Condec UPC5200 Operating Manual

UPC5200 & UPC5210

Portable & Rack-mountable Pneumatic

High Pressure Calibration Console

Operation and Maintenance Manual

CONDEC Sales Phone No. (888) 295-8475

CONDEC Web Site: www.4condec.com

63259

Contents

About This Manual................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

2.0 Operation...................................................................................................................................... 4

2.1 Pressure Cylinder (PN 59533) Filling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Initial Setup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Pressure Measurement Sequence (Gage Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Pressure Measurement Sequence (Absolute Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 Calibration.................................................................................................................................... 9

3.1 Pneumatic Calibration Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Instrument Calibration Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Zero/Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Linearity and Hysteresis Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Shunt Resistor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6 Current Input Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.7 Permanent Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.8 Normal Mode Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.9 Self-Check Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.0 Maintenance & Service............................................................................................................. 14

4.1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Maintenance & Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Panel/Chassis Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Accumulator, Intensifier & ORION-3A (PN 55287) Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.3 ORION-3A Manifold, Valve Seat Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.4 ORION-3A Manifold, Vernier Control Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.5 ORION-3A Manifold, Vernier Control Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.6 ORION-3A Manifold, Valve Seat Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.7 Accumulator, Intensifier and ORION-3A Manifold, Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.8 ORION-3A Manifold, Valve Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.9 Accumulator Assembly, O-ring (PN 58051) Replacement, Filter (PN 56993) Cleaning. . . . . . . . . . . . . 21

4.2.10 Intensifier Assembly, O-rings/Seals Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.11 Regulator (Standard Pneumatic) and Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.12 Regulator (Standard Pneumatic) and Solenoid Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.13 Regulator (Tescom) and Solenoid Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.14 Regulator (Tescom) and Solenoid Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.15 Panel Gauge Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.16 Test Port Quick-Connect Fitting (PN 59004) and Filter (PN 54188), Removal and Installation . . . . . . . 28

4.2.17 Test Port (output) Hose Quick-Connect Fitting and Filter (PN 56991), Removal and Installation. . . . . . 28

4.2.18 Input Port Filter (PN 54188), Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.19 Input Port Hose Quick-Disconnect Female Fitting, Removal and Installation . . . . . . . . . . . . . . . . . . . . 29

4.2.20 AC Fuse (PN 57472), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.21 Panel Mounted AC Power/EMI Line Filter (PN 58870), Removal and Installation . . . . . . . . . . . . . . . . . 30

4.2.22 Chassis Mounted EMI Line Filter (PN 59015), Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.23 Pump Control Switch (PN 60307), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.24 Power Switch (PN 58878), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.25 Range Select Switch (PN 55924) and Display Select Switch (PN 55933), Removal and Installation. . . 32

4.2.26 Zero Switch (PN 58886), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.27 CPU Assembly, Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.28 Pump Control Board Assembly, Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.3 ORION-3A Valve Assembly (55287) Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4 Intensifier Assembly Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Copyright © 2002 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

February 2002

5.0 Model Number System .............................................................................................................. 44

6.0 Ranges and Resolutions ............................................................................................................ 45

7.0 Options, Replacement Kits ........................................................................................................ 46

8.0 Specifications............................................................................................................................ 47

UPC5200/UPC5210 Warranty and Return Policy................................................................................... 49

UPC5200/UPC5210 Return Material Authorization Form....................................................................... 50

About This Manual

This manual is intended for use by service technicians

responsible for installing and servicing

UPC5200/UPC5210 pressure calibrators.

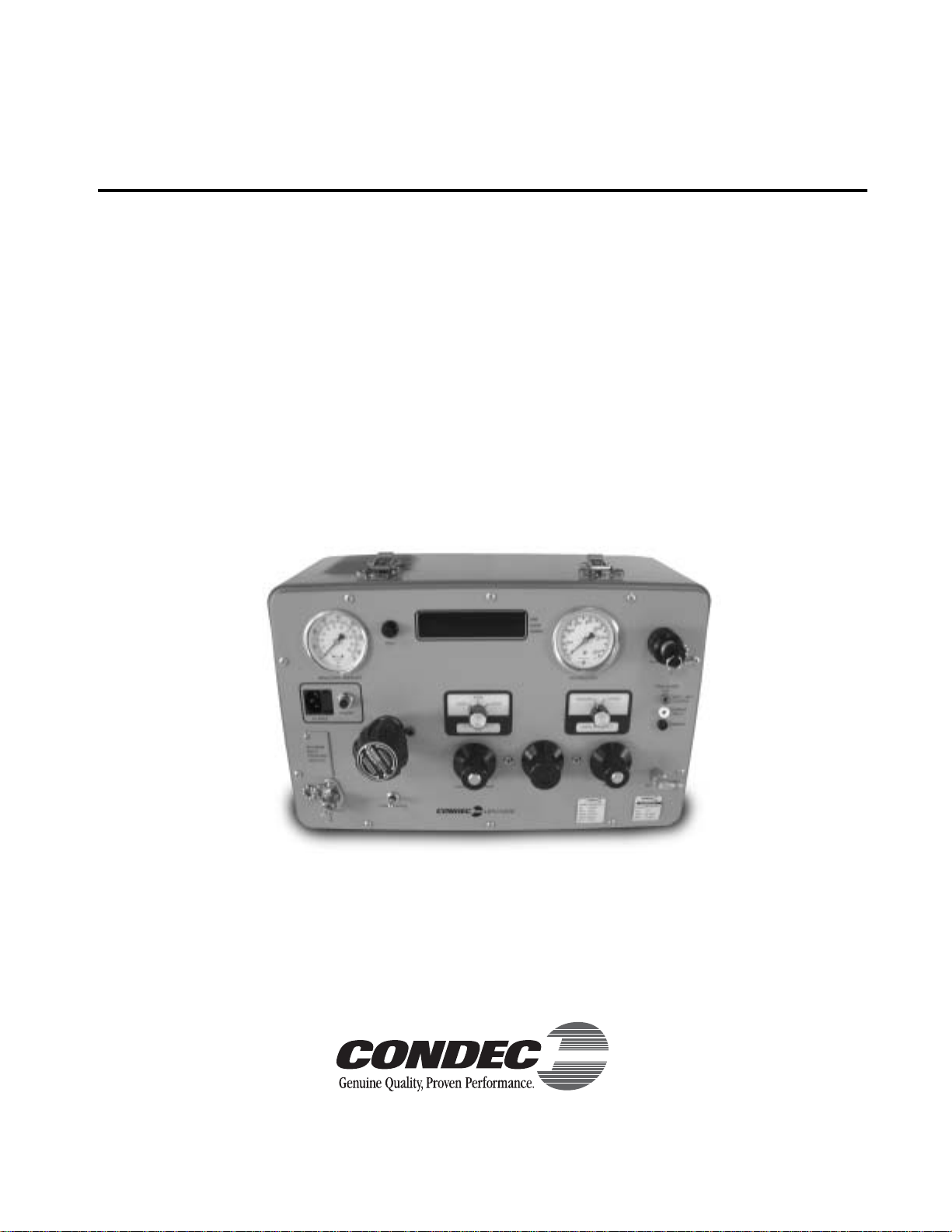

The UPC5200 portable pneumatic pressure calibrator

and the rack-mounted UPC5210 are rugged, compact

instruments manufactured by Condec. They are

designed to provide superior accuracy, range of

calibration and ease of operation when used for the

calibration of a wide variety of pressure sensing and

measuring devices.

This manual has been written to give the user a simple

and clear explanation of how to operate, calibrate and

maintain these instruments.

Warning

system. It is strongly recommended that only personnel

formally trained in the use of pneumatic pressure

equipment be permitted to operate it. Potentially

dangerous conditions can be produced through negligent

handling or operation of the console due to the high

pressure cylinder contained within the unit.

These units are strictly for use with pneumatic pressures.

Erroneous readings and potential damage can result from

the introduction of hydraulic fluids into the internal tubing

lines.

