Page 1

DT-4500 Series

Down Converters

Installation and Operation Manual

Part Number MN/DT4500.IOM

Revision 1

Page 2

Page 3

Comtech EF Data Documentation Update

Subject:

Date:

Document:

Part Number:

Collating Instructions:

Comments:

Add paragraph A.1.1 to read:

Change Specifics:

Added A.1.1 Configure Mute Mode

December 16, 2005

DT-4500 Series, Down Converters, Installation and Operation

Manual, Revision 1, dated June 15, 2005

MN/DT4500.EA1

Attach this page to page A-1

Errata A

A.1.1 Configure Mute Mode

Turns the mute mode ON or OFF. When mute mode is OFF (default), the unit will mute

upon changing RF frequency. When mute mode is ON, the unit will remain whatever its

mute state upon changing RF frequency.

Command Details

Config. Mute Mode: <DEV/CMM_xxx'cr' xxx = ON or OFF

Confirmation: >DEV/CMM_xxx'cr''lf']

Mute Mode Status: <DEV/CMM_'cr'

Confirmation: >DEV/CMM_xxx'cr''lf']

Filename: T_ERRATA 1

Page 4

Comtech EF Data Documentation Update

Subject:

Date:

Document:

Part Number:

Collating Instructions:

Comments:

Add paragraph A.1.1.1 to read:

Change Specifics:

Added A.1.1.1 Packed Configuration Status

December 16, 2005

DT-4500 Series, Down Converters, Installation and Operation

Manual, Revision 1, dated June 15, 2005

MN/DT4500.EB1

Attach this page to page 41

Errata B

A.1.1.1 Packed Configuration Status

Configuration Status: <DEV/PACRCS_'cr'

Confirmation: >DEV/PACRCS_aaaabbbcdeffgghijkl'cr''lf']

where:

aaaa = # of 125kHz steps above base frequency

bbb = # of 0.25 dB steps above 0.00 dB

c = 1 if Transmitter ON, 0 if OFF, 2 if Cold

d = 1 if unit ONLINE, 0 if OFFLINE

e = 1 if Redundancy ON, else 0

ff = converter # (01-12,BU or 00 if e = 0)

gg = 00 if 'ff' is 00 (redundancy OFF)

gg = chain length (01-12) if 'ff' is BU

gg = XX if 'ff' = 01 - 12

h = A if Auto Mode, M if Manual

I = 1 if Cold Start Enabled, else 0

j = 1 if Auto recovery enabled, else 0

K = 1 if an Ext. Ref is present, else 0

l = 1 if Remote Mode, 0 if Local Mode

Notes: 1

If the converter is 1 kHz step size, this will be the number of 1 kHz steps above the

base frequency. Also, this will be 5 bytes(aaaaa) long for model 4513X converters

with 125 KHz frequency step size. This will be 7 bytes(aaaaaaa) long for all 1KHz

step size converters.

If the converter is 0.1 -dB step size, this will be the number of 0.1 -dB steps above

2

the base frequency

If it is a backup Converter, it is always ‘A’.

3

If it is the primary converter, gg = P1 or P2 (single or dual polarity system.

4

2

3

1

Filename: T_ERRATA 1

Page 5

DT-4500 Series

Down Converters

Installation and Operation Manual

Part Number MN/DT4500.IOM

Comtech EF Data is an ISO

9001 Registered Company

Copyright © Comtech EF Data, 2001. All rights reserved. Printed in the USA.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, 480.333.2200, FAX: 480.333.2161.

Revision 1

June 15, 2005

Page 6

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

CUSTOMER SUPPORT

Contact the Comtech EF Data Customer Support Department for:

Product support or training

Information on upgrading or returning a product

Reporting comments or suggestions concerning manuals

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data Number)

480.333.4357 (Customer Support Desk)

480.333.2161 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@comtechefdata.com

Contact us via the web at www.comtechefdata.com.

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

1. Request a Return Material Authorization (RMA) number from the

Comtech EF Data Customer Support Department.

2. Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

3. To ensure that the product is not damaged during shipping, pack the

product in its original shipping carton/packaging.

4. Ship the product back to Comtech EF Data. (Shipping charges should be

prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. xii.

ii

Page 7

Errata C

Comtech EF Data Documentation Update

Subject:

Date:

Document:

Part Number:

Collating Instructions:

Comments:

Add the attached procedure to System Operation

Change Specifics:

Added Dual IF Rack Mount Converters

August 28, 2006

DT-4500 Series, Down Converters, Installation and Operation

Manual, Revision 1, dated June 15, 2005

MN/DT4500.EC1

Attach this page to page 25

Filename: T_ERRATA 1

Page 8

Dual IF Rack Mount Converters

Comtech EF Data offers converters with the ability to switch the output IF frequency (Downconverters)

and/or the input IF frequency (Upconverters) from 70 MHz to 140 MHz or vice versa. The actual IF

bandwidth is maintained as the standard ± 18 MHz (± 20 MHz) of the 70 MHz configurations.

The software modification required for the implementation of the IF frequency switching are:

1. A front panel command to allow the output IF to switch from 70MHz to 140.

a. The new selection is located in the “Configuration” menu tree. The “normal”

FREQ/ATT/MUT menu is split into two. First menu screen now has “RF FRE= XXXXX

MHz on top line, with “IF FRE= XXX MHz” and “Rx= XXX” on second line. A second

menu screen contains the attenuator setting.

b. Mute behavior after changing the IF frequency is the same as the normal mute behavior

after changing the RF frequency.

2. A new remote command is implemented to accomplish the identical operation as in (1).

a. Command structure similar to the RF frequency selection.

The default is 70 MHz

Command Details

Set IF Frequency: <DEV/IFF_xxx'cr' (where xxx is either 140 or 70 without requiring

leading zero.

Confirmation: >DEV/IFF_ xxx'cr''lf'] (where xxx is either 140 or 70 without requiring

leading zero.

Retrieve Frequency: <DEV/IFF_'cr'

Confirmation: >DEV/IFF_ xxx'cr''lf'] (where xxx is either 140 or 70 without requiring

leading zero.

Mute behavior after changing the IF frequency would be the same as the mute behavior after

changing the RF frequency.

Redundant operation

The customer can not “mix” dual IF converters with standard converters in a redundant system

Filename: T_ERRATA 2

Page 9

Table of Contents

Customer Support......................................................................................................................... ii

FIGURES ......................................................................................................................VII

TABLES.......................................................................................................................VIII

About this Manual ....................................................................................................................... ix

Conventions and References ....................................................................................................... ix

Metric Conversion ....................................................................................................................... ix

Trademarks .................................................................................................................................. ix

EMC Compliance......................................................................................................................... ix

Federal Communications Commission (FCC) ........................................................................... x

Safety Compliance ....................................................................................................................... xi

EN 60950 ....................................................................................................................................... xi

Warranty Policy.......................................................................................................................... xii

CHAPTER 1. INTRODUCTION.................................................................................... 1

1.1 Overview .................................................................................................................................. 1

1.2 Functional Description ........................................................................................................... 2

1.3 Specifications........................................................................................................................... 4

1.4 Physical Configuration ......................................................................................................... 15

1.5 Front Panel Display .............................................................................................................. 16

1.6 Front Panel Test Point Samples........................................................................................... 16

1.7 Prime Power Switch.............................................................................................................. 16

iii

Page 10

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

CHAPTER 2. INSTALLATION................................................................................... 19

2.1 Unpacking and Inspection....................................................................................................19

2.2 Rack Mount Installation....................................................................................................... 19

2.3 Prime Power Connection......................................................................................................19

2.4 Cable Connections ................................................................................................................ 20

2.4.1 Rear Panel Connections ................................................................................................... 20

2.4.2 RS-485/RS-232C Interface (COM 1), Connector J1 ....................................................... 21

2.4.3 High Speed Bus (HSB), Connector J3............................................................................. 22

2.4.4 Summary Fault Output (RELAY), Connector P1............................................................ 22

2.4.5 Cable Connections For Non-Redundant System Operation ............................................ 23

2.4.6 Cable Connections For Redundant System Operation..................................................... 23

CHAPTER 3. SYSTEM OPERATION ........................................................................ 25

3.1 Overview ................................................................................................................................ 25

3.2 Switching Power ON............................................................................................................. 27

3.3 Operation ............................................................................................................................... 27

3.3.1 Converter Commands ...................................................................................................... 35

3.3.2 Configuration Functions Menu........................................................................................ 36

3.3.3 Pre-select Function Menu ................................................................................................ 36

3.3.4 Monitor Status Function Menu ........................................................................................ 37

3.3.5 Current Faults Function Menu......................................................................................... 37

3.3.6 Stored Faults .................................................................................................................... 38

3.3.7 Utility Function Menu...................................................................................................... 39

APPENDIX A. REDUNDANT SYSTEM OPERATION ............................................... 41

A.1 Overview ............................................................................................................................... 41

A.2 Backup Converter................................................................................................................ 42

A.2.1 High Speed Bus (HSB) ................................................................................................... 42

A.2.2 Detachable Modules........................................................................................................ 42

A.3 Redundant Configurations.................................................................................................. 43

A.4 Redundant System Configuration ...................................................................................... 49

A.4.1 Initial Configuration........................................................................................................ 49

A.4.2 Automatic Configuration Verification ............................................................................ 50

A.4.3 Manual Configuration/Verification................................................................................. 52

A.4.4 Offset Adjustment........................................................................................................... 54

iv

Page 11

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

A.4.5 Redundancy Systems - Converter Removal.................................................................... 54

APPENDIX B. REMOTE CONTROL.......................................................................... 57

B.1 General .................................................................................................................................. 57

B.2 Protocol ................................................................................................................................. 58

B.2.1 Transmission Mode......................................................................................................... 58

B.2.2 Baud Rate ........................................................................................................................ 58

B.2.3 Format ............................................................................................................................. 58

B.2.4 Character Set ................................................................................................................... 58

B.2.5 Response Timeout........................................................................................................... 58

B.2.6 Bus Inactivity Requirement............................................................................................. 58

B.3 Access Methods..................................................................................................................... 59

