Page 1

INSTALLATION

&OPERATION

MANUAL

NIGHTPROBE

REMOTE CONTROLLED SPOTLIGHT

PATENT PENDING

NP 130

Contents:

NIGHTPROBE

REMOTE CONTROLLED SPOTLIGHT

Introduction (with warnings).......................................2

Unpacking & Pre-Installation.....................................2

Installation & Mounting................................................2

Controller Installation................................................3

Wiring Instructions ......................................................3

Maintenance ...................................................................4

Parts List (Replacement Parts/Exploded View) 5,6

Troubleshooting.........................................................7

Specifications .................................................................7

Warranty ........................................................................... 8

IMPORTANT:

TANT:

Read all instructions and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this

equipment.

Page 2

The use of this or any warning device does not insure that all drivers can or will observe or

react to an emergency warning signal. Never take the right-of-way for granted. It is your

!

WARNING!

responsibility to be sure you can proceed safely before entering an intersection, driving

against traffic, responding at a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and

wiring. Read and follow the manufacturer’s instructions before installing or using this device.

The vehicle operator should insure daily that all features of the device operate correctly. In

use, the vehicle operator should insure the projection of the warning signal is not blocked by

vehicle components (i.e.: open trunks or compartment doors), people, vehicles, or other

obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility to understand and obey all laws regarding emergency warning devices. The user should

check all applicable city, state and federal laws and regulations.

Code 3, assumes no liability for any loss resulting from the use of this warning device.

Note:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

The user is cautioned that changes or modifications not expressly approved by CODE 3 for compliance

could void the user's authority to operate this equipment.

Introduction

The NightProbe , NP 130, product is a remote control spotlight that delivers more signal power and versatility

than any other spotlight product.

Its low profile aerodynamic lines reduce air drag, which results in fuel savings and stability at high speeds.

This product is made of shock-resistant high-temperature engineering thermoplastics and provides a warning

signal that exceeds SAE standards.

The NightProbe and its mounting system is designed to operate in many different locations including on the

driver side, passenger side or center of the automobile hood rear lip.

Unpacking & Pre-installation

Remove the spotlight from the box and examine the unit for transit damage. Refer to parts list to insure that all

parts are present for installation.

