Page 1

INSTALLATION

MX 7000

TM

& OPERATION

MANUAL

MX7000®

LIGHT BAR

Patent Number

5,091,828

D326,621

Contents:

®

DUAL LEVEL

LIGHT BAR

Introduction..........................................................................2

Unpacking & Pre-Installation ............................................... 3

Installation & Mounting........................................................ 3

Hook-on Mounting.............................................................4

Permanent Mounting.........................................................5

Wiring Instructions..........................................................6-7

Options & Specifications ................................................8-14

Maintenance.................................................................15-19

Parts List (Replacement Parts / Exploded View)..........19-24

D-Tech Rotator.............................................................25-26

Trouble Shooting..........................................................27-28

Notes............................................................................29-31

Warranty............................................................................32

Read all instructions and warnings before installing and using.

IMPORTANT:

INSTALLER: This manual must be delivered to the end user of this equipment.

Page 2

Introduction

The MX 7000® Light Bar is a dual-level light bar that is less than 6" high, yet delivers unobstructed 360° warning and

more signal power and versatility than any other light bar of its size.

The low profile and aerodynamic lines of the MX reduce air drag, which results in fuel savings and stability at high

speeds. This light bar has a strong extruded internal frame, shock-resistant polycarbonate lenses, and warning signals that

exceed SAE standards.

The MX is designed on a modular basis, which means that the light bar can be customized to meet any requirements.

Because of its dual-level design, the MX has room for an incredible number of these options: standard or high speed

rotators, StingRay

lower corners, and up to 12 locations for special purpose stationary lights in the lower deck. While we do not recommend

a light installed in every location, the design of the MX 7000 offers the ultimate flexibility in the location of warning and

auxiliary lights.

!

WARNING!

TM

oscillating signals, an OsciLaserTM in the top deck, alley lights and intersection or Pursuit Lights in the

The use of this or any warning device does not insure that all drivers can or will observe or react to an

emergency warning signal. Never take the right-of-way for granted. It is your responsibility to be sure you can

proceed safely before entering an intersection, driving against traffic, responding at a high rate of speed, or

walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and wiring. Read and

follow the manufacturer’s instructions before installing or using this device. The vehicle operator should insure

daily that all features of the device operate correctly. In use, the vehicle operator should insure the projection

of the warning signal is not blocked by vehicle components (i.e.: open trunks or compartment doors), people,

vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility to understand

and obey all laws regarding emergency warning devices. The user should check all applicable city, state and

federal laws and regulations.

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of this warning device.

Proper installation is vital to the performance of this warning device and the safe operation of the emergency

vehicle. It is important to recognize that the operator of the emergency vehicle is under psychological and

physiological stress caused by the emergency situation. The warning device should be installed in such a

manner as to: A) Not reduce the output performance of the system, B) Place the controls within convenient

reach of the operator so that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly protect and use

caution around live electrical connections. Grounding or shorting of electrical connections can cause high

current arcing, which can cause personal injury and/or severe vehicle damage, including fire.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY PERSONNEL

AND THE PUBLIC.

2

Page 3

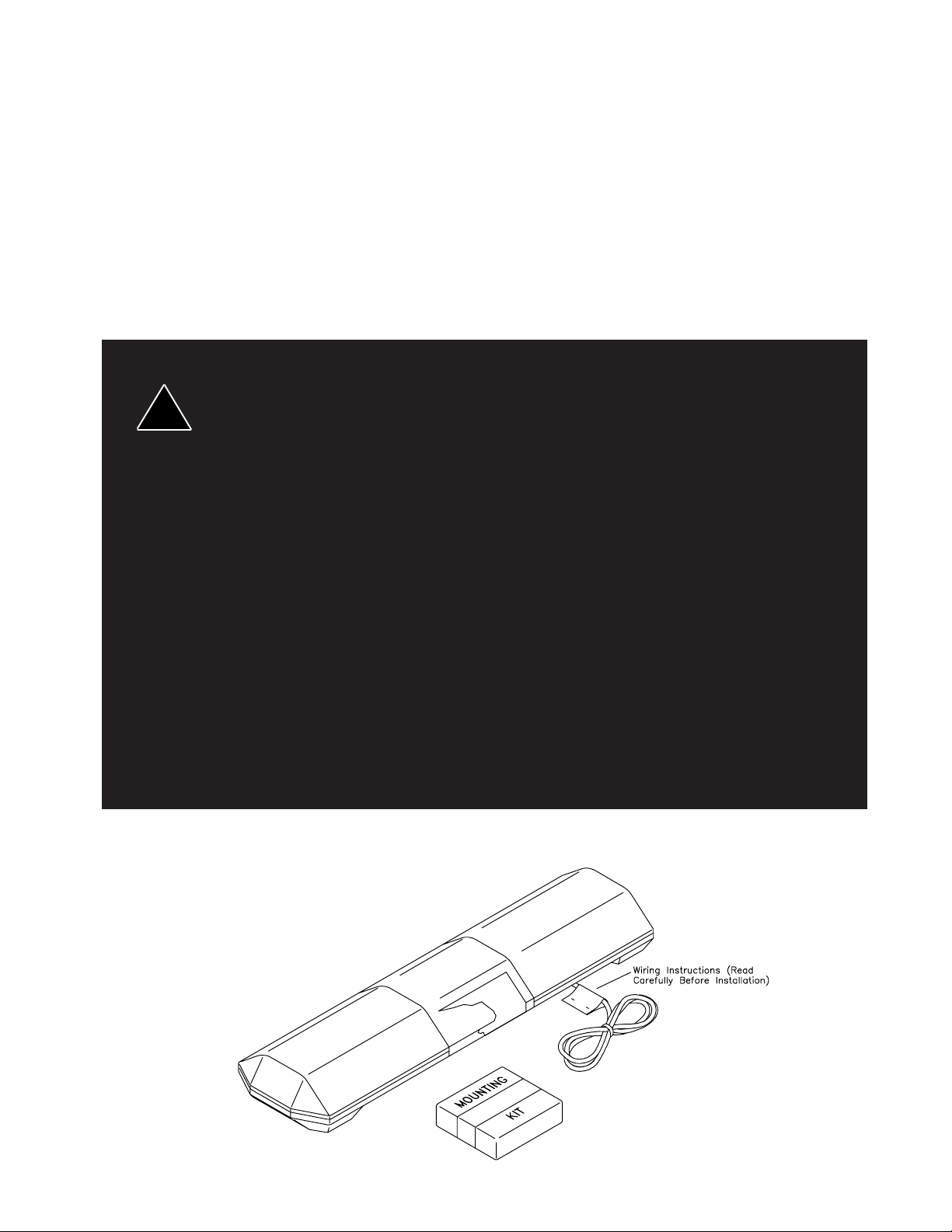

Unpacking & Pre-installation

Carefully remove the light bar and place it on a flat surface, taking care not to scratch the lenses or damage the cable coming out of

the bottom. Examine the unit for transit damage, broken lamps, etc. Report any damage to the carrier and keep the shipping carton.

Standard light bars are built to operate on 12 volt D.C. negative ground (earth) vehicles. If you have an electrical system other than

12 volt D.C. negative ground (earth), and have not ordered a specially wired light bar, contact the factory for instructions.

Test the unit before installation. To test, touch the black wire to the ground (earth) and the other wires to +12 volts D.C., in

accordance with the instructions attached to the cable (an automotive battery is preferable for this test). A battery charger may be

used, but please note that some electronic options (flashers, stingrays, etc.) may not operate normally when powered by a battery

charger. If problems occur at this point, contact the factory.

Installation & Mounting

WARNING!

!

Utilizing non-factory supplied screws and/or mounting brackets and/or the improper

number of screws may result in loss of warranty coverage on the equipment.

MOUNTING HARDWARE-All mounting hardware is packed in a small box inside the main carton. Four standard kits are

available: (1) Hook-On Type, (1) Tow and Recovery and (2)

Permanent Types. These are discussed in detail later. Note:

Hook-on mounting for "gutterless" type vehicles will require a

special hook for mounting. Several are available. Contact the

factory for details.

