Page 1

For machines beginning with Serial no. U-1352

Technical Manual

Champion

Model UH-200B Shown

Undercounter

Dishwasher

Model

UH-200B

UH-200

UH-100B

UH-100

UL-100

High Temperature with Built-in Booster

Fresh Water Final Rinse

High Temperature

Fresh Water Final Rinse

High Temperature with Built-in Booster

Pumped Fresh Water Final Rinse

High Temperature

Pumped Fresh Water Final Rinse

Low Temperature

Chemical Sanitizing Rinse

Machine Serial No.

June, 2001

P. O. Box 4149

Winston-Salem, North Carolina 27115-4149

336/661-1556 Fax: 336/661-1660

Champion Industries, Inc.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Champion Manual P/N 112653 REV. C

2674 N. Service Road

Jordan Station, Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Page 2

Complete the information below for quick reference.

Model Number Serial Number

Voltage and Phase

Champion Parts Supplier Phone

Champion Service Agency Phone

Champion (USA)

National Service Department

Phone: 1(336) 661-1556

1(800) 858-4477

Fax: 1(336) 661-1660

Champion (Canada)

National Service Department

Phone: 1(905) 562-4195

1(800) 263-5798

Fax: 1(905) 562-4618

Note: When calling to order parts, be sure to have the model number, serial number,

voltage and phase of your machine.

Champion

Machine Data Plate with

model & serial number

Machine

located on the front of the

lower panel.

COPYRIGHT © 2001 by Champion Industries, Inc. All Rights Reserved.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

REVISION RECORD

REVISION RECORD

Revision Revised Serial Number Comments

Date Pages Effectivity

2/25/99 All U-1352 First issue of manual and

replacement parts lists

10/25/99 7, 9, 10, ALL Increased size of supply

92, 93 line, line strainer, and PRV

from 1/2" to 3/4" I.D.

10/25/99 75, 99 ALL Corrected Thermistor

Resistance Chart

5/1/00 133 U-1991 Changed Models UH-200 &

UH-200B fill hose, valve to 3/4"

revised fill piping & bracket

5/1/01 142, 143 ALL Changed P/N 112621 to

900827 prior to S/N U1938, and

113292 after S/N U1938. Changed

P/N’s 112622 & 112623 to

900828 prior to S/N U1938 and

113293 after S/N U1938.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

i

Page 4

REVISION RECORD

ii

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 5

SAFETY SUMMARY

SAFETY SUMMARY

Safety Symbols

• The following symbols appear throughout this manual alerting you to potential

hazards. Statements associated with each symbol are printed in italics.

WARNING:

Warning statements indicate any condition or practice that

could result in personal injury or possible loss of life.

CAUTION:

!

Caution statements indicate any condition or practice which,

if not strictly observed or remedied, could result in damage to

or destruction of the dishwasher.

NOTE:

Note statements indicate any condition or practice which,

if observed, will help in the safe completion of a task.

General Safety Rules

• The following general safety rules must be observed in addition to the specific cautions and

warnings presented in this manual.

• Your Champion dishwasher uses hot water to clean and sanitize a variety of wares.

(Model UL-100 uses chemicals to sanitize wares.)

Machine surfaces and wares become hot during and immediately following normal operations.

Operators should use caution when loading and unloading wares from the machine.

• Operators must NOT bypass a safety interlock or control to operate the dishwasher.

• The service and maintenance instructions contained in this manual are intended for qualified

service personnel. These instructions assume that you are trained in basic electricity and

mechanical theory. If you are not a trained technician, then do not attempt to adjust or repair the

dishwasher as serious personal injury or damage to the dishwasher may result.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

iii

Page 6

LIMITED WARRANTY

LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), P.O. Box 4149, Winston-Salem, North Carolina 27115,

and P.O. Box 301, 2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts, as set out

below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name

"Champion" and installed within the United States and Canada to be free from defects in material and workmanship for a period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by

Champion, whichever occurs first. [See below for special provisions relating to glasswashers.] The warranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided, however, as to glasswashers, Champion's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Champion

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion authorized service technician. Defective parts become the property of Champion.

Use of replacement parts not authorized by Champion will relieve Champion of all further liability in connection

with its warranty. In no event will Champion's warranty obligation exceed Champion's charge for the machine.

