Page 1

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

First Published: 2016-07-04

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Text Part Number:

Page 2

©

Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

Preface 9

Document Revision History 9

Document Audience 9

Document Organization 9

Document Conventions 10

Obtaining Documentation and Submitting a Service Request 12

CHAPTER 1

Cisco ASR 920 Series Aggregation Services Router Overview 1

Cisco ASR 920 Router Features 1

GigabitEthernet Copper Ports 2

GE SFP Ports 2

SFP+ Ports 3

External Interfaces 8

Network Interfaces 8

Network Timing Interfaces 9

External Alarm Inputs 9

Management Interfaces 9

Management ENET Port 9

RS232 Console Port 9

USB Console 10

USB Mass Storage 10

Zero Touch Provisioning Button 10

RS232 Auxiliary Console Port 10

Power Supply and Fans 10

LED Indicators 11

PWR and STAT LEDs 11

CPU Management Port LEDs 13

SFP LEDs 13

SFP+ LEDs 13

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

iii

Page 4

Contents

RJ-45 LEDs 14

Power Supply Unit LEDs 14

System–Interface LED Behavior 15

Online Insertion and Removal 16

Licensing 16

CHAPTER 2

Preparing for Installation 19

Safety Guidelines 20

Safety Warning Statements 20

Safety Guidelines for Personal Safety and Equipment Protection 20

Safety Precautions for Module Installation and Removal 21

Safety with Electricity 21

Power Supply Considerations 22

Preventing ESD Damage 22

Site Planning 23

General Precautions 23

Site Planning Checklist 23

Site Selection Guidelines 24

Environmental Requirements 24

Physical Characteristics 24

Air Flow Guidelines 24

Air Flow Guidelines for ETSI Rack Installation 26

Floor Loading Considerations 26

Site Power Guidelines 27

Electrical Circuit Requirements 27

Site Cabling Guidelines 27

Asynchronous Terminal Connections 28

Interference Considerations 28

Electromagnetic Interference 28

Radio Frequency Interference 29

Lightning and AC Power Fault Interference 29

Rack-Mounting Guidelines 29

Precautions for Rack-Mounting 29

Rack Selection Guidelines 30

Equipment Rack Guidelines 30

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

iv

Page 5

Contents

Locating for Safety 30

Locating for Easy Maintenance 30

Locating for Proper Airflow 31

Installation Checklist 31

Creating a Site Log 32

Chassis-Lifting Guidelines 33

Tools and Equipment 33

Unpacking and Verifying the Shipped Contents 34

CHAPTER 3

Installing the Cisco ASR 920 Series Router 37

Prerequisites 38

Installing the Router in a Rack 38

Attaching Brackets to the Router 39

Attaching Brackets for 19-Inch Racks 40

Attaching Brackets for 23-Inch Racks 42

Attaching Brackets for ETSI Racks 44

Mounting the Router in a Rack 45

Installing the Router Chassis in the Rack 46

Attaching the Cable Guides 47

Wall Mounting the Router 49

Attaching the Brackets to the Router for Wall-Mounting 49

Mounting Router on the Wall 50

Installing and Removing SFP Modules 52

Installing SFP Modules 52

Removing SFP Modules 54

Connecting to the Copper Ports 55

Connecting to SFP Modules 56

Connecting to Fiber-Optic SFP Modules 56

Installing the Chassis Ground Connection 57

Installing and Removing the Fan Tray 60

Installing the Fan Tray 60

Removing the Fan Tray 62

Interface Module Installation 63

Installing an Interface Module 64

Removing an Interface Module 64

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

v

Page 6

Contents

Installing the Power Supply 65

Power Connection Guidelines 65

Guidelines for DC-Powered Systems 66

Guidelines for AC-Powered Systems 66

Preventing Power Loss 66

Installing the DC Power Supply Module 67

Activating a DC Power Supply Module 69

Installing the DC Power Cables 69

Removing the DC Power Supply Module 71

Installing the AC Power Supply Module 73

Installing the AC Power Cables 76

Activating an AC Power Supply Module 77

Removing the AC Power Supply Module 77

Powering On the Router 80

Connecting the Router to the Network 80

Connecting Console Cables 80

Connecting to the USB Serial Port Using Microsoft Windows 80

Connecting to the Console Port Using Mac OS X 81

Connecting to the Console Port Using Linux 82

Installing the Cisco USB Device Driver 82

Uninstalling the Cisco USB Driver 84

Connecting to the EIA Console Port 85

Connecting a Management Ethernet Cable 87

Installing and Removing SFP and SFP+ Modules 87

Connecting a USB Flash Device 87

Removing a USB Flash Device 88

Connecting Timing Cables 88

Connecting Cables to a GPS Interface 88

Connecting a Cable to the Input 10-Mhz or 1-PPS Interface 89

Connecting a Cable to the Output 10-Mhz or 1-PPS Interface 89

Connecting a Cable to the ToD Interface 89

Connecting a Cable to the GNSS Antenna Interface 90

Connecting Ethernet Cables 91

Connecting Cables to SFP Modules 91

Connector and Cable Specifications 91

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

vi

Page 7

Contents

CHAPTER 4

CHAPTER 5

Initial Configuration 93

Checking Conditions Prior to System Startup 93

Powering Up the Router 94

Verifying the Front Panel LEDs 94

Verifying the Hardware Configuration 94

Checking Hardware and Software Compatibility 94

Configuring the Router at Startup 95

Accessing the CLI Using the Console 95

Configuring Global Parameters 96

Checking the Running Configuration Settings 97

Saving the Running Configuration to NVRAM 97

Safely Powering Off the Router 97

Troubleshooting 99

Pinouts 99

GPS Port Pinouts 99

CHAPTER 6

Time-of-Day Port Pinouts 100

Alarm Port Pinouts 100

Management GigabitEthernet Port Pinouts 101

USB Console Port Pinouts 101

USB Flash or MEM Port Pinouts 102

Optical Fiber Specifications 102

Alarm Conditions 102

LED Summary 103

Power Supply LEDs 103

Fan Tray LEDs 104

Site Log 105

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

vii

Page 8

Contents

viii

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

Page 9

Preface

The preface describes the revision history, audience, organization, and conventions of the Cisco ASR 920

Series Aggregation Services Routers. It also lists sources for obtaining additional information and technical

assistance from Cisco.

This document covers the following variants of the Cisco ASR 920 Series Aggregation Services Routers:

• ASR-920-12SZ-IM— Four 10G SFP+ ports, Four 1G SFP ports, Eight 1G Copper/SFP Combo ports

and Two 1G/10G Dual Rate ports, with redundant AC or DC power supplies

• ASR-920-12SZ-IM-CC—Has the same specifications as the above variant. However, this chassis is

coated with an acrylic-based material to help improve the reliability against air-borne contamination.

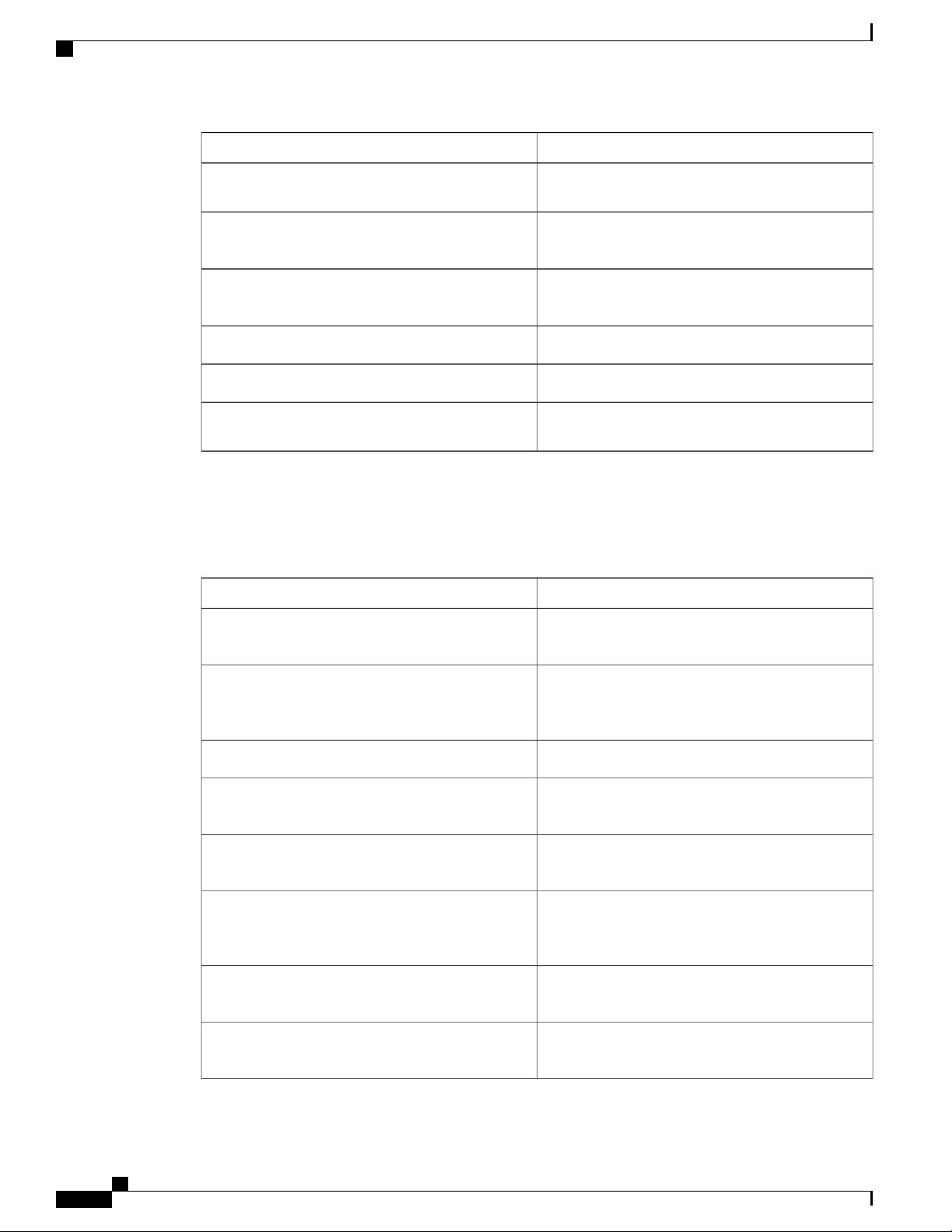

Document Revision History

The following table lists the major changes made to this document.

Change SummaryDateRelease

First ReleaseMay 29, 2015Cisco IOS XE Release 3.16.S

Document Audience

This guide is intended for users who are responsible for installing the Cisco ASR 920 Series Aggregation

Services Router. It is intended for users who may not be familiar with the initial configuration and

troubleshooting tasks, the relationship among tasks, or the Cisco IOS software commands necessary to perform

particular tasks.

Document Organization

This guide includes the following sections:

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

9

Page 10

Document Conventions

Preface

DescriptionTitle

Cisco ASR 920 Series Aggregation Services Router

Overview, on page 1

Preparing for Installation , on page 19

Installing the Cisco ASR 920 Series Router, on page

37

Site Log, on page 105

Document Conventions

This document uses the following conventions:

bold font

Describes the features and specifications of the Cisco

ASR 920 Series Aggregation Services Router.

Describes the installation of the Cisco ASR 920 Series

Router at your site.

Describes the installation of router on a rack as well

as installation of its components.

Describes basic router configuration.Initial Configuration, on page 93

Describes troubleshooting information.Troubleshooting, on page 99

Provides a record of actions related to installing and

maintaining the router.

IndicationConvention

Commands and keywords and user-entered text

appear in bold font.

italic font

{x | y | z }

[ x | y | z ]

string

courier font

< >

Document titles, new or emphasized terms, and

arguments for which you supply values are in italic

font.

Elements in square brackets are optional.[ ]

Required alternative keywords are grouped in braces

and separated by vertical bars.

Optional alternative keywords are grouped in brackets

and separated by vertical bars.

A nonquoted set of characters. Do not use quotation

marks around the string or the string will include the

quotation marks.

Terminal sessions and information the system displays

appear in courier font.

