Page 1

INSTALLATION

& OPERATION

MANUAL

MODEL

OLRD

OLDM

Patent Pending

IMPORTANT:

OSCILASER

TM

REAR DECK/DASH MOUNT

Contents:

Introduction..................................................................... 2

Unpacking & Pre-Installation .......................................... 2

Installation & Mounting ................................................ 2-3

Maintenance ................................................................... 4

Cleaning ......................................................................... 4

Changing Lamps ............................................................ 4

Troubleshooing............................................................... 5

Parts List (Replacement Parts / Exploded View) ............ 5

Warranty ......................................................................... 6

Read all instructions and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this equipment.

Page 2

Introduction

The OLRD is an oscillating warning light designed to be mounted with the "L" bracket included in the rear deck

or front bumper of a vehicle. The OLDM is the same oscillating light assembly with the addition of a cord and

cigarette lighter plug, as well as an adjustable mounting bracket for use in the front windshield area of a

vehicle. Both of these highly effective warning light systems feature the OsciLaserTM light assembly with its

constant 35 watt for 12V and 32 watt for 24V Halogen signal that covers all areas within its field of illumination

at least once per second.

The use of this or any warning device does not insure that all drivers can or will observe or

react to an emergency warning signal. Never take the right-of-way for granted. It is your

responsibility to be sure you can proceed safely before entering an intersection, driving

against traffic, responding at a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and

wiring. Read and follow the manufacturer’s instructions before installing or using this

device. The vehicle operator should insure daily that all features of the device operate

!

WARNING!

correctly. In use, the vehicle operator should insure the projection of the warning signal is

not blocked by vehicle components (i.e.: open trunks or compartment doors), people,

vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility to understand and obey all laws regarding emergency warning devices. The user

should check all applicable city, state and federal laws and regulations.

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of this

warning device.

Proper installation is vital to the performance of this warning device and the safe operation

of the emergency vehicle. It is important to recognize that the operator of the emergency

vehicle is under psychological and physiological stress caused by the emergency situation.

The warning device should be installed in such a manner as to: A) Not reduce the output

performance of the system, B) Place the controls within convenient reach of the operator

so that one can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly

protect and use caution around live electrical connections. Grounding or shorting of

electrical connections can cause high current arcing, which can cause personal injury and/

or severe vehicle damage, including fire.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER

USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY

OF EMERGENCY PERSONNEL AND THE PUBLIC.

Unpacking and Preinstallation

Carefully unpack the unit and check the contents against the parts list on page # 5 of this booklet. Be careful

to open the proper end of the OsciLaser light carton so the lens is not damaged or cut. Test the operation of

the OsciLaser light assembly before installation by connecting the red power wire to applicable +12 or 24 volt

D.C. lead and the black wire to ground (earth).

Installation and Mounting

Larger wires and tight connections will provide longer service life for components. For high

!

WARNING!

the current carrying capacity of wires, fuses, and circuit breakers. Use "SXL" type wire in

engine compartment. All wiring should conform to the minimum wire size and other

recommendations of the manufacturer and be protected from moving parts and hot

surfaces. Looms, grommets, cable ties, and similar installation hardware should be used to

current wires it is highly recommended that terminal blocks or soldered connections be used

with shrink tubing to protect the connections. Do not use insulation displacement

connectors (e.g. 3M® Scotchlock type connectors). Route wiring using grommets and

sealant when passing through compartment walls. Minimize the number of splices to

reduce voltage drop. High ambient temperatures (e.g. underhood) will significantly reduce

2

Page 3

anchor and protect all wiring. Fuses or circuit breakers should be located as close to the

power takeoff points as possible and properly sized to protect the wiring and devices.

Particular attention should be paid to the location and method of making electrical

!

WARNING!

NOTE : All of the information listed in this

booklet must be given to the end user by

the installer.

