Page 1

LEXION 470 - 420 Montana

Technical

Systems

Electric/Hydraulic

System

Supplement

Page 2

Electric System LEXION-Montana TIC

Page 3

TIC LEXION-Montana Electric System

The present document exclusively describes all special electric and hydraulic

functions of the LEXION Montana series.

Explanations and descriptions concerning the basic machine and the front attachments

can be found in the relevant Electric System (297 550.x) and Hydraulic System

(297 549.x) documents.

D-S - Central terminal compartment on Montana machines 014 501.0

(with RIO module A50) ................................................................................. ZE-s-2

D-S - Central terminal compartment on Montana machines 014 501.0

(with HBM module A45) ............................................................................... ZE-s-4

Module A35 - Montana control unit, for Montana machines

(with RIO module A50) ................................................................................. ZE-s-9

Module A35 - Montana control unit, for Montana machines

(with HBM module A45) ............................................................................. ZE-s-10

Module A36 - Montana gearshift module.................................................................. ZE-s-11

Module A45 - Ground drive hydraulic motor brake restrictor (HBM) ......................... ZE-s-12

Module A50 - Montana RIO module ......................................................................... ZE-s-12

01s - Main power supply, diesel engine electric starting motor,

for Montana machines.................................................................................... 01s-2

02s - Starting the diesel engine, diesel engine speed adjustment

- for Montana machines.................................................................................. 02s-2

04s - Road travel activation, working hydraulics master valve,

for Montana machines with module A50 (RIO)............................................... 04s-2

04t - Road travel activation, working hydraulics master valve,

for Montana machines with module A45 (HBM) ..............................................04t-2

05s - Terminal, keyboard, rotary switch, printer,

for Montana machines with module A50 (RIO)............................................... 05s-2

05t - Terminal, keyboard, rotary switch, printer,

for Montana machines with module A45 (HBM) ..............................................05t-2

06s - CAN bus, module power supply,

for Montana machines with module A50 (RIO)............................................... 06s-2

06t - CAN bus, module power supply,

for Montana machines with module A45 (HBM) ..............................................06t-2

Page 4

Electric System LEXION-Montana TIC

Page 5

TIC LEXION-Montana Electric System

17s - Front attachment drive, reverser drive for Montana machines ....................... 17s-2

20s - Raise / lower front attachment, cross levelling – for Montana machines........ 20s-2

26s - Machine monitoring, for Montana machines................................................... 26s-2

41s - Axle control system and front attachment control system,

for Montana machines with module A50 (RIO)............................................... 41s-2

41t - Axle control system and front attachment control system,

for Montana machines with module A45 (HBM) ..............................................41t-2

42s - Ground drive and brake control,

for Montana machines with module A50 (RIO)............................................... 42s-2

42t - Ground drive and brake control,

for Montana machines with module A45 (HBM) ..............................................42t-2

Index .................................................................................................................... Index-3

Page 6

Electric System LEXION-Montana TIC

Page 7

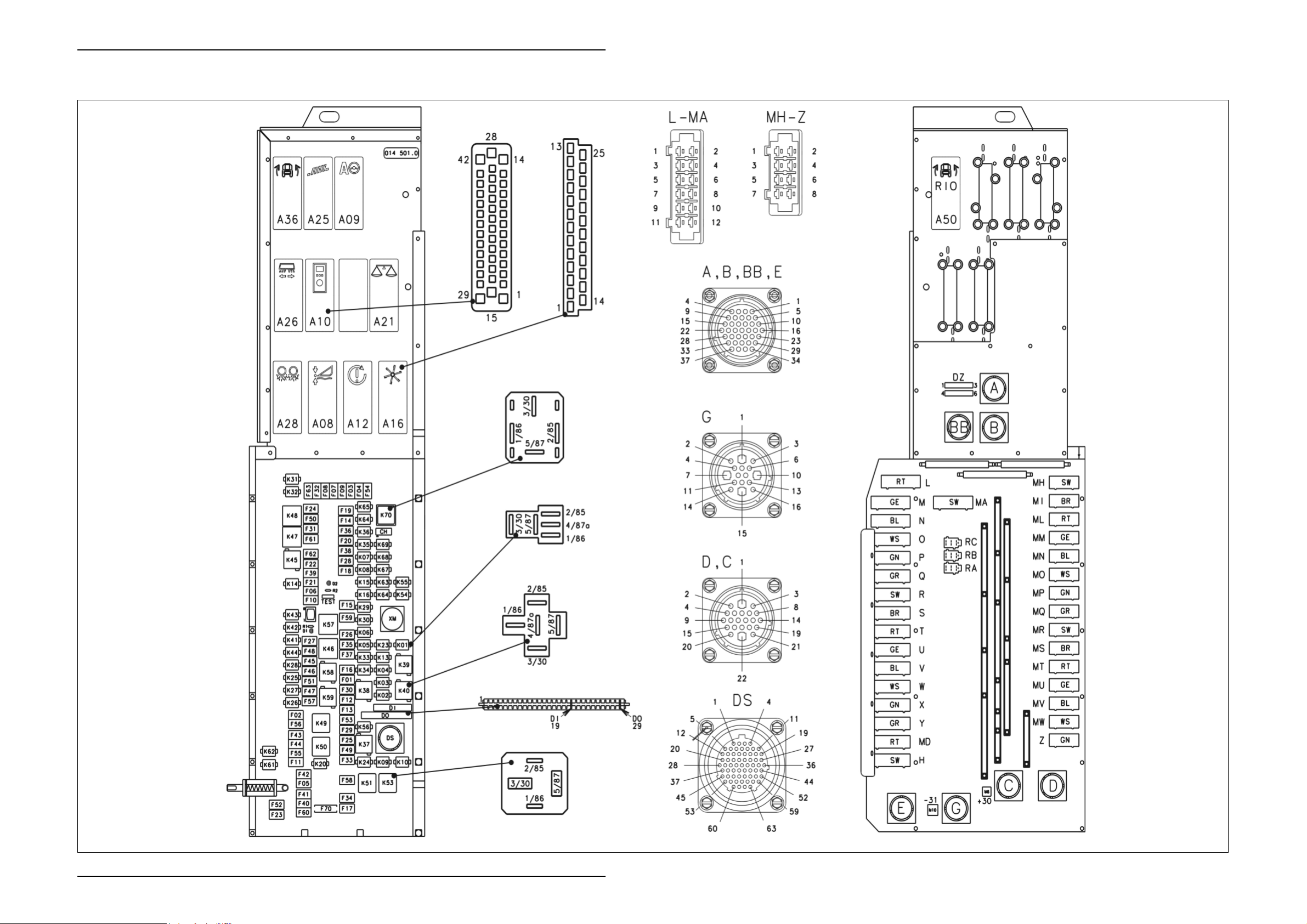

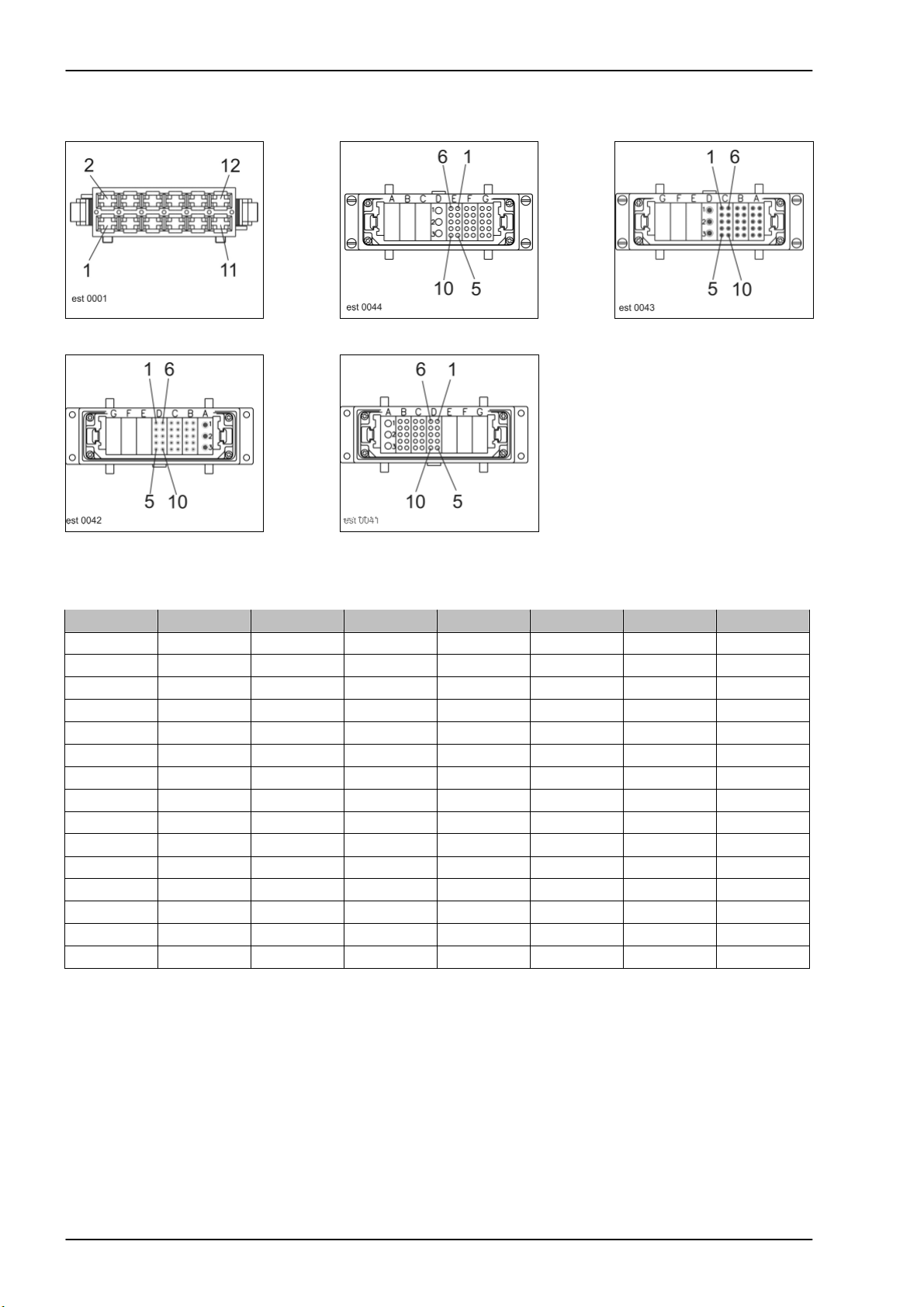

D-S

Central terminal compartment

014 501.0

Montana (with RIO module A50)

Page 8

Electric System LEXION Montana TIC

D-S - Central terminal compartment on Montana machines

014 501.0 (with RIO module A50)

ZE-s-2 Lex-e-ZE 03/04

Page 9

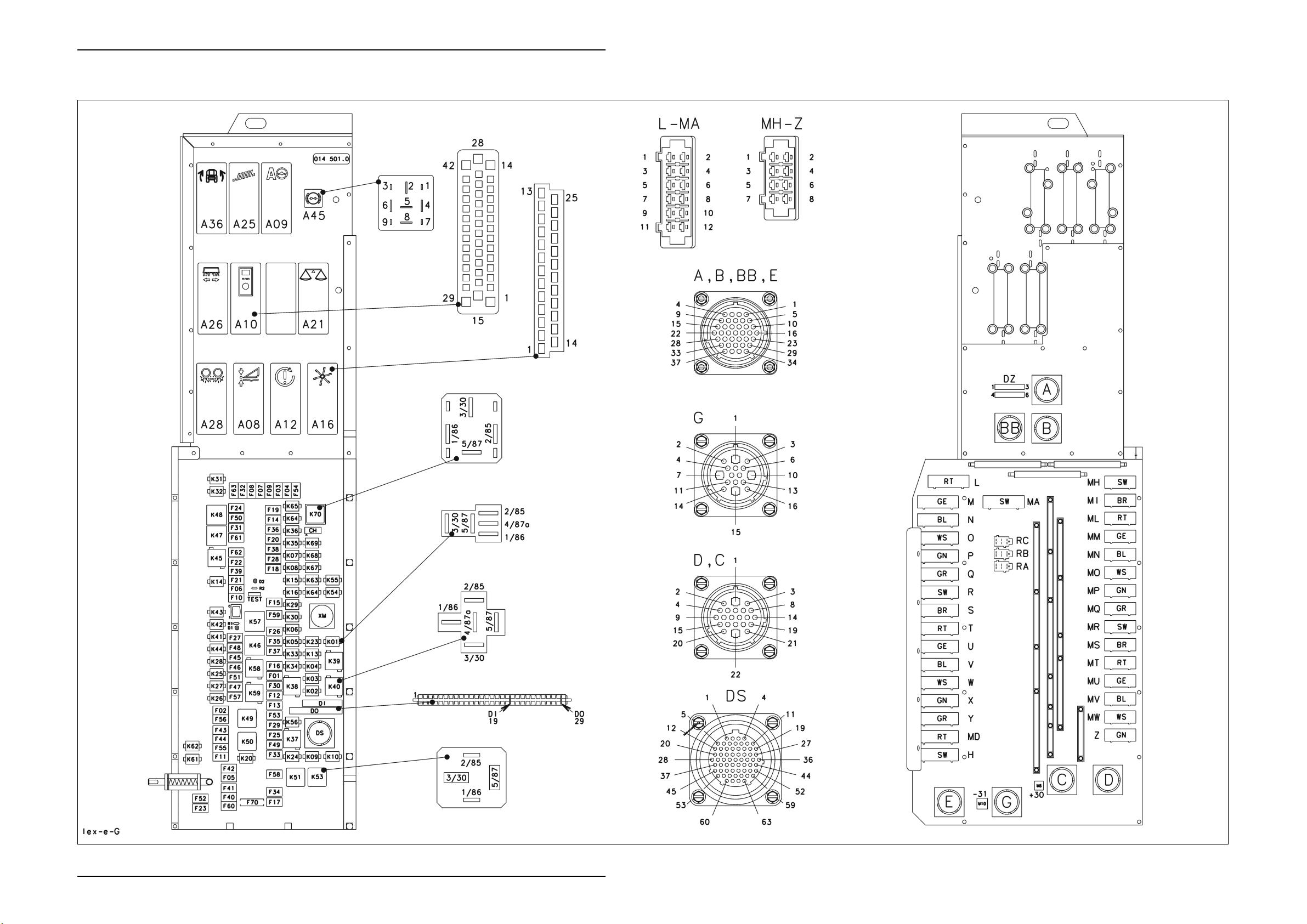

D-S

Central terminal compartment

014 501.0

Montana (with HBM module A45)

