Claas Rollant 240, Rollant 250, Rollant 250RC, Rollant 254RC, Rollant 255RC User Manual

ROLLANT 240

ROLLANT 250 / 250 ROTO CUT ROLLANT 254 ROTO CUT ROLLANT 255 ROTO CUT

Operating instructions

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

s |

! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

t |

i |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

l |

a |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

eg |

u |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ty |

r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a |

f |

e |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

s |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

ve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

s |

e |

r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

b |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

o |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

d |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

d |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

e |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 Introduction

|

Introduction |

|

|

INTRODUCTION |

This operating manual for the Rollant 240/250/254/255 |

|

round baler (applicable from 72505431/74800011/ |

|

75400011/74900011) is primarily intended for the |

|

machine operator; it provides information on the use of |

|

the round baler, including its settings and operation. |

|

Please comply with the guidelines for correct care and |

|

maintenance of your round baler to ensure permanent |

|

availability and a long service life of the round baler. |

|

Have your round baler inspected by your CLAAS |

|

workshop immediately after harvest within the |

|

framework of these winter storage recommendations. |

|

Deficiencies in maintenance or incorrect operation |

|

lead to a drop in performance and result in time losses. |

|

Use the experience and latest knowledge in long stalk |

|

harvest implemented in this round baler by correct |

|

operation and thorough maintenance, and your round |

|

baler will always produce excellent results. |

|

Your CLAAS Service Department |

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 |

1.1.1 |

Introduction

1.1.2 |

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5 |

2 Contents

Contents

CONTENTS

1. Introduction

Introduction ............................................................................ |

1.1.1 |

2. Contents |

|

3. General notes |

|

Road traffic ............................................................................ |

3.1.1 |

To be observed especially ..................................................... |

3.2.1 |

Type plate (baler) ............................................................ |

3.3.1 |

Machine serial number .................................................... |

3.3.1 |

4. Safety precautions |

|

Safety precautions ................................................................. |

4.1.1 |

Personal injury may result if these safety precautions |

|

are not followed ............................................................... |

4.1.1 |

Safety signs ..................................................................... |

4.1.3 |

Transporting baler on a public thoroughfare .................... |

4.1.3 |

Transporting baler on a public thoroughfare .......................... |

4.1.5 |

Recommended warning lights ......................................... |

4.1.5 |

Preparing for transport ..................................................... |

4.1.5 |

4. |

|

4. Safety signs |

|

5. Specifications |

|

CLAAS Rollant 240/250/Rollant 250/254/255 RC .................. |

5.1.1 |

Feeder mechanisms ........................................................ |

5.1.1 |

Wrapping unit .................................................................. |

5.1.2 |

Wheels ............................................................................. |

5.1.3 |

Hydraulic system ............................................................. |

5.1.3 |

Required tractor hydraulics .............................................. |

5.1.3 |

Flow rate of hydraulic oil .................................................. |

5.1.3 |

Electrical systems ............................................................ |

5.1.3 |

Weights ............................................................................ |

5.1.3 |

CLAAS Rollant 240/250/Rollant 250/254/255 RC .................. |

5.1.4 |

Dimensions of the round baler ......................................... |

5.1.4 |

CLAAS Rollant 240/250/Rollant 250/254/255 RC .................. |

5.1.5 |

Safety features ....................................................................... |

5.1.5 |

6. Description and function |

|

Transmission of power .................................................... |

6.1.1 |

Pick-up ............................................................................. |

6.1.1 |

Crop guard ....................................................................... |

6.1.1 |

Baffle plate ....................................................................... |

6.1.1 |

Roller crop guard ............................................................. |

6.1.1 |

Cutting unit |

|

(ROLLANT 250/254/255 RC) .......................................... |

6.1.1 |

Rotor backwinding unit |

|

(ROLLANT 240/250/254/255) .......................................... |

6.1.2 |

Hydraulic rotor reverse device |

|

(ROLLANT 254/255 with control panel) ........................... |

6.1.2 |

Hydraulic rotor reverse device from tractor |

|

(ROLLANT 250/254/255) ................................................. |

6.1.2 |

Bale chamber .................................................................. |

6.1.2 |

Wrapping ......................................................................... |

6.1.2 |

Bale discharge ramp ........................................................ |

6.1.3 |

Bale transport .................................................................. |

6.1.3 |

Storage of round bales .................................................... |

6.1.3 |

7. Prior to operation

Check and observe before starting operation ....................... |

7.1.1 |

Attach the baler ..................................................................... |

7.2.1 |

Connecting the universal drive shaft to the baler ............ |

7.2.1 |

Universal drive shaft with taper lock ................................ |

7.2.2 |

Fitting the drive shaft with the CC taper lock ................... |

7.2.2 |

Jack stand ....................................................................... |

7.2.2 |

Before you hitch the baler: .............................................. |

7.2.2 |

Attaching to the swinging drawbar with a safety nut ....... |

7.2.3 |

Attaching to the swinging drawbar with a counter nut ..... |

7.2.4 |

Adjusting the length of the drawbar fork arms ................. |

7.2.4 |

Adjusting the hitch eye .................................................... |

7.2.5 |

Greasing the hitch eye .................................................... |

7.2.5 |

Connecting the universal drive shaft to the tractor |

|

(for swinging drawbar hitching) ....................................... |

7.2.6 |

Shortening the propeller shaft ......................................... |

7.2.7 |

Attaching to the jaw-type hitch with a safety nut |

|

(In Germany only permitted with |

|

type-approved drawbar) .................................................. |

7.2.8 |

Attaching to the jaw-type hitch with a counter nut ........... |

7.2.9 |

Adjusting the drawbar fork arms ..................................... |

7.2.9 |

Adjusting the hitch eye .................................................. |

7.2.10 |

Set up ball head coupling .............................................. |

7.2.10 |

Attaching the universal drive shaft to the tractor |

|

(for top-fitted tow jaw) .................................................... |

7.2.11 |

Electrical systems .................................................................. |

