CM-ET Lodestar User Manual

83877

EENNTTEERRTTAAIINNMMEENNTT

®

Manual No. E627

Operating, Maintenance &

PPaarrttss MMaannuuaall

11//44 TToo 22 TToonn

225500 KKgg.. TToo 22000000 KKgg..

Columbus McKinnon Corporation

CM Entertainment Division

140 John James Audubon Parkway

Amherst, New York 14228-1197

1-800-888-0985

1-716-689-5400

cmrigging.com

®

LIMITATION OF WARRANTIES, REMEDIES AND DAMAGES

THE WARRANTY STATED BELOW IS GIVEN IN PLACE OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS FOR APARTICULAR PURPOSE, OR

OTHERWISE, NO PROMISE OR AFFIRMATION OF FACT MADE

BY ANY AGENT OR REPRESENTATIVE OF SELLER SHALL

CONSTITUTE AWARRANTY BY SELLER OR GIVE RISE TO

ANY LIABILITY OR OBLIGATION.

Seller warrants that on the date of delivery to carrier the goods are

free from defects in workmanship and materials.

SELLER’S SOLE OBLIGATION IN THE EVENTOF BREACH OF

WARRANTY OR CONTRACT OR FOR NEGLIGENCE OR OTHERWISE WITH RESPECT TO GOODS SOLD SHALL BE EXCLUSIVELYLIMITED TO REPAIR OR REPLACEMENT, F.O.B. SELLER’S

POINT OF SHIPMENT, OFANY PARTS WHICH SELLER DETERMINES TO HAVE BEEN DEFECTIVE or if Seller determines that

such repair or replacement is not feasible, to a refund of the purchase price upon return of the goods to Seller.

Any action against Seller for breach of warranty, negligence or otherwise, must be commenced within one year after such cause of

action occurs.

NO CLAIM AGAINST SELLER FOR ANY DEFECT IN THE GOODS

SHALL BE VALID OR ENFORCEABLE UNLESS BUYER’S WRITTEN NOTICE THEREOF IS RECEIVED BY SELLER WITHIN ONE

YEAR FROM THE DATE OF SHIPMENT.

Seller shall not be liable for any damage, injury or loss arising out of

the use of the goods if, prior to such damage, injury or loss, such

goods are (1) damaged or misused following Seller’s delivery to carrier; (2) not maintained, inspected, or used in compliance with applicable law and Seller’s written instructions and recommendations; or

(3) installed, repaired, altered or modified without compliance with

such law, instructions or recommendations.

UNDER NO CIRCUMSTANCES SHALLSELLER BE LIABLE FOR

INCIDENTALOR CONSEQUENTIAL DAMAGES AS THOSE

TERMS ARE DEFINED IN SECTION 2-715 OF THE UNIFORM

COMMERCIAL CODE.

INDEMNIFICATION AND SAFE OPERATION

Buyer shall comply with and require its employees to comply with

directions set forth in instructions and manuals furnished by Seller

and shall use and require its employees to follow such instructions

and manuals and to use reasonable care in the use and maintenance of the goods. Buyer shall not remove or permit anyone to

remove any warning or instruction signs on the goods. In the event

of personal injury or damage to property or business arising from

the use of the goods, Buyer shall within 48 hours thereafter give

Seller written notice of such injury or damage. Buyer shall cooperate

with Seller in investigating any such injury or damage and in the

defense of any claims arising therefrom.

If Buyer fails to comply with this section or if any injury or damage is

caused, in whole or in part, by Buyer’s failure to comply with applicable federal or state safety requirements, Buyer shall indemnify

and hold Seller harmless against any claims, loss or expense for

injury or damage arising from the use of the goods.

®

V

!!

WARNING

Alterations or modifications of equipment and use of nonfactory repair parts can lead to dangerous operation and

injury.

TO AVOID INJURY:

• Do not alter or modify equipment.

• Do use only CM replacement parts.

Columbus McKinnon Corporation

CM Entertainment Division

140 John James Audubon Parkway

Amherst, New York 14228-1197

1-800-888-0985

1-716-689-5400

Fax 1-716-689-5644

cmrigging.com

© 2006 Columbus McKinnon Corp. 8/06 Printed in USA

All Columbus McKinnon (CM®) Lodestar Electric Chain

Hoists are thoroughly inspected and performance tested

prior to shipment. If any properly maintained hoist develops

a performance problem due to a material or workmanship

defect, as verified by CM, repair or replacement of the unit

will be made to the original purchaser without charge. This

repair/replacement policy applies only to Lodestar Hoists

installed, maintained and operated as outlined in this manual,

and specifically excludes parts subject to normal wear,

abuse, improper installation, improper or inadequate maintenance, hostile environmental effects and unauthorized

repairs/modifications.

We reserve the right to change materials or design, if, in our

opinion, such changes will improve our product. Abuse,

repair by an unauthorized person, or use of non-CM

replacement parts voids the guarantee and could lead to

dangerous operation. For full Terms of Sale, see Sales

Order Acknowledgement. Also, refer to the back cover for

Limitations of Warranties, Remedies and Damages, and

Indemnification and Safe Operation.

GENERAL INFORMATION

CM HOIST PARTS AND SERVICES ARE AVAILABLE WORLD WIDE

As a CM Hoist user, you are assured of reliable repair and parts services through a network of Master Parts Depots and Service Centers that are strategically located World Wide. These facilities have been selected on the basis of their demonstrated ability to handle all parts and repair requirements

promptly and efficiently.

Below is a list of the Master Parts Depots and Entertainment Hoist Service Stations. To quickly obtain the name of the U.S. Service Center located nearest you, call (800) 888-0985. Fax: (716) 689-5644.

ARGENTINA

IFAN RENIERI Y CIA SA.

Aristobulo Del Valle 1933/43

(1295) Buenos Aires,

Argentina

UPSTAGE, S.A.

Warnes 2351

(1427) Capital Federal

Buenos Aires, Argentina

AUSTRIA

Tüchler GmbH

Rennbahnweg 78

Vienna 1220

Austria

(43)-1-400-10-23

Fax (43)-1-400-10-20

AUSTRALIA

PWB ANCHOR

441 Grimshaw Street

Bundoora Victoria,

Australia 3083

(61)-39-467-2933

Fax (61)-39-467-4320

BRASIL

HABITASUL S.A. COMERCIO

EXTERI

157-Sala 1302

90.010.030

Porto Alegre-RS-Brasil

ROSCO DO BRASIL

Rua Antonio De Barros #827

Cep 03401-000

Sao Paulo, Brasil

BOLIVIA

SONILUM ILUMINACION Y

SONIDO

Tucuman 20 (6 Este) Equipetrol

Santa Cruz De La Sierra

Bolivia

CHINA

HANGZHOU, LILA LIFT./LASH. CO.

Zhijiang Hi-Tech Zone

Hangzhou, Zhejiang, 310053

P.R. Of China

(86)-571-8669-6946

Fax (86)-571-8669-6219

ENGLAND

TOMCAT UK Ltd.

Unit 2, Skiddaw Rd

Croft Business Park

Bromborough, Wirral CH62 3RB

United Kingdom

(44)-151-482-3100

Fax (44)-151-482-3111

FRANCE

SONOSS

Avenue De La Rotonde

Sac Postal 9

59465 Lomme, France

Lomme (Cedex)

(33)-3-20-00-92-10

Fax (33)-3-20-00-92-11

GERMANY

LMP LICHTTECHNIK

Gildestrasse 55

49477 Ibbenburen, Germany

PFAFF SILBERBLAU

Postfach 102229

Augsburg 86012, Germany

HOAC HANDELS GMBH

Pferdsweide 39C

Nordrhein-Westfalen, Deutschla

Mores, Germany 47441

(49)-2841-90-828-28

Fax (49) 2841-90-828-70

ISRAEL

GILON SUPPLY (1946) LTD

21, Frug St.

Tel-Aviv, 63417, Israel

ITALY

Litec Srl

Via Venier 52

30020 Macron (Ve)

Italy

(39)-041-596-0000

Fax (39) 041-595-1082

JAPAN

KATSUYAMA KIKAI LTD

104-18 Honjounishi 2

Chome, Higashiosaka,

Osaka, 578-0965

Japan

(81)-6-6747-6390

Fax (81)-6-6748-2039

SHIMIZU OCTO INC

1-4-1 Shimoochiai, Shinjuku-Ku

Tokyo 161-0033

Japan

(81)-0-3-3360-7743

Fax (81)-0-3-3360-1664

MEXICO

COLUMBUS McKINNON

De Mexico S.A. De C.V.

Venustiano Carranza #301

Santiago Tianguistenco

C.P. 52600, Mexico

NETHERLANDS

Louis Reyners B.V.

Symon Spiersweg 13A

Postbus 2118

1500 GC Zaandam

Netherlands

(31)-75-650-4750

Fax (31)-75-650-4760

SINGAPORE

CSP PRODUCTIONS (PTE) LTD

No 3 Upper Aljunied Link 05-04

Joo Seng Warehouse Tower B

Singapore 367902

(65)-6283-0220

Fax (65)-6284-0220

CALIFORNIA

OTTO SYSTEMS, INC.

12010 Bloomfield Ave.

Sante Fe Springs, CA 90670

562/462-1612 or 800/596-7392

Fax 562/462-1617

or

7656 Las Positas Road

Livemore, CA 94551

925/245-8800 or 800/508-6886

Fax 925/245-8804

STAGE RIGGING

2690 Middlefield Road, Unit F

Redwood City, CA 94063

650/299-1189

Fax 650/299-1617

FLORDIA

NATIONAL PRODUCTIONS SERVICES

9561 Satellite Blvd.

Orlando, FL 32837

407/857-6446

Fax 407/857-6264

GEORGIA

ATLANTA RIGGING SYSTEMS

1270 Tacoma Dr.

Atlanta, GA 30318

404/355-4370

Fax 404/355-4360

ACE INDUSTRIES, INC.

6295 McDonough Drive

Norcross, GA 30093

770/441-0898 or 800/733-2231

Fax 800/628-3648

ILLINOIS

REED RIGGING

2309 S. Keeler Ave.

Chicago IL 60623

773/521-7333

Fax 773/521-1709

INDIANA

HORNER ELECTRIC COMPANY, INC.

1521 East Washington Street

Indianapolis, IN 46201

317/639-4261

Fax 317/639-4342

IOWA

VMI HOIST & CRANE SERVICES

901 17th Street NE

Cedar Rapids, IA 52406

319/365-4662

Fax 319/365-8075

LOUISIANA

BEERMAN PRECISION, INC.

4206 Howard Ave.

New Orleans, LA 70125

504/486-9391

Fax 504/486-7482

MASSACHUSETTS

ABEL DISTRIBUTORS, INC.

50 Parker Street, Unit 2

Newburyport, MA 01950

978/463-0700

Fax 978/463-5200

MISSOURI

INDEPENDENT ELECTRIC MACHINERY

4425 Oliver Street

Kansas City, MO 66106

913/362-1155

Fax 913/904-3330

NEVADA

SILVER STATE WIRE ROPE

5380 S. Valley View Blvd.

Suite A

Las Vegas, NV 89118

702/597-2010

Fax 702/896-1977

TOMCAT USA, INC

4020 Ali Baba Lane

Bldg. D. Suite A

Las Vegas, NV 89118

702/798-6200

Fax 702/798-6225

NEW JERSEY

SHUPPER-BRICKLE EQUIPMENT CO.