Nonprinting characters such as passwords are in angle

brackets.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

10

Page 11

Preface

Document Conventions

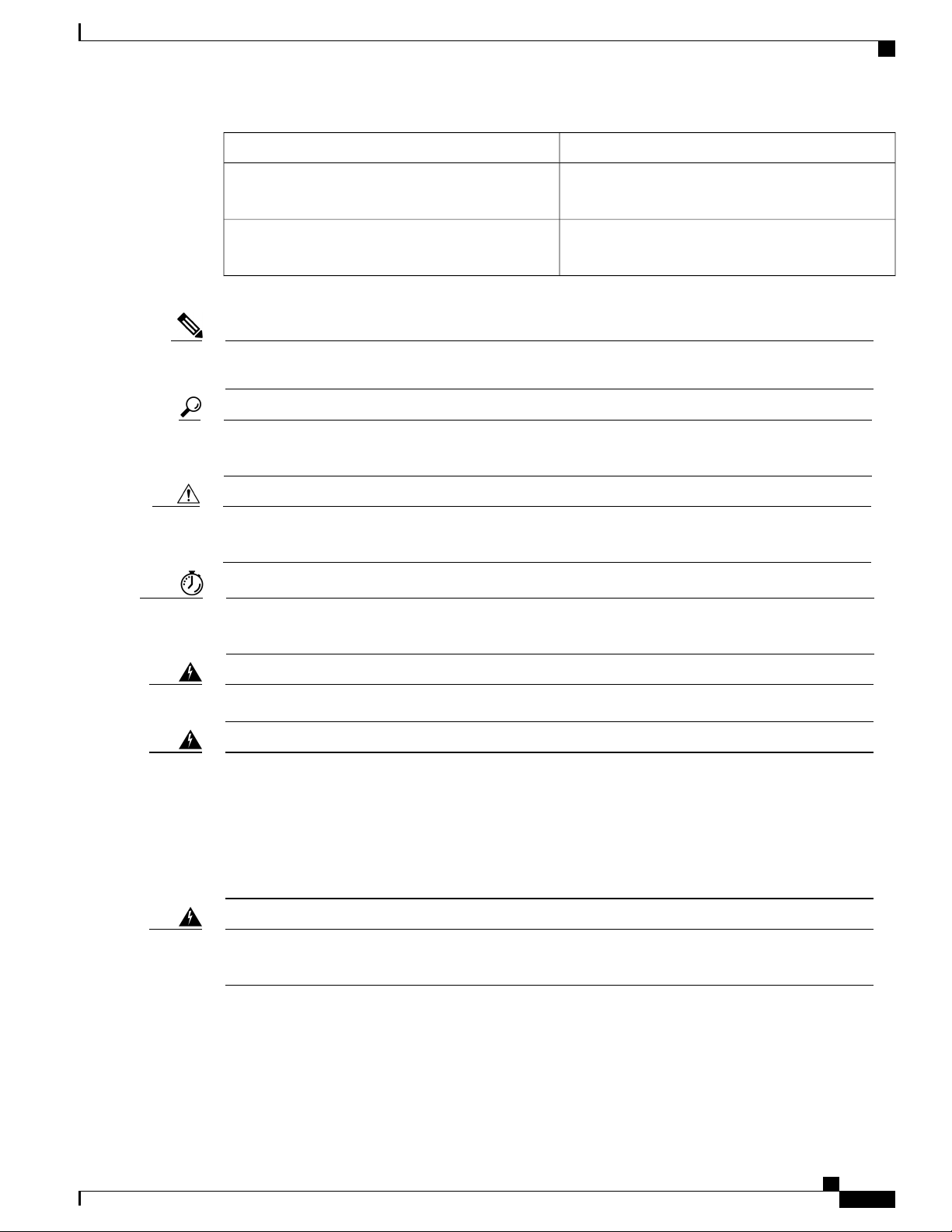

IndicationConvention

Note

Tip

Caution

Timesaver

[ ]

Default responses to system prompts are in square

brackets.

!, #

An exclamation point (!) or a pound sign (#) at the

beginning of a line of code indicates a comment line.

Means reader take note. Notes contain helpful suggestions or references to material not covered in the

manual.

Means the following information will help you solve a problem. The tips information might not be

troubleshooting or even an action, but could be useful information, similar to a Timesaver.

Means reader be careful. In this situation, you might perform an action that could result in equipment

damage or loss of data.

Means the described action saves time. You can save time by performing the action described in the

paragraph.

Warning

Warning

Warning

Means reader be warned. In this situation, you might perform an action that could result in bodily injury.

IMPORTANT SAFETY INSTRUCTIONS.

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Statements using this symbol are provided for additional information and to comply with regulatory and

customer requirements.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

11

Page 12

Preface

Obtaining Documentation and Submitting a Service Request

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information,

see the monthly What’s New in Cisco Product Documentation, which also lists all new and revised Cisco

technical documentation.

Subscribe to the What’s New in Cisco Product Documentation, which lists all new and revised Cisco technical

documentation as an RSS feed and delivers content directly to your desktop using a reader application. The

RSS feeds are a free service.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

12

Page 13

CHAPTER 1

Cisco ASR 920 Series Aggregation Services Router Overview

The Cisco ASR 920 Series Aggregation Services Router is a family of fixed configuration routers that

provides common network architecture to the Service Providers for macro and small cell networks.

This router acts as an access device for mobile backhaul services—macro Cell Site Router (CSR) and Small

Cell Router (SCR). As an access device, it provides capabilities like 1GE/10GE, MPLS, H-QoS, Services,

GPS clocking, PoE and fit within ETSI 300 mm depth cabinet. It can easily be integrated into the Unified

MPLS for Mobile Transport (UMMT) and Fixed Mobile Convergence (FMC) solution.

Cisco ASR 920 Router Features, page 1

•

GigabitEthernet Copper Ports, page 2

•

GE SFP Ports, page 2

•

SFP+ Ports, page 3

•

External Interfaces, page 8

•

Cisco ASR 920 Router Features

The router provides 1GE/10GE, MPLS, H-QoS, high availability hardware design, advanced Ethernet

Operations, Administration, and Maintenance (OAM), as well as advanced timing support, including satellite

timing (GNSS) based clocking, and PoE in one platform.

• ASR-920-12SZ-IM—This router has fixed Ethernet interfaces (8x1G copper + 4x1G SFP + 4x10G/1G

(dual rate)

• ASR-920-12SZ-IM-CC—Has the same specifications as the above variant. However, this chassis is

coated with an acrylic-based material to help improve the reliability against air-borne contamination.

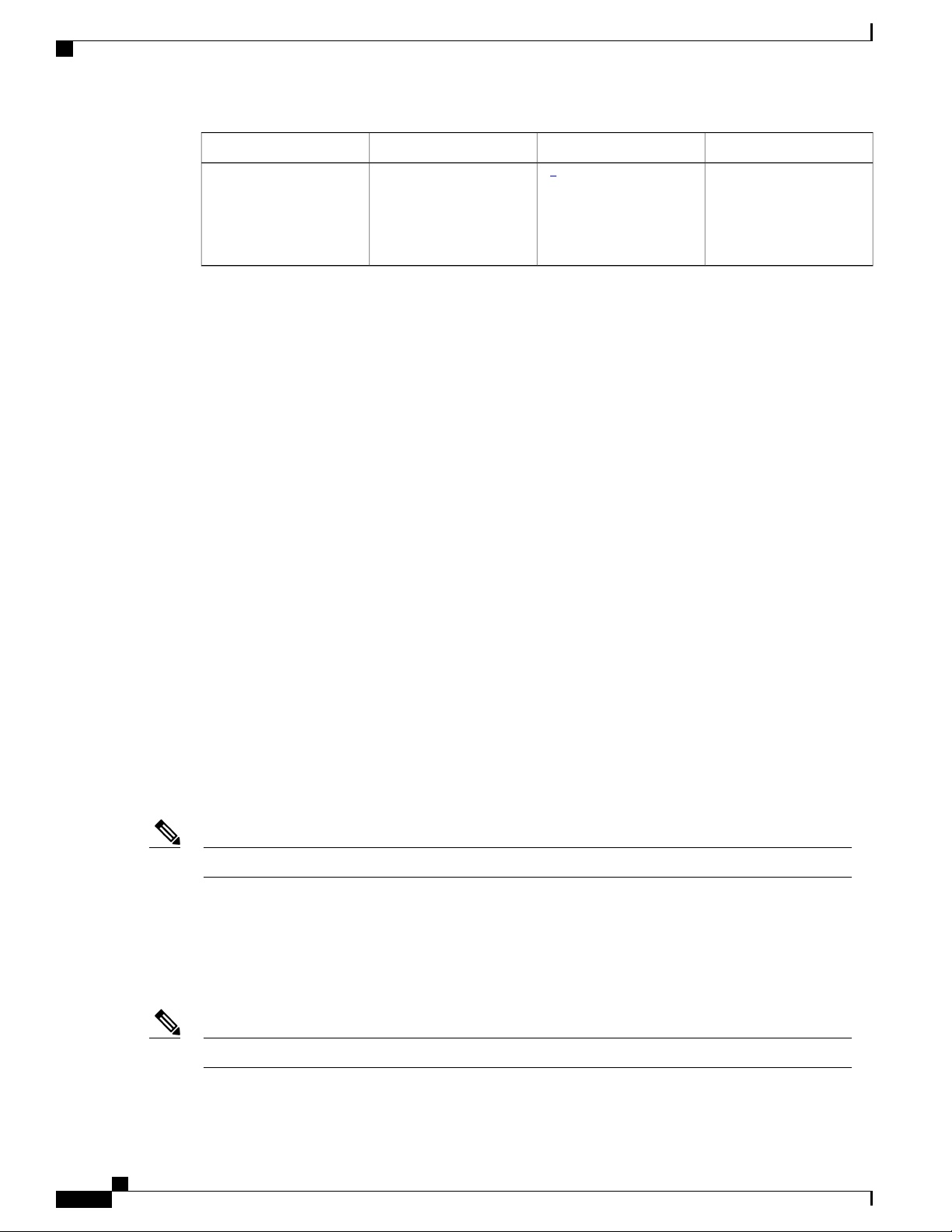

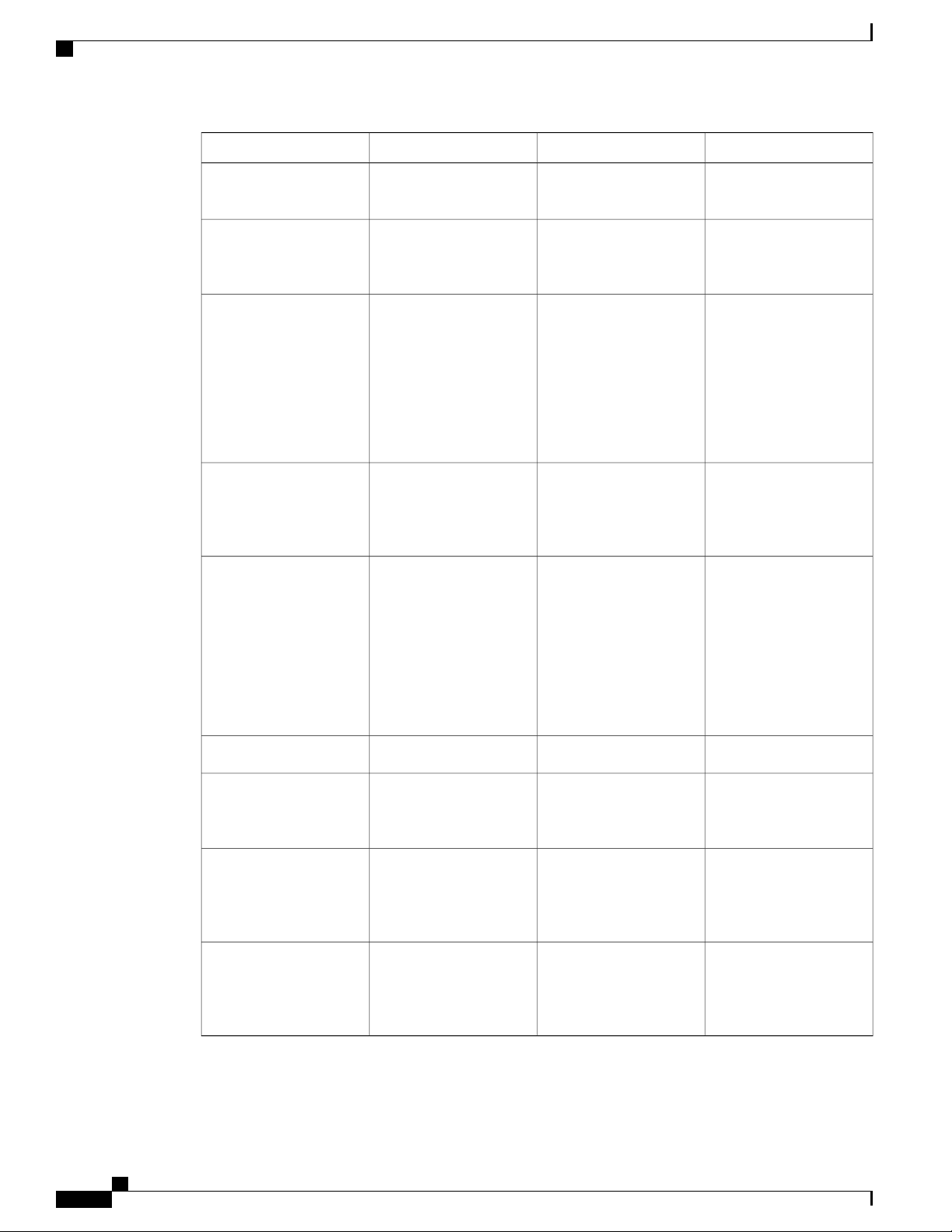

The following table provides snapshot of the number and type of supported ports:

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

1

Page 14

Cisco ASR 920 Series Aggregation Services Router Overview

GigabitEthernet Copper Ports

Type of 1 GE PortDual Rate 1G/10G Port1 GE PortASR 920 Sub-family

1

12ASR-920-12SZ-IM,

ASR-920-12SZ-IM-CC

1

Each port can operate at either 1G or 10G, and operates in a mutually exclusive way. You cannot insert both 1G and 10G together. If you insert IG IMs

(A900-IMA8T1Z, A900-IMA8S1Z, A900-IMA8T, A900-IMA8S), the dual rate port would support only 10G.

