Page 1

ICE DISPENSER

D45 and D90

Installation Manual

Publication Number: 91561

Revision Date: January 23, 2012

Revision: C

Visit the IMI Cornelius web site at

www.cornelius.com for all your Literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possi

ble contingency in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic,

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warrant applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained per

sons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of “non-authorized” parts (i.e., parts that are not 100%

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

-

-

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

Printed in U.S.A.

Page 3

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Different Types of Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Qualified Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mounting in or on a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Ice Dispenser Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DISPENSER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DAILY (OR AS REQUIRED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WEEKLY (OR AS REQUIRED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MONTHLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BLOWN FUSE OR CIRCUITBREAKER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

GATE DOES NOT OPEN. AGITATOR DOES NOT TURN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

GATE DOES NOT OPEN OR IS SLUGGISH. AGITATOR TURNS. . . . . . . . . . . . . . . . . . . . . . . 9

GATE OPENS. AGITATOR DOES NOT TURN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ICE DISPENSES CONTINUOUSLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SLUSHY ICE. WATER IN HOPPER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Solenoid Assembly-Exploded View and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dispensing Levers and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 4

Ice Dispenser D45 and D90 Installation Manual

!

DANGER:

!

WARNING:

CAUTION:

!

!

WARNING:

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview

• Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/caution labels on the unit (decals, labels or

laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health Administration) safety regulations before

operating this unit.

Recognition

Recognize Safety Alerts

This is the safety alert symbol. When you see it in this manual or on the unit,

be alert to the potential of personal injury or damage to the unit.

DIFFERENT TYPES OF ALERTS

Indicates an immediate hazardous situation which if not avoided WILL result in serious injury, death or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result in serious injury, death, or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury or equipment

damage.

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and safety signs on the unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is not intended for use by very young children or

infirm persons without supervision. Young children should be supervised to ensure that they do not play with the appliance.

• Keep your unit in proper working condition and do not allow unauthorized modifications to the unit.

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit. ALL WIRING AND

PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

© 1992-2011, IMI Cornelius Inc. - 2 - Publication Number: 91561

Page 5

Ice Dispenser D45 and D90 Installation Manual

!

WARNING:

CAUTION:

!

CAUTION:

!

!

WARNING:

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure continued protection

observe the following:

Disconnect power to the unit before servicing following all lock out/tag out procedures established by the user. Verify

all of the power is off to the unit before any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment damage.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may result in

injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all sanitizing solution must be drained

from the system. A freezing ambient environment will cause residual sanitizing solution or water remaining inside the

unit to freeze resulting in damage to internal components.

MOUNTING IN OR ON A COUNTER

When installing the unit in or on a counter top, the counter must be able to support a weight in excess of 115 lbs for

D45 and 200 lbs for D90 to insure adequate support for the unit. FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

NOTE:Many units incorporate the use of additional equipment such as icemakers. When any

addition equipment is used you must check with the equipment manufacturer to determine the

additional weight the counter will need to support to ensure a safe installation.

Publication Number: 91561 - 3 - © 1992-2011, IMI Cornelius Inc.

Page 6

Ice Dispenser D45 and D90 Installation Manual

!

WARNING:

!

WARNING:

CAUTION:

!

CAUTION:

!

CAUTION:

!

CAUTION:

!

ICE DISPENSER SAFETY PRECAUTIONS

Disconnect power to the dispenser before servicing or cleaning.

Failure to disconnect the power could result in serious injury, death or equipment damage.

Never place hands inside of hopper or gate area without disconnecting power to the dispenser. Agitator rotation

occurs automatically when dispenser is energized!

This ice dispenser has been specifically designed to provide protection against personal injury and eliminates

contamination of ice.

Be sure removable lid is properly installed to prevent unauthorized access to the hopper interior and possible

contamination of the ice.

Be sure the upper and lower front panels are securely fastened.

To ensure continued protection and sanitation, observe the following:

Keep area around the dispenser clean of ice cubes.

Dispenser cannot be used with crushed or flaked ice. Use of bagged ice that has frozen into large chunks can void

warranty. The dispenser agitator is not designed to be an ice crusher. Use of large chunks of ice that “jam up” inside

the hopper will cause failure of the agitator motor and damage to the hopper. If bagged ice is used, it must be carefully

and completely broken into small, cube-sized pieces before filling into the dispenser hopper.

