Page 1

MORTISE ATTACHMENT

MORTISE ATTACHMENT

OPERATING & MAINTENANCE

INSTRUCTIONS

0305

Model No. CMA 1B

Part No. 6500023

Page 2

-2-

Fence Size ............................................................ 40x350mm

Net Weight ........................................................... 24kg

Chisel Collar Size ................................................. 3/4”

SPECIFICATIONS

Before operating the machine, please read this leaflet thoroughly and follow the

instructions carefully. In doing so you will ensure the safety of yourself and that of

others around you, and you can look forward to the machine giving you long

and satisfactory service.

This CLARKE product is guaranteed against faulty manufacture for a period

of 12 months from the date of purchase. Please keep your receipt as proof

of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product

can be returned to us without prior permission.

This guarantee does not effect your statutory rights.

GUARANTEE

This attachment is compatible with the following CLARKE Drill Presses.

Thank you for selecting this CLARKE Bench Mortising Attachment.

CDP3201B • CDP251F • CDP301B • CDP351F

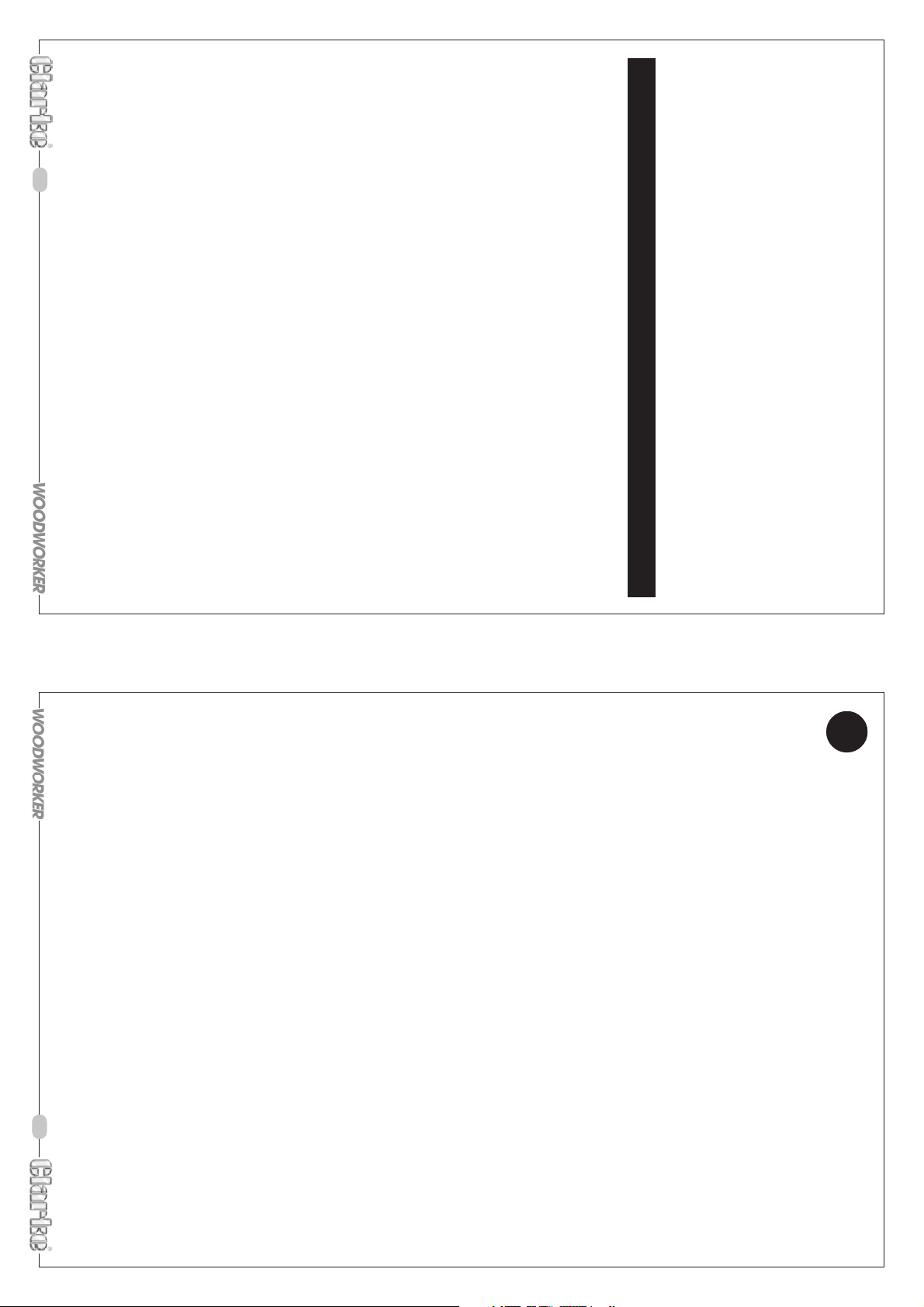

-11-

3. 13mm (1/2”).................. 9mm .................................. 6500027

4. 16mm (5/8”)................. 13mm ................................. 6500028

1. 6mm (1/4”)................... 5mm .................................. 6500025

2. 9mm (3/8”)................... 6mm .................................. 6500026

The following Morticing Chisels and Bits are available from your CLARKE dealer.

Mortise Width Bit Shank Size Part No.

1 1/2” Chisel 1 6500027

1 5/8” Chisel 1 6500028

2 Chisel Holder 1 EFCMA1B02

3 Reducing Collar (set) 1 EFCMA1B03

ACCESSORIES

6 Hold Down Post 1 EFCMA1B06

7 Fence 1 EFCMA1B07

8 Screw w/Wing Nut 2 Not Available

9 Hooks 2 EFCMA1B09

1 1/4” Chisel 1 6500025

1 3/8” Chisel 1 6500026

4 Hold Down 1 EFCMA1B04

5 Hold Down Support 1 EFCMA1B05

No. Description Qty Part No.

REPLACEMENT PARTS

No. Description Qty Part No.

Page 3

-10-

Use a Mortise chisel cutter with the correct size

