Claas Lexion 570 Service Manual

LEXION 570 – 520 Montana

Technical Systems

Electric System

Electric System LEXION 500 TIC

TIC LEXION 500 Electric System

Layout of electric circuit diagrams

Lex-e-01a

Following the circuit diagram layout, all electric circuits are shown in

individual circuit diagrams. Some explanations are given below to illustrate

the layout.

Numbering of circuit diagrams

- The respective numbering can be found on the corresponding cover

sheet and in the footer.

- Depending on the machine no., the components fitted and the country

specification, there may be several individual circuit diagrams 01a,

01b, 01c, etc. for a given function.

Potentials

- Main power supply (battery)

- Ignition switch power supply (switched)

- Relay-controlled power supply

- Earth

- Housing earth (external)

Connections

- The description provided inside the circle (e.g. „S25”) defines the

connection.

- Numbers next to the circle (e.g. „1”) describe the continuation of the

cabling in accordance with the circuit diagram numbering. This circuit

diagram numbering can be taken among others from the footer.

Example: Many electric circuits depend on the seat contact switch Z5 (see

circuit diagram 17a). The number next to the circle (e.g. 15)

indicates the number of the circuit diagram on which another

function depending on the seat contact is shown.

Designations

- Connectors (e.g. „M”, pin 9 and 17) .

Each chapter lists the respective connectors and their pin assignment

in the individual connection tables.

- Modules (e.g. „A12 - Speed monitor“)

The arrows identify the functional inputs and outputs according to the

assignment table provided in chapter ZE.

Electric System LEXION 500 TIC

7-n-21

- Position of components according to component grid coordinates

A 1 ... Z 99

- Component designation according to CLAAS standards catalogue

A- Terminal / Module

B- Sensor

E- Lighting

F- Fuse

G- Voltage Source

H- Signalling Device / Lamp

K- Relay

M- Electric Motor

P- Gauge

R- Potentiometer / Resistor

S- Switches – Cab Operation

T- Switches – Terminal Operation

U- Switches – External Operation

V- Electronic Component

W- Antenna

X- Connector

Y- Solenoid coil

Z- Actual Value Function Switch

Connections list

from to 1

BB - 5 S 54 0.5 bl-wh

BB -10 Y 25 0.5 bk

MW-17 K49/86 0.75 br

mm2 Colour

- List of connections within the central terminal compartment, stating

cross-section (mm²) and colour of cables connected to the machine.

rd - red

bk - black

br - brown

wh - white

bl - blue

gr -grey

ye - yellow

gn - green

pi - pink

or - orange

vi - violet

TIC LEXION 500 Electric System

Contents:

Central terminal compartment ......................................................................................................................ZE-2

Pin assignment in modules............................................................................................................................ M-2

01a Main power supply, diesel engine electric starting motor................................................................ 01a-2

01s Main power supply, diesel engine electric starting motor - Montana 570-520 .................................01s-2

02a Starting the diesel engine, diesel engine electric starting motor - CAT C12, C10, C9, 3126B ....... 02a-2

02b Starting the diesel engine, diesel engine electric starting motor- DC 502 LA ................................. 02b-2

02s

Starting the diesel engine, diesel engine speed adjustment - CAT C12, C10, C9, 3126B,

Montana 570-520 - with external MONTANA control unit ................................................................02s-

Starting the diesel engine, diesel engine speed adjustment - CAT C12, C10, C9, 3126B,

02t

Montana 570-520 - with integrated MONTANA control unit............................................................. 02t-

Diesel engine cut-off system ........................................................................................................... 03a-2

03a

04a

Road travel activation, master valve................................................................................................ 04a-2

04s

Road travel activation, working hydraulics master valve, Montana 570-520

- with external MONTANA control unit..............................................................................................04s-

04t Road travel activation, working hydraulics master valve, Montana 570-520

- with integrated MONTANA control unit .......................................................................................... 04t-

05a Terminal, keyboard, rotary switch, printer ....................................................................................... 05a-2

05b

Terminal, keyboard, rotary switch, printer - with electro-hydraulic ground drive (EFA) .................. 05b-2

06a

CAN bus, module power supply, for diesel engine CATERPILLAR - C12, C10, C9, 3126B .......... 06a-2

06b CAN bus, module power supply, for diesel engine Daimler - Chrysler DC 502 LA......................... 06b-2

06s

CAN bus, module power supply, Montana 570-520 - with external MONTANA control unit ...........06s-2

06t

CAN bus, module power supply, Montana 570-520 - with integrated MONTANA control unit ........ 06t-2

07a

Threshing mechanism circuit ........................................................................................................... 07a-2

2

2

2

2

Electric System LEXION 500 TIC

08a Concave adjustment / Threshing drum variable-speed drive ..........................................................08a-2

09a Rotor flap adjustment / Rotor variable-speed drive .........................................................................09a-2

10a Fan variable-speed drive .................................................................................................................10a-2

11a Sieve adjustment .............................................................................................................................11a-2

12a Deflector adjustment ........................................................................................................................12a-2

13a Straw and chaff spreader, uni-spreader - LEXION 580................................................................... 13a-2

13b Straw and chaff spreader, radial spreader....................................................................................... 13b-2

14a Swinging the grain tank unloading tube........................................................................................... 14a-2

15a Grain tank unloading / Grain tank unloading aid.............................................................................. 15a-2

16a Rape cutting knife circuit.................................................................................................................. 16a-2

17a Front attachment drive, reverser drive, front attachment quick stop ...............................................17a-2

17s

Front attachment drive, reverser drive, front attachment quick stop, Montana 570-520

- with external MONTANA control unit............................................................................................. 17s-

18a

Front attachment variable-speed drive ............................................................................................18a-2

19a Straw chopper.................................................................................................................................. 19a-2

19b Straw chopper, radial spreader without chaff spreader ................................................................... 19b-2

19c

Straw chopper, radial spreader with chaff spreader ........................................................................ 19c-2

20a

Front attachment raise/lower, cross levelling................................................................................... 20a-2

20s

Raise/lower front attachment, cross levelling - Montana 570-520................................................... 20s-2

21a

Reel adjustment - Standard cutterbar.............................................................................................. 21a-2

21b Reel adjustment - VARIO cutterbar .................................................................................................21b-2

21c

Reel adjustment - Folding cutterbar................................................................................................. 21c-2

21d

Folding the maize picker, snapping plate adjustment, down maize augers .................................... 21d-2

22a Reel variable-speed drive ................................................................................................................ 22a-2

23a

Cutting table adjustment (Vario), folding the cutterbar ....................................................................23a-2

24a AUTOCONTOUR (CAC)..................................................................................................................24a-2

Speed monitor..................................................................................................................................25a-2

25a

2

TIC LEXION 500 Electric System

26a Machine monitor .............................................................................................................................. 26a-2

26s Machine monitor, Montana 570-520 - with external MONTANA control unit ...................................26s-2

Machine monitor, Montana 570-520 - with external MONTANA control unit ................................... 26t-2

26t

27a

Yield meter / Grainmeter ................................................................................................................. 27a-2

28a

AUTOPILOT – Laser system........................................................................................................... 28a-2

AUTOPILOT – Feeler system.......................................................................................................... 28b-2

28b

28c

AUTOPILOT – GPS-controlled steering...........................................................................................28c-2

29a

Performance monitor ....................................................................................................................... 29a-2

Open / close grain tank (electric), grain tank full signal, warning beacon ....................................... 30a-2

30a

30b

Open / close grain tank (hydraulic), grain tank full signal, warning beacon .................................... 30b-2

31a

Front attachment dampening........................................................................................................... 31a-2

32a

All-wheel drive, fuel tank.................................................................................................................. 32a-2

32b

All-wheel drive - Overdrive, fuel tank............................................................................................... 32b-2

33a Cutterbar spring lock........................................................................................................................ 33a-2

34 *not available

35 *not available

36a

Indicator system (Europe) ............................................................................................................... 36a-2

36b

Indicator system (USA).................................................................................................................... 36b-2

37a Windscreen wiper, windscreen washer ........................................................................................... 37a-2

38a

Compressor-type air conditioner ..................................................................................................... 38a-2

38b

Automatic air conditioner ................................................................................................................. 38b-2

39a Cab comfort equipment – Operator's seat....................................................................................... 39a-2

40a

Additional sockets, fuse tester......................................................................................................... 40a-2

41s Axle control system, front attachment control system, Montana 570-520

- with external MONTANA control unit..............................................................................................41s-

41t

Axle control system and front attachment control system, Montana 570-520

- with integrated Montana control unit .............................................................................................. 41t-

42a Ground drive and brake control ....................................................................................................... 42a-2

42s

Ground drive and brake control, Montana 570-520 - with external MONTANA control unit ............42s-2

42t

Ground drive and brake control, Montana 570-520 - with integrated MONTANA control unit......... 42t-2

43 *not available

2

2

Electric System LEXION 500 TIC

44a

Electro-hydraulic gearshift - 3-speed manual gearbox .................................................................... 44a-2

45a

Main lighting circuit, taillight, position light ....................................................................................... 45a-2

