Page 1

Electro-Hydraulic Tire Changer

For Medium and Large Size Tires

CHD-9551

OPERATING AND MAINTENANCE INSTRUCTIONS

READ these instructions before placing unit in service KEEP

these and other materials delivered with the unit in a binder

near the machine for ease of reference by supervisors and

operators.

85010081/00

Revision 07/08

Page 2

INDEX

1 - GENERAL INFORMATION...............................................................................................................................................................................3

2 - TECHNICAL DATA...........................................................................................................................................................................................3

3 - GENERAL SAFETY REGULATION.....................................................................................................................................................................3

4 - SAFETY DEVICES.............................................................................................................................................................................................3

5 - TRANSPORT.....................................................................................................................................................................................................3

6 - UNPACKING...................................................................................................................................................................................................4

7 - INSTALLATION................................................................................................................................................................................................4

7.1 Installation place ........................................................................................................................................................................................................................4

7.2 Workplace requirements...........................................................................................................................................................................................................4

7.3 Electric hook up..........................................................................................................................................................................................................................6

Sense of rotation check

8 - LAYOUT OF FUNCTIONAL PARTS...................................................................................................................................................................7

9 - IDENTIFYING WARNING SIGNALS.................................................................................................................................................................8

10 - IDENTIFICATION OF CONTROL....................................................................................................................................................................9

11- WORKING POSITION.....................................................................................................................................................................................9

12 - CORRECT OPERATION CHECKS..................................................................................................................................................................9

13 - OPERATION................................................................................................................................................................................................11

13.1 Locking the wheel..................................................................................................................................................................................................................11

Light-alloy rim locking

13.2 Tubeless and supersingle wheels..........................................................................................................................................................................................12

Bead breaking

Demounting

Mounting

13.3 Tubed wheels..........................................................................................................................................................................................................................16

Bead breaking

Demounting

Mounting

13.4 Wheels with split ring...............................................................................................................................................................................................................20

Bead breaking and demounting

Mounting

14 - ORDINARY MAINTENANCE.......................................................................................................................................................................23

15 - TROUBLE SHOOTING..................................................................................................................................................................................24

16- MOVING THE MACHINE.............................................................................................................................................................................24

17- STORING......................................................................................................................................................................................................24

18- SCRAPPING A MACHINE............................................................................................................................................................................24

19- DATA ON SERIAL PLATE...............................................................................................................................................................................25

20- ACCESSORIES.............................................................................................................................................................................................25

ELECTRIC DIAGRAM..........................................................................................................................................................................................26

2

Page 3

1

This tyre changer has been specically designed to demount and mount truck, bus and commercial van tyres, with rims from 14" to 56"

and a maximum 2.400 mm diameter.

Any other use is improper and therefore not authorized. Before beginning any kind of work on or with this machine, carefully read and

understand the contents of these operating instructions.

The manufacturer shall not liable for any injury to persons or damage to things caused by improper use of this machine.

KEEP THIS MANUAL NEAR THE MACHINE AND CONSULT IT AS NEEDED DURING OPERATIONS.

GENERAL INFORMATION

2

GENERAL SAFETY REGULATIONS

3

The use of this machine is reserved to specially trained and authorized personnel.

Any unauthorized changes or modications to the machine, in particular to its electric system, relieve the manifacturer from all liability.

Removing or tampering with the safety devices installed on this machine is in violation of European Safety Regulations.

Any work, however minor, on the electric system must be done exclusively by professionally qualied personnel.

TECHNICAL DATA

Electric Power requirement

Pump motor

Gear-box motor

Handles rim from

Max. wheel diameter

Max. wheel width

Max. wheel weight

Weight (with standard accessories)

Acoustic pressure level (at work)

220V - 3 PH - 60Hz 15 Amp

1,1 kw

1,8 / 1,85 kw

14" - 56"

2.400 mm

1.300 mm

1800 kg

1025 Kg

LpA <70 dB (A)

