Page 1

MM200

High Speed

Microwave Modem

Installation and Operation Manual

TM086 - Rev. 4.1

Comtech EF Data • 2114 W 7th St. • Tempe, AZ 85281 • (480) 333-2200 • Fax: (480) 333-2540 • www.comtechefdata.com

Page 2

Page 3

MM200 High-Speed Microwave Modem Warranty Policy

iii

WP

Warranty Policy

Comtech EF Data products are warranted against defects in material and workmanship for a period of two

years from the date of shipment. During the warranty period, Comtech EF Data will, at its option, repair or

replace products that prove to be defective.

For equipment under warranty, the owner is responsible for freight to Comtech EF Data and all related

customs, taxes, tariffs, insurance, etc. Comtech EF Data is responsible for the freight charges only for

return of the equipment from the factory to the owner. Comtech EF Data will return the equipment by the

same method (i.e., Air, Express, Surface) as the equipment was sent to Comtech EF Data.

All equipment returned for warranty repair must have a valid RMA number issued prior to return and be

marked clearly on the return packaging. Comtech EF Data strongly recommends all equipment be returned

in its original packaging.

Comtech EF Data Corporation’s obligations under this warranty are limited to repair or replacement of failed

parts, and the return shipment to the buyer of the repaired or replaced parts.

Limitations of Warranty

The warranty does not apply to any part of a product that has been installed, altered, repaired, or misused

in any way that, in the opinion of Comtech EF Data Corporation, would affect the reliability or detracts from

the performance of any part of the product, or is damaged as the result of use in a way or with equipment

that had not been previously approved by Comtech EF Data Corporation.

The warranty does not apply to any product or parts thereof where the serial number or the serial number of

any of its parts has been altered, defaced, or removed.

The warranty does not cover damage or loss incurred in transportation of the product.

The warranty does not cover replacement or repair necessitated by loss or damage from any cause beyond

the control of Comtech EF Data Corporation.

The warranty does not cover any labor involved in the removal and or reinstallation of warranted equipment

or parts on site, or any labor required to diagnose the necessity for repair or replacement.

The warranty excludes any responsibility by Comtech EF Data Corporation for incidental or consequential

damages arising from the use of the equipment or products, or for any inability to use them either separate

from or in combination with any other equipment or products.

A fixed charge established for each product will be imposed for all equipment returned for warranty repair

where Comtech EF Data Corporation cannot identify the cause of the reported failure.

Exclusive Remedies

Comtech EF Data Corporation’s warranty, as stated is in lieu of all other warranties, expressed, implied, or

statutory, including those of merchantability and fitness for a particular purpose. The buyer shall pass on to

any purchaser, lessee, or other user of Comtech EF Data Corporation’s products, the aforementioned

warranty, and shall indemnify and hold harmless Comtech EF Data Corporation from any claims or liability

of such purchaser, lessee, or user based upon allegations that the buyer, its agents, or employees have

made additional warranties or representations as to product preference or use.

The remedies provided herein are the buyer’s sole and exclusive remedies. Comtech EF Data shall not be

liable for any direct, indirect, special, incidental, or consequential damages, whether based on contract, tort,

or any other legal theory.

Warranty Repair Return Procedure

TM086 - Rev. 4.1

Page 4

Warranty Policy MM200 High-Speed Microwave Modem

iv

Before a warranty repair can be accomplished, a Repair Authorization must be received. It is at this time

that Comtech EF Data will authorize the product or part to be returned to the Comtech EF Data facility or if

field repair will be accomplished. The Repair Authorization may be requested in writing or by calling:

Comtech EF Data Corporation

2114 W 7th Street.

Tempe, Arizona 85281 (USA)

ATTN: Customer Support

Phone: (480) 333-2200

Fax: (480) 333-2540

Any product returned to Comtech EF Data for examination must be sent prepaid via the means of

transportation indicated as acceptable to Comtech EF Data. Return Authorization Number must be clearly

marked on the shipping label. Returned products or parts should be carefully packaged in the original

container, if possible, and unless otherwise indicated, shipped to the above address.

Non-Warranty Repair

When a product is returned for any reason, Customer and its shipping agency shall be responsible for all

damage resulting from improper packing and handling, and for loss in transit, not withstanding any defect or

nonconformity in the product. By returning a product, the owner grants Comtech EF Data permission to

open and disassemble the product as required for evaluation. In all cases, Comtech EF Data has sole

responsibility for determining the cause and nature of failure, and Comtech EF Data’s determination with

regard thereto shall be final.

iv TM086 - Rev. 4.1

Page 5

MM200 High-Speed Microwave Modem Preface

P

Preface

This manual provides installation and operation information for the Radyne RCS20 M:N

Redundancy Switch. This is a technical document intended for use by engineers, technicians,

and operators responsible for the operation and maintenance of the RCS20.

Conventions

Whenever the information within this manual instructs the operator to press a pushbutton switch

or keypad key on the Front Panel, the pushbutton or key label will be shown in "less than" (<) and

"greater than" (>) brackets. For example, the Reset Alarms Pushbutton will be shown as

<RESET ALARMS>, while a command that calls for the entry of a ‘7’ followed by ‘ ENTER’ Key will

be represented as <7,ENTER>.

Cautions and Warnings

A caution icon indicates a hazardous situation that if not avoided, may result in minor or moderate

injury. Caution may also be used to indicate other unsafe practices or risks of property damage.

A warning icon indicates a potentially hazardous situation that if not avoided, could result in death

or serious injury.

A note icon identifies information for the proper operation of your equipment, including helpful

hints, shortcuts, or important reminders.

Trademarks

TM086 - Rev. 4.1 v

Page 6

Preface MM200 High-Speed Microwave Modem

vi

Level

3.3

12-11-01

Revised Electrical Interfaces Section.

Product names mentioned in this manual may be trademarks or registered trademarks of their

respective companies and are hereby acknowledged.

Copyright

2008, Comtech EF Data This manual is proprietary to Comtech EF Data and is intended for the

exclusive use of Comtech EF Data’s customers. No part of this document may in whole or in part,

be copied, reproduced, distributed, translated or reduced to any electronic or magnetic storage

medium without the express written consent of a duly authorized officer of Comtech EF Data

Disclaimer

This manual has been thoroughly reviewed for accuracy. All statements, technical information,

and recommendations contained herein and in any guides or related documents are believed

reliable, but the accuracy and completeness thereof are not guaranteed or warranted, and they

are not intended to be, nor should they be understood to be, representations or warranties

concerning the products described. Comtech EF Data assumes no responsibility for use of any

circuitry other than the circuitry employed in Comtech EF Data systems and equipment.

Furthermore, since Comtech EF Data is constantly improving its products, reserves the right to

make changes in the specifications of products, or in this manual at any time without notice and

without obligation to notify any person of such changes.

Record of Revisions

Revision

Date Reason for Change

1.0 6-16-00 New Release.

2.0 4-19-01 Revised and reformatted manual.

3.0 5-4-01 Revised User Interfaces Section.

3.1 6-4-01 Revised Electrical Interfaces Section.

3.2 10-9-01 Revised the Detailed Command Descriptions Section.

3.4 1-8-02 Added MIB.

4.0 3-27-03 Revised and Reformatted Technical Manual.

4.1 12-18-06 Revised and Reformatted Technical Manual

Comments or Suggestions Concerning this Ma nual

Comments or suggestions regarding the content and design of this manual are appreciated.

To submit comments, please contact the Comtech EF Data Corporation Customer Service

Department.

TM086 - Rev. 4.1

Page 7

MM200 High-Speed Microwave Modem Table of Contents

ToC

Table of Contents

Warranty Policy ............................................................................................................ iii

Preface ........................................................................................................................... v

Conventions ___________________________________________________________ v

Cautions and Warning s __________________________________________________ v

Trademarks ___________________________________________________________ v

Copyright ____________________________________________________________ vi

Record of Revisions ____________________________________________________ vi

Comments or Suggestions Concerning this Manual ___________________________ vi

Section 1 - Introduction ............................................................................................. 1-1

1.0 Description ______________________________________________________ 1-1

Section 2 - Installation ............................................................................................... 2-1

2.1 Unpacking _______________________________________________________ 2-1

2.2 Removal and Assembly ____________________________________________ 2-2

2.3 Mounting Considerations ___________________________________________ 2-2

2.4 Modem Checkout _________________________________________________ 2-2

2.4.1 Initial Power-Up _________________________________________________ 2-3

Section 3 - Theory of Operation ................................................................................ 3-1

3.0 Theory of Operation _______________________________________________ 3-1

3.1 Signal Flow ______________________________________________________ 3-1

3.1.1 Interfaces ______________________________________________________ 3-1

3.1.2 Data Mux ______________________________________________________ 3-2

3.1.3 RF Modulators __________________________________________________ 3-3

3.1.4 RF Demodulators ________________________________________________ 3-3

3.1.5 Diversity (Option) ________________________________________________ 3-3

3.2 Start-Up Procedures _______________________________________________ 3-3

3.2.1 Initial Start-up Procedure __________________________________________ 3-3

TM086 - Rev. 4.1 vii

Page 8

Table of Contents MM200 High-Speed Microwave Modem

viii

3.2.2 Sample Setups __________________________________________________ 3-4

3.2.2.1 Transmitting G.703 T3 From Interface Slot 3 (ot her int er faces disabled) ___ 3-4

3.2.2.2 Transmitting STM-1 From Interface Slot 1 (other interfaces disabled) _____ 3-4

3.2.3 Hardware Reset _________________________________________________ 3-4

3.3 Calculating 3 dB Bandwidth of MM200 Modulated Carrier __________________ 3-5

3.4 Input Level ______________________________________________________ 3-5

Section 4 - User Interfaces ....................................................................................... 4-1

