HYDRAULICS

ELECTRICS

TECHNICAL DATA

CLCL

CL

CLCL

AA

AS TAS T

A

AS T

AA

AS TAS T

ARGO K50 K60 K70ARGO K50 K60 K70

ARGO K50 K60 K70

ARGO K50 K60 K70ARGO K50 K60 K70

The machines in this handbook are designed essentially for agricultural and associated applications. This is

their intended use.

Any modifications made to the machine without prior written approval from CLAAS or if the machine is used

in any way contrary to the intended use or if the machine is not properly driven or maintained then the

Company will not accept any liability whatsoever for any damage or injury (whether direct or consequential).

The method of operation and maintenance specified in this handbook should be strictly adhered to.

For your parts requirements, it is essential that only genuine CLAAS parts are fitted. Any resultant damage

from non-genuine parts will invalidate your machine warranty.

CLAAS operates a policy of continuous improvement to its products and reserve the right to change specifi-

cations and equipment without notice. Therefore some information within this handbook may differ from your

machine.

This manual is designed to service machines:

from Serial No. 51200011

up to Serial No. 51200727.

from Serial No. K5D00100

from Serial No. K6D00100

from Serial No. K7D00100

CONTENTS

INTRODUCTION

General

Machine identification

Health and Safety

SAFETY WARNINGS

SECTION 1

HYDRAULICS

Description and Operation 1.1

Description 1.1

General 1.1

Dumping (dissipation) of hydraulic pressure 1.1

To dump brake system pressure 1.1

To dump a system pressure 1.1

Hydraulic Circuit - Single Circuit Braking (up to Machines S/No.51200317) 1.2

Hydraulic Circuit - Single Circuit Braking (from Machines S/No.51200318 to 51200471) 1.4

Hydraulic Circuit - Single Circuit Braking (from Machines S/No.51200472 to 51200551) 1.6

Hydraulic Circuit - Single Circuit Braking (from Machines S/No.51200552 to 51200727) 1.8

Hydraulic Circuit - Dual Circuit Braking (up to Machines S/No.51200317) 1.10

Hydraulic Circuit - Dual Circuit Braking (from Machines S/No.51200318 to 51200471) 1.12

Hydraulic Circuit - Dual Circuit Braking (from Machines S/No.51200472 to 51200551) 1.14

Hydraulic Circuit - Dual Circuit Braking (from Machines S/No.51200552 to 51200727) 1.16

Components

General 1.18

Hydraulic tank 1.18

Suction line connections to hydraulic tank 1.18

Return hose connections to hydraulic tank (up to Machines S/No.51200471) 1.18

Return hose connections to hydraulic tank (from Machines S/No.51200472) 1.18

Hydraulic pump (load sensing) 1.19

Pump compensator (load sensing) 1.19

Tank filter 1.19

Filler/Breather 1.19

Auxiliary hydraulic pump 1.19

Fan motor (up to Machines S/No.51200471) 1.20

Fan reverse motor (from Machines S/No.51200472) 1.20

Pressure reducing valve (PRV) for the parking brake (up to Machines S/No.51200551) 1.21

Pressure filter 1.21

Single circuit brake pressure servo valve (MICO) (up to Machines S/No.51200471) 1.22

Duel circuit brake pressure servo valve (MICO) (up to Machines S/No.51200471) 1.22

Single circuit brake pressure servo valve (SAFIM) (from Machines S/No.51200472) 1.23

Duel circuit brake pressure servo valve (SAFIN) (from Machines S/No.51200472) 1.23

Accumulator(s) 1.24

Pressure switch 1.24

Pressure switch (transmission dump) 1.24

Front axle 1.25

Steering cylinder (front) 1.25

Pressure switch (brake light) 1.25

Pressure switch (parking brake) 1.26

Rear axle 1.26

Steering cylinder (rear) 1.26

Non-return valve 1.26

Steering valve 1.27

Steering in Neutral position 1.27

Steering in Operation 1.28

Pressure relief valve 1.28

Steering selector valve 1.29

CONTENTS

Components (continued)

Control valve 1.30

Outlet section (PVP) 1.31

Function 1.31

Extension section 1.32

Function 1.32

Crowd section 1.33

Function 1.33

Lift section 1.34

Function 1.34

1st service/2nd service section 1.35

Function 1.35

Inlet section (PVSP) section 1.36

Function 1.36

Accumulator 1.38

Tap 1.38

Trailer brake valve 1.38

Trailer brake coupling 1.38

Extension cylinder 1.39

Load control valve 1.39

Crowd cylinder 1.40

Load control valve 1.40

Compensator cylinder 1.41

Lift cylinder 1.41

Load control valve 1.42

Diverter valve 1.43

Manifold 1.43

Autohitch cylinder 1.44

1st service couplings 1.44

2nd service couplings 1.44

Trailer tipping connection 1.44

St art-up valve 1.44

Non-return valve (up to Machine S/No.51200317 only) 1.45

Pressure relief valve (up to Machine S/No.51200471 only) 1.45

Breather 1.45

Parking brake valve (from Machine S/No.51200552 only) 1.46

Fan reverse valve (from Machine S/No.51200472 only) 1.47

Oil cooler (from Machine S/No.51200472 only) 1.48

Operation 1.49

General 1.49

Relief valves 1.49

System pressure checks 1.50

LS pump 1.52

LS pump compensator operation 1.52

Standby position (engine switched off) 1.53

Standby position (engine started) 1.54

Pump goes into delivery 1.56

Constant volumetric flow 1.58

Downstroking of the pump 1.59

Maximum pressure limiting (pressure relief valve function) 1.45

Adjusting the pump 1.63

CONTENTS

Maintenance 1.64

Torque tightening 1.64

Hydraulic level 1.66

Check 1.66

Hydraulic tank 1.67

Removal 1.67

Installation 1.67

Hydraulic pump (LS) 1.68

Removal 1.68

Installation 1.68

Auxiliary hydraulic pump 1.69

Removal 1.69

Installation 1.69

Fan motor (up to Machines S/No.51200471 only) 1.70

Removal 1.70

Installation 1.70

Fan motor bearings (up to Machines S/No.51200471 only) 1.71

Removal 1.71

Installation 1.71

Fan motor (from Machines S/No.51200472 only) 1.72

Removal 1.72

Installation 1.72

Fan drive bearings (from Machines S/No.51200472 only) 1.73

Removal 1.73

Installation 1.73

Fan reverse valve (from Machines S/No.51200472 only) 1.74

Removal 1.74

Installation 1.74

Parking brake valve (from Machines S/No.51200472 only) 1.75

Removal 1.75

Installation 1.75

Hydraulic filter 1.76

Removal 1.76

Installation 1.76

Brake valve (MICO) (up to Machines S/No.51200471 only) 1.77

Operation 1.77

Brake valve (SAFIM) (from Machines S/No.51200472 only) 1.77

Operation 1.77

Single brake valve (MICO) (up to Machines S/No.51200471 only) 1.78

Removal 1.78

Installation 1.78

Servicing 1.79

Dismantling 1.79

Assembly 1.80

Single brake valve (SAFIM) (from Machines S/No.51200472 only) 1.81

Removal 1.81

Installation 1.81

Servicing 1.82

Dismantling (General) 1.82

Assembly (General) 1.82

Dismantling (Brake master module) 1.83

Assembly (Brake master module) 1.83

Dismantling (Brake valve module) 1.84

Assembly (Brake valve module) 1.84

CONTENTS

Dual brake valve (MICO) (up to Machines S/No.51200471 only) 1.85

Removal 1.85

Installation 1.85

Servicing 1.86

Dismantling 1.86

Assembly 1.88

Dual brake valve (SAFIM) (from Machines S/No.51200472 only) 1.89

Removal 1.89

Installation 1.89

Servicing 1.90

Removal and installation (General) 1.90

Dismantling (Brake master module) 1.90

Assembly (Brake master module) 1.90

Dismantling (Brake valve module) 1.91

Assembly (Brake valve module) 1.91

Trailer brake valve 1.92

Removal 1.92

Installation 1.92

Servicing 1.93

Dismantling 1.93

Assembly 1.94

Brake system bleeding 1.95

General 1.95

Diverter valve 1.96

Removal 1.96

Installation 1.96

Manifold 1.97

Removal 1.97

Installation 1.97

Control valve 1.98

Removal 1.98

Installation 1.98

Servicing 1.99

Dismantling 1.99

Assembly 1.99

Spool sections 1.101

General 1.101

Dismantling 1.101

Assembly 1.101

Inlet section (PVSP) 1.103

General 1.103

Dismantling 1.103

Assembly 1.103

Outlet section (PVP) 1.104

General 1.104

Dismantling 1.104

Assembly 1.104

Steering 1.105

Description 1.105

Operation 1.105

Checking the steering system 1.107

Steering cylinder 1.107

Steering unit (OSPF) 1.107

Servicing 1.107

Steering valve assembly 1.108

Removal 1.108

Installation 1.108

Servicing 1.109

Dismantling 1.109

Assembly 1.109

CONTENTS

Hydraulic cylinders 1.110

Extension cylinder 1.110

Removal 1.110

Installation 1.111

Crowd cylinder 1.112

Removal 1.112

Installation 1.112

Compensator cylinder 1.113

Removal 1.113

Installation 1.113

Lift cylinder 1.114

Removal 1.114

Installation 1.114

Extension, crowd, compensator and lift cylinder 1.115

Servicing 1.115

Dismantling 1.115

Assembly 1.115

Autohitch cylinder 1.117

Removal 1.117

Installation 1.117

Dismantling 1.117

Assembly 1.118

Carriage locking cylinder 1.119

Removal 1.119

Installation 1.119

Dismantling 1.119

Assembly 1.120

Steering cylinder 1.121

Removal 1.121

Installation 1.121

Dismantling 1.122

Assembly 1.122

SECTION 2

ELECTRICS

Circuit diagrams

Circuit diagram key - Wiring terminations 2.1

Circuit diagram key - Components 2.2

Circuit diagram key - General Information 2.4

Power generation, S tarting, Non APC (Sheet 1) 2.4

Power generation, Starting, With APC (Sheet 1A) 2.5

Hydraulic controls, Steering control, Safe load indicator , Large lock out relay (Sheet 2) 2.6

Hydraulic controls, Steering control, Safe load indicator , Mini lock out relay (Sheet 2A) 2.7

Wipers, Washers, Horn, Worklights (Sheet 3) 2. 8

Wipers, Washers, Horn, Worklights combined boom/side worklights, Switching (Sheet 3A) 2.9

Head/side lights, Fog lights, Number plate lights, Head Flasher (Sheet 4) 2.10

Head/side lights, Fog lights, Number plate lights, Head Flasher (Sheet 4A) 2.11

Turn indicators, Reverse lamps, S teer sensors, S top lights, Radio (Sheet 5) 2.12

Inst display , Sensor switches, Fan motor , Aircon, Interior light, Beacon, Fuel Sender ,

Fan reverse, Hydraulic temp. (Sheet 6) 2.13

APC 50 with Ign controlled APC bat feed, Screened sensor cable, P/brake link (Sheet 7) 2.14

Non APC,Correct P/brake and trans dump, No P/brake controller , Circuit link (Sheet 7A) 2.15

Chassis loom (Illustration) 2.16

Engine loom (Illustration) 2.17

Cab loom (Illustration) 2.18

CONTENTS

Longitudinal stability indicator 2.19

Description 2.19

Sensor 2.20

Specification 2.20

Display Module 2.20

Specification 2.20

Testing and adjustment 2.23

Troubleshooting 2.23

Visual inspection 2.23

System check 2.24

Error indications from the display module 2.25

Sensor - test 2.25

General 2.25

Procedure to test the operation of the sensor 2.26

Procedure to install a sensor 2.27

Procedure to replace the display module 2.28

Calibration 2.29

Calibration procedure 2.29

Resetting the zero point 2.31

Testing load sensor function 2.32

Functional test of load sensor indicator 2.32

Procedure 2.33

Main instrument panel 2.34

Description 2.34

Removal 2.34

Installation 2.34

Functional description 2.35

Solo control joystick 2.36

Removal 2.36

Installation 2.36

Starter 2.37

Removal 2.37

Installation 2.37

Fusebox and relays 2.38

Description 2.38

Removal 2.38

Installation 2.38

Alternator 2.40

Alternator drive belt check 2.40

Removal 2.41

Installation 2.41

Automatic powershift 2.42

Automatic powershift controller 2.42

Removal 2.42

Installation 2.42

Forward / Neutral / Reverse (FNR) switch assembly 2.43

Removal 2.43

Installation 2.43

CONTENTS

SECTION 3

TECHNICAL DATA

Dimensions 3.1

Performance 3.2

Machine speed (km/hr) for 106 hp 3.2

Carriage 3.3

Cycle time 3.3

Engine 3.4

Cooling 3.4

Transmission 3.4

Tyres 3.4

Hydraulics 3.5

Electrics 3.5

Capacities 3.5

INTRODUCTION

General

The contents of this Repair Manual, although correct at the time of publication, may be subject to alteration

by the manufacturer without notice.

This manual assumes that maintenance personnel have a sound knowledge of workshop practices and

safety procedures associated with the repairs of this type of machine. This manual is designed to assist with

the more specialised information required for removal and strip-down of major components.

It is recommended that the relevant part of this Repair Manual is studied carefully before proceeding with

any maintenance.

