CM-ET 653 User Manual [en, es, fr]

OPERATING, MAINTENANCE &

PARTS MANUAL

MANUAL DE FUNCIONAMIENTO,

MANTENIMIENTO Y PIEZAS

MANUEL D'ENTRETIEN,

D'OPÉRATION ET DE PIÈCES

HAND OPERATED LEVER HOIST

POLIPASTO MANUEL DE PALANCA

PALANS MANUELS À LEVIER

Before installing hoist, fill in the information below.

Antes de instaar el polipasto, rellene los datos siguientes.

Enregistrez les informations suivantes avant de faire l'installation

Rated Load/Carga nominal/Charge nominale

Serial No./Nº de serie/No. de Ser.

Purchase Date/Fecha de compra/Date d'achat

Capacidades de Carga:

3/4, 1,1½, 2, 3 y 6 toneladas

(750, 1000, 1500, 2000, 3000

y 6000 kg.)

Siga todas las instrucciones y

advertencias para inspeccionar,

mantener y operar éste polipasto.

El uso de cualquier polipasto presenta

algunos riesgos de daños a las personas o

a las cosas. Este riesgo se ve

incrementado si no se siguen

correctamente las instrucciones y

advertencias. Antes de usar el polipasto

el operario debería estar familiarizado

con todas las advertencias, instrucciones y

recomendaciones de éste manual.

Guarde éste manual para futuras

consultas.

Entregue éste manual al operario. Si el

equipo no se maneja tal y como se

recomienda en el presente manual, es

posible que se produzcan situaciones de

peligro que pueden resultar en daños

personales.

Charges nominales:

3/4, 1, 1½, 2, 3 et 6 tonnes

(750, 1000,1500, 2000, 3000

et 6000 kg.)

Veuillez vous conformer à toutes les

instructions et avertissements

d'inspection, d'entretien et d'opération

de ce palan.

L'utilisation de tout appareil de levage

comporte des risques de blessures ou de

dégâts matériels. Ces risques sont de

beaucoup accrus si les instructions et

avertissements ne sont pas suivis.Tous

les opérateurs devraient se familiariser

Complètement avec toutes les

recommandations Instructions et

avertissements de ce manuel avant

d'utiliser ce palan. Conservez ce

manuel pour utilisation et référence

future.

Remettre ce manuel à l'opérateur.

L'utilisation de cet équipement

contrairement aux directives de ce

manuel peut causer des blessures.

53855

Manual No. 653-B

Series 653

®

Rated Loads:

3/4, 1, 1½, 2, 3 and 6 ton

(750, 1000, 1500, 2000,

3,000 and 6,000 kg.)

Follow all instructions and

warnings for inspecting,

maintaining and operating this

hoist.

The use of any hoist presents some

risk of personal injury or property

damage. That risk is greatly

increased if proper instructions and

warnings are not followed. Before

using this hoist, each operator

should become thoroughly familiar

with all warnings, instructions and

recommendations in this manual.

Retain this manual for future

reference and use.

Forward this manual to operator.

Failure to operate equipment as

directed in manual may cause injury.

LEVER HOIST

Note: When ordering parts, always furnish rated load and serial number of hoist on which the parts are to be used.

To quickly obtain the name of the Master Parts Depot or Service Center located nearest you, call (800) 888-0985. Fax: (716) 689-5644.

LIMITATION OF WARRANTIES, REMEDIES AND DAMAGES

THE WARRANTY STATED BELOW IS GIVEN IN PLACE OF ALLOTHER WARRANTIES,

EXPRESS OR IMPLIES, OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, NO PROMISE OR AFFIRMATION OF FACTMADE BY

ANYAGENT OR REPRESENTATIVE OF SELLER SHALL CONSTITUTE AWARRANTY

BY SELLER OR GIVE RISE TO ANYLIABILITY OR OBLIGATION.

Seller warrants that on the date of delivery to carrier the goods are free from defects in

workmanship and materials.

SELLER’S SOLE OBLIGATION IN THE EVENTOF BREACH OF WARRANTYOR

CONTRACT OR FOR NEGLIGENCE OR OTHERWISE WITH RESPECT TO GOODS

SOLD SHALL BE EXCLUSIVELYLIMITED TO REPAIR OR REPLACEMENT, F.O.B.

SELLER’S POINT OF SHIPMENT, OF ANY PARTS WHICH SELLER DETERMINES TO

HAVE BEEN DEFECTIVE or if Seller determines that such repair or replacement is not

feasible, to a refund of the purchase price upon return of the goods to Seller.

Any action against Seller for breach of warranty, negligence or otherwise, must be

commenced within one year after such cause of action occurs.

NO CLAIM AGAINSTSELLER FOR ANYDEFECT IN THE GOODS SHALL BE VALID OR

ENFORCEABLE UNLESS BUYER’S WRITTEN NOTICE THEREOF IS RECEIVED BY

SELLER WITHIN ONE YEAR FROM THE DATE OF SHIPMENT.

Seller shall not be liable for any damage, injury or loss arising out of the use of the goods, if,

prior to such damage, injury or loss, such goods are (1) damaged or misused following

Seller’s delivery to carrier; (2) not maintained, inspected, or used in compliance with applicable law and Seller’s written instructions and recommendations; or (3) installed, repaired,

altered or modified without compliance with such law, instructions or recommendations.

UNDER NO CIRCUMSTANCES SHALLSELLER BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES AS THOSE TERMS ARE DEFINED IN SECTION 2-715 OF

THE UNIFORM COMMERCIAL CODE.

INDEMNIFICATION AND SAFE OPERATION

Buyer shall comply with and require its employees to comply with directions set forth in

instructions and manuals furnished by Seller and shall use and require its employees to follow

such instructions and manuals and to use reasonable care in the use and maintenance of the

goods. Buyer shall not remove or permit anyone to remove any warning or instruction signs

on the goods. In the event of personal injury or damage to property or business arising from

the use of the goods, Buyer shall within 48 hours thereafter give Seller written notice of such

injury or damage. Buyer shall cooperate with Seller in investigating any such injury or

damage and in the defense of any claims arising therefrom.

If Buyer fails to comply with this section or if any injury or damage is caused, in whole or in

part, by Buyer’s failure to comply with applicable federal or state safety requirements, Buyer

shall indemnify and hold Seller harmless against any claims, loss or expense for injury or

damage arising from the use of the goods.

Nota: Cuando solicite piezas de repuesto proporcione siempre la carga nominal y el número de serie del polipasto para el que se solicitan las piezas.

Para obtener la dirección del almacén de piezas de repuesto o del centro de servicio más cercano, llame al teléfono (800) 888-0985. Fax: (716) 689-5644.

LIMITACIÓN DE GARANTÍAS, VÍAS Y DAÑOS

ESTAGARANTÍAES LAÚNICAGARANTÍAVÁLIDAY ANULA CUALQUIER OTRA

EXPRESA O IMPLÍCITADE APROVECHAMIENTO, APTITUD PARA UN PROPÓSITO

ESPECÍFICO O CUALQUIER OTRA, SIN PROMESA NI AFIRMACIÓN DE HECHO

REALIZADA POR CUALQUIER AGENTE O REPRESENTANTE DEL VENDEDOR QUE

CONSITUYAUNAGARANTÍAPOR PARTE DELVENDEDOR NO REPRESENTARÁ

NINGUNA OBLIGACIÓN O RESPONSABILIDAD.

El vendedor garantiza que en la fecha de entrega del producto al transportista éste está

libre de defectos de materiales o de mano de obra.

LA ÚNICA OBLIGACIÓN DEL VENDEDOR EN CASO DE INCUMPLIMIENTO DE LA

GARANTÍA O CONTRATO POR NEGLIGENCIAO POR CUALQUIER OTRO MOTIVO

CON RESPECTO ALOS BIENES VENDIDOS ESTARÁ LIMITADAEXCLUSIVAMENTE

A LA REPARACIÓN O CAMBIO DESDE EL PUNTO DE ENVÍO DELVENDEDOR, DE LAS

PIEZAS QUE EL VENDEDOR DETERMINE QUE SON DEFECTUOSAS o bien, si el

Vendedor determina que tales reparaciones o cambios no son feacibles, devolverá al

Comprador el importe del precio abonado cuando el Comprador devuelva la mercancía la

Vendedor.

Cualquier acción contra el Vendedor por incumplimiento de la garantía, negligencia o por

cualquier otro motivo deberá iniciarse el mismo año en que tal acción tenga lugar.

SI LAS RECLAMACIONES CONTRA EL VENDEDOR POR CAUSA DE CUALQUIER

DEFECTO DE LOS PRODUCTOS NO SE REALIZAMEDIANTE UN ESCRITO POR

PARTE DELCOMPRADOR EN ELMISMO AÑO DE LA FECHA DE ENVÍO NO SERÁ

VÁLIDA NI SE PODRÁ EJECUTAR.