4.0 User Interfaces ___________________________________________________ 4-1

4.1 Front Panel User Interface __________________________________________ 4-1

4.1.1 Front Panel LCD Display __________________________________________ 4-2

4.1.2 Cursor Control Arrows ____________________________________________ 4-2

4.1.3 Front Panel Keypad ______________________________________________ 4-2

4.1.4 Front Panel LED Indicators ________________________________________ 4-3

4.1.5 Parameter Setup ________________________________________________ 4-3

4.2 Front Panel Control Screen Menus ____________________________________ 4-4

4.3 Level 2 Menu Screens _____________________________________________ 4-4

4.3.1 Main Menu Screens ______________________________________________ 4-4

4.3.2 MODULATOR (menu) ____________________________________________ 4-5

4.3.3 DEMODULATOR (menu) __________________________________________ 4-6

4.3.4 REPEATER (Menu) ______________________________________________ 4-8

4.3.4 APC (Menu) ____________________________________________________ 4-8

4.3.5 TX INTERFACE (Menu) ___________________________________________ 4-9

4.3.6 RX INTERFACE (Menu) _________________________________________ 4-10

4.4 All Level Menu Screens ___________________________________________ 4-12

4.4.1 Main Menu Screens _____________________________________________ 4-12

4.4.2 MODULATOR (menu) ___________________________________________ 4-12

4.4.3 DEMODULATOR (menu) _________________________________________ 4-13

4.4.4 REPEATER (menu) _____________________________________________ 4-17

4.3.4 APC (Menu) ___________________________________________________ 4-17

4.4.5 TX INTERFACE (Menu) __________________________________________ 4-17

4.4.6 RX INTERFACE (Menu) _________________________________________ 4-20

4.4.7 MONITOR (Menu) ______________________________________________ 4-21

4.4.8 ALARMS (Menu) _______________________________________________ 4-24

4.4.8.1 Active Alarms ________________________________________________ 4-24

TM086 - Rev. 4.1

Page 9

MM200 High-Speed Microwave Modem Table of Contents

ix

4.4.8.2 Latched Alarms _______________________________________________ 4-28

4.4.8.3 Clear Alarms _________________________________________________ 4-28

4.4.9 SYSTEM (Menu) _______________________________________________ 4-28

4.4.10 TEST (Menu) _________________________________________________ 4-30

4.5 Remote Port User Interface ________________________________________ 4-30

4.5.1 Protocol Structure ______________________________________________ 4-31

4.5.2 Protocol Wrapper _______________________________________________ 4-31

4.5.3 Frame Description and Bus Handshaking ____________________________ 4-33

4.5.4 Global Response Operational Codes _______________________________ 4-34

4.5.5 Collision Avoidance _____________________________________________ 4-36

4.5.6 Software Compatibility ___________________________________________ 4-37

4.5.7 RLLP Summary ________________________________________________ 4-38

4.6 Simple Network Management Protocol (SNMP) _________________________ 4-38

4.7 The Management Inform at ion Base ( MIB) _____________________________ 4-38

4.8 Directory _____________________________________________________ 4-38

4.9 Mgmt ______________________________________________________ 4-39

4.10 Experimental _________________________________________________ 4-39

4.11 Private _____________________________________________________ 4-39

4.12 Terminal Port User Interface _______________________________________ 4-40

4.13 Modem Configuration ____________________________________________ 4-40

4.14 Connecting the Terminal __________________________________________ 4-40

4.15 SNMP Option __________________________________________________ 4-42

4.16 Network Configuration ___________________________________________ 4-42

4.17 Terminal Screens _______________________________________________ 4-42

4.18 Logging on and Passwords________________________________________ 4-43

4.19 Exiting SNMP Configuration _______________________________________ 4-44

4.20 Logging On ____________________________________________________ 4-44

4.21 Changing the Logon Password _____________________________________ 4-44

4.22 Logging Of f ____________________________________________________ 4-45

4.23 Changing Your Authentication Password _____________________________ 4-45

4.24 Changing Your Privacy Password __________________________________ 4-45

4.25 Modem MM200 High-Speed Microwave Modem Ethernet Address _________ 4-46

4.26 Modem IP Address ______________________________________________ 4-46

4.27 Server Ethernet Address __________________________________________ 4-46

4.28 Server IP Address _______________________________________________ 4-46

TM086 - Rev. 4.1

Page 10

Table of Contents MM200 High-Speed Microwave Modem

x

4.29 Server Host Name ______________________________________________ 4-46

4.30 Router IP Address _______________________________________________ 4-47

4.31 IP Address Mask ________________________________________________ 4-47

4.32 Boot Mode (Optional) ____________________________________________ 4-47

4.33 Community ____________________________________________________ 4-47

4.34 Trap Type and Trap Hosts ________________________________________ 4-47

4.35 Trace Mode ____________________________________________________ 4-48

4.36 SNMP V1 & 2 Access View________________________________________ 4-48

4.37 Key Generation Mode ____________________________________________ 4-48

4.38 Context Engine ID _______________________________________________ 4-48

4.41 Connect the Ethernet Cable _______________________________________ 4-49

4.42 Ping Program __________________________________________________ 4-50

4.43 SNMP Test ____________________________________________________ 4-51

Section 5 - Electrical Int erfaces ................................................................................ 5-1

5.0 MM200 Connections _______________________________________________ 5-1

5.1 Power __________________________________________________________ 5-1

5.1.1 AC Power ______________________________________________________ 5-1

5.1.2 DC Power ______________________________________________________ 5-1

5.2 Alarm Port _______________________________________________________ 5-2

5.3 Terminal Port (I/O ) ________________________________________________ 5-3

5.4 Remote Port (I/O) _________________________________________________ 5-3

5.4.1 Remote Port Cabling for a St andard Computer RS-232 COM Port _________ 5-4

5.5 Ethernet Interf ace ( I/O) _____________________________________________ 5-5

5.6 TX RF Port (Output ) _______________________________________________ 5-5

5.7 RX RF Port (Input) ________________________________________________ 5-5

5.8 External Reference (Input) __________________________________________ 5-5

5.9 Interface Slots 1 T hr ough 4 _________________________________________ 5-6

5.10 High-Speed G.703/DS3, E3, STS-1 Rear Panel Interface _________________ 5-6

5.10.1 G.703 OUT Female BNC Connector (J15) ___________________________ 5-6

5.10.2 CLK IN Female BNC Connector (J16) _______________________________ 5-6

5.10.3 G.703 IN Female BNC Connector (J17) _____________________________ 5-6

5.11 Overhead/DS0 Audio Rear Panel Interface ____________________________ 5-7

5.11.1 DS01 15-Pin Female HD ‘D’ Sub Connector (J7) ______________________ 5-8

5.11.2 DS02 15-pin female HD ‘D’ sub connector (J8) ________________________ 5-8

TM086 - Rev. 4.1

Page 11

MM200 High-Speed Microwave Modem Table of Contents

xi

5.11.3 DS03 15-pin female HD ‘D’ sub connector (J9) ________________________ 5-8

5.11.4 DS04 15-pin female HD ‘D’ sub connector (J10) _______________________ 5-8

5.11.5 DS05 15-pin female HD ‘D’ sub connector (J11) _______________________ 5-8

5.11.6 DS06 15-pin female HD ‘D’ sub connector (J12) _______________________ 5-8

5.11.7 DS07 15-pin female HD ‘D’ sub connector (J13) _______________________ 5-9

5.11.8 DS08 15-pin female HD ‘D’ sub connector (J14) _______________________ 5-9

5.12 Optical/OC3 STM-1 Rear Panel Interface _____________________________ 5-9

5.12.1 ELEC OUT Female BNC Connector (J15) ___________________________ 5-9

5.12.2 ELEC IN Female BNC Connector (J16)______________________________ 5-9

5.12.3 OPTICAL IN SC Connector (J17) __________________________________ 5-9

5.12.4 Optical Out SC Connector (J18) ___________________________________ 5-9

5.12.5 REF OUT Female BNC Connector (Optional) (J19) ____________________ 5-9

5.12.6 REF IN Female BNC Connector (Optional) (J20) ______________________ 5-9

5.13 ASI Rear Panel Interface _________________________________________ 5-10

5.13.1 ASI OUT Female BNC Connector (J15) ____________________________ 5-10

5.13.2 ASI IN Female BNC Connector (J16) ______________________________ 5-10

5.14 Wayside G.703/ T1, E1 Rear Panel Interface __________________________ 5-10

5.14.1 IN Female BNC Connector (J15) __________________________________ 5-10

5.14.2 OUT Female BNC Connector (J16) ________________________________ 5-11

5.14.3 BALANCED 15-pin female ‘D’ sub connector ________________________ 5-11

5.14.4 CLK OUT (J17) _______________________________________________ 5-11

5.14.5 CLK IN Female BNC Connector (J18) ______________________________ 5-11

5.15 Parallel RS-422/DVB, M2P ________________________________________ 5-11

5.15.1 PARALLEL TX 25-pin female ‘D’ sub connector ( J15) _________________ 5-12

5.15.2 PARALLEL RX 25-pin female ‘D’ sub connector (J16) _________________ 5-13

5.15.3 CLK IN (J17) _________________________________________________ 5-13

5.15.4 CLK IN Female BNC Connector (J18) ______________________________ 5-13

5.16 Parallel LVDS/DVB, M2P _________________________________________ 5-14

5.16.1 PARALLEL TX 25-pin female ‘D’ sub connector ( J15) _________________ 5-14

5.16.2 PARALLEL RX 25-pin female ‘D’ sub connector (J16) _________________ 5-15

5.16.3 CLK IN (J17) _________________________________________________ 5-15

5.16.4 CLK IN Female BNC Connector (J18) ______________________________ 5-16

5.17 SMPTE/310M Rear Panel Interface _________________________________ 5-16

5.17.1 EXT CLK (J15) ________________________________________________ 5-16

5.17.2 SMPTE IN Female BNC Connector (J16) ___________________________ 5-16

TM086 - Rev. 4.1

Page 12

Table of Contents MM200 High-Speed Microwave Modem

xii

Section 6 - Maintenance and Troubleshooting ........................................................ 6-2

6.0 Periodic Maintenance ______________________________________________ 6-2

6.1 Maintenance Philosophy ____________________________________________ 6-2

6.2 Customer Service _________________________________________________ 6-2

6.3 Troubleshooting __________________________________________________ 6-3

Section 7 - Technical Specifications ........................................................................ 7-1

7.0 Introduction ______________________________________________________ 7-1

7.1 Specifications ____________________________________________________ 7-1

7.2 Options _________________________________________________________ 7-1

7.3 Optional Data Interfaces ____________________________________________ 7-2

7.4 Optional Overhead Interfaces ________________________________________ 7-2

Appendix A - Remote RLLP ...................................................................................... A-1

A.1 MM200 Opcode Command Set ______________________________________ A-1

A.2 Modem Command Set _____________________________________________ A-1

A.3 Detailed Command Descriptions _____________________________________ A-4

Appendix B - SNMP MIB ........................................................................................... B-1

Glossary ..................................................................................................................... G-1

TM086 - Rev. 4.1

Page 13

MM200 High-Speed Microwave Modem Introduction

1

Introduction

1.0 Description

The Radyne MM200 Microwave Modem is a high-speed, multi data rate Modulator/Demodulator.

It is a single rack digital modem for point-to-point or point-to-multipoint communication links and is

ideal for microwave link upgrades or retrofits.

The MM200 utilizes a proprietary matrix modulation format that provides maximum bandwidth

efficiency and data rates up to 176 Mbps (200 Mbps optional). Increased performance is

achieved in multi-path or fading environments over conventional QAM modulation.

The MM200 offers a large variety of interfaces such as T3, E3, STS1, DVB SPI, DVB ASI,

OC3/STM-1, T1, E1, E2, 10Base T, and others.