7.3.1 |

Control box ...................................................................... |

7.3.1 |

Standard operation .......................................................... |

7.3.1 |

Control Terminal .............................................................. |

7.3.1 |

Power supply ................................................................... |

7.3.2 |

Machines with lighting equipment ................................... |

7.3.2 |

Hydraulic System .................................................................. |

7.4.1 |

Hydraulic system for standard machines ........................ |

7.4.1 |

Hydraulic system of CLAAS Control Terminal models .... |

7.4.2 |

Before transporting the baler ................................................. |

7.5.1 |

Bale discharge ramp ............................................................. |

7.6.1 |

Installing the bale discharge ............................................ |

7.6.1 |

Ramp setting to signal bale ejection ............................... |

7.6.5 |

8. Setting up the baler

Pick-up .................................................................................. |

8.1.1 |

Pick-up, transport and work positions ............................. |

8.1.1 |

Adjusting the working height of the pick-up |

|

(pick-up without gauge wheels) ....................................... |

8.1.1 |

Adjusting the working height of the pick-up |

|

(pick-up with gauge wheels) ............................................ |

8.1.1 |

Support wheels ............................................................... |

8.1.2 |

Pick-up crop guard .......................................................... |

8.1.2 |

Short crop baffle .............................................................. |

8.1.2 |

Roller crop guard ............................................................. |

8.1.3 |

Adjusting the roller crop guard ........................................ |

8.1.4 |

Adjusting the roller crop guard where there are |

|

problems with the bale material feed .............................. |

8.1.5 |

Driving the baler with the roller crop guard ..................... |

8.1.5 |

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 |

2.1.1 |

Contents

Blockage in the roller crop guard ..................................... |

8.1.6 |

Cutting unit |

|

(ROLLANT 250/254/255 RC) ........................................... |

8.1.7 |

Blanking knives ................................................................ |

8.1.7 |

Installing and removing the knives ................................... |

8.1.8 |

Locking the knives ........................................................... |

8.1.8 |

Knife - blanking knife holder (option) ............................... |

8.1.8 |

Hydraulic baling pressure preadjustment ........................ |

8.1.9 |

Adjusting the baling pressure with a pivoting segment .. |

8.1.10 |

Spring tension adjustment ............................................. |

8.1.10 |

Safety lock for the tailgate ............................................. |

8.1.11 |

Ladder |

|

(for baling with net wrapping) ......................................... |

8.1.11 |

Wrapping ................................................................................ |

8.2.1 |

Net wrapping .................................................................... |

8.2.1 |

Inserting the net ............................................................... |

8.2.1 |

ROLLANT 240/250 with twine and net wrapping |

|

(Standard) ........................................................................ |

8.2.6 |

ROLLANT 254/255 with twine and net wrapping |

|

(Standard) ........................................................................ |

8.2.7 |

ROLLANT 254/255 with twine and net wrapping |

|

(High Convenience) ......................................................... |

8.2.7 |

Engaging the drive for net wrapping ................................. |

8.2.8 |

Disengaging the twine wrapping drive .............................. |

8.2.8 |

V-belt drive for net wrapping ............................................ |

8.2.8 |

Setting the number of net wraps ...................................... |

8.2.9 |

Double twine wrapping .................................................. |

8.2.10 |

Twine box ...................................................................... |

8.2.10 |

Threading the twine ....................................................... |

8.2.10 |

Threading the twine ROLLANT 240/250/254/255 |

|

with standard controls .................................................... |

8.2.11 |

Threading the twine ROLLANT 254/255 with |

|

CLAAS Control Terminal ............................................... |

8.2.12 |

Adjusting the twine wrap on the outer edges |

|

of the bale ...................................................................... |

8.2.13 |

Turn in the twine deflector ............................................. |

8.2.13 |

Engaging the drive for the twine wrapping |

|

mechanism .................................................................... |

8.2.13 |

Disengaging the drive of the net wrapping |

|

mechanism .................................................................... |

8.2.14 |

Setting the number of twine wraps ................................. |

8.2.14 |

Discharging bales without the bale discharge unit.......... |

8.2.15 |

Reel ........................................................................................ |

8.3.1 |

9. Operation

Balers with standard Controls (ROLLANT 240/250) .............. |

9.1.1 |

Automatic twine and net wrapping ................................... |

9.1.2 |

Manual net wrapping ....................................................... |

9.1.3 |

Wrapping ends ................................................................. |

9.1.3 |

Discharging bales ............................................................ |

9.1.4 |

Bale counter ..................................................................... |

9.1.5 |

Switch position with net wrapping .................................... |

9.1.5 |

Switch position with double twine wrapping ..................... |

9.1.5 |

Manual override of automatic wrapping operation ........... |

9.1.6 |

Delay time for automatic net wrapping ............................ |

9.1.7 |

Checking the delay time .................................................. |

9.1.7 |

Setting the delay time ...................................................... |

9.1.8 |

Activate manual net wrapping .......................................... |

9.1.9 |

Blockages .............................................................................. |

