Page 1

Text Part Number:

Contents

78-6525-01 Rev. A0

Catalyst 5000 Series

Supervisor Engine III G Installation and

Configuration Note

Product Numbers:

WS-X5550(=) Supervisor Engine III G without Uplink Module

This configuration note contains procedures for installing and verifying the operation of the

Catalyst 5000 series Supervisor Engine III G.

This document contains the following sections:

• Supervisor Engine III G Overview, page 2

Corporate Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

Copyright © 1999

Cisco Systems, Inc.

All rights reserved.

• Supervisor Engine III G Front Panel Components, page 2

• Safety Recommendations, page 6

• Removing and Replacing the Supervisor Engine, page 7

• Connecting a Terminal to the Console Port, page 10

• Connecting to the Interface Ports, page 12

• Verifying System Operation, page 14

• FCC Class A Compliance, page 15

• Related Documentation, page 15

• Cisco Connection Online, page 16

• Documentation CD-ROM, page 17

1

Page 2

Supervisor Engine III G Overview

Supervisor Engine III G Overview

Supervisor Engine III G includes the following features:

• Bridge address table for up to 16,000 active Media Access Control (MAC) addresses and

associated virtual local-area networks (VLANs) allocated dynamically between active ports

• Switching engine that provides data path and control for all network interfaces including two

integratedFastEthernetinterfacesthat can support redundancy using thespanning-treealgorithm

or load sharing when used with VLANs

• Gigabit Ethernet multimode fiber (MMF) or single-mode fiber (SMF) interfaces using

SC connectors

• Management functions that include monitoring the interface and environmental status and

providing Simple Network Management Protocol (SNMP) management and the

console/Telnet interface

• 37.5-MHz MCF5102 Network Management Processor (NMP)

• Switch fabric interface with a capability of over one million packets per second (pps)

• Hardware support for up to 1024 VLANs

• Gigabit Interface Converter (GBIC)-based uplink ports

• Onboard NetFlow Feature Card II (NFFC II) chipset for core switching logic

Supervisor Engine III G Front Panel Components

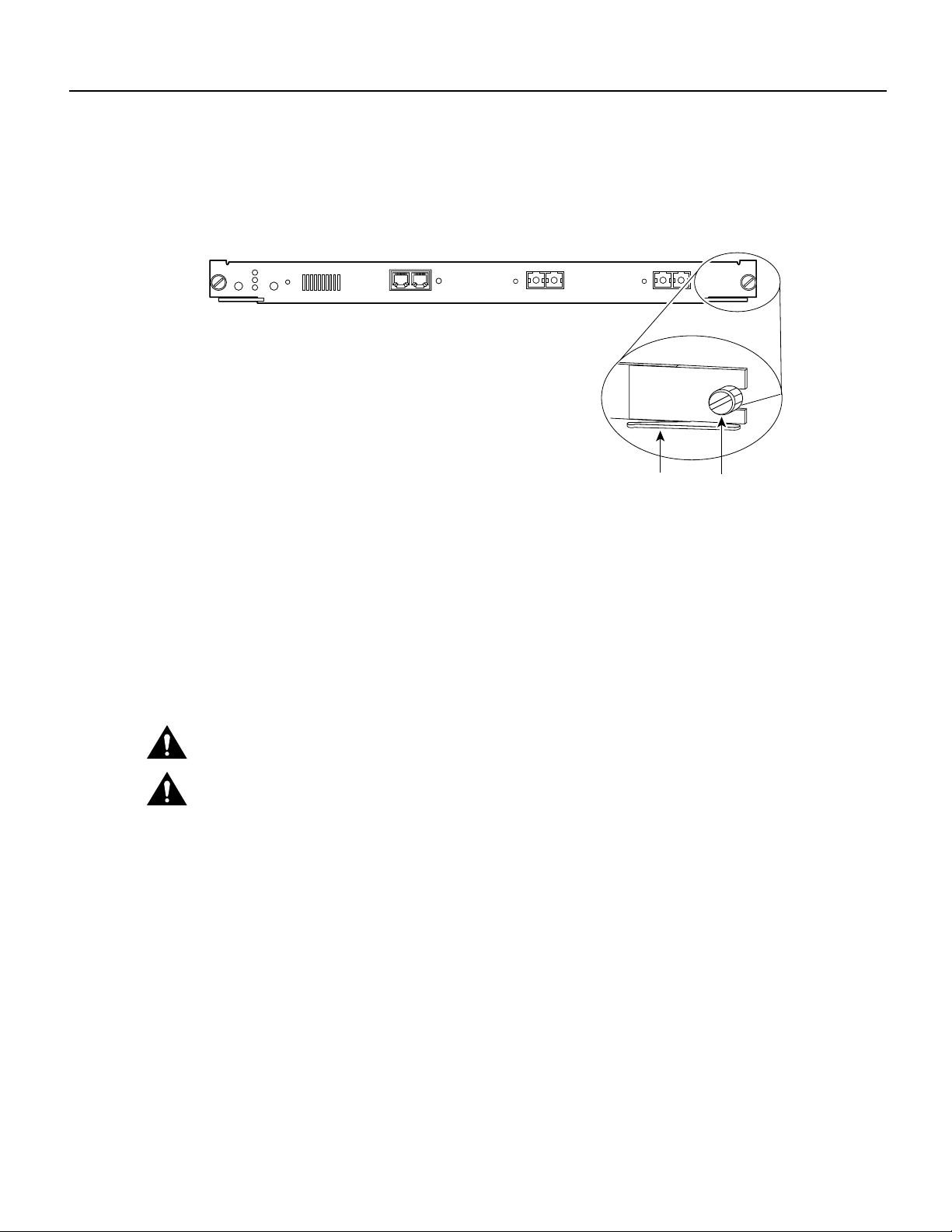

The Supervisor Engine III G front panel is shown in Figure 1.