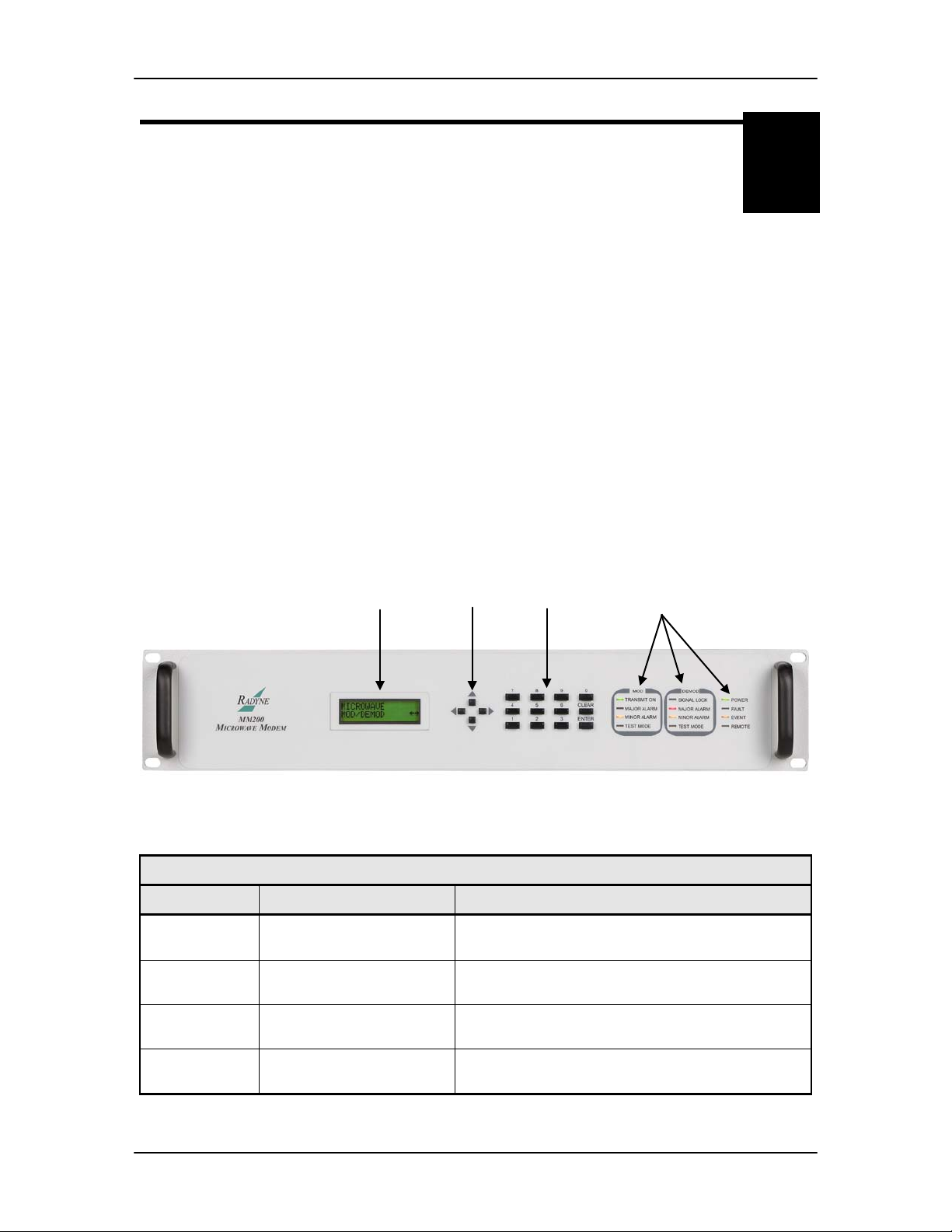

Figure 1-1. MM200 Microwave Modem

TM086 - Rev. 4.1 1-1

Page 14

Introduction MM200 High-Speed Microwave Modem

1-2 TM086 - Rev. 4.1

Page 15

MM200 High-Speed Microwave Modem Installation

2

Installation

2.0 Installation Requirements

The MM200 is designed to be installed within any standard 19-inch equipment cabinet or rack,

and requires 2 rack unit (RU) mounting spaces (3.5 inches) vertically and 19 inches of depth.

Including cabling, a minimum of 20 inches of rack depth is required. The rear panel of the MM200

is designed to have power enter from the left and IF cabling enter from the right when viewed from

the rear of the unit. Data and control cabling can enter from either side although they are closer to

the center. The unit can be placed on a table or suitable surface if required.

There are no user-serviceable parts or configuration settings located

inside the MM200 chassis. There is a pot ential shock haz ard internally at

the power supply module. DO NOT open the MM200

circumstances.

Before initially applying power to the unit, it is a good idea to disconnect

the transmit output from the operating station equipment. This is

especially true if the current MM200 configuration settings are unknown,

where incorrect setting could disrupt exis ting communications traffic.

The MM200 contains a Lithium Battery. DANGER OF EXPLOSION exists if

the battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the manufacturer. Dispose of used

batteries in accordance with manufacturers instructions

chassis under any

2.1 Unpacking

The MM200 Modem was caref ully packaged to avoid dam age and should arrive com plete with the

following items for proper installation:

MM200 Unit

Prime power connection

Installation and Operation Manual

TM086 - Rev. 4.1 2-1

Page 16

Installation MM200 High-Speed Microwave Modem

2.2 Removal and Assembly

If using a knife or cutting blade to open the carton, exercise caution to ensure that the blade does

not extend into the carton, but only cuts the tape holding the carton closed. Carefully unpack the

unit and ensure that all of the above items are in the carton. If the Primary AC power available at

the installation site requires a different power cord/AC connector, then arrangements to receive

the proper device will be necessary before proceeding with the installation.

The MM200 modem is shipped fully assembled and does not require removal of the covers for

any purpose in installation. Should the power cable AC connector be of the wrong type for the

installation, either the cable or the power connector end should be replaced. The power supply

itself is designed for universal application using from 100 to 240 VAC, 50-60 Hz, 1A or 37 – 75

VDC @ 4A.

2.3 Mounting Considerations

When mounted in an equipment rack, adequate ventilation must be provided. The MM200 draws

air in from the left hand side and exhausts from the right rear and side (as viewed from the front).

Do not install the unit in closed locations where this airflow will be restricted. The exhaust air must

be allowed to vent away from the unit and not be allowed to flow back into the air input. The

ambient temperature in the rack should be between 0° and 50° C, and held constant for best

equipment operation. The air available to the rack should be clean and relatively dry

Do not mount the MM200 in an unprotected outdoor location where there is direct contact with

rain, snow, wind or sun. The MM200 is designed for indoor applications only.

The only tools required for rack mounting the MM200

an appropriate screwdriver. Rack mount brackets are an integral part of the cast front bezel of the

unit and are not removable.

Shielded cables with the shield terminated to the conductive backshells are required in order to

meet EMC directives. Cables with insulation flammability ratings of 94 VO or better are required

in order to meet low voltage directives.

is a set of four rack mounting screws and

2.4 Modem Checkout

The following descriptions assume that the MM200 is installed in a suitable location with prime

power and supporting equipment available.

2-2 TM086 - Rev. 4.1

Page 17

MM200 High-Speed Microwave Modem Installation

2.4.1 Initial Power-Up

Before initial power up of the MM200, it is a good idea to disconnect the

transmit output from the operating ground station equipment. This is

especially true if the current modem co nfiguration settings are unknown,

where incorrect setting could disrupt existing communications traffic.

New units from the factory are normally shipped in a default

configuration which includes setting the transmit carrier off.

Turn the unit ‘ON’ by applying power (DC versions), or placing the rear panel switch (above the

power entry connector) to the ‘ON’ position (AC versions). Upon initial and subsequent powerups, the MM200 microprocessor will test itself and several of its components before beginning its

main monitor/control program. These power-up diagnostics show no results if successful.

TM086 - Rev. 4.1 2-3

Page 18

Installation MM200 High-Speed Microwave Modem

2-2 TM086 - Rev. 4.1

Page 19

MM200 High-Speed Microwave Modem Theory of Operation

3

Theory of Operation

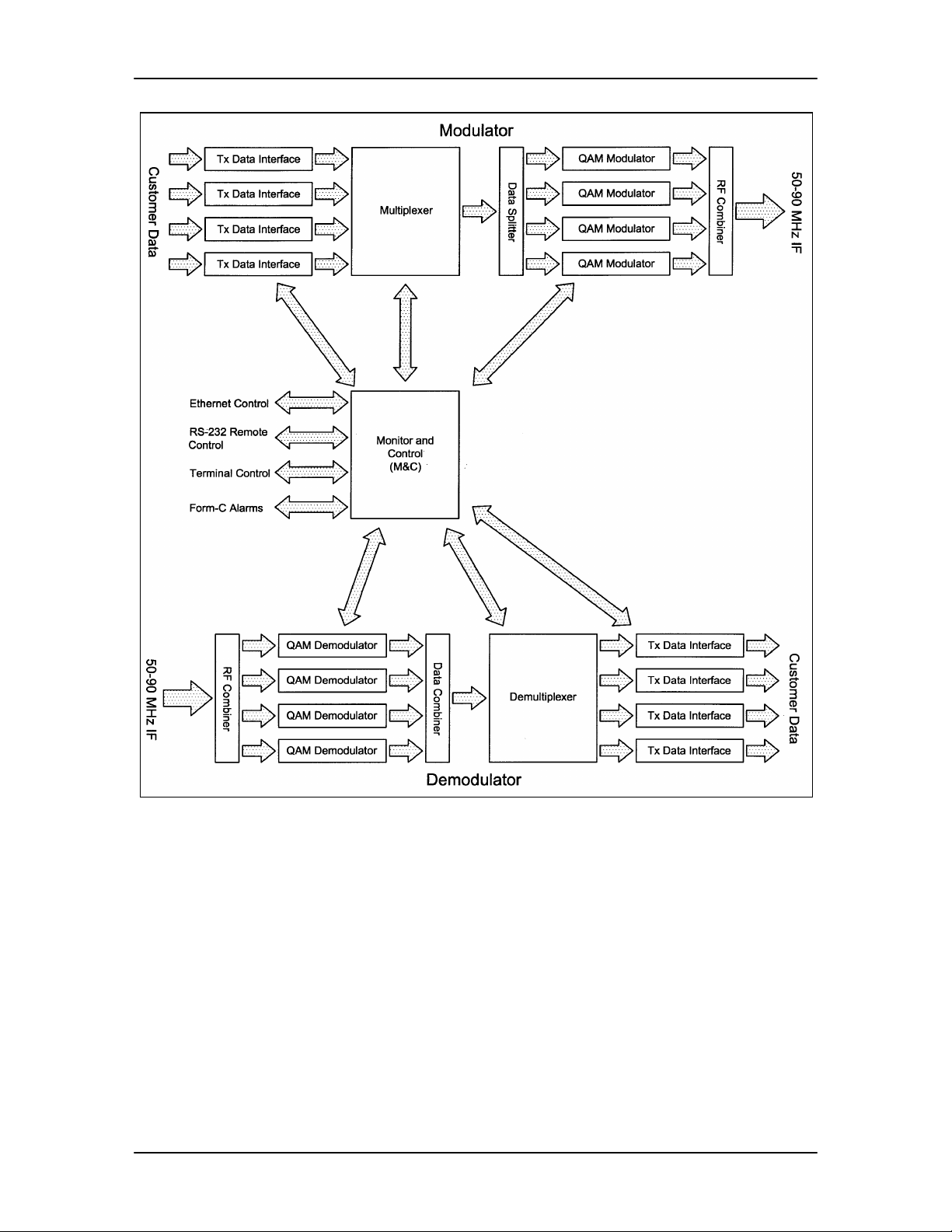

3.0 Theory of Operation

The MM200 Microwave Modem is a highly flexible platform for the transmission of high-speed

data across links such as microwave and cable. The 2 RU-rack mount unit can be supplied in

many different configurations and was designed to be expanded in the field to meet new and

changing operating conditions. Available in Duplex and Simplex Configurations, the unit can be

optioned with up to four industry standard interfaces in any combination, Diversity (requires two

chassis), maximum rates of 50, 100, 150, 175, and 200 Mbps, and world standard AC or DC

prime power.