B.3.1 Direct Access................................................................................................................... 59

B.3.2 Indirect Access ................................................................................................................ 59

B.4 Addresses............................................................................................................................... 60

B.4.1 Physical Address ............................................................................................................. 60

B.4.2 Virtual Address ............................................................................................................... 60

B.5 Message Structure................................................................................................................ 61

B.5.1 Start Character................................................................................................................. 61

B.5.2 Device Address ............................................................................................................... 61

B.5.3 Command ........................................................................................................................ 61

B.5.4 Confirmation Response................................................................................................... 61

B.5.5 Error Response ................................................................................................................ 62

B.5.6 End Of Message .............................................................................................................. 62

B.6 Command/Response Pairs................................................................................................... 63

B.6.1 Utility Commands ........................................................................................................... 63

B.6.2 Configuration Commands ............................................................................................... 66

B.6.3 Modes.............................................................................................................................. 69

B.6.4 Status Commands............................................................................................................ 71

B.6.5 Stored Alarm ................................................................................................................... 75

B.7 Error Processing................................................................................................................... 77

B.7.1 General Errors ................................................................................................................. 77

B.7.2 Configuration Errors ....................................................................................................... 77

B.7.3 Mode Errors..................................................................................................................... 77

B.7.4 Time-Outs........................................................................................................................ 77

B.8 Converter Remote Command Summary ........................................................................... 78

v

Page 12

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

APPENDIX C. THEORY OF OPERATION................................................................. 81

C.1 Applications .......................................................................................................................... 81

C.2 RF Signal Conversion .......................................................................................................... 82

C.3 Monitor & Control............................................................................................................... 84

C.4 Installation, Operation and Maintenance.......................................................................... 84

APPENDIX D. MAINTENANCE AND TROUBLESHOOTING ................................... 85

D.1 Overview ............................................................................................................................... 85

D.2 Maintenance Testing............................................................................................................ 86

D.2.1 Test Point Samples.......................................................................................................... 86

D.2.2 Troubleshooting .............................................................................................................. 87

D.2.3 Converter Faults.............................................................................................................. 87

D.2.4 Converter I/O Modules ................................................................................................... 89

D.3 Spares .................................................................................................................................... 89

INDEX ...........................................................................................................................91

vi

Page 13

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

Figures

Figure 1. Front Panel (Model UT-4511 shown) ............................................................................ 2

Figure 2. Rear Panel (shown with RSM Module).......................................................................... 2

Figure 3. Typical Functional Block Diagram (Model DT-4512 shown)....................................... 3

Figure 4. UT-4511 Dimensional Envelope.................................................................................. 14

Figure 5. Physical Configuration - Down Converter................................................................... 15

Figure 6. Cable Interconnect Diagram......................................................................................... 23

Figure 7. Non-Redundant Converter Configuration .................................................................... 24

Figure 8. Non-Redundant Converter Configuration With Receive Switch Module ................... 24

Figure 9. Front Panel (Model DT-4511 shown) .......................................................................... 25

Figure 10. Rear Panel (with RSM Module)................................................................................. 25

Figure 11. Keypad........................................................................................................................ 27

Figure 12. Converter Operating Command Functions................................................................. 28

Figure 13. Configuration Menu Commands - Redundancy OFF. ............................................... 29

Figure 14. Configuration Menu Commands - Redundancy ON, Backup Unit Not Selected ...... 30

Figure 15. Configuration Menu Commands - Redundancy ON and Backup Unit Selected ...... 31

Figure 16. Pre-Select Menu Commands ...................................................................................... 32

Figure 17. Monitor Status Menu Commands............................................................................... 32

Figure 18. Current Faults Menu Commands................................................................................ 33

Figure 19. Stored Faults Menu Commands ................................................................................. 33

Figure 20. Utility Function Menu Commands............................................................................. 34

Figure 21. 1:1 Redundant Configuration .................................................................................... 44

Figure 22. 1:1 Redundant Configuration Diagram ..................................................................... 44

Figure 23. 1:1 Redundant Configuration Diagram ..................................................................... 45

Figure 24. 1:1 Redundant Configuration - Dual Source IF Input................................................ 46

Figure 25 1:1 Redundant Configuration Diagram .................................................................... 46

Figure 26. Dual Source1:N Redundant Configuration with PSM-XX and RSM-XX Installed .. 47

Figure 27. Dual Source 1:N Redundant ...................................................................................... 48

Figure 28. 1:3 Front Panel Displays ............................................................................................ 49

Figure 29. 1:3 System in AUTO Redundant Mode ..................................................................... 50

Figure 30. Converter #1 Being Backed Up.................................................................................. 51

Figure 31. Converter #1 in MANUAL, Others in AUTO............................................................ 52

Figure 32. Forced BU of Converter #1 ........................................................................................ 53

Figure 33. Typical Converter Functional Block Diagram (Model UT-4512 shown).................. 83

Figure 34. Converter Signal and Interconnecting Cable Diagra.................................................. 86

vii

Page 14

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

Tables

Table 1. DT-4503 C-Band Down Converter Specifications.......................................................... 4

Table 2. DT-4503/E C-Band Down Converter Specifications ...................................................... 6

Table 3. DT-4503/X C-Band Down Converter Specifications...................................................... 8

Table 4. DT-451X Ku-Band Down Converter Specifications..................................................... 10

Table 5. DT-4513 and UT-4513/E Ku-Band Down Converter Specifications............................ 12

Table 6. Rear Panel Connectors................................................................................................... 20

Table 7. J1, 2 Wire RS-485 Interface Pin-Out............................................................................. 21

Table 8. J1, 4 Wire RS-485 Interface Pin-Out............................................................................. 21

Table 9. J1, RS-232C Interface Pin-Out ..................................................................................... 21

Table 10. J3, High Speed Bus Connector Pin-Out....................................................................... 22

Table 11. P1, Summary Fault Connector Pin-Out ....................................................................... 22

Table 12. Operating Functions – Front Panel .............................................................................. 26

Table 13. 4500 Series Down Converter Configurations.............................................................. 43

Table 14. Remote Command Summary....................................................................................... 78

viii

Page 15

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

ABOUT THIS MANUAL

This manual provides installation and operation information for the Comtech EF Data

DT4500 Series Down Converters. This is a technical document intended for earth station

engineers, technicians, and operators responsible for the operation and maintenance of

the DT4500 Series Down Converters.

CONVENTIONS AND REFERENCES

CAUTIONS AND WARNINGS

Indicates information critical for proper equipment function.

IMPORTANT

CAUTION

Indicates a hazardous situation that, if not avoided, may result in minor or moderate

injury. CAUTION may also be used to indicate other unsafe practices or risks of

property damage.

Indicates a potentially hazardous situation that, if not avoided, could result in

WARNING

death or serious injury.

METRIC CONVERSION

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

TRADEMARKS

All product names mentioned in this manual may be trademarks or registered trademarks

of their respective companies and are hereby acknowledged.

REPORTING COMMENTS OR SUGGESTIONS CONCERNING THIS MANUAL

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EF Data Customer

Support Department.

EMC COMPLIANCE

This is a Class A product. In a domestic environment, it may cause radio interference that

requires the user to take adequate protection measures.

ix

Page 16

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

EN55022 COMPLIANCE

This equipment meets the radio disturbance characteristic specifications for information

technology equipment as defined in EN55022.

EN50082-1 COMPLIANCE

This equipment meets the electromagnetic compatibility/generic immunity standard as

defined in EN50082-1.

FEDERAL COMMUNICATIONS COMMISSION (FCC)

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio frequency energy. If not installed

and used in accordance with the instruction manual, it may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference; in which case, users are required to correct the interference at their

own expense.

Note: To ensure compliance, properly shielded cables for DATA I/O shall be used. More

specifically, these cables shall be shielded from end to end, ensuring a continuous shield.

x

Page 17

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

SAFETY COMPLIANCE

EN 60950

Applicable testing is routinely performed as a condition of manufacturing on all units to

ensure compliance with safety requirements of EN60950.

This equipment meets the Safety of Information Technology Equipment specification as

defined in EN60950.

LOW VOLTAGE DIRECTIVE (LVD)

The following information is applicable for the European Low Voltage Directive

(EN60950):

<HAR> Type of power cord required for use in the European Community.

!

CAUTION: Double-pole/Neutral Fusing.

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung.

International Symbols:

Symbol Definition Symbol Definition

Alternating Current.

Fuse.

Protective Earth.

Chassis Ground.

Note: For additional symbols, refer to “Cautions” listed earlier in this preface.

xi

Page 18

DT4500 Series Down Converters MN/DT4500.IOM

Preface Revision 1

WARRANTY POLICY

This Comtech EF Data product is warranted against defects in material and workmanship

for a period of two years from the date of shipment. During the warranty period, Comtech

EF Data will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech EF

Data and all related custom, taxes, tariffs, insurance, etc. Comtech EF Data is responsible

for the freight charges only for return of the equipment from the factory to the customer.

Comtech EF Data will return the equipment by the same method (i.e., Air, Express,

Surface) as the equipment was sent to Comtech EF Data.

LIMITATIONS OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repackaging of

equipment for return to Comtech EF Data.

No other warranty is expressed or implied. Comtech EF Data specifically disclaims the

implied warranties of merchantability and fitness for particular purpose.

EXCLUSIVE REMEDIES

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech EF

Data shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

DISCLAIMER

Comtech EF Data has reviewed this manual thoroughly to provide an easy-to-use guide

to your equipment. All statements, technical information, and recommendations in this

manual and in any guides or related documents are believed reliable, but the accuracy and

completeness thereof are not guaranteed or warranted, and they are not intended to be,

nor should they be understood to be, representations or warranties concerning the

products described. Further, Comtech EF Data reserves the right to make changes in the

specifications of the products described in this manual at any time without notice and

without obligation to notify any person of such changes.

If you have any questions regarding the equipment or the information in this manual,

please contact the Comtech EF Data Customer Support Department.

xii

Page 19

Chapter 1. Introduction

DT-4500

Series

Down

Converter

1.1 OVERVIEW

This manual provides instructions on the installation, operation and maintenance of the

DT-4500 Series Down Converters manufactured by Comtech EF Data Corp.

