Page 1

Cisco RF Gateway 10 Hardware Installation Guide

July 25, 2012

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO

CHANGE WITHOUT NOTICE. ALL STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS

MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY

PRODUCTS.

Cisco Systems, Inc.

www.cisco.com

Cisco has more than 200 offices worldwide.

Addresses, phone numbers, and fax numbers

are listed on the Cisco website at

www.cisco.com/go/offices.

Text Part Number: OL-16264-04

Page 2

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this

URL: www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display

output, network topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in

illustrative content is unintentional and coincidental.

© 2012 Cisco Systems, Inc. All rights reserved.

Page 3

iii

CONTENTS

CHAPTER

1 Overview 1-1

Cisco RFGW-10 Features 1-2

Cisco RFGW-10 Functional Overview 1-2

Cisco RFGW-10 IOS Software 1-4

Cisco RFGW-10 Hardware 1-5

Cisco RFGW-10 System Configuration 1-5

Cisco RFGW-10 Slot Numbering 1-6

Cisco RFGW-10 Components 1-7

Fan Assembly 1-7

DC PEMs 1-10

Front Panel Display 1-14

Supervisor Engines 1-15

Cisco Supervisor Engine V-10GE 1-15

Supervisor Engine Components 1-16

Supervisor Engine LEDs 1-16

Ethernet Management Port 1-16

Supervisor Memory 1-17

Cisco RFGW 10 Supervisor Engine 7-E 1-17

Features of the Cisco RFGW-10 Supervisor Engine 7-E 1-18

Front Panel LED 1-19

Physical and Environmental Specifications 1-20

Cisco RFGW-10 DS-48 Line Card 1-20

DS-48 Line Card Components 1-21

Cisco RFGW-10 DS-384 Line Card 1-23

TCC/DTI Card 1-23

RF Switch Card 1-27

CHAPTER

OL-16264-04

Supported External AC-Input Power Shelf 1-29

Lineage AC-DC Power Shelf 1-29

2 Preparing Your Site for Installation 2-1

Safety Recommendations 2-2

Book Title

iii

Page 4

Contents

REVIEW DRAFT—CISCO CONFIDENTIAL

Compliance Requirements 2-3

NEBS Level 3 Compliance 2-3

Cautions and Regulatory Compliance Statements for NEBS 2-3

Standard Warning Statements 2-4

General Safety Warnings 2-4

Site Planning 2-7

General Precautions 2-7

Site Selection Guidelines 2-7

Site Environmental Requirements 2-8

Physical Characteristics 2-8

Floor Loading Considerations 2-9

Site Power Guidelines 2-9

Electrical Circuit Requirements 2-10

Site Cabling Guidelines 2-10

Asynchronous Terminal Connections 2-11

Interference Considerations 2-11

Rack-Mounting and Location Guidelines 2-12

Precautions for Rack-Mounting 2-12

Rack Selection Guidelines 2-13

Equipment Rack Guidelines 2-13

Site Planning Checklist 2-14

CHAPTER

Preventing Electrostatic Discharge Damage 2-15

Electrical Safety 2-15

Receiving a Cisco RFGW-10 UEQAM 2-17

Chassis-Lifting Guidelines 2-17

Tools and Equipment 2-19

Unpacking and Verifying Shipping Contents 2-19

Checking the Shipping Container Contents 2-20

Cisco RFGW-10 UEQAM Installation Checklist 2-21

3 Cisco RFGW-10 UEQAM Installation 3-1

Cisco RFGW-10 UEQAM Description 3-1

Front View 3-2

Rear View 3-3

Installation Methods 3-4

General Rack Installation Guidelines 3-4

Rack-Mounting a Cisco RFGW-10 UEQAM 3-5

Verifying Rack Dimensions 3-5

Book Title

iv

OL-16264-04

Page 5

REVIEW DRAFT—CISCO CONFIDENTIAL

Installing the Chassis Installation Brackets 3-6

Installing the Chassis Installation Handles 3-7

Attaching the Chassis Rack-Mount Brackets 3-9

Chassis Front Rack-Mount Brackets Installation 3-9

Chassis Mid-Mounted Rack-Mount Bracket Installation 3-10

Installing the Cisco RFGW-10 UEQAM in a Rack 3-12

Two-Post Rack Installation Mid-Mounted 3-16

Attaching a Chassis Ground Connection 3-18

Attaching the Cable-Management Bracket 3-20

Connecting Power to Cisco RFGW-10 UEQAM 3-21

Connecting DC-Input Power to Cisco RFGW-10 UEQAM 3-22

Powering On the Cisco RFGW-10 UEQAM 3-28

Connecting System Cables 3-28

Connecting the Lineage Power Shelf to the Cisco RFGW-10 3-28

Cabling the Power Shelf 3-29

Prerequisites 3-29

Required Tools and Equipment 3-29

Steps 3-29

Connecting a Single Power Shelf 3-30

Required Tools and Equipment 3-30

Steps 3-31

Connecting Dual Power Shelves 3-32

Required Tools and Equipment 3-32

Steps 3-32

Disconnecting Cables from the Power Shelf 3-34

Steps 3-34

Contents

CHAPTER

CHAPTER

OL-16264-04

4 Thermal Management 4-1

Blank Panels 4-1

Cooling Path 4-2

Fan Tray Removal 4-2

Environmental Monitoring 4-3

5 Installing and Removing FRUs 5-1

Installation and Removal of the DC PEM 5-2

Installing a DC PEM 5-3

Removing a DC PEM 5-6

Installation and Removal of the Fan Assembly 5-7

Book Title

v

Page 6

Contents

REVIEW DRAFT—CISCO CONFIDENTIAL

Removing the Fan Assembly 5-7

Installing the Fan Assembly 5-8

Verifying the Fan Assembly Installation 5-9

Installation and Removal of the Supervisor Cards 5-9

Installing the Supervisor Cards 5-10

Verifying the Status of the Supervisor Card 5-13

Removing the Supervisor Card 5-13

Installation and Removal of the RF Switch Card 5-14

Installing the RF Switch Card 5-15

Verifying the RF Switch Card Status 5-17

Removing the RF Switch Card 5-18

Installation and Removal of the TCC Cards 5-19

Installing the TCC Card 5-19

Verifying the Status of the TCC Card 5-22

Removing the TCC Card 5-22

CHAPTER

Installation and Removal of the Line Cards 5-23

Installing the DS-48 Line Card 5-23

Verifying the Status of the DS-48 Line Card 5-26

Removing the DS-48 Line Card 5-26

Installation and Removal of the SFP Modules 5-27

Installing SFP Modules 5-27

Mylar Tab SFP Modules 5-28

Actuator/Button SFP Modules 5-29

Bale Clasp SFP Modules 5-31

6 Cabling the Cisco RFGW-10 UEQAM 6-1

Part Numbers 6-5

Nominal Attenuation 6-6

Safety Information and Warnings 6-7

Electrical Equipment Guidelines 6-7

Preventing Electrostatic Discharge Damage 6-8

Installing the UCH on the Cisco RFGW-10 UEQAM RF Switch Card 6-8

Installing or Replacing the Cables in the UCH2 6-10

Installing the Cables in the UCH2 6-10

Removing Cables 6-13

Verifying the RF Switch Card Installation 6-14

Downstream RF Power Measurement Caution 6-14

Broken Lead Screws 6-15

Book Title

vi

OL-16264-04

Page 7

REVIEW DRAFT—CISCO CONFIDENTIAL

Cabling the Supervisor Engine 6-15

Features of the Supervisor Engine Front Panel 6-15

LEDs 6-15

10-Gigabit Ethernet Uplink Ports 6-16

Gigabit Ethernet SFP Uplink Ports 6-16

Ethernet Management Port 6-16

Console Port 6-16

Reset Button 6-17

Compact Flash Port 6-17

Port Cabling Specifications 6-17

Maximum Cable Distances 6-18

Attaching Module Interface Cables 6-18

SC Connector 6-19

LC Connector 6-20

Configuring Your Supervisor Engine 6-20

X2 Handling Guidelines and Installation 6-21

Installing the 10-Gigabit Ethernet X2 Transceiver 6-22

Removing the 10-Gigabit Ethernet X2 Transceiver 6-24

X2 Transceiver Maintenance Guidelines 6-24

SFP Guidelines 6-25

Fiber-Optic SFP Modules 6-25

1000BASE-T SFP Modules 6-27

CWDM SFP Modules 6-27

Cleaning the Fiber-Optic Connectors 6-28

Contents

CHAPTER

OL-16264-04

Cabling the TCC Card 6-29

Preventing Electrostatic Discharge Damage 6-29

TCC Card LED Summary 6-30

DTI Physical Connector 6-30

Cabling the Line Cards 6-31

Preventing ESD Damage 6-31

Connecting the Gigabit Ethernet Ports 6-32

Installing SFP Transceiver Modules in the Line Cards 6-32

Removing SFP Transceiver Modules 6-34

Connecting to the ASI Monitor Port (Optional) 6-36

Configuring the ASI Port for Monitoring 6-37

7 Cisco RFGW-10 UEQAM System Specifications 7-1

System Specifications 7-1

Power Requirements 7-2

Book Title

vii

Page 8

Contents

REVIEW DRAFT—CISCO CONFIDENTIAL

viii

Book Title

OL-16264-04

Page 9

Preface

This preface discusses the objectives, audience, and organization of the Cisco RF Gateway 10 Hardware

Installation Guide. The following sections are in this preface:

• Document Revision History, page 1

• Document Objectives, page 2

• Audience, page 2

• Document Organization, page 2

• Document Conventions, page 3

• Safety Warnings, page 4

• Related Documentation, page 4

• Obtaining Documentation and Submitting a Service Request, page 5

Document Revision History

The Document Revision History table below records technical changes to this document.