The following are not covered by Champion's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage caused by

labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION'S WARRANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING

MACHINES AND CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED,

INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion dishwashing machines,

to change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

iv

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 7

TABLE OF CONTENTS

TABLE OF CONTENTS PAGE

Revision Record ........................................................................................................... i

Safety Summary ........................................................................................................... iii

Limited Warranty ......................................................................................................... iv

PART 1: GENERAL SPECIFICATIONS........................................................

1.1 About this Manual................................................................................................ 1

1.2 Model Numbers ................................................................................................... 2

1.3 Standard Equipment and Options ........................................................................ 3

1.4 Dimensions, Capacities, and Rough-in ................................................................ 4

PART 2: INSTALLATION ..............................................................................

2.1 Introduction .......................................................................................................... 7

2.2 Unpack the Dishwasher ....................................................................................... 7

2.3 Permanent Placement ........................................................................................... 8

2.4 Water Connections .............................................................................................. 8

2.4.1 Model UH-200B, UH-200 ......................................................................... 9

2.4.2 Model UH-100B, UH-100, UL-100........................................................... 10

2.5 Drain Connections (All models) .......................................................................... 11

2.6 Installation and Service Switch (Model UH-200B, UH-100B Only) .................. 12

2.7 Electrical Connections (Single Phase) ................................................................. 13

2.7.1 Model UH-200B, UH-100B....................................................................... 13

2.7.2 Model UH-200, UH-100, UL-100 ............................................................. 14

2.8 Electrical Connections (Three Phase) .................................................................. 15

2.8.1 Model UH-200B, UH-100B....................................................................... 15

2.9 Chemical Connections ......................................................................................... 16

2.9.1 General (All Models) ................................................................................. 16

2.9.2 Models UH-200B, UH-200 (Chemical Adjust and Prime) ........................ 19

2.9.3 Models UH-100B, UH-100 (Chemical Adjust and Prime) ........................ 20

2.9.4 Model UL-100 (Chemical Adjust and Prime)............................................ 21

2.10 Installing Optional Chemical Pumps ................................................................... 22

2.10.1 Model UH-200B, UH-200 ....................................................................... 22

2.10.2 Model UH-100B, UH-100 ....................................................................... 25

2.11 Initial Start-up (All Models) ................................................................................ 26

2.11.1 Model UH-200B, UH-200 ....................................................................... 27

2.11.2 Model UH-100B, UH-100, UL-100......................................................... 28

1

7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

v

Page 8

TABLE OF CONTENTS

PART 3: DAILY OPERATION........................................................................

3.1 Introduction .......................................................................................................... 29

3.2 Preparing your Dishwasher (All Models) ............................................................ 29

3.3 Loading your Dishwasher (All Models) .............................................................. 30

3.4 Description of Operator Controls and Displays (All Models) ............................. 31

3.5 Basic Operation.................................................................................................... 34

3.5.1 Model UH-200B, UH-200 ......................................................................... 34

3.5.2 Model UH-100B, UH-100, UL-100........................................................... 36

PART 4: CLEANING and MAINTENANCE ..................................................

4.1 Introduction .......................................................................................................... 39

4.2 Daily Cleaning Schedules (All Models) .............................................................. 39

4.3 Deliming Schedules (All Models) ....................................................................... 40

4.3.1 Deliming Procedure (All Models) ............................................................. 40

4.4 Preventive Maintenance Schedules (All Models) ................................................ 41

4.5 Lubrication (All Models) ..................................................................................... 41

PART 5: OPERATOR TROUBLESHOOTING ...............................................

5.1 Introduction .......................................................................................................... 43

5.2 Troubleshooting Basics........................................................................................ 43

5.3 Using the Touchpad/Display to Evaluate Problems ............................................. 44

5.4 Reading Error Codes ............................................................................................ 45

5.5 Troubleshooting Guide ........................................................................................ 46

29

39

43

PART 6: SERVICE TROUBLESHOOTING ...................................................

6.1 Introduction .......................................................................................................... 51

6.2 Operation Sequence and Timing Charts .............................................................. 52

6.2.1 Model UH-200B, UH-200 ......................................................................... 52

6.2.2 Model UH-100B, UH-100 ......................................................................... 54

6.2.3 Model UL-100 ........................................................................................... 56

6.3 Error Codes .......................................................................................................... 58

6.4 Troubleshooting Guide ........................................................................................ 60

51

vi

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 9

TABLE OF CONTENTS

PART 7: SOLID STATE CIRCUIT BOARDS .................................................

