Page 1

ASSEMBLY MANUAL

1

PRECISION SHANK DRILL

Printed in USA (74363) 6/19

Page 2

AGCO-Amity JV LLC LIMITED WARR ANTY TERMS AND CONDITIONS – UNITED STATES AND CANADA

2

EFFECTIVE FOR EQUIPMENT RETAILED AND DELIVERED AFTER JUNE 1, 2018

WHAT IS WARRANTED AGCO Amity JV warrants its new equipment to be free of defects in material and workmanship at time of delivery to the first retail

purchaser, renter, or lessee. These terms apply to all Wishek, Wil-Rich, and Amity brands of new equipment originally marketed in the United States and

Canada.

WARRANTY PERIOD

• 12 Months from the date of delivery to the first retail purchaser, renter or lessee.

• 483 Disk Chisel, Field Cultivator, and Disk Cultivators: 3 years on main frames, wing frames, and shank assemblies

• Precision Shank Drill: 3 years on main frame, wing frame, and rockshafts.

EXCEPTIONS FROM THIS WARRANTY

• Freight Charges - This warranty does not cover freight charges.

• Improvements, Changes, or Discontinuance AGCO Amity JV reserves the right to make changes and improvements in design or changes in

specifications at any time to any product without incurring any obligations to owners of products previously sold.

• Repairs and Maintenance Not Covered Under Warranty - This warranty does not cover conditions resulting from misuse, natural calamities,

use of non-AGCO-Amity JV parts, negligence, alteration, accident, use of unapproved attachments, usage which is contrary to the intended

purposes, or conditions caused by failure to perform required maintenance. Replacement of Wear or Maintenance items (unless defective) such as

but not limited to, filters, hoses, belts, lubricants, light bulbs, wheel alignment, tightening of nuts, belts, bolts, and fittings, service tune-up,

computer parameter adjustments and general adjustments which may from time to time be required are not covered.

• Rubber Tire Warranty - Rubber tires are warranted directly by the respective manufacturer only and not by AGCO Amity JV.

• Satellite Outages - Interruptions in satellite interfaces and satellite communications are outside the control of this product and are not covered by

this warranty. The company is not responsible for issues or degradation of system performance resulting from such interruptions in satellite

interfaces and satellite communications where the issues are not related to defects in this product.

OWNER’S OBLIGATION

It is the responsibility of the Owner to transport the equipment or parts to the service shop of an authorized AGCO Amity JV Dealer or alternatively to

reimburse the Dealer for any travel or transportation expense involved in fulfilling this warranty. This Warranty does NOT cover rental of replacement

equipment during the repair period, damage to products which have been declared a total loss and subsequently salvaged, overtime labor charges, freight

charges for replacement parts, or special handling requirements (such as, but not limited to, the use of cranes).

EXCLUSIVE EFFECT OF WARRANTY AND LIMITATION OF LIABILITY

THIS WARRANTY IS IN LIEU OF ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PURPOSE OR OTHER REPRESENTATIONS, WARRANTIES

OR CONDITIONS, EXPRESSED OR IMPLIED. The remedies of the Owner set forth herein are exclusive. The Company neither assumes nor authorizes any

person to assume for it any other obligation or liability in connection with the sale of covered machines. Correction of defects, in the manner and for applicable

period of time provided above, shall constitute fulfillment of all responsibilities of AGCO Amity JV to the Owner, and AGCO Amity JV shall not be liable for

negligence under contract or in any manner with respect to such machines. IN NO EVENT SHALL THE OWNER BE ENTITLED TO RECOVER FOR INCIDENTAL,

SPECIAL OR CONSEQUENTIAL DAMAGES SUCH AS BUT NOT LIMITED TO, LOSS OF CROPS, LOSS OF PROFITS OR REVENUE, OTHER COMMERCIAL

LOSSES, INCONVENIENCE OR COST OF RENTAL OR REPLACEMENT EQUIPMENT.

Some States or Provinces do not permit limitations or exclusions of implied warranties or incidental or consequential damages, so the limitations or exclusions in this warranty may

not apply.

“AGCO Amity JV” AS REFERRED TO HEREIN WITH RESPECT TO SALES IN: UNITED STATES and CANADA: AGCO Amity JV LLC

PO Box 1030

Wahpeton, ND 58074

Additional Warranty Information

New Equipment Warranty - Equipment is eligible for warranty service only if it qualifies under the provisions of the New Equipment Warranty. The selling

dealer will deliver this Warranty to the original retail purchaser at the time of sale, and the dealer will register the sale and Warranty with AGCO Amity JV

LLC.

Subsequent Owners - This Warranty covers the first retail purchaser and all subsequent owners of the equipment during the specified warranty period.

Should the AGCO Amity JV Dealer sell this equipment to a subsequent owner, the Dealer must deliver the warranty document to the subsequent owner so the

subsequent owner can register ownership with AGCO Amity JV and obtain the remaining warranty benefits, if available, with no intermission in the Warranty

Period. Subsequent Owner Procedure will apply. It is the responsibility of the subsequent owner to transport the equipment to the service shop of an

authorized AGCO Amity JV Dealer or alternatively to reimburse the Dealer for any travel or transportation expense involved in fulfilling this warranty. This

Warranty does NOT cover charges for rental or replacement equipment during the repair period, products which have been declared a total loss and

subsequently salvaged, overtime labor charges, freight charges for replacement parts, or units sold at auction.

Warranty Service - To be covered by Warranty, service must be performed by an authorized AGCO Amity JV Dealer. It is recommended that you obtain

warranty service from the Dealer who sold you the equipment because of that Dealer’s continued interest in you as a valued customer. In the event this is

not possible, warranty service may be performed by any other authorized AGCO Amity JV Dealers in the United States or Canada. It is the responsibility

of the Owner to transport the equipment to the service shop of an authorized AGCO Amity JV Dealer or alternatively to reimburse the Dealer for any travel or

transportation expense involved in fulfilling this warranty.

Maintenance Service - The Owner’s Manual furnished to you with the equipment at the time of delivery contains important maintenance and service information.

You must read the manual carefully and follow all the maintenance and service recommendations. Doing so will result in greater satisfaction with your equipment

and help avoid service and warranty problems. Please remember that failures due to improper maintenance of your equipment are not covered by warranty.

Maintenance Inspections - To insure the continued best performance from your agricultural equipment, we recommend that you arrange to make your

equipment available to your selling Dealer for a maintenance inspection 30 days prior to warranty expiration.

Page 3

PERSONAL SAFETY IS IMPORTANT!

3

ALL PERSONNEL INVOLVED WITH THE ASSEMBLY AND/OR OPERATION OF THIS

EQUIPMENT MUST BE INFORMED OF PROPER SAFETY PROCEDURES. OPERATOR’S/

ASSEMBLY MANUALS PROVIDE THE NECESSARY INFORMATION. IF THE MANUAL

IS LOST FOR A PARTICULAR IMPLEMENT, ORDER A REPLACEMENT AT ONCE.

OPERATOR’S AND ASSEMBLY MANUALS ARE AVAILABLE AT NO CHARGE UPON REQUEST.

The Safety Alert symbol iden-

This Safety Alert symbol

means ATTENTION! BE-

COME ALERT YOUR

SAFETY IS INVOLVED!

tifies important safety messages on the Amity Precision Shank Drill and in this

manual. When you see this

symbol, be alert to the possibility of personal injury or death.

Follow the instructions in the

safety message.

3 Big Reasons

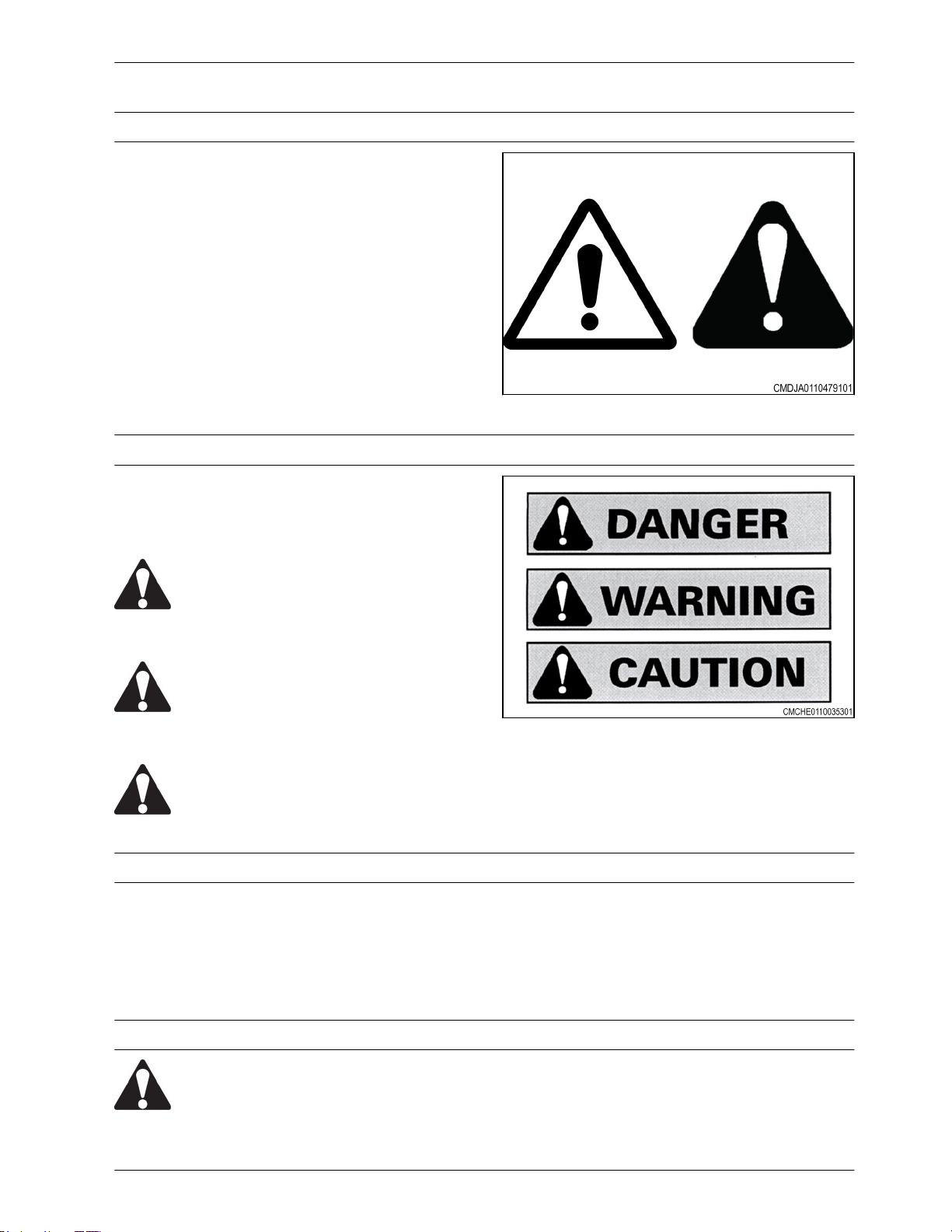

SIGNAL WORDS:

Note the use of the signal

words

DANGER, WARNING

and CAUTION

messages. The appropriate

signal word for each message

has been selected using the

following guidelines:

with the safety

Why is SAFETY important to you?

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

DANGER

An immediate and specific hazard which WILL

result in severe personal

injury or death if the

proper precautions are

not taken.

ADDRESS INQUIRIES TO: AGCO Amity JV LLC

2800 7th Avenue North

Fargo, ND 58102

PH (701) 232-4199 FAX (701) 234-1716

WARNING

A specific hazard or unsafe practice which

COULD result in severe

personal injury or death if

the proper precautions

are not taken

CAUTION

Unsafe practices which

COULD result in personal

injury if proper practices

are not taken, or as a reminder of good safety

practices.

Page 4

Table of contents

4

Precision Shank Drill

1 Safety .....................................................................8

1.1 Introduction .........................................................8

1.1.1 Safety alert symbol ................................................8

1.1.2 Safety messages ..................................................8

1.1.3 Informational messages .. ..........................................8

1.1.4 Safety signs ...................................................... 8

1.1.5 A word to the operator ..............................................9

1.1.6 This manual .. ..................................................10

1.2 Operation . ........... ............ ............. ............ ...... .11

1.2.1 Prepare for operation . ............ ............. ............ .......11

1.2.2 General information ....... .... .. ............. ... ............ ....11

1.2.3 Personal protective equipment ....................................... ..12

1.2.4 Seat instructions .................................................13

1.2.5 Shield and guards ......................... .......................13

1.2.6 Exhaust warning . .... ............ ............. ............ ......13

1.2.7 Flying debris .................................................... 14

1.2.8 Agricultural chemicals .............................................14

1.3 Travel on public roads ............. ............ ............. ...... ..15

1.4 Maintenance .. ..... ............ ............. ............ ...........17

1.4.1 General maintenance information .....................................17

1.4.2 Fire prevention and first aid .........................................18

1.4.3 High pressure leaks ...... ............ ............. ............ ....19

1.4.4 Tire safety ...................................................... 20

1.4.5 Replacement parts ................................................20

1.5 Transport locks ........... ............. ............ ............. ... 21

1.6 Marker lamps ...................................................... 22

1.7 Safety sign location .......... ............ ............. ............. 23

1.7.1 Safety sign descriptions .........................................24-28

2 Introduction ..............................................................29

2.1 Introduction ........................................................30

2.1.1 Units of measurement .............................................30

2.1.2 Replacement parts ................................................30

2.1.3 Intended use ....................................................30

2.1.4 Proper disposal of waste ...........................................30

2.2 Machine identification ..............................................32

2.2.1 Serial number plate location .........................................32

2.2.2 Serial number description ........................................32-33

Page 5

Table of contents

5

Assembly ................... .............. ...........................34-35

3.

