Page 1

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086 615/641-7533 800/688-6359 Manual Part No.: 85000267 03

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 02/13

APX Tire Changer Series

Unloading Procedures

®

User Instructions

READ these instructions before placing unit in

service KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

This is a supplement to your operating manual and covers unloading pro-

cedures for the COATS®APX Series Tire Changers. If you do not have your

original operating manual, please call COATS at 1-800-688-6359 to request

an additional copy.

Page 2

CAUTION

Watch for this symbol:

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Unload Instructions

Review the following unload procedures carefully.

Refer to them as necessary when the machine is delivered and unloaded to verify that you are proceeding

properly and safely.

This unit weighs over 1,200 lbs. Do not

attempt to lift or move without assistance.

Make sure all moving parts are secured

before moving the unit.

Proper unit installation is necessary for safe

use and efficient operation. Proper installation also helps protect the unit from damage and makes service easier. Always place

safety poster and instructions near the unit.

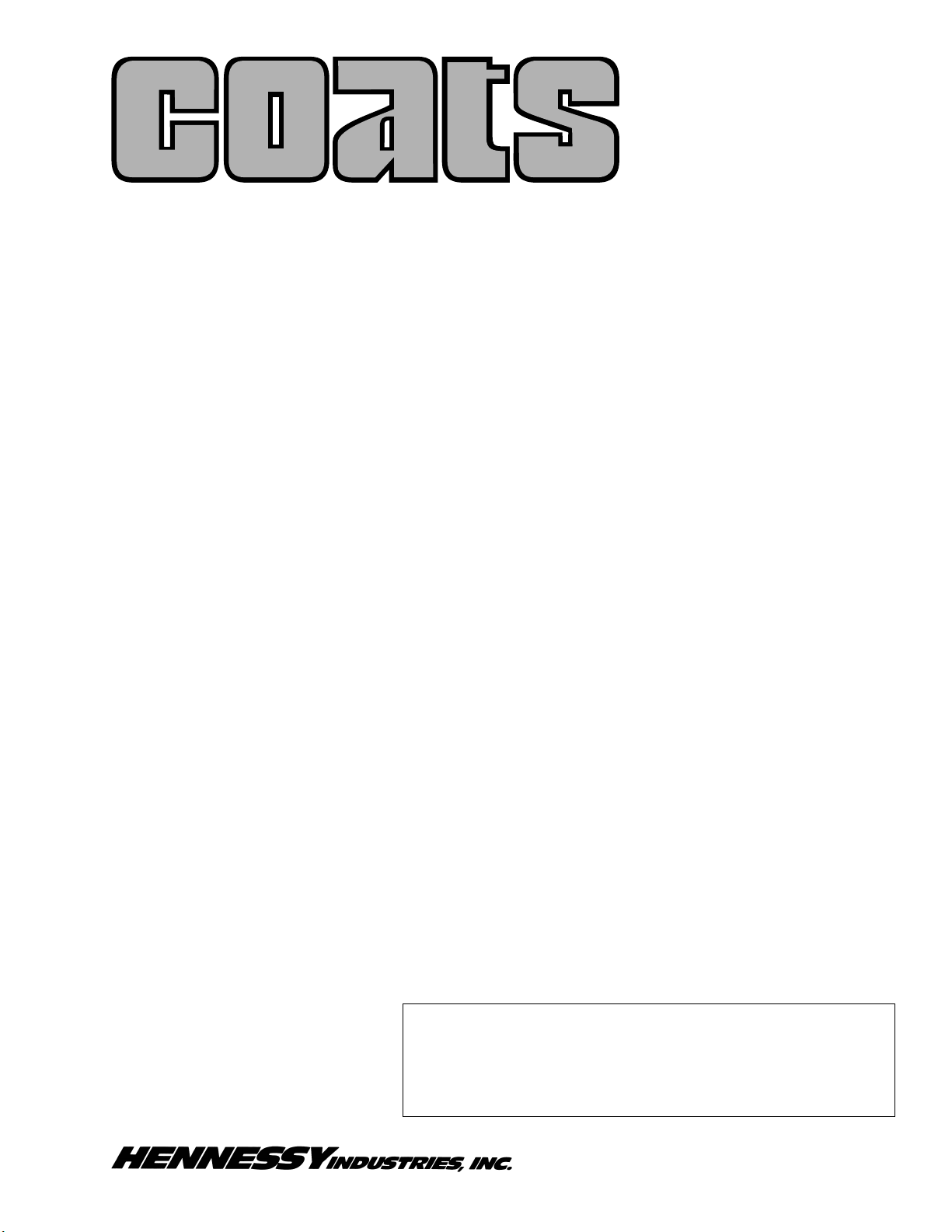

Machine Delivery Unload Procedure

A. It is acceptable to use a fork-truck to unload the

machine that is on a pallet from a delivery truck.