The fully configured MM200 includes a data multiplexer/demultiplexer for interfacing to multiple

data sources, a modulator, and a demodulator. The MM200 is capable of data rates up to

200 Mbps at any of six different Quadrature Amplitude Modulation (QAM) schemes including

QAM256 (optional). The unique modulation/demodulation scheme uses multiple carriers to slow

the modulated symbol rate to up to four times slower than conventional modems. The lower

symbol rate is inherently more resilient to the multipath environment common to microwave

systems. An extremely powerful equalizer, working at the lower symbol rate, removes multipath

and is coupled with Reed Solomon Noise Reduction System to form a robust, reliable

communications link. Additionally, two receivers can be optioned with diversity cards. The two

chassis are then coupled via a high-speed data link to allow the automatic hitless switching to the

receiver with no errors. This feature can be used for standard path redundancy on long links or to

improve the capacity (via an increase in modulation mode) of an existing link. Refer to Figure 3-1

for operational block diagram.

3.1 Signal Flow

3.1.1 Interfaces

The transmit customer data interface consists of four “slots”. Each slot can accept one of a range

of industry standard interface cards including:

DVB ASI (1 to 160 Mbps)

DVB SPI (1 to 160 Mbps)

G.703 E3/DS3/STS-1

G.703 T1/E1

G.703 E2

OC3/STM-1 optical/electrical

Orderwire, 8 synchronous, 64 Kbps, RS-422 (one channel can be switched to ADPCM)

10Base T Ethernet

Data between interface slots can be Asynchronous and in any combination. Careful attention to

the maximum data rate and its relationship to bandwidth are required for the correct operating

conditions.

Some Interface Cards are capable of multiple standards such as the DS3,E3 or STS-1. These

cards can operate in any one of the standards listed. Changing to another standard simply

requires a change in the front panel configuration.

TM086 - Rev. 4.1 3-1

Page 20

Theory of Operation MM200 High-Speed Microwave Modem

Figure 3-1. MM200 Microwave Modem Block Diagram

3.1.2 Data Muxiplexer

The multiplexer works on a constant output data rate. This data rate is directly related to the

symbol rate used by the modulators. The Symbol Rate is directly related to Bandwidth of the IF

carrier. The output of the multiplexer contains Reed Solomon overhead and mux/demux

overhead. The ratio between multiplexer input data and output data is 184/204. To

accommodate changes in the data rate supplied by the customer and the constant output of the

mux, the gaps are filled with null data that is later removed by the demux. Therefore, the

customer data is completely variable up to the point where the mux overflows. Variable interfaces

like the DVB ASI can take full advantage of this feature.

The single stream output of the mux is sent to a digital splitter that can have between one and

four outputs, which corresponds to the number of RF modulators installed.

3-2 TM086 - Rev. 4.1

Page 21

MM200 High-Speed Microwave Modem Theory of Operation

Data is always evenly divided between the number of channels selected i.e. each RF modulator

runs at the same rate.

3.1.3 RF Modulators

The number of active modulators (up to the maximum number installed in the chassis, from 1 to

4) is determined by front panel selection in which case any unused modulator is “parked” or

turned off. Each modulator is capable of modulating a carrier between 50 and 90 MHz with QAM

4,16,32,64,128 or 256 (optional). The range of symbol rates per modulator is 3.5 to 7 Msps giving

a total range of 3.5 to 28 Msps. The four outputs are combined to a single IF output. Output

power is adjusted by a 1 dB step attenuator.

3.1.4 RF Demodulators

The RF Demodulators mirror the RF Modulators in their specifications. The receive signal is split

four ways each going to an independent demodulator. Again, the number of demodulators (up to

the maximum number installed in the chassis, from 1 to 4) can be set from the front panel. The

Modulator and Demodulator setup must be identical for the signal to pass.

Each demodulator has a powerful digital equalizer to remove multipath and other signal

degradations.

The Demux removes the overhead and sends the appropriate data to the appropriate interface as

identified by its unique PID (Packet Identifier). The Tx interface must match the Rx interface.

3.1.5 Diversity (Option)

When the system requires Diversity such as Space Diversity or Frequency Diversity, the receiving

site must have two independent receive signals. Each of the two MM200 chassis are required to

be optioned with a minimum of identical receivers (number of RF channels) and a diversity card.

Only one chassis needs to be optioned with interfaces if no equipment redundancy is required.

The transmit side of both chassis are completely independent from diversity operation and can

therefore be optioned in any configuration.

Data from the demux is sent to the diversity card where it is buffered and aligned in time with the

signal received from the other diversity card. Both these signals appear at the hitless switch.

Error information from all receivers is sent to the hitless switch driver where a decision is made as

to which stream to output. The output will be error-free providing one of the demodulator chassis

is receiving an error-free signal. If both chassis are receiving errored signals, the output can still

be error-free providing errors occur in different Reed-Solomon packets.

Both diversity cards send and receive data to and from the other unit, so both chassis will output

the best data stream of the two units.

3.2 Start-Up Procedures

3.2.1 Initial Start-up Procedure

1. Turn the unit on.

2. Set Tx Power to ‘–10 dBm’.

3. Set the Demodulator Attenuation to ‘20 dB’.

4. Under the Mod/Demod Test, set PRBS to ‘–2e23M’.

5. Connect IF Out to IF In via a 75Ω Coax Cable.

TM086 - Rev. 4.1 3-3

Page 22

Theory of Operation MM200 High-Speed Microwave Modem

6. Modem should lock with SNRs > 32 dB.

3.2.2 Sample Setups

3.2.2.1 Transmitting G.703 T3 From Interface Slot 3 (other interfaces

disabled) Sample Setup

1. In System, User Mode, set to ‘Level 2’.

2. In Modulator, set the frequency to ’70 MHz’.

3. In Tx Interface 3, set Control to ‘Enable’ (ensure all other interfaces are disabled).

4. Set Interface to ‘T3’.

5. Set Data Inv to ‘Norm’.

6. Set Bandwidth in the Modulator Menu to ‘30,000,000’.

7. Set the Demodulator to a frequency of ‘70 MHz’.

8. In Rx Interface 3, set Control to ‘Enable’ (ensure all other interfaces are disabled).

9. Set Interface to ‘T3’.

10. Set Data Inv to ‘Norm’.

11. Set the bandwidth in the Demodulator Menu to ‘30,000,000’.

3.2.2.2 Transmitting STM-1 From Interface Slot 1 (other interfaces

disabled) Sample Setup

1. In System, User Mode, set to ‘Level 2’.

2. In Modulator, set the frequency to ’70 MHz’.

3. In Tx Interface 1, set Control to ‘Enable’ (ensure all other interfaces are disabled).

4. Set Interface to ‘STM-1’.

5. Set Data Inv to ‘Norm’.

6. Set the bandwidth in the Modulator Menu to ‘30,000,000’.

7. Set the Demodulator to a frequency of 70 MHz.

8. In Rx Interface 1, set Control to ‘Enable’ (ensure all other interfaces are disabled).

9. Set Interface to ‘STM-1’.

10. Set Data Inv to ‘Norm’.

11. Set the Bandwidth in the Demodulator Menu to ‘30,000,000’.

3.2.3 Hardware Reset

3-4 TM086 - Rev. 4.1

Page 23

MM200 High-Speed Microwave Modem Theory of Operation

This section is not yet complete.

3.3 Calculating 3dB Bandwidth of MM200 Modulated Carrier

1. Find the combined interface data rate:

DR

= Interface 1 Data Rate + Interface 2 Data Rate + Interface 3 Data Rate + Interface 4

C

Data Rate

2. Find the Total Data Rate plus R/S mux overhead, and guard band overhead:

DR

= DRC x (204/184) x 1.001

T

3. Find Channel Baud Rate:

BR

= DRT /(QAM x NC)

C

Where N

= number of channels (one to four)

C

and QAM = 2 for 4 QAM

4 for 16 QAM

5 for 32 QAM

6 for 64 QAM

7 for 128 QAM

8 for 256 QAM

4. Select Channel Spacing:

C

= from 1.1 to 1.5 times channel baud rate.

S

This number is usually 1.25 but may be set anywhere within the range of 1.1 to 1.5.

5. Total 3 dB bandwidth = BR

x CS x (NC – 1) + BR

C

C

3.4 Input Level

Each IF channel has an independent dynamic range of 15 - 20 dB. This allows greater

performance during frequency selective fades. For normal operation, the MM200 was designed

to work with radios that have automatic gain control (AGC). The radio AGC will generally use the

average power of all the IF channels to set its power unlike the MM200 that independently AGCs

on each IF channel. When setting up the input level to the MM200, use the following procedure.

1. If the Radio has a IF output level setting, adjust to the manufactures optimum point. If

there is none, set between 0 and –10 dBm.

2. Verify that the input to the radio is not experiencing frequency selective fading or a deep

flat fade.

3. Set the MM200 Demodulator attenuator (in the Demod menu) so that the AGC level

display reads approximately 340 (in the Monitor, Demodulator Menu). When multiple IF

channels exist there will be differences in AGC from channel to channel. These should

only be of concern if any channel exceeds 300 or is lower than 400. The AGC display

displays the value the M&C has assigned to the channel.

This display is un-calibrated and has a useful range of approximately 300 to 655. The number is

inversely proportional to the incoming signal (a higher number indicates a lower incoming signal).

TM086 - Rev. 4.1 3-5

Page 24

Theory of Operation MM200 High-Speed Microwave Modem

3-6 TM086 - Rev. 4.1

Page 25

MM200 High-Speed Microwave Modem User Interfaces

4

User Interfaces

4.0 User Interfaces

There are four user interfaces available for the MM200. These are:

Front Panel Control.

Command Interface Control.

Terminal Interface

Ethernet SNMP

Any of these methods may be used separately or together to monitor and control the MM200.

Each of these interfaces and their respective methods are discussed separately below.

4.1 Front Panel User Interface

The front panel of the MM200 allows for complete monitor and control (M&C) of all parameters

and functions via a keypad, LCD display and status LEDs.

The front panel layout is shown in Figure 4−1, showing the location and labeling of the front panel.

The front panel is divided into four functional areas: the Front Panel LCD Display, the Cursor

Control Arrows, the Numeric Keypad, and the Front Panel LED Indicators, each described below

in Table 4-1.