7.1 Introduction ..................................................................................................... 61

7.2 Control Cabinet Layout and Board Function .................................................. 61

7.3 Replacement Circuit Board Set-up .................................................................. 62

7.3.1 Timer Control Board Program Jumper Settings .................................... 62

7.3.2 Timer Control Board LED Status Lights............................................... 63

7.3.3 Temperature/Pressure Control Board Program Jumper Settings ........... 64

7.3.4 Temperature/Pressure Control Board LED Status Lights ..................... 65

7.3.5 Time Select (Fill/Chemical Dispenser) Board....................................... 66

7.4 Circuit Board Connector Diagrams and Test Points ........................................ 70

7.4.1 Timer Control and Time Select (Fill/Chemical Dispenser) Board ....... 72

7.4.2 Temperature/Pressure Display Board ................................................... 74

7.4.3 Touchpad/Display ................................................................................. 76

7.5 Circuit Board Removal and Replacement ....................................................... 78

7.5.1 Timer Control Board Removal .............................................................. 78

7.5.2 Temperature/Pressure Display Board Removal ..................................... 80

7.5.3 Touchpad/Display Removal and Replacement ...................................... 82

7.5.4 Time Select (Fill/Chemical Dispenser) Board Removal ....................... 85

PART 8: COMPONENT REPAIR AND REPLACEMENT .............................

8.1 Introduction .......................................................................................................... 87

8.1.1 Special Tools and Materials................................................................ 87

8.1.2 Electrical Component Locator Diagram............................................. 88

8.1.3 Troubleshooting the 10-point Terminal Board ................................... 90

8.2 Components ......................................................................................................... 92

8.2.1 Pressure Reducing Valve, (PRV), Adjustment .................................... 92

Model UH-200B, UH-200

8.2.2 Water Line Strainer ............................................................................. 93

Model UH-200B, UH-200

Model UH-100B, UH-100, UL-100

8.2.3 Fill/Rinse Water Solenoid Valve ......................................................... 93

Model UH-200B, UH-200

Model UH-100B, UH-100, UL-100

8.2.4 Water Level Probe .............................................................................. 95

Model UH-200B, UH-200

8.2.5 Vacuum Breaker ................................................................................. 96

Model UH-200B, UH-200

8.2.6 Pressure Transducer ............................................................................ 97

Model UH-200B, UH-200

8.2.7 Thermistors (All Models) ................................................................... 99

8.2.8 Wash Tank Heater and High Limit Thermostat .................................. 100

(All models except UL-100)

8.2.9 Booster Tank Heater and High Limit Thermostat .............................. 101

Model UH-200B, UH-100B

61

87

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

vii

Page 10

TABLE OF CONTENTS

PART 8: ..........................................................................................................

COMPONENT REPAIR AND REPLACEMENT (CONT.)

8.2 Components (Cont.)

8.2.10 Wash Pump/Motor (All Models) ........................................................................ 102

8.2.11 Drain Pump/Motor, Drain Valve (All Models) .................................................. 104

8.2.12 Wash Arm Bearings (All Models) ...................................................................... 105

8.2.13 Rinse Arm Bearings ............................................................................................ 106

Model UH-200B, UH-200

8.2.14 Door Shock and Hinge Assembly (All Models)................................................. 107

8.2.15 Door Safety Switch and Magnet (All Models) ................................................... 108

8.2.16 Circuit Breaker (All Models).............................................................................. 109

PART 9: REPLACEMENT PARTS ..........................................................

PART 10: ELECTRICAL SCHEMATICS ...................................................

A701543 UH-200B Single Phase

A701542 UH-200 Single Phase

A701545 UH-100B Single Phase

A701544 UH-100 Single Phase

A701546 UL-100 Single Phase

A701628 UH-200B Three Phase

A701627 UH-100B Three Phase

111

155

viii

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 11

TABLE OF CONTENTS

LIST OF FIGURES

Figure 2.4.1 – Water Connections ( UH-200B, UH-200) .............................................. 9

Figure 2.4.2 – Water Connections (UH-100B, UH-100, UL-100) ................................. 9

Figure 2.5.3 – Recommended Direct Drain Connections for All Models ...................... 11

Figure 2.6.1 – Installation and Service Switch (UH-200B, UH-100B Only) ................ 12

Figure 2.9.1 – Control Cabinet Retaining Screws .......................................................... 17

