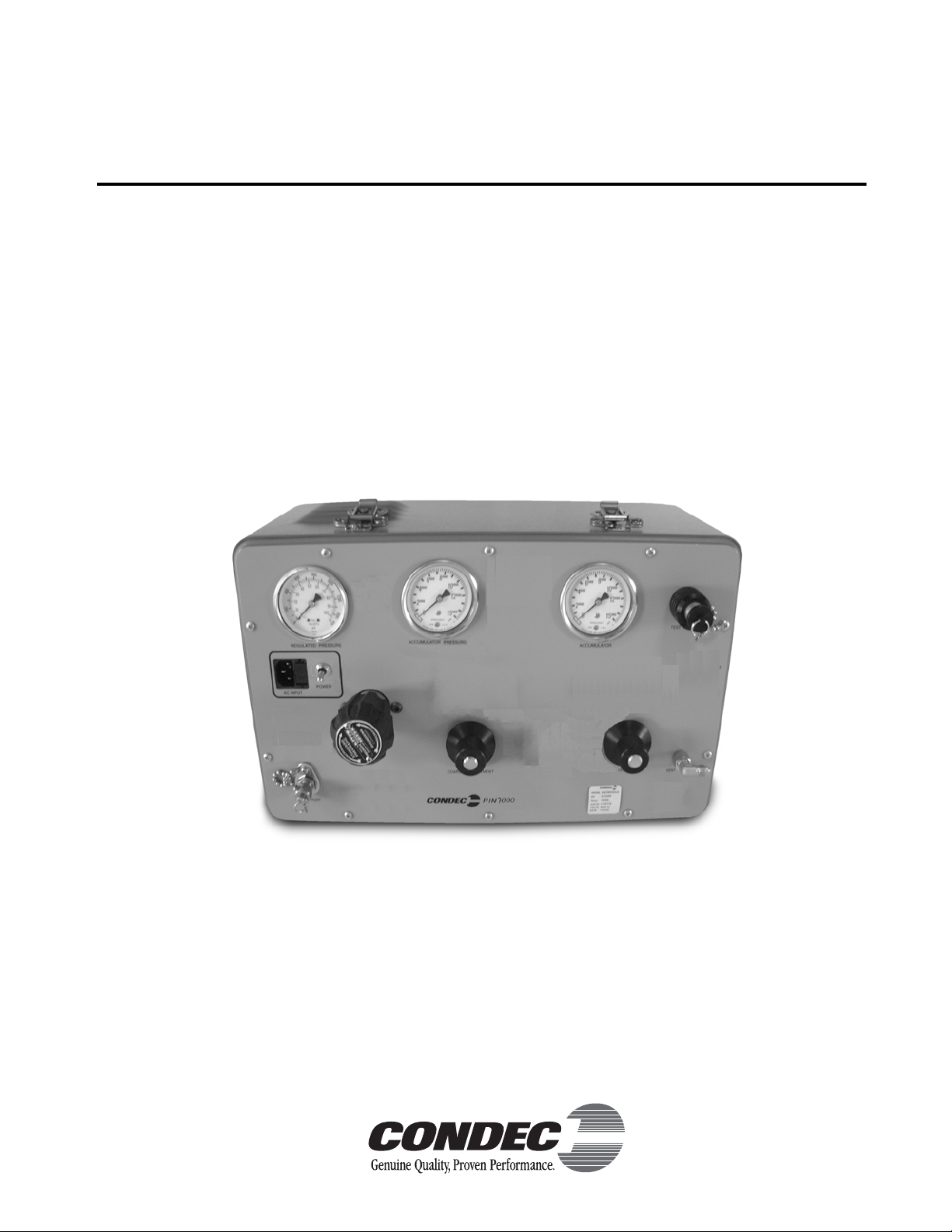

Condec PIN7000 Operating Manual

PIN7000 & PIN7010

Portable & Rack-mountable Pneumatic

High Pressure Intensifier Console

Operation and Maintenance

Manual

CONDEC Sales Phone No.: (888) 295-8475

CONDEC Web Site: WWW.4CONDEC.COM

63258

Contents

About This Manual ................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

2.0 Operation...................................................................................................................................... 3