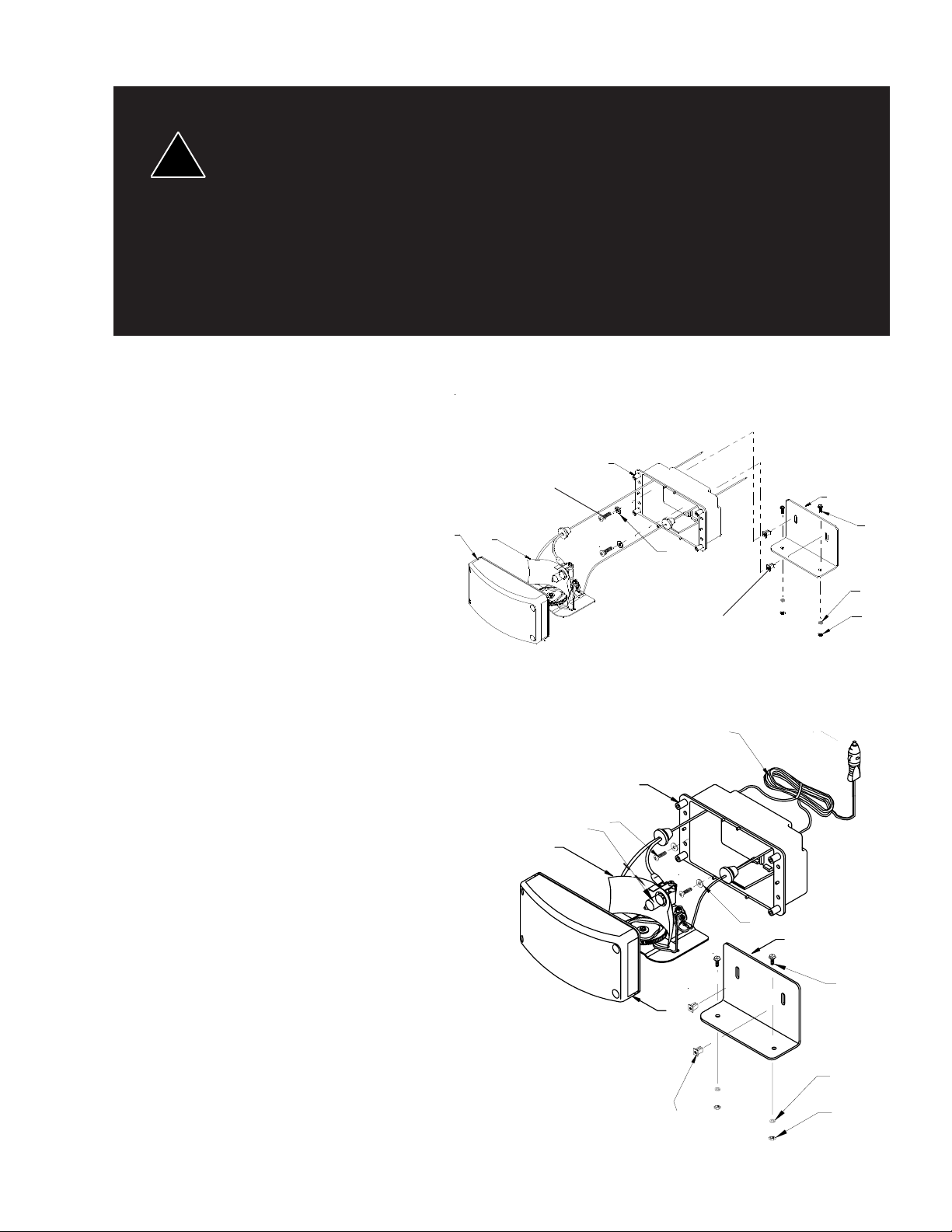

OLRD INSTALLATION:

connections and splices to protect these points from corrosion and loss of conductivity.

Ground terminations should only be made to substantial chassis components, preferably

directly to the vehicle battery. The user should install a fuse sized to approximately 125% of

the maximum Amp capacity in the supply line to protect against short circuits. For example, a

30 Amp fuse should carry a maximum of 24 Amps.

DO NOT USE 1/4" DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR

CONTINUOUS DUTY IN SIZES ABOVE 15 AMPS.

