Page 1

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688-6359 Manual Part No.: 8112596 01

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 08/99

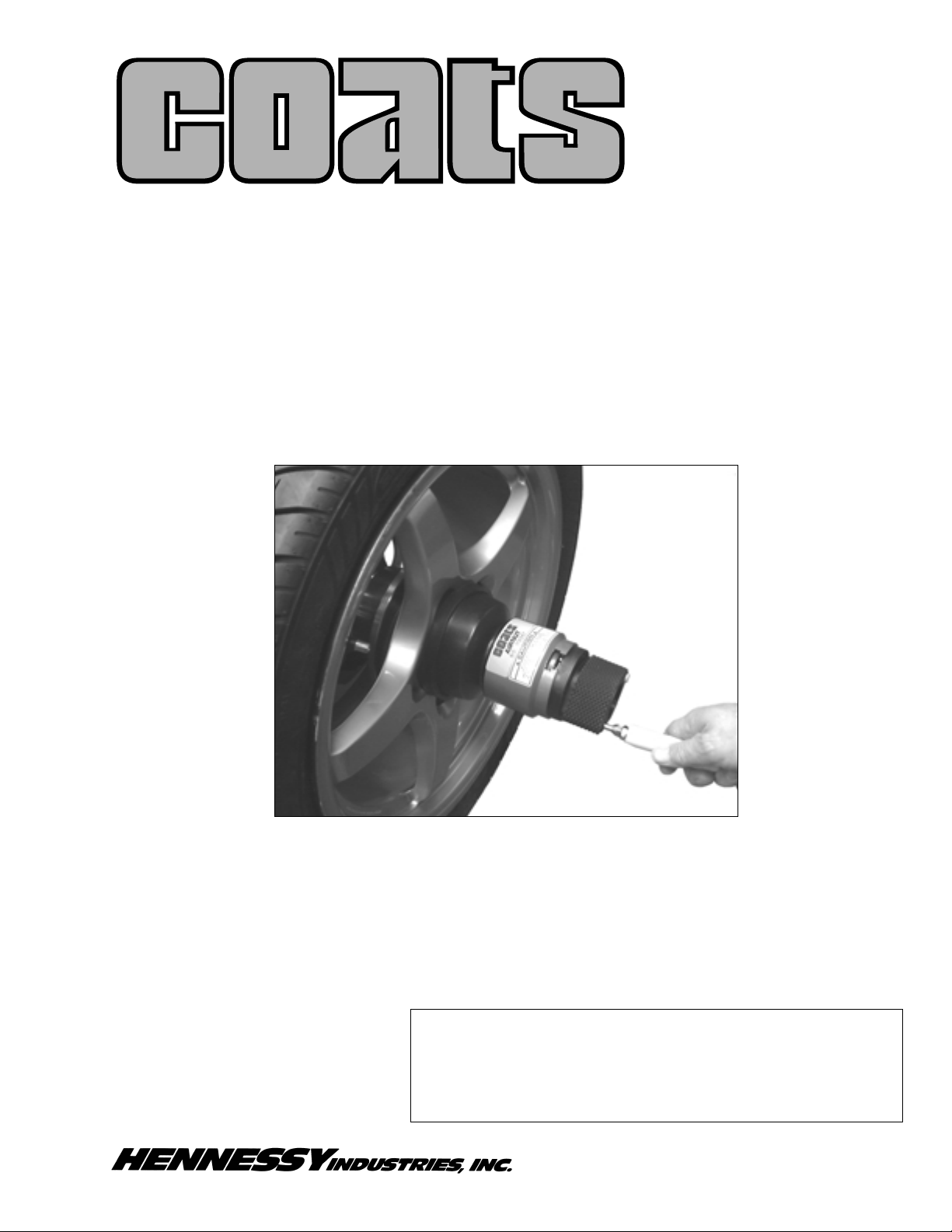

AirNut

No. 8112567 (1.1258”) ID

No. 8112568 (40mm) ID

For Use on COATS Wheel Balancers

®

Installation Instructions

Operating Instructions

Safety Instructions

Maintenance Instructions

READ these instructions before placing unit in

service KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

Page 2

ii • COATS AirNut

Contents

Table of Contents

Owner’s Responsibilitiy . . . . . . . . . . . . . . .iii

Definitions of Hazard Levels . . . . . . . . . . . .iii

Important Safety Instructions . . . . . . . . . . .iv

Before You Begin

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Air Requirements . . . . . . . . . . . . . . . . . . . . . . . .1

Standard Accessories . . . . . . . . . . . . . . . . . . . . .1

Optional Accessories . . . . . . . . . . . . . . . . . . . . . .1

Assembly and Setup

Unpacking the Unit . . . . . . . . . . . . . . . . . . . . . . .2

Standard Parts List . . . . . . . . . . . . . . . . . . . . . . .2

Initial Testing of the AirNut . . . . . . . . . . . . . . . .2-3

Operating the AirNut

General Instructions . . . . . . . . . . . . . . . . . . . . . .3

AirNut Engagement . . . . . . . . . . . . . . . . . . . . . . .3

AirNut Release . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance and Service

Preventative Maintenance . . . . . . . . . . . . . . . . . .4

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . .4

Parts Identification . . . . . . . . . . . . . . . . . . . .5

Page 3

COATS AirNut • iii

Owner’s Responsibility

To maintain machine and user safety, the responsibility

of the owner is to read and follow these instructions:

• Follow all installation instructions and make sure

installation conforms to all applicable Local, State,

and Federal Codes, Rules, and Regulations; such as

State and Federal OSHA Regulations and Electrical

Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep them

readily available for machine operators.

• Make certain all operators are properly trained,

know how to safely and correctly operate the unit,

and are properly supervised.

• Allow unit operation only with all parts in place and

