

No calibration required

Periodic Safety Check required

ntheForceTria

Covidien | December 7, 2011 | Confidential

Calibration Level 1 Scanner Calibration

Calibration Level 2 System Leakage Null Calibration

Calibration Level 3

Calibration Level 4

Calibration Level 5

Calibration Level 6 Full calibration required

System Leakage Null Calibration

Power Calibration

System Leakage Null Calibration

Power Calibration

External Sensor Calibration

System Leakage Null Calibration

Main Menu

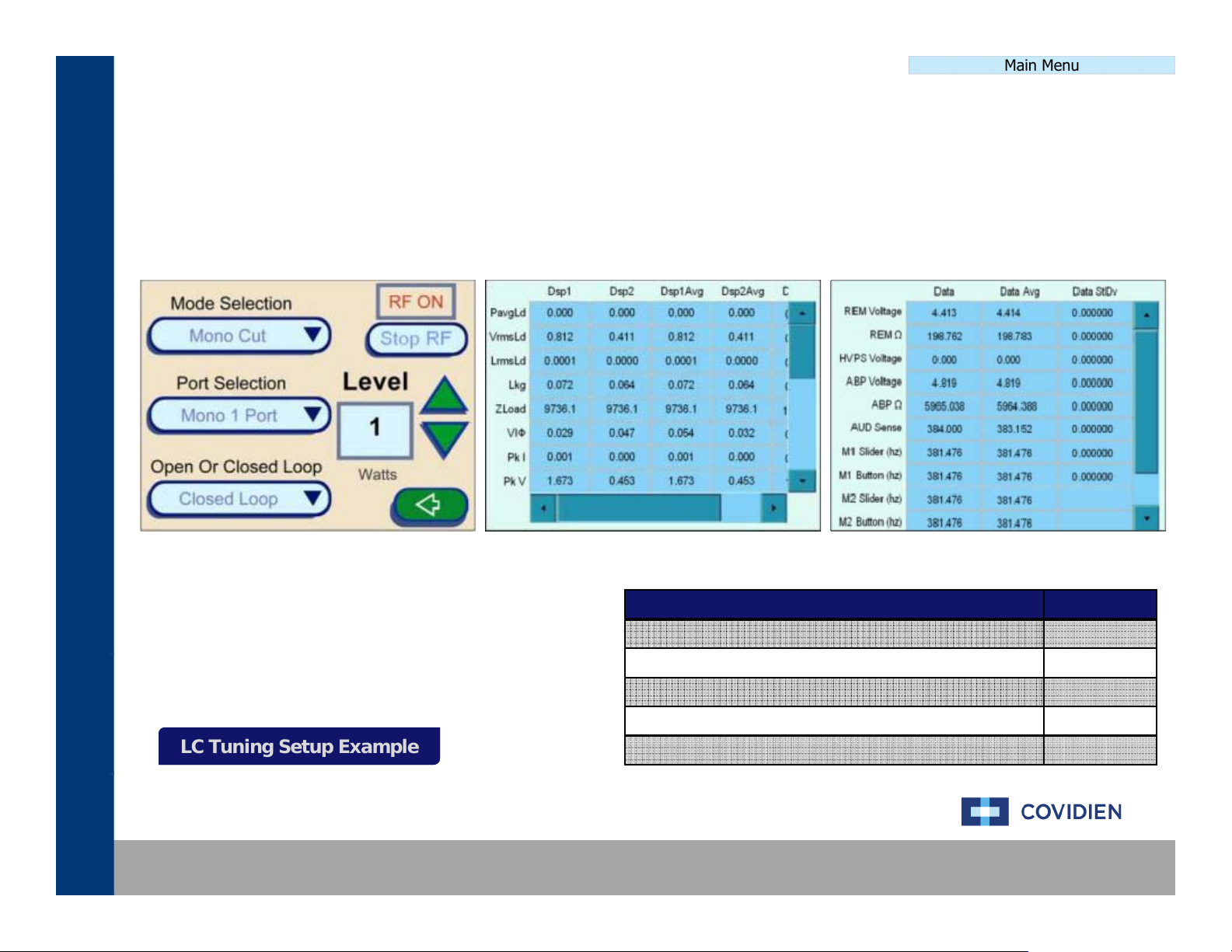

The

System

Leakage

Null

Calibration

process

consists

of

adjusting

theLCTuning

on

the

system

This

is

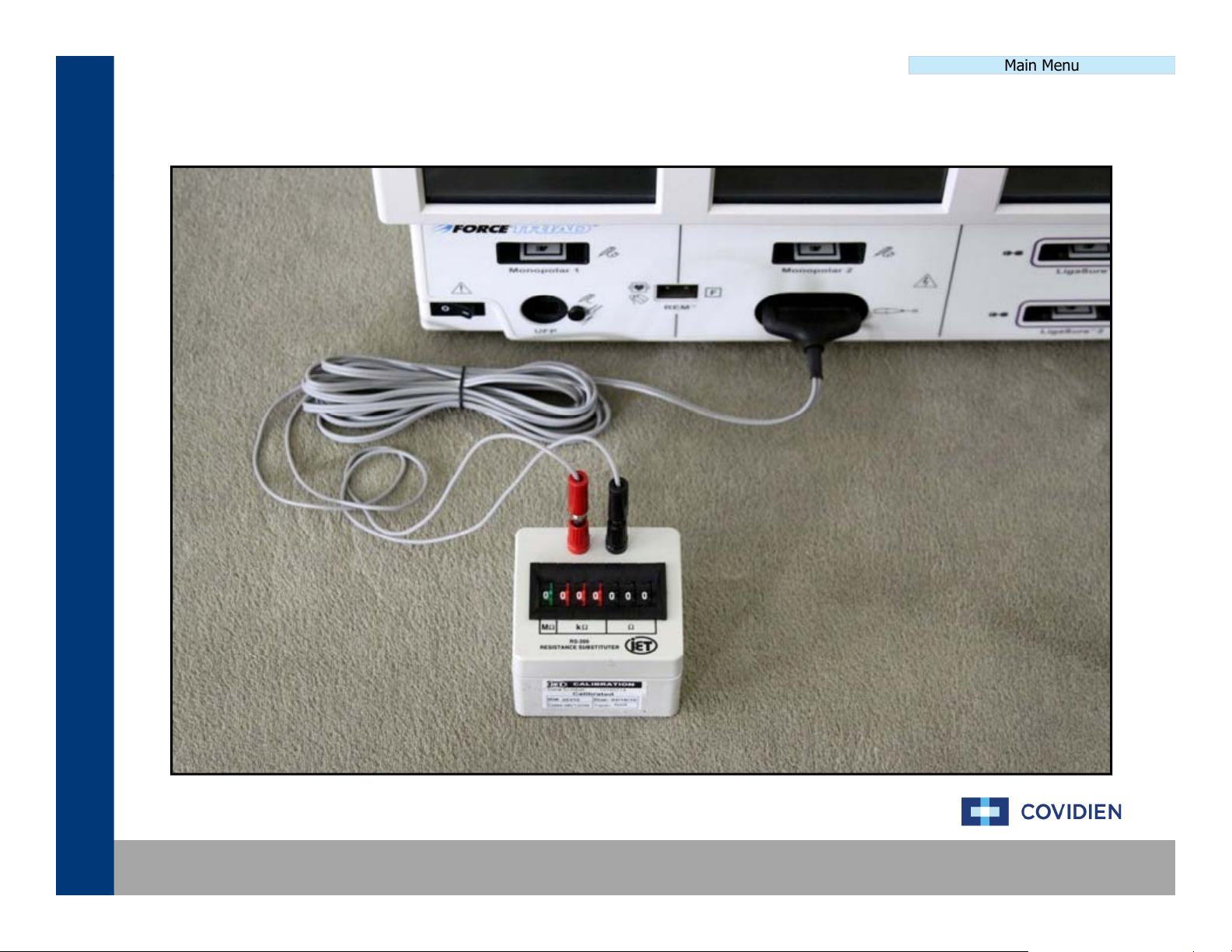

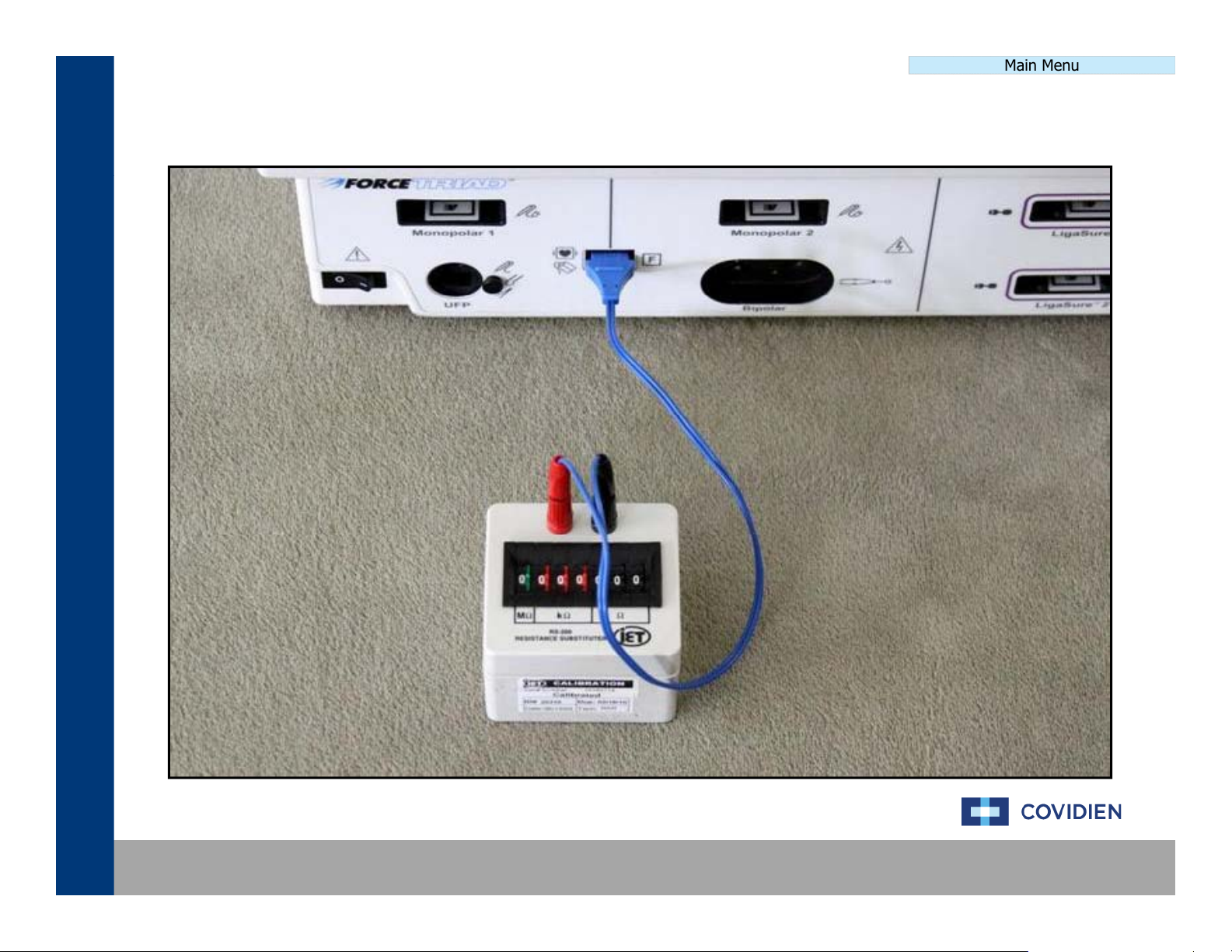

Calibration Procedure

LC Tuning Setup Example

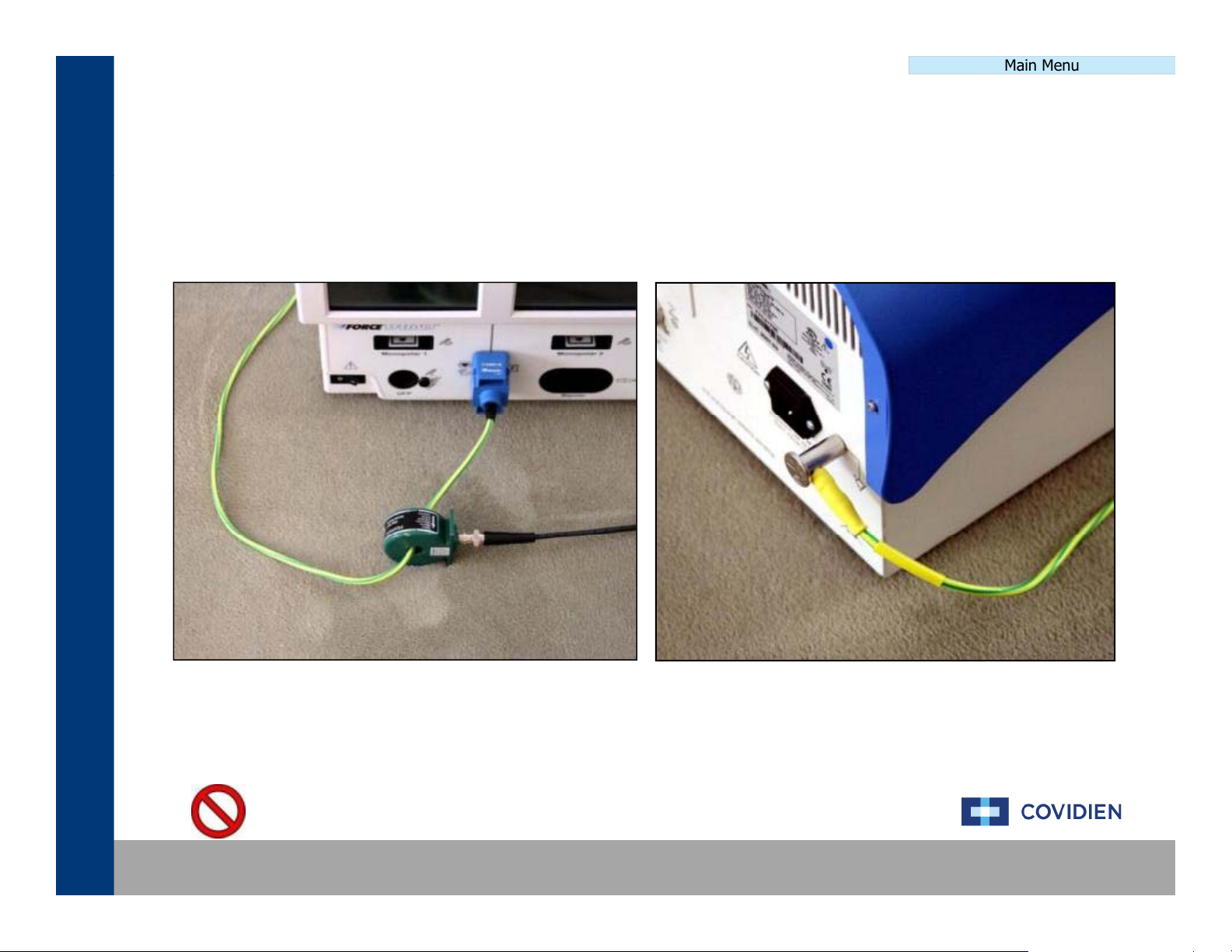

System Leakage Null CalibrationSystem Leakage Null Calibration

.

accomplished by using the equipment outlined below and using the touch screen menu navigating to the