Figure 2.9.2 – Fill/Chemical Dispenser Circuit Board................................................... 18

Figure 2.9.3 – Chemical Bottle Placement ..................................................................... 18

Figure 2.9.4 – UH-200B, UH-200 Touchpad/Display ................................................... 19

Figure 2.9.5 – Rinse Aid Injection Point (UH-200B, UH-200) ..................................... 19

Figure 2.9.6 – UH-100B, UH-100 Touchpad/Display ................................................... 20

Figure 2.9.7 – Fill Chute (UH-100B, UH-100, UL-100) ............................................... 20

Figure 2.9.8 – UL-100 Touchpad/Display...................................................................... 21

Figure 2.9.9 – Fill Chute Discharge (UH-100B, UH-100, UL-100) .............................. 21

Figure 2.10.1 – UH-200B, UH-200 Chemical Pumps .................................................... 22

Figure 2.10.2 – Chemical Pump Connection Terminal Block ......................................... 22

Figure 2.10.3 – UH-100B, UH-100 Chemical Pumps ..................................................... 25

Figure 3.4.1 – Door Safety Magnet Location................................................................. 31

Figure 3.4.2 – Circuit Breaker Location ........................................................................ 31

Figure 5.3.1 – Self-Diagnostics Display ........................................................................ 44

Figure 5.3.2 – LO Temperature Displayed ..................................................................... 44

Figure 6.2.1 – Timing Chart (UH-200B, UH-200) ........................................................ 53

Figure 6.2.2 – Timing Chart (UH-100B, UH-100) ........................................................ 55

Figure 6.2.3 – Timing Chart (UL-100)........................................................................... 57

Figure 7.2.1 – Circuit Board Layout (All Models) ........................................................ 61

Figure 7.3.1 – Timer Control Board Jumpers and.......................................................... 62

LED Status Lights

Figure 7.3.2 – Temperature/Pressure Display Board Jumpers ....................................... 64

and LED Status Lights

Figure 7.3.3 – Time Select (Fill/Chemical Dispenser)................................................... 66

Board Potentiometers

Figure 7.3.4 – Rinse Aid and Sanitizer Pump Adjustment ............................................. 69

Figure 7.4.1 – Timer Control Board and Time Select Board ......................................... 72

Connector Diagrams

Figure 7.4.2 – Temperature/Display Board .................................................................... 74

Connector Diagrams

Figure 7.4.3 – Touchpad/Display Connector Diagram................................................... 76

Figure 8.1.1 – Electrical Component Locator Diagram ................................................. 88

Figure 8.1.2 – 10-Point Terminal Board ......................................................................... 90

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

ix

Page 12

TABLE OF CONTENTS

Figure 9.1 – Upper Hood Assembly and Control Cabinet (All Models) ......................... 112

Figure 9.2 – Tank, Base, Guide Rails, and Panels (UH-200B, UH-200) ........................ 114

Figure 9.3 – Tank, Base, Guide Rails, and Panels (UH-100B, UH-100, UL-100).......... 116

Figure 9.4 – Door and Door Safety Switch Assembly (All Models)............................... 118

Figure 9.5 – Final Rinse Manifold Assembly (UH-200B, UH-200) ............................... 120

Figure 9.6 – Chemical Injection Points, Water Level Probe Assy. (UH-200B, UH-200. 122

and Fill Chute Assemby (UH-100B, UH-100, UL-100)

Figure 9.7 – Sump and Spray Piping Assembly (UH-200B, UH-200)............................ 124

Figure 9.8 – Sump and Spray Piping Assembly (UH-100B, UH-100, UL-100) ............. 126

Figure 9.9 – Spray Arm Assembly (UH-200B, UH-200) ................................................ 128

Figure 9.10 – Spray Arm Assembly (UH-100B, UH-100, UL-100) ................................. 130

Figure 9.11 – Fill/Rinse Valve Assembly (UH-200B, UH-200)........................................ 132

Figure 9.12 – Fill/Rinse Valve Assembly (UH-100B, UH-100, UL-100) ......................... 134

Figure 9.13 – Wash Pump Piping, Drain Pump, Drain Valve and Drain Piping ............... 136

(All Models)

Figure 9.14 – Wash Pump/Motor Assembly (All Models) ................................................ 138

Figure 9.15 – Booster Assembly (UH-200B, UH-100B) .................................................. 140