46a

Dipped headlights, full beam, dipped headlights changeover switch .............................................. 46a-2

47a

Work lights I .....................................................................................................................................47a-2

Work lights II ....................................................................................................................................48a-2

48a

49a

Sieve, grain tank and returns lighting, reversing horn, brake light................................................... 49a-2

50a

Instrument lighting, broadcast receiver, mirror adjustment.............................................................. 50a-2

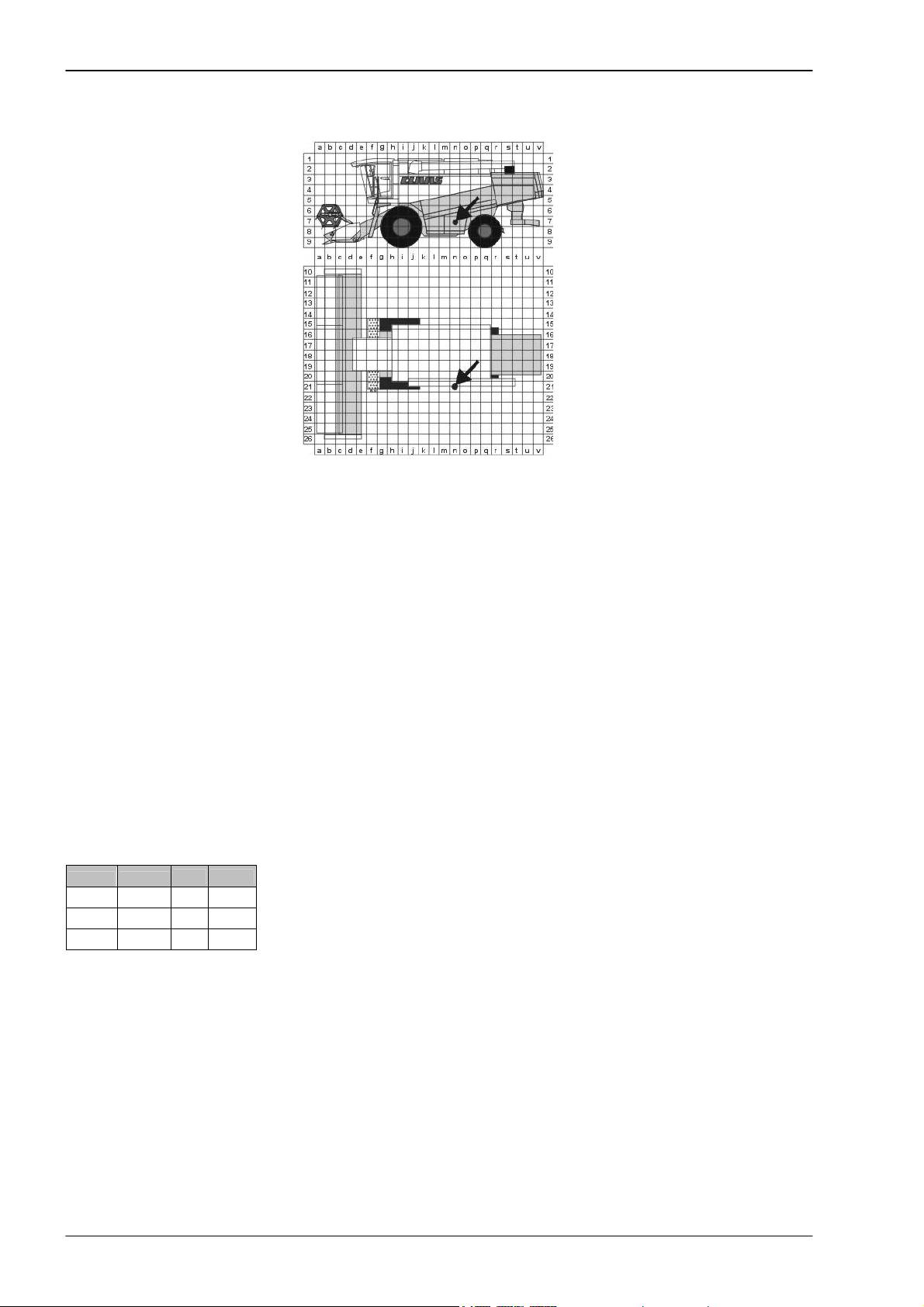

Component grid ............................................................................................................................................. R-2

Index ...................................................................................................................................................... index-2

