CM-ET 622 User Manual

© 1996 Columbus McKinnon Corp. Printed in USA

Note: When ordering parts, always furnish rated load and serial number of hoist on

which the parts are to be used.

For the location of the nearest CM Master Parts Depot, see the list located on the

inside front cover.

Columbus McKinnon Corporation • Industrial Products Division • 140 John James Audubon Parkway

Amherst, New York 14228-1197 • 1-800-888-0985 • Fax 716-689-5644

LIMITATION OF WARRANTIES, REMEDIES AND DAMAGES

THE WARRANTY STATED BELOW IS GIVEN IN PLACE OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

OR OTHERWISE, NO PROMISE OR AFFIRMATION OF FACT

MADE BY ANY AGENT OR REPRESENTATIVE OF SELLER

SHALL CONSTITUTE A WARRANTY BY SELLER OR GIVE RISE

TO ANY LIABILITY OR OBLIGATION.

Seller warrants that on the date of delivery to carrier the goods

are free from defects in workmanship and materials.

SELLER’S SOLE OBLIGATION IN THE EVENT OF BREACH OF

WARRANTY OR CONTRACT OR FOR NEGLIGENCE OR

OTHERWISE WITH RESPECT TO GOODS SOLD SHALL BE

EXCLUSIVELY LIMITED TO REPAIR OR REPLACEMENT, F.O.B.

SELLER’S POINT OF SHIPMENT, OF ANY PARTS WHICH

SELLER DETERMINES TO HAVE BEEN DEFECTIVE or if Seller

determines that such repair or replacement is not feasible, to a

refund of the purchase price upon return of the goods to Seller.

Any action against Seller for breach of warranty, negligence or

otherwise, must be commenced within one year after such

cause of action occurs.

NO CLAIM AGAINST SELLER FOR ANY DEFECT IN THE

GOODS SHALL BE VALID OR ENFORCEABLE UNLESS

BUYER’S WRITTEN NOTICE THEREOF IS RECEIVED BY

SELLER WITHIN ONE YEAR FROM THE DATE OF SHIPMENT.

Seller shall not be liable for any damage, injury or loss arising

out of the use of the goods if, prior to such damage, injury or

loss, such goods are (1) damaged or misused following Seller’s

delivery to carrier; (2) not maintained, inspected, or used in

compliance with applicable law and Seller’s written

instructions and recommendations; or (3) installed, repaired,

altered or modified without compliance with such law,

instructions or recommendations.

UNDER NO CIRCUMSTANCES SHALL SELLER BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES AS THOSE

TERMS ARE DEFINED IN SECTION 2-715 OF THE UNIFORM

COMMERCIAL CODE.

INDEMNIFICATION AND SAFE OPERATION

Buyer shall comply with and require its employees to comply

with directions set forth in instructions and manuals furnished

by Seller and shall use and require its employees to follow

such instructions and manuals and to use reasonable care in

the use and maintenance of the goods. Buyer shall not remove

or permit anyone to remove any warning or instruction signs

on the goods. In the event of personal injury or damage to

property or business arising from the use of the goods, Buyer

shall within 48 hours thereafter give Seller written notice of

such injury or damage. Buyer shall cooperate with Seller in

investigating any such injury or damage and in the defense of

any claims arising therefrom.

If Buyer fails to comply with this section or if any injury or

damage is caused, in whole or in part, by Buyer’s failure to

comply with applicable federal or state safety requirements,

Buyer shall indemnify and hold Seller harmless against any

claims, loss or expense for injury or damage arising from the

use of the goods.

®

SOLUTIONS

OPERATING,

MAINTENANCE &

PARTS MANUAL

HAND OPERATED

CHAIN HOIST

Price: $5.00 Manual No. B622-B

Before installing hoist, fill in the

information below.

Rated Load __________________

Serial No. ____________________

Purchase Date _______________

22950

®

Rated Loads:

1/2, 1, 2, 3, 5 and 10 tons

(500,1000, 2000, 3000, 5000,

and 10,000kg.)

Follow all instructions and warnings for

inspecting, maintaining and operating this hoist.

The use of any hoist presents some risk of personal

injury or property damage. That risk is greatly

increased if proper instructions and warnings are not

followed. Before using this hoist, each operator

should become thoroughly familiar with all warnings,

instructions and recommendations in this manual.

Retain this manual for future reference and use.

Forward this manual to operator.

Failure to operate equipment as directed

in manual may cause injury.

SERIES 622

SS 1/00

S

eries

622

CM HOIST PARTS AND SERVICES ARE AVAILABLE IN THE UNITED STATES AND IN CANADA

As a CM Hoist user, you are assured of reliable repair and parts services through a network of Master Parts Depots and

Service Centers that are strategically located in the United States and Canada. These facilities have been selected on the

basis of their demonstrated ability to handle all parts and repair requirements promptly and efficiently.

