Page 1

Xiamen Clarion Electrical Enterprise Co., Ltd

8/F., Xiamen Mail Processing Centre, No.275 Lujiang Road , Xiamen,China

Tel:+86-592-2389080 Fax:+86-592-2389089

Clarion Co., Ltd.

7-2, Shintoshin, Chuo-Ku, Saitama-Shi, Saitama 330-0081, Japan

Service Manual

CD/USB/MP3/WMA/AAC Receiver

with CeNET Control

Published by Service Dept.

298-6525-00 JAN. 2008P

Printed in P.R.C.

(DXZ785USB)

This product is a lead free model.

Lead free solder is used in PWB stamped LF mark.

Please keep the following conditions when you repair.

1. Use lead free solder.

* Koki's lead free solder S3X-55M 0.6mm

(CLARION Parts No.642-0231-01)

* Koki's lead free solder S3X-55M 1.0mm

(CLARION Parts No.642-0231-02)

2. Use a nitrogen solder system.

3. Do not use "General solder" and "Lead free solder"

together.

SPECIFICATIONS

FM tuner section

Frequency range: 87.9MHz to 107.9MHz

(PE-3041B-A)

87.0MHz to 108.0MHz

(PE-3041K-A/B)

Usable sensitivity: 9dBf

50dB quieting sensitivity: 15dBf

Alternate channel selectivity: 70dB

Stereo separation: 35dB(1kHz)

Frequency response: 30Hz to 15kHz(+3/-3dB)

AM tuner section

Frequency range: 530kHz to 1710kHz

(PE-3041B-A)

531kHz to 1629kHz

(PE-3041K-A/B)

Usable sensitivity: 25uV

CD player section

System: Compact disc digital audio

system

Usable discs: Compact disc

Model

DXZ785USB

(PE-3041B-A for U.S.A)

Model

DXZ786USB

(PE-3041K-A/B for Other Countries)

Frequency response: 5Hz to 20kHz(+1/-1dB)

Dynamic range: 95dB(1kHz)

Harmonic distortion: 0.01%

MP3/WMA/AAC mode

MP3 Sampling rate: 8kHz to 48kHz

MP3 Bit rate: 8kbps to 320kbps / VBR

WMA Bit rate: 8kbps to 320kbps

AAC Sampling rate: 8kHz to 48kHz

AAC Bit rate: 8kbps to 320kbps / VBR

Logical format: ISO9660 level1, 2

JOLIET or Romeo or APPLE ISO

file system

Audio section

Maximum power output: 53Wx4

Bass control action: +12/-12dB(80Hz)

Treble control action: +12/-12dB(10kHz)

Line output level: 5.8V(CD 1kHz)

General

Power supply voltage: 14.4V DC(10.8 to 15.6V allowable),

negative ground

Current consumption: Less than 15A

Speaker impedance: 4ohm(4ohm to 8ohm allowable)

Weight: Source unit 1.6kg

Remote control unit

40g(including battery)

Dimensions(mm): Source unit

178(W)x50(H)x158(D)

Remote control unit

44(W)x113(H)x11(D)

NOTE

We cannot supply PWB with component parts in principle. When

*

a circuit on PWB has failure, please repair it by component parts

base. Parts which are not mentioned in service manual are not

supplied.

Specifications and design are subject to change without notice for

*

further improvement.

-1-

DXZ785USB/DXZ786USB

Page 2

Use only compact discs bearing the or mark.

*

Some CDs recorded in CD-R/CD-RW mode may not be usable.

* Windows Media , and the Windows logo are trademarks, or re-

gistered trademarks of Microsoft Corporation in the United States

and/or other countries.

* WMA is the abbreviation of Windows Media Audio, an audio file

format developed by Microsoft Corporation.

* This product includes technology owned by Microsoft Corporation

and cannot be used or distributed without a license from MSLGP.

* As for this model, the tuner of the DSP type is used.When you

exchange it due to the tuner pack(BL1:880-2091E) trouble, it is

necessary to adjust for S-meter etc.Special JIG is necessary for

an accurate adjustment.The procedure document for the exclusive

use jig is appended to it.

* This DSP IC SAF7730HN219A(051-6706-40) of main PWB is ex-

posed die soldering pad type. The middle of this IC package is so-

ldered with the main PWB, and it cannot remove in an ordinary s-

oldering iron.Please use special removal JIG at the time of IC exc-

hange.

* This unit is compatible with USB 1.1/2.0 with maximum data tran-

sfer rates of 12 Mbps.USB memory devices that can be played by

connecting to the unit's USB connector are limited to those recog-

nized as "USB mass storage class devices"; operation is not gua-

ranteed with all USB memory devices.

* To prevent the accidental loss of data, always back up important

data on your computer.

* This unit does not support connections to a computer.In addition,

connections made through a USB hub device are also not

supported.

* This unit supports USB Digital Media Streaming.USB Digital Media

Streaming is a function used to play music files transmitted using

Media Transfer Protocol (MTP). This function also supports the

playback of WMDRM 10 files.

* Insert and remove a USB memory device only when the device is

not being accessed. Connecting or disconnecting the device at the

following times may result in the loss of data:

- If the USB memory device is removed or power is disconnected

during writing to the device.

* iPod is for legal or rightholder-authorized copying only. Don't st-

eal music. iPod is a trademark of Apple Computer, Inc., registered

in the U.S and other countries.

COMPONENTS

PE-3041B-A/PE-3041K-A/B

1. Source unit 1

2. Remote control unit RCB-176-200 1

3. Battery(CR2025) 1

4. Mounting bracket(PE-3041B-A) 300-8088-00 1

5. Mounting bracket(PE-3041K-A/B) 300-7742-00 1

6. Mounting bracket(PE-3041K-A/B) 300-4976-00 1

7. DCP case 335-6035-04 1

8. Escutcheon(OUT-ES)

9. Extension lead 854-6433-50 1

10. RCA PIN CORD 855-5520-56 1

11. Parts bag

11-1. Removal key 331-2497-00 2

11-2. Part screw(M1.7x6)(PE-3041B-A) 716-0872-61 1

11-3. Screw(M5x8) 716-0496-51 1

11-4. Rubber part 345-3799-20 8

DXZ785USB/DXZ786USB

370-6226-04 1

1

To engineers in charge of repair or inspection of our products.

Before repair or inspection, make sure to follow the

instructions so that customers and Engineers in charge

of repair or inspection can avoid suffering any risk or

injury.

1. Use specified parts.

The system uses parts with special safety features against fire

and voltage. Use only parts with equivalent characteristics

when replacing them.

The use of unspecified parts shall be regarded as remodeling

for which we shall not be liable. The onus of product liability

(PL) shall not be our responsibility in cases where an accident

or failure is as a result of unspecified parts being used.

2. Place the parts and wiring back in their original positions after

replacement or re-wiring.

For proper circuit construction, use of insulation tubes, bond-

ing, gaps to PWB, etc, is involved. The wiring connection and

routing to the PWB are specially planned using clamps to keep

away from heated and high voltage parts. Ensure that they are

placed back in their original positions after repair or inspec-

tion.

If extended damage is caused due to negligence during re-

pair, the legal responsibility shall be with the repairing com-

pany.

3. Check for safety after repair.

Check that the screws, parts and wires are put back securely

in their original position after repair. Ensure for safety reasons

there is no possibility of secondary ploblems around the re-

paired spots.

If extended damage is caused due to negligence of repair, the

legal responsibility shall be with the repairing company.

4. Caution in removal and making wiring connection to the parts

for the automobile.

Disconnect the battery terminal after turning the ignition key

off. If wrong wiring connections are made with the battery con-

nected, a short circuit and/or fire may occur. If extensive dam-

age is caused due to negligence of repair, the legal responsi-

bility shall be with the repairing company.

5. Cautions in soldering

Please do not spread liquid flux in soldering.

Please do not wash the soldering point after soldering.

6. Cautions in soldering for chip capacitors

Please solder the chip capacitors after pre-heating for replace-

ment because they are very weak to heat.

Please do not heat the chip capacitors with a soldering iron

directly.

7. Cautions in handling for chip parts.

Do not reuse removed chips even when no abnormality is ob-

served in their appearance. Always replace them with new

ones. (The chip parts include resistors, capacitors, diodes, tran-

sistors, etc).

Please make an operation test after replacement.

8. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the iron

tip temperature is around 270

iron tip repeatedly(more than three times)to the same patterns.

Also take care not to apply the tip with force.

9. Turn the unit OFF during disassembly and parts replacement.

Recheck all work before you apply power to the unit.

-2-

. Take care not to apply the

Page 3

10. Cautions in checking that the optical pickup lights up.

Error Display Cause Measure

ERROR 2 A CD is caught inside the CD deck and is not ejected. This is a failure of CD deck’s mechanism.

ERROR 3 A CD cannot be played due to scratches, etc. Replace with a non-scratched, non-warped-disc.

ERROR 6 A CD is loaded upside-down inside the CD deck and Eject the disc then reload it properly.

does not play.

ERROR 2 A CD inside the CD changer is not loaded. This is a failure of CD changer’s mechanism.

ERROR 3 A CD inside the CD changer cannot be played due to Replace with a non-scratched, non-warped disc.

scratches, etc.

ERROR 6 A CD inside the CD changer cannot be played Eject the disc then reload it properly.

because it is loaded upside-down.

ERROR 2 A DISC inside the DVD changer cannot be played. This is a failure of DVD mechanism.

ERROR 3 A DISC cannot be played due to scratches, etc. Retry or replace with a non-scratched,

non-warped disc.

ERROR 6 A DISC inside the DVD changer cannot be played Eject the disc then reload it properly.

because it is loaded upsidedown.

ERROR P Parental level error Set the correct Parental level.

ERROR R Region code error Eject the disc and replace correct region code disc.

ERROR 2 The files are not proper MP3/WMA/AAC format. Use only properly encoded MP3/WMA/AAC files.

ERROR 3 The MP3/WMA/AAC files are improperly encoded. Use only properly encoded MP3/WMA/AAC files.

(USB/MTP mode)

ERROR 3 The iPod contains no audio files. Insert an iPod containing audio files.

(iPod mode)

ERROR 5 The connected devices are not recognized. Disconnect the devices and reconnect.

BUS-PWR Overcurrent detection. Disconnect the devices and reconnect. If the

devices are still not recognized, try replacing with

a different devices.

HUB The connected devices are not recognized. Disconnect the devices and reconnect. If the

devices are still not recognized, try replacing with

a different devices.

CD/MP3/

WMA/AAC

CD

changer

DVD

changer

USB/MTP/

iPod

The laser is focused on the disc reflection surface through the

lens of the optical pickup. When checking that the laser opti-

cal diode lights up, keep your eyes more than 30cms away

from the lens. Prolonged viewing of the laser within 30cms

may damage your eyesight.

11. Cautions in handling the optical pickup

The laser diode of the optical pickup can be damaged by elec-

trostatic charge caused by your clothes and body. Make sure

to avoid electrostatic charges on your clothes or body, or dis-

charge static electricity before handling the optical pickup.

11-1. Laser diode

The laser diode terminals are shorted for transportation in or-

der to prevent electrostatic damage. After replacement, open

the shorted circuit. When removing the pickup from the mecha-

nism, short the terminals by soldering them to prevent this

damage.

11-2. Actuator

The actuator has a powerful magnetic circuit. If a magnetic

material is put close to it. Its characteristics will change. En-

sure that no foreign substances enter through the ventilation

slots in the cover.

11-3. Cleaning the lens

Dust on the optical lens affects performance.

To clean the lens, apply a small amount of isopropyl alcohol to

lens paper and wipe the lens gently.

CAUTION

Use of controls, adjustments, or performance of procedures other

than those specified herein, may result in hazardous radiation ex-

posure.

The compact disc player should not be adjusted or repaired by

anyone except properly qualified service personnel.

276-0379-00

PE-3041B

Bottom view of DXZ785USB

ERROR DISPLAYS

If an error occurs, one of the following displays is displayed. Take the measures described below to eliminate the problem.

* If an error display other than the ones described above appears, press the reset button.

* When the power supply is turned on for the first time, the bolero microcomputer version display is mistake.

It is solved by turning ACC on and off once again.

-3-

DXZ785USB/DXZ786USB

Page 4

TROUBLESHOOTING

Problem Cause Measure

Power does not turn on. Fuse is blown. Replace with a fuse of the same amperage.

(No sound is produced.) Incorrect wiring. Read the attached "Installation/Wire connection Guide" once again

and wire properly.

No sound output when Power antenna lead is shorted to 1. Turn the unit off.

operating the unit with ground or excessive current is 2. Remove all wires attached to the power antenna lead. Check

amplifiers or power required for remote-on the amplifiers each wire for a possible short to ground using an ohm meter.

antenna attached. or power antenna. 3. Turn the unit back on.