Mainframe................................................36

Front inner wing anchor/rest............................................37

Front hitch pivot....................................................... 38

Front caster mount.....................................................39

Front caster mount-mainframe..........................................40

Front hitch pivot assembly..............................................41

Front lift cylinders-mainframe............................................42

Front hitch...............................................43

Hydraulic jack.........................................................44

Docking station........................................................45

Rear inner wing anchor/rest 51ft.........................................46

Rear inner wing anchor/rest 61ft.........................................47

Inner wing 51ft..........................................................48

Inner wing 61ft..........................................................49

Outer wings..............................................50

Outer wing fold linkage.................................................51

Outer wing latch........................................................52

Outer wing latch system................................................53

51ft inner wing fold cylinder mounts.....................................54

51ft inner wing fold cylinder rod connection/wing rest.....................55

61ft inner wing fold cylinder mounts......................................56

51ft outer wing fold cylinders ..................................57

61ft outer wing fold cylinders............................................58

Rear axle..............................................................59

Rear hitch.............................................................60

Rear lift cylinders-mainframe............................................61

Lift axle-rear wing.......................................................62

Rear lift cylinder-inner & outer wing ......................................63

Front lift assembly left-inner & outer wing.........................64

Front lift assembly right-inner & outer wing...............................65

Front lift cylinder-inner & outer wing.....................................66

Row unit-frame mount..................................................67

Row unit placement-mainframe.........................................68

Row unit placement-51ft inner wing......................................69

Row unit placement-61ft inner wing......................................70

Row unit placement-51ft outer wing......................................71

Row unit placement-61ft outer wing......................................72

Page 6

Table of contents

6

3. Assembly-continued

Hose channel-mainframe..................................... 73

Hose channel-inner wing...............................................74

Hose channel-front hitch...............................................75

Down pressure valve...................................................76

Down pressure valve mount.............................................77

Hydraulic hose assembly sequence......................................78

51ft lift hydraulics...............................

61ft lift hydraulics.... ............. ............ ............80

51 & 61ft lift hydraulics.. ... .. ........................................81

51ft wing fold hydraulics................................................82

51ft wing fold hydraulics................................................83

61ft wing fold hydraulics................................................84

61ft wing fold hydraulics..................................... ............85

Down pressure hydraulics-DP block......................................86

Down pressure hydraulics-DP block.............................87

Down pressure hydraulics-mainframe.. ... .. ............................88

Down pressure hydraulics-inner wing....................................89

Down pressure hydraulics-outer wing....................................90

Rear hitch hydraulics................................................91-92

Rear hitch hydraulic & electrical fittings..................................93

Front light mount........................................................94

SMV sign & stop collars ......................................95

........................79

Rear lights, light module, & lift switch....................................96

Lift switch... . .......................................................97-99

Bleeding air from the hydraulic lift system...............................100

Bleeding air from the hydraulic fold system..............................101

Leveling the mainframe.................................................102

Leveling the wings ..................................................103-104

Model decals-front hitch.....................................105

Model decals-outer wing................................................ 106

Tire air pressure....... ...............................................107

Page 7

Page Left Blank Intensionally

7

Page 8

1. Safety

8

1.1 Introduction

1.1.1 Safety alert symbol

The safety alert symbol means Attention! Become

Alert! Your Safety Is Involved!

Look for the safety alert symbol both in this

manual and on safety signs on this machine. The

safety alert symbol will direct your attention to

information that involves your safety and the

safety of others.

1.1.2 Safety messages

The words DANGER, WARNING or CAUTION are

used with the safety alert symbol. Learn to

recognize these safety alerts and follow the

recommended precautions and safety practices.

Fig. 1

DANGER:

Indicates an imminently hazardous

situation that, if not avoided, will

result in DEATH OR VERY SERIOUS

INJURY.

WARNING:

Indicates a potentially hazardous

situation that, if not avoided, could

result in DEATH OR SERIOUS

INJURY.

CAUTION:

Indicates a potentially hazardous

situation that, if not avoided, may

result in MINOR INJURY.

Fig. 2

1.1.3 Informational messages

The words important and note are not related to personal safety, but are used to give additional

information and tips for operating or servicing this equipment.

IMPORTANT: Identifies special instructions or procedures which, if not strictly observed, could result in

damage to or destruction of the machine, process, or its surroundings

NOTE: Identifies points of particular interest for more efficient and convenient repair or operation.

1.1.4 Safety signs

WARNING:

Do not remove or obscure safety signs. Replace any safety signs that are not readable or

are missing. Replacement signs are available from your dealer in the event of loss or

damage. The actual location of the safety signs is illustrated at the end of this section.

Keep signs clean by wiping off regularly. Use a mild soap and water solution if necessary.

Page 9

1. Safety

9

If parts have been replaced or a used machine has been purchased, make sure all safety signs are present

and in the correct location and can be read. Illustrations of safety sign locations are located at the rear of

this section.

Replace any safety signs that can not be read, are damaged, or are missing. Clean the machine surface

thoroughly with a mild soap and water solution before replacing signs. Replacement safety signs are

available from your dealer.

1.1.5 A word to the operator

It is your responsibility to read and understand the

safety section in this manual and the manual for all

attachments before operating this machine.

Remember you are the key to safety. Good safety

practices not only protect you, but also the people

around you.

Study the content in this manual and make the

content a working part of your safety program.

Keep in mind that this safety section is written

only for this type of machine. Practice all other

usual and customary safe working precautions,

and above all remember - safety is your

responsibility. You can prevent serious injury or

death.

Fig. 3

This safety section is intended to point out some

of the basic safety situations that may be

encountered during the normal operation and

maintenance of your machine. This section also

suggests possible ways of dealing with these

situations. This section is not a replacement for

other safety practices featured in other sections of

this manual.

Personal injury or death may result if these

precautions are not followed.

Learn how to operate the machine and how to use

the controls properly.

Do not let anyone operate the machine without

instruction and training.

For your personal safety and the personal safety of

others, follow all safety precautions and

instructions found in the manuals and on safety

signs affixed to the machine and all attachments.

Use only approved attachments and equipment.

Make sure your machine has the correct

equipment needed by the local regulations.

WARNING:

An operator should not use alcohol or

drugs which can affect their alertness

or coordination. An operator on

prescription or 'over the counter'

drugs needs medical advice on

whether or not they can properly

operate machines.

Page 10

1. Safety

10

CAUTION:

If any attachments used on this

equipment have a separate Operator

Manual, see that manual for other

important safety information.

1.1.6 This manual

This manual covers general safety practices for this machine. The operator manual must always be kept

with the machine.

Right-hand and left-hand, as used in this manual, are determined by facing the direction the machine will

travel when in use.

The photos, illustrations, and data used in this manual were current at the time of printing, but due to

possible in-line production changes, your machine can vary slightly in detail. The manufacturer reserves the

right to redesign and change the machine as necessary without notification.

WARNING:

In some of the illustrations and photos used in this manual, shields or guards may have

been removed for clarity. Never operate the machine with any shields or guards removed.

If the removal of shields or guards is necessary to make a repair, they must be replaced

before operation.

Page 11

1. Safety

11

1.2 Operation

1.2.1 Prepare for operation

Read and understand all operating instructions and precautions in this manual before operating or servicing

the machine.

Make sure you know and understand the positions and operations of all controls. Make certain all controls

are in neutral and the park brake is applied before starting the machine.

Make certain all people are well away from your area of work before starting and operating the machine.

Check and learn all controls in an area clear of people and obstacles before starting your work. Be aware of

the machine size and have enough space available to allow for operation. Never operate the machine at

high speeds in crowded places.

Emphasize the importance of using correct procedures when working around and operating the machine.

Do not let children or unqualified persons operate the machine. Keep others, especially children, away

from your area of work. Do not permit others to ride on the machine.

Make sure the machine is in the proper operating condition as stated in the Operator Manual. Make sure

the machine has the correct equipment required by local regulations.

1.2.2 General information

When parking, park the machine and the tractor on

a solid level surface. put all controls in neutral and

apply the tractor park brake. Stop the tractor

engine and take the key with you.

Make sure the tractor and implement are in the

proper operating condition according to the

operator manuals. Make sure the tractor brakes

and the machine brakes are adjusted correctly.

The tractor must have enough weight and braking

capacity, especially when operating on roads and

terrain that is not even. Use a tractor of

recommended size and weight to tow the

machine. See the machine specifications for the

minimum tractor size and weight.

Tractor must be equipped with rollover protective

structure (ROPS) and a seat belt. use seat belt

during operation.

Do not dismount from moving machinery.

Always operate the machine with the terminal

turned on.

Never start the tractor with the PTO engaged or

terminal turned on.

Stay off slopes too steep for operation.

Where possible avoid operating the machine near

ditches, embankments, and holes. Reduce ground

speed when operating on rough, slippery, or

muddy surfaces and when turning or crossing

slopes.

Fig. 4

Be aware of the size of the machine and have

enough space available to allow for operation.

Page 12

1. Safety

12

Always lower the machine when not in use and

relieve the pressure in the hoses and cylinders.

Do not stand between the tractor and the

implement to install the hitch pin when the tractor

engine is running.

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

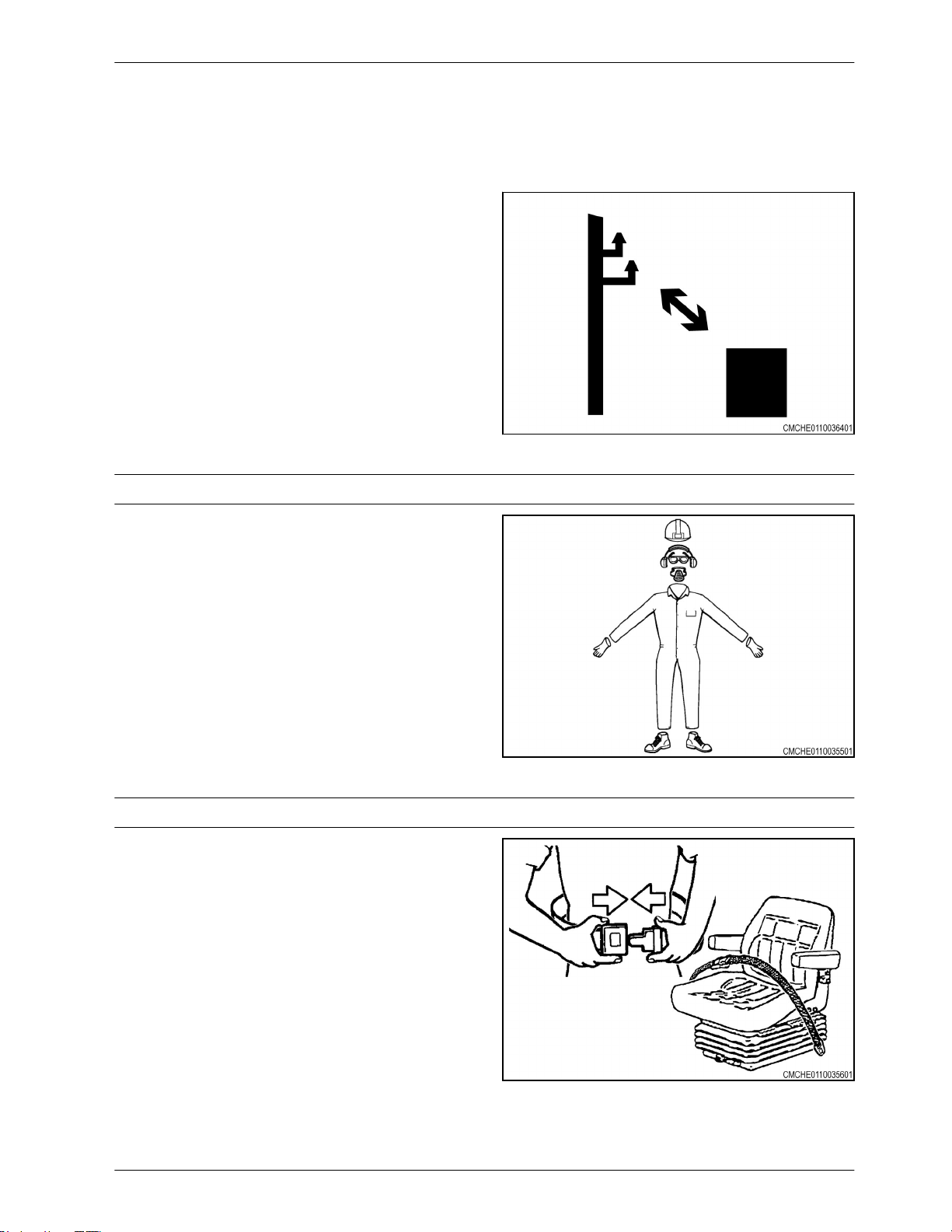

1.2.3 Personal protective equipment

Fig. 5

Wear all personal protective equipment (PPE) and

protective clothing issued to you or called for by

job conditions and country/local regulations. PPE

includes, but is not limited to, equipment to

protect eyes, lungs, ears, head, hands and feet

when operating, servicing, or repairing equipment.

Always keep hands, feet, hair, and clothing away

from moving parts. Do not wear loose clothing,

jewelry, watches, or other items that could

entangle in moving parts. Tie up long hair that can

also entangle in moving parts.

1.2.4 Seat instructions

Securely fasten the seat belt before operating the

machine. Always remain seated and have the seat

belt fastened while operating the machine.

Replace the seat belts when they become worn or

broken.

Never wear a seat belt loosely or with slack in the

belt system. Never wear the seat belt in a twisted

condition or pinched between the seat structural

members.

Fig. 6

When using the instructional seat, if equipped,

securely fasten the seat belt. The instructional seat

is to be used only to train new operators or

diagnose a problem. The instructional seat is only

intended for short periods of use. Extra riders,

especially children, are not permitted on the

machine.

Fig. 7

Page 13

When the instructional seat is used the machine

13

must be driven at a slower speed and on level

ground. Avoid quick starts, stops, and sharp turns.

Avoid driving on highways or public roads.