2394 Route 130, Suite C

Dayton, NJ 08810

732/438-3888

Fax 732/438-3889

NEW YORK

VOLLAND ELECTRIC EQUIPMENT CO.

75 Innsbruck Drive

Buffalo, NY 14227

716/656-9900

Fax 716/656-8898/8899

NORTH CAROLINA

TEAM SESCO

2225 Freedom Drive

Charlotte, NC 28208

704/372-4832 or 800/487-3726

Fax 704/358-1098

OHIO

MAZZELLA LIFTING TECHNOLOGIES

21000 Aerospace Parkway

Cleveland, OH 44142

440/239-5700 or 800/362-4601

Fax 440/239-5707

PENNSYLVANIA

AMICK ASSOCIATES, INC.

11 Sycamore Street

Carnegie, PA 15106-0529

412/429-1212 or 800/445-9456

Fax 412/429-0191

RAM MOTORS & CONTROLS, INC.

5460-B Pottsville Pike

Leesport, PA 19533

610/916-8000 or 877/916-8018

Fax 610/916-7957

MOUNTAIN PRODUCTIONS

80 New Fredrick St.

Wilkes-Barre, PA 18702

570/826-5566 or 800/733-5553

Fax 570/824-6139

TEXAS

ABEL EQUIPMENT CO., INC.

3710 Cavalier Drive

Garland, TX 75042

972/272-7706

Fax 972/272-6955

HYDRAULIC EQUIPMENT SERVICES,

INC.

1021 North San Jacinto Street

Houston, TX 77002

713/228-9601

Fax 713/228-0931

SHIMIZU INTERNATIONAL PRODUCTION SERVICES, INC.

1500 East Belt Line Road

Carrollton, TX. 75006

TOMCAT USA

2160 Commerce Dr

Midland TX 79703

432/694-7070

Fax 432/689-3805

WISCONSIN

TRESTER HOIST & EQUIPMENT, INC.

W136 N4863 Campbell Drive

Menomonee Falls, WI 53051

262/790-0700 or 800/234-6098

Fax 262/790-1009

ALBERTA

BENNETT & EMMOTT, LTD.

18131 118th Avenue

Edmonton, Alberta T5S 1M8

403/454-9000

Fax 403/454-8990

CHRISTIE LITES

2610 3rd Avenue

Calagary, AB T2A 2L5

403/243-2688

Fax 403/243-2689

MASTER PARTS DEPOT

i

“ENTERTAINMENT HOIST”

SERVICE STATIONS

“ENTERTAINMENT HOIST”

SERVICE STATIONS

ALBERTA

**COLUMBUS McKINNON, LTD.

10311-174th Street

Edmonton, Alberta T5S 1H1

800/263-1997

Fax 403/486-6160

BRITISH COLUMBIA

FLECK BROTHERS, LTD.

4084 McConnel Court

Burnaby, British Columbia V5A 3N7

CHRISTIE LITES

3686 Bainbridge Ave.

Burnaby, BC V5C 5A9

604/255-9943

Fax 604/255-9194

STUDIO CITY RENTALS

2050 Alfa Avenue

Burnaby, BC V5C 5A9

604/291-9414

Fax 604/292-6786

MANITOBA

KING’S ELECTRIC MOTORS, INC.

633 Tyne Avenue

Winnipeg, Manitoba R2L 1J5

204/663-5332

Fax 204/663-4059

NOVA SCOTIA

*W & A MOIR

95 Ilsley Ave.

Burnside Park, Nova Scotia B3B 1L5

902/468-7720

Fax 902/468-3777

ONTARIO

CHRISTIE LITES

102-15 North Queen St.

Toronto, ON M8Z 6C1

416/644-1010

Fax 416/644-0404

PRG LIGHTING

2480 Tedlo St.

Mississaua, ON L5A 3V3

905/270-9050

Fax 905/270-2590

*R & W HOIST REPAIR, LTD.

790 Redwood Square

Units 5, 6, & 7

Oakville, Ontario L6L 6N3

905/825-5500

Fax 905/825-5315

STUDIO CITY RENTALS

75 Commissioner St.

Toronto, ON M5A 1A6

416/465-6434

Fax 416/465-7008

*TORONTO ELECTRIC HOIST SALES & SERVICE

9 CoDeco Court

North York, Ontario M3A 1A1

416/386-0820

Fax 416/386-0821

*MASLACK SUPPLY, LTD.

488 Falconbridge Road

Sudbury, Ontario P3A 4S4

705/566-1270

Fax 705/566-4208

*COLUMBUS McKINNON, LTD.

P.O. Box 1106

10 Brook Road, North

Cobourg, Ontario K9A 4W5

905/372-0153

Fax 905/372-3078

QUEBEC

*HERCULES SLING & CABLE

3800 TransCanada Highway

Pointe-Claire, Quebec H9R 1B1

514/428-5511

514/48631-5511

Fax 514/428-5555

*LEGER PALANS ET OUTILLAGES, INC.

7995-17th Ave.

Montreal, Quebec H1Z 3R2

514/376-3050

Fax 514/376-0657

SOLOTECH

4820 4th Avenue

Montreal, QC H1Y 2T8

514/526-7725

Fax 514/526-7729

**ARE ALSO MASTER PARTS DEPOTS

**MASTER PARTS DEPOT ONLY

“ENTERTAINMENT HOIST”

SERVICE STATIONS

“ENTERTAINMENT HOIST”

SERVICE STATIONS

1. NOT lift people.

2. NOT allow people on unsecured load without fall protection.

3. NOT exceed rated capacity of hoist.

4. NOT remove or obscure any capacity or warning label.

5. Check the supporting structure. The connection between the

load hook and structure. The load itself and the connection between

the hoist support and the load for their ability to withstand the loads

imposed with an adequate design factor.

6. Tie off the load with auxiliary chains or cables before access to

the area beneath the load is permitted. As an alternative, the

system may be designed such that malfunction or failure of one

hoist’s load bearing components does not cause load loss and/or

overloading of any other hoists in the system. Note that in such a

system, hoist performance and function must be monitored visually

or with use of load cells.

7. Read hoist manual and special instructions before installing and

operating the hoist.

Successful Theatrical Hoist Operation Requires the following actions:

At the loose end, maintain a minimum of 24 inches of chain freely

hanging over the side of hoist.

Keep load chain well lubricated using Lubriplate® 10R Bar and

Chain oil.

Do make sure hoist is phased properly and chain travel limits

function properly.

If a chain container is used, inspect before each use for damaged,

loose hardware and water drainage provisions. Make certain container

attachment hardware has an adequate design factor of a minimum of

5 to 1. Also, make sure chain container is of sufficient capacity: chain

chain in fully loaded container shall not exceed 75% of container

height.

1. Maintain a firm footing or be otherwise secured when operating

the hoist.

2. Check brake function by tensioning the hoist prior to each lift

operation.

3. Use hook latches. Latches are to retain slings, chains, etc. under

slack conditions only.

4. Make sure the hook latches are closed and not supporting any

parts of the load.

5. Make sure the load is free to move and will clear all obstructions.

6. Avoid swinging the load or hook.

7. Make sure hook travel is in the same direction as shown on the

controls.

8. Inspect the hoist regularly, replace damaged or worn parts, and

keep appropriate records of maintenance.

9. Use CM parts when repairing the unit.

10. Lubricate load chain per instructions in this manual.

11. NOT

use the hoist load limiting or warning device to measure load.

12. NOT use limit switches as routine operating stops. They are

emergency devices only.

13. NOT allow your attention to be diverted when operating hoist.

14. NOT allow the hoist to be subjected to sharp contact with other

hoists, structures, or objects through misuse.

15. NOT adjust or repair the hoist unless qualified to perform such

adjustments or repairs.

SAFETY PRECAUTIONS

Each Entertainment-Lodestar Electric Hoist is built in accordance with the specifications contained herein and at the time of

manufacture complied with our interpretation of applicable sections of the *American Society of Mechanical Engineers Code

B30.16 “Overhead Hoists”, the National Electrical Code (ANSI/NFP A70), the Occupational Safety and Health Act, British Health

Safety Executives, TUV and CE Directive. Since OSHA states the National Electrical Code applies to all electric hoists,

installers are required to provide current overload protection and grounding on the branch circuit section in keeping with the

code. Check each installation for compliance with the application, operation and maintenance sections of these articles.

The safety laws for elevators, lifting of people and for dumbwaiters specify construction details that are not incorporated in CM

industrial hoists. For such applications, refer to the requirements of applicable state and local codes, and the American

National Safety Code for elevators, dumbwaiters, escalators and moving walks (ASME A17.1). Columbus McKinnon

Corporation cannot be responsible for applications other than those for which CM equipment is intended.

*Copies of this Standard can be obtained from ASME Order Department, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300,

U.S.A.

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND

ANY PROVIDED WITH THE EQUIPMENT BEFORE ATTEMPTING TO OPERATE YOUR

LODESTAR HOIST.

V

!! !!

WWAARRNNIINNGG

Usage of hoists that do not involve lifting of the load on

the lower hook or using hoists in the inverted position

without special precaution may cause an accident

resulting in injury and/or property damage.

WWAARRNNIINNGG

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result

in death

or serious injury. To avoid such a potentially

hazardous situation, the operator shall:

CCAAUUTTIIOONN

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result

in minor or moderate injury. To avoid such a potentially

hazardous situation, the operator shall:

ii

V

!! !!

V

!!

V

!!

V

!!

CCAAUUTTIIOONN

V

!!