Figure 4-1. MM200 Front Panel Controls and Indicators

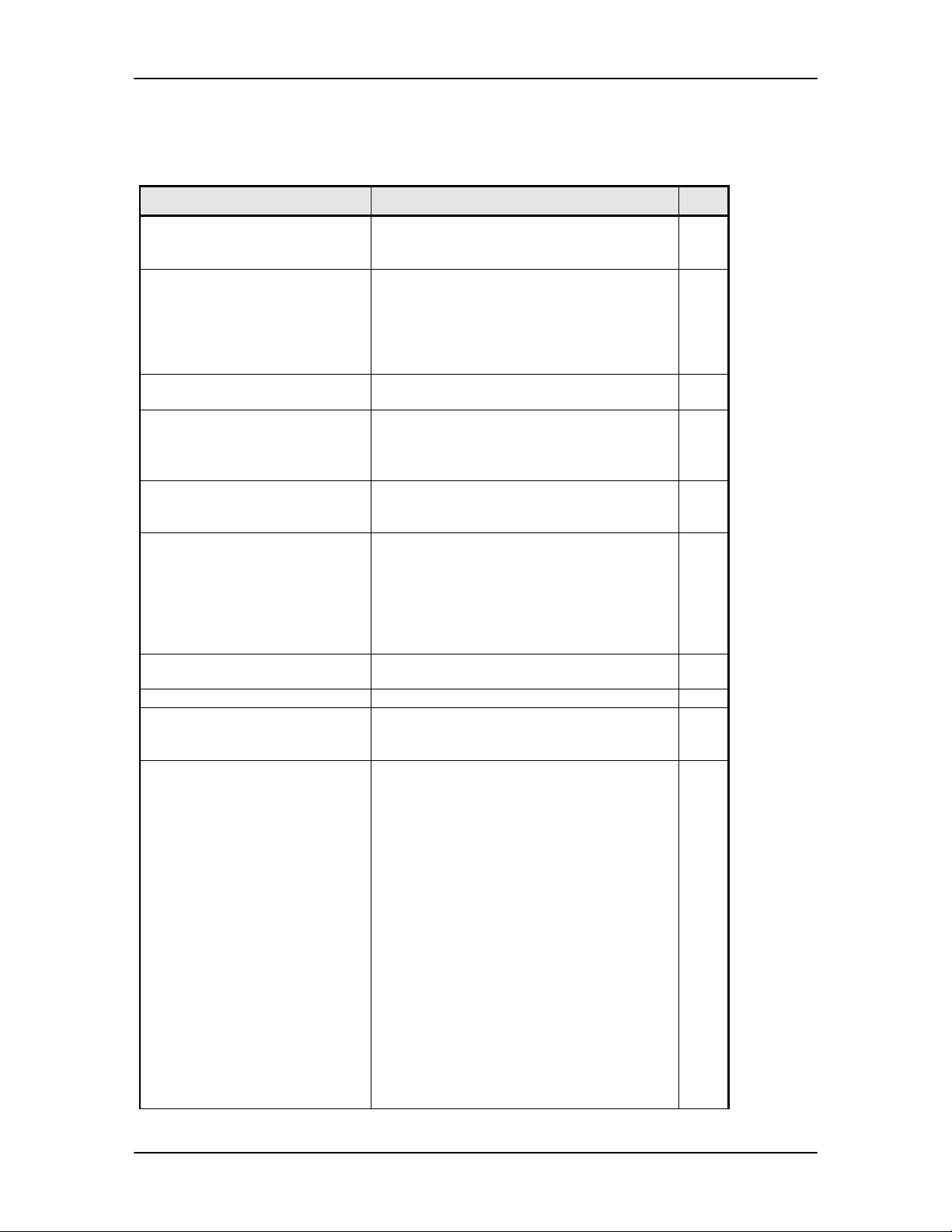

Table 4-1

Item No. Description Function

1 Front Panel LCD Display Displays MM200 Operating parameters and

Configuration data.

2 Cursor Control Arrows Controls the up, down, left, and right movement

of the cursor in the Front Panel LCD Display.

3 Numeric Keypad Allows entry of numeric data, and the Clear and

Enter function keys.

4 Front Panel LED

Indicators

TM086 - Rev. 4.1 4-1

Refer to Section 4.1.2 for an itemized description

of these LEDs.

Page 26

User Interfaces MM200 High-Speed Microwave Modem

↑ ↓ ← →

←

→

4.1.1 Front Panel LCD Display

The front panel display is a 2 line by 16-character LCD display. The display is lighted and the

brightness can be set to increase when the front panel is currently in use. The LCD display

automatically dims after a period of inactivity. The display has two distinct areas showing current

information. The upper area shows the current parameter being monitored, such as ‘Frequency’

or ‘Data Rate’. The lower line shows the current value of that parameter. The LCD display is a

single entry window into the large matrix of parameters that can be monitored and set from the

front panel.

4.1.2 Cursor Control Arrows

The ‘Cursor’ or ’Arrow’ Keys (↑), (↓), (→), (←), are used to navigate the parameter currently being

monitored or controlled. Table 4-2 describes the key functions available at the front panel.

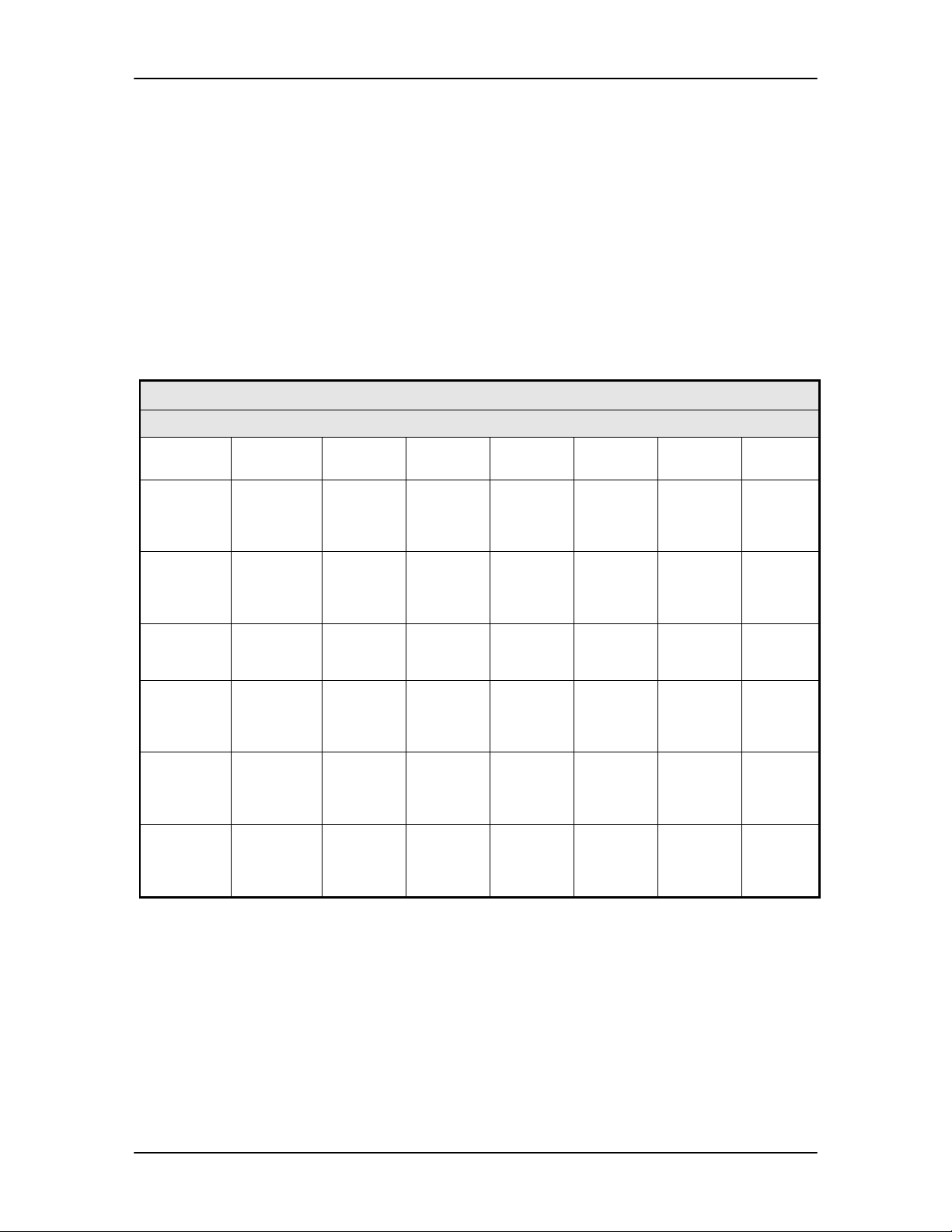

Table 4-2.

Edit Mode Key Functions (Front Panel Only)

Parameter

Type

Fixed Point

Decimal

Unsigned

Hexadecimal

Enumerated N/A Previous

Date/ Time Changes Digit

IP Address Changes Digit Increments

Text Strings Changes

0 – 9

Changes Digit Toggles ±

Changes Digit Increments

Character

(If Signed)

Digit Value

Value in

List

N/A N/A Moves

Digit Value

Increments

Character

Value

Toggles ±

(If Signed)

Decrements

Digit Value

Next

Value in

List

Decrements

Digit Value

Decrements

Character

Value

Moves

Cursor 1

Position

Left

Moves

Cursor 1

Position

Left

N/A N/A N/A N/A

Cursor 1

Position

Left

Moves

Cursor 1

Position

Left

Moves

Cursor 1

Position

Left

Moves

Cursor 1

Position

Right

Moves

Cursor 1

Position

Right

Moves

Cursor 1

Position

Right

Moves

Cursor 1

Position

Right

Moves

Cursor 1

Position

Right

‘Clear’ &

N/A N/A

N/A N/A

N/A N/A

N/A N/A

Clears to

Left of

Cursor

Inclusive

Clears to

Inclusive

‘Clear’ &

Right of

Cursor

4.1.3 Front Panel Keypad

The Front Panel Keypad consists of a 10-key numeric entry with two addi tional keys for the ‘Enter’

and ‘Clear’ functions. Table 4-2 describes the key functions available at the front panel.

4-2 TM086 - Rev. 4.1

Page 27

MM200 High-Speed Microwave Modem User Interfaces

4.1.4 Front Panel LED Indica tors

There are 12 LEDs on the MM200 front panel to indicate the status of the MM200’s operation

(refer to Table 4-3). The LED colors maintain a consistent meaning. Green signifies that the

indication is appropriate for normal operation, Yellow means that there is a condition not proper

for normal operation, and Red indicates a fault condition that will result in lost communications.