Below is a list of the Master Parts Depots in the United States and Canada. To quickly obtain the name of the U.S. Service

Center located nearest you, call (800) 888-0985. Fax: (716) 689-5644. In the following list, the Canadian Service Centers

are indicated.

UNITED STATES

MASTER PARTS DEPOT

ALABAMA

ABB POWER SERVICES

612 32nd Street, South

Birmingham, AL 35233

205/328-5952

Fax 205/251-6759

CALIFORNIA

OTTO SYSTEMS, INC.

12010 Bloomfield Ave.

Santa Fe Springs, CA 90670

310/462-1612

Fax 310/462-1617

or

2439 Verna Court

San Leandro, CA 94577

510/667-3730

Fax 510/667-3726

COLORADO

MATERIALS HANDLING EQUIPMENT CO.

1740 W. 13th Ave.

Denver, CO 80204

303/573-5333

Fax 303/893-3854

FLORIDA

TAMPA ARMATURE WORKS, INC.

440 South 78th Street

Tampa, FL 33619

813/621-5661

Fax 813/622-7040

GEORGIA

ACE INDUSTRIES, INC.

6295 McDonough Drive

Norcross, GA 30093

770/441-0898

Fax 770/441-0326

ILLINOIS

SERVICE ELEVATOR & ELEC. CO.

5819 West Irving Park Rd.

Chicago, IL 60634

312/545-5848

Fax 312/545-8610

TORRANCE ELECTRIC COMPANY

415-31st. Ave.

Rock Island, IL 61204-6008

309/786-7777

Fax 309/786-8705

INDIANA

HORNER ELECTRIC COMPANY, INC.

1521 East Washington St.

Indianapolis, IN 46201

317/ 639-4261

Fax 317/639-4269

LOUISIANA

BEERMAN PRECISION, INC.

4206 Howard Avenue

New Orleans, LA 70125

504/486-9391

Fax 504/486-7482

MASSACHUSETTS

ABEL DISTRIBUTORS, INC.

70 Flagship Drive

N. Andover, MA 01845

508/975-8234

Fax 508/683-7025

MICHIGAN

GAYLORD HOIST SALES & SERVICE

34471 Industrial Road

Livonia, MI 48150

313/261-1910

Fax 313/261-1788

MISSOURI

INDEPENDENT ELECTRIC MACHINERY

310 West 20th Street

Kansas City, MO 64108

816/471-2610

Fax 816/421-3054

NEW JERSEY

LIVELY AND COMPANY

10 Merry Lane

East Hanover, NJ 07936

201/887-6440

Fax 201/887-9586

NEW YORK

VOLLAND ELECTRIC EQUIPMENT CO.

75 Innsbruck Drive

Buffalo, NY 14227

716/656-9900

Fax 716/656-8898, 8899

NORTH CAROLINA

SOUTHERN ELECTRIC SERVICE CO., INC.

2225 Freedom Drive

Charlotte, NC 28208

704/372-4832

Fax 704/342-2604

OHIO

MAZZELLA WIRE ROPE & SLING COMPANY

14600 Brookpark Road

Cleveland, OH 44135

216/362-4600

Fax 216/362-4952

PENNSYLVANIA

AMICK ASSOCIATES, INC.

11 Sycamore Street

Carnegie, PA 15106-0529

412/429-1212

Fax 412/429-0191

RAM INDUSTRIES, INC.

70 Pitney Rd.

Lancaster, PA 17602

717/392-2128

Fax 717/392-2788

TEXAS

ABEL EQUIPMENT CO., INC.

3710 Cavalier Drive

Garland, TX 75042

214/272-7706

Fax 214/272-6955

HYDRAULIC EQUIPMENT SERVICE, INC.

1021 North San Jacinto St.

Houston, TX 77002

713/228-9601

Fax 713/228-0931

WASHINGTON

UNITED ELECTRIC MOTORS

308 9th Ave. North

Seattle, WA 98109

206/624-0044

Fax 206/622-4894

WISCONSIN

TRESTER HOIST & EQUIPMENT, INC.

4465 North 124th St.,Unit B

Brookfield, WI 53005

414/790-0700

Fax 414/790-1009

CANADIAN

SERVICE CENTERS

ALBERTA

**COLUMBUS McKINNON, LTD.

10311-174th Street

Edmonton, Alberta T8H 1N3

NOVA SCOTIA

*W & A MOIR

95 Ilsley Ave.

Dartmouth, Nova Scotia B3B 1L5

902/468-7720

Fax 902/468-3777

ONTARIO

*R & W HOIST REPAIR, LTD.