Before attempting to use either style

pressure calibrator, the following

instructions must be carefully read

and understood by personnel using

the equipment. This is a high-pressure

Authorized distributors and their

employees can view or download this

manual from the Condec distributor site

at

www.4condec.com

.

1.0 Introduction

The UPC5200/UPC5210 pressure calibrators utilize an extremely repeatable sensor coupled to

microprocessor-based electronic circuitry and a selectable units display system. This provides easily readable

and accurate digital representation of the measured pressure. This all electro-mechanical device utilizes our

precision Orion-3A vernier, which has one test port. Front panel gages tell the operator accumulator pressure, as

well as regulated input pressure. The pressure regulator acts as a pressure limiter so that the operator can adjust

input system pressure to 1/10 of the target value. Fill and test hoses are supplied for the customer. Standard front

panel buttons and switches provide selection of the desired pressure range, push-button zeroing and the unique

internal self-check feature. For field use, the UPC5200 has a separate 83.3 cubic foot, 2,216 psi cylinder to

provide many hours of use.

Utilizing microprocessor technology , the UPC5200 and rack-mounted UPC5210 instruments of fer a combination

of features, performance, versatility and reliability not previously available in a single, self-contained pressure

calibration instrument. Some of the features are listed below:

• Three independent switch-selectable pressure ranges per instrument.

•Accuracy of each range equal to or better than ±0.05% Full Scale.

•Both gage and absolute pressure calibration models are available.

•Automatic self-check: Computer-controlled internal circuitry provides automatic maintenance of both zero

and span calibration data to insure long-term stability and accuracy.

•Digital Display: Eliminates parallax, interpolation and operator judgement errors. Large, bright, red LED.

digits provide excellent readability under all lighting conditions (also available with an LCD).

•Using a manually adjustable regulator, the maximum system input pressure is adjusted to any desired value

higher (typically 20 to 50%) than the full scale range of the device being tested. By virtue of this technique,

the unit under test is fully protected from being inadvertently over-pressurized.

• Portable: These compact, self-contained systems are easily carried and operated by only one person. Total

weight is approximately 50 lbs.

• System Calibration: The instruments may be completely calibrated without being removed from the

external case. A separate plug-in calibration console (PN 60109) provides access to the computer when

calibration is to be performed. No manual alignment or potentiometer adjustments are required.

Introduction

1

2

•Calibration Integrity: Tamper-proof design. Once calibrated, numerous safeguards guarantee the integrity

of pressure readings obtained. Display prompting provides the operator with functional status information

during both operation and calibration.

• Pressure Source (UPC5200 only): An external supply cylinder with a volume of 83.3 std. cu. ft. of N

provides up to 2,216 psig of pressure for calibration and test. This pressure source drives a pneumatically

operated 10 to 1 intensifier contained within the UPC5200. Therefore, a 1,000 PSI input is amplified to

10,000 PSI.

• Simple Operation: All controls, indicators and pressure ports are accessible from the front panel.

Accompanying operator's manual provides clear, concise instructions for system operation.

•Data Input Capability: A front panel-mounted connector and selector switch permit the 4-20 mA current

signal from the gauge-under-test or voltage to be displayed. Transducer excitation voltage of 28 VDC is

provided standard.

• Safe, Clean Operation: All pressure components are made of stainless steel and proof-tested to at least

150% of maximum operating pressure. In addition, the system contains a high-pressure burst disk to

protect both the operator and system components from harm in the event of inadvertent o v er -pressurization.

The heart of this calibration system is a highly stable and repeatable pressure transducer. These sensors produce

an electrical output signal which is linearly proportional to the applied pressure. By combining the sensors with

sophisticated microprocessor-based circuitry, an even higher degree of operational accuracy and precision has

been accomplished. For example, computer-generated correction curves for both the non-linearity and the

hysteresis of the sensors improve these characteristics by an order of magnitude or more. In addition, a self-check

feature ensures long-term accuracy by utilizing the computer to generate and control an internal shunt calibration

mode of operation. The indicators full-scale reading is compared against, and if necessary, corrected to the

digitally-stored value for full scale obtained at the time of initial pressure calibration.

2

In addition to the features, the UPC5200/UPC5210 pressure calibrator is easy to use. Two micro-metering valves

and vernier are provided to control the internally intensified nitrogen while the digital display indicates precisely

the magnitude of the applied test pressure. Also, a simple push-button switch provides zeroing of the pressure

display. The

selection, as well as,

Range

Pressure

and

Current

display selections are accomplished via a pair of

clearly marked rotary switches. Over-pressure protection is provided through a fully-adjustable pressure

regulator, which is manually set for each new device being tested.

With respect to calibration, the instruments have been designed and programmed to provide the operator with

various prompting symbols and legends during each phase of the calibration sequence. Also, to prevent

unauthorized tampering or calibrations, programming or calibration can only be achieved with the aid of a

separate, plug-in calibration console (PN 60109). Also, the electronic circuitry has been designed without any

potentiometers or adjustments, eliminating the possibility of unwanted changes. Finally, the computer has been

programmed with a series of internal self-diagnostic routines which continually monitor and check every bit of

data stored and processed by this system. The computer immediately notes or shuts down operation in the event

of an out-of-tolerance reading or any outright failures.

UPC5200/UPC5210 Operation and Maintenance Manual

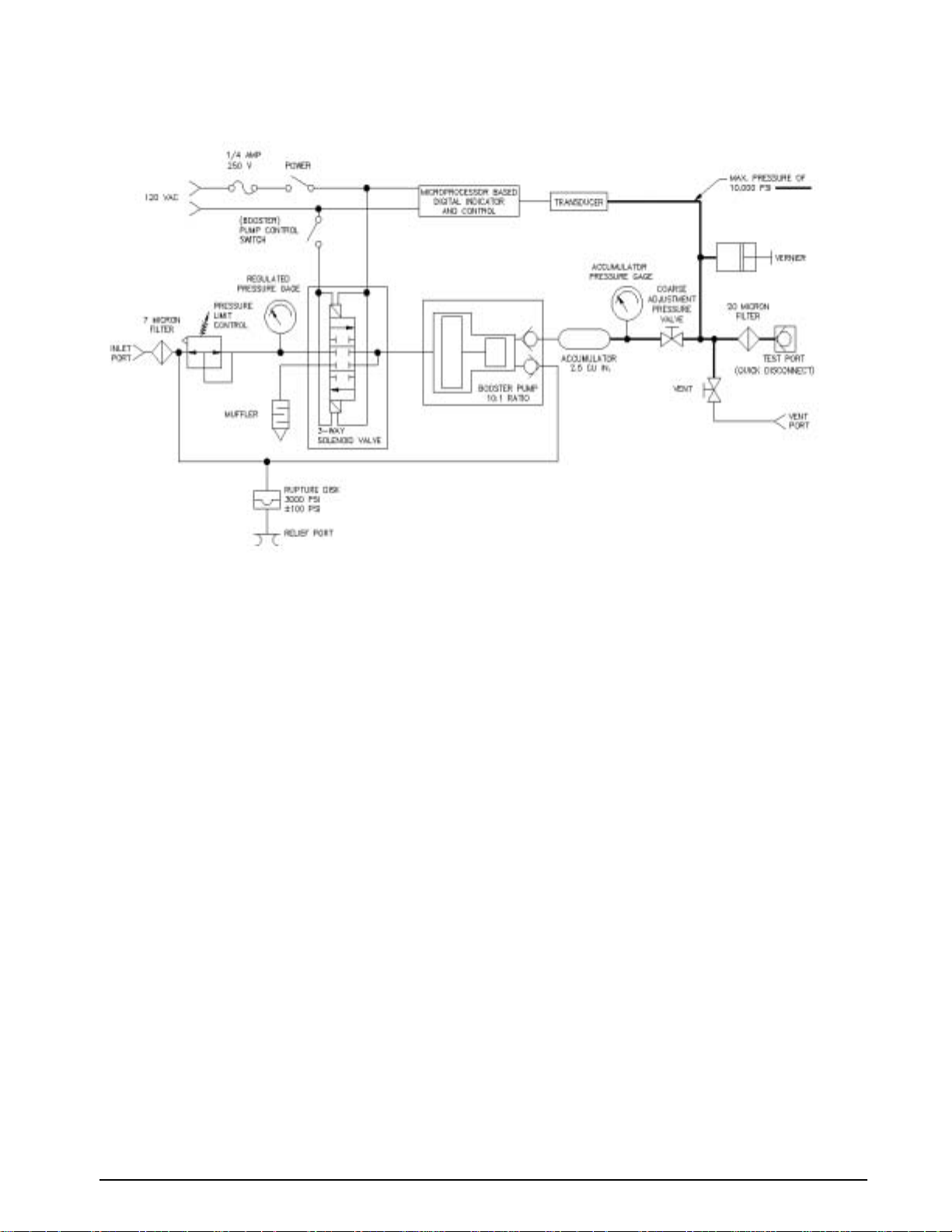

Figure 1-1 provides an overview of the UPC5200/UPC5210’s function.