Document

Version Date Change Summary

OL-16264-01 January 2009 This is the first version of this document.

OL-16264-02 April 2009 Updated with the new cable assembly information.

OL-16264-03 June 2012 Updated with information about:

OL-16264-04 September, 2012 Added information about Lineage AC-DC power shelf

• Cisco RF Gateway 10 UEQAM Downstream 384

Line Card (also called Cisco RFGW-10 DS-384)

• Cisco RF Gateway 10 Supervisor Engine 7-E

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1

Page 10

Document Objectives

This publication describes Cisco RF Gateway 10 (RFGW-10) Universal Edge Quadrature Amplitude

Modulation (UEQAM) installation, and replacement or upgrading of field-replaceable units (FRUs). The

purpose of this guide is to enable a safe and efficient installation of the Cisco RFGW-10 UEQAM.

Audience

This publication is primarily designed for the person responsible for installing, and maintaining the

Cisco RFGW-10 UEQAM. The users of this guide should:

• Be familiar with electronic circuitry and wiring practices.

• Have experience as electronic or electromechanical technicians.

• Have experience in installing high-end networking equipment. Certain procedures described in this

guide require a certified electrician.

Document Organization

The major sections of this installation guide are:

Section Description

Chapter 1, “Overview” This chapter provides an overview of the Cisco

RFGW-10 UEQAM.

Chapter 2, “Preparing Your Site for Installation” This chapter provides site preparation guidelines for

installing the Cisco RFGW-10 UEQAM.

Chapter 3, “Cisco RFGW-10 UEQAM Installation” This chapter describes the installation procedures of the

Cisco RFGW-10 UEQAM.

Chapter 4, “Thermal Management” This chapter describes thermal management of the Cisco

RFGW-10 UEQAM.

Chapter 5, “Installing and Removing FRUs” This chapter describes the installation and removal

procedures for the field-replaceable units (FRUs).

Chapter 6, “Cabling the Cisco RFGW-10 UEQAM” This chapter describes the cabling information for the

Cisco RFGW-10 UEQAM.

Chapter 7, “Cisco RFGW-10 UEQAM System Specifications” This chapter lists the specifications of the Cisco

RFGW-10 UEQAM.

Cisco RF Gateway 10 Hardware Installation Guide

2

OL-16264-04

Page 11

Document Conventions

This document uses the following conventions:

Convention Indication

bold font Commands and keywords and user-entered text appear in bold font.

italic font Document titles, new or emphasized terms, and arguments for which you supply

values are in italic font.

[ ] Elements in square brackets are optional.

{x | y | z } Required alternative keywords are grouped in braces and separated by

vertical bars.

[ x | y | z ] Optional alternative keywords are grouped in brackets and separated by

vertical bars.

string A nonquoted set of characters. Do not use quotation marks around the string or

the string will include the quotation marks.

courier font Terminal sessions and information the system displays appear in courier font.

< > Nonprinting characters such as passwords are in angle brackets.

[ ] Default responses to system prompts are in square brackets.

!, # An exclamation point (!) or a pound sign (#) at the beginning of a line of code

indicates a comment line.

Note Means reader take note.

Tip Means the following information will help you solve a problem.

Caution Means reader be careful. In this situation, you might perform an action that could result in equipment

damage or loss of data.

Timesaver Means the described action saves time. You can save time by performing the action described in

the paragraph.

Warnin g

Means

bodily injury.

reader be warned

. In this situation, you might perform an action that could result in

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

3

Page 12

Safety Warnings

Most safety warnings for the Cisco RF Gateway 10 are placed in relevant sections throughout the

document. For translated safety warnings, see the Regulatory Compliance and Safety Information for the

Cisco RF Gateway 10.

Warning Definition

Warnin g

MPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before

you work on any equipment, be aware of the hazards involved with electrical circuitry and be

familiar with standard practices for preventing accidents. To see translations of the warnings

that appear in this publication, refer to the translated safety warnings that accompanied this

device.

Note: SAVE THESE INSTRUCTIONS

Note: This documentation is to be used in conjunction with the specific product installation

guide that shipped with the product. Please refer to the Installation Guide, Configuration Guide,

or other enclosed additional documentation for further details.

Statement 1071

Related Documentation

Your Cisco RF Gateway 10 (RFGW-10) Universal Edge Quadrature Amplitude Modulation (UEQAM)

and the Cisco IOS software running on it contain extensive features and functionality, which are

documented in the following resources:

• All documentation related to the Cisco RF Gateway 10 is listed in the online Cisco RF Gateway 10

Documentation Roadmap.

• The Cisco RF Gateway 10 Quick Start Guide contains installation and configuration information. It

contains quick reference information about chassis or parts installation.

• The Regulatory Compliance and Safety Information for the Cisco RF Gateway 10 document

provides international agency compliance, safety, and statutory information for the Cisco RF

Gateway 10.

• Cisco IOS software documentation contains Cisco IOS software configuration information and

support. See the modular configuration and modular command reference publications in the set that

corresponds to the software release installed on your Cisco hardware.

• To check the minimum software requirements of Cisco IOS software with the hardware installed on

your router, Cisco maintains the Software Advisor tool on Cisco.com. This tool does not verify

whether modules within a system are compatible, but it does provide the minimum IOS requirements

for individual hardware modules or components.

Note Access to this tool is limited to users with Cisco.com login accounts.

Cisco RF Gateway 10 Hardware Installation Guide

4

OL-16264-04

Page 13

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional

information, see the monthly What’s New in Cisco Product Documentation, which also lists all new and

revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What’s New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed

and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free

service and Cisco currently supports RSS version 2.0.

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

5

Page 14

Cisco RF Gateway 10 Hardware Installation Guide

6

OL-16264-04

Page 15

CHAPTER

1

Overview

The Cisco RF Gateway 10 (RFGW-10) is a Carrier Class Universal Edge QAM (UEQAM) platform that

offers concurrent support for Standard and High Definition Digital Broadcast Television, Switched

Digital Video (SDV), Video on Demand (VoD), and DOCSIS/Modular CMTS services.

The Cisco RFGW-10 UEQAM is a chassis-based product that is based on open standards with superior

performance, capacity, power consumption, ease of management and scalability. All components of the

Cisco RFGW-10 UEQAM are designed for high availability including dual Supervisor and Ethernet

switching line cards, N:1 Universal Edge QAM line cards, dual Timing and Control line cards, dual load

balancing and load sharing Direct Current Power Entry Modules (DC PEMs) and integrated RF

switching modules.

The Cisco RFGW-10 is part of the Cisco Cable ecosystem, and is fully integrated and tested as part of

the Cisco Digital Broadband Delivery System (DBDS) video solution and Cisco uBR10012 DOCSIS 3.0

and Modular CMTS solution.

The Cisco RFGW-10 is a centralized switching architecture leveraged from the Cisco Catalyst 4500

Series switches. The Cisco RFGW-10 is a 13 rack unit carrier class, modular chassis designed for

providing front-to-back airflow and system level redundancy. All chassis components are hot-swappable

and redundant. The chassis supports “wire-once” cabling for RF line cards and an integrated dual-zone

RF switch matrix. The supervisor engine provides non-blocking, Layer 2 to Layer 4 switching with the

addition of wire-speed 10-Gigabit Ethernet uplinks, 136-Gbps capacity, and 102-mpps packet

throughput.

The Cisco RFGW-10 system is a UEQAM that supports both upstream and downstream RF cards over a

frequency range of 5 MHz to 1.2 GHz. The initial line card release is a UEQAM downstream card that

supports the DOCSIS (1.0/2.0/3.0), the EURODOCIS, and J-DOCSIS specifications.

Based on the Cisco IOS networking software, the Cisco RFGW-10 supports advanced switching and

routing features.