4

Te0/0/12 – Te 0/0/15

8 Cu ports Ge0/0/0 –

Ge0/0/7

4 SFP ports Ge0/0/8 –

Ge0/0/11

GigabitEthernet Copper Ports

Fixed copper GigabitEthernet (GE) interfaces are provided through standard RJ-45 connectors. These ports

support the following features:

Standard 100/1000Base-T/TX operation with forced or auto-negotiation for speed and duplex.

•

GE SFP Ports

The GE SFP ports support the following features:

Smart SFPs are not supported on the router.Note

Automatic crossover (auto-MDIX) for straight-through and crossover connections.

•

Pause flow control as defined by the 802.3x standard.

•

Frame size of 9216 bytes.

•

Synchronous ENET operation that provides its recovered receive clock as an input clock source for the

•

SETS as well as uses the system-wide reference clock to derive its transmit clock.

100Base-FX and 1000Base-X SFP modules.

•

Digital optical monitoring as specified by the SFP.

•

Any mix of SFPs is supported unless specifically noted.

•

Pause flow control as defined by the 802.3x standard.

•

Frame size of 9216 bytes.

•

Synchronous ENET operation that provides its recovered receive clock as an input clock source for the

•

SETS as well as uses the system-wide reference clock to derive its transmit clock.

Copper based SFPs do not support synchronous ENET operations.Note

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

2

Page 15

Cisco ASR 920 Series Aggregation Services Router Overview

SFP+ Ports

The SFP+ ports support the following features:

Digital optical monitoring as specified by the optical transceiver module.

•

Any mix of SFPs is supported unless specifically noted.

•

Pause flow control as defined by the 802.3x standard.

•

Frame size of 9216 bytes.

•

SFP+ Ports

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

3

Page 16

SFP+ Ports

Cisco ASR 920 Series Aggregation Services Router Overview

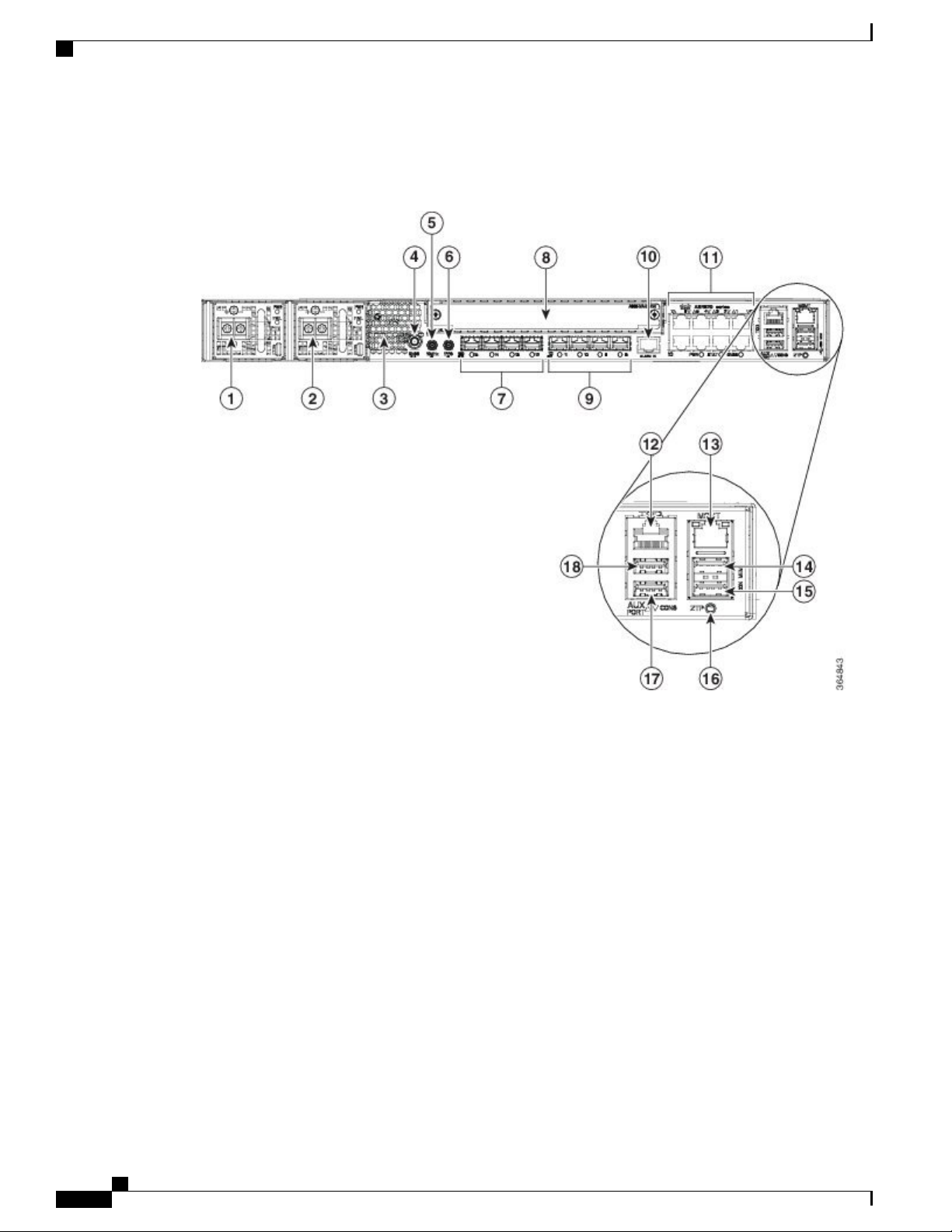

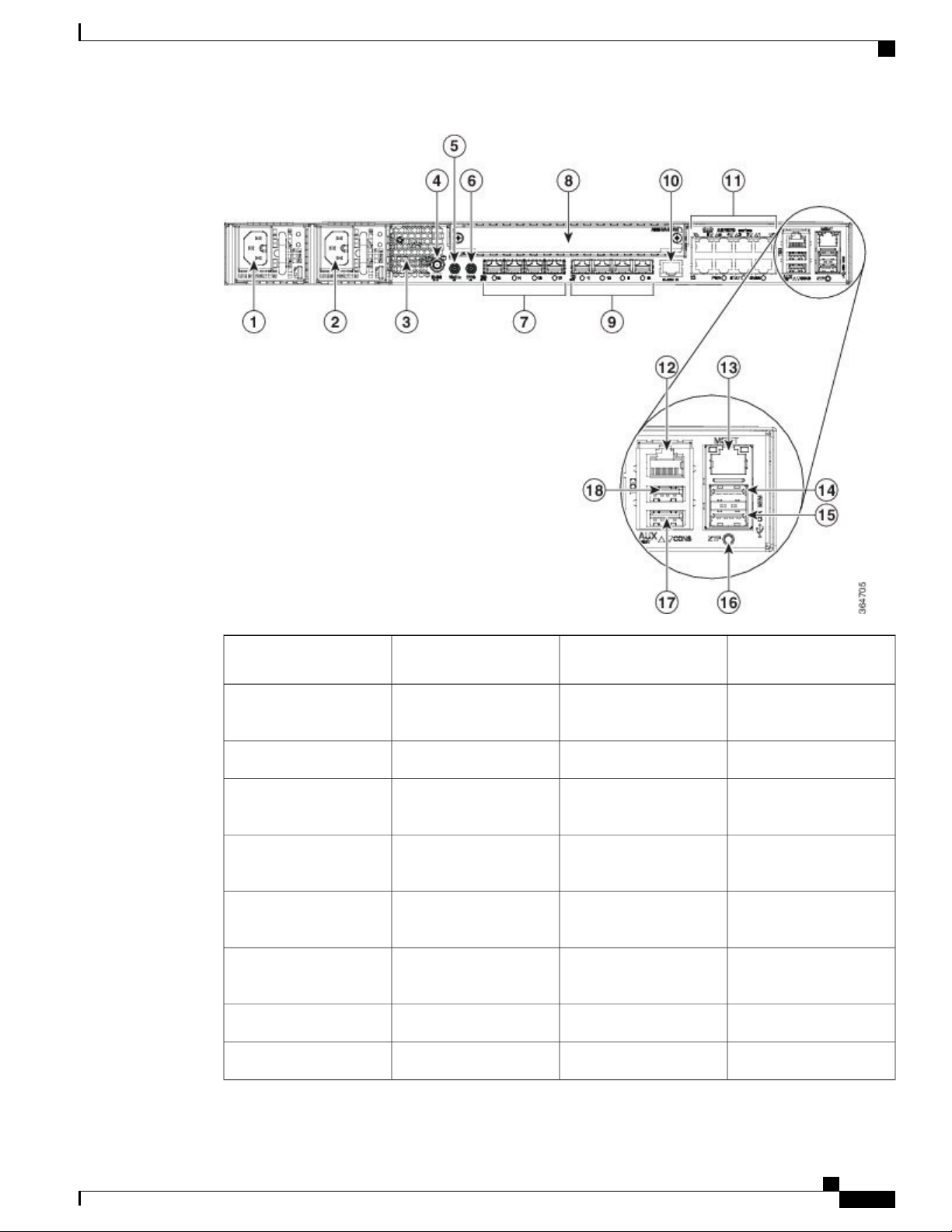

The following figures show the port numbering for the Cisco ASR 920 router:

Figure 1: Front Panel of Cisco ASR-920-12SZ-IM Router —With DC Power Supply

Figure 2: Front Panel of Cisco ASR-920-12SZ-IM Router —With AC Power Supply

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

4

Page 17

Cisco ASR 920 Series Aggregation Services Router Overview

SFP+ Ports

1

Alarm port10Power Supply 0 (AC or

DC)

2

11Power Supply 1 (AC or

DC)

Eight Copper port (1G

PoE)

ToD port12Front Air-Inlet Area3

4

Management Port13GNSS RF IN (SMA

threaded connector)

5

USB Memory port14SMB Snap-in connector

(10MHZ)

6

USB Console port15SMB Snap-in connector

(1PPS)