TABLE OF CONTENTS

Master Parts Depots And Service Centers . . . . . . . . . .i

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

General Information

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CM Repair/Replacement policy . . . . . . .(Back Page)

Accessories

Hook Suspensions . . . . . . . . . . . . . . . . . . . . . . . . .3

Latchlok Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation

Unpacking Information . . . . . . . . . . . . . . . . . . . . . .3

Installing Suspension . . . . . . . . . . . . . . . . . . . . . . .3

Attaching Load Chain . . . . . . . . . . . . . . . . . . . . . . . . . .4

Power Supply and Electrical Connections . . . . . . . . . .5

Operating Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operating Instruction-Hoist . . . . . . . . . . . . . . . . . . .7

Safety Procedures . . . . . . . . . . . . . . . . . . . . . . . . . .7

Inspection

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Frequent Inspections . . . . . . . . . . . . . . . . . . . . . . . .8

Periodic Inspections . . . . . . . . . . . . . . . . . . . . . . . .8

Preventative Maintenance . . . . . . . . . . . . . . . . . . . .8

Hook Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Load Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Maintenance

Protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Hoist Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . .11

Adjustments

Electric Brake . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . .12

Recommended Spare Parts . . . . . . . . . . . . . . . . . .13

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . .15-16

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . .17-20

Assembly Instructions

Hook Suspension . . . . . . . . . . . . . . . . . . . . . . . . .21

Gearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Lower Hook Block Pin . . . . . . . . . . . . . . . . . . . . . .22

Removal and Installation of Load Chain . . . . . . . .23

Cutting Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Ordering Instructions . . . . . . . . . . . . . . . . . . . . . . . . .24

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-42

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44-46

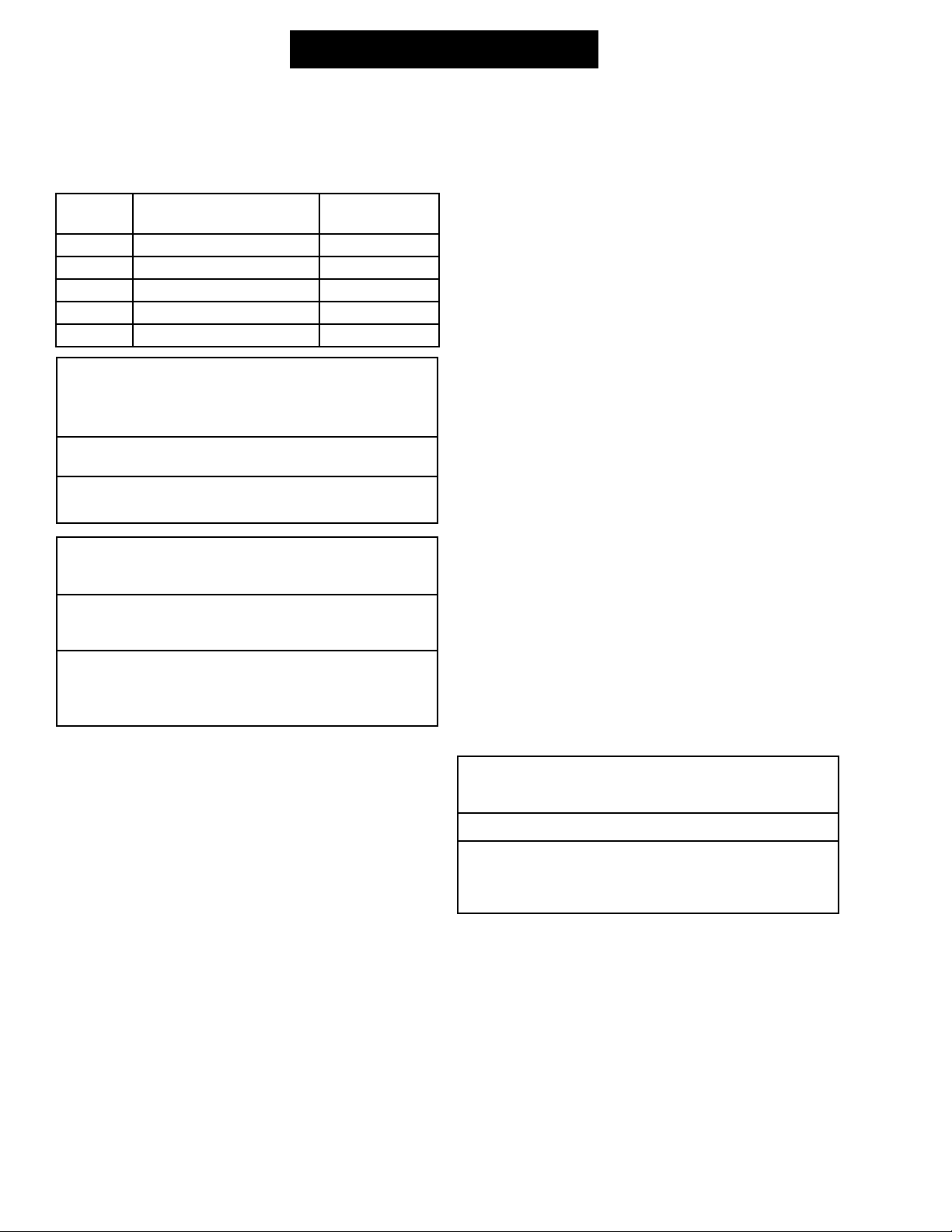

LIST OF TABLES

Table Title Page

1 Lodestar Electric Chain Hoist Specs. . . . . .2

2 Recommended Seating Torques for

Suspension Adapter Screws . . . . . . . . .4

4 Minimum Frequent Inspections . . . . . . . . . .9

5 Minimum Periodic Inspections . . . . . . . . . .9

6 Limit Switches . . . . . . . . . . . . . . . . . . . . .13

7 Electrical Data . . . . . . . . . . . . . . . . . . . . .14

8 Troubleshooting . . . . . . . . . . . . . . . . . .15,16

LIST OF ILLUSTRATIONS

Figure Table Page

1 Hook Suspensions . . . . . . . . . . . . . . . . . . .3

2 Upper or Lower Latchlok Hook . . . . . . . . . .3

7 Attaching Load Chain . . . . . . . . . . . . . . . . .4

8 Contact Block . . . . . . . . . . . . . . . . . . . . . . .4

12 Voltage Change Board . . . . . . . . . . . . . . . .5

13 Locations of Components . . . . . . . . . . . . . .5

14 Hook Inspection . . . . . . . . . . . . . . . . . . . .10

15 Chain Wear areas . . . . . . . . . . . . . . . . . . .10

16 Chain Inspection . . . . . . . . . . . . . . . . . . . .10

17 Chain Embossing . . . . . . . . . . . . . . . . . . .10

18 Limit Switches Models B, C & F . . . . . . . . .12

18A Rotatable Limit Switches Models B, C & F 12

19 Limit Switches Models J, L, R, LL & RR . . . .12

19A Rotatable Limit Switch J, L , R, LL& RR .12-13

20 Typical Wiring Diagrams . . . . . . . . . . .17-20

21 Swivel Hook Suspensions . . . . . . . . . . . .21

22 Non-Circular Gearing . . . . . . . . . . . . . . . .22

23 Cutting Chain By Nicking . . . . . . . . . . . . .24

24 Cutting Chain With ABolt Cutter . . . . . . . .24

25 Exploded View-

Components . . . . . . . . . . . . . . . . . 25-42

FORWARD

This manual contains important information to help you properly install, operate and maintain your hoist for maximum performance,

economy and safety.

Please study its contents thoroughly before putting your hoist into operation. By practicing correct operating procedures and by

carrying out the recommended preventive maintenance suggestions, you will experience long, dependable and safe service.

After you have completely familiarized yourself with the contents of this manual, we recommend that you carefully file it for future

reference.

The information herein is directed to the proper use, care and maintenance of the hoist and does not comprise a handbook on the

broad subject of rigging.

Rigging can be defined as the process of lifting and moving heavy loads using hoists and other mechanical equipment. Skill

acquired through specialized experience and study is essential to safe rigging operations. For rigging information, we recommend

consulting a standard textbook on the subject.

1

SSPPEECCIIFFIICCAATTIIOONNSS

The Lodestar Electric Chain Hoist is a highly versatile materials handling device that can be used to lift loads that are

within its rated capacity. The mechanical features of these

hoists include an alloy liftwheel, Load Protector, hardened

steel chain guides, hardened steel load chain, hardened steel

gear train, life-time lubrication, forged steel hooks, and lightweight aluminum frame. The electrical features included

hoist-duty motor, rugged hoist brake, magnetic reversing contactor and voltage conversion board (dual voltage units).

Follow all instructions and warnings for

inspecting, maintaining and operating this hoist.

The use of any hoist presents some risk of personal injury or

property damage. That risk is greatly increased if proper

instructions and warnings are not followed. Before using this

hoist, each operator should become thoroughly familiar with

all warnings, instructions, and recommendations in this manual.

Retain this manual for future reference and use.

Forward this manual to the hoist operator.

Failure to operate the equipment as directed in the manual

may cause injury.

Before putting hoist into service, fill in the information below.

Refer to the hoist identification plate.

MMooddeell NNuummbbeerr

__________________________________

SSeerriiaall NNuummbbee

r ____________________________________

PPuurrcchhaassee DDaattee

__________________________________

VVoollttaaggee

__________________________________________

RRaatteedd LLooaadd

______________________________________

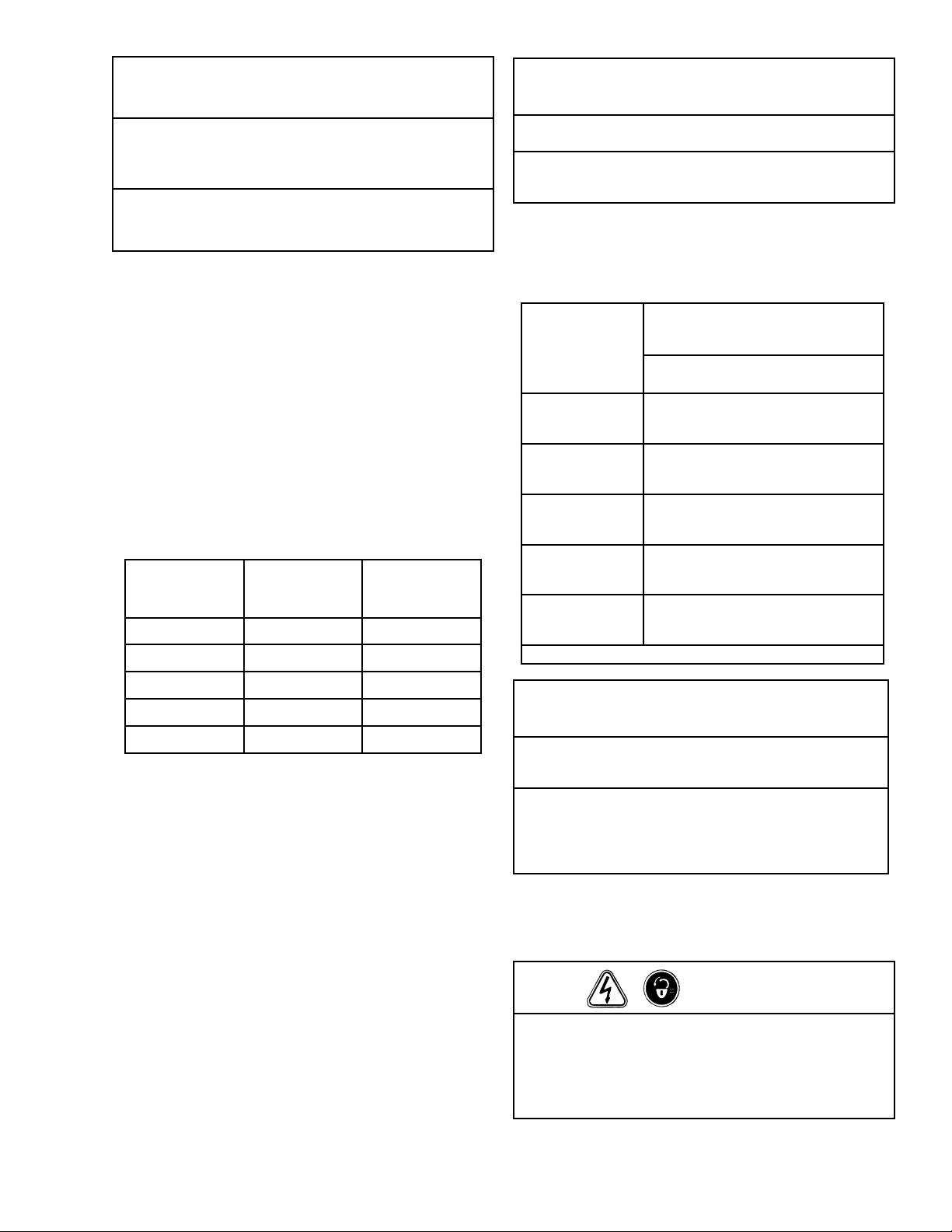

Table 1. Specifications

Entertainment-Lodestar Electric Chain Hoists

Maximum

Capacity

(Tons)

Model

*Lifting

Speed

Per Min.