2.1 Optional External Pressure Cylinder (PN 59533) Filling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Initial Setup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 Maintenance & Service ............................................................................................................... 5

3.1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Maintenance & Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.1 Panel/Chassis Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.2 Accumulator, Intensifier & MPV Valves (PN 65076) Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.3 MPV Valve, Valve Seat Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.4 MPV Valve, Valve Seat Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.5 Accumulator, Intensifier and MPV Valves, Panel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.6 MPV Pressure Valve, Adjustment Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.7 MPV Vent Valve, Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.8 Accumulator Assembly, O-ring (PN 58051) Replacement, Filter (PN 56993) Cleaning . . . . . . . . . . . . . 11

3.2.9 Intensifier Assembly, O-rings/Seals Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.10 Regulator (Standard Pneumatic) and Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.11 Regulator (Standard Pneumatic) and Solenoid Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.12 Panel Gauge Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.13 Test Port Quick-Connect Fitting (PN 59004) and Filter (PN 54188), Removal and Installation . . . . . . . 15

3.2.14 Test Port (output) Hose Quick-Connect Fitting and Filter (PN 56991), Removal and Installation . . . . . . 16

3.2.15 Input Port Filter (PN 54188), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.16 Input Port Hose Quick-Disconnect Female Fitting, Removal and Installation . . . . . . . . . . . . . . . . . . . . 17

3.2.17 AC Fuse (PN 57472), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.18 Panel Mounted AC Power/EMI Line Filter (PN 58870), Removal and Installation . . . . . . . . . . . . . . . . . 18

3.2.19 Power Switch (PN 60307), Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.20 Pump Control Board Assembly, Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 MPV Valve Assembly (PN 65076) Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Intensifier Assembly Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.0 Model Number System .............................................................................................................. 27

5.0 Options, Replacement Kits ........................................................................................................ 28

6.0 Specifications............................................................................................................................ 29

PIN7000/PIN7010 Warranty and Return Policy ..................................................................................... 30

PIN7000/PIN7010 Return Material Authorization Form ........................................................................ 31

© 2005 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Version 2.0, June 2005

About This Manual

This manual is intended for use by service technicians responsible for installing and servicing PIN7000/PIN7010

pressure intensifiers.

The PIN7000 portable pneumatic pressure intensifier and the rack-mounted PIN7010 are rugged, compact

instruments manufactured by Condec. They are designed for custom use and ease of operation.

This manual has been written to give the user a simple and clear explanation of how to operate and maintain

these instruments.

Before attempting to use either style pressure intensifier, the following instructions must be carefully

#AUTION

These units are strictly for use with pneumatic pressures. Erroneous readings and potential damage can result from the

introduction of hydraulic fluids into the internal tubing lines.

read and understood by personnel using the equipment. This is a high-pressure system. It is strongly

recommended that only personnel formally trained in the use of pneumatic pressure equipment be

permitted to operate it. Potentially dangerous conditions can be produced through negligent

handling or operation of the console due to the high pressure output of the unit.

Authorized distributors and their

employees can view or download this

manual from the Condec distributor site

www.4condec.com.

at

1.0 Introduction

The PIN7000/PIN7010 pressure intensifier is an electro-mechanical device that utilizes our precision MPV type

micro-metering valves for pressure adjustment and venting. The unit has one test port, one input port and three

front panel gauges, for the operator to monitor accumulator pressure, regulated input pressure, and intensified

output pressure. The pressure regulator acts as a pressure limiter so that the operator can adjust input system

pressure to 1/10 of the target value. Fill and test hoses are supplied for the customer. A front panel switch

provides selection of the desired pump control mode, momentary (jog) or co ntin uo us. Fo r field u se, the PIN7000

has a optional 83.3 cubic foot, 2,216 PSI cylinder available to provide many hours of use.

The PIN7000 and rack-mounted PIN7010 instruments offer a combination of features, performance, versatility

and reliability not previously available in a pressure intensified instrument. Some of the features are listed below:

• Switch-selectable pressure pump control mode, momentary (jog) and continuous.

• Pressure monitoring: Three front panel mounted gauges provide excellent readability.