Figure 1 Supervisor Engine III G

LEDs

WS-X5550

SUPERVISOR ENGINE III G-SERIES

SYSTEM

STATUS

FAN

PS2

PS1

Status

LEDs

The LEDs on the supervisor engine front panel indicate the status of the system, which includes the

states of the supervisor engine, the power supplies, and the fan assembly. Table 1 describes the

LEDs.

RESET

ACTIVE

Reset

button

SWITCH

100%

1%

LOAD

Switch

Load display

CONSOLE

RSFC CONSOLE

Console ports

CONSOLE

PORT MODE

LINK

PORT 1 PORT 2

Uplink ports with

GBIC fiber-optic connections

LINK

18937

Table 1 LED Descriptions

LED State Description

SYSTEM

STATUS

Indicates the status of the switch based on a series of self-tests and

diagnostic tests.

Green All the tests pass.

Red Any test fails.

2 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Page 3

Table 1 LED Descriptions (continued)

LED State Description

SYSTEM

Red During system boot or if the module is disabled.

STATUS

(continued)

Orange The redundant power supply is installed but not turned on or receiving input.

Orange The fan module fails.

FAN Indicates the status of whether or not the fan is operational.

Green The fan is operational.

Red The fan is not operational.

PS1 Indicates the status of the power supply in the left bay.

Catalyst 5000, Catalyst 5505, Catalyst 5509, and Catalyst 5500 switches:

Green The power supply in the left bay is operational.

Red The power supply in the left bay is not operational, switched off, or not

receiving input power.

Off The power supply in the left bay is off or not installed.

Note The Catalyst 5500 power supply LED is red when no modules are

installed.

Catalyst 5002 switch:

Green The power supply associated with the PS1 AC receptacle or DC terminal

block is operational.

Red The power supply associated with the PS1 AC receptacle or DC terminal

block is not receiving input power.

PS2 Indicates the status of the power supply in the right bay.

Catalyst 5000, Catalyst 5505, Catalyst 5509, and Catalyst 5500 switches:

Green The power supply in the right bay is operational.

Red The power supply in the right bay is not operational, switched off, or not

receiving input power.

Off The power supply in the right bay is off or not installed.

Note The Catalyst 5500 power supply LED is red when no modules are

installed.

Catalyst 5002 switch:

Green The power supply associated with the PS2 AC receptacle or DC terminal

block is operational.

Red The power supply associated with the PS2 AC receptacle or DC terminal

block is not receiving input power.

SWITCH LOAD 1-100% If the switch is operational, the switch load display indicates (as an

approximate percentage) the current traffic load over the backplane (see

Figure 2).

ACTIVE Green The supervisor engine is operational and active.

Orange The supervisor engine module is in standby mode.

100 Mbps Green The port is operating at 100 Mbps.

1000 Mbps Green The port is operating at 1000 Mbps.

LEDs

Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note 3

Page 4

Supervisor Engine III G Front Panel Components

Table 1 LED Descriptions (continued)

LED State Description

LINK Green The port is operational.

Orange The link has been disabled by software.

Flashing Orange The link is bad and has been disabled due to a hardware failure.

Off No signal is detected.

Reset Button

The Reset button allows you to restart the switch.

Note Use a paper clip or other small, pointed object to access the Reset button.

Switch Load

The Switch Load display provides you with a visual approximation of the current traffic load across

the backplane. The Supervisor Engine III G Switch Load display indicates the current aggregate

traffic load across all buses. Figure 2 shows the appearance of the Switch Load display.

Figure 2 Switch Load Display

Switch

Load

Load %

1-9 10-19 20-29 30-39 40-49 50-59 60-69 70-79 80-89 90-100

Console and RSFC Console Ports

The console port and RSFC console port allow you to perform the following functions:

• The console port enables you to configure the switch from the CLI

• Monitor network statistics and errors

• Configure SNMP agent parameters

• Downloadsoftware updates to the switch or distributesoftware images residing inFlash memory

to attached devices

The RSFC console port enables you to configure the switch for multiprotocol routing using

Cisco IOS software.

12815

The console port and RSFC console port are EIA/TIA-232 asynchronous, serial, full-featured data

terminalequipment (DTE) connectionswith hardware flow control andRJ-45 connectors. A console

port accessory kit with the necessary cabling and adapters is provided for making your terminal

connection.

4 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Page 5

Console Port Mode Switch

The console port mode switch allows you to connect a terminal to the supervisor engine using the

desired console cable.

Note The cable and adapters shipped with the switch are the same ones used on the Cisco 2500

series routers (and other Cisco products).

You can also connect a modem to the console port using the cable and adapter provided with

the switch.

Use the console port mode switch as follows:

• Mode 1—Switch in the in position. Use this mode to connect a terminal to the console port using

the console cable and data terminal equipment (DTE) adapter (labeled “Terminal”) that shipped

with the supervisor engine.

You can also use this mode to connect a modem to the console port using the console cable and

data communications equipment (DCE) adapter (labeled“Modem”) that shippedwith the switch.

• Mode 2—Switch in the out position. Use this mode to connect a terminal to the console port

using the Supervisor Engine III console cable (not provided).

Console Port Mode Switch

Memory

Flash Memory

EEPROM

For more information on using the console port, refer to the Catalyst 5000 Series Supervisor Engine

Installation Guide.

Onboard memory consists of dynamic random-access memory (DRAM) for the default system

software, Flash memory for downloading and storage of the system software, and nonvolatileRAM

(NVRAM) for the configuration file. Refer to the release notes for your Catalyst 5000 series

supervisor engine software release for the minimum requirements.

Flash memory allows you to load and store system software images. Supervisor Engine III G has

8 MB of Flash memory. You can download a new software image over the network or from a local

Trivial File Transfer Protocol (TFTP) server.