© 1992-2011, IMI Cornelius Inc. - 4 - Publication Number: 91561

Page 7

Ice Dispenser D45 and D90 Installation Manual

DESCRIPTION

The D45 or D90 ice dispensers solve your ice and beverage service needs in a sanitary, space saving, economical

way. Designed to be manually filled with ice from any remote ice-making source, these dispensers will dispense

cubes (up to 1-1/4” inch size), cubelets and hard-chipped or cracked ice.

Table 1. Specifications

Model D45

Ice Storage: 45 pounds

Electrical: 120/1/60, 3 Amps

Drain Connection 3/4” FPT

Electrical Connection 6” 3--Wire Cord with 3--Prong Ground Type Plug

Dimensions: 16” W x 22” D x 28”H (40.6 cm W x 55.9 cm D x 71 cm H)

Model: D90

Ice Storage: 90 pounds

Electrical: 120/1/60, 3 Amps

Drain Connection 3/4”FPT

Electrical Connection: 6” 3--Wire Cord with 3--Prong Ground Type Plug

Dimensions: 16” W x 28” D x 32”H (40.6 cm W x 71 cm D x 81.3 cm H)

Publication Number: 91561 - 5 - © 1992-2011, IMI Cornelius Inc.

Page 8

Ice Dispenser D45 and D90 Installation Manual

!

WARNING:

INSTALLATION INSTRUCTIONS

1. Locate the dispenser indoors on a level counter top. Unpack the four (4) legs and install them into the

threaded holes provided in the bottom of the unit.

2. Connect the 3/4?IPS (or equal) drain line to the 3/4?threaded drain connections at the lower rear of the

unit. This line must pitch downward to an open drain and must contain no traps, or improper drainage will

result.

3. Clean the hopper interior. (See Cleaning Instructions on page 3.)

4. Connect the power cord to a 120 volt, 60 hertz, 3--wire grounded receptacle. All electrical wiring must conform to national and local electrical codes.

CLEANING INSTRUCTIONS

DISCONNECT POWER BEFORE CLEANING! Do not use metal scrapers, sharp objects or abrasives on the ice

storage hopper, top cover and the agitator disk, as damage may result. Do not use solvents or other cleaning agents,

as they may attack the plastic material.

DISPENSER

1. Clean the ice dispenser interior at least once a month.

2. Lift off agitator assembly and wash and rinse it thoroughly.

3. Wash down the inside of the hopper and top cover with a mild detergent solution and rinse thoroughly to

remove all traces of detergent.

4. Replace the agitator.

5. Sanitize the inside of the hopper and agitator with a solution of 1 ounce of household bleach in 2 gallons of

water.

6. Remove ice chute cover as follows:

A. Flex sides outward to disengage lower pins.

B. Lift ice chute cover to disengage upper pins.

C. Lower ice chute cover down out of unit.

NOTE: It may be helpful to twist cover slightly.

7. Clean the inside of the ice chute and ice chute cover with a mild detergent solution and rinse thoroughly to

remove all traces of detergent.

8. Sanitize as described in Step 5.

9. Reverse steps above to reassemble ice chute.

© 1992-2011, IMI Cornelius Inc. - 6 - Publication Number: 91561

Page 9

Ice Dispenser D45 and D90 Installation Manual

OPERATING INSTRUCTIONS

Fill the hopper with ice and replace the lid. Pushing the dispenser lever will cause ice to flow from the ice chute. Ice

flow will continue until the lever is released. If ice does not dispense, see the TROUBLESHOOTING GUIDE to find

the cause.

NOTE: Use caution to avoid spilling ice when filling dispenser. Immediately clean up any spilled ice

from filling or operating the unit. To prevent contamination of ice, the lid must be installed on the

unit at all times.

Publication Number: 91561 - 7 - © 1992-2011, IMI Cornelius Inc.

Page 10

Ice Dispenser D45 and D90 Installation Manual

MAINTENANCE

The following dispenser maintenance should be performed at the intervals indicated:

CLEANING

DAILY (OR AS REQUIRED)

Remove foreign material from the vending area sink to prevent drain blockage.

WEEKLY (OR AS REQUIRED)

Clean the vending area. Check for proper water drainage from the vending area sink.

MONTHLY

Clean and sanitize the hopper interior. (See CLEANING INSTRUCTIONS.)

If the dispenser fails to dispense ice when operated, check that the hopper has ice in it and that power is being

supplied to the unit. If the problem persists, check the following:

1. Determine if the agitator is rotating (check for the sound of ice movement in the hopper).

2. Observe whether the gate is operating.

After checking the above, refer to the TROUBLESHOOTING GUIDE for possible problem causes and corrective

action.