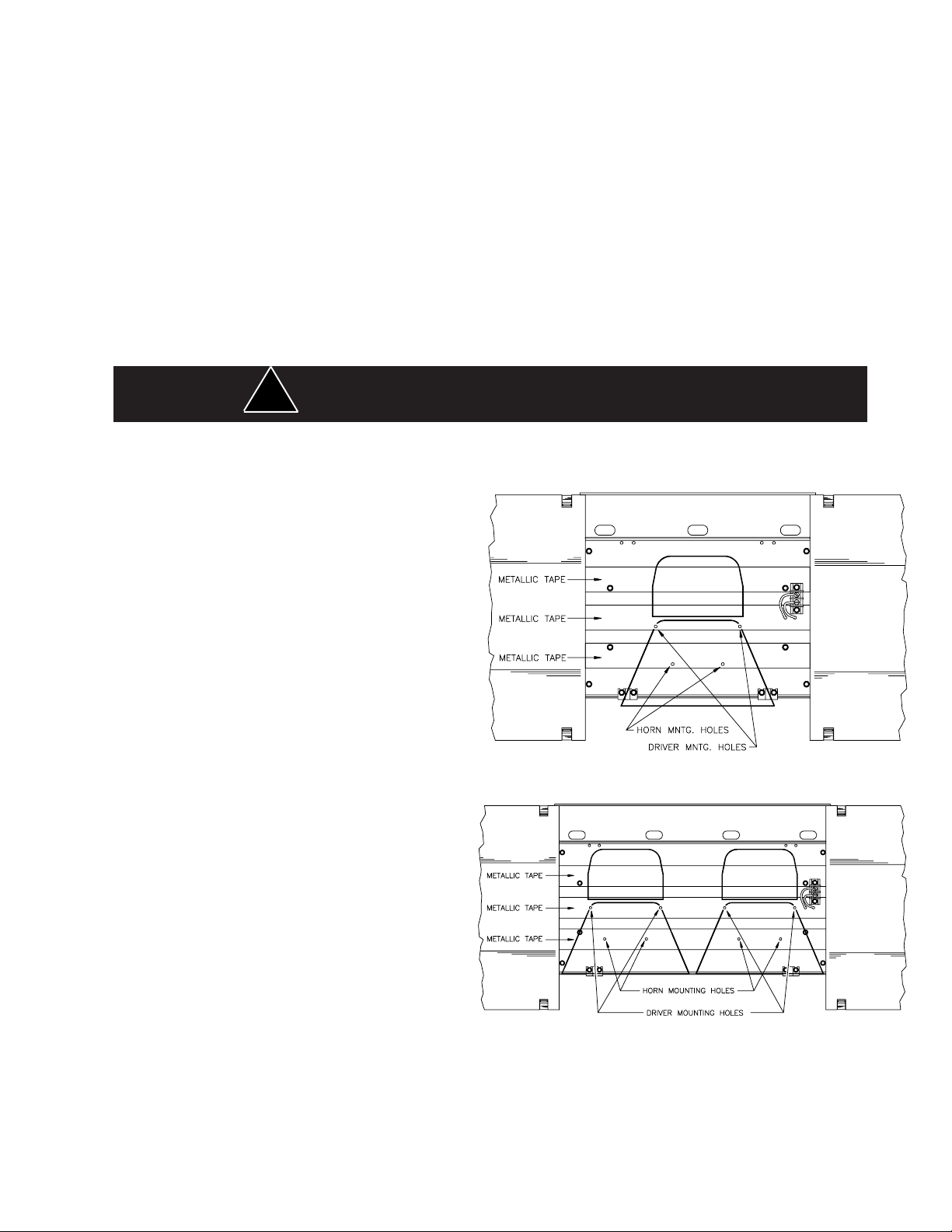

SIREN SPEAKERS

(Single Speaker Installation in 43", 47", 52" & 58"

Light bars) Speaker Installation is advised at this

point while the speaker section is easily accessible.

To install a speaker, first remove the two (2) hexhead screws, (4 screws on 58 1/4" bars) from the

bottom of the perforated side of the speaker cover.

The cover is hinged at the back--pull the front of the

cover up and over the lenses to remove it. Figure 1

shows the speaker cover opened and location holes

for installing a Code 3 "LP" speaker. If other than a

Code 3® "LP" speaker is used, two possibilities

exist for speaker installation. An "LPSPKR"

conversion kit is available from the factory to

mount an existing speaker in an MX7000TM.

Otherwise, holes must be drilled for installation.

The center speaker deck is 1/8" thick aluminum and

may be drilled almost anywhere. Before drilling,

however, it is imperative to remove the speaker

deck so as not to damage any components below.

All holes in this area not used must be sealed with

some type of water resistant caulking so that

components below are protected from the

elements. Re-install the speaker deck, then mount

the speaker and connect the leads to the terminal

block. Non "LP" speaker bells must be trimmed to

match the speaker cover contour.

Replace the cover.

Figure 1

Figure 2

3

Page 4

(Dual Speaker Installation in 52" & 58 1/4" Light bars) Using the same procedure as above, install the speakers using the

mounting holes in Figure 2 (For a Code 3 "LP" speaker). When using the two speakers , follow the manufacturer's

instructions for correct phasing of speakers.