Machine identification

To make sure that the correct parts are obtained, always quote the machine Serial Number when ordering

parts.

Health and Safety

To prevent injury to personnel and damage to equipment and machinery, care must be taken to operate in a

safe manner. Read the Safety Warnings that follow and always work in a safe manner and obey the relevant

Warnings.

Throughout this manual and on the machine there are safety notes. Each note starts with a single word. The

meaning of these single words is as follows:

Identifies a hazard exists. If proper precautions are not taken, it is highly probable that the

operator (or others) could be killed or seriously injured.

Identifies a reminder of safety practices. Failure to observe these safety practices could result

in injury to the operator (or others) or damage to the machine.

In general these notes are used to indicate that the procedures being described in the manual must be

followed to avoid serious injury or death to yourself or others. The notes are also used to protect the machine from unsafe maintenance practices.

NOTE: An identification number in bold type, after an item, refers to the number of that item in the main

hydraulic schematic illustration.

SAFETY WARNINGS

Always wear correct fitting protective clothing. Loose or baggy clothing can be extremely

dangerous when operating or maintaining a machine.

Where possible, only work on or close to engines or machinery when they are stopped. If this

is not practical, remember to keep tools, test equipment and all parts of your body well away

from moving parts.

Avoid contact with exhaust pipes and exhaust manifolds when the engine is running; these

can be very hot.

Many liquids used on this machine are harmful if taken internally or splashed into the eyes. In

the event of accidentally swallowing oil, diesel fuel, anti-freeze, battery acid etc., DO NOT

induce vomiting, but OBTAIN QUALIFIED MEDICAL ASSISTANCE IMMEDIATELY.

Always obtain advice before mixing oils; some are incompatible.

Never run an engine in an enclosed space unless an exhaust extraction system is used.

Always Disconnect battery cables before using an external charger to prevent damage to

electrical system components.

Always Disconnect battery cables before working on the electrical system to prevent injury

caused by electric shock.

When it is necessary to work on the electrical system with power on, for fault diagnosis,

always have a safety man in attendance

Any dust found on the machine or produced during work on the machine should be removed

by extraction, not by blowing. Dust waste should be dampened, placed in a sealed container

and marked for safe disposal.

Always dump pressure from the hydraulic system before carrying out any maintenance or

adjustment (refer to page 1.1).

Never leave the machine unattended with pressure in the system.

Fine jets of hydraulic fluid at high pressure can penetrate the skin. Do not use your fingers to

check for hydraulic fluid leaks. Do not put your face close to suspected leaks. If hydraulic

fluid penetrates your skin OBTAIN QUALIFIED MEDICAL ASSISTANCE IMMEDIATELY.

Never allow unqualified personnel to attempt to remove or replace any part of the machine.

Always use the correct lifting equipment to remove large or heavy components.

Never attempt to lift or hold up the machine using the lash-down points.

SECTION 1

HYDRAULICS

HYDRAULICS 1.1

DESCRIPTION AND OPERATION

DESCRIPTION

General

The hydraulic system supplies the power for boom

manipulation, attachments, brakes and steering.

A hydraulic oil reservoir has a filter breather cap and

supplies the main and auxiliary hydraulic pumps.

The reservoir is also fitted with a sight gauge. With the

boom in the lower position, retracted and with the carriage

tilted forward, the oil level will be visible in the gauge

above the red line.

The main hydraulic pump is driven from the engine

gearbox and is of the variable displacement type.

Pressurized oil from the hydraulic pump is directed to the

hydraulic control valve assembly (PVG). The control

valve is modular in construction and combines individual

sections (slices), each with a different use. At one end

of the control valve is the priority module (PVSP), which

controls the supply of hydraulic oil to the steering and

brake systems. The remaining oil is supplied to those

sections of the control valve that control each boom

service.

Dumping (dissipation) of hydraulic

pressure

Always dump all hydraulic pressure

from the system before servicing any

hydraulic component.

Ensure there is sufficient space and

headroom around machine before

operating any hydraulic control.

To dump brake system pressure

1. Stop the engine.

2. Make sure the machine is parked on firm and

level ground and chock the wheels.

3. Turn the ignition switch to position (1).

4. Set the parking brake switch, if necessary, to the

parking brake applied position.

The brakes, steering and boom services each supply a

load-sensing signal, hydraulically, to the main hydraulic

pump. This maintains the optimum supply of oil to those

services.

The auxiliary hydraulic pump is driven by the engine

timing case gears and supplies pressurized oil to the

motor of the engine cooling fan. It also supplies oil to the

front axle parking brake units, to keep the parking brake

off. When this hydraulic pressure is released, spring

pressure applies the parking brake.

The hydraulic tank is divided into clean and dirty sides by

a mesh filter. A low-pressure filter is installed in the oil

supply to the cooling fan system. This filter constantly

filters the hydraulic fluid and a blockage indicator, installed

in the filter, operates a warning light in the cab when

servicing is required.

Modifications, such as the introduction of a reverse

cooling fan or different brake servo valves, will change

the basic layout of the system. To obtain the correct

component layout you must refer to the applicable

schematic illustration, which can be located using the

batch Serial Number (S/No.) for the particular machine.

5. Press the brake pedal repeatedly until the brake

charge warning lamp illuminates.

6. Press the brake pedal a further twenty times to

ensure that residual pressure in the brake system is

fully dissipated.

7. Turn the ignition switch to off.

To dump a system pressure

NOTE: This procedure applies to all machine hydraulic

systems, except brakes.

1. Stop the engine.

2. Make sure the machine is parked on firm and

level ground and chock the wheels.

3. Turn the ignition switch to position ‘I’.

3. Operate the applicable system until all hydraulic

pressure has been dissipated.

4. Turn the ignition switch to off.

HYDRAULICS 1.2

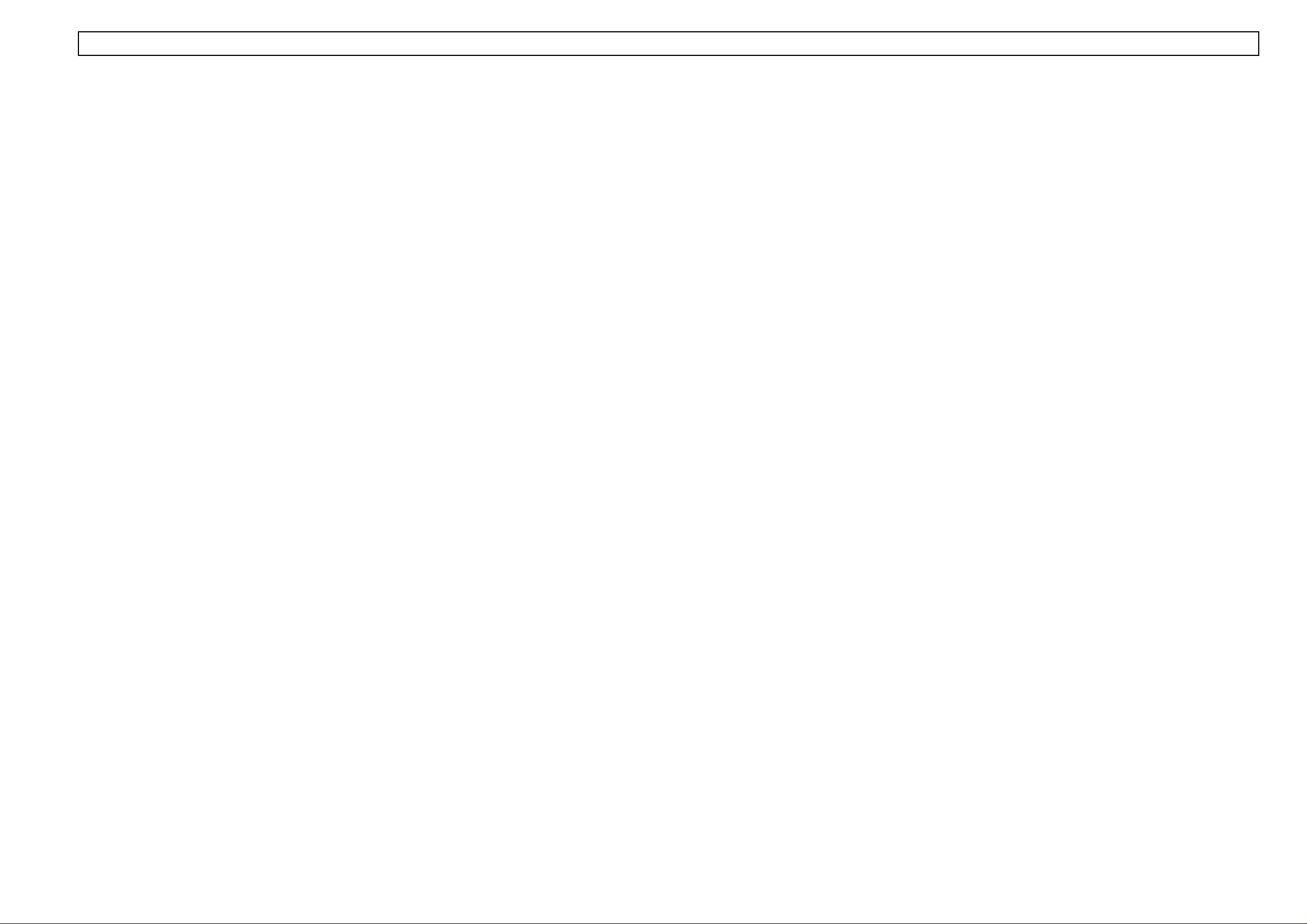

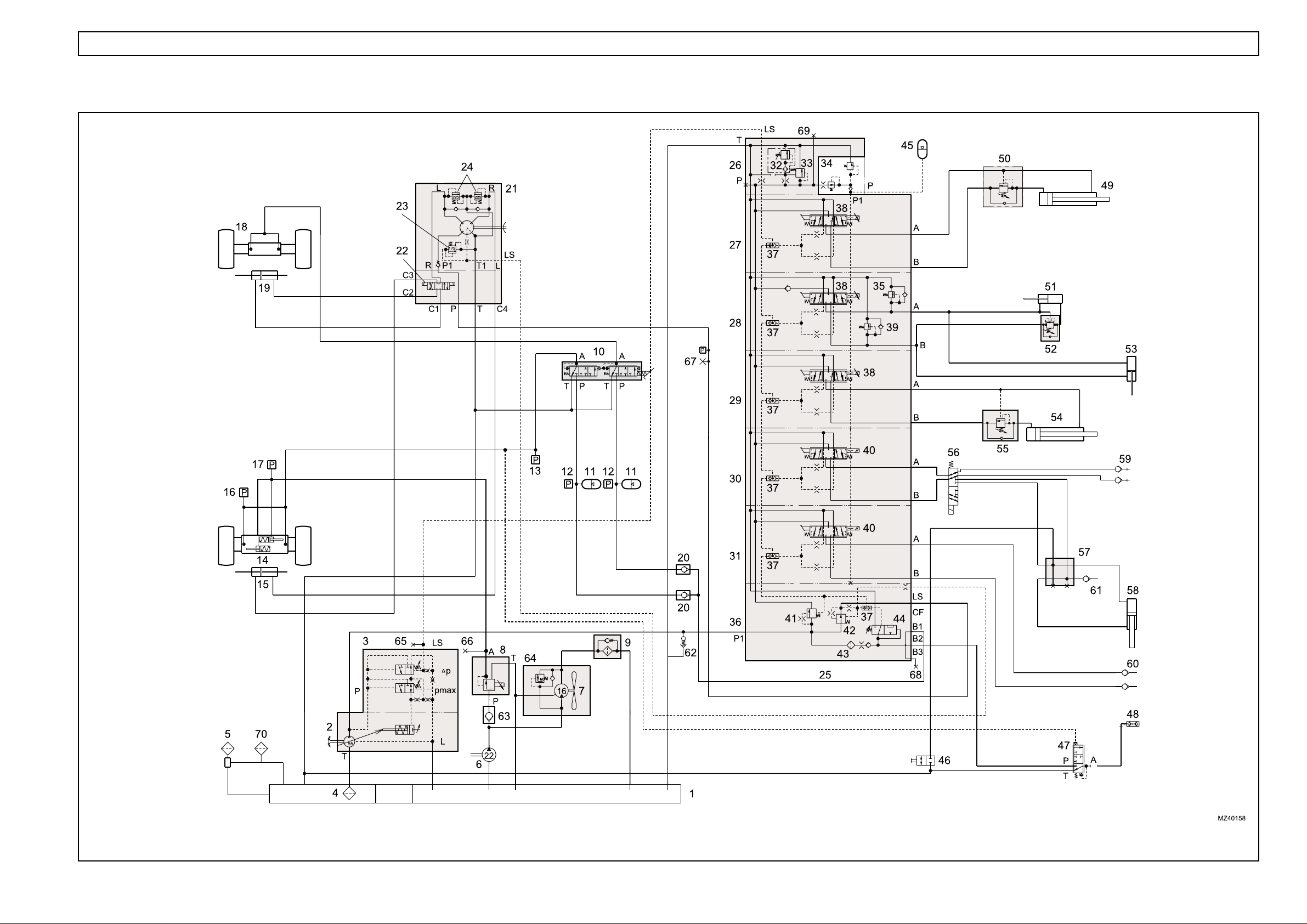

HYDRAULIC CIRCUIT - SINGLE CIRCUIT BRAKING (up to Machine S/No.51200317)