(Feet)

*Lifting

Speed

Per Min.

(M)

Motor

H.P.

Motor

K.W.

Shortest

Distance

Between

Hooks

(Inches)

Shortest

Distance

Between

Hooks

(mm)

Net

Weight

(Lbs.)

Net

Weight

(Kg.)

Single Speed 230/460-3-60 or 220/380-3-50

or 220/415-3-50

1/4 B 16 4.88 1/4

.186

14-1/4

362.0 57 25.8

1/4

1/2

C

F

32

16

9.75

4.88

1/2

1/2

.372

.372

14-1/4

14-1/4

362.0

362.0

65

64

29.5

29.0

1/2

1

2

J

L

R

32

16

8

9.75

4.88

2.44

1

1

1

.746

.746

.746

15-9/16

15-9/16

22-1/2

395.3

395.3

571.5

115

117

136

52.2

53.1

61.7

Single Speed 230/460-3-60 or 220/380-3-50

or 220/415-3-50

1 LL 32 9.75 2 1.49 15-9/16 395.3 121 54.9

2 RR 16 4.88 2 1.49 22-13/16 579.4 136 61.7

*Lifting and travel speeds listed are for 60 Hertz units. For

50 Hertz units, these speeds will be 5/6 of those listed.

2

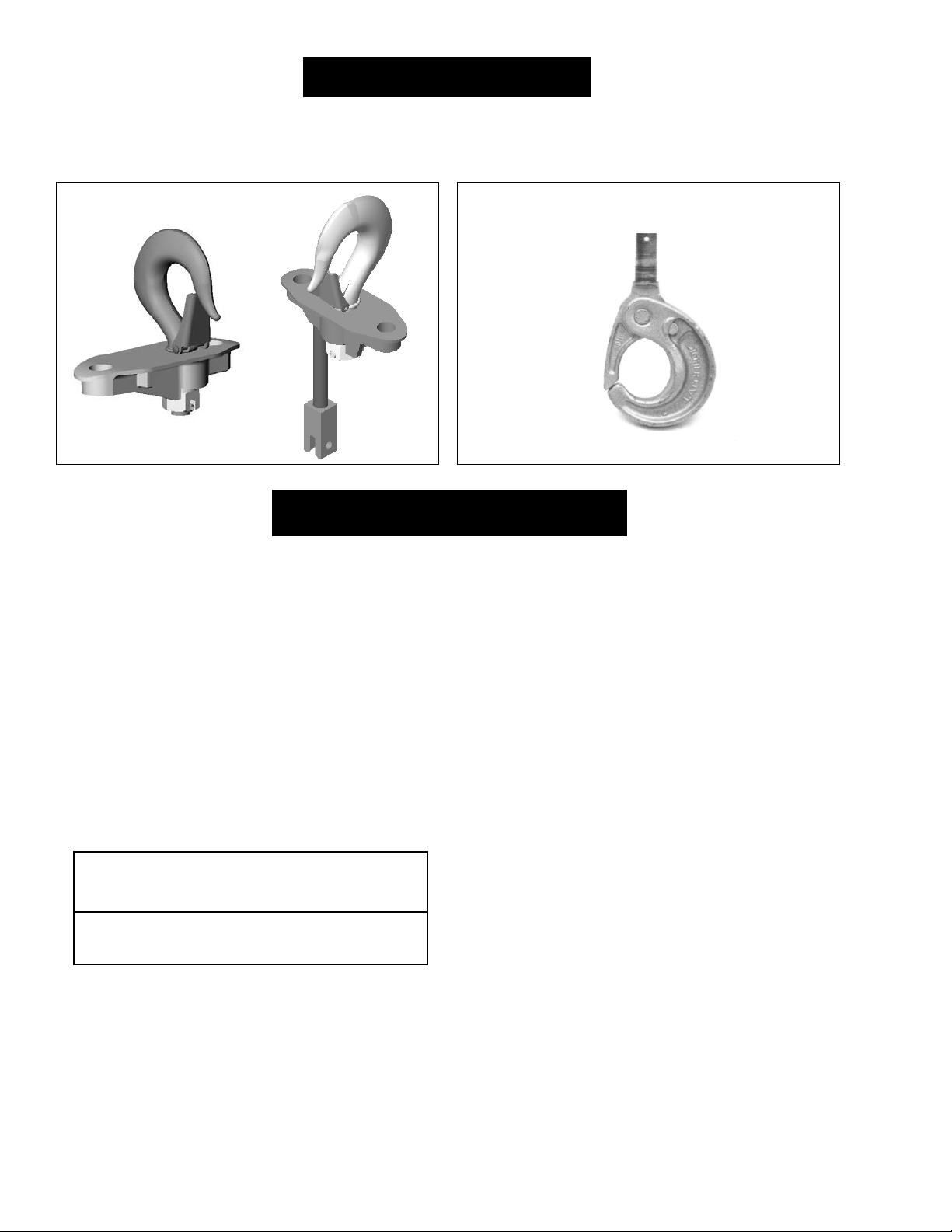

HOOK SUSPENSIONS

Swivel and rigid type hook suspensions (see Figure 1) are

available for all Lodestar Electric Hoists. However, swivel

type hook suspensions are normally recommended for most

applications.

UNPACKING INFORMATION

When received, the hoist should be carefully inspected for

damage which may have occurred during shipment or handling. Check the hoist frame for dents or cracks, the external

cords for damaged or cut insulation, the control station for cut

or damaged enclosure, and inspect the load chain for nicks

and gouges. If shipping damage has occurred, refer to the

packing list envelope on the carton for claim procedure.

Before using the hoist, make sure the voltage change board

(Key# 627-1013) is connected for the intended power supply

the hoist is to be operated.

NOTE: To assure long life and top performance, be sure

to follow the load chain lubricating instructions on page

11.

INSTALLING THE SUSPENSION

A. Single Reeved Units:

Remove the hook suspension from its carton and the two

suspension screws. Place the suspension assembly into the

recess on top of the hoist so that the adapter body follows the

contour of the hoist. Insert the suspension screws through

the holes in the adapter and hand thread these into the self

locking nuts enclosed in the hoist. The screws will turn freely

into the nuts until the last 1/4” (6.35 mm) of travel, during

which the resistance of the nut locking collar will be encountered. Securely tighten the screws to the recommended seating torque (see Table 2) using a 12 point socket (½” (13mm)

socket) which fits the head of the screw.

LATCHLOK®HOOKS

CM’s Latchlok hooks (see Figure 2) are available to replace

the standard upper and lower hooks used on the Lodestar

Electric Hoists.

B. Double Reeved Units:

Remove the hook suspension from its carton and the two

suspension screws, dead end pin, washer and cotter pin. It

should be noted that the suspension includes a dead end bolt

and block for supporting the dead end of the load chain as

shown in Figure 7.

Place the suspension assembly into the recess on top of the

hoist. The dead end block should project through the bottom

of the hoist with the pin hole and slot aligned to the underside of the hoist as shown in Figure 7. If these are not

aligned as shown, lift the head of the bolt from the hex

recess in the adapter and turn the bolt and block assembly

and reseat the bolt head to obtain the proper alignment. Do

not change the position of the dead end block on the bolt to

attain this alignment.

Check the position of the pin hole in the dead end block to

make sure it has not been disturbed from its factory setting.

The distance from the top of the pin hole to the bottom of the

hoist should not exceed 7/16” (1 1.11 mm) for the Models R and

RR. If the distance is not correct, adjust the position of the

dead end block to obtain the proper distance (see Page 21).

INSTALLATION

ACCESSORIES

Figure 1. Hook Suspensions

Figure 2. Upper or Lower Latchlok

®

Hook

3

CCAAUUTTIIOONN

USE OF IMPACT TOOLS (ELECTRIC OR PNEUMATIC)

MAY CAUSE PREMATURE FAILURE OF ATTACHING

HARDWARE.

V

!!

Now, insert the suspension screws through the holes in the

adapter and hand thread these into the self locking nuts

enclosed in the hoist frame. The screws will turn freely into

the nut until the last 1/4” (6.35mm) of travel during which

the resistance of the nut locking collar will be encountered.

Securely tighten the screws to the recommended seating

torque (see Table 2) using a 12 point socket which fits the

head of the screw.

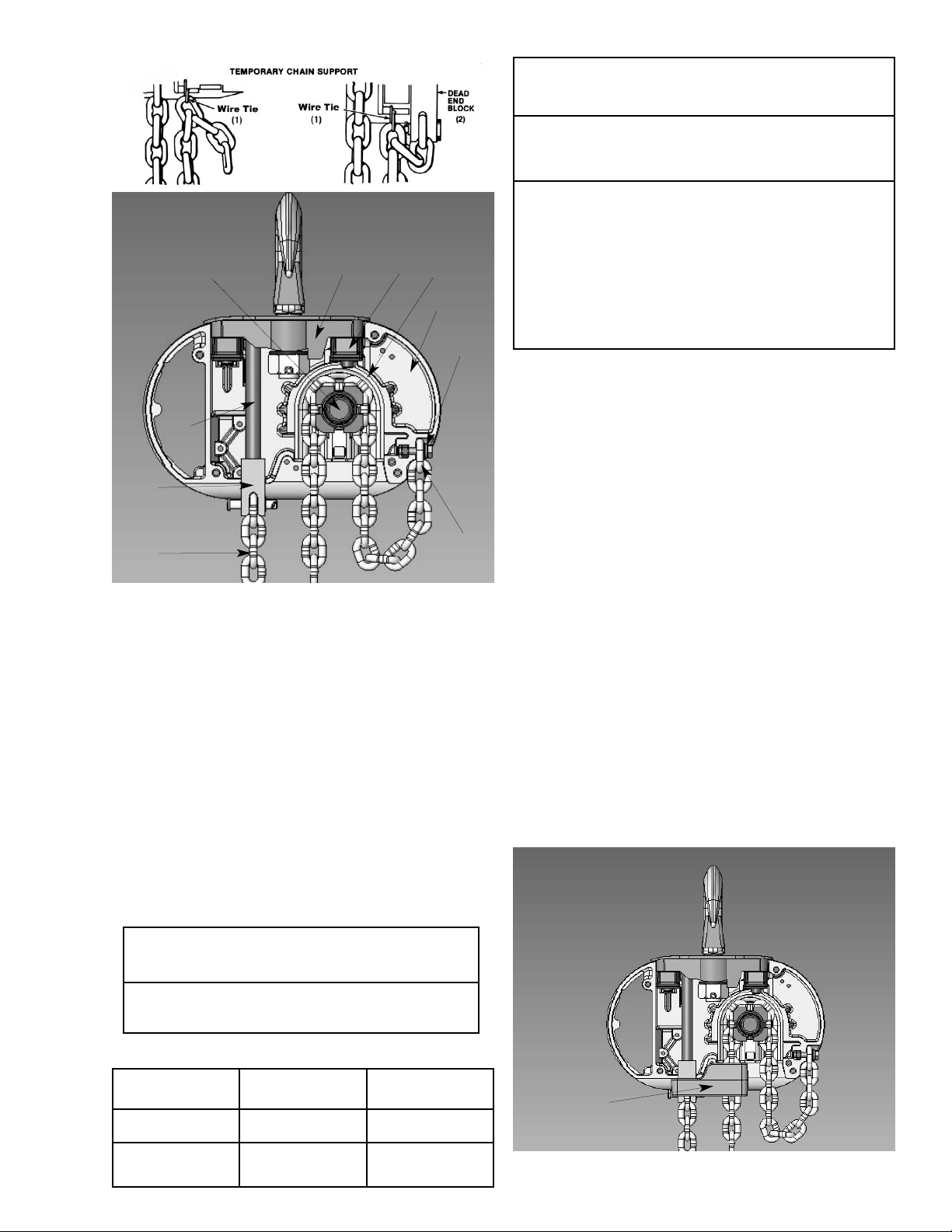

The dead end of the load chain is temporarily positioned (a

few links from the end) by a wire tie. Do not remove this tie

before attaching the chain to the dead end block. (See Fig.7).