El Vendedor no se responsabiliza de los daños, pérdidas o lesiones resultantes del uso de

los productos si anteriormente a dichos daños, pérdidas o lesiones tales productos están (1)

dañados o se ha hecho un uso indebido después de la entrega por parte del Vendedor al

transportista; (2) no se ha mantenido, inspeccionado o utilizado de acuerdo a las leyes

aplicables y a las instrucciones y recomendaciones por escrito proporcionadas por el

Vendedor; o (3) se ha instalado, reparado, alterado o modificado fuera del ámbito de dichas

leyes, instrucciones o recomendaciones.EL VENDEDOR NO SE RESPONSABILIZARÁ EN

NINGÚN CASO DE DÑAOS INCIDENTALES O CONSECUENCIALES DISTINTOS A LOS

TÉRMINOS EXPUESTOS EN LASECCIÓN 2-715 DEL CÓDIGO DE COMERCIO.

INDEMNIZACIÓN Y FUNCIONAMIENTO SEGURO

El comprador cumplirá con las indicaciones descritas en las instrucciones y en los manuales

proporcionados por el Comprador y se preocupará de que sus empleados las cumplan y

usen y mantengan de forma razonable los bienes. El Comprador no retirará ni permitirá la

retirada de ninguno de los signos de advertencia o instrucción que aparecen en los bienes.

En el caso de que se produzcan daños personales o en la propiedad o negocio derivados

del uso de los bienes, el Comprador deberá notificarlo por escrito al Vendedor en la 48

horas siguientes a la producción de dichos daños o lesiones. El Comprador deberá

cooperar con el Vendedor en la investigación de tales daños o lesiones y en la defensa de

cualquier petición reultante de las mismas.

Si el Comprador no cumple con esta sección o si se causa cualquier tipo de daño o lesión,

en todo o en parte, por causa incumplimiento de los requisitos de esguridad estatales o

locales por parte del Comprador, el Comprador deberá indemnificar y mantener la inocencia

del Vendedor contra cualquier petición, pérdida o gasto por lesiones o daños resultantes del

uso de los bienes.

Note : Mentionnez toujours la charge nominale du palan, et son no. de série lorsque vous commandez des pièces de rechange.

Appelez le (800) 888-0985. Fax: (716) 689-5644 pour obtenir rapidement le nom du dépôt de pièces maîtresses ou du centre de service situé le

plus près.

DOMMAGES, CORRECTIFS ET LIMITATION DE GARANTIE--

LAGARANTIE ÉNONCÉE CI-DESSOUS REMPLACE TOUTE AUTRE GARANTIE

EXPRESSE OU IMPLICITE, DE PROMOTION, D'APPLICATION P ARTICULIÈRE OU

AUTRE; ETAUCUNE AUTRE PROMESSE OU AFFIRMA TION DE F AITFAITE PAR

QUELQUE AGENTOU REPRÉSENT ANTDE MAISON DE VENTE NE

CONSTITUERAUNE GARANTIE P AR LE VENDEUR OU DONNERALIEU À

QUELQUE OBLIGATION OU RESPONSABILITÉ.

Le vendeur garantit que le matériel est libre de défaut de matériau ou de

main-d'œuvre à la date de remise au transporteur.

EN CAS DE RÉCLAMATION DE GARANTIE OU DE DÉFAUT DÛ À LA

NÉGLIGENCE OU AUTRE CONCERNANTLE MATÉRIELVENDU, LA

SEULE OBLIGATION DU VENDEUR SERALIMITÉE EXCLUSIVEMENTÀ

LA RÉPARATION OU AU REMPLACEMENTAU POINTDE VENTE F.A.B.

DE TOUTE PIÈCE JUGÉE DÉFECTUEUSE PAR LE VENDEUR ou si le

vendeur détermine que telle réparation ou remplacement n'est pas réalisable,

à un remboursement du prix d'achat sur retour du matériel au vendeur.

Toute action contre le vendeur pour cause de négligence de respect de

contrat ou autrement doit être entamée en dedans d'un an de la cause de la

réclamation.

AUCUNE RÉCLAMATION AU VENDEUR POUR TOUT DÉFAUT DU

MATÉRIELNE SERAVALIDÉE OU ADMISSIBLE À MOINS QU'UN AVIS

ÉCRIT SOIT REÇU PAR LE VENDEUR EN DEDANS D'UN AN DE LADATE

D'EXPÉDITION.

Le vendeur ne sera responsable d'aucun dommages, blessure ou perte

résultant de l'utilisation du matériel si au préalable de tel dommages,

blessures ou pertes le dit matériel est (1) endommagé ou utilisé de façon

inadéquate après sa remise au transporteur; (2) non entretenu, inspecté ou

utilisé en accord avec les règlements applicables et les instructions et

recommandations écrites du vendeur; ou (3) installé, réparé, altéré ou modifié

sans respecter de tels règlements, instructions ou recommandations.

LE VENDEUR NE PORTERAEN AUCUN CAS LARESPONSABILITÉ POUR

DOMMAGES CONSÉCUTIFS ET D'INCIDENCE SELON LA DÉFINITION DE

CES TERMES À LASECTION 2-715 DU CODE UNIFORME DE PRATIQUES

COMMERCIALES ("UNIFORM COMMERCIAL CODE")

OPÉRATION SÉCURITAIRE ET INDEMNISATION

L'acheteur devra se conformer et obtenir de ses employés de se conformer aux directives

établies dans les manuels et instructions fournis par le vendeur et devra utiliser et obtenir de

ses employés l'observance de ces manuels et instructions et de prendre un soin

raisonnable à l'utilisation et l'entretien du matériel. L'acheteur ne devra pas enlever ou

permettre à quiconque d'enlever tout affichage d'instruction ou d'avertissement sur le

matériel. En cas de blessure ou de dommages à la propriété ou commerce dû à l'utilisation

du matériel, l'acheteur doit aviser le vendeur par écrit en moins de 48 heures de l'incident.

L'acheteur devra coopérer avec le vendeur dans l'investigation de cause de telles blessures

ou dommages et pour la défense contre toute réclamation résultante.

Si l'acheteur ne se conforme pas à cette section ou si toute blessure ou

dommage est causé en partie ou en entier par le manque de l'acheteur de se

conformer aux exigences de sécurité fédérales ou provinciales applicables,

l'acheteur devra indemniser et dégager le vendeur de toute réclamation, pertes

ou dépenses pour blessures ou dommages résultant de l'utilisation du matériel.

Columbus McKinnon Corporation Industrial Products Division 140 John James Audubon Parkway

Amherst, New York 14228-1197 1-800-888-0985 Fax 716-689-5644

Printed in USA

®

©

2004 Columbus Mckinnon Corp.

i

CM HOIST PARTS AND SERVICES ARE AVAILABLE

IN THE UNITED STATES AND IN CANADA

As a CM Hoist and Trolley user you are assured of reliable repair and parts services through a network of

Master Parts Depots and Service Centers that are strategically located in the United States and Canada.

These facilities have been selected on the basis of their demonstrated ability to handle all parts and

repair requirements promptly and efficiently. To quickly obtain the name of the Master Parts Depot or

Service Center located nearest you, call (800) 888-0985. Fax: (716) 689-5644.

LAS PIEZAS Y REPARACIONES DE LOS POLIPASTOS DE CM

ESTÁN ASEGURADAS EN ESTADOS UNIDOS Y CANADÁ

Como usuario de un polipasto y carro de CM le aseguramos cualquier reparación o la disponibilidad de

cualquier pieza de repuesto a través de una red de almacenes de piezas de repuesto y centros de servicio

situados estratégicamente en Estados Unidos y Canadá. Estas instalaciones se han seleccionado en base a

su capacidad demostrada en la reparación de equipos y suminstro de piezas de repuesto de forma

rápida y eficaz. Para obtener la dirección del almacén de piezas de repuesto o del centro de servicio más

cercano, llame al teléfono (800) 888-0985. Fax: (716) 689-5644 (sólo en Estados Unidos y Canadá).

LE SERVICE DE RÉPARATION ET DE PIÈCES POUR PALANS CM EST DISPONIBLE

AUX ÉTATS-UNIS ET AU CANADA

Soyez assurés qu’en temps d’utilisateur de palan et treuil CM, d’un service de réparation et de pièces

fiable par l’entremise d’un réseau de Centres de service et de Dépôts de pièces maîtresses qui sont

stratégiquement situés aux États-Unis et au Canada. Ces établissements ont été sélectionnés sur une base

de leur habileté démontrée à s’occuper promptement et efficacement des besoins de réparation de

pièces. Appelez le (800) 888-0985. Fax: (716) 689-5644 pour obtenir rapidement le nom du dépôt de

pièces maîtresses ou du centre de service situé le plus près.

1

Improper operation of a hoist can create a

potentially hazardous situation which, if not

avoided, could result in death

, or serious injury. To

avoid such a potentially hazardous situation, the

operator shall:

1. NOT operate a malfunctioning or unusually performing

hoist.

2. NOT operate the hoist until you have thoroughly read

and understood this manual.

3. NOT operate a hoist which has been modified without

the manufacturer’s approval or certification to be in

conformity with applicable OSHA regulations.