4

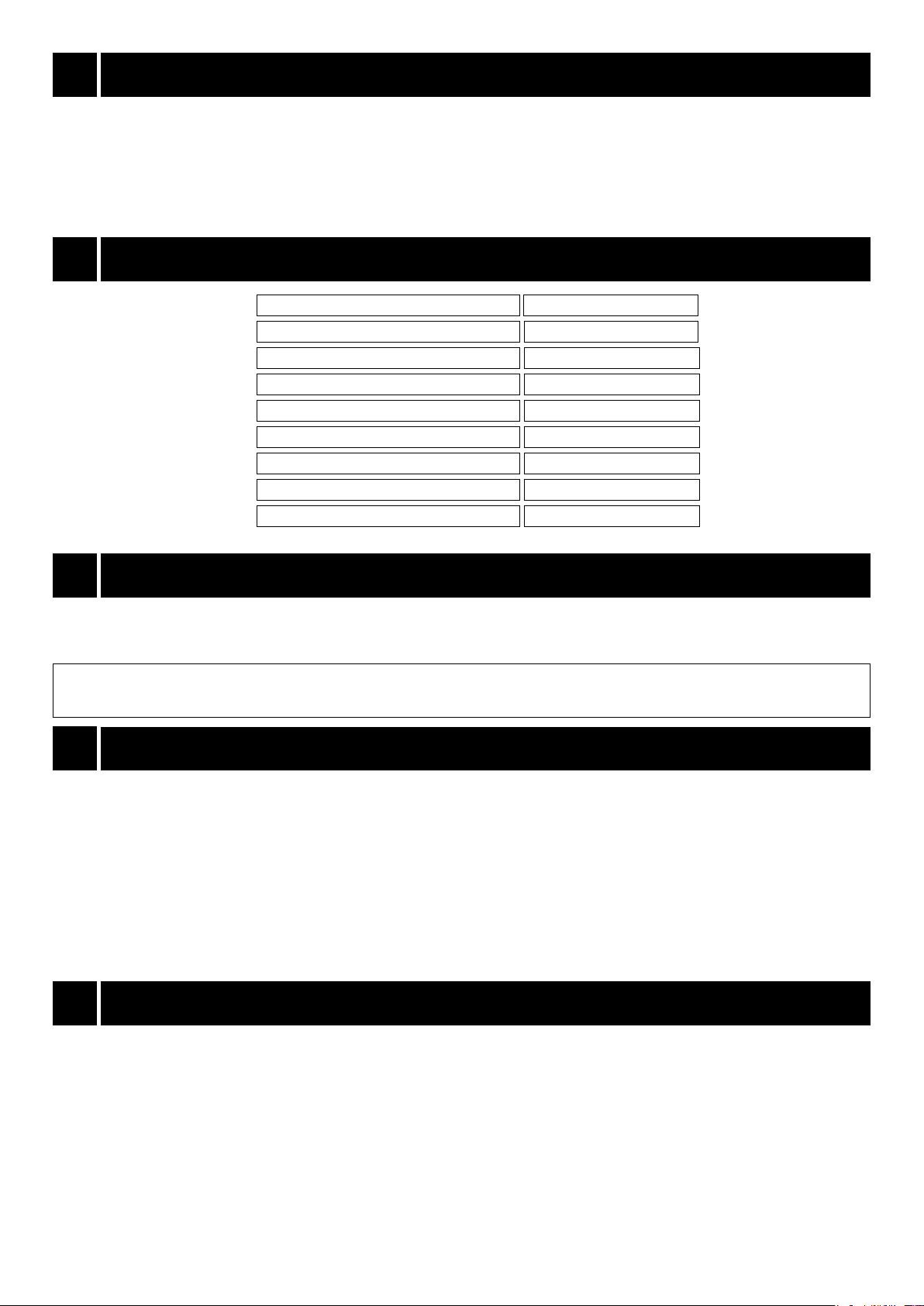

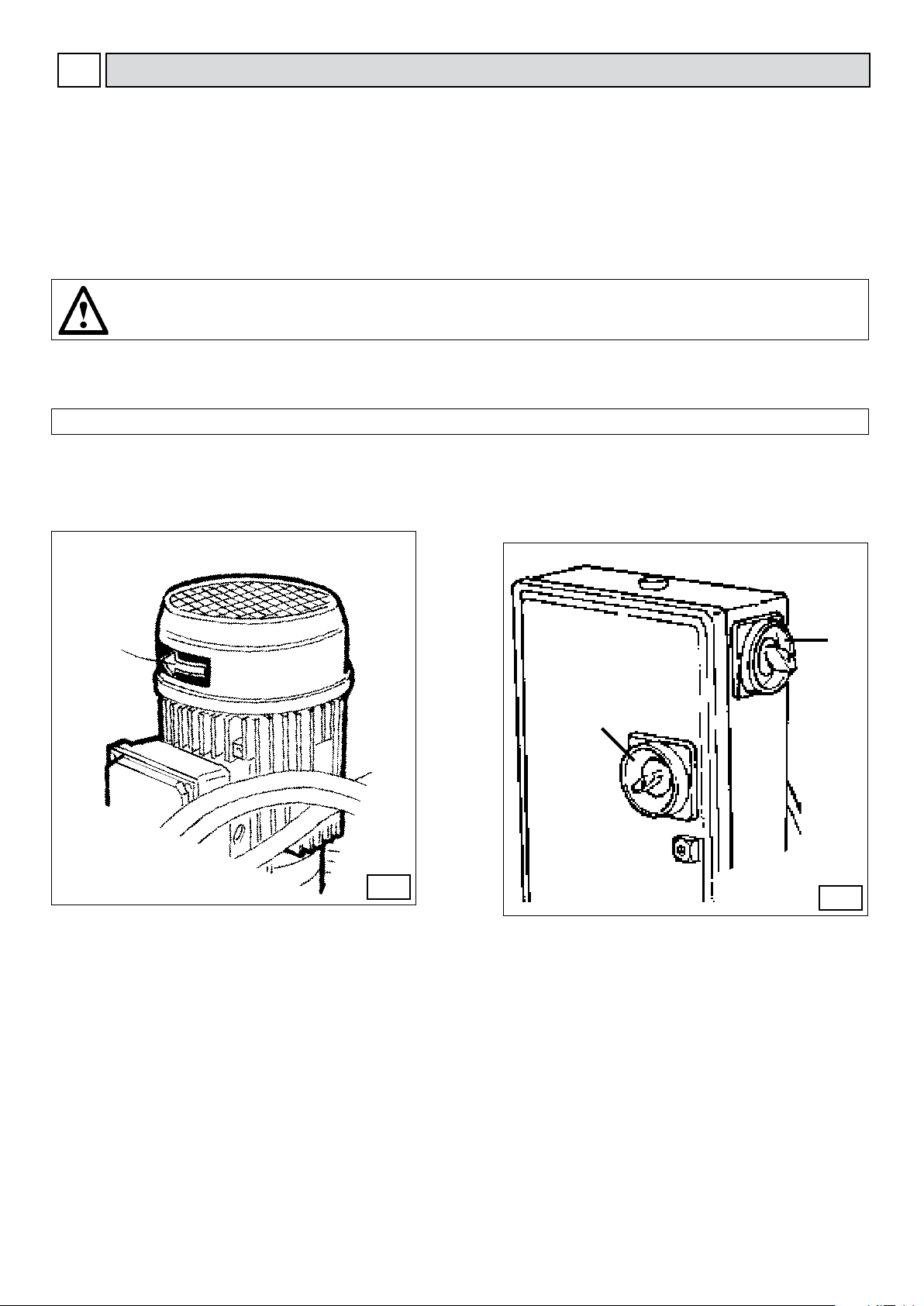

The tire changer has a number of safety devices designed to guarantee the utmost operator safety:

1. Check valve on the spindle opening hydraulic line (inside the swivel connector, see g. B/1). This prevents the wheel from falling from

the spindle if the hydraulic line is accidentally broken.

2. Pressure relief valve factory set at 1.885 PSI (130 bar ±10%) (See Fig. B/2).

This limits the pressure in the hydraulic circuit and ensure correct operation of the plant.

3. Pump motor overload shut-out (inside the electric enclosure).

This provides automatic shut-off for the motor to prevent damage from overheating.

5

The machine is delivered in a wooden crate with pallet

The machine must be handled with a fork-lift truck with the forks positioned as shown in the gure A/2.

Shipping weight for the machine is 2.745 lbs (1245 kg.)

SAFETY DEVICES

TRANSPORT

3

Page 4

lbs 2745

(KG. 1245)

B/1

B/2

A/2

6

Once the packing material has been removed, check the machine visually for any signs of damage.

Keep the packing materials out of the reach of children as they can be a source of danger.

N.B.: Keep the packing for possible future transport.

7

7.1

Choose the place the machine is to be installed in compliance with current work place safety regulations. The oor should not be broken

or uneven so that the machine will be stable and the platform rollers can move freely.

If the installation is outdoor, it must be protected by some kind of roong against rain.

The following work environment conditions are applicable:

Relative humidity: from 30-95% without condensation;

Temperature: from 32°-131° F (0-55° C.)

ATTENTION!

The machine must not be operated in explosive atmospheres.

7.2

Maximum machine space requirements are 88.2x6.3 inches (2240x 1640 mm) with a minimum distance from walls as shown in the diagram.

CAUTION! These measurements are also the tyre changers working range. Persons other than specially trained and authorized operators

are expressly forbidden to enter this area.

