Champion UH-170 Service Manual

Installation Manual with Service Replacement Parts

Undercounter

High Temperature

Dishwasher

Models:

UH-170B

UH-200B

UH-100B

UH-200B

UH-200

UH-170B

UH-170

Dishwasher Serial No.

UH-100B

UH-100

UL-100

www.championindustries.com

P.O. Box 4183

Winston-Salem, NC 27115

336/661-1556 Fax: 336/661-1979

Toll-free: 800.532.8591

Issue Date: January, 2007

Manual P/N 0512241

For machines beginning with S/N W11948 and above

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800.263.5798

File: NUC4246

Printed in the USA

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Champion Service Agent __________________________________ Tel:______________________

Champion Parts Distributor _________________________________ Tel:______________________

For all models:

The data plate is located on

the bottom right-hand side of

the dishwasher.

National Service Department

In Canada: In the USA:

Toll-free: 800/ 263-5798 Toll-free: 800/ 532-8591

Tel: 905/ 562-4195 Tel: 336/ 661-1556

Fax: 905/ 562-4618 Fax: 336/ 661-1979

email: service@moyerdiebellimited.com email: service@championindustries.com

ATTENTION:

The dishwasher model no., serial no.,

voltage, Hz and phase are needed to

identify your machine and to answer

questions.

We support

Please have this information on-hand

if you call for service assistance.

COPYRIGHT © 2006 All rights reserved Printed in the USA

Revisions to this Manual

1.16.07 17,19 W11948 Changed operation instructions

deleting step 1, which was out

of sequence

_______________________ Revisions to this Manual

This is where we record changes to the manual. A revision might be a part

number change, new instructions, or information that was not available at print

time.

We reserve the right to make changes to this manual without notice and without

incurring any liability by making the changes.

Revision Revised Serial Number Revision

Date Pages Effectivity Description

ALL W11948 Released First Edition

i

Limited Warranty

___________________________

ii

Model Description

___________________________ Model Description

UH-200B, UH-170B, and UH-100B Models

High temperature sanitizing dishwashers with built in booster heaters.

UH-200, UH-170, and UH-100 Models

High temperature sanitizing dishwashers.

UL-100 Model

Low temperature sanitizing dishwasher.

Optional Equipment

70°F Rise Booster

•

Three Phase Connection (UH-170B and UH-200B only)

•

iii

Table of Contents

Table of Contents ______________________________

Revisions to this manual ______________________________________________ i

Limited Warranty ____________________________________________________ ii

Model Descriptions __________________________________________________ iii

Installation Guide ____________________________________________________ 1

" Unpack and Place " Drain Connection

" Electrical Connection " Initial Start-up

" Water Connection " Chemical Dispensers

How to Operate Your Dishwasher

How to Clean Your Dishwasher

How to Maintain Your Dishwasher

All Models

The Troubleshooter ________________________________________________ pg.25

Service Replacement Parts _________________________________________ pg.27

Electrical Schematics ______________________________________________pg.67

Timer Charts _____________________________________________________ pg.73

iv

Unpack and Place

_____________________________ Installation Guide

! Unpack and Place

Unpacking of Dishwasher

NOTE:

The installation of your dishwasher must be performed by qualiÞ ed service

personnel. Problems due to improper installation are not covered by the

Warranty.

1. Inspect the outside of the dishwasher carton for signs of damage.

2. Remove the shipping box and inspect the dishwasher for damage.

3. Immediately contact the freight company and your equipment dealer to

report the damage.

4. Save all packing materials.

CAUTION:

Be careful when lifting and moving the dishwasher to prevent damage to the

machine.

5. Check your packing list and identify the accessories shipped with your

dishwasher. Immediately report missing items to your dealer.

6. Turn to the front of this manual and complete the warranty card. Mail the

card at once.

7. Move the dishwasher near its permanent location.

8. Locate the Quick Check Installation Guide located on the dishwasher. Use

the card and the manual installation guide to properly install the dishwasher.

Placement of Dishwasher

CAUTION:

Be careful when lifting and moving the dishwasher to prevent damage to the

machine.

NOTE:

The installation of the dishwasher must comply with local health codes.