4. NOT lift or pull more than rated load for the hoist.

5. NOT use damaged hoist or hoist that is Not working

properly.

6. NOT use hoist with twisted, kinked, damaged, or worn

load chain.

7. NOT operate with any lever extension (cheater bar).

8. NOT attempt to “free chain” the hoist while a load is

applied.

9. NOT use the hoist to lift, support, or transport people.

10. NOT lift loads over people and make sure all personnel

remain clear of supported load.

11. NOT attempt to lengthen the load chain or repair damaged load chain.

12. Protect the hoists load chain from weld splatter or other

damaging contaminants.

13. NOT operate a hoist when it is restricted from forming a

straight line from hook to hook in the direction of loading.

14. NOT use load chain as a sling or wrap load chain around

load.

15. NOT apply the load to the tip of the hook or to the

hook latch.

16. NOT apply load unless load chain is properly seated in

the chain wheel(s) or sproket(s).

17. NOT apply load if bearing prevents equal loading on all

load supporting chains.

18. NOT operate beyond the limits of the load chain travel.

19. NOT leave load supported by the hoist unattended

unless specific precautions have been taken.

20. NOT allow the chain or hook to be used as an electrical

or welding ground.

21. NOT allow the chain or hook to be touched by a live

welding electrode.

22. NOT remove or obscure the warnings on the hoist.

23. NOT operate a hoist which has Not been securely

attached to a suitable support.

24. NOT operate a hoist unless load slings or other approved

single attachments are properly sized and seated in the

hook saddle.

25. NOT lift loads that are Not balanced and the holding action is Not secure, taking up slack carefully.

26. NOT operate a hoist unless all persons are and remain

clear of the supported load.

27. Report malfunctions or unusual performances of a hoist,

after it has been shut down until repaired.

28. NOT operate a hoist on which the safety placards or

decals are missing or illegible.

29. Be familiar with operating controls, procedures and

warnings.

Improper operation of a hoist can create a

potentially hazardous situation which, if not

avoided, could result in minor

or moderate injury. To

avoid such a potentially hazardous situation, the

operator shall:

1. Maintain a firm footing or be otherwise secured when

operating the hoist.

2. Check brake function by tensioning the hoist prior to each

lift or pulling operation.

3. Use hook latches. Latches are to retain slings, chains, etc.

under slack conditions only.

4. Make sure the hook latches are closed and not supporting

any parts of the load.

5. Make sure the load is free to move and will clear all

obstructions.

6. Avoid swinging the load or hook.

7. Avoid lever “fly-back” by keeping a firm grip on the lever

until operating stroke is completed and lever is at rest.

8. Inspect the hoist regularly, replace damaged or worn parts,

and keep appropriate records of maintenance.

9. Use Columbus McKinnon parts when repairing the

unit.

10. Lubricate load chain as recommended in this manual.

11. NOT operate except with manual power.

12. NOT permit more than one operator to pull on lever at

the same time. More than one operator is likely to cause

hoist overload.

13. NOT allow your attention to be diverted from operating

the hoist.

14. NOT allow the hoist to be subjected to sharp contact with

other hoists, structures, or objects through misuse.

15. NOT adjust or repair the hoist unless qualified to perform

such adjustments or repairs.

T

he hoists are intended for general industrial use for

moving loads within their load ratings. Prior to

installation and operation, the user should review

the application for abnormal environmental or

handling conditions.

GENERAL SAFETY INFORMATION

ADVERSE ENVIRONMENTAL CONDITIONS

Do not use the hoists in areas containing flammable

vapors, liquids, gasses or any combustible dust or fibers. Do

not use the hoist in highly corrosive, abrasive, wet

environments or in applications involving exposure to

temperatures below -10 or above 130

o

F.

MOVING HAZARDOUS LOADS

The hoists are not recommended for lifting materials that

could cause widespread damage if dropped. The lifting or

moving of materials that could explode or cause chemical

or radioactive contamination requires fail-safe, redundant

supporting devices that are not incorporated into these

hoists.

2

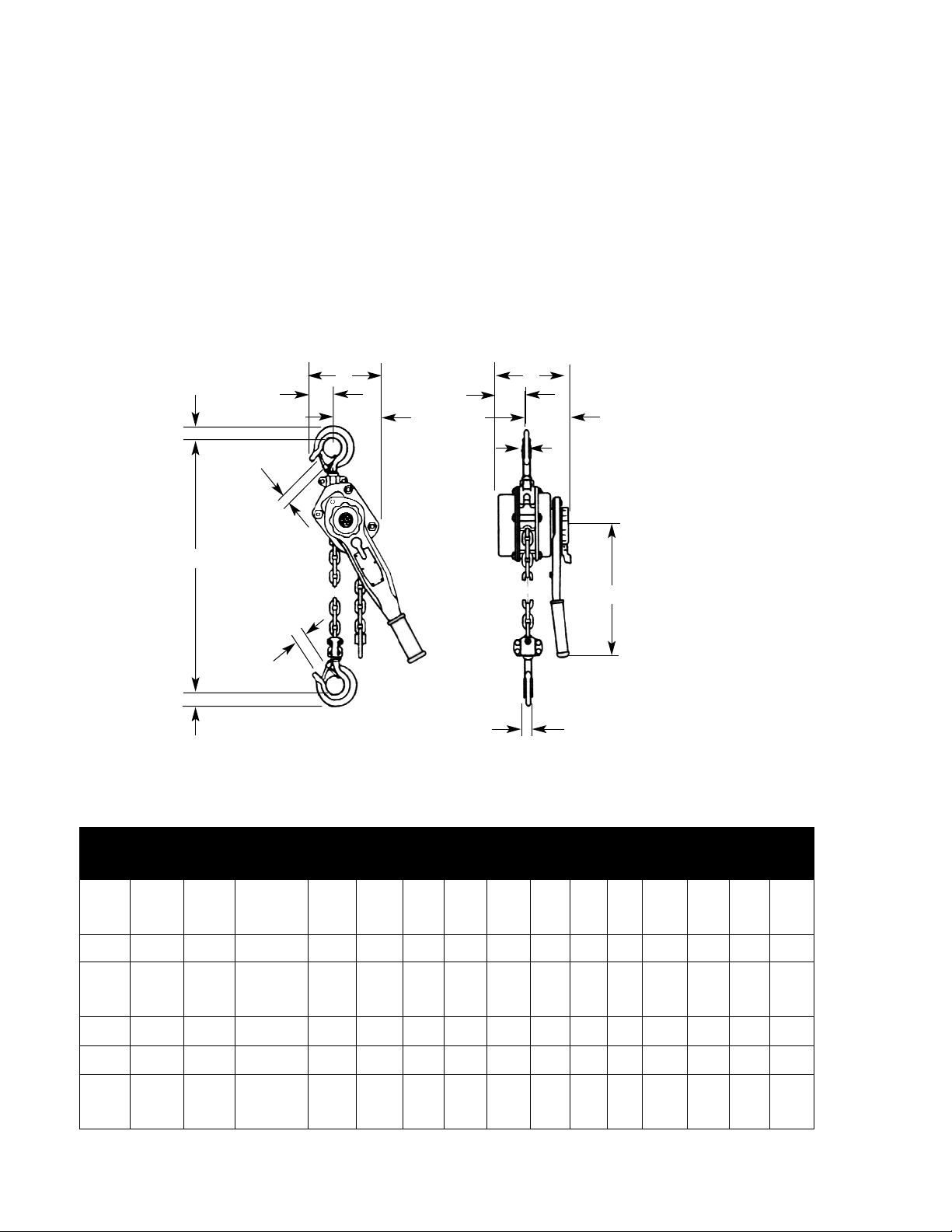

Figure 2 - Specifications

Specifications

E

C

C

B

B

D

D

K

L

A

F

G

J

H

Description

Series 653 Hand Operated Lever Hoists are highly versatile tools that can be used in any position to efficiently pull, lift, drag

or stretch. The frame, covers and lever are made from steel stampings. The gears are heat treated steel, upper and lower

hooks are forged steel and the chain is heat treated, welded link type.

Hoist with load ratings of 3/4, 1, 1½, 2 and 3 ton are available and this manual applies to all of these units. The hoists are

available with 5, 10, 15 and 20 foot long chains.

Hooks with latches are standard on all units.

Series 653 Hand Operated Lever Hoists are built in accordance with the specification contained herein and at the time of

manufacture complies with the applicable sections of the American Society of Mechanical Engineers (ASME) Standard B30.21:

Manually Operated Lever Hoists.

Model

No.

Load

Rating

(Tons.)

Lift or

Reach

(Ft.)

Lever pull

T o Lift Rated

Load (Lbs.)