9.2.1 |

Cam-type cut-out clutch – universal drive shaft |

|

(optional equipment) ........................................................ |

9.2.1 |

Rotor reverse, manual ..................................................... |

9.2.2 |

Rotor reverse rotation device, hydraulic (from tractor) |

|

(optional fitting for ROLLANT 250/254/255 with rotor |

|

and standard operation) .................................................. |

9.2.3 |

Cutting unit ...................................................................... |

9.2.4 |

Engaging the knives ........................................................ |

9.2.4 |

Disengaging the knives ................................................... |

9.2.4 |

Switch position ................................................................ |

9.2.4 |

Standard operation baling (ROLLANT 254/255) ............. |

9.2.5 |

Starting operation of the round baler ............................... |

9.2.6 |

Automatic wrapping ......................................................... |

9.2.7 |

Binding and ejecting bales .............................................. |

9.2.7 |

Laying down the bales ..................................................... |

9.2.8 |

Bale counter .................................................................... |

9.2.8 |

Round baler with net wrapping ........................................ |

9.2.9 |

Round baler with twine and net wrapping ....................... |

9.2.9 |

Round baler with twine wrapping .................................... |

9.2.9 |

Manual overload of the automatic wrapping .................. |

9.2.10 |

Triggering early wrapping .............................................. |

9.2.10 |

Delaying the wrapping process: .................................... |

9.2.10 |

Setting the delay period to automatic net binding ......... |

9.2.11 |

Cutting device (ROTO CUT) ......................................... |

9.2.11 |

Swashing the knives in .................................................. |

9.2.11 |

Swashing the knives out ................................................ |

9.2.12 |

Adjusting the volume of the audible warning signal ...... |

9.2.12 |

10. Control Terminal

Baling with the high convenience operation |

|

(optional for ROLLANT 254/255) ......................................... |

10.1.1 |

Control terminal - overview ............................................ |

10.1.2 |

Status display ................................................................ |

10.1.3 |

Setting the type of wrapping .......................................... |

10.1.4 |

Start wrapping cycle manually ....................................... |

10.1.4 |

Delay wrapping cycle .................................................... |

10.1.4 |

Pick-up up / down (without floating position) ................. |

10.1.4 |

Pick-up in float position / up .......................................... |

10.1.5 |

Engage / disengage knives ........................................... |

10.1.5 |

Rotor reverse ................................................................. |

10.1.5 |

Open / close tailgate ...................................................... |

10.1.6 |

Job data ............................................................................... |

10.2.1 |

Settings ................................................................................ |

10.3.1 |

Set number of wraps ..................................................... |

10.3.1 |

Call up “User settings” submenu ................................... |

10.3.2 |

Making user settings ..................................................... |

10.3.2 |

Setting the delay time until the start of automatic |

|

or manual wrapping ....................................................... |

10.3.3 |

Engaging / disengaging automatic tailgate |

|

operation ....................................................................... |

10.3.4 |

Manual override of automatic tailgate operation ........... |

10.3.4 |

Recharge pressure ........................................................ |

10.3.5 |

Clean knives .................................................................. |

10.3.5 |

Select language ............................................................. |

10.3.6 |

Bale wrapper ................................................................. |

10.3.6 |

Counter ................................................................................ |

10.4.1 |

Daily and overall counter ............................................... |

10.4.1 |

Reset maintenance display ........................................... |

10.4.2 |

2.1.2 |

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5 |

Contents

Reset daily counter ........................................................ |

10.4.2 |

Special counter .............................................................. |

10.4.3 |

Start special counter ...................................................... |

10.4.3 |

Correct bale count ......................................................... |

10.4.4 |

Reset job ....................................................................... |

10.4.4 |

Fault display ......................................................................... |

10.5.1 |

Error display in text mode .............................................. |

10.5.1 |

Switch off warning signal ............................................... |

10.5.2 |

Delete fault .................................................................... |

10.5.2 |

Application example ............................................................. |

10.6.1 |

11. CLAAS COMMUNICATOR

Overview – CLAAS COMMUNICATOR |

|

(ROLLANT 254/255 optional) .............................................. |

11.1.1 |

Switching on the Claas Communicator .......................... |

11.1.2 |

Overview – Claas Communicator .................................. |

11.1.3 |

Incremental encoder and keys ...................................... |

11.1.4 |

Incremental encoder ...................................................... |

11.1.4 |

Softkeys ......................................................................... |

11.1.4 |

Navigational keys for the menu ..................................... |

11.1.4 |

Main menu ..................................................................... |

11.1.5 |

Application menu ........................................................... |

11.1.6 |

Work functions ............................................................... |

11.1.6 |

Information window in the application menu .................. |

11.1.7 |

Setup menu ................................................................... |

11.1.7 |

Functions in the settings menu ...................................... |

11.1.7 |

Functions with set parameters ....................................... |

11.1.7 |

Counter menu ................................................................ |

11.1.8 |

Main menu ..................................................................... |

11.1.8 |

Display window current job ............................................ |

11.1.8 |

Fault menu ..................................................................... |

11.1.9 |

System information menu .............................................. |

11.1.9 |

Operator settings ................................................................. |