4. Reconnect each amplifier remote wire to the power antenna lead

one by one. If the amplifiers turn off before all wires are attached,

an external relay to provide remote-on voltage (excessive current

required).

Nothing happens when The microprocessor has

Turn off the power, then press the [

RELEASE

]

buttons are pressed. malfunctioned due to noise, etc. button and remove the DCP.

Press the reset button for about

Display is not accurate. 2 seconds with a thin rod.

DCP or main unit connectors Wipe the dirt off with a soft cloth moistened with

are dirty. cleaning alcohol.

No sound heard The speaker protection circuit Turn down sound volume. Function can also be restored by

is operating. turning the power off and on again. (Speaker volume is reduced

automatically when the speaker protection circuit operates).

No sound heard MP3/WMA/AAC files are Write MP3/WMA/AAC files onto the disc properly.

absent in a disc.

Files are not recognized as Use MP3/WMA/AAC files encoded properly.

an MP3/WMA/AAC file.

File system is not correct. Use ISO9660 level 1, 2 or JOLIET or Romeo or

APPLE ISO file system.

Sound skips or is noisy. Compact disc is dirty. Clean the compact disc with a soft cloth.

Compact disc is heavily Replace with a compact disc with no scratches.

scratched or warped.

Sound is cut or skipped. MP3/WMA/AAC files are not Use MP3/WMA/AAC files encoded properly.

Noise is generated or encoded properly.

noise is mixed with sound.

Sound is bad directly after Water droplets may form on Let dry for about 1 hour with the power on.

power is turned on. the internal lens when the car

is parked in a humid place.

Wrong filename File system is not correct. Use ISO9660 level 1, 2 or JOLIET or Romeo or

APPLE ISO file system.

No sound heard The device contains no MP3/ Record MP3/WMA/AAC files properly to the device.

WMA/AAC files.

The files are not proper MP3/ Use only properly encoded MP3/WMA/AAC files.

WMA/AAC format.

Connectors are loose. Disconnect the device and reconnect securely.

Sound is interrupted or The MP3/WMA/AAC files are Use only properly encoded MP3/WMA/AAC files.

has noise. improperly encoded.

The device isn’t The device is damaged. Disconnect the device and reconnect. If the device is still not

recognized. Connectors are loose. recognized, try replacing with a different device.

According to the state of operation Disconnect the device and reconnect.

on the device, the communication

fault is caused.

Can’t insert the device. The device has been inserted Try reversing the connection direction of the device

improperly. (usually the brand name surface should be facing left).

The connector is broken. Replace with a new device.

GeneralUSBMTP/iPod CD/MP3/WMA/AAC

Reset button

DXZ785USB/DXZ786USB

-4-

Page 5

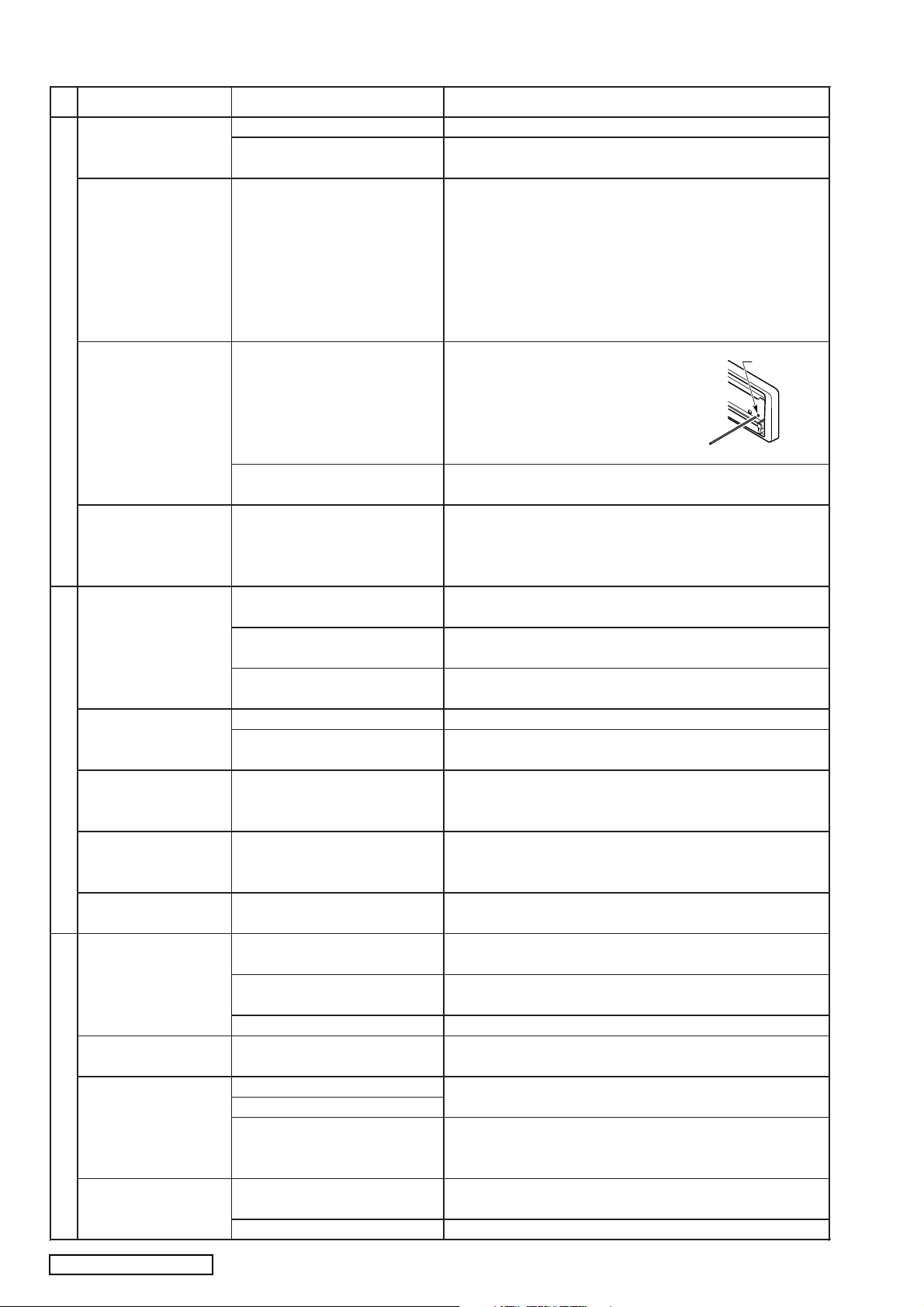

BLOCK DIAGRAM

Main section

Q

CONTROL

RECEPT

RECEPT

BUILT-IN for ALL WORLD

TMP92CD28AFG

-6UP2

FJ

-TR

IC3

M30876MJB-713GP

MECH PWB

IC1

-5-

DXZ785USB/DXZ786USB

Page 6

ADJUSTMENTS

1.Terminal Description

pin 1

:NC:IN:

Ground.

pin 2

:

OEM-REMOCON

:IN:

The steering remote controller signal input.

pin 3

:

IE-BUS-TX

:O:

IE Bus serial data output.

pin 4

:

IE-BUS-RX

:IN:

IE Bus serial data input.

pin 5

:

AUTO-ANT

:O:

Motor antenna signal output.

pin 6

:

BYTE(GND):IN

:

Connect to VSS.

pin 7

:

CNVSS

:IN:

Connect to VSS.

(with internal pull-down resistor)

pin 8

:

XCIN

:IN:

The crystal resonator for sub-clock.

pin 9

:

XCOUT

:IN:

The crystal resonator for sub-clock.

pin 10

:

RESET

:IN:

The reset signal input.

pin 11

:

X-OUT

:O:

The resonator for main clock.

pin 12

:

GND

:-:

Ground.

pin 13

:

X-IN

:IN:

The resonator for main clock.

pin 14

:

VCC1

:-:

Positive power supply.

pin 15

:

VCC

:-:

Positive power supply.

pin 16

:

ACC-DET

:IN:

ACC detection signal input.

pin 17

:

B/U-DET1

:IN:

Backup detection signal input.

pin 18

:

ILL-DET

:IN:

The illumination detection signal input.

pin 19

:

OFFSET-DET:IN

:

The emergency signal input from the power IC.

pin 20

:

E2P-DO

:O:

The serial data output to the E2PROM.

pin 21

:

E2P-SCK

:O:

The clock pulse output to the E2PROM.

pin 22

:

E2P-DI

:IN:

The serial data output to the E2PROM.

pin 23

:

E2P-CS

:O:

E2PROM chip selection signal output.

pin 24

:NC:IN:

Ground.

pin 25

:NC:IN:

Ground.

pin 26

:NC:IN:

Ground.

pin 27

:

TUN-SCL

:O:

The clock pulse output to the BUS tunner.

pin 28

:

TUN-SDA

:

I/O

:

The serial data input/output to the BUS tunner

pin 29

:

FLASH TX

:O:

The flash serial data output.

pin 30

:

FLASH RX

:IN:

The flash serial data input.

pin 31

:

FLASH-SCL:IN

:

Ground.

pin 32

:

FLASH-BUSY:O

:

Not in use.

pin 33

:

BOLERO-SDA:I/O

:

The serial data input/output to the BOLERO.

pin 34

:

BOLERO-SCL:O

:

The clock pulse output when to the BOLERO.

pin 35

:

Z-MUTE-CUT:O:The cut of contral signal output to the MUTE.

(CD:H:no cut; out of CD:L:cut)

pin 36

:

A-MUTE(TEST):IN

:

Test pin.

pin 37

:

EMPH

:O:

Test pin.

052-3977-10 M30873MHB-709GP Main System controller

pin 38

:

BOLERO-RESET

:O:

The reset signal output of the BOLERO.

pin 39

:

FLASH-EPM:IN

:

Ground.

pin 40

:NC:IN:

Not in use.

pin 41

:NC:IN:

Not in use.

pin 42

:NC:IN:

Not in use.

pin 43

:

CATS-LED

:O:

CATS LED drive output.

pin 44

:

FLASH-CE

:IN:

The serial data output for the flash memory.

pin 45

:NC:O:

Not in use.

pin 46

:NC:IN:

Not in use.

pin 47

:NC:IN:

Not in use.

pin 48

:NC:IN:

Not in use.

pin 49

:NC:IN:

Not in use.

pin 50

:

BOLERO-REQ:IN

:

The request signal input to the BOLERO.

pin 51

:

AMP-MUTE

:O:

Muting signal output to the

Audio Power Amplifier.

pin 52

:NC:

I/O

:

Not in use.

pin 53

:NC:O:

Not in use.

pin 54

:NC:O:

Not in use.

pin 55

:

DSP-RESET:O

:

Reset signal output to the DSP IC.

pin 56

:

DSP-INIT

:IN:

The initial finished signal input from the

Radio-Audio-DSP.

pin 57

:

AMP-STBY

:O:

ON signal output to the internal Amplifier.

pin 58

:

EXT-AMP-REM:O

:

ON signal output to the external Amplifier.

pin 59

:

NOISE-CUT:O

:

The cut of contral signal output to the noise.

pin 60

:

VCC

:-:

Positive power supply.

pin 61

:NC:IN:

Ground.

pin 62

:

GND

:-:

Ground.

pin 63

:

AM/FM-ON

:O:

The 8.5V power supply ON signal output.

pin 64

:

AM/FM-5V-ON:O

:

The 5V power supply ON signal output.

pin 65

:

DSP2-INIT

:O:

The initial reset signal output to DSP2.

pin 66

:

DSP2-RESET:O

:

The reset pulse output to DSP2.

pin 67

:

DSP2-REQ

:O:

The request signal output to DSP2.

pin 68

:

DSP2-SCK

:O:

The clock pulse output to DSP2.

pin 69

:

DSP2-SO

:O:

The serial data output to DSP2.

pin 70

:

DSP2-RDY

:IN:

The ready signal input to DSP2.

pin 71

:

KEY-INT

:IN:

Key interrupting signal input.

pin 72

:

B/U-DET2

:IN:

Backup detection signal input.

pin 73

:

BOLERO-ACC:O

:

The ACC signal of the BOLERO.

pin 74

:

PHONE-IN

:IN:

The telephone interrupt signal input.

pin 75

:

AMP-REM-DET:IN

:

Remote controller wire short detection.

pin 76

:

MOTOR+

:O:

The control signal output to the motor.

pin 77

:

MOTOR-

:O:

The control signal output to the motor.

pin 78

:NC:IN:

Ground.

ADJUSTMENT OF BUS-TUNER : 880-2091E

This adjustment sets some values of the tuner.The adjustment

data is written in EEPROM(IC605).The special jig and software

are necessary for this adjustment.