1. Compare the utility connections with the dishwasher's utility connections.

Contact your supervisor if problems are found.

1

Unpack and Place

Installation Guide _____________________________

! Unpack and Place

Placement of Dishwasher (continued)

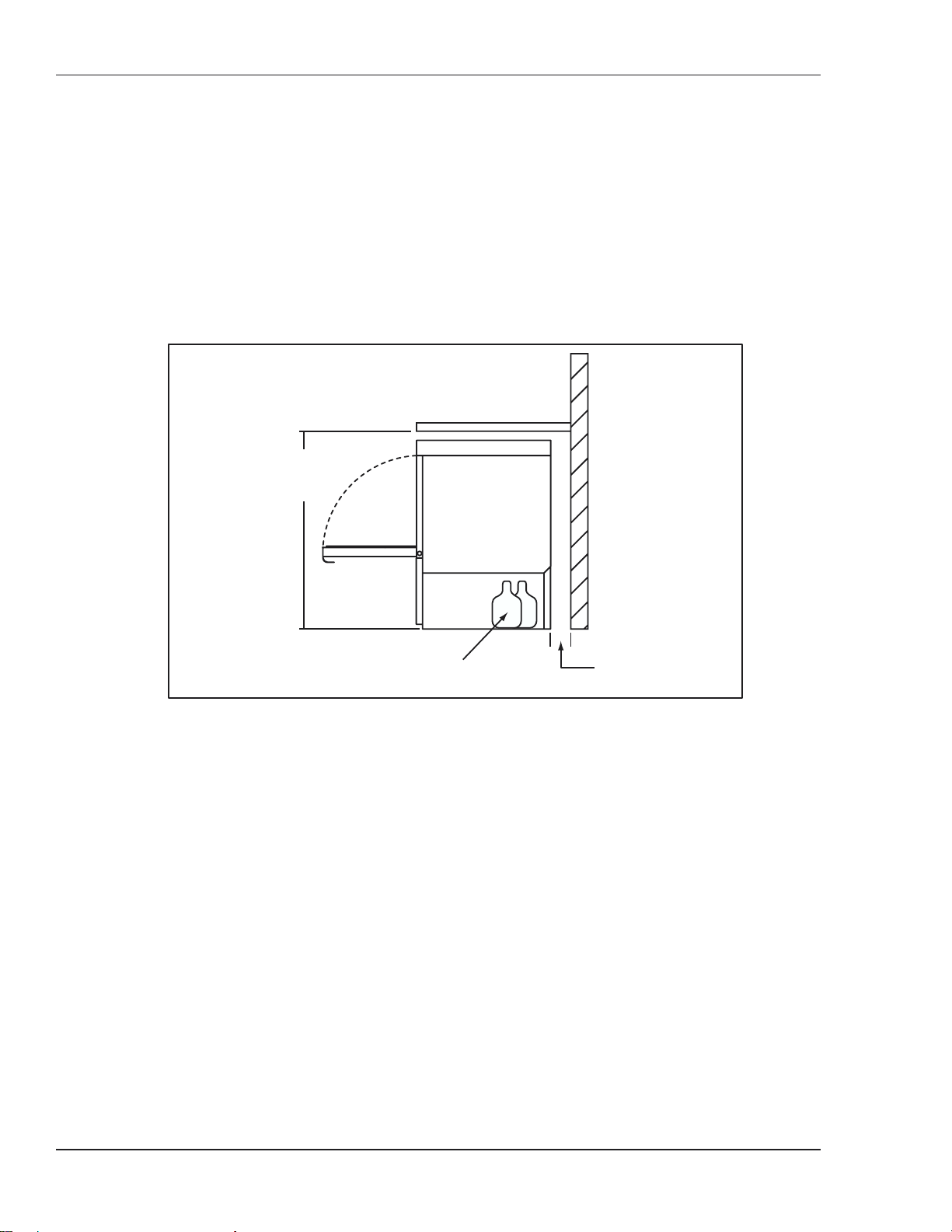

2. Your dishwasher may be installed as a free-standing unit or under a countertop.

3. Typical counter-top height is 34". Refer to the illustration.

Countertop

Wall

34"

Minimum

Height

Floor

Chemical Supply

Containers

Typical Undercounter Installation

4. Counter installations must provide storage space for the dishwasher's

chemical supply containers. Container height must not exceed 10" above the

ß oor.