11.2.1 |

Select type of wrapping ................................................. |

11.2.1 |

Setting the number of net windings ............................... |

11.2.2 |

Setting the twine length ................................................. |

11.2.2 |

Setting the delay between end of baling and start |

|

of net wrapping .............................................................. |

11.2.3 |

Setting the automatic opening of the tailgate ................ |

11.2.4 |

Setting the recharging of the baling pressure in |

|

the hydraulic cylinder ..................................................... |

11.2.5 |

Knife cleaning sequence ............................................... |

11.2.6 |

Settings in the counter menu ............................................... |

11.3.1 |

Selecting job orders ....................................................... |

11.3.1 |

Resetting the work record counter ................................. |

11.3.1 |

Resetting the daily counter ............................................ |

11.3.2 |

Resetting the service display ......................................... |

11.3.2 |

Fault display ......................................................................... |

11.4.1 |

Main menu »Service« .......................................................... |

11.5.1 |

Opening the adjustment menu ...................................... |

11.5.1 |

System information menu .............................................. |

11.5.2 |

Image adjustment menu ................................................ |

11.5.3 |

Setting the contrast ........................................................ |

11.5.3 |

Setting the brightness .................................................... |

11.5.3 |

Time and date menu ...................................................... |

11.5.4 |

Setting the time or date ................................................. |

11.5.4 |

Memory management menu .......................................... |

11.5.5 |

Administration of the saved projects .............................. |

11.5.5 |

Reduce conflicts between the baler and the tractor ...... |

11.5.6 |

Language selection menu ............................................. |

11.5.7 |

Setting the language ..................................................... |

11.5.7 |

Aux. menu ..................................................................... |

11.5.8 |

Pre-settings ......................................................................... |

11.6.1 |

Pick-up function ................................................................... |

11.6.1 |

Pick-up .......................................................................... |

11.6.1 |

Activate cutting unit ....................................................... |

11.6.2 |

Checking the position of the cutting unit ....................... |

11.6.3 |

Standard machines: ...................................................... |

11.6.3 |

Cutting unit active .......................................................... |

11.6.3 |

Cutting unit deactivated ................................................. |

11.6.3 |

Recharging the cylinder pressure starting with |

|

the first bale ................................................................... |

11.6.4 |

Process for activating the function starting with |

|

the first bale ................................................................... |

11.6.4 |

Turn rotor back .............................................................. |

11.6.5 |

Baling and wrapping ...................................................... |

11.6.6 |

Automatic twine wrapping ............................................. |

11.6.6 |

Automatic net wrapping ................................................. |

11.6.7 |

Manual wrapping - twine wrapping and net wrapping ... |

11.6.8 |

Bale output .................................................................... |

11.6.9 |

Automatic opening of tailgate ........................................ |

11.6.9 |

Opening the tailgate manually ....................................... |

11.6.9 |

Fault in the bale chute ................................................. |

11.6.10 |

States of the baler ....................................................... |

11.6.11 |

Twine wrapping without recharging the pressure ........ |

11.6.11 |

Net wrapping without recharging the pressure ............ |

11.6.13 |

12. Faults and remedies

Faults, Cause or remedy ..................................................... |

12.1.1 |

Twine wrapping ............................................................. |

12.1.1 |

Net wrapping ................................................................. |

12.1.2 |

13. After using the baler

Unhitching the baler ............................................................ |

13.1.1 |

Wheel chocks ................................................................ |

13.1.1 |

Parking support ............................................................. |

13.1.1 |

Control box .................................................................... |

13.1.2 |

Standard operation ........................................................ |

13.1.2 |

Control panel (ROLLANT 254/255 optional) ................. |

13.1.2 |

Claas Communicator (ROLLANT 254/255 optional) ..... |

13.1.3 |

Removing the hydraulic hoses and cables .................... |

13.1.3 |

Propeller ........................................................................ |

13.1.3 |

Castor gauge wheels (ROLLANT 250/245/255) ........... |

13.1.4 |

14. Maintenance

Important notes on maintenance ......................................... |

14.1.1 |

General notes on maintenance ..................................... |

14.1.1 |

Maintenance and lubricant tables ........................................ |

14.2.1 |

Maintenance table ......................................................... |

14.2.1 |

Lubricants table ............................................................. |

14.2.2 |

Drive system ........................................................................ |

14.3.1 |

Shearing bolt on main drive |

|

(optional for ROLLANT 240/250/254) ........................... |

14.3.1 |

Shear bolt pick-up drive ................................................ |

14.3.1 |

Angle drive gearbox ...................................................... |

14.3.2 |

Adjusting the tension of the drive chains ....................... |

14.3.3 |

Tightening the pick-up drive chain ................................ |

14.3.4 |

Adjusting the chain tightener ......................................... |

14.3.4 |

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 |

2.1.3 |

Contents

Spring-loaded cylinder for bale-forming roller |

|

drive – tailgate ............................................................... |

14.3.5 |

Spring-loaded cylinder for the bottom bale-forming |

|

roller drive ...................................................................... |

14.3.5 |

Adjusting the spring-loaded cylinder for the front |

|

bale-forming roller drive ................................................. |

14.3.5 |

Adjustment of tension springs ........................................ |

14.3.6 |

Adjusting the tension spring for the net roll tightening |

|

clamp (Adjustment done without net roll) ....................... |

14.3.6 |

Tension spring |

|

(Adjustment done without net roll) ................................. |

14.3.6 |

Adjusting the tension spring for the net brake ............... |

14.3.7 |

Adjusting the pressure springs for the pressure roller ... |

14.3.7 |

Adjusting the tightening device for the net knife ............ |

14.3.7 |

Adjusting the twine tightener .......................................... |

14.3.8 |

Adjusting the twine knife control .................................... |

14.3.8 |

Lubrication system ............................................................... |

