Page 1

Liner 3000 with Communicator

Technical Systems

Electric System /

Hydraulic System

Page 2

Page 3

TIC Liner 3000 with Communicator Electric System

Contents Electric System

CCU – Claas Control Unit.............................................................................................. ZE-2

Pin assignment in modules.......................................................................................... ZE-10

01a - Main power supply- Circuit diagram with

„Basic tractor equipment“ retrofit kit (ISO socket) .............................................01a-2

01b - Main power supply- Circuit diagram without

„Basic tractor equipment“ retrofit kit (2-pin power supply socket) .....................01b-2

05a - Terminal............................................................................................................05a-2

06a - CAN bus, power supply of modules Circuit diagram with „Basic tractor

equipment“ retrofit kit (ISO socket) ...................................................................06a-2

06b - CAN bus, power supply of modules Circuit diagram without

„Basic tractor equipment“ retrofit kit (2-pin power supply socket) .....................06b-2

07a - Chassis transport and working position ............................................................07a-2

08a - Turning area circuit...........................................................................................08a-2

10a - Raking height adjustment .................................................................................10a-2

11a - Raising and lowering the rotor arms .................................................................11a-2

13a - Adjusting the front rotor working width..............................................................13a-2

26a - Machine monitoring ..........................................................................................26a-2

Index ....................................................................................................................... Index-3

Page 4

Electric System Liner 3000 with Communicator TIC

Page 5

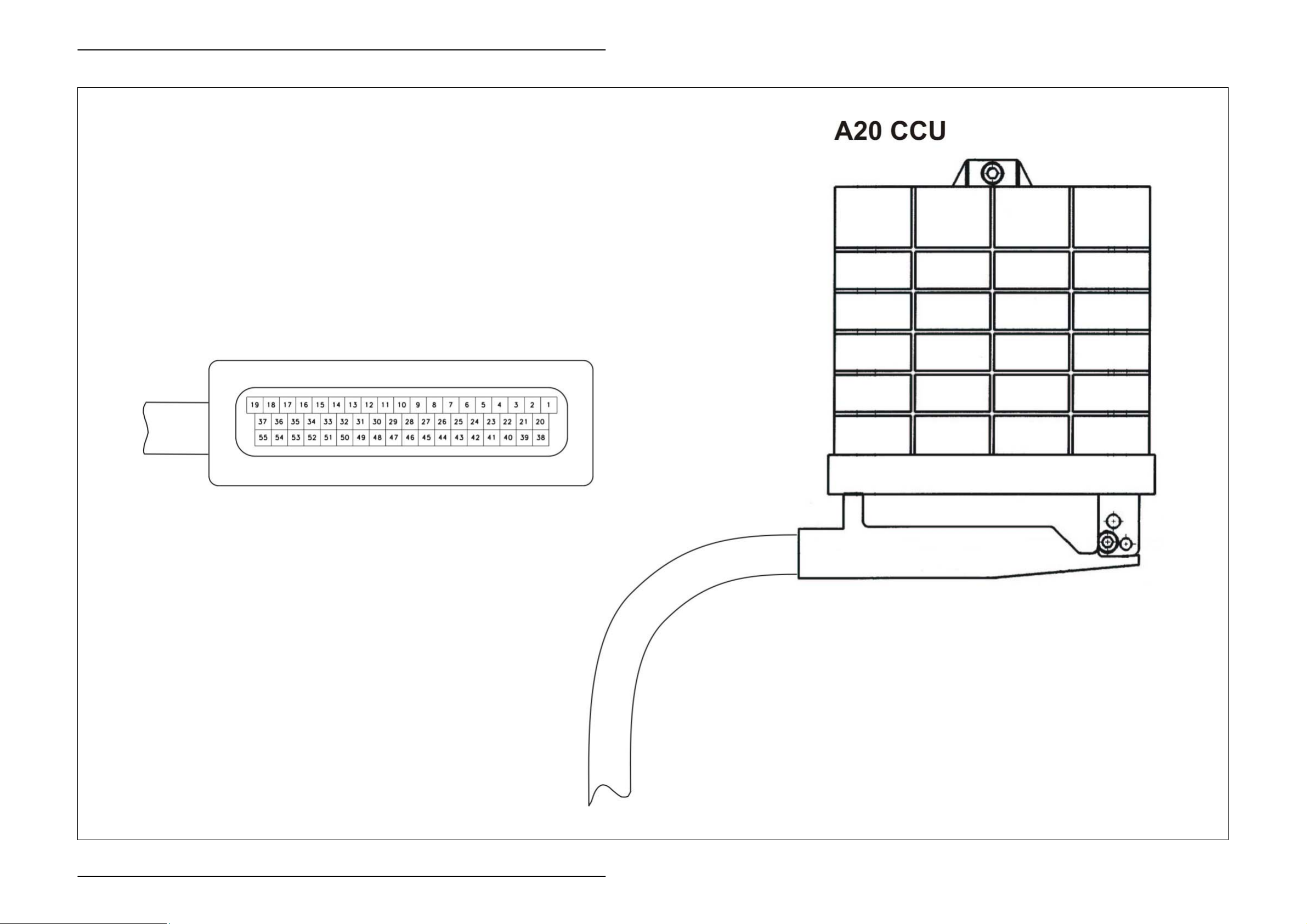

CCU – Claas Control Unit

Page 6

Electric System Liner 3000 with Communicator TIC

CCU – Claas Control Unit

ZE-2 Lin-e-ze 12/03

Page 7

TIC Liner 3000 with Communicator Electric System

Key to diagram:

A20 CCU Module

12/03 Lin-e-ze ZE-3

Page 8

Electric System Liner 3000 mit Communicator TIC

ZE-4 Lin-e-ze 12/03

Page 9

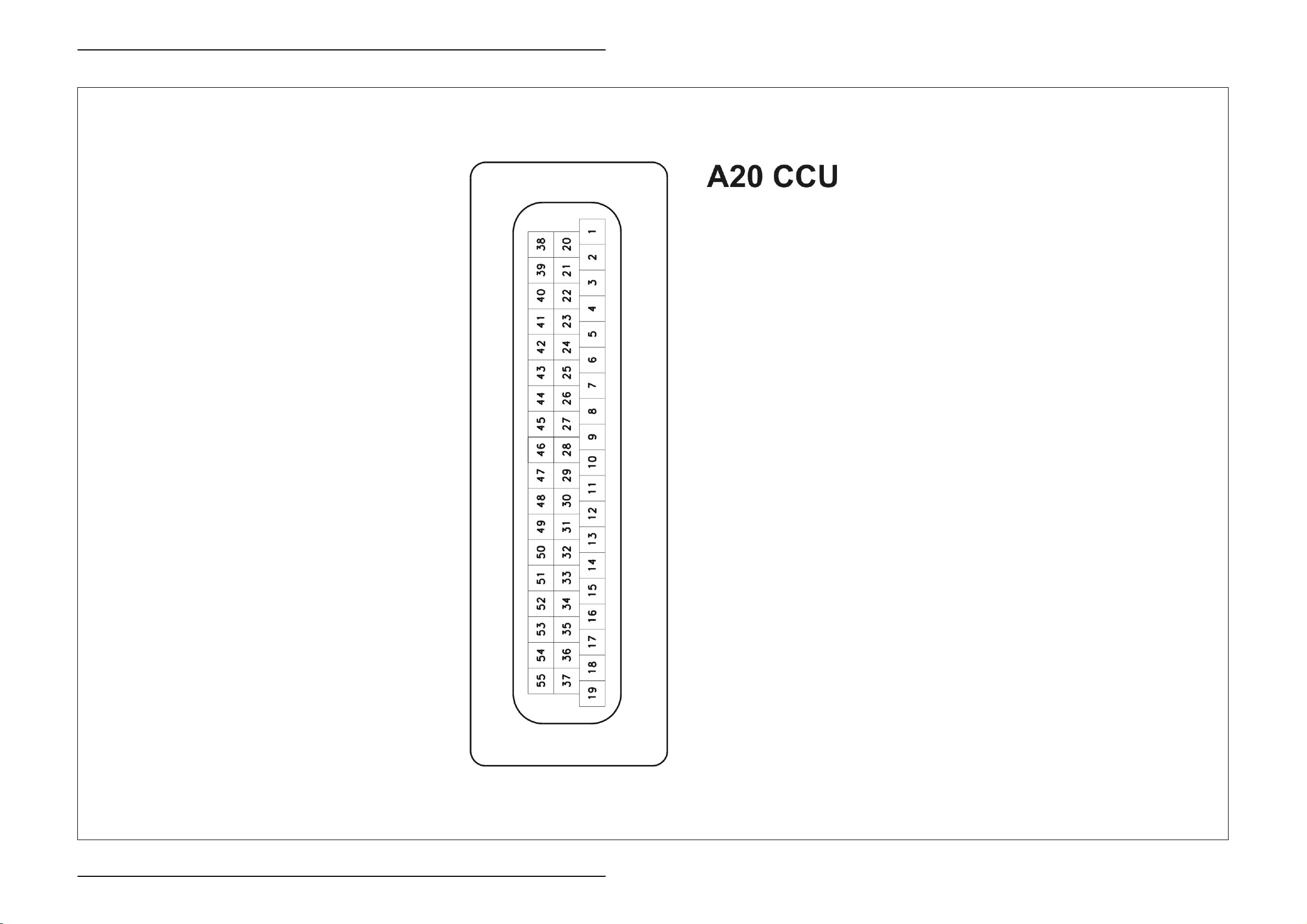

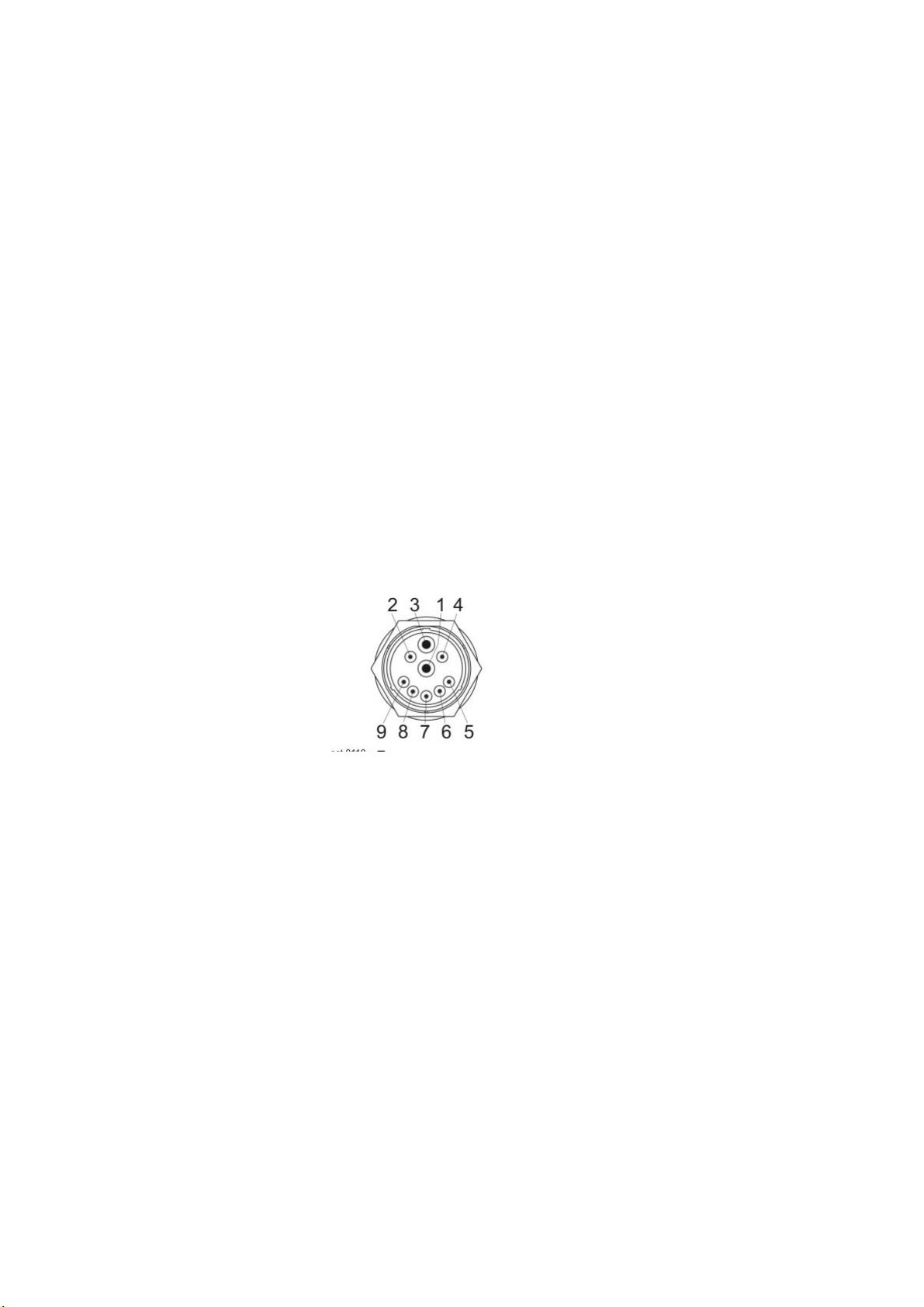

Pin assignment in modules

Page 10

Electric System Liner 3000 with Communicator TIC

Pin assignment in modules

ZE-10 Lin-e-ze 12/03

Page 11

TIC Liner 3000 with Communicator Electric System

A20 CCU module

Pin Function Component Measuring

1 Power earth 31 Earth Input 6

2 Wheel revolution connector - - - 8

3 Not used - - - -

4 Offset correction of rotor position

sensors

5 Electronics plus +30/E 12 V Input 6

6 Not used - - - -

7 Not used - - - -

8 Temperature connector - - - 26

9 Not used - - - -

10 Not used - - - -

11 Not used - - - -

12 Power supply of rotor position sensors B121 12 V Output 8

13 Signal input B121-1 PWM. 5-95% Input 8

14 Signal input B121-3 PWM. 5-95% Input 8

15 Not used - - - -

16 Not used - - - -

17 CAN low - - - 6

18 Not used - - - -

19 Electronics earth XD pin 7 32 Earth Input 5

20 Drive speed B9 Earth frequency Input 8

21 Chassis position Z99 Earth Input 7

22 Lower rotor height adjustment V16-1 5 V Output 10

23 Switch on electronic unit +15/T12 12 V Input 6 and 1

24 Diagnosis plug XD pin 1 XD Boot signal Input 5

25 Not used - - - -

26 Not used - - - -

27 Not used - - - -

28 Not used - - - -

29 Not used - - - -

30 Not used - - - -

31 Temperature connector - - - 26

32 Signal input B121-2 PWM. 5-95% Input 8

33 Signal input B121-4 PWM. 5-95% Input 8

34 Not used - - - -

35 Not used - - - -

36 CAN high - - - 6

37 Not used - - - -

38 Power plus +30/P 12 V Input 7, 10, 11, 13

39 Power plus +30/P 12 V Input 7, 10, 11, 13

40 Electronics plus +30/E 12 V Input 6

Direction Circuit

variable

V16-2 5 V Output 8

diagram no.

12/03 Lin-e-ze ZE-11

Page 12

Electric System Liner 3000 with Communicator TIC

A20 CCU module

Pin Function Component Measuring

variable

41 Raise rotor height adjustment Y157 12 V Output 10

42 Increase working width Y162 12 V Output 13

43 Decrease working width Y163 12 V Output 13

44 Lower chassis Y159 12 V Output 7

45 Raise chassis Y158 12 V Output 7

46 Raise rear right rotor Y160 12 V PWM Output 11

47 Raise rear left rotor Y161 12 V PWM Output 11

48 Lower rear right rotor Y169 12 V PWM Output 11

49 Lower rear left rotor Y168 12 V PWM Output 11

50 CAN bus socket (7-pin) XD pin 2 serial

XD Data - 5

interface

51 CAN bus socket (7-pin) XD pin 3 serial

XD Data - 5

interface

52 Lower front left rotor Y166 12 V PWM Output 11

53 Lower front right rotor Y164 12 V PWM Output 11

54 Raise front left rotor Y167 12 V PWM Output 11

55 Raise front right rotor Y165 12 V PWM Output 11

Direction Circuit

diagram no.

Circuit diagram assignment

of fuses and relays

Component Designation Circuit Diagram

F1.1 5 A fuse 1a, 1b

F1.2 25 A fuse 1a, 1b

F2 1A fuse (basic tractor equipment) 1a

F3 60 A fuse (basic tractor equipment) 1a

F4 25 A fuse (basic tractor equipment) 1a

V16-1 Amplifier 10

V16-2 Amplifier 8

E-12 Lin-e-ze 12/03

Page 13

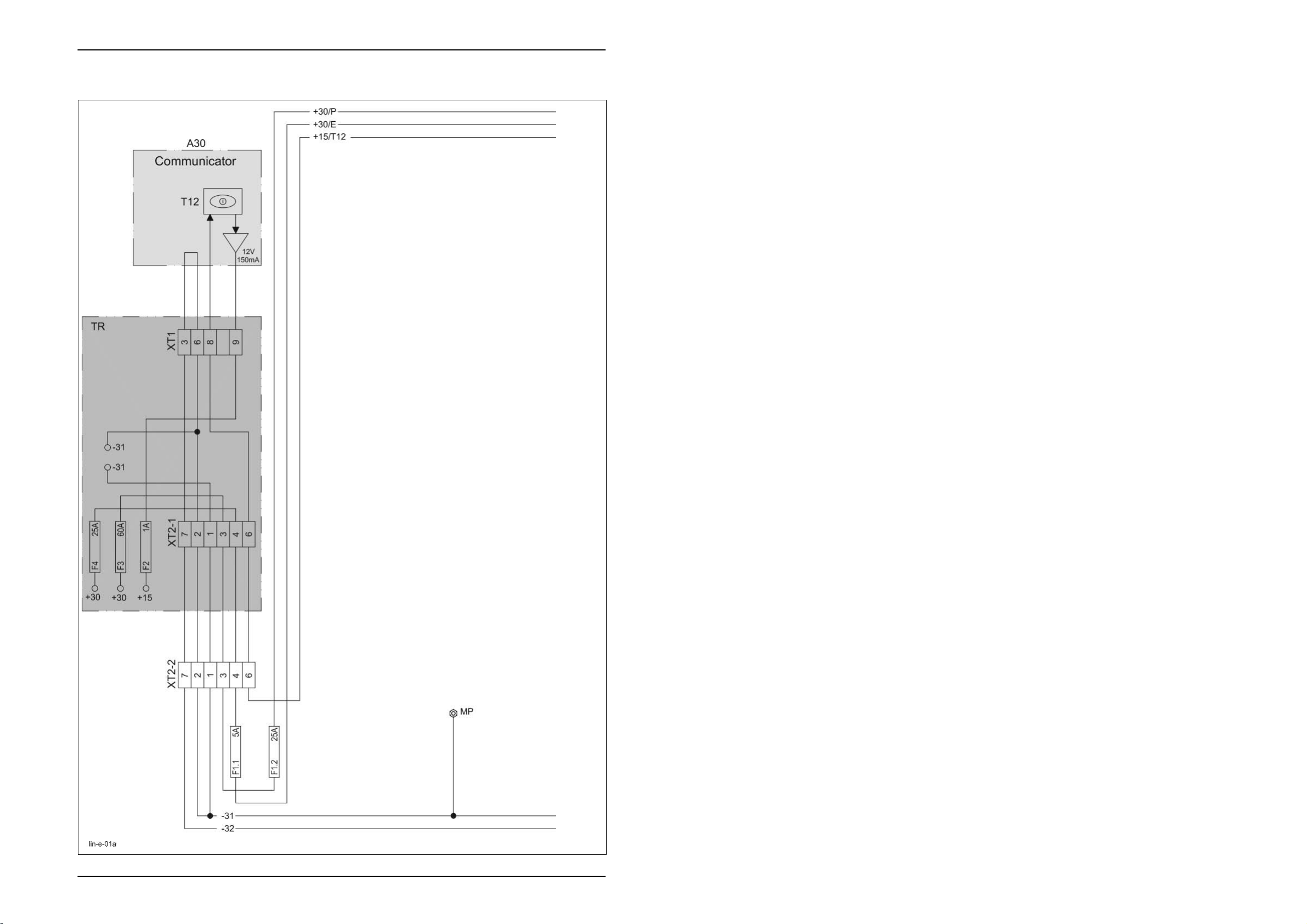

1a

Main power supply

Liner 3000 with Communicator

Circuit diagram with „Basic tractor equipment“ retrofit kit

(ISO socket)

Page 14

Electric System Liner 3000 with Communicator TIC

01a - Main power supply -

Circuit diagram with „Basic tractor equipment“ retrofit kit (ISO socket)

Key to diagram:

A30 Terminal

F2 1 A fuse

F3 60 A fuse

F4 25 A fuse

F1.1 5 A fuse

F1.2 25 A fuse

MP Earth point

TR Basic tractor equipment

(tractor retrofit kit according to ISO standard)

T12 Main switch

XT1 Terminal connector

XT2-1 Tractor connector, 9-pin (acc. to ISO standard)

XT2-2 Implement connector, 9-pin (acc. to ISO standard)

+30/P Potential, power plus

+30/E Potential, electronics plus

-31 Potential, power earth

-32 Potential, electronics earth

1a-2 Lin-01-el. 12/03

Page 15

TIC Liner 3000 with Communicator Electric System

Description of function:

TR Basic tractor equipment Before using the implement, the basic tractor equipment wiring loom must

be fitted. The tractor is now equipped with a standardized (ISO) socket.