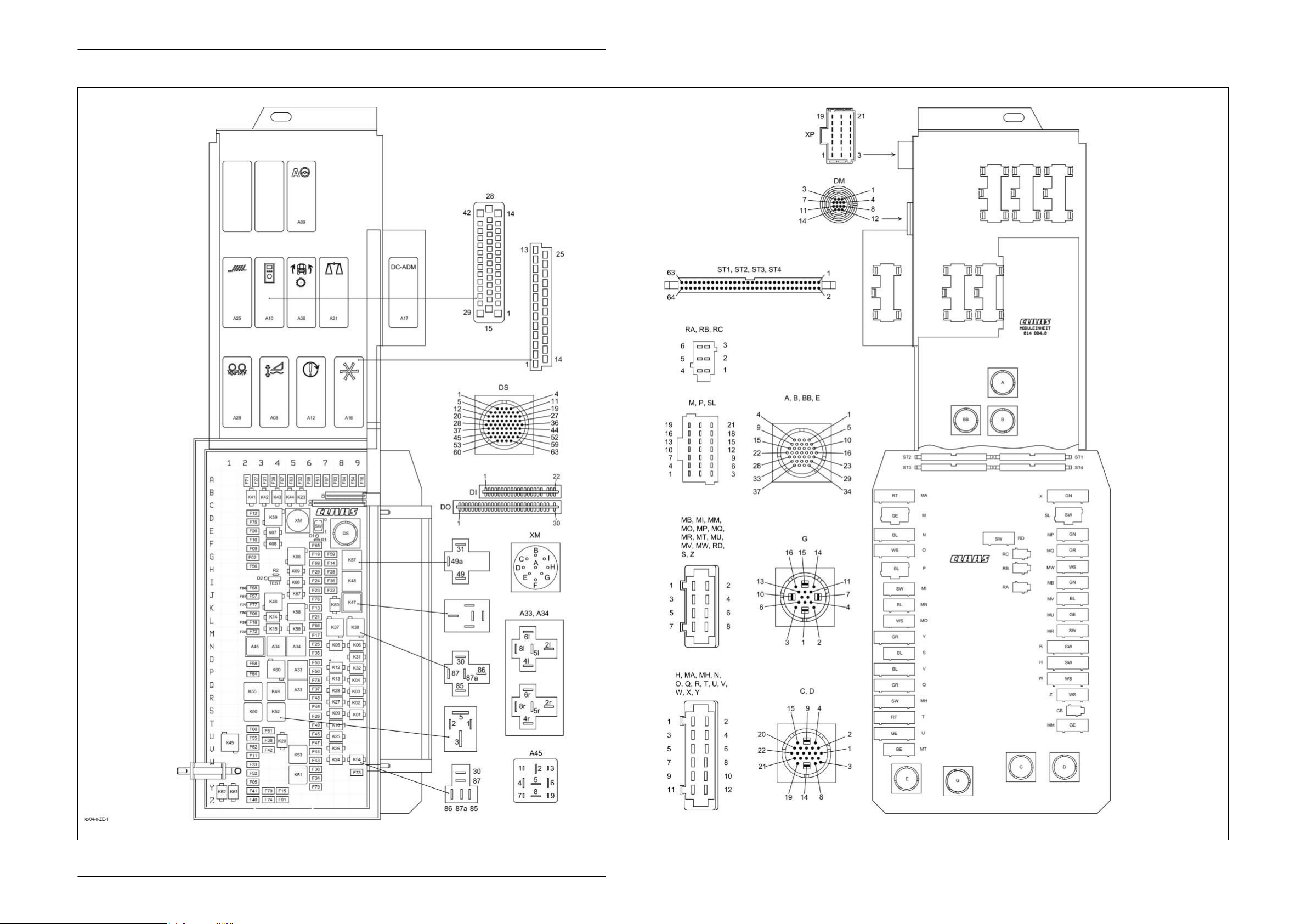

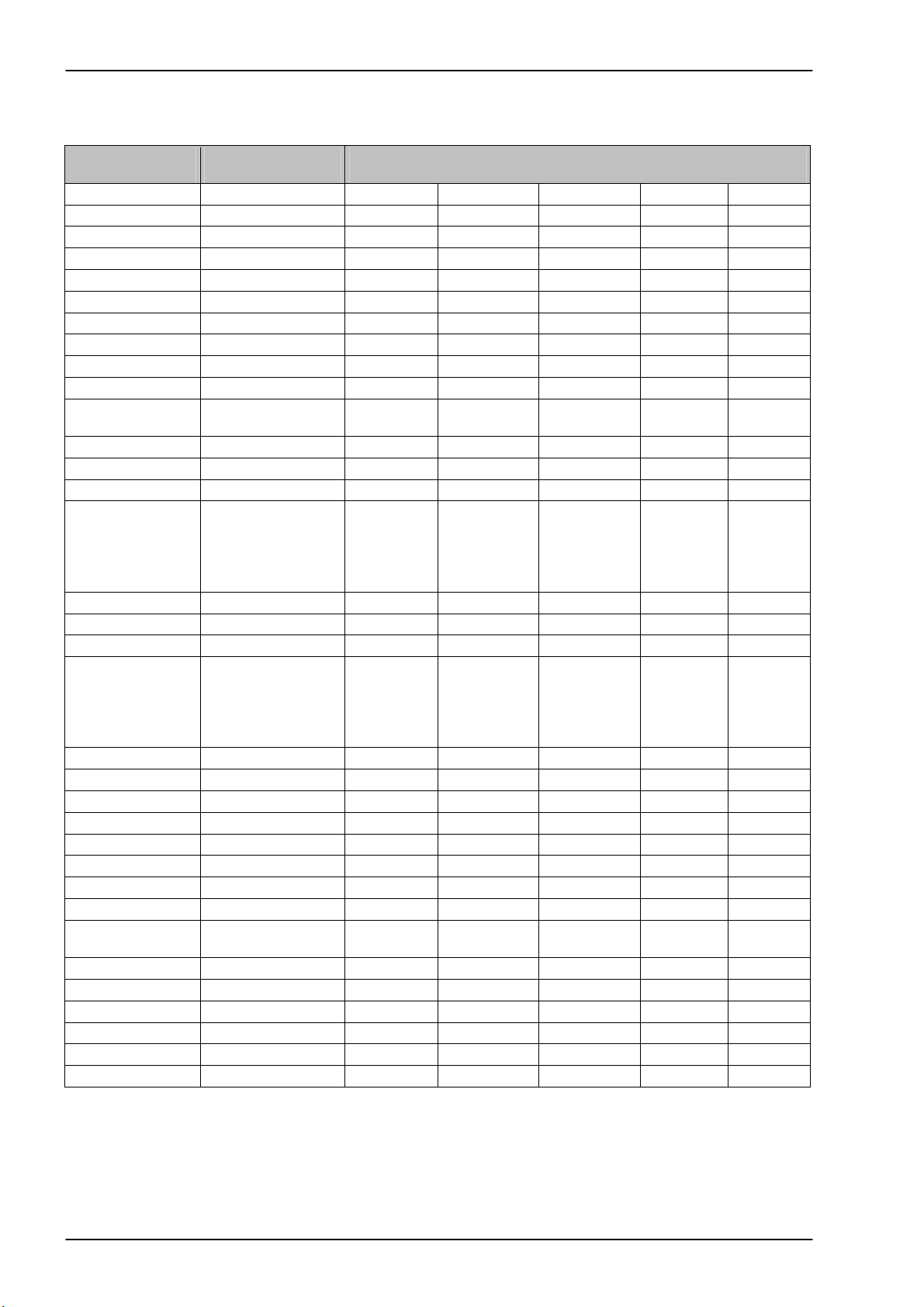

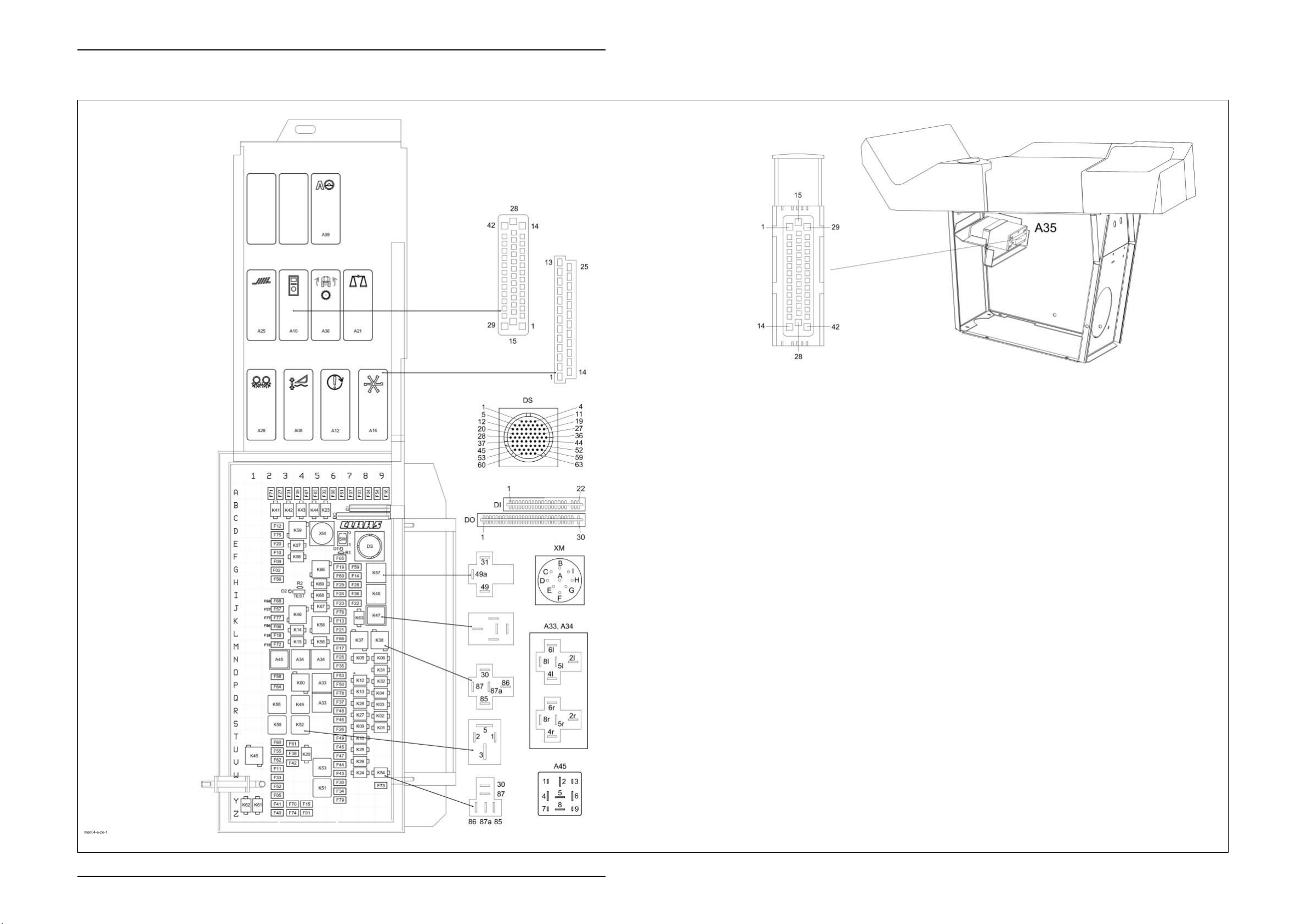

Central terminal compartment

Electric System LEXION 500 TIC

Central terminal compartment

ZE-2 Lex-e-ZE 03/05

TIC LEXION 500 Electric System

Key to diagram:

Centr. term. comp.

position

A08 AUTOCONTOUR module (CAC)

A09 AUTOPILOT module

A10 Fieldwork computer module (BIF/CAB)

A12 Speed monitor module (DZW)

A16 Reel controller module (HAS)

A17 Engine adaptation module (ADM)

A21 YIELD METER module (LEM)

A25 Sieve adjustment module

A28 Uni-spreader module (VGS)

A33 Sidefinder module

A34 Grain tank module

A37 Electro-hydraulic gearshift (EHS) module

A45 Ground drive hydraulic motor brake

DI Warning device diode PCB

D0 Master valve diode PCB

DS Diagnosis (63-pin) VIA

ST1 Connecting cable (ribbon cable)

ST2 Connecting cable (ribbon cable)

ST3 Connecting cable (ribbon cable)

ST4 Connecting cable (ribbon cable)

F1

F2 Sieve adjustment module 12 V control

F3

F4 +12 V electronic unit A 8

F5

F6 Spare (plug MU) K-L 2

F7

F8

F9

F10 Yield meter F 2

F11

F12 Work lights relay C-D 2

F13

F14

F15 Dipped headlights / Full beam Y 4

F16

F17 Electronic unit plus RIO M 6

F18 Cutterbar quick stop L 2

F19

F20 All-wheel drive 12 V switch E 2

F21 Threshing mechanism relay L 6

F22

F23 Hazard warning switch 30 I-J 6

F24

F25

F26 Reel controller S 6

F27 Upper/lower sieve A 2-3

F28

F29 Ground speed control lever limit switch

F30 Brake light switch 12 V / Sieve pan light W-X 6

Modules

restrictor module (HBM)