Individual specifications for each model are included in this section.

DT-4503

DT-4503C

DT-4503D

DT-4503E

DT-4510

DT-4510D

DT-4511

DT-4512

DT-4512E

DT-4513

DT-4513E

1

Page 20

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

1.2 FUNCTIONAL DESCRIPTION

The DT-4500 Series Down Converters are designed for use in communication systems,

or in satellite downlink data systems, for the transmission of SCPC, DAMA and TDMA

communication signals. The Down Converters can also be used in communications

system applications with full transponder HDTV and analog TV.

The converter is designed to be hard mounted in a standard 19-inch (48.26 cm) rack or

cabinet, or to be rack mounted using slide mechanisms provided with the converter to

allow it to be serviced without its removal from the rack. An internally mounted exhaust

fan for cooling is mounted on the rear of the chassis. An AC power connector, with an

on/off switch, is also located on the rear on the chassis. A six-foot AC power cord is

supplied with the converter.

All operator controls, indicators and displays for local and remote operation are located

on the front panel of the converter. Connectors for the external interface connections are

located on the rear of the converter chassis.

MADE IN USA

Figure 1. Front Panel (Model DT-4511 shown)

J4 J6 J8 J5

P1 RELAY

J1 COM 1

EXT REF

EXT REF

J2B OUT

J2A IN

Figure 2. Rear Panel (shown with RSM Module)

RFLP OUTLP INIFJ3 HSB

2

Page 21

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

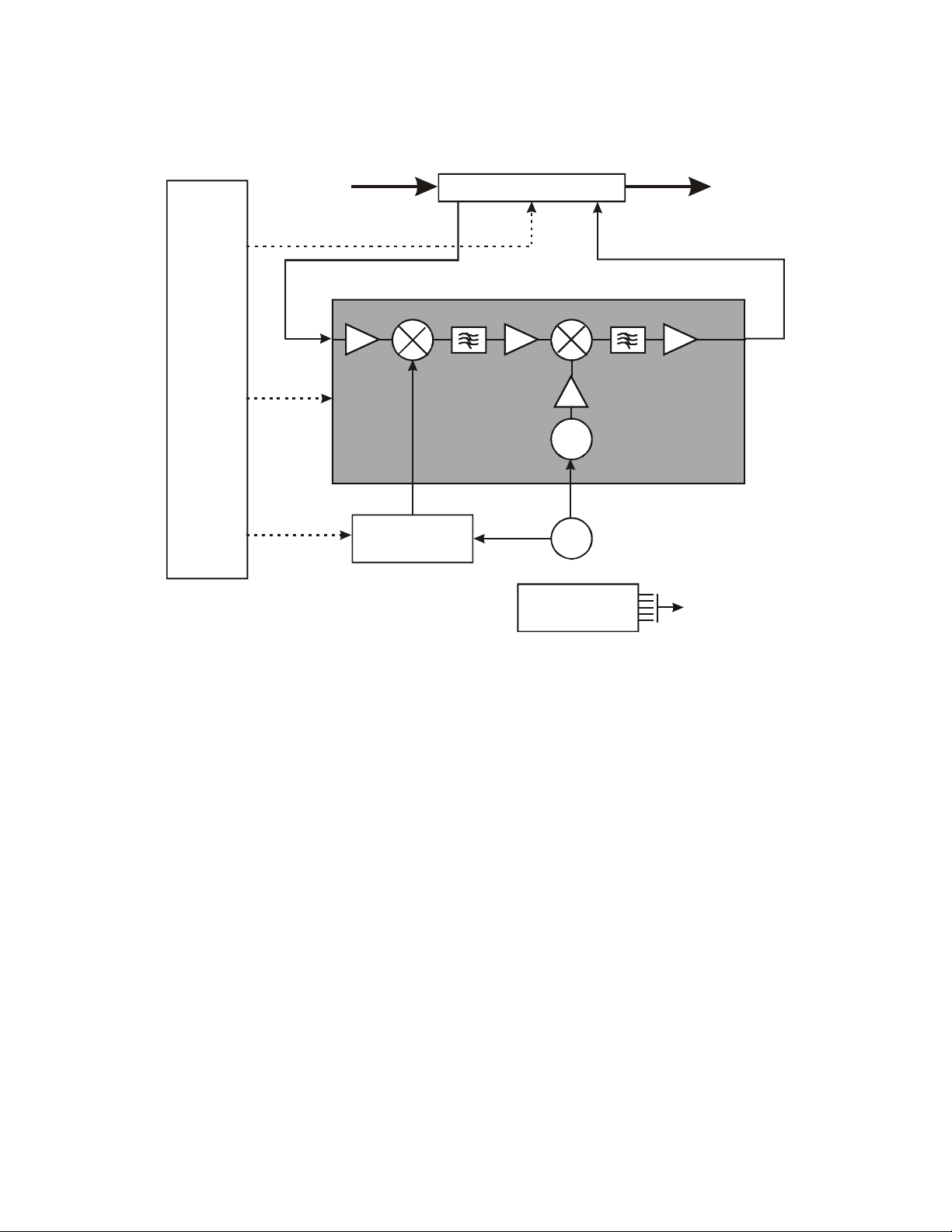

MONITOR

&

CONTROL

RF INPUT

(12200-12750 MHz)

SYNTHESIZER

I/O MODULE

OSC.

OSC

IF OUTPUT

(70 or 140 MHz)

CONVERTER

SIGNAL PATH

MODULE

5/10 MHz

REF. OSC.

POWER SUPPLY

Figure 3. Typical Functional Block Diagram (Model DT-4512 shown)

3

Page 22

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

1.3 SPECIFICATIONS

Note: Contact CEFD with specific requirements.

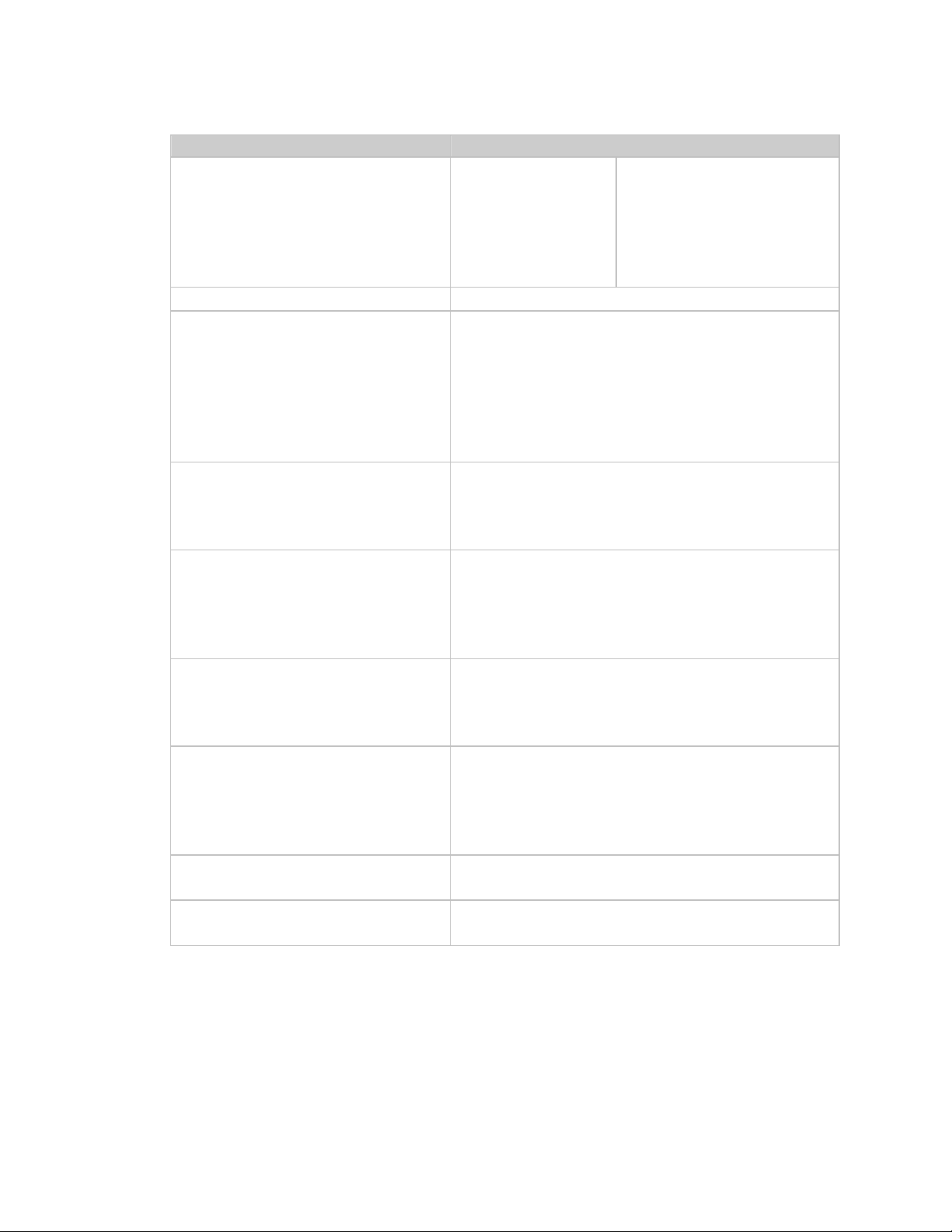

Table 1. DT-4503 C-Band Down Converter Specifications

Characteristic Specification

Frequency Range

DT-4503/C

Conversion

Step Size

Preset Channels

Stability Over Time

Stability Over Temp

RF Input

Noise Figure

Level

Impedance

Return Loss

IF Output

Range

Output Level

Intermodulation

Non–carrier Spurious

Carrier Spurious

Return Loss

Impedance

Transfer

Gain

Attenuation Adjust

Gain Stability

Ripple: 70MHz IFCF

140 MHz IFCF

Slope

Image Rejection

AM to PM

IF Bandwidth

External Ref.