16Four 1G/10G SFP+7

Zero Touch Provisioning

button

RS232 Console port17Interface Module8

RS232 Aux Console port18Four 1G SFP9

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

5

Page 18

SFP+ Ports

Cisco ASR 920 Series Aggregation Services Router Overview

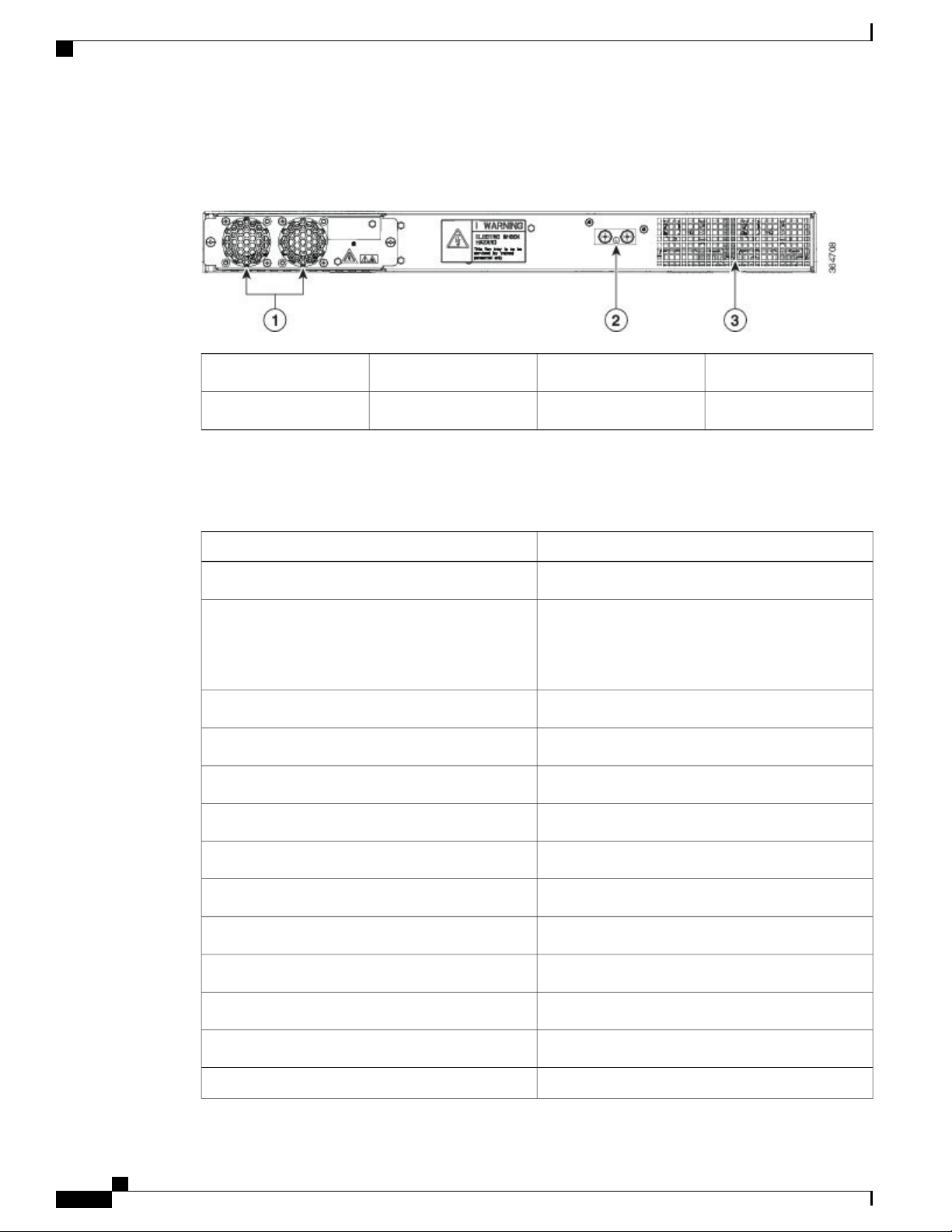

Figure 3: Rear View of Cisco ASR-920-12SZ-IM Router

Air vents3Fan tray1

Grounding lug2

—

The following table describes the other features of Cisco ASR-920-12SZ-IM (AC and DC) Router.

Table 1: Cisco ASR-920-12SZ-IM Router Specifications

ASR-920-12SZ-IMSpecification

17.5 x 9.88 x 1.73 inchesDimensionWidth x Depth x Height

Weight

Total weight: 4.83 kg

Weight of PSU: 0.59 kg

Weight of Fan: 0.33 kg

One RURack Unit

Front to backAirflow

Front cable accessCable access

60 Gbps, 95 MppsSystem throughput

Power Supply

YesRedundant

YesAC

85V AC to 264V AC, nominal 100/240 VACVoltage Range

47 Hz to 63 Hz, nominal 50/60 HzFrequency Range

360 WMaximum Power

YesDC

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

6

Page 19

Cisco ASR 920 Series Aggregation Services Router Overview

SFP+ Ports

ASR-920-12SZ-IMSpecification

-18 VDC to -32 VDC or -40 VDC to -72 VDCVoltage Range

-24 VDC/-48 VDC/-60 VDCNominal Voltage Range

375 WMaximum Power

Operating Temperature

Alarms

Supported Interface Modules

Mounting option

Port Numbering

–40º C to 70º C

4 alarm dry contact inputs (normally open)

•

LED indicators for critical, major, and minor

•

alarms

For more information on these IM modules, see the

Cisco ASR 903 Aggregation Series Router Hardware

Installation Guide .

For more information on the supported IMs, see the

Cisco ASR920 Data sheet.

Front or rear rail 19 or 23 inches

•

ETSI 300 mm open cabinet

•

Wall mount

•

12x1G and 4x10G/1G portsPort Configuration

4x10G SFP+ – Port [12:15]

4x1G SFP – Port [8:11]

8x1G PoE RJ45/Cu ports [0:7]

Ports 12 to 15 are Dual Rate portsCombo Ports

Link/Activity/FaultCopper/1G/10G Port LEDs

Four temperature sensorsTemperature Sensors

External ports for 1PPS/TOD1PPS/ToD

Provides power over EthernetPoE

Connects to the external GPSGNSS

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

7

Page 20

External Interfaces

Cisco ASR 920 Series Aggregation Services Router Overview

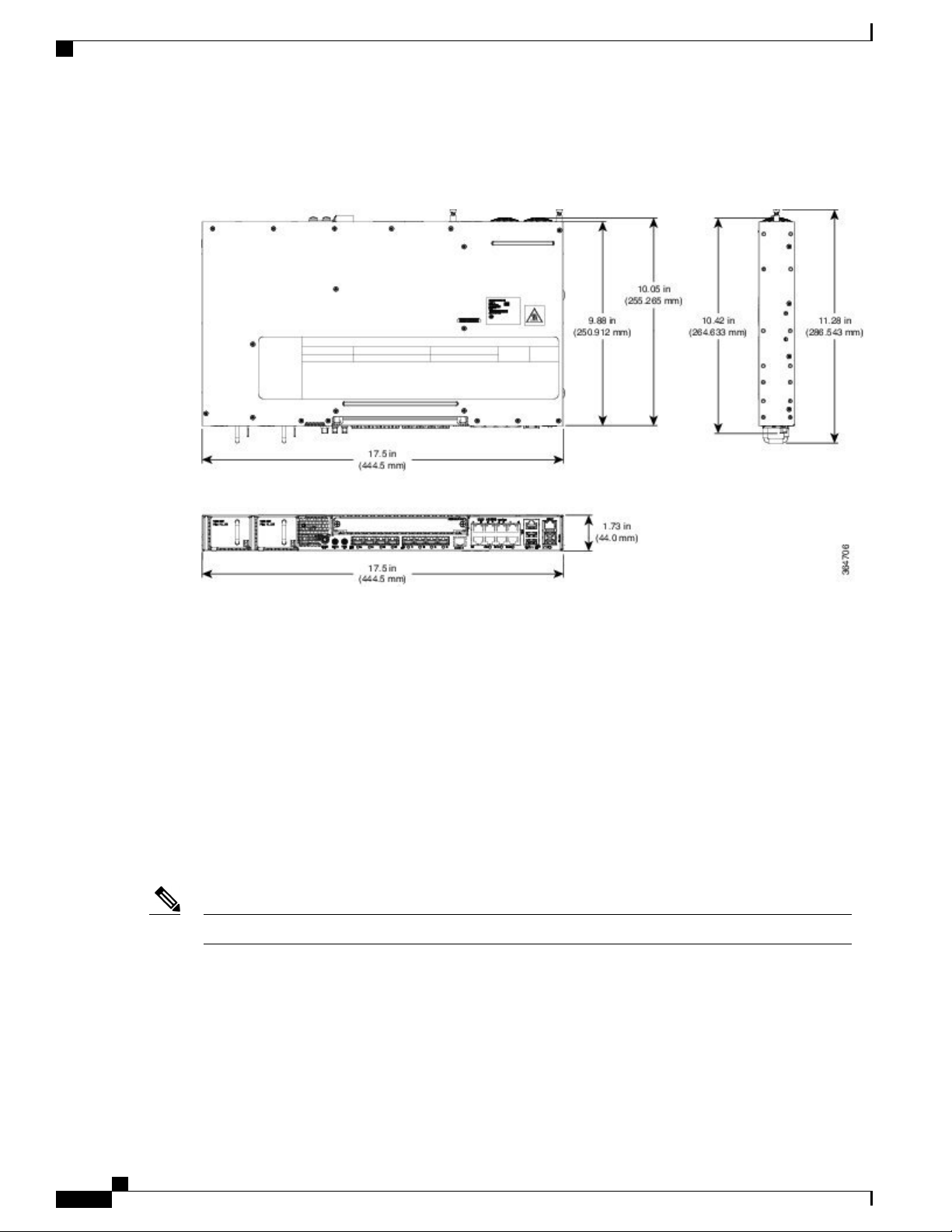

Figure 4: Cisco ASR-920-12SZ-IM Router—Dimensions

External Interfaces

The external physical interfaces on the front panel of the router are given below:

Network Interfaces

The network interfaces are provided through fixed ports.

• GE SFP ports—supports 100/1000 modes

• GE Copper RJ-45 ports—supports 10/100/1000 operation. All eight copper RJ-45 ports support

PoE/PoE+/UPoE with overall power budget of 180 W.

PoE is not supported when the system is powered with 24 V DC.Note

• 10GE SFP+—supports 10G/1G mode depending on the SFP+/SFP in the network interface slot.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

8

Page 21

Cisco ASR 920 Series Aggregation Services Router Overview

Network Timing Interfaces

• 10Mhz input or output—Miniature coaxial connectors for 10Mhz timing (input or output). You can use

this interfaces with an external GPS device to send or receive clocking from the router

• 1PPS input or output and ToD input or output—This interface is used for input or output of time-of-day

(ToD) and 1PPS pulses. ToD format includes both NTP and IEEE 1588-2008 time formats.

The same RS422 pins for 1PPS and TOD are shared between input and output directions. The direction for

each can be independently configured through software.

• GNSS RF IN—This interface is used to connect the external GPS antenna to the in-built GPS module.

External Alarm Inputs

The router supports four dry contact alarm inputs through an RJ-45 jack on the front panel.

Network Timing Interfaces

• Normally Open—indicates that no current flows through the alarm circuit and the alarm is generated

when the current is flowing.

Each alarm input can be provisioned as critical, major, or minor.

Management Interfaces

The following management interfaces are supported:

Management ENET Port

A single management copper ENET port supporting 100/1000Base-T operation is provided on the front panel.

It uses a standard RJ-45 jack.

RS232 Console Port

The RS232 console port provides transmission (Tx), reception (Rx), and ground (Gnd).

Note

The RS232 console port is enabled only through the Cisco-designed cable adapter USB type A cable to

RJ-45 adapter cable. To use this port, disable the flow control on the terminal.

Do not plug the USB-to-RJ45 adapter cable in the USB Memory port.Caution

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

9

Page 22

Power Supply and Fans

USB Console

Cisco ASR 920 Series Aggregation Services Router Overview

A single USB 2.0 Type-A receptacle on the front panel of the router provides console access to ROMMON,

Cisco IOS-XE and diagnostics. While it uses the Type-A connector, it operates as a USB peripheral only for

connection to an external host computer. This interface requires the use of a Type-A to Type-A connector

instead of a standard USB cable.

Note

Use of the USB console is mutually exclusive of the RS232 console port. This interface requires the use

of a Type-A to Type-A USB cable.

USB Mass Storage

A single USB 2.0 Type-A receptacle on the front panel of the router allows external USB mass storage devices,

such as standard USB flash drives. This interface is used to load images, load or store configurations, write

logs, and so on.

More than 8 GB is not supported in ROMMON mode,Note

Zero Touch Provisioning Button

The Zero Touch Provisioning (ZTP) button on the front panel initiates the ZTP process on a short press of

less than eight seconds. Pressing the ZTP button for more than eight seconds causes a board reset.

RS232 Auxiliary Console Port

The RS232 Aux console port provides transmission (Tx), reception (Rx), and ground (Gnd).

Note

The RS232 Aux console port is enabled only through the Cisco-designed cable adapter from USB type

A cable to RJ-45 adapter cable.

