Page 1

INSTALLATION

& OPERATION

MANUAL

PSE475

REMOTE STROBE

POWER SUPPLY

TM

PSE475

REMOTE STROBEREMOTE STROBE

REMOTE STROBE

REMOTE STROBEREMOTE STROBE

POWER SUPPLY POWER SUPPLY

POWER SUPPLY

POWER SUPPLY POWER SUPPLY

IMPORTANT:

Contents:

Introduction ......................................................... 2

Standard Features .............................................. 2

Specifications ..................................................... 2

Unpackaging & Pre-installation .......................... 3

Installation & Mounting ....................................... 4

Wiring Instructions ....................................... 4-10

Flash Control Options ......................................... 7

Switching Control Variations ......................... 7-10

Maintenance ..................................................... 11

Troubleshooting................................................ 11

Warranty ........................................................... 12

Read all instructions and warnings before installing and using.

INSTALLER:

This manual must be delivered to the end user of this equipment.

Page 2

Introduction

The PSE475 Series Remote Strobe Power Supply represents the latest in state-of-the-art strobe warning

technology. The latest in MOSFET technology and advanced design provide efficient operation, meaning

superior performance , reliability and long life. The use of intelligent microprocessor control allows the Model

PSE475 series to offer more light pattern options and versatility than any other remote system available. The

user may select the standard Quad flash pattern or select any of five additional auxiliary patterns. In addition,

the user can utilize all flash options with

possible patterns. When connected to remote strobe heads , the PSE475 delivers the highest available level of

emergency warning signals.

Cycle Flash

TM

a feature that allows cycling continuously through all

Standard Features

All MODEL PSE475 Remote Strobe Power Supplies come equipped with the following standard features:

(See fig. 3, page 5)

MULTIPLE OPERATING VOLTAGES

10-30 VDC operation only. Reverse polarity protected

EXTERNAL FUSE PROTECTION

User replacable 15 AMP fuse for +12 VDC operation.

NOTE: For +24 VDC operation, the user should replace this with a 7.5 AMP fuse.

OUTPUT SHORT CIRCUIT/FLASHTUBE FAILURE PROTECTION

Power supply will shut-off when trying to flash any heads that have been shorted, or have a failed flash tube.

MULTIPLE USER SELECTABLE FLASH PATTERNS

User may select either Quad Flash, Double Flash, Fast Double flash, Triple Flash, Five Flash, or Cycle Flash

patterns. See Flash Control Options Section, page 7.

SELECTABLE SWITCHING CONTROL OF OUTLET PAIRS

Allows user, when in the standard Quad Flash mode, to select either alternating outlet pairs 1 and 4 only, or 2

and 3 only.

NOTE: Additional auxiliary flash modes utilize all outlets, 2 outlets alternate with 2 outlets. There is no selectable switching available.

HI/LO POWER CONTROL

Allows reduction of strobe light intensity using either +VDC or (earth) ground switching for night time use.

LOW CURRENT SWITCHING, SEE PAGE 10

Specifications

OPERATING VOLTAGE: 10-30 VDC

OUTPUT POWER: 75 WATTS NOMINAL

OUTPUT ENERGY: 64 JOULES NOMINAL

STANDARD FLASH RATE: EACH STROBE LIGHT OUTLET 70 QUAD FLASHES/MIN.

ALTERNATING PAIRS 140 QUAD FLASHES/MIN.

POWER CONSUMPTION: 7 AMPS AVERAGE AT 12.8 VDC (HIGH POWER)

3 AMPS AVERAGE AT 25.6 VDC (HIGH POWER)

2

Page 3

!

WARNING!

The use of this or any warning device does not insure that all drivers can or will observe or

react to an emergency warning signal. Never take the right-of-way for granted. It is your

responsibility to be sure you can proceed safely before entering an intersection, driving

against traffic, responding at a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and

wiring. Read and follow the manufacturer’s instructions before installing or using this

device. The vehicle operator should insure daily that all features of the device operate

correctly. In use, the vehicle operator should insure the projection of the warning signal is

not blocked by vehicle components (i.e.: open trunks or compartment doors), people,

vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility to understand and obey all laws regarding emergency warning devices. The user

should check all applicable city, state and federal laws and regulations.

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of

this warning device.

Proper installation is vital to the performance of this warning device and the safe operation

of the emergency vehicle. It is important to recognize that the operator of the emergency

vehicle is under psychological and physiological stress caused by the emergency situation.