OL-16264-04

This document contains the following sections:

• Cisco RFGW-10 Features, page 1-2

• Cisco RFGW-10 Functional Overview, page 1-2

• Cisco RFGW-10 IOS Software, page 1-4

• Cisco RFGW-10 Hardware, page 1-5

• Cisco RFGW-10 Components, page 1-7

• Supported External AC-Input Power Shelf, page 1-29

Cisco RF Gateway 10 Hardware Installation Guide

1-1

Page 16

Cisco RFGW-10 Features

Cisco RFGW-10 Features

The Cisco RFGW-10 has the following features:

• 13 Rack-Unit Carrier Class Chassis

–

19-inch rack-mount capability

–

4536 watt capacity

–

Front-to-rear airflow design

–

Integrated RF switching

–

Cable-once (wire-once) coaxial connections

–

LCD front panel display

–

Greater than 100 Gbps system performance

–

System level redundancy

• Redundancy System Architecture

–

All major FRUs redundant (supervisor, line card, power supply)

Chapter 1 Overview

–

Dual zone integrated RF data path switch

–

500-ms line card failover

–

Full software and hardware High Availability support

- External Gigabit Ethernet and 10 Gigabit Ethernet redundancy

- DOCSIS Timing Interface (DTI) redundancy

–

System operation from single power supply

• Major System Components

–

2 Supervisor Card Slots (1:1 Redundant)

–

2 Timing, Communication, and Control (TCC)/DTI Card Slots (1:1 Redundant)

–

10 Universal Line Card Slots (N:1 Redundant)

–

12 RF Switch Card Slots (Dual Zone Redundancy)

–

2 DC PEM Slots (1:1 Redundant)

–

1 Fan Tray Module

Cisco RFGW-10 Functional Overview

The Cisco RFGW-10 is a Carrier Class Universal Edge QAM (UEQAM) platform that offers concurrent

support for Standard and High Definition Digital Broadcast Television, Switched Digital Video (SDV),

Video on Demand (VoD), and DOCSIS/Modular CMTS services. The Cisco RFGW-10 is an edge

modulation device that aggregates multiple High Speed Data and/or Video sources, processes and

modulates the digital MPEG content, and forwards the QAM modulated MPEG data to the subscriber

side devices (cable modems and set-top boxes).

1-2

The initial application of the Cisco RFGW-10 is primarily as a downstream data delivery system

(downstream from the Cisco RFGW-10 to the cable modem or set-top box). External data and

management sources (VoD servers, MCMTS devices, DNCS, and so on) aggregate into the system via

the Gigabit Ethernet and 10 Gigabit Ethernet interfaces on the Supervisor and the RF line cards. The

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 17

Chapter 1 Overview

Cisco RFGW-10 Functional Overview

Cisco RFGW-10 architecture is based on a centralized Layer 2 to Layer 4 Ethernet switch fabric. All

external Ethernet interfaces, whether on the line cards or on the Supervisor front panel, terminate at the

Supervisor engine’s switch fabric. Traffic on any of the external interfaces can be routed to any card in

the chassis.

The supervisor engine receives either DEPI (DOCSIS) data or Video data (MPEG/UDP/IP) and forwards

the data to the RF line cards based on either the DEPI session content (IP/L2TP) or encapsulated video

session information (IP/UDP). All data path traffic is terminated at the line cards. The supervisor

receives data traffic, classifies the traffic, and forwards the data traffic to the line cards.

Control traffic for DOCSIS (DEPI mode), Video, and HA functionality is terminated on the Supervisor.

Local video mode (CLI, GUI, SNMP), remote video mode control plane (DNCS, GQI), and Native video

mode (GQI v2, object model) are implemented in the IOS and terminate at the Supervisor.

The Cisco RFGW-10 supports redundant, DTI source device inputs as part of the system clocking

architecture. It includes redundant DTI/TCC cards, which support DTI client functionality.

All line cards and modules are redundant. The Supervisors (RPR, SS), TCC, and DC PEMs support 1:1

redundancy. The line card slots can be enabled in either a single N+1 redundancy configuration or a dual

redundancy configuration (N+1, M+1). RF data path redundancy is enabled by the integrated RF Switch

matrix, which supports dual redundancy groups.

The following sections provide a high-level overview of the downstream data path:

1. Data packets are received by the Cisco RFGW-10 UEQAM via either the 10GE or multiple 1GE

interfaces.

2. Data packets are received by the switch fabric on the Supervisor card (all external Ethernet ports

terminate at the Supervisor Switch fabric). The supervisor forwards data traffic to the line cards

based on the session information and IP address. For data traffic, the supervisor de-encapsulates

IP/LT2P DEPI traffic and for Video, the supervisor de-encapsulates based on the IP address/UDP

range information.

3. All data path traffic terminates at the specific RF line card (chassis slots 3:12). All cards in the

system are synchronous to the DTI system clock reference.

4. For DEPI traffic, the DS line card extracts L2TP header information, parses and processes DOCSIS

packets, re-stamps data with DOCSIS time stamps, and completes the J.83 FEC processing.

5. For Video traffic, the DS line card classifies the video packets, manages intra-QAM scheduling,

PCR re-stamping, PID re-mapping, and J.83/FEC encoding.

6. The J.83 FEC encoded data is forwarded to the upconverter module, which modulates, upconverts,

and forwards data downstream in MPEG-2/MPEG-4 encoding.

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-3

Page 18

Cisco RFGW-10 IOS Software

Table 1-1 DOCSIS and EuroDOCSIS Downstream Data Rates

Chapter 1 Overview

Downstream Channel

Width, MHz

6 64 QAM (6)

8 64 QAM (6)

Modulation Scheme,

bit/symbol Baud Rate, MSym/sec Raw Bit Rate, Mb/sec

5.056

256 QAM (8)

256 QAM (8)

5.360

6.952

6.952

Cisco RFGW-10 IOS Software

The Cisco RFGW-10 UEQAM runs the Cisco IOS software, which is stored on the compact flash

memory disks that fit in the single compact flash memory slot on the front of the Supervisor Cards. The

compact flash can store a Cisco IOS image or the configuration file.

In addition to the flash memory disks, each Supervisor module contains onboard flash memory that

stores a boot loader. The loader executes following a system reset to reload and execute the Cisco IOS

software on the flash memory disks.

The Supervisor module also stores the system configuration in the onboard flash memory. The

configuration information read from the flash memory is buffered in the operational memory following

initialization, and is written to the flash memory device when the configuration is saved.

Each line card also contains an onboard flash memory that is used to store a boot loader, similar in

function to that used on the Supervisor card. However, the line card loader executes following a system

reset, line card reset, or line card insertion to reload and executes any code that must run on the line card.

Software images may also be stored on an external TFTP server. Based on the configuration, the proper

image might be downloaded from the TFTP server and executed.

30.34

42.88

41.71

55.62

Throughput (Bit Rate

- Overhead), Mb/sec

27

38

37

48

1-4

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 19

Chapter 1 Overview

Cisco RFGW-10 Hardware

This section describes the Cisco RFGW-10 system and components.

Cisco RFGW-10 System Configuration

Figure 1-1 shows the location of the front and the rear system components for the Cisco RFGW-10

UEQAM.

Figure 1-1 Cisco RFGW-10 Chassis Components—Front and Rear View

3

Cisco RFGW-10 Hardware

4

2

1

7

5

6

1 Universal RF line card slots 5 TCC/DTI card slots

2 Supervisor card slots 6 DC PEMs

3 LCD/Push button panel 7 RF switch cards/coaxial cable termination slots

4 Fan assembly

271377

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-5

Page 20

Cisco RFGW-10 Hardware

273847

2

1

4

3

The Cisco RFGW-10 UEQAM is installed in a standard 19-inch equipment or telco rack. A rack-mount

kit ships from the Cisco factory with each router. The rack-mount kit includes the hardware needed to

mount the router in a standard 19-inch equipment rack or telco-type rack. Mounting in 23-inch

equipment rack is possible with optional third-party mounting hardware.

The components in the front include the Supervisor Cards, RF line cards, and the front panel LCD. The

components on the rear include the Fan Assembly, RF Switch cards (coaxial terminations), TCC (DTI

Clock) cards, and the power supply modules.

All components (excluding the LCD) are hot-swappable and field replaceable. A fully configured system

will operate with a single DC PEM installed; the second PEM is required for power supply redundancy

and power load sharing.

Note Proper configuration of the DC power input requires that both Input 1 and Input 2 are connected to the

external power source and the GND connections are connected to the Earth GND. Input 1 and Input 2

on the DC PEMs are not redundant power inputs. If only one of the inputs is connected to the external

power, the Cisco RFGW-10 UEQAM will not power-on correctly.