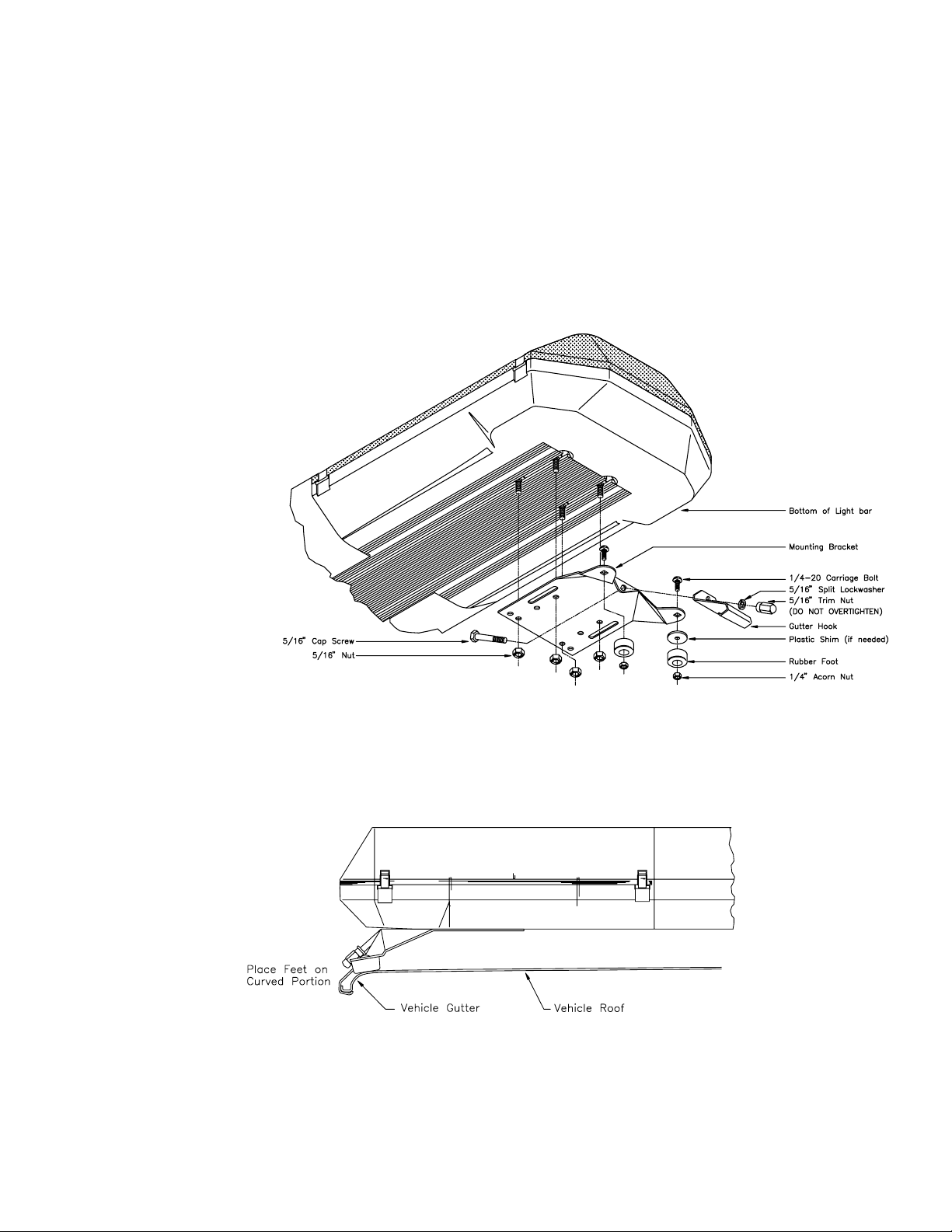

Hook-on Mounting

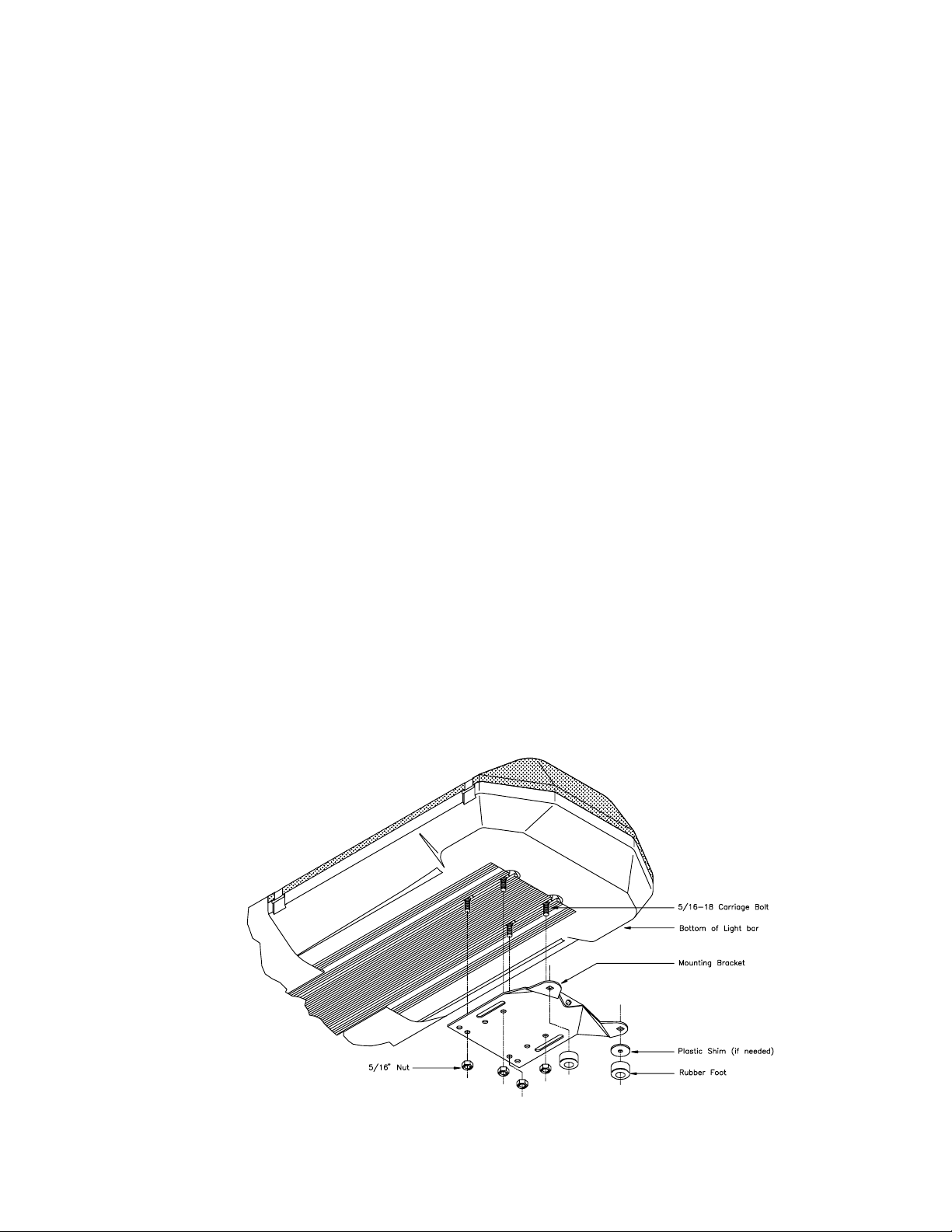

Begin the installation by attaching the rubber feet to the mounting brackets using the black 1/4" carriage bolts and 1/4" nuts

provided. See Figure 3 (Do not install shims at this time).

Place the light bar upside down on a table or other work surface, being careful not to scratch the lenses. Slide the 5/16"

carriage bolts into the frame. Secure the mounting brackets finger tight so they support the weight of the light bar, but still are

positionable. Locate the vehicle on a level surface.

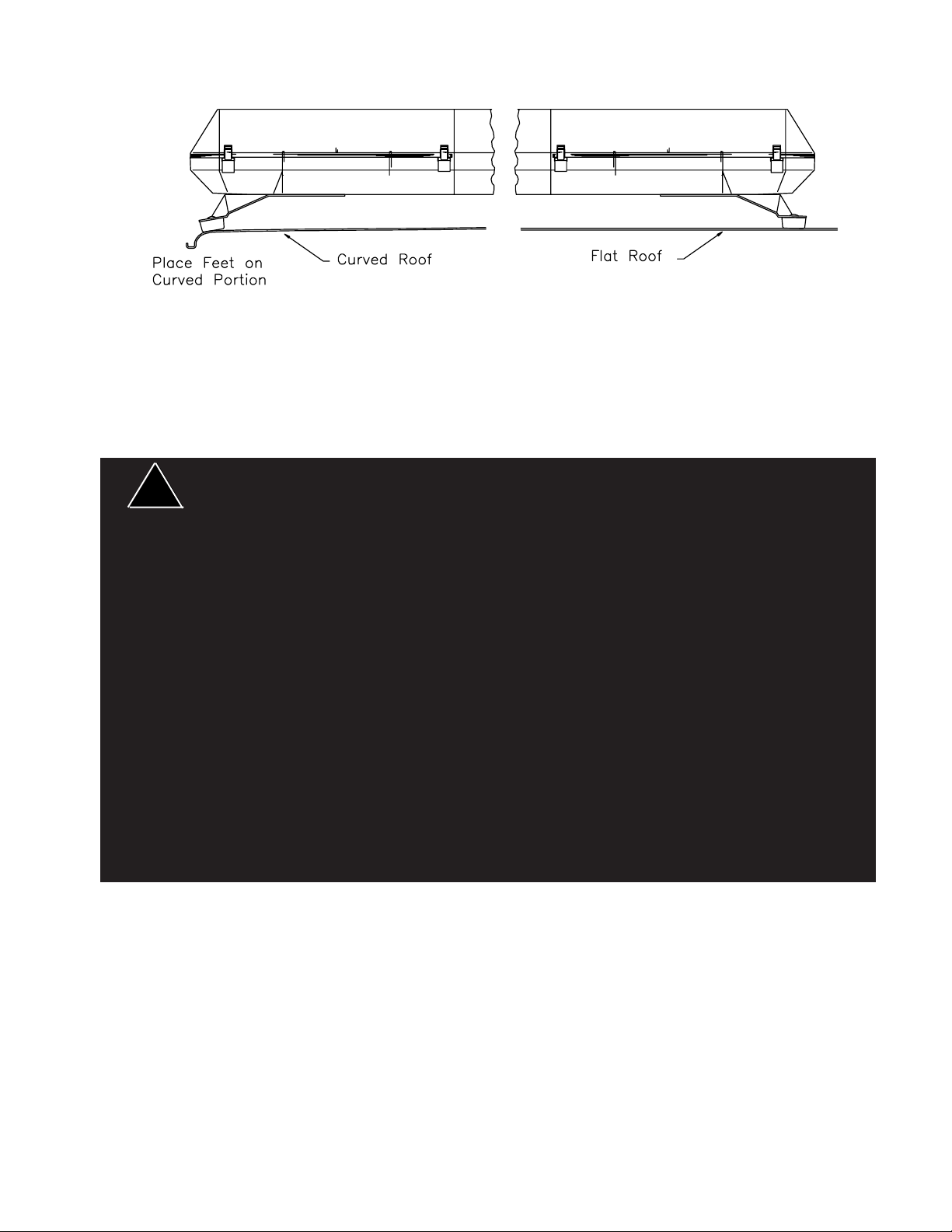

Place the light bar on the roof of the vehicle. Place a soft pad in the center of the roof to protect the paint. The mounting

brackets must be placed so that the rubber feet are resting on the curved section of the roof, see Figure 4. This is the

strongest part of the roof. Once the light bar is centered, tighten the mounting bracket to the light bar.

Using a tape measure and a level, center the light bar from side to

side and locate a position on the roof where the light bar is

level.

Figure 3

Figure 4

4

Page 5

The shims provided may be used here to help level the light bar, see Figure 3. Also, the tabs on the mounting brackets may be

bent at any angle to match the curvature of the roof.

Select the appropriate length cap screw and insert through the holes in the gutter hook and mounting bracket, and into a

lockwasher and acorn nut as shown in Figure 3. If a special hook for a "gutterless" vehicle is used, refer to the instructions for

that hook at this time. The stainless steel cap screws supplied are sized for the most common installations, but longer and

shorter bolts are available at any hardware store.

Tighten the cap screws on both sides evenly keeping the light bar centered and level.

NOTE: Tighten only until the bar is secure (bar does not move when bumped sharply with the heel of the palm). It is NOT

necessary to dimple the roof to obtain a stable attachment. If the light bar "bows" more than 3/16" (determined by placing a

straightedge along the front, bottom part of the frame and measuring downward at the center of the frame), loosen the 5/16"

trim nut sightly.