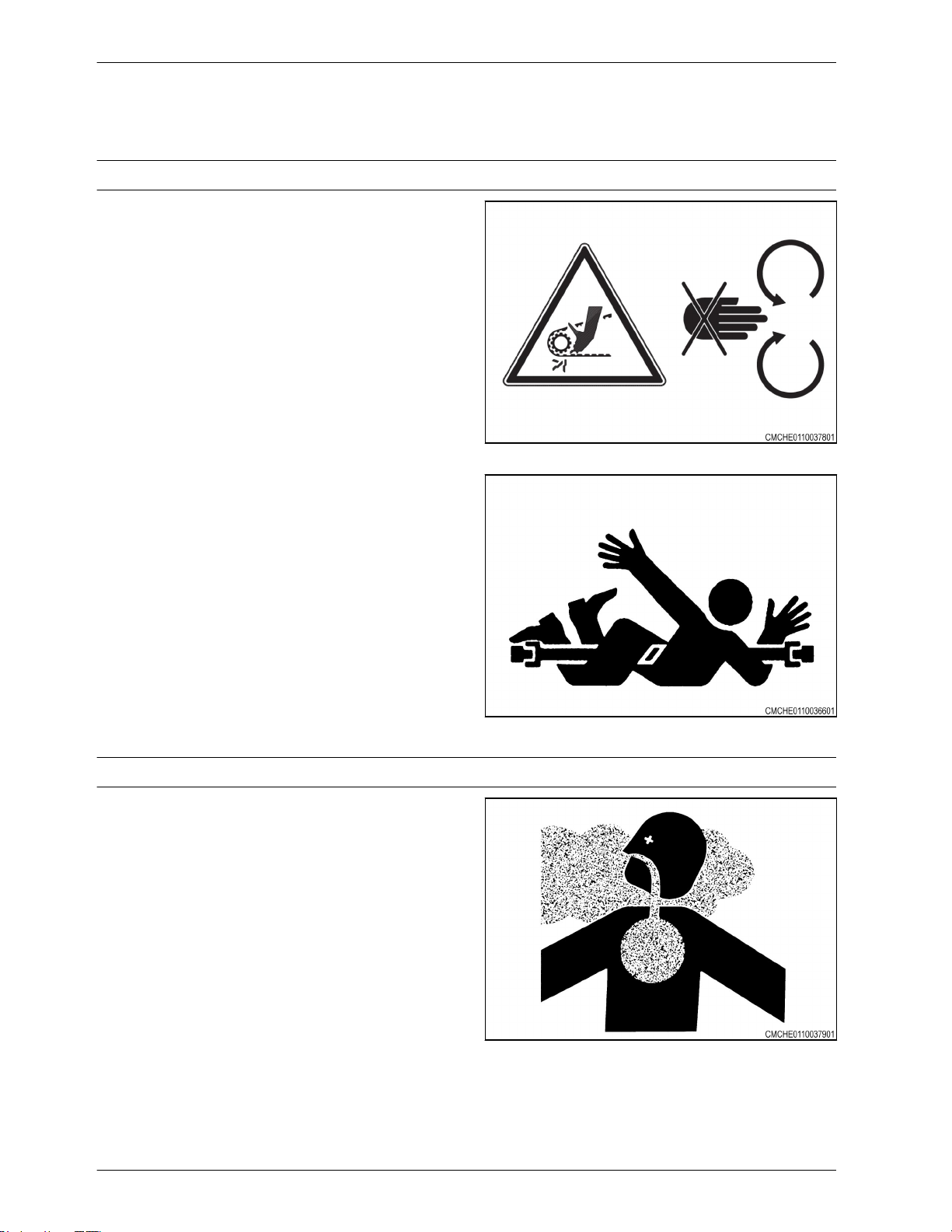

1.2.5 Shield and guards

All shields and guards must be in the correct

operating position and in good condition.

Do not open, remove, or reach around shields

while the engine is operating. Entanglement in

rotating belts and components can cause serious

injury or death. Stay clear of rotating components.

Do not operate the machine with the drive shaft

shields open or removed. Entanglement in rotating

drive shafts can cause serious injury or death. Stay

clear of rotating components.

1. Safety

Fig. 8

Make sure rotating guards turn freely.

1.2.6 Exhaust warning

Never operate the engine in a closed building

unless the exhaust is vented outside.

Do not tamper with or modify the exhaust system

with unapproved extensions.

Fig. 9

Fig. 10

Page 14

1. Safety

14

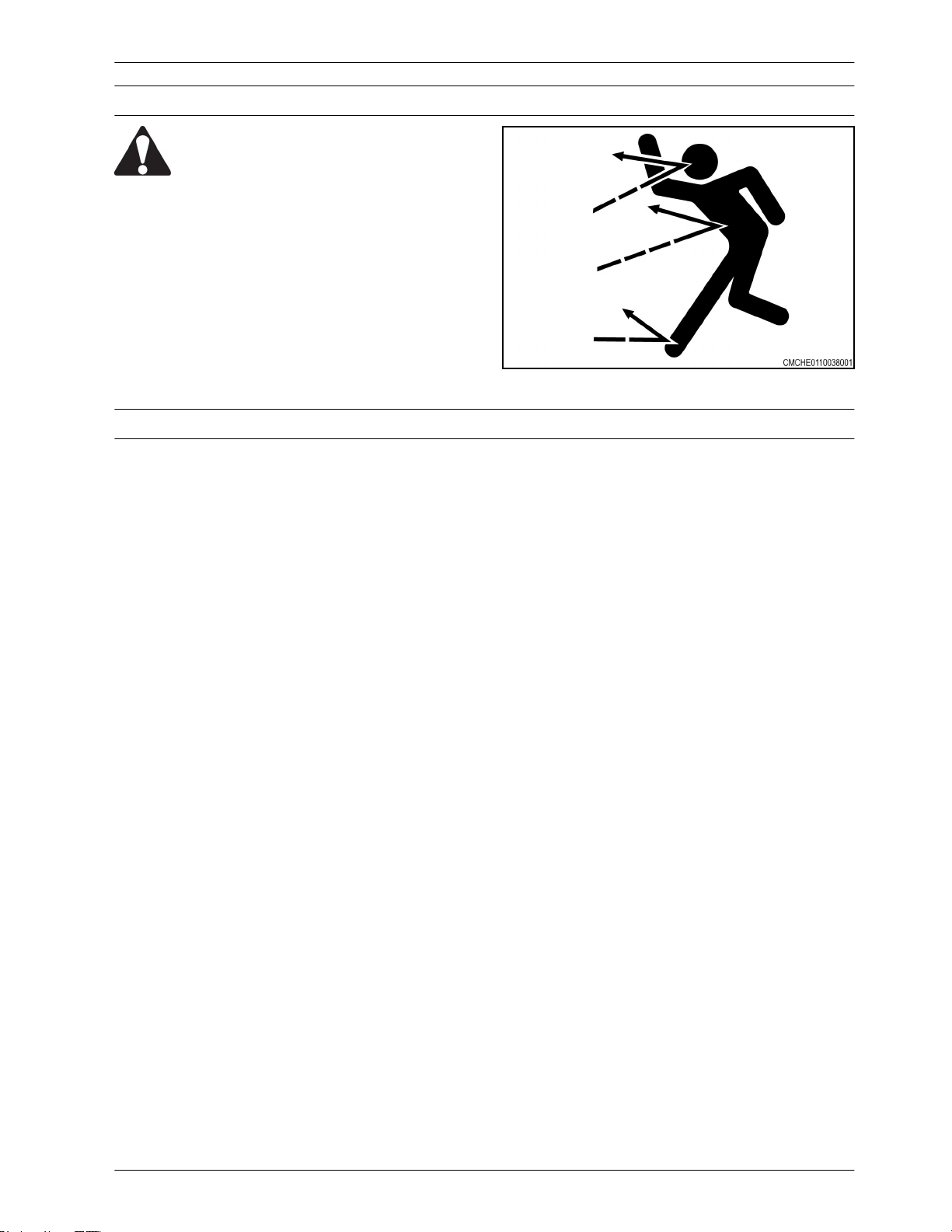

1.2.7 Flying debris

WARNING:

Be careful when operating along the

side of a road or building. Rocks or

other debris can be thrown from the

machine during operation possibly

resulting in injury.

Never stand near the machine during operation.

Debris can be thrown from the machine during

operation possibly resulting in injury.

Fig. 11

1.2.8 Agricultural chemicals

Agricultural chemicals can be very hazardous. Improper use of fertilizer, fungicides, herbicides, insecticides

and pesticides can injure people, plants, animals, soil and other people's property.

Always read and follow all manufacturers' instructions before opening any chemical container.

Even if you think you know the instructions, read and follow instructions each time you use a chemical.

Use the same precautions when adjusting, servicing, cleaning or storing the machine as used when

installing chemicals into the hoppers or tanks.

Inform anyone who comes in contact with chemicals of the potential hazards involved and the safety

precautions required.

Stand upwind and away from smoke from a chemical fire.

Store or dispose of all unused chemicals only in a manner as specified by the chemical manufacturer.

Page 15

1.3 Travel on public roads

15

Make sure you understand the speed, brakes,

steering, stability, and load characteristics of this

machine before you travel on public roads.

Use good judgment when traveling on public

roads. Maintain complete control of the machine at

all times. Never coast down hills.

The maximum speed of farm equipment is

governed by local regulations. Adjust travel speed

to maintain control at all times.

Familiarize yourself with and obey all road

regulations that apply to your machine. Consult

your local law enforcement agency for local

regulations regarding movement of farm

equipment on public roads. Use head lamps,

flashing warning lamps, tail lamps and turn signals,

day and night, unless prohibited by local law.

Make sure all the flashers are operating prior to

driving on the road. Make sure reflectors are

correctly installed, in good condition, and wiped

clean. Make sure the Slow Moving Vehicle (SMV)

emblem is clean, visible, and correctly mounted on

the rear of the machine.

1. Safety

Fig. 12

Lock brake pedals together (if equipped with dual

brake pedals) so both wheel brakes will be applied

at the same time.

Raise implements to transport position and lock in

place. Place all implements into narrowest

transport configuration.

Disengage the power take-off and differential lock.

With towed implements, use a proper hitch pin

with a clip retainer and safety transport chain.

Be aware of other traffic on the road. Keep well

over to your own side of the road and pull over,

whenever possible, to let faster traffic pass.

Be aware of the overall width, length, height, and

weight of the machine. Be careful when

transporting the machine on narrow roads and

across narrow bridges.

Page 16

1. Safety

16

Watch for overhead wires and other obstructions.

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

Fig. 13

Page 17

1. Safety

17

1.4 Maintenance

1.4.1 General maintenance information

Before doing any unplugging, lubricating, servicing,

cleaning, or adjusting:

• Park the machine on a solid level surface.

• Make sure all controls are in the neutral

position and apply the park brake.

• Make sure all implements and attachments

have been lowered to the ground.

• Stop the engine and take the key with you.

• Look and Listen! Make sure all moving parts

have stopped.

• Put blocks in front of and behind the wheels of

the machine before working on or under the

machine.

Do not leave the tractor or implement unattended with the engine running.

Do not pull crop or any other object from the machine while the machine engine is running. Moving parts

can pull you in faster than you can move away.

Fig. 14

Check all nuts and bolts periodically for tightness, especially wheel mounting hardware.

Do not attempt to service or adjust the machine until all moving parts have stopped.

Check all nuts and bolts periodically for tightness, especially wheel mounting hardware.

Be aware of the size of parts when doing service work. Never stand under or near a part being moved with

lifting equipment.

After unplugging, lubricating, servicing, cleaning, or adjusting the machine make sure all tools and

equipment have been removed.

Make sure electrical connectors are clean and free of dirt or grease before connecting.

Check for loose, broken, missing, or damaged parts. Make sure the machine is in good repair. Make sure

all guards and shields are in position.

Always raise implement, shut off tractor engine, apply the parking brake, shift to park position (or neutral)

remove the key and install the cylinder stops channels before working around the machine.

Avoid working under the machine. However, if it becomes unavoidable to do so, make sure the machine is

securely blocked and the cylinder lockup channels are in position.

When working around discs or shanks, be careful to not get cut on sharp edges.

Never service, check or adjust drive chains or belts

while the engine is running.

Fig. 15

Page 18

1. Safety

18

Do not operate the machine with the drive shaft

shields open or removed. Entanglement in rotating

drive shafts can cause serious injury or death.

Stay clear of rotating components.

Make sure rotating guards turn freely.

A loose yoke can slip off a shaft and result in injury

to persons or damage to the machine.

When installing a quick disconnect yoke, the

spring activated locking pins must slide freely and

be seated in the groove on the shaft. Pull on the

driveline to make sure the quick disconnect yoke

can not be pulled off the shaft.

Remove spilled oil, antifreeze or fuel immediately

from the steps, platform, and other access areas.

Keep all access areas clean and free of

obstructions.

Fig. 16

1.4.2 Fire prevention and first aid

Be prepared for emergencies.

Keep a first aid kit handy for treatment of minor

cuts and scratches.

Always carry one or more fire extinguishers of the

correct type. Check fire extinguishers regularly as

instructed by the manufacturer. Make sure fire

extinguishers are properly charged and in

operating condition.

Due to the nature of the crops this machine will

operate in, the risk of fire is of concern. Use a

water type fire extinguisher or other water source

for a fire in crop.

For fires involving anything other than crop, such

as oil or electrical components, use a dry chemical

fire extinguisher with an ABC rating.

Mount fire extinguishers within easy reach of

where fires can occur.

Frequently remove accumulated crop material

from the machine and check for overheated

components. Check the machine daily for any

noises that are not normal. Such noises could

indicate a failed component that can cause excess

heat.

Fig. 17

Fig. 18

Page 19

If any flame cutting, welding, or arc welding is to

19

be done on the machine or attachments, make

sure to clear any crop material or debris from

around the area. Make sure the area below the

work area is clear of any flammable material as

falling molten metal or sparks can ignite the

material.

If fire occurs stand upwind and away from smoke

from the fire.