Cisco RFGW-10 Slot Numbering

Chapter 1 Overview

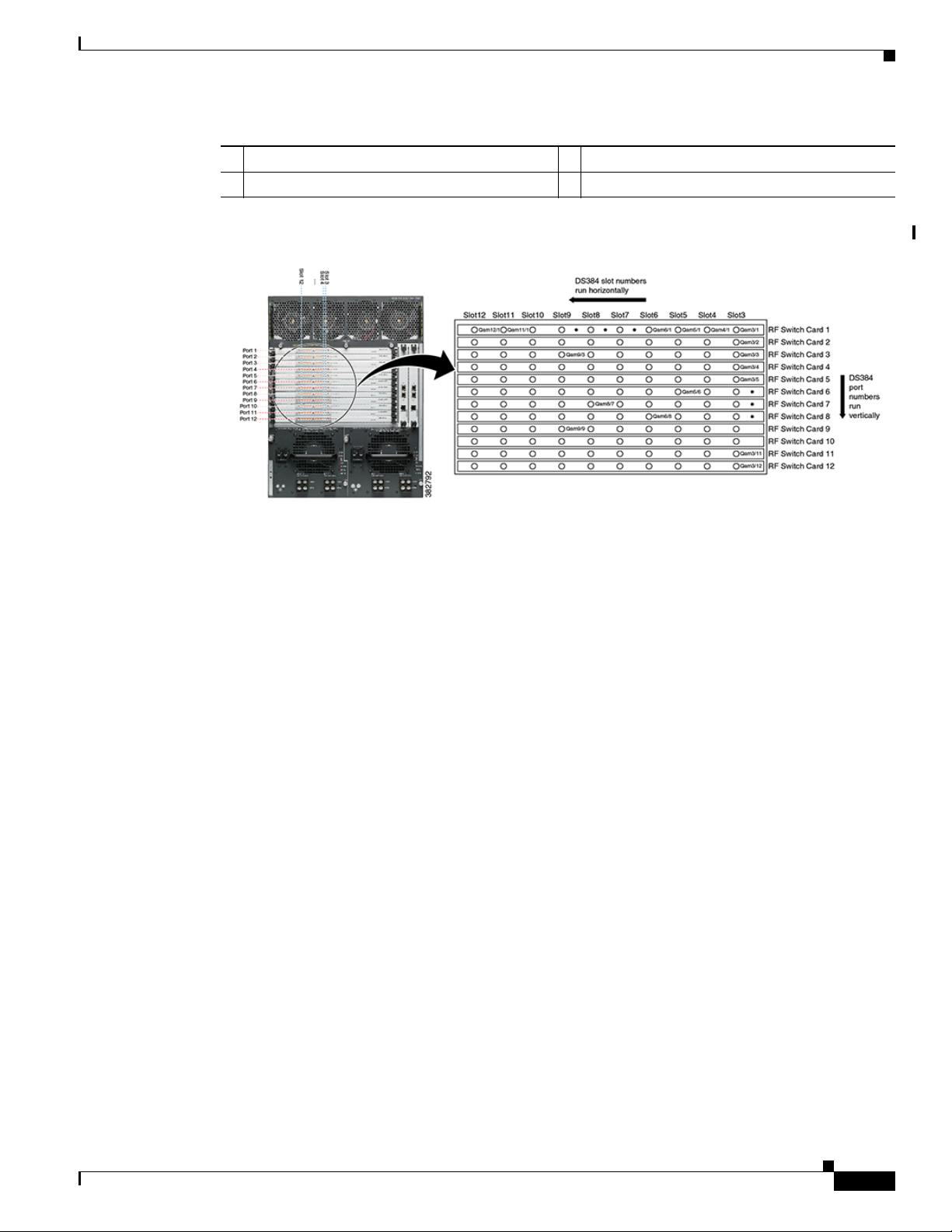

The figures below show the slot numbering in a Cisco RFGW-10 chassis.

Figure 1-2 Cisco RFGW-10 Slot Numbering

1-6

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 21

Chapter 1 Overview

Cisco RFGW-10 Components

1 Supervisor Engine slots 1 and 2 3 RF Switch slots 1 through 12

2 Universal RF card slots 3 through 12 4 TCC cards slots 13 and 14

Figure 1-3 Cisco RFGW-10 Slot/Port Numbering

Cisco RFGW-10 Components

The following sections describe the components in the Cisco RFGW-10:

• Fan Assembly, page 1-7

• DC PEMs, page 1-10

• Front Panel Display, page 1-14

• Supervisor Engines, page 1-15

• Cisco RFGW 10 Supervisor Engine 7-E, page 1-17

• Cisco RFGW-10 DS-48 Line Card, page 1-20

• Cisco RFGW-10 DS-384 Line Card, page 1-23

• TCC/DTI Card, page 1-23

• RF Switch Card, page 1-27

Fan Assembly

The Cisco RFGW-10 UEQAM system uses a modular fan assembly to dissipate heat from the system

and control the temperature of the chassis system components (except the DC PEM, which contains its

own internal fan). The fan assembly is a multi-fan design that pulls ambient air from the lower front of

the chassis and exhausts air out of the rear top of the chassis. The fan assembly provides individual fan

control and failure monitoring, multiple thermistors to monitor exhaust air and a wide range of speed

control parameters based on the system and the environmental conditions. Inlet air monitoring is

communicated to the fan tray via the system software from the sensors on each of the RF line cards.

The fan tray module provides the following features:

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-7

Page 22

Cisco RFGW-10 Components

273848

• Online insertion and removal OIR support

• Failure monitoring of individual fans

• Backup temperature monitoring to control individual fan rotation per minute (RPM)

• Usage counter based on hours of operation (CLI-based)

• Front panel LED for alarm status indication

• Control and power circuit failure alarms

• On board multi-level fan speed control based on system temperature

The fan assembly draws air into the chassis and directs it across the internal system components. The

heated air exhausts out of the rear of the chassis as shown in Figure 1-4.

Figure 1-4 Cisco RFGW-10 Airflow

Chapter 1 Overview

The fan tray has four speed levels based on the operating control modes for the system. After power on,

the fan speed is set according to the Supervisor provided ambient average air temperature and the

configured speed control mode in the system configuration. The default control mode setting configures

the fans at maximum speed. The speed of the fans regulate to a slower speed when the fan controller

stabilizes to the ambient temperature and chassis temperature. After startup, it may take up to 30 seconds

for the fans to stabilize at the requested RPM.

Figure 1-5 and Figure 1-6 show the fan assembly module. The fan tray has a single LED indicator (FAN

OK) located in the center of the module. The FAN OK LED status indicators are defined in Ta ble 1 - 2:

Table 1-2 Fan Assembly LED

Cisco RF Gateway 10 Hardware Installation Guide

1-8

OL-16264-04

Page 23

Chapter 1 Overview

273443

Cisco RFGW-10 Components

LED Color Status Description

Green System OK System is functioning normally, all fans

are operating.

Amber Failure (Any Type of Failure) A single fan has failed, system triggers

alarms, but the fan assembly is still able

to cool the chassis. Repair or replace the

fan assembly as soon as possible.

Figure 1-5 Cisco RFGW-10 Fan Assembly Faceplate

Figure 1-6 Cisco RFGW-10 Fan Assembly

273444

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-9

Page 24

Cisco RFGW-10 Components

DC PEMs

Note Each DC PEM has an earth ground connection and two DC power input connections (Input 1 and Input

Chapter 1 Overview

The Cisco RFGW-10 system is powered by redundant DC PEMs. An individual PEM is capable of

providing 4536 watts of total output. The redundant modules work as a 1:1 redundancy configuration

and support OIR (hot swapping). These modules do not support current sharing as they are non-isolated

PEMs, which are diode OR'd into two separate load zones.

Each PEM includes two 60A input lines that operate between –40VDC and –60VDC input voltages.

Proper configuration and operation requires that both DC inputs are properly wired. The PEM also

includes an earth ground connection (this is not power return) for grounding the chassis.

2). Both external DC inputs (Input 1 and Input 2) must be connected as shown in Figure 1-7. Input 1 and

Input 2 are individual power inputs. Both power inputs on the PEM must be wired to external power for

the Cisco RFGW-10 UEQAM to operate properly. If both inputs are not connected to external power, the

Cisco RFGW-10 UEQAM will not power on.

DC PEM features:

• Closed frame, NEBS-compliant module design

• Front-to-back airflow (exhaust air exits out of the rear of the chassis)

• Power input range: –48VDC to –60VDC

• 4536W power capacity

• Supports OIR (hot swap)

• Supports 1:1 redundancy (system can run with a single PEM)

• CLI interface support for status and configuration

• Remote shutdown feature

• Front panel LED status and alarm indicators

Note When both the DC PEMs are installed, both need to operate with the breaker switches and the OUTPUT

OK LED on. If one PEM is not operational, it is recommended that the PEM either be removed from the

system or the power input cables be removed to limit the power supply Conductive Emissions (FCC

conductive Emission Requirements).

1-10

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 25

Chapter 1 Overview

273170

Cisco RFGW-10 Components

Figure 1-7 shows the DC PEM faceplate.

Figure 1-7 DC PEM Faceplate

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-11

Page 26

Chapter 1 Overview

Cisco RFGW-10 Components

Table 1-3 DC PEM LEDs

LED Status Description

–48V1 Green Power input is wired correctly and

receiving proper DC power input.

Red Fault with power input. Typically this

means that the power input is wired

incorrectly with reverse polarity.

Sometimes it also indicates a failure on

the power input.

Blank External power source is not providing

power correctly (typically no power is

provided).

–48V2 Green Power input is wired correctly and

receiving proper DC power input.

Red Fault with power input. Typically this

means that the power input is wired

incorrectly with reverse polarity.

Sometimes it also indicates a failure on

the power input.

Blank External power source is not providing

power correctly (typically no power is

provided).

FAN FAIL Blank Normal Operation.

Red Alarm Condition. Fan operation is not

normal.

Fault Blank Normal Operation.

Red Alarm Condition. System Fault -

General fault indications. Power supply

is not operating normally.

CUR LIM FAIL Blank Normal Operation.

Red Alarm Condition. System is

experiencing an over current or over

power condition (exceeding 60A on

inputs).

TEMP FAIL Blank DC PEM is operating within functional

temperature range.

Red Alarm Condition. DC PEM is

experiencing an over temperature

condition.

OUTPUT OK Green All outputs from the PEM to the system

are within normal operating ranges.

Red Alarm Condition. Indicates that one of

the system voltages from the DC PEM is

out of range.