Re-Installation: When moving a light bar from one vehicle to another, we suggest that new rubber feet be used. These are

standard hardware items, and can usually be found at any hardware store, or can be ordered from the factory.

The special hooks are stainless steel and should be saved and reused. Mounting kit parts are available to permit remounting

on vehicles of different design or make. Consult your local dealer or Code 3, Inc. for detailed information.

Permanent Mounting

Typical Mounting: Refer to Figure 5. Place the light bar upside down on a table or other work surface, being careful not to

scratch the lenses. Slide the 5/16" carriage bolts into the frame. Secure the mounting brackets finger tight so they support the

weight of the light bar.

Place the unit on the roof of the vehicle. Place a soft pad in the center of the roof to protect the paint. The mounting brackets

must be placed so that they are resting on the curved section of the roof, see Figure 6. This is the strongest part of the roof.

Once the light bar is centered, tighten mounting brackets to light bar.

Using a tape measure and a level, center the light bar from side to side and locate a position of the roof where the light bar is

level. The shims provided may be used here to help level the light bar. Also, the tabs on the mounting bracket may be bent at

any

angle to match the curvature of the roof (see Figure 6).

Figure 5

5

Page 6

Figure 6

Once the light bar is level and centered, mark the holes through the mounting tabs and remove the light bar from the vehicle.

Make sure that the drill will not damage anything when penetrating the roof. Drill the mounting holes and remove any burrs.

Attachment can be made using 1/4" cap screws, toggle bolts, or other fasteners as may be convenient. Use sealant as

necessary to prevent water leakage into the vehicle.

Wiring Instructions

!

WARNING!

Before attempting to connect wiring refer to wire tag attached to the lightbar’s main cable. Each wire in the cable controls a separate

lightbar function as described in the wire tag.

Larger wires and tight connections will provide longer service life for components. For high

current wires it is highly recommended that terminal blocks or soldered connections be used

with shrink tubing to protect the connections. Do not use insulation displacement connectors

(e.g. 3M® Scotchlock type connectors). Route wiring using grommets and sealant when

passing through compartment walls. Minimize the number of splices to reduce voltage drop.

High ambient temperatures (e.g. underhood) will significantly reduce the current carrying

capacity of wires, fuses, and circuit breakers. Use "SXL" type wire in engine compartment. All

wiring should conform to the minimum wire size and other recommendations of the

manufacturer and be protected from moving parts and hot surfaces. Looms, grommets, cable

ties, and similar installation hardware should be used to anchor and protect all wiring. Fuses or

circuit breakers should be located as close to the power takeoff points as possible and

properly sized to protect the wiring and devices. Particular attention should be paid to the

location and method of making electrical connections and splices to protect these points from

corrosion and loss of conductivity. Ground terminations should only be made to substantial

chassis components, preferably directly to the vehicle battery. The user should install a fuse

sized to approximately 125% of the maximum Amp capacity in the supply line to protect

against short circuits. For example, a 30 Amp fuse should carry a maximum of 24 Amps. DO

NOT USE 1/4" DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR

CONTINUOUS DUTY IN SIZES ABOVE 15 AMPS. Circuit breakers are very sensitive to high

temperatures and will "false trip" when mounted in hot environments or operated close to their

capacity.

The only significant difference between the MX 7000® with optional ArrowStik® and a conventional MX 7000, is the additional, thinner

cable exiting the bottom of the lightbar. The larger cable is the lightbar power cable. Route the wiring cable into the engine or

passenger compartment, taking care to use grommets and to apply sealant around openings to keep water out. It is advisable to

leave an extra loop of cable when installing the light bar to allow for future changes or reinstallations. Connect the black lead to a

solid frame ground (earth), preferably, the (-) or ground (earth) side of the battery and bring the other wires to the control heads or

switches. Connect the wires as directed by the wiring instructions on the cable.

6

Page 7

Arrowstik® / Narrowstik®

OPTIONAL HALOGEN ARROWSTIK® (7-wire) / L.E.D. NARROWSTIK® (11-wire) WIRING AND CONTROL

HEAD INST ALLATION - After inst allation of the lightbar, route the smaller of the two power cables through the

vehicle to the location chosen for the control head. Cut the cable to length and strip back the outer insulation

to expose the seven or eleven colored wires. Strip back 1/8” - 1/4” of colored insulation from each of the wires

in the cable. Connect these wires to the seven position / eleven position terminal plug enclosed in the user

parts bag, according to the diagram on the bottom of the control head.

- Refer to the control head manual packaged with the lightbar for control

head installation and operation instruction.

Route the wiring cable into the engine or passenger compartment, taking care to use grommets and to apply sealant around

openings to keep water out. It is advisable to leave an extra loop of cable when installing the light bar to allow for future

changes or reinstallations. Connect the black lead to a solid frame ground (earth), preferably, the (-) or ground (earth) side of

the battery and bring the other wires to the control head or switches. Connect the wires to the control head or switch (as

directed by the wiring instructions on the cable). Next, calculate the light bar power draw. Table 1 consists of an equation

and data for quick calculating of light bar load. Run a power wire from the control head to the (+) or positive side of the

battery, the alternator, or to the stud on the battery side of the starter solenoid. Use Table 2 for reference.

Speaker Wires: If the light bar has a speaker

section, the blue wires go to the siren amplifier

and are to be connected in accordance with the

siren manufacturer's instructions. Test the unit for

proper operation. Caution - Operating a siren

with a live speaker can inflict hearing damage-always use hearing protection.