Electronic components

Fuses

Dipped headlights circuit Z 4

unit

CAN connection of performance monitor A 7-8

12 V air conditioner fan X-Y 2

CAC module A 7

Reel module A 6

Yield meter F 2

Inside work lights V-W 2

Cigarette lighter K 6

Seat socket G-H 7

12 V CAB/DZW A 9

Engine speed switch G 6

Threshing mechanism ON I-J 7

Hazard warning switch 15 I 6

Fan speed relay N 6

Autopilot switch H 7

12 V

Connection

between basic PCB

and module PCB /

Interconnection list

on page ZE-6

G 2

H 6

03/05 Lex-e-ZE ZE-3

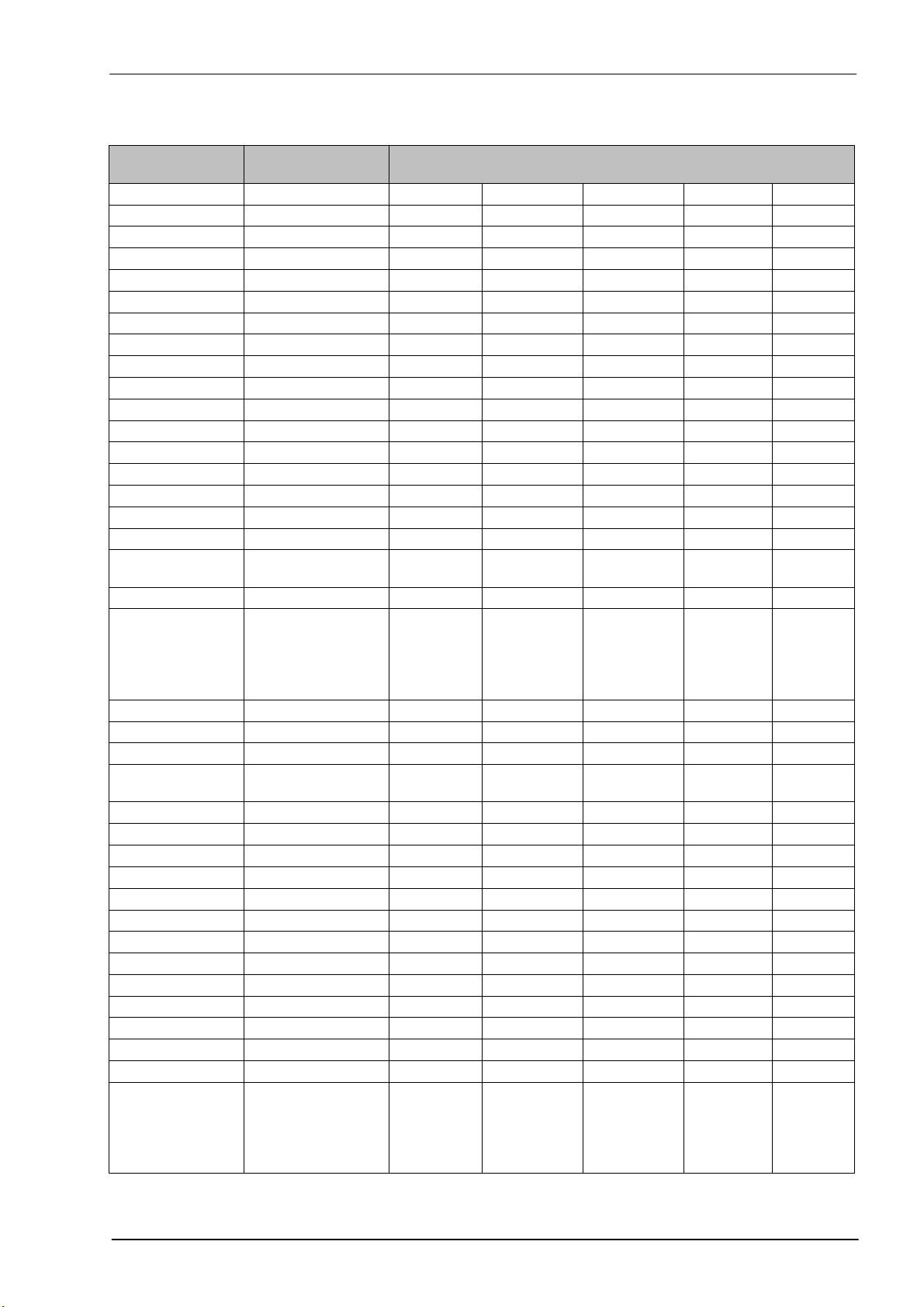

Electric System LEXION 500 TIC

Key to diagram:

Centr. term. comp.

position

F31

F32 12 V IMO A 5

F33

F34 Engine ignition X 6

F35 Fold cutterbar N-O 6

F36

F37 12 V grain tank drive Q 6

F38 Work light U 3

F39

F40 Vehicle lighting switch 12 V Z 2

F41

F42 12 V horn / wiper and washer system V 3

F43 Position light, left-hand W 6

F44

F45 Left-hand full beam relay U 6

F46 Left-hand dipped beam relay S 6

F47

F48 Right-hand dipped beam relay R 6

F49 Table adjustment T 6

F50

F51 Ignition diagnosis plug A 6

F52 Instrument lighting X 2

F53

F54 Uni-spreader/Autopilot module A 9

F55 Worklight switch U 2

F56

F57 Spare module J 2

F58 Spare (connector H) O 2

F59

F60 12 V sockets LP/HP T-U 2

F61

F62 Outside railing worklights relay V 2

F63 Power supply for 12 V potentiometers A 5

F64

F65 Spare relay 40A incl. 12 V/30A F 6

F66

F67

F68

F69

F70

F71

F72

F73

F74 Broadcast radio / radio 12 V constant plus Z 3

F75

F76 Maintenance lights J 6

F77 Front attachment electronic unit plus K 2

F78

F79 VCU terminal 30 Y 6

Fuses

Rotary switch 12 V A 3

Air conditioner relay W 2

Grain tank extension I 7

Chopper ON/OFF pushbutton A 4

Warning beacon Y 2

Position light, right-hand V 6

Right-hand full beam relay U-V 6

Grain tank extension P 6

Returns lighting O 6

Spare module H 2

Engine diagnosis G 7

Sidefinder T-U 3

12V speed sensors P 2

12 V deflector adjustment RIO / radial

spreader

Rotor flaps RIO / rotor variator A 4

Wheel position worklights I-J 2

Cooling box socket outlet 12V G-H 6

Ignition switch back-up fuse Y 3

Sieve adjustment module 12V power A 2

MINI ECU M 2

Stubble lighting worklights X 9

Transmission controller 12 V power supply D 2

Diagnosis DC terminal 15 P-Q 6

L 6

ZE-4 Lex-e-ZE 03/05

TIC LEXION 500 Electric System

Key to diagram:

Centr. term. comp.