Net

Weight

(Lbs.) A B C D

E F G H

J K L

5310

5311

5312

5313E

3/4

5

10

15

20

33

15.0

15.8

16.6

17.3

125/8

15

/

16

11/

8

11

/

16

11 43/823/162 3/16515/16 23/83 9/

16

5328

1 5 44 15.0

12 5/

8

1

5

/

16

11/

8

11

/

16

11 43/823/1623/16515/1623/83 9/

16

5315

5316

5317

5318E

11/

2

5

10

15

20

51

27.0

31.4

35.8

40.2

1413/16

11/

8

11/

4

13

/

16

16 1/443/423/823/867/

8

3 3 15/

16

5329 2

5 68

27.0

1413/16 11/813/

8

13

/

16

16 1/443/423/823/867/

8

3

3 15/

16

5320

5321

3

5

10

77

45.0

52.3

1811/

16

111/1619/1611/4161/471/233/843/

16

77/833/84 9/

16

5330

5331

5332

5333E

6

5

10

15

20

77

78.0

94.0

110.0

126.0

231/4 113/1623/1611/2161/471/23 3/843/

16

77/833/84 9/

16

Dimensions (in.)

Unpacking

After unpacking the hoist, inspect

carefully for any damage that may have

occurred during transit. Check for loose,

missing or damaged parts. Shipping

damage claims must be filed with

carrier. The hoist is supplied completely

assembled and ready to use.

CM®REPAIR/REPLACEMENT

POLICY

All Columbus McKinnon (CM®) Series

653 Hoists are inspected and

performance tested prior to shipment.

If any properly maintained hoist

develops a performance problem,

within one year of shipment, due to a

material or workmanship defect, as

verified by CM

®

, repair or replacement

of the unit will be made to the original

purchaser without charge. This

repair/replacement policy applies only

to CM

®

Series 653 Hoists installed,

maintained and operated as outlined in

this manual, and specifically excludes

hoists subject to normal wear, abuse,

improper installation, improper or

inadequate maintenance, hostile

environmental effects and

unauthorized repairs/modifications.

We reserve the right to change

materials or design if, in our opinion,

such changes will improve our product.

Abuse, repair by an unauthorized

person, or use of non-CM

®

replacement

parts voids the guarantee and could

lead to dangerous operation. For full

Terms of Sale, see Sales Order

Acknowledgement. Also, refer to the

back cover for Limitations of

Warranties, Remedies and Damages,

and Indemnification and Safe

Operation.

Installation

Before installing the hoist:

1. Estimate the weight of the load that

is to be lifted or moved and make

sure it does not exceed the rated load

of the hoist.

2. Make sure the support or sling to

which the upper hook is attached is

strong enough to hold several times

the weight of the load to be lifted or

moved. Be sure the hoist is solidly

held in the uppermost part of the

upper hook and the latch is closed

and not in contact with the support

or sling.

3. The area in which the hoist is

installed must provide sufficient

room for:

-The operator to operate the lever.

-The operator and other personnel

to stand clear of the load at all

times.

-Firm footing for the operator.

-Clearance between the hoist frame

and any object. The frame must be

free to swivel on the upper hook.

Attaching the hoist from an inadequate

support may allow the hoist and load to fall

and cause injury and/or property damage.

TO AVOID INJURY:

Make sure the structure has sufficient

strength to hold several times the hoist

weight and its rated load.

Operation

If not used as directed, lever hoist may cause

injury.

TO AVOID INJURY:

Use only as directed below. Read all

instructions before operating the Series 653

Hand Operated Lever Hoist.

GENERAL

1. The hoist must be kept clean to

assure proper operation. Before use,

check to be sure the load chain is

clean, that there is no foreign

material in the liftwheel area and

that the lever operates freely.

2. Do not load beyond the rated

capacity. Overload can cause

immediate failure or cause damage

resulting in future failure, even at

less than rated capacity.

3. Do not use this hoist or any other

material handling equipment for

lifting or moving people, or lifting

loads over people.

4. Stand clear of all loads and warn

other people of your intention to

move a load in their area.

5. Do not leave a load on the unit

unattended.

6. Read warnings and instructions on

the hoist before each use.

7. Do not hold the load chain while

operating the hoist. Should the hoist

not operate properly, serious injury

may occur.

8. Never operate the hoist when

flammable materials or vapors are

present. Contact between metal parts

may produce sparks that can cause a

fire or explosion.

9. STAY ALERT! Watch what you are

doing and use common sense. Do

not use the hoist when you are tired,

distracted or under the influence of

drugs, alcohol or medication causing

diminished control.

Malfunction of unit, rigging slip or loss of

footing may cause user to slip resulting in

injury.

TO AVOID INJURY:

Always have a firm and secure footing when

using the Series 653 Hand Operated Lever

Hoist.

FREE CHAINING

In this mode of operation, the chain can

be pulled through the hoist in either

direction by hand for quick attachment

to the load.

T o engage the free chaining feature,

remove any load from the hoist and

move the directional lever to the (“N”)

position.

3

T urn the free chaining knob counter clockwise ( ) to disengage the brake

and pull on either chain until the lower

hook is at the desired position. T o

disengage the free chaining feature,

move the directional lever to the load

(Ï) or unload position (Ð). Pull the load

chain in either direction to insure the

unit is out of the free chaining mode.

Do not take up the load chain to the

point where the chain stop or lower

hook block becomes jammed against

the frame.

ATTACHING THE LOAD

Attach the lower hook to the load so

that it is seated in the bowl of the hook

and is not bearing against the tip of the

hook or latch, and the latch is tight

against the hook tip.

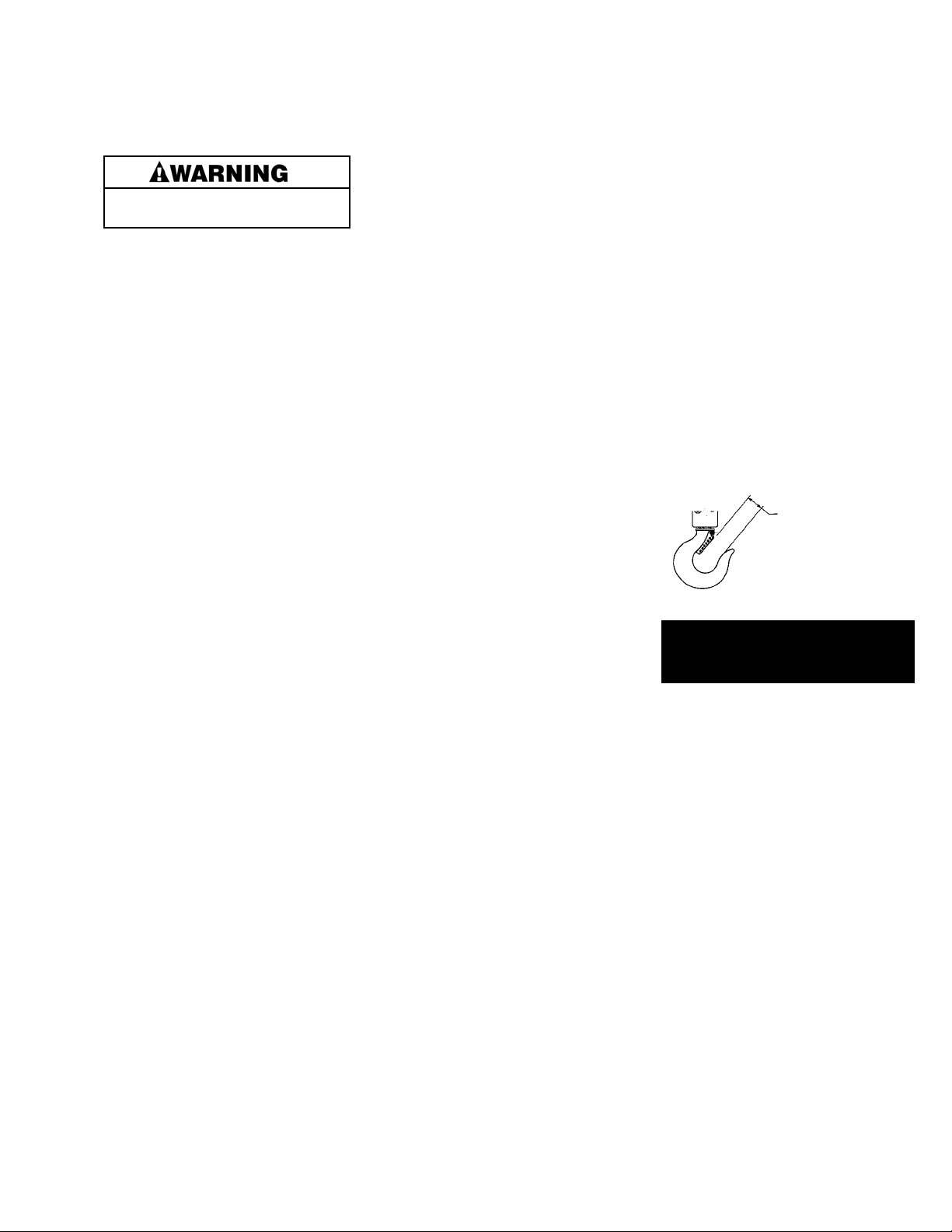

Do not wrap the chain around the load

and hook onto itself as a choker chain

sling or bring the load in contact with

the hoist. Doing this will result in the

loss of the swivel effect of the hook

which could cause twisted chain and a

jammed liftwheel. Also, the chain may

be damaged at the hook. Make sure the

upper and lower hooks are in a straight

line and the frame is free to swivel on

the upper hook.