Circuit breakers are very sensitive to high temperatures and will "false trip" when mounted in

hot environments or operated close to their capacity.

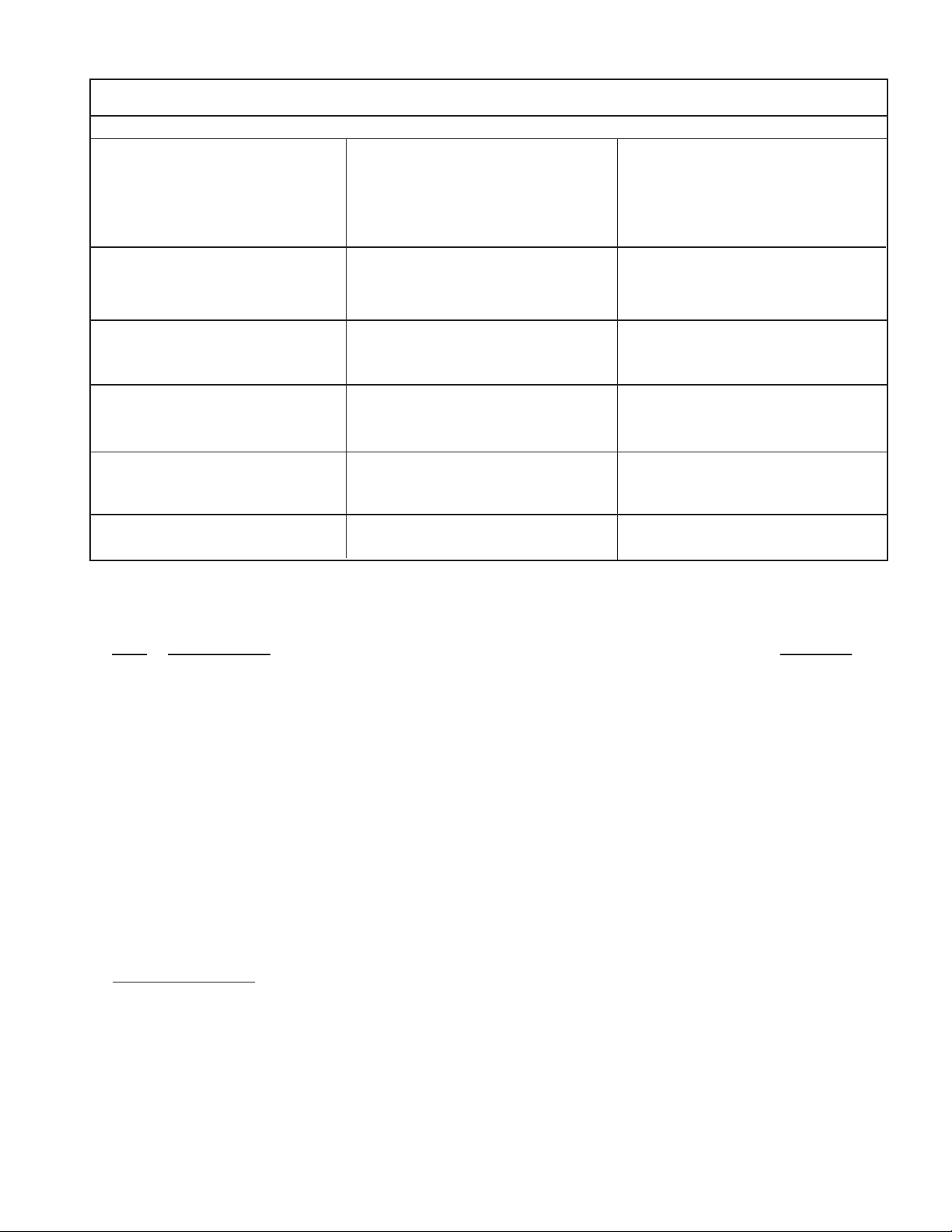

Mounting the L Bracket

1) Choose a suitable location for mounting

the Oscilaser , Using the square

mounting holes in the bottom of the

bracket as a template, mark the mounting hole positions. (NOTE: The bracket

bottom "L" can be turned either direction

based on mounting requirements.) Drill

one (5/16)" hole at each mark.