* CeNET-analyzer

* Personal computer

*SG

* Adjustment-Software:Adjustment system for DSP N217

with CeNET(Ver.Y4-S024-103-20060623)

Preparation

1. Installation of software

Execute the windows installer package in the set-folde

of the writing E2P.

PRN data writing

1) Click [prn FILE LOAD], and select PRN-FILE.

2) Click [EEPROM WRITE], the PRN-data is write in EEPROM

of the unit.

Adjustments

1. FM S-meter

1) Set SG output to 65dBuV.(FM)

2) Click [Adjustment] of "FM S-Meter".(Wait until the value stops.)

2. FM IF-Count

1) Click [Adjustment] under "FM IF-COUNT".(The FM-IFOffset data of EEPRON is effective.)

2) Click [Check], and confirm the display is within +/-500.0.

2. Connection

1) Connect CeNET-analyzer to the unit with the CeNET-cable.

2) Connect CeNET-analyzer(MASTER/SLAVE side) to the

PC with the serial crossing cable.

3) Connect POWER-lead of CeNET-analyzer to the

POWER-lead of the unit.

4) Connect the antenna to the unit.(FM-ANT for first adjustment)

5) Turn on CeNET-analyzer,and press the RESET-button of it.

Set up the software

1) Click [ADJ_DSP].

2) Click [open Comm PORT].(To open the COM port of PC)

3) Click [Initialization of JIG].(The BUS-analyzer sounds)

4) Click [Incoming connection].(The unit is recognized to

the BUS-analyzer)

The data is displayed, and the display changes regularly.

EXPLANATION OF IC

Main section

DXZ785USB/DXZ786USB

3. Set up AM IF Offset data

* Exchange the antenna for "AM-ANT-dummy"

1) Click [Adjustment] under "AM IF-COUNT".(The AM-IFOffset data of EEPRON is effective.)

2) Click [Check], and confirm the display is within +/-500.0.

4. AM S-meter

1) Set SG output to 70dBuV.(AM)

2) Click [Adjustment] of "AM S-Meter".(Wait until the value stops.)

Finally, push the reset button of the unit.

When computer continues to freeze, click [RESET] of "MENU", and

readjust the lost adjustment point.IF not returning, press the

RESET-button of CeNET-analyzer.and restart adjustment from

the first step.

-6-

Page 7

pin 79

:

CLOSE-POSI:IN

:

The close position detect signal input.

pin 80

:

OPEN-POSI:IN

:

The open position detect signal input.

pin 81

:

ILL-DET-OUT:O

:

Illumination ON signal output.

pin 82

:

DISP-REM

:O:

The power supply control signal output for the

displayer.

pin 83

:NC:IN:

Ground.

pin 84

:

DD-REM

:O:

pin 85

:

DD-F-SW

:O:

The frequency control signal output

for DC_DC_Converter.

pin 86

:

MOTOR-REM:O

:

Motor power ON signal output.

pin 87

:

KEY-ILL-REM:O

:

The key illumination ON signal output.

pin 88

:

DISP-RESET:O

:

Display reset signal output.

pin 89

:

KEY-A/D

:IN:

The input terminal of the internal ADC

for key judgment.

pin 90

:

SYS-ACC

:O:

ACC detection signal input.

pin 91

:

SYS-MUTE

:O:

System muting signal output.

pin 92

:

INT1

:IN:

The destination setting input.

pin 93

:

INT2

:IN:

The destination setting input.

pin 94

:

AVSS(GND)

:-:

Negative voltage supply for A/D converter.

pin 95

:

TEST

:O:

Test pin.

pin 96

:

VREF

:IN:

Reference vlotage input for A/D converter .

pin 97

:

AVDD

:-:

Positive voltage supply for A/D converter.

pin 98

:

DSP-SCL

:O:

I2BUS serial clock output

for the Radio-Audio-DSP.

pin 99

:

DSP-SDA

:

I/O

:

I2BUS serial data input/output

for the Radio-Audio-DSP.

pin100:NC

:IN:

Ground.

1.Terminal Description

pin 1

:

LCD-ON

:O:

LCD power supply.

pin 2

:

INT1

:IN:

The destination setting input.

pin 3

:

IE-BUS-TX

:O:

IE Bus serial data output.

pin 4

:

IE-BUS-RX

:IN:

Bus serial data input.

pin 5

:

REMOCON

:IN:

Remote controller signal input terminal.

pin 6

:

BYTE(GND)

:IN:

Connect to VSS.

pin 7

:

CNVSS

:IN:

Connect to VSS.

pin 8

:NC:IN:

Ground.

pin 9

:NC:IN:

Ground.

pin 10

:

RESET

:IN:

The reset signal input.

pin 11

:

X-OUT

:O:

The resonator for main clock.

pin 12

:

GND

:-:

Ground.

pin 13

:

X-IN

:IN:

The resonator for main clock.

pin 14

:

VCC

:-:

Positive power supply.

pin 15

:

VCC

:IN:

Positive power supply.

pin 16

:

SYS-ACC-IN

:IN:

ACC detect signal output.

pin 17

:NC:IN:

Ground.

pin 18

:NC:IN:

Ground.

pin 19

:NC:IN:

Ground.

pin 20

:

VARI-BLUE

:O:

Variable blue.

pin 21

:NC:IN:

Ground.

pin 22

:

VARI-GREEN

:O:

Variable green.

pin 23

:

BACK-L-ON

:O:

The backlight control signal output.

pin 24

:

VARI-RED

:O:

Variable red.

pin 25

:

KEY-ILL

:O:

The key illumination ON signal output.

pin 26

:NC:IN:

Ground.

pin 27

:NC:IN:

Ground.

pin 28

:

LCD-CS

:O:

Chip select signal output to LCD.

pin 29

:

FLASH TX

:O:

The serial data output for flash memory.

pin 30

:

FLASH RX

:IN:

The serial data input for flash memory.

pin 31

:

FLASH-SCL

:IN:

Ground.

pin 32

:

FLASH-BUSY

:O:

Not in use.

pin 33

:

LCD-SI

:O:

The serial data input to the LCD driver.

pin 34

:

LCD- AO

:O:

LCDdriverdatatypecontrol.

pin 35

:

LCD-CLK

:O:

The clock pulse output to the LCD driver.

pin 36:LCD-RESET

:O:

LCD driver reset signal output.

pin 37

:NC:IN:

Ground.

pin 38

:NC:IN:

Ground.

pin 39

:

FLASH-EPM

:IN:

Ground.

pin 40

:NC:IN:

Ground.

pin 41

:NC:IN:

Ground.

pin 42

:NC:IN:

Ground.

pin 43

:NC:IN:

Ground.

pin 44

:

FLASH-CE

:IN:

The chip enable signal input for flash memory

pin 45

:NC:IN:

Ground.

pin 46

:NC:IN:

Ground.

pin 47

:NC:IN:

Ground.

pin 48

:NC:IN:

Ground.

052-7302-10 M30876MJB-713GP Switch System controller

pin 49:KO0

:O:

Key scanning output terminal.

pin 50

:

KO1

:O:

Key scanning output terminal.

pin 51

:

KO2

:O:

Key scanning output terminal.

pin 52

:

KO3

:O:

Key scanning output terminal.

pin 53

:NC:IN:

Ground.

pin 54

:NC:IN:

Ground.

pin 55

:

KI0

:IN:

Key scanning intput terminal.

pin 56

:

KI1

:IN:

Key scanning intput terminal.

pin 57

:

KI2

:IN:

Key scanning intput terminal.

pin 58

:

KI3

:IN:

Key scanning intput terminal.

pin 59

:NC:IN:

Ground.

pin 60

:

VCC

:-:

Positive power supply.

pin 61

:NC:IN:

Ground.

pin 62

:

GND

:-:

Ground.

pin 63

:NC:IN:

Ground.

pin 64

:NC:IN:

Ground.

pin 65

:NC:IN:

Ground.

pin 66

:NC:IN:

Ground.

pin 67

:NC:IN:

Ground.

pin 68

:NC:IN:

Ground.

pin 69

:NC:IN:

Ground.

pin 70

:NC:IN:

Ground.

pin 71

:NC:IN:

Ground.

pin 72

:NC:IN:

Ground.

pin 73

:

ILL-DET

:IN:

The illumination detection signal input.

pin 74

:NC:IN:

Ground.

pin 75

:NC:IN:

Ground.

pin 76

:NC:IN:

Ground.

pin 77

:NC:IN:

Ground.

pin 78

:NC:IN:

Ground.

pin 79

:NC:IN:

Ground.

pin 80

:NC:IN:

Ground.

pin 81

:NC:IN:

Ground.

pin 82

:NC:IN:

Ground.

pin 83

:NC:IN:

Ground.

pin 84

:NC:IN:

Ground.

pin 85

:NC:IN:

Ground.

pin 86

:NC:IN:

Ground.

pin 87

:NC:IN:

Ground.

pin 88

:NC:IN:

Ground.

pin 89

:NC:IN:

Ground.

pin 90

:NC:IN:

Ground.

pin 91

:NC:IN:

Ground.

pin 92

:NC:IN:

Ground.

pin 93

:NC:IN:

Ground.

pin 94

:

AVSS(GND)

:-:

Negative voltage supply for A/D converter .

pin 95

:NC:IN:

Ground.

pin 96

:

VREF

:IN:

Reference vlotage input for A/D converter .

pin 97

:

AVDD

:-:

Positive voltage supply for A/D converter.

pin 98

:NC:IN:

Ground.

pin 99

:NC:IN:

Ground.

pin100

:NC:IN:

Ground.

pin 1

:

VCC

:-:

Supply volltage positive terminal.

pin 2

:

XIN

:-:

32.768 kHz crystal oscillator or external

clock sourcer.

pin 3

:

XOUT

:-:

32.768 kHz crystal oscillator or external

clock sourcer.

pin 4

:

CLOCK_ENAB

:I:

CLOCK_OUT enable(active high).

pin 5

:NC:-:

Not in use.

pin 6

:NC:-:

Not in use.

pin 7

:

I2C_SCL

:

I/O

:

I C clock.

pin 8

:

I2C_ADDR0

:I:

I C slave address selection

pin 9

:

I2C_ADDR1

:I:

I C slave address selection

pin 10

:

I2C_ADDR2

:I:

I C slave address selection

pin 11

:

CP_READY

:O:

CP ready to receive next instruction

(active high).

pin 12

:

MODE0

:I:

Operating voltage selection.

pin 13

:

MODE1

:I:

Communication mode selection.

pin 14

:NC:-:

Not in use.

pin 15

:

I2C_SDA

:

I/O

:

ICdata.

pin 16

:

MODE2

:I:

Communication mode selection.

pin 17

:

ROSC

:I:

Connect via 100k¡1% resistorto VCC.

pin 18

:

SPI_nSS

:I:

SPI slave select (active low).

pin 19

:

SPI_SIMO

:I:

SPI master-to-slave data.

pin 20

:

SPI_SOMI

:O:

SPI slave-to-master data.

pin 21

:

SPI_UCLK

:I:

SPI clock.

051-6928-90 341S2094 iPod Authentication Coprocessor Specification

The control signal output for DC_DC_Converter.