calibration section.

Main Menu Service Diagnostics Debug Mode

LC Tuning Setup ExampleLC Tuning Setup Example

Covidien | December 7, 2011 | Confidential

Item Qty

Ground Lug Cable 1

D4 Cable with Current Probe 1

Current Monitor 1

REM Adaptor 1

#0 Flathead Screwdriver 1

LC Tuning Calibration SetupLC Tuning Calibration Setup

System Leakge Null Cal

Main Menu

Covidien | December 7, 2011 | Confidential

Utility CalibrationUtility Calibration

The

Utility

Calibration

process

consists

of

setting

up

the

date

&

time

screen

brightness

touch

screen

and

p

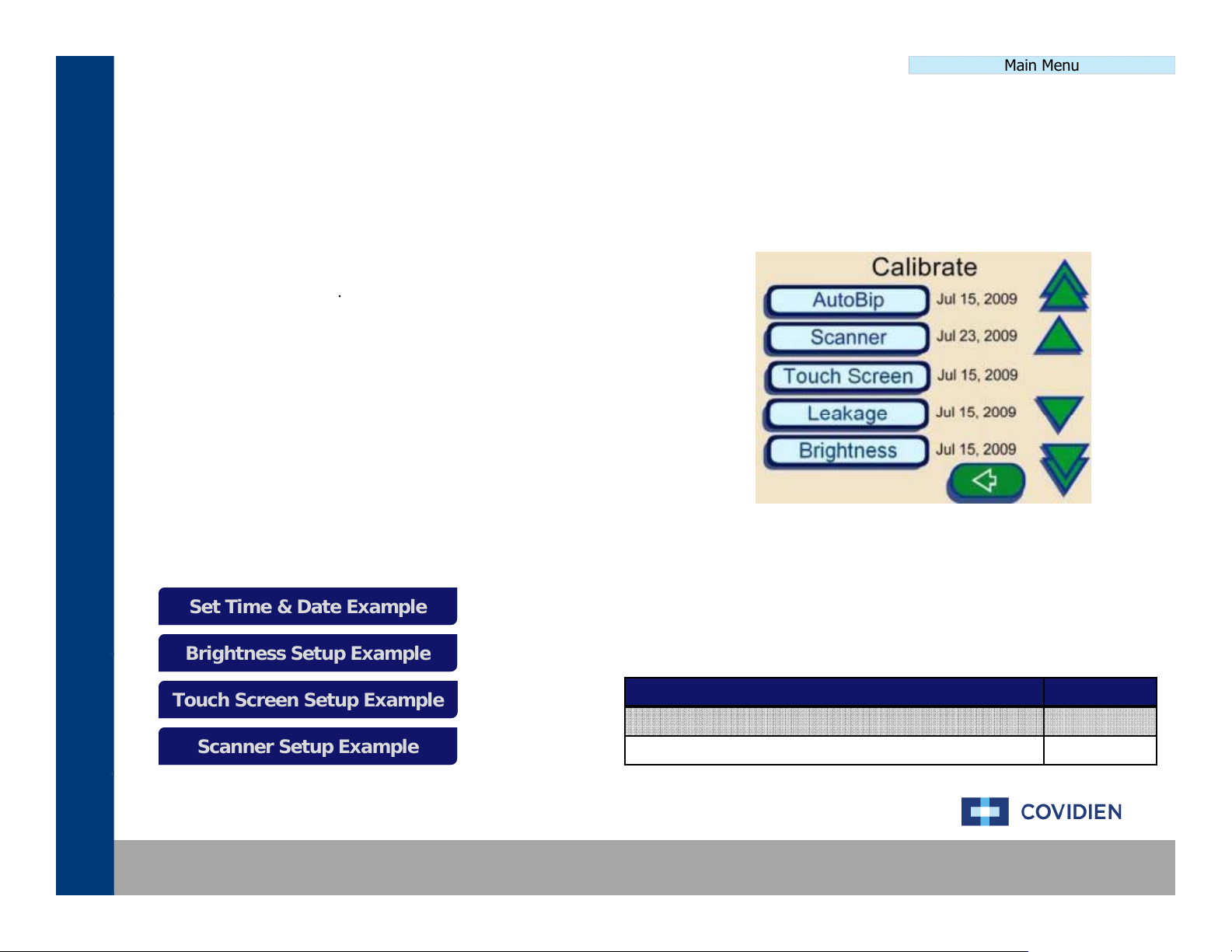

Brightness Setup ExampleBrightness Setup Example

Calibration Procedure

Set Time & Date Example

Brightness Setup Example

Touchscreen Setup Example

Scanner Setup Example

Main Menu

,

scanners on the system. This is accomplished by using the equipment outlined below and using the touch

screen menu navigating to the calibration section.