position

K1

K2 Lower reel R-S 9

K3

K4 Reel backward P-Q 9

K5 Raise cutterbar N 7-8

K6

K7 Cutterbar left-hand cross levelling E 3-4

K8 Cutterbar right-hand cross levelling F 3-4

K9

K10 Table adjustment backward T 7-8

K12

K13 Threshing mechanism On/Off P-Q 7-8

K14 Threshing mechanism On/Off L 3-4

K15

K20 Lighting main relay U-V 4

K23 Generator B-C 5

K24

K25 Left-hand full beam relay U 7-8

K26 Right-hand full beam relay V 7-8

K27

K28 Right-hand dipped beam relay Q-R 7-8

K31 Grain tank extension up O 9

K32

K37 Fan speed - L-M 7-8

K38 Fan speed + L-M 8-9

K41

K42 Upper sieve adjustment + B-C 3

K43 Lower sieve adjustment - B-C 4

K44

K45 Work lights U-V 1

K46

K47 Flash relay USA J-K 8-9

K48 Indicator relay Europe I 8-9

K49

K50 Work lights relay S 2

K51

K52

K53

K54

K55

K56

K57

K58

K59

K60 Wheel position work lights O-P 4

K61

K62 Warning beacon grain tank 70% full Y-Z 1

K63 Fan speed relay J-K 7-8

K66

K67 Spare relay J 5

K68

K69 Spare relay H 5

Relay

Raise reel S 9

Reel forward Q-R 9

Lower cutterbar N 9

Table adjustment forward S 7-8

Ground speed control lever zero position P 7-8

Cutterbar quick stop L-M 3-4

Air conditioner relay W 7-8

Left-hand dipped beam relay R-S 7-8

Grain tank extension down P 9

Upper sieve adjustment - B-C 2

Lower sieve adjustment + B-C 5

Maintenance lights J-K 3-4

Road travel main relay Q-R 4

Relay 15 X 5

Ignition relay 15a S 4

Start relay V-W 5

Stubble lighting W 9

Work lights relay Q-R 2

Electronic unit plus L-M 5

Transducer G-H 8-9

Alternator relay K-L 5

Work lights relay D 3-4

Warning beacon Y-Z 1

Spare relay 40 A G 5

Spare relay I 5

03/05 Lex-e-ZE ZE-5

Electric System LEXION 500 TIC

Connecting cable Boards – Central terminal compartment

(Assignment table: Module → Connector): 1/5

Module board

Module / Pin

A08 01

A08 02

A08 03

A08 05

A08 06

A08 07

A08 08

A08 12

A08 13

A08 14

A08 15

A08 16

A08 18

A08 19

A08 20

A08 22

A08 25

A10 01

A10 02

A10 03

A10 04

A10 05

A10 06

A10 09

A10 10

A10 13

A10 14

A10 15

A10 16

A10 17

A10 18

A10 19

A10 20

Connecting cable

ST 1-4 Pin

ST3 36

ST2 63,64

ST1 23

ST2 43

ST2 51

ST4 13

ST1 35

ST2 40

ST2 36

ST3 35

ST3

17

18

ST1 21

ST2 49

ST2 41

23, 24

25, 26

ST2

27, 28

29, 30

31, 32

ST1 39

ST3 32

55, 56

57, 58

ST3

59, 60

61, 62

63, 64

ST2 50

ST4 13

ST2 58

ST2 33

ST2 46

ST3 54

ST2 19

ST1 21

ST3

33

34

ST3 53

ST3 50

ST4 1

ST2 57

ST2 52

ST4 12

Motherboard

Connector / Pin

K8 87 SL 10 MQ 3

Z 8 Q 12

MW 3 MV 3 MU 3

M 3

M 5

H 3 DS 53 W 2

E 25 DS 48

V 5 K5 87 DO 8

V 6 K6 87 DS 6

K7 87 MQ 4 SL 11

F07 a DS 5

MW 4 MV 4 MU 4

M 6

M 1

N 12 F35 a U 7

E 27

DO 1

F16 a

K38 86

H 3 DS 53 W 2

P 6 MO 1

MA 8

Z 3

M 9 DI 1

P 4 R 1 A34 2R

E 30 MO 4 MP 4

F04 a

V 2 DO 13

K37 86

P 14

SL 7 DS 2

O 10 DS 1 SL 8

W 1 F22 a K63 86 MN 2 DS 52

ZE-6 Lex-e-ZE 03/05

TIC LEXION 500 Electric System

Connecting cable Boards – Central terminal compartment

(Assignment table: Module → Connector): 2/5

Module board

Module / Pin

A10 24

A10 27

A10 29

A10 32

A10 33

A10 34

A10 40

A10 41

A10 42

A12 01

A12 02

A12 03

A12 04

A12 12

A12 13

A12 14

A12 15

A12 16

A12 20

A12 25

A16 01

A16 02

A16 03

A16 04

A16 05

A16 07

A16 08

A16 09

A16 10

A16 13

A16 14

A16 15

A16 16

A16 17

A16 18

A16 20

Connecting cable

ST 1-4 Pin

ST4 10

ST2 13

ST2 34

ST1 20

ST4 2

ST1 32

ST1 23

ST2 47

ST2 11

ST3 49

ST3 38

ST1 23

ST1 19

ST1 42

ST3 4

ST2 10

ST3

33

34

ST1 21

55, 56

57, 58

ST3

59, 60

61, 62

63, 64

ST2 14

ST2 48

ST2

63

64

ST1 23

ST1 40

ST1 36

ST2 37

ST1 22

ST3 3

ST2 54

ST2 22

ST2 56

ST3 1,2

ST1 21

ST1 34

ST3 20

19, 20

21, 22

ST3

23, 24

25, 26

27, 28

Motherboard

Connector / Pin

O 9

G 11 XM G

V 1

Z 4

P 15

C 18 G 16 K58 86 MM 8

E 31 MO 7 MP 3

G 9 XM F

G 12 XM C

Q 1 DO 17

Y 1 Y 12 MO 8 E 1 E 12

E 31 MO 7 MP 3

W 10 MN 3 DS 17

V 8 DO 15

V 7 DO 16

Q 2

F04 a

E 30 MO 4 MP 4

F16 a

P 7

E 6 DS 20 DO 3 K1 87

Z 8 Q 12

MW 3 MV 3 MU 3

P 8 MQ 5 DO 2 DS 7 SL 12

E 22

N 11

E 24

Z 5

E 28

Q 7 DS 24

E 7 K2 87 DS 21

F08 a