WORKPLACE REQUIREMENT

UNPACKING

INSTALLATION

INSTALLATION PLACE

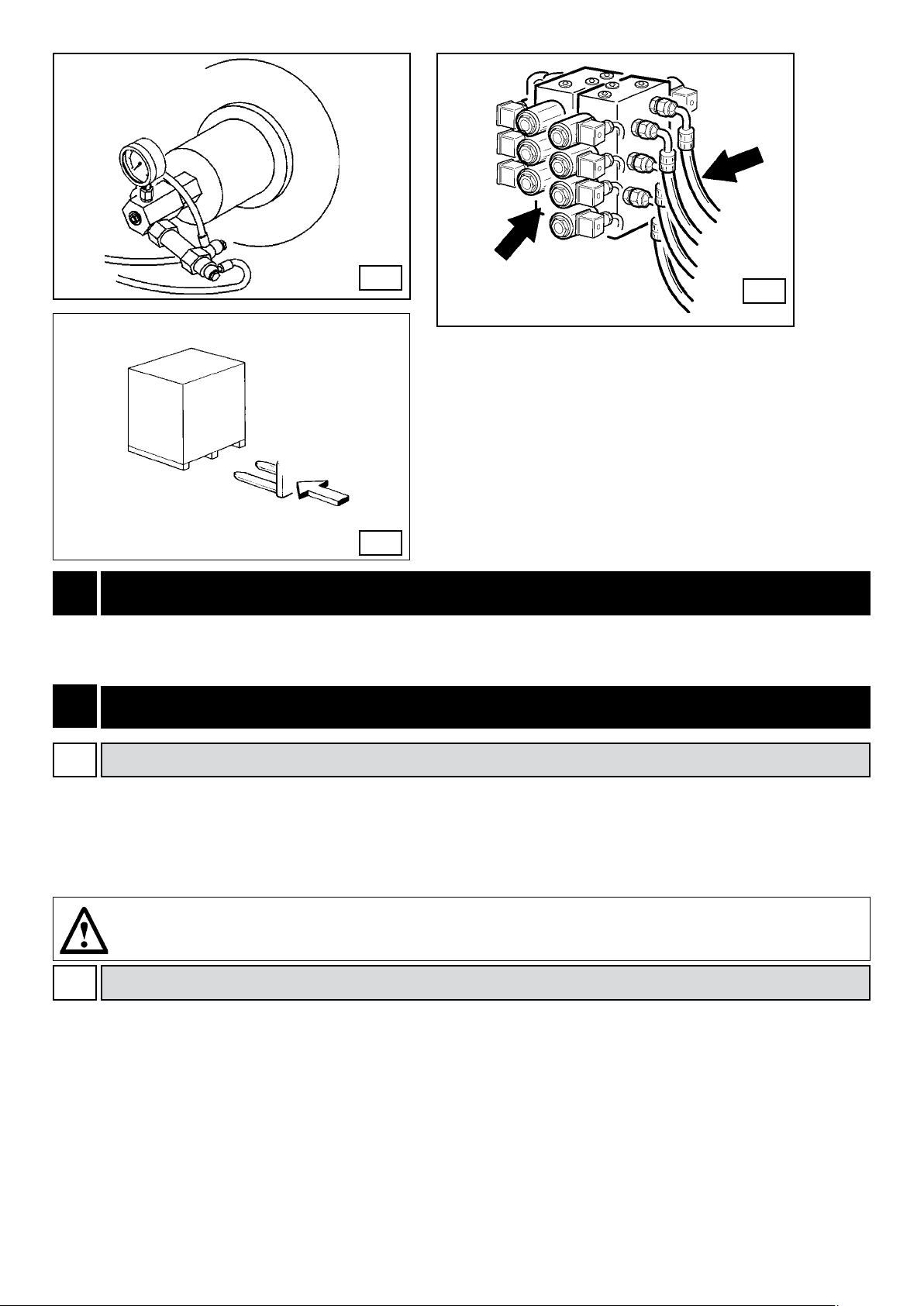

Position the tire changer lifting it with the specic bracket (1, Fig. A) with the tool carrier arm (2, Fig. A) lowered all the way, the spindle

(3, Fig. A) closed and the tool carrier slide (4, Fig. A) at its stop close to the arm.

The mobile control unit has no xed position, but it must be

positioned in a way that the user can observe the machine when working

4

Page 5

1

Foundationsdimensions inch (cm).

Concrete

quality

Min. pressure

resistence

Length Width Thickness

B25

937 lbs/sqft

(425 Kg / cm2)

78,74

(200)

64,5

(164)

5,9

(15)

98.4 inches

(2,500 mm)

27.5 inches

(700 mm)

1

98.4 inches

(2,500 mm)

2

39.3 inches

(1,000 mm)

B/5

3

4

The universal tire-changer must be installed on a levelled concrete oor at least 8” (20 cm.) thick, with a minimum concrete quality of

B25 in accordance with DIN 1045 requirements (foundations).

For your reference see the side drawing as well as the table herebelow.

Ground

Reinforced concrete

Electrowelded grid

Pebble gravel

If a oor of this type is not available on site, fastening points of the specied concrete quality are acceptable.

The surface, on which the universal tyre-changer is to be installed, must be at and well levelled in all directions.

Inclinations up to 0,25% relative to the horizontal can be compensated using suitable shims, wedges or the alike.

A

When working with tire assembly, whose weight is higher than 2,204 lbs (1000 kg.), it is necessary to

fasten the tire-changer to the oor by means of proper anchor bolts.

By means of a Widia bit Ø 16, drill a 0,63 inch (130 mm) into the oor passing through the holes provided on the base frame.

If there is an additional oor covering (B), or if shims or wedges are necessary for levelling (C), longer anchor bolts must be used.

Place an anchor bolt into each hole.

Make sure the anchor bolts extend at least 4.9” (125 mm.) into the concrete slab, as indicated in the drawing.

Tighten the anchor bolts fully.

3,93

inches

ø 0,31

inches

3,93

1,96

5,90

3,93

Ø 0,7

Ø 0,7

4,9

Ø 0,7

4,9

MAX 0,25%

4,9

5

Page 6

7.3

Before making any electric hook up, check to be certain that the mains voltage corresponds to that stamped on the voltage tag (attached to the cord near the tire changer’s plug).

It is absolutely essential that :

- the system is equipped with a good grounding circuit.

- The current instake is adeguately protected against overcurrents with fuses or automatic magneto-thermic switch.

Note the required power draw as highlighted on the data plate xed to the tire changer. Check to make sure the shop electric wiring

circuit is dimensioned sufciently to carry this.

Work on the electric system, even if minor, must be done exclusively by professionally qualied electrician.

Manufacturer shall not be liable for any injury to persons or damage to things caused by failure to comply with these regulations and

can cancel warranty coverage.

Connect the machine to the mains, switch “ON” (5, g. B/7) and check that the gearbox motor rotation corresponds to the indicating

arrow (6, g. B/6). If not, switch two wires in the plug .

