Condec DLR334 Operating Manual

DLR3110

Rack-mountable Pneumatic

Pressure Calibration Console

Technical Manual

• Operation

• Calibration

• Maintenance

• Service

CONDEC Sales Phone No.: (888) 295-8475

CONDEC Web Site: WWW.4CONDEC.COM

74843

Contents

About This Manual................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

2.0 Installation and Wiring................................................................................................................ 3

2.1 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Rear Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4 Hardware Configuration and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Display/Keyboard Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6 Freeze Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6.1 Freeze Mode Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7 Min and Max Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7.1 Resetting Min and Max Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.8 Remote Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 Operation...................................................................................................................................... 8

3.1 Initial Setup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Pressure Measurement Sequence (Gage) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Pressure Measurement Sequence (Absolute). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 Re-Calibration Only.................................................................................................................... 10

4.1 Pneumatic Calibration Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Instrument Calibration Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Re-Calibration Procedure (Zero, Linearity and Hysteresis) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.0 Configuration and Calibration.................................................................................................... 12

5.1 Pneumatic Calibration Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Instrument Calibration Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 Mode Selection Switch (S1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.4 Main Set-Up Mode Menu Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.5 Auto Set-Up Configuration Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.5.1 Auto Set-Up Menu (General). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.5.2 Auto Set-Up Menu (Gage). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5.3 Auto Set-Up Menu (Absolute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Calibration Set-Up Configuration Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6.1 Calibration Mode Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7 Modifying Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.8 Span Calibration Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.9 Resetting Span Calibration Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.10 Overwriting Span Calibration Points and Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.11 Configuration Set-Up Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.12 Conversion Set-Up Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.13 I/O Set-Up Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.13.1 Port 1 Set-Up Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.13.2 Port 1 Printer Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.13.3 Port 1 Duplex Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.13.4 Port 1 RS485 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.13.5 Port 1 Simplex Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.13.6 Port 2 Set-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.13.7 Time and Date Set-Up Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.13.8 Input Set-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.13.9 Print and Zero Wiring Configration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Copyright © 2002 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

December 2002

ii

6.0 Serial Input/Output..................................................................................................................... 32

6.1 ASCII - Data Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Printer (Port One or Port Two) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3 Duplex (Port One Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.1 Full Duplex Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.2 Command Code <cmd> Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.3 Basic RS485 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4 Continuous Simplex Output (Compressed Format) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5 Serial Output Wiring and Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.0 Maintenance and Service.......................................................................................................... 39

7.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2 Maintenance and Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.1 Panel/Chassis Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.2 ORION-2C (PN 55283) or ORION-3A (PN 55287) Manifold Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2.3 ORION Manifold - Valve Seat Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2.4 ORION Manifold - Vernier Control Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2.5 ORION Manifold - Vernier Control Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.6 ORION-2C Manifold - Valve Seat Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.7 ORION Manifold - Panel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2.8 ORION-2C Manifold - Valve Adjustment Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2.9 ORION-3A Manifold - Valve Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.10 Pressure Limit Control (Standard Pneumatic), Regulator Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2.11 Pressure Limit Control (Standard Pneumatic), Regulator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2.12 Pressure Limit Control (Tescom), Regulator Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.13 Pressure Limit Control (Tescom), Regulator Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.14 Panel Gauge Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.15 Panel Gauge Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.16 Test Port Quick-Connect Fitting (PN 59762) Removal and Installation - 3 and 100 Full Scale PSI . . . . 48

7.2.17 Test Port Filter (PN 54188) Removal and Installation - 250 and 2500 Full Scale PSI . . . . . . . . . . . . . . 49

7.2.18 Test Port Quick-Connect Fitting (PN 59004) and Filter (PN 54188) Removal and Installation - 5000 and

7.2.19 Test Port (Output) Hose Quick-Connect Fitting and Filter Removal and Installation (PN 56991)- 5000 and

7.2.20 Input Port Filter (PN 54188) Removal and Installation - 2500 Full Scale PSI. . . . . . . . . . . . . . . . . . . . . 50

7.2.21 AC Fuse (PN 58076) - Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.2.22 Input Port Filter (PN 54188) Removal and Installation - 5000 and 10000 Full Scale PSI. . . . . . . . . . . . 51

7.2.23 AC Fuse (PN 58076) - Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.2.24 AC Power/EMI Line Filter (PN 58870) - Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.2.25 Power Switch (PN 58878) - Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10000 Full Scale PSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

10000 Full Scale PSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.3 ORION-2C Valve Assembly Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4 ORION-3A Valve Assembly Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.0 Model Numbering System......................................................................................................... 62

9.0 Auto Selection Default Tables ................................................................................................... 63

10.0 Conversion Factors.................................................................................................................... 66

11.0 Options, Replacement Kits ........................................................................................................ 67

12.0 Specifications............................................................................................................................ 68

DLR3110 Warranty and Return Policy.................................................................................................... 69

DLR3110 Return Material Authorization Form....................................................................................... 70

DLR3110 Rack Mount Digital Pressure Indicator Manual

About This Manual

This manual is intended for use by service technicians

responsible for installing and servicing the DLR3110

Digital Pressure Calibrator.

The DLR3110 series rack-mount combines the DLR

Digital Pressure Calibrator with the Orion vernier for

calibration of a wide variety of pressure sensing and

measuring devices.

The DLR3110 utilizes a repeatable sensor coupled to

microprocessor-based electronic circuitry and a

selectable units conversion display system to provide

digital representation of measured pressure. The unit

has one test port. Dependent on model, a front panel

mounted gauge tells the operator system pressure and

includes a pressure regulator so the operator can not

over-pressure a unit under test. Test hose is supplied

standard for the customer. Front panel buttons provide

Warning

equipment. This is a high-pressure system. Only

personnel formally trained in the use of pneumatic

pressure equipment should be permitted to operate it.

Potentially dangerous conditions can be produced

through negligent handling or operation of the console

due to the high pressure used within the unit.

These units are strictly for use with pneumatic pressures.

Erroneous readings and potential damage could result

from the introduction of hydraulic fluids into the internal

tubing lines.

Before attempting to use either style

pressure calibrator, the following

instructions must be read and

understood by personnel using the

Authorized distributors and their

employees can view or download this

manual from the Condec distributor site

at

www.4condec.com

.

selection of the desired functions, including zeroing

(GAGE models only).

1.0 Introduction

Using microprocessor technology, the rack-mountable DLR3110 instrument offers a combination of features,

performance, versatility and reliability not previously available in a single, rack-mount pressure calibration

instrument. Some of the features of the DLR3110 are listed below:

• Streamlined, multi-function keyboard.

• Selectable configurations, automatic set-up mode and multiple conversion units.

•Based on model, accuracy equal to or better than ±0.05%, ±0.1% or ±0.25% of indicated value from 20%

of full scale.

•Alpha-numeric display prompting provides the operator with functional status information during both

operation and calibration.

•A manually adjustable regulator (when applicable) allows the maximum system input pressure to be

adjusted to any desired value higher (typically 20 – 50%) than the full scale range of the device being

tested. This regulator helps protect the unit under test from being inadvertently over-pressurized.

•No manual alignment or potentiometer adjustments are required for system calibration. (50,000

displayed graduations; ten-point linearity compensation; automatic gain adjustment).

•Calibration integrity: Tamper-proof design. Once calibrated, numerous safeguards guarantee the

integrity of pressure readings obtained.

•Operation: All controls, indicators and test port are accessible from the front panel. A version with test

port on rear of unit is available by special order. See Section 3.0 on page 8 for instructions on system

operation.

•For safe, clean operation, all pressure components are made of brass, copper, aluminum, or stainless steel

and proof-tested to at least 150% of maximum operating pressure. In addition, the system contains a

high-pressure burst disk and relief valves to protect both the operator and system components from harm

in the event of inadvertent over-pressurization.

The heart of this calibration system is a stable and repeatable pressure transducer. These sensors produce an

electrical output signal that is linearly proportional to the applied pressure.

Introduction

1

2

By combining these sensors with microprocessor-based circuitry, an even higher degree of operational accuracy

and precision has been accomplished. For example, computer-generated correction curves for both the

non-linearity and the hysteresis of the sensors improve these characteristics by an order of magnitude or more.

Two micro-metering valves and vernier are provided to control the external nitrogen source while the digital

display indicates the magnitude of the applied test pressure. Also, a push-button switch provides the “zeroing” of

the pressure display (on GAGE models). Over-pressure protection, based on model, is provided via a fully

adjustable pressure regulator which is manually set for each new device being tested.

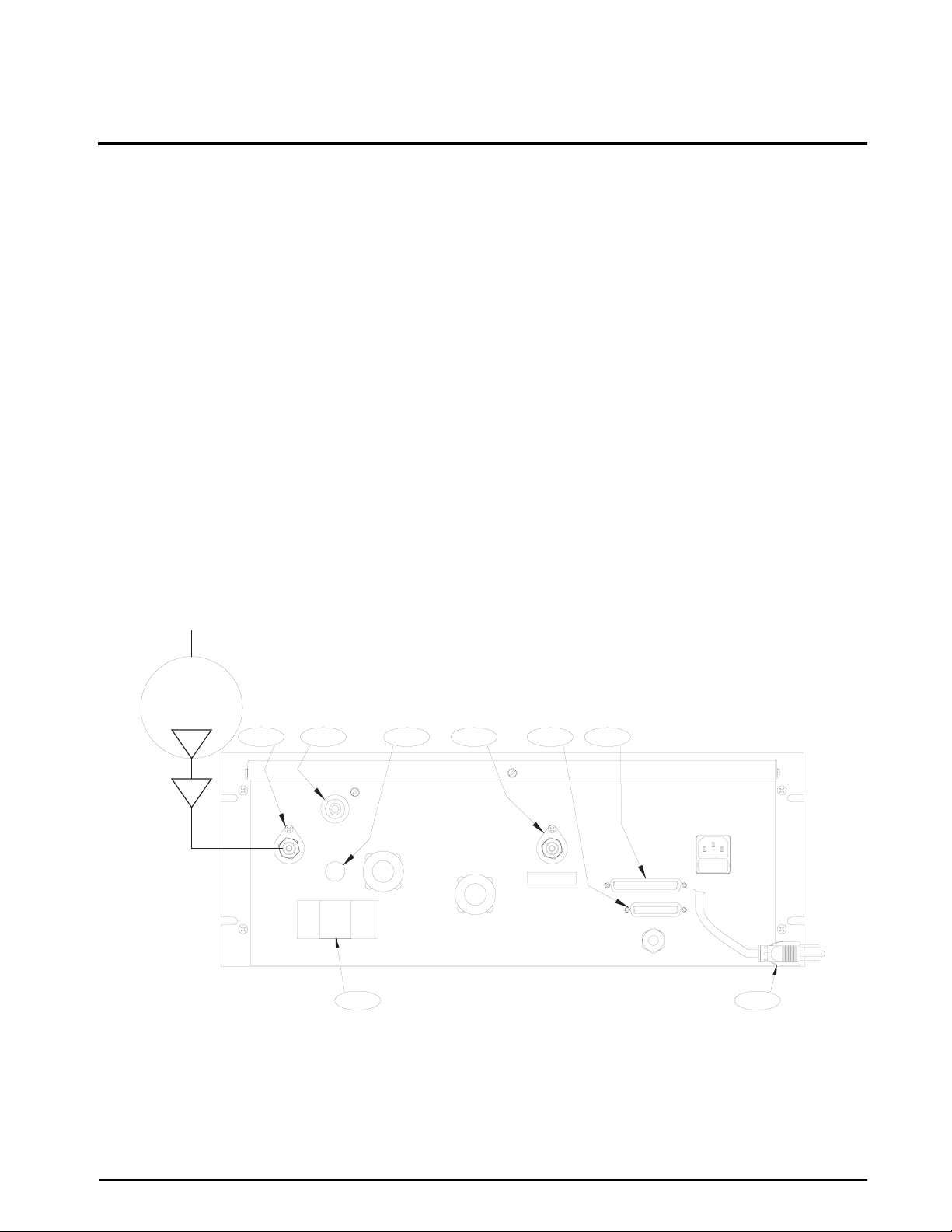

Figure 1-1 provides an overview of the DLR3110’s function.