1. Safety

Fig. 19

1.4.3 High pressure leaks

Fluid leaking from the hydraulic system or the fuel

injection system under high pressure can be very

hard to see. The fluid can go into the skin causing

serious injury.

Fluid injected into the skin must be surgically

removed within a few hours. If not removed

immediately, serious infection or reaction can

develop. Go immediately to a doctor who knows

about this type of injury.

Use a piece of cardboard or wood to search for

possible leaks. Do not use your bare hand. Wear

leather gloves for hand protection and safety

goggles for eye protection.

Relieve all pressure before loosening any hydraulic

lines. Relieve the pressure by lowering raised

equipment, shutting off accumulator valve, if

equipped, and shutting off the engine. Tighten all

connections securely before applying pressure.

Fig. 20

Fig. 21

Page 20

1. Safety

20

1.4.4 Tire safety

Check tires for cuts, bulges, and correct pressure.

Replace worn or damaged tires. When tire service

is needed, have a qualified tire mechanic service

the tire. Tire changing can be very hazardous and

must be done by qualified tire mechanic using

proper tools and equipment. See the

Specifications Section for the correct tire size.

Tire explosion and/or serious injury can result from

over inflation. Do not exceed the tire inflation

pressures. See the Specifications Section for the

correct tire pressure.

Do not inflate a tire that is seriously under inflated

or has been run flat. Have the tire checked by

qualified tire mechanic.

Do not weld on the rim when a tire is installed.

Welding will make an air/gas mixture that can

cause an explosion and burn with high

temperatures. This danger applies to all tires,

inflated or deflated. Removing air or breaking the

bead is not enough. The tire must be completely

removed from the rim prior to welding.

Fig. 22

When preparing a calcium chloride solution for

fluid ballast the tractor tires, never pour water onto

the calcium chloride. A chlorine gas can be

generated which is poisonous and explosive. This

can be avoided by slowly adding calcium chloride

flakes to water and stirring until they are dissolved.

When seating tire beads onto rims, never exceed

2.4 bar (35 psi) or the maximum inflation pressure

specified on the tire. Inflation beyond this

maximum pressure may break the bead, or even

the rim, with explosive force.

1.4.5 Replacement parts

Where replacement parts are necessary for

periodic maintenance and servicing, genuine

replacement parts must be used to restore your

equipment to original specifications.

The manufacturer will not accept responsibility for

installation of unapproved parts and/or accessories

and damages as a result of their usage.

Fig. 23

Page 21

1.5 Transport locks

21

The machine is equipped with transport locks and

depth stop collars. Use the transport locks and

depth stop collars in the operating position (1)

when moving the machine on roads. When not in

use, keep the transport locks and depth stop

collars in the storage position (2).

2

FRONT

1. Safety

1

2

701304

REAR

1

2

1

2

701303

Page 22

1.

22

Safety

1.6 Marker lamps

The machine has marker lamps that must be used

when moving the machine in the folded position

on roads.

The machine is equipped with two red lamps (1)

located toward the rear center of the machine.

The machine is equipped with two amber lamps

(1) located at the front outside edges of the folded

machine.

FRONT

1

REAR

1

701305

1

701305

1

Page 23

1. Safety

23

1.7 Safety sign location

8

2

1

2

2

8

1

1

8

2

1

8

7

4

3

5

2

1

1

1

1

2

2

9

2

6

2

1

1

2

8

1

2

2

1

8

Fig. 26

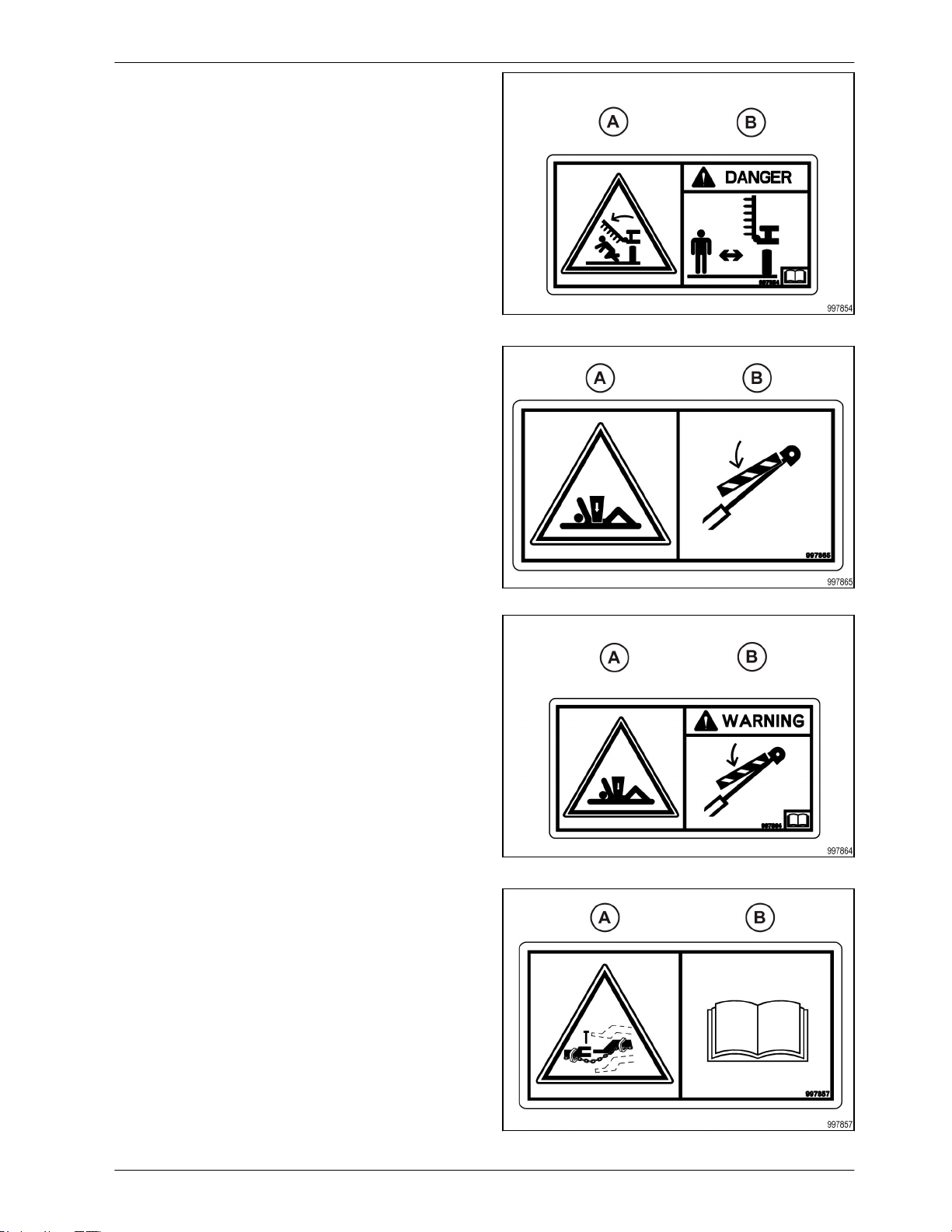

(1) Danger/Folding Wings

(2) Warning/Lockout

(3) Safety Decal Set

(4) Warning/Read Operator Manual

(5) Danger/High Line

(6) Slow Moving Vehicle

(7) Maximum Speed

(8) Reflector/Amber

(9) Depth Indicator Decal

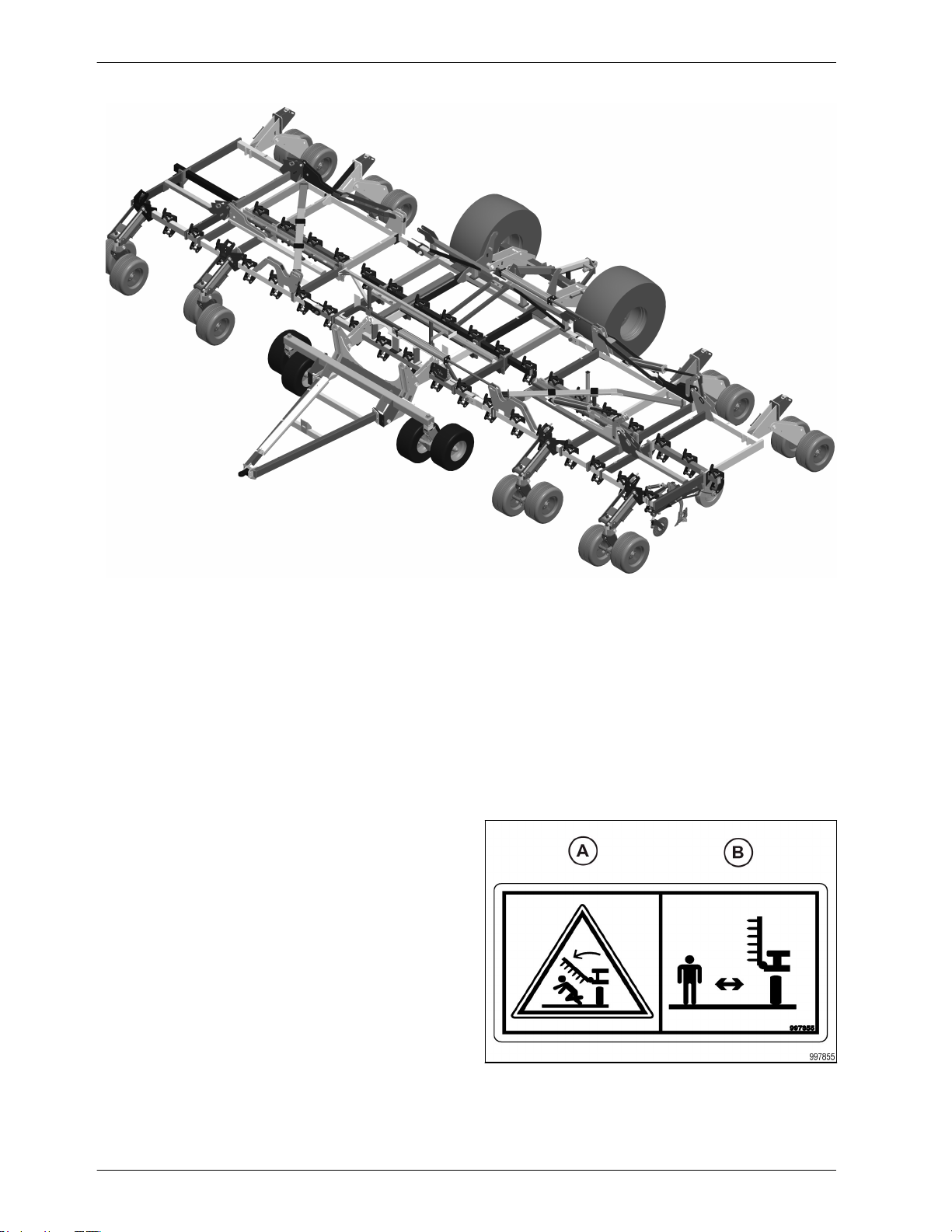

(1) Danger/folding wings

Hazard (A): Overhead crushing hazard from

lowering or falling wing.

Avoidance (B): Stay clear of this area while

engine and machine are operating. For service

work, install the wing lock pins before getting under

the wing.

Fig. 27

Page 24

1. Safety

24

(2) Warning/lockout

Hazard (A): Crushing hazard.

Avoidance (B): Stay clear of this area while engine

and machine are operating. For service work,

install the wing lock pins before getting under the

wing.

Fig. 27

(3) Caution/safety chains

Hazard (A): Loss of machine control.

Avoidance (B): Install the safety chains when

connecting the machine to the tractor. Read the

operators manual for safety information and the

operating instruction before operating the

machine.

Fig. 28

Fig. 28

Fig. 29

Page 25

(4) Warning/negative tongue weight

25

Hazard (A): Negative tongue weight will cause the

tongue to rise immediately when disconnecting

the machine.

Avoidance (B): Stay clear of the tongue when

disconnecting the machine from the tractor. Read

the operators manual for safety information and

operating the instructions before operating the

machine.