An electronically erasable programmable ROM (EEPROM) component on the supervisor engine

stores module-specific information, such as the module serial number, part number, controller type,

hardware revision, configuration information, and other details unique to each module. The

supervisor engine EEPROMalso contains an address allocator,which is a bank of 1024 hardware or

media access control (MAC)-level addresses, one for each possible VLAN in the system.

NVRAM

The configuration file is stored in nonvolatile random-access memory (NVRAM).

Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note 5

Page 6

Safety Recommendations

Safety Recommendations

Safety warnings appear throughout this note in procedures that, if performed incorrectly, may harm

you. A warning symbol precedes each warning statement.

Warning This warning symbol means danger. You are in a situation that could cause bodily injury.

Before you work on any equipment, be aware of the hazards involved with electrical circuitry and

be familiar with standard practices for preventingaccidents. To see translations of the warnings that

appear in this publication, refer to the appendix “Translated Safety Warnings” in the Catalyst 5000

Series Supervisor Engine Installation Guide.

Ensuring Safety

This section covers the following topics:

• Following Basic Electrical Safety Guidelines, page 6

• Preventing ESD Damage, page 7

Use the following guidelines to ensure your safety and protect the equipment. This list does not

include all potentially hazardous situations during installation, so be alert.

Note Power supplies in the Catalyst 5002 switch do not have on/off switches.

Warning Only trained and qualified personnel should install, replace, or service this equipment.

• Alwaysturn allpower supplies off(the position marked zero), andunplug all power cords before

installing or removing a chassis.

• Keep the chassis area clear and free of dust during and after installation.

• Keep tools and chassis components off the floor and away from foot traffic.

• Avoid wearing jewelryand securely fastenany loose clothing that couldget caught in the chassis.

Warning Before workingonequipment that is connectedto powerlines, remove jewelry (including

rings, necklaces, and watches).Metal objects will heat up when connected to powerand ground and

can cause serious burns or weld the metal object to the terminals.

Warning Ultimate disposal of this product should be handled according to all national laws

and regulations.

Following Basic Electrical Safety Guidelines

When working with electrical equipment, exercise these basic safety guidelines:

• Never install equipment that appears to be damaged.

• Locate the emergencypower-offswitch for the room in which you are working before beginning

any procedures that require access to the chassis interior.

• Disconnect all power and external cables before installing or removing a chassis.

• Do not work alone when potentially hazardous conditions exist.

6 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Page 7

• Never assume that power has been disconnected from a circuit; always check.

• Do not perform any action that creates a potential hazard to people or makes the equipment

• Examine your work area carefully for possible hazards such as moist floors, ungrounded power

Warning Do not work on the system or connect or disconnect cables during periods of

lightning activity.

Preventing ESD Damage

ESD damage occurs when electronic modules or components are improperly handled and can result

in complete or intermittent failures. To prevent ESD damage, follow these guidelines:

• Always use an ESD-preventive wrist or ankle strap and ensure that it makes good skin contact.

• When handling modules orcoming into contactwith any internal components, always use a wrist

Removing and Replacing the Supervisor Engine

unsafe.

extension cables, and missing safety grounds.

strap connected to one of the following:

— Captive installation screws on an installed module or power supply

— ESD wrist strap connector

— Any unpainted surface on the chassis

• Handle modules by the edges only.

• Avoid contact between the modules and clothing. The wrist strap protects only the module from

ESD voltages on the body; ESD voltages on clothing can still cause damage.

• After removing a supervisor engine, place it on an antistatic surface or in a static-shielding bag.

If you plan to return the module to the factory, immediately place it in a static-shielding bag.

Caution Periodically check the resistance valueof the antistatic strap. The measurement should be

between 1 and 10 megohms (Mohms).

Removing and Replacing the Supervisor Engine

Note To support supervisor engine redundant operation, both the supervisor engines must be

Supervisor Engine III Gs.

Note Catalyst 5505, Catalyst 5509, and Catalyst 5500 switches—When two supervisor engines

are installed, hot swapping allows you to remove and replace one of the supervisor engines without

turning off the system power.