Figure 9.16 – Solid State Controls (All Models) ............................................................... 142

Figure 9.17 – Base Mounted Electrical Controls (All Models)......................................... 144

Figure 9.18 – (Optional) Detergent Pump for High Temp Machines ................................ 146

(UH-200B, UH-200, UH-100B, UH-100)

Figure 9.19 – (Optional) Rinse Aid Pump for High Temp Machines................................ 148

(UH-200B, UH-200, UH-100B, UH-100)

Figure 9.20 – (Standard) Chemical Dispensing Pumps for Low Temp Machines ............ 150

(UL-100)

Figure 9.21 – Dishracks, Line Strainer, PRV (All Models) ............................................... 152

LIST OF FIGURES (Cont.)

x

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

Part 1: GENERAL SPECIFICATIONS

PART 1: GENERAL SPECIFICATIONS

1.1 About this Manual

All information, illustrations and specifications contained in this manual are based upon the

latest product information available at the time of publication. Champion constantly improves

its products and reserves the right to make changes at any time or to change specifications or

design without notice and without incurring any obligation.

Manual Organization

This manual is divided into eleven parts:

♦ Part 1, General Specifications, introduces this manual and the dishwasher models

in general.

♦ Part 2, Installation, explains the installation of the dishwasher and describes the

connection of utilities, chemical dispensing pumps, and initial start-up.

♦ Part 3, Daily Operation, explains operator controls and basic operation.

♦ Part 4, Cleaning and Maintenance, explains cleaning, deliming, preventive maintenance,

and lubrication.

♦ Part 5, explains basic troubleshooting for the operator.

♦ Part 6, explains basic troubleshooting for the service technician.

♦ Parts 7-8, provide detailed repair procedures for the trained service technician.

♦ Part 9, contains parts diagrams and parts lists.

♦ Part 10, contains electrical schematics.

NOTE:

Unless noted otherwise, dimensions, capacities, temperatures, etc., given in this

manual are U.S. Customary Measures and the Metric Equivalents of the U.S.

customary measures.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

1

Page 14

Part 1: GENERAL SPECIFICATIONS

1.2 Model Numbers

UH-200B

The UH-200B is a high temperature (180°F/82°C) sanitizing machine with a built-in booster.

(40°F/22°C) rise booster is standard requiring a minimum incoming water supply temperature

of 140°F/60°C. A (70°F/39°C) rise booster is available which requires a minimum incoming

water supply temperature of 110°F/43°C. The UH-200B is a fresh water rinse machine. Final

rinse water enters the final rinse spray system under line pressure. A portion of the final rinse

water is retained for the next wash cycle.

UH-200

The UH-200 is a high temperature (180°F/82°C) sanitizing machine without a built-in

booster. It requires a minimum incoming water supply temperature of 180°F/82°C. The

UH-200 is a fresh water rinse machine. Final rinse water enters the final rinse spray system

under line pressure. A portion of the final rinse water is retained for the next wash cycle.

UH-100B

The UH-100B is a high temperature (180°F/82°C) sanitizing machine with a built-in booster.

(40°F/22°C) rise booster is standard requiring a minimum incoming water supply temperature

of 140°F/60°C. A (70°F/39°C) rise booster is available which requires a minimum incoming

water supply temperature of 110°F/43°C. The UH-100B is a fresh water pumped final rinse

machine. Final rinse water enters the wash tank and is recirculated by the wash pump. The

final rinse water is retained for the next wash cycle.

UH-100

The UH-100 is a high temperature (180°F/82°C) sanitizing machine without a built-in

booster. It requires a minimum incoming water supply temperature of 180°F/82°C. The

UH-100 is a fresh water pumped final rinse machine. Final rinse water enters the wash tank

and is recirculated by the wash pump. The final rinse water is retained for the next wash

cycle.

UL-100

The UL-100 is a low temperature (140°F/60°C) chemical sanitizing machine for use with a

sodium hypochlorite (chlorine) based sanitizer at a minimum concentration of 50 PPM (for

USA/Consult the local authority for Canada) in the final rinse. It requires a minimum

incoming water supply temperature of 140°F/60°C. The UL-100 is a fresh water pumped

final rinse machine. Final rinse water enters the wash tank and is recirculated by the wash

pump. The final rinse water is retained for the next wash cycle.