HYDRAULICS 1.3

Key to hydraulic circuit - single circuit braking

1. Hydraulic tank (reservoir)

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake control)

9. Pressure filter

10. Brake servo valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulics control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(up to Machine S/No.51200317)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. Non-return valve

64. Pressure relief valve (160 bar)

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

HYDRAULICS 1.4

HYDRAULIC CIRCUIT - SINGLE CIRCUIT BRAKING (from Machine S/No.51200318 to 51200471)

HYDRAULICS 1.5

Key to hydraulic circuit - single circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake control)

9. Pressure filter

10. Brake valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200318 to 51200471)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder (autohitch)

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure relief valve (160 bar)

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

HYDRAULICS 1.6

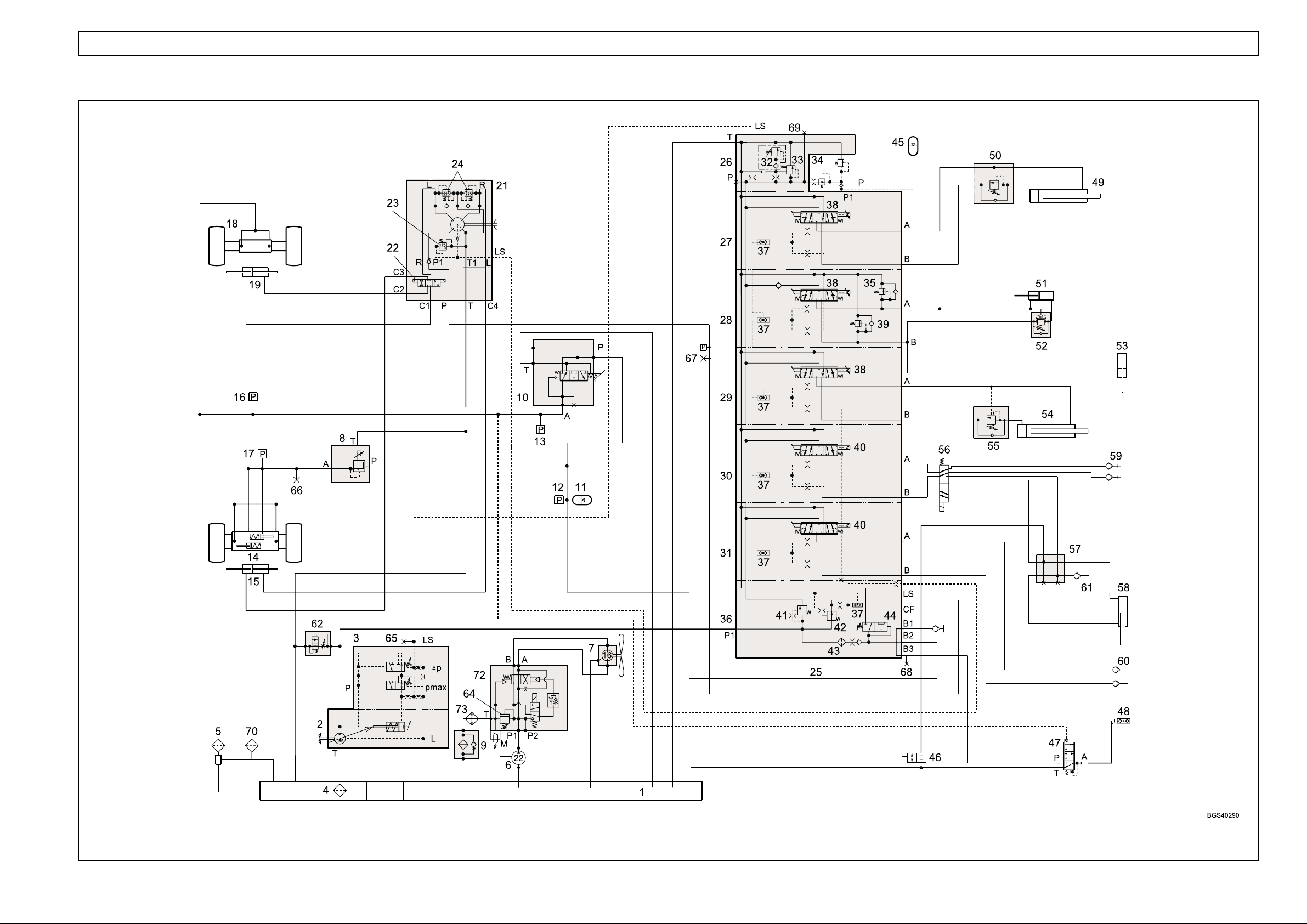

HYDRAULIC CIRCUIT - SINGLE CIRCUIT BRAKING (from Machine S/No. 51200472 to 51200551)

HYDRAULICS 1.7

Key to hydraulic circuit - single circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake control)

9. Pressure filter

10. Brake valve (Safim type)

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. NOT FITTED

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200472 to 51200551)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure regulator, 120 bar

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

71. NOT FITTED

72. Fan reverse valve

73. Oil cooler

HYDRAULICS 1.8

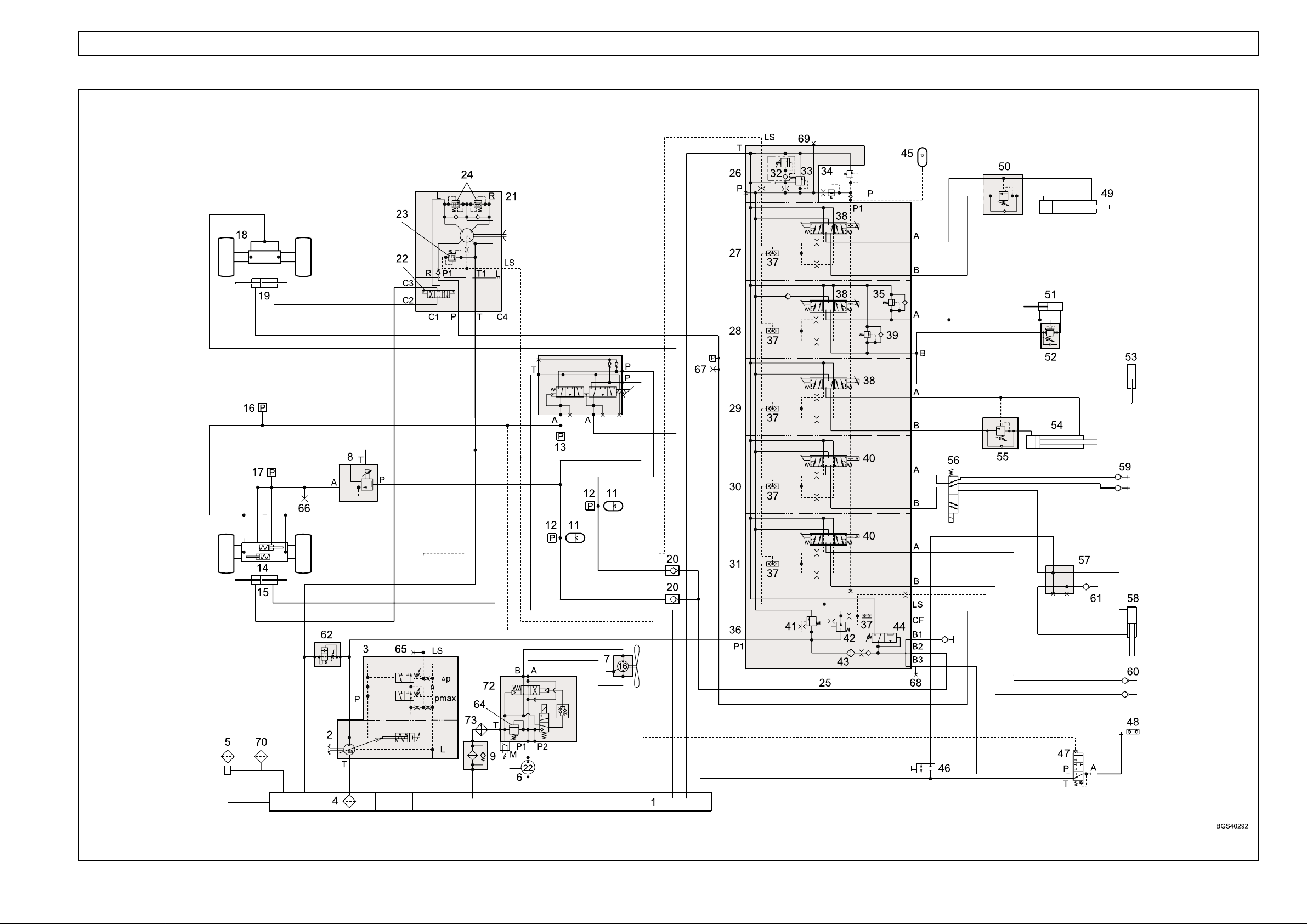

HYDRAULIC CIRCUIT - SINGLE CIRCUIT BRAKING (from Machine S/No. 51200552 to 51200727)

HYDRAULICS 1.9

Key to hydraulic circuit - single circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. NOT FITTED

9. Pressure filter

10. Brake valve (Safim type)

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. NOT FITTED

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200552 to 51200727)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure regulator, 120 bar

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

71. Parking brake valve

72. Fan reverse valve

73. Oil cooler

HYDRAULICS 1.10

HYDRAULIC CIRCUIT - DUAL CIRCUIT BRAKING (up to Machine S/No.51200317)

HYDRAULICS 1.11

Key to hydraulic circuit - dual circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake control)

9. Pressure filter

10. Brake valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller, (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(up to Machine S/No.51200317)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. Non-return valve

64. Pressure relief valve (160 bar)

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

HYDRAULICS 1.12

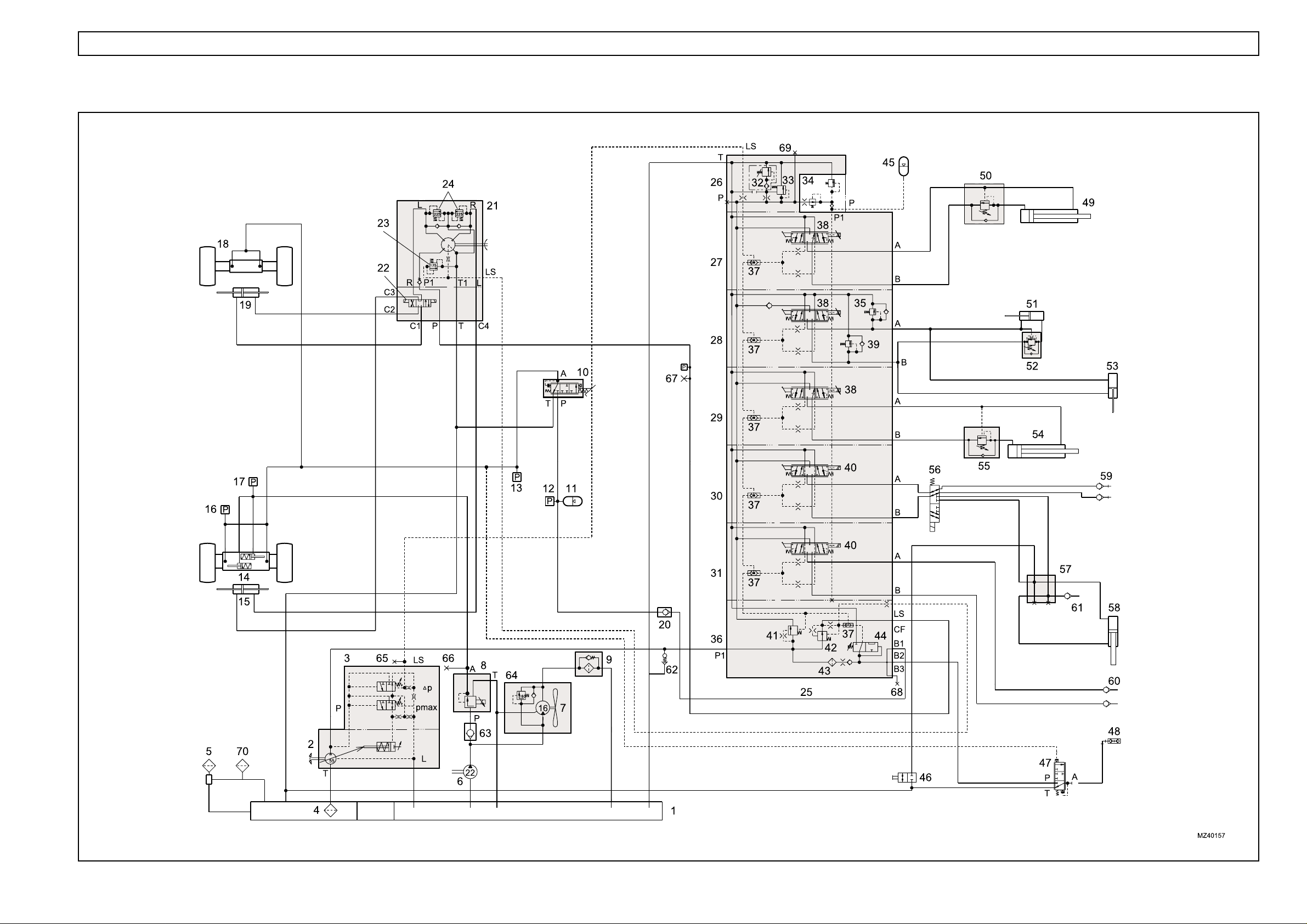

HYDRAULIC CIRCUIT - DUAL CIRCUIT BRAKING (from Machine S/No.51200318 to 51200471)