3400 to 4200 MHz

Dual, No Inversion

125 kHz standard, 1kHz optional

32 Frequencies

± 1 x 10

± 1 x 10

-9

/Day

-8

0 to 50°C (32 to 122°F)

11 dB Maximum at 0 dB Attenuation

-45 dBm Typical

50 Ω

20 dB Min. with RF/IF connector module

+20 dBm at 1 dB Compression

52 to 88 or 104 to 176 MHz), optional 50 to 80

MHz or 100 to 180 MHz, (see Note)

-60 dBc @ 0 dBm Output SCL

-80 dBm

-65 dBc @ 0 dBm Output

23 dB Minimum

50 or 75 Ω

45 dB ± 2 dB

0 to 20 in 0.25 dB Steps

0.1 dB Steps Optional

± 0.25 dB/Day

± 0.25 dB (± 18 MHz), optional ± 20 MHz,

(see Note)

0.75 dB (± 36 MHz), optional ± 40 MHz,

(see Note)

0.05 dB/MHz

-80 dB Inband

o

0.1

. / dB for Output up to –5 dBm

36 or 72 MHz), optional 40 or 80 MHz,

(see Note)

Input 5 or 10 MHz @ +3 dBm

Optional 10 MHz Rear Panel Reference Output

4

Page 23

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

Characteristic Specification

Group Delay

Phase Noise

Linear Group Delay

Parabolic Delay

Group Delay Ripple

100 Hz

1 kHz

10 kHz

100 kHz

1 MHz

Remote Control (Rear Panel)

Indicators (Front Panel)

Power On

Receive

Remote

On Line

Stored Fault

Fault

Test Points (Front Panel)

RF Sample

IF Sample

Optional L.O. Sample

Power

Voltage

Frequency

Dissipation

Power Option

Environmental

Temperature

Altitude

Humidity

Physical

Width

Height

Depth

Weight

MTBF

Summary Alarm

Relay Closure

0.03 ns/MHz

0.01 ns/MHz

2

1.0 ns Peak-to-Peak

Limit (dBc/Hz)

-80

-89

-95

-105

-120

Typical (dBc/Hz)

-83

-92

-97

-109

-124

Comm Port RS-485 or RS-232

Green LED

Yellow LED

Yellow LED

Yellow LED

Red LED

Red LED

SMA, -20 dBc Nominal

BNC, -20 dBc Nominal

90 to 250 Vac

47 to 63 Hz

60 Watts

-48 Vdc

0 to 50° C (32 to 122° F)

10,000 Feet MSL

0 to 95 % Relative

19 Inches (48.26 cm)

1.75 Inches (4.44 cm)

22 Inches (55.88 cm)

25 Pounds (11.40 kg)

49,740 hrs. (calculated)

>100,000 hrs. (field experience)

Form C

5

Page 24

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

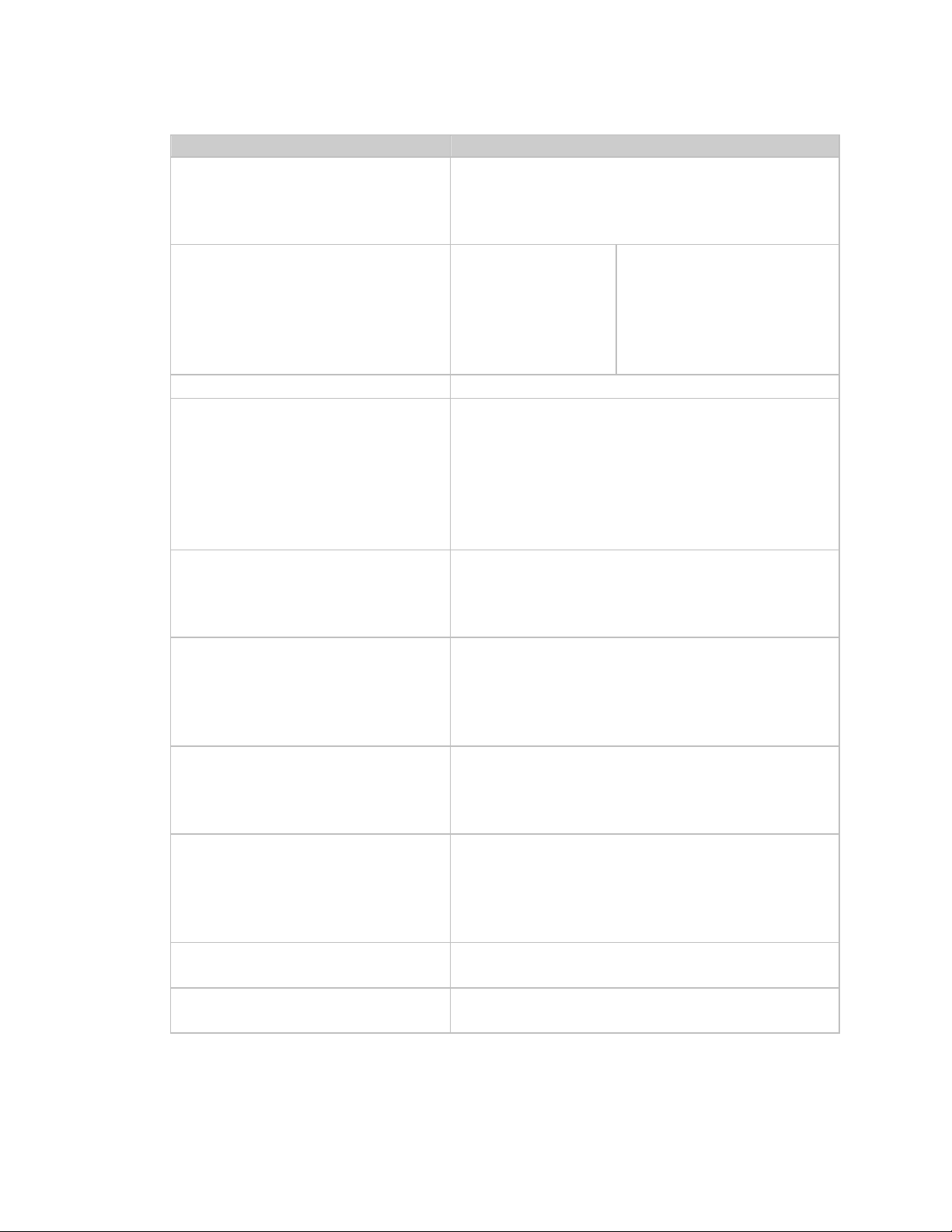

Table 2. DT-4503/E C-Band Down Converter Specifications

Characteristic Specification

Frequency Range

DT-4503/E

Conversion

Step Size

Preset Channels

Stability Over Time

Stability Over Temp

RF Input

Noise Figure

Level

Impedance

Return Loss

IF Output

Range

Output Level

Intermodulation

Non–carrier Spurious

Carrier Spurious

Return Loss

Impedance

Transfer

Gain

Attenuation Adjust

Gain Stability

Ripple: 70 MHz IFCF

140 MHz IFCF

Slope

Image Rejection

AM to PM

IF Bandwidth

4500 to 4800 MHz

Dual, No Inversion

125 kHz standard, 1kHz optional

32 Frequencies

± 1 x 10

± 1 x 10

-9

/Day

-8

/Day 0 to 50 °C ( 32 to 122 °F)

11 dB Maximum at 0 dB Attenuation

-45 dBm Typical

50 Ω

20 dB Min. with RF/IF Connector Module

+20 dBm at 1 dB Compression

52 to 88 or 104 to 176 MHz), optional 50 to 80

MHz or 100 to 180 MHz (see Note)

-60 dBc @ 0 dBm Output SCL

-80 dBm

-65 dBc @ +3 dBm Output

23 dB Minimum with RF/IF connector module

50 or 75 Ω

45 dB ± 2 dB

0 to 20 in 0.25 dB Steps

0.1 dB Steps Optional

± 0.25 dB/Day

± 0.25 dB (± 18 MHz), optional ± 20 MHz,

(see Note)

0.75 dB (± 36 MHz), optional ± 40 MHz,

(see Note)

0.05 dB/MHz

-80 dB Inband

o

0.1

./ dB for Output up to –5 dBm

36 or 72 MHz), optional 40 or 80 MHz,

(see Note)

External Ref.

Group Delay

Linear Group Delay

Parabolic Delay

Group Delay Ripple

Input 5 or 10 MHz @ +3dBm

Optional 10 MHz Rear Panel Reference Output

0.03 ns/MHz

0.01 ns/MHz

2

1.0 ns Peak-to-Peak

6

Page 25

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

Characteristic Specification

Phase Noise

100 Hz

1 kHz

10 kHz

100 kHz

1 MHz

Remote Control (Rear Panel)

Indicators (Front Panel)

Power On

Receive

Remote

On Line

Stored Fault

Fault

Test Points (Front Panel)

RF Sample

IF Sample

Optional L.O. Sample

Power

Voltage

Frequency

Dissipation

Power Option

Environmental

Temperature

Altitude

Humidity

Physical

Width

Height

Depth

Weight

MTBF

Summary Alarm

Relay Closure

Limit (dBc/Hz)

-80

-89

-95

-105

-120

Typical (dBc/Hz)

-83

-92

-97

-109

-124

Comm Port RS-485 or RS-232

Green LED

Yellow LED

Yellow LED

Yellow LED

Red LED

Red LED

SMA, -20 dBc Nominal

BNC, -20 dBc Nominal

90 to 250 Vac, Autoranging, optional –48 VDC

47 to 63 Hz

60 Watts

-48 Vdc

0 to 50°C (32 to 122° F)

10,000 Feet MSL

0 to 95 % Relative

19 Inches (48.26 cm)

1.75 Inches (4.44 cm)

22 Inches (55.88 cm)

15 Pounds (7.00 kg)

49,740 hrs. (calculated)

>100,000 hrs. (field experience)