1-12

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 27

Chapter 1 Overview

Table 1-4 DC PEM Wiring Definitions

Connector Wiring Point Description

Input 1

Input 1 RTN

Input 2

–48V • Negative DC input from external

battery source

• Input Voltage Range: –48VDC to

–60VDC (nominal), –40VDC to

–60VDC (full range)

• Wiring: #2 Gauge, #4 Gauge

• Must use Right Angle Power LUG

• Battery Return for DC input 1

• Input Voltage Range: –48VDC to

–60VDC (nominal), –40VDC to

–60VDC (full range)

• Wiring #2 Gauge, #4 Gauge

• Must Use Right Angle Power LUG

–48V • Negative DC input from external

battery source

• Input Voltage Range: –48VDC to

–60VDC (nominal), –40VDC to

–60VDC (full range)

• Wiring: #2 Gauge, #4 Gauge

Cisco RFGW-10 Components

Input 2 RTN

GND GND

• Must use Right Angle Power LUG

• Battery Return for DC input 1

• Input Voltage Range: –48VDC to

–60VDC (nominal), –40VDC to

–60VDC (full range)

• Wiring #2 Gauge, #4 Gauge

• Must Use Right Angle Power LUG

• Earth Ground Connection for PEM

and Chassis

• Wiring: #2 Gauge, #4 Gauge

• Must use Right Angle Power LUG

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-13

Page 28

Cisco RFGW-10 Components

Table 1 - 5 lists the DC power specifications.

Table 1-5 DC Power Specifications

Specifications Requirements

Power Input Range Input voltage:

Chapter 1 Overview

–48 VDC or –60 VDC (nominal), range –40 to –60 VDC

Recommended DC service: Four 60A services @ nominal

–48 VDC or –60 VDC (two 60A

services per PDU)

Required Lugs: 90° angled industry standard 2-hole compression lugs with holes on 5/8inch centers (for example, for AWG no. 4 wire: for example Panduit LCD4-14AF-L or

equivalent.

Caution The input wire gauge should be selected by certified electricians based on the

local electrical code.

Power Consumption Maximum system power is limited to 4536 watts (15,474.06 Btu/hour)

Thermal Requirements Maximum Ambient Temperature must be less than 122°F (50°C)

Power Redundancy Two DC PDUs and two DC PEMs—2N redundancy

Power Supply Ground Lug Industry standard 2-hole compression lug with holes on 5/8- inch centers (for example,

Panduit part number LCD4-14AF-L, or equivalent)

Front Panel Display

Integrated with the Cisco RFGW-10 chassis is the Front Panel Display (FPD) and Push Button Select

module. The purpose of the module is to provide real time information of the chassis configuration, IOS

images, alarm status and management, and general system auditing. The LCD is field upgradeable, but

not hot-swappable.

1-14

Figure 1-8 shows the Cisco RFGW-10 front panel display.

Figure 1-8 Cisco RFGW-10 Front Panel Display

POWER

ALARM

STATUS

The FPD is a 40 character x 4 line LCD module. The push button display and status LEDs are integrated

as part of the chassis front faceplate. The push button display provides the menu selection and a screen

scrolling mechanism to provide navigation capabilities. The FPD navigation features are not enabled in

this release of the system.

Cisco RF Gateway 10 Hardware Installation Guide

TOP

ALARM

BACK

281009

OL-16264-04

Page 29

Chapter 1 Overview

120474

STATUS LED

RESET

button

10 GE uplink

ports

Gigabit SFP

ports

Switch load

indicators

CONSOLE port

Ethernet

management port

Compact

Flash

port

Cisco RFGW-10 Components

Table 1-6 Front Panel Display LEDs

LED Color/Status Description

POWER Blank Power is not on

Green Power is on

ALARM Blank No system alarms reported

Orange System alarms are reported. Refer to the

CLI and system logs for the specific

alarms.

STATUS Green Future LED. Is Green when the system

is powered on normally.

Note The FPD features depend on the release of the Cisco IOS software running on the Cisco RFGW-10. The

initial release of the IOS software for the Cisco RFGW-10 will include the basic FPD features,

Hostname, IP Address, and IOS Version, and Customer Configured Description Field. Please refer to the

release notes for the Cisco IOS release running on the platform.

Supervisor Engines

This section describes the following supervisor engines for the Cisco RFGW-10:

• Cisco Supervisor Engine V-10GE, page 1-15

• Cisco RFGW 10 Supervisor Engine 7-E, page 1-17

Cisco Supervisor Engine V-10GE

Figure 1-9 Supervisor Engine V-10GE for the DS-48 Line Card

OL-16264-04

Note The Cisco Supervisor Engine V-10GE doe not support the Cisco RFGW-10 DS-384 line card.

Cisco RF Gateway 10 Hardware Installation Guide

1-15

Page 30

Cisco RFGW-10 Components

Supervisor Engine Components

The following connectors, LEDs, and buttons are located on the front panel of the supervisor engine:

• The STATUS LED, which indicates the operating state of the module

• Two Gigabit uplink ports

• Four SFP Gigabit uplinks ports

• Eight utilization indicator LEDs, which provide an approximation of the current traffic across the

backplane

• A console port (RJ-45)

• An Ethernet management port (RJ-45)

• A link status LED, which provides status for the management port

• The Reset button (recessed), which allows you to reset the system

• The Compact Flash port and eject button

Supervisor Engine LEDs

Chapter 1 Overview

Table 1 - 7 describes the meaning of the Supervisor Engine LEDs.

Table 1-7 Supervisor Engine LEDs

LED Status Meaning

STATUS Green All diagnostic tests passed.

Red A test failed.

Orange System boot or diagnostic test is in progress.

Off Supervisor is disabled.

UTILIZATION Green 1-100% If the switch is operational, this display indicates the current

traffic load over the backplane (as an approximate

percentage). Each LED lit green indicates approximately

12.5% of the load.

LINK Green The link is operational.

Orange The link is disabled by user.

Flashing orange The power-on self-test indicates a faulty port.

Off No signal is detected or there is a link configuration failure.

Active Green The port is active.

Off The port is not active.

Ethernet Management Port

The supervisor engine has a 10/100 BASE-T Ethernet management port. The Supervisor engine uses an

RJ-45 connector on the front panel with a link status LED.

Cisco RF Gateway 10 Hardware Installation Guide

1-16

OL-16264-04

Page 31

Chapter 1 Overview

Note To meet the electromagnetic interference (EMI) requirements, special UTP cables (with ferrites) should

be used for SUP Console and Auxiliary ports.

TCP/IP-based management services available through inband access also are provided through this port

(Telnet and SNMP). This management port also supports image download.

Note The 10/100 BASE-T Ethernet management ports are for network management only. These ports do not

support network switching.

Supervisor Memory

The Cisco RFGW-10 Supervisor provides 512-MB SODIMM SDRAM, 64-MB flash memory, and

512-KB NVRAM.

Cisco RFGW 10 Supervisor Engine 7-E

Cisco RFGW-10 Components

Starting with Cisco IOS-XE Release 3.2.0SQ, the Cisco RFGW-10 supports a new supervisor engine for

the Cisco RFGW-10 DS-384 line card.

Note The Cisco Supervisor Engine 7-E also supports the DS-48 line card.