Table 2. Recommended Seating Torques For Suspension

Adapter Screws

ATTACHING LOAD CHAIN

The Model R & RR are shipped with the dead end of the load

chain temporarily connected to the bottom of the hoist by a

wire tie (1) as shown in Figure 7. The clip is located a few links

from the end of the chain, and it should not be removed until

the chain is to be attached to the dead end block (2). To attach

the chain to the dead end block, proceed as follows:

1. Suspend the hoist from an adequate support.

2. The hoist is shipped with the dead end of the load chain

temporarily positioned a few links from the end by a light

wire clip (1) as shown in Figure 7. Do not remove this clip

until the chain is secured.

3. Remove the clip (1) by inserting a screw driver blade

through a chain link and levering against the bottom of

the hoist. Slide the contact block up the chain until it is

against the bottom of the hoist and the dead end block is

projecting through the square opening in the bottom of

the block. Insert the last link of the load chain, making

sure there are no twists between the hook block and the

dead end block, into the dead end block. Push the

contact block up slightly and secure the load chain to the

dead end block using the dead end pin, washer and

cotter pin furnished with the suspension. The dead end

pin also supports the contact block (See Figure 8).

4. Do not remove the wire ties from the load chain at this

time.

Models No’s Screw Size

Recommended

Seating Torque

B, C & F 3/8”-16UNC-2A

40.7 to 61.0 Nm

(30 to 45 lb. ft.)

J, L, R, LL & RR 1/2”-20UNF-2A

54.2 to 108.5 Nm

(40 to 80 lb. ft.)

1. Wire Clip 7. Chain guide

2. Dead end block

8. Loose end link

3. Suspension assembly 9. Liftwheel

4. Suspension self-locking nut 10. Gear housing

5. Dead end bolt 11. Loose end screw

and lockwasher

6. Load Chain

(Do not order parts by these numbers. See parts list).

WWAARRNNIINNGG

Using other than CM supplied high strength suspension

screws to attach the suspension adapter to the hoist may

cause the screws to break and allow the hoist and load to

fall.

TO AVOID INJURY:

Use only the CM supplied suspension screws to attach the

suspension to the hoist and hand torque these screws to

the recommended seating torque as specified above.

DO NOT apply any type of lubricant to the threads of these

screws. Lubricating the threads will reduce the effort to seat

the screws and as a result, tightening the screws to the above

recommended torque may break the screw, damage the suspension adapter, strip the nuts and/or damage the hoist

frame.

V

!!

Figure 7. Attaching Load Chain Models R and RR

4

3

5

6

Dead

End

2

Contact

Block

Removed For

Clarity

4

8

Loose

End

11

10

9

Contact

Block

Figure 8. Contact Block Used On Models R & RR.

CCAAUUTTIIOONN

USE OF IMPACT TOOLS (ELECTRIC OR PNEUMATIC)

MAY CAUSE PREMATURE FAILURE OF ATTACHING

HARDWARE.

V

!!

7

POWER SUPPLY AND

ELECTRICAL CONNECTIONS

The hoist should be connected to a branch circuit which complies with the requirements of the National Electrical Code

and applicable local codes.

It is recommended, especially for a single phase hoist with a

one horsepower motor (.746 Kilowatts), that a line of adequate capacity be run directly from the power supply to the

hoist to prevent having problems with low voltage and circuit

overloads.

For grounding of the hoist, the power cord includes a grounding conductor (green yellow, G-Y). Before connecting the

hoist to the power supply, check that the power to be used

agrees with the position of voltage change plug on the voltage change board. The nominal hoist voltage rating corresponding to the voltage range given on hoist identification

plate is:

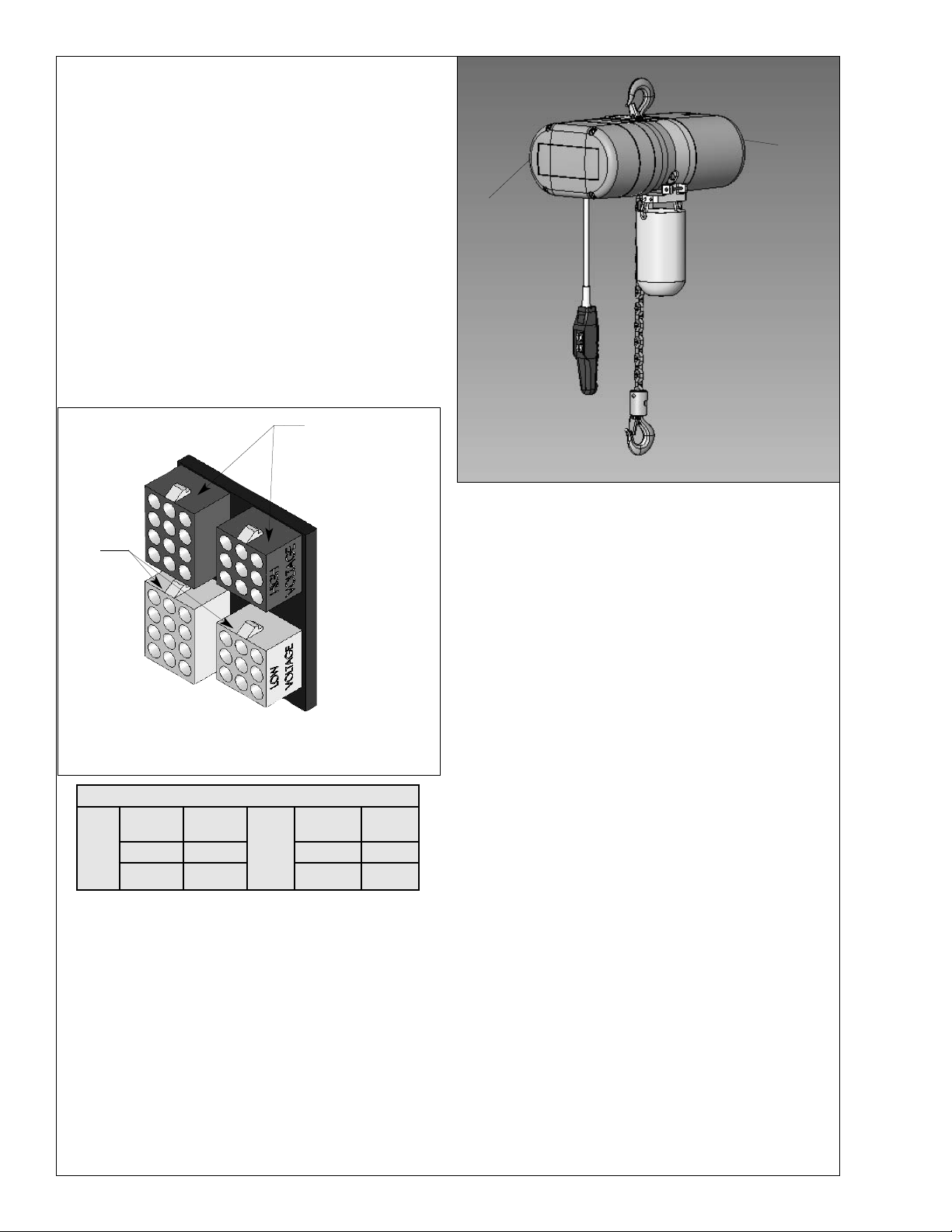

THREE PHASE HOIST

Unless ordered on a special basis, all single speed dual voltage (230/460-3-60, 220/380-3-50 and 220/415-3-50) hoists

are factory arranged to operate on 460-3-60 (or 380-3-50 or

415-3-50). However, a voltage change board is provided to

easily and quickly change from 460 to 230 (or 380 to 220 or

415 to 220) volt operation. The voltage change board shown

in Figure 12 is located in the hoist as shown in Figure 13.

Voltage change board is located under back frame cover

(1) for Models B, C & F and under motor housing cover

(2) for Models J, L, R, LL and RR.

The voltage change board is color coded to indicate high and

low volt connections. Connecting the 9 and 12 pin plugs into

the “Red” voltage change board recepticles will connect the

hoist for high voltage (380-3-50, 415-3-50 or 460-3-60). To

change the hoist voltage to low voltage (208-3-60, 220-3-50 or

230-3-60) simply remove the 9 and 12 pin plugs from the

“Red” recepticles and insert same into the “White” recepticles

located on the voltage change board.

Be sure to make a notation of the new hoist voltage on the tag

attached to the power cord.

PROPER PHASING

Since the motor in a three phase hoist can rotate in either

direction, depending on the manner in which it is connected

to the power supply, the direction of hook movement must be

checked prior to each usage.

NOTE: Serious damage can result if the hook is run to

the upper or lower limit of travel with the hook operating

in a direction opposite to that indicated by the control station. Therefore, proceed as follows:

1. Make temporary connections at the power supply.

2. Operate

(UP) control momentarily. If hook raises,

connections are correct and can be made permanent.

3. If hook lowers, it is necessary to change direction by inter

changing the Blue lead and the Black lead of hoist power

cord at power supply. Under no circumstances should the

internal wiring of the control device or hoist be changed to

reverse hook direction. The wiring is inspected and tested

before leaving the factory.