Page 10

Electric System LEXION Montana TIC

D-S - Central terminal compartment on Montana machines

014 501.0 (with HBM module A45)

ZE-s-4 Lex-e-ZE 03/04

Page 11

TIC LEXION Montana Electric System

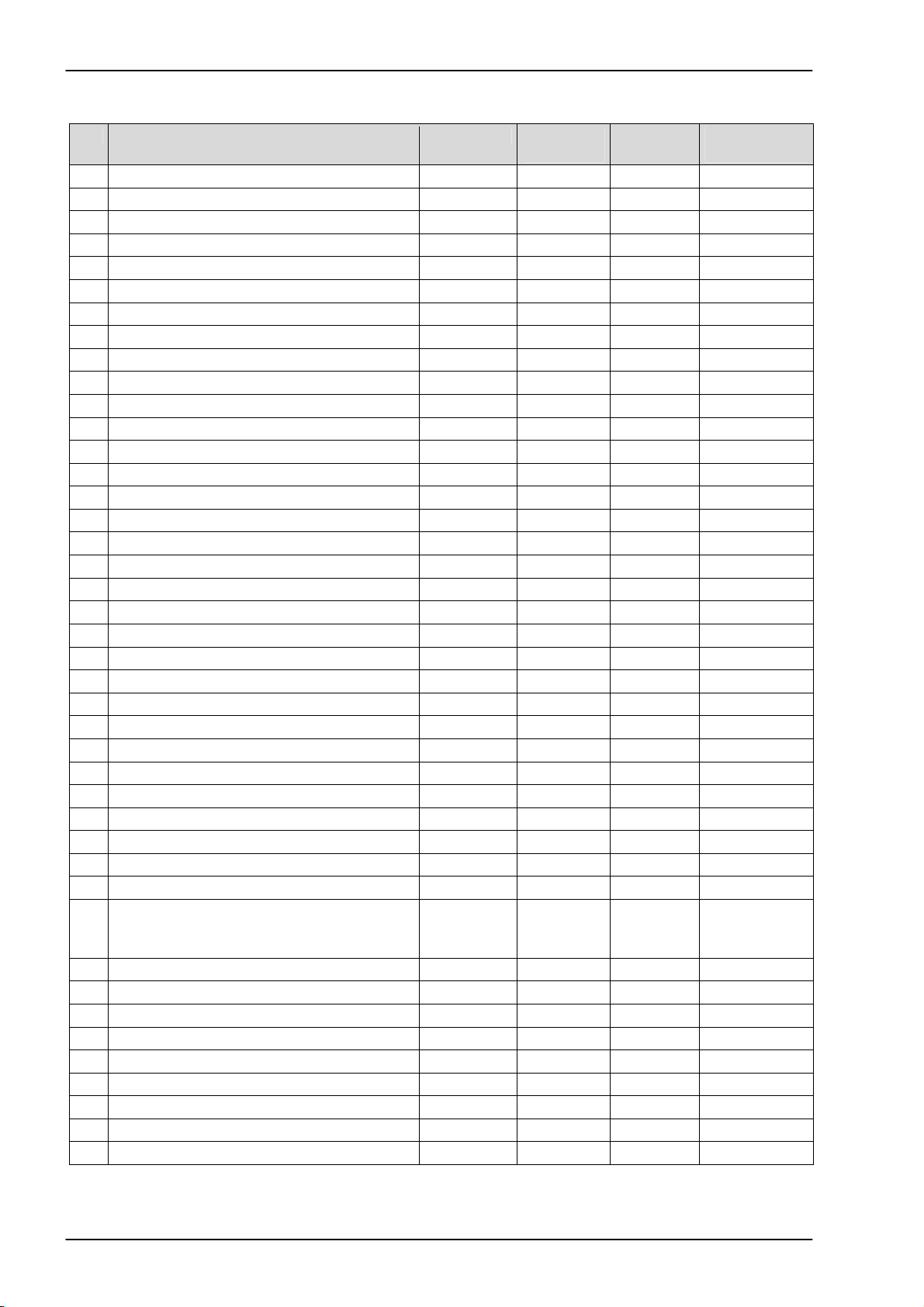

Key to diagram:

A08 AUTOCONTOUR module (CAC)

A09 AUTOPILOT module

A10 Fieldwork computer module (BIF/CAB)

A12 Speed monitor module (DZW)

A16 Reel controller module (HAS)

A21 YIELD METER module (LEM)

A25 Sieve adjustment module

A26 Deflector adjustment module

A28 Uni-spreader module (VGS)

A36 Electro-hydraulic gearshift module

A45 Ground drive hydraulic motor brake restrictor module (HBM)

A50 RIO module (ground drive hydraulic motor brake restrictor)

DI Warning device diode PCB

D0 Master valve diode PCB

DS Diagnosis (63-pin) VIA

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16

F17

F18

F19

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

F31

F32

F33

F34

F35

Modules

Electronic components

Fuses

Dipped headlights circuit

Sieve adjustment module 12 V control unit

CAN connection of performance monitor

+12 V electronic unit

12 V air conditioner fan

##

CAC module

Reel module

Yield meter

Yield meter

Inside work lights

Work lights

Cigarette lighter

Seat socket

Drum/rotor speed adjustment

Concave adjustment

Diagnosis LED

Cutterbar

Engine speed switch

All-wheel drive 12 V switch

Threshing mechanism relay

Fan speed relay

Hazard warning switch 30

Hazard warning switch 15

Fan speed relay

Reel controller

Upper/lower sieve

Autopilot switch

12 V / K56 pin 30

Brake light switch 12 V / Sieve pan light

12 V IMO

12 V IMO

Air conditioner relay

Engine control unit 12 V power supply

CAC module / VGS module

03/04 Lex-e-ZE ZE-s-5

Page 12

Electric System LEXION Montana TIC

Key to diagram:

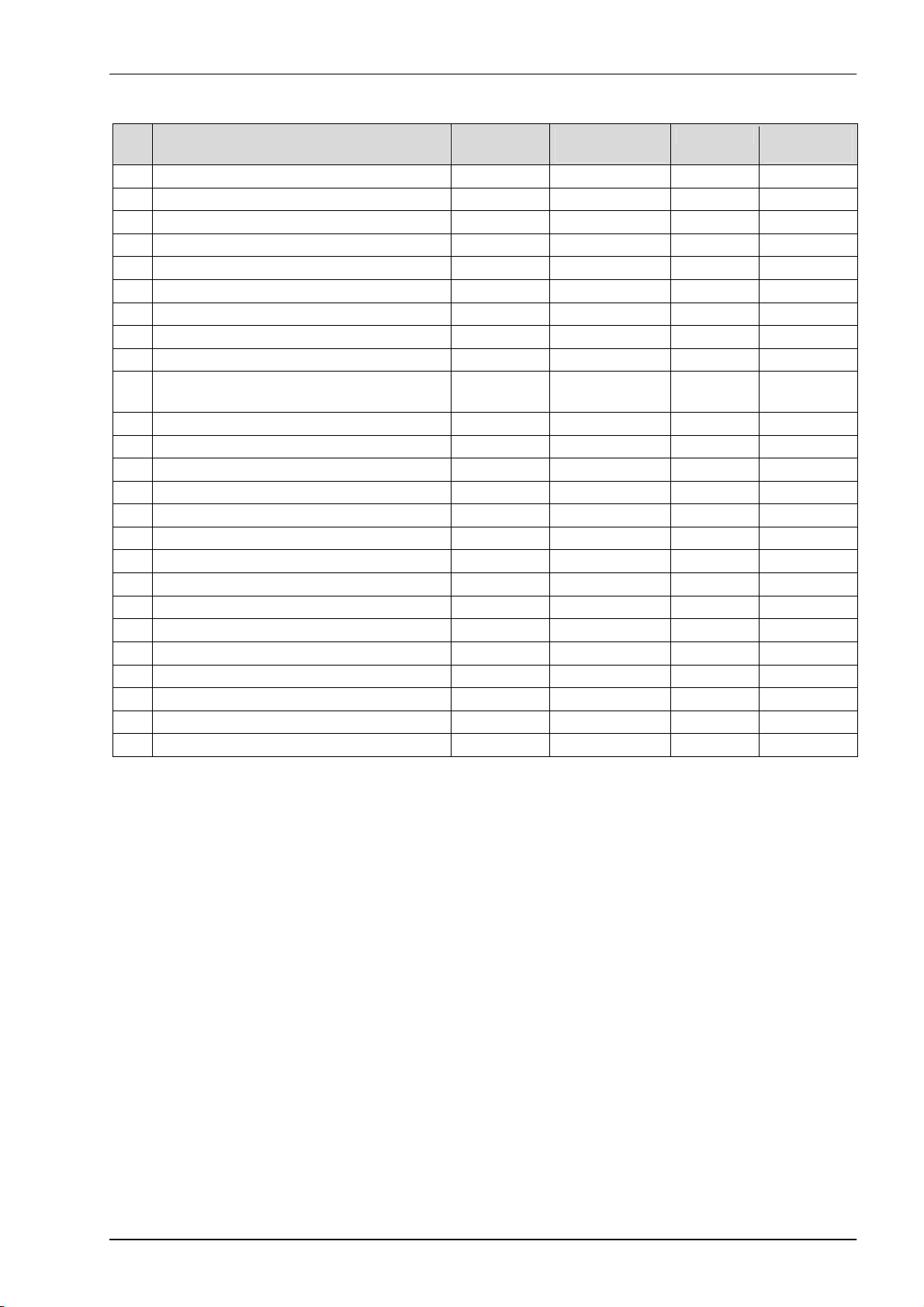

Fuses

F36

Grain tank extension

12 V grain tank drive

F37

F38

Work light

F39

Chopper On/Off pushbutton

F40

Vehicle lighting switch 12 V

F41

Warning beacon

12 V horn / wiper and washer system

F42

F43

Position light, left-hand

F44

Position light, right-hand

F45

Left-hand full beam relay

F46

Left-hand dipped beam relay

F47

Right-hand full beam relay

Right-hand dipped beam relay

F48

F49

Table adjustment

F50

Grain tank extension

F51

Ignition diagnosis plug

F52

Instrument lighting

F53

Returns lighting

Uni-spreader/Autopilot module

F54

F55

Worklight switch

F56

Spare module

F57

Spare module

F58

Spare (connector H)

Engine diagnosis

F59

F60

12 V sockets LP/HP

F61

###

F62

Outside railing worklights relay

F63

12 V sensors power supply

F64

###

###

F65

F70

Ignition switch back-up fuse

ZE-s-6 Lex-e-ZE 03/04

Page 13

TIC LEXION Montana Electric System

Key to diagram:

K1

K2

K3

K4

K5

K6

K7

K8

K9

K10

K13

K14

K15

K16 Cutterbar

K20

K23

K24

K25

K26

K27

K28

K29 Drum speed adjustment relay

K30 Drum speed adjustment relay

K31

K32

K33 Concave clearance +

K34 Concave clearance K35 Front attachment speed +

K36 Front attachment speed K37

K38

K39 Reel speed K40 Reel speed +

Relays

Raise reel

Lower reel

Reel forward

Reel backward

Raise cutterbar

Lower cutterbar

Cutterbar left-hand cross levelling

Cutterbar right-hand cross levelling

Table adjustment forward

Table adjustment backward

Threshing mechanism On/Off

Threshing mechanism On/Off

Cutterbar

Lighting main relay

Alternator

Air conditioner relay

Left-hand full beam relay

Right-hand full beam relay

Left-hand dipped beam relay

Right-hand dipped beam relay

Grain tank extension up

Grain tank extension down

Fan speed +

Fan speed -

03/04 Lex-e-ZE ZE-s-7

Page 14

Electric System LEXION Montana TIC

Key to diagram:

K41

K42

K43

K44

K45

K46

K47

K48

K49

K50

K51

K53

K54

K55

K56

K57

K58

K59

K61

K62

K63

K64 Reel speed relay

K67

K68

K69

K70 Grain tank unloading relay

Relays

Upper sieve adjustment -

Upper sieve adjustment +

Lower sieve adjustment -

Lower sieve adjustment +

Work lights

Grain tank unloading tube swing time relay

Flash relay USA

Indicator relay Europe

Road travel main relay

Work lights relay

Relay 15

Start relay

Rotor variator +

Rotor variator -

Plus 15 power supply

Transducer

Alternator relay

Work lights relay

Warning beacon

Warning beacon grain tank 70% full

Fan speed relay

Spare relay

Spare relay

Spare relay

ZE-s-8 Lex-e-ZE 03/04

Page 15

TIC LEXION Montana Electric System

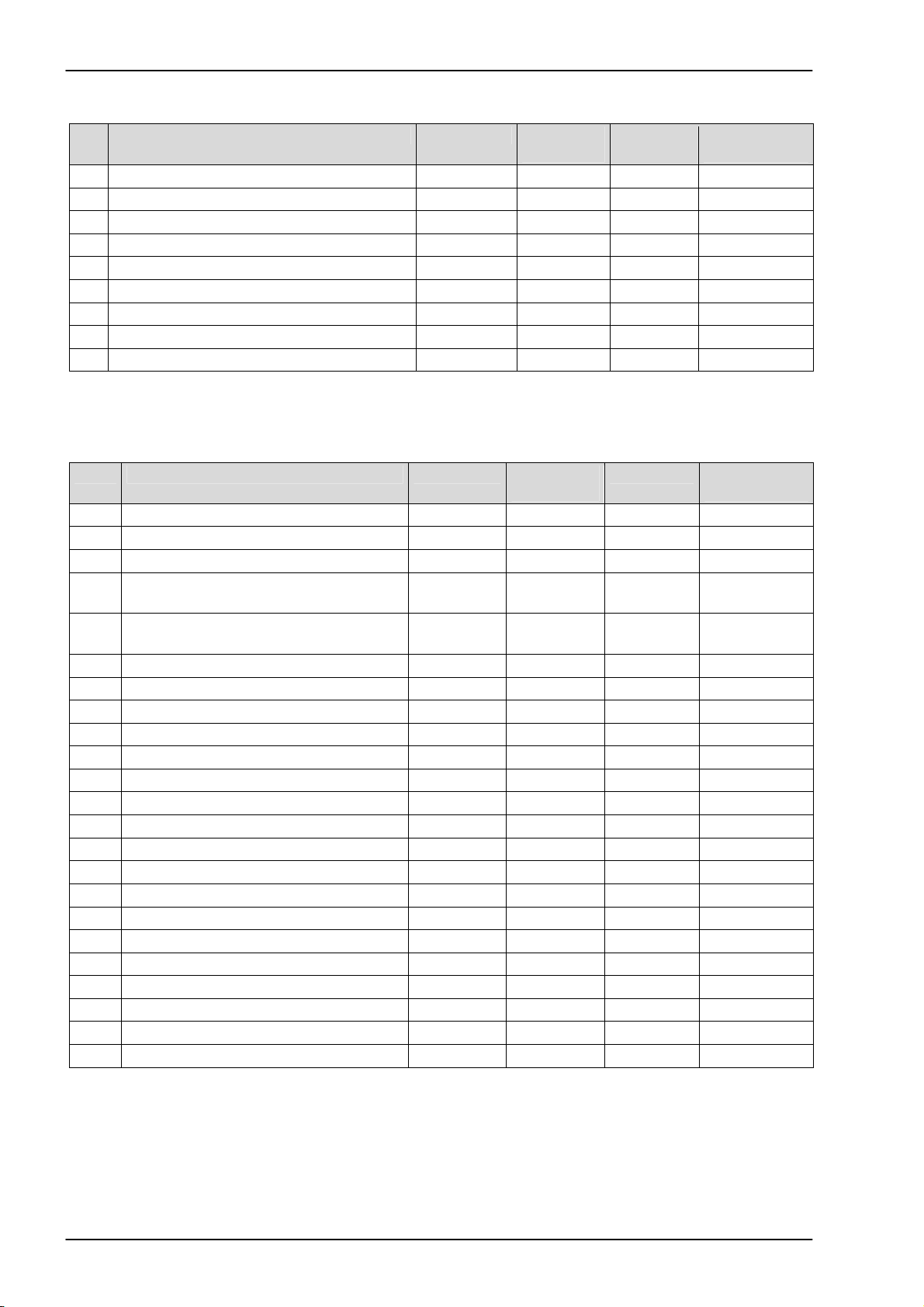

Module A35 - Montana control unit, for Montana machines (with RIO module A50)