Installation & Mounting

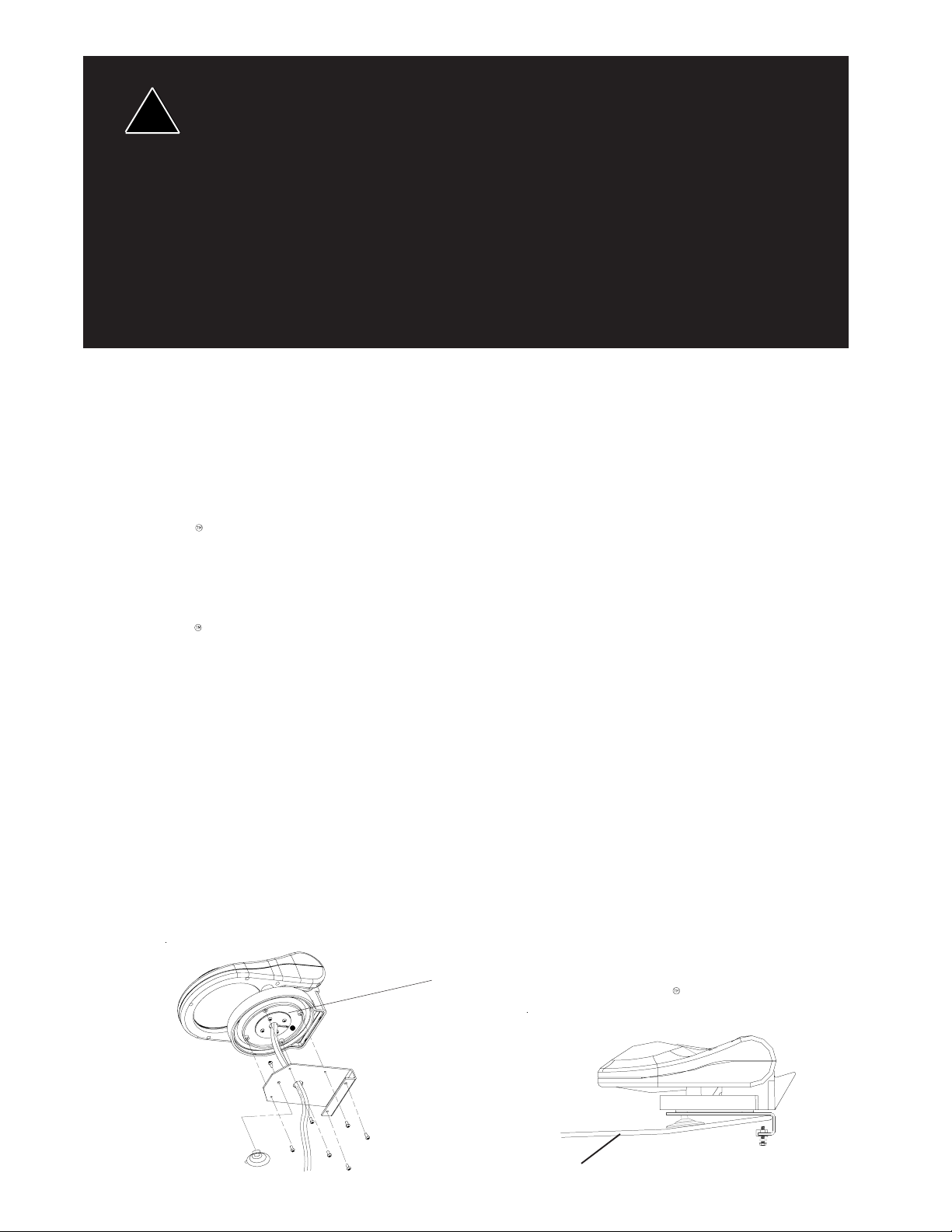

1. Attach suction cup to bottom of mounting bracket with the #10 self tapping screw, do not over tighten.

2. Route the cables from the bottom of the spotlight through the mounting bracket as shown in Figure 1.

3. Attach bracket to spotlight with four round hd phillips 6-20 x 3/8" SS as shown in Figure 1.

4. Choose a location where the spotlight is to be mounted.

5. Lay out the cable to insure that there is an adequate amount to reach the area in which the controller is to

be mounted.

6. Fold wires into pocket of bracket in between the two mounting screws

7. Push bracket over lip of the hood and push down on suction cup

8. Tighten screws under hood until bracket is snug.

For proper bracket alignment make sure that

the mark is to rear of NightProbe as shown.

Figure 1

Vehicle

2

Page 3

Route wiring using grommets and sealant when passing through compartment walls. High

ambient temperatures (e.g. under-hood) will significantly reduce the current carrying capacity of

wires, fuses, and circuit breakers. Use "SXL" type wire in engine compartment. Minimize the

!

WARNING!

!

WARNING!

number of splices to reduce voltage drop. All wiring should conform to the minimum wire size

and other recommendations of the manufacturer and be protected from moving parts and hot

surfaces. Looms, grommets, cable ties, and similar installation hardware should be used to

anchor and protect all wiring. Particular attention should be paid to the location and method of

making electrical connections and splices to protect these points from corrosion and loss of

conductivity. Ground terminations should only be made to substantial chassis components,

preferably directly to the vehicle battery. The user should install a fuse sized to approximately

125% of the maximum amp capacity in the supply line and each switched circuit to protect

against short circuits.

Any electronic device may create or be affected by electromagnetic interference. After installation

of any electronic device, operate all equipment simultaneously to insure that operation is free of

interference.