ELECTRIC HOOK UP

SENSE OF ROTATION CHECKS

6

B/6

12

5

B/7

6

Page 7

8

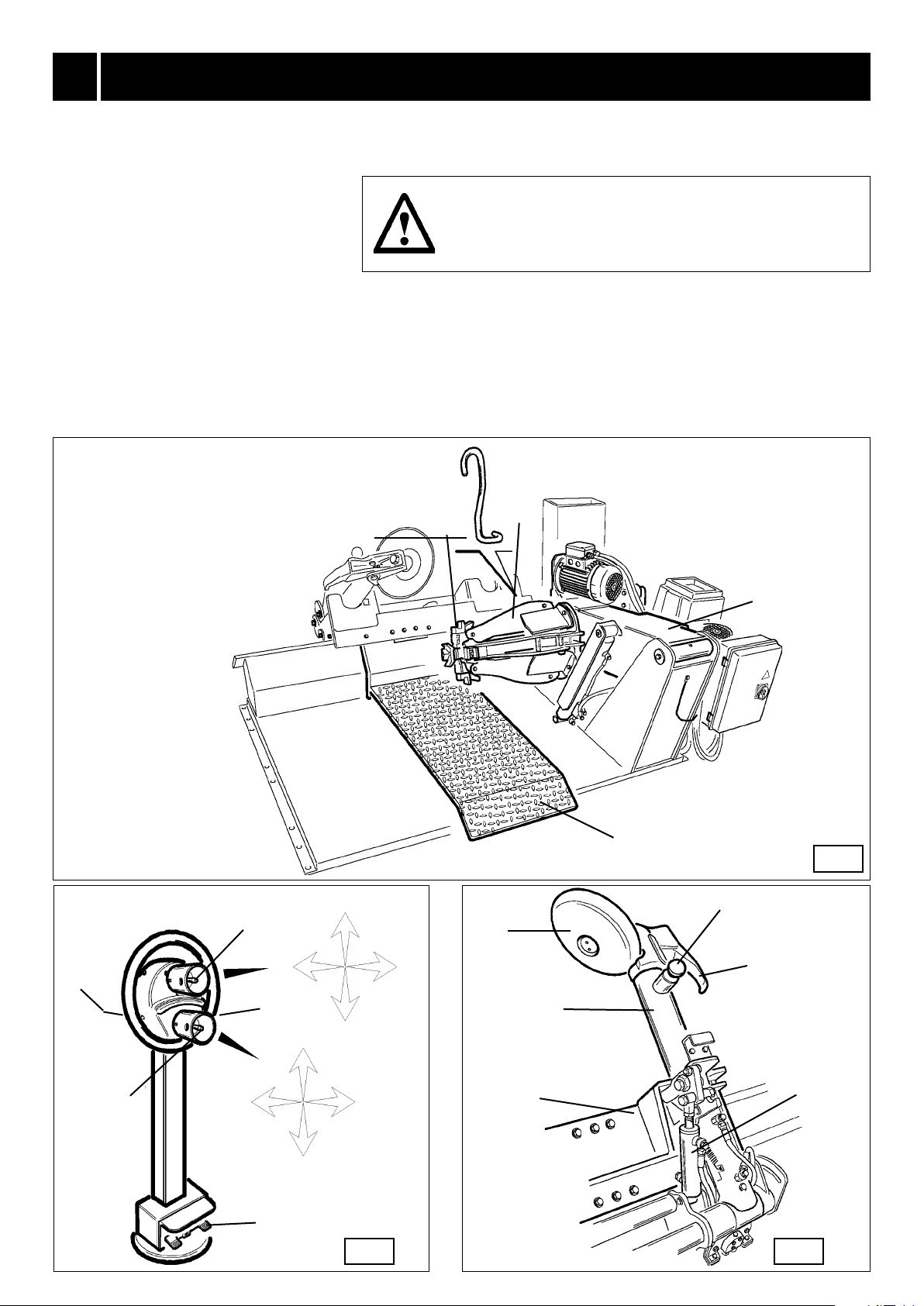

1 - Lifting bracket

2 - Self-centering chuck holding arm

3 - Self-centering chuck

4 - Sliding ramp

5 - Switch

8 - Handler

9 - Switch

10 - Pedal

11 - Handler

13 - Carriage

14 - Tool holding arm

15 - Arm lever

17 - Bead breaking disk

18 - Tool

19 - Arm locking cylinder

22 - Jaw

LAYOUT OF FUNCTIONAL PARTS

WARNING!

During all operations, keep hands and other parts of the body

as far as possible from moving parts of the machine. Necklaces,

bracelets and too large clothes, can be dangerous for the operator.

1

22

3

2

4

A

a

8

15

17

5

c

9

e

b

11

g

h

d

14

13

18

19

f

10

C

7

D

Page 8

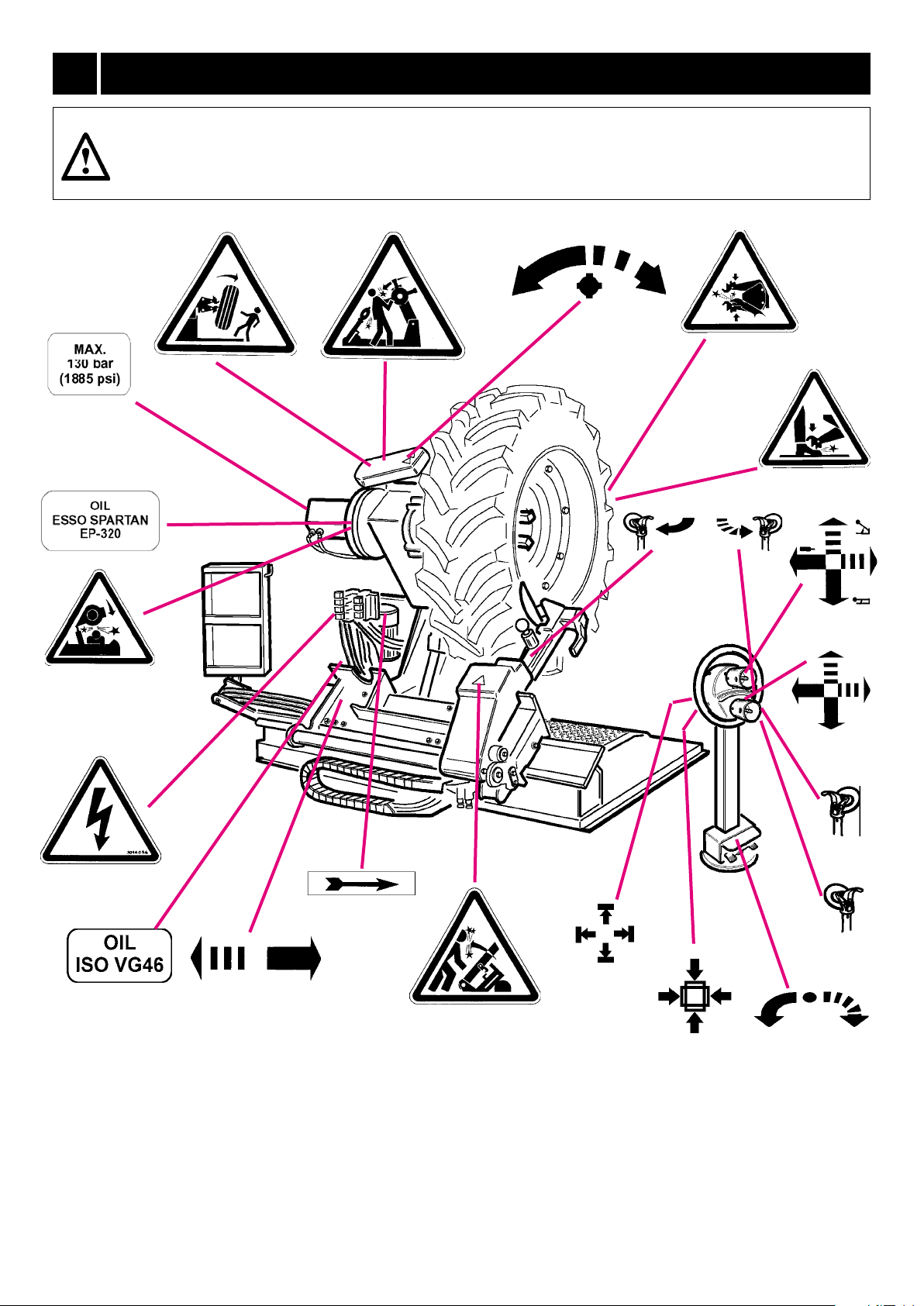

9

IDENTIFYING WARNING SIGNALS

WARNING:

Unreadable and missing warning labels must be replaced immediately. Do not use the tyre changer

if one or more labels are missing. Do not add any object that could prevent the operator from seeing

the labels.Use ref. code #2019225 to order labels set, if needed.

8

Page 9

10

The mobile control unit (C) enables the operator to work at any position around the machine. On this mobile control unit controls are

located:

-The lever (8, g. C) : which in position position [a] lifts the chuck arm, and in position [b] lowers it; in position [c] moves the tool

holder arm and the sliding ramp towards the self-centering chuck, and in position [d] moves them away. Note: to memorize this last

operation, there is a hole in the lever guard corresponding to position [c].

-The lever (11, g. C) : which in position [e] lifts the tool holder arm, and in position [f] in lowers it; in position [g] moves the tool carriage

leftwards, and in position [h] moves it rightwards.

-The chuck (5, g. C) : when moved upwards, opens the arms of the self-centering chuck (locking), and when moved down close

close the arm of the self-centering chuck (unlocking).

-The chuck (9, g. C) : when moved upwards turns the tool with disc towards the spindle, and when moved down ward, turns the tool

with the ngen towards the spindle (17 g. D or 18, g. D).

-The pedal (10, g. C): when pressed on the left or right side rotates the self-centering chuck in the same directionas shown by the

arrows placed on the foot pedal. Both rotations can be made with two different speeds, just placing the selector (12, g B/7) in

position 1 for setting slow rotation and in position 2 for fast rotation of the turntable. The tire changer also has a knob (15, g. D) on the

tool arm, to unlock the double tool and help replacement of double tool with tubeless tires tting/removing tower (on demand, ref.