Pin Function Component Measuring

variable

1 Earth A41 Earth Output 05S

2 CAN Low Montana A41 - Output 05S

3 CAN High Montana A41 - Output 05S

4 Power supply (CAN) A41 12 V Output 05S

5 not used --- --- --- ---

6 Parking brake signal S93 12 V Input 41S

7 Montana cross levelling sensor signal B94 0.25-4.75 V Input 41S

8 Montana feed rake conveyor sensor signal B95 0.25-4.75 V Input 41S

9 Right-hand axle angle sensor signal B92 0.25-4.75 V Input 41S

10 not used --- --- --- ---

11 Oil quantity increase Y118 12 V Output 41S

12 Master valve (Montana) Y128 12 V Output 4S, 4t

13 Lower axle, right-hand side Y116 12 V Output 41S

14 Raise axle, right-hand side Y117 12 V Output 41S

15 Rotate front attachment to the right Y112 12 V Output 41S

16 Lower cutting angle Y111 12 V Output 41S

17 Power supply (K69) --- 12 V Input 41S, 4S

18 Power supply (K69) --- 12 V Input 41S, 4S

19 RS 232 --- --- --- 05S

20 RS 232 --- --- --- 05S

21 RS 232 --- --- --- 05S

22 RS 232 (Boot) --- --- --- 05S

23 not used --- --- --- ---

24 Earth sensors B91, B92,

B93, B94,

B95

25 Cutting angle sensor signal B93 0.25-4.75 V Input 41S

26 Left-hand axle angle sensor signal B91 0.25-4.75 V Input 41S

27 Power supply of sensors B91, B92,

B93, B94,

B95

28 not used --- --- --- ---

29 Master valve (Working hydraulics) Y77 12 V Output 4S

30 Lower axle, left-hand side Y114 12 V Output 41S

31 Raise axle, left-hand side Y115 12 V Output 41S

32 Rotate front attachment to the left Y113 12 V Output 41S

33 Raise cutting angle Y110 12 V Output 41S

34 Earth --- Earth Input 41S, 4S

35 Earth --- Earth Input 41S, 4S

Earth Output 41S

12 V Output 41S

Direction Circuit

diagram no.

03/04 Lex-e-ZE ZE-s-9

Page 16

Electric System LEXION Montana TIC

Module A35 - Montana control unit, for Montana machines (with HBM module A45)

Pin Function Component Measuring

variable

1 Power supply (K69) --- 12 V Input 41t, 4t

2 Lower axle, left-hand side Y114 12 V Output 41t

3 Raise axle, left-hand side Y115 12 V Output 41t

4 Raise axle, right-hand side Y117 12V Output 41t

5 Lower axle, right-hand side Y116 12 V Output 41t

6 Rotate front attachment to the left Y113 12 V Output 41t

7 Rotate front attachment to the right Y112 12 V Output 41t

8 Raise cutting angle Y110 12 V Output 41t

9 Lower cutting angle Y111 12 V Output 41t

10 Master valve (Montana) Y128 12 V Output 4t

11 Master valve (Working hydraulics) Y77 12 V Output 4t

12 Oil quantity increase Y118 12 V Output 41t

13 not used --- --- --- ---

14 Earth --- Earth Input 41t

15 Power supply (K69) --- 12 V Input 41t, 4t

16 Left-hand axle angle sensor signal B91 0.25-4.75 V Input 41t

17 Montana cross levelling sensor signal B94 0.25-4.75 V Input 41t

18 not used --- --- --- ---

19 not used --- --- --- ---

20 not used --- --- --- ---

21 CAN Low (Inclinometer) B126 - Output 05t

22 not used --- --- --- ---

23 CAN Low (Montana) A41 - Output 05t

24 Earth A41 Earth Output 05t

25 RS 232 --- --- --- 05t

26 RS 232 --- --- --- 05t

27 not used --- --- --- ---

28 Earth --- Earth Input 41t

29 Power supply (K69) --- 12 V Input 4t

30 Right-hand axle angle sensor signal B92 0.25-4.75 V Input 41t

31 Cutting angle sensor signal B93 0.25-4.75 V Input 41t

32 Parking brake signal S93 12V Input 41t

33 Earth sensors B91, B92,

B93, B94,

B95, B126

34 not used --- --- --- ---

35 not used --- --- --- ---

36 CAN High (Inclinometer) B126 - Output 05t

37 Power supply (CAN) A41 12 V Output 05t

38 CAN High (Montana) A41 - Output 05t

39 RS 232 (Boot) --- --- --- 05t

40 RS 232 --- --- --- 05t

41 not used --- --- --- ---

42 not used --- --- --- ---

Earth Output 41t

Direction Circuit

diagram no.

ZE-s-10 Lex-e-ZE 03/04

Page 17

TIC LEXION Montana Electric System

Module A36 - Montana gearshift module

Pin Function Component Measuring

variable

1 Earth --- Earth Input 42s, 42t

2 Power supply (+15) K56 12 V Input 42s, 42t

3 Gearbox shifting release S90 12 V Output 42s, 42t

4 2nd gear signal Z83 12 V Input 42s, 42t

5 1st gear signal Z82 12 V Input 42s, 42t

6 Gearbox shift 1st gear Y107 12 V Output 42s, 42t

7 Gearbox shift 2nd gear Y108 12 V Output 42s, 42t

8 Ground speed control lever neutral signal Z57 Earth Input 1s;42s, 42t

9 Ground drive control pressure circuit SH Y125 12 V Output 42s, 42t

10 Engine speed maximum

reduced

--- 12 V – 1st gear

0 V – 2

nd

gear

11 Engine speed (Gearshift control) --- 12 V Input 42s, 42t

12 Parking brake circuit Y123 12 V Input 42s, 42t

13 Shifting aid uphill signal Y121 12 V Input 42s, 42t

14 Shifting aid downhill signal Y122 12 V Input 42s, 42t

15 Working hydraulics master valve Y77 12 V Output 4s, 4t

16 Working hydraulics master valve Y77 12 V Output 4s, 4t

17 Montana master valve Y128 12 V Output 4s, 4t

18 Montana master valve Y128 12 V Input 4s, 4t

19 Montana master valve Y128 12 V Input 4s

20 Working hydraulics master valve Y77 12 V Input 4s, 4t

21 Working hydraulics master valve Y77 12 V Input 4s, 4t

22 Working hydraulics master valve Y77 12 V Input 4s, 4t

23 Working hydraulics master valve Y77 12 V Input 4s, 4t

24 Shifting aid Y121; Y122 12 V Output 42s, 42t

25 not used --- --- --- ---

Direction Circuit

diagram no.

Output 42s, 42t

03/04 Lex-e-ZE ZE-s-11

Page 18

Electric System LEXION Montana TIC

Module A45 - Ground drive hydraulic motor brake restrictor (HBM)

Pin Function Component Measuring

variable

1 --- --- --- --- ---

2 Master valve Y77 12 V Output 42t

3 CAN high - - - 6t

4 Power +15 K51/87 12 V Input 6t

5 --- --- --- --- ---

6 Earth (GND) -31 Earth Input 6t

7 --- --- --- --- ---

8 Brake restrictor Y124 12 V Output 42t

9 CAN low - - - 6t

Module A50 - Montana RIO module

Pin Function Component Measuring

variable

R0/1 +12 V electronic unit --- --- --- ---

R0/2 +12 V power --- --- --- ---

R0/3 Output 1 Montana master valve Y128 12 V Output 4s, 42s

R0/4 Ground drive hydraulic motor brake

restrictor (output 3)

R0/5 Working hydraulics

master valve output 2

R0/6 Output 4 --- --- --- ---

R0/7 Sensor 1 --- --- --- ---

R0/8 Sensor 2 --- --- --- ---

R0/9 Earth --- --- --- ---

R0/10 Earth --- --- --- ---

R0/11 Module code 1 --- --- --- ---

R0/12 Module code 2 --- --- --- ---

R0/13 Module code 3 --- --- --- ---

R0/14 Module code 4 --- --- --- ---

R0/15 Sensor 3 --- --- --- ---

R0/16 Sensor 4

R1/1 CAN low --- --- --- 6s

R1/2 +12 V electronic unit --- 12 V Input 2s, 6s

R1/3 +12 V power --- 12 V Input 2s, 6s

R1/4 CAN high --- --- --- 6s

R1/5 Earth --- Earth Input 6s

R1/6 Earth --- Earth Input 6s

Y124 12 V Output 42s

Y77 12 V Output 4s, 42s

Direction Circuit

diagram no.

Direction Circuit

diagram no.

ZE-s-12 Lex-e-ZE 03/04

Page 19

01s

Main power supply,

Diesel engine electric starting motor

for Montana machines

Page 20

Electric System LEXION Montana TIC

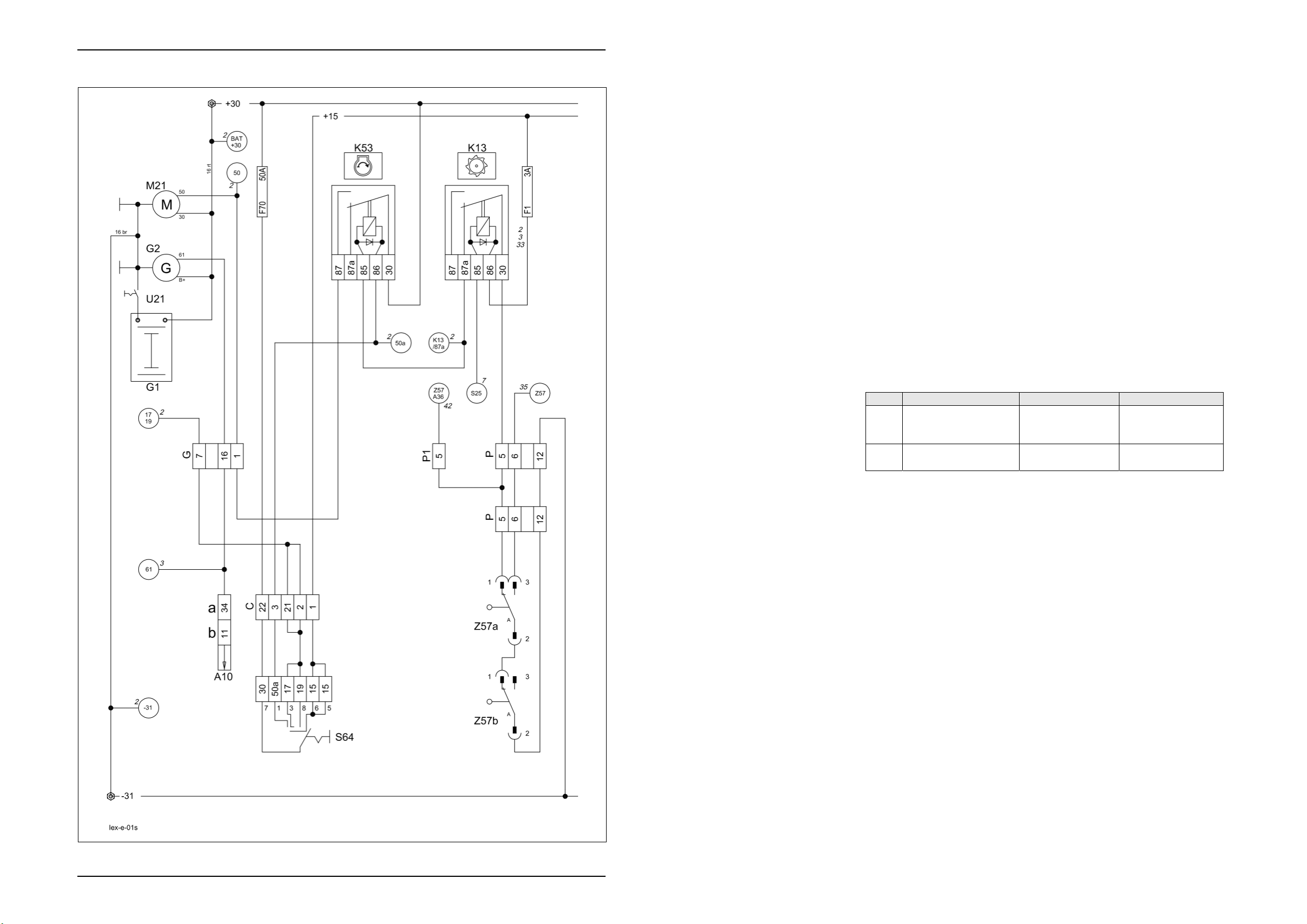

01s - Main power supply, diesel engine electric starting motor, for Montana machines

Key to diagram:

Coordinates

A10 Fieldwork computer module (BIF/CAB) ............................. 2-h-20

G1 Battery................................................................................ 7-n-21

G2 Generator........................................................................... 1-g-17

K13 Threshing mechanism relay............................................... 3-h-20

K53 Start relay........................................................................... 3-h-20

M21 Electric starting motor ........................................................ 3-n-19

S64 Ignition switch ..................................................................... 3-f-18

U21 Battery isolating switch ...................................................... 6-o-20

Z57 Ground speed control lever

neutral position switch - safety start switch ....................... 3-g-18

Measured value table:

Item Component Measured value Remark

K13 Remote control relay

15 A

30 A

K53 Remote control relay

70 A

95±10 Ω

115±10 Ω

(Pin 86/1 – 85/2)

(Pin 87a/4 – 30/3)

(Pin 87/5 – 30/3)

(Pin 86/1 – 85/2)

(Pin 87/5 – 30/3)

1s-2 Lex-e-01s 03/04

Page 21

TIC LEXION-Montana Electric System

Description of function:

Montana machine: In this circuit, the difference between the standard machine and the

Diesel engine electric

starting motor

Montana machine is only in a cable branch at connector P to P1. The

signal of ground speed control lever in neutral position (Z57) is required

on Montana machines for releasing the gear shifting.