2) Using the supplied lockwashers, nuts,

and carriage bolts, mount the bracket to

the drilled holes. (See Figure 2.) Insure

that the fasteners are sufficiently tight.

Mounting the Oscilaser:

3) To install the Oscilaser to the "L"

Bracket, remove four lens screws and

pull lens from housing. Pull the Oscilaser

oscillating unit (Part #2) from housing.

4) Insert the supplied plastic inserts (Part

#7) into the back of the bracket. (Note:

push the inserts in from the side that the

light will be mounted on.)

5) Using the supplied screws and washers

(Parts #5 and #6, see Figure 1), attach

the housing to the inserts in the bracket.

Insure that the fasteners are sufficiently

tight.

6) Reassemble the Oscilaser, making sure

not to pinch the wires when tightening

the lens screws.

OLDM INSTALLATION:

The OLDM can be mounted with the "L"

Bracket in the same fashion as described above or it can be mounted using

the adjustable bracket.

TM

3

5

1

2

6

5

7

7

OLRD

FIGURE 1

11

3

5

13

2

5

3

1

OLDM

6

4

8

9

10

4

8

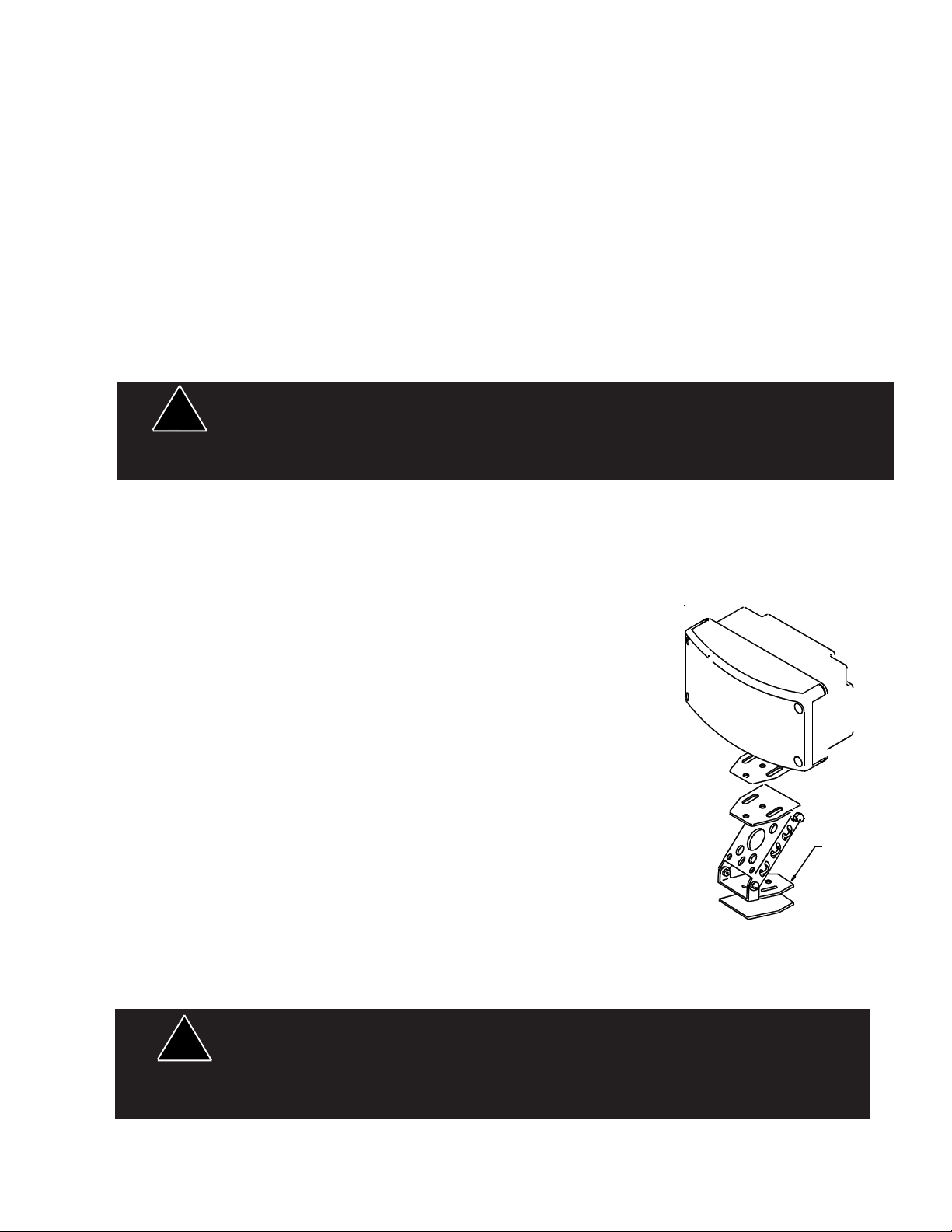

1) Assemble the Dash Mount bracket

according to Figure 2 or 3 per applicable

mounting.

2) Find a suitable flat mounting position for

the unit.

FIGURE 2

7

9

10

3

Page 4

3) Peel the protective paper backing from one side of a piece of the double-sided tape and stick it to the top of

the bracket, (See Figure 3) for modes with adjustable mounting brackets.

4) Peel the remaining side of the paper and attach the bracket to the Oscilaser .

5) Peel the paper backing from one side of the other piece of double-sided tape and stick it to the bottom of

the bracket.

6) Remove the remaining side of paper and adhere it to the desired surface.

WIRING THE OSCILASER:

1) Using one of the supplied butt splices, connect the red power wire to the appropriate switched positive(+)

lead from the lighting control.