Please refer to the Operator's Manual for further information.

Main power supply Power supply from the tractor is via the (ISO) socket connector XT1-1,

XT1-2.

Potential + 30/P The potential + 30/P (battery power plus) is safeguarded with 25 A by fuse

F1.2 at the implement.

Potential + 30/E The potential + 30/E (battery electronic plus) is safeguarded with 5 A by

fuse F1.1 at the implement.

Potential + 15/T12 This potential is switched by the tractor potential 15 (ignition plus) and by

the main switch T12 at terminal A30 and serves for switching on the

electronic unit.

Note: When switching the ignition off, the electronic unit of the

implement is also shut down.

12/03 Lin-01-el. 1a-3

Page 16

Electric System Liner 3000 with Communicator TIC

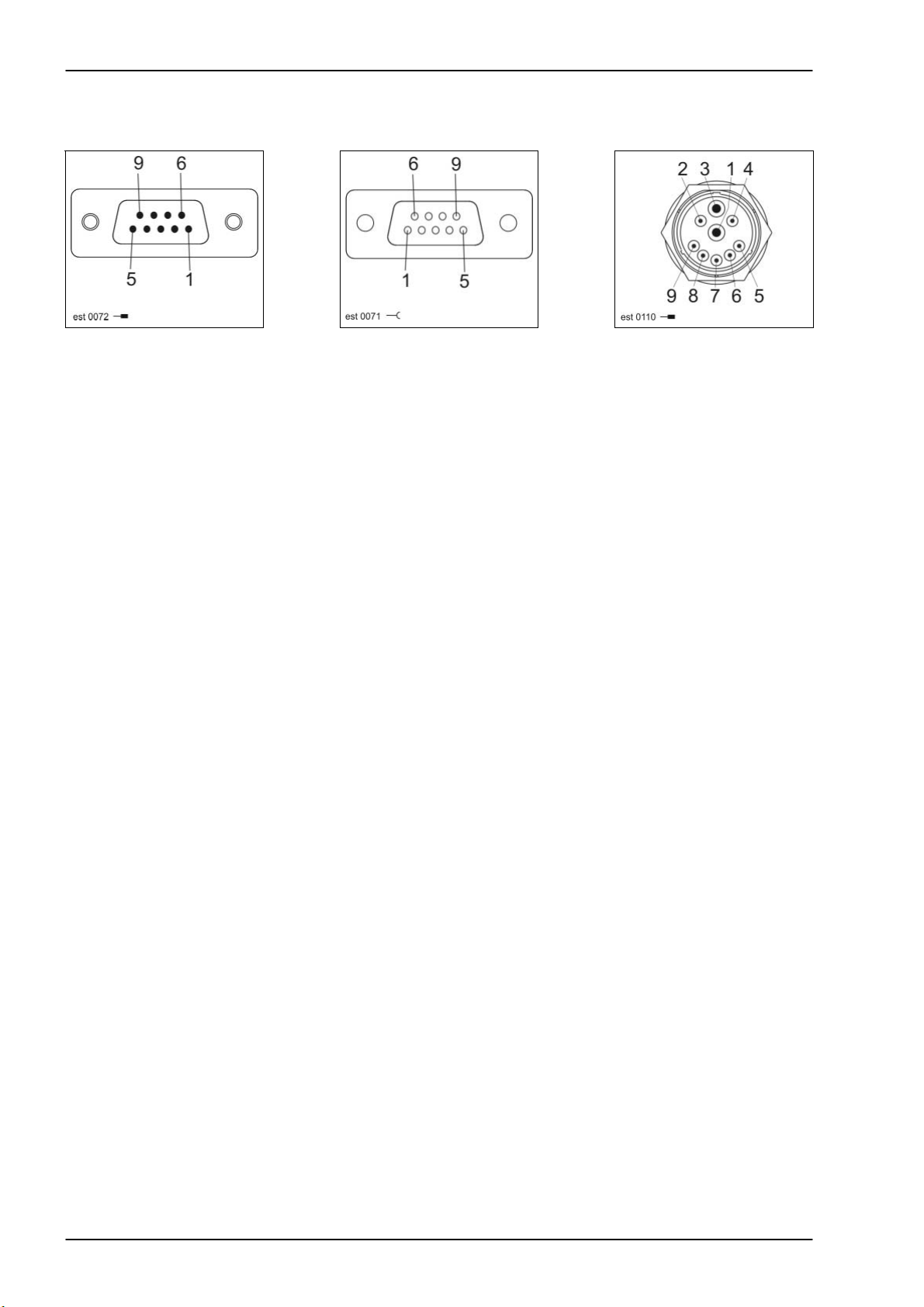

Connector pin definition:

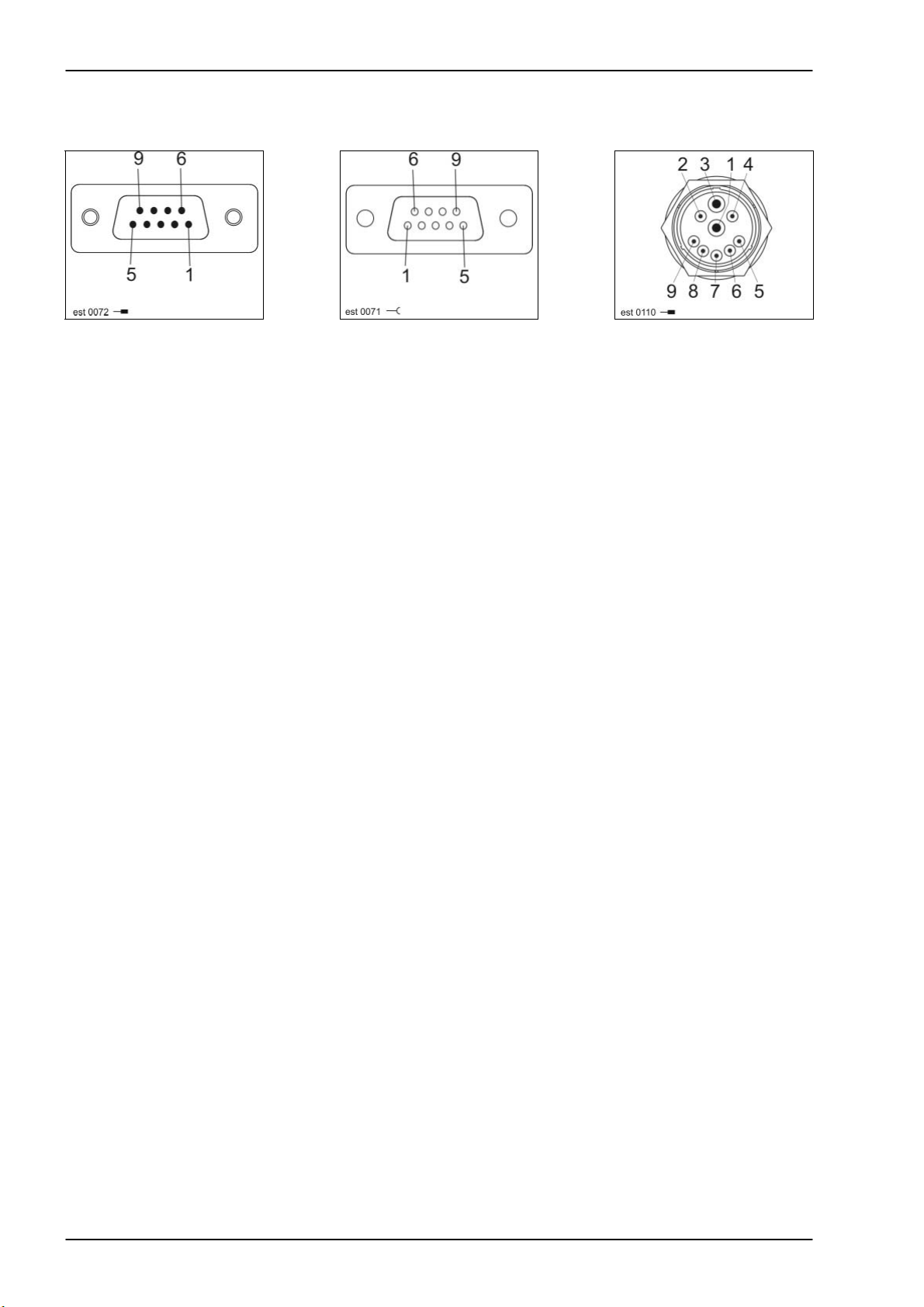

Connector XT1 Socket XT1 Connector XT2-1 XT2-2

1a-4 Lin-01-el. 12/03

Page 17

1b

Main power supply

Liner 3000 with Communicator

Circuit diagram without

„Basic tractor equipment“ retrofit kit

(2-pin power supply socket)

Page 18

Electric System Liner 3000 with Communicator TIC

01b - Main power supply-

Circuit diagram without „Basic tractor equipment“ retrofit kit (2-pin power supply socket)

Key to diagram:

A30 Terminal

F1.1 5 A fuse

F1.2 25 A fuse

MP Earth point

T12 Main switch

XT1 Terminal connector

XT2 Implement connector, 9-pin (acc. to ISO standard)

XV Power supply connector

+30/P Potential, power plus

+30/E Potential, electronics plus

-31 Potential, power earth

-32 Potential, electronics earth

1b-2 Lin-01-el. 12/03

Page 19

TIC Liner 3000 with Communicator Electric System

Description of function:

Main power supply Power supply from the tractor is via the XV connector.

Potential + 30/P The potential + 30/P (battery power plus) is safeguarded with 25 A by fuse

F1.2 at the implement.

Potential + 30/E The potential + 30/E (battery electronic plus) is safeguarded with 5 A by

fuse F1.1 at the implement.

Potential + 15/T12 This potential is switched the main switch T12 at terminal A30 and serves

for switching on the electronic unit.

Note: To avoid tractor battery discharge during extended breaks, the

electronic unit of the implement should be shut down using the

main switch T12 on terminal A30.