pilot to sharpen the chisel. Two or three turns of

the cutter in a carpenters hand brace should be

enough to sharpen the chisel. Remove any burrs

from the outside of the chisel with a fine oilstone.

Chisels and bits will need replacing when they

become badly worn and difficult to sharpen.

affect the diameter of the bit.

For best performance the chisel and bit need to be kept sharp. Blunt cutting

edges will give untidy and inaccurate mortises, and can cause overheating

and breaking of the chisel and bit.

Sharpen the bit by using a small smooth

file, following the original shape of the

bit. File the inside edge of the spur, the

sides of the brad point, and the cutting

edge inwards towards the flutes of the

bit to restore sharpness. Do not file the

outside edge of the spur as this will

SHARPENING THE DRILL BIT & CHISEL

8. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

9. DON’T FORCE the Machine. It will do a better and safer job at the rate for

10. REMOVE ADJUSTING KEYS AND WRENCHES. Form the habit of checking to see that

11. DRUGS, ALCOHOL, MEDICATION. Do not operate machine whilst under the

12. USE RECOMMENDED ACCESSORIES. The use of improper accessories could

13. NEVER LEAVE MACHINE RUNNING UNATTENDED. Turn power OFF. Do not leave

which it was designed.

keys and adjusting wrenches are removed from the machine before switching on.

influence of drugs, alcohol or any medication.

be hazardous.

machine until it comes to a complete stop.

-3-

2. EARTH ALL MACHINES. If the machine is equipped with three-pin plug, it should

5. DISCONNECT the MACHINE from the power supply before servicing and when

6. KEEP GUARDS in place and in working order.

7. ALWAYS WEAR SAFETY GOGGLES, manufactured to the latest European Safety

of parts, mountings, and any other condition that may affect the machines’

operation. Any damage should be properly repaired or the part replaced. If

in doubt, DO NOT USE the machine. Consult your local dealer.

Standards. Also use face or dust mask if cutting operation is dusty. Everyday

eyeglasses do not have impact resistant lenses, they are NOT safety glasses.

changing accessories or performing maintenance tasks.