5. Chemical supply containers must be placed as close as possible to the side of

the dishwasher.

6. Check that the ß oor is level at the permanent location.

7. The dishwasher has adjustable feet for leveling.

8. Level the dishwasher front to back and side to side with a 24" bubble level to

match the permanent location.

9. Your dishwasher is ready for the utility connections.

3" Minimum Wall

Clearance

2

Electrical Connection

_____________________________ Installation Guide

! Electrical Connection

Electrical Connection

NOTE:

The electrical connection must be performed by a qualiÞ ed electrician in

accordance with local codes and the National Electrical Code.

WARNING:

For models UH-100B, UH-170B, and UH-200B disconnect the main power at

the main disconnect switch. Tag and lockout the switch to indicate that work

is being done on the circuit.

1. Refer to the connection diagrams below for proper dishwasher power

connection at the dishwasher main terminal block (MTB).

Ground

208-

230V

120V

L1 L1L2 L2 L3N N

Single Phase

3-Wire Plus Ground

2. (a) Electrical supply must be a

single phase 3-wire plus ground

which includes a current carrying

neutral.

3. The dishwasher MTB is located at the

front right-side of dishwasher.

4. Remove the dishwasher's lower front

access panel by removing the two

truss head screws.

Ground

208-

230V

4-Wire Plus Ground

208-

230V

120V

Three Phase

(b) For a three phase the electrical

supply must be a 4-wire plus ground

which includes a current carrying

neutral.

Front Panel Screw Location

3

Electrical Connection

Installation Guide _____________________________

! Electrical Connection

Electrical Connection (continued)

5. Carefully bump the lower front access

panel up as you pull forward. Be

careful not to damage the pressure

gauge mounted on the left side of the

panel (not supplied on models UL-100,

UH-100, or UH-100B).

6. Remove the main terminal block cover.

The machine's electrical schematic

is located on the inside of the front

panel. Check the min/max data on the

schematic.

7. Loosen the two screws securing the

MTB. Then, pull the MTB up and

forward.

8. Connect a ß exible power cord conduit to the MTB. The power cord must

extend a minimum of 3ft out the back of the dishwasher so the machine can

be pulled out for servicing.

NOTE:

Models UL-100, UH-100, UH-170, UH-200 are already equipped with a 4 foot

power cord and plug suitable for 115V-15A service.

9. Re-install the MTB and the lower front access panel.

Main Terminal Block (MTB)

4

Water Connection

_____________________________ Installation Guide

! Water Connection

Water Connection UH-170, UH-170B, UH-200, UH-200B

NOTE:

Plumbing connections must comply with national, local plumbing and

sanitary codes.

NOTE:

Route the ß exible Þ ll hose in a manner that prevents kinks.

1. All models have a 6ft ß exible hot water Þ ll hose with a 3/4" female garden

hose connector.

2. A 1/2" or larger shut off valve should be installed upstream from the

dishwasher.

3. A pressure regulating valve, PRV, (supplied by others) must be installed after

the shut-off valve if incoming water pressure exceeds 20psi.

4. The hot water supply must provide a minimum of 140°F, measured at the

dishwasher for the 40°F rise booster. For the 70°F rise booster the hot water

supply must provide a minimum of 110°F measured at the dishwasher.

5. The incoming hot water supply line must be a 1/2" line and be able to

maintain a ß owing pressure of 20-22psi.

5

Water Connection

Installation Guide _____________________________

! Water Connection

Water Connection UL-100, UH-100, UH-100B

NOTE:

Plumbing connections must comply with national, local plumbing and

sanitary codes.

NOTE:

Route the ß exible Þ ll hose in a manner that prevents kinks.

1. All models have a 6ft ß exible hot water Þ ll hose with a 3/4" female garden

hose connector.

2. A 1/2" or larger shut off valve should be installed upstream from the

dishwasher.

3. All models have a built-in ß ow control. The incoming hot water supply must

supply no less than 25-95psi ß owing pressure.