12/03 Lin-01-el. 1b-3

Page 20

Electric System Liner 3000 with Communicator TIC

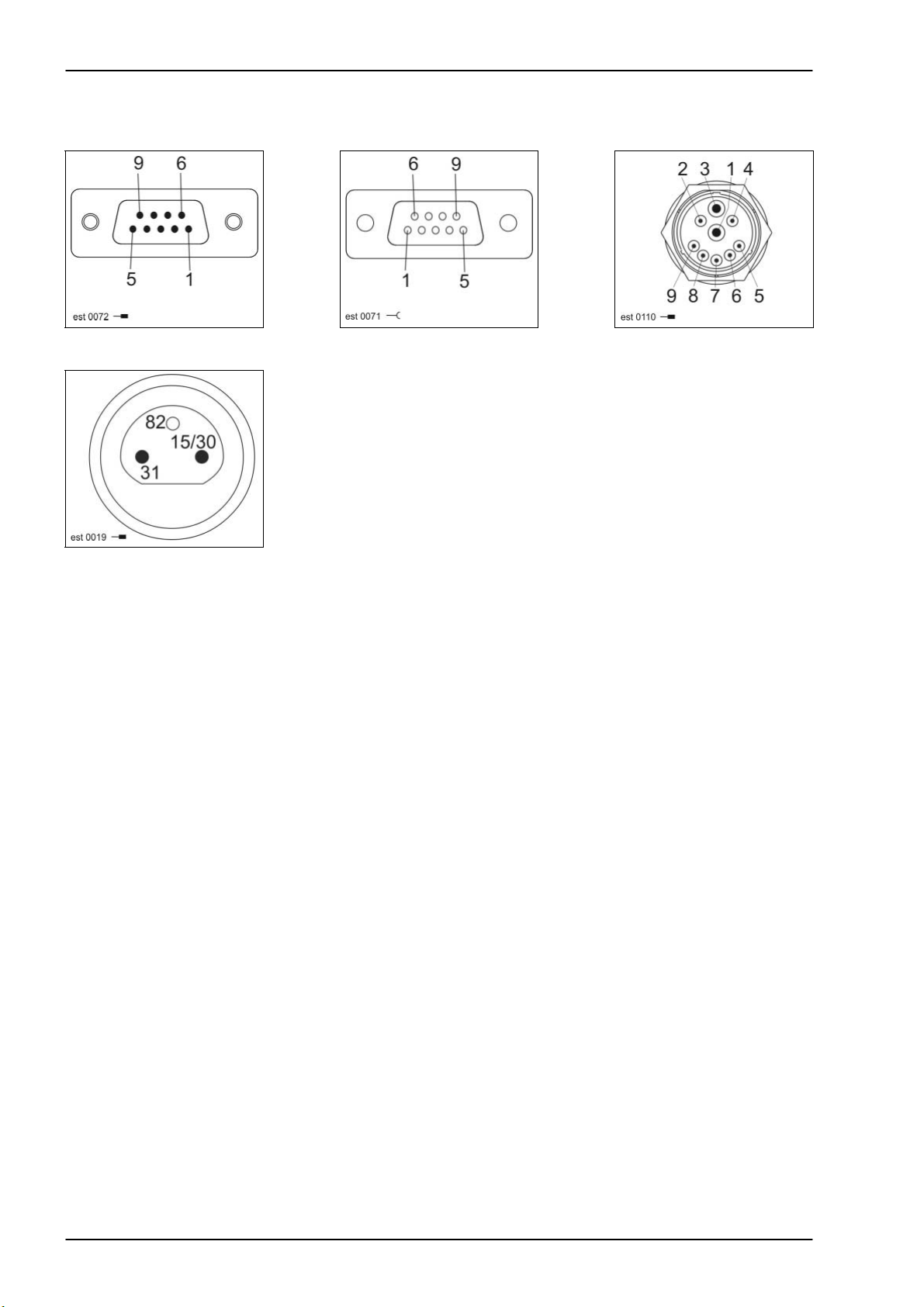

Connector pin definition:

Connector XT1 Socket XT1 Connector XT2

Connector XV

1b-4 Lin-01-el. 12/03

Page 21

5a

Terminal

Liner 3000 with Communicator

Page 22

Electric System Liner 3000 with Communicator TIC

05a - Terminal

Key to diagram:

A20 CCU module

CAN_

END

V18 Active CAN bus termination

XD CAN bus socket (7-pin)

Wiring loom connector

5a-2 Lin-05-el. 12/03

Page 23

TIC Liner 3000 with Communicator Electric System

Description of function:

Terminal The XD connector serves for diagnosis with the CDS CLAAS Diagnosis

system.

12/03 Lin-05-el. 5a-3

Page 24

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

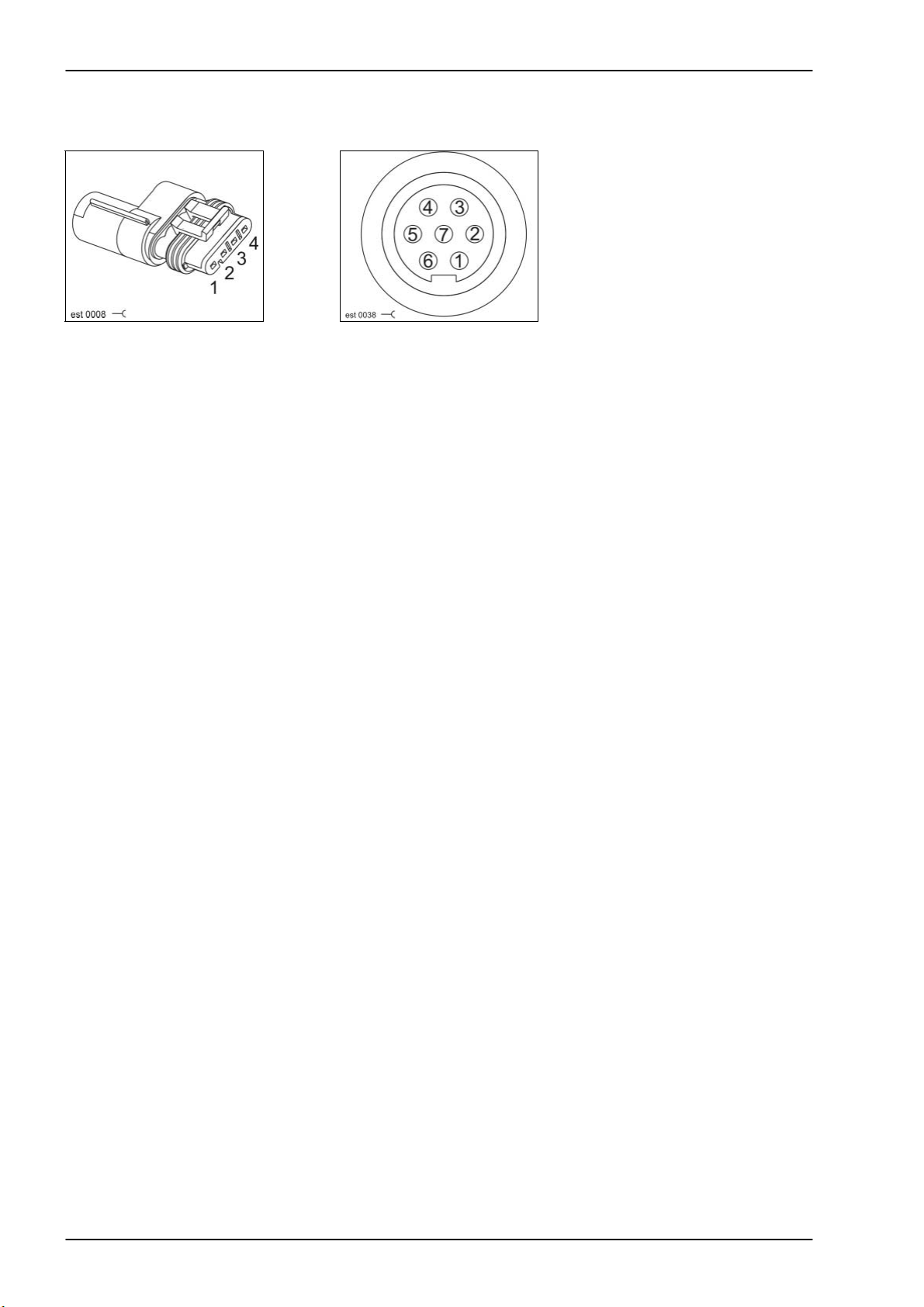

Connector CAN_END Socket XD

5a-4 Lin-05-el. 12/03

Page 25

6a

CAN bus, power supply of modules

Liner 3000 with Communicator

Circuit diagram with

„Basic tractor equipment“ retrofit kit

(ISO socket)

Page 26

Electric System Liner 3000 with Communicator TIC

06a - CAN bus, power supply of modules

Circuit diagram with „Basic tractor equipment“ retrofit kit (ISO socket)

Key to diagram:

A20 CCU module

A30 Terminal

XT1 Terminal connector

XT2-1 Tractor connector, 9-pin (acc. to ISO standard)

XT2-2 Implement connector, 9-pin (acc. to ISO standard)

6a-2 Lin-06-el. 12/03

Page 27

TIC Liner 3000 with Communicator Electric System

Description of function:

The performance data (operating hours, ...) are stored in module A 20.

Communication of the module with the CCT terminal A30 is via the

CAN bus.

12/03 Lin-06-el. 6a-3

Page 28

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

Connector XT1 Socket XT1 Connector XT2-1, XT2-2

6a-4 Lin-06-el. 12/03

Page 29

6b

CAN bus, power supply of modules

Liner 3000 with Communicator

Circuit diagram without

„Basic tractor equipment“ retrofit kit

(2-pin power supply socket)