As a safety start switch, relay K53 is supplied with earth only when

switches (Z57a/Z57b) on the ground speed control lever are in neutral

position and the threshing mechanism is disengaged via relay K13. The

ignition lock (S64) then actuates the diesel engine starting motor (M21)

via relay K53 with +50a.

03/04 Lex-e-01s 1s-3

Page 22

Electric System LEXION Montana TIC

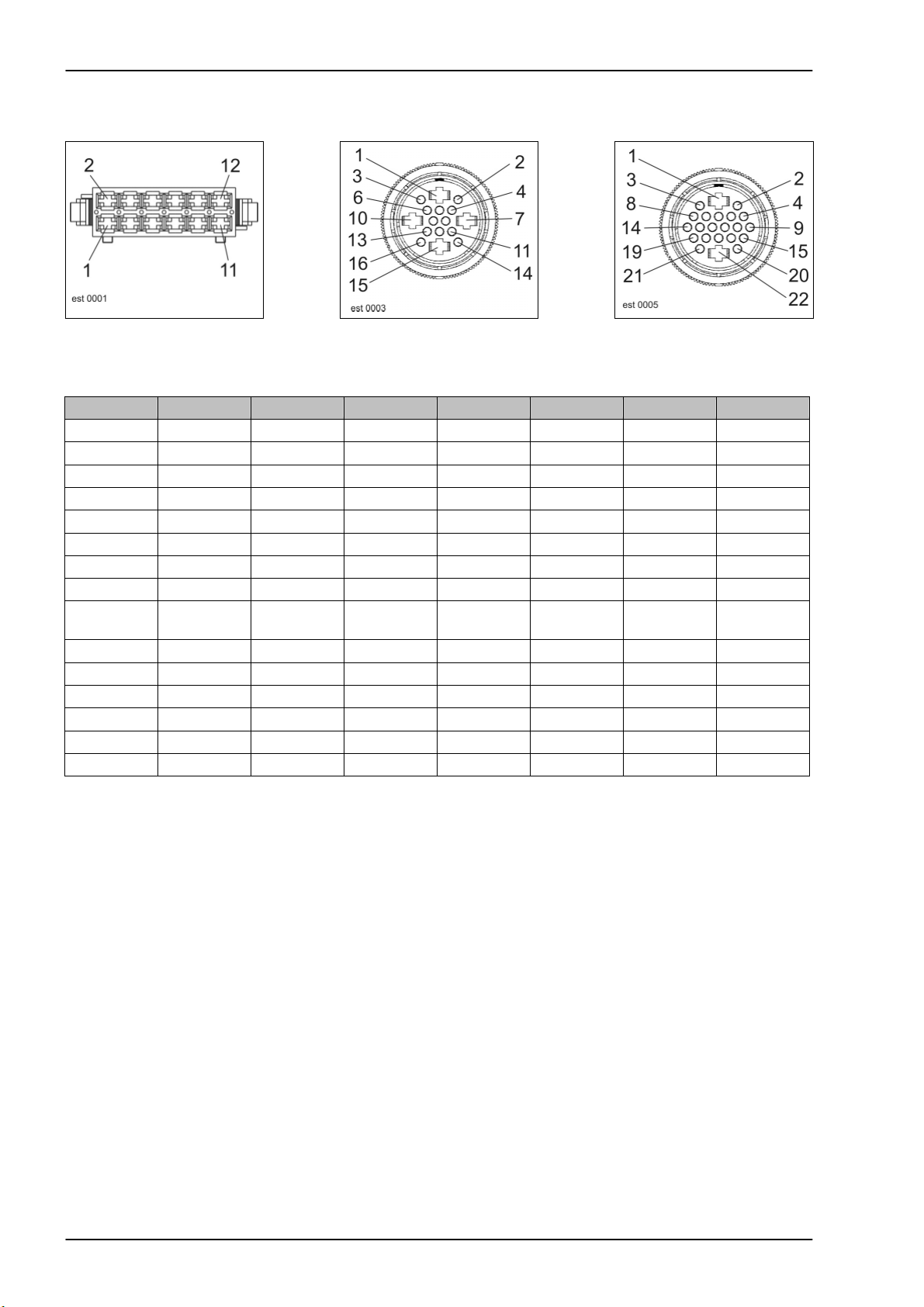

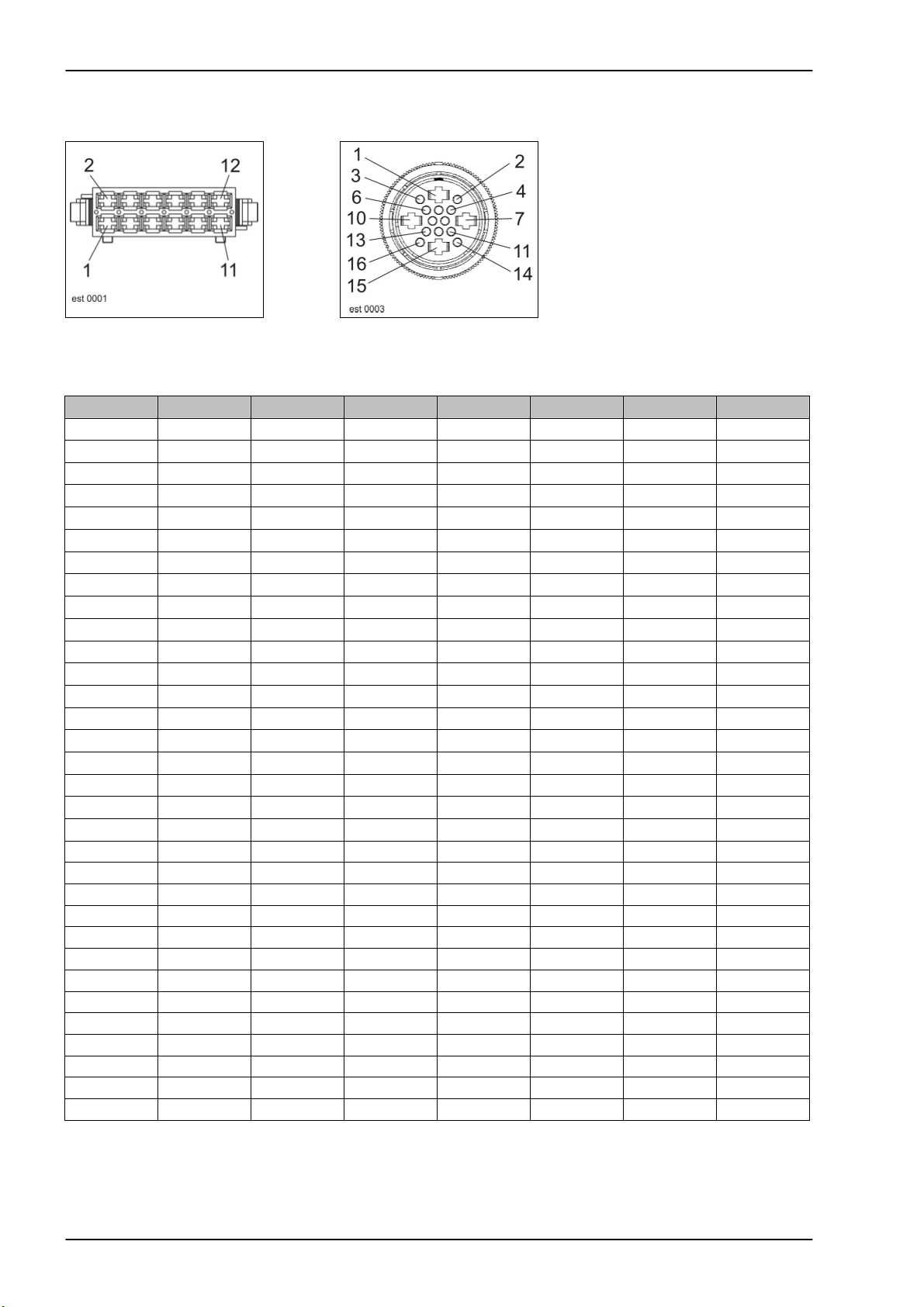

Connector pin definition:

Connector P, P1 Connector G Connector C

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

C-1 15 6 bk

C-2 G-7 C-21 1.5 bk-rd

C-3 K53-86 K56-86 K52-86 0.75 bk-ye

C-21 G-7 C-2 1.5 bk-rd

C-22 30 6 rd

G-1 K53-87 DS-43 4 bk-ye

G-7 C-2 C-21 1.5 bk-rd

G-16 C-18 K58-86 Cab-34 /

P-5 K13-30 1.5 vi-br

P-6 X-7 DI-7 1.5 vi-ye

P-12 31 2.5 br

P1-5 P-5 A36-8 1.5 vi-bl

0.75 bl

Bif-11

1s-4 Lex-e-01s 03/04

Page 23

02s

Starting the diesel engine,

Diesel engine speed adjustment

for Montana machines

Page 24

Electric System LEXION Montana TIC

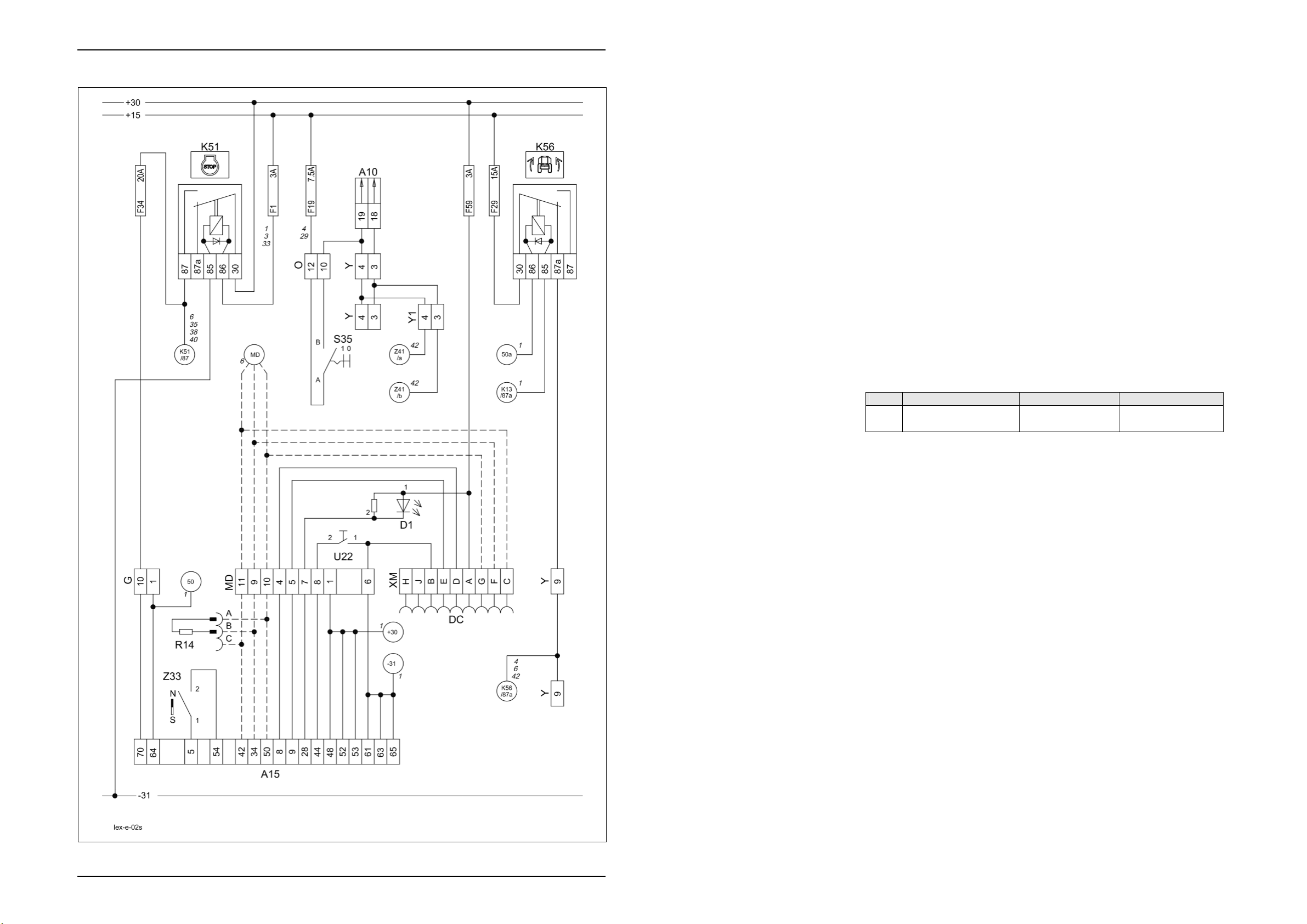

02s - Starting the diesel engine, diesel engine speed adjustment - for Montana machines

Key to diagram:

Coordinates

A10 Fieldwork computer module (BIF/CAB) ............................. 2-h-20

A15 Electronic engine control module ...................................... 2-o-18

D1 Diesel engine error code LED............................................ 3-h-20

DC Caterpillar diagnosis .......................................................... 3-h-20

K51 Ignition switch relay ........................................................... 3-h-20

K56 Montana relay .................................................................... 3-h-20

R14 CAN bus matching resistor (J1939)................................... 3-h-20

S35 Engine speed adjustment switch ....................................... 3-g-17

U22 Diesel engine diagnosis switch.......................................... 3-h-20

Z33 Coolant level switch without engine cut-off system .......... 1-m-17

Measured value table:

Item Component Measured value Remark

K51 Remote control relay

70 A

115±10 Ω

(Pin 86/1 – 85/2)

(Pin 87/5 – 30/3)

2s-2 Lex-e-02s 03/04

Page 25

TIC LEXION Montana Electric System

Description of function:

Montana machine: In this circuit, the difference between the standard machine and the

Starting The safety start switch circuit of this engine is identical with the one used

Engine monitoring All sensors relevant for operation and monitoring of the engine are

Engine diagnosis The number of the engine errors occurred and the corresponding error

Diesel engine speed

adjustment

LEXION

Montana

Montana machine is only in a cable branch at connector Y to Y1. The

gearbox switch on connector Y is dropped for Montana machines.