# 9299274)

CONTROLS DESCRIPTION

11

The diagram B/8 illustrates the various working positions (A,B,C,D) referred to in the following pages describing how to use the tyre changer.

Use of these positions ensures greater precision, speed and safety for those using the machine.

12

Before using the tyre changer, a number of checks should be made to ensure it works correctly.

CAUTION! The operations described here should be done with the tool carrier arm in its non-working position.

CORRECT OPERATION CHECKS

WORKING POSITION

a

d

c

b

B/8

a

8

5

c

9

e

11

g

d

b

h

f

10

C

15

17

18

14

13

Act rst on lever (11, Fig. C) to tip the arm to this position.

CAUTION!

Do not move your face close to the tool carrier arm when you release it to tip it as needed.

1) Move the lever (8, Fig. C) up (a): the spindle carrier arm (2, Fig. A) should lift; move the lever down (b): the arm should lower.

19

D

9

Page 10

DANGER!

When the spindle carrier arm is lowered, there is always a potential for crushing anything in its movement

range. Always work from the position given in the instructions keep well out of the working range of the various moving arms.

Move the joystick towards the lift (c): the tool carriage and the mobile platform (13, Fig. D) shall move towards the spindle (3, Fig. A);

move the jlever towards the hight (d): the carriage and platform shall move away from the spindle.

2) Move the joystick (11, Fig. C) to all available positions and check for each the related movement that must correspond to what

described in chap. 10, “Controls description”.

3) Move switch lever (5, Fig. C) towards the top: the chuck arms (3, Fig. A) should open; move the lever down and the spindle arms

should close.

DANGER!

When the spindle arms open or closed, there is always a potential for crushing anything in their movement range. Always work from the position given in the instructions keep well out of the spindle’s working

range.

3) Depress the right pedal (10, Fig. C): the spindle (3, Fig. A) should turn clockwise; depress the left pedal: the spindle should turn coun-

terclockwise.

a

8

15

17

5

c

9

e

11

g

f

10

d

b

14

18

h

13

19

C

D

E/1

4) Check to be certain the hydraulic circuit is working correctly:

- move switch lever (5, Fig. C) towards the top until the spindle arms are fully extended.

- hold the switch lever in this position (top) and check if the pressure shown on the gauge on the swivel tting is 1,885 PSI (130 bar ±10%).

If the pressure shown in not as indicated here, DO NOT USE the tire changer and call your nearest Service Center.

10

Page 11

13

OPERATION

13.1

1) Take the mobile control unit to work position B.

2) Pull the tool-holder arm (14, g. D) into the upright position.

3) Operating from the mobile control centre, move the sliding table (13, g. D) away from the self-centering chuck and place the tire

assembly in vertical position over the sliding ramp.

DANGER! POTENTIALLY HAZARDOUS OPERATION!

Do it manually only if you are certain you can keep the tire assembly balanced. For large and heavy tyres an

adequate lifting device must be used.

4) Continuing to operate from the mobile control centre, lift or lower the arm in order centre the self-centering chuck (3, g. A) relative

to the rim.

5) With the jaws (22, g. A) in the closed position, move the tire assembly on the sliding ramp to the self-centering chuck. Operate the

chuck switch (5, g. C) to open the self-centering chuck and clamp the inner side of the rim.

RIM CLAMPING

WARNING!

In rim clamping, make sure that jaws are properly positioned on the rim, so as to prevent the tire from

falling over

E/2

E/3

The most convenient clamping position on the rim may be selected according to gs E/1 - E/2 - E/3 - E/4 - E/5 and E/6.

Always remember that the safest clamping is on the central ange.

For rims with drop center clamping, clamp the wheel so that the drop center is near the outside of the rim (g. E/1).

For rims exceeding a diameter of 46" and without a ange with center hole, the rim can be clamped with the 4 clamping extensions

provided on demand (# 9299270)

(# 9299272) LIGHT-ALLOY RIM CLAMPING

A set of clamps - especially designed for operating on light alloy rims without damaging them - is available upon request.

These clamps are to be inserted (bayonet-like mounting) into the jaw support of the self-centering chuck (see g. E/7).

Thanks to a wing screw the clamp can be locked on the support.

Clamp the rim as illustrated in g. E/8. The specially-made alloy-rim pliers are also available (# 9299271).

E/4

E/5

11

Page 12

DANGER!

Do not very the work area with a wheel clamped on the tire changer and lifted up from the oor.

13.2

1) Clamp the tire assembly on the self-centering chuck, as previously described, and ensure that the tire is deated.

3) Lower the tool-holder arm (14, g. F) into working position and allow it to lock.

TUBELESS AND SUPERSINGLE TIRES

BEAD LOOSENING

2) Take the mobile control unit to work position C.

DANGER!

Always check to be certain that the arm is correctly hooked to the carriage.

E/6

E/7

E/8

4) Operating from the mobile control centre, manoeuvre the wheel until the outside of the rim skims the bead-loosener disk (g. F).

DANGER!

The bead loosener disk must NOT be pressed against the rim but against the tire bead.

5) Rotate the wheel and at the same time, advance the loosener disk plate with small forward movements following the prole of the

rim.

6) Continue until the rst bead is fully detached.

To facilitate this operation, lubricate the bead and the edge of the rim with tire lubricant whilst the tire assembly is rotated.

CAUTION!

To avoid all risk, lubricate the beads turning the tire assembly CLOCKWISE if you are working on the outside

face and COUNTERCLOCKWISE if working on the inside face.

12

Page 13

Remember that the stronger the tire’s adherence to the rim, the slower must be the disk’s penetration.

7) Move the tool carrier arm (14, Fig. F) back from the edge of the rim. Release the hook, raise the arm to its non-working position, shift it

and rehook it in its second work position (Fig. G).

DANGER!

Do not hold your hands on the tool when you bring it back to its work position. Your hand(s) could be trapped

between the tool and the tire assembly.

8) Push the double headed tool lever (9, g.C) and turn the head180° until it locks automatically. Then slide the tool-holder arm along

the sliding table and lock it in position.

9) Take the mobile control unit to work position D.

Repeat the operation previously described until the second bead is completely loosened.

During the bead loosening operation, the nger tool (18, g.G) can be lowered so that it is out of the way.

18

14

DEMOUNTING

Tubeless tires can be demounted in two ways:

1) If the tire is not difcult to demount, once the beads have been loosened, use the bead disk to push against the inside plane of the

tire until both beads come off the rim (See Fig. H). Always keep the tire rotating while pushing with the bead disck

2) With Supersingle or very hard tires the procedure described above cannot be used. The hook tool will have to be used as follows:

- Transfer the tool carrier arm to the outside plane of the tire.

Take the mobile control unit to work position C.

- Rotate the tire assembly and at the same time move the hook tool forward inserting it between rim and bead until it is anchored to

the bead (See Fig. I).

-Move the rim 1.5-2 inch (4-5 cm) from the tool taking care that it does not unhook from the bead.

-Move the hook tool towards the outside until the red reference dot is by the outside edge of the rim.

Take the mobile control unit to position B.

- Insert lever (17, Fig. I) between rim and bead at the right of the tool.

-Press down on the lever and lower the tire assembly to bring the edge of the rim about 2 inches (5 cm) from the hooked tool.

-Turn the tire assembly counterclockwise pressing down on lever until the bead is completely off.

-Move the tool carrier arm to its non-working position and then move it to the inside face of the tire assembly.

F

G

Take the mobile control unit to work position D.

13

Page 14

-Place the tool carrier arm in the working position, then the bead disk to push against the inside face of the tire (see g. H). It’s is best to

do this with the wheel turning.

17

H

I

Take the mobile control unit to work position B.