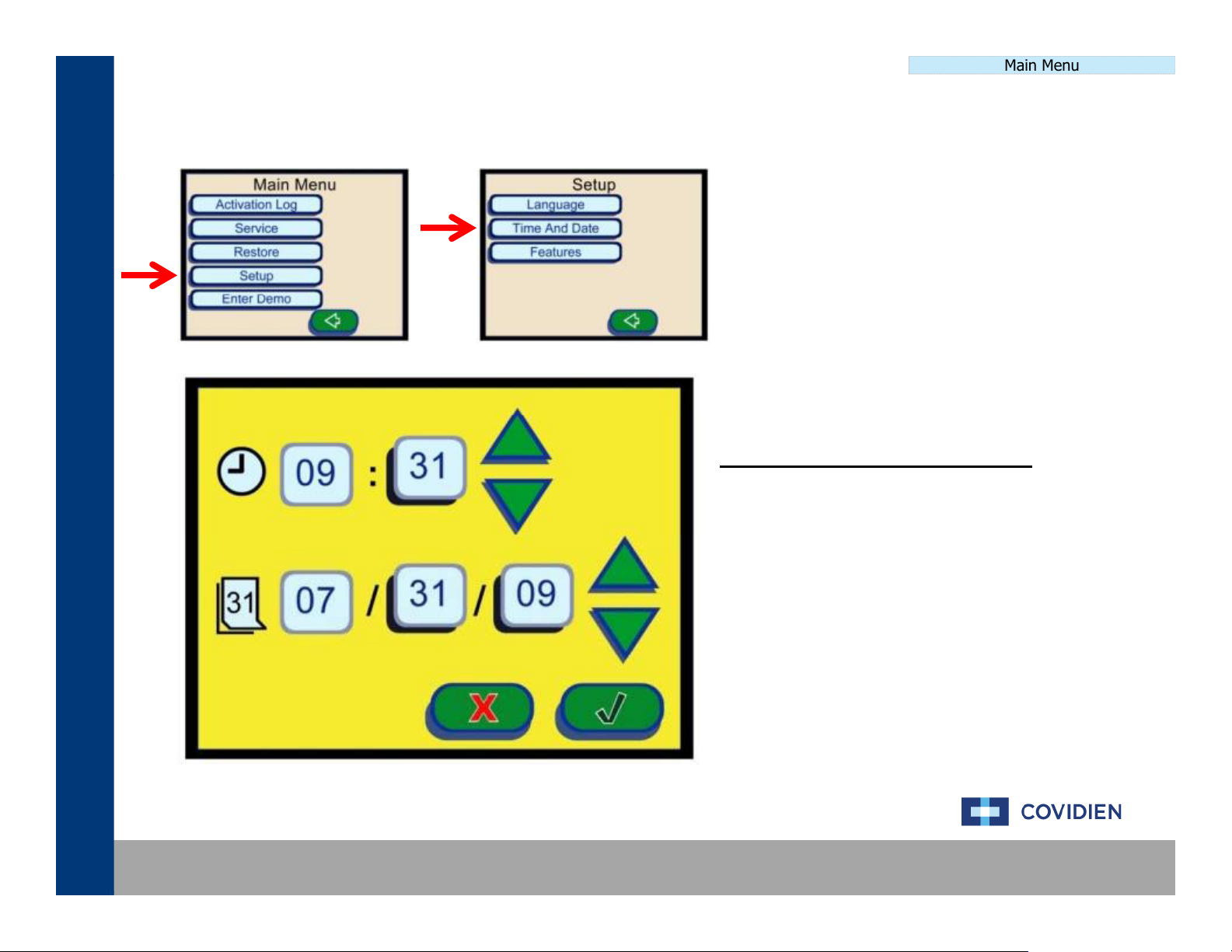

TIME & DATE:

Main Menu Setup TimeAnd Date

BRIGHTNESS, TOUCH SCREEN, & SCANNER:

Main Menu Service Maintenance Calibrate Brightness

Touch Screen

Scanner

Set Time & Date ExampleSet Time & Date Example

,

,

Touch Screen Setup ExampleTouch Screen Setup Example

Scanner Setup ExampleScanner Setup Example

Covidien | December 7, 2011 | Confidential

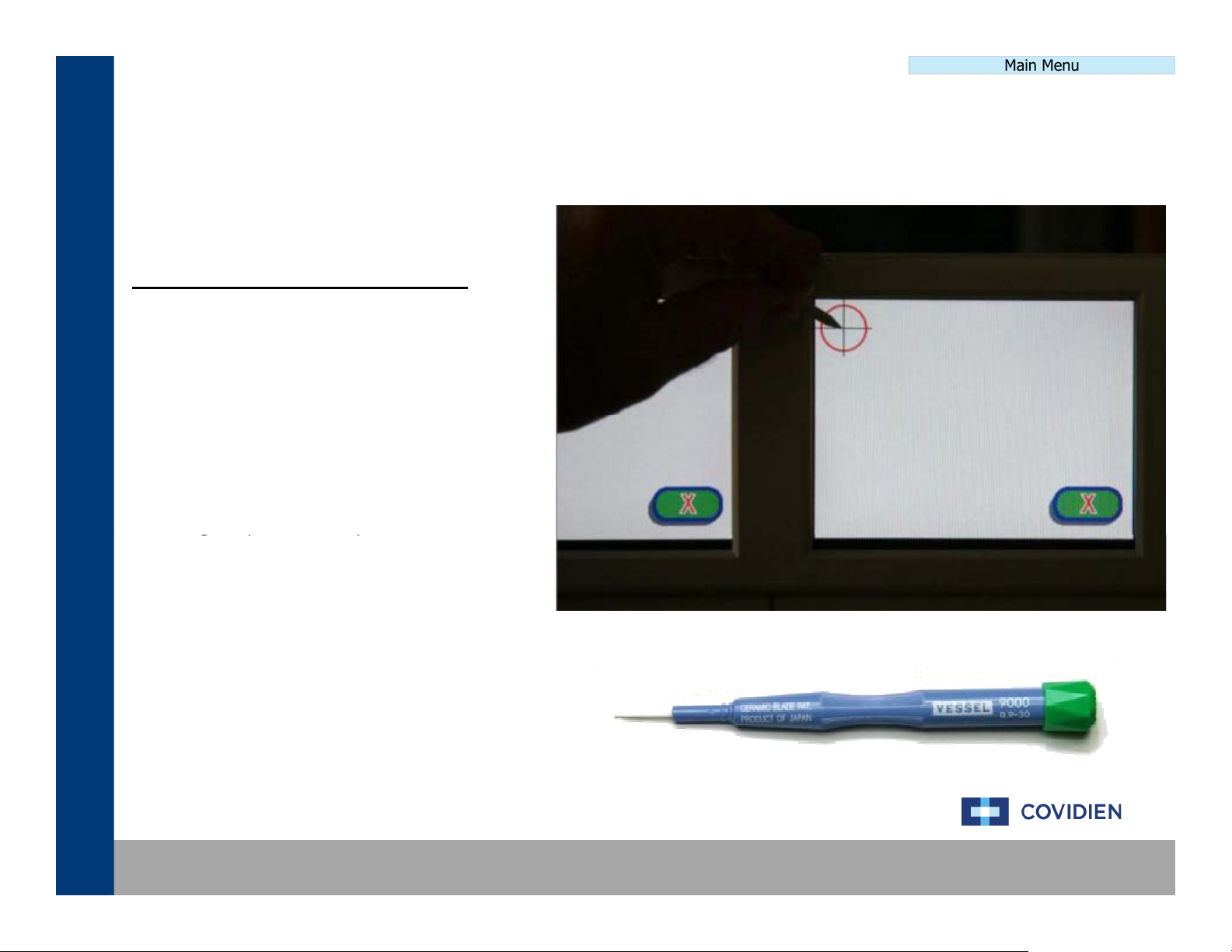

Item Qty

Stylus (Optional) 1

Ligasure 1 Dot Code Instrument 1

Set Time & Date SetupSet Time & Date Setup

time

Utility Calibration

Main Menu

DATE & TIME SETUP PROCEDURE

Navigate the ForceTriad touch screen menu to

“Setup”, then “Time And Date” to the screen to the

left. On this screen, use thegreen up and down

arrows to set the date and time.

After completion of setting the date and time,

select the green check mark to store the date &

.