The Montana functions are supplied with power via the unactuated relay

K56. During the starting process, relay K56 is actuated and thus interrupts

the power supply.

on the mechanically controlled engines.

The engine controller module (A15) is activated via relay K51 by the

ignition lock (S64). During the starting procedure, the engine controller

module (A15) receives the speed signal from the sensor provided on the

camshaft and starts the injection.

mounted on the engine wiring loom. Only the water level sensor is

connected to the CLAAS wiring loom.

The engine controller module (A15) transmits the signals for displaying

the engine speed and the coolant temperature to the CAB module (A10)

via the CAN bus J1939. The CAN module (A10) converts this signal to the

CLAAS CAN bus, thus allowing display on the terminal.

codes can be displayed in the terminal

(see also the error code list in the Electric System documentation

297550.x - Diagram 2e).

Further diagnosis is carried out via the diagnosis plug in the central

terminal compartment, using the Caterpillar diagnosis tool CAT-ET. The

display of error codes can also be activated by the diagnosis LED (D1)

after actuating the rocker switch (U22).

The diesel engine speed depends on the position of switch S35 and of the

2nd gear actual value switch (Z83) – see also circuit diagram 42s.

If full throttle speed is selected and the 2nd gear engaged (signal input

A36 / pin 4), the connection between Z41a and Z41b inside the Montana

gearshift control module (A36) is cut (pins 10 and 11) – see also circuit

diagram 42s.

The full throttle speed is reduced to road travel speed, depending on the

contry version. The maximum speed which can be achieved now can be

configured using the Claas diagnosis system CDS.

Type

470-420

Idle speed

(S35)

1200 rpm 2100 rpm 1568 rpm 1960 rpm

Full throttle at

no load

(S35)

20km/h

(Z83)

25km/h

(Z83)

03/04 Lex-e-02s 2s-3

Page 26

Electric System LEXION Montana TIC

Connector pin definition:

Connector MD, O, Y, Y1 Connector G

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

G-1 K53-87 DS-43 A15-64 M21-50 4 bk-ye

G-10 F34-A DS-4 A15-70 4 bk-rd

Y-3 W-7 DS-2 Cab-18 1.5 br-wh

Y-4 W-6 DS-1 O-10 Cab-19 1.5 br-ye

Y-9 K56-87a DS-3 1.5 bk

O-10 W-6 DS-1 Y-4 Cab-19 1.5 wh-rd

O-12 F19-A 2.5 bk

MD-1 30 A15-48 A15-52 A15-53 0.5 wh

MD-4 A15-8 XM-D 0.5 wh

MD-5 A15-9 XM-E 0.5 wh

MD-6 31 A15-61 A15-62 A15-63 XM-B

U22-1 0.5 wh

MD-7 A15-28 D2-K 0.5 wh

MD-8 A15-44 U22-2 0.5 wh

MD-9 A15-34 R14-B 0.5 wh

MD-10 A15-50 R14-A 0.5 wh

MD-11 A15-42 R14-C 0.5 wh

XM-A F59-A 0.5 wh

XM-B MD-6 U22-1 0.5 wh

XM-C MD-11 0.5 wh

XM-D MD-4 0.5 wh

XM-E MD-5 0.5 wh

XM-F MD-9 0.5 wh

XM-G MD-10 0.5 wh

Y1-3 Y-3 A36-10 1.5 br-gr

Y1-4 Y-4 A36-11 1.5 br-ye

Y1-9 Y-9 A50-RI-2+3 XSA-C4 XSA-B5 A36-2 1.5 bk

2s-4 Lex-e-02s 03/04

Page 27

4s

Road travel activation, master valve

for Montana machines (with RIO module A50)

Page 28

Electric System LEXION Montana TIC

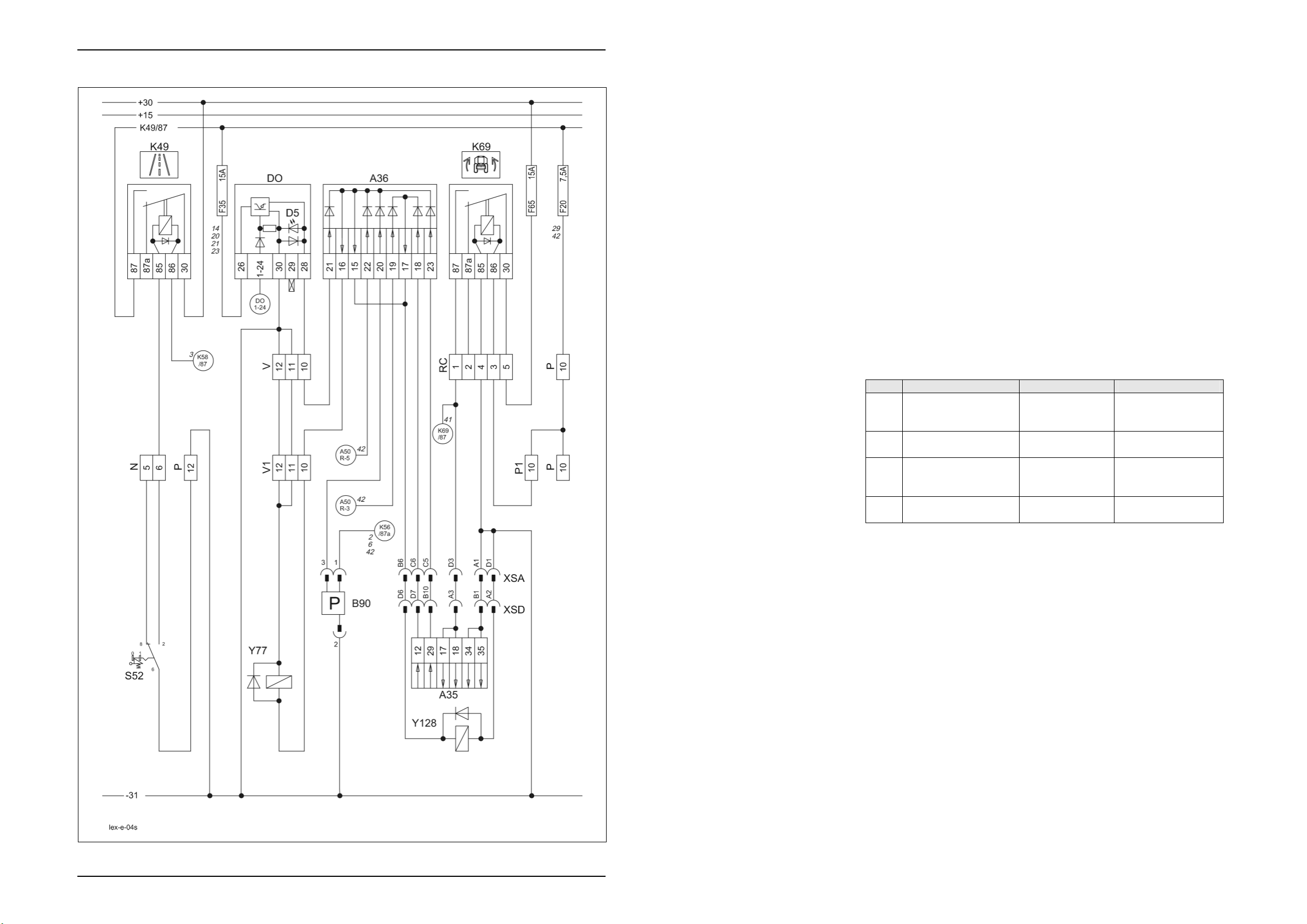

04s - Road travel activation, working hydraulics master valve, for Montana machines with module A50 (RIO)

Key to diagram:

Coordinates

A35 Montana control unit module ...............................................7-i-18

A36 Montana gearshift control module ..................................... 2-h-20

B90 Brake accumulator pressure sensor/switch....................... 5-g-20

DO Master valve diode PCB .................................................... 3-h-20

D5 Master valve DO diode PCB LED...................................... 3-h-20

K49 Road travel main relay....................................................... 3-h-20

K69 Montana relay .................................................................... 3-h-20

S52 Road travel switch (red)..................................................... 3-g-17

Y77 Working hydraulics master valve solenoid coil ................. 6-m-21

Y128 Montana master valve solenoid coil .................................. 7-h-18

Measured value table:

Item Component Measured value Remark

B90 Brake circuit oil

pressure / charge

pressure

K49 Remote control relay

70 A

K69 Remote control relay

15 A

30 A

Y77

Y128

Solenoid coil 3.8 A

ON

OFF

115±10 Ω

95±10 Ω

3.2 Ω

< 135 bar

> 165 bar

(Pin 86/1 – 85/2)

(Pin 87/5 – 30/3)

(Pin 86/1 – 85/2)

(Pin 87a/4 – 30/3)

(Pin 87/5 – 30/3)

4s-2 Lex-e-04s 03/04

Page 29

TIC LEXION Montana Electric System

Description of function:

Montana machine: On Montana machines, actuation of the working hydraulics master valve

Activation of road travel During road travel, the road travel switch (S52) must be locked in order to

Working hydraulics master

valve

Montana axle hydraulics

master valve

Montana brake pressure

accumulator

Increased brake effect

Montana – only with module

A50 (RIO)

(Y77) is always via the gearshift control module (A36).

cut the power supply for all unnecessary electrical and hydraulic

functions.

In order to be able to build up the necessary working pressure for many

hydraulic controls, the neutral hydraulic circulation must be blocked (see

also the "Hydraulic system" section). In this case, the solenoid coil (Y77)

is actuated in parallel with the function directly via the diode PCB (DO)

and the gearshift control module (A36).

A LED (D5) provided on the diode PCB indicates the activation of the

circuit.

For the Montana functions as well, the circulation of the independent axle

control system hydraulics must be blocked (see also "Hydraulic System"

document).

According to the actuated functions, the Montana control unit (A35)

actuates the Montana master valve (Y128) and/or the working hydraulics

master valve (Y77) via the gearshift control module (A36).

The sensor/switch (B90) controls the brake system accumulator pressure

and, if necessary, actuates the working hydraulics master valve (Y77) via

the gearshift control module (A36) in order to recharge the brake circuit

accumulator.

If the diesel engine speed drops below 2300 rpm while braking, the RIO

module (A50) actuates the working hydraulics master valve (Y77) via

A50/pin R5 and the axle hydraulics master valve (Y128) via A50/pin R3.

This hydraulic load on the diesel engine increases the braking effect. In

addition, a brake restrictor is activated in the hydrostatic ground drive –

circuit diagram 42s.

03/04 Lex-e-04s 4s-3

Page 30

Electric System LEXION Montana TIC

Connector pin definition:

Connector N, P, P1, V, V1 Connector XSA Connector XSA

Connector XSD Connector XSD

Interconnection list: I

from to 1 to 2 to 3 to 4 to 5 mm² Colour

N-5

N-6 K49-85 0.5 br-bl

P-10 F20-A 1.5 gn-rd

P-12 31 2.5 br

V-10 DO-28 A36-21 DS-50 1.5 pi-wh

V-11 31 2.5 br

V-12 31 2.5 br

P1-10 P-10 1.5 gn-rd

V1-10 A36-15+16 1.5 wh-pi

V1-11 V-11 2.5 br

V1-12 V-12 2.5 br

4s-4 Lex-e-04s 03/04

Page 31

TIC LEXION Montana Electric System

Interconnection list: II

from to 1 to 2 to 3 to 4 to 5 mm² Colour

XSA-A1 XSD-B1 1.5 br

XSA-B6 XSD-D6 1.5 gr-bl

XSA-C5 XSD-B10 1.5 rd-wh

XSA-C6 XSD-D7 1.5 gn-bk

XSA-D1 XSD-A2 4 br

XSA-D3 XSD-A3 4 rd-bk

XSD-A2 XSA-D1 1.5 br

XSD-A3 XSA-D3 1.5 gr-bl

XSD-B1 XSA-A1 1.5 rd-wh

XSD-B10 XSA-C5 1.5 gn-bk

XSD-D6 XSA-B6 4 br

XSD-D7 XSA-C6 4 rd-bk

03/04 Lex-e-04s 4s-5

Page 32

Electric System LEXION Montana TIC

4s-6 Lex-e-04s 03/04

Page 33

4t

Road travel activation, master valve

for Montana machines with module A45 (HBM)

Page 34

Electric System LEXION Montana TIC

04t - Road travel activation, working hydraulics master valve, for Montana machines with module A45 (HBM)

Key to diagram:

Coordinates

A35 Montana control unit module ...............................................7-i-18

A36 Montana gearshift control module ..................................... 2-h-20

B90 Brake accumulator pressure sensor/switch....................... 5-g-20

DO Master valve diode PCB .................................................... 3-h-20

D5 Master valve DO diode PCB LED...................................... 3-h-20

K49 Road travel main relay....................................................... 3-h-20

K69 Montana relay .................................................................... 3-h-20

S52 Road travel switch (red)..................................................... 3-g-17

Y77 Working hydraulics master valve solenoid coil ................. 6-m-21

Y128 Montana master valve solenoid coil .................................. 7-h-18

Measured value table:

Item Component Measured value Remark

B90 Brake circuit oil

pressure / charge

pressure

K49 Remote control relay

70 A

K69 Remote control relay

15 A

30 A

Y77

Y128

Solenoid coil 3.8 A

ON

OFF

115±10 Ω

95±10 Ω

3.2 Ω

< 135 bar

> 165 bar

(Pin 86/1 – 85/2)

(Pin 87/5 – 30/3)

(Pin 86/1 – 85/2)

(Pin 87a/4 – 30/3)

(Pin 87/5 – 30/3)

4t-2 Lex-e-04t 03/04

Page 35

TIC LEXION Montana Electric System

Description of function:

Montana machine: On Montana machines, actuation of the working hydraulics master valve

Activation of road travel During road travel, the road travel switch (S52) must be locked in order to

Working hydraulics master

valve

Montana axle hydraulics

master valve

Montana brake pressure

accumulator

Increased brake effect

Montana – only with module

A45 (HBM)

(Y77) is always via the gearshift control module (A36).

cut the power supply for all unnecessary electrical and hydraulic

functions.

In order to be able to build up the necessary working pressure for many

hydraulic controls, the neutral hydraulic circulation must be blocked (see

also the "Hydraulic system" section). In this case, the solenoid coil (Y77)

is actuated in parallel with the function directly via the diode PCB (DO)

and the gearshift control module (A36).

