Champion U-HB, U-LD General Manual

Technical Manual

Undercounter

Dishwasher

Model

U-HB

High Temperature

with Built-in Booster

U-H1

High Temperature

U-LD

Low Temperature

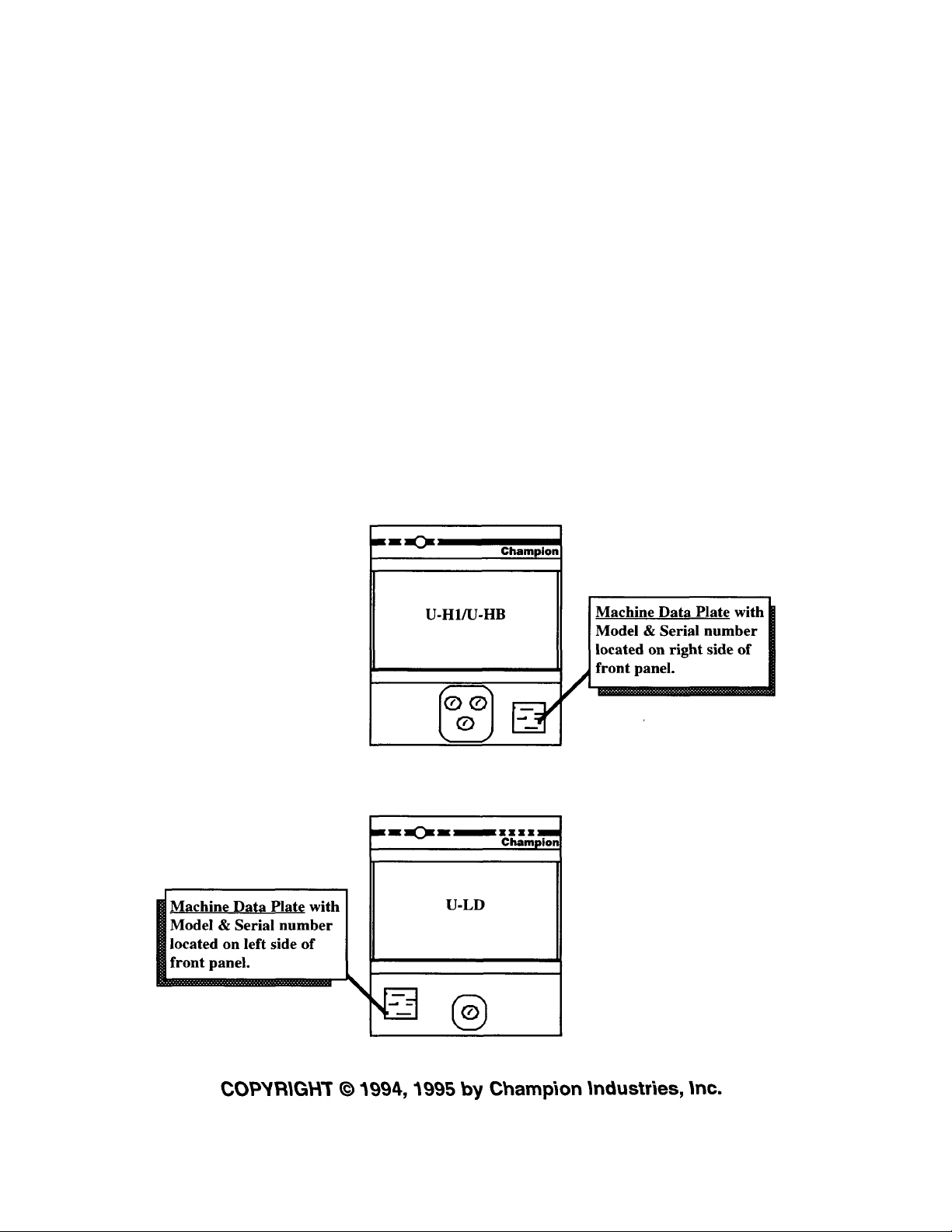

Machine Serial No.

June, 1995 Manual P/N 111752-1

P.O. Box 4149 Winston-Salem, North

Carolina 27115-4149

Champion Industries, Inc. 336/661-1556 Fax:336/661-1660

Complete the information below so it will be available for quick reference.

Model Number __________________ Serial Number______________________

Voltage and Phase __________________________________________________

Champion Parts Distributor ________________________ Phone _____________

_________________________________________________________________

Champion Service Agency________________________ Phone ______________

_________________________________________________________________

Champion Industries Service: 1-800-858-4477 Champion Service Fax: 1-336-661-1660

We strongly recommend that you fax your orders.

NOTE: When calling to order parts, be sure to have the model number, serial

number, voltage, and phase of your machine.