Page 30

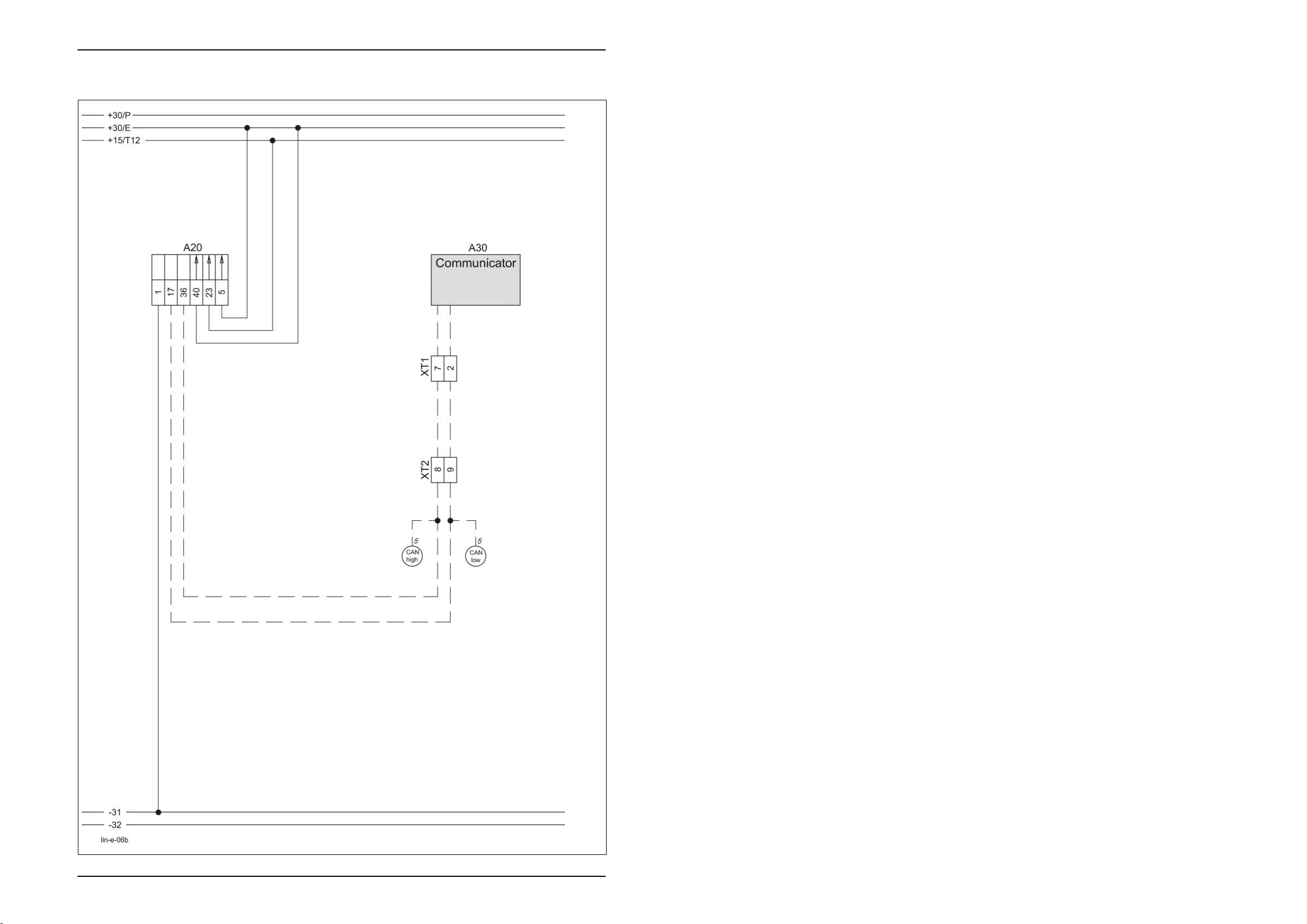

Electric System Liner 3000 with Communicator TIC

06b - CAN bus, power supply of modules

Circuit diagram without „Basic tractor equipment“ retrofit kit (2-pin power supply socket)

Key to diagram:

A20 CCU module

A30 Terminal

XT1 Terminal connector

XT2 Tractor connector, 9-pin (acc. to ISO standard)

6b-2 Lin-06-el. 12/03

Page 31

TIC Liner 3000 with Communicator Electric System

Description of function:

The performance data (operating hours, ...) are stored in module A 20.

Communication of the module with the CCT terminal A30 is via the

CAN bus.

12/03 Lin-06-el. 6b-3

Page 32

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

Connector XT1 Socket XT1 Connector XT2

6b-4 Lin-06-el. 12/03

Page 33

7a

Chassis transport and working

position

Liner 3000 with Communicator

Page 34

Electric System Liner 3000 with Communicator TIC

07a - Chassis transport and working position

Key to diagram:

A20 CCU module

Axle Wiring loom connector

MV9 Wiring loom connector

MV10 Wiring loom connector

Y158 Raise chassis solenoid coil

Y159 Lower chassis solenoid coil

Z99 Chassis position actual value switch

Measured value table:

Item Component Measured value Remark

Y158

Y159

Z99 Chassis position

Solenoid coil 3.8 A

3.2 Ω

1 – 0 (Earth signal) Reed contact

actual value switch

See inscription

7a-2 Lin-07-el. 12/03

Page 35

TIC Liner 3000 with Communicator Electric System

Description of function:

Module A 20 actuates the corresponding solenoid coils Y 158 and Y159

for raising and lowering the chassis.

This is done automatically with the program "Approach working position /

Transport position" or using the "Manual operation" function.

Working position = chassis raised

Transport position = chassis lowered.

Secondary chassis raise When the turning area circuit is running, the Chassis raise solenoid coil

(Y158) is actuated for 2 seconds in parallel with lowering of the rotors.

This keeps the chassis from lowering when in the working position due to

a possible leak.

Chassis position The chassis position switch (Z99) transmits a signal to the electronic unit

when the chassis is raised.

If the chassis position is not detected in the "Approach working position"

and "Reset basic values" programs, the automatic functions are aborted.

Adjustment of sensors The chassis position switch (Z99) is set to a clearance of 4 mm from the

signal magnet with the chassis raised.

In this position, the signal magnet and the sensor should not be centred

opposite each other, but slightly offset.

12/03 Lin-07-el. 7a-3

Page 36

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

Socket MV9, MV10 Axle connector

7a-4 Lin-07-el. 12/03

Page 37

8a

Turning area circuit

Liner 3000 with Communicator

Page 38

Electric System Liner 3000 with Communicator TIC

08a - Turning area circuit

Key to diagram:

A20 CCU Module

B9 Drive speed sensor

B121-1 Rotor position sensor, front left

B121-2 Rotor position sensor, front right

B121-3 Rotor position sensor, rear left

B121-4 Rotor position sensor, rear right

D1-4 Diode component

V16-2 Amplifier

S-LV Wiring loom connector

S-RV Wiring loom connector

S-LH Wiring loom connector

S-RH Wiring loom connector

Wheel

rev.

Wiring loom connector

Measured value table:

Item Component Measured value Remark

B121 Rotor position

sensors

B121 Rotor position

sensors

B6 Drive sensor 1 – 0 earth signal Metal is detected

Approx. 5% PWM

signal

Approx. 95% PWM

signal

Cylinder retracted

Cylinder extended

by sensor or not.

Lin-08-el. 12/03

8a-2

Page 39

TIC Liner 3000 with Communicator Electric System

Description of function:

To control the automatic functions, the electronic unit monitors:

- the drive speed

- the position of the rotor arms' hydraulic cylinders

Rotor position sensors B121 The rotor position sensors are integrated in the hydraulic cylinders as

contactless position measuring sensors.

A spindle with a steep thread inside the hydraulic cylinders rotates a

signal generator.

The angle of rotation between the retracted and the extended cylinder

position is < 360°.

The signal generator emits a magnetic field to the sensor electronic unit

located opposite of it. The position of the magnetic field which

corresponds to the hydraulic cylinder position is detected by the sensor

electronic unit.

The sensor electronic unit transmits a pulse-width modulated signal

(PWM, corresponding to the hydraulic cylinder position) to module A 20.

With the hydraulic cylinder retracted, this signal is 5% and with the

cylinder extended, it is 95% PWM.

See also the Technical Systems / Hydraulic system documentation.

Offset of rotor position

sensors B 121

The position "Hydraulic cylinder retracted" must be programmed in the

sensor electronic unit (= sensor offset).

This programming changes when the ram rod of a hydraulic cylinder is

rotated, e.g. during service work.

For offset programming, the sensor signal output must be connected to

the 12 V sensor supply voltage for at least 2 seconds.

The CCU module carries out this offset programming during each basic

initialisation. This is done by the diode component D.1-4 and amplifier

V16-2.

This is detected at terminal A30. When the basic initialisation is carried

out, a cylinder position of 100% and then of 5% is displayed for a short

time when in transport position (cylinder retracted).

When a hydraulic cylinder position which is illogical to the electronic unit is

detected, e.g. due to service work, an error is reported.

In order to remove the error, the operator may move to transport position

or carry out a basic initialisation.

The PWM signal from sensors B121 is also displayed as cylinder position

on terminal A30. This involves slight deviations:

90% signal change = 100% change of display on terminal A30.

Approach transport position

program

If the drive sensor B9 detects a signal change (universal drive shaft is

rotating), approaching the transport position in automatic mode is not

possible.

Adjustment of

drive sensor B9

Sensor B9 is set to a clearance of 3-4 mm from the outside profile of the

drive shaft.

12/03 Lin-08-el.

08a-7

Page 40

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

Connector B9

Socket B121, wheel rev.

Relay socket V16-2

Lin-08-el. 12/03

8a-4

Page 41

10a

Raking height adjustment

Liner 3000 with Communicator

Page 42

Electric System Liner 3000 with Communicator TIC

10a - Raking height adjustment

Key to diagram:

A20 CCU module

V16-1 Amplifier

Y156 Lower rotor height solenoid coil

Y157 Raise rotor height solenoid coil

Y158 Raise chassis solenoid coil

Y164 Lower front right rotor solenoid coil

Y166 Lower front left rotor solenoid coil

Y168 Lower rear left rotor solenoid coil

Y170 Front right height blocking valve solenoid coil

Y171 Front left height blocking valve solenoid coil

Y172 Rear right height blocking valve solenoid coil

Y173 Rear left height blocking valve solenoid coil

MV13 Wiring loom connector

MV14 Wiring loom connector

MV15 Wiring loom connector

MV16 Wiring loom connector

MV17 Wiring loom connector

MV18 Wiring loom connector

Measured value table:

Item Component Measured value Remark

Y156

Y157

Y158

Y164

Y166

Y168

Y170

Y171

Y172

Y173

Solenoid coil 3.8 A

3.2 Ω

See inscription

Lin-10-el. 12/03

10a-2

Page 43

TIC Liner 3000 with Communicator Electric System

Description of function:

To adjust the raking height, the module A 20 actuates the corresponding

solenoid coils.

Lower rotor height

adjustment

The rotor height adjustment solenoid coil (Y 156) is actuated by amplifier

V16-1.

Parallel functions for rotor

height adjustment

To actuate the height blocking valves (Y170-173), the corresponding

functions "Lower rotors" or "Raise chassis" are actuated in parallel.

12/03 Lin-10-el.

10a-3

Page 44

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

Socket Y156-173 Relay socket V16-1

Lin-10-el. 12/03

10a-4

Page 45

11a

Raising and lowering

the rotor arms

Liner 3000 with Communicator

Page 46

Electric System Liner 3000 with Communicator TIC

11a - Raising and lowering the rotor arms

Key to diagram:

A20 CCU module

Y160 Raise rear right rotor solenoid coil

Y161 Raise rear left rotor solenoid coil

Y164 Lower front right rotor solenoid coil

Y165 Raise front right rotor solenoid coil

Y166 Lower front left rotor solenoid coil

Y167 Raise front left rotor solenoid coil

Y168 Lower rear left rotor solenoid coil

Y169 Lower rear right rotor solenoid coil

MV1 Wiring loom connector

MV2 Wiring loom connector

MV3 Wiring loom connector

MV4 Wiring loom connector

MV7 Wiring loom connector

MV8 Wiring loom connector

MV11 Wiring loom connector

MV12 Wiring loom connector

Measured value table:

Item Component Measured value Remark

Y160

Y161

Y164

Y165

Y166

Y167

Y168

Y169

Solenoid coil 3.8 A

3.2 Ω

See inscription

Lin-11-el. 12/03

11a-2

Page 47

TIC Liner 3000 with Communicator Electric System

Description of function:

To adjust the rotor height, the module A 20 actuates the solenoid coils

according to the "Turning area function" programming or according to the

operator's wish.