790 Redwood Square

Units 5, 6, & 7

Oakville, Ontario L6L 6N3

905/825-5500

Fax 905/825-5315

*TORONTO ELECTRIC HOIST

SALES & SERVICE

72 Crockford Blvd.

Scarborough, Ontario M1R 3C4

416/755-7716

Fax 800/461-0290

*MASLACK SUPPLY, LTD.

488 Falconbridge Road

Sudbury, Ontario P3A 4S4

705/566-1270

Fax 705/566-4208

*COLUMBUS MCKINNON, LTD.

P.O. Box 1106

10 Brook Road, North

Cobourg, Ontario K9A 4W5

905/372-0153

Fax 905/372-3078

QUEBEC

*HERCULES SLING & CABLE

2525 Louis A. Amos

Lachine, Quebec H8T 1C3

514/631-5511

Fax 514/636-1084

*LEGER HOIST EQUIPMENT CO.

7995-17th Ave.

Montreal, Quebec H1Z 3R2

514/376-3050

Fax 514/376-0657

* ARE ALSO MASTER PARTS DEPOTS

** MASTER PARTS DEPOT ONLY

1

2

3

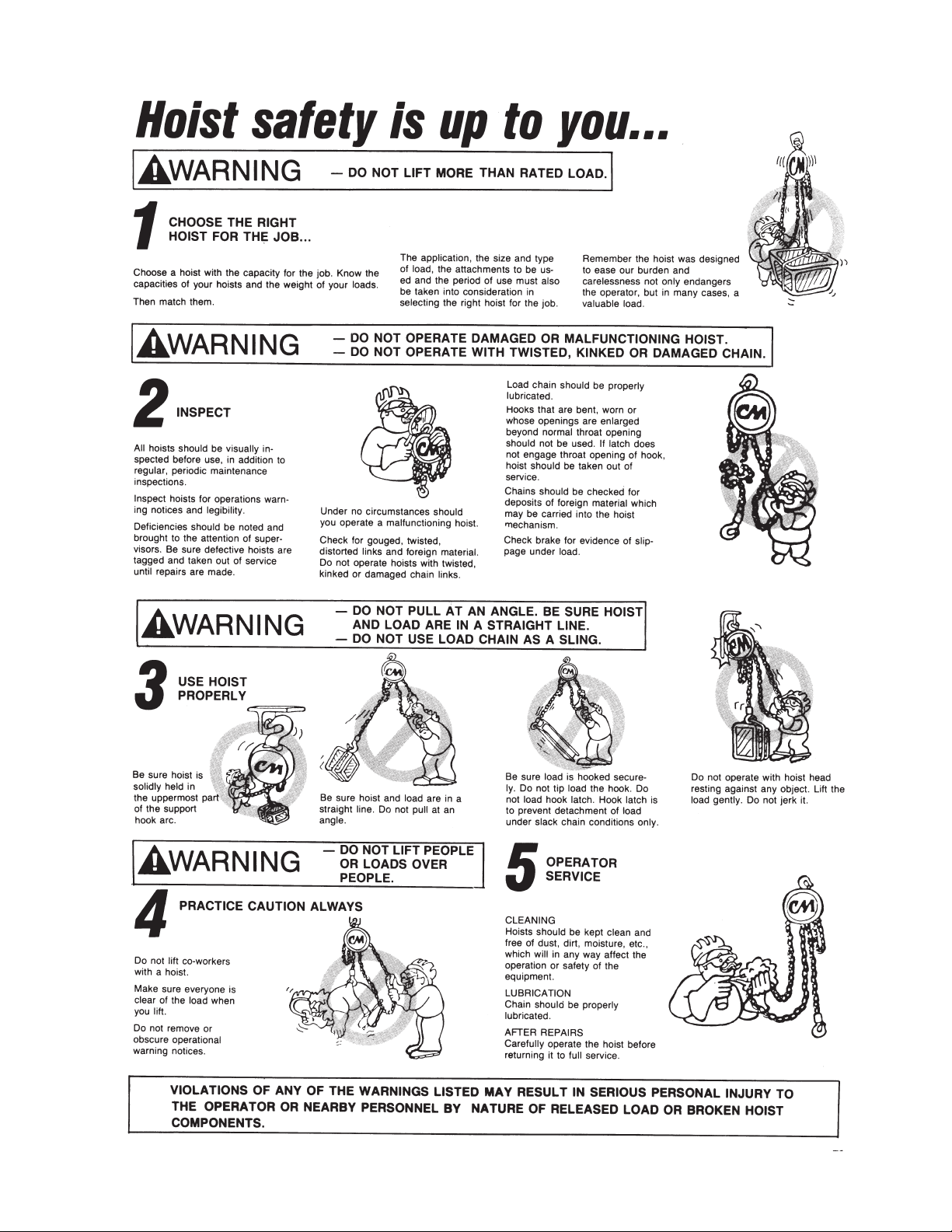

SAFETY PRECAUTIONS

Each Series 622 Hand Hoist is built in accordance with the specifications contained herein and at the time of

manufacture complies with our interpretation of applicable sections of the * American Society of Mechanical

Engineers Code B30.16 “Overhead Hoist” and the Occupation Safety and Health Act.