-7-

2

2

2

2

2

DXZ785USB/DXZ786USB

Page 8

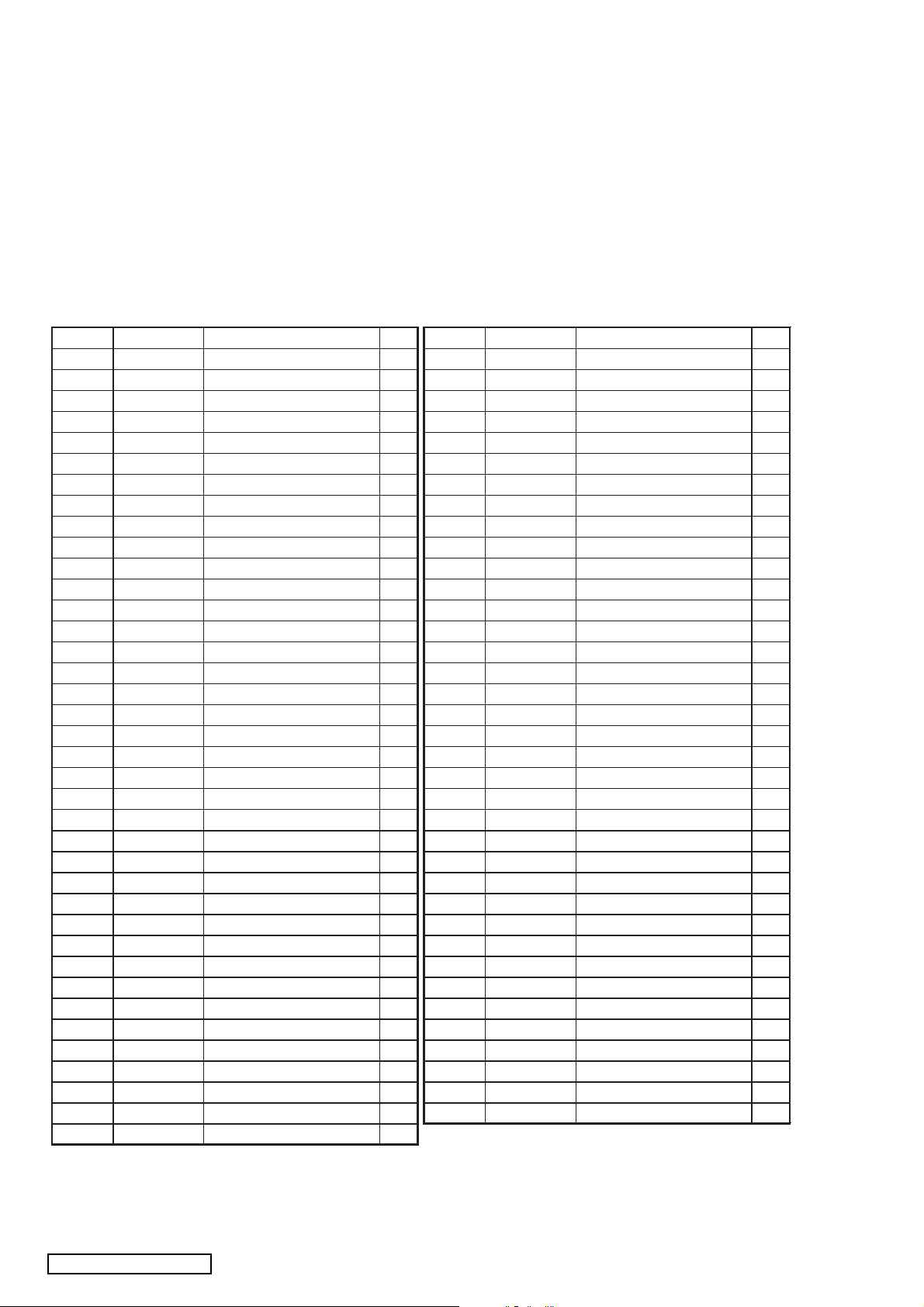

NO. PART NO. DESCRIPTION Q'TY NO. PART NO. DESCRIPTION Q'TY

1 ----------- SENSOR PWB 1 39 621-1750-20 POWER GEAR C 1

2 966-1743-21 DRIVE-PLT-ASSY 1 40 621-1751-20 POWER GEAR D 1

3 SMA-182-100 SPINDLE MOTOR-ASSY 1 41 621-1752-20 DISC STOPPER 1

4 SMA-197-100 SLED MOTOR-ASSY 1 42 621-1753-20 CLAMPER RING 1

5 345-5476-20 CUSHION RUBBER 1 43 621-1754-20 GEAR BASE 1

6 620-1023-23 CLAMPER PLATE 1 44 622-1571-21 ROLLER SHAFT 1

7 620-1026-21 SPRING PLATE 1 45 624-0020-00 LEAD SCREW 1

8 620-1596-23 CLAMPER LINK 1 46 629-0081-21 DAMPER F 2

9 620-1598-22 UPPER CHASSIS 1 47 629-0082-21 DAMPER R 1

10 620-1752-20 SENSOR ARM 1 48 716-1507-01 SCREW(M2x3) 1

11 620-1753-20 ID-LOCK PLATE 1 49 716-1670-01 SCREW(M2x4) 4

12 620-1766-20 LOWER CHASSIS 1 50 716-1733-01 SCREW(M1.7x2.3) 2

13 621-0608-21 SECOND GEAR 1 51 716-3469-01 SCREW(1.7x4) 2

14 621-0609-20 BASE GEAR 1 52 716-3473-01 SCREW(M2x3) 1

15 621-0610-20 IDLE GEAR A 1 53 716-3551-00 SCREW(M1.4x2.5) 2

16 621-0611-20 IDLE GEAR B 1 54 750-7865-20 SHIFT SPRING 1

17 621-0612-21 ROLLER GEAR A 1 55 750-7866-20 RACK SPRING 1

18 621-0620-20 THREAD GEAR A 1 56 750-7867-20 CLAMPER SPRING 1

19 621-0621-20 THREAD GEAR B 1 57 750-7868-20 ID-LOCK SPRING 1

20 621-0623-23 LS-HOLDER 1 58 750-7869-20 SENSOR SPRING 1

21 621-0624-22 GUIDE RAIL 1 59 750-7870-20 DR-SPRING F 2

22 621-0711-21 LOADING ROLLER 2 60 750-7871-20 DR-SPRING RA 1

23 621-0718-21 ROLLER GUIDE 1 61 750-7872-20 DR-SPRING RB 1

24 621-0719-20 ROLLER GEAR 1 62 750-7873-20 DR-SPRING C 1

25 621-0720-20 ROLLER GEAR C 1 63 750-6797-20 ROLLER SPRING L 1

26 621-0721-20 ROLLER GEAR D 1 64 750-6798-20 ROLLER SPRING R 1

27 621-0728-20 STOPPER LINK 1 65 714-2003-8B SCREW(M2x3) 2

28 621-1719-20 IDLE CASE 1 66 780-2025-00 SCREW(M2x2.5) 3

29 621-1726-20 ROLLER SLEEVE 2 67 781-1730-00 SCREW(M1.7x3) 1

30 621-1729-20 SH-BASE 1 68 803-4906-60 VINYL-COAT-WIRE(ORG) 1

31 621-1742-20 UPPER GUIDE 1 69 969-0071-30 PICKUP-ASSY 1

32 621-1743-20 SHIFT LEVER 1 70 816-2590-00 SPECIAL LEAD(GRN) 1

33 621-1744-20 RACK 1 71 816-2591-00 SPECIAL LEAD(YEL) 1

34 621-1745-20 LOCK ARM L 1 72 816-2592-00 SPECIAL LEAD(BLUE) 1

35 621-1746-20 LOCK ARM R 1 73 816-2593-00 SPECIAL LEAD(PUR) 1

36 621-1747-20 GEAR COVER 1 74 966-1722-20 SH-RACK-ASSY 1

37 621-1748-20 POWER GEAR A 1 75 816-2624-50 FLAT WIRE 1

38 621-1749-20 POWER GEAR B 1

EXPLODED VIEW / PARTS LIST

pin 22

:NC:-:

Not in use.

pin 23

:NC:-:

Not in use.

pin 24

:NC:-:

Not in use.

pin 25

:NC:-:

Not in use.

pin 26

:NC:-:

Not in use.

pin 27

:NC:-:

Not in use.

pin 28

:NC:-:

Not in use.

pin 29

:NC:-:

Not in use.

pin 30

:NC:-:

Not in use.

pin 31

:NC:-:

Not in use.

pin 32

:

CLOCK_OUT

:O:

32.768 kHz clock output, if selected by

CLOCK_ENAB.

pin 33

:NC:-:

Not in use.

pin 34

:NC:-:

Not in use.

pin 35

:NC:-:

Not in use.

pin 36

:NC:-:

Not in use.

pin 37

:NC:-:

Not in use.

pin 38

:

nRESET

:I:

CP reset(active low).

pin 39

:

VSS

:-:

Supply voltage, negative terminal.

pin 40

:

VCC

:-:

Supply volltage positive terminal.

CD mechanism section: 929-5016-80

DXZ785USB/DXZ786USB

-8-

* The exploded view is on page 9

Page 9

65

42

27

9

B1

71

H1

46

H2

22

B2

29

H3

23

73

A1

34

63

1

72

48

H4

H5

44

G6

A4

68

75

A4

D1

G13

H6

H7

52

H3

H1

H2

70

to MAIN

31

B1

22

G2

26

H6

G13

60

29

G12

A1

3

H5

H4

A3

D2

65

21

62

A8

64

B2

1

47

67

2

A5

35

G6

66

61

25

G3

K1

C3

K2

7

E2

G12

M1

A2

41

50

43

18

6

11

G14

G14

K3

K4

17

G2

C2

E2

G5

C1

24

37

G4

G5

A3

57

66

G1

G9

C5

G8

8

20

G11

38

M1

32

G4

39

E1

G3

40

56

54

K3

58

10

E1

G11

G8

G9

C5

33

55

53

K4

51

59

D1

12

A8

59

D2

A2

46

5

A5

13

30

74

H6

H7

36

4

49

K1

C3

K2

16

H6

C1

49

14

15

G1

69

45

28

19

C2

-9-

DXZ785USB/DXZ786USB

Page 10

DCP section

NO. PART NO. DESCRIPTION Q'TY NO. PART NO. DESCRIPTION Q'TY

1 DCP-607-600 DCP ASSY(PE-3041B-A) 1 1-25 345-8647-00 CUSHION 1

DCP-629-800 DCP ASSY(PE-3041K-A/B) 1 1-26 347-6977-00 COVER FILM 1

1-1 335-7724-00 BRAND 1 1-27 335-7992-00 SPRING CVR 1

1-2 373-1125-10 SEEK PLATE(PE-3041B-A) 1 1-28 335-7984-00 IR FILTER 1

373-1125-24 SEEK PLATE(PE-3041K-A/B) 1 1-29 750-6720-00 SPRING (REL) 1

1-3 947-0738-00 VOLUME BARS 1 1-30 382-8167-00 RELEASE BUTTON 1

1-4 947-0737-00 SIDE PARTS ASSY 1 1-31 001-7088-90 DIODE 4

1-5 750-6856-00 SPRING 1 1-32 347-8245-00 LEATHER SHEET 1

1-6 347-8210-00 TRIM CVR 2 1-33 347-8246-00 LEATHER SHEET 1

1-7 716-0872-51 SCREW(M1.7x6) 6 1-34 347-8251-00 FILM 6

1-8 335-8004-01 ROLLER 2 1-35

347-7347-00 SPACER FILM 1

1-9 370-6260-14 ESCUTCHEON(PE-3041B-A) 1 1-36 347-8249-00 DOUBLE FACE 4

370-6260-16

ESCUTCHEON(PE-3041K-A/B)

1 1-37 347-8252-00 FILM 2

1-10 335-7989-00 SPRING CAP 6 1-38 347-8208-00 LEATHER SHEET 4

1-11 750-6825-00 SPRING 2 1-39 331-4373-00 LCD COVER 1

1-12 335-8005-00 SPRING CVR 2 1-40 347-8213-00 SHAFD 1

1-13 382-8169-04 BUTTON(ISR) 1 1-41 379-1381-81 INDICATOR(LCD) 1

1-14 382-8165-00 BUTTON(ENT) 1 1-42 347-8212-00 FILM 1

1-15 382-8166-02 BUTTON(SOUND) 1 1-43 347-8211-00 FILM 1

1-16 335-7985-00 INDICATOR-A 2 1-44 335-7351-00 ILLUMI PLATE 1

1-17 335-7987-00 ILLUMI PLATE(R) 1 1-45 335-7988-00 LCD HOLDER 1

1-18 335-6899-02 REAR CVR 1 1-46 060-4017-90 IR-RECIEVER 1

1-19 347-6628-00 SPACER FILM 1 1-47 ------------- SWITCH PWB 1

1-20 716-0872-62 SCREW(M1.7X6) 5 1-48 076-0708-02 PLUG 2

1-21 335-7986-01 ILLUMI PLATE(L) 1 1-49 013-6524-50 TACT SWITCH 9

1-22 382-8164-02 BUTTON(EJECT) 1 1-50 013-7419-00 SWITCH 3

1-23 382-8163-00 BUTTON(SRC) 1 1-51 074-2226-71 OUTLET SOCKET(21P) 1

1-24 382-8168-02 BUTTON(TITLE) 1 1-52 076-0647-00 PLUG (16P) 1

1-36

1-29

1-30

1-4

A

A

1-38

1-3

1-33

1-1

1-2

A

: SANKOL application

B

: Grease application

Note) SANKOL uses G-311S

Grease uses CFD-409Z

1-8

1-16

1-34

1-6

1-10

1-7

1-32

1-38

1-12

1-37

1-20

1-26

1-25

1-23

1-22

B

B

1-19

1-7

1-27

1-5

1-11

1-10

1-35

A

1-10

A

1-24

1-13

1-28

1-16

1-21

1-15

B

1-11

1-50

1-12

B

1-14

1-17

1-49

1-7

1-49

1-18

1-20

1-52

1-31

1-50

1-46

1-31

1-48

1-51

1-50

1-47

1-6

1-7

1-8

1-36

1-9

1-49

1-31

1-45

1-44

1-43

1

1-42

1-39

1-41

1-40

Note) Some parts depend on each model.

The model name is specified in the

description.