Covidien | December 7, 2011 | Confidential

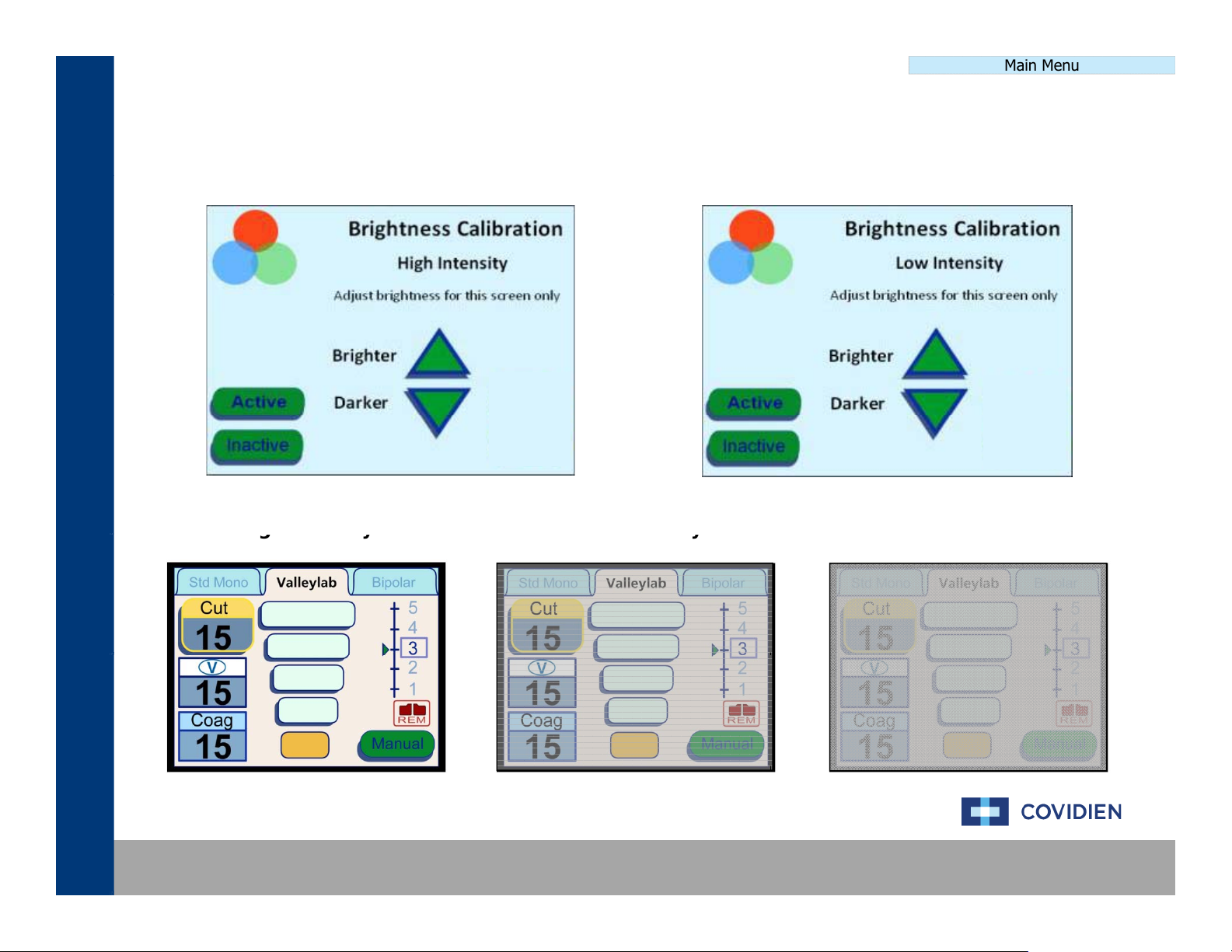

Brightness Calibration SetupBrightness Calibration Setup

High Intensity

Low Intensity

y

y

gy

y

Utility Calibration

Main Menu

Covidien | December 7, 2011 | Confidential

High Intensit

Low Intensit

Inactive Screen

Touch Screen Calibration SetupTouch Screen Calibration Setup

gpp

Utility Calibration

TOUCH SCREEN SETUP PROCEDURE

Under the “Calibration” section of the touch

screen menu, select the touch screen

calibration. You will be prompted to touch the

crosshair icon on the screen.

Preferably using a stylus, begin touching the

center mark of the crosshairs beginning with

the left screen moving right.

Main Menu

Your finger tip is an acceptable alternative to

the stylus.

Covidien | December 7, 2011 | Confidential

Scanner Calibration SetupScanner Calibration Setup

insert

dot

code

handsets

Utility Calibration

Scanner Calibration

Performing initial scanner calibration on all ports.

Please wait for calibration to complete.

Cancel may leave scanners in unusable state.

Main Menu

SCANNER SETUP PROCEDURE

Under the “Calibration” section of the touch screen menu,

select the scanner calibration. You will be prompted to

.

Using appropriate hand pieces, insert the hand piece into

the corresponding receptacles as prompted by the on

screen commands.