HYDRAULICS 1.13

Key to hydraulic circuit - dual circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake

control)

9. Pressure filter

10. Brake valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve, 290 bar

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve, steering

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200318 TO 512471)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure relief valve (160 bar)

65. Test point 1 (main system pressure LS)

66. Test point 2 (Park brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70 Auxiliary breather

HYDRAULICS 1.14

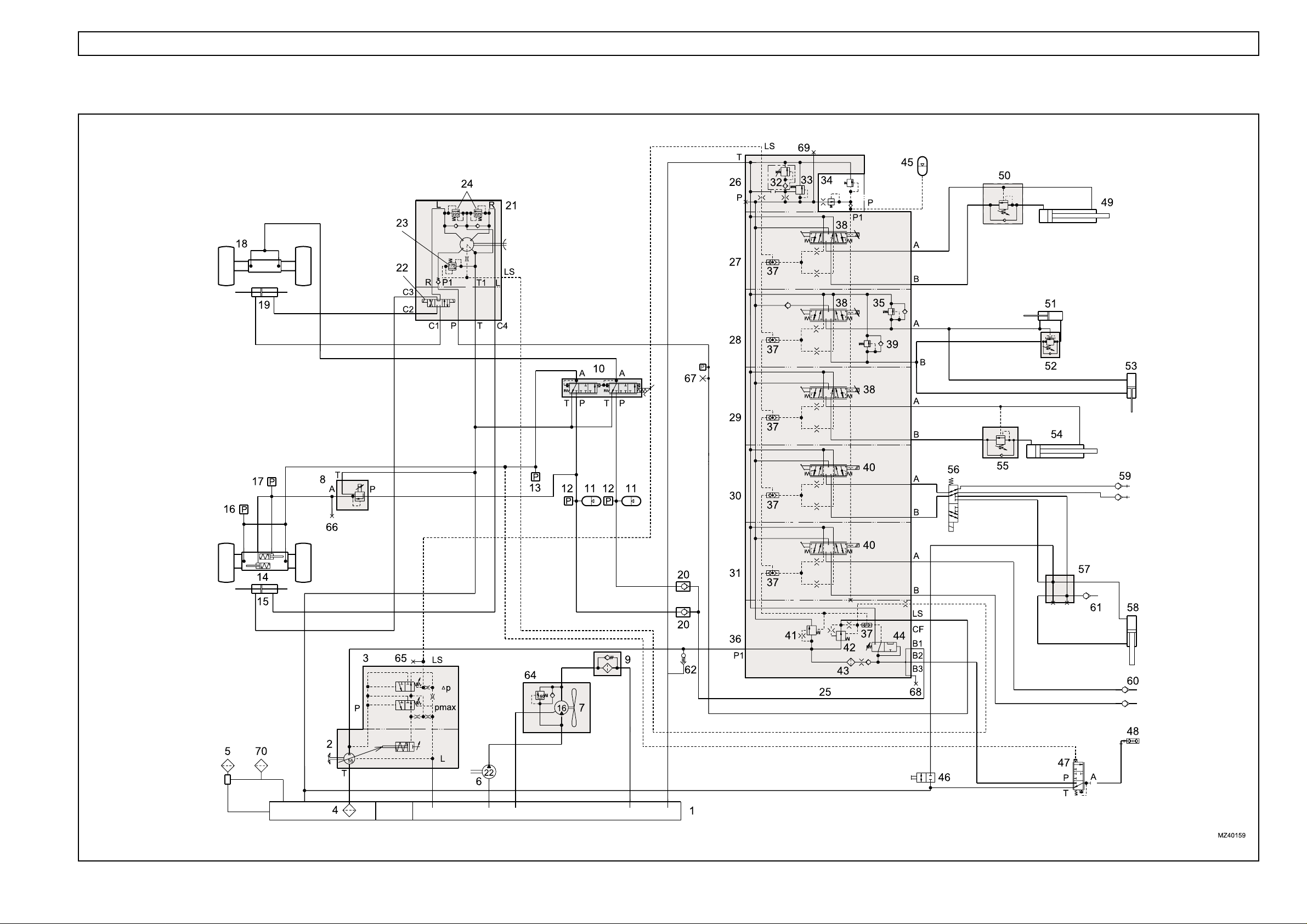

HYDRAULIC CIRCUIT - DUAL CIRCUIT BRAKING (from Machine S/No.51200472 to 51200551)

HYDRAULICS 1.15

Key to hydraulic circuit - dual circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake

control)

9. Pressure filter

10. Brake valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve, 290 bar

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve, steering

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200472 TO 512551)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure regulator, 120 bar