operating safely.

• Carefully inspect the unit on a regular basis and perform all maintenance as required.

• Service and maintain the unit only with authorized

or approved replacement parts.

• Keep all instructions permanently with the unit and

all decals/labels/notices on the unit clean and visible.

Definitions of Hazard

Levels

Identify the hazard levels used in this manual with

the following definitions and signal words:

DANGER

Watch for this symbol:

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

Safety

Failure to follow danger, warning, and caution

instructions may lead to serious personal

injury or death to operator or bystander or

damage to property. Do not operate this

machine until you read and understand all the

dangers, warnings and cautions in this manual. For additional copies of either, or further

information, contact:

Hennessy Industries, Inc.

1601 J.P. Hennessy Drive

LaVergne, TN 37086-3565

(615) 641-7533 or (800) 688-6359

www.ammcoats.com

DANGER

WARNING

CAUTION

WARNING

Page 4

iv • COATS AirNut

Safety

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS

1. Read all instructions

2. Never touch AirNut while the balancer arbor shaft

is in motion. Dismemberment and/or serious lacerations can occur.

3. Failure to push the AirNut on far enough for it to

tighten properly may result in the wheel dismounting, causing personal injury and property

damage.

4. When activating the AirNut, keep all body parts

from between the back side of the wheel’s center

and balancer face plate.

5. When activating the AirNut, keep all body parts

from between the front side of the wheel’s center

and the AirNut pressure cup/nylon spacer.

6. When de-activating the AirNut, keep all body parts

from between the back side of the pressure cup,

no mar ring and AirNut.

7. Adequate ventilation should be provided when

working on internal combustion engines.

8. Keep hair, loose clothing, fingers, and all body

parts away from moving parts.

Only use air gun for intended purpose. If air

is injected into the human body, lacerations, serious injuries, or death can occur.

9. Do not use the AirNut inflation device for any

other use than the inflation of the AirNut. Air

injected into the human body may lead to serious

injuries and often death.