Covidien | December 7, 2011 | Confidential

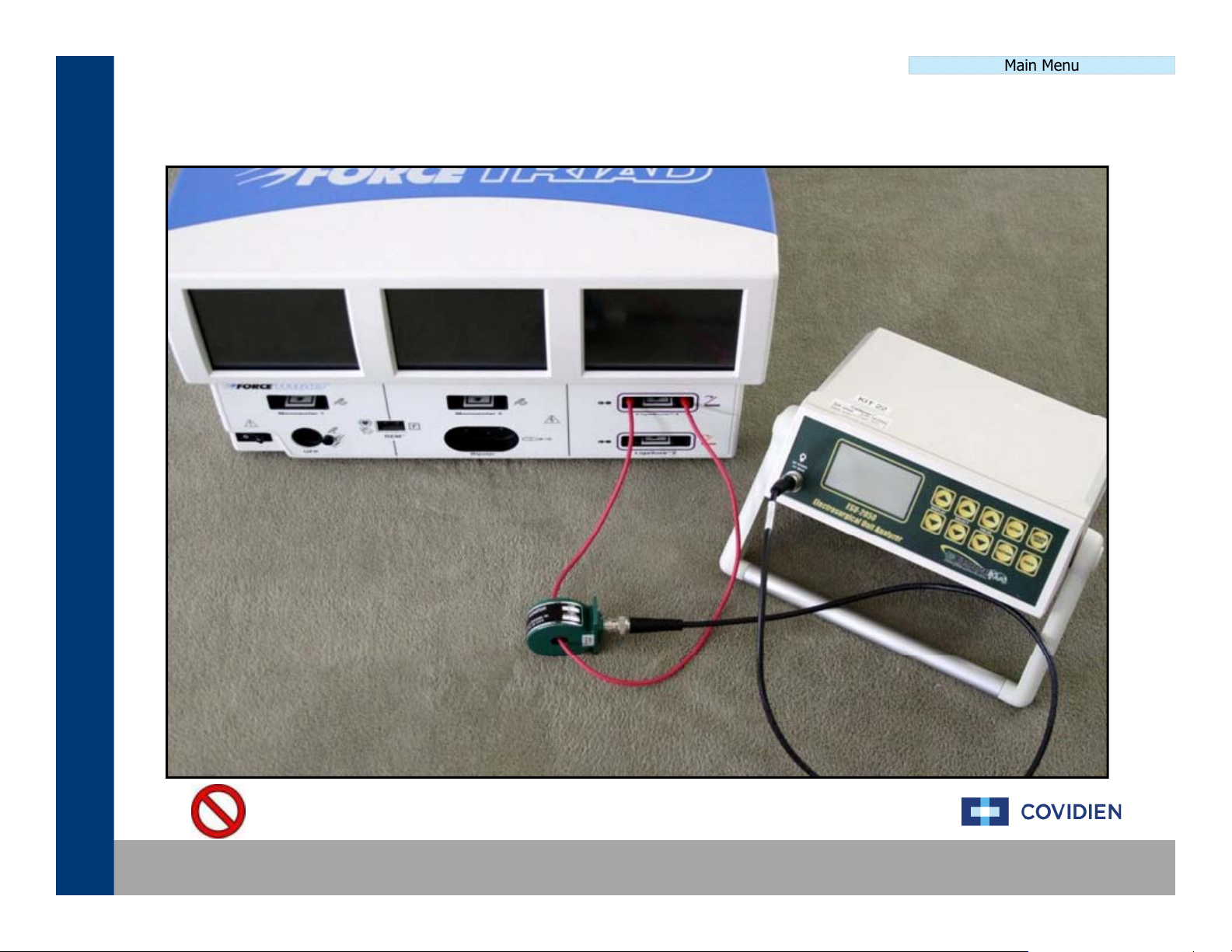

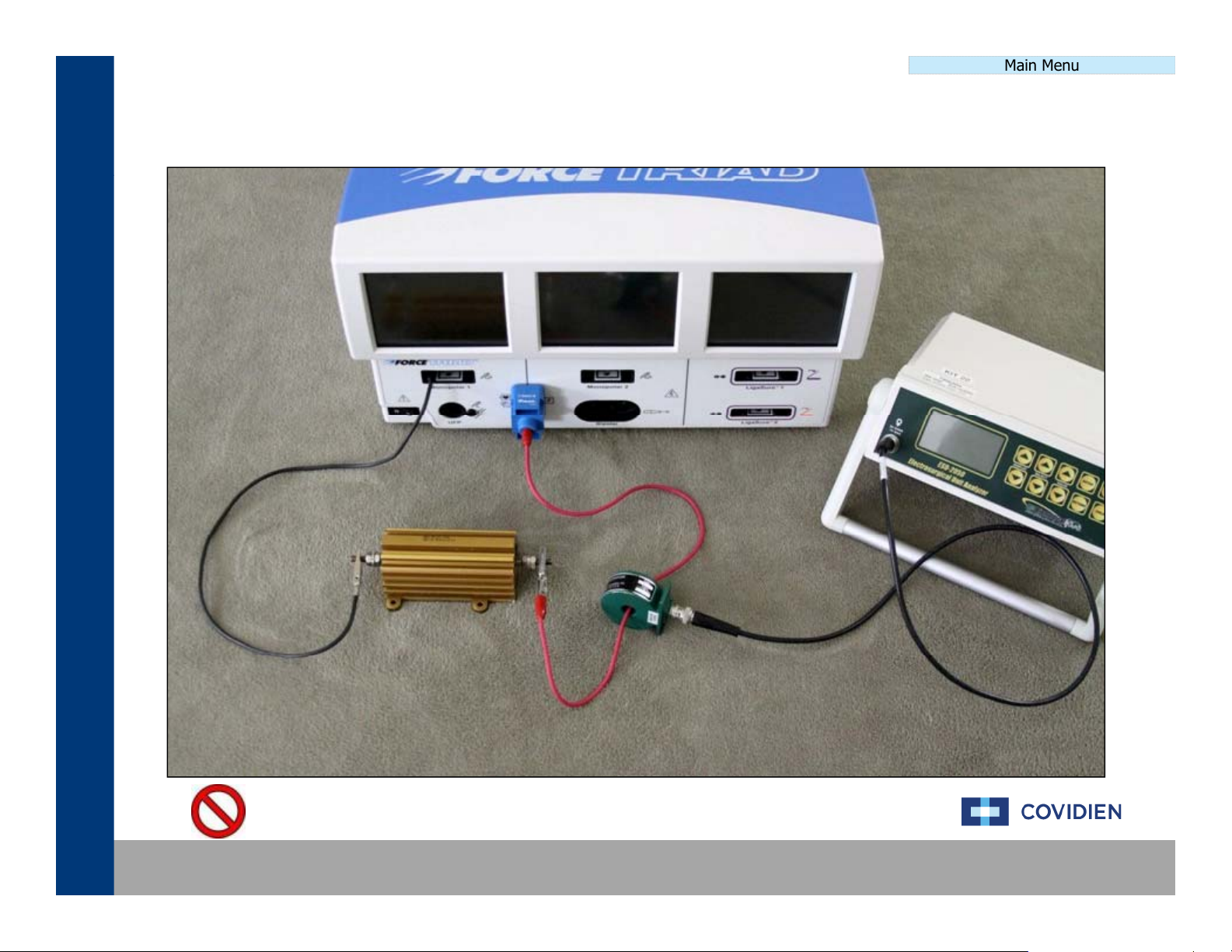

Power CalibrationPower Calibration

The

Power

Calibration

process

consists

of

measuring

theRFleakage

current

and

voltage

on

the

system

This

is

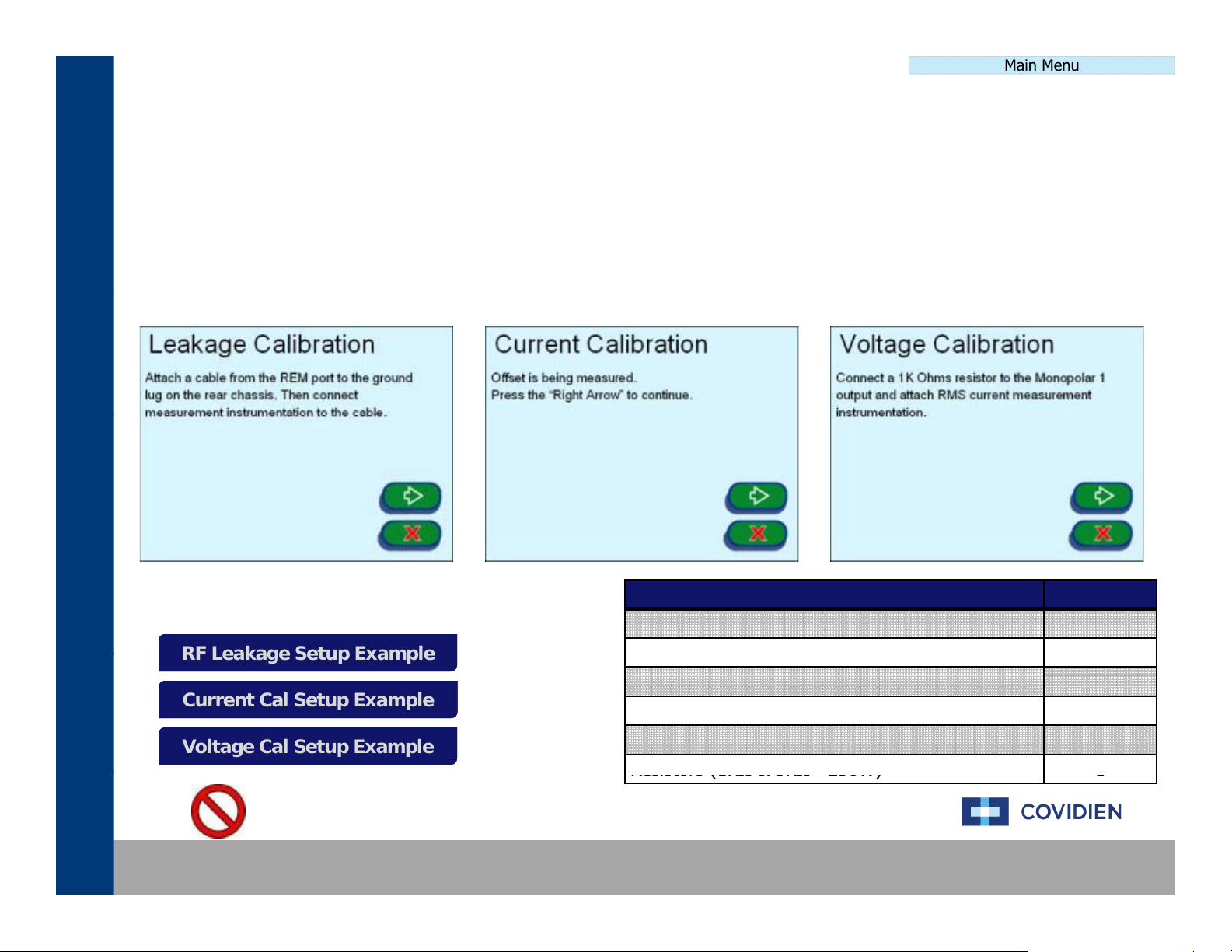

RF Leakage Setup ExampleRF Leakage Setup Example

D4 Cable with Current Probe

1

Resistors (1K

Ω

& 5K

Ω

250W)

1

Calibration Procedure

RF Leakage Setup Example

Current Cal Setup Example

Voltage Cal Setup Example

Main Menu

,

accomplished by using the equipment outlined below and using the touch screen menu navigating to the

calibration section.

Main Menu Service Maintenance Calibrate Leakage

Current Cal

Voltage Cal

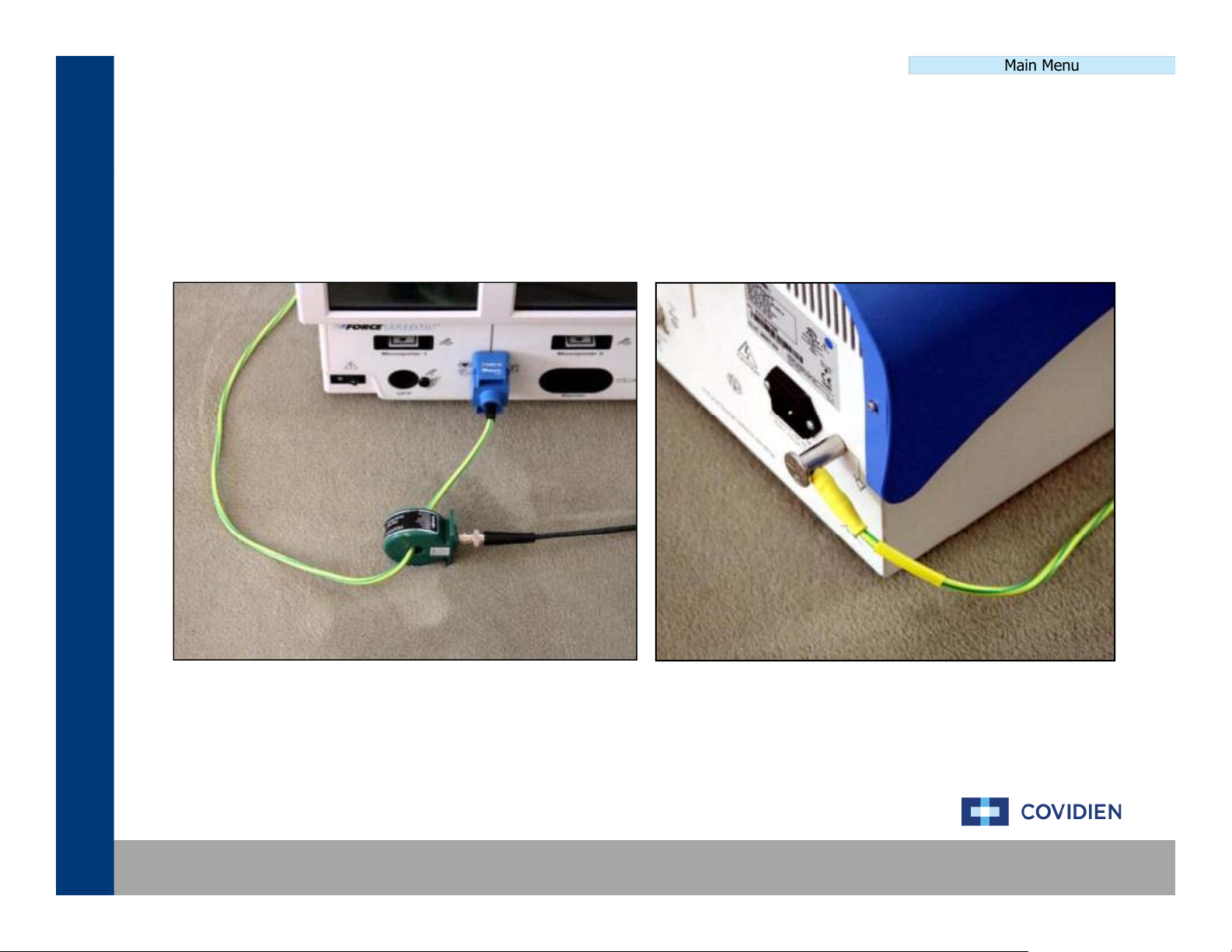

Item Qty

Ground Lug Cable 1

,

.

Current Cal Setup ExampleCurrent Cal Setup Example

Voltage Cal Setup ExampleVoltage Cal Setup Example

Covidien | December 7, 2011 | Confidential

Current Monitor 1

REM Adaptor 1

Cable Lead 2

-

WARNING: Do not hold down on the pushbuttons!

RF Leakage Calibration SetupRF Leakage Calibration Setup

Power Calibration

Main Menu

Covidien | December 7, 2011 | Confidential

WARNING: Do not hold down on the pushbuttons!

Current Calibration SetupCurrent Calibration Setup

Power Calibration

Main Menu

Covidien | December 7, 2011 | Confidential

WARNING: Do not hold down on the pushbuttons!

Voltage Calibration SetupVoltage Calibration Setup

Power Calibration

Main Menu

Covidien | December 7, 2011 | Confidential

WARNING: Do not hold down on the pushbuttons!