DXZ785USB/DXZ786USB

-10-

Page 11

Inner escutcheon section

Finished figure

33

36

Grease

application

33

Grease

application

34

35

application

28

Grease

12

12

18

19

10

11

9

Grease

application

37

33

20

8

12

17

26

32

Grease

application

30

29

38

8

31

41

8

26

Grease

application

8

13

12

6

22

8

12

3

2

40

39

4

23

21

24

25

12

5

7

8

16

15

12

Grease

14

1

12

27

application

Note): Grease uses FLOIL 31SB

NO. PART NO. DESCRIPTION Q'TY NO. PART NO. DESCRIPTION Q'TY

1 370-5935-07 INNER ESCUTCHEON 1

2 074-1278-01 OUTLET SOCKET(16P) 1

3 347-6528-00 INSULATOR 1

4 039-2409-05 INNER ES FPC 1

(WITHOUT COMPONENT)

5 331-3115-01 DCP HOLDER 1

6 335-6903-00 ARM-COVER(L) 1

7 335-6904-00 ARM-COVER(R) 1

8 716-1468-70 SCREW(M2x2.5) 10

9 335-7484-00 HOOK 1

10 750-3431-02 SPRING(HOOK) 1

11 341-1802-00 SHAFT 1

12 716-1715-52 DECO-SCREW(M2) 11

13 335-6499-00 CN-CVR 1

14 331-3117-01 LEVER-UP(R) 1

15 331-3118-01 LEVER-LO(R) 1

16 335-6505-00 ILLUMI PLATE 1

17 331-3119-00 LEVER-LO(L) 1

18 331-3120-00 LEVER-UP(L) 1

19 716-1758-50 PAD SCREW(M2x5) 2

20 341-1740-00 ROLLER(ARM) 1

21 347-6527-01 CUSHION 1

22 750-3457-00 SPRING 1

23 291-0102-02 STICKER 1

24 345-8627-01 CUSHION 1

25 346-0150-02 LEATHER SHEET 1

26 716-0872-50 PAD SCREW(M1.7x5) 4

27 750-3304-20 SPRING(GEAR) 1

28 854-4380-01 EXTENSION LEAD 1

29 309-0772-02 FRONT PLATE 1

30 613-0719-00 ARM GEAR 1

31 750-3432-00 SPRING(MOTO) 1

32 613-0733-00 HUS-GEAR 1

33 746-0768-70 SPECIAL WASHER 4

34 613-0717-00 INPUT GEAR 1

35 634-0024-00 MOTOR-ASSY 1

36 947-0513-04 T-LIM-GEAR-ASSY 1

37 750-3303-20 SPRING(ARM) 1

38 347-8262-00 FILM(FRONT) 1

39 345-5937-00 CUSHION 1

40 347-7347-00 SPACER 1

41 946-0079-01 GEAR-BOX ASSY 1

-11-

DXZ785USB/DXZ786USB

Page 12

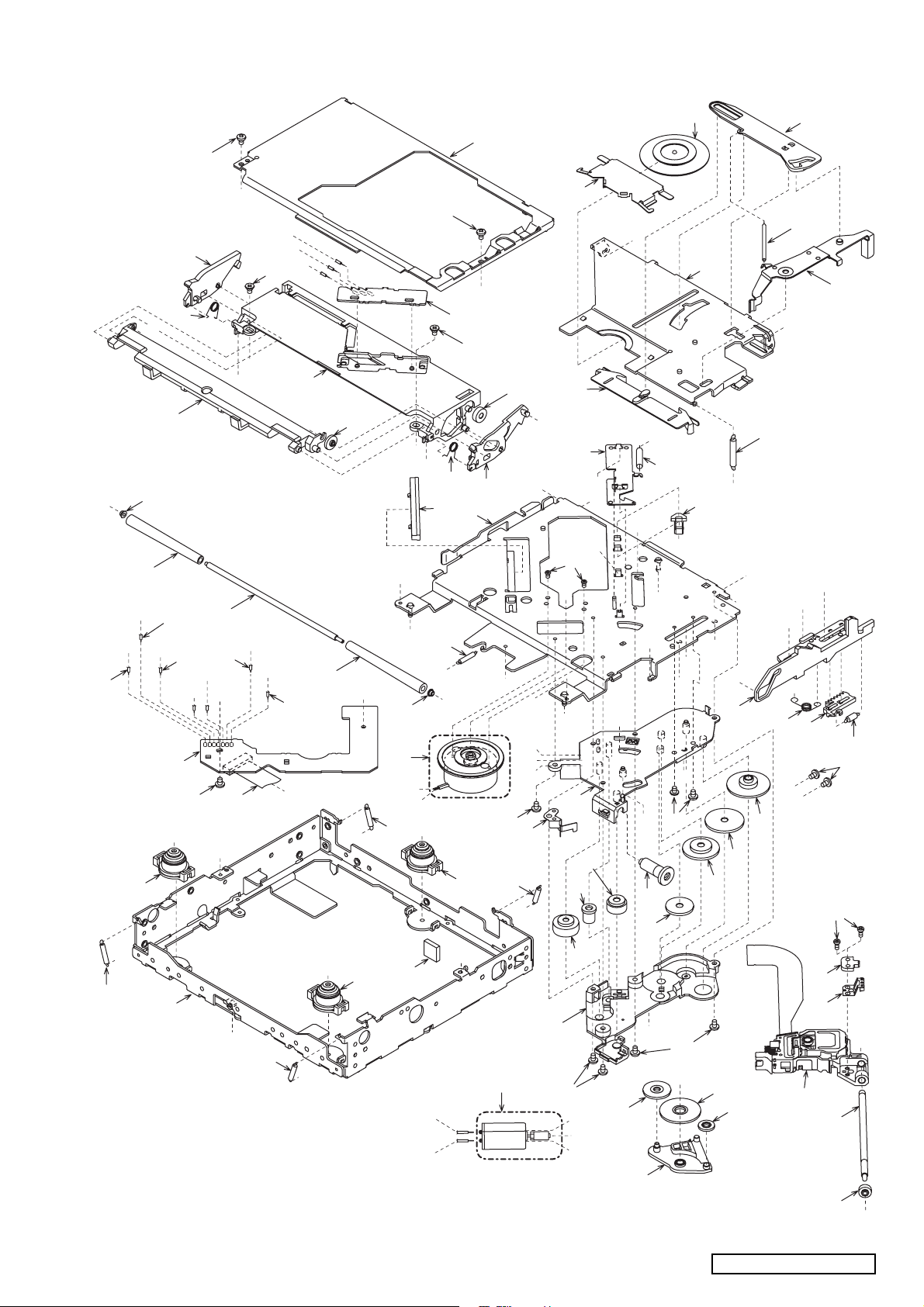

Main section

NO. PART NO. DESCRIPTION Q'TY NO. PART NO. DESCRIPTION Q'TY

1 076-0312-02 PLUG(2P) 1 28 313-1923-00 HEAT SINK 1

2 013-7206-50 DETECTOR SWITCH 1 29 714-3006-8B MACHINE SCREW(M3x6) 7

3 013-7106-00 DETECTOR SWITCH 1 30 074-1138-65 OUTLET SOCKET(15P) 1

4 331-3378-00 SW-HOLDER 1 31 076-0478-55 PLUG(5P) 1

5 880-2091E TUNER 1 32 074-1228-79 OUTLET SOCKET(29P) 1

6 074-1138-79 OUTLET SOCKET(29P) 1 3 3 074-1138-60 OUTLET SOCKET(10P) 1

7 074-1214-50 OUTLET SOCKET(16P) 1 34 ------------- YAMATO PWB 1

8 331-3954-00 IC-HOLDER 1 35 331-2744-00 STOPPER 1

9 076-0368-16 PLUG(16P) 1 36 347-7581-10 CUSHION 2

10 076-6003-18 PLUG(18P) 1 37 303-0472-07 UPPER-CVR 1

11 074-1194-00 OUTLET SOCKET(CeNET) 1 38 347-7579-10 INSULATOR 1

12

347-6215-00 SPACER-FILM 1

39 714-2603-8B MACHINE SCREW(M2.6x3) 7

13 313-1924-00 HEAT SINK 1 40 331-3324-00 CD-SUB-BRKT(R) 1

14 714-3005-8B MACHINE SCREW(M3x5) 4 41 347-8269-00 SPACER 2

15 305-0348-00 SIDE-CVR(R) 1 42 929-5016-80 CD-MECH-MODULE 1

16 013-6100-00 TACT SWITCH 1 43 716-1670-01 SCREW(M2x4) 2

17 ------------- MAIN PWB 1 44 816-4026-50 FLAT WIRE 1

18 001-7062-90 DIODE 1 45 331-4367-00 MECH BRKT(F) 1

19 305-0347-00 SIDE-CVR(L) 1 46 347-6536-00 PROTECT SHEET 1

20

347-8250-00 DOUBLE FACE 1

47 347-7578-10 INSULATOR 1

21 092-2215-50 ANT-RECEPT 1 48 304-0483-00 LOWER-CVR 1

22 074-1198-68 OUTLET SOCKET(18P) 1 49 276-0379-00 SETPLATE(PE-3041B-A) 1

23 307-0723-01 REAR-CVR 1 276-0413-00 SETPLATE(PE-3041K-A) 1

24 074-0898-16 OUTLET SOCKET(16P) 1 276-0414-00 SETPLATE(PE-3041K-B) 1

25 ------------- D/D PWB 1 50

716-0717-60 STEEL SCREW(M2.3x0.4P) 2

26 855-0613-53 USB CABLE 1 51

780-2005-50 SCREW(M2x5) 2

27 731-3006-8B TAPTIGHT(M3x5) 9 52

345-8701-00 CUSHION 1

It attaches in

the open position.

50

51

50

39

20

44

27

46

42

41

39

45

27

29

31

43

26

5

21

40

39

33

28

30

41

39

38

39

34

32

27

27

43

29

37

27

8

7

25

35

36

Inner escutcheon

19

52

4

3

2

9

10

11

24

23

29

13

1

22

18

49

48

47

DXZ785USB/DXZ786USB

12

17

16

-12-

14

6

15

27

14

Page 13

ELECTRICAL PARTS LIST

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

ANT1

092-2215-50

ANT-RECEPT C314 043-1804-90 0.1uF C380 043-1735-90 100pF

BL1 880-2091E TUNER C315 043-1735-90 100pF C382 043-1611-90 2200pF

C2 043-1719-90 22pF C316 043-1735-90 100pF C382 046-2222-58 2200pF

C3 042-1631-50 10V 100uF C317 043-1735-90 100pF C383 043-1611-90 2200pF

C4 043-1802-90 0.01uF C318 043-1802-90 0.01uF C383 046-2222-58 2200pF

C5 043-1821-90 0.022uF C320 043-1804-90 0.1uF C384 043-1819-90 2200pF

C7 043-1800-90 1000pF C321 043-1735-90 100pF C385 043-1819-90 2200pF

C8 187-4763-15 6.3V 47uF C322 042-0654-52 6.3V 10uF C386 043-1819-90 2200pF

C9 043-1608-90 0.1uF C324 043-1804-90 0.1uF C387 043-1819-90 2200pF

C9 046-1042-78 0.1uF C325 043-0552-90 6.3V 47uF C402 042-1563-71 16V 100uF

C10 043-1804-90 0.1uF C327 043-1824-91 0.22uF C409 042-1563-71 16V 100uF

C11 043-1739-90 150pF C327 168-2245-79 0.22uF C410 043-1804-90 0.1uF

C12 043-1735-90 100pF C329 043-0540-00 6.3V 10uF C411 043-0540-00 6.3V 10uF

C13 043-1735-90 100pF C330 043-1841-90 0.047uF C412 043-0540-00 6.3V 10uF

C14 043-1800-90 1000pF C331 043-1608-90 0.1uF C413 043-0540-00 6.3V 10uF

C15 043-0552-90 6.3V 47uF C331 046-1042-78 0.1uF C414 043-0540-00 6.3V 10uF

C101 042-1715-00 16V 3300uF C332 163-2273-25 10V 220uF C415 043-0540-00 6.3V 10uF