1. Safety

Fig. 29

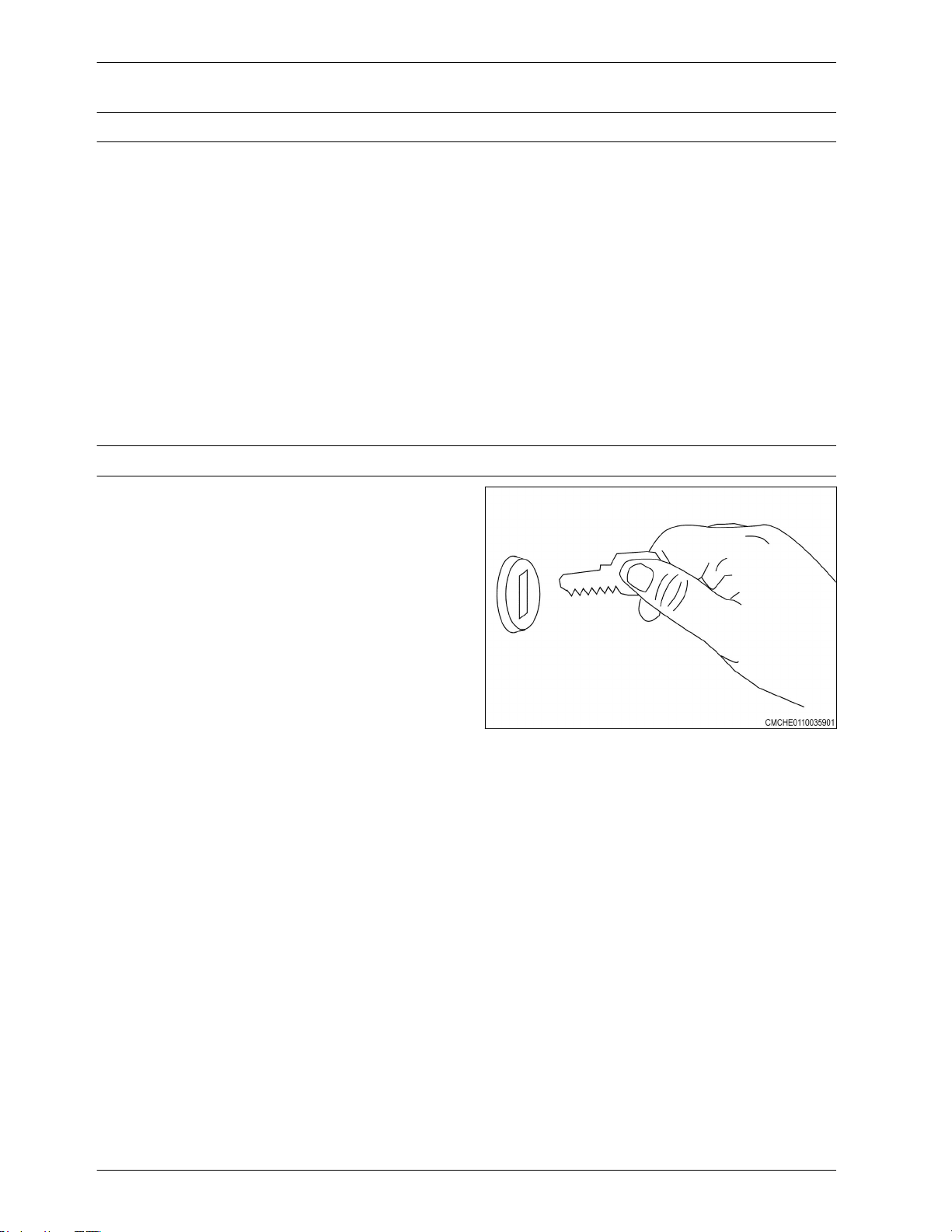

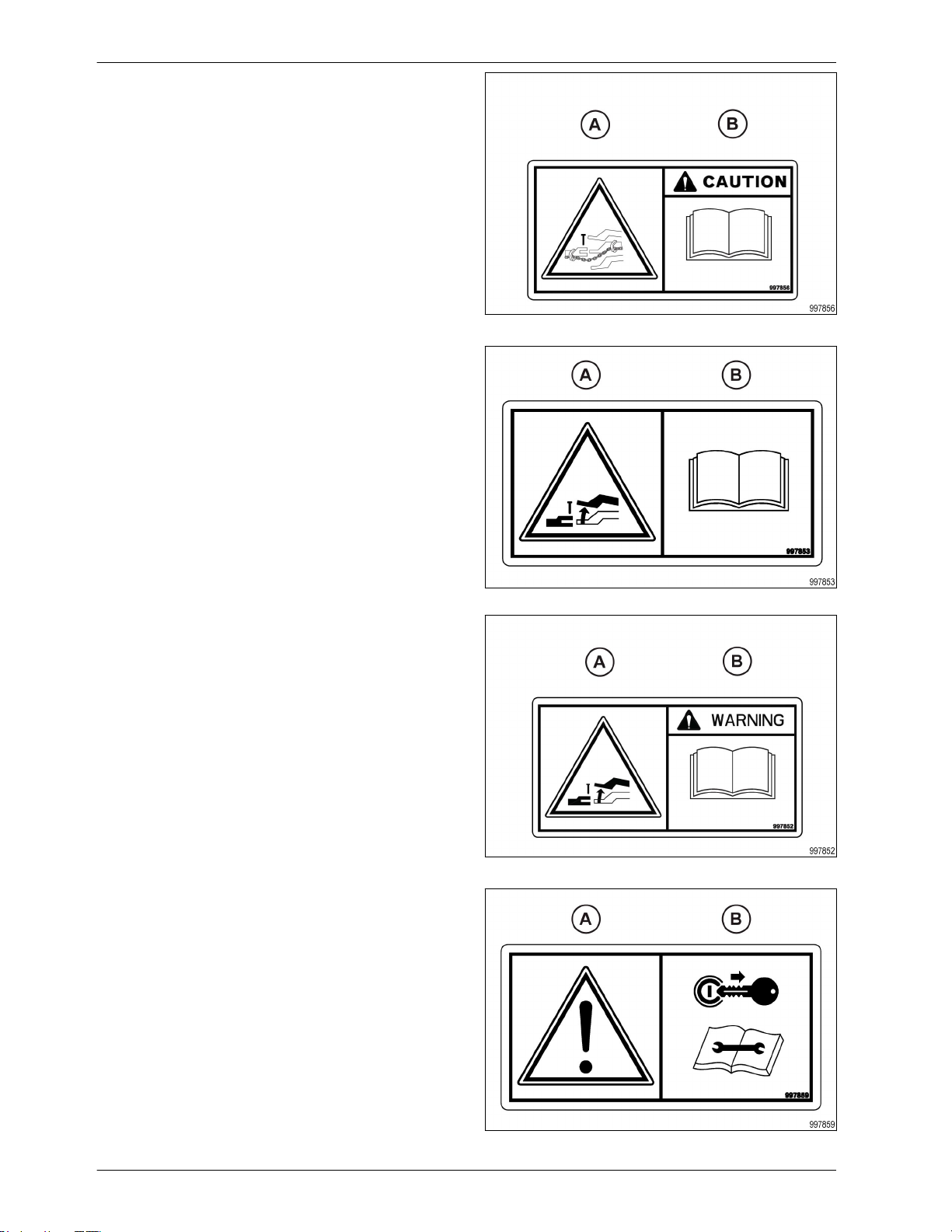

(5) Warning/remove key

Hazard (A): General safety alert.

Avoidance (B): Turn off the machine and remove

the key before maintenance or repair.

Fig. 30

Fig. 30

Fig. 31

Page 26

1. Safety

26

(6) Warning/read operators manual

Hazard (A): General safety alert.

Avoidance (B): Read and understand the

operators manual before operating the machine.

Fig. 31

(7) Danger/high line

Hazard (A): Electrical shock hazard - risk of

personal injury and component damage.

Avoidance (B): Keep the correct distance away

from electrical power lines.

Fig. 32

Fig. 32

Fig. 33

Page 27

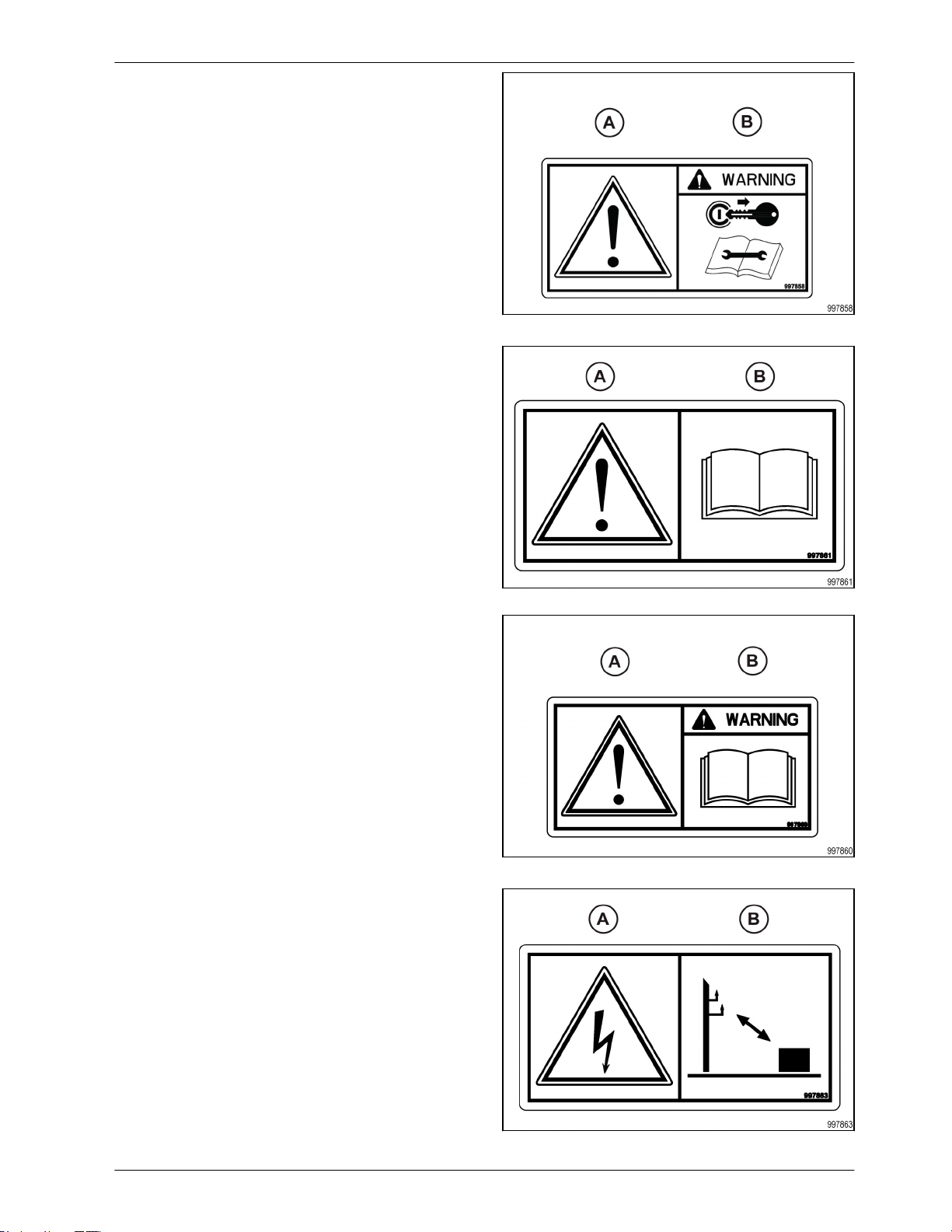

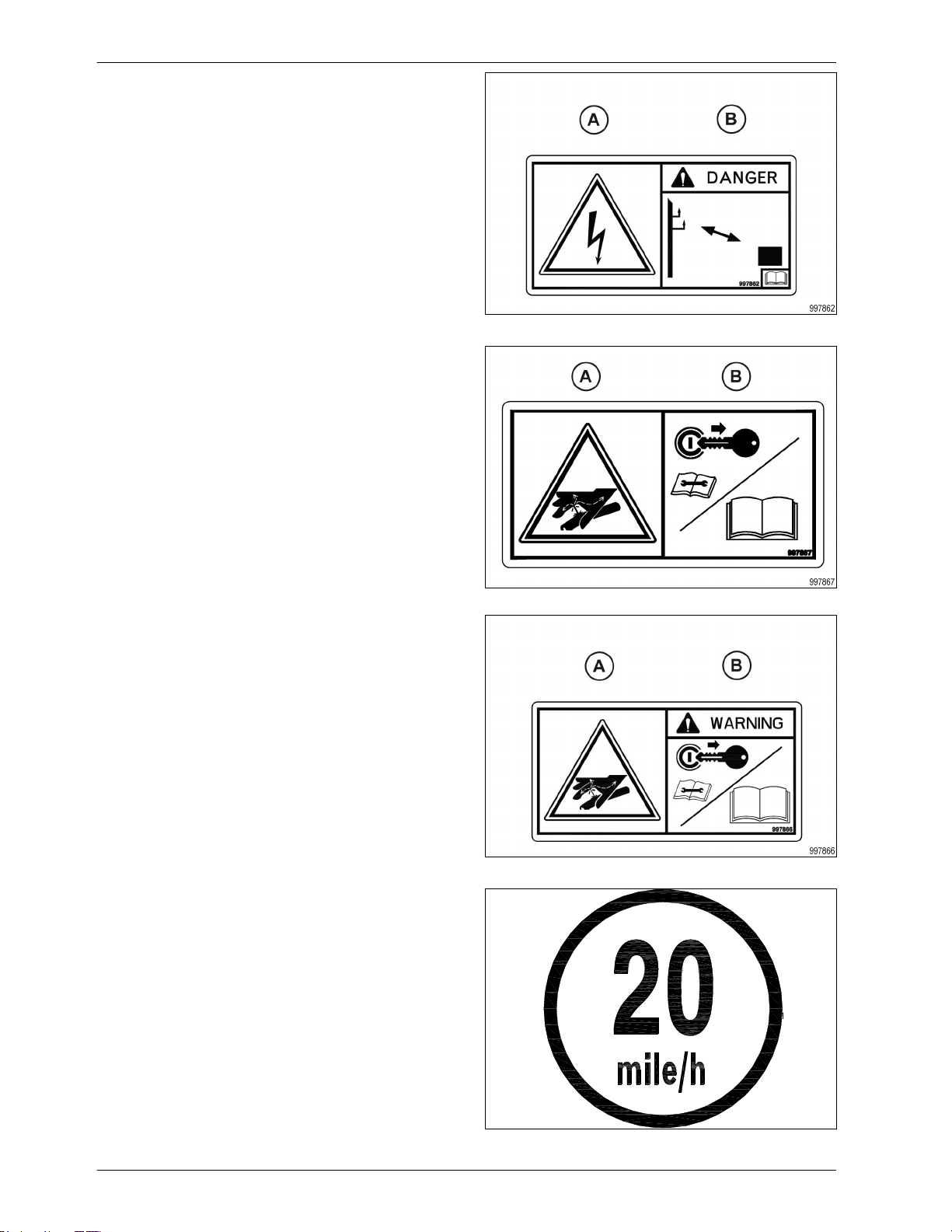

(8) Warning/hydraulic fluid pressure

27

Hazard (A): Injection hazard into skin - escaping

fluid under high pressure.

Avoidance (B): Turn off the engine, remove the

key, relieve the pressure before maintenance or

repair. Refer to the operator manual for the correct

service procedures.