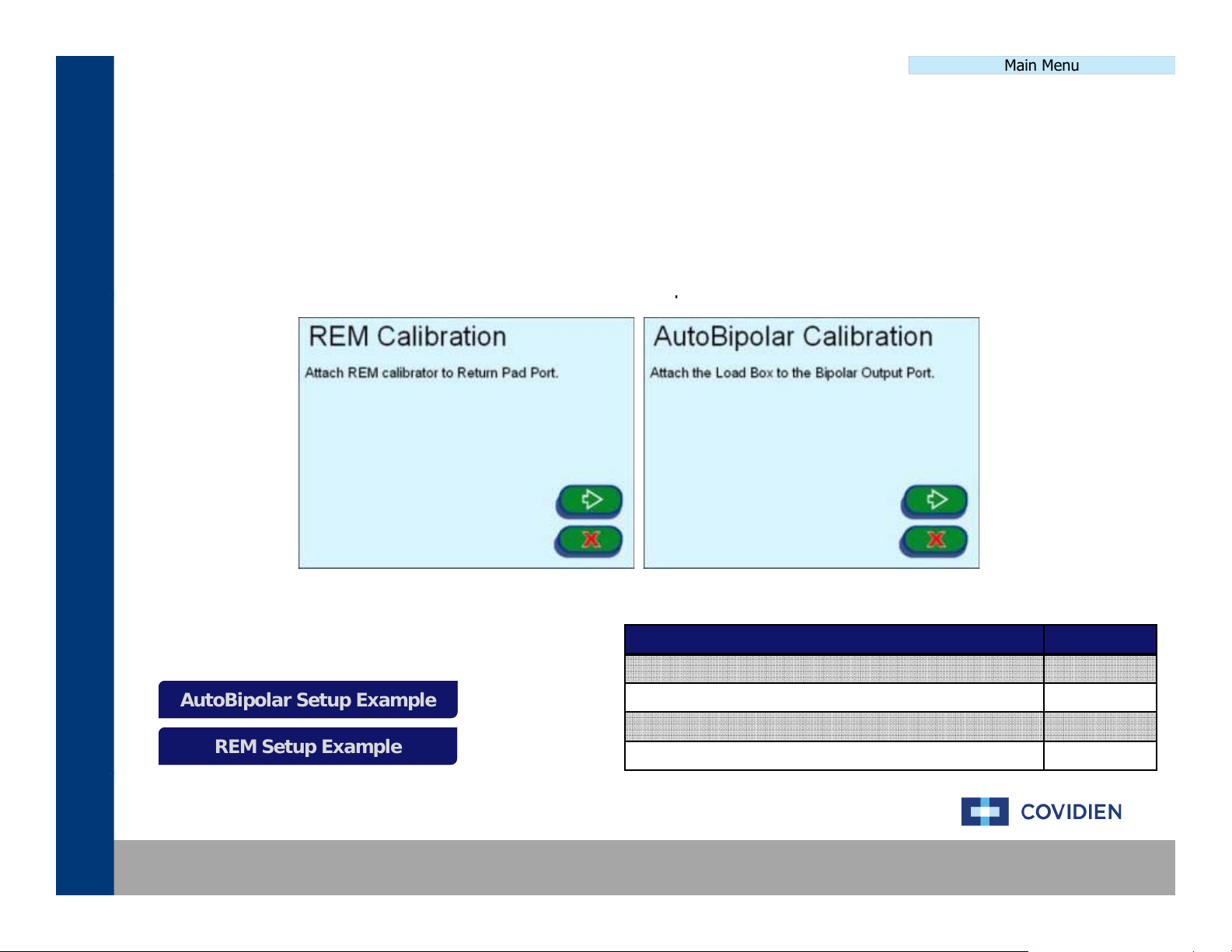

Main Menu

The

External

Sensor

Calibration

process

consists

of

measuring

the

REM

and

AutoBipolar

settings

on

the

system

p

p

Calibration Procedure

Autobipolar Setup Example

REM Setup Example

External Sensor CalibrationExternal Sensor Calibration

This is accomplished by using the equipment outlined below and using the touch screen menu navigating to the

calibration section.

Main Menu Service Maintenance Calibrate REM

AutoBi

.

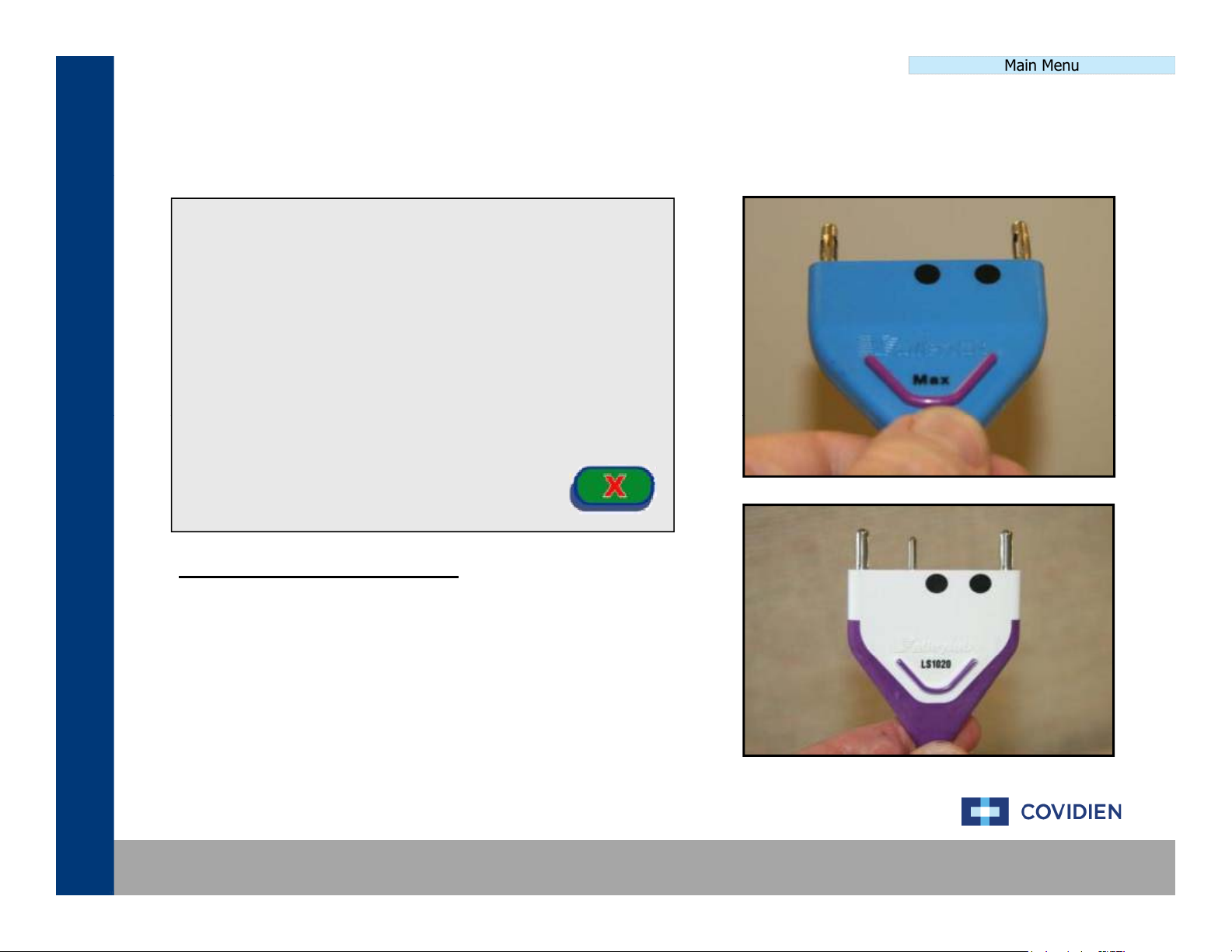

AutoBipolar Setup ExampleAutoBipolar Setup Example

REM Setup ExampleREM Setup Example

Covidien | December 7, 2011 | Confidential

Item Qty

REM Calibrator 1

Load Box 1

REM Calibration Cable 1

AutoBipolar Cable 1

Autobipolar Calibration SetupAutobipolar Calibration Setup

External Sensor Calibration

Main Menu

Covidien | December 7, 2011 | Confidential

REM Calibration SetupREM Calibration Setup

External Sensor Calibration

Main Menu

Covidien | December 7, 2011 | Confidential

Main Menu

E3E3

E12E12

E21E21

E259E259

E268E268

E277E277

E286E286

E295E295

E304E304

E5E5

E14E14

E23E23

E261E261

E270E270

E279E279

E288E288

E297E297

E306E306

E7E7

E16E16

E25E25

E263E263

E272E272

E281E281

E290E290

E299E299

E308E308

E9E9

E18E18

E27E27

E265E265

E274E274

E283E283

E292E292

E301E301

E310E310

Main Menu

E2

E11

E20

E258

E267

E276

E285

E294

E303

E3

E12

E21

E259

E268

E277

E286

E295

E304

E4

E13

E22

E260

E269

E278

E287

E296

E305

E5

E14

E23

E261

E270

E279

E288

E297

E6

E15

E24

E262

E271

E280

E289

E298

E306

E307

E7

E16

E25

E263

E272

E281

E290

E299

E8

E17

E26

E264

E273

E282

E291

E300

E308

E309

E9

E18

E27

E265

E274

E283

E292

E301

E310

E10

E19

E257

E266

E275

E284

E293

E302

E311

Non-Error Code Failures

Error Code Definition & TroubleshootingError Code Definition & Troubleshooting

E2E2

E4E4

E6E6

E8E8

E11E11

E13E13

E15E15

E17E17

E20E20

E22E22

E24E24

E26E26

E258E258

E260E260

E262E262

E264E264

E267E267

E269E269

E271E271

E273E273

E276E276

E278E278

E280E280

E282E282

E285E285

E287E287

E289E289

E291E291

E294E294

E296E296

E298E298

E300E300

E303E303

E305E305

E307E307

E309E309

E10E10

Covidien | December 7, 2011 | Confidential

E19E19

E257E257

E266E266

Non-Error Code FailuresNon-Error Code Failures

E275E275

E284E284

E293E293

E302E302

E311E311

NonNon--Error Code TroubleshootingError Code Troubleshooting

The system responds to a power cycle and begins the system initiation

The three

Dark ScreensDark Screens

display screens show a much darker screen of the expected white Covidien screen.

y

Main Menu

Gray Screens

Black Screens

Dark Screens

Flickering Screens

No Power

User Self-Test Error

Error Code Failures

The system responds to a power cycle and begins the system initiation. The three

Gray ScreensGray Screens

display screens show a blank, gray screen instead of displaying the white Covidien

screen.

Main Menu

Black ScreensBlack Screens

Flickering ScreensFlickering Screens

No PowerNo Power

User Self-Test ErrorUser Self-Test Error

.

display screens show a blank, black screen instead of displaying the white Covidien

screen.

The system responds to a power cycle and begins the system initiation. The three

This can range from slightly darker to nearly unreadable.

The system responds to a power cycle and begins the system initiation. The

screen and/or screens begin to flicker. The flickering can happen once or occur

constantly.

The system does not respond to a power cycle. The system displays and scanners

do not illuminate.

The system initiates the self-test and may pass a portion of the testing. The unit

then fails at some point during the self-test. The unit will generate an error but not

an error code.

Error Code FailuresError Code Failures

Covidien | December 7, 2011 | Confidential

NonNon--Error Code Failures Error Code Failures -- Gray ScreensGray Screens

T

LEADING

COMPONENT

REPLACEMENTS

1.P

Non-Error Code Menu

he failures that aregenerated where the

displays are blank and gray, there are a couple

of scenarios that could cause this. Typically,

cables that are not connected or fully

connected are the cause.

NON-COMPONENT ACTIONS

1. Power cycling the system

2. Inspecting the component cables

1. Ethernet Cable

• (Cable between Controller and Display)

2. Steering Relay Cable

• (Cable between SR and Display)

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

Covidien | December 7, 2011 | Confidential

NonNon--Error Code Failures Error Code Failures -- Black ScreensBlack Screens

T

NON

COMPONENT

ACTIONS

1.

Inverter

Board

1.P

Non-Error Code Menu

he failures that aregenerated where the

displays are blank and black, there is typically

one cause of this type of failure, the inverter

board.