VERNIER

ADJUST

PRESSURE LIMIT

MONITOR

FILTER

20u

INPUT PORT

NOTE: MAX INPUT BASED\P ON MODEL.

PRESSURE LIMIT

CONTROL

BURST DISK

3000 PSI

±50 PSI

RELIEF

VALVE

NOT REQUIRED ON 5K OR 10K MODELS

Figure 1-1. DLR3110 Flow Diagram

PRESSURE

INCREASE

MICROPROCESSOR-BASED

DIGITAL INDICATOR

DLR3110 FLOW DIAGRAM

FILTER

TEST PORT20u

(QUICK DISCONNECT)

VENT

VENT/VACUUM

PORT

TRANSDUCER

DLR3110 Rack Mount Digital Pressure Calibrator Manual

2.0 Installation and Wiring

2.1 Unpacking and Inspection

Carefully remove the instrument from its shipping container. A visual inspection of the instrument's external

surfaces should be performed immediately after unpacking. If obvious damage occurred during transit, notify the

shipping agency and distributor as soon as possible to receive instructions on how to proceed after an assessment

of the damage is completed.

If the instrument shows no signs of damage, check to be sure all the required equipment and accessories were

included. Keep original shipping carton for repacking in case repair is necessary.

2.2 Repacking

If the DLR3110 must be returned for repair, recalibration, or modification, be sure that it is properly cushioned

and packed and that a description of the work to be performed is included. The original shipping carton should be

kept for this purpose.

2.3 Rear Panel Configuration

The rear panel of the rack mount DLR3110 Series, contains the following items:

• AC power cord (1) and input receptacle.

• 7/16-20, 37

NOTE: The maximum input pressure, supplied by user, is noted below input pressure port.

• The unit's identification plate (4) and J6, 25 pin D connector, (5) for serial I/O communication interface.

•Optional if required items: Connector J5, 37 pin D connector, (6) for the Parallel BCD output. Connector

J2 (7) for the Freeze mode cable. Test port (8) in place of front mounted.

°

-4 AN male fittings, vent/vacuum port (2) and input pressure port (3).

VACUUM

PUMP

2 5

TEST PORT

J2

FREEZE MODE

VENT/VACUUM

PORT

4

78

J3

3

J1

INPUT

MAX. XXX

REAR VIEW

Figure 2-1. DLR3110 Rear View

6

AC INPUT

J5

J6

FUSE

1

Installation and Wiring

3

4

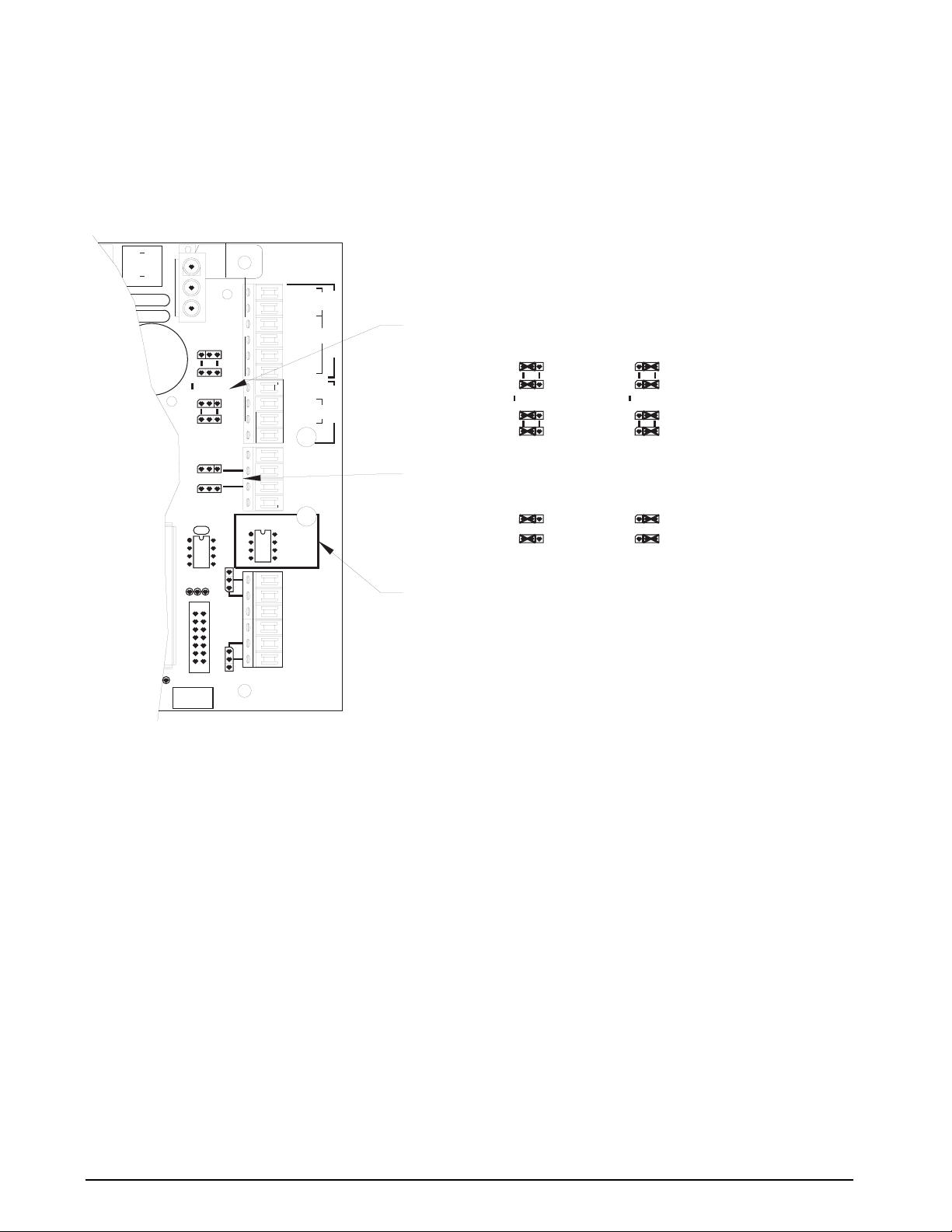

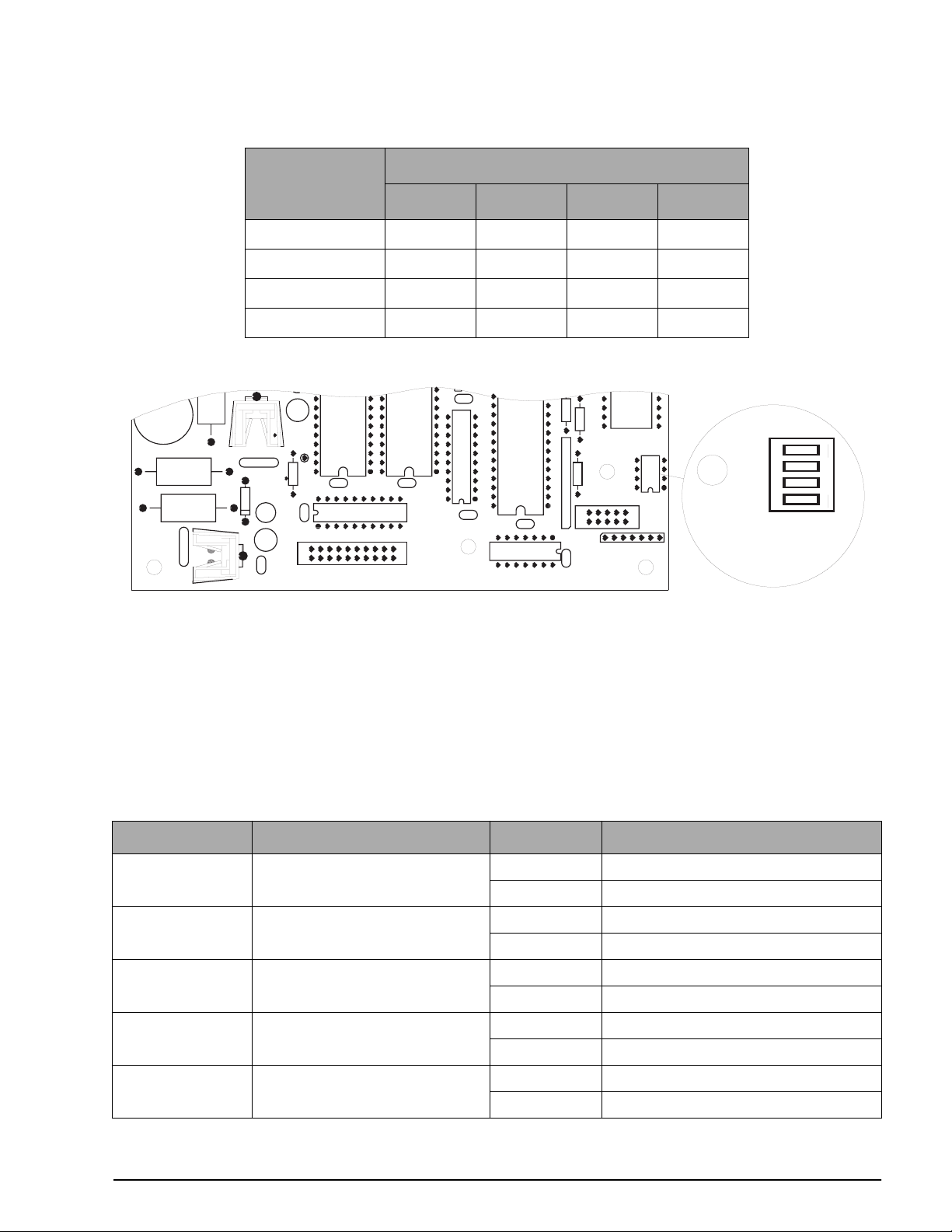

2.4 Hardware Configuration and Wiring

The CPU board in the DLR series has been designed for easy access to wiring and configuration of all available

inputs and outputs. In addition to easy access, the wire and configuration mapping provide clear labeling of all

input and output signals and the associated configurations of their device drivers.