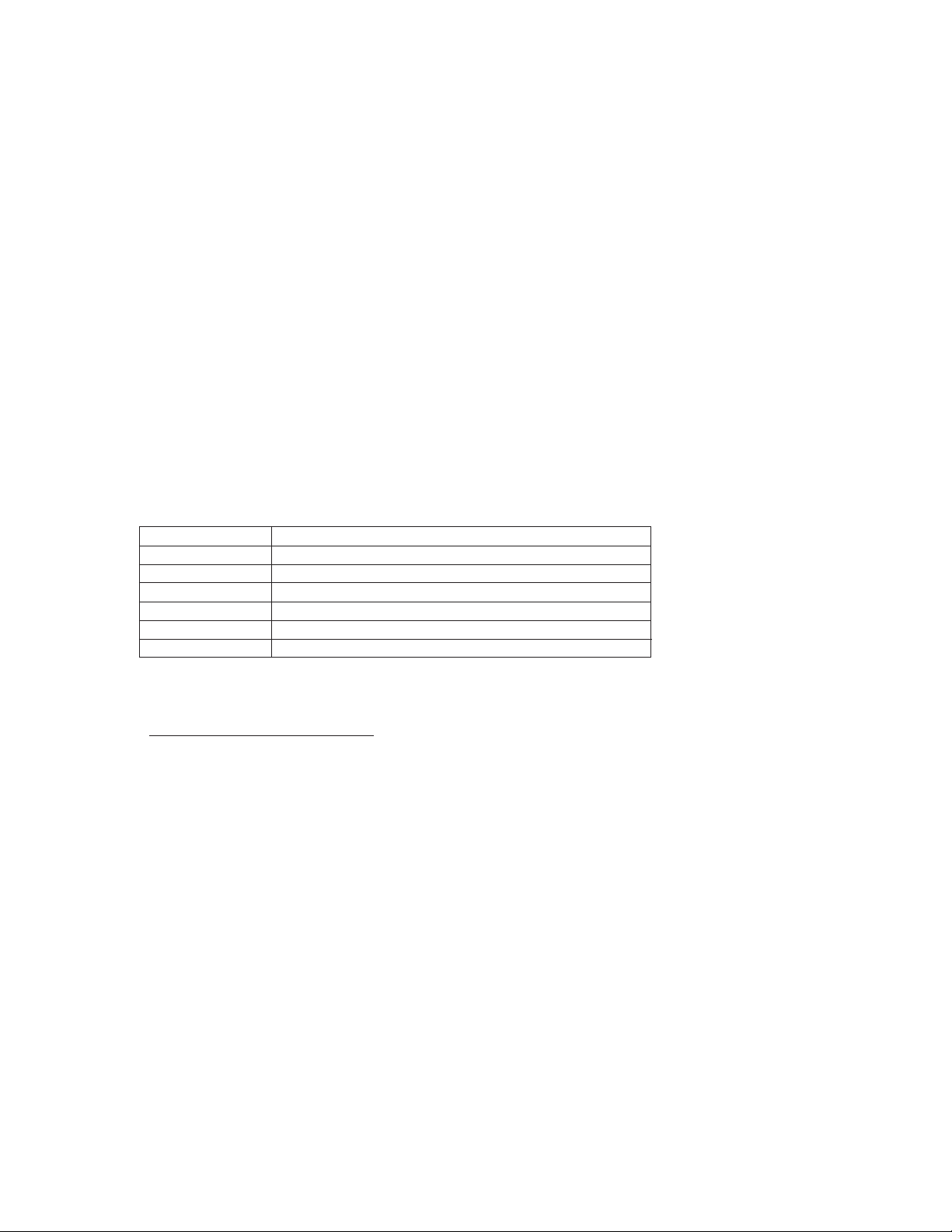

Table 2

RECOMMENDED SWITCH CONTROL MINIMUM WIRE SIZES

Based on 15-Foot Wire Run

Amp Draw Min. Wire Size

Below 8 #16 AWG

9-13 #14 AWG

14-21 #12 AWG

22-36 #10 AWG

37-56 #8 AWG

Table 1

Total Watts in Light bar Divided by 12 Volts Equals Amperage

Draw or: Watts / 12 Volts = Amp Draw

Bulb Type Location Wattage AmpDraw

1156 Stationary/ 28 2.33

S795 Standard Rotating 50 4.17

H-1 Rotating Lamps 55 4.58

H-5 High-Speed Rot. 100 8.33

194 D.O.T. Lamps 3 .25

211-2 ArrowStik

573 ArrowStik 25 2.08

Flashing Lights

Lamps

Alley Lights

Intersection Lights

Stationary/Flashing

Lights

Lamps

®

12 1

7

Page 8

Options & Specifications

Many options are available for the MX 7000. This section is designed to describe the function of, and

maintenance for, the various MX 7000 options.

STINGRAYTM - The StingRay is a modified rotator which produces a patented three-mode signal that (1)

oscillates to the rear, (2) rotates conventionally, and (3) oscillates to the front. Lamp and reflector

maintenance is the same as for a typical rotating lamp.

INTERSECTION LIGHTS - A high intensity 120° oscillator, located in the lower outboard corner of the light

bar. Maintenance of these units is much the same as for a typical rotator. The lamps used here are the

bayonet type. Two mounting screws hold the assembly in place. Note: Never install a black worm gear

on the 120° Intersection Light.

PURSUIT LIGHTS - Same as intersections lights except sweep angle is only 70°.

ALLEY LIGHTS - Located in the lower section of the light bar at each end, to provide light to the side of

the vehicle. The lamps used are a bayonet type and the unit is held down with 2 #8 X 5/8" screws. (An

additional screw in a curved slot controls the aim of the alley light in light bars that do not incorporate an

ArrowStik. Simply loosen this screw, adjust the aim and tighten. (This screw does not need to be

loosened when the whole unit is removed.)

HIGH SPEED ROTATOR - A rotator that produces twice as many flashes as a conventional assembly.

The only significant difference between this unit and a normal assembly is that a faster motor is used.

Maintenance is the same as for a typical rotator.

STATIONARY LAMPS/TAKEDOWN LIGHTS - A stationary reflector assembly used for flashing,

takedown, and/or work light applications. These are located in the lower section of the light bar. Lamps in

these units are bayonet type and the units are mounted with two screws.

LED WARNING MODULES

L.E.D. Fusing Considerations

Although the average current draw per module is very low, due to the type of circuit used to power each module the

instantaneous peak current to a module can be significantly higher during low voltage conditions. To avoid prematurely blowing

ATO style fuses or tripping breakers it is recommended the following rule-of-thumb be used to size fuses or breakers. This is

especially important in lightbars with many LED modules running off a single fused source wire,

Minimum fuse size calculation:

1.5 x (number of modules being fused)

Example:

MX700™ Lightbar with 2 corner modules (2 per module) and 4 directional modules.

Minimum fuse requirement for single fuse - 1.5 (2+2+4) = 10A minimum

WARNING!

This Product contains high intensity LED devices. To prevent eye damage, DO NOT stare

!

into light beam at close range.

8

Page 9

Dim Operation

Lightbar LED modules are equipped with a low power "Dimming" mode as standard. Dimming will be controlled by

applying +12V by way of the appropriate wire(color) in the wire harness/wire list. When DIM is engaged the LED's will

operate in a reduced power mode.

For safety purposes, the corner modules in lightbars are not connected to the dimming circuit.

This ensures that when corner modules are turned on, full 360 degree coverage and

compliance with SAE warning light standards is provided.

The DIM control wires( two white wires) located on each of the modules are connected from one module to

the next. To disable the dimming function on a particular module, disconnect the white wires. Then

reconnect the white wire to the white wire on another module that has dimming enabled.

The Dim setting reduces the light output of emergency warning lights reducing the effectiveness of

!

WARNING!

them especially in brightly lit areas. Failure to use adequate light for the circumstances can cause

motorists to fail to see the emergency vehicle and lead to serious personal injury or death. Never

use the DIM setting in a brightly lit area. Use of the DIM setting may cause emergency lights to not

comply with applicable emergency warning light standards. Use caution when using the DIM setting

to assure that motorists can clearly see the emergency vehicle.

Code 3® OPTIX™ 360 DEGREE CORNER MODULES

The MX7000® Lightbar may be equipped with Code 3® OPTIX™ 360 degree corner LED modules that provide a full 360

degree of warning.The optic has been designed to exceed all applicable requirements for 360 degree warning devices in Red,

Blue, and Amber. The new OPTIX corner module is a ( 1" X 6" ) module and uses larger, higher efficiency, TIR optics to

produce an enhanced corner signal over the exisitng ( 1" X 4" ) Code 3 LED X™ corner module. While the OPTIX will become

the standard corner module for most configurations, the LED X corner module will still be available and may be required for

some configurations. Installation and Operation for both modules will be the same. Consult the factory for further information.

Operating Specifications for 360 degree module:

Operating Voltage: 10-16 VDC, Reverse Polarity Protection

Current Draw : Red/Amber - .5A avg @ 12.8 Volts

Blue/White - .8A avg @ 12.8 Volts

Available Colors - Red, Blue, Amber and White

9

Page 10

Master/Slave Operation

Each 360 degree corner module consists of a "master" and a "slave" driver circuit board, 360 degree optics and LED light

engines along with a single integrated heatsink bracket.

The "master" circuit board (rear position) must always be powered for the "slave"(front position) to flash. The "master" is always

located in the rear position of the module. The lightbar is wired to allow running only the rear facing LED on each module by

removing power to the front facing "slave" module. This gives a "front-cutoff" function. The flash pattern for each corner pair

can be selected by shorting together the 2-pin header J1, on the "master" , momentarily and releasing. The module is set-up

for "Cycleflash" as a standard. Holding down the 2-pin header for 5 sec., or longer, and releasing will return the pattern to

Cycleflash. The following chart describes the available patterns and order;

360 Degree Module Flash Pattern - Table 3

See Figure 22

Flash Pattern Description

Cycle Flash Cycles through various patterns @ 70 fpm

Five Flash Five Pulses per flash @ 70 fpm

Quad Flash Four Pulses per flash @ 70 fpm

NFPA Four Pulses, 70% Duty Cycle @ 75 fpm

Triple Flash Three Pulses per flash @ 70 fpm

Quad Pop Flash Four Pulses per flash (3 equal, 1 extended) @ 70 fpm

Both heads will be in the mode selected. Both heads will flash together unless in Front Cut-off mode.

LED DIRECTIONAL MODULES

In addition to the 360 warning modules the lightbar may be equipped with a number of single head

directional warning LED modules. These modules are available in either the existing LED X™ ( 1" X 4" ) or the new Code 3®

OPTIX™ ( 1" X 6" ) and LC-LED directional modules in stationary and flashing versions ( see figure 8). The stationary versions

can be flashed by connecting the module(s) to any flasher that does not require ground through the load (example: Code 3®

700 series relay flasher). The flashing modules will have "Cycleflash" as the standard pattern. The OPTIX and LEDX flash

pattern can be changed by shorting the 2-pin header, J1 as shown in Figure 22, momentarily then releasing. Table 4 shows

the available patterns and the order when stepping through patterns. The module can be reset to "Cycleflash" by shorting the

header for greater than 5 sec. and releasing.