The warning device should be installed in such a manner as to: A) Not reduce the output

performance of the system, B) Place the controls within convenient reach of the operator

so that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly

protect and use caution around live electrical connections. Grounding or shorting of

electrical connections can cause high current arcing, which can cause personal injury and/

or severe vehicle damage, including fire. Do not touch the strobe light tubes, the strobe

light head assemblies or the strobe power supply while the system is in operation. Wait 5

minutes after turning off the power from system before touching any internal componentry.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER

USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY

OF EMERGENCY PERSONNEL AND THE PUBLIC.

Unpacking and Pre-Installation

Remove the power supply from the box and examine the unit for any transit damage. Report any

damage to the carrier immediately. Inspect the supplied user parts kit , this should contain:

A. 1 POWER INPUT WIRE HARNESS ASSEMBLY consisting of one AMP 3 pin

connector with three wires , Red wire positive ( +Vdc ) , Black wire negative ( Ground / Earth)

and Green wire ( Hi/Lo intensity ). This assembly is to be connected to customer supplied

power cable ( See Installation and Mounting section ).

B. 1 CONTROL WIRE HARNESS ASSEMBLY consisting of one AMP 4 pin connector with

four wires White, Orange , Yellow and Brown. This assembly is to be connected to

customer supplied control switching ( See Installation and Mounting section).

C. 1 ASSEMBLY KIT containing:

Four AMP 3 pin socket housings to be connected to the remote strobe light head assembly

cables ( See Installation and Mounting section ). Four #8 sheet metal screws for mounting.