Figure 1-1. UPC5200/UPC5210 Flow Diagram

Introduction

3

4

2.0 Operation

2.1 Pressure Cylinder (PN 59533) Filling Procedure

NOTE: Condec strongly recommends that the external nitrogen supply cylinder be pressure-tested and re-certified

every five years from date cylinder was manufactured per U.S. DOT. 3AL Regulation, Title 49 CFR, parts 173 and 178.

To initially fill or refill the external pressure cylinder (2,216 PSI max.), proceed as described below.

1. Close the

CYLINDER

valve by rotating clockwise until it stops.

2. Connect the customer supplied fill hose, to a clean regulated nitrogen source, with an output pressure

gauge and vent valve.

3. Connect the other end of the customer supplied fill hose to the female CGA-580 brass

CYLINDER

fitting.

4. Open the

CYLINDER

valve by rotating counter-clockwise until it stops.

5. Slowly open the valve on the nitrogen source and allow the gas to flow into the pressure cylinder. The

customer supplied output pressure gauge indicates the amount of pressure within the internal cylinder.

NOTE: Cylinder is equipped with a rupture disk.

6. Use the following procedure to fill the cylinder:

a) Fill cylinder to 1,000 PSI at a rate of charge equal to a minimum of two minutes, then wait five

minutes for system to stabilize.

b) Fill cylinder from 1,000 PSI to 2,216 PSI at a rate of charge equal to a minimum of two minutes.

c) Wait five minutes for cylinder to stabilize before using.

7. Close the

CYLINDER

valve by rotating clockwise until it stops.Vent nitrogen source and remove fill hose.

2.2 Initial Setup Procedure

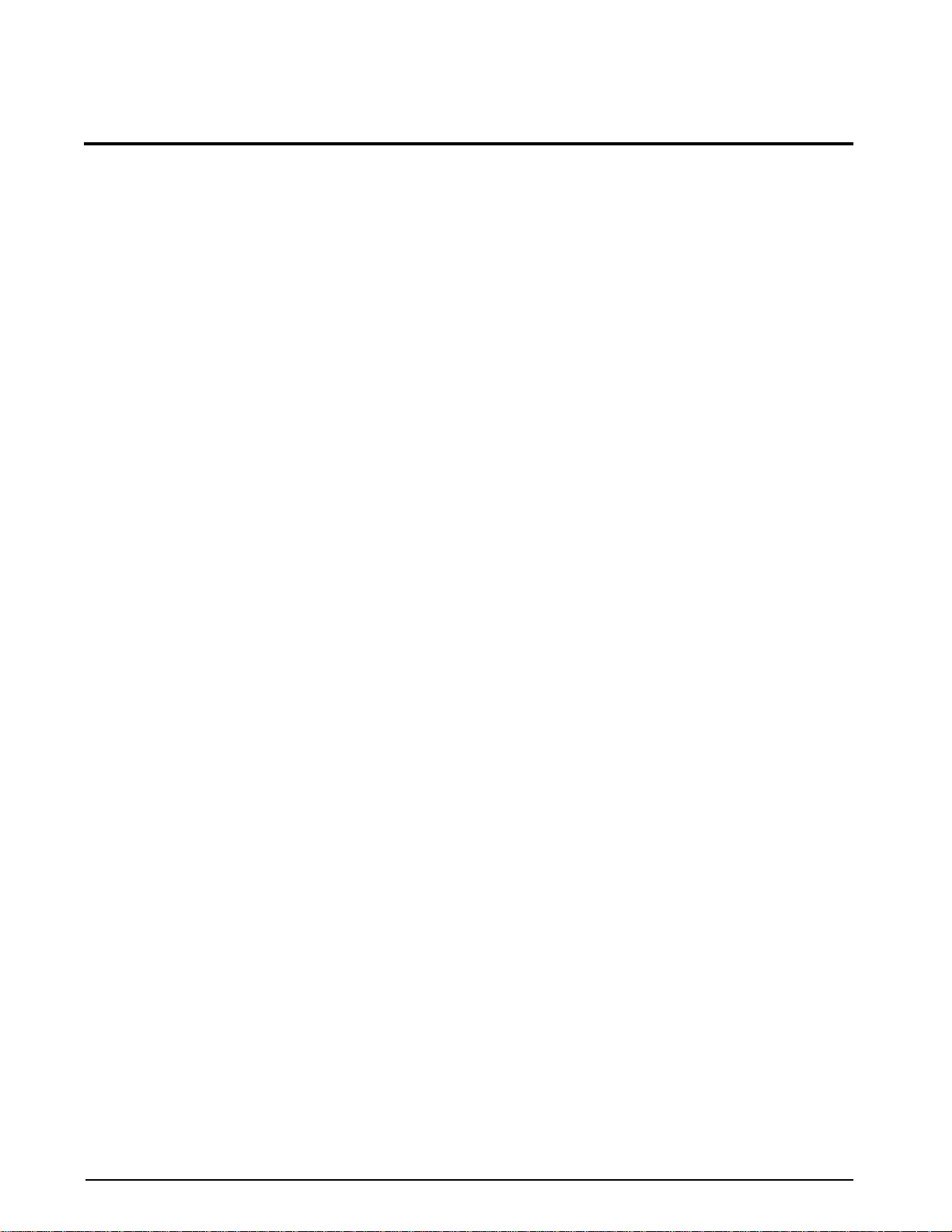

To prepare for actual calibration usage, see Figure 2-1 below and proceed as follows:

1. Check that the

COARSE ADJUSTMENT

Vent valve (8) is open (two turns counter-clockwise from its stop). Verify that the REGULATOR (1) is

closed (rotate counter-clockwise until it stops).

2. Plug in the power cord (7) and energize the unit by depressing the

UPC5200/UPC5210 performs an internal functional self-check. Allo w at least 10 minutes warm-up time.

3. Select the desired full scale pressure range via the three-position rotary switch (19). For the best

accuracy, the selected range must be greater than, but close as possible to, the full scale range of the

device-under-test.

NOTE: Do not switch pressure ranges during a calibration cycle.

4. Set the

DISPLAY SELECT

switch (16) to the PRESSURE position.

5. Connect the male end of the test hose to the TEST PORT (17) fitting.

6. Connect the swivel fitting end (7/16-20) of the test (output) hose to the device-under-test using adapters

if required. Tighten all connections properly.

7. UPC5200: Connect the male end of the input hose (3) to the female CGA-580 brass

fitting.

valve (2) is closed (rotate clockwise until it stops) and that the

POWER

switch (18). The

CYLINDER

valve

(5) valve

UPC5210: Connect the male end of the input hose (3) to the female CGA-580, customer supplied,

pressure source.

8. Connect the swivel fitting end (7/16-20) of the input hose (3) to the INPUT PORT (4) fitting. Tighten all

connections properly.