1. Safety

Fig. 33

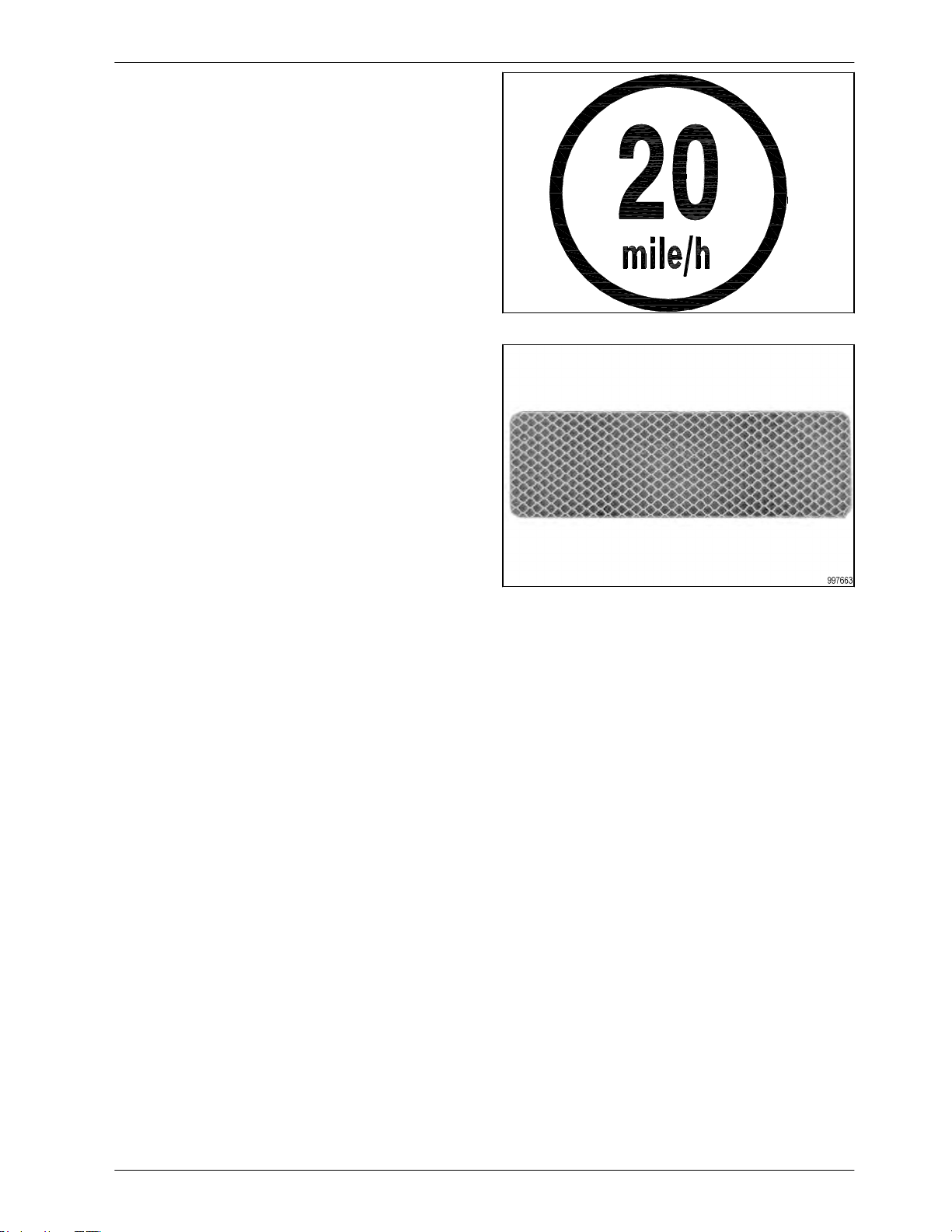

(9) Maximum speed

The maximum speed safety sign displays the

maximum speed to transport the machine.

Fig. 34

Fig. 34

Fig. 35

Page 28

1. Safety

28

(10) Reflector/yellow

Fig. 35

Fig. 36

Page 29

2. Introduction

29

2. Introduction

2.1 Introduction .............................................................28

2.1.1 Units of measurement ..................................................29

2.1.2 Replacement parts .....................................................29

2.1.3 Intended use .........................................................29

2.1.4 Proper disposal of waste ................................................29

2.2 Machine identification ...................................................31

2.2.1 Serial number plate location ..............................................31

2.2.2 Serial number description ................................................31

Page 30

2. Introduction

30

2.1 Introduction

CAUTION:

In some of the illustrations used in this Operator Manual, panels or guards may have been

removed for clarity. Never operate the tractor with these panels and guards removed. If

the removal of a shield is necessary to make a repair, it must be replaced before

operation.

CAUTION:

Read this book in its entirety prior to operating machine. Use only genuine replacement

parts for repairs and/or replacement.

This manual gives the operator the proper instructions needed for operation and maintenance. Read,

understand, and follow these instructions for best machine performance and life. With proper maintenance

and operation procedures, the machine will have better over all performance. Use normally available tools

for maintenance on this machine.

All operators must read and understand this manual before operating this machine. Where possible,

operators who have not operated the machine must receive instruction from an operator who has operated

this machine. Your dealer can give instruction in machine operation. Keep this manual with the machine for

future reference. If the original manual is damaged, order a replacement from your dealer.

See your dealer in for any service problems and adjustments. The dealer is equipped for all service work

and to help with specific applications of the tractor in local conditions.

Left-hand and right-hand are determined by facing the direction the machine will travel when in use.

2.1.1 Units of measurement

Measurements are given in metric units followed by the equivalent in US units. Hardware sizes are given

in millimeters for metric hardware and inches for US hardware.

2.1.2 Replacement parts

To receive prompt efficient service, remember to have the following information:

Correct part description and part number

Model number of the machine

Serial number of the machine

2.1.3 Intended use

This machine is designed solely for use in customary agricultural operations.

Do not use this machine for any application or purpose other than those described in this manual. The

manufacturer accepts no liability for damage or injury resulting from misuse of this machine.

Compliance with the conditions of operation, service and repair as specified by the manufacturer constitute

essential elements for the intended use of this machine.

This machine should be operated, serviced and repaired only by qualified persons familiar with its

characteristics and familiar with the relevant safety rules and procedures.

All generally recognized safety regulations and road traffic regulations must be obeyed at all times.

Any unauthorized modifications performed on this machine will relieve the manufacturer of all liability for

any resulting damage or injury.

2.1.4 Proper disposal of waste

Improper disposal of waste can pollute the environment and ecology. A few examples of potentially

harmful equipment waste can include, but not limited to, items such as oil, fuel, coolant, brake fluid, filters,

battery chemicals, tires, etc.

Page 31

2. Introduction

31

Use leak proof containers when draining fluids. Do not use food or beverage containers to collect waste

fluids, as food or beverage container(s) may mislead someone into drinking from them.

Do not pour or spill waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth's atmosphere. Government

regulations may require a certified air conditioning service center to recover and recycle used air

conditioning refrigerants.

Inquire with local environmental or recycling center on the proper way to recycle or dispose waste.

Page 32

2. Introduction

32

2.2 Machine identification

Each machine is identified by a model and a serial number.

Record these numbers in the spaces given.

Give the model number and serial number to your dealer when parts or service are required.

Machine model number:

Machine serial number:

Date of delivery:

Dealer name:

Dealer address:

Dealer telephone number:

Dealer e-mail address:

Dealer fax number:

2.2.1 Serial number plate location

The serial number plate (1) is located on the side

of the main frame tube.

1

2.2.2 Serial number description

Description of the serial number for model year 2010 and up.

Fig. 1

Fig. 2

(1) Beginning symbol

(2) World manufacturer code

(3) Brand code

(4) Model identifier (model number)

(5) Check letter (0 or used if model identifier is

five digits)

(6) Model year code (A=2010, B=2011, C=2012,

and on)

Page 33

2. Introduction

33

(7) Plant code

(8) Family code

(9) Unit number for the year

(10) Ending symbol

Page 34

3. Assembly

34

Assembly ................... .............. ...........................34-35

3.

Mainframe................................................36

Front inner wing anchor/rest............................................37

Front hitch pivot....................................................... 38

Front caster mount.....................................................39

Front caster mount-mainframe..........................................40

Front hitch pivot assembly..............................................41

Front lift cylinders-mainframe............................................42

Front hitch...............................................43

Hydraulic jack.........................................................44

Docking station........................................................45

Rear inner wing anchor/rest 51ft.........................................46

Rear inner wing anchor/rest 61ft.........................................47

Inner wing 51ft..........................................................48

Inner wing 61ft..........................................................49

Outer wings..............................................50

Outer wing fold linkage.................................................51

Outer wing latch........................................................52

Outer wing latch system................................................53

51ft inner wing fold cylinder mounts.....................................54

51ft inner wing fold cylinder rod connection/wing rest.....................55

61ft inner wing fold cylinder mounts......................................56

51ft outer wing fold cylinders ..................................57

61ft outer wing fold cylinders............................................58

Rear axle..............................................................59

Rear hitch.............................................................60

Rear lift cylinders-mainframe............................................61

Lift axle-rear wing.......................................................62

Rear lift cylinder-inner & outer wing ......................................63

Front lift assembly left-inner & outer wing.........................64

Front lift assembly right-inner & outer wing...............................65

Front lift cylinder-inner & outer wing.....................................66

Row unit-frame mount..................................................67

Row unit placement-mainframe.........................................68

Row unit placement-51ft inner wing......................................69

Row unit placement-61ft inner wing......................................70

Row unit placement-51ft outer wing......................................71

Row unit placement-61ft outer wing......................................72

Page 35

3. Assembly

35

3. Assembly-continued

Hose channel-mainframe..................................... 73

Hose channel-inner wing...............................................74

Hose channel-front hitch...............................................75

Down pressure valve...................................................76

Down pressure valve mount.............................................77

Hydraulic hose assembly sequence......................................78

51ft lift hydraulics.............................

..........................79

61ft lift hydraulics.... ............. ............ ............80

51 & 61ft lift hydraulics.. ... ..

........................................81

51ft wing fold hydraulics................................................82

51ft wing fold hydraulics................................................83

61ft wing fold hydraulics................................................84

61ft wing fold hydraulics..................................... ............85

Down pressure hydraulics-DP block......................................86

Down pressure hydraulics-DP block.............................87

Down pressure hydraulics-mainframe.. ... .. ............................88

Down pressure hydraulics-inner wing....................................89

Down pressure hydraulics-outer wing....................................90

Rear hitch hydraulics................................................91-92

Rear hitch hydraulic & electrical fittings..................................93

Front light mount........................................................94

SMV sign & stop collars ......................................95

Rear lights, light module, & lift switch....................................96

Lift switch... . .......................................................97-99

Bleeding air from the hydraulic lift system...............................100

Bleeding air from the hydraulic fold system..............................101

Leveling the mainframe.................................................102

Leveling the wings ..................................................103-104

Model decals-front hitch.....................................105

Model decals-outer wing................................................ 106

Tire air pressure....... ...............................................107

Page 36

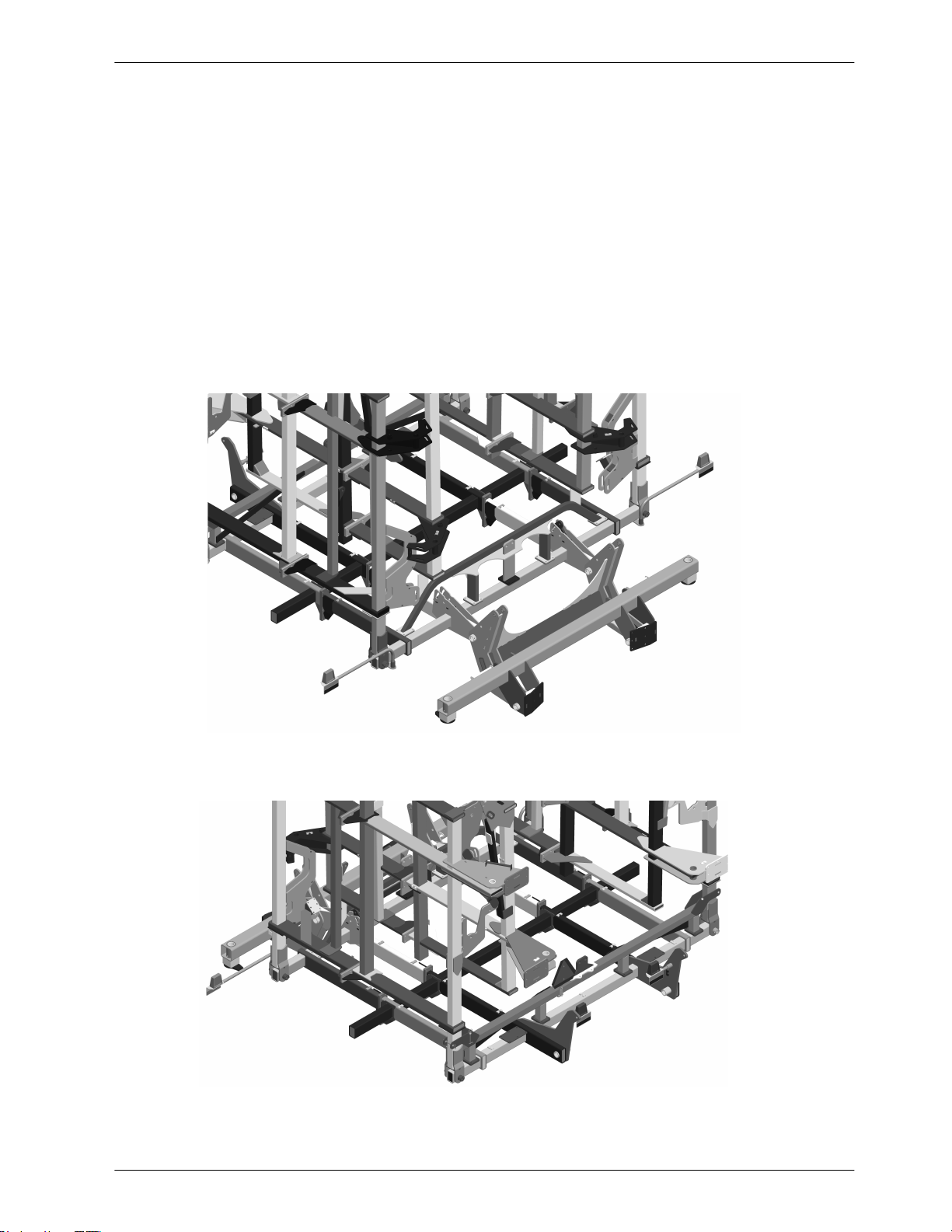

MAIN FRAME

36

3. Assembly

COMPOSITE BEARING

BUSHING 2.027 ID X

2.489 OD X 5.50

356900

COMPOSITE BEARING

BUSHING 2.027 ID X

2.489 OD X 7.88 357547

REAR MAIN FRAME

357894

FRONT MAIN FRAME

357890

ADJUST

ANCHOR 357609

NUT 2POSLK

3/4-10NC 5Z 88356

BLT HEX 3/4-10NC

X 2 8YZ 88290

HEADLESS PIN(2)