65. Test point 1 (main system pressure LS)

66. Test point 2 (Park brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70 Auxiliary breather

71. NOT FITTED

72. Fan reverse valve

73. Oil cooler

HYDRAULICS 1.16

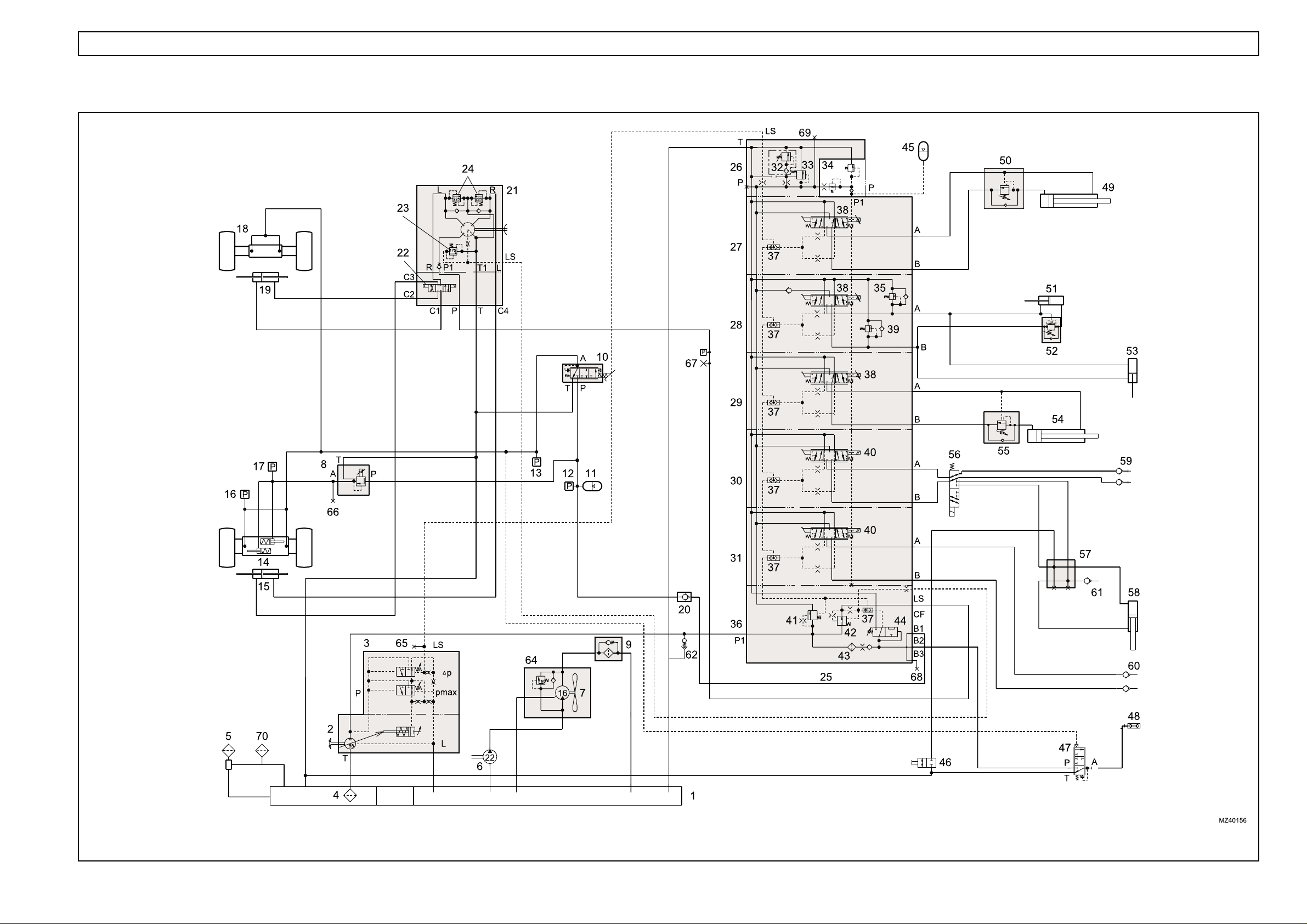

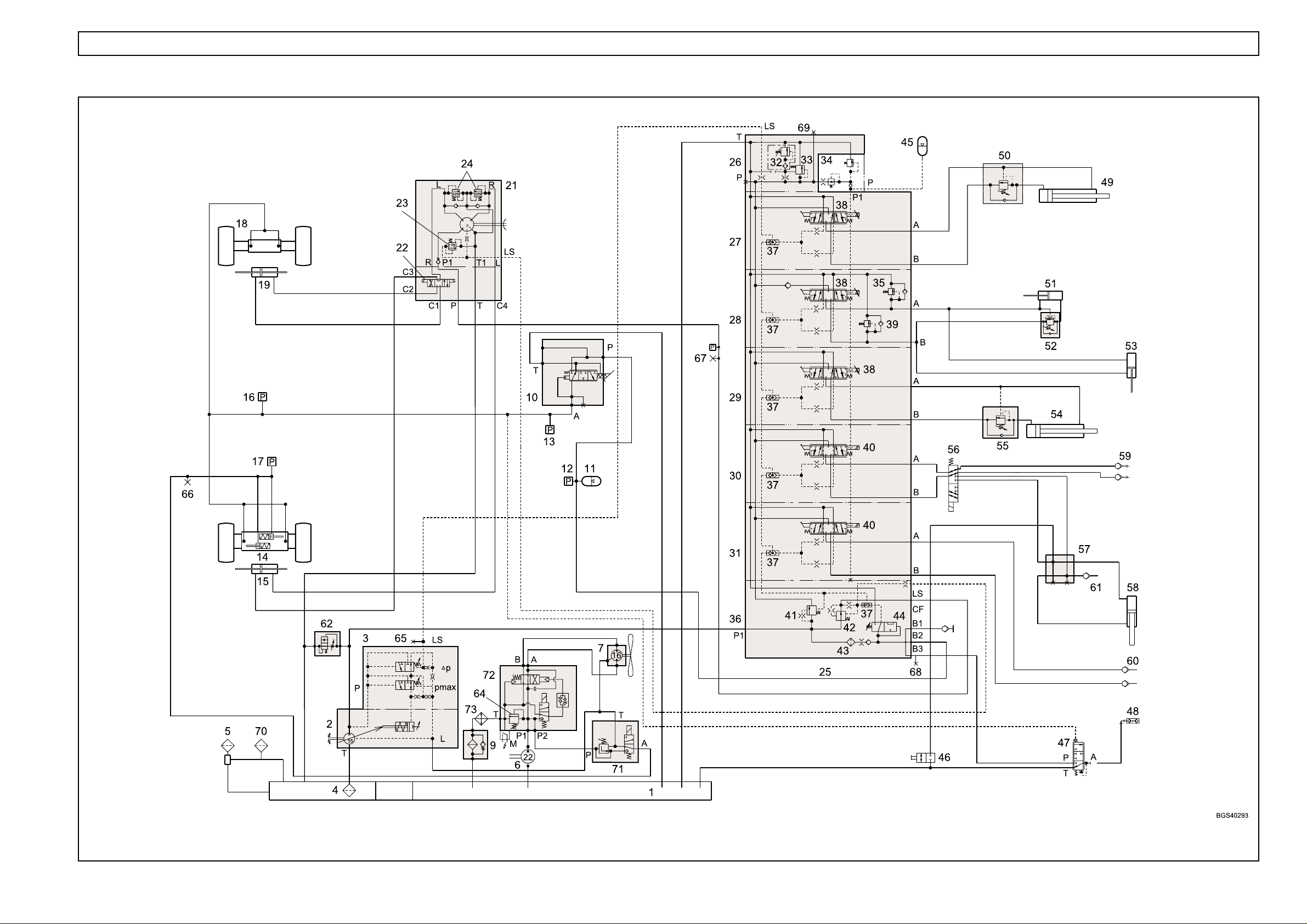

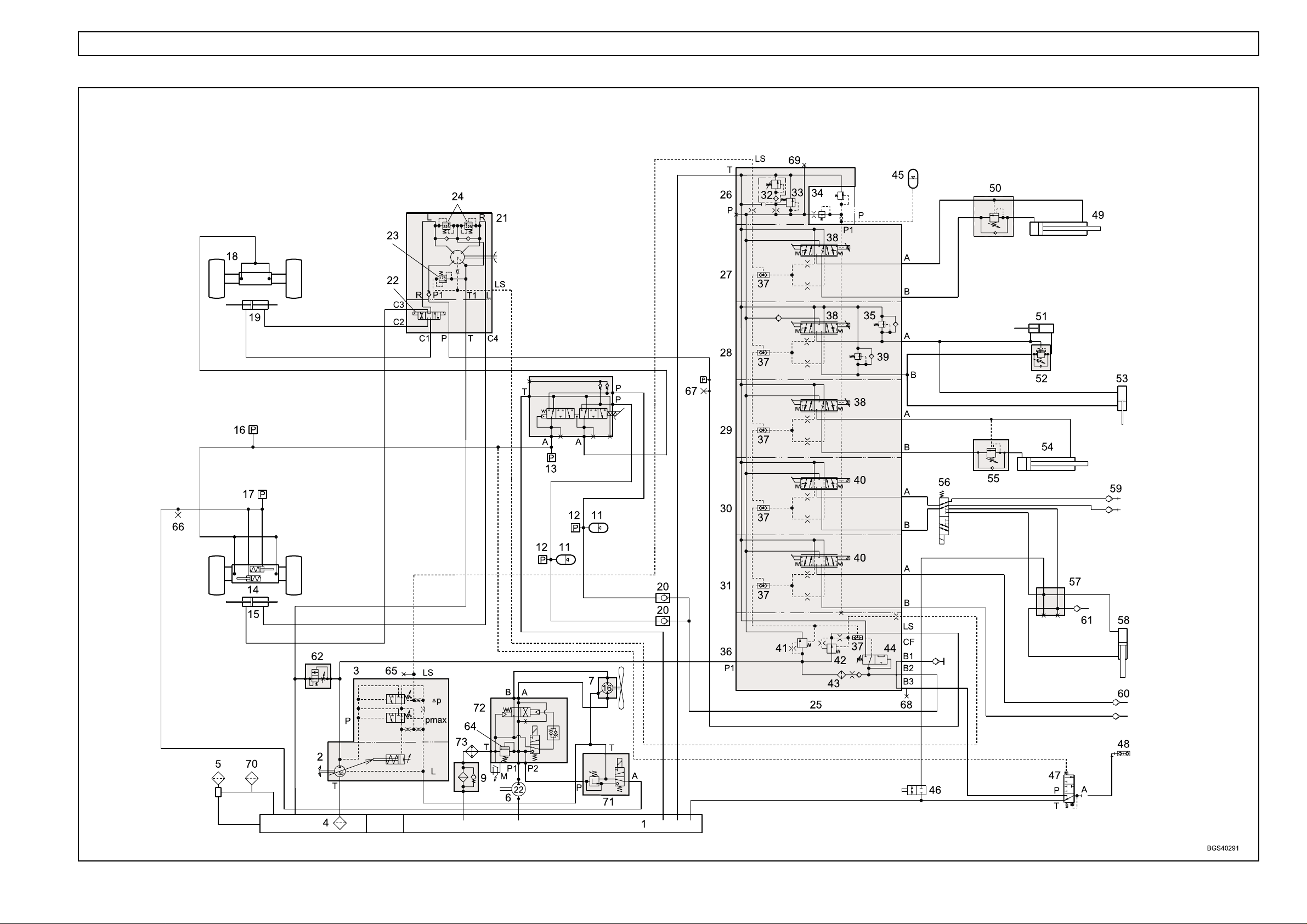

HYDRAULIC CIRCUIT - DUAL CIRCUIT BRAKING (from Machine S/No.51200552 to 51200727)

HYDRAULICS 1.17

Key to hydraulic circuit - dual circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. NOT FITTED

9. Pressure filter

10. Brake valve (Safim type)

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve, 290 bar

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve, steering

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200552 TO 512727)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure regulator, 120 bar

65. Test point 1 (main system pressure LS)

66. Test point 2 (Park brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70 Auxiliary breather

71. Parking brake valve

72. Fan reverse valve

73. Oil cooler

1.18 HYDRAULICS

COMPONENTS

General

NOTE: An identification number in bold type, after an

item, refers to the number of that item in the main

hydraulic schematic illustration.

Hydraulic tank (1)

A single hydraulic reservoir feeds the main and

auxiliary systems of the machine. A sight glass is

fitted to check system contents. An internal 40 µm

mesh filter (pre-filtration) separates the clean and

dirty sides of the tank. Both system suction lines are

taken from the clean side of the mesh filter. All

return lines go to a manifold and return fluid to dirty

side of tank for pre filtration.

Specifications:

Nominal tank capacity 67 litres

Total system capacity (oil) 128 litres

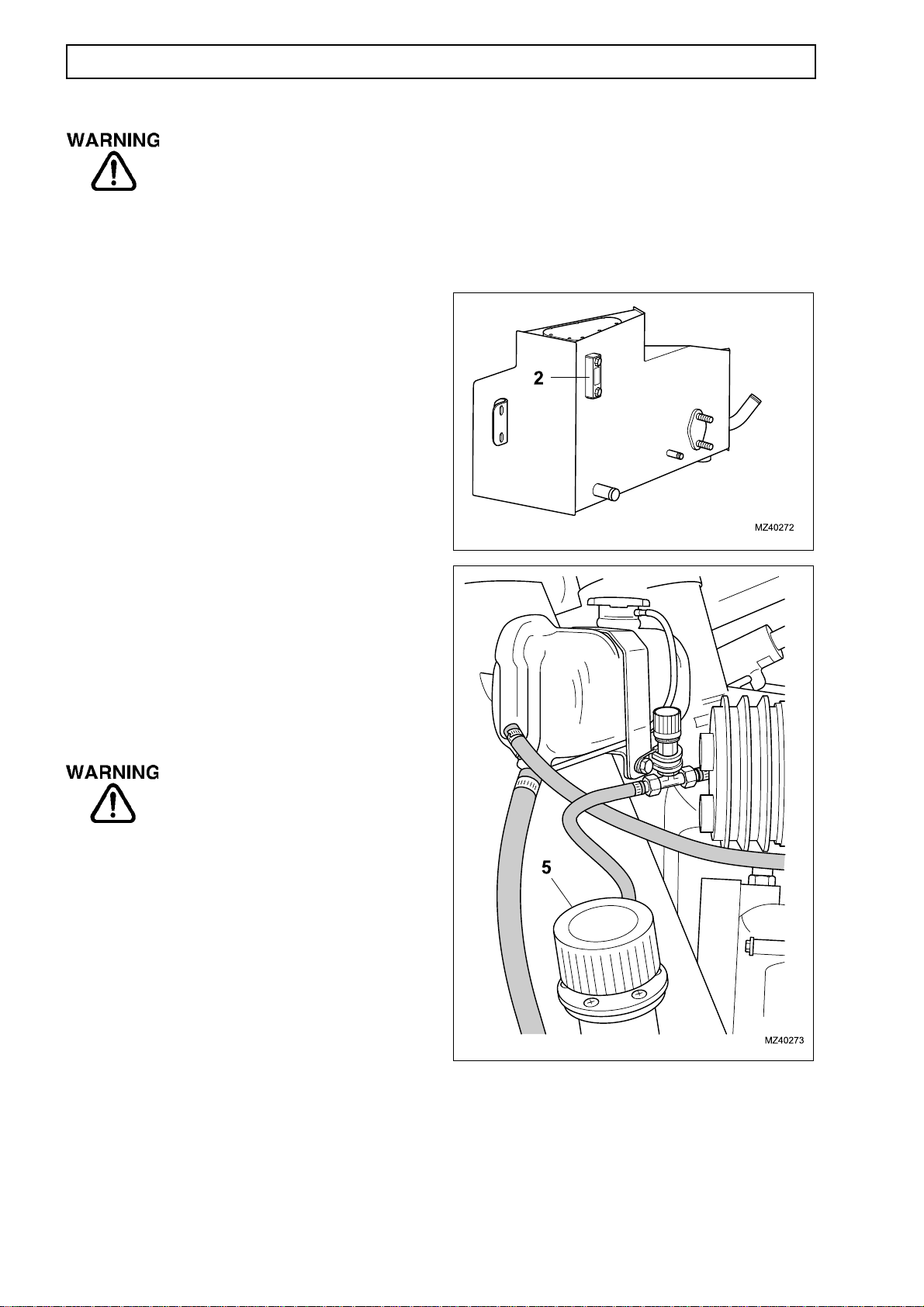

Suction line connections to hydraulic tank

1. Sight glass

2. Suction - Main Pump

3. Drain plug

4. Suction - Auxiliary Pump

5. Filler

Return hose connections to hydraulic tank

(up to Machine S/No.51200471)

5. Return from PVG (Main Control Valve)

6. Return from LS Pump and Filter

7. From LS Pump Case Drain

8. Breather (connected to Filler)

9. Return from Brake and Steering circuits

10. From Trailer Brake (optional)

11. Return from Parking Brake PRV

Return hose connections to hydraulic tank

(from Machine S/No.51200472)

5. Return from PVG (Main Control Valve)

6. Return from LS Pump and Filter

7. (Blank fitted)

8. Breather (connected to Filler)

9. Return from Brake circuit

10. From Trailer Brake (optional)

11. Return from Brake and Parking Brake circuit

HYDRAULICS 1.19

Hydraulic Pump (load sensing) (2)

The load sensing hydraulic pump supplies pressure

to operate all services, except the fan motor and

parking brake circuits.

Specifications

Pressure (P) 250 bar (3625 psi)

Pressure (load sensing) 14 bar (200 psi)

Pressure (stand-by) 20 bar (290 psi)

Capacity (flow)

(up to Machine S/No.51200471)

122 l/min @ 2300 rpm

(from Machine S/No.51200472)

122 l/min @ 2200 rpm

Pump compensator (load sensing) (3)

The LS pump compensator controls the stand-by pressure

of the pump when services are not demanding oil, then

causes the pump to swash and deliver full pressure when

a service is operated. The valve also contains a pressure

relief valve.

Tank filter (4)

The filter (not illustrated) is in the hydraulic tank and

separates the return side from the clean side of the tank

and is rated at 40 mm.

Filler/breather (5)

The hydraulic tank is replenished through the filler/

breather (5) which contains a filter rated at 7µm. The

filler breather maintains a positive pressure of 0.3

bar (4 psi) in the hydraulic tank.

Auxiliary hydraulic pump (6)

The auxiliary pump supplies pressure to operate the

engine cooling fan motor and keep the parking brake

off while the engine is running.

Specifications

Pressure 160 bar (2320 psi)

(Max allowable in circuit)

Capacity (flow) 50 l/min @ 2300 rpm

NOTE: On Machines up to S/No.51200317, a non-return

valve (63), between the auxiliary pump (6) and the PRV

(8) maintains line pressure security from any fluctuation

in the auxiliary circuit. This prevents any immediate

application of the parking brake in the event of engine or

hydraulic failure.

1.20 HYDRAULICS

Fan motor (7)

NOTE: Fitted to machines up to S/No.51200471only.

This type of fan motor is hydraulically operated from

the auxiliary circuit and is fitted as part of the engine

cooling system. The fan is secured to the drive shaft

with a woodruff key, nut and tab washer. A cartridge

pressure relief valve (64) is attached to the fan motor.

Specifications:

Pressure relief valve 160 bar (2320 psi)

1. To pressure filter (9)

2. Fan motor (7)

3. Pressure - auxiliary pump (6)

4. Return to tank (1)

Fan reverse motor (7)

NOTE: Fitted to machines from S/No.51200472 only.

5. Pressure relief valve (64)

This type of fan motor is hydraulically operated from the

auxiliary circuit and is fitted as part of the Reverse Fan

engine cooling system. The fan is secured to the drive

shaft with a woodruff key, nut and tab washer.