B. It is acceptable to use a utility tilt trailer to unload

the machine that is on a pallet from a delivery truck.

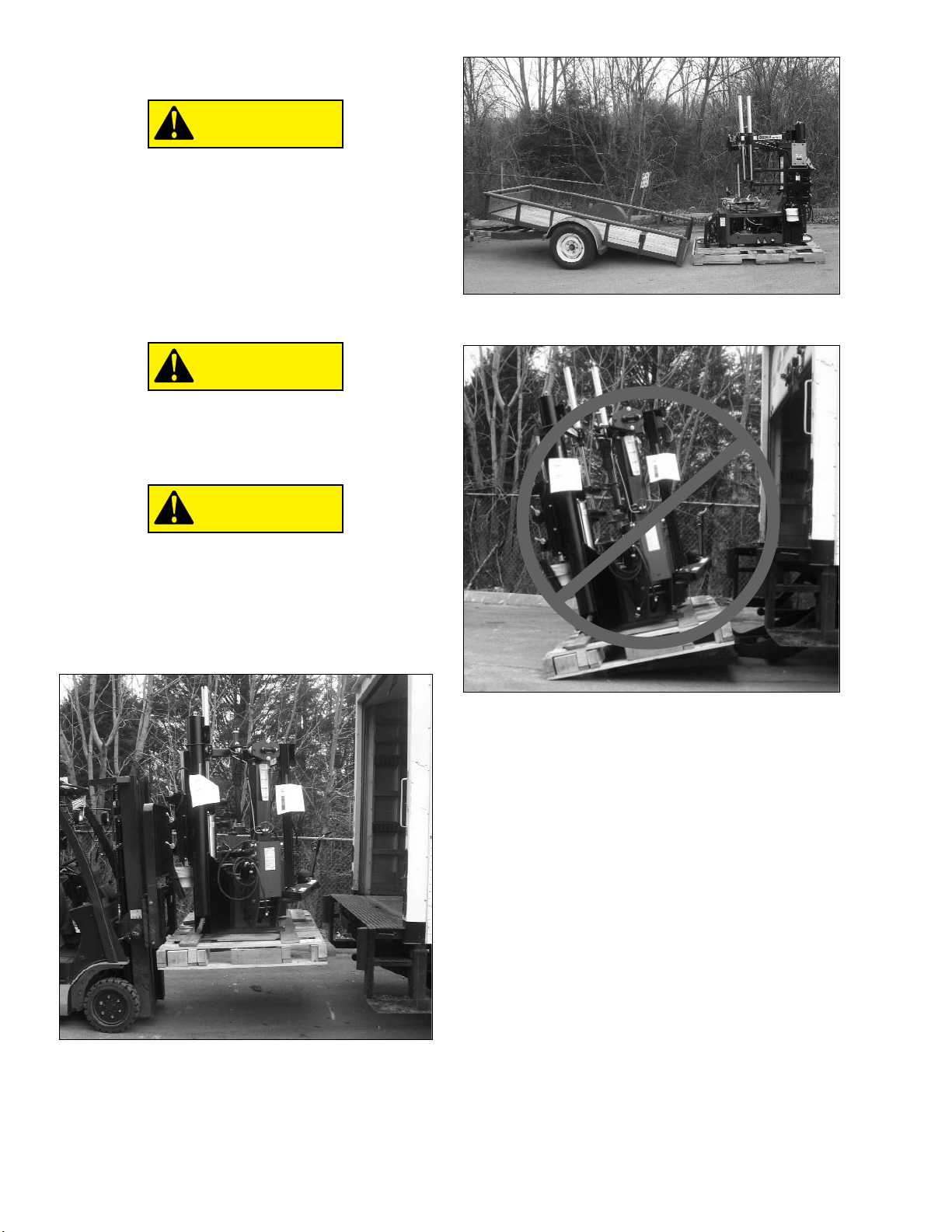

C. It is not acceptable and can be dangerous to use

a lift-gate delivery truck to unload the machine from a

delivery truck.