1X5.12 221344

PIN ROLL 1/4 X 2-1/4 Z

42484

332447

COMPOSITE BEARING

BUSHING 2.527 ID X

2.988 OD X 4.75 357546

WSHR FLAT

1(1-1/16 X 2-1/2ACT)

Z 88196

Page 37

3. Assembly

37

FRONT INNER WING ANCHOR/REST

FRONT WING REST

WELD-51FT ONLY

358622

BLT HEX 5/8-11NC X 3

5Z 88408

WSHR FLAT 5/8(11/16

X 1-3/4ACT) 88277

REST BUMPER

353529

FRONT INNER WING

ANCHOR

332704

NUT TOP LK 1/2-13NC

5Z 88661

BLT HEX 1/2-13NC X 4

5Z 88595

BLT HEX 3/4-10NC

X 2-1/4 8YZ 89433

NUT TOP LK

5/8-11NC 5Z 88845

NUT TOP LK

3/4-10NC 8Z 88665

358622 IS BOLTED ON 51FT MODELS ONLY.

FOR 61FT MODELS THE RUBBER BUMPERS ARE BOLTED ONTO THE

TOP PLATES ON ITEM 332704.

332719

Page 38

FRONT HITCH PIVOT

38

PIN ROLL 3/8DIA X 2-1/2 Z

88770

PIN 1 DIA X 8.88

357522

3. Assembly

WSHR FLAT

1(1-1/16 X 2-1/2ACT)

88196

FRONT HITCH PIVOT

356996

PIN 2.50 DIA X 9.75

357523

COMPOSITE BEARING BUSHING

2.527 ID X 2.988 OD X 9.50

357548

BLT HEX 5/8-11NC X 4

5Z 88298

NUT 2POSLK

5/8-11NC 5Z 88369

332449

Page 39

3. Assembly

39

FRONT CASTER MOUNT

BLT HEX 1-8NC X 3

5Z 88399

NUT 2POSLK 3/4-10NC

5Z 88356

FRONT CASTER MOUNT

356998

TOP TUBE

241563

BLT HEX 3/4-10NC X

5 5Z 88305

BLT HEX 5/8-11NC X

4 5Z 88298

WSHR FLAT

1(1-1/16 X 2-1/2ACT)

88196

NUT 2POSLK

1-8NC 5Z 88348

COMPOSITE BEARING

BUSHING 3.027 ID X

3.487 OD X 5.75

357545

LARGE WEAR PLATE

242932

332451

NUT 2POSLK

5/8-11NC 5Z 88369

PIN 2.50 X

14.50 357524

Page 40

FRONT CASTER MOUNT MAIN FRAME

40

RIGHT MAIN WALKER

333107

FRONT CASTER MOUNT

356998

3. Assembly

LEFT MAIN WALKER

333106

INSIDE WHEEL TO LEAD ON BOTH RIGHT

WALKER & LEFT WALKER

701381

Page 41

3. Assembly

41

FRONT MAIN FRAME

357890

FRONT HITCH PIVOT ASSEMBLY

ADJUST

ANCHOR 357609

PIN COT 3/16DIA X 2 Z

88133

BLT HEX 1/2-13NC X 3-1/4 5Z

88680

HEADLESS

PIN(2) 1X3-7/16

42430

HYD CYL 4-3/4

X 12 (AM-2540)

235968

HITCH ADJUST

SHIM-THICK

358909

FRONT HITCH PIVOT

356996

FRONT CASTER MOUNT

356998

NUT 2POSLK

1/2-13NC 5Z

88363

HITCH ADJUST SHIM

357610

HEADLESS PIN

1X5.12 221344

PIN ROLL 1/4 X

2-1/4 42484

WSHR FLAT

1(1-1/16 X

2-1/2ACT) 88196

701117

Page 42

FRONT LIFT CYLINDERS-MAINFRAME

42

3/4IN CYLINDER STOP (YELLOW)

241647 QTY2

1-7/16 IN CYLINDER STOP (BLUE)

244586 QTY2

1-1/2IN CYLINDER STOP (GRAY)

241649 QTY4

3. Assembly

TRANSPORT CHANNEL

358289

HYD CYL 4-3/4 X 12 (AM-2540)

235968

ADJUST ANCHOR

357609

701364

Page 43

3. Assembly

43

NUT TOP LK 1-8NC 5Z

88658

FRONT HITCH

FRONT CASTER MOUNT

356998

BLT HEX 1-8NC X

3 5Z 88399

JACK LEG WELD

239727

JACK TUBE WELD

239728

MAIN HITCH

240469

NUT TOP LK

5/8-11NC 5Z 88845

HITCH BOLT 1-1/4 X 7

UNC X 7.00 LONG

354313

BLT-U 5/8-11NC X 4 X 5-1/2

Z 45633

NUT JAM 1-1/4-7NC 5Z

88622

CAST DUAL

HITCH 18236

332450

Page 44

HYDRAULIC JACK

44

3. Assembly

PIN ROLL 1/4 X 2-1/4 Z

42484

HEADLESS PIN(2) 1X4.00

221714

ELB 6MJ X 6MORB

61239

HSE 3KPSI 1/4X120 6FJX-6FJX

238617

JACK TUBE

239728

PIN,CLICK 7/16X1-1/2

32990

HITCH PIN 1-1/8X4-3/4

23011

QUICK COUPLER 8 ORB

247425

JACK LEG

239727

ADP 6 MJ X 8 MORB

58543

HYD CYL, 3X24 FGS #A519CY10

51241F

Page 45

3. Assembly

45

WSHR FLAT 1/4(5/16 X 3/4ACT) Z

88261

NUT TOP LK 1/4-20NC 5Z

89501

DOCKING STATION

BLT HEX 1/4-20NC X

3/4 5Z 88993

STORAGE TUBE-OWNERS

MANUAL 234313

PLUG HOLDER

223329

BLT HEX 1/4-20NC X 1 5Z

88203

BLT HEX 1/4-20NC X 1-1/2 5Z

88504

DS COLLAR

322417

DS HOSE CRADLE

322412

NUT HEX 3/8-16NC 5Z

88103

NUT 2POSLK 1/4-20NC 5Z

88237

DOCKING STATION

322425

U-BOLT .375 X 5.125 X

8.063 X 5.125

A64244

WSHR HLK 3/8ID Z

88362

332426

Page 46

REAR INNER WING ANCHOR/REST 51FT

46

INNER WING ANCHORREAR MF 51FT 358603

1/2X6-1/2 HITCH PIN W/

HAIRPIN 350876

3. Assembly

BLT HEX 3/4-10NC X 2-1/4

8YZ 89433

REAR MAIN FRAME

357894

NUT TOP LK

3/4-10NC 8Z 88665

332452

Page 47

3. Assembly

47

1/2X6-1/2 HITCH

PIN W/HAIR PIN

350876

REAR INNER WING ANCHOR/REST 61FT

INNER WING

ANCHOR-REAR

MF 61FT 358246

NUT TOP LK

3/4-10NC 8Z 88665

REAR MAIN FRAME

357894

BLT HEX 3/4-10NC

X 2-1/4 8YZ 89433

332778

Page 48

INNER WING 51FT

48

3. Assembly

LIFT CYLINDER PIN

1" DIA X 7.63 357531

PIN ROLL

3/8DIA X 2-1/2 Z

88770

COMPOSITE BEARING

BUSHING 2.027 ID X

2.489 OD X 6.75 357551

NUT 2POSLK

5/8-11NC

88369

REAR LIFT

ANCHOR 358378

WSHR FLAT

1(1-1/16 X

2-1/2ACT)

88196

BLT HEX 5/8-11NC X 2 5Z

88294

NUT 2POSLK

5/8-11NC

88369

STUB WELDINNER WING

BRACE 358602

COMPOSITE BEARING

BUSHING 1.277 ID X

1.742 OD X 4.06 357560

BLT HEX

5/8-11NC X 2

88294

INNER WING BRACE-51FT

358610

BACK PLATECROSS BRACE

358663

BLT HEX

5/8-11NC X 4

88298

LIFT CYLINDER PIN

1" DIA X 8.88 357522

NUT JAM

1-1/4-7NC 88622

COMPOSITE BEARING

BUSHING 1.527 ID X

2.240 OD X 7.44

355388

51FT RIGHT INNER

WING - REAR

358373

51FT LEFT INNER

WING - REAR

358371

BLT-U 5/8-11NC

X 4 X 7-1/4 Z

89097

NUT 2POSLK

3/4-10NC 5Z

88356

BLT HEX 3/4-10NC X

2 8YZ 88290

PIN 2 X 10.88

358276

NUT 2POSLK

5/8-11NC

88369

51FT LEFT INNER

WING - FRONT

358372

51FT RIGHT INNER

WING - FRONT

358374

BLT HEX

5/8-11NC X

3-1/2 5Z

88292

CYLINDER

ADJUST ROD

69567

BLT HEX

3/8-16NC X

2-3/4 5Z

88582

NUT TOP LK

3/8-16NC 5Z 88659

PIVOT PIN (1-1/2 X 10)

235801

332787

Page 49

3. Assembly

49

STUB WELDINNER WING

BRACE 358602

INNER WING 61FT

ALL COMPONENTS THE SAME AS PAGE

30 EXCEPT AS NOTED

INNER WING BRACE-61FT

358395

61FT LEFT INNER

WING - REAR

358228

61FT RIGHT INNER

WING - REAR

358248

STUB WELD-LH

FRONT 358642

STUB WELDRH FRONT

358643

61FT LEFT INNER

WING - FRONT

357884

61FT RIGHT INNER

WING - FRONT

358227

332784

Page 50

OUTER WINGS

50

PIN ROLL

3/8DIA X 2-1/2 Z

88770

WSHR FLAT

1(1-1/16 X

2-1/2ACT)

88196

REAR LIFT

ANCHOR 358378

BLT HEX 5/8-11NC

X2 8829488294

3. Assembly

COMPOSITE BEARING

BUSHING 2.027 ID X

2.489 OD X 6.75 357551

LIFT CYLINDER PIN

1" DIA X 7.63 357531

NUT TOP LK

3/8-16NC 5Z

88659

NUT 2POSLK

5/8-11NC

88369

BLT HEX 3/8-16NC

X 2-1/2 5Z

89012

1-1/4 DIA X 7.38 HINGE

PIN-OUTER WING

358616

51FT LEFT OUTER WINGREAR 358360(SHOWN)

51FT RIGHT OUTER WINGREAR 358361

61FT LEFT OUTER WINGREAR 358234

61FT RIGHT OUTER WINGREAR 358235

LIFT CYLINDER PIN

1" DIA X 8.88 357522

PIN ROLL 3/8DIA X

2-1/2 Z 88770

BLT HEX

3/8-16NC X

2-3/4 5Z 88582

COMPOSITE BEARING

BUSHING 1.527 ID X

2.240 OD X 7.44

355388

NUT JAM

1-1/4-7NC 88622

WSHR FLAT

1(1-1/16 X

2-1/2ACT)

88196

NUT 2POSLK

3/4-10NC 5Z

88356

BLT HEX 3/4-10NC

X 2 8YZ 88290

51FT LEFT OUTER WINGFRONT 358358(SHOWN)

51FT RIGHT OUTER

WING-FRONT 358359

61FT LEFT OUTER WINGFRONT 358225

61FT RIGHT OUTER

WING-FRONT 358226

332796

PIVOT PIN (1-1/2 X 10)

235801

CYLINDER

ADJUST ROD

69567

NUT TOP LK

3/8-16NC 5Z

88659

Page 51

3. Assembly

51

NUT 2POSLK 1-1/4-7NC

5Z 88430 51FT

NUT TOP LK 1-1/2-6NC 5Z

89126 61FT

OUTER WING FOLD LINKAGE

51FT BANNANA ARM

ASSEMBLY-OUTER WING

359424

51FT BANNANA ARM

WELD-OUTER WING

359419

WSHR FLAT 1-1/4(1-3/8 X

3ACT) Z 88602 51FT ONLY

WSHR FLAT 1-1/2(1-5/8 X

3-1/2) Z 88616 61FT ONLY

BLT HEX 1-1/4-7NC X 7

5Z 89134 51FT ONLY

BLT HEX 1-1/2-6NC X

7-1/2 5Z 89124 61FT

ONLY

NUT 2POSLK 1-1/4-7NC

5Z 88430

BLT HEX 1-1/4-7NC X 7

5Z 89134

701384A

51FT OUTER WING FOLD

LINK ASSEMBLY 1-1/2

DIA 359425

61FT OUTER WING FOLD

LINK 1-1/2 DIA 359423

Page 52

OUTER WING LATCH

52

3. Assembly

PIVOT TUBE-LATCH

358687

NUT 2POSLK 3/4-10NC 5Z

88356

BLT HEX 3/4-10NC X 5 5Z

88305

WSHR FLAT 3/4(13/16 X

2ACT) 88131

LATCH WELDMENT

358277

SPRING,EXT 30-COILS

1.5-OD 9.5-LONG

25863

BLT HEX 3/8-16NC X 2-1/2 5Z

89012

PIN BUSHING

359427

NUT TOP LK

3/8-16NC 5Z

88659

LOCK PIN-OUTER WING

(ZP) 359426

701384B

Page 53

3. Assembly

53

(1) Latch

(2) Latch pin

(3) Spring

(4) Latch stop

Figure 1 shows the latch system with the outer wing

unfolded. Make sure items 1 thru 4 are bolted tightly

and secured before folding and unfolding the outer

wing. The purpose of the latch system is to

make sure the outer wing folds and

unfolds smoothly without any abrupt changes in

the folding speed during the fold process.