If the unit is not rigged in a straight line

hook to hook manner, and if the frame is not

free to swivel, lever pull may break frame

and cause physical injury and loss of load.

TO AVOID INJURY:

Rig the unit in a straight line hook to hook

manner and keep frame free to swivel (See

Figure 4).

4

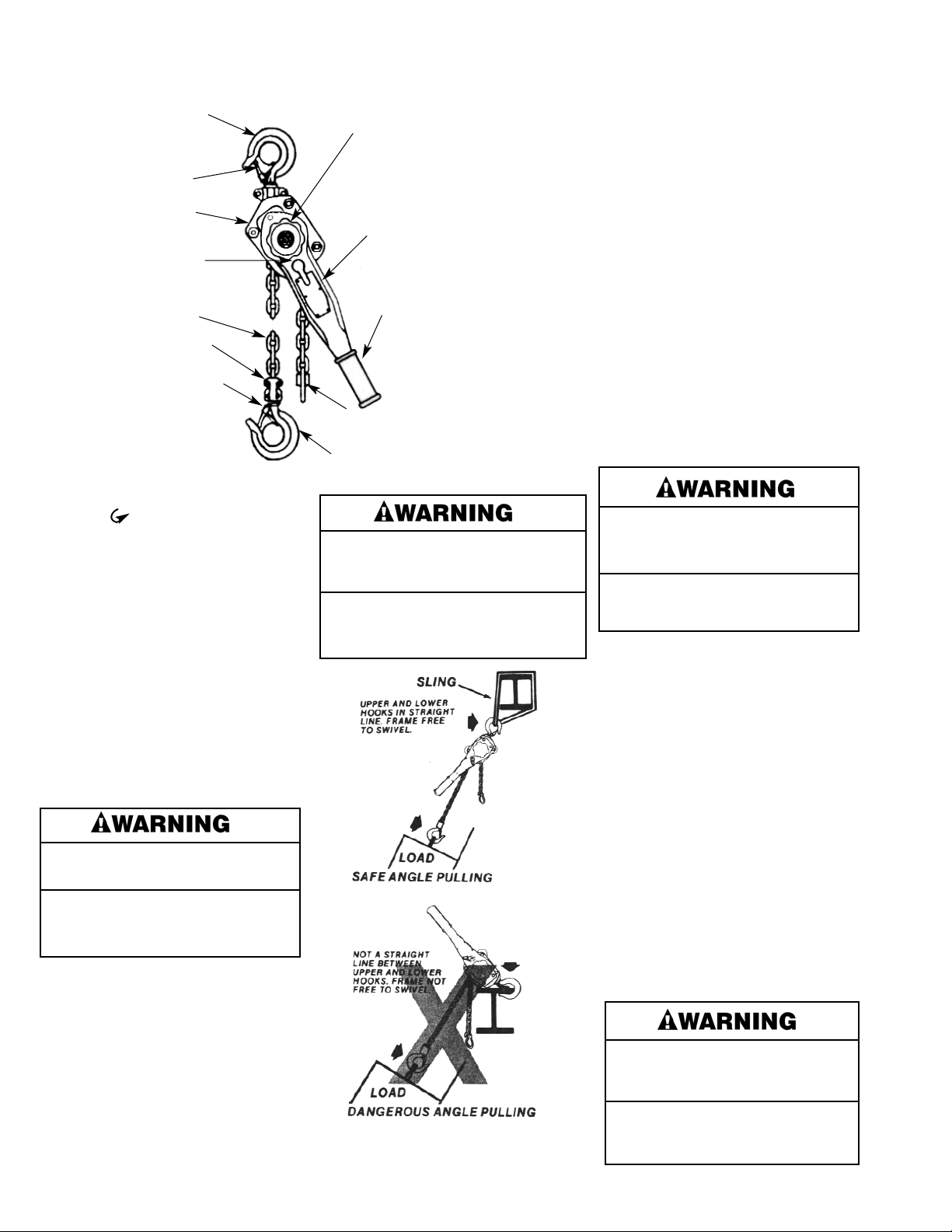

Free Chaining

Knob

Nameplate

Lever

Chain Stop

Lower Hook

Latch

Lower Hook

Block

Load Chain

Directional

Lever

Frame

Latch

Figure 3 - Main Parts of Lever Hoist

Operation (Continued)

Upper Hook

TO PULL OR LIFT LOAD

Move directional lever to load (Ï)

position. Operate lever in up and down

motion to shorten the distance

between hooks and thus pull or lift the

load.

When pulling or lifting move the load

only enough to slightly load the unit,

then check to be sure that the

attachments to the hooks and load are

firmly seated. Continue movement only

after you are assured the load is free of

all obstructions.

The hoist has been designed for hand

powered operation only . Do not use an

extension on the lever. Lever pulls of 33

pounds on 3/4 ton unit, 44 pounds on 1

ton unit, 51 pounds on 1½ ton unit, 68

pounds on 2 ton unit and 77 pounds on

the 3 and 6 ton unit will result in rated

capacity on the unit. Any greater pull is

an indication of either an overload or

an incorrectly maintained unit.

TO LOOSEN OR LOWER LOAD

Move directional lever to unload (Ð)

position. Again, operate lever in an up

and down motion to increase the

distance between hooks and thus

loosen or lower the load.

LOCKED BRAKE

If a hoist which is under load is

suddenly relieved of the load by lifting

the load off of the lower hook by some

other means or pulling down walls, the

brake will lock.

The brake will also lock if the lower

hook block is pulled tightly against the

frame.

T o unlock the brake, turn the

directional lever to the unload (Ð)

position and pull on the lever sharply .

Power operation may cause structural

damage or premature wear that in turn

may cause a part to break and allow the

load to fall.

TO AVOID INJURY:

Operate the Series 653 Lever Hoist using

hand power only!

Allowing the load to bear against the hook

latch and/or hook tip can result in loss of

load.

TO AVOID INJURY:

Do not allow the load to bear against the

hook latch and/or hook tip. Apply load to

hook bowl or saddle only.

Figure 4 - Pulling at an Angle

Turning the Free Chaining Knob with a

load attached will allow the load to

release and may cause injury.

TO AVOID INJURY:

Never turn the Free Chaining Knob when

the lever hoist is under load.

INSPECT HOIST

Before each use and at specified

intervals as directed in the inspection

section.

1. DO NOT exceed capacity shown on

nameplate.

2. DO NOT use to lift people or loads over

people.

3. DO NOT use unless the hoist’s frame and

chain form a straight line between hooks.

4. DO NOT use if the frame is in contact with

any object.

5. DO NOT use if the unit is damaged or

malfunctions.

6. DO NOT use extension on lever. Use hand

power only.

7. DO NOT use if chain is twisted, kinked or

damaged.

Maintenance

INSPECTION

T o maintain continuous and satisfactory

operation, a regular inspection

procedure must be initiated so that

worn or damaged parts can be replaced

before they become unsafe. The

intervals of inspection must be

determined by the individual

application and are based upon the

type of service to which the hoist is

subjected. The intervals indicated as

follows are based on normal service.

The inspections are divided into two

general classifications designated as

“frequent” and “periodic”.

FREQUENT INSPECTIONS

These inspections are usually visual

examinations by the operator. Frequent

inspections are to be performed daily

or before each use and they are to

include:

1. Braking mechanism for evidence of

slippage.

2. Operation of the directional lever

for free movement.

3. Load chain for lubricant, wear,

damaged links or foreign material.

4. Hooks for damage, cracks, twists,

latch engagement and latch

operation.

PERIODIC INSPECTIONS

These are visual inspections of external

and internal conditions by a designated

person making records to provide the

basis for continuing evaluation of the

condition of the hoist. The periodic

inspection should include those items

listed under frequent inspection as well

as the following:

1. Chain for excessive wear or stretch

(See Figures 6 and 7, page 6) - every

three months.

2. Worn, cracked or distorted parts

such as lower hook block, upper

hook block, upper hook pin, chain

guide rollers, bushings, lever, brake

cover, free chaining knob, directional

pawl, friction hub and lever ratchet

- every three months.

3. Inspect for wear on the tip of the

pawls, teeth of the ratchet, and

pockets of the liftwheel - every three

months.

4. Loose or missing bolts, nuts, pins or

rivets - every three months.

5. Inspect the brake components for

worn, glazed or contaminated

friction discs and scoring of the

friction hub and ratchet. Replace

friction washers if contaminated,

glazed or if thickness is less than

0.094 in. (2.4 mm) - every three

months.

6. Corroded, stretched or broken pawl

springs, directional lever pawl spring

and lever ratchet spring - every three

months.

7. Hooks - dye penetrant, magnetic

particle or other suitable crack

detecting inspection should be

performed at least once a year, if

external conditions indicate there has

been unusual usage.