4. The hot water supply must provide a minimum of 140°F, measured at the

dishwasher for the 40°F rise booster. For the 70°F rise booster the hot water

supply must provide a minimum of 110°F measured at the dishwasher.

5. The incoming hot water supply line must be a 1/2" line.

6

Drain Connection

_____________________________ Installation Guide

! Drain Connection

Drain Connection

1. All models have a 6ft, 5/8" I.D. drain hose. Maximum drain hose height is 3ft.

with a recommended height of 17" above the ß oor.

2. The drain hose is located on the right rear of the machine. A 5/8" hose barb 3/4" NPT adapter Þ tting is strapped to the end of the drain hose for the drain

connection.

3. The maximum drain ß ow is 15gpm.

NOTE:

The dishwasher drains in 8 seconds and drain water exits the hose with

considerable force.

CAUTION:

Do not connect the drain hose to a disposer. The dishwasher will not drain

correctly.

4. The drain hose is clamped to the rear of the machine to provide a goose

neck bend. DO NOT remove this clamp.

5. Connect the drain hose to a wye Þ tting installed in the house drain. DO NOT

connect to a tee Þ tting.

6. Do not kink the drain hose.

7

Blank Page

This Page Intentionally

Left Blank

8

Initial Start-Up

_____________________________ Installation Guide

! Initial Start-Up

Initial Start-Up All Models

1. Remove any protective Þ lm from

dishwasher. Check the interior for

foreign material.

2. ConÞ rm that all utility connections

are complete and that the

dishwasher is in it's permanent

location.

3. Inspect the ß exible drain hose and

hot water Þ ll hose to ensure they

are not kinked.

4. Check the chemical supply

containers to ensure they are full.

5. Check that the scrap screen and

the overß ow guard (Models

UH-170, UH-170B, UH-200, and

UH-200B only) are in place.

6. Check the spray arms are in place

and that they spin freely.

7. Fully close the dishwasher door.

8. Turn hot water supply on and

check for leaks.