C102 172-1041-15 0.1uF C333 043-1804-90 0.1uF C416 043-0540-00 6.3V 10uF

C103 189-1083-12 6.3V 1000uF C334 043-1711-90 10pF C417 043-0540-00 6.3V 10uF

C104 042-0654-52 6.3V 10uF C335 043-1824-91 0.22uF C418 043-0540-00 6.3V 10uF

C105 042-0654-52 6.3V 10uF C335 168-2245-79 0.22uF C419 043-0540-00 6.3V 10uF

C106 042-0654-52 6.3V 10uF C336 043-1821-90 0.022uF C420 043-0540-00 6.3V 10uF

C107 042-0654-52 6.3V 10uF C337 043-1606-90 1000pF C421 043-0540-00 6.3V 10uF

C108 042-0654-52 6.3V 10uF C337 046-1022-58 1000pF C422 043-0540-00 6.3V 10uF

C109 042-0654-52 6.3V 10uF C338 043-1606-90 1000pF C423 043-0264-52 1000pF

C110 163-2253-65 50V 2.2uF C338 046-1022-58 1000pF C424 043-1731-90 68pF

C114 178-4742-78 0.47uF C340 043-1751-90 470pF C425 043-1731-90 68pF

C115 178-4742-78 0.47uF C341 043-1821-90 0.022uF C426 0 43-0264-52 1000pF

C116 178-4742-78 0.47uF C342 043-1821-90 0.022uF C427 0 43-0264-51 2200pF

C117 178-4742-78 0.47uF C343 043-1711-90 10pF C428 043-1735-90 100pF

C119 163-1053-65 50V 1uF C344 043-0540-02 16V 1uF C429 043-1735-90 100pF

C120 163-1063-35 16V 10uF C345 043-1821-90 0.022uF C430 043-0264-51 2200pF

C121 043-1802-90 0.01uF C346 043-1821-90 0.022uF C431 0 43-0264-51 2200pF

C124 043-1804-90 0.1uF C347 043-1802-90 0.01uF C432 043-1735-90 100pF

C125 043-1800-90 1000pF C350 043-0540-00 6.3V 10uF C433 043-1735-90 100pF

C126 043-1800-90 1000pF C351 043-1751-90 470pF C434 043-0264-51 2200pF

C127 043-1800-90 1000pF C352 043-1821-90 0.022uF C435 043-1731-90 68pF

C128 043-1800-90 1000pF C355 043-1804-90 0.1uF C436 043-1735-90 100pF

C129 043-1800-90 1000pF C356 043-1606-90 1000pF C437 043-1735-90 100pF

C130 043-1800-90 1000pF C356 046-1022-58 1000pF C438 043-1731-90 68pF

C131 043-1800-90 1000pF C357 043-1741-90 180pF C439 043-1735-90 100pF

C132 043-1800-90 1000pF C357 166-1811-50 180pF C440 043-1735-90 100pF

C133 043-1711-90 10pF C358 043-0551-90 6.3V 4.7uF C441 043-1804-90 0.1uF

C134 043-1711-90 10pF C359 043-0551-90 6.3V 4.7uF C442 043-0264-52 1000pF

C135 043-1711-90 10pF C360 043-1800-90 1000pF C443 043-0264-52 1000pF

C136 043-1711-90 10pF C361 042-0654-52 6.3V 10uF C444 043-0264-51 2200pF

C137 043-1800-90 1000pF C362 043-0551-90 6.3V 4.7uF C445 043-0264-51 2200pF

C138 043-1800-90 1000pF C363 043-1821-90 0.022uF C446 043-0264-51 2200pF

C139 043-1800-90 1000pF C364 043-1831-90 0.033uF C447 043-0264-51 2200pF

C140 043-1800-90 1000pF C365 043-1804-90 0.1uF C452 163-1063-35 16V 10uF

C301 178-4742-78 0.47uF C366 043-1735-90 100pF C600 042-1563-71 16V 100uF

C302 043-0540-00 6.3V 10uF C367 043-1821-90 0.022uF C601 043-1804-90 0.1uF

C303 163-1073-15 6.3V 100uF C368 043-1608-90 0.1uF C602 163-2263-35 16V 22uF

C304 043-1601-90 100pF C368 046-1042-78 0.1uF C603 043-1841-90 0.047uF

C304 045-1011-50 100pF C369 043-0551-90 6.3V 4.7uF C604 043-1735-90 100pF

C305 043-1601-90 100pF C370 042-0654-52 6.3V 10uF C605 042-1631-50 10V 100uF

C305 045-1011-50 100pF C371 043-1608-90 0.1uF C606 043-1606-90 1000pF

C306 043-0540-00 6.3V 10uF C371 046-1042-78 0.1uF C606 046-1022-58 1000pF

C307 043-0540-00 6.3V 10uF C372 042-0654-52 6.3V 10uF C607 043-1606-90 1000pF

C308 043-0540-00 6.3V 10uF C373 043-1608-90 0.1uF C607 046-1022-58 1000pF

C309 043-0540-00 6.3V 10uF C373 046-1042-78 0.1uF C608 187-4763-35 16V 47uF

C310 043-0540-00 6.3V 10uF C374 043-0552-90 6.3V 47uF C609 043-1602-90 18pF

C311 043-1606-90 1000pF C376 043-1821-90 0.022uF C609 045-1801-50 18pF

C311 046-1022-58 1000pF C377 043-1608-90 0.1uF C610 043-1603-90 22pF

C312 043-1606-90 1000pF C377 046-1042-78 0.1uF C610 045-2201-50 22pF

C312 046-1022-58 1000pF C378 043-1601-90 100pF C611 042-1631-50 10V 100uF

C313 043-1606-90 1000pF C378 045-1011-50 100pF C612 043-1804-90 0.1uF

C313 046-1022-58 1000pF C379 043-1735-90 100pF C613 187-4763-35 16V 47uF

Main PWB (B1) section

Note)1. Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

2. Some parts depend on each model.

The model name is specified in the description.

-13-

DXZ785USB/DXZ786USB

Page 14

DXZ785USB/DXZ786USB

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C614 043-1821-90 0.022uF D606 001-0644-90 MA113 L602 010-6025-00 10uH

C615 163-1073-35 16V 100uF D607 001-1310-00 KDS160 L603 010-3406-54 2.2uH

C616 172-4731-15 0.047uF D608 001-2601-90 MA728 L801 010-3112-91

1.5k ohm/100MHz

C617 042-1576-00 5.5V 0.1F D609 001-1310-00 KDS160 L802 010-3112-91

1.5k ohm/100MHz

C618 042-1577-00 6.3V 100uF D610 001-0466-91 S5688G L803 010-3112-91

1.5k ohm/100MHz

C619 043-0510-51 25V 10uF D611 001-0529-26 MA8047M L805 010-3112-91

1.5k ohm/100MHz

C620 043-0540-00 6.3V 10uF D612 001-1310-00 KDS160 L807 010-3112-91

1.5k ohm/100MHz

C621 043-1607-90 0.01uF D613 001-1310-00 KDS160 L808 010-3112-91

1.5k ohm/100MHz

C621 046-1032-78 0.01uF D614 001-0466-91 S5688G L809 010-3112-91

1.5k ohm/100MHz

C624 043-1824-91 0.22uF D615 001-4301-44 HZU8.2B2 L810 010-3112-91

1.5k ohm/100MHz

C624 168-2245-79 0.22uF D616 001-0504-33 HZS6B2L L811 010-3112-91

1.5k ohm/100MHz

C625 043-1608-91 0.1uF D617 001-0644-90 MA113 L812 010-3112-91

1.5k ohm/100MHz

C625 046-1042-78 0.1uF D618 001-0644-90 MA113 L813 010-3112-91

1.5k ohm/100MHz

C626 187-1063-35 16V 10uF D801 001-0584-16 MA8039M L814 010-3112-91

1.5k ohm/100MHz

C628 043-1804-90 0.1uF FIL401 060-3115-51

CKD310JB1C224ST

L815 010-3105-67 1k ohm/100MHz

C629 163-3363-25 10V 33uF FIL404 060-3115-51

CKD310JB1C224ST

L816 010-3105-67 1k ohm/100MHz

C630 043-1804-90 0.1uF IC1 051-1905-91 AN77L05M L817 010-3105-67 1k ohm/100MHz

C631 043-1802-90 0.01uF IC101 051-2056-00 TB2913HQ L818 010-3105-67 1k ohm/100MHz

C632 043-1804-90 0.1uF IC301 -----------

SAF7730HN219A

L819 010-3105-67 1k ohm/100MHz

C633 043-1606-90 1000pF IC402 051-3026-90 NJM4580V L820 010-3105-67 1k ohm/100MHz

C633 046-1022-58 1000pF IC403 051-3026-90 NJM4580V L821 010-3105-67 1k ohm/100MHz

C634 163-1063-35 16V 10uF IC404 051-3026-90 NJM4580V L822 010-3105-67 1k ohm/100MHz

C635 043-1735-90 100pF IC602 051-6078-90 BA6285AFP L823 010-3105-67 1k ohm/100MHz

C636 163-1063-35 16V 10uF IC603 052-3977-10

M30873MHB-

L824 010-3105-67 1k ohm/100MHz

C637 043-0540-00 6.3V 10uF 709GP L825 010-3105-67 1k ohm/100MHz

C638 043-1804-90 0.1uF IC604 051-3335-90 AN77L04M L826 010-3105-67 1k ohm/100MHz

C639 043-1802-90 0.01uF IC605 051-9402-68 BR93L58F-WE2 L827 010-3105-67 1k ohm/100MHz

C640 043-1601-90 100pF IC606 051-5437-58 R3111N211A Q1 125-7005-90 PHK04P02T

C640 045-1011-50 100pF IC606 051-5437-08 S-80821CNMC- Q2 191-1197-50 2SB1197K

C641 043-1735-90 100pF B8GT2G Q2 190-1365-50 2SA1365

C801 043-1607-90 0.01uF IC607 051-6600-90 LA2335M Q3 125-2027-95

DTC143EUA-T106

C801 046-1032-78 0.01uF IC608 051-3406-90 NJM2078M Q3 125-2041-96 RT1N436M

C802 043-0540-00 6.3V 10uF IC801 051-9109-70 IS62LV256 Q4 125-2027-95

DTC143EUA-T106

C803 043-1804-90 0.1uF IC802 051-6705-00 AK7720A Q4 125-2041-96 RT1N436M

C804 043-0540-00 6.3V 10uF J101 074-1214-50 16P Q5 190-1576-00 2SA1576A-T106

C805 043-0540-00 6 .3V 10uF J102 076-6003-18 18P Q5 125-3014-90 ISA1602A

C806 043-1804-90 0.1uF J602 074-1198-68 18P Q101 125-4012-90 KTD1304

C807 043-0540-00 6.3V 10uF J603 076-0312-02 2P Q102 125-4012-90 KTD1304

C808 043-1804-90 0.1uF J604 074-1194-00 CeNET 13P Q103 125-4012-90 KTD1304

C809 043-1804-90 0.1uF J605 074-1138-79 20P Q104 125-4012-90 KTD1304

C810 043-1804-90 0.1uF J606 076-0368-16 16P Q105 125-4012-90 KTD1304

C811 043-1850-90 6800pF L1 010-2003-04 30uH(Variable) Q106 125-4012-90 KTD1304

C812 043-1804-90 0.1uF L2 010-2279-50 4.7uH Q108 125-2027-92

DTC124EUA-T106

C813 043-1804-90 0.1uF L3 010-2279-50 4.7uH Q108 125-2041-93 RT1N241M

C814 043-1804-90 0.1uF L101 010-8038-01

CHOKE COIL 130uH

Q109 125-0021-95

DTA143ZUA-T106

C815 043-0540-00 6.3V 10uF L102 010-3105-67 1k ohm/100MHz Q109 125-0034-96 RT1P436M

C816 043-0540-00 6.3V 10uF L103 010-3105-67 1k ohm/100MHz Q110 125-2027-95

DTC143EUA-T106

C817 043-1800-90 1000pF L104 010-3105-67 1k ohm/100MHz Q110 125-2041-96 RT1N436M

C818 043-1802-90 0.01uF L105 010-3105-67 1k ohm/100MHz Q112 192-4081-00 2SC4081-T106

C888 043-1802-90 0.01uF L106 010-3105-67 1k ohm/100MHz Q112 192-4155-49 2SC4155A

CCT401

010-3042-54

600 ohm x4/100MHz

L107 010-3105-67 1k ohm/100MHz Q401 125-4012-90 KTD1304

CCT402

010-3042-54

600 ohm x4/100MHz

L303 010-3112-90 1k ohm/100MHz Q402 125-4012-90 KTD1304

CCT403

010-3042-54

600 ohm x4/100MHz

L305 010-3112-90 1k ohm/100MHz Q403 125-4012-90 KTD1304

CCT404

010-3042-54

600 ohm x4/100MHz

L306 010-3112-90 1k ohm/100MHz Q404 125-4012-90 KTD1304

CCT405

010-3042-54

600 ohm x4/100MHz

L309 010-3112-91

1.5k ohm/100MHz

Q405 125-4012-90 KTD1304

CCT406

010-3042-54

600 ohm x4/100MHz

L311 010-3105-67 1k ohm/100MHz Q406 125-4012-90 KTD1304

D1 001-1310-00 KDS160 L312 010-3105-67 1k ohm/100MHz Q407 125-4012-90 KTD1304

D2 001-2601-90 MA728 L313 010-3112-91

1.5k ohm/100MHz

Q408 125-4012-90 KTD1304

D3 001-4301-28 HZU5.1B1 L314 010-3105-67 1k ohm/100MHz Q409 125-4012-90 KTD1304

D101 001-0592-61 1N5404 L315 010-3105-67 1k ohm/100MHz Q410 125-4012-90 KTD1304

D102 001-0466-91 S5688G L316 010-3112-91

1.5k ohm/100MHz

Q411 125-4012-90 KTD1304

D103 001-1310-00 KDS160 L317 010-3112-91

1.5k ohm/100MHz

Q412 125-4012-90 KTD1304

D104 001-1310-00 KDS160 L318 010-3112-91

1.5k ohm/100MHz

Q600 125-4015-90 KTC2026

D105 001-4301-43 HZU8.2B1 L319 010-3112-91

1.5k ohm/100MHz

Q601 198-0302-50 2SK302

D130 001-1310-00 KDS160 L320 010-3112-90 1k ohm/100MHz Q602 190-1576-00 2SA1576A-T106