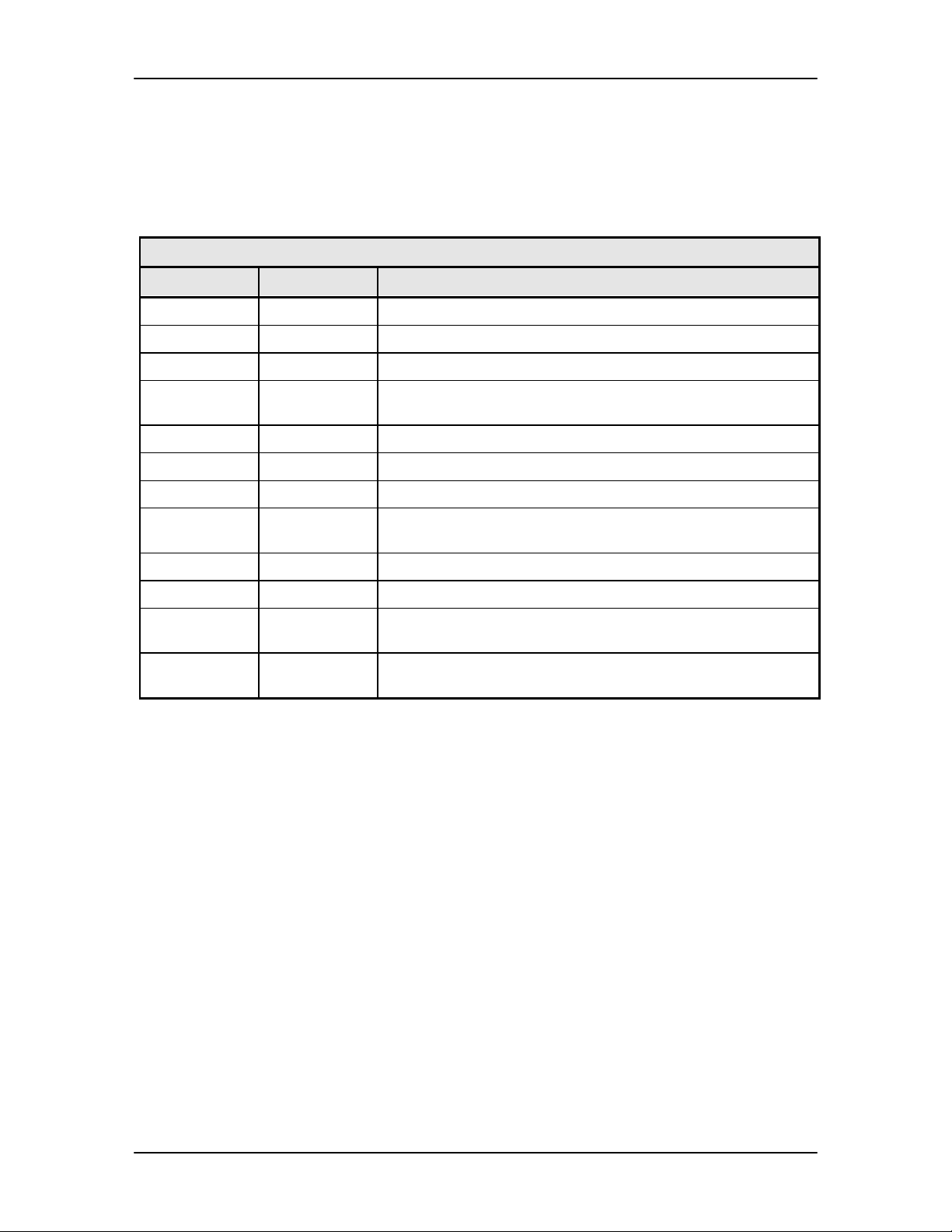

Table 4-3

LED Color Function

Transmit On Green Indicates the MM200 Transmitter is turned on.

Major Alarm Red Indicates that the transmit direction has failed, losing traffic.

Minor Alarm Yellow Indicates a transmit warning condition exists.

Test Mode Yellow Indicates the modulator is involved in a current test mode

activity.

Signal Lock Green Indicates the modem has received a signal and is locked

Major Alarm Red Receive direction failed.

Minor Alarm Yellow Receive learning condition.

Test Mode Yellow Indicates the modem is involved in a current test mode

activity.

Power Green Indicates the MM200 unit is currently powered-up.

Fault Red Indicates a general equipment fault.

Event Yellow Indicates that a new event has been logged into the Event

Buffer.

Remote Green Indicates that the unit is set to respond to the remote control

or terminal input.

4.1.5 Parameter Setup

Use the four arrow keys, to navigate the menu tree and select the parameter to be set. After

arriving at a parameter that needs to be modified, depress <ENTER>. The first space of the

modifiable parameter highlights (blinks) and is ready for a new parameter to be entered. After

entering the new parameter using the keypad, depress <ENTER> to lock in the new parameter. If

a change needs to be made prior to pressing <ENTER>, depress <CLEAR> and the display

defaults back to the original parameter. Depress <ENTER> again and re-enter the new

parameters followed by <ENTER>.

Following a valid input, the MM200 will place the new setting into the nonvolatile EEPROM making

it available immediately and available the next time the unit is powered-up.

TM086 - Rev. 4.1 4-3

Page 28

User Interfaces MM200 High-Speed Microwave Modem

4.2 Front Panel Control Screen Me nus

The Front Panel Control Screen Menus are listed below. The MM200 Microwave Modem may be

operated in three different levels:

Level 0 - is for specialized factory configurations. Every screen is available including

those used for factory calibration and diagnostics.

Level 1 – includes those screens necessary for field maintenance.

Level 2 – is the default setting and is shipped from the factory in this mode. The screens

are available that provide the quickest form of setup and use.

Note: Screens Menus are listed below by level (L0, L1, and L2) and may be Read/Write

(RW) or Read Only (RO).

4.3 Level 2 Menu Screens

Level 2 menus screens allow for the quickest operation and system setup.

4.3.1 Main Menu Screens

Main Menu Screens (one of which is a Title Screen) are listed below:

MM-200 MODULATOR Title Screen:

Not a modifiable screen.

MODULATOR (menu):

DEMODULATOR (menu):

REPEATER (menu):

APC (menu):

TX INTERFACE (menu):

RX INTERFACE (menu):

MONITOR (menu):

ALARMS (menu):

SYSTEM (menu):

TEST (menu):

4-4 TM086 - Rev. 4.1

Page 29

MM200 High-Speed Microwave Modem User Interfaces

FREQUENCY (Hz)

{50 – 90 MHz}

Frequency Control is set to ‘User’.

RW

CHANNELS

{Auto, 1 - 4}

better bandwidth efficiency.

RW

Controls the total Symbol Rate.

RO

required bandwidth.

RO

BANDWIDTH (Hz)

Enters the 3 dB bandwidth of the

dB bandwidth.

RW

UTILIZATION (%) *

Displays the percentage of the data being

channels).

RO

MAX PAYLOAD (Hz)

Displays the maximum total data rate that

is useable for the current settings.

RO

SPECTRUM

{Normal, Inverted}

through the radio, try these settings.

RW

Sets the IF Output Power in 1 dB steps.

RW

Forces the Carrier to Off or On.

RW

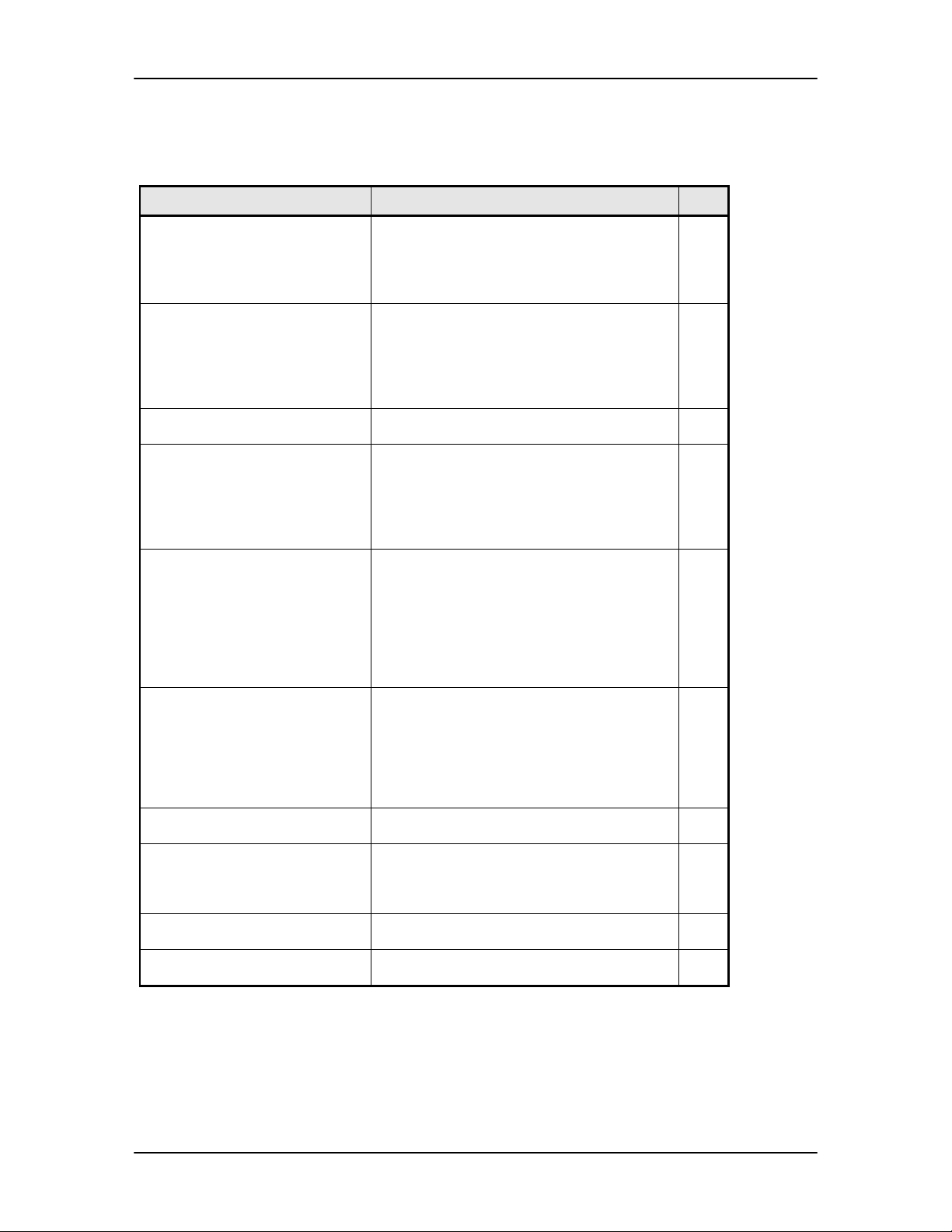

4.3.2 MODULATOR (menu) *

The Modulator Menu Screens are listed below:

Screen Name Selections and Des criptions L2

Controls the current center band of the

operating frequency width, or the

individual channel frequency if the System

Controls the number of channel cards

where 0 = auto, and 1 – 4 = the number of

cards. Increase this number for better

performance. Lower this number for

SYMB RATE (SPS) {3.5 – 28 Msps}

MODULATION {QAM4, QAM16, QAM32, QAM64,

QAM128, QAM256}

Displays the current Modulation Scheme.

Performance is increased by using the

lowest QAM Mode possible for the

modulated IF Output. When the radio

must meet a particular spectral mask, set

this number to something below the

masks 3 dB points (i.e. 5% less). For best

performance, do not allow the MM200s

bandwidth to be greater than the radios 1

transferred that is being used by the

selected interfaces. Must be less than

100% (Maximize this number for best

bandwidth efficiency by lowering the

symbol rate, QAM Mode, or the number of

Used for inverting the spectrum. If the

unit cannot lock to the signal after passing

TX POWER {0 to –25 dBm}

TX ENABLE {Off, On}

TM086 - Rev. 4.1 4-5

Page 30

User Interfaces MM200 High-Speed Microwave Modem

FREQUENCY (Hz)

{50 – 90 MHz}

operating frequency width.

RW

CHANNELS

{Auto, 1 – 4, Debug}

better bandwidth efficiency.

RW

Controls the total Symbol Rate.

RO

Scheme.

RO

BANDWIDTH (Hz)

Displays the frequency difference between

and the lowest channel’s lower 3-dB point.

RW

UTILIZATION (%)

Displays the percentage of the data being

channels.

RO

Displays the maximum total data rate that

is useable for the current settings.

RO

SPECTRUM

{Normal, Inverted}

RW

ATTENUATION

{0 - 31}

in 1 dB steps.