Scrap Screen

9

Initial Start-Up

Installation Guide _____________________________

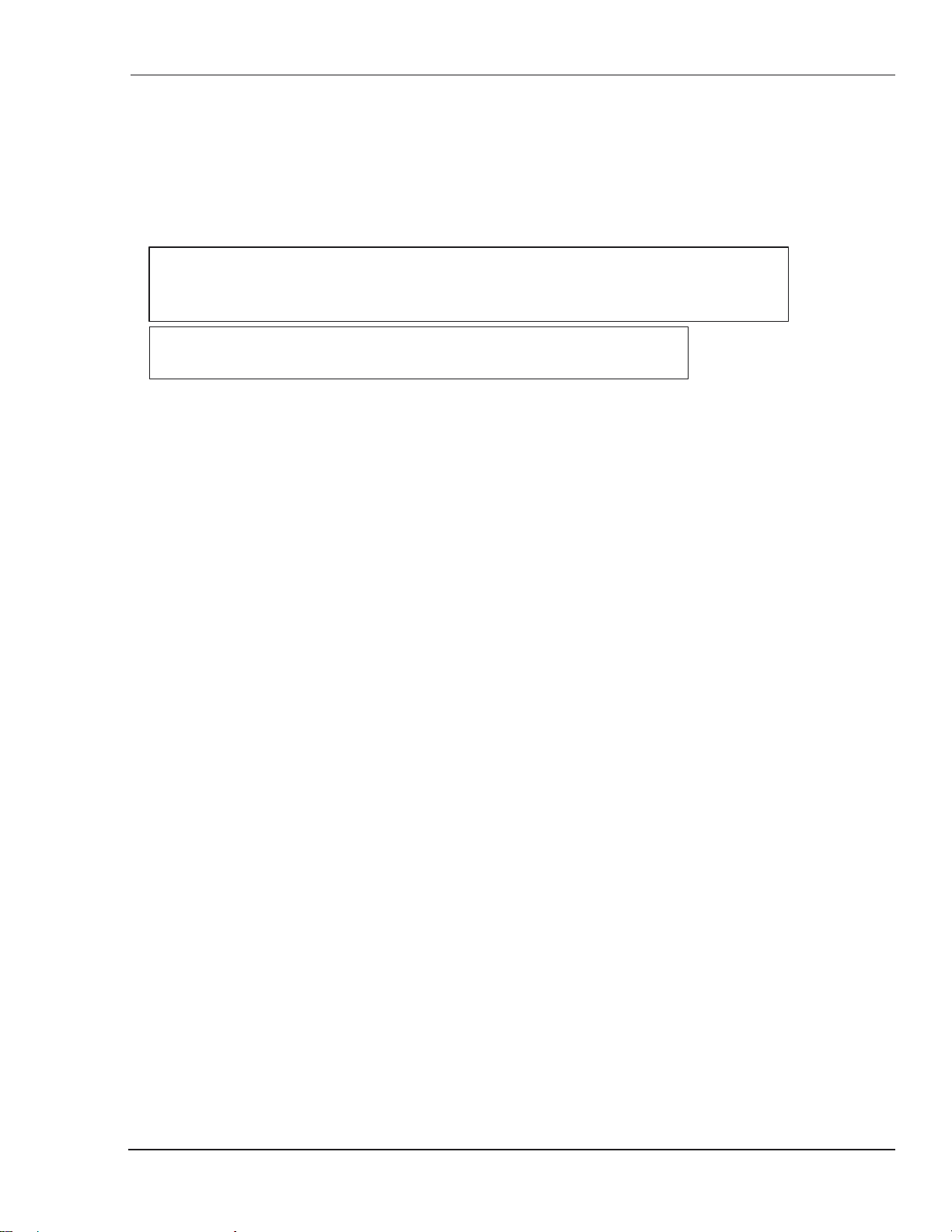

Models: UH-100B, UH-170B, and UH-200B only

Booster Service Switch

The booster is Þ lled with the booster service

switch. It is located behind the lower front

access panel on the left center of the

machine.

! Initial Start-Up

ATTENTION:

The Dishwasher's built-in booster heater was drained prior to

shipment. The booster must be Þ lled before operating the

dishwasher. Not following this procedure will void warranty.

To Fill the Booster:

1. Remove the lower front access panel.

2. Locate the booster service switch and

note the 2 switch positions indicated

on the switch label.

3. Turn the main power supply on. Verify

correct voltage at MTB.

4. Press and hold the booster service

switch down to Þ ll the booster.

5. Continue to hold the switch down until

you hear the water spraying inside

the dishwasher.

6. Release the switch, then ß ip the

switch up to the ON position. The

dishwasher is now powered up.

Booster Service Switch Location

10

Booster Service Switch Fill Position

Initial Start-Up

_____________________________ Installation Guide

! Initial Start-Up

Booster Service Switch (continued)

7. Flip the dishwasher POWER switch

up to the " I " position. The POWER

switch illuminates and the machine

Þ lls with water. See Proper Water Fill

Line illustration.

8. Press and release the START switch.

The green in-cycle light illuminates.

9. Check wash and Þ nal rinse gauges

to ensure they have reacted to the

incoming hot water.

10. Check that the Þ nal rinse pressure

gauge reacts during the Þ nal rinse.

(Models UH-170, UH-170B, UH-200,

and UH-200B only)

Power Switch

11. Flip the POWER switch down to the

"O" position. The green in-cycle light

stays on and begins the drain cycle.

12. The green in-cycle light goes out

when the machine has drained

completely.

13. The Initial start-up is complete.

Proper Water Fill Line

Wash and Rinse Temperature Gauge

Final Rinse Pressure Gauge

11

Chemical Dispensers

Installation Guide _____________________________

! Chemical Dispensers

Chemical Dispensers

1. All models come equipped with a builtin detergent dispensing pump and a

rinse-aid dispensing pump. The pumps

are located behind the lower front

access panel.

2. Each pump is Þ tted with 6ft of pick-

up supply tubing, a stand-pipe, and a

strainer.

3. Pick-up tubes are marked detergent

and rinse-aid. Make sure the pickup tubes are placed in the correct

chemical supply container (chemicals

supplied by others).

Dispenser Pump Location

4. The chemical dispensers require nonchlorinated liquid detergent and rinseaid. Your chemical supplier must adjust

the dispensers for the supplied product.