J2

GND

LO

HI

S9

S8

S7

S6

S5

S4

C38

E11

E12

REMOTE SENSING

7

1

J3

+EXC

TB3

OUT

TB2

U18

10

RS485

AB

RS422

BA

1

3

1

S3

S2

20mA LOOP

P2

-OUT

+OUT

-IN

P1

+IN

-OUT

+OUT

SIG COM

IN

OUT

OUTOUT

+5V

I/O 2

I/O 1

RETURN

S10

P1 IN

RS232

OFF

20mA

RS485

RS422

6

-EXC

-SENSE

-SIG

+SIG

+SENSE

+EXC

1

CPU

TB1

TB1

ASSEMBLY

KKR8924-[]

DATE []

REV []

PORT 1 CONFIGURED FOR 20ma

CURRENT LOOP

RS232

P1

PORT 1 CONFIGURED FOR RS232

P2

SHOWN CONFIGURED AS INPUTS

SERIAL INPUT/OUTPUT SELECTION

JUMPER POSITION

P1

20mA

RS232

S9

S8

S7

S6

RS485

RS422

JUMPER POSITION

BA

AB

P1

20mA

RS232

RS485

S9

AB

PORT 1 CONFIGURED FOR RS485 OR

RS422 (TRANSMITTER)

S8

RS422

S7

PORT 1 CONFIGURED FOR RS485 OR

BA

RS422 (RECEIVER)

S6

INPUT/OUTPUT CONFIGURA TION

JUMPER POSITION

INS5OUT

S4

JUMPER POSITION

INS5OUT

S4

SHOWN CONFIGURED AS OUTPUTS

PORT 1 SERIAL INPUT SELECTION

THE PORT 1 INPUT SWITCH SELECTS FROM WHICH DEVICE THE SERIAL DATA IS RECEIVED

F1

C2

C1

3

20mA

P1

RS232

IN

E10

14

8

E8

S13

-EXC

Figure 2-2. CPU Configuration

NOTE: Unit is shipped previously set up and configured. For information on changing hardware configuration see

Section 5.11 on page 21.

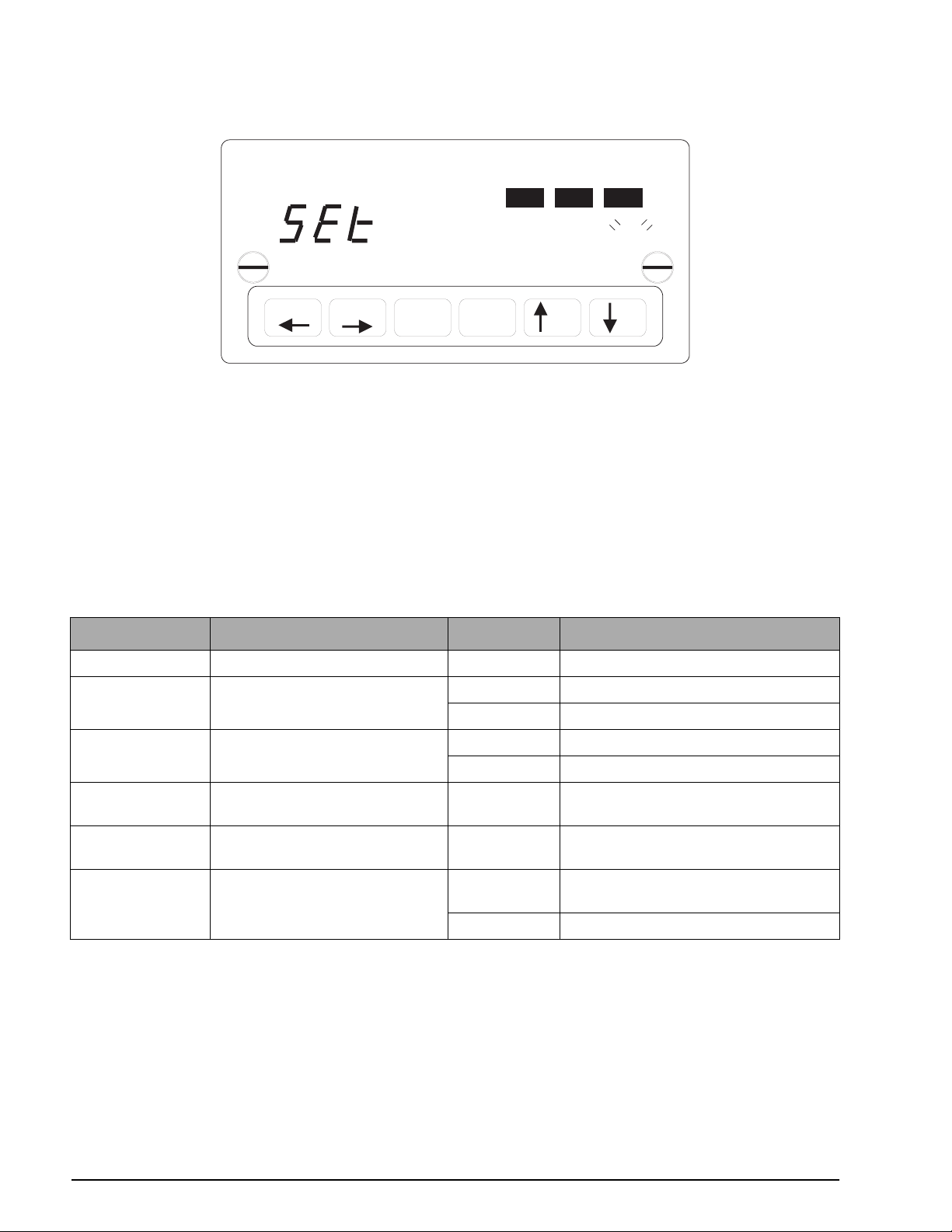

2.5 Display/Keyboard Functions

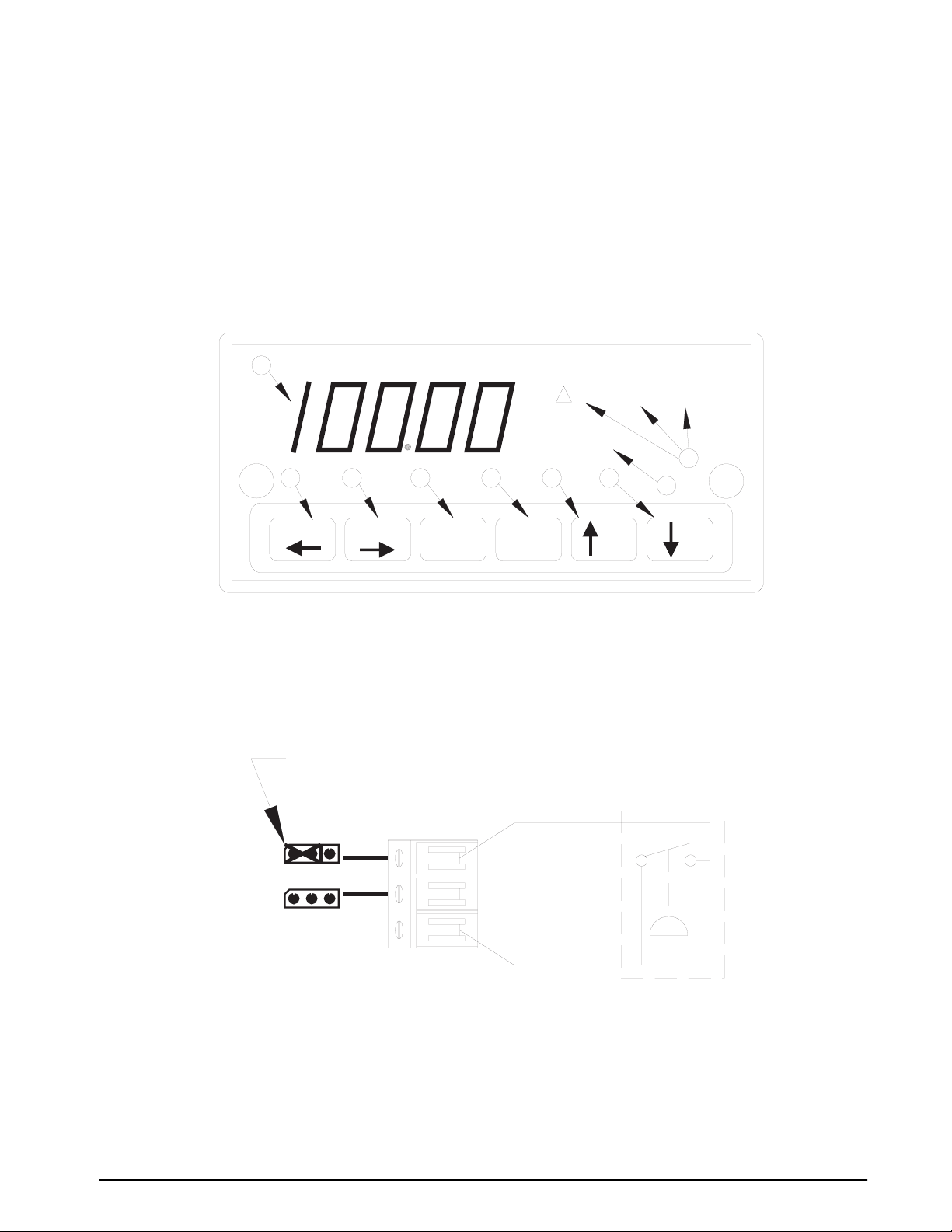

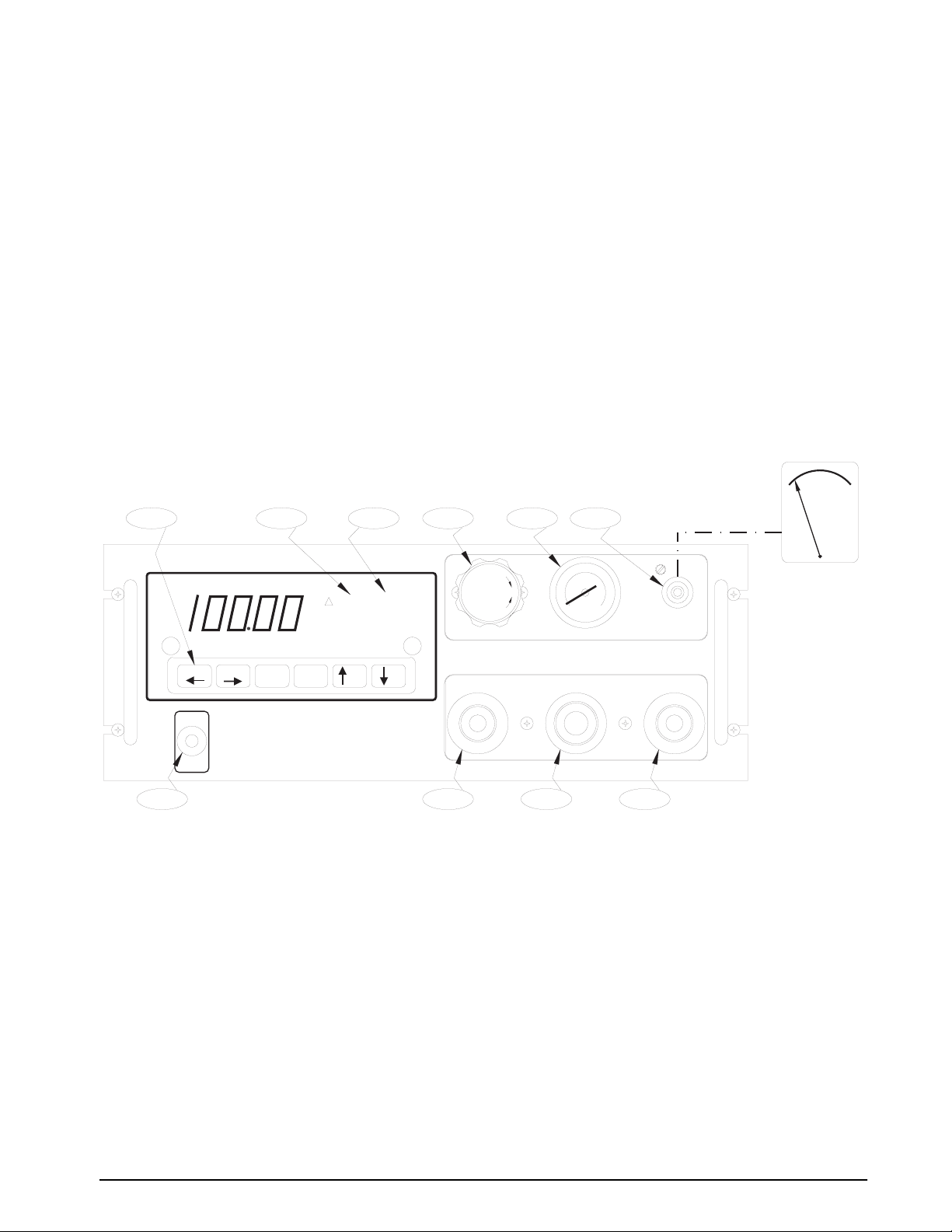

See Figure 2-3 on page 5 for information on display and keyboard functions.