-Always keep the rotating counterclockwise, while pushing with the bead disk.

Turn the wheel counterclockwise pushing with disk until the tire comes completely off the rim.

DANGER!

When the beads come off the rim, the tire will fall. Check to make sure there are no by-standers in the work

area.

MOUNTING

Tubeless tires can be mounted using either the bead loosener disk or the hook tool. If the tire is not problematic, use the bead loosener

disk. If the tire is very rigid, the hook tool must be used.

TIRE MOUNTING WITH THE DISK

Follow these steps:

1) If the rim has been removed from the spindle, put it back on the spindle as described in the section on “RIM CLAMPING”.

2) Lubricate both beads and the rim with tyre manufacturer recommended lubricant.

3) Attach the g-clamp to the outside edge of the rim at the highest point (See Fig. M).

CAUTION!

Make sure the g-clamp is rmly attached to the rim.

Take the mobile control unit to work position B.

4) Put the tire on the platform and lower the spindle (make sure the g-clamp is at the high point).

5) Lift the rim with the tire hooked to it and turn it anticlockwise about 6-8 inches (15-20 cm). The tyre will be positioned included across

the rim.

14

Page 15

M

L

Take the mobile control unit to work position C.

6) Position the bead loosener disk against the second bead of the tire and turn the spindle until the g-clamp is at the low point (at 6

o’clock).

7) Move the disk away from the tire assembly.

8) Remove the g-clamp and riposition it at 6 o’clock outside the second bead (See Fig. N).

9) Turn the spindle clockwise 90° to bring the g-clamp to 9 o’clock.

10) Move the disk forward until it is about 0.5-1 inches (1-2 cm) inside the edge of the rim. Begin to turn the spindle clockwise checking

to make sure that, with a 90° turn, the second bead begins to slip into the drop center.

11) When the bead is fully mounted, move the tool away from the tire assembly, tip it to its non-working position and remove the gclamp.

Take the mobile control unit to work position B.

13) Close the arms of the spindle completely. Support the tire assembly to prevent it falling off.

DANGER!

Potentially hazardous operation!

Do it manually only if you are certain you can keep the tire assembly balanced. For large and heavy tires

14) Move the ramp to remove the tire asembly from the spindle.

15) Remove the tire assembly.

If the tire permits it, the operation described above can be speeded up by mounting both beads at the same time:

- Follow the steps described under points 1,2,3,4 described above but instead of attaching the g-clamp to just the rst bead (refer to

point 4) clip it to both.

- Lift the rim with the tire hooked to it and turn it counterclockwise 6-8 inches (15-20 cm) (g-clamp at 10 o’clock).

- Follow the steps described in points 10,11,12,13,14,15 above.

N

15

Page 16

MOUNTING WITH THE HOOKED TOOL

1) Follow the steps described in points 1,2,3,4,5 for mounting with the disk.

2) Move the tool carrier arm to its non-working position. Move it to the inside face of the tire and rehook it at this position.

3) Check to make sure the hook tool is positioned facing the tire bead. If not, press lever (9, Fig. C) and turn it 180°.

Take the mobile control unit to work position D.

4) Move the tool forward until the red reference dot is lined up with the outside edge of the rim and about 1/4 inch (5 mm) from it (See

Fig. O).

Take the mobile control unit to work position C.

5) Move to the outside of the tire assembly and check the exact position of the hook visually and adjust it as needed. Then turn the

spindle clockwise until the clip is at the bottom (6 o’clock). The rst bead will be on the rim.

6) Remove the g-clamp.

Take the mobile control unit to work position D.

7) Remove the tool from the tire.

8) Move the tool carrier arm to its non-working position. Move it to the outside plane of the tire and rehook it in this position.

9) Turn the tool 180° with lever (9, Fig. C).

10) Attach the g-clamp at the bottom (6 o’clock) outside the second bead (See Fig. N).

Take the mobile control unit to work position C.

11) Turn the spindle counterclockwise to about 90° (clip at 9 o’clock).

12) Bring the tool forward until the red reference dot is lined up with the outside edge of the rim and about 1/4 inch (5 mm) from it. Begin

to turn the spindle counterclockwise and check if, after about 90° of rotation the second bead has started to slip into the drop center.

Continue turning until the g-clamp is at the bottom (6 o’clock).

The second bead will now be mounted on the rim.

13) Follow the steps described in points 11, 12, 13, 14, 15 for mounting with the disk, since this will ensure that the tire assembly is removed

correctly from the machine.

N

O

13.3

BEAD LOOSENING

WARNING: Release ination valve when deating the tyre so that the valve, falling inside the rim, is not an obstacle during bead loosening.

Follow all the steps described previously for bead loosening tubeless tyres.

With tube tires, however, stop disk movement as soon as the bead has loosened to avoid damaging the tube ination valve.

Take the mobile control unit to work position C.

TUBE TIRE

DEMOUNTING

16

Page 17

1) Tip the tool carrier arm (14, Fig. D) to its non-working position. Move it to the outside face of the tire and rehook it in this position.

2) Rotate the tire assembly and at the same time move the hook tool (18, Fig. D) forward inserting it between rim and bead until it is

anchored to the tool.

3) Move the rim 1.5-2inch (4-5 cm) from the tool taking care that it does not unhook from the bead.

4) Move the hook tool towards the outside until the red reference dot is by the outside face of the rim.

Take the mobile control unit to work position B.

5) Insert lever (see Fig. P) between rim and bead at the right of the tool.

6) Press down on the lever and lower the tire assembly bring the edge of the rim about /4 inch (5 mm) from the hooked tool.

7) Turn the tire counterclockwise pressing down on lever until the bead is completely off.

8) Move the tool carrier arm to its non-working position. Lower the spindle until the tire is pressed down against the ramp . As the ramp is

moved slightly towards the outside, the tyre will open a little and thus create enough space to remove the inner tube.

9) Remove the inner tube and lift the tire assembly back up.

15

17

18

14

13

P

Take the mobile control unit to work position D.

10) Move the tool carrier arm to the inside face of the tire, turn the hook tool 180° and lower the arm to its work position. Insert it between

rim and bead and move it until the bead is by the front edge of the rim (best to do this with the tire assembly turning).

11) Move the rim about 4-5 cm from the tool making sure the hook does not detach from the rim.

Take the mobile control unit to work position B.

12) Move the hook tool so that its red reference dot is about 1,2 inch (3 cm) inside the rim.

13) Insert lever between rim and bead at the right of the tool (See Fig. Q).

14) Press down on the lever and lower the tire to bring the edge of the rim about 2 inches (5 cm) from the hooked tool.

Turn the tire assembly counterclockwise pressing down on lever until the tyre comes completely off the rim.

19

D

DANGER!

When the beads come off the rim, the tire will fall. Check to make sure there are no by-standers in the

work area.

MOUNTING

1) If the rim has been removed from the spindle, put it back on the spindle as described in the section on “RIM CLAMPING”.

2) Lubricate both beads and the rim with tire manufacturer recommended lubricant.

3) Attach the g-clamp to the outside edge of the rim at the highest point (See Fig. R).

CAUTION!

Make sure the g-clamp is rmly attached to the rim.

17

Page 18

Take the mobile control unit to work position B.

4) Put the tire on the ramp and lower the spindle (make sure the g-clamp is at the high point) to hook the rst bead on the g-clamp.

Q

5) Lift the rim with the tire hooked to it and turn it counterclockwise about 6-8 inches (15-20 cm). The tyre will be positioned inclined

across the rim.

6) Move the tool carrier arm to its non-working position. Move it to the inside face of the tire and rehook it in this position.

7) Check to make sure the hook tool is positioned facing the bead. If not, press lever (9, Fig. C) and turn it 180°.