• Using a manua lly adjustable regulator, the maximum system input pressure is adjusted to slightly above

1/10 desired value of the full scale range of the device being tested. By using this technique, the device

that is to be pressurized is fully protected from being inadvertently over-pressurized.

• Portable: These compact, self-contained systems are easily carried and operated by only one person.

Total weight is approximately 38 lbs.

• P ressure Source: Nitrogen or clear dry air is supplied by the customer. In either instrument, the pressure

source drives a pneumatically operated 10 to 1 intensifier contained within the PIN7000/PIN7010.

Therefore, a 1,000 PSI input is amplified to 10,000 PSI. An optional external supply cylinder may be

purchased that will contain a volume of 83.3 standard cubic feet off nitrogen and provide up to 2,216

PSIG of pressure for calibration and test.

• S imple Operation: All controls, indicators and pressure ports (PIN7000 only) are accessible from the

front panel. Accompanying operator's manual provides clear, concise instructions for system operation.

• S afe, Clean Operation: All pressure components are made of stainless steel and proof-tested to at least

150% of maximum operating pressure. In addition, the system contains a high-pressure burst disk to

protect both the operator and system components from harm in the event of inadvertent

over-pressurization.

Introduction 1

In addition to the features, the PIN7000/PIN7010 pressure intensifier is easy to use. Two MPV style

micro-metering valves are provided to control the internally intensified nitrogen while the output pressure gauge

indicates the magnitude of the applied test pressure. Over-pressure protection is provided through a

fully-adjustable pressure regulator, which is manually set for each new device being tested.