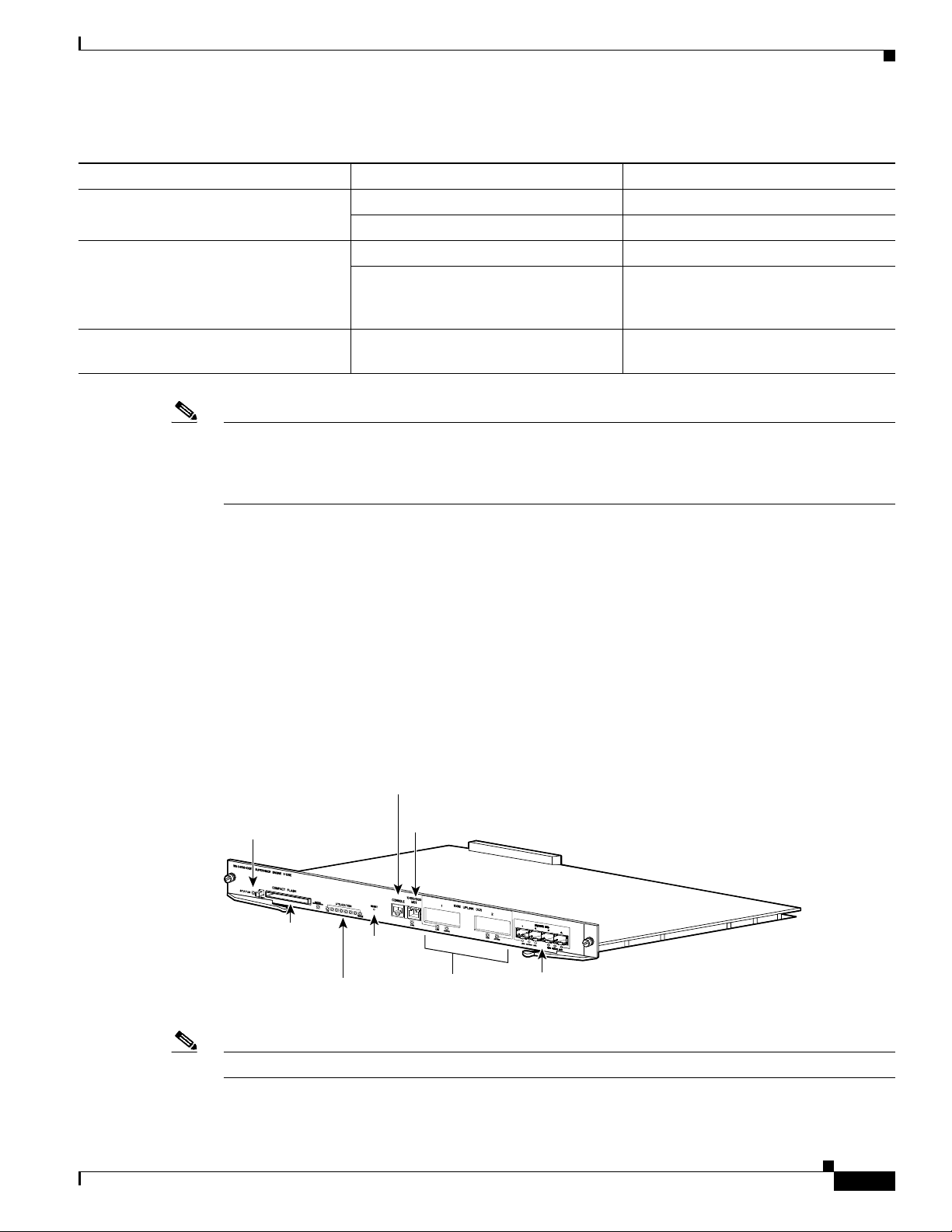

Figure 1-10 and Figure 1-11 show the faceplate and front view of the Supervisor Engine 7-E with the

major features identified.

Figure 1-10 Faceplate - Cisco RF Gateway 10 Supervisor Engine 7-E for the Cisco RFGW-10 DS-384 Line

Card

284034

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-17

Page 32

Cisco RFGW-10 Components

Figure 1-11 Cisco RFGW Supervisor Engine 7-E

1

W

S-X

45

-

S

U

P

7

-

E

S

T

A

T

U

S

1 STATUS LED 4 UTILIZATION LEDs 7 CONSOLE port (RJ-45

2 RESET switch (recessed) 5 USB ports 8 10/100/1000 MGT port (RJ-45

3 ACTIVE SUP (active su-

R

E

S

E

T

A

C

T

I

VE

S

U

P

U

T

IL

I

Z

A

T

I

O

N

2

3

4

pervisor engine) LED

Chapter 1 Overview

U

S

B

S

E

C

U

R

C

E

O

NS

D

10

I

/100/1000

G

O

L

I

T

E

AL

MG

T

1

-

2

A

C

T

I

V

1G

E

/

10G UP

L

I

N

K

S

(S

F

P

’

S

F

P+

)

3

-4

A

C

T

I

V

L

INK

1

G

5

7

6

8

E

1

0

G

9

connector)

connector)

6 SECURE DIGITAL slot 9 1G/10G UPLINKS (SFP/SFP+)

ports

279968

Features of the Cisco RFGW-10 Supervisor Engine 7-E

Table 1-8 Cisco RFGW-10 Supervisor Engine 7-E Features

Feature Description

Bandwidth per slot 48-Gbps

Memory 2-GB (upgrade to 4-GB)

Front panel features

STATUS LED The status LED indicates the current health of the supervisor engine and the current

software state. See Table 1 - 9 .

RESET switch The RESET switch is used to reset and restart the switch.

Note Use a paper clip or other small, pointed object to press the RESET switch.

ACTIVE SUP LED The active supervisor engine LED indicates whether the supervisor engine is active or

in standby mode in redundant supervisor engine configurations. See Ta b le 1 - 9 .

UTILIZATION LEDs Eight LEDs indicate (as an approximate percentage) the current traffic load over the

backplane. SeeTab le 1- 9 .

USB connectors Two USB 2.0 ports are provided. Port 1 operates in device mode (upstream) and port 2

in host mode (downstream). Port 1 has a standard Type B USB connector and can be

used as a USB console.Port 2 has a USB type A connector and a standard USB 2.0 device

like a flash memory device can plug into this connector.

SECURE DIGITAL slot A standard Secure Data (SD) memory card interface is provided on the front panel

1-18

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 33

Chapter 1 Overview

Cisco RFGW-10 Components

Feature Description

CONSOLE port This is a 10/100/1000 port that uses an RJ-45 connector. The console port allows you

access the switch either locally (with a console terminal) has an RJ-45 connector. The

console port allows you to perform the following functions:

• Configure the switch from the CLI

• Monitor network statistics and errors

• Configure SNMP agent parameters

10/100/1000 MGT port The Ethernet management port is a Layer 3 host port to which you can connect a PC.

You can use the Ethernet management port instead of the console port for network management.

Note When connecting a PC to the Ethernet management port, you must assign an IP

address.

LINK LED The 10/100/1000 MGT port has a link LED associated with it. See Tab l e 1- 9 .

1G/10G UPLINKS

(SFP/SFP+) ports

Uplink port LEDs Each of the four uplink ports has two LEDs associated with it. One LED displays port

The Supervisor Engine 7-E has four 1-G or 10-G ports that use either SFP transceivers

or SFP+ transceivers.

status when a 1-GB SFP transceiver is installed in the port socket. The second LED

displays uplink port status when a 10-GB SFP+ transceiver is installed in the port socket.

See Table 1 - 9.

Front Panel LED

Table 1-9 Cisco RFGW-10 Supervisor Engine 7-E Front Panel LEDs

LED Color and Meaning

STATUS The STATUS LED indicates the status of he supervisor engine.

• Green—All diagnostic tests have passed

• Orange—System boot or a diagnostic test is in progress.

• Red—A diagnostic test failed.

• Off—The supervisor engine is disabled or is not powered up.

ACTIVE SUP Indicates whether the supervisor engine is active or standby.

• Green—Supervisor engine is active (in redundant supervisor engine

configurations)

• Off—Supervisor engine is in standby mode (in redundant supervisor

engine configurations)

UTILIZATION When the switch is operational, the eight utilization LEDs indicate the current

traffic load over the backplane as an approximate percentage value. Each LED

lit green indicates approximately 12.5 percent of load.

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-19

Page 34

Cisco RFGW-10 Components

Table 1-9 Cisco RFGW-10 Supervisor Engine 7-E Front Panel LEDs (continued)

LED Color and Meaning

MGT port Indicates the status of the 10/100/1000BASE-T Ethernet management port

• Green—The link is operational.

• Orange—The link is disabled by user.

• Flashing orange—The power-on self-test indicates a faulty port.

• Off—No signal is detected or there is a link configuration failure.

Uplink link Indicates the status of the uplink port

• Green—The link is operational.

• Orange—The link is disabled by user.

• Flashing orange—The power-on self-test indicates a faulty port.

• Off—No signal is detected or there is a link configuration failure.

Physical and Environmental Specifications

Chapter 1 Overview

Table 1-10 Cisco RFGW-10 Supervisor Engine 7-E Physical and Environmental Specifications

Item Specification

Dimensions (H x W x D) 1.75" x 14.5" x 11"

Weight 5.5 lbs

Power requirement 302 W

Environmental

Operating temperature

• Certified for operation: 32° to 104°F (0° to 40°C)

• Designed and tested for operation: 32° to 130°F (0° to

55°C)

Humidity (RH) ambient (non-condensing) 10 to 90%

Operating altitude

• Certified for operation: 0 to 6500 ft (0 to 2000 m)

• Designed and tested for operation: –200 to 10,000 ft (–60

to 3000 m)

Operating temperature

• Certified for operation: 32° to 104°F (0° to 40°C)

• Designed and tested for operation: 32° to 130°F (0° to

55°C)

Cisco RFGW-10 DS-48 Line Card

1-20

The Cisco RFGW-10 DS-48 line card is a QAM modulator and upconverter product designed to support

DOCSIS downstream data traffic (DEPI D-MPT) and video applications (VoD, SDV, and broadcast

video). The DS-48 card is similar to the traditional QAM solutions where the card receives encapsulated

data, de-packetizes/re-formats the packets, maps them to the output QAM channel, and performs QAM

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 35

Chapter 1 Overview

Cisco RFGW-10 Components

modulation and frequency upconversion. From a high level, the DS-48 line card receives Video and

DOCSIS data encapsulated over Ethernet and outputs analog QAM data to the subscriber devices (STB,

DOCSIS modems).

As a DOCSIS engine, the DS-48 line card supports DEPI D-MPT mode (future SW releases may support

PSP mode). DEPI is based on the L2TPv3 protocol, which includes a data plane and a control plane.

DEPI data plane traffic is terminated at the line card. The Cisco RFGW-10 Supervisor terminates DEPI

control and communicates the control to each line card in the system via the chassis IPC infrastructure.

DOCSIS timing information (10.24MHz synchronous DTI clock) is received by the line card from the

system TCC cards.

As a video engine, the DS-48 terminates video data path traffic forwarded from the Supervisor Engine

(video control plane traffic is terminated and processed by the system Supervisor). The DS-48

processing path classifies video packets, performs inter QAM processing, bitrate scheduling, program

muxing/scheduling, PID remapping, PCR re-stamping, and CC re-stamping.