Operating Specifications for directional module:

Operating Voltage: 10-16 VDC, Reverse Polarity Protection

Current Draw : Flashing Module

Red/Amber - .25A avg @ 12.8 Volts

Blue/White - .4A avg @ 12.8 Volts

Steady Burn Module

Red/Amber - .5A avg @ 12.8 Volts

Blue/White - .8A avg @ 12.8 Volts

Available Colors - Red , Blue, Amber, and White

10

Page 11

Directional module Flash Pattern - Table 2

Flash Pattern Description

Cycle Flash Cycles through various patterns @ 70 fpm

Steady-Burn Steady-Burn

Five Flash Five Pulses per flash @ 70 fpm

Quad Flash Four Pulses per flash @ 70 fpm

Triple Flash Three Pulses per flash @ 70 fpm

Double Flash Two Pulses per flash @ 70 fpm

Fast Double Flash Two Pulses per flash @ 85 fpm

NFPA Four Pulses, 70% Duty Cycle @ 75 fpm

Quad Pop Flash Four Pulses per flash (3 equal, 1 extended) @ 70fpm

Triple Pop Flash Three Pulses per flash (2 equal, 1 extended) @70fpm

Double Pop Flash Two Pulses per flash (1 equal, 1 extended) @ 70fpm

Momentarily short and release

to change patterns

PCB

J1

Flash Pattern Header for OPTIX/LEDX

FIGURE 22

11

Page 12

STOP/TURN/TAIL LIGHTS - Located in the upper or lower section of the light bar facing rear, one on the

driver side, one on the passenger side, these lights provide stop, turn and tail signals to following traffic when

connected to the vehicle lighting system. Lamps used are an 1157 bayonet type.

D.O.T. LIGHTS - A set of three marker lights as required by the Department of Transportation for truck

application. Lamps are wedge base '194' type.

FLASHER - Table 3 (below) shows the different models and their functions.

TABLE 3 - FLASHER TYPE

Features 360RS 360RD 360RDK 700 710/711

100W (2 lights), X X

Alternating Flash

200W (4 lights), X X

Alternating Flash,

Rear Only or Front

& Rear

200W (4 lights), X

Alternating Flash

Rear Only, Front &

Rear, or Steady Burn

Front/Rear Flash

200W Heavy Duty X X

Alternating Flash

200W Heavy Duty X

Programmed Flash

STROBE LIGHTING CONNECTIONS

Flash Patterns - All power supplies offer “Quad Flash” and “Random Flash”. The flash patterns are controlled

by jumpers on the power supply and can be changed by first removing the power supply from the lightbar and

then setting the jumpers. Refer to the following tables:

6-Head Flash Patterns (FIG.18)

Jumper

J9

J36

Quad

2 - 3

2 - 3

Random

1 - 2

2 - 3

4-Head Flash Patterns (FIG.20)

Jumper Quad

J31

2 - 3 1 - 2

Random

PSE 490E (FIG.18A)

Quad

YELLOW

N/C +12

Random

Rear Only Flash Pattern

Connect the RED and/or RED/BLK wire in the 16 wire cable to + 12 VDC through a user supplied

switch.

4/6 Head: Rear inboard and outboard strobes on each side will flash at a minimum rate of 70 FPM

(flashes per minute).

2 Head: If rear inboard strobes are present, strobes will flash at a minimum rate of 70 FPM.

Alternating Flash Pattern

Connect the RED and/or RED/BLK wire and the GREEN wire in the 16 wire cable to + 12 VDC through

a user supplied switch. This mode overrides REAR ONLY MODE.

4/6 Head: Front and Rear inboard and outboard strobes on each side will flash at a minimum rate of

70 FPM.

2 Head: If rear inboard strobes are present, strobes will flash at a minimum rate of 70 FPM.

Pursuit Flash Pattern

Connect the RED and/or RED/BLK wire and the GRN/BLK wire in the 16 wire cable to +12 VDC

through a user supplied switch. This mode overrides ALL OTHER MODES.

4/6 Head: Front inboard and outboard strobes on each side will flash at a minimum rate of 70 FPM.

2 Head: If front inboard strobes are present, strobe will flash at a minimum rate of 70 FPM.

12

Page 13

OSCILASERTM - This is a highly effective warning light that

features a constant 35 watt halogen signal that covers every area

within it's field of illumination at least once per second. It has an

up and down as well as a side to side signal. Maintenance for

these units is much the same as a typical rotator. The lamps used

are bayonet type. This unit is located in the upper center section

and/or in the center position in the outboard sections of the light

bar. See Figure 8.

Figure 8

Multi-Functional Intersection Control System - This system allows multiple lighting options with a single

pair of intersection lights. The control center of the system is the Multi-Functional Control Module located in

the lower section of the light bar. This combined with the Sensing Lighthead Assemblies, located in the front

lower section, allows the operator to select (4) four modes of operation - intersection, driver side alley,

passenger side alley and takedown positions.

Passenger’s Side Driver’s Side

Control Module

Figure 9

Sensing Lighthead Assembly - As with the standard

intersection lights, these are high intensity 120 degree

oscillating light assemblies. With addition of the Position

Sensing module these lights can be placed in the takedown or

alley positions.

Note: If the gear assembly is replaced, care must be taken to

insure that the flat nylon washer is seated between the gear

and the bottom plate to prevent premature wear and failure.

Multi-Functional Control Module Using standard lighting controls the operator

can select the operation of the Lighthead

assemblies.

Figure 10

S50690 - Driver side assembly

S50691 - Passenger side assembly

* - see wire tag for

exact wire color code.

Figure 11

S55401 - Multi-Functional Control Module

Sensor Wiring Harness -

Red - Power

Blk - Ground

Grn - Alley

Y el - T akedown

Figure 12

13

Page 14

Operation: The Multi-Functional Intersection Control System will allow the user to obtain Takedown, Intersec-

tion and Alley functions with a single p air of intersection modules. The operation is as follows;

NOTE: Wiring Colors May Vary, Refer T o Wire T ag For Exact Colors.

Passenger Side Alley - When the ( YEL/BLK ) wire is connected to a source of +12VDC the p assenger’s side

intersection module will move to the alley position.

Driver Side Alley - When the ( YEL ) wire is connected to a source of +12VDC the driver’s side intersection

module will move to the alley position.

Intersection - When the ( WHT/BLK ) wire is connected to a source of +12VDC both intersection modules will

oscillate.

overridden. The user cannot obtain Alley functions while in Intersection mode.

Takedown - When the ( ORG/BLK ) wire is connected to a source of +12VDC both intersection modules will

move to the takedown position.

den.

When Intersection mode is selected the Passenger side and Driver side Alley mode will be

When in T akedown mode, the Alley and Intersection modes are overrid-

NOTE: ALL DEVICES USED T O SWITCH +12VDC TO EACH CONTROL WIRE

MUST BE RATED FOR A MINIMUM OF 10A.

14

Page 15

Maintenance

Lens Cleaning

Use plain water and a soft cloth, or Code 3® lens polish and a very soft paper towel or facial tissue.

Because plastic scratches easily, cleaning is recommended only when necessary (about every six

months). Do not subject the lenses to car washes that use brushes, as these will scratch the lenses.

Lens Removal

First, if there is a speaker cover,

remove it as outlined in the PreInstallation Section of this manual.

Next, disengage the lens clips (4

per lens) as shown in Figure 13.

Finally, insert a screwdriver into

the inside edge or corner of the

lens, see Figure 13, and twist the

screwdriver to lift the lens.

Changing Rotating Reflector Lamps

Lamps are extremely hot! Allow to cool completely before attempting to

WARNING!

!

remove. Gloves and eye protection should be worn when handling halogen

lamps as they are pressurized and accidental breakage can result in flying

glass.

Figure 13

Remove the lens as outlined above. Next, inspect the lamp and compare to Figure 14 to determine lamp

type. It may be necessary to remove any rotating or cylindrical filters to make access easier. Note:

Make sure lamp is cool before attempting to change it. Also, when installing a new lamp, be sure not to

touch the glass with fingers. If contact is made, clean the glass with a soft cloth after inspection.

H-1: First grasp lamp at base and turn

until retaining clip tab is accessible.

Using a blade screwdriver, remove

retaining clip and pull lamp straight up.

Replace with new lamp. Insure that the

power lead and retaining clip is fully

seated.

S-795 (Bayonet Style): Push down

and turn to remove lamp. Install a new

lamp the same way.

Note: If attempting to clean the

reflector, use only a mild glass cleaner

and a very soft cloth. Do not attempt to

use any wax type products as these will

burn onto the reflector.

Changing Lower Unit Lamp and/or Filter

Refer to Figure 16. Remove closeout plate by lifting front of plate and sliding tabs out of midplate to

expose components below. In most cases, these lamps will be a bayonet style, so simply push in and

turn counterclockwise to remove. Lower filters can be taken out by removing mounting screw and sliding

filter past reflector while tilting reflector back slightly. Refer to Figure 15. All lights have a special "J" slot

socket that keeps the lamp filament horizontal . Insert the replacement lamp with a socket pin in the 11

o'clock position then push in and turn clockwise until the filament is horizontal.

Figure 14

15

Page 16

Maintenance for Upper and Lower Level Components

(including Flasher and Stingray Electronics)

Upper level components may be replaced by removing the appropriate fasteners attaching the

components as shown in Figure 19. Carefully pull the electrical leads up through the access hole in the

midplate and disconnect at the quickslide terminal. The midplate assembly can be removed entirely from

the light bar in Steps 1 and 2 below and serviced at a workbench. Reassemble as explained in Step 5.