© 1992-2011, IMI Cornelius Inc. - 8 - Publication Number: 91561

Page 11

Ice Dispenser D45 and D90 Installation Manual

TROUBLESHOOTING GUIDE

Should your unit fail to operate properly, check that there is power to the unit and that the hopper contains ice. If the

unit still does not dispense, check the following chart under the appropriate symptoms to aid in locating the defect.

Trouble Probable Cause Remedy

BLOWN FUSE OR CIRCUITBREAKER.

GATE DOES NOT OPEN. AGITATOR

DOES NO

GATE DOES NOT OPEN OR IS SLUGGISH. AGITATOR TURNS.

GATE OPENS. AGITATOR DOES NOT

TUR

ICE DISPENSES CONTINUOUSLY.

T TURN.

N.

A. Short circuit in wiring.

. Defective gate solenoid.

B

C. Defective agitator motor.

A. No power.

. Bent depressor plate (does

B

not actuate switch).

C. Defective dispensing switch.

A. Defective gate solenoid

. Weak gate spring.

B

C. Excessive pressure against

gate slide.

A. Ice solidified in hopper.

. Defective agitator motor.

B

C. Defective capacitor (D90

only).

A. Stuck or bent depressor plate

does not release switch)

(

B. Defective dispensing switch

C. Improper switch installation.

A. Repair wiring.

B. Replace gate solenoid.

C. Replace agitator motor.

A. Restore power.

B. Replace depressor plate.

C. Replace dispensing switch.

A. Replace gate solenoid.

B. Replace gate spring.

C. Reduce pressure against gate

slide.

A. Break up ice in hopper.

B. Replace agitator motor.

C. Replace capacitor.

A. Replace depressor plate.

B. Replace dispensing switch.

C. Properly install switch.

SLUSHY ICE. WATER IN HOPPER.

A. Blocked drain.

. Unit not level.

B

C. Poor ice quality due to water

quality or ice maker problems.

A. Open drain.

B. Level unit.

C. Clean hopper, then replace ice.

Publication Number: 91561 - 9 - © 1992-2011, IMI Cornelius Inc.

Page 12

Ice Dispenser D45 and D90 Installation Manual

MOUNTING TEMPLATES

Figure 1.

© 1992-2011, IMI Cornelius Inc. - 10 - Publication Number: 91561

Page 13

Ice Dispenser D45 and D90 Installation Manual

WIRING DIAGRAM

Figure 2.

Publication Number: 91561 - 11 - © 1992-2011, IMI Cornelius Inc.