This is a debug-only port. it is recommended that this port be used by field service engineers only.Note

Power Supply and Fans

The router supports AC, D, or a combination of both power supplies in a 1+1 redundant configuration.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

10

Page 23

Cisco ASR 920 Series Aggregation Services Router Overview

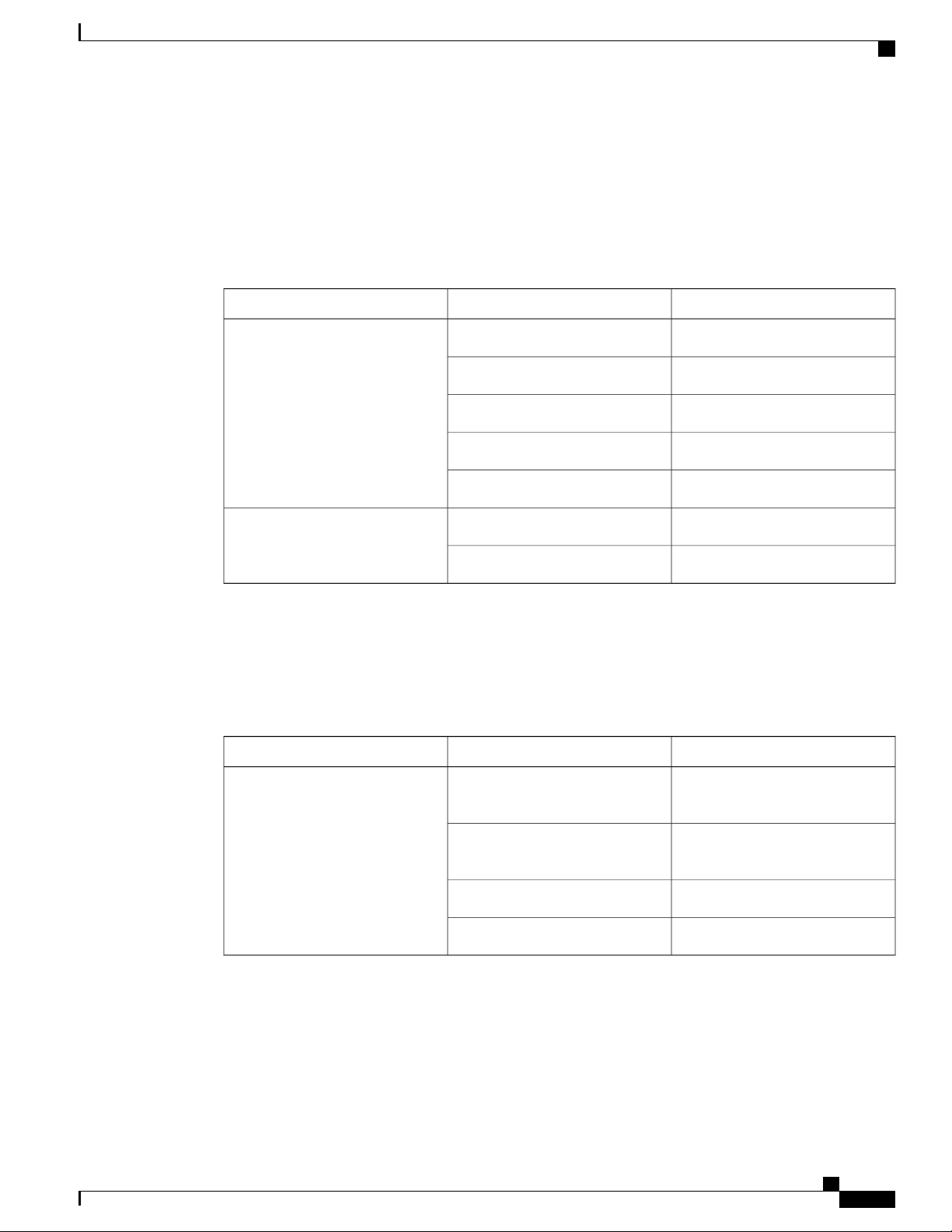

Table 2: Power Supply Specification

LED Indicators

DC (A920-PWR400-D)AC (A920-PWR400-A)Specification

Note

Note

LED Indicators

Voltage

Current

5A through a standard C16 type

receptacle

24 V – 60 V100 V – 240 V

20A through a two-position

terminal block

375 W360 WInput Power

This product requires surge protection as part of the building installation. To comply with the Telcordia

GR-1089 NEBS standard for electromagnetic compatibility and safety, an external surge protective device

(SPD) is required at the AC power service equipment.

For DC systems, if a surge of more than 500 V is expected, add an appropriate external surge protective

device.

The router has a single fan-tray with four fans. The system is designed to operate at its maximum operating

temperature of 70º C, in case of failure of a single fan operating temperature of 65º C. The fan tray is

field-replaceable.

This section describes the different types of LEDs and their behavior.

PWR and STAT LEDs

The PWR LEDs are available on the front panel. These LEDs provide power on the board (PWR) status.

During power up state, these LEDs provide booting status and report errors.

Note

The digital code signing functionality validates the integrity and authenticity of the ROMMON image

before booting it.

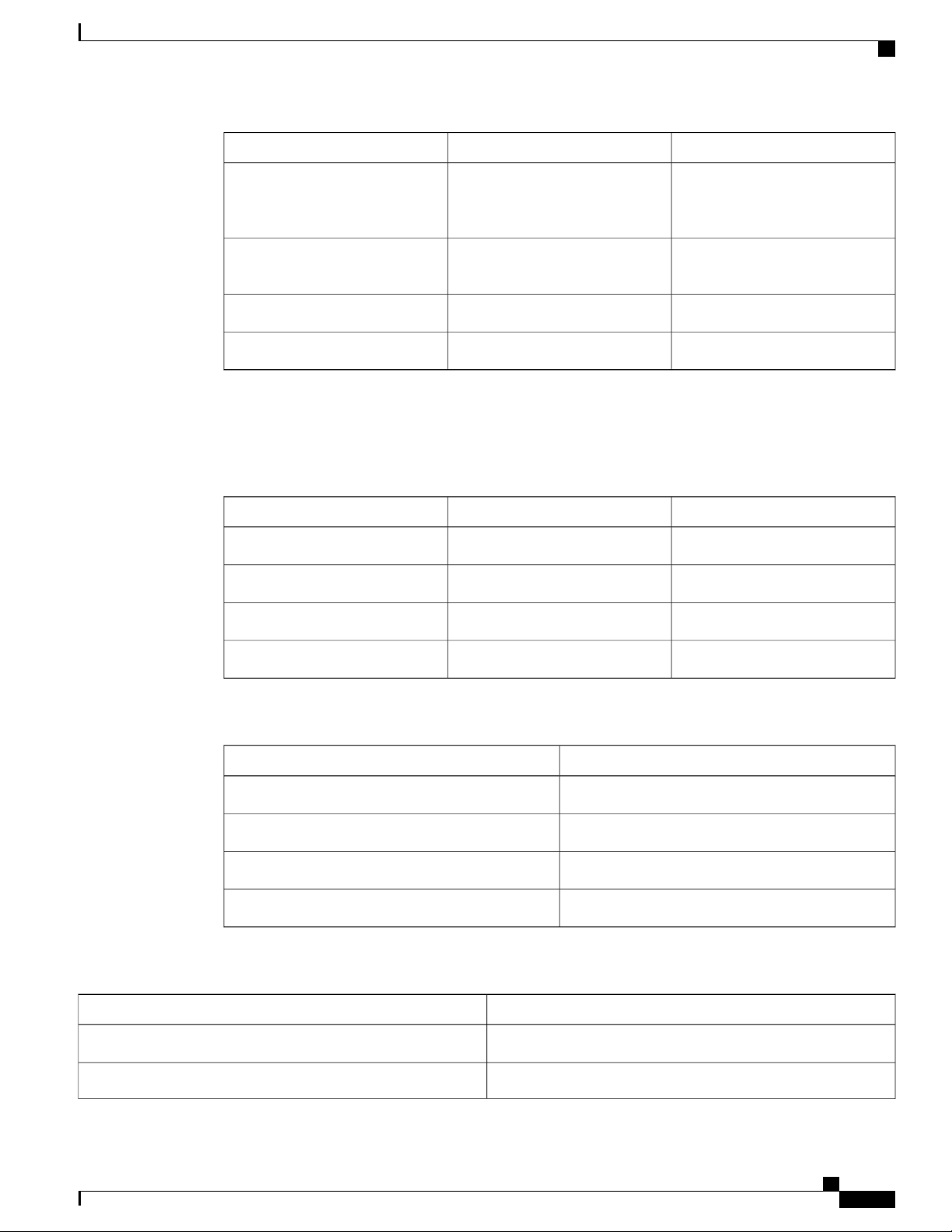

Table 3: PWR and STAT LED Indications

CommentIndicationSTAT LED statePWR LED State

OffAmber

Power in the system is all

right and FPGA

configuration is taking

Permanent Amber/Off

indicates FPGA

configuration failure.

place.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

11

Page 24

LED Indicators

Cisco ASR 920 Series Aggregation Services Router Overview

CommentIndicationSTAT LED statePWR LED State

Green alternatively

Green alternatively

Green alternatively

RedAmber

FPGA Image Validation

Error.

AmberFlashing Amber and

Upgrade FPGA image

System is in unresponsive

state.

—

error, continuing with

Golden FPGA image.

OffFlashing Amber and

FPGA configuration

—

successful and Digital

code signing successfully

validated FPGA image.

Digital code signing

passed the control to

Microloader to boot

ROMMON.

RedFlashing Amber and

Digital code signing

—

reported failure in

ROMMON image

validation.

Flashing AmberFlashing Amber

ZTP process has begun.

Note

A short press of

the ZTP button

Both LEDs turn Green

once provisioning is

complete.

triggers the

provisioning. A

longer press of

more than eight

seconds, resets

the board.

IOS-XE image is booting.OffGreen

GreenGreen

Successfully booted and

—

system is operating

normally.

AmberGreen

A minor alarm or

—

synchronization is in

Holdover or free-running

mode

RedGreen

A major or critical alarm

—

(high temperature

reported for any sensor)

or multiple fan failure.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

12

Page 25

Cisco ASR 920 Series Aggregation Services Router Overview

CPU Management Port LEDs

The LED for the 100/1000 Management port is integrated on the connector itself. There are two LEDs in the

connector—the LED on the left indicates the Link/Activity status and the LED on the right indicates the

duplex status of the link.

Table 4: CPU Management Port LED Indication

LED Indicators

IndicationLED StateLED

Link up in 1000 MbpsGreenLeft

Activity in 1000 MbpsBlinking Green

Link up in 100 MbpsAmber

Activity in 100 MbpsBlinking Amber

SFP LEDs

Each SFP port has an LED indicator.

Table 5: SFP Port LED Indication

number

GreenLabeled same as the SFP port

Blinking Green

Link downOff

Link up in full duplexGreenRight

Link up in half duplexOff

IndicationLED StateLED

Link up in

1000Base-X/100Base-FX

Activity in 1000

Base-X/100Base-FX

Fault/Error/Link downAmber

Administratively downOff

SFP+ LEDs

Each SFP+ port has an LED indicator.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

13

Page 26

LED Indicators

RJ-45 LEDs

Cisco ASR 920 Series Aggregation Services Router Overview

Table 6: SFP+ Port LED Indication

IndicationLED StateLED

Link up in 10G/1GGreenLabeled same as the SFP port

number

Activity in 10G/1GBlinking Green

Fault/Error/Link downAmber

Administratively downOff

There is only one LED on each RJ45 port on the fixed slot (slot 0/0) and this indicates only the link or speed

status. There is no LED to show the Duplex state. However, there are two LEDs for IM RJ45 ports and they

indicate the Link and Duplex state.

Table 7: RJ-45 LED Indication

Power Supply Unit LEDs

Each power supply unit has a corresponding LED on the front panel.