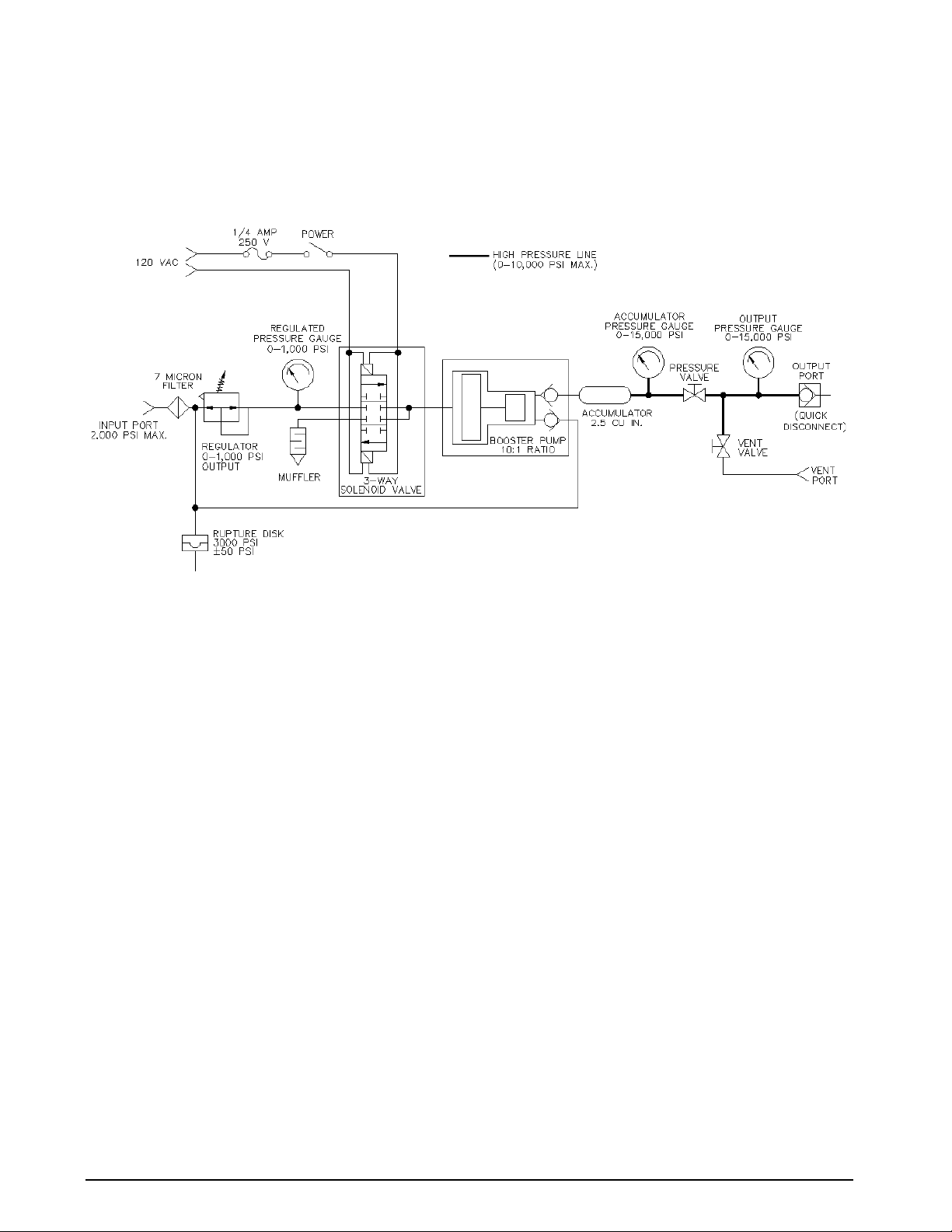

Figure 1-1 provides an overview of the PIN7000/PIN7010’s function.

Figure 1-1. PIN7000/PIN7010 Flow Diagram

2 PIN7000/PIN7010 Operation and Maintenance Manual

2.0 Operation

2.1 Optional External Pressure Cylinder (PN 59533) Filling Procedure

NOTE: Condec strongly recommends that the external nitrogen supply cylinder be pressure-tested and re-certified

every five years from date cylinder was manufactured per U.S. DOT. 3AL Regulation, Title 49 CFR, parts 173 and 178.

To initially fill or refill the external pressure cylinder (2,216 PSI max.), proceed as described below.

1. Close the CYLINDER valve by rotating clockwise until it stops.

2. Connect the customer supplied fill hose, to a clean regulated nitrogen source, with an output pressure

gauge and vent valve.

3. Connect the other end of the customer supplied fill hose to the female CGA-580 brass CYLINDER valve

fitting.

4. Open the CYLINDER valve by rotating counter-clockwise until it stops.

5. Slowly open the valve on the nitrogen source and allow the gas to flow into the pressure cylinder. The

customer supplied output pressure gauge indicates the amount of pressure within the internal cylinder.

NOTE: Cylinder is equipped with a rupture disk.

6. Use the following procedure to fill the cylinder:

a) Fill cylinder to 1,000 PSI at a rate of charge equal to a minimum of two minutes, then wait five

minutes for system to stabilize.

b) Fill cylinder from 1,000 PSI to 2,216 PSI at a rate of charge equal to a minimum of two minutes.

c) Wait five minutes for cylinder to stabilize before using.

