Page 1

UPC5000/UPC5010

Pressure Calibration Standard

Cover provides

convenient storage of

hoses and fittings.

Please refer to price schedule for part numbers and

part numbering guide.

Combining heavy-duty construction and precision

performance, the UPC5000 offers flexibility for a variety of

pressure calibrating applications.

The compact UPC5000 includes a self-contained nitrogen cylinder, our patented Orion 2C valve and rechargeable battery, as well as all controls, hoses and connections required for rapid on-site calibration. A weight of

less than 33 pounds makes this instrument truly portable.

Whether your destination is a mountain-side wellhead

transmitter or your own standards lab, this system

provides industry-leading convenience for calibrating

transmitters, transducers, gauges, and other pressure

sensitive devices.

Each UPC5000 series model is equipped with an

exclusive precision vernier that provides infinite control

to secure the most accurate readings possible. Three

independent selectable ranges provide accuracy within

0.05% up to 2000 psi. Readings appear on a large

digital LED display, eliminating parallax, interpolation and

operator error. Increased protection is provided by a

self-relieving regulator that eliminates costly repairs due to

inadvertent pressure overshooting. The UPC5000 is easy

to operate and training can be accomplished in as little as

10 minutes. Different technicians can calibrate the same

transmitter and get identical results...every time.

Whether working in aircraft manufacturing, electric power

supply, or general industry, the UPC5000 performs beyond

the standard for accurate, on-site calibration.

Applications

• Engine test

• Food processing

• Pneumatic system checks

• Aircraft manufacturing, government laboratories, oil industry, electric

power plants (nuclear and fossil), and general industry

Standard Features

• Available in self-contained enclosure with carrying handles

(UPC5000) or 19 inch rack-mount version (UPC5010)

• Six sets of ranges to choose from: 2000/1000/400 psi,

1000/500/200 psi, 500/250/100 psi, 100/50/20 psi,

50/25/10 psi, and 15/7.5/3 psi

• Three independent selectable ranges in each instrument

• ±0.05% F.S. accuracy of each independent selectable range

• Available with Light Emitting Diode (LED) or Liquid Crystal Display

(LCD)

• Pressure display resolution 0.02% F.S. typical for each range

• State-of-the-art push button calibration - No analog

potentiometers or adjustments required

• Lightweight, less than 33 pounds

• Adjustable overpressure protection

• Precision pressure vernier control

• Self-contained 2215 psi nitrogen cylinder

• Voltage/current display mode for transducer testing

• Supplies DC loop power

• Non-destructible, nger tip control micro-metering valves for pres-

sure control

• Quick-disconnect tting and hose included

• Traceable to the National Institute of Standards

and Technology (NIST)

• Pneumatic only - no hydraulic uid or distilled water messes

Options/Accessories

58483 ........Pressure trap (UPC5000/UPC5010)

Literature sheet PN 58609

63256 ........Additional operating and maintenance manual

55294 ........Test port quick-disconnect with 1/4 NPT female

(finger tighten to DUT, no tools required)

55279 ........Additional test port (output) 5 ft. long hose with

quick-disconnect plug (SST) on one end and 1/4 inch

37º female AN swivel tube coupling on the other end.

55282 ........Additional fill port (input) 5 ft. long hose fitted with

quick-disconnect plug (brass) on one end and 1/4

inch 37° female AN swivel coupling on the other end.

(Specifications on back)

CP-1

Page 2

UPC5000/UPC5010

Specications

AVAILABLE PRESSURE CALIBRATIONS:

Gauge, absolute or gauge and absolute

OVERALL ACCURACY:

±0.05% F.S. maximum. Accuracy statement includes all effects

of linearity, hysteresis, repeatability and ambient temperature.

POWER:

115 or 230 VAC 50/60 Hz and 12 volt, 2.2 min., rechargeable

internal, sealed lead acid battery, standard

TEMPERATURE RANGE:

Operating: 40°F to 140°F (4°C to 60°C)

Storage: 0°F to 185°F (-17°C to 85°C)

Relative humidity: 95%, non-condensing

PRESSURE MEDIA:

Clean dry gaseous nitrogen, standard

INTERNAL PRESSURE CYLINDER:

Capacity: 7.0 standard cubic feet

Volume: 80 cubic inches

Rating: 2215 psi

PRESSURE SUPPLY GAUGE:

Size: Two-inch diameter

Range: 0-3000 psig

OVERPRESSURE RUPTURE DISC:

Rating: 3000 psig, nominal

Material: Stainless steel outer case

PRESSURE MEDIA FILTER:

Rating: 7 microns, nominal

Type: Field replaceable filter cartridge

CONTROL VALVES:

Type: Micro-metering with positive shut off, adjustable stop and

replaceable seat, non-destructible

Material: Aluminum/stainless steel

INTERNAL PIPING:

Tubing: 1/8 in. O.D., 0.028 in. wall thickness, copper, seamless

Couplings: Brass Swagelok

®

FILL AND TEST PORTS:

Style: Quick-disconnect type

Fill Port Pressure Rating: 3000 psig connected, 2000 psig

disconnected

Test Port Pressure Rating: 5000 psig

PRESSURE HOSES:

Quantity supplied: Two; one input and one output

Length: 5 feet, nominal

VERNIER CONTROL:

Volume: 0.25 cubic inches

Material: Aluminum/stainless steel

PRESSURE LIMIT MONITOR GAUGE:

Size: Two-inch diameter

Range: As appropriate for UPC5000/UPC5010 model

range utilized

PRESSURE LIMIT CONTROL:

Pressure Rating: 3000 psig maximum (inlet)

Output Pressure Range: As appropriate for UPC5000/UPC5010

model range utilized

Construction: Self-relieving, single stage regulator

INTERNAL PRESSURE SENSOR:

Type: Bonded, metal foil strain gauge or equal

Sensitivity: 3 mV/V, nominal

Construction: Completely weld sealed stainless steel outer body

and pressure cavity

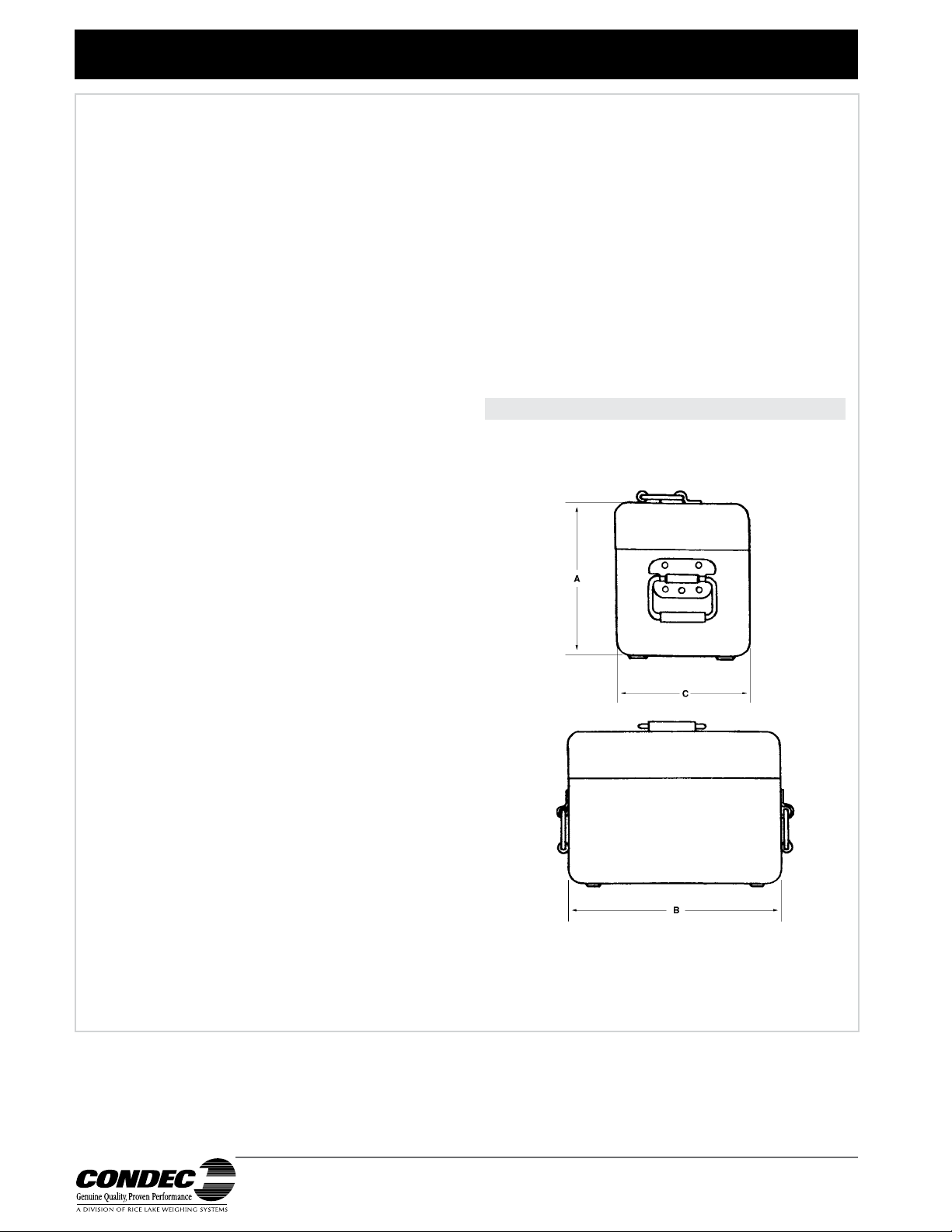

UPC5000 ExTERNAL CARRYING CASE:

Type: Aluminum case with cover and carrying handle

Material thickness: 0.090 in. nominal

Finish: Grey polyurethane baked-enamel paint, textured finish

CURRENT DISPLAY:

0-20.000 mA counting by 0.005 mA

WEIGHT:

UPC5000: Less than 33 lb (14.9 kg) including two hoses and

one cable

UPC5000 OVERALL DIMENSIONS

A = 11.5 in. (292.10 mm) C = 10.0 in. (254.00 mm)

B = 16.0 in. (406.40 mm)

UPC5010 (not shown) dimensions —excluding front handles):

19 in. (482.6 mm) W x 8.1 in. (205.74 mm) D x 10.5 in. (266.7 mm) H

Rack-mount dimensions are for reference only. Consult factory for

cutout dimensions.

Specifications subject to change without notice

© Condec 2012 Catalog PN 64749 1/12

Loading...

Loading...