To replace a lower level component, follow these steps:

1.) Remove the Closeout plates by lifting the outer edge and sliding the tabs out of the midplate.

2.) Remove four 8-32 X 3/8" screws to detach the midplate (see Figure 15, the rotating reflector may

be moved for better access by turning the drive worm with thumb or forefinger.) Remove the

midplate by disconnecting the rotator electrical leads at their quick slide terminals.

3.) It is important that all lower level components are attached with fasteners that extend through the

locator strip and into the frame. Use #8 X 1/2" S.S. sheet metal screws for stationary reflectors

and #8 X 5/8" S.S. sheet metal screws for all other lower level components.

4.) Flasher and electronic boxes may be replaced at this step. They are attached using a 8-32 X 1"

S.S. machine screw.

5.) Make sure that all components and electrical leads are attached before reassembly. The midplate

must be temporarily grounded to the frame if recommended electrical testing is done before

reassembly. (Rotators will not operate.) Reassemble in reverse order being careful not to pinch

the chassis wires.

High voltage and/or temperatures are present inside the unit. Disconnect from

WARNING!

!

power and wait 10 minutes prior to servicing or troubleshooting. Using hand

and eye protection when changing halogen lamps or flashtubes.

Midplate

Closeout Plate

8-32X3/8"

Screw

Closeout Plate

Figure 16

Lower Unit Light

Figure 15

16

Page 17

Strobe Filter Replacement

Refer to Figure 17. The filter can be removed by unsnapping it from the light head and by removing the mirror if

present for clearance. Prying the filter from the front may damage the glass strobe tube or reflector.

To replace the filter , reverse the above procedure. The filter should be fully engaged on the light head assembly . Care should be taken to not damage the strobe tube or to scratch the reflective surface of the reflector

when replacing the filter.

Strobe Light Head Replacement

Refer to Figure 17. Disconnect the light head assembly from the strobe power supply and remove the filter if

any . Unfasten the screws attaching the light head mounting bracket to the light bar chassis and remove the

light head from the light bar. On a bench or other work suit able work surface unfasten the screws attaching the

strobe light head assembly from the light head mounting bracket. Install the new strobe light head assembly to

the light head mounting bracket and reinstall the light head back onto the light bar chassis. Reconnect the light

head wiring to the strobe power supply and reattach the filter . It is import ant to reroute and secure the wiring as

close as possible to its original position.

Caution, verify that no wires are interfering with the operation of the fan located at the end of the

power supply .

Electronics Module Removal

In the event that the power supply or a strobe lamp assembly must be returned to the factory for service,

mark each wire with a tag to identify each function and note the proper location before disconnecting the

wiring. Figure 18 can be used to mark the locations of the individual connections as well.

Refer to Figure 18 for power supply removal. Remove the four (4) screws holding the power supply.

Disconnect the wire leads, and move the power supply to the side. Remove the 2 screws holding the

capacitor assembly and lift the strobe power supply/capacitor assembly from the lightbar as a unit. To

reinstall the power supply reverse the above steps.

Caution: Verify that wires are not pinched or damaged when reinstalling power supply.

Strobe Lighthead

Assembly

Filter (if supplied)

FIGURE 17

17

Page 18

The power supply can be located in three locations - Driver’s side and Passenger’s side outboards and the

center section. The power supply location will depend on the configuration of the MX Strobe lightbar.

Rear Output

( YEL,BLK,BLK/WHT )

Control Wire Harness

( YEL\BLK,BRN\BLK)

Ground Wire

(BLK)

+12VDC

( RED )

FIGURE 18

Power Supply Wiring Detail

(6 Head Power Supply Shown)

Rear Output

( GRN,BLK,BLK/WHT )

Rear Aux. Output

( RED,BLK,BLK/WHT )

Front Output

( BRN,BLK,BLK/WHT )

Front Output

( ORN,BLK,BLK/WHT )

Front Aux. Output

( WHT ,BLK,BLK/WHT )

1

2

FRONT

+12v(RED)

3

REAR

4

5 N/C

GND(BLK)

N/C(GREY)

FRONT(GRN)

REAR(BLUE)

RANDOM

FLASH

(YEL)

18

PSE 490E

FIGURE 18A

Page 19

Figure 19

MX 7000 Exploded View - Outboard Section Shown

19

Page 20

20

Page 21

Parts List

Ref No. Description Part No.

1 #8 x .270" Sheet Metal Screw T01215

2 MX Torque Plate T08637

3 MX 1/2 Diamond Mirror S25408M

MX Full Diamond Mirror S13625M

4 #8 x 3/8" Sheet Metal Screw T00243

5 MX Cyl. Filter T0225X

Green - 2250, Red - 2252, Blue - 2253, Amber - 2254

6 #8-1/2" Sheet Metal Screw T00238

7 MX Closure Plate Outboard T05308

8 MX Outboard Midplate S50265M

9 MX S795 Stationary Module S50346M

MX 1156 Stationary Module S50348M

10 D.S. Alley Light Module S50361M

P.S. Alley Light Module S50362M

11 Rotator Module 55W H-1 Std Speed S95983M

Rotator Module 55W H-1 Fast Speed S95984M

Rotator Module 50W Bayonet Std Speed S95985M

Rotator Module 50W Bayonet Fast Speed S95986M

Rotator Module 24V S95987M

13 MX Osc. D.S. Front 120° Intersection Module S50406M

MX Osc. P.S. Front 120° Intersection Module S50407M

MX Osc. D.S. Fast Front 70° Pursuit Module S50408M

MX Osc. P.S. Fast Front 70° Pursuit Module S50409M

Multi Function Intersection D.S. Module S50690M

Multi Function Intersection P.S. Module S50691M

14 5-Hole Stationary Filter with Optics T0255X

Green - T02550, Red - T02552, Blue - T02553, Amber - T02554

5-Hole Stationary Filter without Optics T0209X

Green - T02090, Red - T02092, Blue - T02093, Amber - T02094

3-Hole Stationary Filter T0214X

Green - T02140, Red - T02142, Blue - T02143, Amber - T02144,

Black - T02146, Translucent White - T02147

15 Lens Clip T01777

16 MX Bottom Lens - Clear S50260M

17 H-1 55W 12V Bulb T01543

S795 50W 12V Bulb T01540

18 H-1 Lamp Retaining Clip T04933

19 Rotating Filter for free form reflector with mtg. screws

Green - S95988M, Red -S95989M, Blue - S95990M, Amber - S95991M

20 Screw, 2 X 3/8 Pan HD T02655

21 Splash Bracket T09330

22 MX Outboard Locator Strip T05022

23 #8-32 X 1" Machine Screw T04884

26 #8 X 5/8" Sheet Metal Screw T02921

27 MX Speaker Deck Assembly S25399M

28 MX Regular Frame S50354M

30 Midplate Mounting Bracket T04810

31 #8-32 X 3/8" Sheet Metal Screw T04888

32 3/8" X 3/8" Open Cell Foam T02919

21

Page 22

PARTS NOT SHOWN

MX Top Outboard Lens

Clear T02101

Red T02102

Blue T02103

Amber T02104

Terminal Block - 2 Pole, 1 Row T00028

5/16" Cable Clamp T00346

1/2" Cable Clamp T00903

3/8" Cable Clamp T00938

3/4" Snap Bushing T00336

MX Cornering Filter - (D.S. Front/P.S. Rear)

Red T02182

Blue T02183

Amber T02184

Black T02186

MX Cornering Filter - (D.S. Rear/P.S. Front)

Red T02192

Blue T02193

Amber T02194

Black T02196

OPTIONS NOT SHOWN

MX StingRayTM Module (S795) S50400M

P.S. 2-Step Cascade Mirror S55006M

D.S. 2-Step Cascade Mirror S55009M

MX Flat Mirror Outbd.-Driver Front or Passenger Rear T04278

MX Flat Mirror Outbd.-Driver Rear or Passenger Front T04279

MX 104° V-Mirror S55012M

MX Stop/Turn/Tail Light Assembly Upper W/Adapter Plate S50296M

MX Stop/Turn/Tail Light Assembly Lower S50342M

MX External D.O.T. Strip Assembly S50021M

MX Closure Plate Center T05307

MX Center Locator Strip T05021

MX Center Midplate T05386

MX Center Midplate Module S50264M

MX Top Center Lens

Clear T02131

Red T02132

Blue T02133

Amber T02134

White T02137

MX Bottom Center Lens Module - Clear S25444M

OsciLaser Module 35W S50343M

Multi-Functional Control Box S55401M

22

Page 23

Parts & Exploded Views - Outboard Section

For Additional Parts, see MX7000 Bar Manual

4

3

2

5

1

FIGURE 20

Parts list

No. Description Part No. Qty

1 MX Strobe Motor Plate T08604 2

2 MX Strobe Midplate - Front T08602 2

3 MX Strobe Midplate - Rear T08603 2

4 MX Strobe Power Supply Assembly, 6 Head S80352M

1

MX Strobe Power Supply Assembly, 4 Head S80305M 1

MX Strobe Power Supply Assembly, 2 Head S80310M 1

23

Page 24

Parts & Exploded\ Views- Outboard Section

Strobe Lighthead

Assembly

Filter (if supplied)

FIGURE 21

Parts List

No. Description Part No. Qty.