UPC5200/UPC5210 Operation and Maintenance Manual

Figure 2-1. Initial Setup Procedure

NOTE: UPC5200 shown, AC Input (7) and Input Port (4) are on back side of UPC5210 Rack Mountable Calibrator.

9. Optional - if the current (4.000 to 20.000 mA) measurement features are to be used, connect the

provided Transducer Test Cable (PN 55092) to the Transducer Test Jacks (14).

When connected, this cable provides +28 VDC e xcitation. The internal impedance (load) is 10 ohms. The display

scaling for these current measurements are as follows:

SWITCH POSITION

Current 0-20.000 mA by 0.005 mA

Table 2-1. Display Select Switch (16)

DISPLAY READING

The test cable connector wiring is as follows:

CONNECTOR PIN DESIGNATION FUNCTION

A+ VDC

B+ SIGNAL

C NOT USED

D VOLTAGE & SIGNAL COMMON

Table 2-2. Transducer Test Cable (PN 55092)

NOTE: Connector pin designations are for reference only, and are no longer a connector on newer units. See Figure 2-1

on page 5 (14).

2.3 Pressure Measurement Sequence (Gage Only)

NOTE: See Figure 2-2 on page 6, when following these steps.

1. Note that the indicator on the right end of the display indicates GAGE mode (10).

2. Zero unit by depressing the

any time, as long as the VENT valve (8) is open, by depressing the

NOTE: If ZERO switch is depressed longer than 5 seconds unit will perform an internal, functional self-check.

3. UPC5200: Open the cylinder valve (5) by rotating counter-clockwise slowly until it stops.

UPC5210: Open the, customer supplied, pressure source valve.

switch (12) for less than five seconds. The instrument can be zeroed at

ZERO

switch (12).

ZERO

Operation

5

6

4. Using the REGULATOR (1), adjust the maximum intensifier pump input pressure, as read by the

REGULATED PRESSURE gauge (6), to 1/10 of the full-scale range of the device-under-test. The unit

utilizes an internal intensifier with a 10:1 ratio. As an example, setting regulated pressure to 300 PSI

would generate an output pressure of 3,000 PSI. Using this technique, the device under test is fully

protected from being accidentally over-pressurized.

5. To generate pressure, enable the

PUMP CONTROL

the ACCUMULATOR gauge (9). Turn the

PUMP CONTROL

switch (20) and monitor the pressure as it builds in

switch (20) off when 10% more than the

target pressure has been achieved.

NOTE: The intensifier PUMP CONTROL switch (20) can be operated in two modes. The up position is

continuous and the down position is momentary/jog.

6. To apply pressure, the

VENT

valve (8) must remain closed. Open the

COARSE ADJUSTMENT

valve (2),

approximately 1/2 turn counter-clockwise, until the numerical display begins to move. In general, the

pressure may be changed rapidly until reaching approximately 90% of the desired final value.

7. Use either the

COARSE ADJUSTMENT

(2) or

valve (8) to obtain a specific pressure reading. Both

VENT

provide precise control. As the pressure approaches the desired value, the valve being used for control

should be rotated slowly clockwise to its closed position. With a little experience, pressure values very

close to the desired final value may be quickly achieved.

NOTE: Use the intensifier PUMP CONTROL switch if the ACCUMULATOR gauge (9) reading falls below

required target pressure value.

8. To obtain exact pressure readings, slowly rotate the

VERNIER

control (13) knob in the direction required

(clockwise to increase pressure) as indicated by the electronic numerical display.

9. Transducer Current Measurement - the current signal from the transducer may be displayed at any time

simply by placing the

DISPLAY SELECT

switch (16) to its CURRENT position.

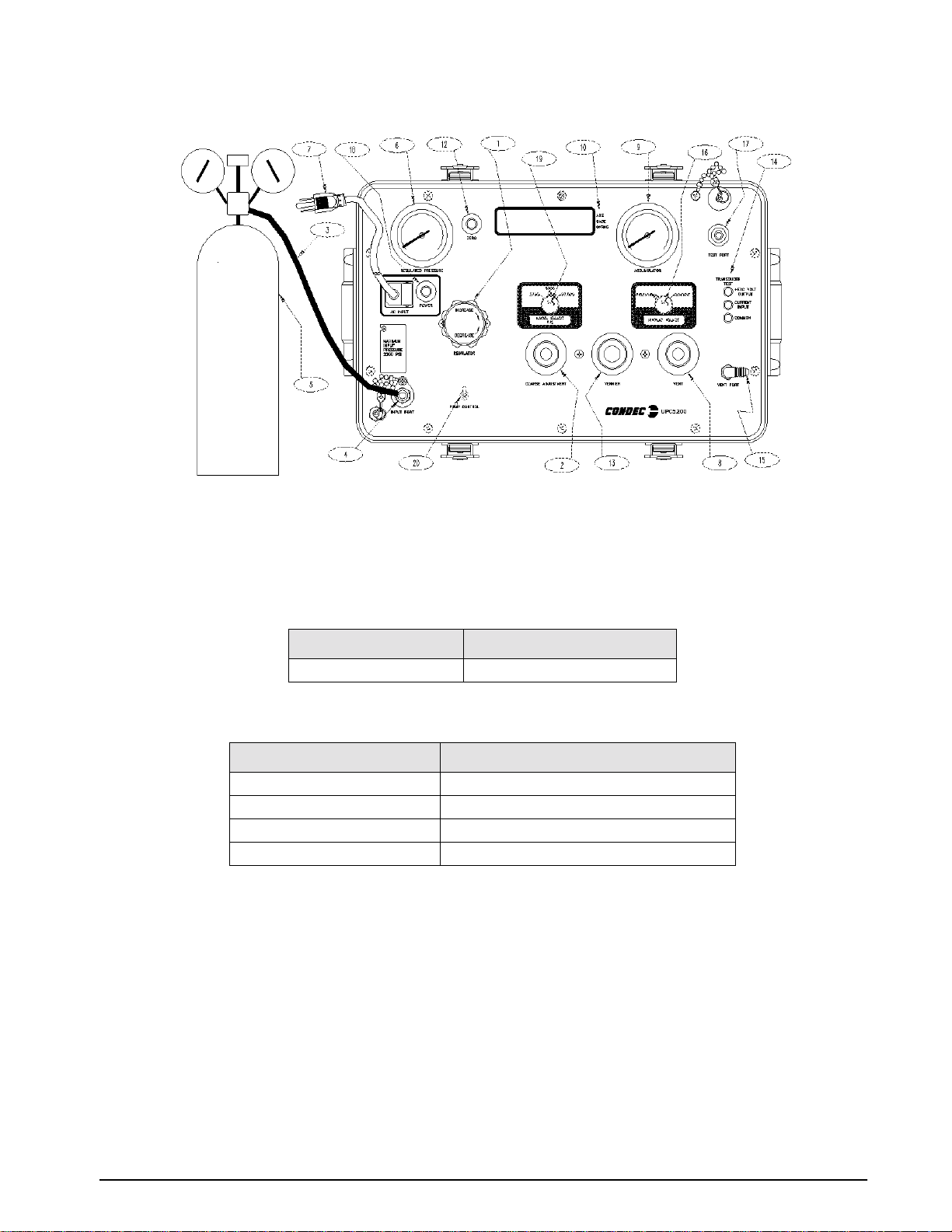

Figure 2-2. Pressure Measurement Sequence (Gage Only)

NOTE: UPC5200 shown, AC Input (7) and Input Port (4) are on back side of UPC5210 Rack Mountable Calibrator.

2.4 Pressure Measurement Sequence (Absolute Only)

NOTE: See Figure 2-3 on page 8, when following these steps.

1. Note that the indicator on the right end of the display indicates ABSOLUTE mode (10).

2. If only pressure measurements greater than barometric are required, continue to step 2.1. If pressure

measurements below atmospheric pressure are required go to step 3.