14.4.1 |

Automatic chain lubrication ............................................ |

14.4.1 |

Mechanical lubrication of the central chain |

|

(Rollant 254/255 - Option) ............................................. |

14.4.2 |

Overview of the mechanical lubricating pump ............... |

14.4.2 |

Making adjustments to the mechanical |

|

lubricating pump ............................................................ |

14.4.2 |

....................................................................................... |

14.4.2 |

Lubricant ........................................................................ |

14.4.3 |

Bearings to be greased and main lubrication |

|

installation (for ROLLANT 254/255 - optional) ............... |

14.4.3 |

Automatic central lubrication of the bearing |

|

(Rollant 254/255 - Option) ............................................. |

14.4.4 |

Overview ........................................................................ |

14.4.4 |

Adjusting the flow rate ................................................... |

14.4.4 |

Setting the stop on the grease pump ............................. |

14.4.5 |

Filling the grease container ............................................ |

14.4.5 |

Cutting unit ........................................................................... |

14.5.1 |

Adjusting the height of the cutting knives |

|

(ROLLANT 250/254/255 RC) ......................................... |

14.5.1 |

ROLLANT 254/255 - from 75400181/74802194 ............ |

14.5.1 |

Hydraulic oil filter |

|

(machine with filter system) ................................................. |

14.6.1 |

Bleed valve combination with pressure limiting valve .... |

14.6.2 |

Equipment ............................................................................ |

14.7.1 |

Fire extinguisher (Rollant 254/255 optional) .................. |

14.7.1 |

Clean the rollers (Rollant 254/255) ................................ |

14.7.1 |

Tyres .................................................................................... |

14.8.1 |

Check tight fit of wheel nuts ........................................... |

14.8.1 |

Monitoring intervals ........................................................ |

14.8.1 |

Procedure: ..................................................................... |

14.8.1 |

Setting (locking) the bearing clearance ......................... |

14.8.1 |

Proposals for winter storage ................................................ |

14.9.1 |

15. Lubrication plan

Lubricants and notes ............................................................ |

15.1.1 |

16. Index

2.1.4 |

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5 |

3

General notes

General notes

ROAD TRAFFIC |

The machine operator must always have a copy of |

|

the General Type Approval (ABE) issued by the |

|

Kraftfahrt Bundesamt (KBA) or the individual type |

|

approval and two wheel chocks at hand. |

|

When driving on public roads with the lof working |

|

equipment attached, all duties determined under C |

|

in the copy of the ABE issued by the KBA (§ 18, |

|

para. 5 StVZO) or the duties and notes listed in the |

|

individual type approval must be observed. |

|

Above all, no bale must be in the round baler. |

|

If parts of the baler, the conditions of which are |

|

clearly specified, are later changed or modified in |

|

such a way that their operation will endanger any |

|

other participants in traffic, the type approval will |

|

become invalid and a new type approval must be |

|

applied for. In this case the Iof working equipment |

|

must be presented to the responsible technical |

|

inspection authority for motor vehicles (e.g. TÜV) for |

|

issuing an expertise (§ 19 para. 2 StVZO). |

|

If you are in doubt that this may be the case, please |

|

contact us as the manufacturer. |

|

If the round baler is pulled after a tractor, especially |

|

the following devices have to be connected: |

|

- The cable of the lighting equipment. |

|

- The cable for power supply. |

|

Before starting to drive the condition of: |

|

- the connection between pulling vehicle and baler |

|

- the lighting equipment must be checked. |

|

If the license plate given to the vehicle owner for |

|

one his tractors is concealed when the baler is |

|

hitched up, attach a picture of this plate, including its |

|

lighting, onto the baler. |

|

The local road traffic regulations may differ in |

|

individual countries. |

|

The maximum speed under the road traffic |

|

regulations for the country of operation must be |

|

observed. However, the hitched baler is designed to |

|

travel at a maximum speed of 40 km/h (25 mph). It |

|

is not permissible to exceed that speed. |

|

|

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 |

3.1.1 |

General notes

|

|

3.1.2 |

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5 |

General notes

TO BE OBSERVED ESPECIALLY |

In order to avoid any dangers all information in |

|

these operating instructions must be read and |

|

applied by all persons using, maintaining, |

|

repairing or inspecting this round baler. Read in |

|

particular the section “Concerning safety”. |

|

The use of spare parts, accessories and |

|

attachments not originally supplied by CLAAS |

|

and not tested and approved by CLAAS may |

|

impair design specific characteristics of CLAAS |

|

machines or have a negative effect on their |

|

functionality, thereby impairing the active and/ |

|

or passive driving as well as the working safety. |

|

CLAAS does not assume liability for damage |

|

resulting from the use of parts, accessories and |

|

attachments not originally manufactured and |

|

supplied by CLAAS. |

|

Technical data, dimensions and weights are |

|

non-binding. The right for changes in the course |

|

of technical development and errors remains |

|

reserved. |

|

The terms front, rear, right and left always apply |

|

in travel direction. |

|

|

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 |

3.2.1 |

General notes

|

|

3.2.2 |

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5 |

General notes

|

1 |

A |

B |

|

C |

|

D |

800001 |

2 |

3

When ordering spare parts or if you have any technical questions please provide the machine number of the round baler together with the respective serial number. This is absolutely necessary in order to avoid wrong spare parts deliveries.