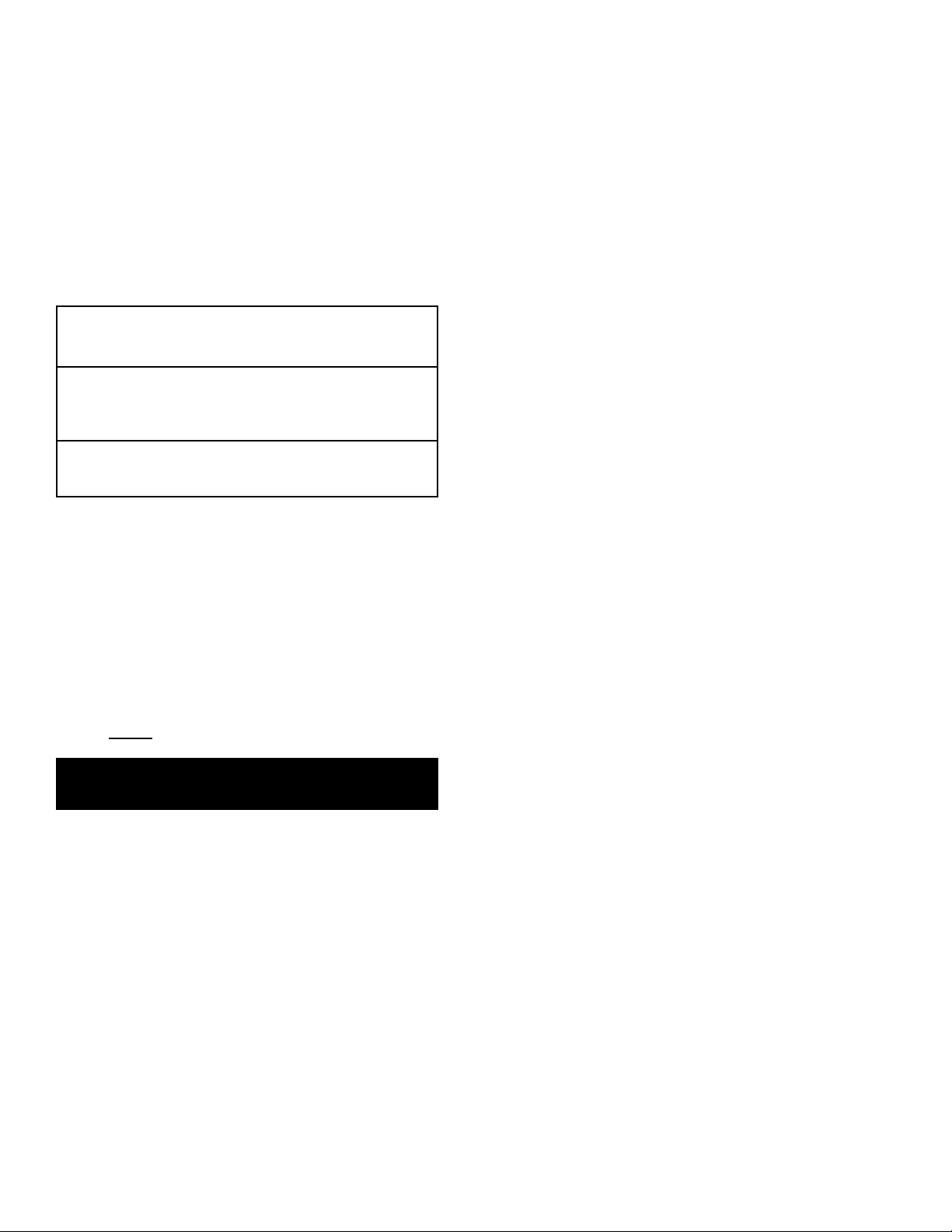

SINGLE SPEED UNITS

Low

Range Nominal

Volts

High

Range Nominal

Volts

380-415

400

220-240 230 440-460 460

5

Figure 12. Voltage Change Board

Figure 13. Location of Components

2

1

HIGH

VOLTAGE (RED)

LOW

VOLTAGE

(WHITE)

Do not force the Lodestar Protector to compensate for

improperly adjusted limit switches or reverse voltagephasing.

CHECKING FOR TWIST IN LOAD CHAIN Models R, RR

The best way to check for this condition is to run the lower

hook, without a load, up to within about 2 feet (.61 Meters) of

hoist. If the dead end of the chain has been properly installed,

a twist can occur only if the lower hook block has been capsized between the strands of chain. Reverse capsize to

remove twist.

CHECKING FOR ADEQUATE VOLTAGE AT HOIST

The hoist must be supplied with adequate electrical power in

order to operate properly. For proper operation, the voltage,

(measured at the hoist end of the standard power cord with

the hoist operating in the , up direction with full load) must

be as indicated in the table below.

SIGNS OF INADEQUATE ELECTRICAL POWER

(LOW VOLTAGE) ARE:

• Noisy hoist operations due to brake and/or contactor

chattering.

• Dimming of lights or slowing of motors connected to

the same circuit.

• Heating of the hoist motor and other internal compo-

nents as well as heating of the wires and connectors

in the circuit feeding the hoists.

• Failure of the hoist to lift the load due to motor stalling.

• Blowing of fuses or tripping of circuit breakers.

To avoid these low voltage problems, the hoist must be connected to an electrical power supply system that complies

with the National Electrical Code and applicable local codes.

This system must also provide (slow blow fuses or inversetime type circuit breakers) and provisions for grounding the

hoist.

Low voltage may also be caused by using an undersized

cord and/or connectors to supply power to the hoist. The following chart should be used to determine the size wires in

the extension cord in order to minimize the voltage drop

between the power source and the hoist.

Remember, operation with low voltage can void the CM

repair/replacement policy. When in doubt about any of the

electrical requirements, consult a qualified electrician.

WWAARRNNIINNGG

Allowing the hook block to run into the bottom of the hoist

when raising a load or allowing the chain to become taut

between the loose end screw and the frame when lowering

a load may break the chain and allow the load to drop.

TTOO AAVVOOIIDD IINNJJUURRYY::

Do not allow the hook block to contact the bottom of the

hoist or the loose end chain to become taut.

V

!!

NOMINAL

CURRENT

MINIMUM

RUNNING

VOLTAGE

MINIMUM

STARTING

VOLTAGE

230-3-60 187 460-3-60 396 220-3-50 198 380-3-50 365 415-3-50 399 -

6

WWAARRNNIINNGG

Failure to properly ground the hoist presents the danger of

electric shock.

TTOO AAVVOOIIDD IINNJJUURRYY::

Permanently ground the hoist as instructed in this manual.

V

!!

LENGTH

OF

EXTENSION

CORD

THREE

PHASE

HOISTS

MINIMUM

WIRE SIZE

UP TO 50 FEET #16 AWG

(1.6 mm)

80 FEET

(24.4 M)

#16 AWG

(1.6 mm)

120 FEET

(36.7 M)

#14 AWG

(2.0 mm)

200 FEET

(61.0 M)

#14 AWG

(2.0 mm)

300 FEET

(91.4 M)

#12 AWG

(2.7 mm)

For runs beyond 300 Feet contact factory.

WWAARRNNIINNGG

Failure to provide a proper power supply system for the

hoist may cause hoist damage and offers the potential for

a fire.

TTOO AAVVOOIIDD IINNJJUURRYY::

Provide each hoist with a 20 amp, minimum, overcurrent

protected power supply system per the National Electrical

Code and applicable local codes as instructed in this

manual.

V

!!

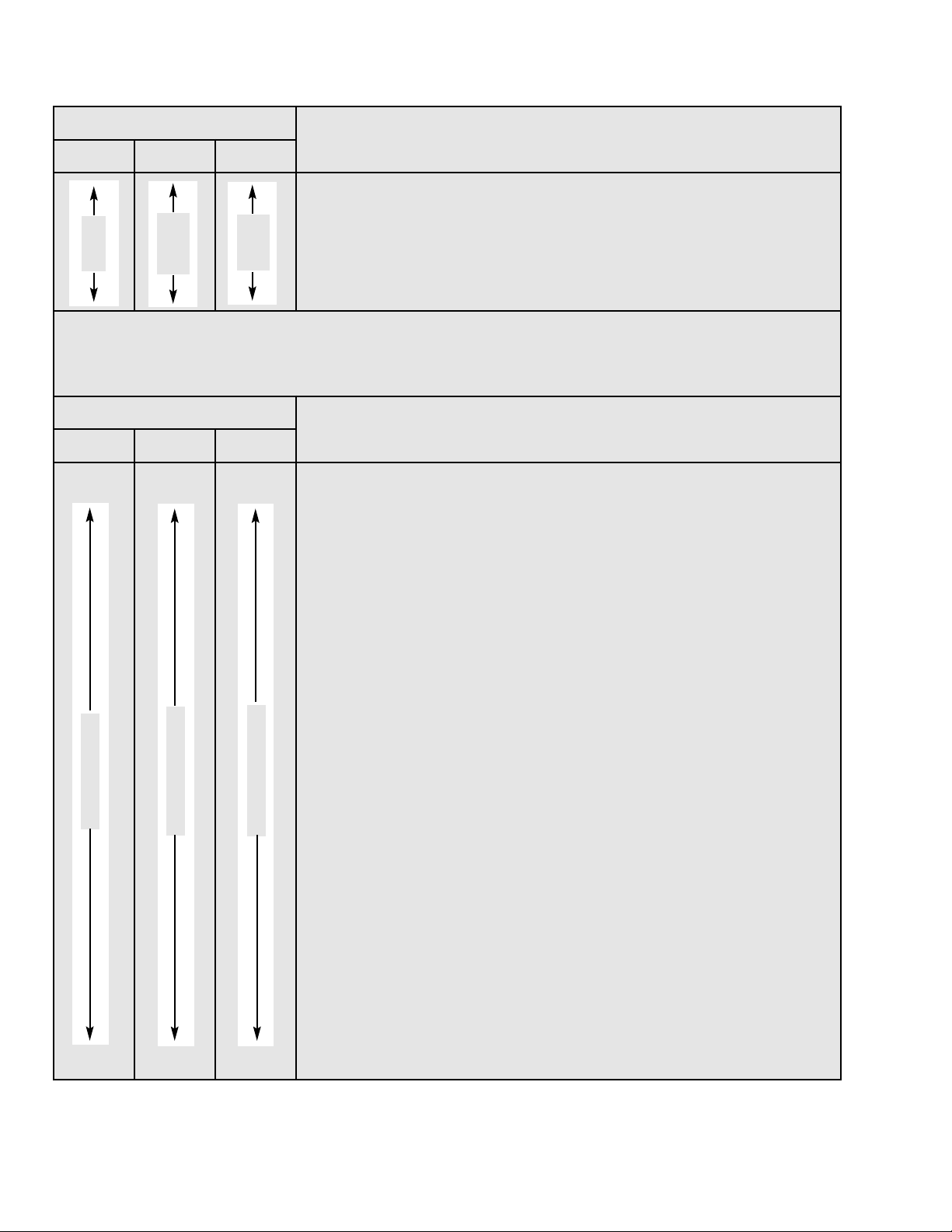

WWAARRNNIINNGG

TTOO AAVVOOIIDD IINNJJUURRYY::

Always disconnect the power cord from the power supply

system and lockout/tagout disconnecting means before

servicing the hoist. Working in or near exposed energized

electrical equipment presents the the danger of electric

shock.

CHECKING LIMIT SWITCH OPERATION IF HOIST IS

EQUIPPED

Operate hoist over the entire length of its rated lift, checking

upper and lower limit switches for correct operation as follows:

1. Press (UP) control and raise the lower hook until

top of hook block is about one foot (.30 M) below the

hoist.

2. Cautiously continue raising the hook until the upper

limit switch stops the upward motion. The upper limit

switch is set at the factory to stop the hook block 6

inches (152 mm) from the bottom of all hoists.

3. If adjustment is necessary, see page 12.

4. Press (DOWN) control and cautiously lower hook

until lower limit switch stops the downward motion.

Maintain a minimum of 24” (610 mm) of chain freely

hanging over the side of the hoist.

5. If adjustment is necessary, see page 12.

NOTE: If the hoist is equipped with a chain

container/bag, reset the upper and lower limit

switches as indicated on page 12.

Under no condition should the hook block or load

be permitted to come in contact with the chain

container/bag. If contact is made, the function of

the chain container can be interfered with and its

fasterners imperiled.