RW

ACQUISITION (men u ):

The Demodulator Acquisition Frequency

2. Continue to try to acquire for the length

4.3.3 DEMODULATOR (menu)

The Demodulator Menu Screens are listed below:

Screen Name Selections and Des criptions L2

Displays the current center band of the

Controls the number of channel cards

where 0 = auto, and 1 – 4 = the number of

cards. Increase this number for better

performance. Lower this number for

SYMB RATE (SPS) {3.5 – 28 Msps}

DEMODULATION {QAM4, QAM16, QAM32, QAM64,

QAM128, QAM256}

Displays the current Demodulation

the highest channel’s upper 3-dB point

MAX PAYLOAD (Hz)

transferred that is being used by the

selected interfaces. Must be less than

100%. Maximize this number for best

bandwidth efficiency by lowering the

symbol rate, QAM Mode, or the number of

Sets the Demodulator Input IF Attenuator

range can be set by the user. This is

required at higher QAM rates when using

radios with significant frequency drift. As

QAM rates increase, the ability of the

receiver to acquire to a signal that is offset

from the programmed demodulator

frequency is reduced. At QAM256 the

acquisition window can be as low as ± 50

kHz. Yet at QAM4, the window can be

over ± 1 MHz. This range can be further

reduced by noise or degraded receive

signals.

When trying to acquire a signal, the

MM200 follows this procedure:

1. Try to acquire at the Demodulator

Programmed Frequency.

4-6 TM086 - Rev. 4.1

Page 31

MM200 High-Speed Microwave Modem User Interfaces

of time set in ACQ DELAY (sec).

DIVERSITY (menu):

MODE

Diversity

{Disable, Auto, Force A, Force B}

ACQ CONTROL

ACQ BW (kHz)

ACQ DELAY (sec)

REACQ DELAY (sec)

ACQ STEP (kHz)

TRACKING STEP (Hz)

3. Step the Demodulator frequency up

one step size programmed in ACQ

STEP (KHz).

4. Repeat Steps 1 through 3 until the

Demodulator Frequency exceeds the +

side of the ACQ BW.

5. Set the Demodulator to the negative

side of ACQ BW.

6. Repeat until demodulator acquires.

Once acquired, the demodulator will

have an offset between the frequency

at which the demodulator is set and the

incoming signal frequency. This is due

to demodulator frequency acquisition

window and radio drift. This can cause

degraded performance and, in the case

of radio drift, possible loss of lock. To

overcome this, once acquired, the

demodulator reduces this offset to 0 Hz

by slowly incrementing/decrementing

the demodulator frequency. The speed

can be adjusted by adjusting the

TRACK STEP (Hz). It is suggested

that this parameter normally be set to

10 Hz.

{Off, Acquire}

Always set to Acquire.

{50 KHz – 400 kHz}

Sets the ± acquisition bandwidth. There is

a tradeoff between this number and

acquisition speed.

{10 – 255 sec}

Sets the time that the demodulator stays

at a frequency before trying the next step.

{10 – 255 sec}

Sets the time that the demodulator

remains at frequency after it first loses

lock.

{10 – 100 kHz}

Sets the frequency step size the

demodulator will take when trying to

acquire.

{10 – 100 Hz}

Sets the step size that the demodulator

will use to remove the frequency error of a

locked signal. Normally set to 10 Hz.

RW

RW

RW

RW

RW

RW

TM086 - Rev. 4.1 4-7

RW

Page 32

User Interfaces MM200 High-Speed Microwave Modem

Controls the diversity mode.

Enables the repeater feature.

RW

TRANSMIT (menu):

APC Transmit settings.

MONITOR (menu):

MUX STATUS

FIFO A STATUS

FIFO B STATUS

CHANNEL A ERR

CHANNEL B ERR

CHANNEL AB ERR

Diversity channel and FIFO status.

{Unused, Channel A, Channel B, Null

Frames}

Specifies the multiplexer status.

{No Flags, Empty, Full}

Specifies the status of FIFO A.

{No Flags, Empty, Full}

Specifies the status of FIFO B.

Displays the Channel A error counter.

Displays the Channel B error counter.

Displays the Channel A and B error

counter.

RO

RO

RO

4.3.4 REPEATER (Menu)

The primary Repeater screen is listed below:

Screen Name Selections and Des criptions L2

MODE {Off, On}

RW

RW

RW

4.3.4 APC (Menu)

The primary APC screen is listed below:

Screen Name Selections and Des criptions L2

XMT CONTROL

MAX TX LEVEL

MIN TX LEVEL

DEF TX LEVEL

STEP SIZE

APC RANGE

APC SPEED

{TXDOWN, TXUP, AUTO}

Controls the local TX level.

Sets the maximum TX power level.

Shows the minimum TX power level.

Sets the default TX power level.

Sets the TX power step size.

Sets the power level range.

Sets the TX power step speed.

RW

RW

RO

RW

RW

RW

RW

4-8 TM086 - Rev. 4.1

Page 33

MM200 High-Speed Microwave Modem User Interfaces

RECEIVE (menu):

APC Receive settings.

Transmit Interface 1

RCV CONTROL

LEVEL (dBm)

HYSTERESIS

MONITOR (menu):

XMT STATUS

RCV STATUS

4.3.5 TX INTERFACE (Menu)

The primary Tx Interface Screens and their sub-menus as listed below:

Screen Name Selections and Descriptions L2

TX INTRFC1 (menu):

CONTROL

DATA RATE (BPS)

INTERFACE

FRAMING

JIT CONTROL

NULL PID

{RXDOWN, RXUP, AUTO}

Controls the remote TX level.

Desired RX power level.

APC Hysteresis.

APC Monitor.

{NOCHANGE, TXDOWN, TXUP}

Displays APC transmit status.

{NOCHANGE, RXDOWN, RXUP}

Displays APC receive status.

{Disable, Enable}

Enables or disables the installed interface.

Dependant upon interface type. For

variable interfaces, this unit must be set

by the user. Will not show up on fixed

rate interfaces.

Dependant upon interface type. Selects

the interface standard for multiple

standard interface card, or displays

standard for fixed interfaces.

{Unframed, MPEG188, MPEG204}

Used for DVB Interface framing selection.

Shows only in DVB Framed Interfaces.

Note: Only appears when s u p p o rted

by the installed interface.

{NORMAL, STAMP2, STAMP3}

Normal or Time-Stamped packets.

{2-Byte Packet ID}

Defines the 2-byte packet ID, program ID

for null padding packets. This number

must match the corresponding receive

demux null PID. This number must be

unique and not be duplicated by an

interface PID or any DVB transport stream

RW

RW

RW

RO

RO

RW

RW

RW

RW

RW

RW

TM086 - Rev. 4.1 4-9

Page 34

User Interfaces MM200 High-Speed Microwave Modem

PIDs on a framed interface.

by the installed interface.

INTRFC1 (menu) for descriptions.

TX INTRFC3 (menu)

Transmit Interface 3. Refer to TX

INTRFC1 (menu) for descriptions.

INTRFC1 (menu) for descriptions.

RX INTRFC1

Receive Interface 1

CLK POLARITY

DATA INVERT

BB LOOP

VOLUME

Note: Only appears when using DVB

Framed Interfaces such as L0I.

{Normal, Inverted}

Sets the polarity of the clock.

Note: Only appears when s u p p o rted

by the installed interface.

{Normal, Inverted}

Sets the polarity of the data.

Note: Only appears when s u p p o rted

by the installed interface.

{Normal, Inverted}

Baseband Loopback. Not yet

implemented, for future expansion.

{0 - 255}

Allows the user to set volume level

(Orderwire only).

Note: Only appears when s u p p o rted

TX INTRFC2 (menu) Transmit Interface 2. Refer to TX

RW

RW

RW

RW

TX INTRFC4 (menu) Transmit Interface 4. Refer to TX

4.3.6 RX INTERFACE (Menu)

The primary Rx Interface Screens and their sub-menus as listed below:

Screen Name Selections and Descriptions L2

CONTROL

DATA RATE (BPS)

INTERFACE

FRAMING

{Disable, Enable}

Enables or disables the installed interface.

Dependant upon interface type. For

variable interfaces, this unit must be set

by the user. Will not show up on fixed

rate interfaces.

Dependant upon interface type. Selects

the interface standard for multiple

standard interface card, or displays

standard for fixed interfaces.

{Unframed, MPEG188, MPEG204}

Used for DVB Interface framing selection.

Shows only in DVB Framed Interfaces.

RW

RW

RW

RW

4-10 TM086 - Rev. 4.1

Page 35

MM200 High-Speed Microwave Modem User Interfaces

Note: Only appears when s u p p o rted

JIT CONTROL

NULL PID

CLK POLARITY

DATA INVERT

TERR LOOP

PRBS

BUFF ENABLE

CLK SOURCE

CLK FREQ

BUFF DEPTH (MS)

by the installed interface.

{INCH, SLOW, MEDIUM, FAST,

STAMP2, STAMP3}

Clock recovery DLL speed, or TimeStamped packets.

{2-Byte Packet ID}

Defines the 2-byte packet ID, program ID

for null padding packets. This number

must match the corresponding receive

demux null PID. This number must be

unique and not be duplicated by an

interface PID or any DVB transport stream

PIDs on a framed interface.

Note: Only appears when using DVB

Framed Interfaces such as L0I.

{Normal, Inverted}

Sets the polarity of the clock.

Note: Only appears when s u p p o rted

by the installed interface.

{Normal, Inverted}

Sets the polarity of the data.

Note: Only appears when s u p p o rted

by the installed interface.

{Normal, Loopback}

Interface Loopback

{Normal, Ones, PAT001, PRBS2047}

Breaks the data path and inserts a pseudo

random sequence into the modulators.

‘None’ is used for normal operation, the

others are for Radyne Inc. Corporation

configuration.

{Disable, Enable}

Not currently implemented, for future

expansion.

{RxClk, Ext BNC, Ext Bal, Internal,

TxCLK}

Not currently implemented, for future

expansion.

{2.048 MHz, 5.0 MHz, 10.0 MHz, Data

Rate}

Not currently implemented, for future

expansion.

Not currently implemented, for future

expansion.

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

TM086 - Rev. 4.1 4-11

Page 36

User Interfaces MM200 High-Speed Microwave Modem

PRESS CLR TO

Centers the buffer.

that support Byte Gap only).

RW

RX INTRFC2

Receive Interface 2. Refer to RX

INTRFC1 (menu) for descriptions.

RX INTRFC3

Receive Interface 3. Refer to RX

INTRFC1 (menu) for descriptions.

RX INTRFC4

Receive Interface 4. Refer to RX

INTRFC1 (menu) for descriptions.

Controls the current center band of the

RW

RW

RW

4.4 All Level Menu Screens

4.4.1 Main Menu Screens

Main Menu Screens (one of which is a Title Screen) are listed below:

4.4.2 MODULATOR (menu) *

The Modulator Menu Screens are listed below:

CENTER BUFFER

VOLUME

BYTE GAP

MM-200 MODULATOR Title Screen:

Not a modifiable screen.

MODULATOR (menu):

DEMODULATOR (menu):

REPEATER (menu):

APC (menu):

TX INTERFACE (menu):

RX INTERFACE (menu):

MONITOR (menu):

ALARMS (menu):

SYSTEM (menu):

TEST (menu):

Screen Name Selections and Des criptions L0 L1 L2

FREQUENCY (Hz) {50 – 90 MHz}

{0 - 255}

Allows the user to set volume level

(Orderwire only).