2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

1.3 Standard Equipment

All Models

♦ 304 stainless steel construction

♦ Interchangeable upper and lower spray arms

♦ 3/4 Hp pump/motor assembly

♦ Top mounted slide-out control cabinet

♦ Solid state electronic controls

♦ Pumped drain

♦ Flexible fill and drain hoses

♦ Door safety switch

♦ Easily removable scrap screen

♦ Dishracks (peg rack and flat bottom rack)

Part 1: GENERAL SPECIFICATIONS

UH-200B

♦ 40°F/22°C rise booster

♦ Tank heater

♦ Low water tank heat protection

♦ Top and side panels

UH-100B

♦ 40°F/22°C rise booster

♦ Tank heater

♦ Low water tank heat protection

UL-100

♦ Three built-in chemical dispensing pumps

for detergent, rinse aid, and sanitizer

1.3 Options

UH-200B

♦ 70°F/39°C rise booster

♦ Detergent pump kit (P/N 900799)

♦ Rinse aid pump kit (P/N 900803)

♦ Pressure reducing

valve 3/4" (P/N 107550)

UH-200

♦ Tank heater

♦ Low water tank heat protection

♦ Top and side panels

UH-100

♦ Tank heater

♦ Low water tank heat protection

UH-200

♦ Detergent pump kit (P/N 900799)

♦ Rinse aid pump kit (P/N 900803)

♦ Pressure reducing

valve 3/4" (P/N 107550)

UH-100B

♦ 70°F/39°C rise booster

♦ Detergent pump kit (P/N 900800)

UH-100

♦ Detergent pump kit (P/N 900800)

♦ Rinse aid pump kit (P/N 900802)

♦ Rinse aid pump kit (P/N 900802)

♦ Full side panel kit (P/N 900804)

All Models

♦ 6" Legs (set of 4) (P/N 324087)