3

Page 4

Installation and Mounting

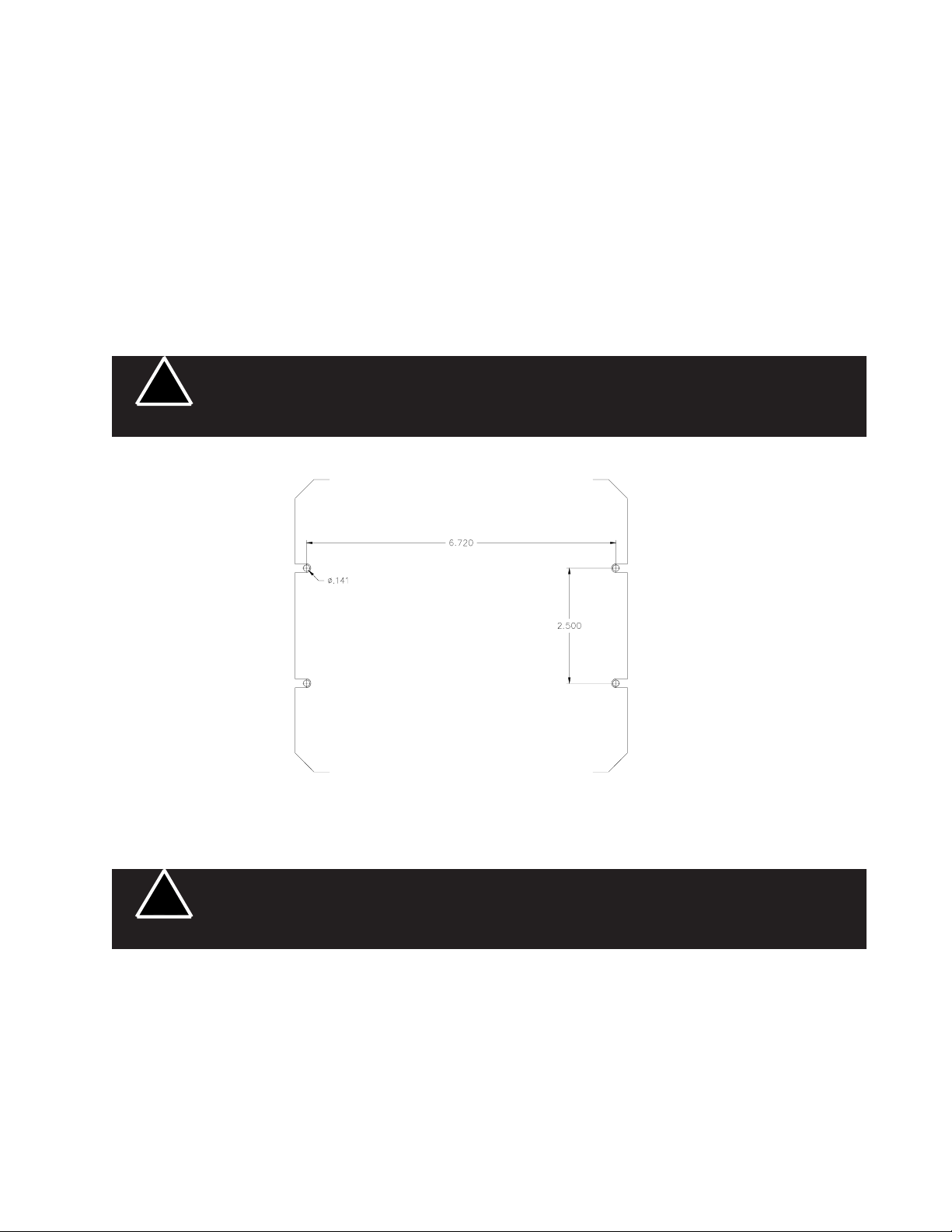

MOUNTING THE MODEL PSE475 STROBE LIGHT POWER SUPPLY

To obtain maximum performance and durability the Model PSE475 strobe light power supply

should be mounted as follows:

1. Mount the unit with the strobe light outlets located in such a way that they are easily accessible.

2. Mount the unit with the four supplied #8 sheet metal screws. If possible, a metal surface should be

chosen for best heat dissipation. The mounting hole pattern dimensions are shown in Figure 1. The power supply

can be used as a template to mark the drill locations. Predrill this surface with a 9/64 drill and secure

the unit.

!

WARNING!

High voltages and/or temperatures are present inside the unit. Disconnect from power and

wait 10 minutes prior to servicing or troubleshooting. Use hand and eye protection when

changing halogen lamps or flashtubes.

FIGURE 1

!

The Model PSE475 Strobe Power Supply is NOT waterproof and should be located in an area

protected from the weather and water.

WARNING!

WIRING

STROBE LIGHT HEAD CABLE CONNECTIONS

1. Install the strobe light heads in the preferred locations and route the shielded three wire cable from the

light heads to the PSE475 power supply. Leave enough cable at the power supply location so that the cables

will not be strained when connected to the power supply outlets. Follow the lighthead user instructions for

connecting the cables to the strobe light heads.

4

Page 5

NOTE: USE AMP HAND TOOL PART NO. 90124-2 OR EQUIVALENT TO CRIMP SOCKET PINS TO THE

WIRES.

CRIMP TO INSULATION ONLY

CRIMP OVER BARE WIRE

STRIP INSULATION TO EXPOSE

BARE WIRE AS SHOWN

THIS END TO POWER

SUPPLY

AMP 3 PIN SOCKET HOUSING

PN 1-480303-0

AMP SOCKET PIN

PN 60619-9

FIGURE 2

1/8 INCH

WHITE WIRE - (TRIGGER) POSITION 3

BLACK WIRE - (CATHODE) POSITION 2

RED WIRE - (ANODE) POSITION 1

SHIELD WIRE

CONNECT TO CHASSIS

GROUND

2. After the cables have been properly installed and routed, the three wires will have to be inserted

into the AMP 3 pin socket housing before being plugged into the power supply.

NOTE: IT IS VERY IMPORTANT TO OBSERVE THE PIN LOCATIONS AND ORDER OF COLOR ON THE

AMP 3 PIN SOCKET HOUSING. IMPROPER CONNECTIONS COULD DAMAGE THE POWER SUPPLY

AND STROBE TUBE ASSEMBLIES. SEE FIGURE 2

STROBE HEAD OUTLET #1

FIGURE 3

5

15 AMP FUSE FOR STROBE

POWER SUPPLY PROTECTION

POWER INPUT HARNESS

FLASH CONTROL HARNESS

STROBE HEAD OUTLET #4

STROBE HEAD OUTLET #3

STROBE HEAD OUTLET #2

Page 6

3. With the AMP 3 pin connectors terminated properly , plug each cable into the appropriate 3 position socket

on the PSE475 strobe power supply. The outlet chosen for each cable will be determined by the Flash pattern

selected. See Flash Control Switching Options Section for further details on flash selection.

POWER-INPUT WIRE HARNESS ASSEMBLY

The Power-input wire harness is to be connected to the 3 position socket connector on the PSE475 strobe

power supply. See Figure 3, page 5.