Form C

7

Page 26

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

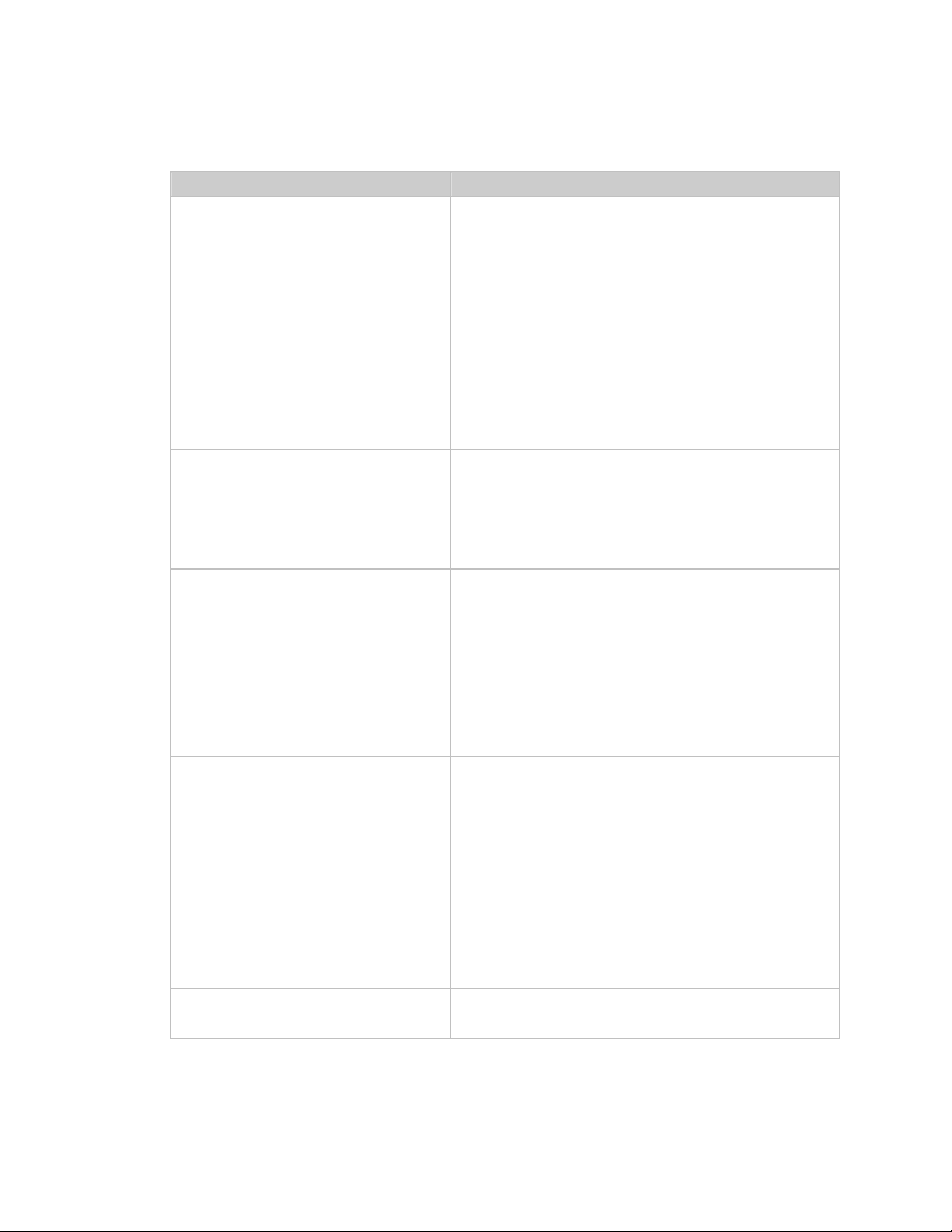

Table 3. DT-4503/X C-Band Down Converter Specifications

Characteristic Specification

Frequency Range

DT-4503

DT-4503/D

DT-4503/E

Conversion

Step Size

Preset Channels

Stability Over Time

Stability Over Temp

RF Input

Noise Figure

Level

Impedance

Return Loss

IF Output

Range

Output Level

Intermodulation

Non–carrier Spurious

Carrier Spurious

Impedance

Return Loss

Transfer

Gain

Attenuation Adjust

Gain Stability

Ripple: 70 MHz IFCF

140 MHz IFCF

Slope

Image Rejection

AM to PM

IF Bandwidth

3625 to 4200 MHz

3400 to 3700 MHz

Refer to Table 2.

Dual, No Inversion

125 kHz standard, 1kHz optional

32 Frequencies and Gains

± 1 x 10

± 1 x 10

-9

/Day

-8

0 to 50°C (32 to 122oF)

11 dB Maximum at 0 dB Attenuation

-45 dBm Typical

50 Ω

20 dB Min. with RF/IF Connector Module

+20 dBm at 1 dB Compression

52 to 88 or 104 to 176 MHz), optional 50 to 80

MHz or 100 to 180 MHz, (see Note)

-60 dBc @ 0 dBm Output SCL

-80 dBm

-65 dBc @ +3 dBm Output

50 or 75 Ω

23 dB Min. with RF/IF connector module

or SW Module

45 dB ± 2 dB

0 to 20 in 0.25 dB Steps

0.1 dB Steps Optional

± 0.25 dB/Day

± 0.25 dB (± 18 MHz), optional ± 20 MHz,

(see Note)

0.75 dB (± 36 MHz), optional ± 40 MHz, (see

Note) 10.05 dB/MHz

0.05 dB/MHz

-80 dB Inband

o

0.1

./ dB for Output up to –5 dBm

36 or 72 MHz), optional 40 or 80 MHz,

(see Note)

External Ref.

Input 5 or 10 MHz @ +3dBm

Optional 10 MHz Rear Panel Reference Output

8

Page 27

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

Characteristic Specification

Group Delay

Phase Noise

Linear Group Delay

Parabolic Delay

Group Delay Ripple

100 Hz

1 KHz

10 KHz

100 KHz

1 MHz

Remote Control (Rear Panel)

Indicators (Front Panel)

Power On

Mute

Remote

On Line

Stored Fault

Fault

Test Points (Front Panel)

RF Sample

IF Sample

Optional L.O. Sample

Power

Voltage

Frequency

Dissipation

Power Option

Environmental

Temperature

Altitude

Humidity

Physical

Width

Height

Depth

Weight

MTBF

Summary Alarm

Relay Closure

0.03 ns/MHz

0.01 ns/MHz

2

1.0 ns Peak-to-Peak

Limit (dBc/Hz)

-80

-89

-95

-105

-120

Typical (dBc/Hz)

-83

-92

-97

-109

-124

Comm Port RS-485 or RS-232

Green LED

Yellow LED

Yellow LED

Yellow LED

Red LED

Red LED

SMA, -20 dBc Nominal

BNC, -20 dBc Nominal

90 to 250 Vac Autoranging

47 to 63 Hz

60 Watts

-48 Vdc

0 to 50° C (32 to 122° F)

10,000 Feet MSL

0 to 95 % Relative

19 Inches (48.26 cm)

1.75 Inches (4.44 cm)

22 Inches (55.88 cm)

15 Pounds (7.00 kg)

49,740 hrs. (calculated)

>100,000 hrs. (field experience)

Form C

9

Page 28

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

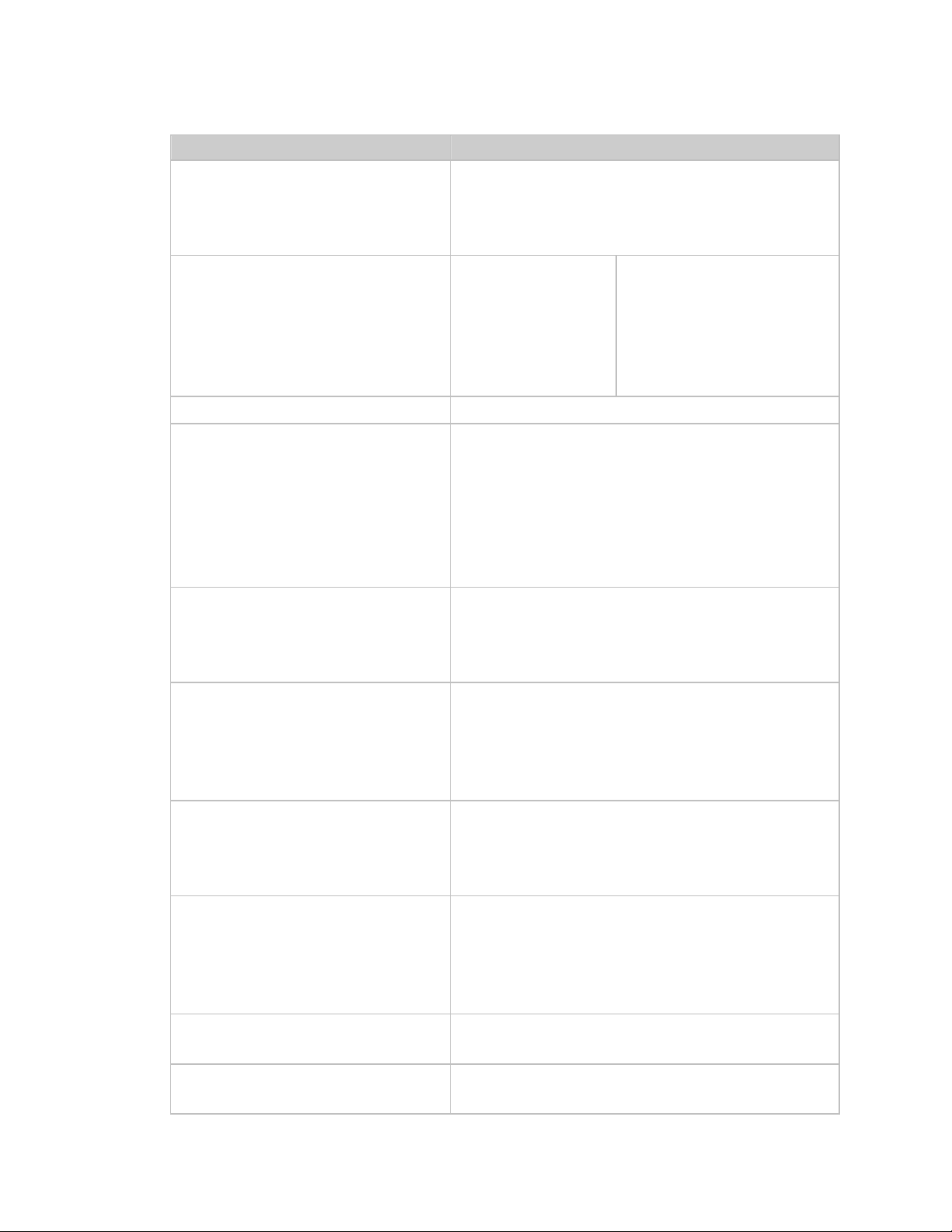

Table 4. DT-451X Ku-Band Down Converter Specifications

Characteristic Specification

Frequency Range

DT-4510

DT-4510/D

DT-4511

DT-4512

DT-4512/E

Conversion

Step Size

Preset Channels

Stability Over Time

Stability Over Temp

RF Input

Level

Return Loss

Impedance

Noise Figure

IF Output

Level

Range

Intermodulation

Non–carrier Spurious

Carrier Spurious

Impedance

Return Loss

Transfer

Gain

Attenuation Adjust

Gain Stability

Ripple: 70 MHz IFCF

140 MHz IFCF

Slope

Image Rejection

AM to PM

External Ref.