-

1. Power cycling the system

2. Inspecting the component cables

LEADING COMPONENT REPLACEMENTS

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

Covidien | December 7, 2011 | Confidential

NonNon--Error Code Failures Error Code Failures ––No PowerNo Power

T

LEADING

COMPONENT

REPLACEMENTS

1.P

Non-Error Code Menu

he failures that aregenerated where the

system does not power on nor is there any

indication that the system received a signal to

power on. There are a couple of possibilities

to cause this type of failure.

NON-COMPONENT ACTIONS

1. Power cycling the system

2. Inspecting the component cables

1. System Fuse

2. Power Cable

3. Controller Board

4. Low Voltage Power Supply

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

Covidien | December 7, 2011 | Confidential

NonNon--Error Code Failures Error Code Failures ––User SelfUser Self--TestTest

T

NON

COMPONENT

ACTIONS

1.

Footswitch

Board

1.P

Non-Error Code Menu

he failure that isgenerated where the system

fails a user generated self-test via the

“Diagnostics” menu the typical failure mode is

the Footswitch Board.

-

1. Power cycling the system

2. Inspecting the component cables

LEADING COMPONENT REPLACEMENTS

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

Covidien | December 7, 2011 | Confidential

Main Menu

T

NON

COMPONENT

ACTIONS

er

Cable

oe

Cab e

1.P

Non-Error Code Menu

NonNon--Error Code Failures Error Code Failures –– Flickering ScreensFlickering Screens

he failure that isgenerated where the system

fails a user generated self-test via the

“Diagnostics” menu the typical failure mode is

the Footswitch Board.

-

1. Power cycling the system

2. Inspecting the component cables

LEADING COMPONENT REPLACEMENTS

1. Pow

• (Cable between SR and Display)

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

Covidien | December 7, 2011 | Confidential

NonNon--Error Code Failures Error Code Failures –– Dark ScreensDark Screens

T

NON

COMPONENT

ACTIONS

G

COMPO

S

G

CO O

CS

1.P

Non-Error Code Menu

he failure that isgenerated where the system

fails a user generated self-test via the

“Diagnostics” menu the typical failure mode is

the Footswitch Board.

-

1. Power cycling the system

2. Inspecting the component cables

3. Brightness calibration

Main Menu

LEADIN

1. Display Inverter

NENT REPLACEMENT

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a brightness calibration as outlined in the Service Manual.

Covidien | December 7, 2011 | Confidential

E2 E2 –– ERR_SE_ICL_ERRORERR_SE_ICL_ERROR

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E2 error code is designated and issued to

signify that the unit is unable to communicate

to the hardware using the HOST ICL registers.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E3 E3 –– ERR_SE_APP_ROM_FAILERR_SE_APP_ROM_FAIL

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E3 error code is designated and issued to

signify that the DSP application ROM check

failed during start-up.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E4 E4 –– ERR_SE_BOOT_ROM_FAILERR_SE_BOOT_ROM_FAIL

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E4 error code is designated and issued to

signify that the DSP boot ROM check failed

during start-up.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E5 E5 -- ERR_SE_RAM_FAILERR_SE_RAM_FAIL

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E5 error code is designated and issued to

signify that the DSP RAM check failed during

start-up.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E6 E6 –– ERR_SE_RTOS_FAILERR_SE_RTOS_FAIL

T

NON

COMPONENT

ACTIONS

1.

Controller

Board

1.P

Error Code Definition Menu

he E6 error code is designated and issued to

signify that a software error has occurred.

The E6 error code is typically issued during

real time to signify an operating system error.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

2. System Display

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E7 E7 –– ERR_SE_GEN_FAILERR_SE_GEN_FAIL

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E7 error code is designated and issued to

signify that the generator has developed a

general system error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E8 E8 -- ERR_SE_CRITICAL_DATAERR_SE_CRITICAL_DATA

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E8 error code is designated and issued to

signify that the system has a software error

caused by a corrupt data string.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E9 E9 -- ERR_SE_ASSERTERR_SE_ASSERT

T

NON

COMPONENT

ACTIONS

Controller

d

Co t o e

oa d

1.P

Error Code Definition Menu

he E9 error code is designated and issued to

signify that the system has developed a

software error that has generated an

assertion.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1.

Boar

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E10 E10 -- ERR_SE_INVALID_DATAERR_SE_INVALID_DATA

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E10 error code is designated and issued

to signify that a software failure occurred

because of an invalid data string.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

E11 E11 -- ERR_SE_MACHINE_CHECK_EXCEPTIONERR_SE_MACHINE_CHECK_EXCEPTION

he E11 error code is designated and issued

to signify that a HOST processor machine

check exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

E12 E12 -- ERR_SE_DATA_STORAGE_EXCEPTIONERR_SE_DATA_STORAGE_EXCEPTION

he E12 error code is designated and issued

to signify that a HOST processor data storage

exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E13 E13 -- ERR_SE_ISI_EXCEPTIONERR_SE_ISI_EXCEPTION

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E13 error code is designated and issued

to signify that a HOST processor data storage

exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E14 E14 -- ERR_SE_ALIGNMENT_EXCEPTIONERR_SE_ALIGNMENT_EXCEPTION

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E14 error code is designated and issued

to signify that a HOST processor alignment

exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E15 E15 -- ERR_SE_PROGRAM_EXCEPTIONERR_SE_PROGRAM_EXCEPTION

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E15 error code is designated and issued

to signify that a HOST processor program

exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

E16 E16 -- ERR_SE_FP_UNAVAILABLE_EXCEPTIONERR_SE_FP_UNAVAILABLE_EXCEPTION

he E16 error code is designated and issued

to signify that a HOST processor floating point

unavailable exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E17 E17 -- ERR_SE_SYS_CAL_EXCEPTIONERR_SE_SYS_CAL_EXCEPTION

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E17 error code is designated and issued

to signify that a HOST processor system call

exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E18 E18 -- ERR_SE_TRACE_EXCEPTIONERR_SE_TRACE_EXCEPTION

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E18 error code is designated and issued

to signify that a HOST processor trace

exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E19 E19 -- ERR_FP_ASSIST_EXCEPTIONERR_FP_ASSIST_EXCEPTION

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E19 error code is designated and issued

to signify that a HOST processor floating point

assist exception has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E20 E20 -- ERR_SE_MEM_ALLOC_FAILERR_SE_MEM_ALLOC_FAIL

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E20 error code is designated and issued

to signify that a memory allocation failure

within the unit has occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E21 E21 -- ERR_SE_UNKNOWN_EXCEPTIONERR_SE_UNKNOWN_EXCEPTION

T

NON

COMPONENT

ACTIONS

Controller

d

Co t o e

oa d

1.P

Error Code Definition Menu

he E21 error code is designated and issued

to signify that a HOST processor has

generated an unknown exception and that the

exception vector is not a valid vector.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1.

Boar

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E22 E22 -- ERR_SE_UNKNOWN_INTERRUPTERR_SE_UNKNOWN_INTERRUPT

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E22 error code is designated and issued

to signify that a HOST processor has received

an interrupt that is not initialized.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E23 E23 -- ERR_SE_STACK_OVERFLOWERR_SE_STACK_OVERFLOW

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E23 error code is designated and issued

to signify that a thread on the HOST has

overflowed its stack.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E24 E24 -- ERR_SE_DMA_FAILUREERR_SE_DMA_FAILURE

T

2.Performing

a

full

recalibration

1.P

Error Code Definition Menu

he E24 error code is designated and issued

to signify that the iDMA is stuck.

NON-COMPONENT ACTIONS

1. Power cycling the system

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E25 E25 -- ERR_SE_UNHANDLED_INTERRUPTERR_SE_UNHANDLED_INTERRUPT

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E25 error code is designated and issued

to signify that a HOST processor has received

an interrupt that it does not how to handle..

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

E26 E26 -- ERR_SE_MAX_NUM_THREADS_REGERR_SE_MAX_NUM_THREADS_REG

he E289 error code is designated and issued

to signify that a HOST code has attempted to

register more threads than what is allowed.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E27 E27 -- ERR_SE_NULL_POINTERERR_SE_NULL_POINTER

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E27 error code is designated and issued

to signify that a HOST code has detected a

pointer that has a NULL value.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E257 E257 -- ERR_NR_DOSAGEERR_NR_DOSAGE

T

1.Power

cycling

the

system

2.RFBoard

1.P

Error Code Definition Menu

he E257 error code is designated and issued

to signify that the system has a general RF

dosage error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E258 E258 -- ERR_NR_MEM_ALLOC_FAILERR_NR_MEM_ALLOC_FAIL

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E258 error code is designated and issued

to signify that the system has generated a

memory allocation software error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E259 E259 -- ERR_NR_INVALID_DATAERR_NR_INVALID_DATA

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E259 error code is designated and issued

to signify that the system has generated

invalid data causing a software error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E260 E260 -- ERR_NR_COM_ERRORERR_NR_COM_ERROR

T

1.Power

cycling

the

system

1.P

seated

Error Code Definition Menu

he E260 error code is designated and issued

to signify that the system has generated a

generic communication error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Verify the ribbon cables and FTSW cable connections are securely

.

4. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E261 E261 -- ERR_NR_HW_ERRORERR_NR_HW_ERROR

T

1.Power

cycling

the

system

tage

er

Supply

o

o tage

oe

Supp y

1.P

Error Code Definition Menu

he E289 error code is designated and issued

to signify that the system has generated a

hardware or controller error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. HVDC Board

2. LowVol

Pow

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E262 E262 -- ERR_NR_ACT_DENIEDERR_NR_ACT_DENIED

T

1.Power

cycling

the

system

d

S

oa d

1.P

Error Code Definition Menu

he E262 error code is designated and issued

to signify that the system has denied activation

and generated an error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

2. FTSWBoar

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E263 E263 -- ERR_NR_INVALID_STATEERR_NR_INVALID_STATE

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E263 error code is designated and issued

to signify that the system has entered an

invalid state and generated an error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E264 E264 -- ERR_NR_UNSUPPORTED_CMDERR_NR_UNSUPPORTED_CMD

T

NON

COMPONENT

ACTIONS

Controller

d

Co t o e

oa d

1.P

Error Code Definition Menu

he E264 error code is designated and issued

to signify that the system has interrupted a

command that is not supported and generated

and error.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1.