A critical feature for the DS-48 line card is redundancy and high availability support. The line cards are

designed to detect and react to a wide range of faults and failures and respond with sub-second failover

to a dedicated protect card.

The DS-48 line card is designed to support a wide range of line card health conditions and initiate

failover events if considered catastrophic:

• QAM/upconverter HW failure. The line card monitors both the digital and RF data integrity. The

modules also provide a comprehensive alarm structure to the system CPU, which allows constant

monitoring of the UPX.

• Environmental alarms (temperature, voltage, frequency).

• Software kernel failures.

• Software module failure.

• DTI Clock/Timing failures (both internal and external).

• SFP failures.

The DS-48 line card has 12 physical RF ports, which support up to four QAMs per port. The number of

QAM outputs is configurable on a per port basis (meaning an individual port can support 1, 2, or 4 QAMs

as well as muting of individual QAMs within a QAM group). In stacked QAM mode, the QAMs are

stacked contiguously over a 24-MHz or 32-MHz band. The line card supports a downstream channel

frequency range of 88 MHz to 870 MHz.

The front panel includes two 1xGE ports and a single DVB-ASI interface (covers all video output

streams). The front panel connectors support both copper and fiber SFP modules. The front panel GE

ports are not processed directly by the line card, these are independent of the line card and route directly

to the Supervisor switch fabric. These ports do not become out of service if the line card crashes and a

failover to the redundant card occurs.

DS-48 Line Card Components

OL-16264-04

The following connectors and LEDs are located on the front panel of the DS-48 line card:

• STATUS LED that indicates the operating state of the line card

• ALARM LED that indicates the general health of the line card

• TRAFFIC LED that indicates whether the card is a primary (working card) or a protect card

• LINK LED that indicates whether the link is operational

• DVB-ASI BNC Coax Interface

Cisco RF Gateway 10 Hardware Installation Guide

1-21

Page 36

Cisco RFGW-10 Components

• Two SFP Gigabit uplink ports

Chapter 1 Overview

1-22

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 37

Chapter 1 Overview

273679

Cisco RFGW-10 Components

Table 1-11 DS-48 Line Card LEDs

LED Color/Status Description

STATUS Green Line card is powered correctly and has initialized correctly

Off Line card is not initialized correctly, not booted up

ALARM Blank Normal operation

Yellow Minor line card error

Red Major line card error

TRAFFIC Green Line card is active and traffic is processed by the card

Blue Slot [11:12]: Card is configured as backup card

Red Slots[3:10]: Card has failed over to protect slot

LINK Green The Link is operational

Blank The link is not operational

Figure 1-12 shows the DS-48 faceplate.

Figure 1-12 DS-48 Line Card Faceplate

Cisco RFGW-10 DS-384 Line Card

For information about the Cisco RFGW-10 DS-384 line card, see Cisco RF Gateway 10 Downstream 384

Line Card Hardware Installation Guide.

TCC/DTI Card

The Cisco RFGW-10 UEQAM supports two Timing, Communication, and Control (TCC) slots. The

TCC card acts as a secondary processor that controls the overall system clock generation and

distribution, DOCSIS timestamp synchronization, and system control of the Front Panel Display (FPD)

and the RF Switch cards.

The TCC card’s most critical function is distribution of the system clocking, in particular the DTI

interface. The TCC card is a DTI client interface. It supports dual DTI external input allowing DTI server

redundancy. Based on the DTI input information, the TCC card generates DOCSIS 10.24-MHz clock and

timestamp information to every line card in the chassis. All clocks and DOCSIS information are

redundant. When there is no external DTI clock, the TCC provides an internal DOCSIS DTI clock and

time stamp reference.

When two TCC cards are installed, they are configured as active and backup (redundant). If the TCC

card in the first slot is working at system power-up, it automatically becomes the active card and the TCC

card in the second slot becomes the backup card (typically Slot 13 boots as the primary TCC and Slot

14 as the secondary, but this is not mandatory).

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-23

Page 38

Cisco RFGW-10 Components

In terms of the overall system high availability, the TCC cards work autonomously from the centralized

control mechanisms. Redundant TCC cards monitor each other’s priority information so that when the

active card fails, the active card role is transferred to the redundant backup card without loss of data.

The following is a summary of the TCC card’s functions and features:

• Generates and distributes 10.24 MHz clock references and 32-bit timestamp references to every

• Drives the LCD module used to display the system configuration and status information

• Proxy control mechanism (via supervisor cards) for the RF Switch Cards

• Front Panel LEDs providing Status and Alarm Indicators

• Provides two RJ-45 ports supporting redundant DTI server sources

Chapter 1 Overview

cable interface line card

1-24

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 39

Chapter 1 Overview

Cisco RFGW-10 Components

Table 1-12 TCC Card LEDs

LED Color/Status Description

POWER Green Power is being supplied to the TCC card.

Off Power off

STATUS Yellow Indicates that the CPU is in the bootup process,

self-test, or downloading code.

Green Indicates that the CPU has successfully completed

the boot, self-test, and code download process and

the TCC card is the Active card.

Blinking green Indicates that the CPU has successfully completed

the boot, self-test, and code download process.

Blinking green means the TCC card is the backup

card.

MAINTENANCE Off Indicates normal off. No maintenance action is

required.

Yellow Indicates that the maintenance operation is required,

and the TCC card can be hot-swapped.

DTI 1 ACT Yellow Indicates that the DTI server is connected, however

the DTI lock and communication is not established.

Off When DTI ACT is Off and the DTI Link is Green, it

indicates normal DTI connection.

When DTI ACT is Off and the DTI LINK is Off, it

indicates that the DTI interface is not linked with the

Server.

DTI 1 LINK Green Indicates that the DTI Client has established

connection with the server and the frequency is

locked.

Off When DTI ACT is Off and the DTI Link is Green, it

indicates normal DTI connection.

When DTI ACT is Off and the DTI LINK is Off, it

indicates that the DTI interface is not linked with the

server.

DTI 2 ACT Yellow Indicates that the DTI Server is connected, however

DTI lock and communication is not established.

Off Indicates that the DTI Server is not recognized or not

connected.

DTI 2 LINK Green Indicates that the DTI Client has established

connection with the server and the frequency is

locked.

Off Indicates that the DTI Server has not locked with the

DTI Client.

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

1-25

Page 40

Cisco RFGW-10 Components

281014

Note There are two LEDs for each DTI port (ACK and LINK). Only one of these can be on at a time.

The upper LED (ACK) indicates whether the RFGW-TCC is connected (linked) with the DTI server. It

does not indicated a frequency lock with the DTI server. Yellow illumination indicates a positive

communication link with the server. The lower LED (LINK) can either be green or off. When green, it

indicates that the DTI client has established connection with the server and the frequency is locked.

A typical transition of the LEDS is the ACK LED illuminates yellow (linked) after the system comes up

and when the DTI frequency is locked, the ACK LED becomes off and the LINK LED illuminates green.

Figure 1-13 and Figure 1-14 show the TCC/DTI Card.

Figure 1-13 TCC Card Faceplate

Chapter 1 Overview

1-26

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 41

Chapter 1 Overview

281011

Figure 1-14 TCC/DTI Card

RF Switch Card

The RF Switch provides RF data path redundancy at both the line card (slot) level and the RF port level

for bi-directional DOCSIS traffic upto 1.2 GHz. Additionally, the RF Switch cards are the coaxial cable

termination point for the Cisco RFGW-10.

Functionally the RF Switch card physically switches out a failed line card (port by port) at the RF data

path level. The card is capable of supporting (two) simultaneous RF line card failures. It is designed to

support dual N+1 redundancy groups (where N is a group of RF line cards associated with a single

“protect” card).

Cisco RFGW-10 Components

273441

There are 12 RF Switch cards per chassis providing 120 RF ports for the system (Note: the chassis

MUST include all 12 RF Switch cards for proper operation). Each Switch Card supports a single Cisco

UCH2 connector header; the UCH2 supports 10 MCX coaxial connections per card. The RF Switch card

is physically separate from the RF line cards slots allowing insertion or removal of the RF line cards

without disruption of the cable plant wiring.

The RF Switch Card is the central hardware component for chassis-level HA features. The card can be

configured and controlled via the system level CLI functionality. The RF Switch card is a hardware and

firmware based module (no operating software) that can be field upgraded via the chassis CLI.

The RF Switch Card faceplate includes a single LED, which provides very high level status for power

and functionality. The LED does not indicate a line card failover.

Figure 1-15 and Figure 1-16 show the RF Switch Card.