Table 8: PSU LED Indication

IndicationLED State

Link up in 10/100/1000Base-TGreen

Activity in 10/100/1000Base-TBlinking Green

Fault/Error/Link downAmber

Administratively downOff

Power Supply ConditionFAIL LEDPower LED

OffGreen

Power Supply ON; valid

input/output

Red 1Hz blinkingYellow 1Hz blinking

PSU Warning due to OCP, OTP,

UV, OV, OP, abnormal fan

operation

PSU continues to operate

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

14

Page 27

Cisco ASR 920 Series Aggregation Services Router Overview

LED Indicators

Power Supply ConditionFAIL LEDPower LED

System–Interface LED Behavior

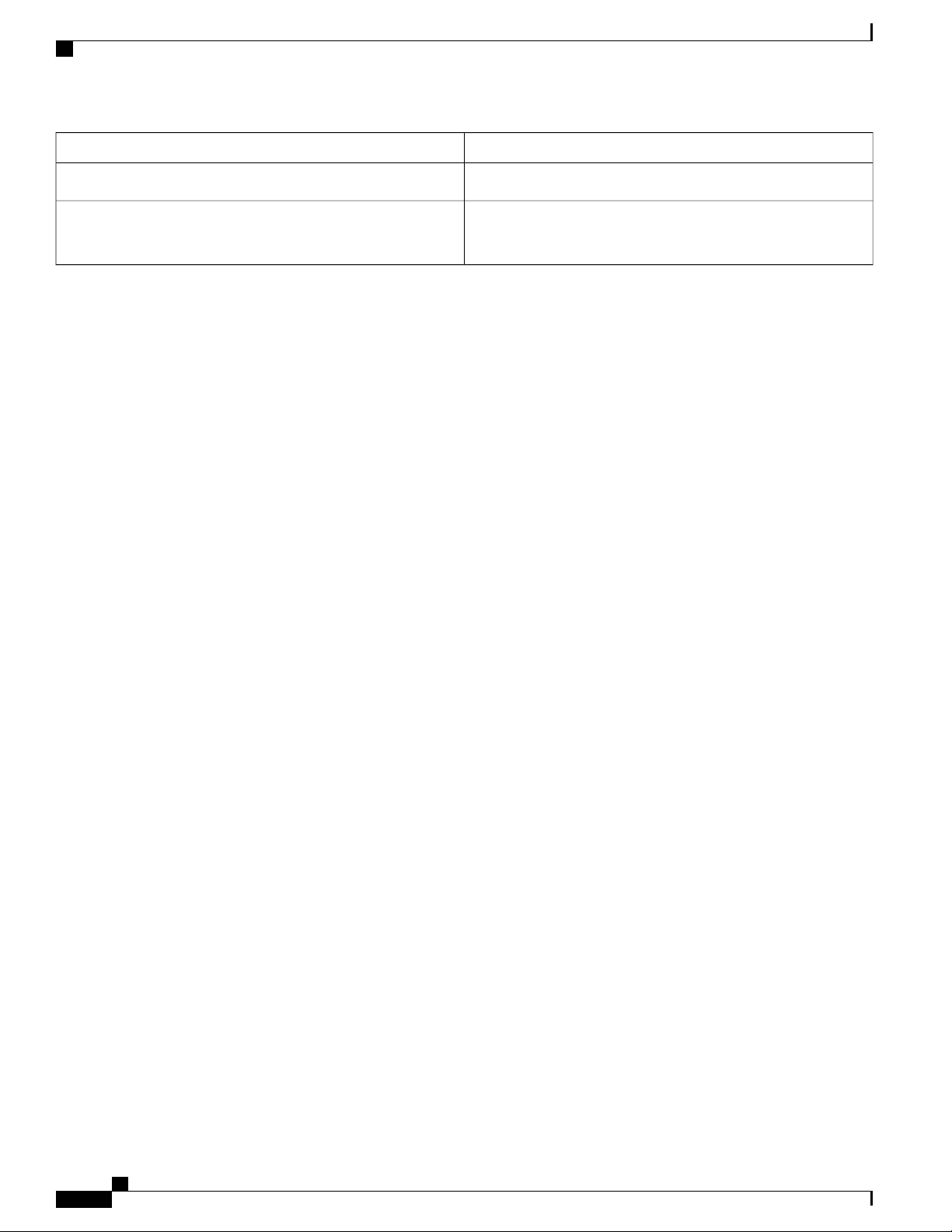

Table 9: 1G Copper and 1G SFP LED Indication

OnOff

PSU failure due to OCP, OTP, UV,

OV, OP, abnormal fan operation.

No valid output.

OffGreen 1Hz blinking

Valid power present, shutdown by

system.

Input voltage lowOffYellow

No valid power input.OffOff

1G SFP Port LEDs1G Copper Port LEDs (Link)Event

OffOffROMMON

OffOffIOS Shut

AmberAmberIOS No shut (cable disconnect)

Table 10: Dual Rate Port LED Indication

Table 11: Management Port LED Indication

GreenGreenIOS No shut (Link Up)

Dual Rate (1G/10G) Port LEDsEvent

OffROMMON

OffIOS Shut

AmberIOS No shut (cable disconnect)

GreenIOS No shut (Link Up)

Management Port LEDs (Link/Duplex)Event

Green/OffROMMON

Off/OffIOS Shut

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

15

Page 28

Online Insertion and Removal

Cisco ASR 920 Series Aggregation Services Router Overview

Management Port LEDs (Link/Duplex)Event

Amber/OffIOS No shut (cable disconnect)

IOS No shut (cable connect)

Online Insertion and Removal

This router supports the following OIR operations:

When an SFP is removed, there is no effect on traffic flowing on other ports.

•

When an SFP is installed, the system initializes that port for operation based upon the current

•

configuration. If the inserted SFP is incompatible with the current configuration for that port, the port

does not become operational until the configuration is updated.

Both power supplies are installed and active and the load may be shared between them or a single PSU

•

could support the whole load. When a power supply is not working or the input cable is removed, the

remaining power supply takes the entire load without disruption.

When a fan tray is removed or replaced, there is no need to power down the router. However, when the

•

fan tray is removed from the router, the router shuts down automatically after some time, depending on

the ambient temperature. The time duration before the router shuts down is shown in the table below:

Green/Green in 1G mode

Amber/Green in 100M mode

Licensing

The router supports the following types of licenses:

• Port Licensing—Port Upgrade license is available as a "Pay as you Grow" model.

6 ports 1GE upgrade license

◦

2 ports 10G upgrade license

◦

Bulk License to enable 12x1port 1GE and 4x10GE ports

◦

Advanced Metro IP Access

•

Metro IP Access

•

Metro Access (default)

•

Feature licensing

•

The following methods are used to activate the above licenses:

• Cisco Software Licensing—The Cisco Software License Activation feature is a set of processes and

components to activate Cisco software feature sets by obtaining and validating fee-based Cisco software

licenses.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

16

Page 29

Cisco ASR 920 Series Aggregation Services Router Overview

Licensing

Note

Licenses generated by the Cisco Software Licensing are tied to the UDI of the chassis and a corresponding

watchtower device certificate (WDC) is stored in the system.

• Cisco Smart Licensing—Smart Licensing is usage-based licensing where devices register with the Cisco

Secure server.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

17

Page 30

Licensing

Cisco ASR 920 Series Aggregation Services Router Overview

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

18

Page 31

CHAPTER 2

Preparing for Installation

This chapter describe how to prepare for the installation of the router at your site.

Safety Guidelines, page 20

•

Safety Warning Statements, page 20

•

Safety Guidelines for Personal Safety and Equipment Protection, page 20

•

Safety Precautions for Module Installation and Removal, page 21

•

Safety with Electricity, page 21

•

Power Supply Considerations, page 22

•

Preventing ESD Damage, page 22

•

Site Planning, page 23

•

Air Flow Guidelines, page 24

•

Floor Loading Considerations, page 26

•

Site Power Guidelines, page 27

•

Electrical Circuit Requirements, page 27

•

Site Cabling Guidelines, page 27

•

Asynchronous Terminal Connections, page 28

•

Interference Considerations, page 28

•

Installation Checklist, page 31

•

Creating a Site Log, page 32

•

Chassis-Lifting Guidelines, page 33

•

Tools and Equipment, page 33

•

Unpacking and Verifying the Shipped Contents, page 34

•

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

19

Page 32

Safety Guidelines

Safety Guidelines

Before you begin the installation, review the safety guidelines in this chapter to avoid injuring yourself or

damaging the equipment.

In addition, before replacing, configuring, or maintaining the router, review the safety warnings listed in the

Regulatory Compliance and Safety Information document.

Safety Warning Statements

Preparing for Installation

Warning

Warning

Warning

Warning

Before working on a system that has an on/off switch, turn OFF the power and unplug the power cord.

Statement 1

This unit might have more than one power supply connection. All connections must be removed to

de-energize the unit. Statement 1028

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority

or an electrician if you are uncertain that suitable grounding is available. Statement 1024

Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces,

and watches). Metal objects will heat up when connected to power and ground and can cause serious burns

or weld the metal object to the terminals. Statement 43

For other standard warning messages and their translations, see the Regulatory Compliance and Safety

Information for the Cisco ASR 920 Series Aggregation Services Router document.

Safety Guidelines for Personal Safety and Equipment Protection

The following guidelines help ensure your safety and protect the equipment. This list does not include all the

potentially hazardous situations. Therefore, you should be on alert.

Before moving the system, always disconnect all the power cords and interface cables.

•

Never assume that power is disconnected from a circuit; always check.

•

Before and after installation, keep the chassis area clear and dust free.

•

Keep tools and assembly components away from walk areas where you or others could trip over them.

•

Do not work alone if potentially hazardous conditions exist.

•

Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

•

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

20

Page 33

Preparing for Installation

Safety Precautions for Module Installation and Removal

Do not wear loose clothing that may get caught in the chassis.

•

When working under conditions that may be hazardous to your eyes, wear safety glasses.

•

Safety Precautions for Module Installation and Removal

To see the safety precautions for module installation and removal, see the Regulatory Compliance and Safety

Information for the Cisco ASR 920 Series Aggregation Services Router document.

Safety with Electricity

To see the safety with electricity, see the Regulatory Compliance and Safety Information for the Cisco ASR

920 Series Aggregation Services Router document.

When working on equipment powered by electricity, follow these guidelines:

• Locate the room’s emergency power-off switch. If an electrical accident occurs, you will be able to

quickly turn off the power.

Before starting work on the system, turn off the DC main circuit breaker and disconnect the power

•

terminal block cable.

Before doing the following, disconnect all power:

•

Working on or near power supplies

◦

Installing or removing a router chassis or network processor module

◦

Performing most hardware upgrades

◦

Never install equipment that appears damaged.

•

Carefully examine your work area for possible hazards, such as moist floors, ungrounded power extension

•

cables, and missing safety grounds.

Never assume that power is disconnected from a circuit; always check.

•

Never perform any action that creates a potential hazard to people or makes the equipment unsafe.

•

If an electrical accident occurs, proceed as follows:

•

Use caution, and do not become a victim yourself.

◦

Turn off power to the router.

◦

If possible, send another person to get medical aid. Otherwise, determine the condition of the

◦

victim, and then call for help.

Determine whether the person needs rescue breathing or external cardiac compressions; then take

◦

appropriate action.

In addition, use the following guidelines when working with any equipment that is disconnected from a power

source, but still connected to telephone wiring or network cabling:

Never install telephone wiring during a lightning storm.

•

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

21

Page 34

Power Supply Considerations

Never install telephone jacks in wet locations unless the jack is specifically designed for it.

•

Never touch uninsulated telephone wires or terminals unless the telephone line is disconnected at the

•

network interface.

When installing or modifying telephone lines, use caution.

•

Power Supply Considerations

Check the power at your site to ensure that you are receiving clean power (free of spikes and noise). Install a

power conditioner, if necessary.

Preventing ESD Damage

Preparing for Installation

Warning

This equipment needs to be grounded. Use a green and yellow 6 AWG ground wire to connect the host

to earth ground during normal use. Statement 383

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD may occur when

electronic printed circuit cards are improperly handled and can cause complete or intermittent failures. When

removing and replacing modules, always follow ESD prevention procedures:

Ensure that the router chassis is electrically connected to earth ground.

•

Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. To channel unwanted

•

ESD voltages safely to ground, connect the clip to an unpainted surface of the chassis frame. To guard

against ESD damage and shocks, the wrist strap and cord must operate effectively.

If no wrist strap is available, ground yourself by touching a metal part of the chassis.

•

When installing a component, use any available ejector levers or captive installation screws to properly

•

seat the bus connectors in the backplane or midplane. These devices prevent accidental removal, provide

proper grounding for the system, and help to ensure that bus connectors are properly seated.

When removing a component, use available ejector levers or captive installation screws, if any, to release

•

the bus connectors from the backplane or midplane.

Handle components by their handles or edges only; do not touch the printed circuit boards or connectors.

•

Place a removed component board side up on an antistatic surface or in a static-shielding container. If

•

you plan to return the component to the factory, immediately place it in a static-shielding container.

Avoid contact between the printed circuit boards and clothing. The wrist strap only protects components

•

from ESD voltages on the body; ESD voltages on clothing can still cause damage.