• Six-digit LED display of the measured pressure (1).

• Three annuciators: Two of the LEDs are used for indicating whether the unit is operating as a GAGE

pressure unit or as an absolute (ABS) pressure unit. The LED marked

delta P display mode (2).

• Eight character LED display for indicating the conversion units that the pressure data is currently being

displayed in. This display also scrolls prompting messages if corrective action is required or a problem

occurred in performing an operation (3).

For example, if attempting to perform a push to ZERO while the pressure data is in motion, the display

shows

Unit is in MOTION

• In GAGE units, the

.

function key (4) allows the indicator to be zeroed if it is within the limits

ZERO

defined by the ZERO configuration.

•

DISPLAY

key (5). In the normal operating mode this key is used to select and vie w all acti v e displays that

were enabled in the Configuration mode (i.e., Pressure data, MIN/MAX data, Freeze mode data, and

delta P display mode data).

indicates that the unit is in the

P

DLR3110 Rack Mount Digital Pressure Calibrator Manual

TARE

•

function key (6). The AUTO TARE (Auto.tr) feature is enabled in the Configuration mode under

the ZERO SET selection. When AUTO TARE is enabled, pressing the

TARE

key automatically tares out

the value of the current pressure display reading and shifts the display to the P (delta P) mode. The

resultant ZERO reference reading is useful in cases where it is desirable to subtract the atmospheric

pressure from an absolute reading to obtain a quick gauge reference.

NOTE: This pseudo-gage reading is only valid for the current atmospheric pressure that was tared out. Any

subsequent changes in atmospheric pressure result in an error.

PRINT

•

•

key (7) issues a demand serial printout of the display data from the indicator.

UP

(8) and

DOWN

(9) arrow keys step through and display the data in the conversion units that were

selected in the Configuration mode.

1

P Gage Abs

PSI

2

54

6

7

8 9

3

ZERO

DISPLAY

TARE

CE ENTER

PRINT

YES

NO

Figure 2-3. Display/Keyboard Functions

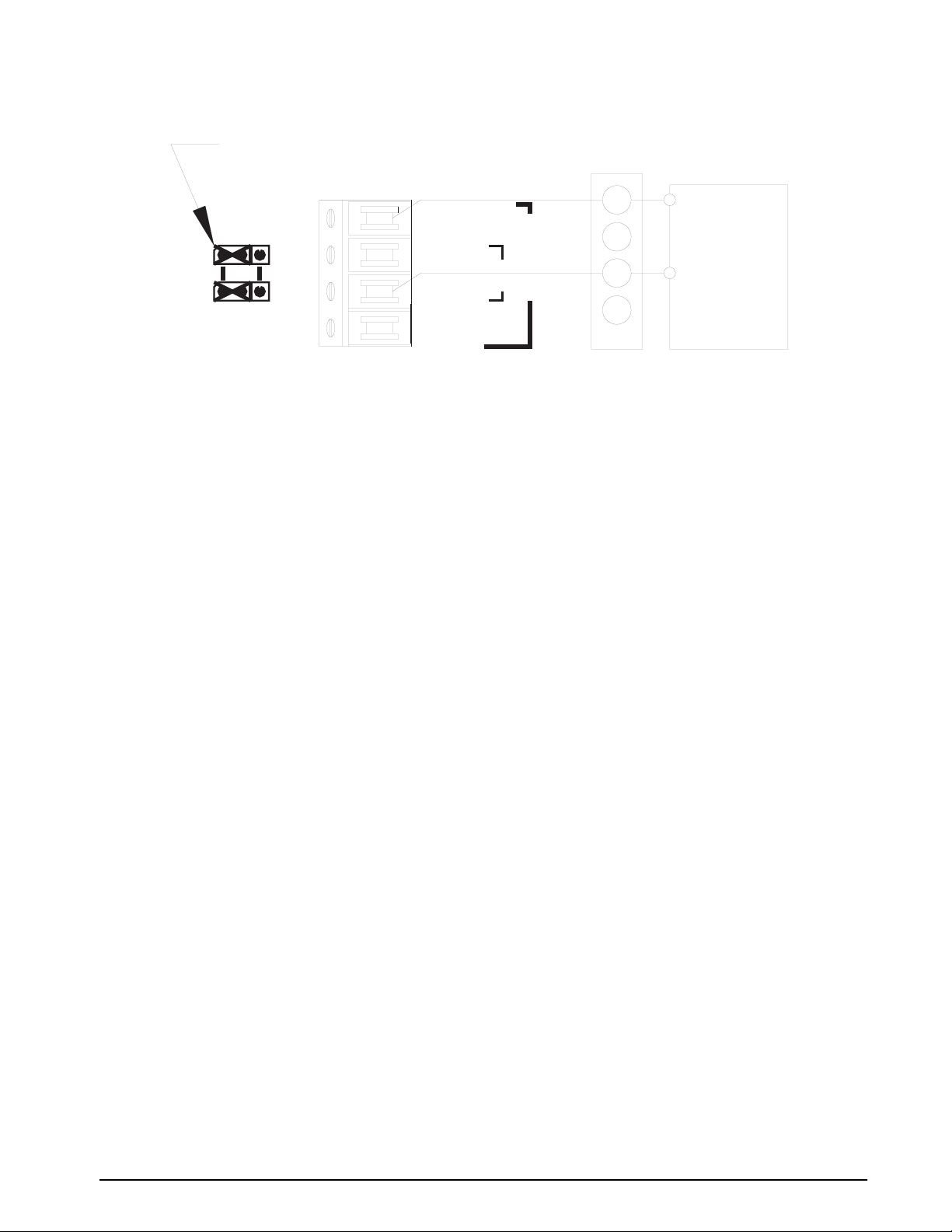

2.6 Freeze Mode

Freeze mode, used for testing pressure switches, is an edge triggered input signal that freezes the last display

update for the number of seconds (1 – 10 seconds) selected in the Configuration mode. The Freeze mode is

enabled in the CONFIG ?

Freeze mode).

menu under freeze time selections (Refer to Section 5.11 on page 21 for enabling the

JUMPER PLUG SHOWN ON S5 CONFIGURED AS AN INPUT

PRESSURE SWITCH

(+5 VDC)

S5

I/O 2

IN

S4

OUT

TB2

I/O 1

RETURN

(DIGITAL COMMON)

Figure 2-4. Freeze Mode CPU Connections

Either opening or closing of a switch contact between an active input (I/O 1 or I/O 2) and RETURN “freezes”

the

display (for the pre-selected amount of time in seconds) as shown above. However, while the display is in the

freeze condition, it does not respond to another contact transition

.

Installation and Wiring

5

6

2.6.1 Freeze Mode Specifications

The following bullet points outline general specifications for the DLR3110’s Freeze mode.

• The freeze input “freezes”

the display for approximately five seconds on the rise and fall time of the

input (edge not level triggered) and can not be re-triggered.

• Input pulse > 100 ms required to guarantee detection.

• Freeze mode “freezes”

the 6 digit numeric and LED bar displays in whatever mode it is in (for example,

Normal, Net, Min and Max mode).

•Alphanumeric display prompts

•During the “freeze”

the front panel keys are inactive.

• Inputs are a +5 VDC logic level. Sinking current approximately

FREEZE

.

0.5 mA.

2.7 Min and Max Mode

The Min and Max mode is designed to capture and store the highest and the lowest pressure readings. These

values may be recalled at anytime in the normal operating mode by repeatedly pressing the

DISPLAY

the desired value is displayed. When either the minimum or maximum value is selected, the alphanumeric

display flashes between the mode (Min and Max) and its units.

NOTE: The Min and Max mode pressure data is automatically converted to any of the active conversion units by

stepping through the conversion units using the UP or DOWN arrow keys.

Both the Min and Max mode are independent of each other and are enabled (turned ON) in the Configuration

mode (see Section 5.11 on page 21).

key until

2.7.1 Resetting Min and Max Values

To reset the stored minimum or maximum value:

1. Select the Min or Max display to be reset using the

key. One of the following messages appears on the alphanumeric

2. Press the

YES OR NO; RESET MIN? YES OR NO.

CE

3. At the display prompt shown above, press the

resetting the value.

NOTE: Min and Max data work with the standard pressure, not delta pressure data.

DISPLAY

key to reset the value or press the

YES

key.

display:

NO

RESET MAX?

key to abort

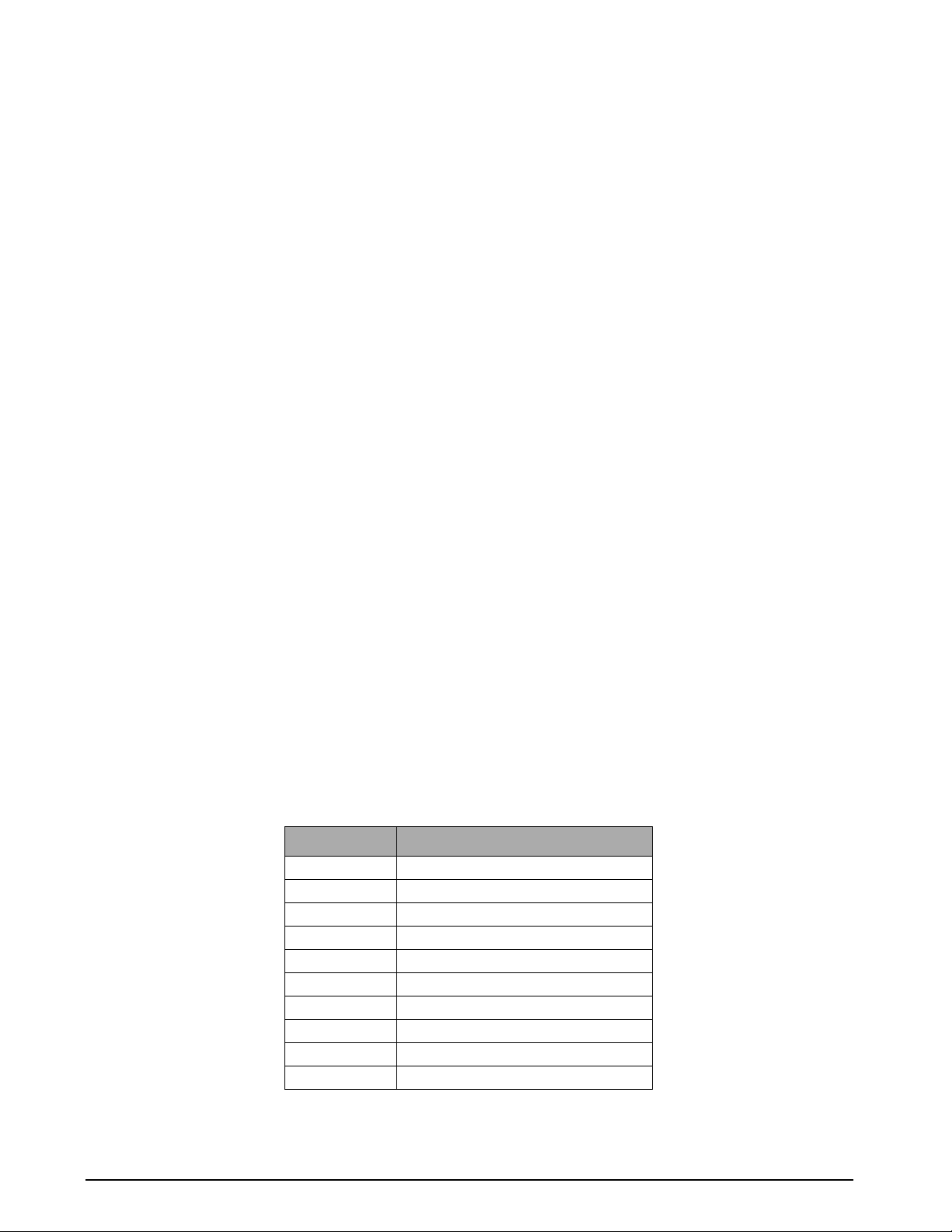

2.8 Remote Display Mode

The following describes the setup for connecting the optional six-digit remote display (PN 74683). The display

duplicates the DLR3110 six-digit front panel display for all ranges and units selected (see Figure 2-5 on page 7).