Figure 1-15 RF Switch Card Faceplate

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-27

Page 42

Cisco RFGW-10 Components

Figure 1-16 RF Switch Card

The RF Switch Card supports the following features:

• 10 RF bi-directional RF ports per RF Switch card

Chapter 1 Overview

273442

–

System support for 12 RF Switch cards, 120 RF Ports per chassis

–

Wire once interface: Coax cables are independent of the RF card insertion and removal

• OIR (Hot Swap) and field upgradeability

• Supports SW field upgrades

• Exceeds DOCSIS DRFI compliance requirements over 5 MHz to 1.2 GHz frequency range

• No active gain in any switch path

• Support for Cisco UCH2 Dense (MCX) connector

• Upto two flexible redundancy groups, each capable of N:1

• LED to indicate RF Switch’s active or fail mode

• CLI support for configuring and monitoring the status information

Tabl e 1- 1 3 Stat u s LE D s

LED Color/Status Description

POWER Blank RF Switch is not powered or Severe

firmware corruption

Green Normal operating conditions

Blinking Green Severe error condition (possibly power

out of specification or firmware

corruption)

1-28

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 43

Chapter 1 Overview

Supported External AC-Input Power Shelf

Supported External AC-Input Power Shelf

The AC-input power shelf converts AC power from an external AC power supply source into DC power

that is suitable for powering on the Cisco RFGW-10.

The Lineage AC-DC power shelf is supported on the Cisco RFGW-10.

Table 1 - 14 lists the Lineage power shelf specifications and the configurations supported on the

Cisco RFGW-10.

Table 1-14 Lineage Shelf Configurations Supported on Cisco RFGW-10

Component Configuration 1 Configuration 2

No. of Lineage Shelves

(Part Number J85480S1 L21)

Maximum Output Power

Rectifiers Modules

Power Output for Rectifiers

DC Power Output

AC Power Output

Operating Temperature

AC Power Cables

DC Power Cables

1

12

11 KW 16 KW

4 CP2725TEZ 8 CP2725TEZ or

2725 W (maximum) 1200 W (maximum)

–54 VDC –54 VDC

200–240 VAC 100–120 VAC

–40 C to 45 C –5 C to 45 C

240 VAC AC power—4 120 VAC AC power—8

Amphenol Y cables

CP2000AC54

2

Elmech straight cables

1. For more information on ordering the Lineage kit, visit www.arrow.com

2. The AC power cables supplied may vary with the country where the equipment is deployed.

For information on installation, power shelf safety features, safety warnings, and troubleshooting the

Lineage power shelf, see the product documentation available at http://www.lineagepower.com/.

Lineage AC-DC Power Shelf

The external Lineage AC-DC power shelf (part number J85480S1 L21) with AC module (CP2725TEZ

or CP2000AC54PE) is one-rack unit high (1.75 inch), and can be mounted on a standard 19-inch 4-post

equipment rack or telco-type rack. It is recommended that the Lineage power shelf is installed such that

the power connections face inside of the rack when viewed from the front. This allows the DC output

terminals of the external AC-input power shelf to be on the same side as the DC-input terminals of the

Cisco RFGW-10 chassis.

The Lineage AC-DC power shelf has two DC power sources, four AC-input power supply sources, and

J1 and J2 Jumper connectors. The J1 connector is used to connect a control interface cable and J2

connector is used for a shelf-to-shelf connection.

Note Jumpers must be removed prior to inserting a connector into the J1 housing.

• Black—2

• Red—2

• Black—4

• Red—4

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

1-29

Page 44

Supported External AC-Input Power Shelf

278055

3 4

2 2

11

Front view

Rear view

Each AC-input power supply module is automatically powered on when it is plugged into the wall

socket. (See Figure 1-17).

Figure 1-17 Lineage AC-DC Power Shelf - Front and Rear View

Chapter 1 Overview

1 DC power source terminal blocks 3 J2 connector

2 AC-input power connectors 4 J1 connector

All cable connections for AC-input power, DC-output power, and status signals are made from the rear

of the power shelf. Each AC power supply module has an individual AC facility cord attachment. All

four AC-input cords must be attached to the facility for all four AC power modules to function. The

DC-interconnect cables provide DC-output power to the DC PEM modules on the Cisco RFGW-10. (See

Figure 1-18).

Note The AC-input and DC-output power cables are supplied along with the Lineage kit. It is recommended

that you use these cables for cabling the shelf to the Cisco RFGW-10.

1-30

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 45

Chapter 1 Overview

334294

1

1

22

Supported External AC-Input Power Shelf

Figure 1-18 Rear View of the Lineage AC-DC Power Shelf with Cables

1 DC-output power supply cables 2 AC-input power supply cables

To meet compliance standards, use the DC power cables (3 m cable supplied along with the Lineage

power shelf) while cabling the Lineage AC-DC power shelf to the Cisco RFGW-10.

For information on connecting the Lineage power shelf see, Connecting the Lineage Power Shelf to the

Cisco RFGW-10, page 3-28.

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

1-31

Page 46

Supported External AC-Input Power Shelf

Chapter 1 Overview

1-32

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 47

CHAPTER

2

Preparing Your Site for Installation

Before you install the Cisco RFGW-10 UEQAM, consider:

• The power and cabling requirements that must be in place at your installation site

• The equipment required to install the router

• The environmental conditions your installation site must meet to maintain normal operation

This chapter contains important safety information you should know before working with the Cisco

RFGW-10 UEQAM and guides you through the process of preparing your site for router installation.

Note Do not unpack the system until you are ready to install it. Keep the chassis in the shipping container to

prevent accidental damage until you determine an installation site. Use the appropriate unpacking

documentation included with the system.

Warnin g

Warnin g

Warnin g

Warnin g

Read the installation instructions before connecting the system to the power source.

1004

Only trained and qualified personnel should be allowed to install, replace, or service

this equipment.

Ultimate disposal of this product should be handled according to all national laws and

regulations.

Class 1 laser product.

This chapter contains the following sections:

• Safety Recommendations, page 2-2

• Compliance Requirements, page 2-3

• Cautions and Regulatory Compliance Statements for NEBS, page 2-3

• Standard Warning Statements, page 2-4

• Site Planning, page 2-7

Statement 1030

Statement 1040

Statement 1008

Statement

OL-16264-04

Cisco RF Gateway 10 Hardware Installation Guide

2-1

Page 48

Safety Recommendations

• Preventing Electrostatic Discharge Damage, page 2-15

• Electrical Safety, page 2-15

• Receiving a Cisco RFGW-10 UEQAM, page 2-17

• Chassis-Lifting Guidelines, page 2-17

• Tools and Equipment, page 2-19

• Checking the Shipping Container Contents, page 2-20

• Cisco RFGW-10 UEQAM Installation Checklist, page 2-21

Safety Recommendations

The following guidelines will help to ensure your own safety and protect your Cisco equipment. This list

does not cover all potentially hazardous situations, so be alert.

• Cisco safety policy is that all of its routers must conform to the requirements of IEC 60950, with

appropriate national deviations, as a minimum. In addition, Cisco routers must also meet the

requirements of any other normative documents (for example, standards, technical specifications,

laws or regulations).

• Review the safety warnings listed in the Regulatory Compliance and Safety Information Guide that

accompanied your Cisco RFGW-10 UEQAM before installing, configuring, or maintaining the

router.

• Never attempt to lift an object that might be too heavy for you to lift by yourself.

Chapter 2 Preparing Your Site for Installation

• Always turn all the DC PEMs off and disconnect all power cables before opening the chassis.

• Always disconnect the power cables before installing or removing a chassis.

• Keep the chassis area clear and dust free during and after installation.

• Keep the tools and chassis components away from walk areas.

• Do not wear loose clothing, jewelry (including rings and chains), or other items that could get caught

in the chassis. Fasten your tie or scarf and sleeves.

• The Cisco RFGW-10 UEQAM operate safely when it is used in accordance with its marked

electrical ratings and product usage instructions.

2-2

Cisco RF Gateway 10 Hardware Installation Guide

OL-16264-04

Page 49

Chapter 2 Preparing Your Site for Installation

Compliance Requirements

This section includes Safety Compliance and Network Equipment Building Systems (NEBS) standards.

The Cisco RFGW-10 UEQAM is in compliance with national and international standards as described

in Table 2 -1.

Table 2-1 NEBS Compliance Requirements

Safety Compliance and NEBS Requirements

Specification Description

Safety

Telc o r d ia NE BS

GR-1089-Core Statement

IEC 60950-1 First 2001

EN 60950-1: 2001 +A11

CAN/CSA-C22.2 No. 60950-1-03 1st. / UL 60950-1 First.

Caution To comply with the Telcordia GR-1089 NEBS standard for electromagnetic

compatibility and safety, for Ethernet RJ-45 ports, use only shielded Ethernet cables

that are grounded on both ends. In a NEBS installation, all Ethernet ports are limited

to intrabuilding wiring.

Compliance Requirements

GR-1089-CORE

GR-63-CORE

NEBS Level 3 Compliance

The Cisco RFGW-10 UEQAM is designed to meet Network Equipment Building System (NEBS) Level

3 requirements per GR-1089-CORE and GR-63-CORE.

Cautions and Regulatory Compliance Statements for NEBS

This section lists the cautions, regulatory compliance statements, and requirements for the Network

Equipment-Building System (NEBS) certification from the Telcordia Electromagnetic Compatibility

and Electrical Safety – Generic Criteria for Network Telecommunications Equipment (A Module of

LSSGR, FR-64; TSGR, FR-440; and NEBSFR, FR-2063) Telcordia Technologies Generic

Requirements, GR-1089-CORE, Issue 4, June 2006.

Caution Wear an ESD protective wrist-strap on your wrist and attach the other end to a bare metal grounded

surface to prevent ESD.

OL-16264-04