2.1. UPC5200: Open the cylinder valve (5) by rotating counter-clockwise slowly until it stops.

UPC5210: Open the pressure source valve (customer supplied).

UPC5200/UPC5210 Operation and Maintenance Manual

2.2. Using the REGULATOR (1), adjust the maximum intensifier pump input pressure, as read by the

REGULATED PRESSURE gauge (6), to 1/10 of the full-scale range of the device-under-test. The

unit utilizes an internal intensifier with a 10:1 ratio. As an example, setting regulated pressure to 300

PSI would generate an output pressure of 3,000 PSI. Using this technique, the device under test is

fully protected from being accidentally over-pressurized.

2.3. To generate pressure, enable the

PUMP CONTROL

in the ACCUMULATOR gauge (9). Turn the

switch (20) and monitor the pressure as it builds

PUMP CONTROL

switch (20) off when 10% more

than the target pressure has been achieved.

2.4. To apply pressure, close the VENT valve (8) approximately two turns to its stop and open the

COARSE ADJUSTMENT valve (2) approximately 1/2 turn counter-clockwise until the numerical

display begins to move. In general, the pressure may be changed rapidly until reaching

approximately 90% of it desired final value.

2.5. Use either the COARSE ADJUSTMENT (2) or VENT valve (8) to obtain a specific pressure

reading. Both provide precise control. As the pressure approaches the desired value, the valve being

used for control should be rotated slowly clockwise to its closed position. With a little experience,

pressure values very close to the desired final value may be quickly achieved.

NOTE: Use the intensifier PUMP CONTROL switch if the ACCUMULATOR gauge (9) reading falls below

required target pressure value.

2.6. To obtain exact pressure readings, slowly rotate the VERNIER control (13) knob in the direction

required (clockwise to increase pressure) as indicated by the electronic numerical display.

3. If pressure measurements below atmospheric pressure are required, connect a vacuum pump to the

VENT/VACUUM port (15) as shown in Figure 2-3 on page 8.

3.1. Open the VENT valve (8), but the COARSE ADJUSTMENT valve (2) must remain closed. Apply

power to the vacuum pump and allow it to evacuate the system for several minutes or until the

digital display reading reaches equilibrium near 0 PSIA. Press the

button to establish a zero

ZERO

reference on the display.

3.2. With the vacuum pump still running, close the VENT valve (8) and check for system leaks. If there

are none, continue to step 3.3.

3.3. Remove the vacuum pump.

3.4. To apply vacuum, COARSE ADJUSTMENT (2) valve must remain closed. Open the VENT valve

(8) counter-clockwise slowly until the numerical display begins to move.

3.5. As the pressure approaches the desired value, the VENT valve (8) should be rotated slowly

clockwise to its closed position. With a little experience, pressure values very close to the desired

final value may be quickly achieved.

3.6. To obtain exact PSIA readings, slowly rotate the VERNIER control (13) knob in the direction

required (clockwise to increase pressure) as indicated by the electronic numerical display.

4. Transducer Current Measurement - the current signal from the transducer may be displayed at any time

simply by placing the

DISPLAY SELECT

switch (16) to its CURRENT position.

Operation

7

8

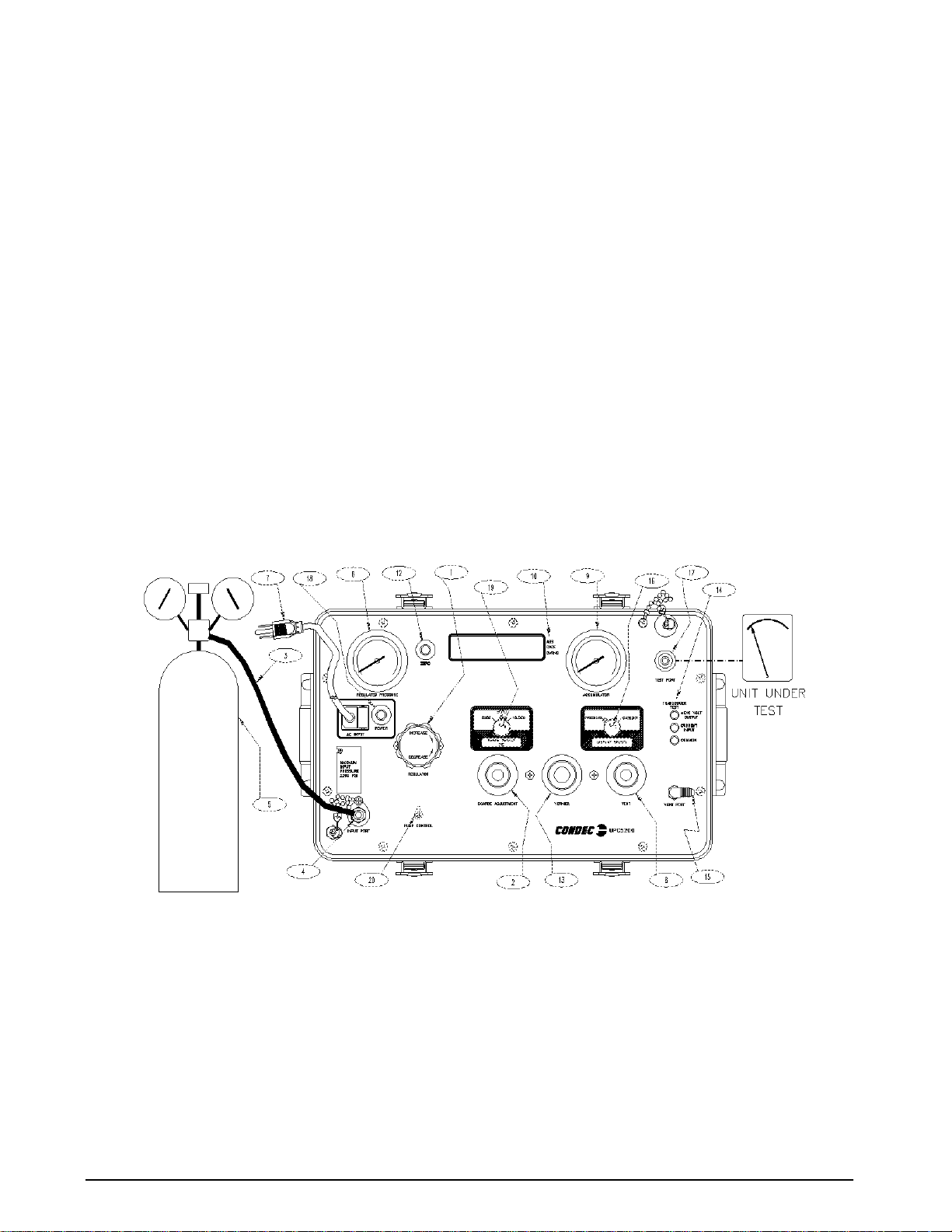

Figure 2-3. Pressure Measurement Sequence (Absolute Only)

NOTE: UPC5200 shown, AC Input (7) and Input Port (4) are on back side of UPC5210 Rack Mountable Calibrator.

UPC5200/UPC5210 Operation and Maintenance Manual

3.0 Calibration

Follow the procedure on the following pages for calibrating the UPC5200/UPC5210.

NOTES:

• When calibrating, the computer within the UPC5000/UPC5010 is actually being re-programmed, therefore it is

important that the pressure standard being used is in satisfactory operating condition and that the technician

fully understands its operating characteristics and methods of usage. In addition, the UPC5000/UPC5010 itself

must be properly warmed up (approximately 10 minutes) and electrically stabilized prior to performing a

calibration cycle.

• The Condec Repair Lab is equipped to do calibrations on Condec calibrators and pressure standards.

Calibrations include a certification and are traceable to N.I.S.T (see “UPC5200/UPC5210 Return Material

Authorization Form” on page 50).