8. Nameplate and Warning Labels for

legibility and retension-every three

months.

9. Chain stop in place and properly

secured - every three months.

Any deficiency should be corrected

before the hoist is returned to service.

Also, the external conditions may show

the need for more detailed inspection

which, in turn, may require the use of

non-destructive type testing.

Any parts deemed unserviceable are to

be replaced with new parts before the

hoist is returned to service. It is very

important that the unserviceable parts

are destroyed and properly disposed of

to prevent their possible future use as a

repair item.

When the unit is subjected to heavy

usage or dusty , gritty, moist or corrosive

atmospheric conditions, shorter time

periods must be assigned. Inspection

must be made of all parts for unusual

wear, corrosion or damage, in addition

to those specifically mentioned in the

schedule.

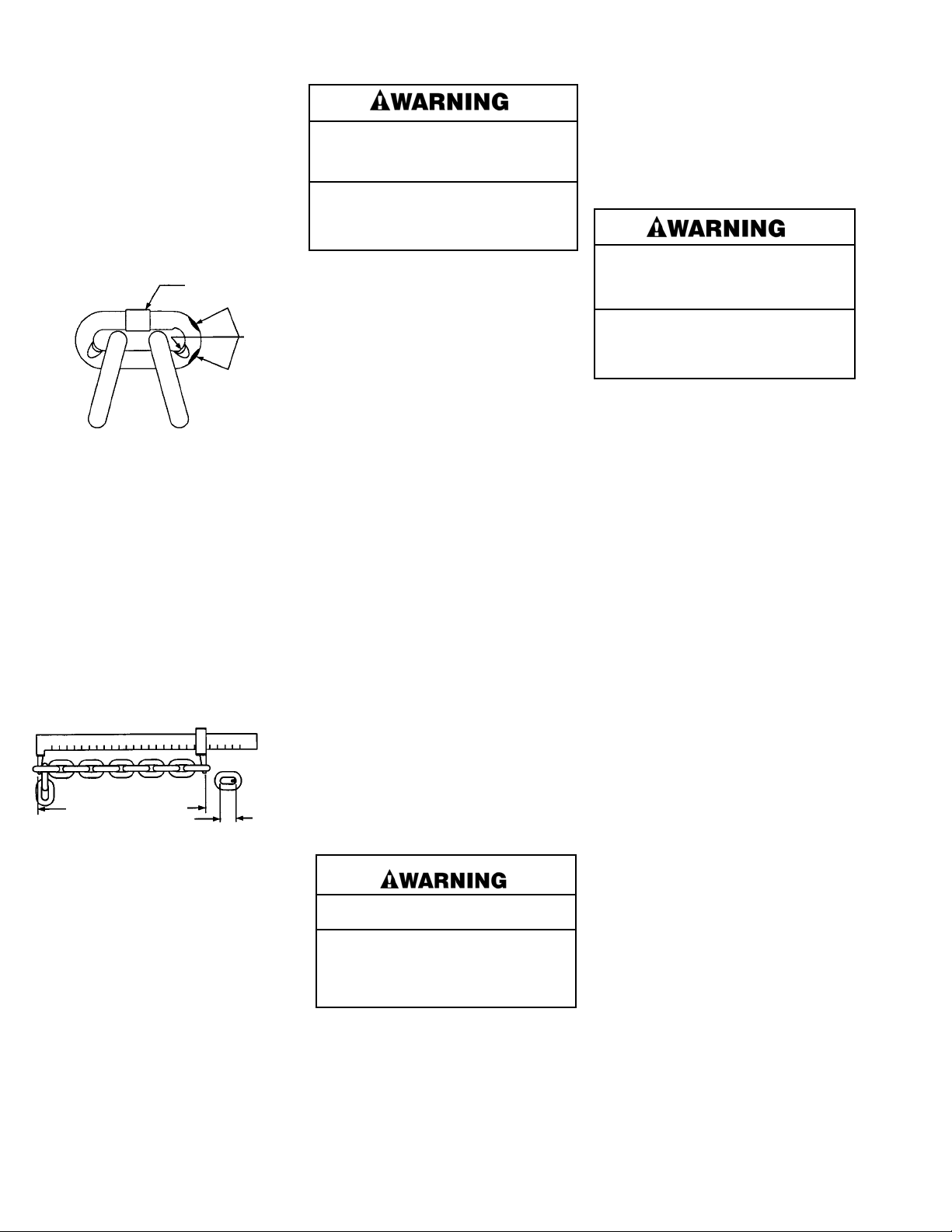

HOOK INSPECTION

Hooks damaged from chemicals,

deformations or cracks, or that have

more than a 10° twist from the plane of

the unbent hook, excessive opening or

seat wear, must be replaced. Also,

hooks that are opened to the extent

that the latch does not engage the tip

must be replaced. Any hook that is

twisted or has excessive throat opening

indicates abuse or overloading of the

hoist. Other load sustaining parts

should be inspected for damage.

3/4 1 ¼

11¼

1½ 1

3

/

8

21½

31

23

/

32

62

5

/

16

Check to assure the latch is not

damaged or bent and that it operates

properly . It should have sufficient

spring pressure to keep it tightly

against the tip of the hook and allow it

to spring back to the tip when released.

If the latch does not operate properly ,

replace the latch.

The chart above should be used to

determine when the hook must be

replaced.

LOAD CHAIN

Chain should feed smoothly into and

away from the hoist. If chain binds,

jumps or is noisy , first clean and

lubricate it (See Page 6). If trouble

persists, inspect chain and mating parts

for wear, distortion or other damage.

Use as directed above. Failure to do so

may cause injury to you or others.

5

Depress latch to

measure throat

opening

Figure 5 - Hook Inspection

Hoist Replace Hook When

Capacity Opening is Greater

(Tons) Than: (in.)

6

Maintenance (Continued)

CHAIN INSPECTION

First clean chain with a non-caustic/ non-

acid type solvent and make a link by link

inspection for nicks, gouges, twisted

links, weld spatter, corrosion pits,

sitriations (minute parallel lines), cracks

in weld areas, wear and stretching.

Chain with any one of these defects

must be replaced.

Slack the portion of the chain that

normally passes over the liftwheel.

Examine the interlink area for the point

of maximum wear (polishing). Measure

and record the stock diameter at this

point of the link. Then measure stock

diameter in the same area on the link

that does not pass over the liftwheel

(use the link adjacent to the chain stop

for this purpose). Compare these two

measurements. If the stock diameter of the

worn link is 0.010 inches (0.254mm), or more,

less than the stock diameter of the unworn

link, the chain must bereplaced.

Also check chain for stretch using a

vernier caliper as shown in Figure 7.

Select an unused, unstretched section of

chain (usually at the loose end) and

measure and record the length over 11

chain links (pitches). Measure and

record the same length on a worn

section of chain.

If the result (amount of stretch and

wear) is greater than 0.145 inch (3.7

mm), the chain must be replaced.

Use only a “Knife-Edge” caliper to

eliminate possibility of false reading by

not measuring full pitch length.

Note that worn chain can be an

indication of worn hoist components.

For this reason, the hoist’s frame,

stripper, and liftwheel should be

examined for wear and replaced as

necessary when replacing worn chain

(See DISASSEMBLY and ASSEMBLY

below).

Also, the load chain is specially heat

treated and hardened and should never

be repaired.

IMPORTANT: Do not use replaced chain

for other purposes such as lifting or

pulling. Load chain may break suddenly

without visual deformation. For this

reason, cut replaced chain into short

lengths to prevent use after disposal.

CHAIN LUBRICA TION

A small amount of lubricant will greatly

increase the life of load chain. Do not

allow the chain to run dry . Keep it clean

and lubricate at regular intervals with

Lubriplate

®

Bar and Chain Oil 10-R (Fiske

Bros. Refining Co.) or equal lubricant.

Normally , weekly lubrication and

cleaning is satisfactory , but under hot

and dirty conditions, it may be necessary

to clean the chain at least once a day

and lubricate it several times between

cleanings.

When lubricating the chain, apply

sufficient lubricant to obtain natural

run-off and full coverage, especially in

the interlink area.

Hoist normally requires no additional

lubrication except when it had been

disassembled for cleaning or repairs.

IMPORTANT: Brake is designed to

operate dry . Do not use any grease or

lubricant on the braking surfaces.

When lubricating parts adjacent to the

brake, do not use an excessive amount

of lubricant which could seep onto the

brake surfaces.

When the hoist is disassembled for

cleaning or repairs, the following

locations should be lubricated with

approximately 1 oz. per hoist of

Molykote BR-2-S (Dow Corning),

Molytex #2 (T exaco) or TopMoly

(T opsall) grease or equal lubricant:

gears, rollers of the liftwheel bearing,

exterior of pinion shaft, surfaces of

frame bushings and surface of gear

cover bushings. Be sure to thoroughly

clean the old grease from these parts

before re-lubricating.