OUTER WING LATCH SYSTEM

1

2

3

figure 1

4

Figure 2 shows the outer wing and latch

system in the folded position.

figure 2

Page 54

51FT INNER WING FOLD CYLINDERS

54

PIN ROLL 1/4 X 2-1/4 Z

42484

3. Assembly

HEADLESS PIN 1-1/4X3-3/4

42431

HYD FOLD CYL, 5 X 48

357897

HYD FOLD CYL, 5 X 48

357897

PORTS TO FACE THE

REAR

REAR INNER WING FOLD

CYLINDER - PORTS TO

FACE THE REAR

701116

Page 55

3. Assembly

55

51FT WING REST

HYD FOLD CYL, 5 X 48

357897

51FT INNER WING FOLD CYL CONNECTION

HYD FOLD CYL, 5 X 48

357897

BLT HEX 1-1/4-7NC X 7 5Z

89134

WSHR FLAT 1-1/4(1-3/8 X

3ACT) 88602

NUT 2POSLK 5/8-11NC 5Z

88369

NUT 2POSLK 1-1/4-7NC 5Z

88430

26.00"

701383

BLT-U 5/8-11NC X 4 X 7-1/4

89097

WING REST WELDOUTER WING 51FT

358618

Page 56

61FT INNER WING FOLD CYLINDERS

56

PIN ROLL 1/4 X 2-1/4 Z

42484

HEADLESS PIN 1-1/4X3-3/4

42431

NUT 2POSLK 1-1/4-7NC 5Z

88430

3. Assembly

WSHR FLAT 1-1/4(1-3/8 X

3ACT) 88602

BLT HEX 1-1/4-7NC X 7 5Z

89134

HYD FOLD CYL, 5 X 48

357897

HYD FOLD CYL, 5 X 48

357897

PORTS TO FACE THE

REAR

REAR INNER WING FOLD

CYLINDER - PORTS TO

FACE THE REAR

701403

Page 57

3. Assembly

57

PIN ROLL 1/4 X 2-1/4 Z

42484

51FT OUTER WING FOLD CYLINDERS

HYD FOLD CYL, 5X36

247829

HEADLESS PIN 1-1/4X3-3/4

42431

701384C

Page 58

61FT OUTER WING FOLD CYLINDERS

58

REAR INNER WING FOLD

CYLINDER - PORTS TO

FACE THE REAR

HYD FOLD CYL, 5 X 48

357897

3. Assembly

HEADLESS PIN 1-1/4X3-3/4

42431

WING REST-OUTER WING

358272

WING REST MOUNTS

4.00" FROM END OF

4SQ TUBE TO

MOUNTING PLATE

PIN ROLL 1/4 X 2-1/4

42484

NUT 2POSLK 5/8-11NC 5Z

88369

BLT-U 5/8-11NC X 4 X 5-1/2

45633

HEADLESS PIN 1-1/2X3-3/4

359432

HYD FOLD CYLINDER 6X36

359392

701394

Page 59

3. Assembly

59

PIN ROLL

3/8DIA X 2-1/2

88770

REAR AXLE

BLT HEX 5/8-11NC X 3-1/2 5Z

88292

NUT TOP LK 5/8-11NC 5Z

88845

MAIN REAR PIVOT PIN 2 DIA

X 12.75 357071

NUT TOP LK

5/8-11NC 5Z 88845

REAR LIFT WHEEL CYL

PIN 1 DIA X 11.50 357521

ASSY-HUB/

SPINDLE A37309

BLT HEX 5/8-11NC X

3-1/2 5Z 88292

NUT TOP LK

5/8-11NC 5Z 88845

BLT HEX 5/8-11NC X

3-1/2 5Z 88292

REAR PIVOT PIN 1.50 DIA

X 10.75

357520

REAR MAIN AXLE-FIRESTONE

358958

NUT TOP LK

3/4-10NC 8Z 88665

BLT HEX 3/4-10NC X

6-1/2 8YZ 88600

332454

Page 60

REAR HITCH

60

REAR HITCH 358252

COMPOSITE BEARING

BUSHING 1.527 ID X

2.240 OD X 4.00 358295

3. Assembly

BLT HEX 3/4-10NC X 6

5Z 88293

BLT HEX

7/8-9NC X 3

8YZ 88468

SWIVEL PINTLE

HOOK 358307

NUT 2POSLK

7/8-9NC 5Z 88836

BLT HEX 5/8-11NC

X 3-1/2 5Z 88292

PIVOT PIN 1.50

DIA X 8.75 358308

REAR HITCH

BRACE TUBE

358258

NUT TOP LK

5/8-11NC 5Z

88845

REAR MAIN AXLEFIRESTONE 358958

PLATE-HITCH

SUPPORT(61FT

ONLY)358299

INNER WING

ANCHOR-61FT

358246

NUT TOP LK

3/4-10NC 8Z 88665

COMPOSITE BEARING

BUSHING 1.527 ID X

2.240 OD X 5.00 357558

COMPOSITE BEARING

BUSHING 1.527 ID X

2.240 OD X 4.00 358295

PIVOT PIN 1.50

DIA X 8.75 358308

BLT HEX 5/8-11NC

X 3-1/2 5Z 88292

332799

REAR HITCH

BRACKET 358256

NUT TOP LK

5/8-11NC 5Z

88845

REAR MAIN FRAME

357894

BLT-U 5/8-11NC

X 6 X 5-1/2 Z

89093

NUT-TOPLOCK

FLANGE .63 NC GR8 ZP

89505

Page 61

3. Assembly

61

REAR LIFT CYLINDERS-MAINFRAME

3/4IN CYLINDER STOP (YELLOW)

241647 QTY2

1-7/16 IN CYLINDER STOP (BLUE)

244586 QTY2

1-1/2IN CYLINDER STOP (GRAY)

241649 QTY4

TRANSPORT CHANNEL

358289

HYD CYL 5 X 12

235967

701363

Page 62

REAR WING AXLE

62

BLT HEX 5/8-11NC X 3-1/2

5Z 88292

3. Assembly

REAR PIVOT PIN 2 DIA X 11.88

357519

OUTER WING WHEEL PIVOT

356857

NUT 2POSLK 1/2-13NC

5Z 88363

NUT 2POSLK

5/8-11NC 5Z 88369

PIN ROLL

3/8DIA X 2-1/2 Z

88770

REAR LIFT

CYLINDER PIN 1 DIA

X 9.75 357525

HUB & 2 IN SPINDLE ASSY

14131

BLT HEX 1/2-13NC

X 3-1/4 5Z 88680

333114

Page 63

3. Assembly

63

REAR LIFT CYLINDER-INNER & OUTER WING

4 X 12 HYD LIFT CYLINDER

358314 INNER WING

3-3/4 X 12 HYD LIFT CYLINDER

358313 OUTER WING

701362

Page 64

FRONT LIFT ASSEMBLY LEFT-WING

64

3. Assembly

BOTTOM LIFT ARM

356853

COMPOSITE BEARING

BUSHING 1.527 ID X 2.240

OD X 5.94 357557

NUT 2POSLK

3/4-10NC 5Z 88356

HEADLESS PIN

1-1/2 X 9-19/32

54595

TOP FRONT LINK ARM

356852

COMPOSITE BEARING

BUSHING 1.527 ID X

2.240 OD X 7.44 355388

BLT HEX

3/4-10NC X 4

5Z 88272

COLLAR

16009

BLT HEX

3/8-16NC X 2-3/4

5Z 88582

NUT TOP LK

3/8-16NC 5Z

88659

NUT TOP LK

3/8-16NC 5Z

88659

BLT HEX

3/8-16NC X

2-3/4 5Z 88582

GAUGE WHEEL

VERTICAL MOUNT

355380

INSIDE WHEEL TO LEAD

HEADLESS PIN

1-

1/2 X 9-19/32

54595

COMPOSITE BEARING

BUSHING 2.560 ID X

2.988 OD X 7.69 355390

COMPOSITE BEARING

BUSHING 1.527 ID X

2.240 OD X 7.44

355388

333111

ASSY - LEFT WING WALKER

333109

Page 65

3. Assembly

65

FRONT LIFT ASSEMBLY RIGHT-WING

ALL COMPONENTS THE SAME AS PAGE

46 EXCEPT AS NOTED

ASSY - RIGHT WING WALKER

333110

INSIDE WHEEL TO LEAD

333112

Page 66

FRONT LIFT CYLINDER-INNER & OUTER WING

66

3. Assembly

HYD LIFT CYL 4-1/2 X 12

235969

INNER WING

HYD LIFT CYL 3-1/2 X 12

358312

OUTER WING

701361

Page 67

3. Assembly

67

ROW UNIT-FRAME MOUNT

CAST CORNER CAP

240694

BLT HEX 3/4-10NC X 2-1/2 8YZ

89389

BASE SHANK ASSEMBLY(ROW UNIT)

357582

NUT 2POSLK 3/4-10NC 5Z

88356

701382A

Page 68

ROW UNIT PLACEMENT-MAINFRAME

68

3. Assembly

30.00

32.5030.00

60.00 60.00

7.86

30.0030.00

60.00 60.00

90.00

90.0090.00

701382

Page 69

3. Assembly

69

ROW UNIT PLACEMENT-51FT INNER WING

2.52

2.46

30.00

60.00

90.00

30.00

60.00

90.00

Page 70

ROW UNIT PLACEMENT-61FT INNER WING

70

3. Assembly

2.52

2.47

30.00

60.00

90.00

30.00

60.00

90.00

120.00

701388

Page 71

3. Assembly

71

ROW UNIT PLACEMENT-51FT OUTER WING

3.00

2.99

30.00

60.00

30.00

60.00

701389

Page 72

ROW UNIT PLACEMENT-61FT OUTER WING

72

3. Assembly

2.96

3.03

30.00

60.00

90.00

120.00

30.00

60.00

90.00

701390

Page 73

3. Assembly

73

HOSE CHANNEL-MAINFRAME

NUT HEX 3/8-16NC 5Z

88103

WSHR FLAT 3/8(7/16 X 1ACT)

88282

FORMED CHANNELCOVER-MF END 29.25"

358664

FORMED CHANNELCOVER MF 81.00"

358662

FORMED CHANNELMF 81.00"

358658

BLT CRG 3/8-16NC X 6

5Z 89494

NUT HEX 1/4-20NC

5Z 88172

WSHR HLK 1/4ID(5/16ACT)

88262

FORMED CHANNELMF 31.00"

358661

BLT CRG 1/4-20NC X

3/4 SHT NK 5Z

88994

FORMED CHANNELMAINFRAME MIDDLE 75.00"

358659

FORMED CHANNELCOVER MF MIDDLE 103.06"

358663

FORMED CHANNELMF 31.00"

358661

701391

Page 74

HOSE CHANNEL-INNER WING

74

NUT HEX 3/8-16NC 5Z

88103

BLT CRG 3/8-16NC X 6

5Z 89494

WSHR FLAT 3/8(7/16 X 1ACT)

88282

3. Assembly

FORMED CHANNELCOVER INNER WING 107.50"

358655

FORMED CHANNELINNER WING 107.50"

358654

701392

Page 75

3. Assembly

75

HOSE CHANNEL-FRONT HITCH

NUT HEX 3/8-16NC 5Z

88103

WSHR FLAT 3/8(7/16 X 1ACT)

88282

FORMED CHANNELCOVER FRONT HITCH 88.00"

358657

FORMED CHANNELFRONT HITCH 88.00"

358656

BLT CRG 3/8-16NC X 6

5Z 89494

701395

BLT CRG 3/8-16NC X 1 (88467) 5Z

89009

Page 76

DOWN PRESSURE VALVE

76

3. Assembly

LEFT CYLINDER EXTEND

LEFT CYLINDER RETRACT

LEFT SIDE VIEW

FRONT VIEW

RIGHT CYLINDER EXTEND

RIGHT CYLINDER RETRACT

RIGHT SIDE VIEW

PRESSURE TRANSDUCER

LOCATION

DOWN PRESSURE

TRACTOR EXTEND

BOTTOM VIEW

DOWN PRESSURE

TRACTOR RETRACT

358905

Page 77

3. Assembly

77

TRANSDUCER-PRESSURE 0-3000 4MB

A35598

DOWN PRESSURE VALVE MOUNT

ELB10MB-8MJ-90

A35598

DOWN PRESSURE REGEN VALVE

PS-00505-VVA-01

A35598

BLT HEX 3/8-16NC X 1 5Z

89034

NUT 2POSLK 5/8-11NC 5Z

88369

WSHR HLK 3/8ID

88362

FORMED PLATE-DP

COVER 358907

VALVE

FORMED PLATE-DP VALVE MOUNT

358908

BLT-U 5/8-11NC X 4 X 7-1/4

89097

701393

Page 78

HYDRAULIC HOSE ASSEMBLY SEQUENCE

78

3. Assembly

1) BOTTOM - HYDRAULIC FOLD HOSES

2) LIFT HYDRAULIC HOSES

3) DOWN PRESSURE HYDRAULIC HOSES

4) ELECTRICAL HARNESSES-DOWN PRESSURE & LIGHTS

5) TOP - HYDRAULIC HOSES - FRONT PULL HITCH TO REAR HITCH

DISCONNECT

Page 79

3. Assembly

79

51FT LIFT HYDRAULICS

Page 80