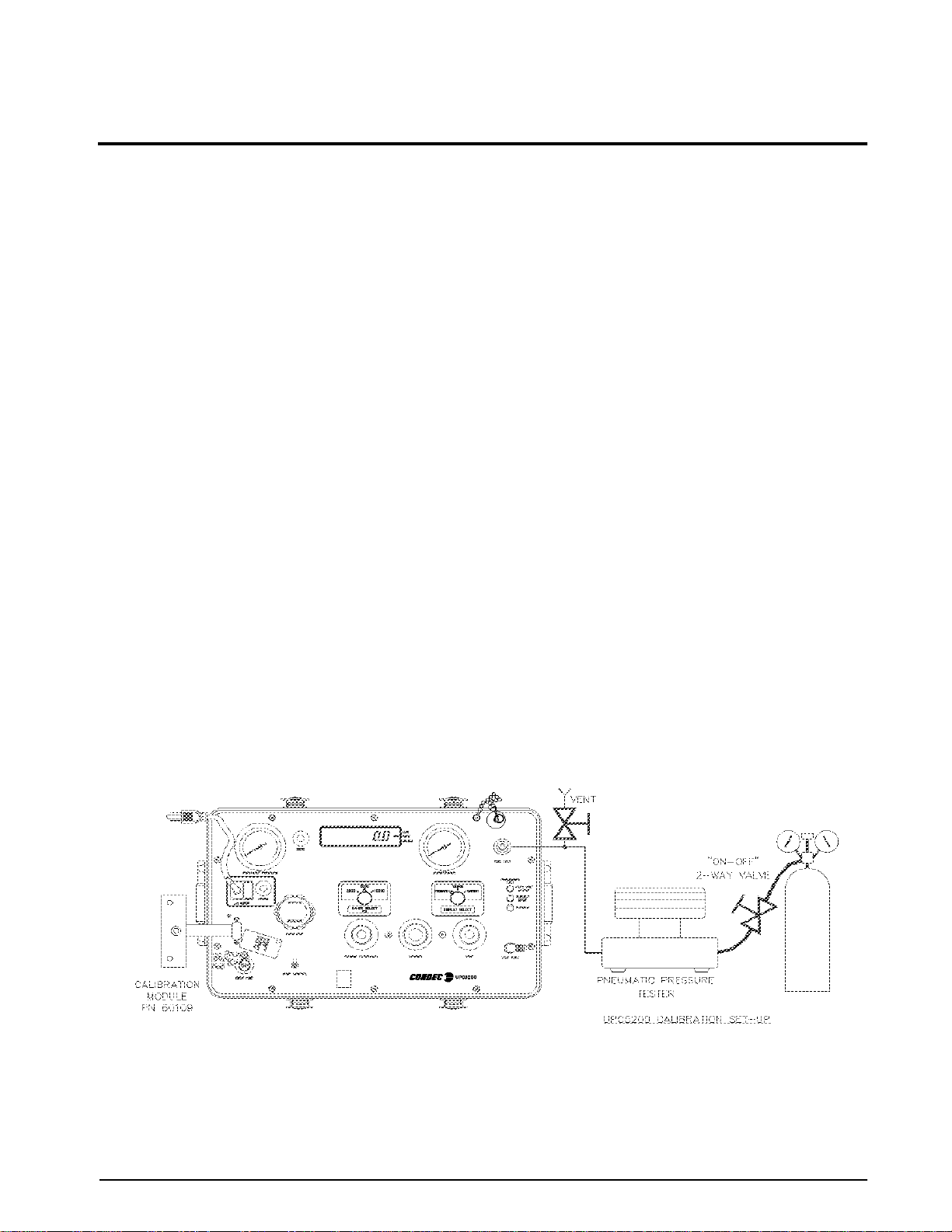

3.1 Pneumatic Calibration Set-Up

A typical GAGE calibration set-up using a floating piston type dead weight tester is shown in Figure 3-1. While

doing an ABSOLUTE only unit calibration, a vacuum pump with a PSIA test standard is required where the dead

weight tester/pressure source is shown in Figure 3-1. This enables going below local barometric pressure.

NOTE: Any type of precision pressure or vacuum standard is acceptable as long as its basic accuracy is ±0.025% of

point or better.

To permit proper calibration, at least an ON/OFF and a VENT valve (connected as shown in Figure 3-1) must be

provided.

3.2 Instrument Calibration Set-Up

The UPC5200/UPC5210 is placed into its calibrate mode by connecting a Condec Calibration Module, PN

60109, via the multi-pin jack. The jack is located behind the small slide plate near the lower left corner of the

panel (see Figure 3-1).

The Condec Calibration Module, provides access to the calibrator's various program modes via a five-position

rotary switch. It also provides a means of entering and storing data via four other momentary action switches.

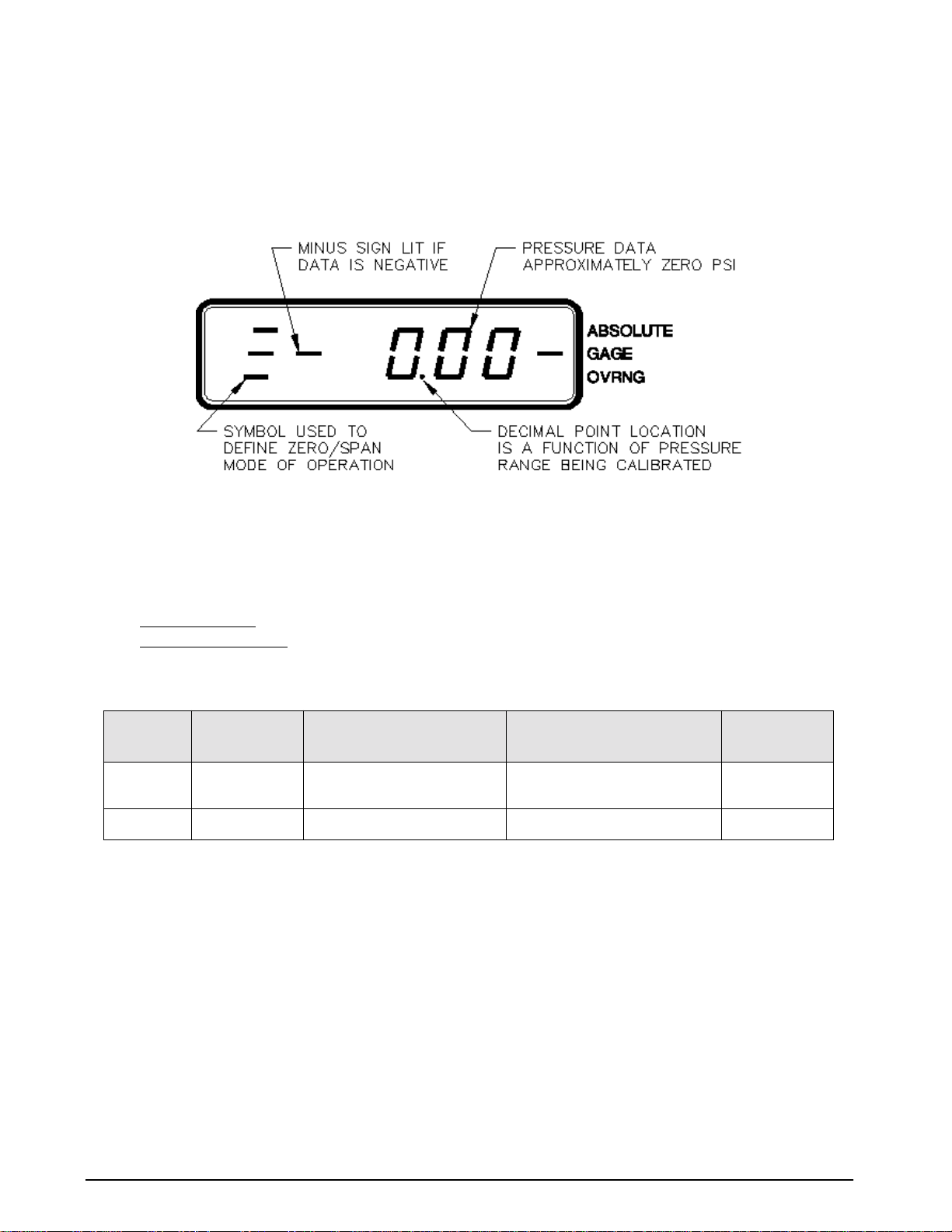

In the calibrate mode, the UPC5200/UPC5210's numerical display is used to provide operator prompting

symbols as well as displaying the various data formats employed. For example, in Figure 3-2, the data format

shown is obtained as soon as the ZERO/SPAN position of the rotary switch has been selected.