2) Using the remaining butt splice, connect the black ground (earth) wire to the vehicle chassis or a negative () wire lead.

(For fusing purposes, each Oscilaser draws approximately 4 amps.)

When mounting the OsciLaser

!

are securely fastened so that in the event of a collision they do not break free and injure the

vehicle occupants.

TM

units inside the vehicle on the rear deck, make sure they

WARNING!

Maintenance

If necessary, maintenance of your OsciLaser

involves the cleaning of the lens and the replace-ment of the lamp on the OsciLaser assembly.

Cleaning

Clean with soap and water to remove all salt, dirt or

mud. Do not use any abrasive cleaners or harsh

chemicals, because the polycarbonate lens will scratch

very easily. Polish the lens with PSE lens polish and a

soft paper cloth or towel.

Changing Lamps

To remove the lens, remove the 4 corner #8 x 5/8"

stainless steel screws. Using a glove or cloth for hand

protection, push in the defective lamp and turn counter

clockwise until the lamp can be removed. Install a new

Osram 64170 AX or equal bayonet-base lamp (non

ceramic base lamps are recommended) and replace

lens.

12

!

WARNING!

ADJUSTABLE MOUNTING BRACKET

FIGURE 3

Lamps are extremely hot! Allow to cool completely before attempting to remove. Gloves

and eye protection should be worn when handling halogen lamps as they are pressurized

and accidental breakage can result in flying glass.

4

Page 5

Troubleshooting guide

PROBLEM (OSCILASERTM LIGHT)

NO LIGHT AND NO OSCILLATION

PROBABLE CAUSE

1) OPEN CIRCUIT IN WIRING

2) LAMP AND MOTOR ARE

DEFECTIVE

3) SHORT CIRCUIT

REMEDY

1) CLOSE CIRCUIT BY CHECKING CONNECTIONS

2) RETURN OSCILASER

ASSEMBLY FOR REPAIR

3) CHECK FOR SHORTS IN LAMP

ASSEMBLY OR WIRING

OSCILLATES WITH NO LIGHT

LIGHT IS ON WITH NO OSCILLATION

LIGHT IS ON WITH SLOW OR

ERRATIC MOVEMENT OF OSCILASER

WATER IS COLLECTING IN HOUSING

UNIT BURNS FUSES/TRIPS CIRCUIT

BREAKERS

1) LAMP IS DEFECTIVE

2) WIRING TO LIGHT, IS LOOSE OR

DISCONNECTED.