Revision History

Revision

Date

12/30/92

1/13/94 — 85680 Relocated final rinse thermometer to back of machine,

1/1/95

1/1/95 22 — Corrected Pump/Motor Removal Instructions (Step 7)

1/1/95 23 — Added Door Switch and Magnet to illustration

1/1/95 29 — Corrected Item #16, changed P/N 104741 to P/N 108349

1/1/95 30 — Added Solenoid Valve detail

1/1/95 33 — Corrected Item #14, changed P/N 104741 to P/N 108349

1/1/95 34 — Added Solenoid Valve detail

1/1/95 39 — Corrected Item #19, changed P/N 110210 to 110211

1/1/95 57 — Corrected Item #4, changed P/N 108265 to P/N 107550,

4/10/95 52-53 87075 Redesigned U-HB Booster Tank for machines beginning

2/9/96 53 87724 Changed control thermostats to P/N 112204

Revised

Pages

Serial Number

Comments

Effectivity

84299 Air Trap/Pressure Switch changed to Float switch/Fill

Timer for automatic fill and low water protection for

Models U-H1/U-HB

added brass cross and barb fittings

Issued Manual P/N 111752-1 which supercedes Manual

P/N 111752 dated May, 1994. For machines beginning

with S/N 84299 and above

changed 1/2" to 3/4"