10.95 to 11.70 GHz

10.70 to 11.70 GHz

11.70 to 12.20 GHz

12.20 to 12.75 GHz

12.50 to 12.80 GHz

Dual, No Inversion

125 kHz standard, 1kHz optional

32 Frequencies and Gains

± 1 x 10

± 1 x 10

-9

/Day

-8

0 to 50°C (32 to 122oF)

-45 dBm Typical

20 dB Min. with IO Module

50 Ω

11 dB Maximum at 0 dB Attenuation

+20 dBm at 1 dB Compression

52 to 88 or 104 to 176 MHz

-60 dBc @ 0 dBm Output SCL

-80 dBm

-65 dBc @ 0 dBm Output

50 or 75 Ω

23 dB Min. with IO Module

45 dB ± 2 dB

0 to 20 in 0.25 dB Steps

0.1 dB Steps Optional

± 0.25 dB/Day

± 0.25 dB (± 18 MHz)

0.75 dB (± 36 MHz)

0.05 dB/MHz

-80 dB Inband

o

0.1

./ dB for Output up to –5 dBm

Input 5 or 10 MHz @ +3dBm

Optional 10 MHz Rear Panel Reference Output

10

Page 29

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

Characteristic Specification

Group Delay

Phase Noise

Linear Group Delay

Parabolic Delay

Group Delay Ripple

100 Hz

1 KHz

10 KHz

100 KHz

1 MHz

0.03 ns/MHz

0.01 ns/MHz

2

1.0 ns Peak-to-Peak

Limit (dBc/Hz)

-72

-79

-89

-98

-110

Typical (dBc/Hz)

-79

-82

-92

-101

-114

Remote Control (Rear Panel)

Indicators (Front Panel)

Power On

Mute

Remote

On Line

Stored Fault

Fault

Test Points (Front Panel)

RF Sample

IF Sample

Optional L.O. Sample

Power

Voltage

Frequency

Dissipation

Power Option

Environmental

Temperature

Altitude

Humidity

Comm Port RS-485 or RS-232

Green LED

Yellow LED

Yellow LED

Yellow LED

Red LED

Red LED

SMA, -20 dBc Nominal

BNC, -20 dBc Nominal

90 to 250 Vac Autoranging

47 to 63 Hz

60 Watts

-48 Vdc

0 to 50° C (32 to 122° F)

10,000 Feet MSL

0 to 95 % Relative

Physical

Width

Height

Depth

Weight

MTBF

Summary Alarm

Relay Closure

19 Inches (48.26 cm)

1.75 Inches (4.44 cm)

22 Inches (55.88 cm)

15 Pounds (7.00 kg)

49,740 hrs. (calculated)

>100,000 hrs. (field experience)

Form C

11

Page 30

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

Table 5. DT-4513/E Ku-Band Down Converter Specifications

Characteristic Specification

Frequency Range

DT-4513

DT-4513/E

Conversion

Step Size

Preset Channels

Stability Over Time

Stability Over Temp

RF Input

Level

Return Loss

Impedance

Noise Figure

IF Output

Level

Range

Intermodulation

Non–carrier Spurious

Carrier Spurious

Impedance

Return Loss

Transfer

Gain

Attenuation Adjust

Gain Stability

Ripple: 70 MHz IFCF

140 MHz IFCF

Slope

Image Rejection

AM to PM

External Ref.

Group Delay

Linear Group Delay

Parabolic Delay

Group Delay Ripple

10.95 to 12.75 GHz

10.70 to 12.75 GHz

Dual, No Inversion

125 kHz standard, 1kHz optional

32 Frequencies

± 1 x 10

± 1 x 10

-9

/Day

-8

0 to 50°C (32 to 122oF)

-45 dBm Typical

20 dB Min. with RF/IF Connector Module

50 Ω

11 dB Maximum at 0 dB Attenuation

+20 dBm at 1 dB Compression

52 to 88 or 104 to 176 MHz

-60 dBc @ 0 dBm Output SCL

-80 dBm

-65 dBc @ 0 dBm Output

50 or 75 Ω

23 dB Min. with IO Module

45 dB ± 2 dB

0 to 20 in 0.25 dB Steps

0.1 dB Steps Optional

± 0.25 dB/Day

± 0.25 dB (± 18 MHz)

0.75 dB (± 36 MHz)

0.05 dB/MHz

-80 dB Inband

o

0.1

./ dB for Output up to –5 dBm

Input 5 or 10 MHz @ +3dBm

Optional 10 MHz Rear Panel Reference Output

0.03 ns/MHz

0.01 ns/MHz

2

1.0 ns Peak-to-Peak

12

Page 31

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

Characteristic Specification

Phase Noise

100 Hz

1 KHz

10 KHz

100 KHz

1 MHz

Limit (dBc/Hz)

-66

-76

-86

-96

-106

Typical (dBc/Hz)

-69

-79

-89

-99

-109

Remote Control (Rear Panel)

Indicators (Front Panel)

Power On

Receive

Remote

On Line

Stored Fault

Fault

Test Points (Front Panel)

RF Sample

IF Sample

Optional L.O. Sample

Power

Voltage

Frequency

Dissipation

Power Option

Environmental

Temperature

Altitude

Humidity

Comm Port RS-485 or RS-232

Green LED

Yellow LED

Yellow LED

Yellow LED

Red LED

Red LED

SMA, -20 dBc Nominal

BNC, -20 dBc Nominal

90 to 250 Vac Autoranging

47 to 63 Hz

60 Watts

-48 Vdc

0 to 50° C (32 to 122° F)

10,000 Feet MSL

0 to 95 % Relative

Physical

Width

Height

Depth

Weight

MTBF

Summary Alarm

Relay Closure

19 Inches (48.26 cm)

1.75 Inches (4.44 cm)

22 Inches (55.88 cm)

15 Pounds (7.00 kg)

49,740 hrs. (calculated)

>100,000 hrs. (field experience)

Form C

13

Page 32

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

1.3.1 DIMENSIONAL ENVELOPE (DT-4500)

Dimensions are shown in both inches and centimeters.

17.00

(432)

1.75”

(4.45)

SAMPLE STATUS

RF IF

POWER ON

TRANSMIT

REMOTE

ON LINE

FAULT

STORED FAULT

18.25

(46.35)

19.0

(48.3)

22.00

(55.9)

ENT

CLR

Figure 4. Dimensional Envelope

14

Page 33

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

1.4 PHYSICAL CONFIGURATION

Figure 5 is a top view layout of a DT-4500 Series Down Converter chassis with the cover

removed. Major chassis components are shown in Figure 5. The major module

assemblies shown in the layout are:

Signal Path Module

Step Loop Module

Monitor & Control Assembly

Transmit I/O Switch Module

Reference Oscillator Assembly

Sum Loop Module

Power Supply Assembly

Sum Module

Signal

Path

Mo ni t o r

& Cont rol

Board

Switch

Module

Power Supply

Fil ter

Module

Ref erence

Oscillator

Step

Module

Figure 5. Physical Configuration - Down Converter

15

Page 34

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

1.5 FRONT PANEL DISPLAY

The front panel display is a two line, 24-character, LCD display. Each configuration

function, or operating mode, is shown on the display when the operator enters a

command into the keypad on the front panel.

1.6 FRONT PANEL TEST POINT SAMPLES

Two test point connections are located on the front panel for monitoring the RF input and

the IF output. An SMA connector is provided for the RF input, and a BNC connector is

provided for the IF output. There is also an optional RF LO monitor available that

replaces the RF monitor.

1.7 PRIME POWER SWITCH

The on/off prime power switch is located on the rear of the chassis adjacent to the prime

power input connector. The power switch contains a filter and dual fuse. The dual fuse

is rated for 2 Amps.

1.8 NEW IN THIS MANUAL

Incorporated Errata’s A though E

Incorporated new figure for TSEQM Connector Locations.

16

Page 35

DT4500 Series Down Converters MN/DT4500.IOM

Introduction Revision 1

NOTES:

17

Page 36

Page 37

2.1 UNPACKING AND INSPECTION

Inspect the shipping container for damage. If the shipping containers are damaged, keep

them until the contents of the shipment have been carefully inspected and checked for

normal operation.

Remove the packing list from the outside of the shipping carton. Open the carton and

remove the contents, checking the contents against the packing list. Verify completeness

of the shipment and that the unit functions correctly. If damage is evident, contact the

carrier and Comtech EF Data immediately and submit a damage report.

If the unit needs to be returned to Comtech EF Data, please use the original shipping

container.

2.2 RACK MOUNT INSTALLATION

Chapter 2. Installation

The DT-4500 Series Down Converters are designed for installation in a standard 19 inch

rack cabinet or enclosure. The converter chassis requires 1-3/4 inches of panel height

space. Adequate air ventilation should be provided on both sides of the rack-mounted

equipment.