A LED (D5) provided on the diode PCB indicates the activation of the

circuit.

For the Montana functions as well, the circulation of the independent axle

control system hydraulics must be blocked (see also "Hydraulic System"

document).

According to the actuated functions, the Montana control unit (A35)

actuates the Montana master valve (Y128) and/or the working hydraulics

master valve (Y77) via the gearshift control module (A36).

The sensor/switch (B90) controls the brake system accumulator pressure

and, if necessary, actuates the working hydraulics master valve (Y77) via

the gearshift control module (A36) in order to recharge the brake circuit

accumulator.

If the diesel engine speed drops below 2300 rpm while braking, the HBM

module (A45) actuates the working hydraulics master valve (Y77) via

A36/pin 22 – Circuit diagram. This hydraulic load on the diesel engine

increases the braking effect.

In addition, a brake restrictor (Y124) is activated in the hydrostatic ground

drive – circuit diagram 42t.

03/04 Lex-e-04t 4t-3

Page 36

Electric System LEXION Montana TIC

Connector pin definition:

Connector N, P, P1, V, V1 Connector XSA Connector XSA

Connector XSD Connector XSD

Interconnection list: I

from to 1 to 2 to 3 to 4 to 5 mm² Colour

N-5

N-6 K49-85 0.5 br-bl

P-10 F20-A 1.5 gn-rd

P-12 31 2.5 br

V-10 DO-28 A36-21 DS-50 1.5 pi-wh

V-11 31 2.5 br

V-12 31 2.5 br

P1-10 P-10 1.5 gn-rd

V1-10 A36-15+16 1.5 wh-pi

V1-11 V-11 2.5 br

V1-12 V-12 2.5 br

4t-4 Lex-e-04t 03/04

Page 37

TIC LEXION Montana Electric System

Interconnection list: II

from to 1 to 2 to 3 to 4 to 5 mm² Colour

XSA-A1 XSD-B1 1.5 br

XSA-B6 XSD-D6 1.5 gr-bl

XSA-C5 XSD-B10 1.5 rd-wh

XSA-C6 XSD-D7 1.5 gn-bk

XSA-D1 XSD-A2 4 br

XSA-D3 XSD-A3 4 rd-bk

XSD-A2 XSA-D1 1.5 br

XSD-A3 XSA-D3 1.5 gr-bl

XSD-B1 XSA-A1 1.5 rd-wh

XSD-B10 XSA-C5 1.5 gn-bk

XSD-D6 XSA-B6 4 br

XSD-D7 XSA-C6 4 rd-bk

03/04 Lex-e-04t 4t-5

Page 38

Electric System LEXION TIC

4t-6 Lex-e-04t 03/04

Page 39

5s

Terminal, keyboard,

rotary switch, printer

for Montana machines with module A50 (RIO)

Page 40

Electric System LEXION Montana TIC

05s - Terminal, keyboard, rotary switch, printer, for Montana machines with module A50 (RIO)

Key to diagram:

Coordinates

A30 Terminal ............................................................................. 3-f-17

A35 Montana control unit module

A41 Montana terminal ................................................................ 3-f-17

T11 Function pre-selection ........................................................ 3-f-17

T19 Minus .................................................................................. 3-f-17

T26 Plus ..................................................................................... 3-f-17

XD CAN bus (7-pin) terminal .................................................... 4-f-17

X3 Printer ................................................................................. 4-f-17

XD2 Connector (data loading) .................................................... 4-f-17

5s-2 Lex-e-05s 03/04

Page 41

TIC LEXION Montana Electric System

r

Desc

iption of function:

Connectors The connectors L and ML are connected with the signal outputs to the

Power supply /

communication

Montana terminal (A41)

Connector XD2 Connector XD2 is used for loading the software of the Montana module

individual machine functions.

Connector A is connected with signal inputs from switches whose

actuated or non-actuated states allow the terminal to identify the machine

functions. The analog signals of the machine sensors are converted by

the corresponding modules (A10/A12) and read by the terminal as digital

signals from the CAN bus system.

The Montana terminal (A41) is supplied with power by the Montana

control unit module (A35) – see "Pin assignment in modules".

The Montana terminal (A41) performs all manual triggering of Montana

functions.

The Montana terminal (A41) communicates with the Montana control unit

module (A35) via an own CAN bus which is independent of the CLAAS

system.

(A35).

03/04 Lex-e-05s 5s-3

Page 42

Electric System LEXION Montana TIC

Connector pin definition:

Connector A Connector L Connector ML

Connector XD Connector XD2 Connector XSD

Connector XSD

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

ML-1 K35-86 0.5 rd-bl

ML-2 K36-86 0.5 rd-bk

ML-3 K54-86 0.5 br-wh

ML-4 K55-86 0.5 br-gr

ML-7 F-31A DS-56 1 bk-wh

ML-8 31 1 br

L-1 K29-86 0.5 ye-rd

L-2 K30-86 0.5 ye-br

L-3 K37-86 Cab-16 /

0.5 ye-bl

Bif-13

L-4 K38-86 Cab-2 /

0.5 ye-bk

Bif-12

L-5 K33-86 0.5 gr-wh

L-6 K34-86 0.5 gr-gn

L-7 K39-86 HAS-13 0.5 gr-rd

L-8 K40-86 HAS-25 0.5 gn-rd

L-9 K41-86 S-5 0.5 gn-br

L-10 K42-86 S-1 0.5 gn-bl

5s-4 Lex-e-05s 03/04

Page 43

TIC LEXION Montana Electric System

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

L-11 K43-86 S-7 0.5 gn-bk

L-12 K44-86 S-6 0.5 rd-wh

A-1 GY-1 0.5 wh

A-2 B-22 0.5 gn

A-3 B-21 0.5 ye

A-4 MN-4 DS-3 0.5 gr

A-5 B-20 W-11 DS-16 DA1-K K11-85

H-6 0.5 pi

A-6 G-2 K24-85 0.5 bl

A-7 B-19 0.5 rd

A-8 K11-87 DS-15 0.5 bk

A-9 MH-6 0.5 vi

A-10 MH-8 0.5 gr-pi

A-11 T-8 Y-2 0.5 rd-bl

A-12 G-6 DI-13 0.5 wh-gn

A-13 G-4 DI-12 0.5 br-gn

A-14 MH-5 K62-85 0.5 wh-ye

A-15 W-9 DI-4 0.5 ye-br

A-16 W-5 0.5 wh-gr

A-17 K23-87a G-13 0.5 gr-br

A-18 K57-49a C-20 0.5 gr

A-19 Cab-40 /

Bif-3

B-13 S-3 MV-3 MW-3 DS-62

E-31 MU-3 VGS-3 0.5 pi-br

A-20 Cab-13 /

Bif-16

B-14 S-9 MV-4 MW-4 DS-63

E-30 MU-4 VGS-16 0.5 wh-bl

A-21 F-32A 1 bk

A-22 31 1 br

A-23 F-51A DS-58 DS-59 1 rd

XSD - B5 0.5 wh-br

XSD - B6 0.5 pi

XSD - B7 0.5 wh-ye

XSD - B8 0.5 wh-rd

XSD - C1 0.5 wh-bl

XSD - C2 0.5 wh-gr

XSD - C3 0.5 wh-vi

XSD - C4 0.5 wh

DZW-3 MP-3 HAS-3 CAC-3

DZW-16 MP-4 HAS-16 CAC-16

03/04 Lex-e-05s 5s-5

Page 44

Electric System LEXION Montana TIC

5s-6 Lex-e-05s 03/04

Page 45

5t

Terminal, keyboard,

rotary switch, printer

for Montana machines with module A45 (HBM)

Page 46

Electric System LEXION Montana TIC

05t - Terminal, keyboard, rotary switch, printer, for Montana machines with module A45 (HBM)

Key to diagram:

Coordinates

A30 Terminal ............................................................................. 3-f-17

A35 Montana control unit module

A41 Montana terminal ................................................................ 3-f-17

T11 Function pre-selection ........................................................ 3-f-17

T19 Minus .................................................................................. 3-f-17

T26 Plus ..................................................................................... 3-f-17

XD CAN bus (7-pin) terminal .................................................... 4-f-17

X3 Printer ................................................................................. 4-f-17

XD2 Connector (data loading) .................................................... 4-f-17

5t-2 Lex-e-05t 03/04

Page 47

TIC LEXION Montana Electric System

r

Desc

iption of function:

Connectors The connectors L and ML are connected with the signal outputs to the

Power supply /

communication

Montana terminal (A41)

Connector XD2 Connector XD2 is used for loading the software of the Montana module

individual machine functions.

Connector A is connected with signal inputs from switches whose

actuated or non-actuated states allow the terminal to identify the machine

functions. The analog signals of the machine sensors are converted by

the corresponding modules (A10/A12) and read by the terminal as digital

signals from the CAN bus system.

The Montana terminal (A41) is supplied with power by the Montana

control unit module (A35) – see "Pin assignment in modules".

The Montana terminal (A41) performs all manual triggering of Montana

functions.

The Montana terminal (A41) communicates with the Montana control unit

module (A35) via an own CAN bus which is independent of the CLAAS

system.

(A35).

03/04 Lex-e-05t 5t-3

Page 48

Electric System LEXION Montana TIC

Connector pin definition:

Connector A Connector L Connector ML

Connector XD Connector XD2 Connector XSD

Connector XSD

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

ML-1 K35-86 0.5 rd-bl

ML-2 K36-86 0.5 rd-bk

ML-3 K54-86 0.5 br-wh

ML-4 K55-86 0.5 br-gr

ML-7 F-31A DS-56 1 bk-wh

ML-8 31 1 br

L-1 K29-86 0.5 ye-rd

L-2 K30-86 0.5 ye-br

L-3 K37-86 Cab-16 /

0.5 ye-bl

Bif-13

L-4 K38-86 Cab-2 /

0.5 ye-bk

Bif-12

L-5 K33-86 0.5 gr-wh

L-6 K34-86 0.5 gr-gn

L-7 K39-86 HAS-13 0.5 gr-rd

L-8 K40-86 HAS-25 0.5 gn-rd

L-9 K41-86 S-5 0.5 gn-br

L-10 K42-86 S-1 0.5 gn-bl

5t-4 Lex-e-05t 03/04

Page 49

TIC LEXION Montana Electric System

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

L-11 K43-86 S-7 0.5 gn-bk

L-12 K44-86 S-6 0.5 rd-wh

A-1 GY-1 0.5 wh

A-2 B-22 0.5 gn

A-3 B-21 0.5 ye

A-4 MN-4 DS-3 0.5 gr

A-5 B-20 W-11 DS-16 DA1-K K11-85

H-6 0.5 pi

A-6 G-2 K24-85 0.5 bl

A-7 B-19 0.5 rd

A-8 K11-87 DS-15 0.5 bk

A-9 MH-6 0.5 vi

A-10 MH-8 0.5 gr-pi

A-11 T-8 Y-2 0.5 rd-bl

A-12 G-6 DI-13 0.5 wh-gn

A-13 G-4 DI-12 0.5 br-gn

A-14 MH-5 K62-85 0.5 wh-ye

A-15 W-9 DI-4 0.5 ye-br

A-16 W-5 0.5 wh-gr

A-17 K23-87a G-13 0.5 gr-br

A-18 K57-49a C-20 0.5 gr

A-19 Cab-40 /

Bif-3

B-13 S-3 MV-3 MW-3 DS-62

E-31 MU-3 VGS-3 0.5 pi-br

A-20 Cab-13 /

Bif-16

B-14 S-9 MV-4 MW-4 DS-63

E-30 MU-4 VGS-16 0.5 wh-bl

A-21 F-32A 1 bk

A-22 31 1 br

A-23 F-51A DS-58 DS-59 1 rd

XSD - B5 0.5 wh-br

XSD - B6 0.5 pi

XSD - B7 0.5 wh-ye

XSD - B8 0.5 wh-rd

XSD - C1 0.5 wh-bl

XSD - C2 0.5 wh-gr

XSD - C3 0.5 wh-vi

XSD - C4 0.5 wh

DZW-3 MP-3 HAS-3 CAC-3

DZW-16 MP-4 HAS-16 CAC-16

03/04 Lex-e-05t 5t-5

Page 50

Electric System LEXION Montana TIC

5t-6 Lex-e-05t 03/04

Page 51

6s

CAN bus, module power supply

for Montana machines with module A50 (RIO)

Page 52

Electric System LEXION Montana TIC

06s - CAN bus, module power supply, for Montana machines with module A50 (RIO)

Key to diagram:

Coordinates

A1 AGROCOM terminal...........................................................2-h-17

A8 AUTOCONTOUR module (CAC) .......................................2-h-20

A9 AUTOPILOT module ..........................................................2-h-20

A10 Fieldwork computer module (BIF/CAB)..............................2-h-20

A12 Speed monitor module (DZW)............................................2-h-20

A13 Performance monitor module (DKG) ..................................4-p-21

A16 Reel controller module (HAS).............................................2-h-20

A21 YIELD METER module (LEM) ............................................2-h-20

A25 Sieve adjustment module ...................................................2-h-20

A27 VARIO module....................................................................2-h-20

A28 Uni-spreader module (VGS) ...............................................2-h-20

A40 Axle control system adaptation module..............................2-h-17

A50 Montana RIO module .........................................................2-h-20

B50 AUTOPILOT laser ..............................................................6-d-26

XA Multifunction coupling A......................................................8-e-21

XB Multifunction coupling B......................................................8-e-21

XC Multifunction coupling C .....................................................8-e-21

XV2 AUTOPILOT variant plug....................................................8-e-21

X5 Performance monitor ..........................................................6-p-20

6s-2 Lex-e-06s 03/04

Page 53

TIC LEXION Montana Electric System

Description of function:

Montana machine: On Montana machines, the Montana RIO module (A50) is connected with

the CAN bus by a cable branch line from connector MV to MV1.

Yield data All yield data is saved in the yield meter module (A21) whereas all other

performance data is saved in the fieldwork computer / CAN bridge module

(A10). It is therefore recommended to transmit these data prior to

replacing a defective module, using the diagnosis system

CDS3000/CDS5000.

Axle control system

adaptation

The CAN bus data of the separate Montana control unit are converted in

the axle control system adaptation module A40 and made available to the

CLAAS CAN bus system.

According to the axle position, the value of the feed rake conveyor

position sensor (B35) is offset in the AUTOCONTOUR module (CAC).

This allows working in hilly ground with the CAC function "Pre-set cutting

height control" and area counting.

AUTOCONTOUR (CAC)

Settings for Montana

The adaptation of the AUTOCONTOUR (CAC) and the axle control

systems requires special settings for Montana machines.

machines

- Cutterbar spring

setting

The 5 mm cutterbar spring setting (see also Operator's Manual) must be

made at a 50 % axle position.