Boar

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E265 E265 -- ERR_NR_ACCESS_FUNCTIONERR_NR_ACCESS_FUNCTION

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E265 error code is designated and issued

to signify that the system has generated an

error while performing an access function.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E266 E266 -- ERR_NR_TIMEOUT_ERRORERR_NR_TIMEOUT_ERROR

T

1.Power

cycling

the

system

1.P

seated

Error Code Definition Menu

he E266 error code is designated and issued

to signify that the system has generated a

timeout and caused an error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Verify the ribbon cables and FTSW cable connections are securely

.

4. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E267 E267 -- ERR_NR_GEN_ERRORERR_NR_GEN_ERROR

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E267 error code is designated and issued

to signify that the system has generated an

unknown system error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E268 E268 -- ERR_NR_SELF_TEST_ERRORERR_NR_SELF_TEST_ERROR

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E268 error code is designated and issued

to signify that the system has failed the initial

start-up self test and generated an error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E269 E269 -- ERR_NR_DISPLAY_ERRORERR_NR_DISPLAY_ERROR

T

1.Power

cycling

the

system

ays

sp ays

1.P

Error Code Definition Menu

he E269 error code is designated and issued

to signify that the system has generated an

error due to a display issue during start-up.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Displays Cables

2. Displ

3. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E270 E270 -- ERR_NR_AUDIBLE_ERRORERR_NR_AUDIBLE_ERROR

T

1.Power

cycling

the

system

2.

Controller

Board

1.P

Error Code Definition Menu

he E270 error code is designated and issued

to signify that the system has failed the

audible self test and generated an error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Foot Switch Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

1.Power

cycling

the

system

2.

Displays

1.P

Error Code Definition Menu

E271 E271 -- ERR_NR_STUCK_BUTTON_ERRORERR_NR_STUCK_BUTTON_ERROR

he E271 error code is designated and issued

to signify that the system has generated an

error during the self-test due to a stuck button.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

3. FTSW Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E272 E272 ––NOT_USEDNOT_USED

T

representative

for

further

information

Error Code Definition Menu

he E272 error code is not used.

Should you have a version of ForceTriad that

delivers a E272 error code, please contact

your local Covidien Customer Service

.

Main Menu

Covidien | December 7, 2011 | Confidential

Main Menu

T

NON

COMPONENT

ACTIONS

Controller

d

Co t o e

oa d

1.P

Error Code Definition Menu

E273 E273 -- ERR_NR_INTER_PROC_COM_ERRORERR_NR_INTER_PROC_COM_ERROR

he E273 error code is designated and issued

to signify that the system has generated an

error during self-test due to an inter-processor

communication issue.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1.

Boar

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

calibration

is

required

on

the

unit

1.P

Error Code Definition Menu

E274 E274 -- ERR_NR_CRITICAL_DATA_ERRORERR_NR_CRITICAL_DATA_ERROR

he E274 error code is designated and issued

to signify that the system has generated an

error during self-test where the unit did not

receive critical information required for startup. This is most commonly seen when

.

NON-COMPONENT ACTIONS

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Scanners

2. Controller Board

3. Scanner Cables

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

1.Power

cycling

the

system

1.P

seated

Error Code Definition Menu

E275 E275 -- ERR_NR_MULTI_TASKING_ERRORERR_NR_MULTI_TASKING_ERROR

he E275 error code is designated and issued

to signify that the system has generated an

error during self-test while multi-tasking.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Verify the ribbon cables and FTSW cable connections are securely

.

4. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

NON

COMPONENT

ACTIONS

1.RFBoard

1.P

Error Code Definition Menu

E276 E276 -- ERR_NR_ANALOG_SENSOR_ERRORERR_NR_ANALOG_SENSOR_ERROR

he E276 error code is designated and issued

to signify that the system has generated an

error during self-test while testing an analog

sensor.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

NON

COMPONENT

ACTIONS

d

C

oa d

1.P

Error Code Definition Menu

E277 E277 -- ERR_NR_RF_SHUT_DWN_1_ERRORERR_NR_RF_SHUT_DWN_1_ERROR

he E277 error code is designated and issued

to signify that the system has generated an

error during RF self-test #1 while attempting to

shutdown the RF generation.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. HVDCBoar

2. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

NON

COMPONENT

ACTIONS

d

oa d

1.P

Error Code Definition Menu

E278 E278 -- ERR_NR_RF_SHUT_DWN_2_ERRORERR_NR_RF_SHUT_DWN_2_ERROR

he E289 error code is designated and issued

to signify that the system has generated an

error during RF self-test #2 while attempting to

shutdown the RF generation.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. RF Boar

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

NON

COMPONENT

ACTIONS

d

oa d

1.P

Error Code Definition Menu

E279 E279 -- ERR_NR_RF_SHUT_DWN_3_ERRORERR_NR_RF_SHUT_DWN_3_ERROR

he E279 error code is designated and issued

to signify that the system has generated an

error during RF self-test #3 while attempting to

shutdown the RF generation.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. RF Boar

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E280 E280 -- ERR_NR_TIMEBASE_ERRORERR_NR_TIMEBASE_ERROR

T

NON

COMPONENT

ACTIONS

1.

Controller

Board

1.P

Error Code Definition Menu

he E280 error code is designated and issued

to signify that the system has generated an

error during self-test while attempting to

compare the time base.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

E281 E281 -- ERR_NR_SYS_WATCH_DOG_ERRORERR_NR_SYS_WATCH_DOG_ERROR

he E281 error code is designated and issued

to signify that the system has generated a

communication error during self-test.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E282 E282 -- ERR_NR_ICL_PROG_ERRORERR_NR_ICL_PROG_ERROR

T

LEADING

COMPONENT

REPLACEMENTS

1.P

Error Code Definition Menu

he E282 error code is designated and issued

to signify that the system has generated an

error during self-test while attempting to pull

information from the ICL chip on the controller

board.

NON-COMPONENT ACTIONS

1. Power cycling the system

2. Performing a full recalibration

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E283 E283 -- ERR_NR_RAM_MEMORY_ERRORERR_NR_RAM_MEMORY_ERROR

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E283 error code is designated and issued

to signify that the system has generated a

RAM error during self-test.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

E284 E284 -- ERR_NR_FLASH_MEMORY_ERRORERR_NR_FLASH_MEMORY_ERROR

he E284 error code is designated and issued

to signify that the system has generated a

flash error during self-test.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

Main Menu

T

software

1.P

Error Code Definition Menu

E285 E285 -- ERR_NR_INVALID_CONFIG_DATAERR_NR_INVALID_CONFIG_DATA

he E285 error code is designated and issued

to signify that the system has generated an

error during self-test. This particular error is to

inform the user the equipment configuration is

not valid or there is checksum error within the

.

NON-COMPONENT ACTIONS

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E286 E286 -- ERR_NR_NULL_PTRERR_NR_NULL_PTR

T

NON

COMPONENT

ACTIONS

1.

Controller

Board

1.P

Error Code Definition Menu

he E286 error code is designated and issued

to signify that the system has generated a

software error where the null pointer was

detected during self-test.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

2. Displays

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E287 E287 -- ERR_NR_AIEERR_NR_AIE

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

Additional Troubleshooting

he E287 error code is designated and issued

to signify that an absolute integer error has

occurred.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

Covidien | December 7, 2011 | Confidential

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Additional TroubleshootingAdditional Troubleshooting

E288 E288 -- ERR_NR_SENSOR_CLIPERR_NR_SENSOR_CLIP

T

1.Power

cycling

the

system

2.RFBoard

1.P

Error Code Definition Menu

he E288 error code is designated and issued

to signify that the system has developed a

DSP sensor clip error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. HVDC Board

3. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E289 E289 -- ERR_NR_SENSOR_COMPAREERR_NR_SENSOR_COMPARE

T

1.Power

cycling

the

system

2.RFBoard

1.P

Error Code Definition Menu

Additional Troubleshooting

he E289 error code is designated and issued

to signify that the sensor comparing the DSPs

has an error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

3. HVDC Board

Main Menu

Covidien | December 7, 2011 | Confidential

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Additional TroubleshootingAdditional Troubleshooting

Main Menu

T

NON

COMPONENT

ACTIONS

1.

Controller

Board

1.P

Error Code Definition Menu

E290 E290 -- ERR_NR_DATA_SAMPLE_ERRORRERR_NR_DATA_SAMPLE_ERRORR

he E290 error code is designated and issued

to signify that the system has generated a

sampling error while conducting data sampling

of the VI.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E291 E291 -- ERR_NR_COMM_WD_ERRORERR_NR_COMM_WD_ERROR

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E289 error code is designated and issued

to signify that the system has generated a

watchdog (communication) error.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E292 E292 -- ERR_NR_DSP_SW_ERRORERR_NR_DSP_SW_ERROR

T

1.Power

cycling

the

system

2.

HVDC

Board

1.P

Error Code Definition Menu

he E292 error code is designated and issued

to signify that the system has generated a

software error caused by issues with the DSP.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E293 E293 -- ERR_NR_FLASH_ERRORERR_NR_FLASH_ERROR

T

NON

COMPONENT

ACTIONS

1.

Controller

Board

1.P

Error Code Definition Menu

he E293 error code is designated and issued

to signify that the system has generated a

software error while attempting to write to the

FLASH memory.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E294 E294 -- ERR_NR_OS_ERRORERR_NR_OS_ERROR

T

1.Power

cycling

the

system

1.P

Error Code Definition Menu

he E294 error code is designated and issued

to signify that the system has generated an

operating system error in real time.

NON-COMPONENT ACTIONS

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

1. Controller Board

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.

Covidien | December 7, 2011 | Confidential

E295 E295 -- ERR_NR_NV_STORE_ERRORERR_NR_NV_STORE_ERROR

T

NON

COMPONENT

ACTIONS

1.

Controller

Board

1.P

Error Code Definition Menu

he E295 error code is designated and issued

to signify that the system has generated a

software error while attempting to write to the

NV store.

-

1. Power cycling the system

2. Performing a full recalibration

LEADING COMPONENT REPLACEMENTS

Main Menu

NON-COMPONENT ACTIONS INSTRUCTION

ower Cycle the unit and allow the system to perform the self-test.

2. Remove the cover to the ForceTriad system and inspect the system

boards ensuring that the boards are properly seated within the

unit and that all cables are also securely connected.

3. Perform a level 6 calibration as outlined in the Calibration Section.