NOTE: Remote display does not show current unit or mode designation.

See Table 5-10 on page 24 for setting the following parameters:

Parameter

Port 1 SIMPLEX

Baud 9600

Parity EVEN

Port 1 Modify

delay 1 AUTO

t –d 1 OFF

data 1 COMPRESS

EOL 1 CR

SOt 1 NONE

EOt 1 NONE

Configuration

Table 2-1. DLR3110 Parameters

DLR3110 Rack Mount Digital Pressure Calibrator Manual

JUMPER PLUGS SHOWN ON S6 & S7 CONFIGURED AS RS232

WIRE\PCOLOR

BLACK

P1

RS232

S7

S6

RS422

TB3

SIG COM

IN

BA

1

OUT

OUT

P1

P2

RS232

RED

Figure 2-5. DLR3110 CPU to Remote Display PN 74683 Wiring

J6

7

2

P2-4

ISO GND

P2-5

RS232 RXD

REMOTE DISPLAY

Installation and Wiring

7

8

3.0 Operation

The following sections provide instructions on various operation procedures for the DLR3110.

3.1 Initial Setup Procedure

To prepare for actual calibration usage, see Figure 3-1 on page 9 and proceed as follows:

1. Check that the INPUT valve (1) is closed (rotate clockwise until it stops) and that the VENT valve (2) is

open (two turns counter-clockwise from its stop).

2. Plug in the power cord (see Section 2.3 on page 3) and power up the unit by pressing the power switch

(3). Allow at least 10 minutes warm-up time.

3. If applicable, use the PRESSURE LIMIT CONTROL REGULATOR (4) to adjust the maximum system

input pressure, as read by the PRESSURE LIMIT MONITOR (5), to any desired value higher (typically

20–50% higher) than the full-scale range of the Device-Under-Test (DUT). This procedure fully protects

the DUT from being accidentally over-pressurized.

4. Connect the male end of the test hose to the TEST PORT (6) fitting.

NOTE: DLR3110 may be ordered with Test port on rear of unit. See Section 2.3 on page 3.

5. Connect the swivel fitting end (7/16-20) of the test (output) hose to the DUT using adapters if required.

Tighten all connections properly.

3.2 Pressure Measurement Sequence (Gage)

Use the following steps to measure pressure with the GAGE model DLR3110:

1. With reference to Figure 3-1 on page 9, check that the indicator on the right end of the display indicates

Gage

(8). If not, see Section 5.11 on page 21.

switch (7). DLR3110’s LEDs momentarily display the word

2. Press and release the

the display returns to a

(2) is open, by momentarily depressing the

3. To apply pressure, close the VENT

the INPUT valve (1) approximately 1/2 turn counter-clockwise until the numerical display begins to

move. The pressure may change rapidly until reaching approximately 90% of the desired final value.

4. Use either the INPUT (1) or VENT valve (2) to obtain a specific pressure reading. Both provide precise

control. As the pressure approaches the desired value, the valve being used for control should be rotated

slowly clockwise to its closed position. With a little experience, pressure values very close to the desired

final value can be quickly achieved.

5. To obtain exact pressure readings, slowly rotate the VERNIER control knob (10) in the direction

required (clockwise to increase pressure) as indicated by the electronic numerical display.

ZERO

0

reading. The instrument may be zeroed at anytime, as long as the VENT valve

switch (7) for less than 5 seconds.

ZERO

valve (2) approximately two turns clockwise until it stops, then open

Zero

3.3 Pressure Measurement Sequence (Absolute)

Use the following steps to measure pressure with the ABSOLUTE model DLR3110:

1. With reference to Figure 3-1 on page 9, check that the indicator on the right end of the display indicates

Abs

(9). If not, see Section 5.11 on page 21.

2. If only pressure measurements greater than barometric are required, continue to step 2.1. If pressure

measurements above and below atmospheric pressure are required go to step 3.

a) To apply pressure, close the VENT valve (2) by turning clockwise approximately two times until it

stops and open the INPUT valve (1) by turning counter-clockwise approximately 1/2 turn until the

numerical display begins to move. In general, the pressure may be changed rapidly until reaching

approximately 90% of the desired final value.

b) Use either the INPUT (1) or VENT valve (2) to obtain a specific pressure reading. Both provide

precise control. As the pressure approaches the desired value, the valve being used for control should

be rotated slowly clockwise to its closed position. With a little experience, pressure values very close

to the desired final value may be quickly achieved.

c) To obtain exact pressure readings, slowly rotate the VERNIER control knob (10) in the direction

required (clockwise to increase pressure) as indicated by the electronic numerical display.

and then

DLR3110 Rack Mount Digital Pressure Calibrator Manual

3. If pressure measurements above and below atmospheric pressure are required, connect a VACUUM

PUMP to the VACUUM/VENT port (2) as shown in Figure 2-1 on page 3.

4. Open the VENT valve (2), close the INPUT valve (1) and apply power to the vacuum pump and allow it

to evacuate the system for several minutes or until the digital display reading reaches equilibrium near

0 PSIA.

5. With the vacuum pump still running, close the VENT valve (2) and check for system leaks. If there are

none, continue to step 5.1.

a) To apply pressure, close the VENT valve (2) by turning clockwise approximately two turns to its

stop and open the INPUT valve (1) by turning counter-clockwise approximately 1/2 turn until the

numerical display begins to move. In general, the pressure may be changed rapidly until reaching

approximately 90% of it desired final value.

b) Use either the INPUT (1) or VENT valve (2) to obtain a specific pressure reading. Both provide

precise control. As the pressure approaches the desired value, the valve being used for control should

be rotated slowly clockwise to its closed position. With a little experience, pressure values very close

to the desired final value may be quickly achieved.

c) To obtain exact pressure readings, slowly rotate the VERNIER control (10) knob in the direction

required (clockwise to increase pressure) as indicated by the electronic numerical display.

7

DISPLAY

ZERO

POWER

89

P Gage Abs

PSI

PRINT

TARE

ENTER

CE

YES

NO

4

INCREASE

DECREASE

CONTROL

INPUT

1

56

PRESSURE LIMIT

MONITOR

VERNIER

DUT

TEST PORT

VENT

23 10

Figure 3-1. Pressure Measurement Sequence

Operation

9

4.0 Re-Calibration Only

NOTE: This section is for the technician that is familiar with the front keyboard menus and is doing nothing more than a

re-calibration. The re-calibration must be done in the same base units as originally calibrated. For a more in-depth

configuration and calibration explanation, see Section 5.0 on page 12.

The step-by-step calibration sequence provided on the following pages permits a qualified technician to calibrate

an entire DLR3110 instrument in approximately 45 minutes.

The instrument has been designed and programmed to provide the operator with various prompting symbols and

legends during each phase of the calibration sequence. Also, to prevent unauthorized tampering or calibrations,

numerous features have been incorporated to minimize this potential danger.

However, it must be emphasized that when performing these tests, the computer within the DLR3110 is actually

being re-programmed and as such, it is imperative that the pressure standard being used is in satisfactory

operating condition and that the technician fully understands its operating characteristics and methods of usage.

In addition, the DLR3110 itself must be warmed up for approximately 30 minutes and electrically stabilized

prior to performing a calibration cycle.

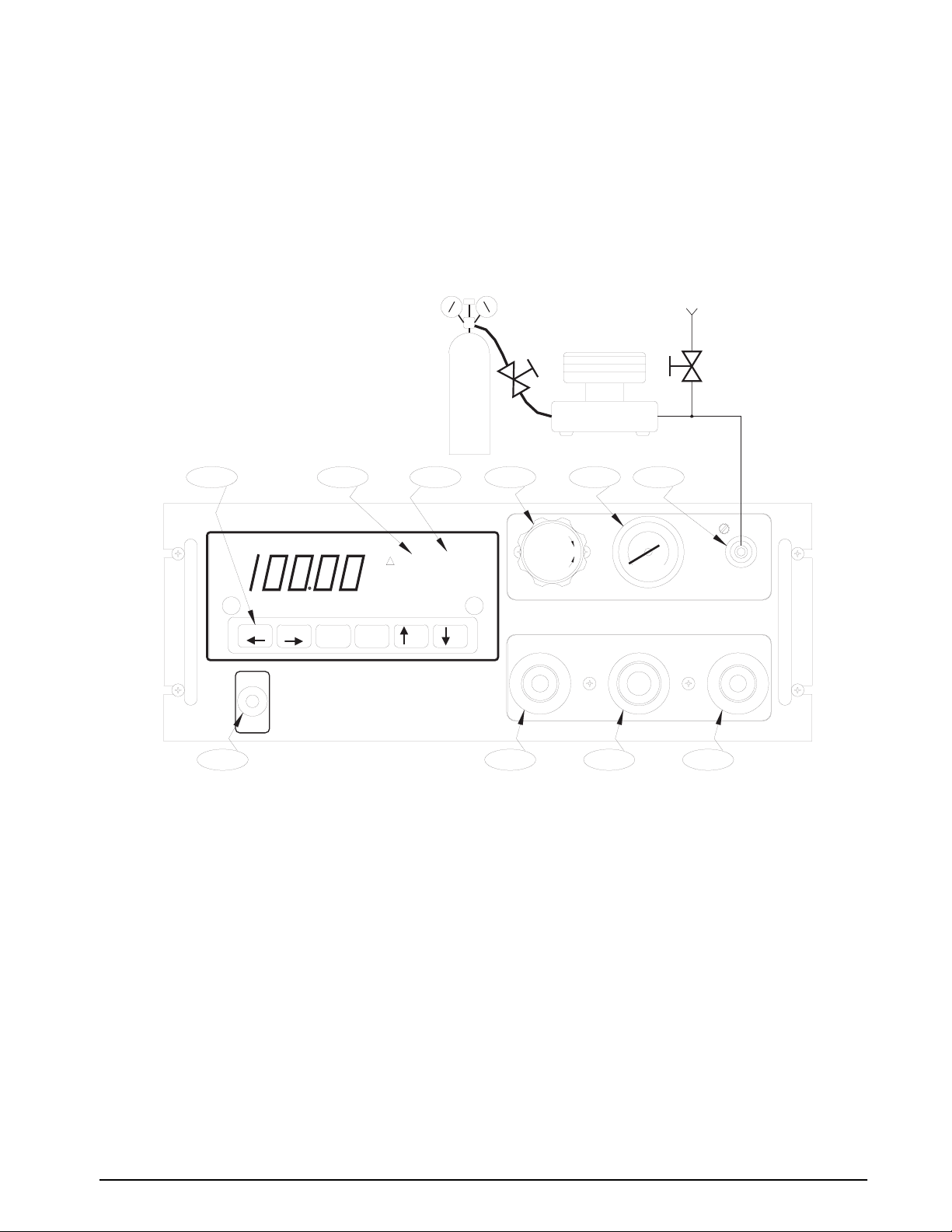

4.1 Pneumatic Calibration Set-Up

Figure 4-1 on page 11 defines a typical calibration set-up using a floating piston type dead weight tester.