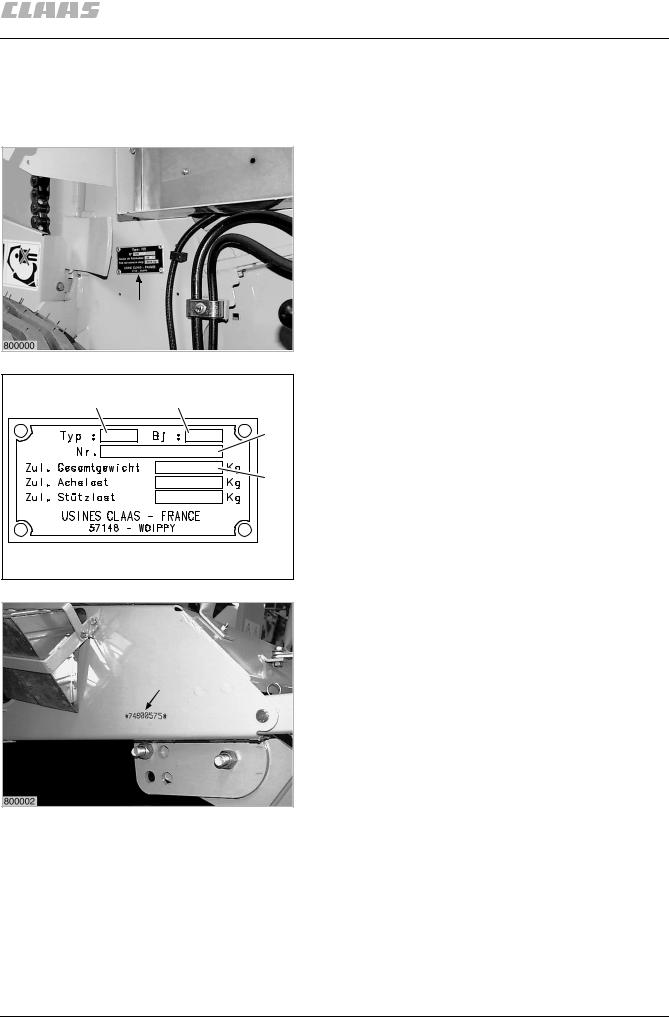

Type plate (baler)

The identification plate with the machine number is fastened to the right hand side panel of the machine above the wheel.

A = Type

B= Year of construction

C= Machine number

D= Permissible total weight (Fig. 1, 2)

Machine serial number

The machine serial number is also engraved on the front right of the platform.

(Fig. 3)

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 |

3.3.1 |

General notes

3.3.2 |

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5 |

4

Safety precautions

SAFETY PRECAUTIONS

For your safety, and those working with you, follow these safety precautions and observe all safety signs on the machine.

In order to provide a better view, certain photographs or illustrations in this manual may show an assembly with the safety shield removed. However, a machine should never be operated in this condition. Keep all shields in place. If shield removal becomes necessary for repairs, replace shield prior to machine operation!

Replace any Danger, Warning, Caution or Instruction Safety signs that are missing or not readable. Location of safety signs are indicated within this manual.

Note!

The figure in () refers to the adjacent picture and indicates the correct location of the safety sign on the machine.

When parts are replaced that have safety signs, make sure you install a new safety sign with each new part.

Note!

New safety signs are available from your CLAAS Dealer.

Attention!

Before using the machine read and understand Operator’s Manual safety messages!

Read and understand all safety signs on the machine.

Learn and practice safe use of controls before operating.

It is your responsibility to understand and follow manufacturers instructions on machine operation, service, and to observe pertinent laws and regulations.

Operator Manuals may be obtained from your CLAAS Dealer.

Safety precautions

Personal injury may result if these safety precautions are not followed

•MAKE SURE no person is allowed on any part of the Baler when tractor is running.

•MAKE SURE all safety shields and covers are installed properly when Baler is operating.

•MAKE SURE all bystanders are in a safe position before starting the tractor or operating Baler.

•MAKE SURE the pickup head is fully lowered before any part of the hydraulic system is disconnected.

•MAKE SURE no one is allowed under the pickup head unless the pickup head is in transport position and securely locked.

•MAKE SURE all safety shields on Baler are in place and secured when any have been removed for servicing, to make adjustments, etc. Remember, these shields are provided for the protection of those working on or around the Baler.

•NEVER STAND in path of Baler while operating.

•KEEP OUT of Baler compartment while operating.

•BE SURE all hydraulic fittings are tightened securely whenever they have been loosened or disconnected. Replace all hoses which have become frayed. Escaping hydraulic oil under pressure can cause personal injury.

•If Baler hydraulic system is equipped with an accumulator, accumulator shutoff valve must be closed before: (a) any part of the hydraulic system is loosened or is to be disconnected, and (b) the Baler is to be transported for any distance.

•TAKE NOTE that hydraulic fluid under pressure escaping from a very small hole can be almost invisible. Use a small piece of cardboard or wood to search/check for possible leaks.

•NEVER use your hands to detect pressure leaks.

•CONSULT A DOCTOR immediately if you sustain an injury by escaping fluids. Serious infection or reactions can develop if proper medical treatment is not administered quickly.