The Power harness assembly consists of red (+Vdc) and black (Ground/Earth) wires that power the

PSE475 strobe power supply and a green wire for Hi/Lo intensity control. Figure 4

The Hi/Lo intensity feature allow the strobe lights of the system to be switched into low power for night use

by connecting the green wire either to + Vdc or Ground (Earth). If this feature is not used

remove this wire.

RED WIRE (POSITIVE)

BLACK WIRE (NEGATIVE)

GREEN WIRE (+/-)

THIS END TO POWER

SUPPLY

Power-Input Harness Assembly

PSE PN 3557

FIGURE 4

it is important to

FLASH CONTROL HARNESS ASSEMBLY

The Flash Control wire harness is to be connected to the 4 position socket connector on the PSE475

strobe power supply (See Figure 3 on page 5). The Flash Control harness consists of an AMP 4 pin connector

with 4 wires : white, orange , yellow and brown (See Figure 5). These are activated by connecting to a source of

+Vdc (they are low current inputs).

This control harness is to be connected to a customer supplied control cable, which in turn is to be connected

to a customer supplied switch to complete the installation.

Refer to the Flash control options and Switching Control variations sections for details on Flash Control

connections.

WHITE WIRE (+) POSITION 4

ORANGE WIRE (+) POSITION 3

THIS END TO POWER

SUPPLY

Flash Control Harness Assembly

PSE PN 3556

FIGURE 5

YELLOW WIRE (+) POSITION 2

BROWN WIRE (+) POSITION 1

6

Page 7

Flash Control Switching Options

To select any one of eight different FLASH MODES, simply connect the White, Orange, Yellow and Brown wires

to a switch or switches, in the combinations indicated in Table 1. NOTE: THE BROWN WIRE WILL PUT THE

PSE475 IN

FLASH MODE SELECTED.

In the following table a “1“ = 12/24 Vdc and a “0 “ = Ground (Earth) or no connection.

BROWN YELLOW ORANGE WHITE FLASH MODE

0 0 0 0 ALL HEADS OFF

0001QUAD FLASH HEADS 1 AND 4

0010QUAD FLASH HEADS 2 AND 3

0011QUAD FLASH ALL HEADS

0100FIVE FLASH ALL HEADS

0101STANDARD DOUBLE FLASH ALL HEADS

0110FAST DOUBLE FLASH ALL HEADS

Cycle Flash

TM

MODE WHEN CONNECTED TO (+ Vdc). THIS WILL OVERRIDE ANY OTHER

0111 TRIPLE FLASH ALL HEADS

1 X X X IN

TABLE 1 - FLASH MODE SELECTION

Cycle Flash

TM

ALL HEADS

Switching Control Variations

The Model PSE475 outlet strobe light flashing sequence variations are controlled by four factors:

1. Selecting one or more of the Flash Modes available (see Table 1).

2. Determining the switching necessary to control these modes (user supplied).

3. Choosing to connect the remote strobe light head assemblies to the alternating or simultaneous

flashing functions on the power supply outlets (see Figure 6, page 8).

4. Number of remote strobe light head assemblies used in the system.

7

Page 8

FIGURE 6 - Switching Controls and Strobe Light Outlet Functions

The following diagrams show some of the wiring configurations possible for various flash modes. All fuses

shown are to be customer supplied, and recommended fuse ratings to be observed. All switches are to be

customer supplied. Additional variations can be used. Refer to Table 1, Page 7 and Figure 6 to determine the

necessary connections.

VARIATIONS IN STANDARD QUAD FLASH MODE

4 OUTLETS

ON-OFF SWITCHING HIGH POWER

ONLY

4 OUTLETS

HIGH POWER - OFF - LOW POWER

8

Page 9

SELECTIVE SWITCHING OF OUTLETS

1 AND 4 (only) - OR - 2 AND 3 (only)

HIGH POWER ONLY

The following switching variations show selection of various optional patterns:

CYCLE FLASH MODE

4 OUTLETS ON-OFF SWITCHING

HIGH POWER ONLY

STANDARD DOUBLE FLASH MODE

4 OUTLETS ON-OFF SWITCHING

HIGH POWER ONLY

9

Page 10

MULTIPLE FLASH MODES

By selecting the proper switching, any number of flash modes can be used.