5. Chemical containers must be placed

as close to the dishwasher as possible

and no higher than 10" above the ß oor.

Pick-Up Tubes

12

Chemical Dispensers

_____________________________ Installation Guide

! Chemical Dispensers

How to Prime the Dispensers

1. Place the chemical containers next to

the dishwasher.

2. Insert the detergent and rinse-aid

pick-up tubes in the correct chemical

supply container.

3. Open the dishwasher door.

4. Press and hold the PRIME switch up

to prime the detergent. Watch the

detergent injection point located on

the right rear wall of the machine until

chemical enters the machine.

Prime Switch Up

Detergent Injection Point

13

Chemical Dispensers

Installation Guide _____________________________

! Chemical Dispensers

How to Prime the Dispensers (continued)

5. Press and hold the prime switch down

for 30 seconds to prime the rinse-aid.

6. All chemicals enter the UL-100, UH100, and UH-100B through the Þ ll

chute injection point located on the

right-side of the wash compartment.

Prime Switch Down

14

Fill Chute Injection Point

Chemical Dispensers

_____________________________ Installation Guide

! Chemical Dispensers

To Chemical Suppliers

How to Adjust Chemical Dispensers:

1. The chemical dispensing pumps are

adjustable.

2. Adjustments are made by turning

the trim potentiometers located

on the dishwasher control board

located at the lower right corner of

the machine.

3. Remove the lower front access

panel and identify the control circuit

board cover. Each dispensing trim

potentiometer is labeled on the

cover.

4. Trim potentiometers are adjusted

using a small screwdriver inserted

into the adjusting slot. Turning the

screwdriver clockwise increases the amount of dispensed chemical; counter

clockwise reduces the amount of chemical dispensed.

Trim Potentiometer Location

15

Blank Page

This Page Intentionally

Left Blank

16

17

Operation

Models UH-170, UH-170B, UH-200, and UH-200B

UH-170B Control Panel

UH-200B Control Panel

Normal Wash Cycle

1. Flip the POWER switch up to the " I " position. The switch illuminates, water

enters the wash compartment. Wash tank heater heats wash water and the

booster heater begins to heat the final rinse water.

2. Prescrap and load wares into the appropriate dishrack.

NOTE:

Do not overload dishrack. Load wares in a peg rack; load silverware in a

single layer in a flat-bottom dishrack. Overloading dishrack will result in

poor washing results.

NOTE:

Wash temperature gauge must read 150°F before proceeding to the next

step.

3. Open dishwasher door and slide dishrack into the machine. Only wash one

dishrack per wash cycle.

4. Close dishwasher door and press the START switch for 1 second. The

green in-cycle light illuminates and the wash cycle begins.

NOTE:

Opening the door stops the cycle. When the dishwasher door is closed the

cycle resumes automatically.

Operation ___________________________________

Normal Wash Cycle (continued)

6. Check the rinse cycle temperature gauge during the Þ nal rinse cycle to

ensure the Þ nal rinse temperature ranges between 180°-195°F.

7. Machine drains wash water and holds Þ nal rinse water for the next wash

cycle. The green in-cycle light goes out completing the cycle.

8. Open the dishwasher door and remove the dishrack of clean wares.

9. Repeat steps 2-8 for additional cycles.

NOTE:

Poor washing results will occur if the scrap screen is not cleaned regularly.

Extended Wash Cycle

The extended wash cycle is ideal for pots, pans, and heavily soiled items.

1. Follow STEPS 1-5 of the Normal Wash Cycle.

2. Wait 10 seconds to allow detergent to enter into the dishwasher.

3. Press the EXT WASH switch. The light above the EXT WASH switch

illuminates, indicating that the dishwasher is in a continuous extended wash

mode.

4. Press the EXT WASH switch again to take the dishwasher out of the

extended wash mode. The light above the EXT WASH switch goes out but

the green light above the START switch will stay illuminated, indicating the

dishwasher has resumed the remainder of the wash cycle.

NOTE:

The dishwasher washes until the extended wash cycle switch is pressed to

stop the extended wash mode, or for a maximum of 15 minutes.

18

Loading...

Loading...