MW 4 MV 4 MU 4

E 29 MA 12

K3 86 K3 30 K4 86 K4 30 K2 30

Q 4 F26 a K1 86 K1 30 K2 86

03/05 Lex-e-ZE ZE-7

Electric System LEXION 500 TIC

Connecting cable Boards – Central terminal compartment

(Assignment table: Module → Connector): 3/5

Module board

Module / Pin

A16 21

A16 22

A16 25

A25 01

A25 02

A25 03

A25 08

A25 12

A25 13

A25 14

A25 15

A25 16

A25 20

A28 02

A28 03

A28 07

A28 11

A28 12

A28 13

A28 15

A28 16

A28 20

A28 25

A28 13

A28 15

A28 16

A28 20

A28 25

Connecting cable

ST 1-4 Pin

ST1 38

ST2 45

ST2 44

ST4 4

ST3 39

ST1 23

ST2 39

ST4 3

ST4 6

ST4 5

ST4 17

ST1 21

ST1

61, 62

63, 64

ST3 40

ST1 23

1, 2, 3, 4

ST1

5, 6, 7, 8

9, 10

ST1 26

ST1

ST1

ST3

11, 12

13, 14

53, 54

55, 56

51

52

ST1 21

1, 2, 3, 4,

ST1

5, 6, 7, 8,

9, 10

ST1

ST1

15, 16

17, 18

53, 54

55, 56

ST3 51, 52

ST1 21

1, 2, 3, 4,

ST1

5, 6, 7, 8

9, 10

ST1

15, 16,

17, 18

Motherboard

Connector / Pin

E 23

Q 3

Q 8 DS 25

K42 86

MH 2 MH 7 MU 2 MP 2 H 1

A45 3 SL 4 MR 3 DS 62

DS 46

K41 86

K44 86

K43 86

MV 1 F02 a MW 1

A45 9 SL 5 MR 4 DS 63

F71 a

R 3 MV 2 K55 85 O 4 MW 2

A45 3 SL 4 MR 3 DS 62

DS 49 MN 7

DS 47

DS 26 MN 5

DS 27 MN 6

MR 1 F54 a

A45 9 SL 5 MR 4 DS 63

DS 49 MN 7

MN 8

DS 27 MN 6

MR 1 F54 a

A45 9 SL 5 MR 4 DS 63

DS 49 MN 7

MN 8

ZE-8 Lex-e-ZE 03/05

TIC LEXION 500 Electric System

Connecting cable Boards – Central terminal compartment

(Assignment table: Module → Connector): 4/5

Module board

Module / Pin

A 01

A 04

A 05

A 06

A 08

A 09

A 10

A 11

A 12

A 14

A 15

A 16

A 17

A 18

A 19

A 20

A 21

A 22

A 23

A 28

A 34

B 01

B 02

B 03

B 07

B 08

B 09

B 10

Connecting cable

ST 1-4 Pin

ST4 19

ST4 15

ST2

59

60

ST1 24

ST2 61

ST1 29

ST1 33

ST2 9

ST2 53

ST1 31

ST2 55

ST2 62

ST2 21

ST4 16

ST1 23

ST1 21

43, 44

45, 46

ST1

47, 48

49, 50

51, 52

ST2

1, 2, 3, 4,

5, 6, 7, 8

5, 6, 7, 8,

ST3

9, 10, 11,

12, 13, 14

ST4 7, 8, 9

ST2

63

64

ST1 41

ST4 18

50, 51

52, 53

54, 55

ST4

56, 57

58, 59

60, 61

62, 63

64

ST4 5

ST4 6

ST4 3

ST4 4

Motherboard

Connector / Pin

U 10 SL 20

MN 4 DS 33

A34 4R H 6 DS 16 W 4

G 14 K24 85

A34 8L W 3 H 5 M 21 DS 15

MH 6

MH 8

T 8 Y 2 SL 6

G 6 DI 13

MH 5 K62 85

W 9 DI 4

W 5

K23 87a G 13

K57 49a C 20

E 31 MO 7 MP 3

E 30 MO 4 MP 4

F32 a

MA 10 DS 61 U 4 MT 8 K46 85

F51 a DS 58 DS 59

F31 a DS 56

Z 8 Q 12

Z 6 DS 51 F64 a

F17 a MO 5 SL 14 K5 86 K5 30

F67 a

K43 86

K44 86

K41 86

K42 86

03/05 Lex-e-ZE ZE-9

Electric System LEXION 500 TIC

Connecting cable Boards – Central terminal compartment

(Assignment table: Module → Connector): 5/5

Module board

Module / Pin

B 11

B 13

B 14

B 15

B 16

B 17

B 20

B 23

B 24

B 25

B 26

B 27

B 28

B 29

B 30

B 31

B 33

B 34

BB 10

BB 12

BB 13

BB 19

BB 24

BB 29

Connecting cable

ST 1-4 Pin

ST1

61, 62

63, 64

ST1 23

ST1 21

32, 33

34, 35

ST4

36, 37

38, 39

40, 41

ST4

ST4

42, 43

44, 45

46, 47

48, 49

ST2 59, 60

ST1 34

ST3 29

ST2 2

ST4

ST4

ST4

ST1

20, 21

22, 23

24, 25

26, 27

28, 29

30, 31

57, 58

59, 60

ST1 27, 28

ST1 35

ST2 64

ST2 39

ST1 35

ST2 64

ST1 27, 28

ST1 26

ST1 41

ST2 3

ST2 24

ST2 25

ST2

15, 16

17, 18

ST3 15, 16

Motherboard

Connector / Pin

F71 a

MW 3 MV 3 MU 3

MW 4 MV 4 MU 4

F39 a

Q 6 DS 18 DO 22

Q 5 DS 19 DO 20

A34 4R H 6 DS 16 W 4

E 29 MA 12

F03 a MU 1

P 12 MI 2 T 7 T 6 C 16

K41 30

K42 30

K43 30

K44 30

DS 57 MU 8 MR 5 F63 a

E 25 DS 48

CB 2 Bridge a E 37

DS 46

E 25 DS 48

CB 2 Bridge a E 37

DS 57 MU 8 MR 5 F63 a

DS 47

Z 6 DS 51 F64 a

MQ 8 V 12 V 11 MT 4 MT 3

K6 30 K6 86 K7 86 K7 30

K8 86 K8 30

ZE-10 Lex-e-ZE 03/05

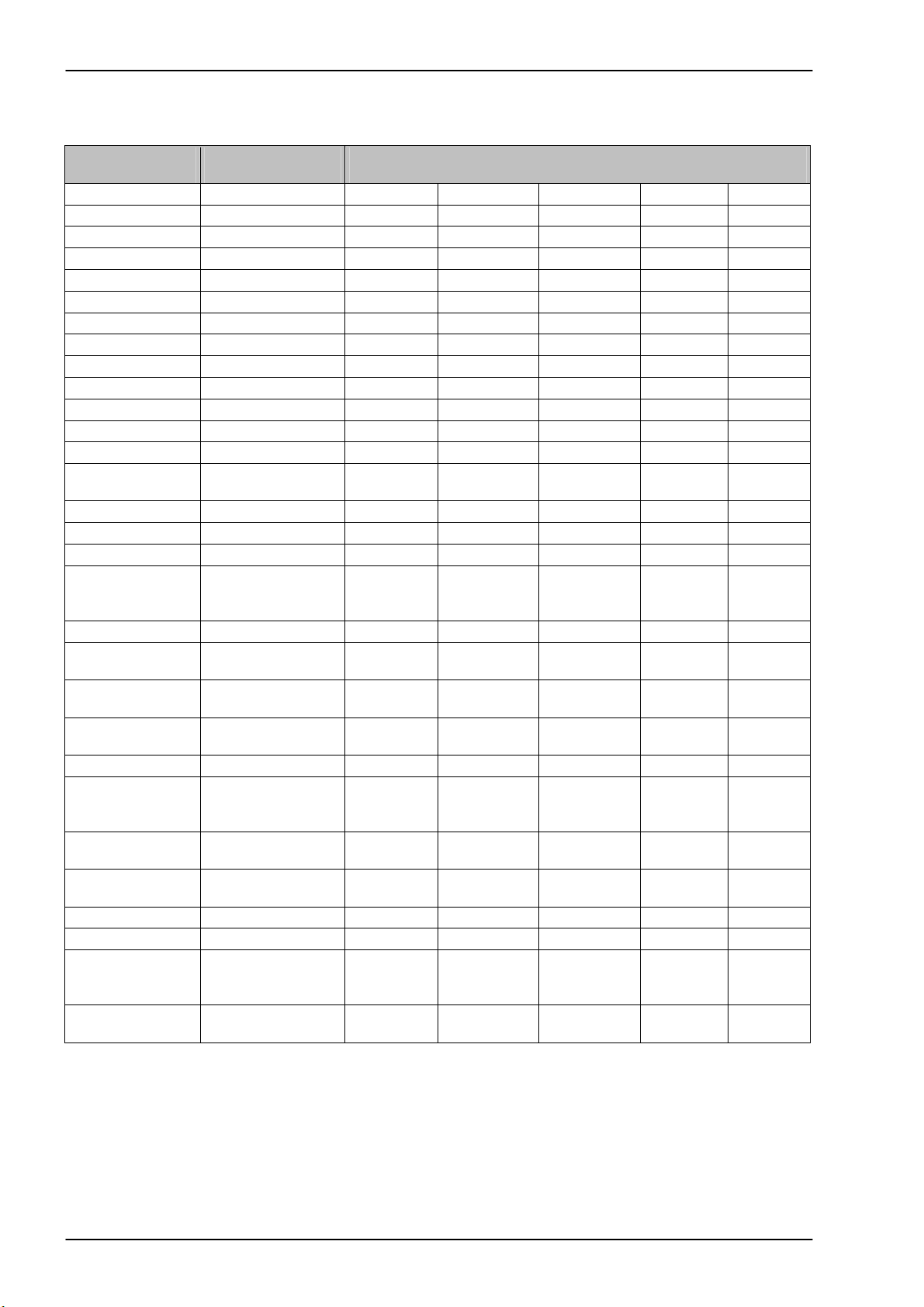

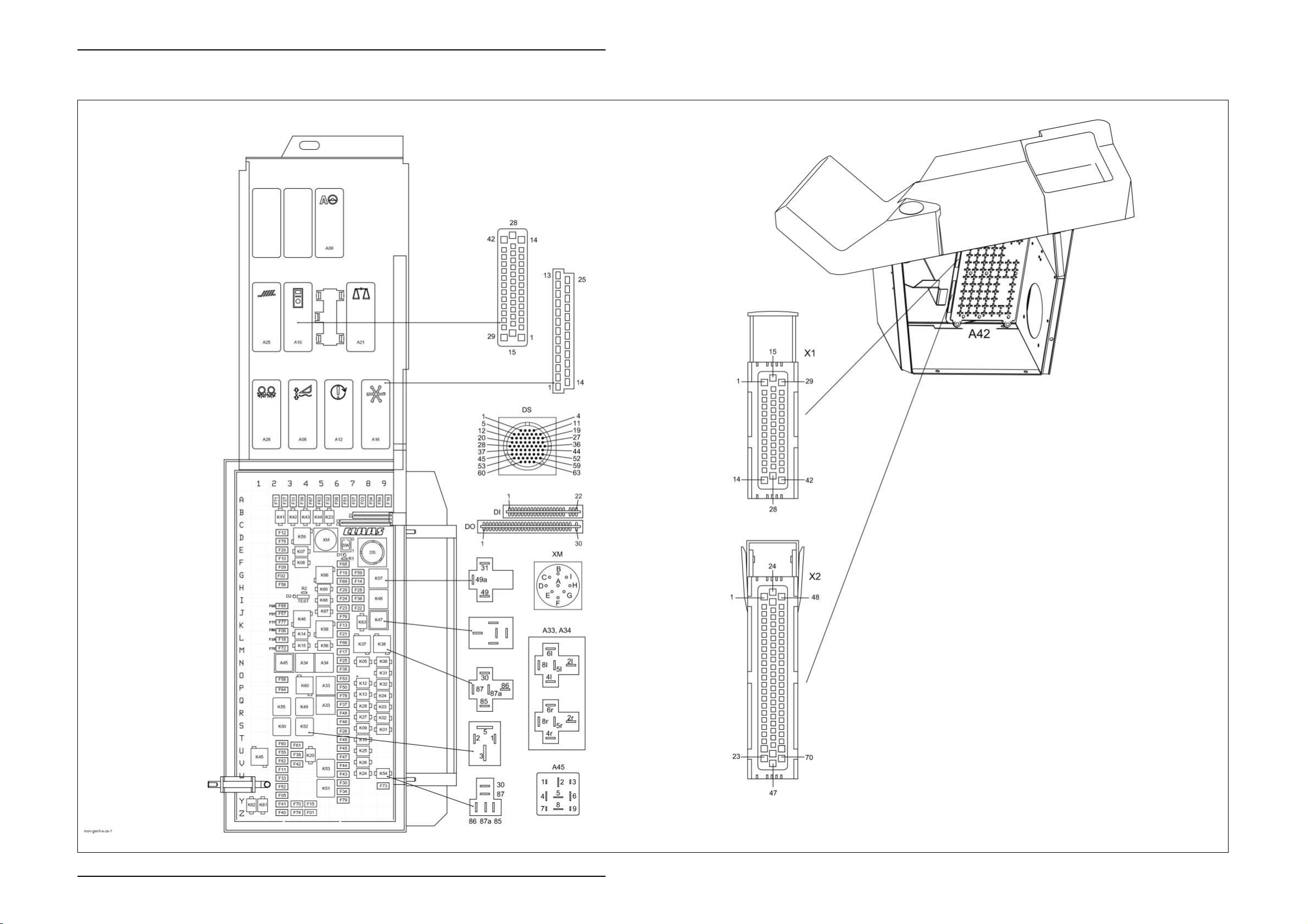

Central terminal compartment

Montana 570-520

- with external MONTANA control unit

- up to serial no. 582 00051

581 00026

580 00028

Electric System LEXION Montana 570-520 TIC

Central terminal compartment Montana 570-520 - with external MONTANA control unit

(up to serial no. 582 00051, 581 00026; 580 00028)

ZE-12 Lex-e-ZE 03/05

TIC LEXION Montana 570-520 Electric System

Key to diagram:

Centr. term.