Figure 3-1. Instrument Calibration Set-Up

NOTE: UPC5200 shown, Power (AC Input) and Input Port are on back side of UPC5210 Rack Mountable Calibrator.

Calibration

9

10

3.3 Zero/Span Calibration

Selecting the ZERO/SPAN position on the Condec Calibration Module (PN 60109) places the instrument into its

ZERO/SPAN calibration mode. The display is shown in Figure 3-2.

NOTE: Absolute only unit requires vacuum pump with PSIA test standard to obtain readings below local barometric

pressure.

Figure 3-2. Zero/Span Calibration for Gage Only Units

Starting with the instrument's lowest pressure range, perform steps 1 and 2 shown in Table 3-1 for each pressure

range.

NOTE: Perform step 1 in all ranges prior to doing step 2.

Perform the following for each step:

1. Gage Only Units

Absolute Only Units:

: Adjust input pressure to the appropriate (either 0 or 100%) value.

Must use a vacuum pump with PSIA test standard, to reach as close to 0 PSIA as

possible (maximum .05 PSIA).

2. Perform the action indicated by Table 3-1 when pressure input readings are stable.

STEP NO. PRESSURE

INPUT VALUE

10%

(Note 3 below)

2 100%

NOTES:

1. If readings are not stable or are not within ± 20% of zero, the zero correction cannot be entered.

2. If readings are not stable or are not within ± 5% of 100%, the span correction cannot be entered.

3. Absolute only unit: Maximum PSIA test standard display reading of 0.05 PSIA.

OPERATOR ACTION

REQUIRED

ENTER

Press

Press

ENTER

Table 3-1. Zero and Span Calibration Sequence

button

button

RESULTING DISPLAY

INDICATION

0% Note 1 below

100% Note 2 below

REMARKS

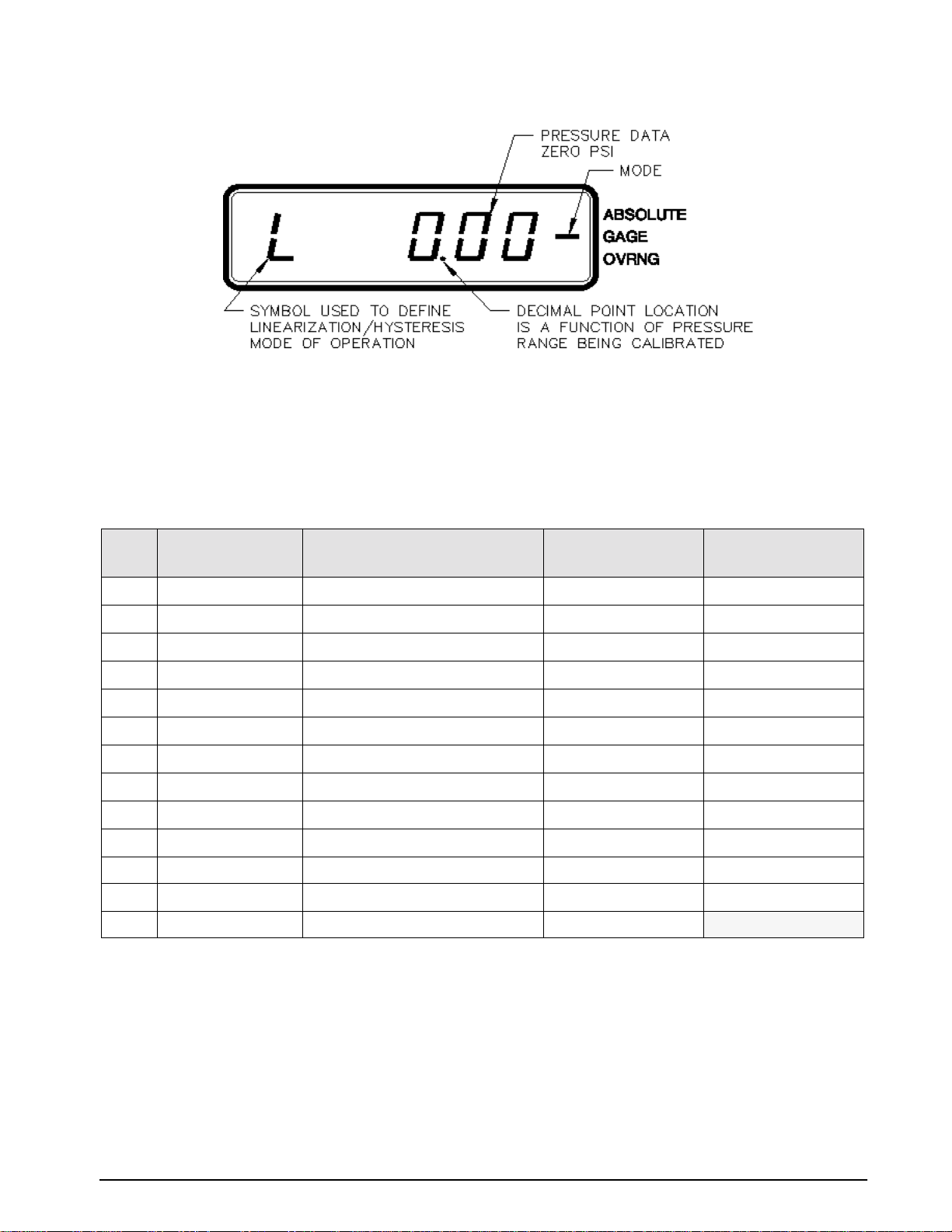

3.4 Linearity and Hysteresis Calibration

Install the Condec Calibration Module, (PN 60109), and select the LYN/HYS position of the rotary switch on the

module. This places the UPC5200/UPC5210 into its linearization/hysteresis calibration mode. The display is

shown in Figure 3-3 below.

NOTE: The Zero/Span Calibration needs to be performed prior to Linearity and Hysteresis Calibration . For Absolute only

unit, vacuum pump with PSIA test standard must be used to obtain readings below local barometric pressure.

UPC5200/UPC5210 Operation and Maintenance Manual

Figure 3-3. Linearity and Hysteresis Calibration

Starting with the instrument's lowest pressure range, sequentially perform the thirteen steps described in

Table 3-2, for each pressure range being calibrated. Perform the following for each step:

1. Adjust input pressure to the appropriate value without overshooting the setting. If value is overshot by

more than 1%, vent unit and repeat steps.

2. Perform the action as indicated when the readings are stable. Should not take longer than 15 minutes. If

it takes longer, check system for leaks. If no leaks are found, the CPU or transducer may be defective.

STEP

NO.

INPUT PRESSURE %

OF RANGE

10 (Note 4 below)

210

320

430

540

650

760

870

980

10 90

11 100 No Action Required H Note 3 below

12 50

13 0 (Note 4 below) No Action Required L

OPERATOR ACTION REQUIRED

Press

ZERO

Switch

ENTER

Press

ENTER

Press

ENTER

Press

ENTER

Press

ENTER

Press

ENTER

Press

ENTER button

Press

Press ENTER button

Press ENTER button

ENTER button

Press

button

button

button

button

button

button

STATUS SYMBOL IN

LEFT MOST DIGIT

L Zero on Display

L Notes 1 & 2 below

L Notes 1 & 2 below

L Notes 1 & 2 below

L Notes 1 & 2 below

L Notes 1 & 2 below

L Notes 1 & 2 below

L Notes 1 & 2 below

L Notes 1 & 2 below

L Notes 1 & 2 below

H Notes 1 & 2 below

REMARKS

Table 3-2. Linearization and Hysteresis Calibration Sequence

When step no. 11 is reached, the display changes so that the left most status symbol is

H

. This remains for step 12

and down to approximately 0.00 PSI.