Note: Only appears when s u p p o rted

by the installed interface.

{0 - 255}

Allows the user to set ASI byte gapping.

Set to 0 for Burst mode. (ASI Interfaces

RW

RW

4-12 TM086 - Rev. 4.1

Page 37

MM200 High-Speed Microwave Modem User Interfaces

operating frequency width, or the

Frequency Control is set to ‘User’.

CHANNELS

{Auto, 1 - 4}

better bandwidth efficiency.

RW

RW

RW

SEPARATION

{100% - 150%}

channels.

RW

RW

DATA RATE (BPS)

{7 – 200 Mbps}

Controls the total Data Rate.

RO

SYMB RATE (SPS)

{3.5 – 28 Msps}

Controls the total Symbol Rate.

RW

RW

RO

MODULATION

{QAM4, QAM16, QAM32, QAM64,

required bandwidth.

RW

RW

RO

BANDWIDTH (Hz)

Enters the 3 dB bandwidth of the

dB bandwidth.

RO

RO

RW

UTILIZATION (%) *

Displays the percentage of the data being

channels).

RO

RO

RO

Displays the maximum total data rate that

is useable for the current settings.

RO

RO

RO

SPECTRUM

{Normal, Inverted}

through the radio, try these settings.

RW

RW

RW

TX POWER

{0 to –25 dBm}

Sets the IF Output Power in 1 dB steps.

RW

RW

RW

TX ENABLE

{Off, On}

Forces the Carrier to Off or On.

RW

RW

RW

individual channel frequency if the System

Controls the number of channel cards

where 0 = auto, and 1 – 4 = the number of

cards. Increase this number for better

performance. Lower this number for

Default 125%. Selects the IF Frequency

Separation between channels expressed

as a percentage of the channel symbol

rate or the symbol rate/number of

QAM128, QAM256}

Displays the current Modulation Scheme.

Performance is increased by using the

lowest QAM Mode possible for the

MAX PAYLOAD (Hz)

4.4.3 DEMODULATOR (menu)

The Demodulator Menu Screens are listed below:

modulated IF Output. When the radio

must meet a particular spectral mask, set

this number to something below the

masks 3 dB points (i.e. 5% less). For best

performance, do not allow the MM200s

bandwidth to be greater than the radios 1

transferred that is being used by the

selected interfaces. Must be less than

100% (Maximize this number for best

bandwidth efficiency by lowering the

symbol rate, QAM Mode, or the number of

Used for inverting the spectrum. If the

unit cannot lock to the signal after passing

TM086 - Rev. 4.1 4-13

Page 38

User Interfaces MM200 High-Speed Microwave Modem

FREQUENCY (Hz)

{50 – 90 MHz}

operating frequency width.

RW

RW

RW

CHANNELS

{Auto, 1 - 4}

better bandwidth efficiency.

RW

RW

RW

cover over the original symbol rate.

RW

RW

DATA RATE (BPS)

{7 – 200 Mbps}

Controls the total Data Rate.

RO

SYMB RATE (SPS)

{3.5 – 28 Msps}

Controls the total Symbol Rate.

RW

RW

RO

DEMODULATION

{QAM4, QAM16, QAM32, QAM64,

Scheme.

RW

RW

RO

BANDWIDTH (Hz)

Displays the frequency difference

3-dB point.

RO

RO

RW

UTILIZATION (%)

Displays the percentage of the data

of channels.

RO

RO

RO

MAX PAYLOAD (Hz)

Displays the maximum total data rate

that is useable for the current settings.

RO

RO

RO

SPECTRUM

{Normal, Inverted}

RW

RW

RW

ATTENUATION

{0 - 31}

in 1 dB steps.

RW

RW

RW

ACQUISITION (men u ):

The Demodulator Acquisition Frequency

Screen Name Selections and Des criptions L0 L1 L2

Displays the current center band of the

Controls the number of channel cards

where 0 = auto, and 1 – 4 = the number

of cards. Increase this number for better

performance. Lower this number for

SEPARATION {100% - 150%}

Selects the IF Frequency Separation in

percent, which is the additional

bandwidth percentage that the carrier will

QAM128, QAM256}

Displays the current Demodulation

4-14 TM086 - Rev. 4.1

between the highest channel’s upper 3dB point and the lowest channel’s lower

being transferred that is being used by

the selected interfaces. Must be less

than 100%. Maximize this number for

best bandwidth efficiency by lowering the

symbol rate, QAM Mode, or the number

Sets the Demodulator Input IF Attenuator

range can be set by the user. This is

required at higher QAM rates when using

radios with significant frequency drift. As

QAM rates increase, the ability of the

receiver to acquire to a signal that is

offset from the programmed demodulator

frequency is reduced. At QAM256 the

acquisition window can be as low as ± 50

kHz. Yet at QAM4, the window can be

over ± 1 MHz. This range can be further

reduced by noise or degraded receive

signals.

When trying to acquire a signal, the

MM200 follows this procedure:

Page 39

MM200 High-Speed Microwave Modem User Interfaces

ACQ CONTROL

ACQ BW (kHz)

ACQ DELAY (sec)

REACQ DELAY (sec)

ACQ STEP (kHz)

1. Try to aquifer at the Demodulator

Programmed Frequency.

2. Continue to try to Acquire for the

length of time set in ACQ DELAY

(sec).

3. Step the Demodulator frequency up

one step size programmed in ACQ

STEP (KHz).

4. Repeat Steps 1 through 3 until the

Demodulator Frequency exceeds the

+ side of the ACQ BW.

5. Set the Demodulator to the negative

side of ACQ BW.

6. Repeat until demodulator acquires.

Once acquired, the demodulator will

have an offset between the frequency

at which the demodulator is set and

the incoming signal frequency. This is

due to demodulator frequency

acquisition window and radio drift.

This can cause degraded

performance and, in the case of radio

drift, possible loss of lock. To

overcome this, once acquired, the

demodulator reduces this offset to 0

Hz by slowly

incrementing/decrementing the

demodulator frequency. The speed

can be adjusted by adjusting the

TRACK STEP (Hz). It is suggested

that this parameter normally be set to

10 Hz.

{Off, Acquire}

Always set to Acquire.

{50 KHz – 400 kHz}

Sets the ± acquisition bandwidth. There

is a tradeoff between this number and

acquisition speed.

{10 – 255 sec}

Sets the time that the demodulator stays

at a frequency before trying the next

step.

{10 – 255 sec}

Sets the time that the demodulator

remains at frequency after it first loses

lock.

{10 – 100 kHz}

Sets the frequency step size the

demodulator will take when trying to

acquire.

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

TM086 - Rev. 4.1 4-15

Page 40

User Interfaces MM200 High-Speed Microwave Modem

TRACKING STEP (Hz)

{10 – 100 Hz}

DIVERSITY (menu):

Diversity

MODE

MONITOR (menu):

MUX STATUS

FIFO A STATUS

FIFO B STATUS

CHANNEL A ERR

CHANNEL B ERR

CHANNEL AB ERR

Sets the step size that the demodulator

will use to remove the frequency error of

a locked signal. Normally set to 10 Hz.

{Disable, Auto, Force A, Force B}

Controls the diversity mode.

Diversity channel and FIFO status.

{Unused, Channel A, Channel B, Null

Frames}

Specifies the multiplexer status.

{No Flags, Empty, Full}

Specifies the status of FIFO A.

{No Flags, Empty, Full}

Specifies the status of FIFO B.

Displays the Channel A error counter.

Displays the Channel B error counter.

Displays the Channel A and B error

counter.

RW RW RW

RW

RW

RW

RW

RO

RO

RO

RW

RW

RW

RW

RO

RO

RO

RW

RW

RW

RW

RO

RO

RO

4-16 TM086 - Rev. 4.1

Page 41

MM200 High-Speed Microwave Modem User Interfaces

MODE

{Off, On}

Enables the repeater feature.

RW

RW

RW

TRANSMIT (menu):

APC Transmit settings.

4.4.4 REPEATER (menu)

The Repeater Menu Screen is listed below:

Screen Name Selections and Des criptions L0 L1 L2

4.3.4 APC (Menu)

The primary APC screen is listed below:

Screen Name Selections and Des criptions L0 L1 L2

XMT CONTROL

MAX TX LEVEL

MIN TX LEVEL

DEF TX LEVEL

STEP SIZE

APC RANGE

APC SPEED

RECEIVE (menu):

RCV CONTROL

LEVEL (dBm)

HYSTERESIS

MONITOR (menu):

XMT STATUS

RCV STATUS

{TXDOWN, TXUP, AUTO}

Controls the local TX level.

Sets the maximum TX power level.

Displays the minimum TX power level.

Sets the default TX power level.

Sets the TX power step size.

Sets the TX APC range

Sets the TX power step speed.

APC Receive settings.

{RXDOWN, RXUP, AUTO}

Controls the remote TX level.

Desired RX power level.

APC Hysteresis.

APC Monitor.

{NOCHANGE, TXDOWN, TXUP}

Displays APC transmit status.

{NOCHANGE, RXDOWN, RXUP}

Displays APC receive status.

RW

RW

RO

RW

RW

RW

RW

RW

RW

RW

RO

RO

RW

RW

RO

RW

RW

RW

RW

RW

RW

RW

RO

RO

RW

RW

RO

RW

RW

RW

RW

RW

RW

RW

RO

RO

4.4.5 TX INTERFACE (Menu)

TM086 - Rev. 4.1 4-17

Page 42

User Interfaces MM200 High-Speed Microwave Modem

TX INTRFC1 (menu):

Transmit Interface 1

Baseband Loopback. Not yet

The primary Tx Interface Screens and their sub-menus as listed below:

Screen Name Selections and Des criptions L0 L1 L2

CONTROL

DATA RATE (BPS)

INTERFACE

FRAMING

JIT CONTROL

NULL PID

PID

CLK POLARITY

DATA INVERT

BB LOOP

{Disable, Enable}

Enables or disables the installed interface.

Dependant upon interface type. For

variable interfaces, this unit must be set

by the user. Will not show up on fixed

rate interfaces.

Dependant upon interface type. Selects

the interface standard for multiple

standard interface card, or displays

standard for fixed interfaces.

{Unframed, MPEG188, MPEG204}

Used for DVB Interface framing selection.

Shows only in DVB Framed Interfaces.

Note: Only appears when s u p p o rted

by the installed interface.

{NORMAL, STAMP2, STAMP3}

Normal or Time-Stamped packets.

{2-Byte Packet ID}

Defines the 2-byte packet ID, program ID

for null padding packets. This number

must match the corresponding receive

demux null PID. This number must be

unique and not be duplicated by an

interface PID or any DVB transport stream

PIDs on a framed interface.

Note: Only appears when using DVB

Framed Interfaces such as L0I.

Interface Packet ID. This number must

match the corresponding interface at the

Rx site. This number must be unique and

not duplicated on other Tx interfaces.

{Normal, Inverted}

Sets the polarity of the clock.

Note: Only appears when supported

by the installed interface.

{Normal, Inverted}

Sets the polarity of the data.

{Normal, Inverted}

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

4-18 TM086 - Rev. 4.1

Page 43

MM200 High-Speed Microwave Modem User Interfaces

implemented, for future expansion.

(Orderwire only).

TX INTRFC2 (menu)