10. Use only as described in this manual. Use only

manufacturer’s recommended attachments.

11. ALWAYS WEAR SAFETY GLASSES. Everyday

glasses only have impact resistant lenses, they

are NOT safety glasses.

12. Replace any damaged or missing safety decals.

They are available from COATS, (615) 641-7533.

13. Read and understand this manual before operating. Abuse and misuse will shorten functional life.

14. Keep guards and safety features in place and in

working order.

15. Wear proper clothing. Safety toe, non-slip

footwear and protective hair covering to contain

hair are recommended. Do not wear jewelry,

loose clothing, neckties, or gloves when operating

the balancer.

16. Keep work area clean and well lighted. Cluttered

and/or dark areas invite accidents.

17. Repair or replace any part that is damaged or worn

and that may cause unsafe balancer operation. Do

not operate damaged equipment until it has been

examined by a qualified service technician.

18. Do not allow untrained persons to operate

machinery.

19. Do not disable hood safety interlock system, or in

any way shortcut safety controls and operations.

WARNING

Page 5

COATS AirNut • 1

Before You Begin

Receiving

The shipment should be thoroughly inspected as

soon as it is received. The signed bill of lading is

acknowledgement by the carrier of receipt in good

condition of shipment covered by our invoice. If any of

the goods called for on this bill of lading are shorted or

damaged, do not accept them until the carrier makes

a notation on the freight bill of the shorted or damaged goods. Do this for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or

damage is discovered after receipt and request the

carrier to make an inspection. If the carrier will not do

so, prepare a signed statement to the effect that you

have notified the carrier (on a specific date) and that

the carrier has failed to comply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER YOU HAVE GIVEN THE CARRIER A

CLEAR RECEIPT.

File your claim with the carrier promptly. Support

your claim with copies of the bill of lading, freight bill,

invoice, and photographs, if available. Although

COATS’ responsibility ceases upon delivery of the

shipment to the carrier, we will gladly assist in tracing

lost shipments. Our willingness to assist in every possible manner does not make COATS responsible for

collection of claims or replacement of lost or damaged

materials. Shipping damage claims will not be handled

under warranty.

Specifications

Minimum Air Pressure Required . . . . . . . .120 PSI

Maximum Air Pressure Required . . . . . . . .200 PSI

Clamping Force . . . . . . . . . . . . . . . .*Over 850 lbs.

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.5 lbs.

Capacity . . . . . . . . . . . . . . . . . . . . .Extends 1.250"

*At Minimum Pressure

Air Requirements

Connect to an air supply that delivers between 120

PSI to 200 PSI.

For convenience to the user and longevity of the

AirNut…

• Run a separate air line to the balancer.

• Mount the regulator assembly and air gun to the

wheel balancer’s hood as outlined in the instructions on page 2.

• Add a water trap and oiler to the air line that will

feed the AirNut.

Standard Accessories

The following are standard accessories included with

the AirNut.

1. Pressure Cup (Part #112579)

2. Rubber Cushion (Part #112580)

3. No Mar Ring (Part #112581)

Figure 1 - Standard Accessories

Optional Accessories

There are two optional accessories available for the

AirNut.

1. Alu-Cup pressure cup (Part #112382) fits 40mm

shaft or (Part #111518) fits 1 1/8 shaft.

Figure 2 - Alu-Cup pressure cup

2. Inline water trap and oiler (Part #110495)

Figure 3 - Inline water trap and oiler

AirNut

#112581#112580#112579

Drain

Petcock

Air In

Oil Flow

Adjust

Oil Fill

Separator

Lubricator

Air Out

Page 6

2 • COATS AirNut

AirNut

Assembly and Setup

Unpacking the Unit

Remove all pieces from the container.

Lay them out and check contents against included

standard parts list on this page.