- Check of cutterbar

spring setting

Check setting dimension when travelling downhill with the axle cylinders

fully extended. This dimension may be only < 15 mm.

- Learning the CAC limit

stops

The limit stops of the CAC sensors must be learned at a 75 % axle

position. While doing this, the cutting angle must be adjusted to the

working position

(cutterbar table surface in parallel with the ground).

- CAC sensitivity The recommended CAC sensitivity for use with the grain cutterbar is 45 %

with Montana machines.

- Drop rate setting

(front attachment)

The drop rate must be adjusted with the machine at operating

temperature and 50 % axle position.

The drop rate is 5 – 6 seconds from the top to the bottom position.

- Set value adjustment

of CAC cutting height

When working in the field, the cutting height control set value (working

within the sensor band range) should not be set higher than position 8.

control

03/04 Lex-e-06s 6s-3

Page 54

Electric System LEXION Montana TIC

Connector pin

assignment:

Connector S Connector

Socket XA Connector XA Socket XB

MV, MV1, MP, MR

Connector B, E

Connector XB Socket XC Connector XC

Connector X5 Connector XV2

6s-4 Lex-e-06s 03/04

Page 55

TIC LEXION Montana Electric System

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

S-2 31 0.5 br

S-3 Cab-40 /

Bif-3

B-13 CAC-3 MV-3 MW-3 DS-62

E-31 MU-3 VGS-3 MR-3 0.5 or

S-8 F-2A MV-1 MW-1 0.5 bk

S-9 Cab-13 /

Bif-16

B-14 CAC-16 MV-4 MW-4 DS-63

E-30 MU-4 VGS-16 MR-4 0.5 ye

MV-1 F2-A MW-1 S-8 0.5 bk

MV-2 31 1.5 br

MV-3 Cab-40 /

Bif-3

B-13 S-3 MW-3 MP-3 DS-62

E-31 MU-3 VGS-3 MR-3 0.5 or

MV-4 Cab-13 /

Bif-16

B-14 S-9 MW-4 MP-4 DS-63

E-30 MU-4 VGS-16 MR-4 0.5 ye

MV-5 F57-A 1.5 bk

MP-1 F9-A 0.5 bk

MP-2 31 1.5 br

MP-3 Cab-40 /

Bif-3

B-13 S-3 MV-3 MW-3 DS-62

E-31 MU-3 VGS-3 MR-3 0.5 or

MP-4 Cab-13 /

Bif-16

B-14 S-9 MV-4 MW-4 DS-63

E-30 MU-4 VGS-16 MR-4 0.5 ye

MR-1 F9-A 0.5 bk

MR-2 31 1.5 br

MR-3 Cab-40 /

Bif-3

B-13 S-3 MV-3 MW-3 DS-62

E-31 MU-3 VGS-3 MP-3 0.5 or

MR-4 Cab-13 /

Bif-16

B-14 S-9 MV-4 MW-4 DS-63

E-30 MU-4 VGS-16 MP-4 0.5 ye

DZW-3 MP-3 HAS-3 A-19

DZW-16 MP-4 HAS-16 A-20

DZW-3 CAC-3 HAS-3 A-19

DZW-16 CAC-16 HAS-16 A-20

DZW-3 CAC-3 HAS-3 A-19

DZW-16 CAC-16 HAS-16 A-20

DZW-3 CAC-3 HAS-3 A-19

DZW-16 CAC-16 HAS-16 A-20

03/04 Lex-e-06s 6s-5

Page 56

Electric System LEXION Montana TIC

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

B-13 Cab-40 /

Bif-3

MV-3 S-3 MW-3 MP-3 DS-62

E-31 MU-3 VGS-3 MR-3 0.5 or

B-14 Cab-13 /

Bif-16

MV-4 S-9 MW-4 MP-4 DS-63

E-30 MU-4 VGS-16 MR-4 0.5 ye

B-24 F3-A MU-1 1.5 bk

B-25 31 1.5 br-bl

E-1 31 1.5 br

E-12 31 1.5 br

E-21 F49-A 1.5 bl

E-30 Cab-13 /

Bif-16

MV-4 S-9 MW-4 MP-4 DS-63

B-14 MU-4 VGS-16 MR-4 0.5 ye

E-31 Cab-40 /

Bif-3

MV-3 S-3 MW-3 MP-3 DS-62

B-13 MU-3 VGS-3 MR-3 0.5 or

E-36 31 2.5 br

MV1-3 MV-3 A50-RI-4 0.5 or

MV1-4 MV-4 A50-RI-1 0.5 ye

DZW-3 CAC-3 HAS-3 A-19

DZW-16 CAC-16 HAS-16 A-20

DZW-16 CAC-16 HAS-16 A-20

DZW-3 CAC-3 HAS-3 A-19

6s-6 Lex-e-06s 03/04

Page 57

6t

CAN bus, module power supply

for Montana machines with module A45 (HBM)

Page 58

Electric System LEXION Montana TIC

06t - CAN bus, module power supply, for Montana machines with module A45 (HBM)

Key to diagram:

Coordinates

A1 AGROCOM terminal...........................................................2-h-17

A8 AUTOCONTOUR module (CAC) .......................................2-h-20

A9 AUTOPILOT module ..........................................................2-h-20

A10 Fieldwork computer module (BIF/CAB)..............................2-h-20

A12 Speed monitor module (DZW)............................................2-h-20

A13 Performance monitor module (DKG) ..................................4-p-21

A16 Reel controller module (HAS).............................................2-h-20

A21 YIELD METER module (LEM) ............................................2-h-20

A25 Sieve adjustment module ...................................................2-h-20

A27 VARIO module....................................................................2-h-20

A28 Uni-spreader module (VGS) ...............................................2-h-20

A40 Axle control system adaptation module..............................2-h-17

A45 Ground drive hydraulic motor brake

restrictor module (HBM) .....................................................2-h-20

B50 AUTOPILOT laser ..............................................................6-d-26

XA Multifunction coupling A......................................................8-e-21

XB Multifunction coupling B......................................................8-e-21

XC Multifunction coupling C .....................................................8-e-21

XV2 AUTOPILOT variant plug....................................................8-e-21

X5 Performance monitor ..........................................................6-p-20

6t-2 Lex-e-06t 03/04

Page 59

TIC LEXION Montana Electric System

Description of function:

Montana machine: On Montana machines, the Montana RIO module (A50) is connected with

the CAN bus by a cable branch line from connector MV to MV1.

Yield data All yield data is saved in the yield meter module (A21) whereas all other

performance data is saved in the fieldwork computer / CAN bridge

module (A10). It is therefore recommended to transmit these data prior to

replacing a defective module, using the diagnosis system

CDS3000/CDS5000.

Axle control system

adaptation

The CAN bus data of the separate Montana control unit are converted in

the axle control system adaptation module A40 and made available to the

CLAAS CAN bus system.

According to the axle position, the value of the feed rake conveyor

position sensor (B35) is offset in the AUTOCONTOUR module (CAC).

This allows working in hilly ground with the CAC function "Pre-set cutting

height control" and area counting.

AUTOCONTOUR (CAC)

Settings for Montana

The adaptation of the AUTOCONTOUR (CAC) and the axle control

systems requires special settings for Montana machines.

machines

- Cutterbar spring setting The 5 mm cutterbar spring setting (see also Operator's Manual) must be

made at a 50 % axle position.

- Check of cutterbar

spring setting

Check setting dimension when travelling downhill with the axle cylinders

fully extended. This dimension may be only < 15 mm.

- Learning the CAC limit

stops

The limit stops of the CAC sensors must be learned at a 75 % axle

position. While doing this, the cutting angle must be adjusted to the

working position

(cutterbar table surface in parallel with the ground).

- CAC sensitivity The recommended CAC sensitivity for use with the grain cutterbar is

45 % with Montana machines.

- Drop rate setting

(front attachment)

The drop rate must be adjusted with the machine at operating

temperature and 50 % axle position.

The drop rate is 5 – 6 seconds from the top to the bottom position.

- Set value adjustment of

CAC cutting height

When working in the field, the cutting height control set value (working

within the sensor band range) should not be set higher than position 8.

control

03/04 Lex-e-06t 6t-3

Page 60

Electric System LEXION Montana TIC

Connector pin

assignment:

Connector S Connector

Socket XA Connector XA Socket XB

MV, MV1, MP, MR

Connector B, E

Connector XB Socket XC Connector XC

Connector X5 Connector XV2

6t-4 Lex-e-06t 03/04

Page 61

TIC LEXION Montana Electric System

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

S-2 31 0.5 br

S-3 Cab-40 /

Bif-3

B-13 CAC-3 MV-3 MW-3 DS-62

E-31 MU-3 VGS-3 MR-3 0.5 or

S-8 F-2A MV-1 MW-1 0.5 bk

S-9 Cab-13 /

Bif-16

B-14 CAC-16 MV-4 MW-4 DS-63

E-30 MU-4 VGS-16 MR-4 0.5 ye

MV-1 F2-A MW-1 S-8 0.5 bk

MV-2 31 1.5 br

MV-3 Cab-40 /

Bif-3

B-13 S-3 MW-3 MP-3 DS-62

E-31 MU-3 VGS-3 MR-3 0.5 or

MV-4 Cab-13 /

Bif-16

B-14 S-9 MW-4 MP-4 DS-63

E-30 MU-4 VGS-16 MR-4 0.5 ye

MV-5 F57-A 1.5 bk

MP-1 F9-A 0.5 bk

MP-2 31 1.5 br

MP-3 Cab-40 /

Bif-3

B-13 S-3 MV-3 MW-3 DS-62

E-31 MU-3 VGS-3 MR-3 0.5 or

MP-4 Cab-13 /

Bif-16

B-14 S-9 MV-4 MW-4 DS-63

E-30 MU-4 VGS-16 MR-4 0.5 ye

MR-1 F9-A 0.5 bk

MR-2 31 1.5 br

MR-3 Cab-40 /

Bif-3

B-13 S-3 MV-3 MW-3 DS-62

E-31 MU-3 VGS-3 MP-3 0.5 or

MR-4 Cab-13 /

Bif-16

B-14 S-9 MV-4 MW-4 DS-63

E-30 MU-4 VGS-16 MP-4 0.5 ye

DZW-3 MP-3 HAS-3 A-19

DZW-16 MP-4 HAS-16 A-20

DZW-3 CAC-3 HAS-3 A-19

DZW-16 CAC-16 HAS-16 A-20

DZW-3 CAC-3 HAS-3 A-19

DZW-16 CAC-16 HAS-16 A-20

DZW-3 CAC-3 HAS-3 A-19

DZW-16 CAC-16 HAS-16 A-20

03/04 Lex-e-06t 6t-5

Page 62

Electric System LEXION Montana TIC

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

B-13 Cab-40 /

Bif-3

MV-3 S-3 MW-3 MP-3 DS-62

E-31 MU-3 VGS-3 MR-3 0.5 or

B-14 Cab-13 /

Bif-16

MV-4 S-9 MW-4 MP-4 DS-63

E-30 MU-4 VGS-16 MR-4 0.5 ye

B-24 F3-A MU-1 1.5 bk

B-25 31 1.5 br-bl

E-1 31 1.5 br

E-12 31 1.5 br

E-21 F49-A 1.5 bl

E-30 Cab-13 /

Bif-16

MV-4 S-9 MW-4 MP-4 DS-63

B-14 MU-4 VGS-16 MR-4 0.5 ye

E-31 Cab-40 /

Bif-3

MV-3 S-3 MW-3 MP-3 DS-62

B-13 MU-3 VGS-3 MR-3 0.5 or

E-36 31 2.5 br

MV1-3 MV-3 A50-RI-4 0.5 or

MV1-4 MV-4 A50-RI-1 0.5 ye

DZW-3 CAC-3 HAS-3 A-19

DZW-16 CAC-16 HAS-16 A-20

DZW-16 CAC-16 HAS-16 A-20

DZW-3 CAC-3 HAS-3 A-19

6t-6 Lex-e-06t 03/04

Page 63

17s

Front attachment drive,

reverser drive

for Montana machines

Page 64

Electric System LEXION Montana TIC

17s - Front attachment drive, reverser drive for Montana machines

Key to diagram:

Coordinates

A8 AUTOCONTOUR module (CAC)....................................... 2-h-20

A10 Fieldwork computer module (BIF/CAB) ............................. 2-h-20

A12 Speed monitor module (DZW) ........................................... 2-h-20

A16 Reel controller module (HAS) ............................................ 2-h-20

K16 Front attachment ON relay ............................................... 3-h-20

S54 Front attachment OFF switch ............................................ 3-g-17

S55 Front attachment ON switch .............................................. 3-g-17

S57 Front attachment reverse switch ..................................... 3-g-17

XEa Montana feed rake conveyor connector ............................ 5-g-17

XSA Montana operator's platform connector ............................. 5-h-17

XSD Montana operator's platform connector ............................. 5-h-17

X8 Ground speed control lever connector .............................. 4-h-17

Y86 Reverse front attachment solenoid coil ............................. 8-e-16

Y88 Front attachment clutch solenoid coil ................................ 2-p-19

Z5 Seat contact switch ............................................................ 4-g-18

Measured value table:

Item Component Measured value Remark

K16 Remote control relay

15 A

30 A

Y86 Solenoid coil 3.8 A

Y88 Solenoid coil 0.75 A

95±10 Ω

3.2 Ω

16 Ω

(Pin 86/1 – 85/2)

(Pin 87a/4 – 30/3)

(Pin 87/5 – 30/3)

17s-2 Lex-e-17s 03/04

Page 65

TIC LEXION Montana Electric System

Description of function:

Montana machine: In this circuit, the difference between the standard machine and the

Front attachment ON/OFF Relay K49 must be actuated by the road travel circuit and the threshing

Reverse front attachment The front attachment must not be engaged as a pre-condition for the

Montana machine is only two additional connectors (XSA and XSD) to

solenoid coil (Y86).

mechanism must be actuated by relay K14 as pre-conditions for the front

attachment drive.

When the START button (S55) is actuated, an earth signal is connected

to the fieldwork computer module (A10). The fieldwork computer module

(A10) now actuates relay K16. Solenoid coil (Y88) is supplied with

power – Front attachment ON function.

When the STOP button (S54) is actuated, an earth signal is connected to

the fieldwork computer module (A10). The fieldwork computer module

(A10) cuts the power supply at relay K16 – Front attachment OFF.

Important! The front attachment circuit depends on the closed seat

contact switch (Z5).

reversing function. The speed monitor module (A12) connects voltage to

the reverse switch (S57) as an additional safety feature only after the

feeder housing speed sensor (B12) stops transmitting a signal for approx.