7. Close the CYLINDER valve by rotating clockwise until it stops.Vent nitrogen source and remove fill hose.

2.2 Initial Setup Procedure

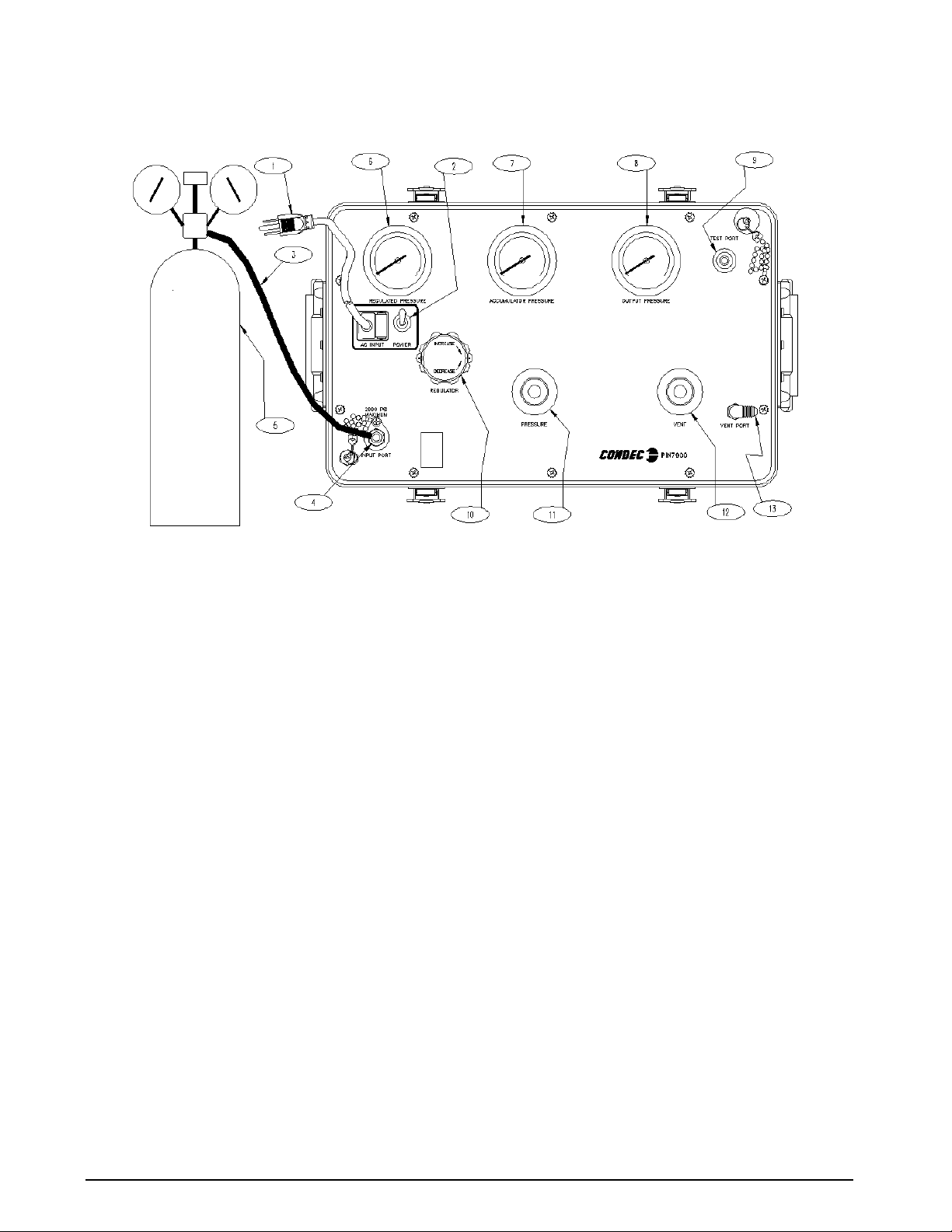

To prepare for actual intensifier usage, see Figure 2-1 below and proceed as follows:

1. Check that the PRESSURE valve (11) is closed (rotate clockwise until it stops) and that the Vent valve

(12) is open (two turns counter-clockwise from its stop). Verify that the REGULATOR (10) is closed

(rotate counter-clockwise until it stops).

2. Plug in the power cord (1).

3. Connect the male end of the test hose to the TEST PORT (9) fitting.

4. Connect the swivel fitting end (7/16-20) of the test (output) hose to the input of the device to be

pressurized using adapters if required. Tighten all connections properly.

5. Optional External Cylinder: Connect the male end of the input hose (3) to the female CGA-580 brass

CYLINDER (5) valve fitting.

Other: Connect the male end of the input hose (3) to the female CGA-580, customer supplied, pressure

source.

6. Connect the swivel fitting end (7/16-20) of the input hose (3) to the INPUT PORT (4) fitting. Tighten all

connections properly.

Operation 3

Figure 2-1. Initial Setup/Operating

NOTE: PIN7000 shown, AC Input (1), Test Port (9) and Input Port (4) are on back side of PIN7010 Rack Mountable

Intensifier.

2.3 Operating Instructions

NOTE: See Figure 2-1, when following these steps.

1. Optional External Cylinder: Open the cylinder valve (5) by rotating counter-clockwise slowly until it

stops.

Other: Open the, customer supplied, pressure source valve.

2. Using the REGULATOR (10), adjust the maximum intensifier pump input pressure, as read by the

REGULATED PRESSURE gauge (6), to 1/10 of the target value. The unit utilizes an internal intensifier

with a 10:1 ratio. As an example, setting regulated pressure to 300 PSI would generate an output pressure

of 3,000 PSI. Using this technique, the device to be pressurized, is fully protected from being

accidentally over-pressurized.