Standard Parts List

1. AirNut

2. Pressure Cup

3. Rubber Cushion

4. No Mar Ring

5. Regulator Assembly

6. Block Air Assembly with Gun Holder

7. Hose Assembly (Regulator to Block)

8. Hose Assembly (Block to Gun–Coiled Hose)

9. Air Gun

Figure 4 - AirNut standard parts

Initial Testing of the AirNut

1. Look through the center hole of the AirNut,

depress and release thumb lever; there should be

noticeable movement of the partial nut, the assembly

should work smoothly.

2. Depress the thumb lever and slide the AirNut

over the arbor shaft. Release thumb lever, pull outward to make sure it is held fast to the arbor shaft.

3. Depress the thumb lever and slide the AirNut off

the arbor shaft.

4. Temporally connect air to the Regulator/Inflator

assembly, and check to see that it will inflate the air

chamber of the AirNut. When fully inflated the piston

will have moved outward 1.250" (31.75mm).

5. Depress the yellow button to exhaust air from the

air chamber. The piston should retract.

6. The pressure cup and the No Mar Ring “snap”

into place on the front end of the AirNut.

Find the most convenient and handy spot on the

wheel balancer’s hood and mount the air gun and regulator assembly as shown in figure 5 below.

Figure 5 - Mounting on wheel balancer hood

7. Remove the rear self tapping screw and discard.

8. Drill a 1/4" hole through the hood and both sides

of the hood bar using the existing hole as a pilot.

9. Mount the block air assembly with gun holder

(item 6 in figure 4) as shown in figure 5.

10. Clean the plastic hood and apply the warning

decal as shown in figure 5.

Failure to secure the air hose as described

may result in severe personal injury if the

airline breaks.

5

6

7

8

9

1

2

3

4

WARNING

Page 7

COATS AirNut • 3

11. Route the airline from the block air assembly

around the inside of the hood and secure the air line

to the hood tube using the wire ties (supplied) as necessary.

12. Locate the regulator assembly on the rear of

the balancer and mark for the two pan head screws

(provided). Be careful to make sure the airline is positioned so that it does not interfere with hood movement as in figure 6.

13. Drill pilot holes and secure the regulator assembly.

14. Connect an airline to the regulator using a quick

coupler. Installation is now complete.

Do not apply more than 200 PSI to the regulator. If the available air supply exceeds

200 PSI, install an appropriate regulator to

reduce air pressure below 200 PSI.

Operating the AirNut

General Instructions

When the AirNut is activated it will extend 1.250"

(31.75mm)

The AirNut will slide freely over the threaded portion

of the arbor shaft when the thumb release is pressed

down. When the thumb release is released, the “partial nut” will engage the arbor shaft threads the AirNut

will be held in place.

The air chamber of the AirNut is activated by pushing

the air gun into the receiving port (opposite the yellow

button) found on the “hand end” of the AirNut. Air is

released through the inflator by pushing the air gun

towards and into the AirNut.

Air pressure is released from the AirNut by pressing

on the yellow button until all air is exhausted from the

air chamber.

AirNut Engagement

Once the cone and wheel are positioned on the balancer’s arbor shaft…

1. Depress the AirNut’s thumb nut release.

2. Slide the AirNut and pressure cup to the wheel

forcing the wheel against the balancer’s face plate.

Pinch Point

- When activating the AirNut

keep all parts of the body from between

wheel and faceplate and from between

AirNut and wheel.

3. Release the thumb nut while pushing inward

4. Remove the air gun from it’s holder.

5. Insert the air gun into the receiving end of the

AirNut to inflate.

Only use air gun for intended purpose. If air

is injected into the human body, lacerations, serious injuries, or death can occur.

Failure to properly tighten the AirNut may

result in the wheel dismounting, causing

personal injury and property damage.

AirNut Release

6. Depress the yellow button to release the air pres-

sure.

Never attempt to release a pressurized

AirNut using any method except by

depressing the yellow release button.

7. Press the thumb release to disconnect from the

arbor shaft.