If the converter is to be mounted on slides, the slides must be the Comtech EF Data rack

slides provided with the converter. Mount the slides on the sides of the converter chassis

with the mounting hardware provided. Then, install the slide rails in the rack cabinet

enclosure.

Slide the converter into the front of the rack cabinet until the rear of the front panel

contacts the mounting surface of the cabinet. Secure the converter to the rack cabinet

with four screws inserted through the converter’s front panel slotted holes.

2.3 PRIME POWER CONNECTION

The detachable power cord mates with the AC Prime power receptacle on the rear of the

converter chassis. A power cord for connection to 90 to 125 Vac, or 205 to 240 Vac,

power sources is provided with the converter.

19

Page 38

DT4500 Series Down Converters MN/DT4500.IOM

Installation Revision 1

2.4 CABLE CONNECTIONS

Connect the signal cables to the connectors on the rear panel as shown in Figure 6. The

cable signal functions are listed in Table 6.

2.4.1 REAR PANEL CONNECTIONS

Table 6. Rear Panel Connectors

Connector Description

Prime Power AC Prime Power Input (AC POWER), Optional –48 Vdc

J1: Serial Communications Interface for RS-485 or RS-232 COMM links (COM 1).

J2: External Reference Oscillator Input

J3: High Speed Bus (HSB)

J4: Converter IF Input (IF).

J5: Converter RF Output (RF).

J6: IF TSM Switching Loop Input (LP IN).

J7: RF TSM Switching Loop Input (LP IN).

J8: IF TSM Switching Loop Output (LP OUT).

J9: RF TSM Switching Loop Output (LP OUT).

P1: Summary Fault Output (RELAY).

20

Page 39

DT4500 Series Down Converters MN/DT4500.IOM

Installation Revision 1

2.4.2 RS-485/RS-232C INTERFACE (COM 1), CONNECTOR J1

The RS-485/RS-232C Interface connector, J1, is 9 pin "D" type DB9F connector socket.

The pin-out specifications for RS-485 are contained in Table 7 and Table 8. The

specification for RS-232 is contained in Table 9. The mating connector is a DB9M.

Table 7. J1, 2 Wire RS-485 Interface Pin-Out Table 8. J1, 4 Wire RS-485 Interface Pin-Out

Pin # Description

1 GND; Ground

2

3

4 +RX/TX; Signal

5 -RX/TX; Signal Complement

6

7

8 +RX/TX; Signal

9 -RX/TX; Signal Complement

Note: Pins 8 & 9 are the loop to the next

converter.

Pin # Description

1 GND; Ground

2

3

4 +TX; Signal

5 -TX; Signal Complement

6

7

8 +RX; Signal

9 -RX; Signal Complement

Table 9. J1, RS-232C Interface Pin-Out

Pin # Description

1

2 TD; Transmit Data

3 RD; Receive Data

4

5 GND; Ground

6 DSR; Unit Ready - always high.

7 RTS; Request to Send. Looped to CTS.

8 CTS; Clear to Send

9

21

Page 40

DT4500 Series Down Converters MN/DT4500.IOM

Installation Revision 1

2.4.3 HIGH SPEED BUS (HSB), CONNECTOR J3

The High Speed Bus connector, J3, is 25-pin "D" type DB25F connector socket. The

pin-out specifications are contained in Table 10. The mating connector is a DB25M.

Note: This is not a “straight through” cable assembly. Contact Comtech EF Data for detailed

wire drawings when cabling between converters.

Table 10. J3, High Speed Bus Connector Pin-Out

Pin # Description Pin # Description Pin # Description

1 Cntl_12 10 Aux_3 18 Cntl_3

2 Cntl_10 11 Aux_1 19 Cntl_1

3 Cntl_8 12 -Rx/Tx 20 +14V Out

4 Cntl_6 13 GND 21 +14V In

5 Cntl_4 14 Cntl_11 22 GND

6 Cntl_2 15 Cntl_9 23 Aux_2

7 Cntl_In 16 Cntl_7 24 GND

8 +14V Out 17 Cntl_5 25 +Rx/Tx

9 +14V In

2.4.4 SUMMARY FAULT OUTPUT (RELAY), CONNECTOR P1

The summary fault output connector, P1, is 9-pin "D" type DB9F connector. The pin-out

specifications are contained in Table 11. The mating connector is a DB9M.

Table 11. P1, Summary Fault Connector Pin-Out

Pin # Description

1 Summary Fault NC

2 Summary Fault NO

3

4

5 Ground

6 Summary Fault Com

7 External Fault Input

8

9

Notes: 1

Pin 1 to Pin 6: Fault.

Pin 2 to Pin 6: No Fault.

2

Pin 7 to Pin 5: Forced Fault. Typically used with external group delay equalizers

3

22

Page 41

DT4500 Series Down Converters MN/DT4500.IOM

Installation Revision 1

Prime Power Cord Input

5/10 MHz Ref. Osc. Input J2

Summary Fault Relay Output

Serial Comm. Interface

(EIA-485 / EIA-232C)- COM 1

High Speed Bus (HSB)

P1

J1

J3

Power

Supply

Monitor & Control Assembly

Reference

Oscillator

Fine

Step

Module

IF Output (IF)

IF Loop Input (LP IN)

IF Loop Output (LP OUT)

RF Input (RF)

(Not Used)

(Not Used)

J4

J6

J8

J5

J7

J9

Receive

I/O Switch

Module

RF Converter

Loop

Module

Figure 6. Cable Interconnect Diagram

2.4.5 CABLE CONNECTIONS FOR NON-REDUNDANT SYSTEM OPERATION

In non-redundant converter configuration the converter has an Input/Output Module

(IOM-XX) for the RF input and the IF Output. A converter with a Transmit or Receive

Switch Module may be operated in a non-redundant configuration if an IOM is

unavailable. Figure 7 is an illustration of the converter cable connections with an IOM

installed. Figure 8 is an illustration of the converter cable connections with a TSM

installed.

2.4.6 CABLE CONNECTIONS FOR REDUNDANT SYSTEM OPERATION

Sum

In subsystems where a redundant converter configuration is used, the backup Converter

has an Input/Output Module (IOM-XX) and the online converters have Receive Switch

Modules (TSM-XX), which switch to the backup Converter when a fault is detected.

Redundant system operation is discussed in Appendix A, Redundant System Operation.

23

Page 42

DT4500 Series Down Converters MN/DT4500.IOM

Installation Revision 1

NO

CONNECTION

RSM-XX

IOM-XX

OUTPUT

J4

IF

J5

RFIFJ3 HSB

RF

INPUT

Figure 7. Non-Redundant Converter Configuration

J4 J6 J8

J5

J3 HSB IF

LP OUTLP IN RF

IF OUTPUT RF INPUT

NO

CONNECTION

DOWN CONVERTER - RSM

IF OUTPUT

Figure 8. Non-Redundant Converter Configuration With Receive Switch Module (RSM-XX) Installed

RF INPUT

24

Page 43

3.1 OVERVIEW

This chapter contains instructions for operating the converter. Illustrations of the front

and rear panels are provided showing the keypad for operator input commands, LCD

Display, LED status indicators, and the connectors. Tables are provided to show the

control and operating functions of the converter.

The front and rear panels are shown below. Table 12 lists of the operating functions for

the keypad, LCD display, LED indicators and test sample connections on the front panel.

Chapter 3. System Operation

Figure 9. Front Panel (Model DT-4511 shown)

J4 J6 J8 J5

P1 RELAY

J1 COM 1

EXT REF

MADE IN USA

EXT REF

J2B OUT

J2A IN

Figure 10. Rear Panel (with RSM Module)

RFLP OUTLP INIFJ3 HSB

25

Page 44

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

Table 12. Operating Functions – Front Panel

Item Reference Designation Functional Description

Enter key Enters commands into the converter.

ENT

Clear key Clears commands and data selected and not

CLR

Right Arrow key Selects functions and the menu operating data.

Left Arrow key Selects functions and the menu operating data.

Up Arrow key Selects the operating menu and data values.

Down Arrow key Selects the operating menu and data values.

entered.

LCD Display Displays commands and data

DT_4511-1

entered into the keypad.

SW VER 4.06 SN45113513

Indicator Color Function

POWER ON

TRANSMIT

REMOTE

ON LINE

FAULT

STORED FAULT

Item Reference

Designation

RF SAMPLE RF An SMA connector test point to sample RF.

IF SAMPLE IF A BNC connector test point to sample IF.

Green

Yellow

Yellow

Yellow

Red

Red

Prime power is applied when the light is on.

Transmit function operating when the light is on.

In Remote Control Mode when the light is on.

Operating on-line to transmit data when the light is

on.

Fault condition exists when the light is on.

Faults stored and logged when the light is on.

Function

26

Page 45

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

3.2 SWITCHING POWER ON

Before turning the Prime Power Switch to the ON position, check to ensure that the

installation is complete, and verify that the converter is connected to the proper prime

power source, RF Input and IF Output.

Switch the ON/OFF Prime Power Switch on the rear panel to ON. Verify that the

cooling fan is operating, and that the POWER ON LED STATUS indicator light is on.

After the AC power is switched on and before pressing the buttons on the keypad, the

LCD display message should be similar to:

DT-4512-X

SW VER 2.08 SN4513XXXX

3.3 OPERATION

Local operation of the RF Down Converter is controlled by operator input commands

initiated through the six-button keypad on the front panel shown in Figure 11. The

keypad is the local operator's interface to control, configure and monitor the status of the

converter. Operator inputs and commands entered into the keypad are displayed by the

front panel 24-character, two line, LCD display. See Appendix B for Remote Control.

There are six operating command functions: Configuration, Pre-Select, Monitor Status,

Currents Faults, Stored Faults and Utility Functions. A flow-chart for selecting the

commands, operating menus, and data inputs is shown in Figure 12 through Figure 20.