Turning area function In the turning area function, the raising height and the time delay for

raising and lowering of the front and rear rotor arms can be programmed.

12/03 Lin-11-el.

11a-3

Page 48

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

Connector Y160-169

Lin-11-el. 12/03

11a-4

Page 49

13a

Adjusting the front rotor

working width

Liner 3000 with Communicator

Page 50

Electric System Liner 3000 with Communicator TIC

13a - Adjusting the front rotor working width

Key to diagram:

A20 CCU module

Y162 Increase working width solenoid coil

Y163 Decrease working width solenoid coil

MV5 Wiring loom connector

MV6 Wiring loom connector

Measured value table:

Item Component Measured value Remark

Y162

Y163

Solenoid coil 3.8 A

3.2 Ω

See inscription

Lin-13-el. 12/03

13a-2

Page 51

TIC Liner 3000 with Communicator Electric System

Description of function:

To adjust the front rotor working width, the module A 20 actuates the

solenoid coils (Y162, Y163) according to the operator's wish.

12/03 Lin-13-el.

13a-3

Page 52

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

Connector Y162, 163

Lin-13-el. 12/03

13a-4

Page 53

26a

Machine monitoring

Liner 3000 with Communicator

Page 54

Electric System Liner 3000 with Communicator TIC

26a - Machine monitorino

Key to diagram:

A20 CCU module

Temp Wiring loom connector

26a-2 Lin-26-el. 12/03

Page 55

TIC Liner 3000 with Communicator Electric System

Description of function:

None

12/03 Lin-01-el.

26a-3

Page 56

Electric System Liner 3000 with Communicator TIC

Connector pin definition:

Temp connector

26a-4 Lin-26-el. 12/03

Page 57

TIC Liner 3000 with Communicator Electric System

Index

12/03 Lin-e-index index-1

Page 58

Electric System Liner 3000 with Communicator TIC

index-2 Lin-e-index 12/03

Page 59

TIC Liner 3000 with Communicator Electric System

Index:

Amplifier 8a, 10a

A

CAN bus 5°, 6°, 6b

C

CAN bus socket (7-pin) 5a

CCU module E-2

Chassis position switch 7a

Drive speed 8a

D

Earth point 1a

E

Fuse 1a, 1b

F

Height blocking valves 10a

H

Increase / decrease working width 13a

I

Lower chassis 7a

L

Main switch 1a

M

Potential 1a

P

Raise chassis 7a

R

Rotor, front, raise / lower 11a

Rotor height adjustment 11a

Rotor position 8a

Rotor, rear, raise / lower 11a

Rotor, rear right, lower 11a

Terminal 1a

T

Tractor, basic equipment 1a

12/03 Lin-e-index index-3

Page 60

Electric System Liner 3000 with Communicator TIC

index-4 Lin-e-index 12/03

Page 61

Liner 3000 with Communicator

Technical Systems

Hydraulic System

Page 62

Page 63

Contents Hydraulic System

Chapter 1 Overall hydraulic system....................................1-1

Chapter 2 Individual functions ............................................2-1

Page 64

Page 65

TIC Liner 3000 with Communicator Overall Hydraulic System

Chapter 1 Overall hydraulic system

1.1 Overall hydraulic system circuit diagram,

up to serial no. 14

Connection to tractor hydraulic system..................1-4

1.2 Overall hydraulic system circuit diagram,

from serial no. 15

Connection to tractor hydraulic system..................1-9

1.3 Valve block, up to serial no. 14............................1-15

1.4 Valve block, from serial no. 15.............................1-18

1.5 Valve block ..........................................................1-22

12/03 Lin-h-Kap1 1-1

Page 66

Overall Hydraulic System Liner 3000 with Communicator TIC

1-2 Lin-h-Kap1 12/03

Page 67

TIC Liner 3000 with Communicator Overall Hydraulic System

1.1

Overall hydraulic system

circuit diagram

- up to serial no. 14

12/03 Lin-h-Kap1 1-3

Page 68

Overall Hydraulic System Liner 3000 with Communicator TIC

1.1 Overall hydraulic system circuit diagram, up to serial no. 14

Connection to tractor hydraulic system

1-4 Lin-h-Kap1 12/03

Page 69

TIC Liner 3000 with Communicator Overall Hydraulic System

Key to diagram:

214-1 Rear right rotor hydraulic motor

214-2 Rear left rotor hydraulic motor

214-3 Front right rotor hydraulic motor

214-4 Front left rotor hydraulic motor

385 Chassis hydraulic cylinder

386 Rear right rotor hydraulic cylinder

387 Rear left rotor hydraulic cylinder

388 Front swath width hydraulic cylinder

389 Front right rotor hydraulic cylinder

390 Front left rotor hydraulic cylinder

410 Orifice plate Ø 1.5 mm

411 Orifice plate Ø 1.8 mm

429 Restrictor Ø 1.5 mm

434 Restrictor Ø 3.0 mm

634 System screw (handwheel)

706 Pressure relief valve 180

734 Lock-up valve unit

763 Input pressure balance

767-1 Flow controller 6l/min ± 0.5 l

767-2 Flow controller 10l/min ± 1.0 l

767-3 Flow controller 10l/min ± 1.0 l

767-4 Flow controller 20l/min ± 0.5 l

768 LS signal shuttle valve

769 Flow divider

Y156 (MV14) Lower rotor height solenoid valve

Y157 (MV13) Raise rotor height solenoid valve

Y158 (MV10) Raise chassis solenoid valve

Y159 (MV9) Lower chassis solenoid valve

Y160 (MV8) Raise rear right rotor solenoid valve

Y161 (MV7) Raise rear left rotor solenoid valve

Y162 (MV5) Increase working width solenoid valve

Y163 (MV6) Decrease working width solenoid valve

Y164 (MV3) Lower front right rotor solenoid valve

Y165 (MV4) Raise front right rotor solenoid valve

Y166 (MV1) Lower front left rotor solenoid valve

Y167 (MV2) Raise front left rotor solenoid valve

Y168 (MV11) Lower rear left rotor solenoid valve

Y169 (MV12) Lower rear right rotor solenoid valve

Y170 (MV15) Front right height blocking valve solenoid valve

Y171 (MV16) Front left height blocking valve solenoid valve

Y172 (MV17) Rear right height blocking valve solenoid valve

Y173 (MV18) Rear left height blocking valve solenoid valve

LS Load sensing port

Re1 Remote port 1

Re2 Remote port 2

P Pump

T Tank

Tr Tractor

+10

bar

12/03 Lin-h-Kap1 1-5

Page 70

Overall Hydraulic System Liner 3000 with Communicator TIC

Connection to tractor

hydraulic system

The attachment can be connected to any tractor hydraulic system

available on the market.

Connection to tractors with

constant-flow hydraulic

system or load-sensing

system

The quick release coupling 801-2 is connected to a control unit port of the

tractor with adjustable oil flow.

This control unit provides oil supply for the attachment and is adjusted to

a constant volume flow of Q

= 50 l/min.

max

The system screw (handwheel) 634 is turned out up to the stop so

that the input pressure balance 763 is operative.

The quick release coupling 801-3 is in general connected to the

pressureless return line T of the tractor.

If a pressureless return line is not allowed in continuous operation (e.g.

because lubrication of the tractor gearbox is not guaranteed), a doubleacting control unit can be used for supplying oil to the attachment.

In this case, the quick release coupling 801-2 is connected to port A

(feed) and quick release coupling 801-3 to port B (return) of the

corresponding tractor control valve.

Adjust the volume flow to Q

= 50 l/min; please refer also to the tractor's

max

Operating Manual, e.g. "Continuous operation of hydraulic motors".

The quick release coupling 801-4 (LS, working hydraulics signal) is not

used with this connection option.

If the tractor is not provided with a flow-adjustable control unit, the volume

flow must not exceed 50 l/min.

Connection to tractors with

constant-pressure hydraulic

system

The quick release coupling 801-2 is connected to a control unit port of the

tractor with adjustable oil flow.

This control unit provides oil supply for the attachment and is adjusted to

an oil flow of approx. Q

= 50 l/min.

max

The system screw (handwheel) 634 is turned in up to the stop so that

the input pressure balance 763 is blocked.

The tractor's hydraulic pump is shut down when the system pressure has

been reached.

The quick release coupling 801-3 is connected to port T (pressureless

return line) of the tractor.

The quick release coupling 801-4 (LS, working hydraulics signal) is not

used with this connection option.

Important! The pressure relief valve 706 must be set approx. 20 bar

higher than the tractor's pressure protection (oil will heat

up!). Block pressure relief valve 706 if necessary.

1-6 Lin-h-Kap1 12/03

Page 71

TIC Liner 3000 with Communicator Overall Hydraulic System

Connection to tractors with

load-sensing system and a

Power Beyond port

The quick release coupling 801-2 is connected directly to the pump via

the Power Beyond port P.

The quick release coupling 801-3 is connected to port T (pressureless

return line) of the tractor.

The quick release coupling 801-4 (LS, working hydraulics signal) is

connected to the tractor's "LS signal" port when using this connection

option.

The system screw (handwheel) 634 is turned in up to the stop so that

the input pressure balance 763 is blocked.

The tractor's hydraulic pump regulates as a function of the attachment's

load signal.

Test points/Characteristics When no function is active on the attachment, the attachment must not

load the tractor hydraulically

(The tractor engine speed must not be reduced).

The allowed temperature of the tractor's hydraulic system must not be

exceeded; see also the Operator's Manual of the tractor.

Important! The pressure relief valve 706 must be set approx. 20 bar

higher than the tractor's pressure protection (oil will heat up!).

Block pressure relief valve 706 if necessary.