NOTES:

1. If reading is in motion or correction required is not within ±0.8% of Full-Scale, no entry is made.

2. If entry is valid, the display momentarily indicates the correction value (in percent) and the memory location

at which it is stored.

3. If 100% ±0.05% is not obtained, repeat the Zero/Span calibration sequence.

4. Absolute only unit: Maximum PSIA test standard display reading of 0.05 PSIA.

Calibration

11

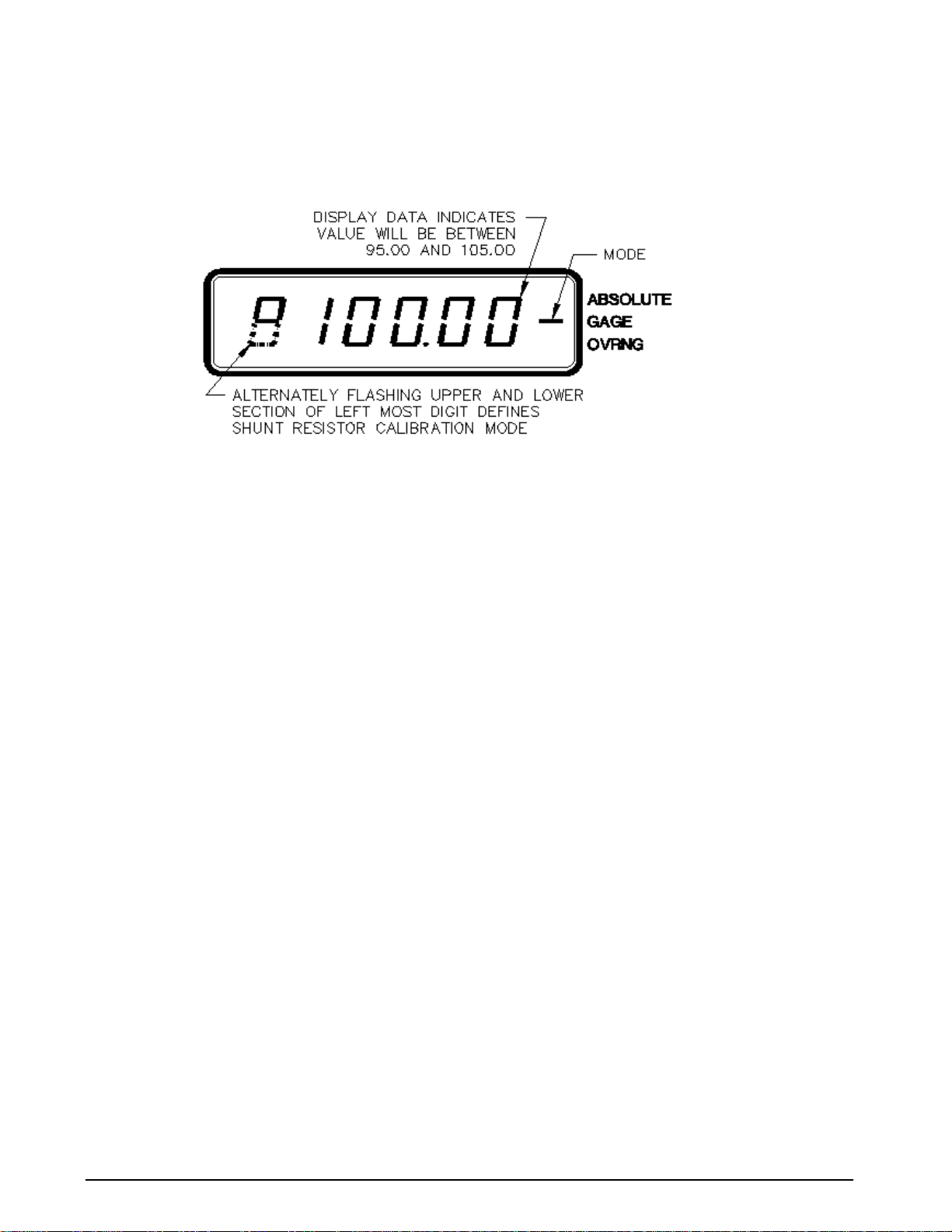

3.5 Shunt Resistor Calibration

Install the Condec Calibration Module (PN 60109) and select the SHUNT position of the rotary switch on the

module. This places the UPC5200/UPC5210 into its SHUNT RESISTOR calibration mode. The display is

shown in Figure 3-4.

Figure 3-4. Shunt Resistor Calibration

With the UPC5200/UPC5210's highest pressure range selected, perform the four step sequence described below:

1. Gage Only Units: Be sure the input pressure to the UPC5200/UPC5210 is at 0 PSIG.

NOTE: Absolute Only Units: Must use a vacuum pump with PSIA test standard, to reach as close to 0 PSIA as

possible (maximum PSIA test standard display reading of 0.05 PSIA).

2. Press and hold the ZERO button on the Condec Calibration Module until a stable zero indication is

obtained.

3. Release the

(100 ± 5.00%)

4. Press the

display digits are momentarily illuminated.

ZERO button and allow the display to stabilize at its shunt resistor calibration number.

ENTER button on the Condec Calibration Module. When accepted, the bottom half of all

3.6 Current Input Calibration

To calibrate the current input, a current generator capable of generating 20 mA must be connected to the

COMMON and CURRENT INPUT jacks, see Figure 2.2 on page 4 (14). The DISPLAY SELECT switch (16)

should be on the CURRENT position.

1. Set the Condec Calibration Module (PN 60109) to the ZERO/SPAN position. The display is similar to

Figure 3-2 on page 10.

2. Press the

3. Set the Current Generator for 20 mA output. Press the

read

NOTE: If the display reading is off, set the Current Generator to 0, and press the ENTER button on the Condec

Calibration Module. Set the Current Generator for 20 mA output. The display reads 20.000. If the display

reading is off, press the

requires servicing.

ZERO button on the module. The display reads 0.00.

ENTER button on the module. The display should

20.00.

ENTER button on the module. If the display reading is not 20.000, CPU is faulty and

4. Disconnect the current generator.

3.7 Permanent Data Storage

After completing the above calibration procedures, the new data that has been entered into the computer must be

permanently stored. The sequence to do this is as follows:

1. Select the DATA RECALL position of the rotary switch on the Condec

2. Press the

STORE pushbutton on the module.

3. If the data is accepted, the four-digit number on the right side of the display indicates

STORE button is pressed.

the

Calibration Module, (PN 60109).

1 020 for as long as

12 UPC5200/UPC5210 Operation and Maintenance Manual

3.8 Normal Mode Test

After completing the above calibration procedures, you must perform a normal mode test. A current generator

capable of generating 20 mA must be connected to the COMMON and CURRENT INPUT jacks, see Figure 2.2

on page 4 (14). The DISPLAY SELECT switch (16) should be on the CURRENT position.

1. Set the Condec Calibration Module to the NORMAL MODE position.

DISPLAY SELECT switch should be in the CURRENT position. The display reads 20.000.

2.

3.9 Self-Check Test

1. Remove the Condec Calibration Module.

2. Press the

100 to verify the unit's accuracy, then it returns to the normal mode automatically.

3. The pneumatic portion of the calibration is now complete. The pressure standard and the Condec

Calibration Module can now be disconnected.

ZERO pushbutton (12) on the UPC5200/UPC5210 until the unit sho ws CAL. The display sho ws

Calibration 13

Loading...

Loading...