Page 14

Ice Dispenser D45 and D90 Installation Manual

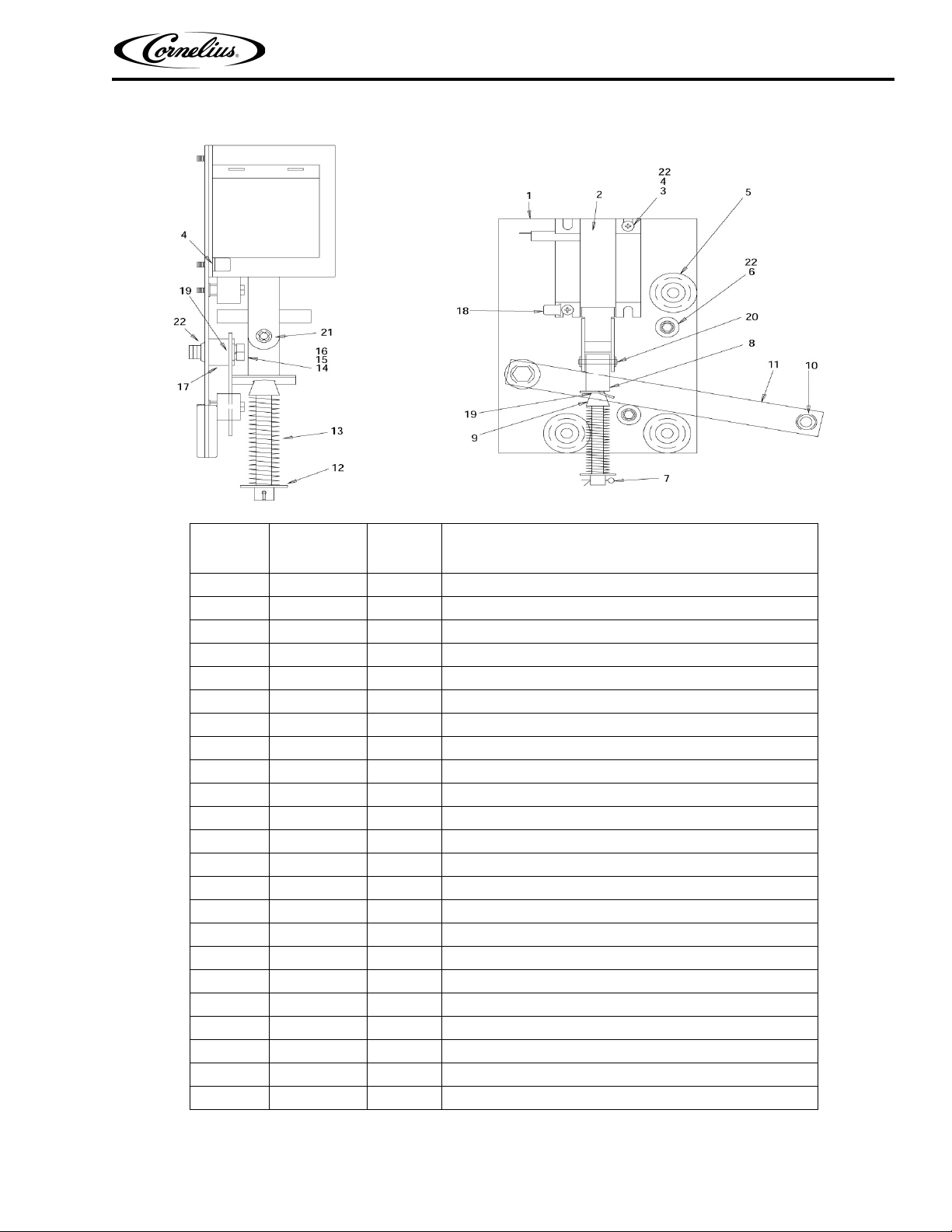

SOLENOID ASSEMBLY-EXPLODED VIEW AND PARTS LIST

Figure 3.

Index

No.

1 21493 1 Solenoid Mounting Plate

2# 31551 1 Solenoid Service Kit

3 70171 2 8--32 x 3/8 Phil Tr HD Screw

4 70121 2 No. 8 Lockwasher

5 50752 3 Isolator

6* 50789 2 Bumper Assembly

7* 70423 1 Cotter Pin

8* 10080 1 Gate Lift Rod

9 10081 1 Gate Lift Rod Bushing

10 50754 1 Gate Arm Bearing

11 21492 1 Gate Lift Arm

12 70043 1 Flatwashe

13* 70422 1 Spring

14 70263 1 1/4-20 x 3/4 Hex Hd Screw

15 70048 1 1/4 Lockwasher

16 70066 1 1/4 Flatwasher

17 10077 1 Pivot Bearing

18 30227 1 1/4 Quick Connect Tab

19 50305 -- Lubricant

20* 21592 1 Solenoid Linkage Pin

21* 70433 2 Retainer Ring

22 51088 -- Loctite

--* 70438 -- Rebuilding Kit

rt No. Qty. Name

Pa

NOTE: * Parts Supplied with rebuilding kit.