3. To generate pressure, enable the POWER switch (2) and monitor the pressure as it builds in the

ACCUMULATOR PRESSURE gauge (7). Turn the

target pressure has been achieved.

NOTE: The intensifier POWER switch (2) can be operated in two modes. The up position is continuous and the down

position is momentary/jog.

4. To apply pressure, the VENT valve (12) must be closed. Open the PRESSURE valve (11), slowly

counter-clockwise, while monitoring the

OUTPUT PRESSURE gauge (8), until reaching the target value.

5. Use either the PRESSURE (11) or VENT valve (8) to obtain a specific pressure reading. Both provide

precise control. As the pressure approaches the desired value, the valve being used for control should be

rotated slowly clockwise to its closed position.

NOTE: Use the intensifier POWER switch (2) if the ACCUMULATOR PRESSURE gauge (7) reading falls below required

target pressure value.

POWER switch (2) off when 10% more than the

4 PIN7000/PIN7010 Operation and Maintenance Manual

3.0 Maintenance & Service

This section outlines the mechanical and basic electrical repair procedures for the PIN7000/PIN7010.

3.1 Troubleshooting

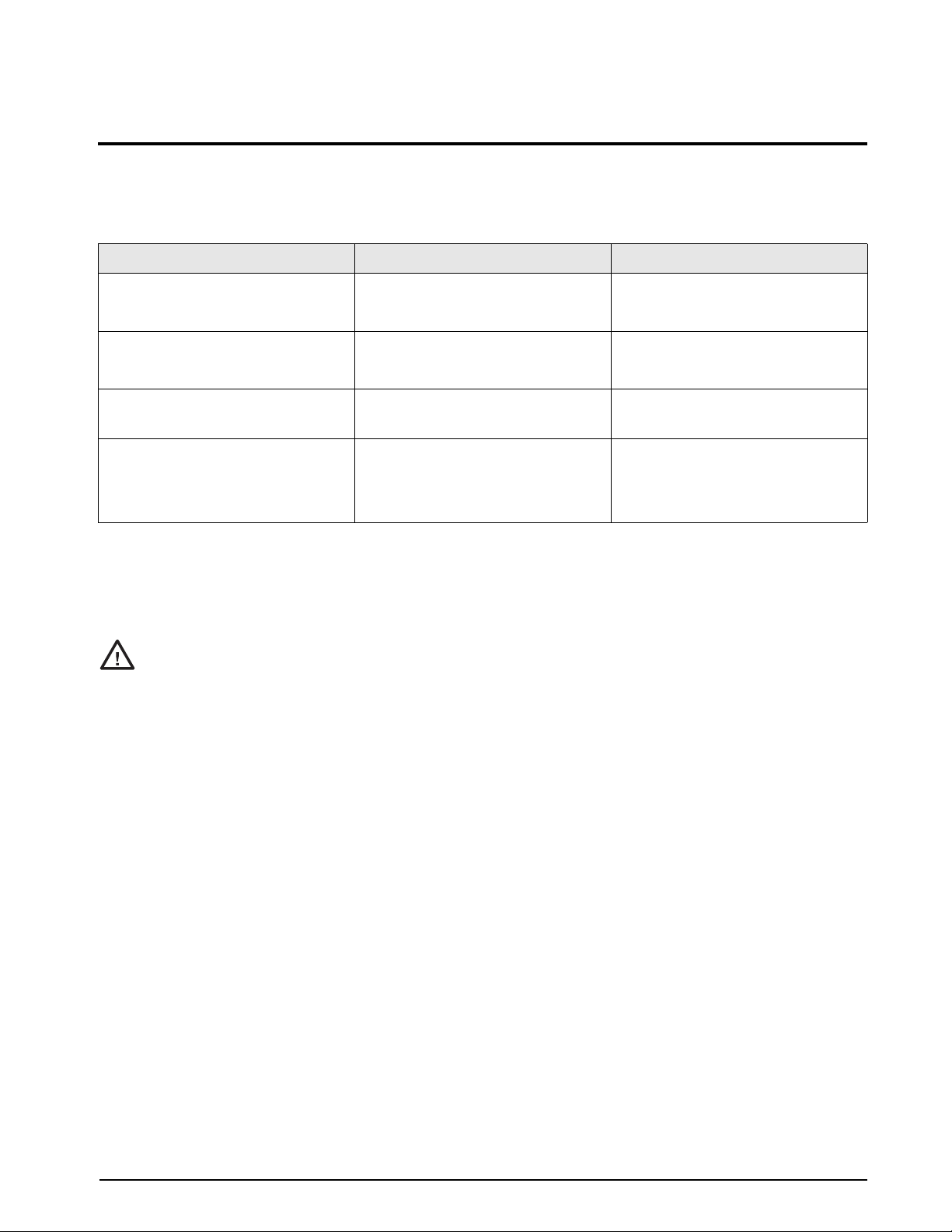

Use T able 3-1 below for information on troubleshooting the PIN7000/PIN7010.

Symptom Problem Remedy

OUTPUT PRESSURE gauge slowly

decreases over time.

OUTPUT PRESSURE gauge increases

or decreases when OUTPUT

PRESSURE or VENT valves are closed.

Unit does not cycle when Pump Control

switch is on.

Unit cycles, but does not pressurize. Debris in check valve seat in intensifier,

Leak in system. Check all compression and pipe fittings

with Snoop®, bottle of liquid leak gas

detector (PN 64781).

No Pressure or Vent control. Replace valve seats or O-rings in valves;

check valve needles.

Fuse blown on Pump Control Board.

No power.

deformity in seat.

No supply pressure.

Replace fuse.

Check that power is on.

Remove seats in intensifier and clean

and/or replace.

Check to see if there is sufficient supply

pressure.

Table 3-1. PIN7000/PIN7010 Troubleshooting

3.2 Maintenance & Service Procedures

The repair procedures cover the major components and sub-assemblies which are critical to the proper

functioning of the calibrators and that need periodic maintenance over the life of the unit.