NOTE:

When chain bag is filled to capacity the

bag must be no more than 75% filled.

GENERAL

1. The Protector is designed to allow the intermediate gear

to slip on an excessive overload. An overload is indicated

when the hoist will not raise the load. Also, some clutching

noise may be heard if the hoist is loaded beyond rated

capacity. Should this occur, immediately release the

(UP) control to stop the operation of the hoist. At this

point, the load should be reduced to the rated hoist capacity

or the hoist should be replaced with one of the proper

capacity. When the excessive load is removed, normal

hoist operation is automatically restored.

CAUTION: The Protector is susceptible to overheating

and wear when slipped for extended periods. Under no

circumstance should the clutch be allowed to slip for

more than a few seconds.

Due to the above, a hoist equipped with a Protector is not recommended for use in any application where there is a possibility of adding to an already suspended load to the point of

overload. This includes dumbwaiter (*see below) installations, containers that are loaded in mid-air, etc.

(*) Refer to limitations on Page ii concerning dumbwaiter

applications.

Also, if a Lodestar Hoist with a Protector is used at unusual

extremes of ambient temperatures, above 66°C (150

0

F), or

below -9°C (15°F), changes in lubricant properties may permit the hoist to raise larger loads than under normal operating conditions and presents possibility of damage or injury.

2. With hoists that are equipped with an adjustable screw

limit switch, the limit switch will automatically stop the

hook at any predetermined point when either hoisting or

lowering.

OPERATING INSTRUCTIONS

HOIST

1. Check to ensure that the load point is in line with the hoist

head.

2. WHEN APPLYING A LOAD, IT MUST BE DIRECTLY

IN LINE WITH HOIST. AVOID OFF-CENTER LOADING

OF ANY KIND.

3. Take up a slack load chain carefully and start load easily

to avoid shock and jerking of hoist load chain. If there is

any evidence of overloading, immediately lower the load

and remove the excess load.

4. Do not allow the load to swing or twist while hoisting.

5. Do not allow the load and/or attachments to bear against

the hook latch.

SAFETY PROCEDURES

For safety precautions and a list of Do’s and Do Not’s for safe

operation of hoists, refer to page i.

1. When preparing to lift a load, be sure that the attachments

to the hook are firmly seated in hook saddle. Avoid off

center loading of any kind, especially loading on the point

of hook.

2. When lifting, raise the load only enough to clear the floor

or support and check to be sure that the attachments to

the hook and load are firmly seated. Continue lift only after

you are assured the load is free of all obstructions.

3. Do not load hoist beyond the rated capacity shown on

hoist identification plate or on the hoist motor housing

cover, Models B, C & F and on hoist back frame cover,

Models J, L, R, LL & RR. Overload can cause immediate

failure of some load-carrying part or create a defect

causing subsequent failure at less than rated capacity.

When in doubt, use the next larger capacity of CM

Lodestar Hoist.

4. Do not use this or any other overhead materials handling

equipment for lifting persons.

5. Warn personnel of your intention to lift a load in the area.

Tie off the load with auxiliary chains or cables before

access to the area beneath the load is permitted.

6. Permit only competent personnel to operate unit.

7. Do not wrap the load chain around the load and hook onto

itself as a choker chain.

Doing this will result in:

a. The loss of the swivel effect of the hook which could

result in twisted chain and a jammed lift wheel.

b. The upper limit switch, if so equipped, is by-passed

and the load could hit the hoist.

c. The chain could be damaged at the hook.

8. Before lifting load, check for twists in the load chain. Atwist

can occur if the lower hook block has been capsized

between the strands of chain. Reverse the capsize to

remove twist.

WWAARRNNIINNGG

Allowing the hook block to run into the bottom of the hoist

when raising a load or allowing the chain to become taut

between the loose end screw and the frame when lowering

a load may break the chain and allow the load to drop.

TTOO AAVVOOIIDD IINNJJUURRYY::

Do not allow the hook block to contact the bottom of the

hoist or the loose end chain to become taut.

V

!!

OPERATING INSTRUCTIONS

7

9. On single reeved chain hoist used in conjuction with head

blocks and ground support systems. Check for twists

between the hoist and head block. Twisted load can result

in a jammed liftwheel.

10.Do not allow the load to bear against the hook latch. The

latch is to help maintain the hook in position while the

chain is slack before taking up slack chain.

1 1.T ake up a slack load chain carefully and st art load easily to

avoid shock and jerking of hoist load chain. If there is any

evidence of overloading, immediately lower the load and

remove the excess load.

12. Do not allow the load to swing or twist while hoisting.

13. Never operate the hoist when flammable materials or

vapors are present. Electrical devices produce arcs or

sparks that can cause a fire or explosion.

14.STAYALERT! Watch what you are doing and use

common sense. Do not use the hoist when you are tired,

distracted or under the influence of drugs, alcohol or

medication causing diminished control.

To maintain continuous and satisfactory operation, a regular

inspection procedure must be initiated to replace worn or

damaged parts before they become unsafe. Inspection intervals must be determined by the individual application and are

based on the type of service to which the hoist will be subjected and the degree of exposure to wear, deterioration or malfunction of the critical components.

The type of service to which the hoist is subjected can be classified as “Normal”, Heavy”, or “Severe”.

Normal Service: Involves operation with randomly distributed

loads within the rated load limit, or uniform loads less than 65

percent of rated load for not more than 25 percent of the time.

Heavy Service: Involves operating the hoist within the rated

load limit which exceeds normal service.

Severe Service: Normal or heavy service with abnormal

operating conditions.

Two classes of inspection - frequent and periodic - must be

performed.

Frequent Inspections: These inspections are visual examinations by the operator or other designated personnel.

Records of such inspections are not required. The frequent

inspections are to be performed monthly for normal service,

weekly to monthly for heavy service, and daily to weekly for

severe service, and they should include those items listed in

Table 4.

Periodic Inspections: These inspections are visual inspections

of external conditions by an appointed person. Records of

periodic inspections are to be kept for continuing evaluation of

the condition of the hoist.

Periodic inspections are to be performed yearly for normal

service, semi-annually for heavy service and quarterly for

severe service, and they are to include those items listed in

Table 5.

CAUTION: Any deficiencies are to be corrected before

the hoist is returned to service. Also, the external conditions may show the need for disassembly to permit a

more detailed inspection, which, in turn, may require the

use of nondestructive type testing.

PREVENTIVE MAINTENANCE

In addition to the above inspection procedure, a preventive

maintenance program should be established to prolong the

useful life of the hoist and maintain its reliability and continued

safe use. The program should include the periodic and frequent inspections with particular attention being paid to the lubrication of the various components using the recommended

lubricants (see page 11).

HOOK INSPECTION

Hooks damaged from chemicals, deformations or cracks, or

that have more than a 10

o

twist from the hook’s unbent plane,

excessive opening or seat wear must be replaced. Also, hooks

that are opened and allow the latch to not engage the tip must

be replaced. Any hook that is twisted or has excessive throat

opening indicates abuse or overloading of the unit. Inspect

other load sustaining parts, hook block screws, load pins and

hook block bodies for damage.

On latch type hooks, check to make sure that the latch is not

damaged or bent and that it operates properly with sufficient

spring pressure to keep the latch tightly against the tip of the

hook and allow the latch to spring back to the tip when

released. If the latch does not operate properly, it should be

replaced. See Figure 14 to determine when the hook must be

replaced.

WWAARRNNIINNGG

Allowing the load to bear against the hook latch and/or hook

tip can result in loss of load.

TTOO AAVVOOIIDD IINNJJUURRYY::

Do not allow the load and/or attachments to bear against

the hook latch and/or hook tip. Apply load to hook bowl or

saddle only.

V

!!

INSPECTION

8

TYPE OF SERVICE

ITEM

Normal Heavy Severe

a) Brake for evidence of slippage.

b) Control functions for proper operation.

c) Hooks for damage, cracks, twists, excessive throat opening, latch engagement and latch

operation - see page 10.

d) Load chain for adequate lubrication, as well as for signs of wear, damaged links or foreign

matter - see page 10.

e) Load chain for proper reeving and twists.

Table 5. Minimum Periodic Inspections

TYPE OF SERVICE

ITEM

Normal Heavy Severe

a) All items listed in Table 4 for frequent inspections.

b) External evidence of loose screws, bolts or nuts.

c) External evidence of worn, corroded, cracked or distorted hook block, suspension screws,

gears, bearings and dead end block and chain pin.

d) External evidence of damage to hook retaining nut and pin. Also check the upper suspen-

sion adapter making sure it is fully seated in the hoist frame and that both screws are tight.

e) External evidence of damage or excessive wear of the liftwheel and hook block sheave

chain pockets. Widening and deepening of the pockets may cause the chain to lift-up in

the pocket and result in binding between liftwheel and chain guides or between the sheave

and hook block. Also, check the chain guide for wear or burring where the chain enters the

hoist. Severely worn or damaged parts should be replaced.

f) External evidence of excessive wear of brake parts, and brake adjustment - see page 11.

g) External evidence of pitting or any deterioration of contactor contacts. Check the opera-

tion of the control station making sure the buttons operate freely and do not stick in either

position.

h) Inspect the electrical cords and cables and control station enclosure for damaged insulation.

i) Inspect trolley trackwheels for external wear on tread and flange and for wear on internal

bearing surfaces as evidenced by a looseness on the stud. Suspension components for

damage, cracks, wear and operation. Also check suspension adapter screws for proper

tightness - see page 4.

j) Inspect the loose end link, loose end screw and dead end block on double reeved units.

Replace worn or distorted parts.

k) Inspect the suspension lug or hook for excess free play or rotation. Replace worn parts as

evidenced by excess free play or rotation.

l) Inspect for signs of lubricant leaks at the gasket between the gear housing and back

frame. tighten screws holding back frame to gear housing. If leak persists, repack housing

and gears with grease and install a new gasket.

Monthly

Weekly

to Monthly

Daily

to Weekly

Yearly

Every 6 Months

Every 3 Months

Table 4. Minimum Frequent Inspections

9

LOAD CHAIN

Chain should feed smoothly into and away from the hoist or

hook block. If chain binds, jumps or is noisy, first clean and

lubricate it (see below). If trouble persists, inspect chain and

mating parts for wear, distortion or other damage.

Chain Inspection

First Clean chain with a non-caustic/non-acid type solvent and

make a link by link inspection for nicks, gouges, twisted links,

weld splatter, corrosion pits, striations (minute parallel lines),

cracks in weld areas, wear and stretching. Chain with any one

of these defects must be replaced.

Slack the portion if the chain that normally passes over the liftwheel. Examine the interlink area for the point of maximum

wear (polishing, see Figure 15). Measure and record the stock

diameter at this point of the link. Then measure stock diameter

in the same area on a link that does not pass over the liftwheel

(use the link adjacent to the loose end link for this purpose).

compare these two measurements. If the stock diameter of the

worn link is 0.010 inches (0.254 mm), or more, less than the

stock diameter of the unworn link, the chain must be replace.

On double reeved units, repeat this examination of the chain

that passes through the hook block.

Also check chain for stretch using a vernier caliper as shown

in Figure 16. Select an unused, unstretched section of chain

(usually at the lose end) and measure and record the length

over 11 chain links (pitches). Measure and record the same

length on a worn section of the chain. Obtain the amount of

stretch and wear by subtracting the measurement of the worn

section. If the result (amount of stretch and wear) is greater

than 0.145 inch (3.7mm), the chain must be replaced.