comp. position

A08 AUTOCONTOUR module (CAC)

A09 AUTOPILOT module

A10 Fieldwork computer module (BIF/CAB)

A12 Speed monitor module (DZW)

A16 Reel controller module (HAS)

A17 Engine adaptation module (ADM)

A21 YIELD METER module (LEM)

A25 Sieve adjustment module

A28 Uni-spreader module (VGS)

A33 Sidefinder module

A34 Grain tank module

A35 MONTANA control unit module

A36 MONTANA gearshift control module

A45 Ground drive hydraulic motor brake restrictor

DI Warning device diode PCB

D0 Master valve diode PCB

DS Diagnosis (63-pin) VIA

ST1 Connecting cable (ribbon cable)

ST2 Connecting cable (ribbon cable)

ST3 Connecting cable (ribbon cable)

ST4 Connecting cable (ribbon cable)

F1

F2 Sieve adjustment module 12 V control unit G 2

F3

F4 +12 V electronic unit A 8

F5

F6 Spare (MU connector) K-L 2

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16 12 V CAB/DZW A 9

F17

F18 Cutterbar quick stop L 2

F19 Engine speed switch G 6

F20

F21 Threshing mechanism relay L 6

F22 Threshing mechanism ON I-J 7

F23

F24 Hazard warning switch 15 I 6

F25

F26

F27 Upper/lower sieve A 2-3

F28

F29

F30 Brake light switch 12 V / Sieve pan light W-X 6

Modules

module (HBM)

Electronic components

Fuses

Dipped headlights circuit Z 4

CAN connection of performance monitor A 7-8

12 V air conditioner fan X-Y 2

CAC module A 7

Reel module A 6

Yield meter F 2

Yield meter F 2

Inside work lights V-W 2

Work lights relay C-D 2

Cigarette lighter K 6

Seat socket G-H 7

Dipped headlights / Full beam Y 4

Electronic unit plus M 6

All-wheel drive 12 V switch E 2

Hazard warning switch 30 I-J 6

Fan speed relay N 6

Reel controller S 6

Autopilot switch H 7

Ground speed control lever limit switch 12 V H 6

Connection

between basic

PCB and module

PCB /

Interconnection

list on page ZE-6

03/05 Lex-e-ZE ZE-13

Electric System LEXION Montana 570-520 TIC

Key to diagram:

Centr. term.

comp. position

F31

F32 12 V IMO A 5

F33

F34 Engine ignition X 6

F35 Cutterbar fold N-O 6

F36

F37 12 V grain tank drive Q 6

F38 Work light U 3

F39

F40 Vehicle lighting switch 12 V Z 2

F41

F42 12 V horn / wiper and washer system V 3

F43 Position light, left-hand W 6

F44

F45 Left-hand full beam relay U 6

F46 Left-hand dipped beam relay S 6

F47

F48 Right-hand dipped beam relay R 6

F49 Table adjustment T 6

F50

F51 Ignition diagnosis plug A 6

F52 Instrument lighting X 2

F53

F54 Uni-spreader/Autopilot module A 9

F55 Worklight switch U 2

F56

F57 Spare module J 2

F58 Spare (connector H) O 2

F59

F60 12V sockets LP/HP T-U 2

F61

F62 Outside railing worklights relay V 2

F63 Power supply for 12 V potentiometers A 5

F64

F65 Spare relay 40 A incl. 12 V/30 A F 6

F66

F67

F68

F69

F70

F71

F72

F73

F74

F75 Transmission controller 12 V power supply D 2

F76

F77 Front attachment electronic unit plus K 2

F78 Diagnosis DC terminal 15 P-Q 6

F79

Fuses

Rotary switch 12 V A 3

Air conditioner relay W 2

Grain tank extension I 7

Chopper On/Off pushbutton A 4

Warning beacon Y 2

Position light, right-hand V 6

Right-hand full beam relay U-V 6

Grain tank extension P 6

Returns lighting O 6

Spare module H 2

Engine diagnosis G 7

Sidefinder T-U 3

12 V speed sensors P 2

12 V Deflector adjustment / Radial spreader L 6

Rotor flaps / rotor variator A 4

Wheel position worklights I-J 2

Cooling box socket outlet 12 V G-H 6

Ignition switch back-up fuse Y 3

Sieve adjustment module 12 V power A 2

MINI ECU M 2

Stubble lighting worklights X 9

Radio / Mobile radio 12 V constant plus Z 3

Maintenance lights J 6

VCU terminal 30 Y 6

ZE-14 Lex-e-ZE 03/05

TIC LEXION Montana 570-520 Electric System

Key to diagram:

Centr. term.