D600 001-0401-47 HZS9C1-TJ L321 010-3112-91

1.5k ohm/100MHz

Q602 125-3014-90 ISA1602A

D601 001-0504-47 HZS9B3L L323 010-3112-90 1k ohm/100MHz Q603 125-2027-92

DTC124EUA-T106

D602 001-0504-45 HZS9B1L L324 010-3112-90 1k ohm/100MHz Q603 125-2041-93 RT1N241M

D603 001-0347-36 MA4062H L325 010-3112-90 1k ohm/100MHz Q605 125-9015-92 RN4902

D604 001-7062-90 RBR1111C L377 010-3112-91

1.5k ohm/100MHz

Q606 125-2027-92

DTC124EUA-T106

D605 001-0644-90 MA113 L601 010-3112-90 1k ohm/100MHz Q606 125-2041-93 RT1N241M

-14-

Page 15

-15-

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

Q607 191-1197-50 2SB1197K R33 119-3331-15 1/10W 33k ohm R303 119-0000-05 1/10W 0 ohm JW

Q607 190-1365-50 2SA1365 R34 119-1831-15 1/10W 18k ohm R304 119-0000-05 1/10W 0 ohm JW

Q608 125-4014-90 KTC2020D R35 119-0000-05 1/10W 0 ohm JW R337 033-1041-15 1/16W 100k ohm

Q609 125-2027-92

DTC124EUA-T106

R36 119-1031-15 1/10W 10k ohm R341 033-1041-15 1/16W 100k ohm

Q609 125-2041-93 RT1N241M R37 119-1031-15 1/10W 10k ohm R355 119-1021-15 1/10W 1k ohm

Q611 125-9015-92 RN4902 R39 119-2201-15 1/10W 22 ohm R361 119-1021-15 1/10W 1k ohm

Q612 125-4014-90 KTC2020D R40 119-0000-05 1/10W 0 ohm JW R401 033-1021-15 1/16W 1k ohm

Q615 125-2041-92 RT1N141M R41 119-1001-15 1/10W 10 ohm R402 033-1021-15 1/16W 1k ohm

Q616 190-1576-00 2SA1576A-T106 R42 119-0000-05 1/10W 0 ohm JW R403 033-1021-15 1/16W 1k ohm

Q616 125-3014-90 ISA1602A R43 119-0000-05 1/10W 0 ohm JW R404 033-1021-15 1/16W 1k ohm

Q617 101-0941-00 2SB941 R44 119-0000-05 1/10W 0 ohm JW R405 033-1021-15 1/16W 1k ohm

Q618 125-0025-93 RN2303-TE85L R45 119-4721-15 1/10W 4.7k ohm R406 0 33-1021-15 1/16W 1k ohm

Q618 125-0034-93 RT1P241M R46 119-4721-15 1/10W 4.7k ohm R407 119-8211-15 1/10W 820 ohm

Q619 190-1576-00 2SA1576A-T106 R49 119-0000-05 1/10W 0 ohm JW R408 119-4711-15 1/10W 470 ohm

Q619 125-3014-90 ISA1602A R50 119-0000-05 1/10W 0 ohm JW R412 032-0140-55

1/10W 4.7k ohm (F)

Q620 190-1576-00 2SA1576A-T106 R51 119-0000-05 1/10W 0 ohm JW R413 032-0140-55

1/10W 4.7k ohm (F)

Q620 125-3014-90 ISA1602A R52 119-0000-05 1/10W 0 ohm JW R414 032-0140-22

1/10W 68k ohm (F)

Q621 192-4081-00 2SC4081-T106 R53 119-1001-15 1/10W 10 ohm R415 032-0140-22

1/10W 68k ohm (F)

Q621 192-4155-49 2SC4155A R54 033-1001-15 1/16W 10 ohm R416 032-0140-55

1/10W 4.7k ohm (F)

Q622 192-4081-00 2SC4081-T106 R56 033-1021-15 1/16W 1k ohm R417 032-0140-55

1/10W 4.7k ohm (F)

Q622 192-4155-49 2SC4155A R59 033-1011-15 1/16W 100 ohm R418 032-0140-07

1/10W 11k ohm (F)

Q623 125-0025-93 RN2303-TE85L R60 119-1031-15 1/10W 10k ohm R419 032-0140-07

1/10W 11k ohm (F)

Q623 125-0034-93 RT1P241M R64 119-0000-05 1/10W 0 ohm JW R420 032-0140-22

1/10W 68k ohm (F)

Q624 125-2027-92

DTC124EUA-T106

R67 119-0000-05 1/10W 0 ohm JW R421 032-0140-22

1/10W 68k ohm (F)

Q624 125-2041-93 RT1N241M R68 033-1011-15 1/16W 100 ohm R422 032-0140-07

1/10W 11k ohm (F)

Q625 125-2027-92

DTC124EUA-T106

R69 119-1031-15 1/10W 10k ohm R423 032-0140-07

1/10W 11k ohm (F)

Q625 125-2041-93 RT1N241M R70 033-1011-15 1/16W 100 ohm R424 032-0140-07

1/10W 11k ohm (F)

Q626 131-1260-00 2SB1260 R71 033-1031-15 1/16W 10k ohm R425 032-0140-07

1/10W 11k ohm (F)

Q627 190-1576-00 2SA1576A-T106 R72 033-1011-15 1/16W 100 ohm R426 032-0140-22

1/10W 68k ohm (F)

Q627 125-3014-90 ISA1602A R73 119-0000-05 1/10W 0 ohm JW R427 032-0140-22

1/10W 68k ohm (F)

Q628 125-2027-92

DTC124EUA-T106

R74 033-1031-15 1/16W 10k ohm R428 032-0140-07

1/10W 11k ohm (F)

Q628 125-2041-93 RT1N241M R75 033-1031-15 1/16W 10k ohm R429 032-0140-07

1/10W 11k ohm (F)

Q629 131-1260-00 2SB1260 R76 119-0000-05 1/10W 0 ohm JW R430 119-4321-15 1/10W 4.3k ohm

Q630 125-4015-90 KTC2026 R77 119-0000-05 1/10W 0 ohm JW R431 032-0140-79

1/10W 2.7k ohm (F)

Q631 125-4015-90 KTC2026 R78 119-1031-15 1/10W 10k ohm R432 032-0140-79

1/10W 2.7k ohm (F)

Q632 190-1576-00 2SA1576A-T106 R79 033-4721-15 1/16W 4.7k ohm R433 119-4321-15 1/10W 4.3k ohm

Q632 125-3014-90 ISA1602A R80 119-1011-15 1/10W 100 ohm R434 119-4321-15 1/10W 4.3k ohm

Q633 125-2027-95

DTC143EUA-T106

R81 119-0000-05 1/10W 0 ohm JW R435 032-0140-79

1/10W 2.7k ohm (F)

Q633 125-2041-96 RT1N436M R82 119-1011-15 1/10W 100 ohm R436 032-0140-79

1/10W 2.7k ohm (F)

Q635 125-0025-93 RN2303-TE85L R86 033-0000-05 0.5A 0 ohm R437 032-0140-79

1/10W 2.7k ohm (F)

Q635 125-0034-93 RT1P241M R87 033-0000-05 0.5A 0 ohm R438 032-0140-79

1/10W 2.7k ohm (F)

Q636 192-4081-00 2SC4081-T106 R90 119-0000-05 1/10W 0 ohm JW R439 119-4321-15 1/10W 4.3k ohm

Q636 192-4155-49 2SC4155A R101 119-1031-15 1/10W 10k ohm R440 032-0140-22

1/10W 68k ohm (F)

Q638 125-9015-92 RN4902 R102 033-3331-15 1/16W 33k ohm R441 032-0140-79

1/10W 2.7k ohm (F)

Q801 125-2027-95

DTC143EUA-T106

R103 033-1021-15 1/16W 1k ohm R442 032-0140-22

1/10W 68k ohm (F)

Q801 125-2041-96 RT1N436M R104 033-5621-15 1/16W 5.6k ohm R443 032-0140-79

1/10W 2.7k ohm (F)

Q907 125-2027-92

DTC124EUA-T106

R108 119-4721-15 1/10W 4.7k ohm R444 032-0140-22

1/10W 68k ohm (F)

Q907 125-2041-93 RT1N241M R110 119-1021-15 1/10W 1k ohm R445 032-0140-22

1/10W 68k ohm (F)

Q908 125-0021-95

DTA143ZUA-T106

R111 119-1021-15 1/10W 1k ohm R446 032-0140-22

1/10W 68k ohm (F)

Q908 125-0034-96 RT1P436M R112 119-1021-15 1/10W 1k ohm R447 032-0140-22

1/10W 68k ohm (F)

R2 119-1031-15 1/10W 10k ohm R113 119-3311-15 1/10W 330 ohm R450 033-1021-15 1/16W 1k ohm

R3 119-1041-15 1/10W 100k ohm R114 119-3311-15 1/10W 330 ohm R452 033-1021-15 1/16W 1k ohm

R6 119-1031-15 1/10W 10k ohm R115 119-3311-15 1/10W 330 ohm R453 033-1021-15 1/16W 1k ohm

R7 119-1031-15 1/10W 10k ohm R116 119-3311-15 1/10W 330 ohm R454 033-1021-15 1/16W 1k ohm

R8 033-1031-15 1/16W 10k ohm R117 119-3311-15 1/10W 330 ohm R455 033-1021-15 1/16W 1k ohm

R10 033-1021-15 1/16W 1k ohm R118 119-3311-15 1/10W 330 ohm R456 033-3311-15 1/16W 330 ohm

R11 033-1031-15 1/16W 10k ohm R119 119-2231-15 1/10W 22k ohm R457 033-1021-15 1/16W 1k ohm

R16 033-1021-15 1/16W 1k ohm R120 119-2231-15 1/10W 22k ohm R458 033-1021-15 1/16W 1k ohm

R17 119-0000-05 1/10W 0 ohm JW R121 119-2231-15 1/10W 22k ohm R459 033-3311-15 1/16W 330 ohm

R18 119-0000-05 1/10W 0 ohm JW R122 119-2231-15 1/10W 22k ohm R460 033-3311-15 1/16W 330 ohm

R22 033-1831-15 1/16W 18k ohm R123 119-2231-15 1/10W 22k ohm R461 033-3311-15 1/16W 330 ohm

R23 119-1031-15 1/10W 10k ohm R124 119-2231-15 1/10W 22k ohm R462 033-1021-15 1/16W 1k ohm

R24 033-1831-15 1/16W 18k ohm R133 116-1521-15 1/4WS 1.5k ohm R463 033-3311-15 1/16W 330 ohm

R25 119-0000-05 1/10W 0 ohm JW R134 119-1021-15 1/10W 1k ohm R464 033-3311-15 1/16W 330 ohm

R26 119-0000-05 1/10W 0 ohm JW R135 119-1021-15 1/10W 1k ohm R465 033-3311-15 1/16W 330 ohm

R27 119-1831-15 1/10W 18k ohm R136 119-1021-15 1/10W 1k ohm R466 033-1021-15 1/16W 1k ohm

R28 119-3331-15 1/10W 33k ohm R137 119-1021-15 1/10W 1k ohm R467 033-3311-15 1/16W 330 ohm

R29 119-1831-15 1/10W 18k ohm R145 032-0140-50

1/10W 10k ohm (F)

R468 033-3311-15 1/16W 330 ohm

R30 119-3331-15 1/10W 33k ohm R151 033-2231-15 1/16W 22k ohm R469 033-1021-15 1/16W 1k ohm

R31 119-3331-15 1/10W 33k ohm R301 119-0000-05 1/10W 0 ohm JW R470 033-3311-15 1/16W 330 ohm

R32 119-1831-15 1/10W 18k ohm R302 119-0000-05 1/10W 0 ohm JW R471 033-1021-15 1/16W 1k ohm

DXZ785USB/DXZ786USB

Page 16

Switch PWB (B2) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C701 043-1741-90