Take the mobile control unit to work position D.

8) Move the tool forward until the red reference dot is lined up with the outside edge of the rim and about 1/4 inch (5 mm) from it (See

Fig. S).

Take the mobile control unit to work position C.

9) Move to the outside of the tire assembly and check the exact position of the hook visually and adjust it as needed. Then turn the

spindle clockwise until the g-clamp is at the bottom (6 o’clock). The rst bead will be on the rim.

Remove the g-clamp.

Take the mobile control unit to work position D.

10) Remove the tool from the tire.

11) Move the tool carrier arm to its non-working position. Move it to the outside face of the tire.

12) Turn the tool 180° with lever (19, Fig. D).

Take the mobile control unit to work position B.

13) Turn the spindle until the valve hole is at the bottom (6 o’clock).

14) Move the ramp (4 Fig. A) under the tire assembly and lower the spindle until the tire is pressed down against the platform . As the

platform is moved slightly towards the outside, the tire will open a little and thus create enough space to insert the inner tube.

NB: The valve hole may be asymmetrical to the centre of the rim. In this case position and insert the inner tube as shown in Fig. T.

Insert the valve through the hole and x it with its locking ring.

15) Place the inner tube in the drop center of the rim (NB: to facilitate this, turn the spindle clockwise).

R

18

Page 19

S

T

16) Turn the spindle until the valve is at the bottom (6 o’clock).

17) Inate the inner tube a little (until it has no folds) so as not to pinch it while mounting the second bead.

18) Attach an extension to the valve and then remove the locking ring.

The purpose of this operation is to allow the valve to be loose so that it is not ripped out during second bead mounting.

Take the mobile control unit to work position C.

19) Lift the tire assembly again and attach the g-clamp outside the second bead about 8 inches (20 cm) to the right of the valve (See

Fig. U).

20) Turn the spindle clockwise until the g-clamp is at 9 o’clock.

21) Move the tool carrier arm (14, Fig. D) to its working position.

22) Bring the tool forward until the red reference dot is lined up with the outside edge of the rim and about 1/4 inch (5 mm) from it.

23) Turn the spindle a little clockwise until you can insert the bead guide lever into its seating on the hook tool (See Fig. V). This lever can

be supplied on demand.

24) Pull back on this lever which will guide the bead into drop center. Continue to turn the spindle until the tire is completely mounted

on the rim.

25) Remove the g-clamp. Remove the hook tool by turning the spindle counterclockwise and moving it towards the outside.

26) Tip the tool carrier arm to its non-working position.

27) Position the ramp directly under the tire assembly and lower the spindle until the tire rests on the ramp.

Take the mobile control unit to work position B.

28) When the tire is resting on the ramp, check to make sure the valve is perfectly centered with its hole. If it is not, turn the spindle slightly

to adjust the position. Fix the valve with its locking ring and remove the extension.

29) Close the arms of the spindle completely. Support the tire to prevent it falling off.

DANGER! POTENTIALLY HAZARDOUS OPERATION!

Do it manually only if you are certain you can keep the tire assembly balanced. For large and heavy tires an adequate

lifting device must be used

U

V

19

Page 20

30) Move the ramp to release the tire from the spindle.

31) Remove the tire.

13.4

TIRES WITH SPLIT RING

BEAD LOOSENING AND DEMOUNTING

TIRE ASSEMBLIES WITH 3-PIECE RINGS

1) Clamp the tire assembly on the spindle as described previously and check to make sure it has been deated.

2) Take the mobile control unit to work position B.

3) Lower the tool carrier arm (14, Fig. D) to its work position until it is locked in position by its hook.

4) Position the bead loosener disk level with the rim (See Fig. W).

5) Turn the spindle and at the same time move the disk forward a bit at a time following the contour of the rim until the rst bead is com-

pletely free (NB: lubricate while doing this).

CAUTION! If the tire has an inner tube, work very carefully and be prepared to stop the disk immediately once the bead has been broken

so as not to damage the valve and the inner tube.

6) Repeat this procedure but this time bring the disk against the split-ring (See Fig. Z) until the lock ring is freed. Remove this with the special

lever (19, Fig. Z) or with the help of the disk.

7) Remove the split-ring.

8) Move the tool carrier arm (14, Fig. D) back from the edge of the rim. Release the hook and tip the arm to its non-working position.

Move the tool carrier arm to the inside face of the tire assembly.

9) Press lever (9, Fig. C) and turn the tool head 180° which will automatically lock in this position. Lower the arm to its working position.

10) Turn the spindle and at the same time bring the bead loosener disk up against the tire following the contour of the split-ring until the

second bead has been broken (NB: Lubricate during this process).

Continue to move the disk forward until about half the tire has demounted from the rim (See Fig. K).

11) Move the tool carrier arm to its non-working position.

12) Move the ramp (4, Fig. A) directly under the tire.

13) Lower the spindle until the tire is resting on the ramp.

W

Take the mobile control unit to work position B.

14) Move the ramp towards the outside until the tire is completely off the rim. Watch out for the valve!

TIRE ASSEMBLIES WITH 5-SEGMENT SPLIT RINGS

1) Clamp the tire assembly on the spindle as described previously and make sure it is deated.

Take the mobile control unit to work position C.

19

Z

20

Page 21

2) Lower the tool carrier arm (14, Fig. D) to its work position until its hook has engaged into position on the carriage.

3) Use the joystick to position the wheel so that the bead loosener disk touches up against outside edge of the centre well rim.

4) Turn the spindle and at the same time move the bead loosener disk forward until the split-ring is detached. Watch out for the O-ring.

5) Repeat this operation but this time move the disk against the split-ring (See Fig. Z) until the locking ring is released. this ring can be

removed with the special lever (19, Fig. Z) or with the help of the bead disk.

6) Remove the O-ring

7) Move the tool carrier arm (14, Fig. D) back from the edge of the rim. Release the hook and tip the arm to its non-working position.

Move the tool carrier arm to the inside face of the tire.

8) Press lever (9, Fig. C) and turn the tool head 180° which will automatically lock in this position. Lower the arm to its working position.

Take the mobile control unit to work position D.

9) Turn the spindle and at the same time bring the bead loosener disk up against the tyre between the rim and bead. Move the disk

into the tyre only when the bead has started to detach from the rim, and move the bead to the outside edge of the rim. (NB: Lubricate

during this process).

10) Tip the tool carrier arm to its non-work position.

Take the mobile control unit to work position B.

11) Move the ramp (4, Fig. A) directly under the tire.

15

17

18

14

13

K

12) Lower the spindle until the tire is resting on the ramp.

13) Move the ramp towards the outside until the tire together with the split ring comes completely off the rim.

14) Remove the rim from the spindle.

15) Position the tire on the platform with the splint ring turned towards the spindle.

16) Clamp the split ring on the spindle as explained in the section of RIM CLAMPING.

DANGER!

The tire is not attached to the split ring completely. Any strain on it during positioning or clamping operations could cause

it to detach and fall.

19

D

Take the mobile control unit to work position D.

17) Lift the tire assembly.

18) Move the tool carrier arm back to its work position.

19) Position the spindle so that the bead loosener disk is lined up with the bead.

20) Turn the spindle and move the disk forward until the tire comes completely off the split ring.

This double bead breaking procedure can be eliminated by using the PAIR OF CLAMPS #9299273 (optional) that x the split-ring to the

rim so that they are loosened out at the same time.

DANGER!

When the beads come off the rim, the tire will fall. Check to make sure there are no by-standers in

the work area.

21

Page 22

MOUNTING

TIRE ASSEMBLY WITH 3-PIECE SPLIT-RINGS

1) Move the tool carrier arm to its non-working position. If the rim has been removed from the spindle, put it back on the spindle as de-

scribed in the section on “RIM CLAMPING”.