with S/N 87075 and above

CONTENTS

The Dishwashing Formula 5

WARRANTY 6

INTRODUCTION 7

GENERAL 8

Model Numbers 8

Standard Equipment 8

Options 8

Accessories 9

Electrical Power Requirements 9

INSTALLATION 9

Unpacking 9

Electrical Connections 10

Plumbing Connections 10

Water Connections 10

Drain Connections 11

Chemical Connections 12

Models U-H1 and U-HB 12

Model U-LD 12

INITIAL START-UP 13

Model U-H1 and U-HB 13

Model U-LD 13

OPERATION 14

Model U-H1 and U-HB 14

Model U-LD 15

MAINTENANCE 16

Maintenance Schedule 16

CLEANING 16

Every 2 Hours or After Each Meal Period 16

Model U-H1 and U-HB 16

Model U-LD 16

Every 8 Hours or at the End of the Day 16

Model U-H1 and U-HB 16

Model U-LD 17

DELIMING 17

Deliming process 17

Model U-H1 and U-HB 17

Model U-LD 18

OPERATION CHECKS 18

Daily 18

Weekly 18

Page

2

CONTENTS

TROUBLESHOOTING 18

BASIC SERVICE 20

Electrical Service 20

Motor Connections 20

Timed Fill/Low Water Tank Heat Protection 20

Mechanical Service 21

Timer Cam Adjustments 21

Pump Seal Replacement 22

U-HB Component Diagram 23

REPLACEMENT PARTS LIST 24

ELECTRICAL SCHEMATICS 58

TIMER CHARTS 60

LIST OF FIGURES

Figure 1— Drain Connection U-H1/U-HB 11

Figure 2— Drain Connection U-LD 11

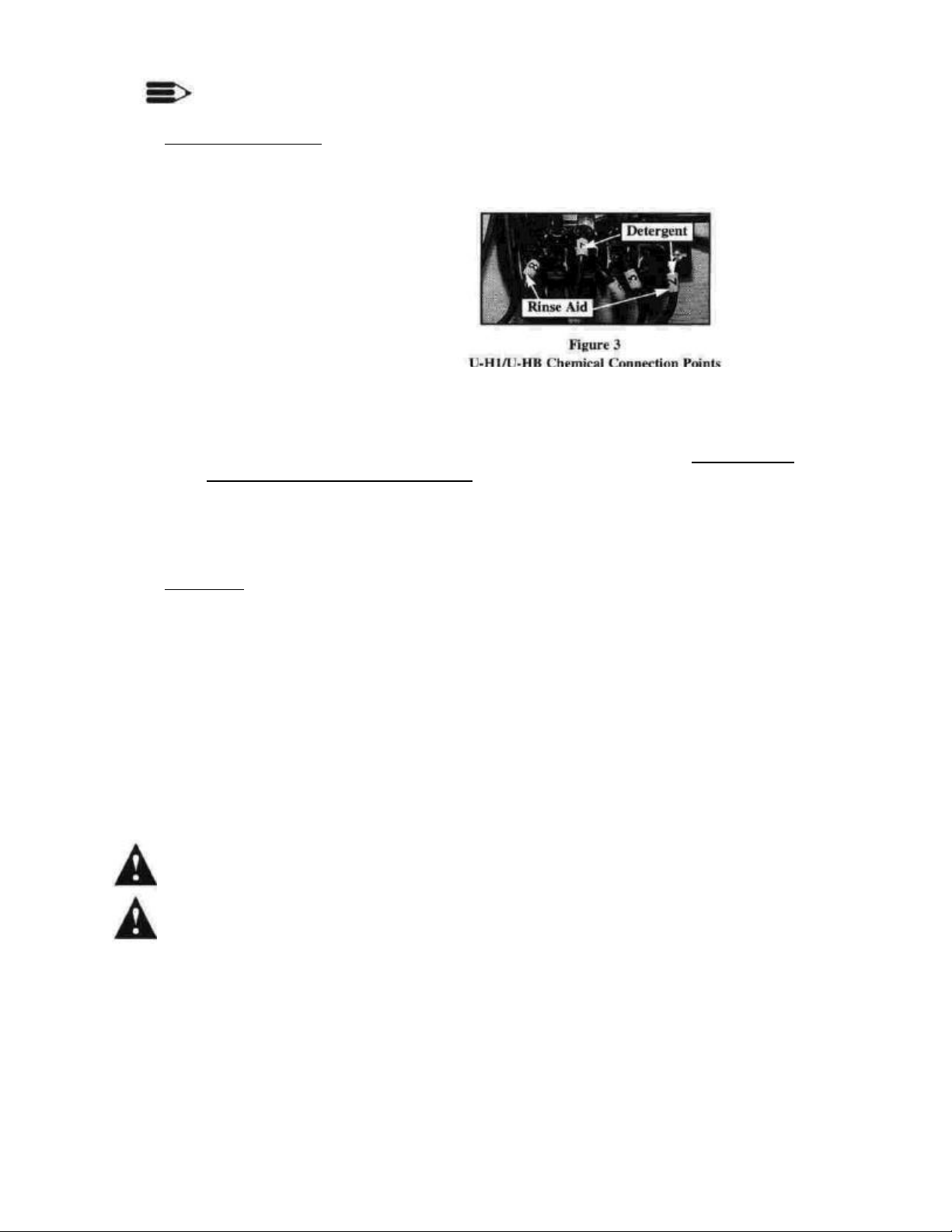

Figure 3— U-H1/U-HB Chemical Connection Points 12

Figure 4— Pump Motor Wiring Diagrams U-H1/U-HB/U-LD 20

Figure 5— U-H1/U-HB Timer Chart 21

Figure 6— U-LD Timer Chart 21

Figure 7— U-LD Timer Cam Locations 21

Figure 8— Pump Seal Replacement 22

Figure 9— Panels and Gauges 24

Figure 10—Door, Tracks, Safety Switch 26

Figure 11—U-H1/U-HB Plumbing 28

Figure 12—U-H1/U-HB Fill Solenoid Valve and Piping 30

Figure 13—U-LD Plumbing 32

Figure 14—U-LD Fill Solenoid Valve and Piping 34

Figure 15—U-LD Chemical Dispensing System 36

Figure 16—U-H1/U-HB Float Switch, Sump, Pump Hoses 38

Figure 17—U-LD Sump, Pump Hoses, Drain Assembly 40

Figure 18—U-H1/U-HB Wash Arm Assembly 42

Figure 19—U-LD Wash Arm Assembly 44

Figure 20—Pump/Motor Assembly 46

Figure 21—U-H1/U-HB Control Cabinet 48

Figure 22—U-LD Control Cabinet 50

Figure 23—U-H1/U-HB Thermostats, Booster Assembly, Wash Tank Element 52

Figure 24—U-H1/U-HB/U-LD Drain Lift Kits (Optional) 54

Figure 25—Dishracks, Strainer, PRV 56

Figure 26—U-H1/U-HB Electrical Schematic 58

Figure 27—U-LD Electrical Schematic 59

Figure 28—Timer Charts (U-H1/U-HB) and U-LD 60

Page

3

The Dishwashing Formula

Five Elements for Cleaning Dishes

A Perfect Score means Clean Ware for your customers...

Peak Dishwasher Performance for you.

Point Value

1. Temperature..............................................................……...... 20

Heated water penetrates and loosens soil on dishes.

2. Time ............................................................…………............. 20

Wash and rinse times (set by NSF and Champion) allow everything to work.

3. Mechanical Action................................................…….......... 20

Pumps produce water pressure which flushes the soil off dishes.

4. Chemical Action ................................................……............. 20

Detergent breaks down grease and loosens soil particles.

5. Procedure.................................................……....................... 20

Pre-scraping and rinsing removes large food particles from the dishes.