8. Remove from arbor by pulling outward.

AirNut

WARNING

WARNING

WARNING

WARNING

WARNING

Page 8

4 • COATS AirNut

AirNut

Maintenance and

Service

Preventative Maintenance

For best results, an inline water trap and oiler should

be installed. To maintain it, follow the manufacturers

recommendations for servicing the water trap and

oiler.

1. Guard against rough handling of the AirNut.

2. Keep the partial nut, thumb lever assembly and

the balancer’s arbor shaft clean and free of any contaminant.

3. Avoid using strong solvents and chemicals for

cleaning. Compressed air and a light penetrating oil

such as WD 40 may be used to clean any part of the

AirNut.

4. There is a filter on the inlet to the air chamber

where the air gun is positioned for inflating. This filter

may be cleaned as described above.

Service

For any service you may require, call customer service (800) 688-6359 for an authorized service center

closest to you.

Troubleshooting

The AirNut has proved to be a very durable piece of

equipment. If maintained and handled properly, it

should give many years of good service.

Should any service be required review the following

section.

Look at the parts illustration on page 5.

1. There are four metric allen screws holding the

handle body to the main casting.

Once the four metric screws are removed and the

handle body is removed, the inlet and outlet valve

assemblies can be removed for cleaning, repair or

replacement. The correct placement of their air check

balls and springs is critical.

The partial nut, thumb release lever and spring may

be serviced when the handle body is separated from

the main casing.

If the AirNut won’t activate, check for air pressure

when the air gun is depressed.

2. Make sure there are no kinked air hoses.

3. Disconnect the air supply from the regulator and

make sure that supply of air is reaching the regulator.

4. If air pressure is present at the regulator, begin to

disconnect at each joint from the regulator and make

sure that supply of air is reaching the regulator.

5. If air pressure is present at the regulator, begin to

disconnect at each joint from the regulator to the gun

until the problem is located.

Wear safety glasses. There may be high air

pressure.

6. If air pressure is coming from the air gun but the

AirNut won’t activate, the filter is suspect. Clean with

WD 40 or equivalent.

If it still won’t inflate…

7. Inoperative inlet valve assembly.

8. If an air leak is noted in/on the AirNut, locate the

source and clean, repair or replace the component

part.

If the AirNut won’t engage with the arbor shaft

threads…

9. Arbor shaft threads are dirty and needs cleaning.

10. Partial nut is dirty and needs cleaning.

11. Partial nut thumb release is in need of disas-

sembly, cleaning or repair.

If the previous doesn’t fix the problem, call customer

service (800) 688-6359 for an authorized service center closest to you.

WARNING

Page 9

COATS AirNut • 5

Parts Identification

PART

ITEM NO. DESCRIPTION

1 8112666 Main Casing (1.125” model only)

8112667 Main Casing (40mm model only)

2 8112668 Air Release Assembly (valve body)

3 8112669 Air Supply Assembly (valve body)

4 8112579 Pressure Cup

5 8112580 Pressure Cup Cushion

6 8112581 No Mar Ring

7 8112671 Regulator Assembly

8 8112583 Air Hose Assembly (regulator to

block)

9 8112584 Air Gun

10 8112673 Air Hose Assembly (block to gun)

PART

ITEM NO. DESCRIPTION

11 8112672 Air Block Assembly

12 8112588 Holder (air gun) and Bolt Assembly

Not Shown

13 8112594 Decal (pinch point) Caution

14 8112595 Decal (air blast) Warning

15 8112590 Decal 1.125” Model

16 8112592 Decal 40mm Model

AirNut

1

2

3

5

6

7

8

9

10

11

12

4

Page 10

6 • COATS AirNut

AirNut

Notes

Page 11

COATS AirNut • 7

Notes

AirNut

Page 12

8112596 01 08/99 © Copyright 1999 Hennessy Industries and COATS, Inc. All Rights Reserved Printed in USA

Loading...

Loading...