If the tire is tubed, position the rim with the valve slot at the bottom (6 o’clock).

2) Lubricate both beads and the rim with tire manufacturer recommended lubricant.

Take the mobile control unit to work position B.

3) Move the platform to be able to place the tire on it.

If the tire is tubed, position the rim with the valve slot at the bottom (6 o’clock).

4) Lower or raise the spindle to centre the rim and the tire.

5) Move the ramp forward until the rim is inserted into the tire.

CAUTION! If the tire is tubed push the valve inside so as not to damage it.

Move forward with the ramp until rim is completely in the tire.

6) Bring the tool carrier arm to the outside face and lower it to its work position with the disk facing the tire.

If the tire is not inserted sufciently on the rim, move the spindle until the tire bead is by the disk. Bring the disk forward (with the spindle

turning) until it is completely inserted.

7) Put the split-ring on the rim and then install the locking ring with the help of the disk as shown in Fig. Y.

8) Move the tool carrier arm to its non-working position and, at the same time, close the spindle arms. Support the wheel so that it does

not fall off.

DANGER!

When the beads come off the rim, the tire will fall. Check to make sure there are no bystanders in the work

area.

9) Move the ramp to free the tire from the spindle.

10) Remove the tire.

WHEELS WITH 5-SEGMENT SPLIT-RINGS

1) Move the tool carrier arm to its non-working position. If the rim has been removed from the spindle, put it back on the spindle as de-

scribed in the section on “RIM CLAMPING”.

2) Lubricate both beads and the rim with tire manufacturer recommended lubricant.

Y

3) Move the platform to be able to place the tire on it.

4) Lower or raise the spindle to centre the rim and the tire.

5) Move the platform forward until the rim is inserted into the tire.

Move forward with the platform until rim is completely in the tire.

6) Put the split-ring on the rim (with the lock ring already mounted).

If the rim and the split-ring have slits for xing devices, make sure they are lined up with each other.

Take the mobile control unit to work position C.

22

Page 23

7) Move the tool carrier arm to the outside in its work position with the bead loosener disk facing the tire.

If the split-ring is not inserted sufciently on the rim, move the spindle until the split-ring is by the disk. Bring the disk forward (with the spindle

turning) until you “observe” the O-ring seating.

8) Lubricate the O-ring and its seating.

Take the mobile control unit to work position B.

9) Position the locking ring on the rim with the help of the disk as shown in Fig. Y.

Move the tool carrier arm to its non-working position and close the spindle arms completely. Support the tire so that it does not fall off

the spindle.

DANGER! POTENTIALLY HAZARDOUS OPERATION!

Do it manually only if you are certain you can keep the wheel balanced. For large and heavy tires an adequate lifting device must be used.

10) Move the ramp to free the tire from the spindle.

11) Remove the tire.

DANGER!!

Do not inate the tire with the wheel mounted on the spindle. Tire ination is potentially hazardous and should

only be done by removing the tire assembly from the spindle and placing it inside a safety cage.

14

ORDINARY MAINTENANCE

WARNING!

Each maintenance operation must be performed only after the disconnetion of the plug from electric

network.

To ensure that this tire changer works perfectly over the years, carry out the routine maintenance schedule described below:

1) Lubricate the following parts from time to time, after a thorough cleaning with naphtha:

- the various swivels on the spindle

- the tool bracket slide runner

- the carriage guide plate.

2) Grease the spindle bracket swivel. Add the grease through the grease nipple (See Fig. J) using ordinary lubricating grease.

3) Frequently check the oil level in the hydraulic power pack. Use the dipstick under the reservoir cap.

If necessary top up with Esso Nuto H46 or similar hydraulic oil (eg, Agip Oso 46, Shell Tellus Oil 46, Mobil DTE 25, Castrol Hyspin AWS 46,

Chevron RPM EP Hydraulic Oil 46, BP Energol HLP).

4) Frequently check the oil level in the gear unit which, when the tool carrier bracket is completely lowered at end travel, should not

show the sight glass on the gear casing as completely empty. If necessary top up with Esso Spartan EP 320 or similar oil (eg, Agip F1 REP

237, BP GRX P 320, Chevron Gear Compound 320, Mobil Gear 632, Shell Omala Oil 320, Castrol Alpha SP 320).

If the oil in the gear unit or the hydraulic power pack has to be changed, note that the gear unit casing and the power pack reservoir

have specic drain plugs.

WARNING!

Dispose of the used oil in approved waste oil contaner

23

Page 24

15

TROUBLE SHOOTING

After having switched on the main power switch on

the electric pack, the general warning light does not

light on and no control can function.

PROBLEM

1) The power plug is not inserted.

2) No power from the mains electric supply.

CAUSES

1) Insert the plug correctly in its socket.

2) Reset the mains electric supply.

REMEDIES

WARNING: If, despite of the above mentioned indications, the tire changer does not work properly, do not use it

and call for technical service and support.

After having switched on the main power switch

on the electric pack the general warning light also

switches on but the motor on the hydraulic power

PROBLEM

pack does not function.

1) The magneto-thermic switch for motor protection

has been engaged, cutting off the circuit.

TROUBLE SHOOTING

CAUSES

1) Call for technical service to see what the problem

and to restore the machine.

REMEDIES

16 MOVING THE MACHINE

The tire changer has got a hook (1, Fig. A) for moving the machine.

Follow these instructions:

1) Lowen the clamping chuck arm (2, Fig. A) completely down.

2) Close completely the jaws of the chuck (3, Fig. A).

3) Bring the sliding table (4, Fig. A) at the end of its travel, near the arm.

4) Insert into the lifting hook a hoisting belt (at least 2.5 inches (60 mm) wide and of a lenght sufcient to bring the hook of the belt above

the tyre changer).

5) With the special belt ring bring the 2 ends of the belt together and lift with a sufciently strong lifting truck.

17

If the machine as to be stored for a long time (3-4 months you have to:

1) Close the jaws of the chuck; llower the clamping chuck and down; low the tool holding arm down, in working position.

2) Disconnect the machine from all power sources.

3) Grease all the parts that could be damaged if they dry out:

- the chuck

- the slot of the tool holding arm

- the slides of the carriage

- the tool

Empty oil/hidraulic uid reservoirs and wrap the machine in a sheet of protective platic to prevent dust from reaching the internal working parts.

If the machine has to start working again after a long storing period, it is necessary to:

- put the oil into the reservoirs again.

- restore the electric connection.

STORING

18 SCRAPPING A MACHINE

When your machine' s working life is over and it can no longer be used, it must be made inoperative by removing any connection to

power sources.

These units are considered as special waste material, and should be broken down into uniform parts and disposed of in compliance with

current laws and regulations. If the packing are not polluting or non-biodegradable, deliver them to appropriate handlind station.

WARNING!

If this machine catches re, use dust or CO estinguishers only.

2

24

Page 25

19 DATA ON SERIAL PLATE

The manufacturer’s Serial plate is xed on the back of the

machine. If gives the following information:

1- Manufacturer information

2- Model

3- Serial number

4- Phases

5- Voltage requirements

6- Frequency

7- Rated draw

8- Year

9-Weight

10-Absorbed power

Type:

Volt: Amp:

Ph: [4] Year: [8]

20 ACCESSORIES

The following op tio nal accessories are ava ila ble for the tire c han ger :

[1]

[2]

[5] [7]

Hz: [6]

Net weight :[8]

Nr.

[3]

Kw:

[10]

25

Page 26

HENNESSY Industries, INC

1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565 USA

Toll Free 800-688-6496

www.ammcoats.com

Loading...

Loading...