SCORE 100

5

LIMITED WARRANTY

6

Champion Industries Inc. (herein referred to as Champion), P.O. Box 4149, Winston-Salem, North Carolina 27115, and

P.O. Box 301, 2674 N. Service Road, Jordan Station, Canada LOR ISO, warrants machines, and parts, as set out below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name

"Champion" and installed within the United States and Canada to be free from defects in material and workmanship

for a period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by

Champion, whichever occurs first. [See below for special provisions relating to glasswashers.] The warranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period. Champion, at its election, will

either repair or replace the defective machine or accept return of the machine for full credit; provided, however, as to

glasswashers. Champion's obligation with respect to labor associated with any repairs shall end (a) 120 days after

shipment, or (b) 90 days after installation, whichever occurs first. In the event that Champion elects to repair, the

labor and work to be performed in connection with the warranty shall be done during regular working hours by a

Champion authorized service technician. Defective parts become the property of Champion. Use of replacement

parts not authorized by Champion will relieve Champion of all further liability in connection with its warranty. In no

event will Champion's warranty obligation exceed Champion's charge for the machine. The following are not

covered by Champion's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator's guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above, (2) Use with utility service other than that designated on the rating plate, (3)

Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from chemicals

dispensed in excess of recommended concentrations, (6) Failure of electrical components due to connection of

chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such leaks caused by the

installer, including those at machine table connections or by connection of chemical dispensing equipment installed

by others, (8) Failure to comply with local building codes, (9) Damage caused by labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free from

defects in material and workmanship for a period of 90 days from date of invoice. If any defect in material and

workmanship is found to exist within the warranty period Champion will replace the defective part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION'S WARRANTY IS

ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQ UENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE THE

EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING

MACHINES AND CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY

LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES .

Champion does not authorize any other person, including persons who deal in Champion dishwashing machines to

change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

INTRODUCTION

7

Welcome to Champion...

and thank you for allowing us to take care of your dishwashing needs.

This manual covers the undercounter series dishwasher models U-H1, U-HB, and U-LD. Your machine was

completely assembled, inspected, and thoroughly tested at our factory before it was shipped to your

installation site.

This manual contains:

• Warranty Information

• Operation and Cleaning Instructions

• Maintenance Instructions

• Troubleshooting Guide

• Basic Service Information

• Replacement Parts Lis ts

• Electrical Schematics

Complete and return your warranty registration card within ten (10) days after the installation of

your machine.

All information, illustrations and specifications contained in this manual are based

upon the latest product information available at the time of publication. Champion constantly

improves its products and reserves the right to make changes at any time

or to change specifications or design without notice and without incurring obligation.

For your protection, factory authorized parts should always be used for repairs.

Replacement parts may be ordered directly from Champion Industries* or from your

Champion authorized parts distributor or authorized service agency. When ordering parts,

please supply the model number, serial number, voltage, and phase of your machine, the part

number, part description and quantity.

'"Champion Industries can only ship parts to customers by C.O.D.

GENERAL

base

• 1-1/4"

I.D. GRAVITY drain connection

• 1-1/4"

I.D. G

RAVITY drain connection

8

This manual covers the Champion undercounter dishwashing machine.

These machines are fully automatic and come equipped with a 3/4 HP pump motor.

All models are available for mounting directly to the floor or on optional stands.

The U-series dishwasher is available in the following models:

Model Numbers

U-H1,U-HB,U-LD

The U-H1 model is a high temperature (82°C/180°F rinse) sanitizing

model without booster.

The U-HB model is a high temperature (82°C/180°F rinse) sanitizing

model with booster.

The U-LD is a low temperature (Min. 490C/1200F-600C/1400F Optimum) sanitizing model for use with a

sodium hypochlorite (Chlorine) based sanitizer at a minimum concentration of 50PPM in the final rinse. A

three pump chemical dispensing system for detergent, sanitizer and rinse aid is included.

Standard Equipment includes:

U-H1 & U-HB

• Top mounted slide-out control cabinet

• Common utility connections

• Fully automatic wash & rinse cycle

• Self-sealing gasketless door

• Door safety switch

• Upper & lower wash/rinse arms

• 90 second time cycle

• Electric tank heater

• Low water tank heat protection

• 3/4HP (208-240V/60/1) wash motor

• Stainless steel heavy gauge construction, including

• Two dish racks (peg and flat bottom)

• Built-in electric booster heater (U-HB Only)

(4°C/40°F temperature rise)

U-LD

• Top mounted slide-out control cabinet

• Common utility connections

• Fully automatic wash & rinse cycle

• Self-sealing gasketless door

• Door safety switch

• Upper & lower wash/rinse arms

• 150 second time cycle

• Three built-in chemical dispensing pumps

• 3/4HP (115V/60/1) wash motor

• Stainless steel heavy gauge construction,

including base

• Two dish racks (peg and flat bottom)