ENT

CLR

Figure 11. Keypad

27

Page 46

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

--------DT-4513--------

-SOFTWARE VERSION-1.00-

---------SELECT---------

----CONFIGURATION-MENU--

---------SELECT---------

----PRE-SELECT MENU-----

-

---------SELECT---------

--MONITOR-STATUS-MENU---

---------SELECT---------

--CURRENT-FAULTS-MENU---

---------SELECT---------

---STORED-FAULTS-MENU---

LEGEND

---------SELECT---------

-UTILITY-FUNCTIONS-MENU-

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

Figure 12. Converter Operating Command Functions

KEY-PAD

ENT

CLR

28

Page 47

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

---------SELECT---------

----CONFIGURATION-MENU--

ENTER

FREQ= 12XXX.XXX-MHz-----

ATTN=-10.00-DB---Rx=OFF-

----EXTERNAL-5-MHz------

--REFERENCE-PRESENT-----

--ENTRY-MODE-=-REMOTE---

-COLD-START-=-DISABLED--

FAULT RECOVERY:-MANUAL--

------------------------

REDUNDANCY-CONFIG?-OFF--

------------------------

* Displayed only when there is

a 5/10 MHz reference input.

LEGEND

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

KEY-PAD

ENT

CLR

Figure 13. Configuration Menu Commands - Redundancy OFF.

29

Page 48

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

---------SELECT---------

----CONFIGURATION-MENU--

ENTER

FREQ= 12XXX.XXX-MHz-----

ATTN=-10.00-DB---Rx=OFF-

** Manual when “Redundancy

Config ON” and not in “BU”

----EXTERNAL-5-MHz------

--REFERENCE-PRESENT-----

--ENTRY-MODE-=-REMOTE---

-COLD-START-=-DISABLED--

FAULT RECOVERY:-MANUAL--

------------------------

REDUNDANCY-CONFIG?-OFF--

------------------------

LEGEND

* Displayed only when there is

a 5/10 MHz reference input.

ENT + DOWN + ENT

CLR

KEY-PAD

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

REDUNDANCY-CONFIG?-ON---

-CONVERTER-#-XX---------

ENT

CLR

Figure 14. Configuration Menu Commands - Redundancy ON, Backup Unit Not Selected

30

Page 49

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

---------SELECT---------

----CONFIGURATION-MENU--

ENTER

FREQ= 12XXX.XXX-MHz-----

ATTN=-10.00-DB---Rx=OFF-

REDUNDANCY-CONFIG?-ON---

-CONVERTER-#-01---------

----EXTERNAL-5-MHz------

--REFERENCE-PRESENT-----

--ENTRY-MODE-=-REMOTE---

-COLD-START-=-DISABLED--

FAULT RECOVERY:-MANUAL--

------------------------

REDUNDANCY-CONFIG?-OFF--

------------------------

ENT + DOWN + ENT

ENT + UP + ENT

REDUNDANCY-CONFIG?-ON---

-CONVERTER-#-XX---------

* Displayed only

when there is

a 5/10 MHz

reference input.

ENT + RIGHT+UP + ENT

LEGEND

ENT + RIGHT+UP . . . +UP + ENT

REDUNDANCY-CONFIG?-ON---

-CONVERTER-#-BU---1:03--

-CONVERTER-123456789ABC-

-AUTO/MAN--AAM----------

CONV-01-OFFSET=+00.00-DB

--ACTIVATE-BACKUP:-NO---

-CONV-#03-FRQ=XXXXX.XXX-

-ATEN=10.00---MANUAL-OK-

KEY-PAD

ENT

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

CLR

Figure 15. Configuration Menu Commands -

Redundancy ON and Backup Unit Selected

31

Page 50

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

---------SELECT---------

-----PRE-SELECT-MENU----

ENTER

-DISPLAY-PRE-SELECT-XX--

XXXXX.XXX-MHz--XX.XX--DB

-CONFIGURE-CONVERTER-TO-

-----PRE-SELECT?-XX-----

-PROGRAM-PRE-SELECT-XX-XXXX.XXX-MHZ---XX.XX-DB-

----CLEAR-DATA-FROM-----

-----PRE-SELECT?-XX-----

LEGEND

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

KEY-PAD

ENT

CLR

Figure 16. Pre-Select Menu Commands

---------SELECT---------

---MONITOR-STATUS-MENU--

ENTER

15VDC=-15.6--14VDC=-14.0

-VCC-=5.0---5VDis-=-4.0-

--CONVERTER-TEMP-=-+50C-

--IFLO-TUNING-=-X.X-V---

SYNTH.-TUNING-=-X.X-V---

--COARSE=X.XX-FINE=X.XX-

LEGEND

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

KEY-PAD

ENT

CLR

Figure 17. Monitor Status Menu Commands

32

Page 51

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

---------SELECT---------

---CURRENT-FAULTS-MENU--

ENTER

------POWER-FAULTS------

15VDC=OK-14VDC-OK-VCC=OK

-INFO-LOCK-DETECT-=-OK--

REFERENCE-LOCK-DET-=-OK-

SYNTH-FAULTS:-SUM-LD=OK-

FINE-LD=OK--COARSE-LD=OK

-CONV-TEMPERATURE-=-OK--

--HIGH-SPEED-BUS-=-OK---

LEGEND

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

KEY-PAD

ENT

CLR

Figure 18. Current Faults Menu Commands

---------SELECT---------

---STORED-FAULTS-MENU---

ENTER

TOTAL-FAULTS-STORED:--XX

LAST-19:20:05---05/19/02

----CLEAR-ALL-STORED----

-------FAULTS?-NO-------

LEGEND

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

ENT + UP

to scroll thru

Stored Faults

KEY-PAD

ENT

CLR

ST-FAULT-XX-----19:20:05

OK-FINE-LOCK----05/19/02

CLR to return

Figure 19. Stored Faults Menu Commands

33

Page 52

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

---------SELECT---------

-UTILITY-FUNCTIONS-MENU-

ENTER

----TIME:-10:22:05AM----

-----DATE:-05/19/02-----

---SERIAL-MODE=EIA232C-ADDR=XXX-BAUD=YYYY-P=ZZ-

-DISPLAY-CONTRAST-=-XX-DISPLAY-BRIGHTNESS-=-XX-

--REFERENCE-FREQUENCY---

----ADJUSTMENT-=-XXX----

---CONVERTER-SLOPE------

----ADJUSTMENT-=-X.X----

-------LAMP-TEST--------

-----------OFF----------

LEGEND

DISPLAY

---------SELECT---------

--MONITOR-STATUS-MENU---

KEY-PAD

ENT

CLR

Figure 20. Utility Function Menu Commands

34

Page 53

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

3.3.1 CONVERTER COMMANDS

The converter commands are in a tree structured menu format designed for access and

execution of all control functions, and to prevent the execution of an invalid entry by the

operator. When the prime power is turned on, the LCD display will contain a message

indicating the converter model number and the version number of the firmware installed

in the converter.

To select a Command Function press the "ENT" button on the keypad. The LCD display

will indicate:

SELECT

CONFIGURATION MENU

This will provide the local operator access to the Command Function Menus, which is the

top-level structure to start the selection of Command Function Menus to input into the

converter. To sequence to the next Command Function Menu press a "DOWN" or "UP"

arrow button on the keypad. The converter will step to the next Command Function

Menu each time a "DOWN" or "UP" arrow button is pressed. The current Command

Function Menu will be displayed on the LCD display. The Command Function Menus

are shown in Figure 12.

To select a specific Command Function Menu press the "ENT" keypad button. If a

function is selected in error, press the clear ("CLR") button, which will return the

converter to the main command menus to allow the selection of another function. Any

one of the six Command Function Menus can be selected using this procedure.

Once a Command Function has been selected, use the "RIGHT" or "LEFT" arrow keypad

buttons to sequence through the Operating Mode Commands. Each of the modes will be

displayed on the LCD display. A specific operating mode is selected by pressing the

"ENT" button. If an mode is selected in error, press the clear ("CLR") button, which will

return the converter to the operating menus to allow the selection of another mode.

When an operating mode is selected, a parameter or a digit within the parameter will be

flashing on the LCD display. Use the "RIGHT" and "LEFT" arrows buttons to sequence

through the parameters or digits to select the next parameter or digit. A specific

parameter or value is selected by pressing the "ENT" button. If a parameter or value is

selected in error, press the clear ("CLR") button, which will return the converter to the

original parameter or value to allow another selection.

After selecting a parameter or digit, use the "UP" or "DOWN" arrow buttons to select the

next parameter, or to increment or decrement the value of a digit. A specific new

parameter or new value is selected by pressing the "ENT" button. If a parameter or value

is selected in error, press the clear ("CLR") button, which will return the converter to the

original parameter or value to allow another selection.

Each time the clear ("CLR") button is pressed, the converter will return to the menu level

prior to the last "ENT" command.

35

Page 54

DT4500 Series Down Converters MN/DT4500.IOM

System Operation Revision 1

3.3.2 CONFIGURATION FUNCTIONS MENU

The Configuration Functions are as follows:

3.3.2.1 FREQUENCY OPERATING MODE

Frequency (FREQ):

Displays the current converter frequency in MHz, and allows the selection of a

new frequency channel between RF

Low

to RF

MHz (e.g.; 10950.000 to

High

12750.000 MHz for Model DT-4513) in 125 KHz steps through keypad inputs.

Attenuation (ATTN):

Input and displays the converter attenuation setting which is selected between

0.00 to 20.00 in 0.25 dB steps. The default setting is 10.00 dB.

Rx: The converter is ON or OFF. The default mode is OFF.

3.3.2.2 EXTERNAL REFERENCE

External Reference:

The External Reference is displayed only when the 5 or 10 MHz external

reference input to the converter is present.

3.3.2.3 ENTRY MODE/COLD START

The entry mode is Local or Remote. The default is Remote.

COLD Start:

The COLD Start Mode, if enabled, mutes the converter output signal for a predetermined time, 15 minutes, after power is applied to the converter to ensure that

the reference oscillator is stable. The default mode is Disabled. This function is

disabled in redundant systems.

3.3.2.4 FAULT RECOVERY

Fault Recovery:

Fault Recovery is Manual or Auto. The default is Auto.

3.3.2.5 REDUNDANCY MODE