Wiring Instructions

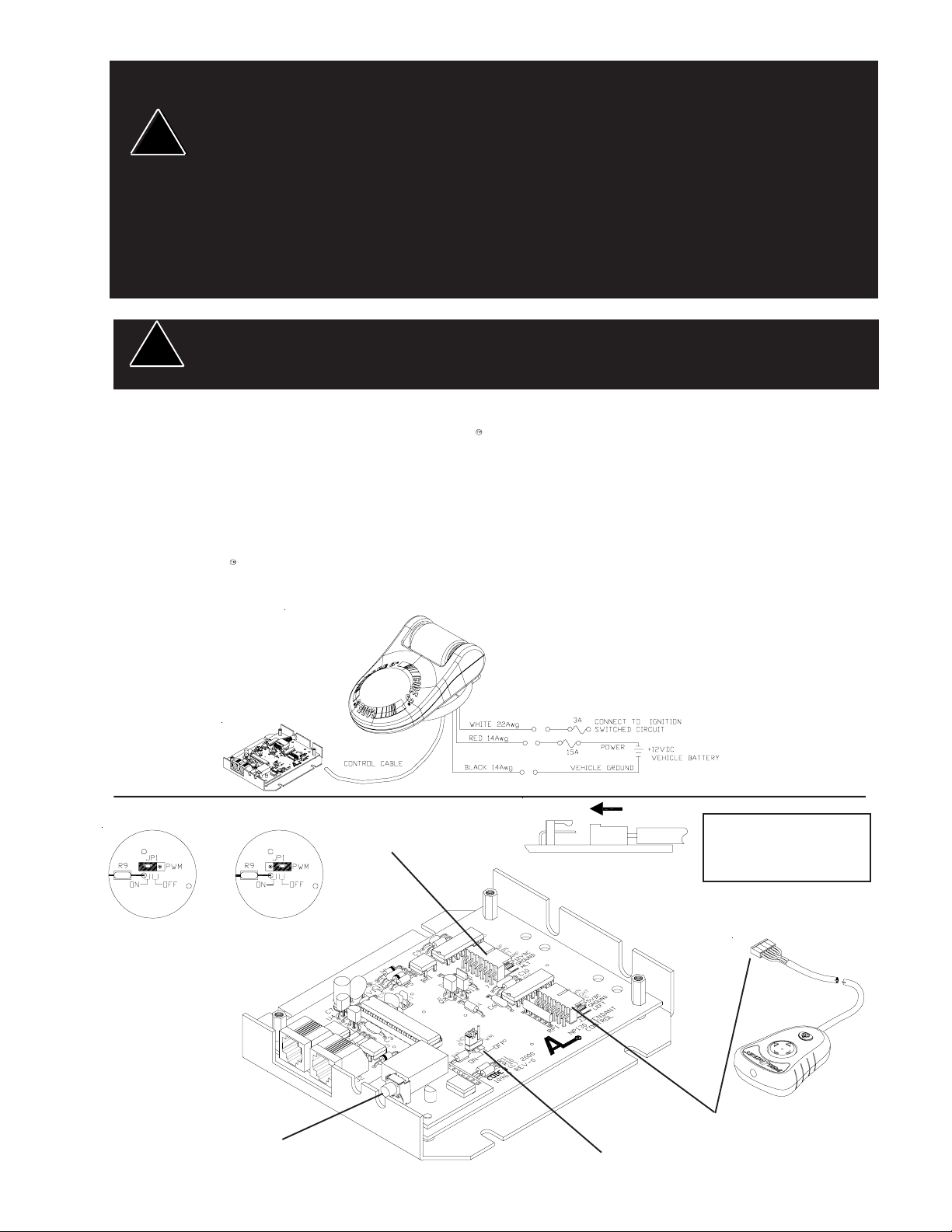

Connect the red and black wires from the NightProbe spotlight as shown in Figure 2. Protect the circuit

with a 15 Amp fuse and use 14 awg (minimum) wire.

Connect the white wire from the unit to an ignition switched circuit protected by a fuse (3 Amp Max.). Use

a 22 awg. (minimum) wire.