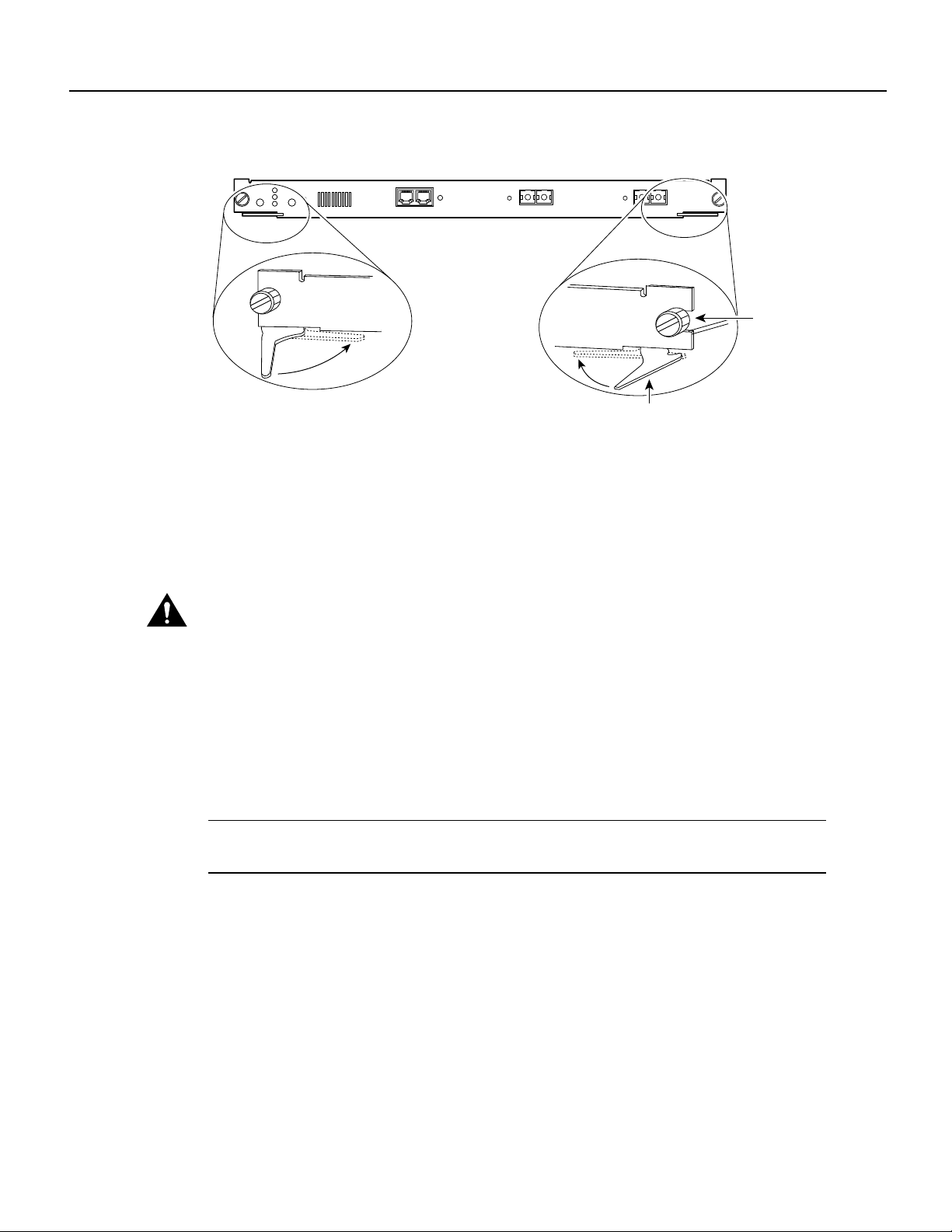

Avoiding Problems When Inserting and Removing Modules

The ejector levers on the supervisor engine align and seat the supervisor engine connectors in the

backplane. (See Figure 3.)If you failto use the ejector levers to insert the supervisorengine, you can

disrupt the order in which the pins make contact with the backplane. When removing a supervisor

Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note 7

Page 8

Removing and Replacing the Supervisor Engine

engine, use the ejector levers to ensure that the supervisorengine connector pinsdisconnect from the

backplane properly. Any supervisor engine or switching supervisor engine that is only partially

connected to the backplane can disrupt the system.

Figure 3 Ejector Levers and Captive Installation Screws

WS-X5550

SYSTEM

STATUS

SUPERVISOR ENGINE III G-SERIES

FAN

PS2

PS1

SWITCH

100%

1%

LOAD

RESET

ACTIVE

CONSOLE

Removing the Supervisor Engine

Before you removea supervisor engine, you shouldfirst upload the current configuration to a server.

This saves time when bringing the supervisor engine back online. Enter the write network

command to upload the configuration file to the network. Enter the copy command to download the

current configuration to a Flash memory device on the new supervisor engine.

To remove the supervisor engine from the switch, follow these steps:

RSFC CONSOLE

CONSOLE

PORT MODE

LINK

PORT 1 PORT 2

LINK

Ejector lever

Captive

installation

screws

24222

Caution To prevent ESD damage, handle switching modules by the carrier edges only.

Caution When removing or inserting a switching module, always wear an ESD wrist strap

connected to the Catalyst 5000 series switch ESD wrist strap connector.

Step 1 Take the necessary precautions to prevent ESD damage, as described in the “Preventing

ESD Damage” section on page 7.

Step 2 If you do not plan to immediately reinstall the supervisor engine you are removing,

disconnect any network interface cables attached to the module ports.

Step 3 Use a screwdriver to loosen the captiveinstallationscrews at theleft and right sides of the

module.

Step 4 Grasp the left and rightejector levers. Simultaneously pull the left lever to the left andthe

right lever to the right to release the module from the backplane connector.

Step 5 Grasp the handleof the modulewith one hand and placeyour other handunder the carrier

to support and guide the module out of the slot. Avoid touching the module itself.

Step 6 Carefully pull the module straight out of the slot, keeping your other hand under the

carrier to guide it. Keep the module at a 90-degree orientation to the backplane.

Step 7 Place the removed supervisor engine on an antistatic mat, foam, or bag.

8 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Page 9

Step 8 If the slot is to remain empty, install a module filler plate to keep dust out of the chassis

and to maintain proper airflow through the module compartment.

Caution Always install a switching module filler plate in empty switching module slots to maintain the

proper flow of cooling air across the modules.

Note When you removeand replace the supervisor engine, the system provides status messages on

theconsole screen. The messagesarefor information only.Enter the show system and showmodule

commandsto view specific information. Foradditionalinformation, refer to theCatalyst 5000 Series

Software Configuration Guide and the Catalyst 5000 Series Command Reference publication.

Installing the Supervisor Engine

When installing the supervisor engine, note that it must go in a specific slot:

• Catalyst 5000—slot 1

• Catalyst 5505, 5509, and Catalyst 5500—slot 1 (if a second, redundant supervisor is installed, it

goes in slot 2)

Installing the Supervisor Engine

• Catalyst 5002—slot 1

To install the supervisor engine, follow these steps:

Caution To prevent ESD damage, handle switching modules by the carrier edges only.

Caution When removing or inserting a switching module, always wear an ESD wrist strap

connected to the Catalyst 5000 series switch ESD wrist strap connector.

Step 1 Take the necessary precautions to prevent ESD damage, as described in the “Preventing

ESD Damage” section on page 7.

Step 2 To install the supervisor engine, hold the front panel with one hand, and place your other

hand under the carrier to support the supervisor engine. Do not touch the printed circuit

boards or connector pins.