# 31551 solenoid Supplied with items 20 & 21.

© 1992-2011, IMI Cornelius Inc. - 12 - Publication Number: 91561

Page 15

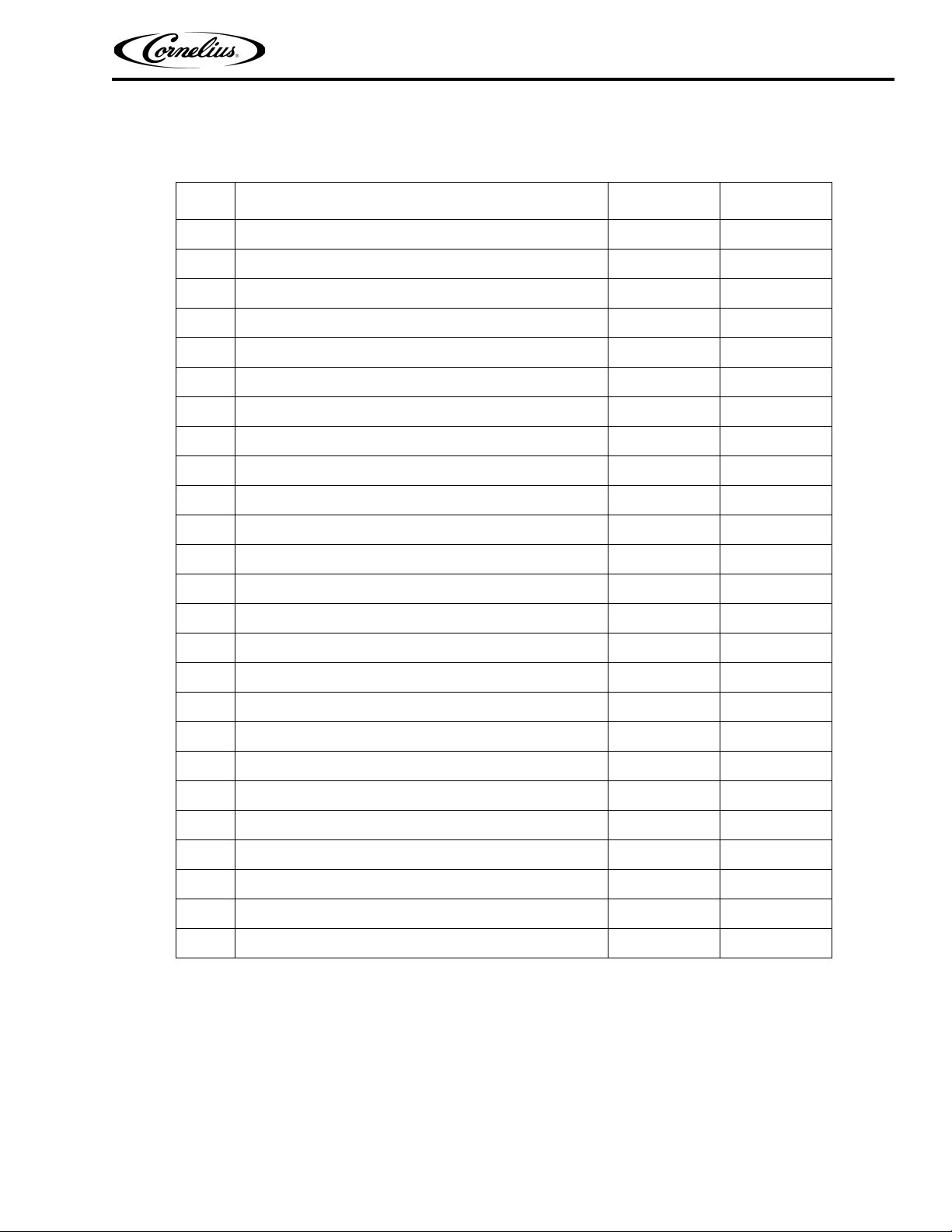

CUP ACTIVATED

PUSH LEVER

Ice Dispenser D45 and D90 Installation Manual

DISPENSING LEVERS AND SWITCHES

Figure 4.

Publication Number: 91561 - 13 - © 1992-2011, IMI Cornelius Inc.

Page 16

Ice Dispenser D45 and D90 Installation Manual

PARTS LIST

Item

1 Gate Slide 21491 21491

2 Depressor, Cup Activated 21515 21515

3 Depressor Retainer (for 21515) 22644 22644

4 Depressor Push Lever 27126 27126

5 Depressor Retainer (for 27126) 27107 27107

6 Agitator 21517 21629

7 Dispense Switch 30895 30895

8 Switch Boot 31007 31007

10 Foam Shield 23062 23062

11 Agitator Motor 629097027 31112-1

12 Motor Shaft Seal 50454 50454

13 Motor Gasket 50481 50481

14 Lid 50748 50791

15 Sink 50750 50793

16 Ice Chute, Back Section 53015 53015

Description Part No. D45 Part No. D90

17 Ice Chute Cover 53016 53016

18 Gate Gasket 51891 51891

19 Sink Grill 70426 70441

20 Leg 70419 70419

21 Cleaning Label 90295 90295

22 Wiring Diagram 90615 90788

23 Front Label 91559 91560

24 Capacitor -------- 30774

25 Solenoid Assembly (see page 7) 31093 31093

26 Rebuilding Kit (see page 7) 70438 70438

© 1992-2011, IMI Cornelius Inc. - 14 - Publication Number: 91561

Page 17

Ice Dispenser D45 and D90 Installation Manual

Publication Number: 91561 - 15 - © 1992-2011, IMI Cornelius Inc.

Page 18

Page 19

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...