1. Fan reverse valve (72)

2. Fan motor (7)

3. Fan reverse valve (72)

4. Return to tank (1)

HYDRAULICS 1.21

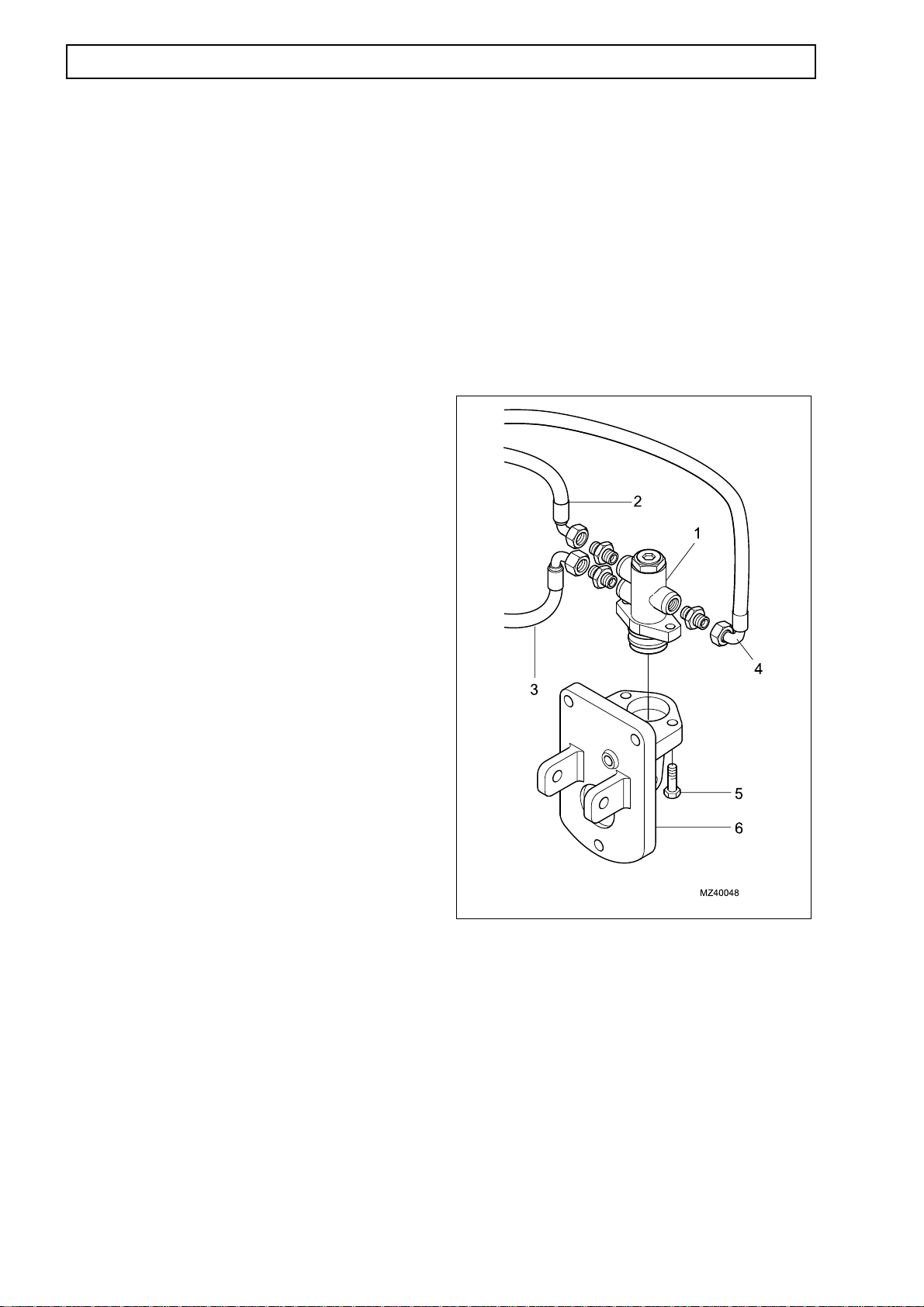

Pressure Reducing Valve (PRV) - for the

parking brake (8)

NOTE: (Fitted to Machines up to S/No.51200551

only

The Pressure Reducing Valve (PRV) (8) for the

parking brake is electrically controlled from a switch

in the cab (refer to electrical section). The PRV is

located in the engine pod for Machines up to S/

No.51200317 and adjacent to the front axle for

Machine S/No's.51200318 to 51200551. The switch

operates a solenoid on the valve to give proportional

operation. The pressure can be tested using test

point 2 (66 - Refer to Page 1.30), which is in the

output from connection A.

NOTE: The voltage to the solenoid is supplied

through a voltage transformer, to achieve the

proportionality required.

Under no circumstances should

battery voltage be applied to this

solenoid.

Specifications:

Operating pressure 16 bar (230 psi)

Maximum pressure 20 bar (290 psi)

Solenoid 3mm/12vdc/100% prop

Pressure filter (9)

NOTE: (Fitted to Machines up to S/No.51200471 only)

The oil pressure filter (9) is installed in the return line,

between the fan motor (7) and the hydraulic tank (1).

NOTE: (Fitted to Machines from S/No.51200472 only)

The oil pressure filter (9) is installed in the return line,

between the reverse fan valve (72) and the hydraulic

tank (1).

If the filter becomes blocked, a filter blockage warning

light in the cab illuminates and a bypass will open at 3.5

bar (50 psi).

T. Return to hydraulic tank (1)

P. Supply from Auxiliary pump (6)

A. Supply to Parking Brake actuators (14)

When the warning light is illuminated

NO filtration is taking place. Always

change the filter IMMEDIATELY.

Specifications

Filtration 10µm

1. Pressure switch

2. Bypass valve

3. Filter bowl

4. Filter media

1.22 HYDRAULICS

Single circuit brake pressure servo valve

(MICO) (10)

NOTE: Fitted to Machines up to S/No.51200471 only.

The brake pressure servo valve can be either single

or dual depending on the model of the machine.

The operation of the servo valve is proportional to

brake pedal movement. When the brake pedal is

pressed, the valve (10) allows pressure in the

accumulator (11) to apply the brakes. When the brake

pedal is released, the valve (10) closes the pressure line

from the accumulator (11) and diverts brake pressure

from the brake units to the hydraulic tank (1), releasing

the brakes.

Specification

Brake pressure at A 44 bar (640 psi)

Dual circuit brake pressure servo valve

(MICO) (10)

NOTE: Fitted to Machines up to S/No.51200471 only.

With a dual brake servo valve (10), the front and rear

brakes are operated independently of each other by

separate feed and return lines from the servo valve.

Specification

Brake pressure at A

(not shown) 44 bar (640 psi)

Servo Valve - Single circuit brake pedal

P Pressure supply from Accumulator (11)

T Return to Hydraulic Tank (1)

A Supply to Brakes on Front (14) and Rear (18)

Axles

Servo Valve - Dual circuit brake pedal

P Pressure supplies from Accumulators (11)

T Return from Hydraulic Tank (1)

A (not shown) - Supply to Brakes on Front (14)

and Rear (18) Axles

HYDRAULICS 1.23

Single circuit brake pressure servo valve

(SAFIM) (10)

NOTE: Fitted from Machines Serial No.51200472

only

The brake pressure servo valve can be either single or

dual depending on the model of the machine. The

valve is constructed from 3 separate modules, the

master cylinder, valve body and end plate. Brake

pedal travel and braking pressure are set using an

adjusting screw, located on the base on the brake

valve.

The operation of the servo valve (1) is proportional to

brake pedal movement. When the brake pedal is

pressed, a pivoted lever moves a master cylinder,

which positions an associated sprung loaded plunger.

The plunger is in contact with the main shuttle valve

in the valve body Refer to Page 1.84). The shuttle

valve controls the flow of the pressure oil supply from

the brake accumulator. The accumulator is supplied

from the inlet (PVSP) section of the main hydraulic

control valve. When the shuttle valve is moved, the

oil supply from the accumulator is allowed to flow to

the outlet connection in the end plate, which supplies

the front and rear brakes units.

Servo Valve - Single circuit brake pedal

P Pressure supply from Accumulator (11)

T Return to Hydraulic Tank (1)

A Supply to Brakes on Front (14) and Rear (18)

Axles

When the brake pedal is released, spring pressure in

the master valve releases pressure on the shuttle

valve and repositions the brake pedal. The shuttle

valve moves under spring pressure to close the oil

supply from the accumulator and divert residual oil

pressure from the brake system to the hydraulic

tank, releasing the brakes.

Specification:

Brake pressure at A 44 bar (640 psi)

Dual circuit Brake pressure servo valve

(SAFIM) (10)

NOTE: Fitted from Machines Serial No.51200472

only

The construction and operation of the dual brake

servo valve is similar to the single servo valve. The

primary difference is that the front and rear brakes are

operated independently of each other by separate

feed and return lines from the servo valve.

Specification:

Brake pressure at A 44 bar (640 psi)

Servo Valve - Dual circuit brake pedal

P Pressure supply from Accumulators (11)

T Return to Hydraulic Tank (1)

A Supply to Brakes on Front (14) and Rear (18)

Axles

1.24 HYDRAULICS

Accumulator(s) (11)

The nitrogen charged accumulator(s) provide

hydraulic pressure for efficient operation of the brakes

under all pump load conditions. One accumulator is

fitted for the single brake system and two are fitted for

the dual brake system. The accumulator(s) are located

in the chassis behind the cab assembly.

Specifications

Pre-charge pressure 41 bar (595 psi)

Oil capacity 0.75 litre

Pressure switch (12)

The pressure switch illuminates a warning light in the

cab when brake pressure drops to a critical level.

The pressure switch is located adjacent to the

accumulator(s) (11) behind of the cab structure,

forward of the rear axle.

Specification

Operating pressure 116 bar (1682 psi) falling

Pressure switch (transmission dump) (13)

When the transmission dump selector switch in the

cab is operated the pressure switch will disconnect

transmission when the brakes are applied. The

pressure switch is located adjacent to the

transmission drop box, above the drive shaft.

Specification

Operating pressure 15 bar (217 psi) rising

HYDRAULICS 1.25

Front axle (14)

The front axle contains double reduction bevel and

planetary hub reduction gears and a limited slip

differential. Braking is by inboard multi-disc units, the

axle also contains a parking brake.

The outboard wheel hubs are steerable, operated

by a steering cylinder (15) attached to the axle.

Steering cylinder (front) (15)

The front steering cylinder is a double acting

hydraulic cylinder, supplied with pressure operating

oil from the Steering Control Valve (21). The two

cylinder rams have a ball joint end fitting, which

connect to the swivel hubs for the front wheels. The

front steering cylinder is attached to the rear of the

front axle, above the drive shaft housing.

Specification

Stroke (lock to lock) 200 mm

Bore 85 mm

Pressure switch (brake light) (16)

When the brake pedal is depressed the pressure

switch operates and illuminates the brake stoplights

at the rear light clusters. The switch is located in the

brake pipes on the right side of the front axle.

Specification

Operating pressure 5 bar (72 psi) rising

1.26 HYDRAULICS

Pressure switch (parking brake) (17)

When the parking brake pressure (17) falls below 16

bar (232 psi) the pressure switch illuminates a

warning light in the cab. The switch is located in the

brake pipes on the right side of the front axle.

If light is on, parking brake has been applied.

If light comes on when parking brake is

not applied, stop vehicle and investigate

fault.

Specification

Operating pressure 16 bar (232 psi) rising

Rear axle (18)

The rear axle (18) contains double reduction bevel

and planetary hub reduction gears and a limited slip

differential. Braking is by inboard multi-disc units

(when taken as an option).

The outboard wheel hubs are steerable, operated by

a steering cylinder (19) attached to the axle.

Steering cylinder (rear) (19)

The rear steering cylinder (19) is a double acting

hydraulic cylinder, supplied with pressure operating

oil from the Steering Control Valve. The two cylinder

rams have a ball joint end fitting, which connect to

the swivel hubs for the front wheels. The rear

steering cylinder is attached to the front of the rear

axle, above the drive shaft housing.

Specification

Stroke (lock to lock) 200 mm

Bore 85 mm

Non-return valve (20)

The non-return valve (NRV) allows pressure supply oil

to be supplied from the main hydraulic control valve to

the Brake Servo valve. The NRV (20) prevents oil

from the brake servo valve returning into the main

control valve. This valve is fitted to Machines for

certain markets only.

HYDRAULICS 1.27

Steering valve (21)

The steering system is dynamic and fully load

sensing and is supplied with pressure operating oil

from the load sensing (LS) output of the inlet section

(PVSP) (36) on the main hydraulic control valve (25).

The valve contains a PRV (23) and two shock valves

(24).

Steering in Neutral position

When the steering valve is in the neutral position, the

spring in the priority valve (42) moves the valve to

allow the oil to pass freely, from the load sensing

line, through the priority valve (42) and the steering

control valve (21) to the hydraulic tank (1). The oil

supply from the hydraulic pump (2) is locked.

As back pressure increases at the spool of the

priority valve (42), the valve spring is compressed and

the spool moves to allow oil to flow to the working

hydraulics.

STEERING - NEUTRAL POSITION

1.28 HYDRAULICS

Steering in Operation

As the steering wheel is turned, the rotary valve

proportionally directs the oil flow from the LS line of

the inlet section (PVSP) (36) to the steering selector

valve (21) (not shown). The LS line is not fully closed

until the rotary valve is fully open. When the steering

input is stopped, the rotor passages close, steering

input stops and the system returns to the loadsensing mode.

Specification

Type OSPF250LS

PRV 170-175 bar (2465-2537 psi)

Shock valve 225-245 bar (3262-3552 psi)

STEERING - RIGHT TURN OPERATION

Pressure relief valve (23)

If an overpressure condition exists, a pressure relief

valve (PRV) will bypass pressure oil from the spring

side of the priority valve (42) to the hydraulic tank (1).

The upstream oil pressure is greater and moves the

spool valve, against the spring, allowing oil to be

supplied to the working hydaulics.

Specification:

Operating pressure 175 bar (254 psi)

HYDRAULICS 1.29

Steering selector valve (22)

The steering selector valve is solenoid operated and

diverts oil to the respective ports of the steering

cylinders. Three modes of steering are available by

selecting the steering mode switch in the cab to give

either two-wheel steering (front wheels), four-wheel

steering or ‘crab’ steering.

The machine must always be

stationary before changing steering

modes.

C 1 To rear steering cylinder (19)

C 2 To rear steering cylinder (19)

C 4 To front steering cylinder (15)

T Return to hydraulic tank (1)

P From inlet section (36) CF - Line

C 3 T o front steering cylinder (15)

O OSPF250 valve

A Adapter

E Selector valve

LS From inlet section (36) LS – Line

1.30 HYDRAULICS

Control valve (25)

The control valve consists of up to five individual spool

valves, with common pressure and return lines, linked

together by an inlet and outlet cover. The inlet

(PVSP) (36) contains a priority valve (43) (steering)

module and brake accumulator charge valve (44). The

spools, outlet cover and PSVP are secured together

with tie bolts. The individual components of the valve

described are (26) to (44).