Step 3 Align the edges of the supervisor engine carrier with the slot guides on the sides of the

switch chassis.

Step 4 Pivot the two module ejector levers out away from the faceplate. The ejector levers are

shown pivoted out in Figure 4.

Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note 9

Page 10

Connecting a Terminal to the Console Port

Figure 4 Module Ejector Lever Operation

WS-X5550

FAN

SYSTEM

STATUS

PS2

PS1

SUPERVISOR ENGINE III G-SERIES

SWITCH

100%

1%

LOAD

RESET

ACTIVE

CONSOLE

RSFC CONSOLE

CONSOLE

PORT MODE

LINK

PORT 1 PORT 2

LINK

Captive

installation

screw

Ejector lever

Step 5 Keeping one hand under the carrier to guide the supervisor engine, carefully slide it into

the slot on the Catalyst 5000 series switch until the ejector levers click into place on the

chassis. Be sure to keep the module horizontal to the backplane and avoid touching any

of the components on the module.

Step 6 Using the thumb and forefinger of each hand, simultaneously pivotin both ejector levers,

as shown in Figure 4, to fully seat the switching module in the backplane connector.

Caution Always use the ejector levers when installing or removing switching modules. A module

that is partially seated in the backplane will cause the system to halt and subsequently crash.

24252

Step 7 Use a screwdriver to tighten the captive installation screws at the left and right sides of

the module.

Connecting a Terminal to the Console Port

Connect the terminal using a thin, flat, RJ-45-to-RJ-45 cable (looks like a telephone cable) and an

RJ-45-to-DB-9, RJ-45-to-D-subminiature female, or RJ-45-to-D-subminiature male adapter.

Note An RJ-45-to-RJ-45 cable and adapters are providedin the console port accessory kit shipped

with your Supervisor Engine III.

See the next section, “Configuring a Terminal for Attachment to the Console Port,” for port

configuration details. Table 2 lists the pinouts for the console port.

10 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Page 11

Configuring a Terminal for Attachment to the Console Port

Table 2 Console Port Pinouts

Console Port Console Device

Pin (signal) Connect to

1 is looped to pin 8

2 (DTR) DSR

3 (RxD) TxD

4 (GND) GND

5 (GND) GND

6 (TxD) RxD

7 (DSR) DTR

8 is looped to pin 1

Table 3 lists the pinouts for the RSFC console port.

Table 3 RSFC Console Port Pinouts

Console Port Console Device

Pin (signal) Connect to

9 is looped to pin 16

10 DTR (out)

11 TxD or RxD

12 (GND)

13 (GND)

14 RxD or TxD

15 RTS (in)

16 is looped to pin 9

Configuring a Terminal for Attachment to the Console Port

Note The console port is an asynchronous serial port; any device connected to this port must be

capable of asynchronous transmission.

Before connecting the console port, check the terminal documentation to determine the baud rate.

The baud rate of the terminal must match the default baud rate (9600 baud) of the console port. Set

up the terminal as follows:

• 9600 baud

• 8 data bits

• No parity

• 1 stop bit

Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note 11

Page 12

Connecting to the Interface Ports

Connecting to the Interface Ports

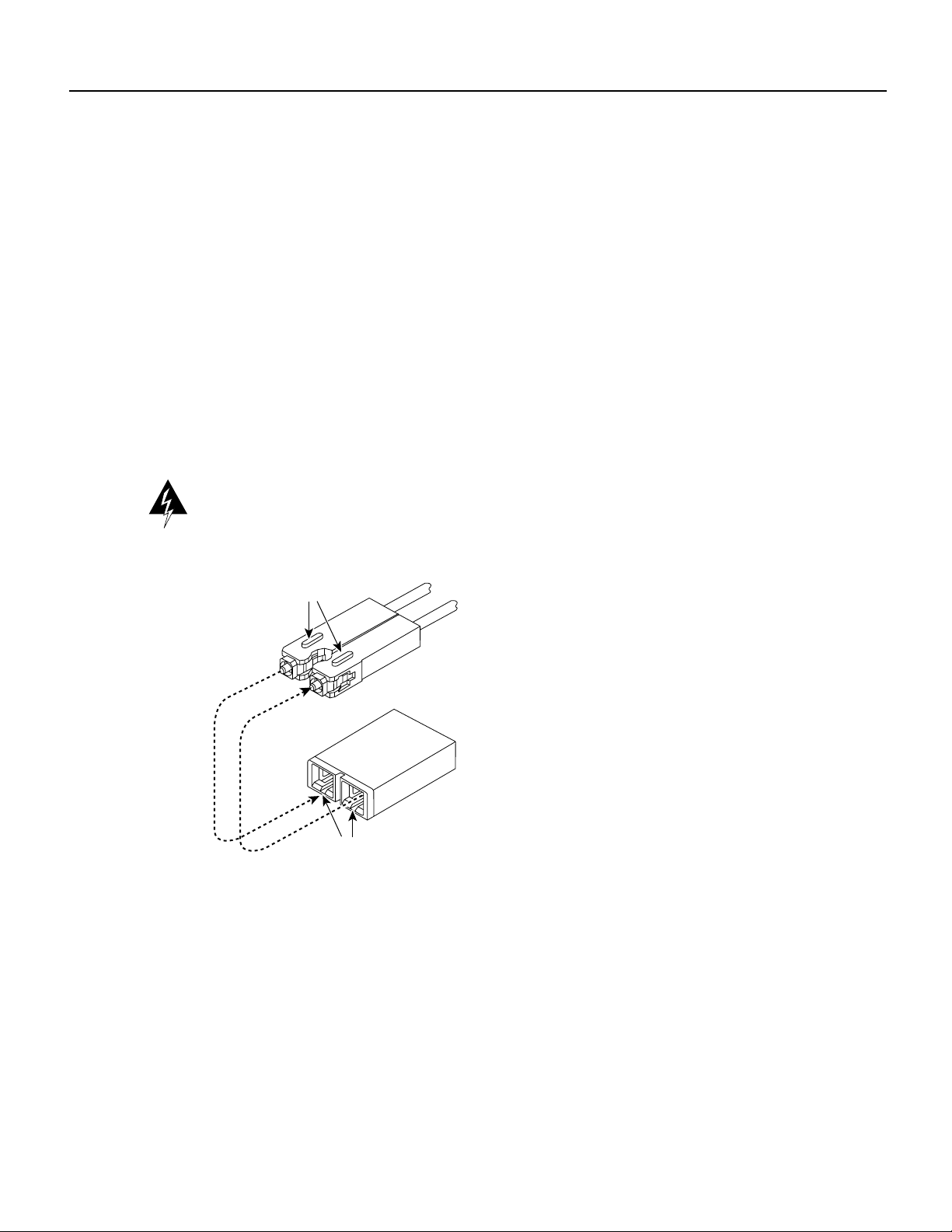

The Supervisor Engine III G has two GBICs with 1000BaseSX MMF connectors, 1000BaseLX/LH

MMF and SMF connectors, or 1000BaseZX connectors (see Figure 5).

The 1000BaseSX MMF, 1000Base LX/LH MMF and SMF, and 1000BaseZX ports operate in

full-duplex mode only.

For information on interface cables and equipment, such as Ethernet transceivers, refer to the

Catalyst 5000 Series Supervisor Engine Installation Guide.

1000BaseSX, 1000BaseLX/LH, and 1000BaseZX (Single-Mode or Multimode

Fiber-Optic Connectors)

Use SC fiber-optic connectors (see Figure 5) to connect to the 1000BaseSX, 1000BaseLX/LH, and

1000BaseZX ports. Always keep caps and plugs on the fiber-optic connectors on the cable and the

switch when they are not in use.

Warning Because invisible laser radiation may be emitted from the aperture of the port when no

cable is connected, avoid exposure to laser radiation and do not stare into open apertures.

Figure 5 SC Fiber-Optic Connector Type

Keys

Light out

of fiber

Light into

fiber

Plug

Cable

Receptacle

Receiver

Transmitter

Key slots

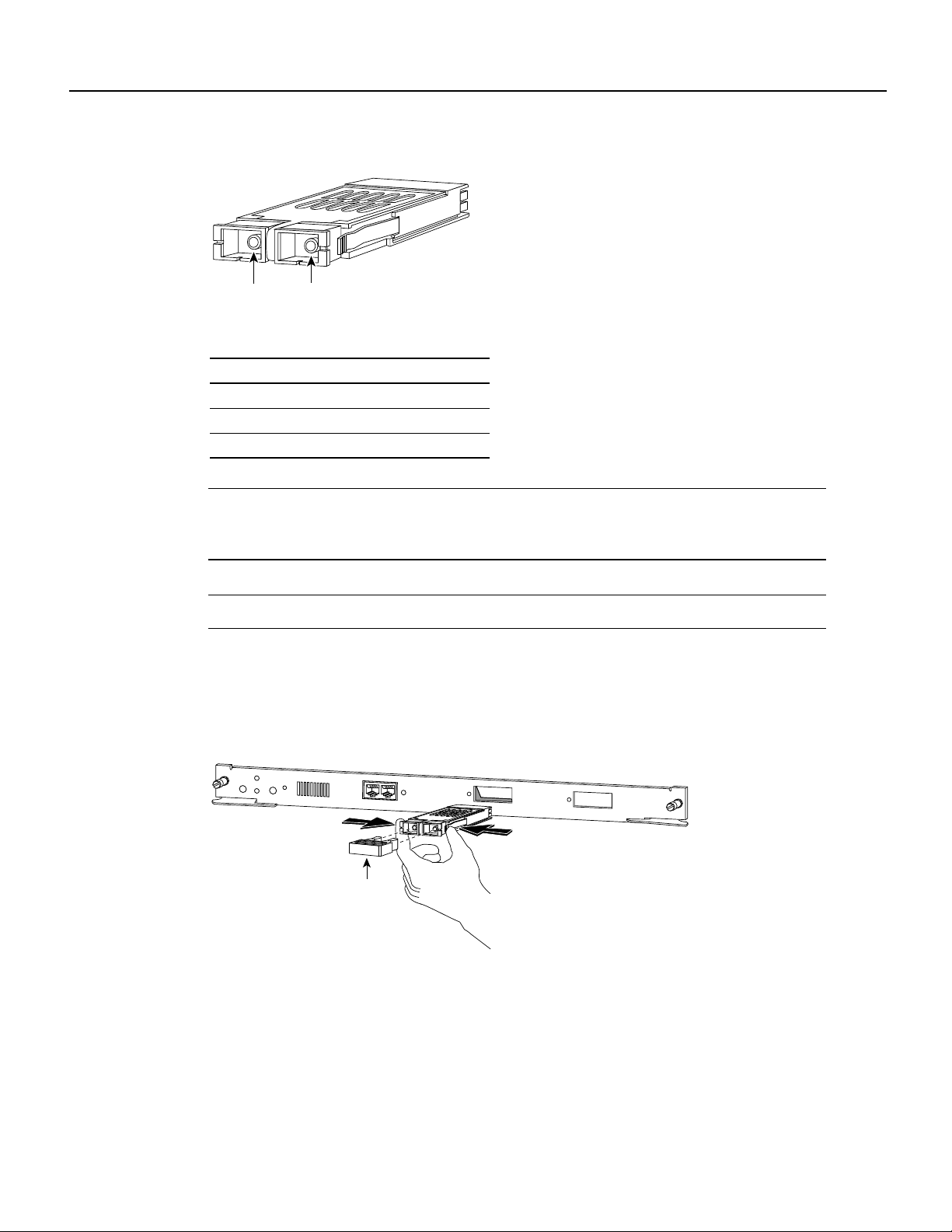

Connecting Gigabit Ethernet Modules

Supervisor Engine III G has Gigabit Ethernet ports that you can configure with any combination of

GBICs. A GBIC, shown in Figure 6, is a hot-swappable input/output device that plugs into the

module, linking the module with the fiber-optic network. GBIC types are listed in Table 4.