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

3

Page 16

Part 1: GENERAL SPECIFICATIONS

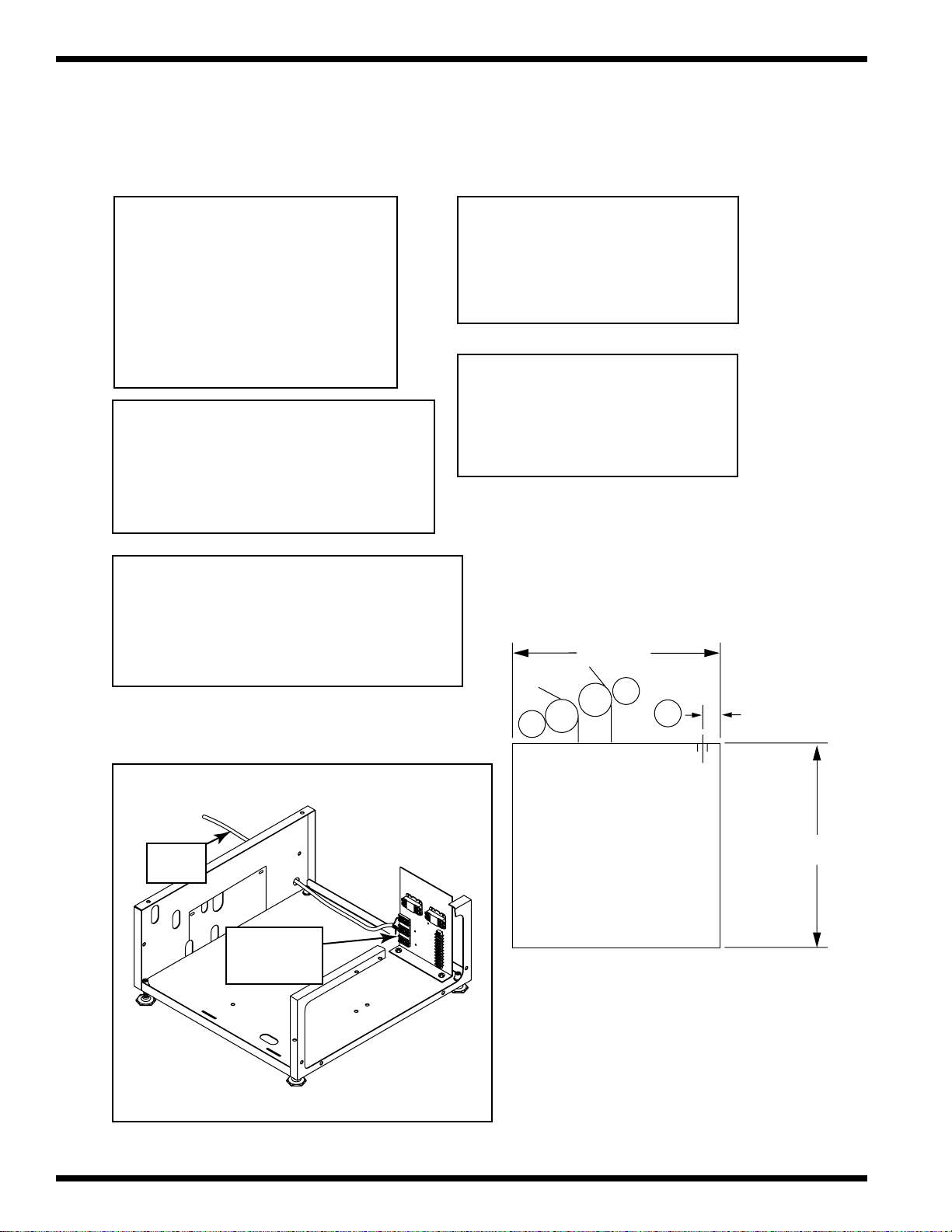

1.4 Dimensions, Capacities, and Rough-in

Dimensions (All Models)

Height 33-3/4" [858mm]

Width 23-7/8" [607mm]

Length 23" [584mm]

Volume crated: 15 cu. ft. [.4 cu.m]

Approx. Shipping

weight crated: 215 lbs [98 Kg]

Wash Tank Capacities

UH-200B, UH-200 ≅ 3.6 US gal. (14 liters)

UH-100B, UH-100 ≅ 1.8 US gal. (7 liters)

UL-100 ≅ 2.3 US gal. (8.7 liters)

Water Usage (per rack)

UH-200B, UH-200 1.1 US gal. (4.2 liters)

UH-100B, UH-100 1.8 US gal. (6.8 liters)

UL-100 2.3 US gal. (8.7 liters)

Total Cycle Time

UH-200B, UH-200 90 seconds

UH-100B, UH-100 120 seconds

UL-100 155 seconds

Racks per hour (NSF rated)

UH-200B, UH-200 30 racks/hr.

UH-100B, UH-100 24 racks/hr.

UL-100 19 racks/hr.

7

"

23

/

8

[607]

Flexible

Conduit

Main Power

Connection

Terminal Block

Electrical Power Routing

3

2

PLAN VIEW

Model UH-200B

Model UH-200

Model UH-100B

Model UH-100

Model UL-100

1

2" [51]

23" [584]

4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 17

Part 1: GENERAL SPECIFICATIONS

1.4 Dimensions and Capacities, and Rough-in

3" [76]

Wall

Clearance

3

2

Electric

1

2

Water

23"

[584]

3

14

/4" [375]

Clearance

5

1

/8"

[42]

SIDE VIEW

1

14

1

/4" [362]

33

[858]

3

/4"

Model UH-200B

Model UH-200

WARNING:

Refer to Part 2: Installation, Sections 2.1 through

2.9, before connecting the dishwasher to utilities.

3

Drain

3" [76]

Wall

Clearance

3

2

23"

[584]

1

15

/2" [394]

Clearance

5

1

/8"

[42]

1

SIDE VIEW

14

1

/4" [362]

33

[858]

3

/4"

Model UH-100B

Model UH-100

Model UL-100

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

5

Page 18

Part 2: INSTALLATION

This Page

Intentionally

Left

Blank

6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 19

Part 2: INSTALLATION

PART 2: INSTALLATION

2.1 Introduction

In This Part—

• Unpacking the dishwasher

• Permanent Placement

• Making Utility Connections

• Installing Optional Components

2.2 Unpack the Dishwasher

Your dishwasher was completely assembled, inspected, and thoroughly tested at our factory

before shipment to your installation site.

• The dishwasher is shipped on a single pallet.

• Optional components may have been shipped separately.

• Check your packing list thoroughly.

NOTE:

Immediately after unpacking your machine, inspect for any shipping damage. If damage

if found, save the packing material and contact the carrier immediately.

BE SURE TO COMPLETE AND RETURN THE

WARRANTY CARD

INCLUDED WITH YOUR MACHINE.

NOTE:

The installation of your dishwasher must meet all applicable

health and safety codes and conform to good trade practice.