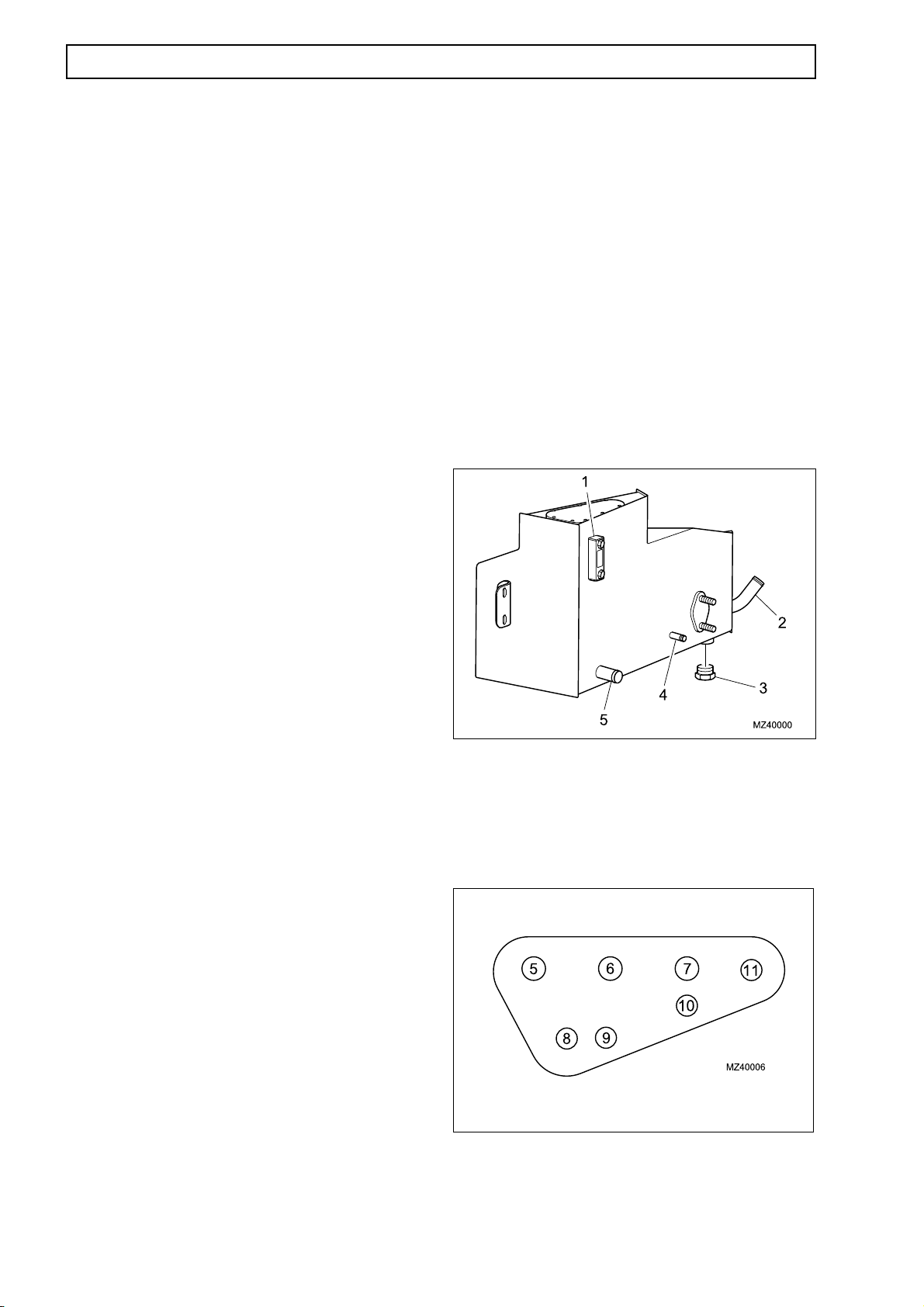

Key to control valve

NOTE: Numbers in bold type refer to identification

numbers on main hydraulic schematic.

1 Outlet section (PVP) (26)

2 Test Point 1 (65)

3 Boom extend/retract section (27)

4 Crowd/compensator section (28)

5 Boom lift/lower section (29)

6 1st auxiliary section (30)

7 2nd auxiliary section (31)

8 Manual operation module

9 Brake and Accumulator Charge valve (BAC) (44)

10 Steering Priority Valve (42)

11 Inlet Section (PVSP) (36)

12 Brakes/Steering Priority Valve (12)

Key to control valve (continued)

13 Tie bolt

14 Washer

15 Nut

16 LS Shuttle Valve (37)

17 Pressure supply (36)

18 Brake and Accumulator Charge valve (BAC) (44)

19 Steering Valve (22)

20 Electric module (38, 40)

21 Test Point 4 (68)

22 2nd Service Couplings (60)

23 2nd Service Couplings (60)

24 Diverter Valve (56)

25 Diverter Valve (56)

26 Load Control Valve (55)

27 Lift Cylinder (54)

28 Relief valve, crowd back (39)

29 Load Control Valve (52)

30 Crowd Cylinder (51)

31 Relief valve, crowd forward (36)

32 Test {Point 5 (69)

33 Extension Cylinder (49)

34 Load Control Valve (50)

35 Relief valve, main system (32)

36 Pilot pressure regulator (34)

37 Hydraulic Tank (1)

HYDRAULICS 1.31

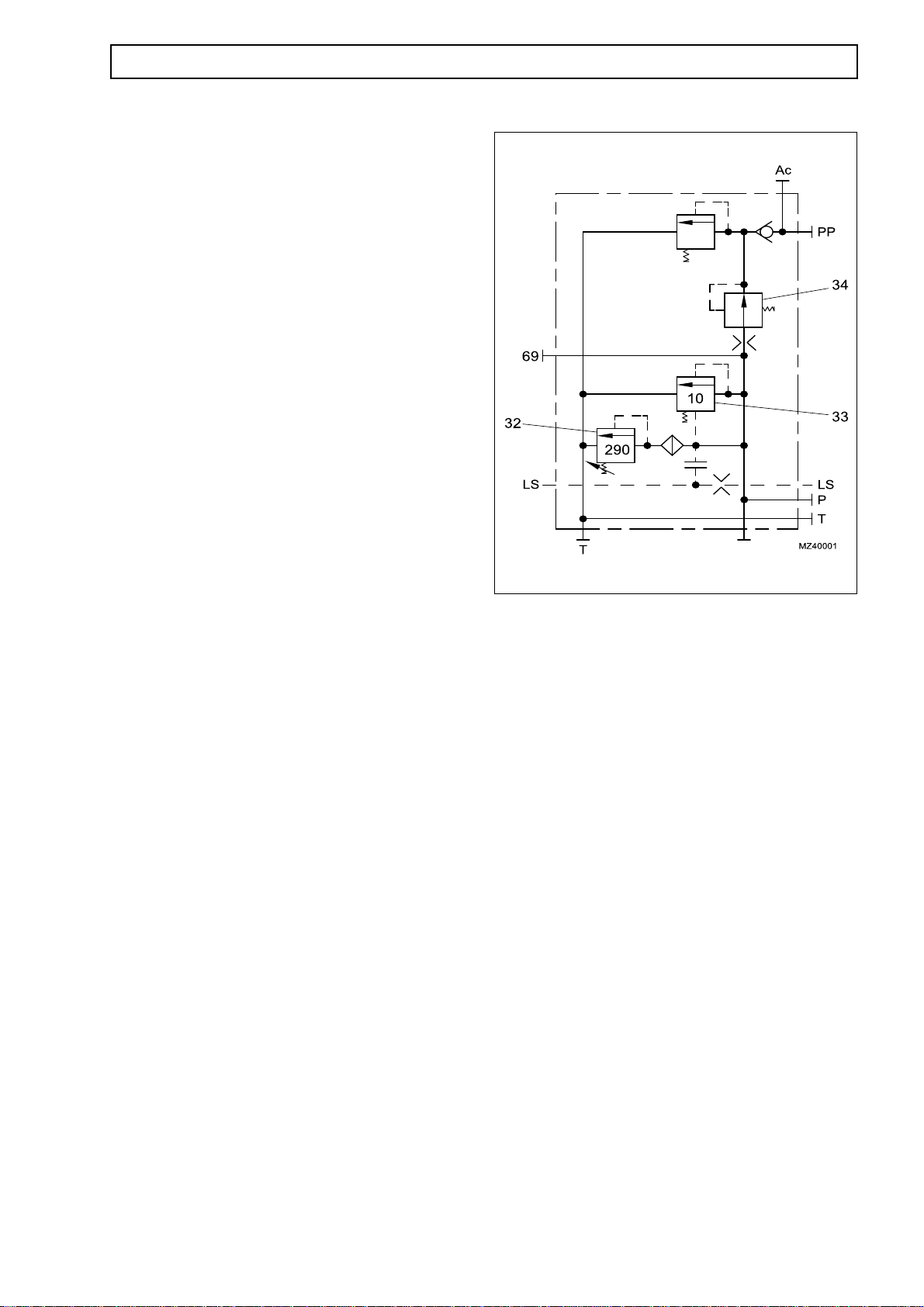

Outlet section (PVP) (26)

Ac Accumulator

PP Pilot pressure

LS Load sensing

T Return to tank

P Pressure

32 Main pressure relief valve (RV1-290 bar)

34 Pilot pressure regulator (14 bar)

33 Compensator (pressure raising spool) (10 bar)

69 Test point

Function

The closed centre provides for ultimate system protection

and the provision of pilot pressure for the operation of the

spools.

1.32 HYDRAULICS

Extension section (27)

A Port A - connection to service

B Port B - connection to service

PP Pilot pressure

LS Load sensing

T Return to tank

P Pressure

(37) LS shuttle valve

(38) Controller, proportional

Function

Extension service is fully proportional and operated

electrically to provide oil flow to the extension circuit.

When the spool is moved from the neutral position, oil

at P (standby pressure 20 bar (290 psi)) is delivered

to the consumer (service). The oil at the consumer

meets a resistance (i.e. to move the piston) and the

pressure at P rises to overcome this force. The P line

is connected permanently to the LS line; therefore the

pump receives a signal to swash to the required

position to provide the pressure required to overcome

the resistance. The pressure at P will therefore be the

LS pressure plus the standby pressure of 20 bar (290

psi).

The pump will always react to the highest pressure

requested when more than one service is operated by

virtue of the LS shuttle valve in each section.

When the valve returns to neutral the pressure at P

drops and therefore the pressure in the LS line also

drops.

The spool is operated by pilot oil pressure delivered

by the electrical actuator under the command of the

‘Solo’ joystick and is fully proportional.

In neutral the spool is ‘half-motored’, connecting port

B to the T line.

HYDRAULICS 1.33

Crowd section (28)

A Port A - connection to service

B Port B - connection to service

PP Pilot pressure

LS Load sensing

T Return to tank

P Pressure

(35) Shock and anti-cavitation valve - Port A

(RV2-175 bar)

(37) LS shuttle valve

(38) Controller, proportional

(39) Shock and anti-cavitation valve - Port B

(RV3-265 bar)

Function

Crowd service is fully proportional and operated

electrically to provide oil flow to the crowd circuit.

When the spool is moved from the neutral position,

oil at P (standby pressure 20 bar (290 psi)) is

delivered to the consumer (service). The oil at the

consumer meets a resistance (i.e. to move the

piston) and the pressure at P rises to overcome this

force. The P line is connected permanently to the LS

line; therefore the pump receives a signal to swash to

the required position to provide the pressure required

to overcome the resistance. The pressure at P will

therefore be the LS pressure plus the standby

pressure of 20 bar (290 psi).

The pump will always react to the highest pressure

requested when more than one service is operated by

virtue of the LS shuttle valve in each section.

When the valve returns to neutral the pressure at P

drops and therefore the pressure in the LS line also

drops.

The spool is operated by pilot oil pressure delivered

by the electrical actuator under the command of the

‘Solo’ joystick and is fully proportional.

In neutral the spool is closed’, neither of the

consumer ports A or B are connected to the T line.

This enables self-levelling operation from the

compensator cylinder.

To protect the circuit, shock valves are provided in

both A and B ports.

1.34 HYDRAULICS

Lift section (29)

A Port A - connection to service

B Port B - connection to service

PP Pilot pressure

LS Load sensing

T Return to tank

P Pressure

(37) LS shuttle valve

(40) Controller, proportional

Function

Lift service is fully proportional and operated

electrically to provide oil flow to the lift circuit.

When the spool is moved from the neutral position,

oil at P (standby pressure 20 bar (290 psi)) is

delivered to the consumer (service). The oil at the

consumer meets a resistance (i.e. to move the

piston) and the pressure at P rises to overcome this

force. The P line is connected permanently to the LS

line; therefore the pump receives a signal to swash to

the required position to provide the pressure required

to overcome the resistance. The pressure at P will

therefore be the LS pressure plus the standby

pressure of 20 bar (290 psi).

The pump will always react to the highest pressure

requested when more than one service is operated

by virtue of the LS shuttle valve in each section.

When the valve returns to neutral the pressure at P

drops and therefore the pressure in the LS line also

drops.

The spool is operated by pilot oil pressure delivered

by the electrical actuator under the command of the

‘Solo’ joystick and is fully proportional.

In neutral the spool is ‘half-motored’, connecting port

B to the T line.