CAUTION

CAUTION

CAUTION

2 • COATS Unloading Instructions

Page 3

COATS Unloading Instructions • 3

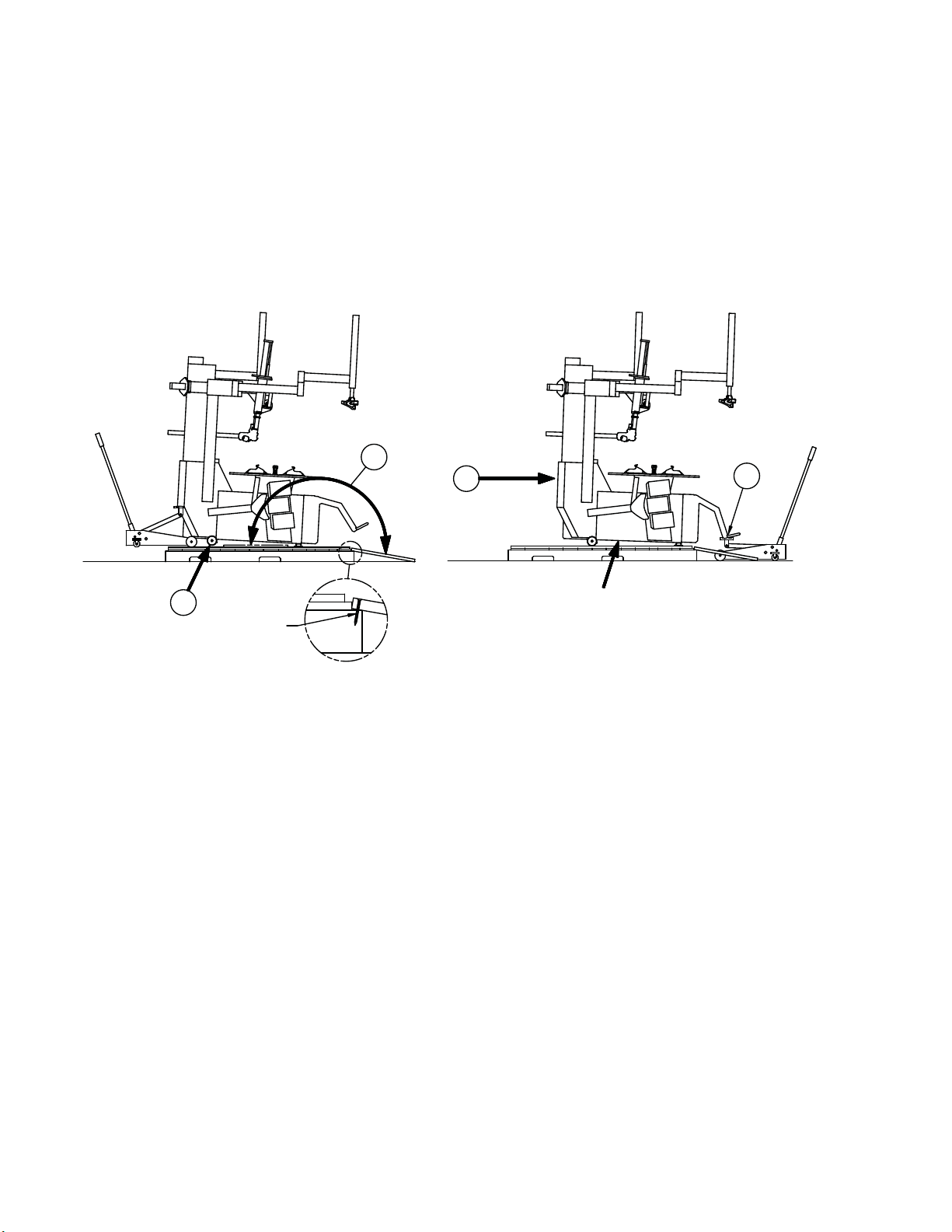

APX80 Unload Instruction

1. Remove lag bolts holding chassis to pallet.

2. Jack up rear of machine; install axle and wheels as

shown.

3. Remove ramp planks and position as shown.

4. Jack up front of machine and install axle and

wheels as shown.

5. Slowly push machine forward to position offload

bracket over jack.

6. Jack up front of machine and slowly move machine

off pallet.

7. Locate machine in shop at proper location and

remove wheels and temporary off-load bracket.

APX80

Ooad

Bracket

6

2

Secure ramp planks

in position with screw

as shown.

3

Ooad

Bracket

DO NOT Fork Machine

Here: Transmission

Damages May Occur

4

5

"X"

Remove Axles, Wheels &

Ooad Bracket After

Locating In Final Position

Page 4

85000267 03 02/13 4 of 4 © COPYRIGHT 2006 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

APX90 Unload Instruction

1. Remove lag bolts holding chassis to pallet.

2. Jack up rear of machine; install axle and wheels as

shown.

3. Remove ramp planks and position as shown.

4. Move jack to front (add air pressure to machine).

5. Slowly push machine off pallet.

6. Locate machine in shop at proper location and

remove wheels.

APX90

3

5

4

2

Secure ramp planks

in position with screw

as shown.

DO NOT Fork Machine

Here: Transmission

Damages May Occur

Loading...

Loading...