IMPORTANT:

Failure to connect the wiring as stated above could cause damage to the unit.

The NightProbe spotlight must never have its lamp on when its head is in the closed position (as

shown in Figure 2). The extreme heat of the 100W lamp will damage the unit base.

Figure 2

PWM ON

NP130

Control Cable

Connector

Orientation

PWM OFF

IMPORTANT:

Make sure connector is

in the correct orientation

Figure 3

RF Remote

Training Switch

Pendant Cable

(Wired version only)

PWM Jumper

3

Page 4

Operation

The NightProbe is designed for Electro-mechanical use.

The Night Probe controller provides a four-position switch for lighthead movement and a push-on/push-off

switch for lamp control. The four-position switch provides either single-speed movement or Pulse Width

Modulated (PWM) acceleration from slowest to fastest speed. This feature is controlled by the position of

the PWM configuration jumper (JP1) which is located inside the Interface Module (see Figure 3). When

the PWM configuration jumper is set to the OFF position depressing and holding the four-position switch in

the LEFT, RIGHT, UP or DOWN direction will cause the Night Probe lighthead to rotate in the appropriate

direction in single speed mode. When the jumper is set to the ON position the Night Probe lighthead will

accelerate from it's slowest speed to full speed over a two second period and stop instantly when the

switch is released. This mode allows for very precise positioning of the light.

The NightProbe 130 RF is designed for use with an optional RF Remote Control.

The NP 130 RF Remote Control comes complete with battery installed. The NP 130 control must be

trained to recognize your remote unit. After installation, apply power to your NP130 system.

Depress and hold the training switch on the receiver located through a hole in the case near

the antenna (see Fig 3). While holding the training switch, depress and release the small

switch (Lamp ON/OFF) on the remote unit. Release the training switch and test the unit.

The RF Remote Control operation is the same as that described for the wired control.

Please note that radio transmitters and other electronic equipment can emit signals

which may interfere with the operation of the RF Remote Control and cause

temporary intermittent operation of the spotlight. This is considered normal. Warning!

CONTROLLER pendant and control module are NOT WATERPROOF

Figure 4

Maintenance

LAMPS ARE EXTREMELY HOT! ALLOW TO COOL COMPLETELY BEFORE ATTEMPT-

!

ING TO REMOVE. GLOVES AND EYE PROTECTION SHOULD BE WORN WHEN HANDLING HALOGEN LAMPS AS THEY ARE PRESSURIZED AND ACCIDENTAL BREAKAGE CAN RESULT IN FLYING GLASS.

WARNING!

Lamp Replacement

1. Insure that ignition is in off position.

2. Lift spotlight head so that it is facing up as in Figure 5.

3. Remove 7 screws in lower bulb shell and lift it off upper bulb shell.

4. Disconnect power and ground wire from lamp.

5. Replace lamp (H-3 100W) as shown in Figure 6.

6. Connect power and ground to lamp.

(IMPORTANT: FEED POWER AND GROUND WIRE BACK THROUGH

HEAT SHIELD WITH FABRIC SIDE FACING BULB AS SHOWN). Both wires must be positioned

behind the protective heatshield.

7. Be sure to align the upper and lower shells with the proper key on the vertical gear (see Figure 7)

Reattach the 7 screws. Do not overtighten.

H-3 100 watt lamp

lower shell key

Fabric side

Figure 5

Figure 6

upper shell key

Figure 7

4

Page 5

Parts & Exploded Views

10

Control Module

To Control Module

CR2032 Type Battery

11

To Control Module

5

Page 6

Parts List

Ref No. Description Part No. Qty.