2 seconds.

If these pre-conditions are met, voltage is connected from the speed

monitor module (A12) to solenoid coil (Y86) via the

reverse switch (S57) – Front attachment reverse function.

The master valve (Y77) is actuated via the diode PCB (DO) in parallel

with the solenoid coil (Y86) because this function requires that pressure is

built up in the system.

Important! When the reversing function is active, a signal is connected

to the reel controller module (A16) which makes the speed

adjustment variable displacement pump swing to maximum

delivery if hydraulic reel drive is used.

03/04 Lex-e-17s 17s-3

Page 66

Electric System LEXION Montana TIC

Connector pin definition:

Connector M, P, W Connector MQ Connector X8

Socket XEa Connector XEa Connector XSA

Connector XSD Connector XSD Connector XSA

17s-4 Lex-e-17s 03/04

Page 67

TIC LEXION Montana Electric System

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

M9 CAC-6 0.5 bl-gr

M10 CAC-18 0.5 wh-gn

W-2 K35-30 K16-87 K8-87 K15-30 CAC-7

K36-30 H-3 K64-86 DS-53 1 ye-rd

W-12 31 2.5 br

MQ-5 P-8 Do-2 DS-7 1.5 ye-bl

MQ-8 31 2.5 br

P-4 K47-TK R-1 0.5 bl-gn

P-7 K65-87a 1.5 gr

P-8 MQ-5 DO-2 DS-7 1.5 gr

P-12 31 2.5 br

XEa-1 XSD-A1 1.5 br

XEa-13 XSD-B4 1.5 ye-bl

XSA-A4 XSD-B4 1.5 ye-bl

XSA-D2 XSD-A1 4 br

XSD-A1 XEa-1 XSA-D2 4 br

XSD-B4 XEa-13 XSA-A4 1.5 ye-bl

03/04 Lex-e-17s 17s-5

Page 68

Electric System LEXION Montana TIC

17s-6 Lex-e-17s 03/04

Page 69

20s

Front attachment raise / lower,

cross levelling

for Montana machines

Page 70

Electric System LEXION Montana TIC

20s - Raise / lower front attachment, cross levelling – for Montana machines

Key to diagram:

Coordinates

A8 AUTOCONTOUR module (CAC)....................................... 2-h-20

K5 Front attachment raise relay .............................................. 3-h-20

K6 Front attachment lower relay ............................................. 3-h-20

K7 Left-hand cutterbar transverse control relay...................... 3-h-20

K8 Right-hand cutterbar transverse control relay ................... 3-h-20

S38a Front attachment raise multifunction pushbutton switch .... 3-f-18

S38b Front attachment lower multifunction pushbutton switch.... 3-f-18

S45 VARIO cutting table adjustment switch .............................. 3-f-18

S46 Cutterbar cross levelling switch (manual) .......................... 3-g-17

S69 Cross levelling /

table adjustment function pre-selection switch .................. 3-g-17

XEa Montana feed rake conveyor connector ............................ 5-g-17

XSA Montana operator's platform connector ............................. 5-h-17

XSD Montana operator's platform connector ............................. 5-h-17

X8 Ground speed control lever connector .............................. 4-h-17

Y67 Solenoid coil

AUTOCONTOUR cross levelling, left ................................. 7-f-16

Y68 Solenoid coil

AUTOCONTOUR cross levelling, right ............................... 7-f-16

Y85 Raise front attachment solenoid coil................................. 6-m-21

Y87 Lower front attachment solenoid coil ................................ 6-m-21

Measured value table:

Item Component Measured value Remark

K 5

K 6

K 7

K 8

Y67

Y68

Y85

Y87

Remote control relay

30 A

Solenoid coil 3.8 A

200±20 Ω

3.2 Ω

(Pin 86/1 - 85/2)

(Pin 87/5 – 30/3)

20s-2 Lex-e-20s 03/04

Page 71

TIC LEXION Montana Electric System

Description of function:

Montana machine: In this circuit, the difference between the standard machine and the

Raise / lower front

attachment

The pushbuttons (S38a and S38b) have different pressure stages. When

When pressing the pushbuttons (S38a or S38b) to the second stage, the

The master valve (Y77) is actuated via the diode PCB (DO) in parallel

During automatic cutterbar guiding, the AUTOCONTOUR module (A8)

Cross levelling When the road travel circuit is unlocked, relays K7 and K8 are supplied

By actuating the function pre-selection switch (S69) to the cross levelling

The master valve (Y77) is actuated via the diode PCB (DO) in parallel

During automatic cutterbar guiding, the AUTOCONTOUR module (A8)

Montana machine is only two additional connectors (XSA and XSD) to the

solenoid coils (Y67 and Y68).

When the road travel circuit is unlocked, relays K5 and K6 are supplied

with power by relay K49.

actuating the pushbutton slightly to the first stage, earth is connected as a

signal to the AUTOCONTOUR module (A8). The module (A8) actuates

the respective solenoid coils (Y85 or Y86) in a modulated way – Slowly

raise/lower function.

corresponding relays K5 and K6 are actuated and consequently also the

respective solenoid coils (Y85 or Y86) – Quickly raise/lower function.

with the front attachment raise solenoid coil (Y85) because this function

requires that pressure is built up in the system.

actuates the corresponding solenoid coils until the set values and actual

values of the corresponding sensors match.

with power by relay K49.

position, the respective relay K5 or K6 and consequently the

corresponding solenoid coil (Y67/Y68) is actuated as a function of switch

(S46).

with the cross levelling solenoid coils (Y67/Y68) because this function

requires that pressure is built up in the system.

actuates the corresponding solenoid coils until the set values and actual

values of the corresponding sensors match.

Important! The switch provided at the bottom side of the multi-function

handle controls both the VARIO cutting table adjustment

(S45) and the manual cutterbar lateral control (S46),

depending on the function pre-selection switch (S69).

03/04 Lex-e-20s 20s-3

Page 72

Electric System LEXION Montana TIC

Connector pin definition:

Connector M, MA, N, P, V Connector MQ Connector X8

Socket XEa Connector XEa Connector XSA

Connector XSD Connector XSD Connector XSA

20s-4 Lex-e-20s 03/04

Page 73

TIC LEXION Montana Electric System

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

MQ-3 K8-87 CAC-1 1.5 ye-vi

MQ-4 K7-87 CAC-14 1.5 ye-br

MQ-8 31 2.5 br

N-7 K7-85 1.5 gn-wh

N-8 K8-85 1.5 gn-ye

MA-6 K9-85 0.5 gr-gn

MA-7 K10-85 0.5 gr-br

V-5 K5-87 CAC-13 Do-8 DS-5 1.5 wh-rd

V-6 K6-87 CAC-12 DS-6 1.5 wh-bk

V-11 31 2.5 br

V-12 31 2.5 br

M-1 CAC-19 0.5 gr-wh

M-2 K6-85 0.5 gr-ye

M-3 CAC-5 0.5 gr-br

M-4 K5-85 0.5 gr-gn

P-12 31 2.5 br

XEa-1 XSD-A1 1.5 br

XEa-11 XSD-B2 1.5 vi-ye

XEa-12 XSD-B3 1.5 ye-br

XSA-A2 XSD-B2 1.5 vi-ye

XSA-A3 XSD-B3 1.5 ye-br

XSA-D2 XSD-A1 4 br

XSD-A1 XEa-1 XSA-D2 4 br

XSD-B2 XEa-11 XSA-A2 1.5 vi-ye

XSD-B3 XEa-12 XSA-A3 1.5 ye-br

03/04 Lex-e-20s 20s-5

Page 74

Electric System LEXION Montana TIC

20s-6 Lex-e-20s 03/04

Page 75

26s

Machine monitor

for Montana machines

Page 76

Electric System LEXION Montana TIC

26s - Machine monitoring, for Montana machines

Key to diagram:

Coordinates

DI Warning device diode PCB................................................ 3-h-20

X13 3D / rear axle connector .................................................... 3-g-17

Z1 3D sieve pan position switch ............................................. 6-o-16

Z19 Hydraulic oil level switch (min.).......................................... 2-p-20

Z20 Hydraulic oil temperature switch ........................................ 2-p-20

Z38 Steering position left switch ............................................... 7-q-16

Z39 Steering position right switch ............................................. 7-q-16

Z46 Low-pressure hydraulics switch /

ground drive oil pressure ................................................... 2-p-19

Z61 Straw blockage warning switch .......................................... 2-t-18

............................................................................................ 4-t-20

Z79 Left brake circuit pressure switch ...................................... 5-g-20

Z80 Right brake circuit pressure switch ................................... 5-g-20

26s-2 Lex-e-26s 03/04

Page 77

TIC LEXION Montana Electric System

Description of function:

Montana machine In this circuit, the difference between the standard machine and the

Filling level warning If the diesel engine is not started, the terminal (A30) recognizes an earth

Oil pressure warning If the diesel engine is started, the terminal (A30) recognizes an earth

Warning: Hydraulic oil

temperature too high

Montana brake oil pressure

warning

Montana machine is a cable branch at connector Y to Y1. The parking

brake switch at the connectors T and U is dropped on Montana machines.

In addition to the warning signals for brake lining wear (Z9) and parking

brake (Z12), insufficient brake oil pressure (Z80) is also displayed in the

terminal.

signal on pin 15 as the signal of the float switch (Z19) and displays the

filling level alarm message. At the same time, the earth signal is sent to

the pulse generator K57 through the diode PCB (DI).

signal on pin 15 as the signal of the oil pressure switch (Z46) and displays

the oil pressure alarm message. At the same time, the earth signal is sent

to the pulse generator K57 through the diode PCB (353).

The earth signal of the hydraulic oil temperature switch (Z20) is connected

to terminal (A30) and displayed as an alarm message.

The earth signal of the left / right brake circuit pressure switch (Z79/Z80)

is connected to the terminal (A30) and displayed as an alarm message.

03/04 Lex-e-26s 26s-3

Page 78

Electric System LEXION Montana TIC

Connector pin definition:

Connector T, U, W, Y, Y1 Connector MW Connector B

Interconnection list:

from to 1 to 2 to 3 to 4 to 5 mm² Colour

T-8 A-11 Y-2 1.5 br-wh

U-4 31 2.5 br

Y-1 31 2.5 br

Y-2 T-8 A-11 0.75 br-rd

W-5 A-16 0.75 br-wh

W-9 A-15 DI-4 1 gn-rd

W-12 31 2.5 br

B-19 A-7 1 bk-gr

B-21 A-3 1 bl-gr

B-22 A-2 1 bl-vi

B-37 31 1.5 br

MW-1 F2-A MV-1 S-8 0.5 bk

MW-2 31 1.5 br

MW-7 DI-10 0.5 wh

Y1-2 Y-2 1.5 br-rd

26s-4 Lex-e-26s 03/04

Page 79

41s

Axle control system,

front attachment control system

for Montana machines with module A50 (RIO)

Page 80

Electric System LEXION-Montana TIC

41s - Axle control system and front attachment control system, for Montana machines with module A50 (RIO)

Key to diagram:

Coordinates

A35 Montana control unit module ...............................................7-i-18

B91 Axle angle sensor, left ........................................................ 7-j-20

B92 Axle angle sensor, right ...................................................... 7-j-16

B93 Cutting angle sensor.......................................................... 7-e-17

B94 Montana cross levelling sensor ......................................... 8-e-16

B95 Montana feed rake conveyor position sensor.................... 6-h-16

XEa Montana feed rake conveyor connector ............................ 5-g-17

XSA Montana operator's platform .............................................. 5-h-17

XSD Montana operator's platform.............................................. 5-h-17

Y110 Raise cutting angle solenoid coil ........................................ 7-f-16

Y111 Lower cutting angle solenoid coil........................................ 7-f-16

Y112 Rotate front attachment to the right solenoid coil ............... 7-f-16

Y113 Rotate front attachment to the left solenoid coil ................. 7-f-16

Y114 Lower axle on left-hand side solenoid coil......................... 7-h-18

Y115 Raise axle on left-hand side solenoid coil ......................... 7-h-18

Y116 Lower axle on right-hand side solenoid coil....................... 7-h-18

Y117 Raise axle on right-hand side solenoid coil ....................... 7-h-18

Y118 Oil quantity increase solenoid coil ..................................... 7-h-18

Measured value table:

Item Component Measured value Remark

B91

B92

B93

B94

Y110

Y111

Y112

Y113

Y114

Y115

Y116

Y117

Y118

Sensor 12 V

0.25 V – 4.75 V

Solenoid coil 3.8 A

3.2 Ω

(Pin 1-2)

(Pin 1-3)

41s-2 Lex-e-41s 03/04

Page 81

TIC LEXION-Montana Electric System

Description of function:

1/5

Axle control system and

front attachment control

system

The system identifies the machine position using an inclination sensor

integrated in the Montana module (A35). The solenoid coils (Y114, Y115,

Y116, Y117) are actuated by the Montana module (A35) so that the

machine is always in a vertical position by means of front axle

movements. If the control system speed is not sufficient, the Montana

module (A35) additionally actuates an oil quantity increase solenoid coil

(Y118) in connection with the working hydraulics master valve (Y77) via

the gearshift control module (A36) – circuit diagram 4.

The position of the front attachment is adapted by rotating the front

attachment frame (Y112, Y113) and by changing the cutting angle (Y110,

Y111). This front attachment control system works independently of the

AUTOCONTOUR system.

The Montana module (A35) receives the necessary feedback about the

current position of the corresponding function from the respective angle

sensors (B91, B92, B93, B94, B95).

Important! All system calibrations using the Montana terminal (A41)

require that the Montana control unit module A35 receives

the signal from the unactuated parking brake (S93) – circuit

diagram 42.

Axle control system

diagnosis via Montana

Call up the diagnosis menu with the menu key, the yellow cutting angle

increase / decrease keys and the Enter key.

terminal A41:

- Diagnosis inputs Select the inputs section using the yellow keys and the Enter key.

Diagnose

Inputs

Inclinometer

Outputs

System

03/04 Lex-e-41s 41s-3

Page 82

Electric System LEXION-Montana TIC

Description of function:

2/5

Go to page 1/6 inputs using the yellow keys and the Enter key.

The parking brake symbol allows checking the function of parking brake

switch S93 (symbol) – closed / open.

Diag. Inputs 1/6

Handbrake

Reserve 1

Reserve 2

Go to page 2/6 inputs using the yellow keys and the Enter key.

The sensor value B91 is displayed.

Diag. Inputs 2/6

Cylinder left

Sensor:

Cal.min.:

Cal.max.:

Position:

3.30 V

0.12 V

4.99 V

65.3%

Go to page 3/6 inputs using the yellow keys and the Enter key.

The sensor value B92 is displayed.