5 Strobe Upper Lighthead Assembly -

Corner Position T09424

Strobe Upper Lighthead Assembly Corner Position Mirror - DS Frt/PS Rr T09409

Strobe Upper Lighthead Assembly Corner Position Mirror - PS Frt/DS Rr T09406

Strobe Upper Light Head Assy – Corner Pos Filter

Red T09442

Blue T09443

Amber T09444

Strobe Upper Light Head Assembly – Directional Position T09425

Strobe Upper Light Head Assy – Directional Pos Filter

Red T09432

Blue T09433

Amber T09434

24

Page 25

2

D-TECH ROT A TOR

4

6

1

DESCRIPTION

1 BAYONET LAMP 50W T01540

2 NEW REFLECTOR ASSEMBLY

RED/BLUE S22179

AMBER/BLUE T02652

3 MOTOR ASSEMBLY

MX,CODE360 S95872M

FAST MX,CODE360 S95873M

4 RETAINING RING T01210

5 D-TECH ROTATOR BASE ASS S14050M

6 NYLON WASHER T04492

5

3

PART NO.

25

Page 26

D-Tech Lamp Replacement Instructions

To remove lamp, first remove D-Tech

Reflector Head. Press DOWN on tab and

rotate D-Tech head counterclockwise to

remove.

26

Page 27

Troubleshooting

All Excalibur strobe lightbars are thoroughly tested prior to shipment. However, should you encounter a

problem during installation or during the life of the product, follow the guide below for information on repair and

troubleshooting. Additional information may be obtained from the factory technical help line at 314-426-2700

ext. 2131.

NO STROBE LIGHTS IN THE LIGHTBAR OPERATE - Check the following: 1) +12 VDC source connection

for the control switch box and any in line fuse 2) Connection of the RED and RED/BLK wire at the control

switch box 3) Check the 15 Amp ATO fuse on each power supply. If the fuse is blown, replace it with another

15 Amp fuse and test the lightbar. If the fuse continues to blow, return the power supply only, NOT the entire

lightbar, to the factory for service. For instructions on power supply removal see the " Electronics Module

Removal " section of this manual.

!

Do not replace the fuse with one of a higher rating. This will damage the power supply and void all

warranties.

WARNING!

ONE STROBE LIGHT MODULE DOES NOT OPERATE - Check the defective strobe light module by

switching it with a module that is known to be working.

PROBLEM POSSIBLE CAUSE SOLUTION

Lighthead oscillates when selecting Lighthead not sensing position.

Alley and/or Takedown modes. Check the following:

Bad wiring harness Replace wiring harness

Bad connection Check connections (Figure 10 & 1 1)

Failed position sensor Replace lighthead assembly

Lighthead doesn’t move when Alley Failed lighthead assembly Replace lighthead assembly

and/or Takedown mode is selected,

but moves in Intersection mode

Lighthead does not move when any Bad motor wire to module Check connections / Replace wire

mode is selected. Failed light bar wire harness Check light bar wiring harness

No power to control module Check +12VDC switching control

Failed lighthead assembly Replace lighthead assembly

Failed control module Replace control module

Lighthead operates properly, Lamp burnt out Replace lamp (50W maximum)

but lamp is not on Bad lamp wire to module Check connections / Replace wire

Driver side lighthead oscillates and Driver side lighthead not sensing

Passenger side lighthead does not Check for the following:

move when Takedown is selected. Bad wiring harness Replace wiring harness

Note: In Takedown mode,PassengerBad wiring harness connection Check connections (Figure 10 & 11)

side lighthead will not move until Failed position sensor Replace lighthead assembly

Driver side lighthead has located

Intersection mode selected, Driver No problem Normal operation, Intersection mode

and Passenger side Alley modes overrides Alley mode.

do not function

Takedown mode selected, no No problem Normal operation, Takedown mode

other modes operational overrides all other modes

27

Page 28

STROBE OPTION

TROUBLESHOOTING GUIDE

PROBLEM

Light heads do

not fire.

. Only front

strobes flash

Follow the guide below for information on repair and trouble shooting for the arrowstik option.

a.Harness that connects power

supply to strobe head has loose

connections or damaged

harness.

b. Faulty strobe Lighthead.

c. High voltage shorting to ground

(earth) through harness.

a. GRN/BLK control wire connected

to +12VDC overrides other

modes.

CAUSE

a. Check all connections.

Check harness by switching harness with functioning

strobe head.

Replace harness.

b. Check with known good Lighthead.

c. Isolate shorted harness by disconnecting one at a time.

Replace harness.

a. See "Strobe Lighting Connections" section.

Reconnect switching.

SOLUTION

ARROWSTIK® OPTION

TROUBLESHOOTING GUIDE

PROBLEM

ArrowStik does not

function when

turned on

QUESTION

Are LED's functioning properly?

Yes

No

CAUSE

a. Plug in rear of control box is

loose or disconnected.

b. Poor ground connection

a. Power from battery has been

disconnected or the control

box has been damaged.

a. Reconnect plug.

b. Reconnect ground.

a. Check connections at the battery

and plug. If connections are good

and voltage is at least 10 volts, the

control box has been damaged.

Repair or return to Code 3.

SOLUTION

Lamp does not

come on when it

should.

Right most lamp

does not come on

in Arrow Left mode

or left most lamp

does not come on

in Arrow Right

mode.

ArrowStik runs

opposite pattern

than selected.

Lamp looks dim.

Are LED's functioning properly?

Yes

No

a. Lamp has burned out.

b. Bad wiring connection.

a. Control box has been

damaged.

a. Normal operation

a. Defective Wiring.

b. Control box has been

damaged.

a. Defective lamp.

b. Low voltage.

c. Poor ground

d. Product is in "Dim" mode.

a. Replace lamp.

b. Repair connection.

a. Repair or return to Code 3.

a. None

a. Check that the cable exit is on the

driver's side

b. Repair or return to Code 3.

a. Repair or return to Code 3.

a. Replace lamp.

b. Check connections or battery.

c. Check ground and wire gauge.

d. Select appropriate mode.

28

Page 29

NOTES

29

Page 30

NOTES

30

Page 31

NOTES

31

Page 32

WARRANTY

This product was tested and found to be operational at the time of manufacture. Provided this product is installed and operated in accordance with the manufacturer's recommendations, Code 3®, Inc. guarantees all parts and components except the lamps for a period of

1 year from the date of purchase or delivery, whichever is later. Units demonstrated to be

defective within the warranty period will be repaired or replaced at the factory service center at

no cost.

Use of a lamp or other electrical load of a wattage higher than installed or recommended

by the factory, or use of inappropriate or inadequate wiring or circuit protection causes this

warranty to become void. Failure or destruction of the product resulting from abuse or unusual

use and/or accidents is not covered by this warranty.

Code 3® shall in no way be liable for other damages including consequential, indirect or

special damages whether loss is due to negligence or breach of warranty.

CODE 3® MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING,

WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH

RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

In order to provide you with faster service, if you are going to return a product for repair

or replacement*, please contact our factory to obtain a Return Goods Authorization Number

(RGA number) before you ship the product to Code 3®. Write the RGA number clearly on

the package near the mailing label. Be sure you use sufficient packing materials to avoid

damage to the product being returned while in transit.

*Code 3® reserves the right to repair or replace product at its discretion. Code 3 assumes no responsibility or liability for expenses incurred for the removal and/or reinstallation

of products requiring service and/or repair.

NEED HELP? Call our Technical Assistance Hotline - (314) 996-2800

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

10986 N. Warson Road

Code 3, Inc.

www.code3pse.com

Code 3 & ArrowStik are registered trademarks of Code 3, Inc.

MX7000, OsciLaser & Stingray are trademarks of Code 3, Inc. a subsidiary of Public Safety Equipment, Inc.

3M® is a registered trademark of 3M Company

16

Revision 18, 10/2006 - Instruction Book Part No. T04813

©2004-6 Code 3, Inc. Printed in USA

Loading...

Loading...