HYDRAULICS 1.35

1st service (30)/2nd service (31) section

A Port A - connection to service

B Port B - connection to service

PP Pilot pressure

LS Load sensing

T Return to tank

P Pressure

(37) LS shuttle valve

(40) Controller, non-proportional

Function

1st service/2nd service is non-proportional and

operated electrically to provide oil flow to the 1st

service/2nd service circuit.

When the spool is moved from the neutral position,

oil at P [standby pressure 20 bar (290 psi)] is

delivered to the consumer (service). The oil at the

consumer meets a resistance (i.e. to move the

piston) and the pressure at P rises to overcome this

force. The P line is connected permanently to the LS

line; therefore the pump receives a signal to swash to

the required position to provide the pressure required

to overcome the resistance. The pressure at P will

therefore be the LS pressure plus the standby

pressure of 20 bar (290 psi).

The pump will always react to the highest pressure

requested when more than one service is operated by

virtue of the LS shuttle valve in each section.

When the valve returns to neutral the pressure at P

drops and therefore the pressure in the LS line also

drops.

The spool is operated by pilot oil pressure delivered

by the electrical actuator under the command of the

‘Solo’ joystick.

These sections, although electrically controlled, are

non-proportional. Operation of the buttons on the

‘Solo’ joystick operate these sections as an on-off

switch.

In neutral the spool is closed, neither of the

consumer ports A and B are connected to the T line.

1.36 HYDRAULICS

Inlet section (PVSP) (36)

LS (1) Load sensing (to steering valve)

CF Steering valve

B1 Main brake

B2 Trailer brake (optional)

B3 Pressure test point (67)

LS Load sensing

T Return to tank

P Pressure

A BAC valve spring

(37) LS shuttle valve

(41) Priority valve

(42) Steering priority valve (compensator)

(43) Filter

(44) Brake accumulator charge (BAC)

(68) Test point

Function

The inlet section (PVSP) provides oil to:

(a) The brake circuit through the BAC valve (44), this

gives a charge of between 138-159 bar (2000-2300

psi) and operates in preference to all other services.

Brake charge pressure can be tested at test point B3

(68).

(b) The steering circuit with oil on demand by the

steering priority valve (42).

The oil arriving at P is delivered to the BAC valve and

onto the accumulators, the resistance to charging the

accumulator causes the pressure to rise at P which,

as it is connected to the LS line via the BAC valve,

signals to the pump. The pump responds by delivering

oil at the required pressure.

The system charges at 138 bar and stops charging at

159 bar. At the upper limit 159 bar, the oil pressure at

P overcomes the force of the BAC valve spring (A)

and closes the connection between P and LS; the

pump therefore goes to standby. When the pressure

in P falls below 138 bar, the spring force opens the

valve and the system recharges.

At the same time, pump pressure is supplied to the

steering unit via the CF port. If the steering is not

being used, the pump at standby pressure overcomes

the spring force in the priority valve (41) and supplies

oil to the other consumers.

When the steering wheel is moved, the resistance to

oil from the steering cylinders builds in the CF line.

This is also sensed by the LS line, which, as it is

linked to the steering priority valve (42). makes sure

steering is given priority as well as signalling the

pressure requirement to the pump.

HYDRAULICS 1.37

1.38 HYDRAULICS

Accumulator (45)

The nitrogen charged accumulators (1) provide

hydraulic pressure for operation of spools when

engine is switched off. The accumulators are

attached to brackets, located adjacent to the main

hydraulic control valve (25).

Specifications

Pre-charge pressure 7 bar (100 psi)

Oil capacity 0.75 litre

Tap (46)

The tap valve (3) (46) is located on the rear service

plate (1) and connects the return line from the

autohitch manifold (2) to the hydraulic tank. When

operated, the tap valve (3) allows return oil from the

autohitch manifold(2) to flow to the hydraulic tank.

The return line downstream from the tap valve (3)

connects to the return line from the trailer brake

valve (4). The tap valve (3) is used to convert the

dual acting service for the autohitch to single acting

service for trailer tipping.

Trailer brake valve (47)

The trailer brake valve, if fitted, is located on the

rear service plate and is connected to the inlet

section (36) of the main hydraulic control valve

(25), the hydraulic tank (1) and the trailer coupling

(48). When a trailer brake is connected to the

trailer brake coupling and the brakes are applied,

the porting of the valve applies proportional

pressure to the trailer brake. When the brakes are

released, the valve diverts the hydraulic oil to the

hydraulic tank (1).

1 Accumulators

1 Service plate 3 Tap valve (46)

2 Manifold 4 Trailer valve

The valve is pilot operated by a signal taken from

the operation of the service brakes.

Key to Trailer Brake Valve

1 Outlet to Trailer Brake Coupling (48)

2 Inlet from Tap (46)

3 Pressure supply (B2)

Trailer brake coupling (48)

The trailer brake coupling (1) is a self-sealing, quick

release coupling, located on the rear service plate

(2). The coupling is used to connect a trailer

braking system to the trailer brake valve (47), if

fitted.

Key to Trailer Brake Coupling

1 Trailer brake coupling

2 Rear service plate

HYDRAULICS 1.39

Extension cylinder (49)

The boom extension cylinder is fitted inside the boom

of the machine and is supplied with operating pressure

oil from a load control valve (50).

Specification:

Type K 50 Stroke 1971 mm

Bore 80 mm

Type K 60 Stroke 2111 mm

Bore 80 mm

Type K 70 Stroke 2917 mm

Bore 80 mm

Load control valve (50)

The load control valve for the extension cylinder is

fitted in the pressure oil supply lines, between the

extension section (27) and the boom extension

cylinder (49). The valve prevents any load

movement in the event of hose bursts or leakage. If

the valve is defective, a complete new cartridge

must be fitted.

The load control valve is factory set and

should never be dismantled or adjusted

except for resealing.

Key to Load Control Valve

1. From the extension section (27)

2. Extension cylinder (rod side)

3. Extension cylinder (full bore side)

4. From the extension section (27)

5. Pilot pressure

6. Supply pressure

7. Pressure relief

1.40 HYDRAULICS

Crowd cylinder (51)

The crowd cylinder is fitted inside the head of the

boom and controls the operation of the head

attachments. The crowd cylinder is supplied with

operating pressure oil from the crowd/compensator

section (28) and a load control valve (52).

Specification:

Stroke 350 mm

Bore 125 mm

Load control valve (52)

The load control valve for the crowd cylinder is

fitted between the crowd cylinder (51) and the

crowd/compensator section (28). The valve

prevents any load movement in the event of hose

bursts or leakage. If the valve is defective, a

complete new cartridge must be fitted.

The load control valve is factory set

and should never be dismantled or

adjusted except for resealing.

Key to Load Control Valve

1. From the crowd/compensator section (28)

2. Crowd/compensator cylinder (rod side)

3. Crowd/compensator cylinder (full bore

side)

4. From the crowd/compensator section (28)

5. Pilot pressure

6. Supply pressure

7. Pressure relief

HYDRAULICS 1.41

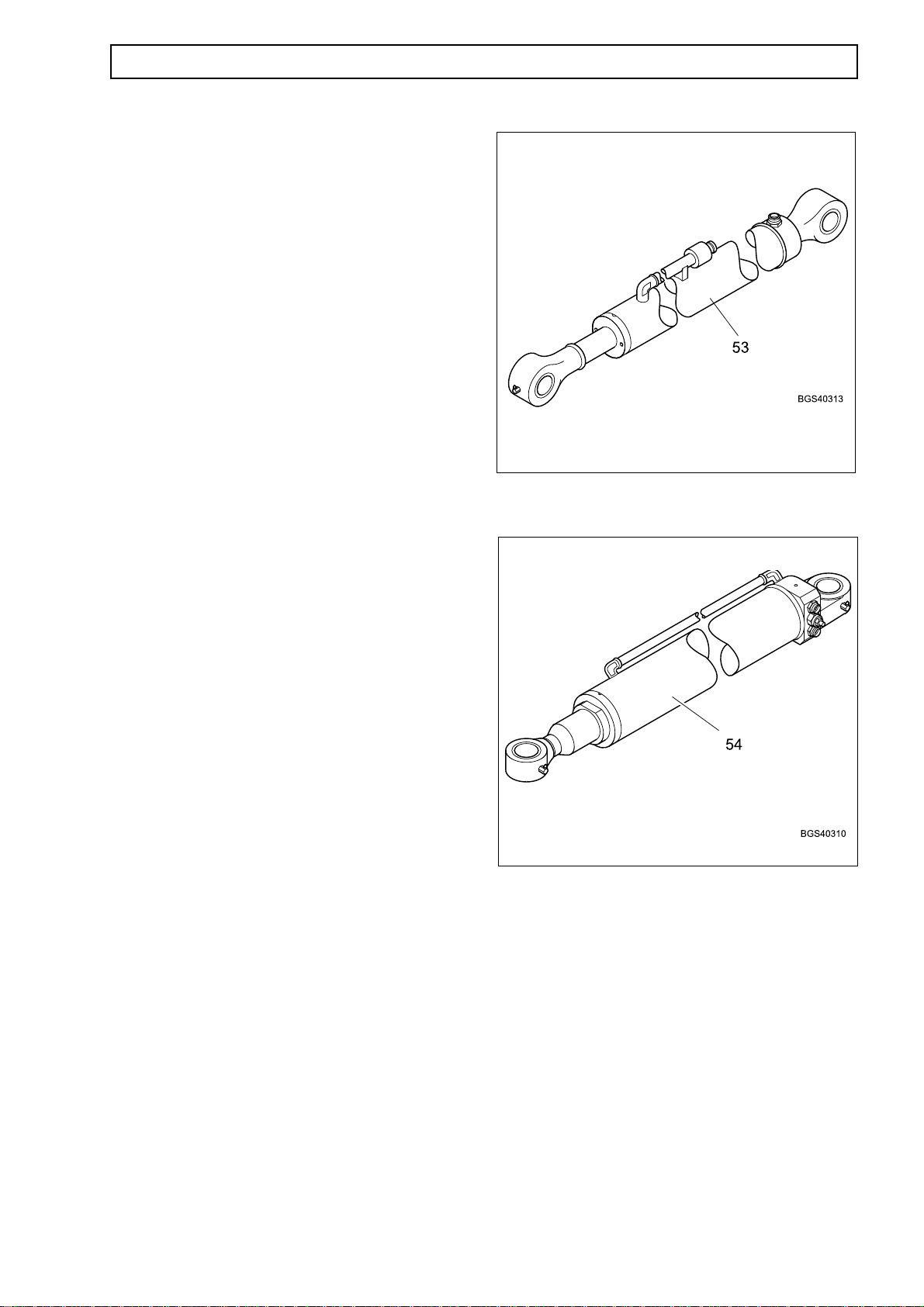

Compensator cylinder (53)

The compensator extension cylinder is fitted below

and to the rear of the extension boom and is

connected to the load control valve (52) and the

crowd/compensator section (28).

Specification

Stroke 750 mm

Bore 63 mm

ILLUSTRATION REQUIRED (IPC 723)

Lift cylinder (54)

The lift cylinder is fitted below and forward of the

extension boom. The lift cylinder is supplied with

operating pressure oil from the lift section (29) and

a load control valve (55).

Specification

Type K50 Stroke 1325 mm

Bore 125 mm

Type K60 Stroke 1325 mm

Bore 125 mm

Type K70 Stroke 1400 mm

Bore 125 mm

1.42 HYDRAULICS

Load control valve (55)

The load control valve for the lift cylinder is fitted in

the pressure oil supply lines, between the lift section

(29) and the lift extension cylinder (54). The valve

prevents any load movement in the event of hose

bursts or leakage. If the valve is defective, a

complete new cartridge must be fitted.

The load control valve is factory set

and should never be dismantled or

adjusted except for resealing.

Key to Load Control Valve

1. From the lift section (29)

2. Lift cylinder (rod side)

3. Lift cylinder (full bore side)

4. From the lift section (29)

5. Pilot pressure

6. Supply pressure

7. Pressure relief

HYDRAULICS 1.43

Diverter valve (56)

The diverter valve, if fitted, is attached to a bracket,

which is fitted to the rear service plate, to the left

side of the chassis member. The valve is

connected between the 1st auxiliary section (30)

and the 1st service couplings (59) and autohitch

manifold (57).

The valve is solenoid operated and selected by a

rocker switch in the cab. When selected, the valve

diverts oil from the 1st auxiliary service to the rear

of the machine where it can be utilized to operate

trailer tipping or autohitch.

Specification:

Solenoid Operating voltage 12V DC

Key to Diverter Valve

1 To the 1st service coupling (59)

2 To the 1st service coupling (59)

3 Autohitch manifold (57)

4. Autohitch manifold (57)

5-10. Not used

11. To the 1st auxiliary section (30)

12. To the 1st auxiliary section (30)

Manifold (57)

The manifold is attached to the rear service plate

and is located between the autohitch cylinder (58)

and the diverter valve (56). The manifold is used to

deliver oil to the autohitch or trailer tipping services.

1.44 HYDRAULICS

Autohitch cylinder (58)

The autohitch cylinder, if fitted, is located on the

rear of the machine and is used to automatically

connect and lift a trailer onto the machine. The

pressure oil supplies to the autohitch cylinder are

from the autohitch manifold (57).

Specification

Stroke 325 mm

Bore 60 mm

1st service couplings (59).

The 1st service couplings (not illustrated) are of the

quick-release type and are used to attach hydraulic

services to the front of the machine.