However, any type of precision standard is acceptable as long as its basic accuracy is twice that of the

DLR3110’s or better.

To permit proper calibration at least an on/off and a vent valve must be provided (connected as shown in

Figure 4-1 on page 11).

10

4.2 Instrument Calibration Set-Up

Check that the INPUT valve (1) is closed (rotate clockwise until it stops) and that the VENT valve (2) is open

(two turns counter-clockwise from its stop).

The DLR3110 is placed into its Calibrate mode by closing rocker switch

the DLR3110's LED and alpha-numeric display is used to provide operator prompting symbols as well as

displaying the various data formats employed.

S1 position 2. In the Calibrate mode,

4.3 Re-Calibration Procedure (Zero, Linearity and Hysteresis)

Use the following steps for the re-calibration procedure of the DLR3110.

1. The alpha-numeric display reads

2. Press the

3. Press the

4. Press the

5. Press the

models and ABS for ABSOLUTE models. For GAGE models continue to step 6. For ABSOLUTE

models go to step 7.

6. Press the

INPUT valve is closed (rotate clockwise until it stops) and that the VENT valve is open (two turns

counter-clockwise from its stop).

Press the

Close the VENT valve (rotate clockwise until it stops). Go to step 7.

7. The alpha-numeric display reads

Set the input pressure from the test standard to the target value on the display. W ait for system to stabilize

and press the ENTER key on the display panel.

8. The alpha-numeric display reads

Set the input pressure from the test standard to the target value on the display. W ait for system to stabilize

and press the

target values.

DOWN arrow key on the display panel. The alpha-numeric display reads CAPACITY.

DOWN arrow key on the display panel. The display reads XXXX x .x.

DOWN arrow key on the display panel. The LED display reads base.

DOWN arrow key on the display panel. The alpha-numeric display reads GAGE for GAGE

DOWN arrow key on the display panel. The alpha-numeric display reads ZERO CAL. V erify the

ENTER key on the display panel. The LED display reads 0.00 (number of zeros arbitrary).

ENTER key on the display panel. Repeat this step for the next eight predetermined SPAN

FILTER X, where “X” represents a numerical variable.

SPAN 1 CAL TARGET=XXX, where “X” represents a numerical variable.

SPAN 2 CAL TARGET=XXX, where “X” represents a numerical variable.

DLR3110 Rack Mount Digital Pressure Calibrator Manual

9. The alpha-numeric display reads HYST. CAL TARGET=XXX (X represents the preset target value on

display). Set the input pressure from the test standard to the target value on the display. Wait for system

to stabilize and press the ENTER key on the display panel.

NOTE: For ABS models, use a vacuum pump to reach the applicable SPAN or HYST target values that are

below local barometric pressure.

10. The alpha-numeric display reads FILTER 5. Save the calibration data by opening rocker switch S1

position 2. DLR3110 returns to normal mode.

11. Vent system and remove test standard.

"ON-OFF"

2-WAY VALVE

PNEUMATIC PRESSURE

TESTER

7

89

4

INCREASE

5

VENT

6

P Gage Abs

PSI

ZERO

POWER

DISPLAY

TARE

PRINT

YES

CE

ENTER

NO

3

DECREASE

CONTROL

INPUT

1

Figure 4-1. Instrument Calibration Set-Up

NOTE: AC input and input port are on back side rack-mountable calibrator.

PRESSURE LIMIT

10

MONITOR

VERNIER

TEST PORT

VENT

2

Re-Calibration Only 11

5.0 Configuration and Calibration

The following sections cover configuration and calibration of the DLR3110. For information on calibrating the unit

without configuration changes, see Section 4.0 on page 10.

During the following procedures, the computer within the DLR3110 is actually being re-programmed. The pressure

standard being used during calibration should be in satisfactory condition and fully understood by the service

technician. In addition, the DLR3110 must be warmed up for approximately 30 minutes and electrically stabilized

prior to performing a calibration cycle.

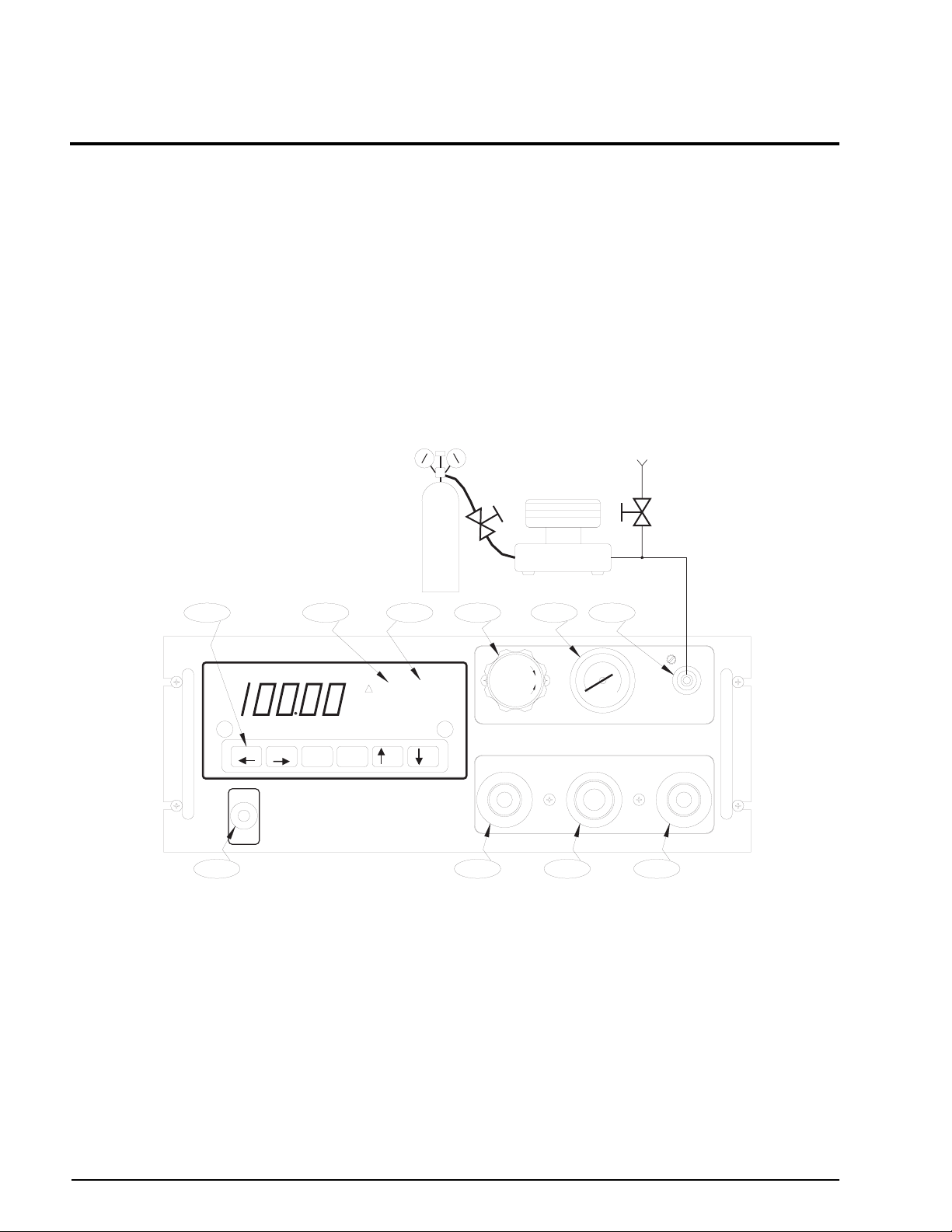

5.1 Pneumatic Calibration Set-Up

Figure 5-1 defines a typical calibration set-up using a floating piston type dead weight tester. Any precision

standard is acceptable to use providing its basic accuracy is at least twice that of the DLR3110’s.

5.2 Instrument Calibration Set-Up

Check that the INPUT valve (1) is closed (rotate clockwise until it stops) and that the VENT valve (2) is open

(two turns counter-clockwise from its stop).

"ON-OFF"

2-WAY VALVE

PNEUMATIC PRESSURE

TESTER

7

DISPLAY

ZERO

POWER

3

8

TARE

PRINT

CE

ENTER

9

P Gage Abs

PSI

YES

NO

4

INCREASE

DECREASE

CONTROL

INPUT

1

5

PRESSURE LIMIT

10

Figure 5-1. Instrument Calibration Set-up

NOTE: AC input and input port are on the back side of rack-mountable calibrator.

MONITOR

VERNIER

VENT

6

TEST PORT

VENT

2

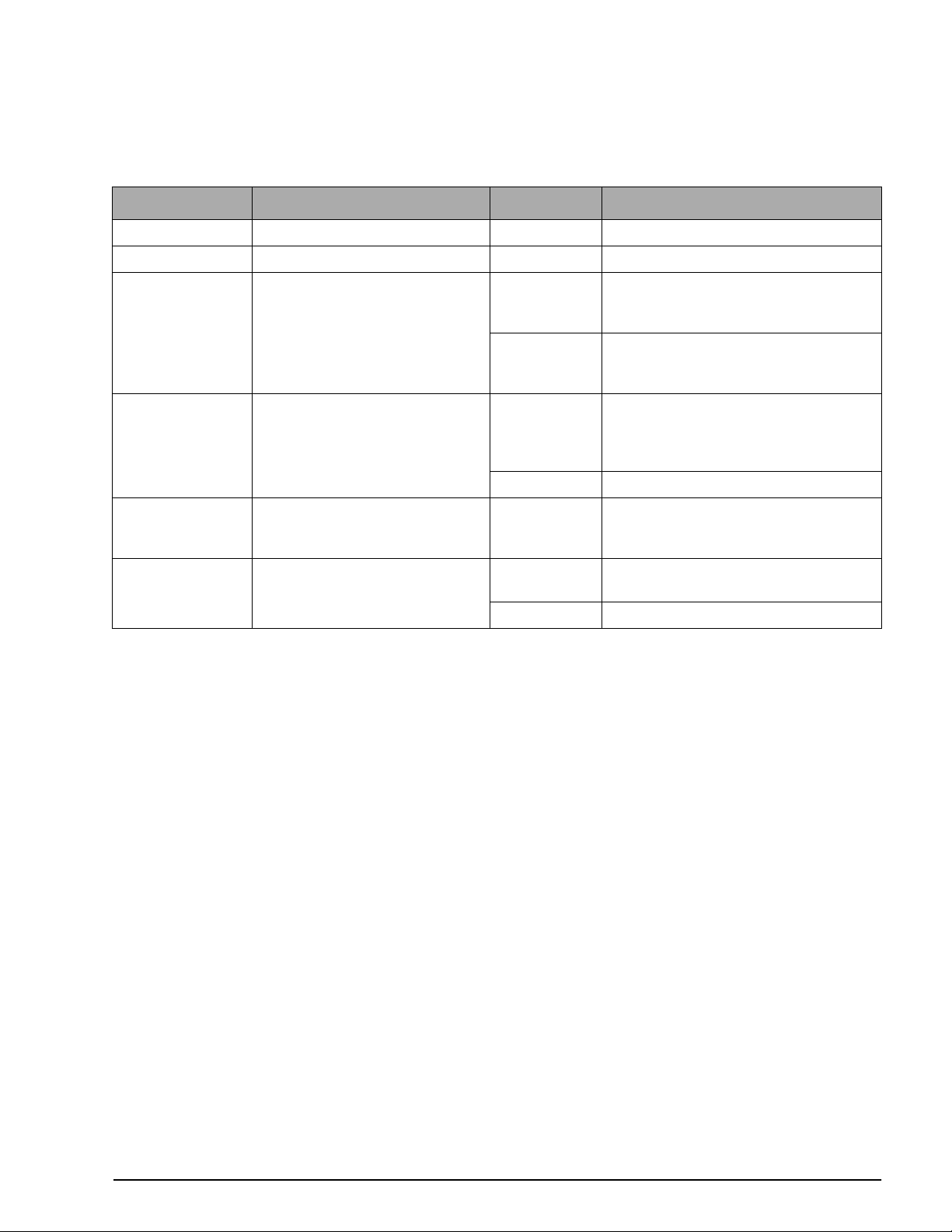

5.3 Mode Selection Switch (S1)

• Main set-up mode - Allows access to the Configuration and Calibration modes.