4. CHECK for DAMAGE. Before using the machine, any damaged part, such as

a guard etc., should be checked to ensure that it will operate properly, and

perform its intended function. Check for alignment of moving parts, breakage

3. ALWAYS ensure that ADEQUATE LIGHTING is available. A minimum intensity of

be plugged into a three-pin electrical socket. Never remove the earth pin.

300 lux should be provided. Ensure that lighting is placed so that you will not

be working in your own shadow.

1. READ and BECOME FAMILIAR with the entire operating manual. Learn the

machines’ applications and limitations as well as the specific potential hazards

peculiar to it.

injury. However, if normal safety precautions are overlooked or ignored, personal

injury to the operator or damage to property, may result.

As with all machinery, there are certain hazards involved with their operation and

use. Exercising respect and caution will considerably lessen the risk of personal

GENERAL SAFETY RULES FOR OPERATING MACHINERY

SAFETY PRECAUTIONS

WARNING:

Page 4

-4-

5. ALWAYS KEEP hands, fingers and hair well away from the rotating bit.

6. DO NOT ATTEMPT to mortise materials that do not have a flat surface.

7. ALWAYS use the ‘Hold Down’ to prevent work from lifting when withdrawing

8. ALWAYS SUPPORT workpiece securely against fence to prevent rotation.

9. ENSURE chisel and bit is sharp, undamaged and properly secured before use.

10. ENSURE the chuck key is removed before starting.

11. NEVER START the machine with the drill bit or chisel pressed against the

12. NEVER PERFORM LAYOUT, assembly or setup work on the machine with the

13. ALWAYS ADJUST DEPTH STOP wherever possible, to avoid drilling into the table.

14. ALWAYS STOP the machine before removing scrap pieces from the table.

15. SHUT OFF POWER, remove the drill bit and chisel and clean the table before

16. NEVER PLACE YOUR FINGERS in a position where the drill or cutting tool could

workpiece.

leaving the machine.

contact them if the workpiece should shift unexpectedly.

cutting tool rotating.

the chisel.

1. DO NOT USE until unit is completely assembled and installed according to

2. IF YOU ARE NOT thoroughly familiar with the mortising operations, you should

4. NEVER TURN MACHINE ON before clearing the table of all objects (tools, scrap

these instructions.

obtain advice from a qualified person.

pieces, etc.).

ADDITIONAL SAFETY INSTRUCTIONS when MORTISING

18. BE AWARE that accidents are caused by carelessness due to familiarity. ALWAYS

footing, wear rubber soled footwear. Keep floor clear of oil, scrap wood, etc.

parts. Wear protective hair covering to contain long hair.

concentrate on the job in hand, no matter how trivial it may seem.

16. DON’T OVERREACH. Keep your proper footing and balance at all times. For best

17. WEAR PROPER APPAREL. Loose clothing or jewellery may get caught in moving

14. KEEP CHILDREN AWAY. All visitors should be kept a safe distance from the work

15. MAINTAIN MACHINE IN TOP CONDITION. Keep tools sharp and clean for the

area, especially whilst operating the unit.

best and safest performance. Follow maintenance instructions.

-9-

• If the Morticing attachment is left on the drill press, ensure the plastic protection

• Always switch the mortising machine off after use. Never leave the machine

• When cutting deep mortises, make the cut in several stages of no more than 25mm

people damaging themselves on the sharp points subsequently.

cap (provided), is placed over the end of the chisel to avoid the possibility of

running unattended.

each, to allow chips to clear.

• Do not have the slot against the blind end of the mortise, as the chips will

breakage to the chisel or bit.

not be able to clear from the chisel. This will cause overheating and possible

• After the first cut, the workpiece must be moved along in the correct direction

• A dull chisel can be detected by the amount of excess force required to

so that the chisel slot is releasing chips into the already cut part of the mortise.

relative to the slot in the chisel, to allow chips to clear freely. Move the workpiece

complete a cut.

combination of friction and resin buildup on the cutting faces of the chisel.

burned off. Bluing of the chisel after initial use is not indicative of a dull chisel, but a

• You may encounter smoke from the bit or material once the chisel has engaged

mortising and is caused by material chip friction and the resins in the stock being

the material. The smoke created is a natural operating occurrence in hollow chisel

• The rate of penetration of the chisel must be fast enough to prevent burning at the

you will find suitable feed rates to suit various types of timber.

tip of the bit, but not so fast as to cause the machine to slow or stall. With experience

• It is recommended that you check the position, and depth of cut, on a piece

of scrap of similar size before cutting your workpiece.