•MAKE SURE all oil or grease is removed from operator’s ladder and platform and other access areas immediately if any is spilled.

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 |

4.1.1 |

Safety precautions

•BE EXTRA CAREFUL to keep hands, feet and loose clothing away from moving parts.

•READ THIS MANUAL and take note of ALL safety precautions included herein.

Attention!

Do not remove, install or make repairs to a tire on a rim. Take tire and rim to the nearest available tire specialist, who have experience and the safety tools. If the tire is not correctly positioned on the rim, or the tire pressure is too high then the tire bead is liable to loosen on one side, resulting in the pressured air to leak out at high speed and with force. This can lead to the risk of the tire flying off and causing serious injury!

A tire can explode during inflation and cause serious injury or death. Never increase air pressure beyond 35 PSI to seat the bead on the rim. Replace a tire if it has a defect. Replace a wheel rim which has cracks, wear or severe rust. Make sure that all the air is removed from a tire before removing the tire from the rim. Never use force on an inflated or partially inflated tire. Make sure the tire is correctly seated before inflating.

Danger!

Check the machine for leaks or any parts that are broken, not working correctly, or missing. Before you start the machine, tighten all caps, dipsticks, battery covers, etc.

Never use gasoline, naphtha or any other volatile material for any cleaning purposes. These materials may be toxic and/or flammable.

Use only metric tools. Other tools may not fit properly. They may slip and cause injury.

Danger!

Before leaving the tractor, stop the engine, and remove the starter key. The gear shift lever must be in neutral and the parking brake engaged.

4.1.2

Attention!

To provide more secure hand and foot mobility, preventing slipping and possible injury, always face the machine when mounting and dismounting.

Danger!

Never operate the engine in a closed building. Proper ventilation is required under all circumstances.

Contact with belts, chains etc. can cause injury. Keep clear.

Attention!

To help prevent personal injuries during operation and maintenance, loose shirts, sleeves or jackets must never be worn by the operator.

Danger!

Before starting the tractor, be sure all operating controls are in neutral. This will ease starting loads on the starter and batteries of the tractor and will eliminate the accidental start up of power driven equipment.

Travel speed should be such that complete control and machine stability is maintained at all times. Where possible, avoid operating near ditches, embankments and holes. Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

Danger!

On highways use lighting equipment according to local laws. Keep SMV emblem clean and visible. Replace SMV emblem when damaged or sun faded.

Stop, look and listen before entering public thoroughfare or a highway.

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5

Attention!

Collision of high speed road traffic and slow moving machines can cause personal injury or death.

Stay off slopes too steep for safe operation. Shift down before you start up or down a hill with heavy load. Avoid ”free wheeling”.

Danger!

Provide a first aid kit for use in case of accident.

As a safety precaution, it is suggested one or more fire extinguishers be carried on the Baler at all times. Fire extinguishers must be purchased from Fire & Safety equipment supply store.

Attention!

Look for this symbol to point out important safety precautions. It means BECOME ALERT! YOUR SAFETY IS INVOLVED.

This machine is of metric design. Measurements in this manual are metric with the customary U.S. measurements following. Use only metric hardware and tools as specified.

Replacement Parts:

–When replacement parts are necessary for periodic maintenance and servicing, genuine CLAAS replacements must be used to restore your equipment to original specifications.

–CLAAS will not claim responsibility for usage of unapproved parts and/or accessories and damages as a result of their usage.

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255

Safety precautions

Safety signs

Attention!

Install new safety signs if the old safety signs are destroyed, lost, painted over or can not be read. When parts are replaced that have safety signs, make sure you install a new safety sign with each new part.

Note!

New safety signs are available from your

Dealer or write to:

CLAAS OF AMERICA Inc.

P.O.Box 3008

3030 Norcross Drive

Columbus Indiana 47201

USA.

Transporting baler on a public thoroughfare

Whenever a Baler is to be transported on a public thoroughfare, the following preparation of the Baler should be made:

•Position pickup in the transport position. Close gate, raise pickup and converging wheels, if equipped.

•Make sure warning devices, such as slow moving vehicle emblem, reflectors, etc., are installed, clean and are in good condition.

•Use flashinglights according to local laws. Keep SMV emblem clean and visible. Replace SMV emblem when damaged or sun faded.

•For reference purposes, measure the overall width and height of the Baler. These measurements are particularly important for transporting along narrow roads and where underpasses may be encountered.

•If the Baler hydraulic system is equipped with an accumulator, make sure the accumulator shutoff valve is closed.

4.1.3

Safety precautions

Danger!

Proper tire pressure should be maintained at all times to insure stability during road travel.

Always use a safety chain while transporting baler. Sudden jolts or rocking could cause the drawbar to break. If a rocking motion occurs when transporting, reduce speed until rocking stops. Check rear tractor wheels for any tire tread wear or pressure loss. Refer to operator’s manual for tractor tire pressures.

Use care when towing baler at transport speeds. Reduce speed if the weight of baler exceeds weight of tractor.

When towing baler on public roads, an extended mirror to improve visibility of traffic behind the baler is recommended. Mirrors are available from your dealer.

When the Baler is being transported on a public thouroughfare, the following precautions must be observed:

•Reduce speed before applying the brakes. Using a hydrostatic transmission to slow the vehicle is more effective than merely applying the brakes.

If in doubt regarding local or state/provincial laws pertaining to transportation of farm equipment, consult your local law enforcement agency.