• Calibration mode - Accesses the Calibration mode directly.

• I/O mode - Allows direct access to the set up of the Serial I/O ports (ports 1 and 2), BCD, Analog output,

discrete inputs/outputs.

• Diagnostic mode - Accesses a diagnostic mode for troubleshooting and evaluation (f actory access only).

12 DLR3110 Rack Mount Digital Pressure Calibrator Manual

Switch Position

Mode

1 2 3 4

Normal Closed Open Open Open

Main set-up Open Closed Open Open

Calibration Open Open Closed Open

Diagnostic Open Open Open Closed

Table 5-1. Mode Selection Switch Modes

1

+

+

C4

R4

R3

CR7

R2

C6

1

U1

C8

U2

C5

E15

C31

R20

C10

+

C22

C7

U14

+

11

1

J5

EXPANDER

C14

C20

U8

20

U7

10

C17

U6

C18

C37

U5

R6

DIAG

I/O

CAL

MAIN

R7

5

10

RP1

J1

U20

1

S1

MODE

6

J4

DISP

KEYBD

C35

DIAG

I/O

CAL

MAIN

OPEN

12 43

1

S1

MODE

FRONT OF DLR3110

Figure 5-2. Rocker Switch S1 Location

5.4 Main Set-Up Mode Menu Selections

Enter the main setup mode by closing switch 1 of S1 located on the main board (see Section 5.3 on page 12). All

other switch positions on

Press

YES key to accept selections, NO key to reject.

LED Display Alpha-Numeric Display Key Pressed Remarks

SET AUTO ? YES key See Section 5.5 on page 14

SET-UP CONFIG ? YES key See Section 5.11 on page 21

---- CAL ? YES key See Section 5.6.1 on page 17

SET-UP I/O ? YES key See Table 5-10 on page 24

SET-UP CONV. ? YES key See Section 5.12 on page 22

S1 must be open. To save the changes and leave MAIN set-up, open switch 1 of S1.

NO key Continue to CONFIG?

NO key Continue to CAL?

NO key Continue to I/O?

NO key Continue to CONV?

NO key Return to AUTO?

Table 5-2. Main Set-Up Mode Selection Parameters

Configuration and Calibration 13

AUTO ?

ZERO

DISPLAY

TARE

CE

PRINT

ENTER

YES

NO

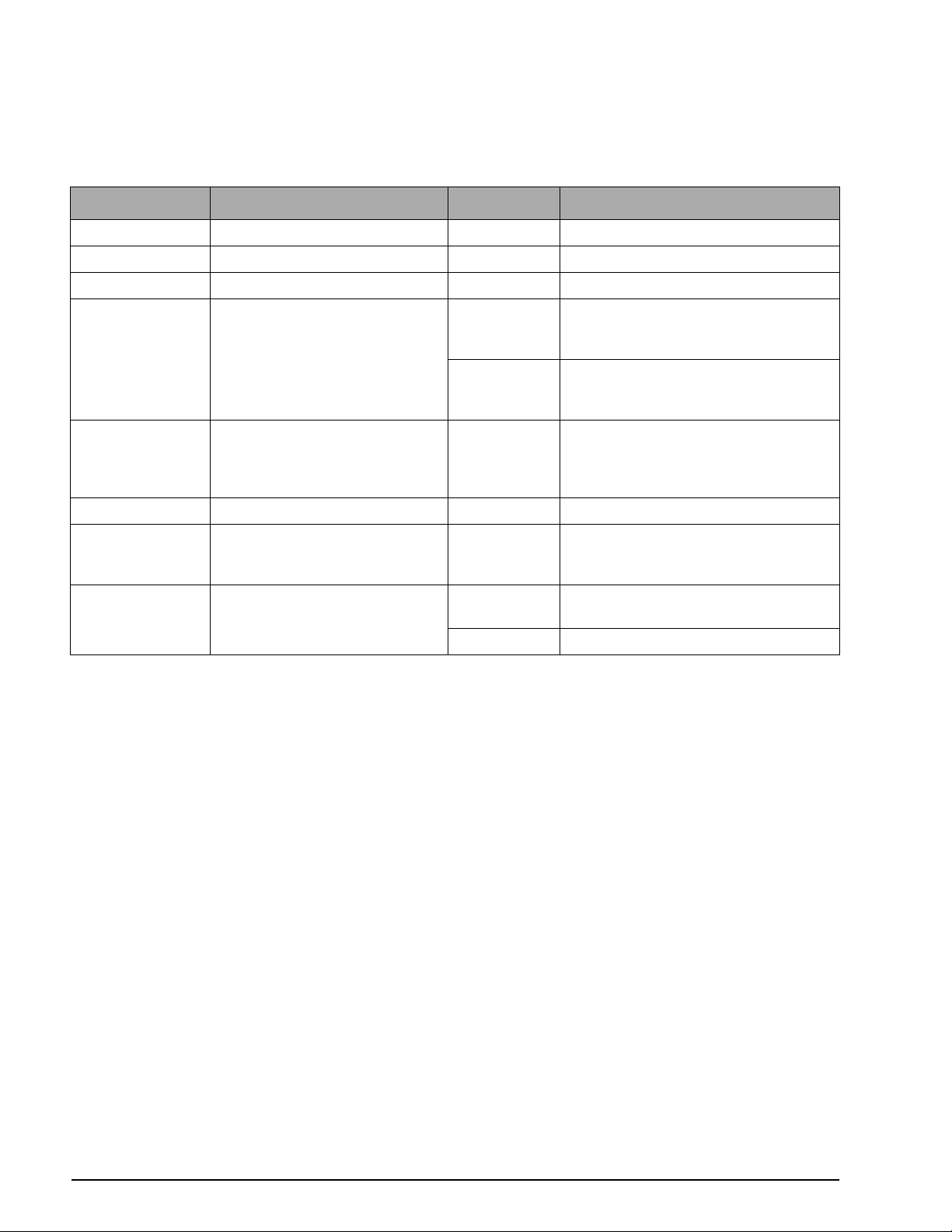

Figure 5-3. Auto Set-Up Mode

5.5 Auto Set-Up Configuration Mode Selection

The auto set-up automatically sets the following conditions in the DLR3110:

•

SET-UP - CONFIG configuration parameters

•

SET-UP - CONV conversion parameters

•

SET-UP - I/O configuration of inputs/outputs

•

---- CAL sets capacity, count by, abs/gage, and cal units; resets all calibration values; sets all cal target

values for span and hysteresis.

5.5.1 Auto Set-Up Menu (General)

LED Display Alpha-Numeric Display Key Pressed* Remarks

SET AUTO ? YES key See Section 5.4 on page 13

---- GAGE ? YES key See Section 5.5.2 on page 15

NO key Continue to ---/ABS?

---- ABS ? YES key See Section 5.5.3 on page 16

NO key Continue to ---/SPECIAL?

---- SPECIAL. ? NO key Allocated for future use, continue to

----/CUSTOM ?

---- CUSTOM ? NO key Allocated for future use, continue to

----/EXIT ?

---- EXIT ? YES key Return to main set-up mode selections

(see Section 5.4 on page 13).

NO key Returns to ----/GAGE ?

Table 5-3. Auto Set-Up Mode Selection Parameters

* Press YES key to accept selection; NO key to reject.

Upon completion and accepting an AUTO set-up configuration, the program automatically advances the

indicator to the calibration mode (see Section 5.6.1 on page 17).

14 DLR3110 Rack Mount Digital Pressure Calibrator Manual

5.5.2 Auto Set-Up Menu (Gage)

See Section 9.0 on page 63 for a complete listing of the default settings for all gage and absolute selections under

the AUTO set-up mode.

LED Display Alpha-Numeric Display Key Pressed Remarks

SET AUTO ? YES key See Section 5.5 on page 14

---- GAGE ? YES key See Section 5.5 on page 14

SET-UP 3 PSIG ? NO key Continue to press NO key until the

alpha-numeric display shows the

DLR3110’s full scale range.

YES key Press YES key when the alpha-numeric

display shows the DLR3110’s full scale

range.

SET-UP ACCEPT ?

YES or NO.

XXXX CAPACITY YES key “XXX” shown on LED display represents

— EXIT ? YES key Return to SET-UP/ I/O?. (see Section 5.4

NO key Continue to press NO key until the

alpha-numeric display shows the

DLR3110’s full scale range. See note

below.

YES key Accept data

the full scale range and is based on

previous selection.

on page 13).

NO key Returns to XXX/CAPACITY

Table 5-4. Auto Set-Up Mode (Gage) Parameters Selections

NOTE: If you continue to press NO key past highest full scale range, DLR3110 will go to exit menu. Hit YES key at exit

menu (see Table 5-3 on page 14).

Configuration and Calibration 15

5.5.3 Auto Set-Up Menu (Absolute)

See Section 9.0 on page 63 for a complete listing of the default settings for all gage and absolute selections under

the AUTO set-up mode.

LED Display Alpha-Numeric Display Key Pressed Remarks

SET AUTO ? YES key See Section 5.5 on page 14

---- GAGE ? NO key See Section 5.5 on page 14

— ABS ? YES key See Section 5.5 on page 14

SET-UP 15 PSIA NO key Continue to press NO key until the

alpha-numberic display shows the

DLR3110’s full scale range.

YES key Press YES key when the alpha-numeric

display shows the DLR3110’s full scale

range.

SET-UP ACCEPT ?

YES or NO

——YES key Accept data

XXXX CAPACITY YES key “XXX” shown on LED display represents

— EXIT ? YES key Return to SET-UP/ I/O?. (see Section 5.4

NO key Continue to press NO key until the

alpha-numberic display shows the

DLR3110’s full scale range. See note

below.

the full scale range and is based on

previous selection.

on page 13).

NO key Return to XXX/CAPACITY

Table 5-5. Auto Set-Up Mode (Absolute) Parameters Selections

NOTE: If you continue to press NO key past highest full scale range, DLR3110 will go to exit menu. Hit YES key at exit

menu (see Table 5-3 on page 14).

5.6 Calibration Set-Up Configuration Mode Selection

Use one of the following methods for configuring the calibration set-up mode:

Method 1

CAL (SELECT). See Section 5.4 on page 13 for information on selecting main mode settings.