7

Observing all precautions (refer to your drill press manual), and ensuring there are

no obstructions, or tools in the vicinity, plug into the mains supply and switch ON.

Gently lower the chisel so that it contacts the work, and, ensuring it is properly

positioned, proceed to force the chisel into the work.

If your drill press is provided with a depth stop, it may be used to limit the depth of

the chisel cut. Refer to your drill press manual for the method of adjustment.

NOTES:

Page 5

Your Morticing Attachment is now set up and ready for use.

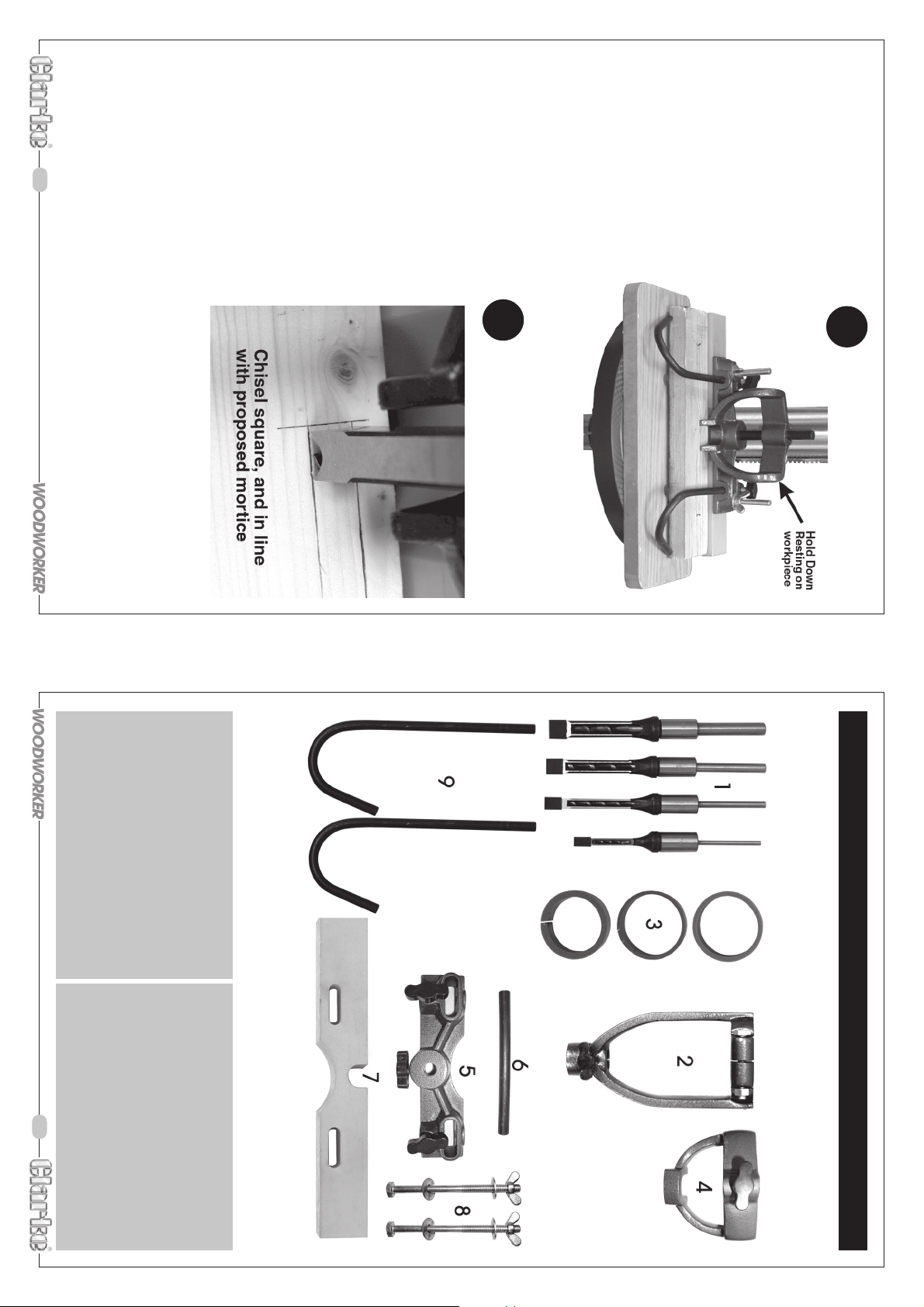

-8-

beforehand.