Never attempt to remove the printed circuit board from the metal carrier.

•

Note

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

22

For the safety of your equipment, periodically check the resistance value of the antistatic wrist strap. It

should be between 1 and 10 Mohm.

Page 35

Preparing for Installation

Site Planning

The sections describe how to plan for the installation of the Cisco ASR 920 Series Router.

General Precautions

Observe the following general precautions when using and working with your router::

Keep your system components away from radiators and heat sources and do not block cooling vents.

•

Do not spill food or liquids on your system components and never operate the product in a wet

•

environment.

Do not push any objects into the openings of your system components. Doing so can cause fire or electric

•

shock by shorting out interior components.

Position system cables and power supply cable carefully. Route system cables and the power supply

•

cable and plug so that they are not stepped on or tripped over. Be sure that nothing else rests on your

system component cables or power cable.

Site Planning

Do not modify power cables or plugs. Consult a licensed electrician or your power company for site

•

modifications. Always follow your local and national wiring rules.

If you turn off your system, wait at least 30 seconds before turning it on again to avoid damage of system

•

components.

Site Planning Checklist

Use the following checklist to perform and account for all the site planning tasks described in this chapter:

The site meets the environmental requirements.

•

• The site’s air conditioning system can compensate for the heat dissipation.

The floor space that the router occupies can support the weight of the system.

•

Electrical service to the site complies with the requirements.

•

The electrical circuit servicing the router complies with the requirements.

•

Consideration has been given to the console port wiring and limitations of the cabling involved, according

•

to TIA/EIA-232F.

The router's Ethernet cabling distances are within the prescribed limitations.

•

The equipment rack in which you plan to install the router complies with prescribed requirements.

•

When selecting the location of the rack, careful consideration must be given to safety, ease of maintenance,

•

and proper airflow.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

23

Page 36

Site Selection Guidelines

Site Selection Guidelines

The router require specific environmental operating conditions. Temperature, humidity, altitude, and vibration

can affect the performance and reliability of the router. The following sections provide specific information

to help you plan for the proper operating environment.

The routers are designed to meet the industry EMC, safety, and environmental standards described in the

Regulatory Compliance and Safety Information for the Cisco ASR 920 Series Router document.

Environmental Requirements

Environmental monitoring of the Cisco ASR 920-24SZ-IM, ASR-920-24SZ-M, ASR-920-24TZ-M Router

protects the system and components from damage caused by excessive voltage and temperature conditions.

To ensure normal operation and avoid unnecessary maintenance, plan and prepare your site configuration

before installation. After installation, make sure that the site maintains the environmental characteristics

described in Cisco ASR-920-12SZ-IM Router Specifications table.

For an outside plant installation (cell site cabinet, hut etc.), it is required that the router be protected against

airborne contaminants, dust, moisture, insects, pests, corrosive gases, polluted air or other reactive elements

present in the outside air. To achieve this level of protection, we recommend that the unit be installed in a

fully sealed enclosure or cabinet. Examples of such cabinets include IP65 cabinets with heat exchanger

complying with Telecordia GR487. Temperature must be maintained within –40º C to 70º C.

The equipment shall be placed inside a space protected from direct outside weather and environmental stresses

by an enclosure, and where the operating climate, as defined by Class 2 of GR-3108-CORE, is between

Preparing for Installation

-40°C (-40°F) and 70°C (158°F)

•

5 and 90% RH

•

Physical Characteristics

Be familiar with the physical characteristics of the router to assist you in placing the system in the proper

location. For more information, see Cisco ASR-920-12SZ-IM Router Specifications table.

Air Flow Guidelines

Cool air is circulated through the router by fans located along the back side of the router.

The internal fans maintain acceptable operating temperatures for the internal components by drawing in cool

air through the vents, and circulating the air through the chassis.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

24

Page 37

Preparing for Installation

Air Flow Guidelines

The direction of air flow is from front-to-back.

Figure 5: Air Flow in the Cisco ASR 920 Series Routers

To ensure adequate air flow through the equipment rack, it is recommended that you maintain a minimum

clearance distance as mentioned below, at all times.

• front clearance—12.7 cm

• rear clearance—14 cm

Note the following points:

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

25

Page 38

Air Flow Guidelines for ETSI Rack Installation

When installing the routerouter in a back-to-back position with another device, ensure that there is a

•

minimum of 10 cm air flow clearance between the two devices.

If airflow through the equipment rack and the routers that occupy it is blocked or restricted, or if the

•

ambient air being drawn into the rack is too warm, an overtemperature condition may occur within the

rack and the routers that occupy it.

The site should also be as dust-free as possible. Dust tends to clog the router fans, reducing the flow of

•

cooling air through the equipment rack and the routers that occupy it, thus increasing the risk of an

overtemperature condition.

Enclosed racks must have adequate ventilation. Ensure that the rack is not congested because each router

•

generates heat. An enclosed rack should have louvered sides and a fan to provide cooling air. Heat that

is generated by the equipment near the bottom of the rack can be drawn upward into the intake ports of

the equipment above.

When mounting a chassis in an open rack, ensure that the rack frame does not block the exhaust fans.

•

When rack-installed equipment fails, especially equipment in an enclosed rack, try operating the equipment

•

by itself, if possible. Power off all the other equipment in the rack (and in adjacent racks) to give the

router maximum cooling air and clean power.

Preparing for Installation

Avoid installing the router in a location in which the chassis air intake vents may draw in the exhaust

•

air from adjacent equipment. Consider how the air flows through the router; the airflow direction is front

to back, with ambient air drawn in from the vents located on the sides of the chassis.

Air Flow Guidelines for ETSI Rack Installation

To install a Cisco ASR 920 Series Router in a 2-post or 4-post rack, the front and rear doors of the cabinet

must be removed. It is recommended that you maintain a minimum clearance distance as mentioned below,

at all times.

• front clearance—12.7 cm

• rear clearance—14 cm

If you are mounting the chassis in a 4-post enclosed cabinet, ensure that you have a minimum of 14 cm of

clearance on each side of the chassis.

Floor Loading Considerations

Ensure that the floor under the rack supporting the Cisco ASR 920 Series Routers is capable of supporting

the combined weight of the rack and all the other installed equipment.

To assess the weight of a fully configured Cisco ASR 920 Series Router, see the Cisco ASR-920-12SZ-IM

Router Specifications table.

For additional information about floor loading requirements, see the GR-63-CORE, Network Equipment

Building System (NEBS) Requirements: Physical Protection document.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

26

Page 39

Preparing for Installation

Site Power Guidelines

The router have specific power and electrical wiring requirements. Adhering to these requirements ensures

reliable operation of the system. Follow these precautions and recommendations when planning your site

power for the router:

The redundant power option provides a second, identical power supply to ensure that power to the chassis

•

continues uninterrupted if one power supply fails or input power on one line fails.

Connect each of the two power supplies to a separate input power source. If you fail to do this, your

•

system might be susceptible to total power failure due to a fault in the external wiring or a tripped circuit

breaker.

To prevent a loss of input power, be sure that the total maximum load on each circuit supplying the

•

power supplies is within the current ratings of the wiring and the breakers.

Check the power at your site before installation, and periodically after installation to ensure that you are

•

receiving clean power. Install a power conditioner, if necessary.

Site Power Guidelines

Provide proper grounding to avoid personal injury and damage to the equipment due to lightning striking

•

power lines or due to power surges. The chassis ground must be attached to a central office or other

interior ground system.

Caution

Note

This product requires short-circuit (overcurrent) protection to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations.

The router installation must comply with all the applicable codes, and is approved for use with copper

conductors only. The ground bond-fastening hardware should be of compatible material and preclude

loosening, deterioration, and electrochemical corrosion of hardware and joined material. Attachment of

the chassis ground to a central office or other interior ground system must be made with a 6-AWG gauge

wire copper ground conductor at a minimum.

For information on power specifications, see Power Supply Specification table.

Electrical Circuit Requirements

Each router requires a dedicated electrical circuit. If you equip the router with dual-power feeds, provide a

separate circuit for each power supply to avoid compromising the power redundancy feature.

The ruters can be powered by a DC source or an AC source. Ensure that equipment grounding is present and

observe the power-strip ratings. Make sure that the total ampere rating of all the products plugged into the

power strip does not exceed 80% of the rating.

Site Cabling Guidelines

This section contains guidelines for wiring and cabling at your site. When preparing your site for network

connections to the router, consider the type of cable required for each component, and the cable limitations.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

27

Page 40

Asynchronous Terminal Connections

Consider the distance limitations for signaling, electromagnetic interference (EMI), and connector compatibility.

Possible cable types are fiber, thick or thin coaxial, foil twisted-pair, or unshielded twisted-pair cabling.

Also consider any additional interface equipment you need, such as transceivers, hubs, switches, modems,

channel service units (CSU), or data service units (DSU).

Before you install the router, have all the additional external equipment and cables on hand. For information

about ordering, contact a Cisco customer service representative.

The extent of your network and the distances between the network interface connections depend, in part, on

the following factors:

Signal type

•

Signal speed

•

Transmission medium

•

The distance and rate limits referenced in the following sections are the IEEE-recommended maximum speeds

and distances for signaling purposes. Use this information as a guideline when planning your network

connections prior to installing the router.

If wires exceed the recommended distances, or if wires pass between buildings, give special consideration to

the effect of a lightning strike in your vicinity. The electromagnetic pulse caused by lightning or other

high-energy phenomena can easily couple enough energy into unshielded conductors to destroy electronic

devices. If you have had problems of this sort in the past, you may want to consult experts in electrical surge

suppression and shielding.

Preparing for Installation

Asynchronous Terminal Connections

The router provides a console port to connect a terminal or computer for local console access. The port has

an RJ-45 connector and supports RS-232 asynchronous data with distance recommendations specified in the

IEEE RS-232 standard.

Interference Considerations

When wires are run for any significant distance, there is a risk that stray signals will be induced on the wires

as interference. If interference signals are strong, they may cause data errors or damage to the equipment.

The sections describe the sources of interference and how to minimize their effects on the router.

Electromagnetic Interference

ll the equipment powered by AC current can propagate electrical energy that can cause EMI and possibly

affect the operation of other equipment. The typical sources of EMI are equipment power cords and power

service cables from electric utility companies.

Strong EMI can destroy the signal drivers and receivers in the router and even create an electrical hazard by

causing power surges through the power lines into installed equipment. These problems are rare, but could

be catastrophic.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

28

Page 41

Preparing for Installation

To resolve these problems, you need specialized knowledge and equipment that could consume substantial

time and money. However, you can ensure that you have a properly grounded and shielded electrical

environment, paying special attention to the need for electrical surge suppression.

For information about the electrode magnetic compliance standards supported on the Cisco ASR 920 Series

Router, see the Regulatory Compliance and Safety Information for the Cisco ASR 920 Series Aggregation

Services Router document.

Radio Frequency Interference

When electromagnetic fields act over a long distance, radio frequency interference (RFI) may be propagated.

Building wiring can often act as an antenna, receiving the RFI signals and creating more EMI on the wiring.

If you use twisted-pair cable in your plant wiring with a good distribution of grounding conductors, the plant

wiring is unlikely to emit radio interference. If you exceed the recommended distances, use a high-quality

twisted-pair cable with one ground conductor for each data signal.

Radio Frequency Interference

Lightning and AC Power Fault Interference

If signal wires exceed the recommended cabling distances, or if signal wires pass between buildings, you

should consider the effect that a lightning strike in your vicinity might have on the router.

The electromagnetic pulse (EMP) generated by lightning or other high-energy phenomena can couple enough

energy into unshielded conductors to damage or destroy electronic equipment. If you have previously

experienced such problems, you should consult with RFI and EMI experts to ensure that you have adequate

electrical surge suppression and shielding of signal cables in your Cisco ASR 920 Series Router operating

environment.

Rack-Mounting Guidelines

The sections provide guidelines for rack-mounting.

Precautions for Rack-Mounting

The following rack-mount guidelines are provided to ensure your safety:

Ensure that the rack is level and stable before extending a component from the rack.

•

Ensure that proper airflow is provided to the components in the rack.

•

Do not step on or stand on any component or system when servicing other systems or components in a

•

rack.

When mounting the router in a partially filled rack, load the rack from the bottom to the top, with the

•

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the

•

unit in the rack.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

29

Page 42

Rack-Mounting Guidelines

Rack Selection Guidelines

The router can be mounted in most two-post or four-post, 19-inch equipment racks that comply with the

Electronic Industries Association (EIA) standard for equipment racks (EIA-310-D 19-inch). The rack must

have at least two posts with mounting flanges to mount the chassis.