Options

Electric booster (21°C/70°F temperature rise ) heater for

43°C/110°F supply water (U-HB only) N/A

Pumped drain lift-out Kit (U-H1 and U-HB) P/N 403898

Drain lift kit (U-LD) P/N 403801

P-Trap (U-H1 and U-HB) P/N 403836

Unmounted Pressure Regulating Valve (3/4" PRV) P/N 107550

1 -1 /4" flexible drain hose (order by the foot) P/N 111032

Accessories

Booster Rise

Power Requirement

Combination 1-RDT table w/ cabinet and sink (specify right hand or left hand sink)

Optional sprayhose for 1-RDT P/N 100243

Wall overshelf for 1 -RDT (holds two racks) P/N 108189

16" Stainless steel stand P/N 305222

6" Stainless steel leg set (Qty.4) P/N 305221

Additional dishracks:

Dish rack (peg) P/N 101285

Silverware rack (flat bottom) P/N 101273

Electrical Power Requirements

Model Voltage

(U-HB Only)

U-H1 208/60/1 — 12 Amps 15 Amps

U-H1 220/60/1 — 11Amps 14 Amps

U-H1 230/60/1 — 11 Amps 14 Amps

U-H1 240/60/1 — 11 Amps 14 Amps

U-HB 208/60/1 40°F 44 Amps 55 Amps

U-HB 220/60/1 40°F 44 Amps 55 Amps

U-HB 230/60/1 40°F 46 Amps 58 Amps

U-HB 240/60/1 40°F 48 Amps 60 Amps

U-HB 208/60/1 70°F 58 Amps 73 Amps

U-HB 220/60/1 70°F 60 Amps 75 Amps

U-HB 230/60/1 70°F 62 Amps 76 Amps

U-HB 240/60/1 70°F 64 Amps 80 Amps

U-LD 115/60/1 — 12 Amps 15 Amps

Machine

Full Load Amps

(125% Service Factor)

INSTALLATION

Unpacking

CAUTION:

Care should be taken when lifting the machine to prevent damage.

1. Immediately after unpacking the machine, inspect for any shipping damage.

If damage is found, save the packing material and contact the carrier immediately.

2. Remove the dishwasher from the skid. Adjust the feet if required, then move the machine

to its permanent location.

3. Level the machine (if required) by placing a level on the top of machine and

adjusting the feet. Level the machine front-to-back and side-to-side.

4. Remove the two dishracks from the interior of the machine.

5. Remove the lower access panel in preparation for service connections.

9

INSTALLATION (Cont'd)

out control cabinet for the

NOTE:

The installation of your machine must meet local health codes.

Some locales may require the base of the machine to be sealed at the floor.

Electrical Connections

WARNING:

Electrical and grounding connections must comply with the National Electrical Code

and/or Local Electrical Codes.

WARNING:

When working on the dishwasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

1. A qualified electrician must compare the electrical power supply with the machine

electrical specifications stamped on the MACHINE ELECTRICAL CONNECTION

PLATE located inside the top mounted control cabinet before connecting to the incoming

service at a fused disconnect switch.

NOTE:

U-H1 and U-HB models require a 208-240V/60Hz/lPH, 2-wire plus ground electrical supply.

U-LD model requires a 115V/60Hz/lPH, 2-wire plus ground electrical supply.

2. A knock-out is provided at the rear of the top mounted slideelectrical service connection. A fused disconnect switch or circuit breaker (supplied by

others) is required to protect each power supply circuit.

10

NOTE:

INSTALLER SHOULD PROVIDE SUFFICIENT CABLE TO ALLOW TOP MOUNTED

SLIDE-OUT CONTROL CABINET TO EXTEND FULLY.

Plumbing Connections

CAUTION:

Plumbing connections must comply with local sanitary and plumbing codes.

Water Connections

1. HOT WATER connection can be made to the machine via the 6 foot reinforced

fill hose supplied with the machine. The fill hose is equipped with a 3/4" NPT connector

and exits the back of the machine.

2. Minimum incoming water supply temperature requirements are listed below

U-HB with built-in 40° rise electric booster (Minimum 60°C/140°F)

(Min./Max. flow pressure 138 kPa/20-22 PSI)

U-HB with built-in 70° rise electric booster (Minimum 43°:)C/1100F)

(Min./Max. flow pressure 138 kPa/20-22 PSI)

Water Connections (Cont.d)

11

U-Hl without built-in booster (Minimum 700C/1800F)

(Min./Max. flow pressure 138 kPa/20-22 PSI)

U-LD (Minimum 49°C/120°F - 600C/1400F Optimum)

(Min./Max. flow pressure 138 kPa/20-22 PSI)

3. A manual shut-off valve (supplied by others) should be installed in supply line to allow for

servicing of the machine.The shut-off valve should be the same size or larger than the supply

line.