Mortise on the workpiece clearly,

You should always mark your

directly beneath the chisel.

so that the proposed Mortise lies

be manoeuvred, in the radial slots,

a position where the assembly can

axis, you need to lock the table in

radial slots, which rotates about its

If you have a round table with

The chisel must be square with the workpiece, as shown. Move the complete

assembly on the table until you are satisfied it is, then clamp the complete assembly

to the table using the wing nuts on the hold down support securing bolts.

directly beneath the chisel.

secured with the hole in the table

NOTE:

about the column, ensure it is

If your table is capable of rotating

Lower the chisel and bit, (or raise

the table) so it is directly above the

proposed Mortise.

hold down - the

workpiece should be

allowed to move laterally

by hand.

• Lower the Hold Down so

firm, but allowed to move

laterally, by hand.

that it makes contact

with the workpiece.

Again DO NOT force the

* Place the workpiece on to

the table, up against the

fence, then attach the two

Hooks in the manner shown,

pulling the workpiece up

against the fence.

DO NOT force the

workpiece, it should be

2. Chisel Holder

3. Chisel Holder Collars Hold Down

4. Hold Down

5. Hold Down Support

Should there be any deficiency or damage to any of the components, please

1. Chisel Sets -4 off (see Accessories)

contact your Clarke dealer immediately

6

5

Unpack the shipping carton, and lay out the components so that they can be

clearly identified. Check them off as follows:

UNPACKING

-5-

9. Workpiece Securing Hooks - 2 off

8. Mounting Bolts w/Wing Nuts

and 2 x Flat Washers - 2 off

6. Hold Down Post

7. Fence

Page 6

-6-

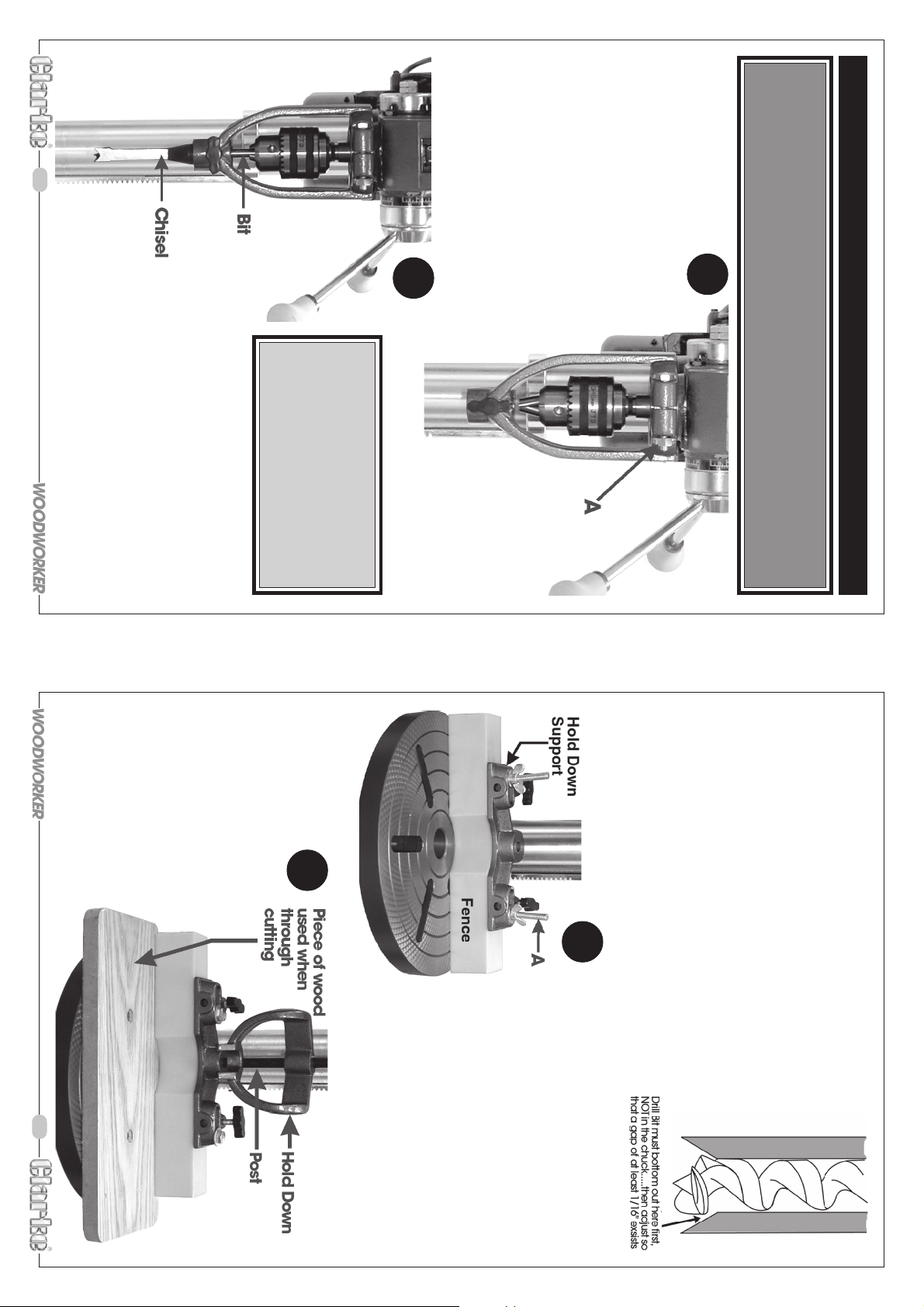

• Mount the Chisel Holder on the

collar surrounding the drill press

spindle, as shown.

It may be necessary to use a

collar insert in order for the

holder to fit correctly. Three

such collars are provided.

Tighten the pinch bolt ‘A’.

For your own safety, do not connect the Drill Press to a power source until

the Morticing Attachment is fully assembled, and you have read and

understood all safety and operational instructions.

INSTALLATION

Chisel Parallel to Workpiece’ on page 10.

allows chips to escape during operation. See ‘Adjusting

NOTE:

to the right or left, never to the front or rear. The opening

The opening in the side of the chisel should always be

holder, and nip up the securing screw to

temporarily hold it in this position.

slide the Hold Down on to it,

securing it temporarily with

the securing knob.

• Separate the chisel and bit, then Insert the

• Push the chisel up as far as possible into the

chisel up through the hole in the Chisel Holder.

Take great care when handling the

chisel and bit...the edges are

extremely sharp.

Use the plastic protection cap

(provided), whenever possible

WARNING!

Insert the Hold Down Post into

the hole in the hold down

support, and secure, then

2

Install the chisel and bit as follows:

cutting deep mortices.

increase the size of the gap with hardwoods, or when

1

WARNING:

It should also be noted that it may be necessary to

coorrect clearance may be set.

holder and lower the holder sufficiently so that a

bit (shank), or, slacken the screw securing the chisel

contact with the chisel, either grind off the end of the

If the bit bottoms out in the chuck before it makes

mating faces of ther chisel and bit, as shown in Fig. 2A.

A clearance of 1/16” (1.5mm) MUST exist between the

IMPORTANT!

•

-7-

4

of table being used).

breakthrough (Depending upon the type

Such a setup is shown in ‘4’ below.

damage to the chisel and bit on

splintering of the workpiece and possible

mortices are to be cut, and will avoid

the workpiece. This is used when through

may be used as a bed, on which to place

be placed beneath the fence, which

long. This is to allow a piece of timber to

stage

Note that the securing bolts (A) are extra

3

Attach the Fence and the Hold Down

Support to the table in the manner shown.

Do not fully tighten the wing nuts at this

Push the bit up throught he chisel, and into the opened

jaws of the chuck.

Fig. 2A

Loading...

Loading...