Preparing for Installation

Caution

Caution

When mounting a chassis in any type of rack equipment, ensure that the inlet air to the chassis does not

exceed 70° C.

The distance between the center lines of the mounting holes on the two mounting posts must be 18.31 inch ±

0.06 inch (46.50 cm ± 0.15 cm). The rack-mounting hardware included with the chassis is suitable for most

19-inch equipment racks.

Consider installing the router in a rack with the following features:

NEBS-compliant, 19-inch wide (48.3-cm) rack.

•

EIA or European Telecommunications Standards Institute (ETSI) hole patterns in the mounting rails.

•

The required mounting hardware is shipped with the router. If the rack that you plan to install the system

in has metric-threaded rails, you must provide your own metric-mounting hardware.

Perforated top and open bottom for ventilation to prevent overheating.

•

Leveling feet for stability.

•

The router is not recommended to be installed in an enclosed rack because the chassis requires an

unobstructed flow of cooling air to maintain acceptable operating temperatures for its internal components.

If you use an enclosed rack, ensure that the air flow requirements are maintained as discussed in Air Flow

Guidelines.

Equipment Rack Guidelines

The placement of a rack can affect personnel safety, system maintenance, and the system’s ability to operate

within the environmental characteristics. Choose a proper location for the router by following the guidelines

described here.

Locating for Safety

If the Cisco ASR 920 Series Router is the heaviest or the only piece of equipment in the rack, consider installing

it at or near the bottom to ensure that the rack’s center of gravity is as low as possible.

For additional information about the proper placement of electronic equipment, consult the GR-63-CORE,

Network Equipment Building System (NEBS) Requirements: Physical Protection document.

Locating for Easy Maintenance

It is recommended that you maintain a minimum clearance distance as mentioned below, at all times.

• front clearance—12.7 cm

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

30

Page 43

Preparing for Installation

Installation Checklist

• rear clearance—10 cm

This space ensures that you can remove the router components and perform routine maintenance and upgrades

easily.

Avoid installing the router in a congested rack and consider how routing of cables from other pieces of

equipment in the same rack could affect access to the router cards.

The front and rear of the chassis must remain unobstructed to ensure adequate airflow and prevent overheating

inside the chassis.

To avoid problems during installation and ongoing operations, follow these general precautions when you

plan equipment locations and connections:

Use the show environment all command regularly to check the internal system status. The environmental

•

monitor continually checks the interior chassis environment; it provides warnings about high temperature

and creates reports on other potentially dangerous occurrences. If warning messages are displayed, take

immediate action to identify the cause, and correct the problem.

Keep the router off the floor and out of areas that collect dust.

•

Follow ESD-prevention procedures to avoid damage to equipment. Damage from static discharge can

•

cause immediate or intermittent equipment failure.

Locating for Proper Airflow

Ensure that the router location has enough airflow to keep the system operating within the environmental

characteristics and the air temperature is sufficient to compensate for the heat dissipated by the system. For

more information, see the Air Flow Guidelines section.

Installation Checklist

To assist you with your installation and to provide a record of what was done by whom and when, photocopy

the Cisco ASR 920 Series Router Installation Checklist shown in the table below. Use this to record the

completion and verification of each procedure. After the checklist is completed, place it in your Site Log along

with the other records pertaining to your new Cisco router.

Table 12: Installation Checklist

Date on which chassis received

Chassis and all accessories

unpacked

Types and numbers of interfaces

verified

DateVerified ByTask

Safety recommendations and

guidelines reviewed

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

31

Page 44

Creating a Site Log

Preparing for Installation

DateVerified ByTask

Installation Checklist copied

Site Log established and

background information entered

Site power voltages verified

Site environmental specifications

verified

Required passwords, IP addresses,

device names, and so on, available

Required tools available

Network connection equipment

available

Cable-management brackets

installed (optional, but

recommended)

AC power cables connected to AC

sources and router

DC power cables connected to DC

sources and router

Network interface cables and

devices connected

System power turned on

System boot complete (STATUS

LED is on)

Correct software configuration

displayed after system banner

appears

Creating a Site Log

The Site Log provides a record of all the actions related to installing and maintaining the router. Keep it in

an accessible place near the chassis so that anyone who performs tasks has access to it.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

32

Page 45

Preparing for Installation

Create the Site Log prior to the installation. (See “Site Log” for more information about the Site Log as well

as a sample Site Log that can be used to make copies.)

Chassis-Lifting Guidelines

The chassis is not intended to be moved frequently. Before you install the system, ensure that your site is

properly prepared so that you can avoid having to move the chassis later to accommodate power sources and

network connections.

Each time you lift the chassis or any heavy object, follow these guidelines:

Ensure that your footing is solid, and balance the weight of the chassis between your feet.

•

Lift the chassis slowly; never move suddenly or twist your body as you lift.

•

Keep your back straight and lift with your legs, not your back. If you must bend down to lift the chassis,

•

bend at the knees, not at the waist, to reduce the strain on your back muscles.

Do not remove installed components from the chassis.

•

Chassis-Lifting Guidelines

Always disconnect all external cables before lifting or moving the chassis.

•

Warning

To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using the

handles on modules (such as power supplies, fans, or cards); these types of handles are not designed to

support the weight of the unit. Lift the unit only by using handles that are an integral part of the chassis,

or by grasping the chassis underneath its lower edge. Statement 163

Tools and Equipment

You need the following tools and equipment to install and upgrade the router and its components:

ESD-preventive cord and wrist strap

•

Antistatic mat or antistatic foam

•

Number 1 and Number 2 Phillips-head screwdrivers

•

#12-24 pan-head screws to secure the router to the equipment rack

•

Cables for connecting to the network ports (depending on the configuration)

•

Note

For more information about cable specifications, see the Troubleshooting section.

Ethernet hub, switch, or PC with a network interface card for connecting to the Ethernet ports

•

Console terminal (an ASCII terminal or a PC running terminal emulation software) that is configured

•

for 9600 baud, 8 data bits, no parity, no flow control, and 1stop bit

Console cable for connecting to the console port

•

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

33

Page 46

Unpacking and Verifying the Shipped Contents

Ratcheting torque screwdriver with a Phillips head that exerts up to 30-pound force per square inch

•

(in-lb) or 0.02-kilograms force per square millimeter (kgf/mm2) of pressure

Crimping tool as specified by the ground lug manufacturer

•

Wire-stripping tools for stripping both 6-AWG and 12-AWG wires

•

Tape measure and level

•

Only trained and qualified personnel should be allowed to install or replace this equipment. Statement 49Warning

Unpacking and Verifying the Shipped Contents

When you receive your chassis, perform the following steps:

SUMMARY STEPS

Preparing for Installation

DETAILED STEPS

Step 1

Step 2

Step 3

Step 4

Inspect the box for any shipping damage. If there is obvious physical damage, contact your Cisco service representative.

Unpack the Cisco ASR 920-24SZ-IM, ASR-920-24SZ-M, ASR-920-24TZ-M Router.

Perform a visual inspection of the chassis.

Use the table below to check the contents of the Cisco ASR 920-24SZ-IM, ASR-920-24SZ-M, ASR-920-24TZ-M Router

shipping container. Do not discard the shipping container. You will need the container if you move or ship the Cisco

ASR 920-24SZ-IM, ASR-920-24SZ-M, ASR-920-24TZ-M Router in the future.

Table 13: Cisco ASR 920-24SZ-IM, ASR-920-24SZ-M, ASR-920-24TZ-M Router Default Shipping Container Contents

Inspect the box for any shipping damage. If there is obvious physical damage, contact your Cisco service

1.

representative.

Unpack the Cisco ASR 920-24SZ-IM, ASR-920-24SZ-M, ASR-920-24TZ-M Router.

2.

Perform a visual inspection of the chassis.

3.

Use the table below to check the contents of the Cisco ASR 920-24SZ-IM, ASR-920-24SZ-M,

4.

ASR-920-24TZ-M Router shipping container. Do not discard the shipping container. You will need the

container if you move or ship the Cisco ASR 920-24SZ-IM, ASR-920-24SZ-M, ASR-920-24TZ-M Router

in the future.

DescriptionComponent

Chassis (PID: ASR-920-12SZ-IM)

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

34

Cisco ASR 920 Series Router chassis

Fan tray (PID: ASR-920-FAN-TRAY). By default, the fan

tray is installed in the chassis.

Page 47

Preparing for Installation

Unpacking and Verifying the Shipped Contents

DescriptionComponent

Accessories kit

Optional equipment

Chassis rack-mount brackets (19-inch EIA) with eight

screws

Two cable guides with two screws

One earth lug with two 10-32 screws

USB Type-A to USB Type-A Male cable

PSU dummy cover (ASR920-PWR-BLANK)

IM dummy cover (ASR900-IMA-BLANK)

One disposable wrist strap (optional)ESD, wrist strap (disposable)

Cisco ASR 920 Series Router Pointer CardDocumentation

Check the container for the following optional equipment:

AC and DC power supplies

•

Note

The AC and DC power supplies are provided

as ordered.

Power cord if an AC power supply was shipped.

•

There are no cords for the DC power supply units.

Note

If you do not specify the type of power

cable, US power cable for the AC router

variant is supplied.

Note

Most Cisco documentation is available online. The Cisco ASR 920 Series Aggregation Services Router Pointer

Card that is shipped with your Cisco ASR 920 Series Router contains links and information about the various

documents that are available online.

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

35

Page 48

Unpacking and Verifying the Shipped Contents

Preparing for Installation

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

36

Page 49

CHAPTER 3

Installing the Cisco ASR 920 Series Router

This chapter describes how to install the router and includes the following sections:

Prerequisites, page 3-1

•

Installing the Router in a Rack, page 3-2

•

Wall Mounting the Router, page 3-13

•

Installing and Removing SFP Modules, page 3-16

•

Connecting to the Copper Ports, page 3-18

•

Installing the Chassis Ground Connection, page 3-20

•

Installing and Removing the Fan Tray, page 3-22

•

Interface Module Installation, page 3-24

•

Installing the Power Supply, page 3-25

•

Connecting the Router to the Network, page 3-35

•

Prerequisites, page 38

•

Installing the Router in a Rack, page 38

•

Mounting the Router in a Rack, page 45

•

Installing the Router Chassis in the Rack, page 46

•

Attaching the Cable Guides, page 47

•

Wall Mounting the Router, page 49

•

Installing and Removing SFP Modules, page 52

•

Connecting to the Copper Ports, page 55

•

Installing the Chassis Ground Connection, page 57

•

Installing and Removing the Fan Tray, page 60

•

Interface Module Installation, page 63

•

Installing the Power Supply, page 65

•

Cisco ASR-920-12SZ-IM Aggregation Services Router Hardware Installation Guide

37

Page 50

Prerequisites

Connecting the Router to the Network, page 80

•

Prerequisites

Before installing the router, it is important to prepare for the installation by:

Preparing the site (site planning) and reviewing the installation plans or method of procedures (MOP).

•

See Site Planning section.

Unpacking and inspecting the router. See Chassis-Lifting Guidelines section.

•

Gathering the tools and test equipment required to properly install the router. See Tools and Equipment

•

section.

For more instructions on how to prepare for the installation of the router, see Preparing for Installation section.

Installing the Router in a Rack

Installing the Cisco ASR 920 Series Router

Caution

Each Cisco ASR 920 Series Aggregation Services Router router includes rack-mounting brackets. Using the

rack-mounting brackets, you can mount the router in a 19-inch, 23-inch, or an ETSI rack that conforms to the

EIA-310-D specification.

Using the two rack-mounting brackets for mounting, you can recess the router in the equipment rack. This

arrangement provides extra space in front of the router for the cables and allows you to close the doors of

racks equipped with front-close doors.

To attach or replace the rack-mounting brackets, see the Attaching Brackets to the Router section.

The rack-mounting brackets are slotted to allow the router to be mounted in racks with EIA 1.25-inch (3.175-cm)

or WECO 1.0-inch (2.54-cm) hole spacing. When installed in the rack, the router requires one EIA 1.75-inch

(4.4-cm) vertical mounting space (or 1 rack unit [RU]) for mounting (see the Mounting the Router in a Rack

section).

Allow clearance on either side of the router for cooling air to be drawn in through the right side and

circulated through the chassis and out the three-fan exhaust ports mounted on the other side of chassis.