IMPORTANT: To insure long life and top

performance, be sure to lubricate the

various parts of the hoist using the

lubricants specified above. If desired,

these lubricants can be purchased from

Columbus McKinnon (See Figure 13,

page 8).

DISASSEMBLY AND ASSEMBLY

The parts illustration and list on pages 12

and 13 show the general arrangement

and name of the parts of the Series 653

Lever Hoist. These should be used when

disassembling and re-assembling the

units so that all parts are properly

installed.

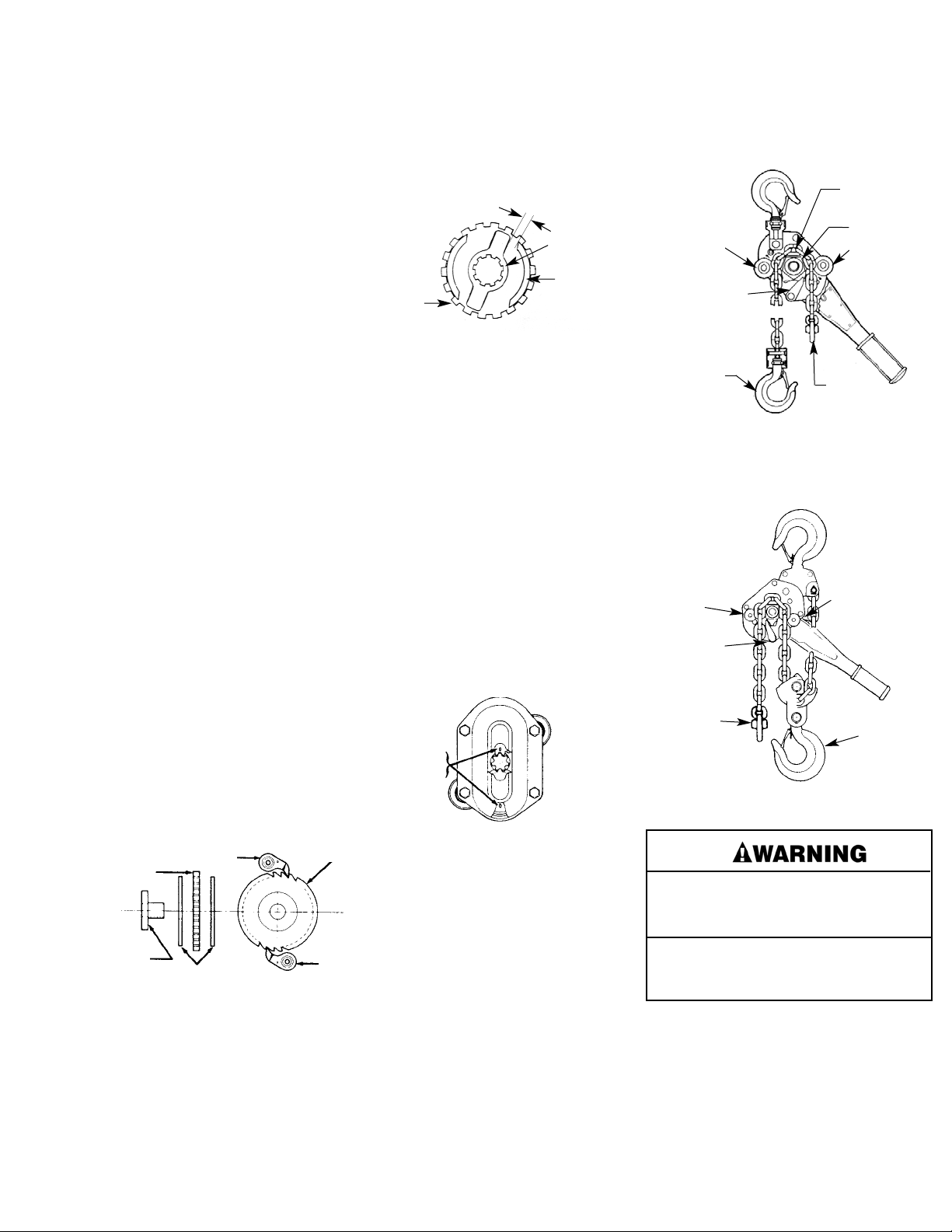

DISASSEMBLY

Points of caution to be observed upon

disassembly of the hoist are:

1. Loose rollers are used for the

liftwheel bearing, (refer to parts

list for number required). Care

must be taken so as to not loose

or misplace these rollers since

they may drop from the unit as

the various parts are disassembled.

Figure 6 - Chain Inspection

Wear

in

These

Areas

Weld

Figure 7 - Chain Inspection

Vernier Caliper

Measure 11 Pitches

One

Pitch

Using other than Series 653 supplied load

chain may cause the chain to jam in the hoist

and/or allow the chain to break and the load

to drop.

TO AVOID INJURY:

Due to size requirements and physical

properties, use only Series 653 supplied load

chain in the Series 653 Lever Hoist.

Used motor oils contain known

carcinogenic materials.

TO AVOID INJURY:

Never use used motor oils as a chain lubricant.

Only use Lubriplate®Bar and Chain Oil 10-R as a

lubricant for the load chain.

Using any grease or lubricant on the

braking surfaces will cause brake slippage

and loss of load control which may result in

injury and/or property damage.

TO AVOID INJURY:

Do not use any grease or lubricant on

braking surfaces. The brake is designed to

operate dry.

Maintenance (Continued)

2. T o replace the liftwheel or stripper,

completely disassemble the unit:

remove the chain (See REPLACING

LOAD CHAIN, page 7) and then

remove the brake nut, cotter pin and

spacer (19), free chaining knob (17),

lever (16), check washer (18), lever

ratchet (33), brake cover (14), friction

discs (12), ratchet (13), spring (6) and

friction hub (11). On the gear side,

remove the gear cover (8), gears (5)

and pinion (7). Remove snap ring and

liftwheel gear (23). Being careful not

to loose the rollers, remove the side

plate assembly (1). Slide the liftwheel

(22) out of the side plate (2), being

careful not to loose the rollers. The

stripper (4) can also be removed now.

Prior to re-assembly , check all parts

for excessive wear, cracks and

distortion. Replace parts as necessary

and then re-assemble the unit in

reverse to the order given above,

making sure to install the chain guide

rollers (10) and upper hook (25) and

pin (26). After assembly , install the

chain (See REPLACING LOAD CHAIN,

page 7) and then test the unit (See

TESTING, page 8).

3. The latch is secured to the hook

(upper and lower) by a rivet. T o

remove the latch, it is necessary to

remove the head of the rivet by

grinding or drilling. For the

replacement of the latch, refer to

the paragraphs under assembly

instructions.

ASSEMBLY:

1. Thread the friction hub (11 ) onto the

pinion shaft (7 ) and assemble the

friction discs and the ratchet on the

friction hub (See Figure 8).

Place the spring (6) over the friction

hub and pinion. Place the brake cover

assembly (14) on the frame and thread

the lever ratchet (33) onto the pinion

shaft. Firmly seat the lever ratchet and

secure the brake cover assembly to the

frame using the four nuts (9).

Place the check washer (18) on the

pinion shaft so that there is 0.094 to

0.312 inches (2 to 8 mm) between the

edge of the check washer and the

raised stop on the lever ratchet hub

(See Figure 9).

Make sure the directional lever is in

the neutral (“N”) position and the

pawl, spring and shaft (20) are in the

lever assembly (16), attach the lever

assembly to the brake cover (14) using

the two locknuts, screw and

lockwasher (15). Place the free

chaining knob (17) on the lever

ratchet hub (33). Place the spacer (19)

over the pinion shaft, thread the

brake nut (19) onto the pinion shaft,

and firmly tighten the nut. Back off

the nut one to two flats and insert the

cotter pin (19). Bend the legs of the

cotter pin to secure.

2. When assembling the latch to the

hook, the end of the rivet must be

peened over. When peening over

rivet, only apply enough force to form

a head to retain the pin. Excessive

force will deform the latch and make

the latch inoperable.

3. When assembling the gears, they

must be orientated with the timing

marks aligned (See Figure 10).

REPLACING LOAD CHAIN

T o replace the load chain, remove the

lower hook block and chain stop from

the chain. Move the directional lever to

the neutral “N” and pull the old chain

out of the hoist. Feed a length of soft

wire through one side of the chain

guide roller and over the liftwheel until

it comes out on the other side of the

chain guide roller. Attach the wire to

the end of the new chain. Position the

chain so that the first link to enter the

chain guide roller will be an upstanding

link and the welds on all upstanding

links will be away from the liftwheel.

Pull on the wire until the chain engages

the liftwheel. T urn the free chaining

knob, while pulling on the wire, until

the chain comes out of the chain guide

roller. Pull the chain through and

remove the wire. On the 3/4, 1, 1 1/2, 2

and 3 T on units attach the lower hook

block to the chain that is directly below

the upper hook. On the 6 T on unit,

reeve the chain as shown below. Attach

the chain stop to the other end of the

chain.