4. A "Y" line strainer (supplied by others) is recommended on the incoming water supply line as

close to machine as possible, but before the pressure regulating valve.

5. A 3/4" Pressure Regulating Valve (PRV),(supplied by others), should be installed on the

incoming water supply line if water flow pressure exceeds 138 kPa/20-22 PSI.

Drain Connections

1. Models U-Hl, U-HB, and U-LD are GRAVITY DRAIN machines equipped with a

1-1/4" hose connection point.

• Drain height for models U-Hl and U-HB must not exceed 4-1/2" above floor level.

• Drain height for model U-LD must not exceed 7-1/2" above floor level.

NOTE:

For drain heights in excess of those listed above, OPTIONAL drain

lift kits are available (See Options, Pg.8)

WARNING:

Connection of the machine to a drain line higher than the machine drain height will

prevent the machine from draining properly.

Refer to Figure 1 and 2 below for machine drain connection locations.

Chemical Connections

NOTE:

Consult a qualified chemical supplier/or your chemical needs.

Models U-H1 and U-HB

1. Labeled connection points (See Fig. 3) are provided inside the

control cabinet for chemical dispensing equipment (supplied by others)

Connection points include:

• Detergent signal 208-240VAC

between Wire #7 and Wire #2 .

(1 Amp Max Amperage Draw)

• Rinse aid signal 208-240VAC

between Wire #8 and Wire #2

(1 Amp Max Amperage Draw)

2. Detergent injection point and location of conductivity cell must be provided by a

qualified chemical supplier.

3. Detergent may be added manually for U-H1/U-HB models not equipped with dispensing

systems. Consult your local chemical supplier for the correct amount of non-chlorinated

automatic dishwashing liquid detergent.

4. U-H1 and U-HB models do not require chemical sanitizing agents.

5. Rinse aid injection point is provided via a 1/2" NPT plug located in the fill manifold piping

The manifold is located after the fill solenoid valve on the center right side of the machine

base behind the gauges.

Model U-LD

1. Equipped with three built-in dispensing pumps for detergent, sanitizer, and rinse aid.

Pump Priming switches are located on the front of the control cabinet. (See ULD Initial Start-up for pump priming instructions, (Pg. 13, Step 10). (See U-LD

Service for timer cam settings and adjustments, (Pg. 21)

2. Chemical pick-up tubes are color coded.

• Red = detergent Blue = Rinse aid Clear = Sanitizer

Chemicals are supplied by others.

3. Use an automatic commercial grade liquid detergent.

Use a sodium hypochlorite (Chlorine) based sanitizer at a minimum concentration of

50PPM in the final rinse.

Use chlorine test papers to verify and monitor the 50PPM chlorine level.

4. Use a liquid rinse aid.

WARNING:

Never premix rinse aid with the sanitizing agent. Mixing may cause hazardous gases to form.

CAUTION:

Some metal, including silver, aluminum, and pewter are attacked by sodium hypochlorite (chlorine

sanitizer). Avoid cleaning these metals in a U-LD dishwasher.

12

INITIAL START-UP

After plumbing and electrical connections are completed,

follow the steps below to place your machine in service.

Model U-H1 and U-HB

1. Remove any foreign material from inside the machine.

Make sure filter, and drain-overflow tube are in place.

2. Close the Door.

3. Turn the water and main power sources to the dishwasher ON.

4 Flip the Power switch to the ON position. The red "power on" light will illuminate and the

machine will automatically fill with water.

5. Check the machine for leaks.

6. Push the Green Start Button to check automatic cycle. Check for leaks.

7. If machine checks okay, remove the drain-overflow tube to drain machine.

8. Flip the power switch to OFF.

Model U-LD

1. Remove any foreign material from inside the machine. Make sure filter, is in place.

2. Close the Door.

3. Turn the water and main power sources to the dishwasher ON.

4 Flip the Power switch to the ON position. The red "power on" light will illuminate.

5. Hold the Fill switch in the "UP" position for about 45 sec. to fill the machine with water.

Machine is full when water level reaches drain overflow located at lower left rear comer of

wash tank interior.

6. Check the machine for leaks.

7. Prime the chemical dispensing pumps.

NOTE:

The pick-up tubes are color coded:

Red = detergent Blue = rinse aid Clear = sanitizer

8. Insert the pick -up tubes in the appropriate chemical containers.

9. Open the door of the machine.

10. Hold each of the three prime switches, located on the front of the control cabinet in the "UP"

position until you see chemical enter the tank interior from all three tubes.