13087

12 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Page 13

Connecting Gigabit Ethernet Modules

Figure 6 GBIC

11825

Receiver Transmitter

Table 4 GBIC Types

GBIC Product Number

1000BaseSX WS-G5484

1000BaseLX/LH WS-G5486

1000BaseZX WS-G5487

Note Cisco 1000BaseLX/LH interfacesfully comply withthe IEEE 802.3z 1000BaseLX standard.

However, the 1000BaseLX/LH has a higher optical quality, allowing link distances of 10 km over

SMF versus the 5 km specified in the standard.

Note A maximum of 12 1000BaseZX GBICs can be installed in a switch chassis.

The GBIC slides through an opening in the front of the Gigabit Ethernet module and mates with a

connector on the module. (See Figure 7.)

Figure 7 Installing a GBIC (WS-X5403 shown)

WS-X5550

FAN

100%

SYSTEM

STATUS

PS2

PS1

SUPERVISOR ENGINE III G-SERIES

SWITCH

LOAD

1%

RESET

CONSOLE

RSFC CONSOLE

CONSOLE

PORT MODE

LINK

PORT 1

LINK

PORT 2

18357

Plug

Use a SC-type single-mode (fiber) connector, shown in Figure 5, to connect the Gigabit Ethernet

module ports with the external network. Connect the Gigabit Ethernet interface cables to the

appropriate Ethernet network connector.

When using the LX/LH GBIC with 62.5-micron diameter MMF, you must install a

mode-conditioning patch cord (Cisco product number CAB-GELX-625 or equivalent) between the

GBIC and the MMF cable on both the transmit and receive ends of the link. The patch cord is

required for link distances greater than 984 feet (300 m). Refer to the Catalyst 5000 Series

Supervisor Engine Installation Guide for more information on patch cords.

Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note 13

Page 14

Verifying System Operation

Note The mode-conditioning patch cord is required to comply with IEEE standards. The IEEE

found that link distances could not be met with certain types of fiber-optic cable due to a problem in

the center of some fiber-optic cable cores. The solution is to launch light from the laser at a precise

offset from the center by using the mode-conditioning patch cord. At the output of the patch cord,

the LX/LH GBIC is compliant with IEEE 802.3z standard for 1000BaseLX.

Verifying System Operation

When all interfaces are connected, check all connections, and then follow these steps to verify that

the switch is operational:

Step 1 Check the console terminal and make sure it is on.

Step 2 Verify that the appropriate PS1 and PS2 LEDs on the supervisor engine front panel are

green.

Step 3 While the system initializes, check that the SYSTEM STATUS LED on the supervisor

engine is orange until the boot is complete.

Step 4 Some interface LEDs might go on or blink for a short time. Some LEDs, such as the Link

LED, stay on during the entire boot process. If an interface is already configured, the

LEDs might be on steadily as they detect traffic on the line. Wait until the system boot is

complete before attempting to verify the switching module LED indications.

Note Catalyst 5505, Catalyst 5509, and Catalyst 5500—If you have a redundant

supervisor engine, refer to the Catalyst 5000 Series Installation Guide for a detailed

description of supervisor engine operation in a redundant configuration. By default, the

supervisor engine in slot 1 is the active supervisor; the second supervisor in slot 2 is the

standby supervisor.

Note Many of the switching module LEDs are not on until you configure the interfaces.

Step 5 When the system boot is complete (it takes a few seconds), the supervisor engine begins

to initialize the switching modules.

During this initialization, the LEDs on each switching module behave differently (most

flash on and off). The Status LED on each switching module goes on when initialization

is complete, and the console screen displays a script and system banner.

Note When switching module LEDs are on, this does not necessarily mean that the

interface ports are functional or enabled. Although the LEDs for many interface types go

on at the initial system startup, they do not indicate an accurate status until the interface

is configured. For detailed module-specific LED descriptions, refer to the Catalyst 5000

Series Module Installation Guide.

14 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Page 15

Note Catalyst 5500 only—The ATM system processor (ASP), ATM port adapter

carrier, and ATM adapter module LEDs are described in the LightStream 1010 ATM

Switch Hardware Installation Guide. The Catalyst 8510 Campus Switch Router (CSR)

Switch Route Processor (SRP) is described in the Catalyst 8510 Campus Switch Router

documentation.These publications are available on the Cisco ConnectionDocumentation

CD and in print.

Note If the system does not complete this verification process, refer to Chapter 6,

“Troubleshooting the Installation,” in the Catalyst 5000 Series Installation Guide for

troubleshooting procedures.

Step 6 Your hardware installation is now complete. Refer to the Software Configuration Guide

and Command Reference publication foryour switch for completesoftware configuration

instructions.

FCC Class A Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which

case users will be required to correct the interference at their own expense.

FCC Class A Compliance

You can determine whether your equipment is causing interference by turning it off. If the

interference stops, it was probably caused by the Cisco equipment or one of its peripheral devices.

If the equipment causes interference to radio or television reception, try to correct the interference

by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That

is, make certain the equipment and the television or radio are on circuits controlled by different

circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems could void the FCC approval and

negate your authority to operate this product.