The safety laws for elevators and for dumbwaiters may specify construction details that are not necessarily

incorporated in CM industrial hoists. We recommend the use of equipment that meets state and national safety

codes. Columbus McKinnon Corporation cannot be responsible for applications other than those for which CM

equipment is recommended.

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH

THE EQUIPMENT BEFORE ATTEMPTING TO OPERATE YOUR SERIES 622 HOIST.

Consult Columbus McKinnon Corporation for any usage of Series 622 Hoists that do not involve raising of the load on the lower hook, or

usage of Series 622 Hoists in the inverted position. Using hoists, without special precautions, in such applications may cause an accident

that could result in injury and/or property damage.

* Copies of this standard can be obtained from ASME Order Department, 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300, U.S.A.

DO’S AND DO NOT’S

Safe Operation of Hoists

The following are Do’s and Do Not’s for safe operation of overhead hoists. Taking precedence over

any specific rule listed here, however, is the most

important rule of all, USE COMMON SENSE. A few

minutes spent reading these rules can make an

operator aware of dangerous practices to avoid and

precautions to take for his own safety and the safety of others. Frequent examinations and periodic

inspections of the equipment as well as a conscientious observance of safety rules may save lives as

well as time and money.

WARNING

- To Avoid Injury:

!

13. DO inspect hoist regularly, replace damaged or

worn parts, and keep appropriate records of

maintenance.

14. DO use CM parts when repairing a hoist.

15. DO use hook latches wherever possible.

16. DO apply lubricant to the load chain as recom-

mended in this manual.

17. DO replace damaged or malfunctioning hook

latch.

18. DO NOT lift more than rated load.

19. DO NOT use damaged hoist or hoist that is not

working correctly.

20. DO NOT use the hoist with twisted, kinked,

damaged or worn chain.

21. DO NOT lift a load unless chain is properly

seated in chain wheel(s).

22. DO NOT use load chain as a sling or wrap

chain around the load.

23. DO NOT lift a load if any binding prevents equal

loading on all supporting chains.

24. DO NOT apply the load to the tip of the hook.

25. DO NOT operate unless load is centered under

hoist.

26. DO NOT operate hoist with other than manual

power.

27. DO NOT permit more than one operator to pull

on a single hand chain at one time.

28. DO NOT allow your attention to be diverted

from operating the hoist.

29. DO NOT operate the hoist beyond limits of load

chain travel.

30. DO NOT use hoist to lift, support or transport

people.

31. DO NOT lift loads over people.

32. DO NOT leave a suspended load unattended

unless specific precautions have been taken.

33. DO NOT allow sharp contact between two

hoists or between hoist and obstructions.

34. DO NOT allow the chain or hook to be used as

a ground for welding.

35. DO NOT allow the chain or hook to be touched

by a live welding electrode.

36. DO NOT remove or obscure the warnings on

the hoist.

37. DO NOT adjust or repair a hoist unless qualified

to perform hoist maintenance.

38. DO NOT attempt to lengthen the load chain or

repair damaged load chain.

1. DO read ASME B30.16 Safety Standard for

Overhead Hoists and this manual thoroughly.

2. DO be familiar with hoist operating controls,

procedures and warnings.

3. DO make sure the hoist suspension hook is

securely attached to a suitable support.

4. DO maintain firm footing or be otherwise

secured when operating hoist.

5. DO make sure that load slings or other

approved single attachments are properly sized

and seated in the hook saddle.

6. DO make sure that the hook latch, if used, is

closed and not supporting any part of the load.

7. DO make sure that load is free to move and will

clear all obstructions.

8. DO take up slack chain carefully, check load

balance, lift a few inches (centimeters) and

check load holding action before continuing.

9. DO make sure that all persons stay clear of the

suspended load.

10. DO avoid swinging of load or load hook.

11. DO protect load chain from weld spatter or

other damaging contaminants.

12. DO promptly report any malfunction, unusual

performance, or damage of the hoist.

!

!

Loading...

Loading...