1) MOTOR IS DEFECTIVE

2) WIRING TO MOTOR IS LOOSE

OR DISCONNECTED

1) OSCILASER ASSEMBLY IS

DEFECTIVE

2) LOW VEHICLE VOLTAGE

1) WIRING HOLES ARE NOT

SEALED PROPERLY

2) HOUSING GASKET IS DEFECTIVE

1) SHORT CIRCUIT

1) REPLACE LAMP

2) RECONNECT WIRE TO

OSCILASER LIGHT

1) RETURN ASSEMBLY FOR

REPAIR

2) RESOLDER WIRE TO MOTOR

1) RETURN ASSEMBLY FOR

REPAIR OR REPLACEMENT

2) CHECK VEHICLE VOLTAGE

1) RESEAL HOLES WITH CAULK

2) REPLACE HOUSING GASKET

ASSEMBLY

1) CHECK ASSEMBLY AND

WIRING FOR SHORT CIRCUIT

Parts & Exploded Views

Ref. Description Part No.

1 Green Lens T05530

2 OsciLaser Assembly S50031

3 Housing T03759

4 "L" Bracket S85897

5 Sheet Metal Screw (6 x 1/2,"B" pt) T06213

6 #6 Flat washer T10155

7 Plasti - Grommet T06521

8 C-Bolt, 5/16 - 18 x 3 1/2" T06716

9 5/16" Split Lockwashers T00245

10 Nut, Hex Head, 5/16" T00244

11 Cordset T01590

12 Adjustable Mounting Bracket S18314

13 Lamp 35 watt Halogen for 12V T01542

Clear Lens T05531

Red Lens T05532

Blue Lens T05533

Amber Lens T05534

Gasket T06512

Lamp 32 watt Halogen for 24V T05160

Parts Not Shown

Mounting Kit - Rear Deck and Dash mount T09004

HEYCO Snub bushings T06523

(2) for OLDM model only

5

Page 6

6

Page 7

7

Page 8

WARRANTY

This product was tested and found to be operational at the time of manufacture. Provided this product is installed and operated in accordance with the manufacturer's recommendations, Code 3, Inc. guarantees all parts and components except the lamps for a period

of 1 years from the date of purchase or delivery, whichever is later. Units demonstrated to be

defective within the warranty period will be repaired or replaced at the factory service center

at no cost.

Use of a lamp or other electrical load of a wattage higher than installed or recommended by the factory, or use of inappropriate or inadequate wiring or circuit protection

causes this warranty to become void. Failure or destruction of the product resulting from

abuse or unusual use and/or accidents is not covered by this warranty.

Code 3, Inc. shall in no way be liable for other damages including consequential, indirect or special damages whether loss is due to negligence or breach of warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY,

WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

In order to provide you with significantly faster service, if you are going to return a

product for repair or replacement*, please contact our factory to obtain a Return Goods

Authorization Number (RGA number) before you mail the product to PSE. Write the RGA

number clearly on the package near the mailing label. Be sure you use sufficient packing

materials to avoid damage to the product being returned while in transit. All plastic domes

and optical lenses are NOT returnable for credit or exchange.

*PSE reserves the right to repair or replace product at its discretion. PSE assumes no responsibility or liability for

expenses incurred for the removal and/or reinstallation of products requiring service and/or repair.

NEED HELP? Call our Technical Assistance Hotline - (314) 996-2800

St. Louis, Missouri 63114-2029—USA

10986 N. Warson Road

Code 3, Inc.

www.code3pse.com

OsciLaser is a trademark and Code 3 is a registered trademark of Code 3, Inc. a subsidiary of Public Safety Equipment, Inc.

3M is a registered trademark of 3M Company

Revision 6, 02/2006 - Instruction Book Part No. T03405

©2002-6 Code 3, Inc. Printed in USA

Loading...

Loading...