RECOMMENDED SPARE PARTS

To insure continued operation, it is

recommended that two friction

discs (12) for each Series 653 lever

hoist in service, be kept on hand

at all times to replace friction

washers that are worn,contaminated or glazed.

7

Chain welds

away from

Liftwheel

Liftwheel

Chain guide

roller-Chain

Stop Side

Stripper

Chain guide

roller-Lower

Hook Side

Lower

Hook

Block

Chain StopPosition as

Shown

Ratchet

Friction

Hub

Friction Disc

Pawl

Ratchet

Pawl

Figure 8 - Brake Assembly

Raised

Stop

Lever

Ratchet

Check

Washer

Figure 9 - Position of Check Washer

Timing

Marks

Figure 10 - Gear Timing

Chain Installation-3/4, 1, 1½, 2 and 3 Ton

0.094 to 0.312 IN.

(2 to 8mm)

Alterations or modifications of equipment and

use of any parts other than Series 653 repair

parts can lead to dangerous operation and

injury.

TO AVOID INJURY:

Do not alter or modify equipment. Do use only

Series 653 provided replacement parts.

Chain Guide

Roller-End

Ring Side

Chain Guide

Roller-Hook

Side

Figure 11. Reeving - 6 Ton

Stripper

End Ring

Lower

Hook

Block

Maintenance (Continued)

PREVENTATIVE MAINTENANCE

In addition to the inspection

procedures, a preventative maintenance

program should be established to

prolong the useful life of the hoist and

maintain its dependability and

continued safe use. The program should

include the periodic inspections with

particular attention being paid to the

lubrication of various components using

the recommended lubricants (See

Figure 13).

TESTING

Prior to initial use, all repaired or used

hoists that have not been operated for

the previous 12 months shall be tested

by the user for proper operation.

T est the unit first in the unloaded state

and then with a light load of 100

pounds (45 kg.) times the number of

load supporting parts of load chains to

be sure it operates properly and the

brake holds the load when the lever is

released; then test with a load of 125%

of rated capacity .

In addition, hoists in which load

sustaining parts have been replaced

must be tested with 125% of rated

capacity by or under the direction of a

designated person and a written report

prepared for record purposes.

NOTE: For additional information on

Inspection and T esting refer to ASME

B30.21 “Manually Lever Operated

Hoists” obtainable from ASME Order

Department, 22 Law Drive, Box 2300,

Fairfield, NJ 07007-2300, U.S.A.

8

INSPECTOR’S REPORT

ITEM REMARKS (LIST DEFICIENCIES AND RECOMMENDED ACTION)

Inspector’s Date

Signature Inspected Approved by Date

Figure 12 — Recommended Inspector’s Report

(*) This lubrication schedule is based on a hoist operating in normal environment conditions. Hoists operating in adverse atmospheres

containing excessive heat, corrosive fumes or vapors, abrasive dust, etc., should be lubricated more frequently.

RECOMMENDED LUBRICATION SCHEDULE*

SERIES 653 HAND OPERATED LEVER HOISTS

REFERENCE NO. COMPONENT TYPE OF LUBRICANT ORDER TYPE OF SERVICE AND

(SEE PAGES 12 & 13) PART NO. FREQUENCY OF LUBRICATION

HEAVY NORMAL INFREQUENT

32

Load Chain Oil (See Page 6) 28619 Daily Weekly Monthly

(1 gal. can)

Gears, Bushings,

5, 1, 8, 24 & 7 Liftwheel rollers Grease (See page 6) 28618 When hoist is disassembled for cleaning

& Pinion shaft (1 lb. can) or repairs

Figure 13 — Recommended Lubrication Schedule

INSPECTION AND MAINTENANCE CHECK LIST

HAND OPERATED LEVER HOIST

Type of Hoist ___________________________________________________________ Capacity (Tons)________________________________________________________

Location _______________________________________________________________ Original Installation Date ______________________________________________

Manufacturer___________________________________________________________ Manufacturer’s Serial No.______________________________________________

Item Frequency of Inspection Possible Deficiencies OK Action

Frequent Periodic

Required

Daily Every 3 Months

Brake Mechanism

* * Slippage or excessive drift.

Worn, glazed or contaminated friction discs. Thickness of discs

less than 0.094 inches.

Directional Lever

* * Binding and does not move freely.

Inadequate lubrication, excessive wear or stretch, cracked

Load Chain * * damaged or twisted links, corroded or clogged with foreign

material.

Hooks

* * Excessive throat opening, twisted more than 10 º, damaged

or non-operating hook latch, chemical damage. Cracks (Use dye

penetrant, magnetic or other suitable detection method at

least once a year).

Lower Hook Block, Upper Hook Cracks, distortion, excessive wear, corrosion or build-up of

Block, Upper Hook Pin, Chain Guide * foreign material.

Rollers, Bushings, Gears, Pinion and

Friction Hub

Tip of Pawls and Lever Pawl Cracks, distortion, excessive wear, corrosion or build-up of

Teeth of Ratchet and Lever Ratchet of foreign material.

*

Pockets of Liftwheel, Stripper

Cracks, distortion, excessive wear, corrosion or build-up of

and Side Plates *

foreign material.

Nuts, Bolts, Pins and Rivets

* Cracks, bending, loose, stripped threads.

Pawl Springs, Directional Pawl Corrosion, stretched or broken.

Spring, and Spring *

Chain Stop * Missing, cracked, not secured to chain, not properly positioned.

Nameplate, Warning Labels and

Free Chaining Tags * Missing, Damaged or illegible.

NOTE: Refer to Maintenance and Inspection Sections of this manual for further details.

FREQUENCY OF INSPECTION

Frequent - Indicates items requiring inspection daily or before each use. These inspections may be performed by the operator if properly designated.

Periodic -- Indicates items requiring inspection every three months. Inspections to be performed by or under the direction of a properly designated person. The

exact period of inspection will depend on frequency and type of usage. Determination of this period will be based on the user’s experience. It is

recommended that the user begin with a quarterly inspection and extend the periods to semi-annually or annually based on the user’s quarterly

experience.

NOTE: This inspection and maintenance check list is in accordance with our interpretation of the requirements of the Safety

Standard for Overhead Hoists ASME B30.16. It is, however, the ultimate responsibility of the employer/user to interpret and

adhere to the applicable requirements of this safety standard.

9

Maintenance (Continued)

Figure 14 — Recommended Inspection and Maintenance Check List

10

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Hoist is hard to operate 1. Load chain worn long to 1. Check chain, (See page 6) and replace if worn

in either direction. gauge, thus binding between excessively .

liftwheel and chain guide roller.

2. Load chain rusty, corroded or 2. Clean chain by tumble polishing or using a

clogged with foreign matter non-acid or non-caustic type solvent. Check chain

such as cement or mud. for gouges, damaged or bent links. Lubricate with

Lubriplate

®

Bar and Chain Oil 10-R (Fiske Bros.

Refining Co.) or equal lubricant.

3. Bushings or liftwheel rollers 3. Disassemble and clean liftwheel rollers and

clogged with matter such as bushings in gear cover and side plate (gear side).

cement or dust. Any parts worn excessively should be replaced.

4. Lever binding. 4. Clean by removing any foreign matter which may

be between the lever and the brake cover.

5. Brake parts corroded or 5. Disassemble brake and clean thoroughly (by wiping

clogged with foreign matter. with a cloth - not by washing in a solvent). Replace

discs if too gummy , worn or scored. Keep discs and

brake surfaces clean and dry .

6. Liftwheel pockets clogged with 6. Clean out pockets and use if not worn excessively.

foreign matter or worn excessively Replace liftwheel if pockets are worn.

causing chain to bind between

liftwheel and chain guide rollers.

7. Liftwheel twisted or bent - gear 7. Excessive overload had been applied. Replace

teeth bent. damaged parts.

8. Check washer not in correct 8. Reposition check washer (See page 7).

position.

Hoist is hard to operate 1. Brake adjusting nut is too tight. 1. See BRAKE ASSEMBLY, page 7.

in down direction.

2. Brake parts corroded or clogged 2. Disassemble brake and clean thoroughly

with foreign matter. (by wiping with a cloth - not by washing in a

solvent). Replace discs if too gummy , worn or

scored. Keep discs and brake surfaces clean

and dry .

3. Chain binding. 3. Check chain, (See page 6) and replace if worn

excessively . Clean chain by tumble polishing or

using a non-acid or non-caustic type solvent. Check

chain for gouges, damaged or bent links. Lubricate

with Lubriplate

®

Bar and Chain Oil 10-R (Fiske

Bros. Refining Co.) or equal lubricant.

Hoist is hard to operate 1. Chain binding. 1. Check chain, (See page 6) and replace if worn

in up direction. excessively . Clean chain by tumble polishing or

using a non-acid or non-caustic type solvent. Check

chain for gouges, damaged or bent links. Lubricate

with Lubriplate

®

Bar and Chain Oil 10-R (Fiske

Bros. Refining Co.) or equal lubricant.

2. Overload. 2. Reduce load or use correct capacity unit.

Loading...

Loading...