Example: Triple Flash with Five Flash

4 OUTLETS ON-OFF-ON

HIGH POWER ONLY

LOW CURRENT SWITCHING CONTROL

The PSE475 Power Supply utilizes low current switching. This means, if desired, the power in (RED) connection can be connected directly to the source (+), and the control connections can be used to switch the strobe

supply on or off using a low current source (+). See Figure 7.

FIGURE 7

10

Page 11

MAINTENANCE

The PSE475 Remote Strobe Power Supply has been designed to provide trouble free service. In case of

difficulty , refer to the Troubleshooting section. Periodic inspection of power supply wiring, and strobe light

head connections for shorted or open wires will assure trouble free operation. The primary cause of short

circuits has been found to be wires passing through firewalls, roofs, etc.

Troubleshooting

NOTE: DO NOT TAMPER WITH THE POWER SUPPLY. THIS UNIT IS SOLD AS A COMPLETE MODULE,

AND IS NOT DESIGNED FOR FIELD REPAIR.

All PSE475 Remote Strobe Power Supply units are thoroughly tested before shipment. However, should you

encounter a problem during installation or during the life of the product , refer to the guide below for information on troubleshooting. In most cases problems that occur will be related either to the power / control wiring,

or to the strobe light head cables that connect them to the strobe power supply. In the event that the strobe

power supply is at fault return the unit to the factory for service. Additional information may be obtained from

the factory technical help line at 314-426-2700 ext. 2132.

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

External fuse blows a. Power input wires reversed. a. Check power connections.

b. Power supply failure. b. Return for service.

c. Incorrect fuse size. c. Replace with a 15A for +12VDC or

7.5A for +24VDC.

Light heads do not fire a. Cable connections loose a. Check all connections.

at power supply or light head. b. Isolate damaged cable by disconnecting

b. Cable to light heads one at a time. Repair or replace the

damaged and shorting to damaged cable.

chassis.

c. Cable terminated improperly c. Check wire orientations at 3 pin connecin 3 pin AMP connector. tors.

d. Bad strobe tube. d. Replace strobe tube assembly.

Incorrect flash pattern a. Control harness wiring a. Check wiring/switches. Refer to Table 1

and or switches not connected to verify selections.

properly.

b. Light heads plugged into b. Follow designations on label for outlets

wrong outlet on the power and move to proper outlet.

supply.

Low strobe light intensity a. Power supply in low power a. Check green wire on power harness.

mode. It should not be connected to power or

ground for HI power mode.

Flash patterns change a. Power supply is in CYCLE a. Brown wire is connected to +VDC. Check

continuously FLASH mode. Proper control harness/switches. If CYCLE MODE

operation. is not desired change connections.

11

Page 12

WARRANTY

This product was tested and found to be operational at the time of manufacture. Provided this

product is installed and operated in accordance with the manufacturer's recommendations, Public Safety

Equipment guarantees the PSE475 for a period of 5 years from the date of purchase or delivery, whichever is later. Units demonstrated to be defective within the warranty period will be repaired or replaced at

the factory service center at no cost.

Use of a lamp or other electrical load of a wattage higher than installed or recommended by the

factory, or use of inappropriate or inadequate wiring or circuit protection causes this warranty to become

void. Failure or destruction of the product resulting from abuse or unusual use and/or accidents is not

covered by this warranty. Use of non-PSE components and assemblies may cause damage to the

system and/or personal injury, and voids all warranties on PSE systems and components.

PSE shall in no way be liable for other damages including consequential, indirect or special damages whether loss is due to negligence or breach of warranty.

PSE MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to obtain a Return

Goods Authorization Number (RGA number) before you ship the product to Code 3, Inc. Write the RGA

number clearly on the package near the mailing label. Be sure you use sufficient packing materials to avoid

damage to the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses

incurred for the removal and /or reinstallation of products requiring service and/or repair.; nor for the packaging, handling, and shipping: nor for the

handling of products return to sender after the service has been rendered.

Problems or Questions? Call our Technical Assistance HOTLINE - (314) 996-2800

Code 3, Inc.

Cycle Flash is a trademark of Code 3, Inc.

Code 3 is a registered trademark Code 3, Inc. a subsidiary of Public Safety Equipment, Inc.

St. Louis, Missouri 63114-2029—USA

Revision 2, 12/2005 - Instruction Book Part No. T07016

10986 N. Warson Road

www.code3pse.com

©2004-5 Code 3, Inc. Printed in USA

Loading...

Loading...