Only those persons who are formally trained as skilled technicians should attempt to repair these units.

#AUTION

All safety precautions should be observed due to the presence of electrical and high-pressure

components. Unit must always be unplugged from power source and vented.

®

Snoop is a registered trademark of ....

Maintenance & Service 5

Figure 3-1. PIN7000/PIN7010 Wiring Diagram

3.2.1 Panel/Chassis Removal and Installation

PIN7000 Removal

Tools required: Phillips screwdriver

1. Loosen and remove the 10 screws (PN 14862) that secure the panel assembly to the enclosure.

2. Lift the panel and chassis by first grasping the regulator knob and test port and second, grasping under

the panel edges. Tilt the panel at an angle by lifting the right side before the left side as you face the

panel. Ensure that the wire harnesses do not catch and snag.

3. Gently set the panel/chassis assembly on a bench top. It can be rested on the panel bottom with the

accumulator supported by a screwdriver handle.

PIN7000 Installation

Tools required: Phillips screwdriver

1. Lift the panel and chassis by first grasping the regulator knob and test port.

2. Gently place panel/chassis assembly into enclosure. Tilt the panel at an angle by lifting the right side

before the left side as you face the panel. Ensure that the wire harnesses do not catch and snag.

3. Align mounting holes and install the 10 screws (PN 14862) that secure the panel assembly to the

enclosure.

PIN7010 Removal

Tools required: Phillips screwdriver

1. Loosen and remove the 14 screws (PN 14861) from top, bottom, and sides that secure the panel assembly

to the enclosure. Also, loosen and remove the three screws (P/N 14861) from the rear of unit that secure

the enclosure to the TEST PORT/AC INPUT/INPUT PORT panel.

2. Lift the panel and chassis by grasping the handles located on the front of the rack mountable panel.

Ensure that the wire harnesses do not catch and snag.

3. Gently set the panel/chassis assembly on a bench top. It can be rested on the panel bottom with the

accumulator supported by a screwdriver handle.

PIN7010 Installation

Tools required: Phillips screwdriver

1. Lift the panel and chassis by grasping the handles located on the front of the rack mountable panel.

6 PIN7000/PIN7010 Operation and Maintenance Manual

Loading...

Loading...