12/03 Lin-h-Kap1 1-7

Page 72

Overall Hydraulic System Liner 3000 with Communicator TIC

1.2

Overall hydraulic system

circuit diagram

- from serial no. 15

1-8 Lin-h-Kap1 12/03

Page 73

TIC Liner 3000 with Communicator Overall Hydraulic System

1.2 Overall hydraulic system circuit diagram, from serial no. 15

Connection to tractor hydraulic system

12/03 Lin-h-Kap1 1-9

Page 74

Page 75

TIC Liner 3000 with Communicator Overall Hydraulic System

Key to diagram:

214-1 Rear right rotor hydraulic motor

214-2 Rear left rotor hydraulic motor

214-3 Front right rotor hydraulic motor

214-4 Front left rotor hydraulic motor

385 Chassis hydraulic cylinder

386 Rear right rotor hydraulic cylinder

387 Rear left rotor hydraulic cylinder

388 Front swath width hydraulic cylinder

389 Front right rotor hydraulic cylinder

390 Front left rotor hydraulic cylinder

410 Orifice plate Ø 1.5 mm

411 Orifice plate Ø 1.8 mm

429 Restrictor Ø 1.5 mm

434 Restrictor Ø 3.0 mm

634 System screw (handwheel)

734 Lock-up valve unit

763 Input pressure balance

767-1 Flow controller 6l/min ± 0.5 l

767-2 Flow controller 10l/min ± 1.0 l

767-3 Flow controller 10l/min ± 1.0 l

767-4 Flow controller 20l/min ± 0.5 l

768 LS signal shuttle valve

769 Flow divider

Y156 (MV14) Lower rotor height solenoid valve

Y157 (MV13) Raise rotor height solenoid valve

Y158 (MV10) Raise chassis solenoid valve

Y159 (MV9) Lower chassis solenoid valve

Y160 (MV8) Raise rear right rotor solenoid valve

Y161 (MV7) Raise rear left rotor solenoid valve

Y162 (MV5) Increase working width solenoid valve

Y163 (MV6) Decrease working width solenoid valve

Y164 (MV3) Lower front right rotor solenoid valve

Y165 (MV4) Raise front right rotor solenoid valve

Y166 (MV1) Lower front left rotor solenoid valve

Y167 (MV2) Raise front left rotor solenoid valve

Y168 (MV11) Lower rear left rotor solenoid valve

Y169 (MV12) Lower rear right rotor solenoid valve

Y170 (MV15) Front right height blocking valve solenoid valve

Y171 (MV16) Front left height blocking valve solenoid valve

Y172 (MV17) Rear right height blocking valve solenoid valve

Y173 (MV18) Rear left height blocking valve solenoid valve

LS Load sensing port

Re1 Remote port 1

Re2 Remote port 2

P Pump

T Tank

Tr Tractor

12/03 Lin-h-Kap1 1-11

Page 76

Overall Hydraulic System Liner 3000 with Communicator TIC

Connection to tractor

hydraulic system

The attachment can be connected to any tractor hydraulic system

available on the market.

Connection to tractors with

constant-flow hydraulic

system or load-sensing

system

The quick release coupling 801-2 is connected to a control unit port of the

tractor with adjustable oil flow.

This control unit provides oil supply for the attachment and is adjusted to

a constant volume flow of Q

= 50 l/min.

max

The system screw (handwheel) 634 is turned out up to the stop so

that the input pressure balance 763 is operative.

The quick release coupling 801-3 is in general connected to the

pressureless return line T of the tractor.

If a pressureless return line is not allowed in continuous operation

(e.g. because lubrication of the tractor gearbox is not guaranteed), a

double-acting control unit can be used for supplying oil to the attachment.

In this case, the quick release coupling 801-2 is connected to port A

(feed) and quick release coupling 801-3 to port B (return) of the

corresponding tractor control valve.

Adjust the volume flow to Q

= 50 l/min; please refer also to the tractor's

max

Operating Manual, e.g. "Continuous operation of hydraulic motors".

The quick release coupling 801-4 (LS, working hydraulics signal) is not

used with this connection option.

If the tractor is not provided with a flow-adjustable control unit, the volume

flow must not exceed 50 l/min.

Connection to tractors with

constant-pressure hydraulic

system

The quick release coupling 801-2 is connected to a control unit port of the

tractor with adjustable oil flow.

This control unit provides oil supply for the attachment and is adjusted to

an oil flow of approx. Q

= 50 l/min.

max

The system screw (handwheel) 634 is turned in up to the stop so that

the input pressure balance 763 is blocked.

The tractor's hydraulic pump is shut down when the system pressure has

been reached.

The quick release coupling 801-3 is connected to port T (pressureless

return line) of the tractor.

The quick release coupling 801-4 (LS, working hydraulics signal) is not

used with this connection option.

Important! The pressure relief valve 706 must be set approx. 20 bar

higher than the tractor's pressure protection (oil will heat

up!). Block pressure relief valve 706 if necessary.

1-12 Lin-h-Kap1 12/03

Page 77

TIC Liner 3000 with Communicator Overall Hydraulic System

Connection to tractors with

load-sensing system and a

Power Beyond port

Test points/Characteristics When no function is active on the attachment, the attachment must not

The quick release coupling 801-2 is connected directly to the pump via

the Power Beyond port P.

The quick release coupling 801-3 is connected to port T (pressureless

return line) of the tractor.

The quick release coupling 801-4 (LS, working hydraulics signal) is

connected to the tractor's "LS signal" port when using this connection

option.

The system screw (handwheel) 634 is turned in up to the stop so that

the input pressure balance 763 is blocked.

The tractor's hydraulic pump regulates as a function of the attachment's

load signal.

load the tractor hydraulically

(The tractor engine speed must not be reduced).

The allowed temperature of the tractor's hydraulic system must not be

exceeded; see also the Operator's Manual of the tractor.

Important! The pressure relief valve 706 must be set approx. 20 bar

higher than the tractor's pressure protection (oil will heat

up!). Block pressure relief valve 706 if necessary.

12/03 Lin-h-Kap1 1-13

Page 78

Overall Hydraulic System Liner 3000 with Communicator TIC

1.3

Valve block

- up to serial no. 14

1-14 Lin-h-Kap1 12/03

Page 79

TIC Liner 3000 with Communicator Overall Hydraulic System

1.3 Valve block, up to serial no. 14

12/03 Lin-h-Kap1 1-15

Page 80

Overall Hydraulic System Liner 3000 with Communicator TIC

Key to diagram:

214-1 Rear right rotor hydraulic motor

214-2 Rear left rotor hydraulic motor

214-3 Front right rotor hydraulic motor

214-4 Front left rotor hydraulic motor

385 Chassis hydraulic cylinder

386 Rear right rotor hydraulic cylinder

387 Rear left rotor hydraulic cylinder

388 Front swath width hydraulic cylinder

389 Front right rotor hydraulic cylinder

390 Front left rotor hydraulic cylinder

410 Orifice plate Ø 1.5mm

429 Restrictor Ø 1.5mm

434 Restrictor Ø 3.0mm

634 System screw

706 Pressure relief valve .................................180

734 Lock-up valve unit

763 Input pressure balance

767-1 Flow controller 6l/min ± 0.5 l

767-2 Flow controller 10l/min ± 1.0l

767-3 Flow controller 10l/min ± 1.0l

767-4 Flow controller 20l/min ± 0.5 l

768 LS signal shuttle valve

769 Flow divider

Y156 (MV14) Lower rotor height solenoid valve

Y157 (MV13) Raise rotor height solenoid valve

Y158 (MV10) Raise chassis solenoid valve

Y159 (MV9) Lower chassis solenoid valve

Y160 (MV8) Raise rear right rotor solenoid valve

Y161 (MV7) Raise rear left rotor solenoid valve

Y162 (MV5) Increase working width solenoid valve

Y163 (MV6) Decrease working width solenoid valve

Y164 (MV3) Lower front right rotor solenoid valve

Y165 (MV4) Raise front right rotor solenoid valve

Y166 (MV1) Lower front left rotor solenoid valve

Y167 (MV2) Raise front left rotor solenoid valve

Y168 (MV11) Lower rear left rotor solenoid valve

Y169 (MV12) Lower rear right rotor solenoid valve

Y170 (MV15) Front right height blocking valve solenoid valve

Y171 (MV16) Front left height blocking valve solenoid valve

Y172 (MV17) Rear right height blocking valve solenoid valve

Y173 (MV18) Rear left height blocking valve solenoid valve

CCU CLAAS Control Unit

LS Load sensing port

Re1 Remote port 1

Re2 Remote port 2

P Pump

T Tank

Tr Tractor

+10

bar

1-16 Lin-h-Kap1 12/03

Page 81

TIC Liner 3000 with Communicator Overall Hydraulic System

1.4

Valve block

- from serial no. 15

12/03 Lin-h-Kap1 1-17

Page 82

Overall Hydraulic System Liner 3000 with Communicator TIC

1.4 Valve block, from serial no. 15

1-18 Lin-h-Kap1 12/03

Page 83

TIC Liner 3000 with Communicator Overall Hydraulic System

Key to diagram:

214-1 Rear right rotor hydraulic motor

214-2 Rear left rotor hydraulic motor

214-3 Front right rotor hydraulic motor

214-4 Front left rotor hydraulic motor

385 Chassis hydraulic cylinder

386 Rear right rotor hydraulic cylinder

387 Rear left rotor hydraulic cylinder

388 Front swath width hydraulic cylinder

389 Front right rotor hydraulic cylinder

390 Front left rotor hydraulic cylinder

410 Orifice plate Ø 1.5 mm

429 Restrictor Ø 1.5 mm

434 Restrictor Ø 3.0 mm

634 System screw

734 Lock-up valve unit

763 Input pressure balance

767-1 Flow controller 6l/min ± 0.5 l

767-2 Flow controller 10l/min ± 1.0 l

767-3 Flow controller 10l/min ± 1.0 l

767-4 Flow controller 20l/min ± 0.5 l

768 LS signal shuttle valve

769 Flow divider

Y156 (MV14) Lower rotor height solenoid valve

Y157 (MV13) Raise rotor height solenoid valve

Y158 (MV10) Raise chassis solenoid valve

Y159 (MV9) Lower chassis solenoid valve

Y160 (MV8) Raise rear right rotor solenoid valve

Y161 (MV7) Raise rear left rotor solenoid valve

Y162 (MV5) Increase working width solenoid valve

Y163 (MV6) Decrease working width solenoid valve

Y164 (MV3) Lower front right rotor solenoid valve

Y165 (MV4) Raise front right rotor solenoid valve

Y166 (MV1) Lower front left rotor solenoid valve

Y167 (MV2) Raise front left rotor solenoid valve

Y168 (MV11) Lower rear left rotor solenoid valve

Y169 (MV12) Lower rear right rotor solenoid valve

Y170 (MV15) Front right height blocking valve solenoid valve

Y171 (MV16) Front left height blocking valve solenoid valve

Y172 (MV17) Rear right height blocking valve solenoid valve

Y173 (MV18) Rear left height blocking valve solenoid valve

CCU CLAAS Control Unit

LS Load sensing port

Re1 Remote port 1

Re2 Remote port 2

P Pump

T Tank

Tr Tractor

12/03 Lin-h-Kap1 1-19

Page 84

Overall Hydraulic System Liner 3000 with Communicator TIC

1-20 Lin-h-Kap1 12/03

Page 85

TIC Liner 3000 with Communicator Overall Hydraulic System

1.5

Valve block

Solenoid coils with plug (German).