Method 2

CAL (DIRECT). Closing only rocker switch position

CALIBRATION mode. See Section 5.3 on page 12.

NOTE: If the AUTO SET-UP selection is accepted and completed, the indicator automatically advances to the calibration

mode (see Section 5.5 on page 14).

2 on switch S1 places the DLR3110 directly into

16 DLR3110 Rack Mount Digital Pressure Calibrator Manual

CAL ?

ZERO

DISPLAY

TARE PRINT

CE ENTER

YES

NO

Figure 5-4. Calibration Mode

5.6.1 Calibration Mode Menu

Press LEFT or RIGHT arrow keys to change values. The various menus may be exited or data selection aborted at

any time by pressing the

either the

YES or NO key is pressed.

LED Display Alpha-Numeric Display Key Pressed Remarks

**XXX CAPACITY DOWN arrow To change the capacity value, see

**XXX X .5 To change the resolution value, press LEFT

BASE PSI Press LEFT or RIGHT arrow key to select

---- GAGE ?

*XX ZERO CAL See step 1 below Does not exist on ABS type units. Disregard

*XX SPAN 1 TARGET VALUE=XX See step 3 below To change the target value, see Section 5.7

CE key. If the CE key is pressed, the prompt Exit ? YES or NO scrolls continuously until

Section 5.7 on page 19.

or RIGHT arrow key.

the base unit used to calibrate indicator. If

for any reason this selection is changed, the

indicator must be calibrated to the new

base unit selection.

Press LEFT or RIGHT arrow key to select

or ABS ?

choice.

steps 1 and 2 below on ABS units.

on page 19.

Table 5-6. Calibration Mode Parameter Selections

*XX represents existing data.

**XXX represents the present capacity of the DLR3110.

Use the following steps to set calibration data in the DLR3110 using the Calibration mode menu.

1. Verify that the INPUT valve (1) is closed (rotate clockwise until it stops) and that the VENT valve (2) is

open (two turns counter-clockwise from its stop). See Figure 5-1 on page 12.

2. Press the

ENTER key on the display panel keypad. The LED display reads 0.00. Close the VENT valve

(rotate clockwise until it stops).

NOTE: If ZERO is not accepted, display shows either SIGNAL INPUT UNDER MINIMUM ZERO RANGE or

INPUT ABOVE CAL INPUT RANGE (NO CAL messages).

3. Set the input pressure from the test standard to the target value on the display. W ait for system to stabilize

and press the ENTER key on the display panel.

NOTE: For pneumatic setup, see Section 5.1 on page 12. For absolute models, use a vacuum pump to reach

the applicable SPAN target values that are below local barometric pressure.

Configuration and Calibration 17

LED Display Alpha-Numeric Display Key Pressed Remarks

CAL SPAN OK N/A Span has been accepted. Proceed to step

4 below. Span may be accepted, but

based on span value, alpha-numeric

display may return with scrolling message

“FULL SCALE WILL NOT BE OBTAINED”.

NO CAL SPAN CAL N/A Span has not been accepted. Repeat step

3 above. If span is not accepted, display

returns with one of the following scrolling

NO CAL messages: “SIGNAL INPUT

UNDER THE MINIMUM ZERO RANGE” or

“INPUT ABOVE CAL INPUT RANGE”.

Table 5-7. Calibration Mode Span Messages

4. The alpha-numeric display reads SPAN 2 CAL TARGET=X (X represents the existing target value on

display). Change target value if required. Set the input pressure from the test standard to the target value

on the display. Wait for system to stabilize and press the ENTER key on the display panel. See Table 5-7

as required.

5. The alpha-numeric display reads

SPAN 3 CAL TARGET=X (X represents the existing target value on

display). Change target value if required. Set the input pressure from the test standard to the target value

on the alpha-numeric display . Wait for system to stabilize and press the ENTER key on the display panel.

Repeat this step for SPAN target values 4 – 10.

LED Display Alpha-Numeric Display Key Pressed Remarks

*XX HYST.CAL TARGET=XXX See step 6 below To change the target value, see Section 5.7

on page 19.

*XX FILTR 5 DOWN arrow To change target value 1 to 10 by 1, 10 to

20 by 2, 20 to 50 by 5, press UP/DOWN

arrow keys.

---- EXIT ? YES key Return to main menu display SET-UP/IO ?.

See Section 5.4 on page 13.

NO key Return to XXX/CAPACITY. See

Section 5.6.1 on page 17.

Table 5-8. Calibration Mode Hysteresis and Filter Target Parameters

6. The alpha-numeric display reads

HYST.CAL TARGET=XXX (X represents the preset target value on

display. See Table 5-8.). Set the input pressure from the test standard to the target value on the

alpha-numeric display. Wait for system to stabilize and press the ENTER key on the display panel.

NOTE: For absolute models, use a vacuum pump to reach the applicable hysteresis target value if below local

barometric pressure.

7. Save the calibration data by opening rocker switch S1 position 2. The DLR3110 returns to normal mode

(see Section 5.3 on page 12).

8. Vent system and remove test standard and/or vacuum pump.

18 DLR3110 Rack Mount Digital Pressure Calibrator Manual

5.7 Modifying Data

Data values previously set are easily altered by pressing either of the horizontal arrow keys to enter the

modification mode. Upon entering the mode, the least significant digit

indicates the current position in the data that can be changed. Press the

desired position indicated by the flashing digit, then use the

UP or DOWN arrow key to increment or decrement

the value of the selected digit. Once the new data value has been set, press the

abort. If an abort is issued, the data reverts back to its former value. The display prompts with

(LSD) begins to flash. A flashing digit

LEFT or RIGHT arrow key to select a

ENTER key to accept or the CE to

ENTER or ABORT

accordingly.

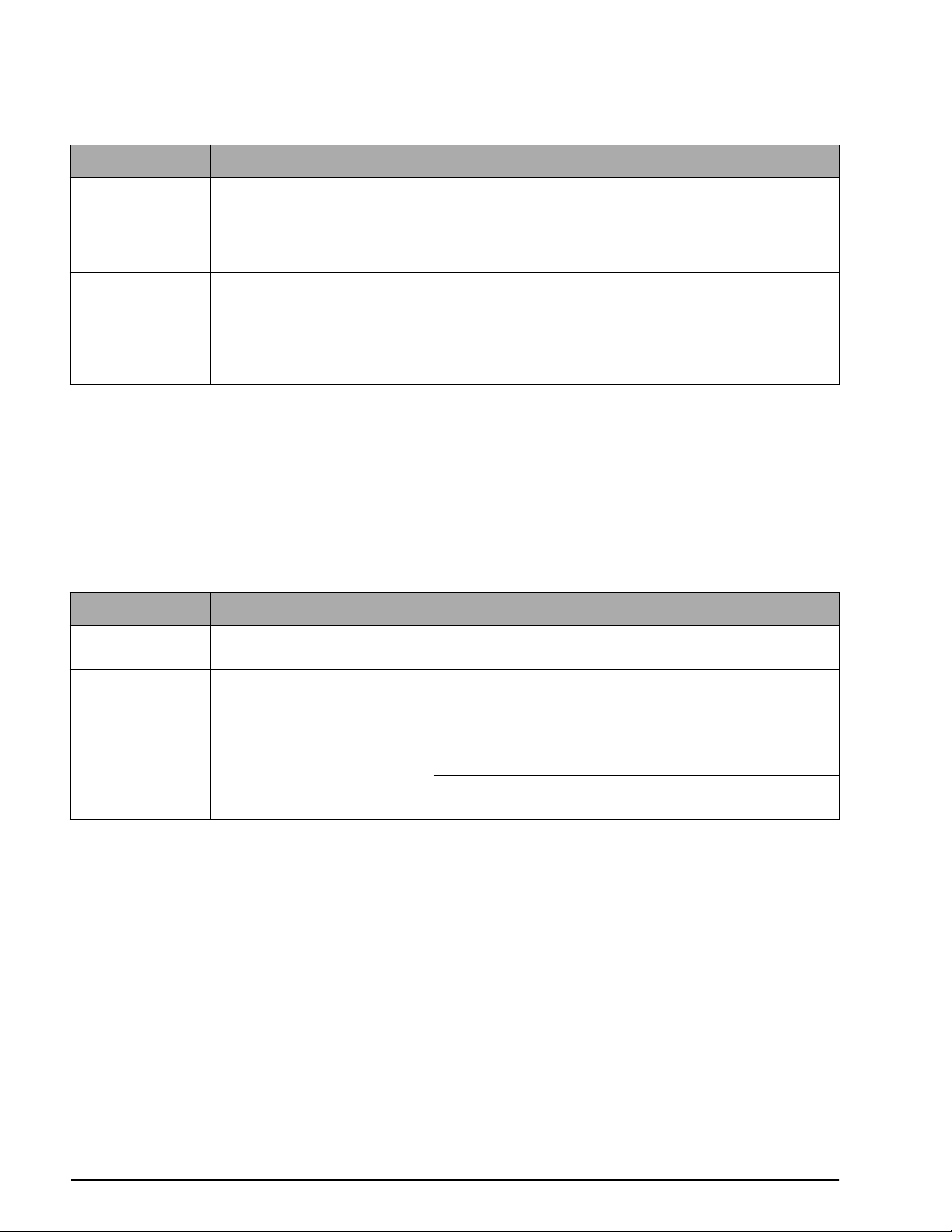

5.8 Span Calibration Points

There are a total of 10 calibration points (SPAN 1 - 10 CAL TARGET) which are sequentially entered. It is not

required that all calibration points be entered. If calibration is performed with less than 10 points, the curve is

extrapolated to full capacity based upon the slope correction between the last two entered SPAN CAL points. In

the example below, if only four span calibration points were entered (SPAN 1 to SPAN 4), the slope correction

from SPAN 4 to full capacity would be defined by the computed slope between SPAN 3 and SPAN 4.

NOTE: If fewer than 10 SPAN CAL points are desired during calibration, simply step past the remaining calibration

points using the DOWN arrow key, until the HYSTERESIS calibration point is reached.

HYSTERESIS\PERROR

DESIRED LINEARITY FROM ZERO TO RATED OUTPUT

SPAN 4

mV/V OUTPUT

SPAN 1

0

LOAD

Figure 5-5. Span Calibration Points

SPAN 3

SPAN 2

NON-LINEARITY\PERROR

5.9 Resetting Span Calibration Points

To reset the span calibration points, use the DOWN arrow key to step to the desired SPAN CAL point and then

press the

CE key. The correction factor of the selected SPAN CAL point and all others beyond will be reset to

unity (see Section 5.6 on page 16).

NOTE: X’s shown on LED display and alpha-numeric display columns represent existing data.

After a reset has been performed, entry of new SPAN CAL points proceeds as described in Section 5.6.1 on

page 17, starting with step 3.

NOTE: If all 10 SPAN CAL points are not used in the calibration, the last span calibration point to appear (SPAN x CAL

TARGET=xx.xx) is not an entered correction point. It only indicates the next span calibration that can be entered.

5.10 Overwriting Span Calibration Points and Hysteresis

Any SPAN CAL point can be overwritten with a new value provided that it remains within the range bounded by

the span calibration points above and below the span point to be overwritten. Figure 5-6 on page 20 shows SPAN

2 CAL point being redefined within the boundaries set by SPAN 1 and SPAN 3. HYSTERESIS can also be

overwritten as long as the new entry is below 80% of the full capacity value. For information on how to reach

SPAN CAL point and HYSTERESIS, see Section 5.6 on page 16.

Configuration and Calibration 19

Loading...

Loading...