NOTE:

The chemical tubes discharge point is on the right side of the wash tank ceiling.

11. The chemical dispensing system will work automatically until the chemical supply is used up.

Re-prime the dispensing pump after replacing a chemical container.

12. Close the door.

13. Push the the Green start button to check the automatic cycle. Check for leaks.

14. If machine checks okay, hold the drain switch in the "UP" position until

machine drains completely.

15. Flip the power switch to OFF.

13

OPERATION

Model U-H1 and U-HB

Red power light illuminates. 1. Close the door and flip power switch ON

2. Monitor wash tank temperature gauge Wait for temperature reading to reach

3.

Prescrap and load ware into rack

4. Open door, insert rack

5.

Close door. Push Green start button

Tank fills automatically and tank heat comes on

Minimum 66°C/150°F

Place dishes edgewise in peg rack,

Cups and bowls upside down in flat rack,

Silverware spread evenly in single layer

in flat rack

Green cycle light will illuminate

Automatic cycle begins.

Machine washes for 67 sec., then pauses for 2 sec

6. During final Rinse

Monitor pressure gauge and

final rinse temperature gauge

7. 90 second cycle complete Green cycle light goes out

8. Open door, remove clean rack Insert another rack of soiled ware

9.

After each meal period or

every two hours operation

Machine final rinses for 21 sec.

Pressure gauge reading must read

between 20-22 PSI

Temperature gauge must read 82-91°C/180-195°F

Remove drain-overflow tube and drain machine.

Flush interior and clean sump filter and pump

intake strainer. Check spray arms and clean if

necessary

NOTE:

Opening the door at any time during the cycle will stop the machine. Closing the door and

pushing the Green start button will resume the cycle where it left off.

14

Model U-LD

1. Close the door and flip power switch ON Red power light illuminates

2. Hold the Fill switch in "UP" position

for about 45 sec.

3. Monitor wash tank temperature gauge Temperature reading must be

4 Prescrap and load ware into rack Place dishes edgewise in peg rack,

5. Open door , insert rack

6. Close door, Push Green start button Green cycle light will illuminate

Wash tank fills with water

Min. 120°F/140°F Optimum

Cups and bowls upside down in flat rack,

Silverware spread evenly in single layer

in flat rack

Automatic cycle begins.

Machine washes for 62 sec., then

Drains and refills for 56 sec.

7. Monitor temperature gauge

If wash temperature drops below 120°F,

Drain and refill machine.

8. 150 second cycle complete Green cycle light goes out

9. Open door, remove clean rack Insert another rack of soiled ware

10. After each meal period or every two hours

operation

Machine final rinses for 32 sec.

Temperature gauge must read a

(Minimum 120°-140° F Optimum)

Hold drain switch in "UP position and

drain machine. Flush interior and clean

filter and strainer plate. Drain again. Check

spray arms and clean if necessary.

NOTE:

Opening the door at any time during the cycle will stop the machine. Closing the door and pushing

the Green start button will resume the cycle where it left off.

15

MAINTENANCE

Cleaning your machine is the best maintenance that you can provide. Components that are not

regularly flushed and cleaned do not perform well.

The Maintenance intervals shown in the following schedules are the minimum requirements

necessary for the proper performance of your machine. Maintenance intervals should be

shortened whenever your machine is faced with abnormal working conditions, hard water, or

multiple shift operations.

Maintenance Schedule

CLEANING

• Every 2 Hours or After Each Meal Period

Model U-H1 and U-HB

1. Flip the power switch OFF.

2. Remove the drain-overflow tube, drain the machine.

3. Flush tank interior with fresh water.

4. Remove and clean the sump filter and pump intake screen.

5. Inspect the spray arm nozzles and clean if necessary.

6. Close door, flip power switch ON to refill machine.

Model U-LD

1. Hold drain switch in "UP" position until tank drains completely.

2. Flip power switch to OFF.

3. Flush tank interior with fresh water.

4. Drain machine again.

5. Remove and clean the sump filter and strainer plate.

6. Inspect the spray arm nozzles and clean if necessary.

7. Close door, flip power switch ON.

8. Hold fill switch in "UP" position to refill machine.

16

• Every 8 Hours or at the End of the Day

Model U-H1 and U-HB

1. Flip the power switch OFF.

2. Remove the drain-overflow tube, drain the machine.

3. Flush tank interior with fresh water.

4. Remove the sump filter and pump strainer.

5. Remove the spray arms.

6. Clean and inspect the spray arm bearings.

7. Remove the spray arm end plugs by twisting counter-clockwise and pulling.

8. Flush the spray arm pipes and nozzles.

9. Replace the end plugs.

10. Back flush the sump filter and pump intake strainer.

11. Thoroughly clean the exterior of the machine. DO NOT HOSE DOWN WITH WATER.

12. Reassemble the machine. Leave the door open to aid overnight drying.

CAUTION:

DO NOT LEAVE WATER IN WASH TANK OVERNIGHT

Cleaning (Cont.d)

17

Model U-LD

1. Hold drain switch in "UP" position until tank drains completely.

2. Flip power switch to OFF.

3. Flush tank interior with fresh water.

4. Remove the sump filter and strainer plate.

5. Remove the spray arms.

6. Clean and inspect the spray arm bearings.

7. Remove the spray arm end plugs by twisting counter-clockwise and pulling.

8. Flush the spray arm pipes and nozzles.

9. Replace the end plugs.

10. Back flush the sump filter and strainer plate

11. Thoroughly clean the exterior of the machine. DO NOT HOSE DOWN WITH WATER.

12. Reassemble the machine. Leave the door open to aid overnight drying.

CAUTION:

DO NOT LEAVE WATER IN WASH TANK OVERNIGHT

DELIMING

Your dishwasher should be delimed regularly depending on the

Inspect the machine interior for mineral deposits and use a

deliming for the best cleaning results.

NOTE:

Consult your chemical supplier for an appropriate deliming solution.

WARNING:

Deliming solutions or other acids must not come in contact with household bleach

(sodium hypochlorite) or any chemicals containing chlorine, iodine, bromine, or fluorine.

Mixing will cause hazardous gases to form.

Skin contact with deliming solutions can cause severe irritation and possible chemical

bums. Consult your chemical supplier for specific safety precautions.

DELIMING PROCESS

Model U-H1 and U-HB (Not equipped with chemical dispensing system)

1. Remove all dishes from machine.

2. Drain the machine and refill with fresh water.

3. Spray interior walls with delimimg solution and let sit for 5 or 10 minutes

depending on amount of build-up. Add deliming solution to wash tank. Do

not let chemicals sit for longer than 15 minutes.

4. Push the Green start button and run an automatic cycle.

5. Repeat Step 3-4 if necessary.

6 Remove the drain-overflow tube and drain the machine.

7. Refill the machine and run a complete cycle two additional times. Drain and

refill the machine after each cycle to thoroughly flush any deliming solution

from the interior of the machine.

8. Flip the power switch to OFF.

9. Drain Machine.

10. Deliming is complete.

DeLiming Process (Cont.d)

18

Model U-LD

1. Remove all dishes from machine.

2. Remove the chemical pick-up tubes from their containers.

3. Place each tube in a container of fresh water and hold each prime switch in the "UP"

position several minutes to thoroughly flush chemical from the lines. Leave pick-up tubes out

of their containers.

4. Hold the drain switch in the "UP" position to drain the machine.

5. Refill the machine with fresh water and drain again. Then refill with water.

6. Spray interior walls with deliming solution and let sit for 5 or 10 minutes depending on

amount of build-up. Add deliming solution to wash tank. Do not let chemicals sit for longer

than 15 minutes.

7. Push the Green start button and run an automatic cycle.

8. Repeat Step 3-6 if necessary.

9. Hold the drain switch in the "UP" position to drain the machine.

10. Refill the machine and run a complete cycle two additional times. Drain and refill the

machine after each cycle to thoroughly flush any deliming solution from the interior of the

machine.

11. Replace the pick-up tubes in their chemical supplies and reprime the system.

12. Flip the power switch to OFF.

13. Deliming is complete.

OPERATION CHECKS

• Daily

1. Check temperature gauges for proper readings.

2. Check pressure gauge for proper reading (U-H1, U-HB ONLY).

3. Check for leaks.

4. Check chemical supplies and refill as necessary.

• Weekly

1. Inspect all water lines for leaks.

2. Clean all detergent residue from the exterior of the machine.

3. Check the drains for leaks.

4. Clean accumulated mineral deposits from the tank heating elements (U-H1, U-HB ONLY)

5. Check that float switch moves freely (U-H1, U-HB ONLY).

6. Check and clean chemical dispensing system (U-LD ONLY).

TROUBLESHOOTING

On occasion your machine may not operate as expected. Use the checklist below before you

decide that a mechanical or electrical failure has occurred.

Checklist

1. All switches are ON?

2. Water supply ON?

3. Drain-overflow tube in place? (U-H1 and U-HB Only)

4. Spray arms and nozzles clean?

5. Spray arm end plugs in place?

6. Sump filter, pump strainer clean?

7. Thermostats set correctly? (U-H1, U-HB Only)

8. Door fully closed?

9. Chemical supplies filled?

Loading...

Loading...