LS port in the input pressure balance block

12/03 Lin-h-Kap1 1-21

Page 86

Overall Hydraulic System Liner 3000 with Communicator TIC

1.5 Valve block

with LS port in the input pressure balance block (763)

1-22 Lin-h-Kap1 12/03

Page 87

TIC Liner 3000 with Communicator Overall Hydraulic System

Key to diagram:

410 Orifice plate Ø 1.5 mm

634 System screw

763 Input pressure balance

767-1 Flow controller 6 l/min ± 1.0 l

767-2 Flow controller 10 l/min ± 1.0 l

767-3 Flow controller 10 l/min ± 1.0 l

767-4 Flow controller 20 l/min ± 1.0 l

768 LS signal shuttle valve

Y156 (MV14) Lower rotor height solenoid valve

Y157 (MV13) Raise rotor height solenoid valve

Y158 (MV10) Raise chassis solenoid valve

Y159 (MV9) Lower chassis solenoid valve

Y160 (MV8) Raise rear right rotor solenoid valve

Y161 (MV7) Raise rear left rotor solenoid valve

Y162 (MV5) Increase working width solenoid valve

Y163 (MV6) Decrease working width solenoid valve

Y164 (MV3) Lower front right rotor solenoid valve

Y165 (MV4) Raise front right rotor solenoid valve

Y166 (MV1) Lower front left rotor solenoid valve

Y167 (MV2) Raise front left rotor solenoid valve

LS Load sensing port

P Pump

T Tank

12/03 Lin-h-Kap1 1-21

Page 88

Page 89

TIC Liner 3000 with Communicator Individual functions

Chapter 2 Individual functions

2.1 Input pressure balance,

system screw and pressure relief valve.................2-2

2.2 Raising/lowering front rotors..................................2-4

2.3 Increasing/reducing the working width...................2-6

2.4 Raising the rear rotor.............................................2-8

2.5 Raising/lowering the chassis ...............................2-10

2.6 Raising/lowering the rotor height adjustment.......2-12

2.7 Hydraulic cylinder ................................................2-14

2.8 Flow divider .........................................................2-16

12/03 Lin-h-Kap2 2-1

Page 90

Individual functions Liner 3000 with Communicator TIC

2.1 Input pressure balance, system screw and pressure relief valve

Key to diagram:

Note: The pressure relief valve (706) is built in only up to serial no. 15.

634 System screw

706 Pressure relief valve 180

763 Input pressure balance

P Pump

T Tank

+10

bar

2-2 Lin-h-Kap2 12/03

Page 91

TIC Liner 3000 with Communicator Individual functions

Description of function:

No volume flow is flowing The pressure spring pushes the control piston of the input pressure

balance (763) to its stop. The connection from P to T is closed.

Volume flow is flowing – no

solenoid valve is actuated

One solenoid valve is

actuated

Volume flow is supplied via channel P and flows to each of the

downstream control units.

Since no solenoid valve has been actuated, each spool blocks the volume

flow.

This builds up pressure which acts on the left-hand end of the input

pressure balance (763) control piston and pushes it against the pressure

spring.

This opens the connection from P to T. At the same time, a partial volume

flow flows via the orifice plate (in the control piston) into the spring space

of the control piston.

The spring space is not pressurized since it is connected to the channel

(LS).

A fixed pressure difference is established at the control piston.

When a downstream solenoid valve is actuated, volume flow flows via

channel P and the spool into the cylinder(s).

The load pressure built up now is directed into the spring space of the

input pressure balance (763) control piston via the LS channel.

The pressure build-up controls the control piston so that the connection

from P to T is partly closed.

This closing is necessary to make volume flow available for actuating the

cylinder(s).

However, the control piston is displaced to the left only until the fixed

pressure difference is re-established.

A partial volume flow will continue to flow into the tank.

When the cylinders are at their stop position, the pressure rises and is

available in the spring space of the input pressure balance (763) control

piston via the LS channel and presses the control piston to its stop. The

pressure in channel P opens the pressure control valve (706).

12/03 Lin-h-Kap2 2-3

Page 92

Individual functions Liner 3000 with Communicator TIC

2.2 Raising/lowering front rotors

Key to diagram:

Y164 (MV3) Lower front right rotor solenoid valve

Y165 (MV4) Raise front right rotor solenoid valve

Y166 (MV1) Lower front left rotor solenoid valve

Y167 (MV2) Raise front left rotor solenoid valve

768 LS signal shuttle valve

P Pump

T Tank

2-4 Lin-h-Kap2 12/03

Page 93

TIC Liner 3000 with Communicator Individual functions

A

Description of function:

No volume flow flowing, the

solenoid valves are not

actuated

Solenoid coil is active The solenoid coil is actuated proportionally by the CCU (CLAAS Control

Due to the two face-end pressure springs, the spool is positioned so that

port P is blocked (see diagram).

Unit). The spool can be positioned in any position, depending on this

actuation.

The active solenoid coil actuates the spool against the face-end pressure

spring.

Volume flow flows from channel (P) via the spool to the consumer port.

t the same time, the volume flow from the other consumer port flows into

the tank (T) via the spool.

12/03 Lin-h-Kap2 2-5

Page 94

Individual functions Liner 3000 with Communicator TIC

2.3 Increasing/reducing the working width

Key to diagram:

Y162 (MV5) Increase working width solenoid valve

Y163 (MV6) Decrease working width solenoid valve

767-4 Flow controller 20l/min ± 0.5 l

768 LS signal shuttle valve

3a Orifice plate

2-6 Lin-h-Kap2 12/03

Page 95

TIC Liner 3000 with Communicator Individual functions

A

Description of function:

No volume flow flowing, the

solenoid valve is not

actuated

Oil supply is available,

but the control unit is not yet

actuated

Example:

Solenoid valve (Y162) is

actuated

Control behaviour of the

flow controller

Due to the two face-end pressure springs, the spool is positioned so that

the ports P and the consumer ports are blocked (see diagram).

The volume flow enters the control unit via channel P. It flows to the spool

through the orifice plate of flow controller (767-4).

Since the spool prevents continued flow, a pressure is built up which acts

on the right-hand face end of flow controller (767-4) and also in the spring

space. Now equal forces act on the flow controller (767-4) and the

pressure spring pushes it to its stop position.

The solenoid coil (Y162) actuates the spool to the left against the

pressure spring.

The connection from the pump (P) to the left-hand consumer port and the

connection of the right-hand consumer port to the tank (T) are opened.

In this position, the flow controller (767-4) controls the volume flow to

20l/min ± 0.5 l. This happens even when the load pressure of the

consumer changes.

When volume flow flows through the flow controller (767-4), different

pressures result:

- The pump pressure acts upstream of the orifice plate (3a)

- The load pressure acts downstream of the orifice plate (3a)

Since the pressure downstream of the orifice plate is lower than the

pressure upstream of the orifice plate, a pressure difference results.

The flow controller keeps this pressure difference constant even when the

load pressure of the consumer (in the spring space) changes.

t a constant pressure difference, the volume flow to the consumer is also

constant.

12/03 Med-h-Kap2 2-7

Page 96

Individual functions Liner 3000 with Communicator TIC

2.4 Raising the rear rotor

Key to diagram:

Y160 (MV8) Raise rear right rotor solenoid valve

Y161 (MV7) Raise rear left rotor solenoid valve

767-2, -3 Flow controller 10l/min ± 1

768 LS signal shuttle valve

3a Orifice plate

2-8 Lin-h-Kap2 12/03

Page 97

TIC Liner 3000 with Communicator Individual functions

Description of function:

No volume flow flowing, the

solenoid valve is not

actuated

Oil supply is available,

but the control unit is not yet

actuated

Solenoid valve is actuated The solenoid coil (Y160, Y161) actuates the spool to the left against the

Control behaviour of the

flow controller

Due to the two face-end pressure springs, the spool is positioned so that

port (P) is blocked and the consumer port is connected to the tank (T)

(see diagram).

The volume flow enters the control unit via channel P.

It flows to the spool through the orifice plate (3a) of flow controller

(767-2. -3).

Since the spool prevents continued flow, a pressure is built up which acts

on the right-hand face end of flow controller (767-2. -3) and also in the

spring space.

Now equal forces act on the flow controller (767-2. -3) and the pressure

spring pushes it to its stop position.

pressure spring.

This opens the connection from the pump (P) to the consumer port.

In this position, the flow controller (767-4) controls the volume flow to

10l/min ± 1 l. This happens even when the load pressure of the consumer

changes.

When volume flow flows through the flow controller (767-2. -3), different

pressures result:

- The pump pressure acts upstream of the orifice plate (3a)

- The load pressure acts downstream of the orifice plate (3a)

Since the pressure downstream of the orifice plate is lower than the

pressure upstream of the orifice plate, a pressure difference results.

The flow controller keeps this pressure difference constant even when the

load pressure of the consumer (in the spring space) changes.

At a constant pressure difference, the volume flow to the consumer is also

constant.

12/03 Lin-h-Kap2 2-9

Page 98

Individual functions Liner 3000 with Communicator TIC

2.5 Raising/lowering the chassis

Key to diagram:

Y158 (MV10) Raise chassis solenoid valve

Y159 (MV9) Lower chassis solenoid valve

732 Non-return valve

768 LS signal shuttle valve

s Ram

2-10 Lin-h-Kap2 12/03

Page 99

TIC Liner 3000 with Communicator Individual functions

Description of function:

No volume flow flowing, the

solenoid valves are not

actuated

Solenoid coil (Y158) is

active

Solenoid coil (Y159) is

active

Due to the two face-end pressure springs, the spool is positioned so that

port P is blocked (see diagram).

The consumer port is blocked by the non-return valve (732).

The solenoid coil (Y158) is actuated by the CCU (CLAAS Control Unit).

The active solenoid coil (Y158) actuates the spool to the left against the

face-end pressure spring.

Volume flow flows from channel (P) via the spool, opens the non-return

valve (732) and reaches the left-hand consumer port.

The solenoid coil (Y159) is actuated by the CCU (CLAAS Control Unit).

The active solenoid coil (Y159) actuates the spool to the right against the

face-end pressure spring.

Volume flow flows from channel (P) via the spool to the closed consumer

port. The pressure which now builds up opens the non-return valve (732)

via the ram (s). The left-hand consumer port is now connected to the tank

(T) via the opened non-return valve and the spool.

12/03 Lin-h-Kap2 2-11

Page 100

Individual functions Liner 3000 with Communicator TIC

2.6 Raising/lowering the rotor height adjustment

Key to diagram:

Y156 (MV14) Lower rotor height solenoid valve

Y157 (MV13) Raise rotor height solenoid valve

767-1 Flow controller 6l/min ± 0.5 l

768 LS signal shuttle valve

3a Orifice plate

2-12 Lin-h-Kap2 12/03

Loading...

Loading...