comp. position

K1

K2 Lower reel R-S 9

K3

K4 Reel backward P-Q 9

K5 Raise cutterbar N 7-8

K6

K7 Cutterbar left-hand lateral levelling E 3-4

K8 Cutterbar right-hand lateral levelling F 3-4

K9

K10 Table adjustment backward T 7-8

K12

K13 Threshing mechanism On/Off P-Q 7-8

K14 Threshing mechanism On/Off L 3-4

K15

K20 Lighting main relay U-V 4

K23 Alternator B-C 5

K24

K25 Left-hand full beam relay U 7-8

K26 Right-hand full beam relay V 7-8

K27

K28 Right-hand dipped beam relay Q-R 7-8

K31 Grain tank extension up O 9

K32

K37 Fan speed - L-M 7-8

K38 Fan speed + L-M 8-9

K41

K42 Upper sieve adjustment + B-C 3

K43 Lower sieve adjustment - B-C 4

K44

K45 Work lights U-V 1

K46

K47 Flash relay USA J-K 8-9

K48 Indicator relay Europe I 8-9

K49

K50 Work lights relay S 2

K51

K52

K53

K54

K55

K56

K57

K58

K59

K60 Wheel position work lights O-P 4

K61

K62 Warning beacon grain tank 70% full Y-Z 1

K63 Fan speed relay J-K 7-8

K66

K67 Spare relay J 5

K68

K69 Spare relay H 5

Relays

Raise reel S 9

Reel forward Q-R 9

Lower cutterbar N 9

Table adjustment forward S 7-8

Ground speed control lever zero position P 7-8

Cutterbar quick stop L-M 3-4

Air conditioner relay W 7-8

Left-hand dipped beam relay R-S 7-8

Grain tank extension down P 9

Upper sieve adjustment - B-C 2

Lower sieve adjustment + B-C 5

Maintenance lights J-K 3-4

Road travel main relay Q-R 4

Relay 15 X 5

Ignition relay 15a S 4

Start relay V-W 5

Stubble lighting W 9

Work lights relay Q-R 2

Electronic unit plus L-M 5

Transducer G-H 8-9

Alternator relay K-L 5

Work lights relay D 3-4

Warning beacon Y-Z 1

Spare relay 40 A G 5

Spare relay I 5

03/05 Lex-e-ZE ZE-15

Electric System LEXION Montana 570-520 TIC

ZE-16 Lex-e-ZE 03/05

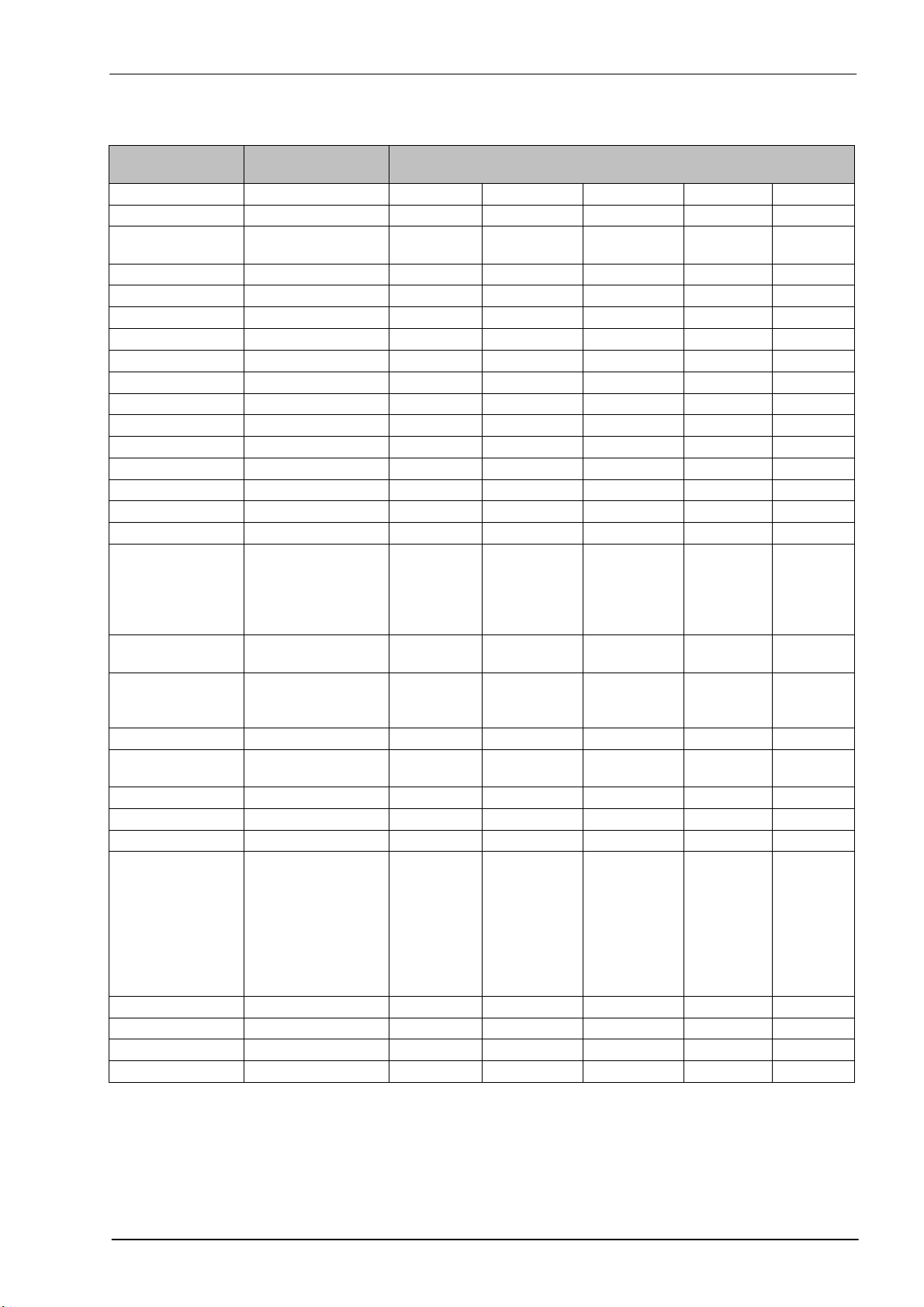

Central terminal compartment

Montana 570-520

- with integrated MONTANA control unit

- from serial no. 581 00027 to 581 00037

Electric System LEXION Montana 570-520 TIC

Central terminal compartment Montana 570-520 - with integrated MONTANA control unit

(from serial no. 581 00027 to 581 00037)

ZE-18 Lex-e-ZE 03/05

TIC LEXION Montana 570-520 Electric System

Key to diagram:

Centr. term.

comp. position

A08 AUTOCONTOUR module (CAC)

A09 AUTOPILOT module

A10 Fieldwork computer module (BIF/CAB)

A12 Speed monitor module (DZW)

A16 Reel controller module (HAS)

A17 Engine adaptation module (ADM)

A21 YIELD METER module (LEM)

A25 Sieve adjustment module

A28 Uni-spreader module (VGS)

A33 Sidefinder module

A34 Grain tank module

A42 MONTANA GEN II module

A45 Ground drive hydraulic motor brake restrictor

DI Warning device diode PCB

D0 Master valve diode PCB

DS Diagnosis (63-pin) VIA

ST1 Connecting cable (ribbon cable)

ST2 Connecting cable (ribbon cable)

ST3 Connecting cable (ribbon cable)

ST4 Connecting cable (ribbon cable)

F1

F2 Sieve adjustment module 12 V control unit G 2

F3 CAN connection of performance monitor A 7-8

F4

F5 12 V air conditioner fan X-Y 2

F6

F7 CAC module A 7

F8

F9

F10

F11

F12

F13

F14

F15

F16

F17 Electronic unit plus M 6

F18

F19 Engine speed switch G 6

F20 All-wheel drive 12 V switch E 2

F21

F22 Threshing mechanism ON I-J 7

F23 Hazard warning switch 30 I-J 6

F24

F25 Fan speed relay N 6

F26

F27

F28 Autopilot switch H 7

F29

F30 Brake light switch 12 V / Sieve pan light W-X 6

Modules

module (HBM)

Electronic components

Fuses

Dipped headlights circuit Z 4

+12 V electronic unit A 8

Spare (MU connector) K-L 2

Reel module A 6

Yield meter F 2

Yield meter F 2

Inside work lights V-W 2

Work lights relay C-D 2

Cigarette lighter K 6

Seat socket G-H 7

Dipped headlights / Full beam Y 4

12 V CAB/DZW A 9

Cutterbar quick stop L 2

Threshing mechanism relay L 6

Hazard warning switch 15 I 6

Reel controller S 6

Upper/lower sieve A 2-3

Ground speed control lever limit switch 12 V H 6

Connection

between basic

PCB and module

PCB /

Interconnection

list on page ZE-6

03/05 Lex-e-ZE ZE-19

Electric System LEXION Montana 570-520 TIC

Key to diagram:

Centr. term.

comp. position

F31

F32 12 V IMO A 5

F33

F34 Engine ignition X 6

F35 Cutterbar fold N-O 6

F36

F37 12 V grain tank drive Q 6

F38 Work light U 3

F39

F40 Vehicle lighting switch 12 V Z 2

F41

F42 12 V horn / wiper and washer system V 3

F43 Position light, left-hand W 6

F44

F45 Left-hand full beam relay U 6

F46 Left-hand dipped beam relay S 6

F47

F48 Right-hand dipped beam relay R 6

F49 Table adjustment T 6

F50

F51 Ignition diagnosis plug A 6

F52 Instrument lighting X 2

F53

F54 Uni-spreader/Autopilot module A 9

F55 Worklight switch U 2

F56

F57 Spare module J 2

F58 Spare (connector H) O 2

F59

F60 12V sockets LP/HP T-U 2

F61

F62 Outside railing worklights relay V 2

F63 Power supply for 12 V potentiometers A 5

F64

F65 Spare relay 40 A incl. 12 V/30 A F 6

F66

F67

F68

F69

F70

F71

F72

F73

F74

F75 Transmission controller 12 V power supply D 2

F76

F77 Front attachment electronic unit plus K 2

F78 Diagnosis DC terminal 15 P-Q 6

F79

Fuses

Rotary switch 12 V A 3

Air conditioner relay W 2

Grain tank extension I 7

Chopper On/Off pushbutton A 4

Warning beacon Y 2

Position light, right-hand V 6

Right-hand full beam relay U-V 6

Grain tank extension P 6

Returns lighting O 6

Spare module H 2

Engine diagnosis G 7

Sidefinder T-U 3

12 V speed sensors P 2

12 V Deflector adjustment / Radial spreader L 6

Rotor flaps / rotor variator A 4

Wheel position worklights I-J 2

Cooling box socket outlet 12 V G-H 6

Ignition switch back-up fuse Y 3

Sieve adjustment module 12 V power A 2

MINI ECU M 2

Stubble lighting worklights X 9

Radio / Mobile radio 12 V constant plus Z 3

Maintenance lights J 6

VCU terminal 30 Y 6

ZE-20 Lex-e-ZE 03/05

TIC LEXION Montana 570-520 Electric System

Key to diagram:

Centr. term.

comp. position

K1

K2 Lower reel R-S 9

K3

K4 Reel backward P-Q 9

K5 Raise cutterbar N 7-8

K6

K7 Cutterbar left-hand lateral levelling E 3-4

K8 Cutterbar right-hand lateral levelling F 3-4

K9

K10 Table adjustment backward T 7-8

K12

K13 Threshing mechanism On/Off P-Q 7-8

K14 Threshing mechanism On/Off L 3-4

K15

K20 Lighting main relay U-V 4

K23 Alternator B-C 5

K24

K25 Left-hand full beam relay U 7-8

K26 Right-hand full beam relay V 7-8

K27

K28 Right-hand dipped beam relay Q-R 7-8

K31 Grain tank extension up O 9

K32

K37 Fan speed - L-M 7-8

K38 Fan speed + L-M 8-9

K41

K42 Upper sieve adjustment + B-C 3

K43 Lower sieve adjustment - B-C 4

K44

K45 Work lights U-V 1

K46

K47 Flash relay USA J-K 8-9

K48 Indicator relay Europe I 8-9

K49

K50 Work lights relay S 2

K51

K52

K53

K54

K55

K56

K57

K58

K59

K60 Wheel position work lights O-P 4

K61

K62 Warning beacon grain tank 70% full Y-Z 1

K63 Fan speed relay J-K 7-8

K66

K67 Spare relay J 5

K68

K69 Spare relay H 5

Relays

Raise reel S 9

Reel forward Q-R 9

Lower cutterbar N 9

Table adjustment forward S 7-8

Ground speed control lever zero position P 7-8

Cutterbar quick stop L-M 3-4

Air conditioner relay W 7-8

Left-hand dipped beam relay R-S 7-8

Grain tank extension down P 9

Upper sieve adjustment - B-C 2

Lower sieve adjustment + B-C 5

Maintenance lights J-K 3-4

Road travel main relay Q-R 4

Relay 15 X 5

Ignition relay 15a S 4

Start relay V-W 5

Stubble lighting W 9

Work lights relay Q-R 2

Electronic unit plus L-M 5

Transducer G-H 8-9

Alternator relay K-L 5

Work lights relay D 3-4

Warning beacon Y-Z 1

Spare relay 40 A G 5

Spare relay I 5

03/05 Lex-e-ZE ZE-21

Electric System LEXION Montana 570-520 TIC

ZE-22 Lex-e-ZE 03/05

Loading...

Loading...