Related Documentation

For more detailed installation and configuration information, refer to the following publications:

• Catalyst 5000 Series Installation Guide

• Catalyst 5000 Series Supervisor Engine Installation Guide

• Catalyst 5000 Series Module Installation Guide

Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note 15

Page 16

Cisco Connection Online

• Software Configuration Guide—Catalyst 5000 Series, Catalyst 4000 Series, Catalyst 2948G

Series, Catalyst 2926G Series

• Command Reference—Catalyst 5000 Series, Catalyst 4000 Series, Catalyst 2948G Series,

Catalyst 2926G Series

• Catalyst 5000 Series Route Switch Feature Card Installation and Configuration Note

Ciscodocumentation and additionalliteratureare availablein a CD-ROMpackage, whichshipswith

your product. The Documentation CD-ROM, a member of the Cisco Connection Family,is updated

monthly. Therefore, it might be more up to date than printed documentation. To order additional

copies of the Documentation CD-ROM, contact your local sales representative or call customer

service. The CD-ROM package is available as a single package or as an annual subscription. You

can also access Cisco documentation on the World Wide Web at http://www.cisco.com,

http://www-china.cisco.com, or http://www-europe.cisco.com.

Cisco Connection Online

CiscoConnection Online (CCO) isCisco Systems’ primary,real-time support channel. Maintenance

customers and partners can self-register on CCO to obtain additional information and services.

Available 24 hours a day, 7 days a week, CCO provides a wealth of standard and value-added

services to Cisco’s customers and business partners. CCO services include product information,

product documentation, software updates, release notes, technical tips, the Bug Navigator,

configuration notes, brochures, descriptions of service offerings, and download access to public and

authorized files.

CCO serves a wide variety of users through two interfaces that are updated and enhanced

simultaneously: a character-based version and a multimedia version that resides on the World Wide

Web (WWW). The character-based CCO supports Zmodem, Kermit, Xmodem, FTP, and Internet

e-mail,and it isexcellentfor quick access toinformation over lowerbandwidths. The WWWversion

of CCO provides richlyformatted documents withphotographs, figures, graphics, and video, as well

as hyperlinks to related information.

You can access CCO in the following ways:

• WWW: http://www.cisco.com

• WWW: http://www-europe.cisco.com

• WWW: http://www-china.cisco.com

• Telnet: cco.cisco.com

• Modem: From North America, 408 526-8070; from Europe, 33 1 64 46 40 82. Use the

following terminal settings: VT100 emulation; databits: 8; parity: none; stop bits: 1; and

connection rates up to 28.8 kbps.

For a copy of CCO’s Frequently Asked Questions (FAQ), contact cco-help@cisco.com. For

additional information, contact cco-team@cisco.com.

Note If you are a network administrator and need personal technical assistance with a Cisco

product that is under warranty or covered by a maintenance contract, contact Cisco’s Technical

Assistance Center (TAC) at 800 553-2447, 408 526-7209, or tac@cisco.com. To obtain general

information about Cisco Systems, Cisco products, or upgrades, contact 800 553-6387,

408 526-7208, or cs-rep@cisco.com.

16 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Page 17

Documentation CD-ROM

Ciscodocumentation and additionalliteratureare availablein a CD-ROMpackage, whichshipswith

your product. The Documentation CD-ROM, a member of the Cisco Connection Family,is updated

monthly.Therefore, it might bemore current thanprinted documentation. To order additional copies

of the Documentation CD-ROM, contact your local sales representative or call customer service.

The CD-ROM package is available as a single package or as an annual subscription. You can also

access Cisco documentation on the World Wide Web at http://www.cisco.com,

http://www-china.cisco.com, or http://www-europe.cisco.com.

If you are reading Cisco product documentation onthe World Wide Web, you can submit comments

electronically. Click Feedback in the toolbar and select Documentation. After you complete the

form, click Submit to send it to Cisco. We appreciate your comments.

Documentation CD-ROM

This document is to be used in conjunction with the Catalyst 5000 Series Installation Guide and the Catalyst 5000 Series Supervisor Engine Installation Guide.

Access Registrar, AccessPath, Any to Any, AtmDirector, CCDA, CCDE, CCDP, CCIE, CCNA, CCNP, CCSI, CD-PAC, the Cisco logo, Cisco Certified Internetwork Expert logo,

CiscoLink, the Cisco Management Connection logo, the Cisco NetWorks logo, the Cisco Powered Network logo, Cisco Systems Capital, the Cisco Systems Capital logo, Cisco Systems

Networking Academy, the Cisco Technologies logo, ControlStream, FastStep, FireRunner, GigaStack,IGX, JumpStart, KernelProxy, MGX, NaturalNetwork Viewer, NetSonar, Network

Registrar, Packet,PIX, Point and Click Internetworking,Policy Builder, Precept, RouteStream, Secure Script, ServiceWay, SlideCast, SMARTnet, StreamView, The Cell, TrafficDirector,

TransPath, ViewRunner, VirtualStream, VisionWay, VlanDirector, Workgroup Director, and Workgroup Stack are trademarks; Changing the Way We Work, Live, Play, and Learn,

Empowering the Internet Generation, The Internet Economy, and The New Internet Economy are service marks; and Asist, BPX, Catalyst, Cisco, Cisco IOS, the Cisco IOS logo, Cisco

Systems, the Cisco Systems logo, the Cisco Systems Cisco Press logo, Enterprise/Solver, EtherChannel, EtherSwitch, FastHub, FastLink, FastPAD, FastSwitch, IOS, IP/TV, IPX,

LightStream, LightSwitch, MICA, NetRanger, Registrar, StrataView Plus, Stratm, TeleRouter, and VCO are registered trademarks of Cisco Systems, Inc. in the U.S. and certain other

countries. All other trademarks mentioned in this document are the property of their respective owners. (9904R)

Copyright © 1999, Cisco Systems, Inc.

All rights reserved.

Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note 17

Page 18

Documentation CD-ROM

18 Catalyst 5000 Series Supervisor Engine III G Installation and Configuration Note

Loading...

Loading...