1 SMS,Pan Hd Phil. #8 x 1/2"lg 'PT' screw T06828 0 7

2 Lower Bulb Shell T06878 0 1

3 H-3 100W Lamp T05379 0 1

4 Heat Shield T06881 0 1

5 Upper Bulb Shell T06877 0 1

6 Motor Housing S81832 01

7 Mounting Bracket S81835 01

8 SMS,Round Hd phil, 6-20 x 3/8", ss T01591 0 4

9 Ms, slot, Hx, Hd ,10-24 x 3/4"lg T06897 0 2

10 NP 130 Wired Control Module S71607 01

Wireless Control Module for S71607 S71613 01

11 NP 130 Wired Control Pendant S71615 01

NP 130 Wireless Control Pendent S71612 01

NOT SHOWN

Belt Clip T10974 01

Boot, vinyl-yellow T10975 01

Battery, CR2032 T10988 01

6

Page 7

Troubleshooting

PROBLEM

Product does not activate a. No power to unit a. Check wiring

Unit operates but no light a. Lamp burned out a. Replace lamp

b. Switch on controller not engaged b. Push button on controller

Light operates but unit not moving

Specifications:

PROBABLE CAUSE

b. Fuse blown b. Replace fuse

c. Ignition not on c. Turn on ignition

d. Controller cable not connected d. Check cable connection

f. Damaged or shorted cabling f. Check cables for damage

a. Motor damage a. Return to Code 3 Inc.

b. Unit hitting obstacle b. Remove obstacle

REMEDY

Mechanical Dimensions: Width: 7.25"

Rotation: 360 degrees

Electrical:

Operating Voltage: 10 - 15 VDC

Current draw:

Lamp 'on' approx. 10A @ 12.8 VDC

Lamp 'off' approx. 35mA @ 12.8 VDC

Lamp Rating 100 Watts @ 12.8 VDC

Depth: 12"

Height:

lamp down 4"

lamp raised 12"

Finishing:

To prepare the surface of the Night Probe for finishing wipe it with alcohol

or clean ultrasonically.

Mask off all bearing surfaces before finishing.

Water base and solvent paints based on aliphatic hydrocarbons (mineral

spirits, heptane, hexane and alcohols) have good compatibility with the

Night Probe material.

Chlorinated and aromatic solvents, as well as ketones should generally be

avoided.

Curing:

Paints used on the Night Probe material can be cured using either air-dry

or bake techniques. Circulating warm air ovens are the best suited and

most economical method of drying.

Curing conditions will vary depending on the coating and part design. Bake

temperatures of 250 degrees F (121degrees C) are acceptable with Night

Probe material.

7

Page 8

WARRANTY

Code 3, Inc.'s emergency devices are tested and found to be operational at the time of

manufacture. Provided they are installed and operated in accordance with manufacturer's

recommendations, Code 3, Inc. guarantees all parts and components except the lamps to a period

of 1 year (unless otherwise expressed) from the date of purchase or delivery, whichever is later.

Units demonstrated to be defective within the warranty period will be repaired or replaced at the

factory service center at no cost.

Use of lamp or other electrical load of a wattage higher than installed or recommended by the

factory, or use of inappropriate or inadequate wiring or circuit protection causes this warranty to

become void. Failure or destruction of the product resulting from abuse or unusual use and/or

accidents is not covered by this warranty. Code 3, Inc. shall in no way be liable for other damages

including consequential, indirect or special damages whether loss is due to negligence or breach of

warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING,

WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to obtain

a Return Goods Authorization Number (RGA number) before you ship the product to Code 3, Inc.

Write the RGA number clearly on the package near the mailing label. Be sure you use sufficient

packing materials to avoid damage to the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses incurred for the

removal and /or reinstallation of products requiring service and/or repair; nor for the packaging, handling, and shipping; nor for the handling of products return to

sender after the service has been rendered.

PROBLEMS OR QUESTIONS? CALL OUR TECHNICAL ASSISTANCE HOTLINE (314) 996-2800

WWW.CODE3PSE.COM

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

Code 3® is a registered trademark of Code 3, Inc., a subsidiary of Public Safety Equipment, Inc.

Part No. T06888 Rev. 7 5/2006

10986 N. Warson Road

Code 3®, Inc.

©2005 Code 3, Inc

8

Loading...

Loading...