Danger!

Use or warning lights and turn signals are recommended when transporting this equipment on public roads, unless prohibited by state or Local Laws.

A safety lighting kit is available from your CLAAS dealer.

Always use a safety chain when transporting baler on public roads. Transporting baler at speeds in excess of 20 mph (32 km/h) is not recommended.

Use care when towing baler at transport speeds. Reduce speed if the combined weight of baler with bale exceeds weight of tractor. The approved minimal total weight of tractor must not receed 2.5 tons (2500 kg).

The towed baler can be transported without brakesystem, when the approved minimal total weight of tractor is 2.5 tons (2500 kg).

Note!

Install new safety signs if the old are destroyed, lost, painted over or can not be read. When parts are replaced that have safety signs, make sure you install a new safety sign with each new part.

New safety signs are available from your Dealer or write to:

CLAAS OF AMERICA Inc.

P.O. Box 3008

3030 Norcross Drive

Columbus Indiana 47201

USA

TO SHOW TECHNICAL DETAILS OF BALER

COMPONENTS AND ASSEMBLIES IN THIS

OPERATOR’S MANUAL, A NUMBER OF SAFETY

SHIELDS AND PANELS WERE REMOVED FOR

PHOTOGRAPHIC PURPOSES ONLY. ALL

SAFETY SHIELDS AND PANELS MUST BE

INSTALLED BEFORE BALING OPERATIONS

COMMENCE.

4.1.4 |

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5 |

Safety precautions

TRANSPORTING BALER ON A PUBLIC

THOROUGHFARE

Attention!

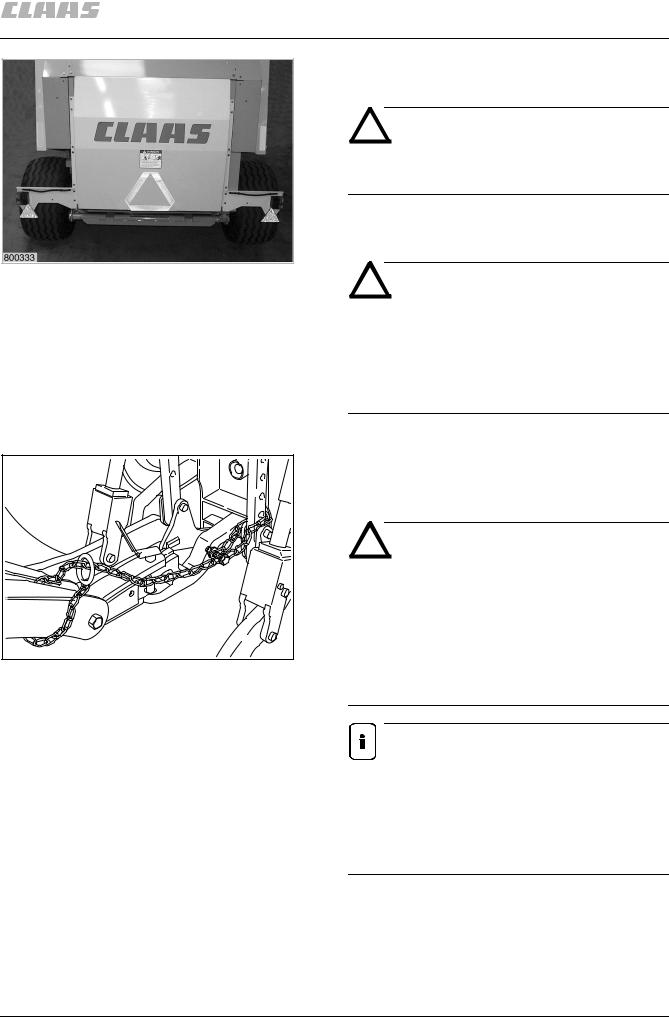

When transporting the baler on a highway use SMV emblem (PN 514 155.1).

Recommended warning lights

1

Attention!

Use of flashing warning lights and turn signals are recommended when towing this equipment on public roadfs unless prohibited by state or local regulations. An implement safety lighting kit is available from your Dealer.

|

|

Preparing for transport |

|

|

Close gate, raise pickup and converging wheels, if |

|

|

equiped. |

|

|

Attention! |

|

|

Always use a safety chain while transporting |

|

|

baler. Sudden jolts or rocking could cause |

|

|

the drawbar to break. If a rocking motion |

|

|

occurs when transporting, reduce speed until |

|

|

rocking stops. Check rear tractor wheels for |

800297 |

2 |

any tire tread wear or air pressure loss. |

|

Refer to operator’s manual for tractor tire |

|

|

|

|

|

|

pressures. |

Note!

Route safety chain from baler through hitch and secure to drawbar supporting structure as shown. Remove all slack except what is needed for turns. Do not make sharp turns when transporting baler. Damage could result if tongue strikes tractor tire.

000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 |

4.1.5 |

Safety precautions

Danger!

Do not secure baler safety chain to drawbar.

Use care when towing baler at transport speeds. Reduce speed if the combined weight of baler with bale exceeds weight of tractor. The approved minimal total weight of tractor must not receed 2.5 tons (2500 kg).

The towed baler can be transported without brakesystem, when the approved minimal total weight of tractor is 2.5 tons (2500 kg).

4.1.6 |

BA ROLLANT 240 - 250 - 254 - 255 - 000 299 119 5 |

Safety signs

Loading...

Loading...