Use only a “Knife-edge” caliper to eliminate possibility of false

reading by not measuring full pitch length.

Note that worn chain can be an indication of worn hoist components. For this reason, the hoist’s chain guide, hook block

and liftwheel should be examined for wear and replaced as

necessary when replacing worn chain.

Also, these chains are specially heat treated and hardened

and should never be repaired.

UUssee oonnllyy SSttaarr ((**)) ggrraaddee llooaadd cchhaaiinn aanndd oorriiggiinnaall rreeppllaacceemmeenntt

ppaarrttss.. UUssee ooff ootthheerr cchhaaiinn aanndd ppaarrttss mmaayy

bbee ddaannggeerroouuss aanndd

vvooiiddss ffaaccttoorryy wwaarrrraannttyy..

IMPORT ANT:

Do not use replaced chain for other purposes such as lifting or pulling. Load chain may break suddenly without visual deformation. For this reason, cut replaced

chain into short lengths to prevent use after disposal.

10

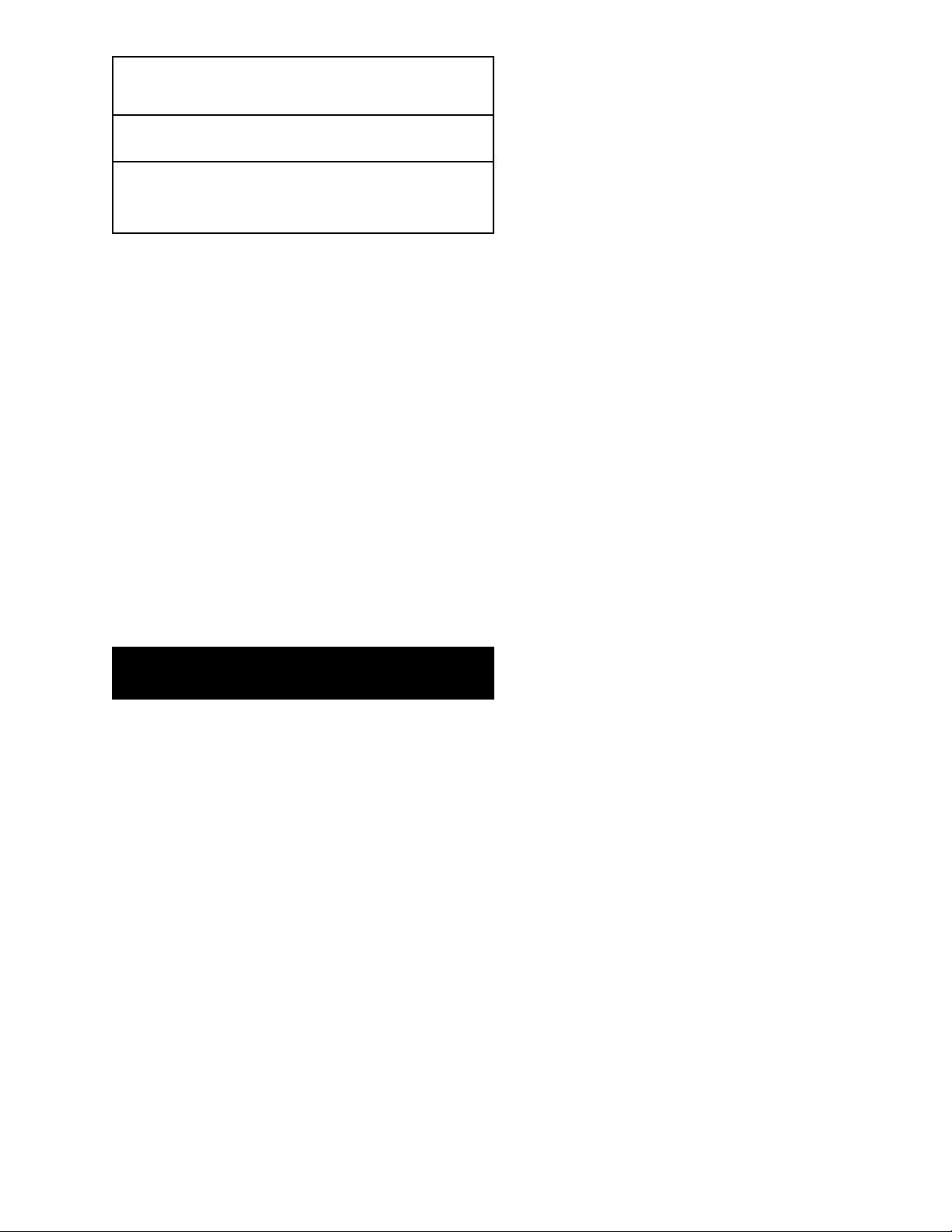

Figure 14. Hook Inspection

MEASURE

OPENING

LATCH TYPE HOOK

(Upper and Lower)

TO MEASURE OPENING,

DEPRESS LATCH AGAINST

HOOK BODY AS SHOWN.

LATCHLOCK®TYPE HOOK

(UPPER AND LOWER)

“A”

“B” Max.

Models

Replace Hooks

When Opening

is Greater

Than

B, C AND F

1 3/16 (30.2mm)

J, L, AND LL

1 5/16 (33.3mm)

R AND RR

1 1/2 (38.1mm)

Models

Replace Hook

When Opening

or Seat are:

B, C, F, J, L, AND LL

“A” Max “B” Max

1 31/64 in.

(37.7mm)

2 1/32 in.

(51.6mm)

R AND RR

1 59/64 in.

(48.8mm)

27/32 in.

(21.4mm)

Figure 15. Chain Wear Areas

WWAARRNNIINNGG

Use of commerical or other manufactures’ chain and parts

to repair Lodestar Hoists may cause load loss.

TTOO AAVVOOIIDD IINNJJUURRYY::

Use only factory supplied replacement load chain and parts.

Chain and parts may look alike, but factory original chain

and parts are made of specific materials or processed to

achieve specific properties. See Figure 17.

V

!!

Figure 17. Chain Embossing

Figure 16. Chain Inspection

PROTECTOR

The Protector should operate for the normal life of the hoist

without service. The device has been lubricated and calibrated

at the factory for a specific model of hoist and is not adjustable

or interchangeable with other models. For proper overload protection, be sure before installing a Protector that it is correct for

the unit. The spring washer of the Protector had been color

coded at the factory as follows:

HOIST LUBRICATION

GEARS

NOTE: To assure extra long life and top performance, be

sure to lubricate the various parts of the Lodestar Hoist

using the lubricants specified below. If desired, these

lubricants may be purchased from CM. Refer to page 29

for information on ordering the lubricants.

• The Protector should operate for the normal life of the

hoist without service. The device has been lubricated and

calibrated at the factory for a specific model of Lodestar

Hoist and is not adjustable or interchangeable with other

models.

CAUTION: The Protector is to be used with “Century

Lubricants HB-1 1 #3” grease. Do not use any other grease

or the Protector will not operate properly and parts could

be damaged.

The gears and Protector (627-327 and 627-328) are packed at

assembly with grease and should not need to be renewed

unless the gears have been removed from the housing and

degreased.

CAUTION: Never degrease the Protector or attempt to

disassemble this device. Degreasing the Protector may

damage parts and using a device that has been degreased

may cause erratic, inconsistent operation. If the Protector

has been degreased, it must be replaced by a factory

calibrated device.

If the gears are removed from the housing, wipe the excess

grease off the outside surfaces of the Protector with a soft cloth

and degrease the remaining gears and housings. Upon

reassembly, add 7 oz. of the above grease to gears and housing. Also, coat the spline on the end of the drive shaft (627-311)

with a Molydisulphide lubricant such as “Super Herculon”.

For Models LL, and RR, see page 22 for special gearing alignment instructions.

• The limit switch gears are of molded nylon and require no

lubrication.

• Apply a light film of machine oil to the limit switch shaft

threads (627-220, page 28) at least once a year.

BEARINGS

• All bearings and bushings, except the lower hook thrust

bearing, are pre-lubricated and require no lubrication.

The lower hook thrust bearing should be lubricated at

least once a month.

CHAIN GUIDES, LIFTWHEELAND LOWER SHEAVE WHEEL

• When the hoist is disassembled for inspection and/or

repair, the chain guides, lower sheave wheel (on double

chain units) and liftwheel must be lubricated with . . . .

Lubriplate Bar and Chain Oil 10-R (Fiske Bros. Refining

Co. or equivalent) prior to reassembly. The lubricant must

be applied in sufficient quantity to obtain natural runoff and

full coverage of these parts.

LOAD CHAIN

Asmall amount of lubricant will greatly increase the life of load

chain. Do not allow the chain to run dry.

Keep it clean and lubricate at regular intervals with

Lubriplate Bar and Chain Oil 10-4 (Fiske Bros. Refining Co.)

or equal lubricant. Normally, weekly lubrication and cleaning

is satisfactory, but under hot and dirty conditions, it may be

necessary to clean the chain at least once a day and lubricate it several times between cleanings.

When lubricating the chain, apply sufficient lubricant to obtain

natural run-off and full coverage, especially in the interlink

area.

ELECTRIC BRAKE ASSEMBLY

The correct air gap between armature and field, when brake

is not energized, is 0.025 inch (.635mm) and need not be

adjusted until the gap reaches 0.045 inch (1.143mm). When

checking brake gap, always reset to .025 inch (.635 mm).

To adjust the brake, proceed as follows:

1. Disconnect hoist from power supply.

2. Remove back frame cover, see figure 13

3. Before adjusting the gap: a) back off the stud nuts

and examine friction linings and friction surfaces for

excessive wear (min. thickness .188 inch, 4.78mm),

scoring or scoring or warpage. b) Check shading

coils to be sure they are in place and not broken. A

missing or broken shading coil will cause the brake

to be noisy when hoist is operated. Any of these

symptoms indicate the need for replacement parts.

MAINTENANCE

WWAARRNNIINNGG

Used motor oils contain known carcinogenic materials.

TTOO AAVVOOIIDD HHEEAALLTTHH PPRROOBBLLEEMMSS::

Never use used motor oils as a chain lubricant. Only use

Lubriplate Bar and Chain Oil 10-R as a lubricant for the load

chain.

V

!!

11

WWAARRNNIINNGG

The lubricants used in and recommended for the Lodestar

Hoist may contain hazardous materials that mandate

specific handling and disposal procedures.

TTOO AAVVOOIIDD CCOONNTTAACCTT AANNDD CCOONNTTAAMMIINNAATTIIOONN::

Handle and dispose of lubricants only as directed in applicable material safety data sheets and in accordance with

applicable local, state and federal regulations.

V

!!

Models Protector Color Code No. of Teeth on

Gear

B White 63

C, F Orange 63

J Red 71

L, R Green 92

LL, RR Yellow 92

WWAARRNNIINNGG

DO NOT REMOVE PROTECTOR SNAP RING

Removing the snap ring on the Protector assembly will

allow the parts to spring apart. Personal injury may occur.

TTOO AAVVOOIIDD IINNJJUURRYY::

Do not attempt to disassemble the Protector.

V

!!

Loading...

Loading...