180pF

D719 001-7088-90 HSMF-A355 R4 033-3941-15 1/10W 390k ohm

C702 042-0397-59

50V 1uF TAN

D720 001-7088-90 HSMF-A355 R700 033-1031-15 1/10W 10k ohm

C703 042-0397-59

50V 1uF TAN

IC701 052-7302-10

M30876MJB-713GP

R701 033-1031-15 1/10W 10k ohm

C704 042-0397-59

50V 1uF TAN

IC702 051-7507-08

SN74LV125APWR

R702 033-1031-15 1/10W 10k ohm

C705 178-2242-78

50V 0.22uF

IR701 060-4017-90 RS-671 R703 033-1031-15 1/10W 10k ohm

C706 178-2242-78

50V 0.22uF

J701 074-2226-71 16P R704 033-1031-15 1/10W 10k ohm

C707 042-0423-97

16V 10uF TAN

L701 010-3407-59 5.6uH R705 119-1031-15 1/10W 10k ohm

C708 178-2242-78

50V 0.22uF

L702 010-3406-54 2.2uH R706 119-1041-15 1/10W 100k ohm

C709 178-2242-78

50V 0.22uF

L703 010-3112-91 GZ1608D15 R707 119-1031-15 1/10W 10k ohm

C710 178-2242-78

50V 0.22uF

L704 010-3112-91 GZ1608D15 R708 119-0000-05

1/10W 0 ohm J W

C711 043-1608-90 0.1uF L705 010-3112-91 GZ1608D15 R713 033-1031-15 1/10W 10k ohm

C711 046-1042-78 0.1uF L706 010-3112-91 GZ1608D15 R718 033-6811-15 1/10W 680 ohm

C712 043-1608-90 0.1uF L708 010-3112-91 GZ1608D15 R719 033-8211-15 1/10W 820 ohm

C712 046-1042-78 0.1uF L709 010-3112-91 GZ1608D15 R720 033-4711-15 1/10W 470 ohm

C713 043-1608-90 0.1uF L710 010-3112-91 GZ1608D15 R721 033-6811-15 1/10W 680 ohm

C713 046-1042-78 0.1uF P701 076-0647-00 16P R722 033-5611-15 1/10W 560 ohm

C714 043-1608-90 0.1uF Q709 125-2017-96 RN1426 R723 033-1521-15 1/10W 1.5k ohm

C714 046-1042-78 0.1uF Q710 125-2017-96 RN1426 R724 033-1021-15 1/10W 1k ohm

C715 043-1608-90 0.1uF Q711

191-1197-50 2SB1197K

R725 033-8211-15 1/10W 820 ohm

C715 046-1042-78 0.1uF Q711 190-1365-50 2SA1635 R726 033-1021-15 1/10W 1k ohm

C716 178-4742-78 0.47uF Q712

191-1197-50 2SB1197K

R727 033-1021-15 1/10W 1k ohm

C717 178-4742-78 0.47uF Q712 190-1365-50 2SA1635 R735 033-1521-15 1/10W 1.5k ohm

C718 043-1741-90

180pF

Q715 125-2017-96 RN1426 R736 033-1521-15 1/10W 1.5k ohm

C719 042-0423-97

16V 10uF TAN

Q716 125-2017-96 RN1426 R738 033-6811-15 1/10W 680 ohm

D701 001-2601-90 MA728 Q717

191-1197-50 2SB1197K

R739 033-8211-15 1/10W 820 ohm

D702 001-2601-90 MA728 Q717 190-1365-50 2SA1635 R740 033-8211-15 1/10W 820 ohm

D703 001-2601-90 MA728 Q718 125-2017-96 RN1426 R742 033-1031-15 1/10W 10k ohm

D704 001-2601-90 MA728 Q719 125-2017-96 RN1426 R743 033-2221-15 1/10W 2.2k ohm

D714 001-2601-90 MA728 R1 033-2241-15 1/10W 220k ohm R744 033-1031-15 1/10W 10k ohm

D717 001-7088-90 HSMF-A355 R2 033-1031-15 1/10W 10k ohm R745 033-2221-15 1/10W 2.2k ohm

D718 001-7088-90 HSMF-A355 R3 033-8241-15 1/10W 820k ohm R746 033-1031-15 1/10W 10k ohm

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R472 033-1021-15 1/16W 1k ohm R637 033-1031-15 1/16W 10k ohm R693 119-0000-05 1/10W 0 ohm JW

R473 033-3311-15 1/16W 330 ohm R638 033-1031-15 1/16W 10k ohm R697 033-4731-15 1/16W 47k ohm

R474 033-1021-15 1/16W 1k ohm R639 033-5621-15 1/16W 5.6k ohm R650 033-3321-15 1/16W 3.3k ohm

R475 033-3311-15 1/16W 330 ohm R640 033-4721-15 1/16W 4.7k ohm R651 033-1531-15 1/16W 15k ohm

R600 119-1011-15 1/10W 100 ohm R641 033-1031-15 1/16W 10k ohm R652 119-3321-15 1/10W 3.3k ohm

R601 033-1031-15 1/16W 10k ohm R642 033-1041-15 1/16W 100k ohm R653 119-0000-05 1/10W 0 ohm JW

R602 033-2231-15 1/16W 22k ohm R643 116-1801-15 1/4WS 18 ohm R654 032-0140-54

1/10W 22k ohm (F)

R603 119-3921-15 1/10W 3.9k ohm R644 119-1041-15 1/10W 100k ohm R655 033-1051-15 1/16W 1M ohm

R604 119-1031-15 1/10W 10k ohm R645 033-4731-15 1/16W 47k ohm R656 119-0000-05 1/10W 0 ohm JW

R605 116-4711-15 1/4WS 470 ohm R646 119-1031-15 1/10W 10k ohm R657 116-1591-15 1/4WS 1.5 ohm

R606 116-4711-15 1/4WS 470 ohm R647 116-1591-15 1/4WS 1.5 ohm R698 033-1041-15 1/16W 100k ohm

R607 033-1031-15 1/16W 10k ohm R648 032-0140-89

1/10W 47k ohm (F)

R801 119-0000-05 1/10W 0 ohm JW

R608 116-1811-15 1/4WS 180 ohm R649 116-1591-15 1/4WS 1.5 ohm R802 119-0000-05 1/10W 0 ohm JW

R609 033-2221-15 1/16W 2.2k ohm R658 033-2231-15 1/16W 22k ohm R803 119-0000-05 1/10W 0 ohm JW

R610 033-1031-15 1/16W 10k ohm R659 033-1031-15 1/16W 10k ohm R804 119-0000-05 1/10W 0 ohm JW

R611 033-1031-15 1/16W 10k ohm R660 116-1591-15 1/4WS 1.5 ohm R805 033-0000-05 0.5A 0 ohm

R612 033-1031-15 1/16W 10k ohm R661 116-6801-15 1/4WS 68 ohm R806 033-0000-05 0.5A 0 ohm

R613 119-1031-15 1/10W 10k ohm R662 033-1041-15 1/16W 100k ohm R807 033-0000-05 0.5A 0 ohm

(PE-3041B-A) R663 033-1031-15 1/16W 10k ohm R808 033-0000-05 0.5A 0 ohm

R614 119-1031-15 1/10W 10k ohm R664 119-4731-15 1/10W 47k ohm R809 033-5611-15 1/16W 560 ohm

R616 119-0000-05 1/10W 0 ohm JW R665 119-4731-15 1/10W 47k ohm R810 033-4711-15 1/16W 470 ohm

R617 119-2231-15 1/10W 22k ohm R666 116-1221-15 1/4WS 1.2k ohm R811 033-4711-15 1/16W 470 ohm

R620 119-1031-15 1/10W 10k ohm R667 032-0140-66

1/10W 220 ohm (F)

R813 033-5611-15 1/16W 560 ohm

(PE-3041K-A/B) R668 032-0140-67

1/10W 3.3k ohm (F)

R815 119-3311-15 1/10W 330 ohm

R622 119-1031-15 1/10W 10k ohm R670 033-4721-15 1/16W 4.7k ohm R816 119-3311-15 1/10W 330 ohm

R623 033-1811-15 1/16W 180 ohm R671 032-0140-56

1/10W 12k ohm (F)

R817 119-0000-05 1/10W 0 ohm JW

R624 033-1031-15 1/16W 10k ohm R672 119-4721-15 1/10W 4.7k ohm R818 119-5621-15 1/10W 5.6k ohm

R625 116-3911-15 1/4WS 390 ohm R673 033-1031-15 1/16W 10k ohm S601 013-6100-00 TACT SWITCH

R626 119-0000-05 1/10W 0 ohm JW R674 033-1031-15 1/16W 10k ohm S602 013-7106-00

DETECTOR SWITCH

R628 119-1011-15 1/10W 100 ohm R675 116-1221-15 1/4WS 1.2k ohm S603 013-7206-50

DETECTOR SWITCH

R629 033-1011-15 1/16W 100 ohm R676 119-0000-05 1/10W 0 ohm JW SUP1 060-8057-90 CSA20-141N-T

R630 119-1011-15 1/10W 100 ohm R677 119-4721-15 1/10W 4.7k ohm X301 061-3537-90 41.6MHz

R631 033-1011-15 1/16W 100 ohm R685 116-3311-15 1/4WS 330 ohm X601 060-1533-90 10MHz

R633 033-1021-15 1/16W 1k ohm R687 119-0000-05 1/10W 0 ohm JW X602 061-1056-00 32.768kHz

R634 033-1041-15 1/16W 100k ohm R688 033-1031-15 1/16W 10k ohm PWB 039-3049-01 PWB(WITHOUT

R635 119-4721-15 1/10W 4.7k ohm R690 119-4731-15 1/10W 47k ohm COMPONENT)

R636 033-1031-15 1/16W 10k ohm R691 119-1031-15 1/10W 10k ohm

DXZ785USB/DXZ786USB

-16-

Page 17

D/D PWB (B3) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C502 042-1563-71 16V 100uF D507 001-0529-57 MA8120H R502 119-1031-15 1/10W 10k ohm

C503 043-1804-90 0.1uF D508 001-2635-90 D1FJ10 R506 119-1031-15 1/10W 10k ohm

C505 042-1563-71 16V 100uF FIL501 060-3116-55

CKD510JB1H102ST

R507 119-4701-15 1/10W 47 ohm

C506 043-1804-90 0.1uF FIL502 060-3116-55

CKD510JB1H102ST

R508 032-0140-90

1/10W 560 ohm F

C507 043-0510-51 25V 10uF FIL503 060-3115-52

CKD510JB1H102ST

R509 032-0164-50 1/10W 0.1 ohm F

C508 043-1800-90 1000pF IC501 051-3924-90 MD1424R R510 032-0164-50 1/10W 0.1 ohm F

C510 043-1800-90 1000pF J501 074-0898-16 16P R511 119-1001-15 1/10W 10 ohm

C511 043-1841-90 0.047uF L501 010-3600-90 2k ohm/100MHz R512 119-5631-15 1/10W 56k ohm

C512 043-1802-90 0.01uF L504 010-3041-90 10uH R513 119-1811-15 1/10W 180 ohm

C513 163-1073-35 16V 100uF L505 010-3108-53

330 ohm/100MHz

R514 119-1811-15 1/10W 180 ohm

C514 042-1697-00 10V 680uF L506 010-2275-50 33uH R516 032-0140-53

1/10W 2.2k ohm F

C517 043-1800-90 1000pF L507 010-2275-50 33uH R521 119-1051-15 1/10W 1M ohm

C521 043-1804-90 0.1uF Q501 125-2027-92

DTC124EUA-T106

R522 119-1031-15 1/10W 10k ohm

C523 163-2263-35 16V 22uF Q501 125-2041-93 RT1N241M R523 032-0140-15

1/10W 6.8k ohm F

C524 163-3363-45 16V 33uF Q502 190-1576-00 2SA1576A-T106 R527 119-1041-15 1/10W 100k ohm

C525 163-2263-35 16V 22uF Q502 125-3014-90 ISA1602A R529 119-3321-15 1/10W 3.3k ohm

C526 163-3363-45 16V 33uF Q503 192-2873-00 2SC2873 R530 119-3321-15 1/10W 3.3k ohm

D502 001-0608-90 D1FS4 Q504 125-2027-92

DTC124EUA-T106

T501 007-1180-00 SRW13EPC

D504 001-0507-90 DAP202K Q504 125-2041-93 RT1N241M PWB 039-3046-00 PWB(WITHOUT

D505 001-0529-57 MA8120H Q506 125-3010-90 KTA1666 COMPONENT)

D506 001-2635-90 D1FJ10 R501 119-1031-15 1/10W 10k ohm

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C2 043-1804-90 0.1uF C41 043-1804-90 0.1uF C90 043-1804-90 0.1uF