Perform the following steps to unpack the dishwasher:

1. Remove protective wrap and hold downs from the pallet.

2. Inspect for any shipping damage. If damage is found, save the packing material

and contact the carrier immediately.

3. Check the interior of the dishwasher for the following items stowed inside:

• 1 set of dishracks

• Upper and lower spray arm assemblies

• Round scrap screen

• Rubber pads for leveling feet (set of 4)

• 3/4" line strainer (P/N 110768) (Model UH-200B, UH-200 Only)

• Warranty information packet

4. Remove the dishwasher from the skid.

5. Move the dishwasher to its permanent location.

Refer to Section 2.3, Permanent Placement.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

7

Page 20

Part 2: INSTALLATION

2.3 Permanent Placement

Special Tools —

• Bubble level (3 ft.)

Perform the following steps to place the dishwasher in its permanent location.

Refer to the machine diagrams in Section 1.4, Dimensions and Capacities, page 4-5.

1. Before moving the dishwasher into position, inspect the location site to ensure the electrical,

plumbing, and ventilation services (if required) are provided in the correct locations.

Compare the site connections with the dishwasher to ensure they will match when the

machine is set in its permanent location.

NOTE:

Some local codes may require that the dishwasher be sealed to the floor with

silicon or comparable sealing method.

2. Lift the dishwasher and adjust the leveling feet out.

3. Position dishwasher in its permanent location.

• Minimum clearance between the rear of the machine and back wall is 3" [76mm].

• Minimum height of the machine with adjustable feet turned in fully is 33-3/4" [858mm].

4. Place a 3 ft. level on top of the dishwasher or inside the dishwasher on the track assembly

to level the dishwasher front to back. Adjust level by turning the adjustable feet. Level side

to side with the level placed on the top of the dishwasher.

5. Pull the dishwasher out far enough to gain access to the rear and prepare utility

connections. A removable rear access door is located at the back of the machine.

6. Install the rubber pads on the leveling feet prior to returning machine to its permanent

position.

2.4 Water Connections

The following warning and attention statements apply to all dishwasher models.

WARNING:

The installation of this unit must conform to local codes or, in the absence of

local codes, to all National Codes governing plumbing, sanitation, safety and

good trade practices.

!! ATTENTION INSTALLER !!

The dishwashers described in Sections 2.4.1 and 2.4.2 are fitted with 6 ft. [1829mm],

1/2" I.D. flexible fill hoses located at the rear of the machine.

Make sure supply hose does not kink, resulting in a water flow restriction.

NOTE:

Your plumbing installation must allow the machine to be pulled out for repair.

8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 21

Part 2: INSTALLATION

2.4.1 (Water Connections) Models UH-200B, UH-200

Refer to the Table below for minimum water supply requirements.

Minimum Minimum-Maximum

Model Temperature Flowing Pressure*

UH-200B with

40°F/22°C Booster 140°F/60°C 20-22 PSI (138-151 kPa)

UH-200B-70 with

70°F/39°C Booster 110°F/43°C 20-22 PSI (138-151 kPa)

UH-200 without

Booster 180°F/82°C 20-22 PSI (138-151 kPa)

*Flowing pressure is observed when the fill water solenoid valve is open while the

machine is in a final rinse operation. Refer to Part 3, Operation, Section 3.21. for a

description of the front panel display final rinse pressure readings.

1. If flowing pressure exceeds 22 PSI/151kPa, a pressure reducing valve, PRV, must be

installed in the incoming water supply, and adjusted to the min/max listed above.

The PRV is supplied by others or may be purchased (unmounted) from Champion.

2. Champion supplies a 3/4" line strainer (unmounted) and shipped inside the dishwasher.

The line strainer must be installed in the water supply line upstream from the PRV.

3. A 3/4" manual shutoff valve (supplied by others) should be installed in the water supply

line upstream from the PRV and line strainer. The valve must be the same size as or larger

than the water supply line. The shutoff valve allows for servicing of the machine.

4. The dishwasher is supplied with a 1/2" I.D., 6 ft. [1829mm], reinforced flexible hose.

The hose is fitted with a 3/4" female garden hose fitting.

Incoming Water Supply Water Supply

CAUTION:

!

The reinforced fill hose supplied with the dishwasher is designed for high pressure and

high temperature application and should never be replaced with common garden hose.

5. Connect a 3/4" I.D. minimum copper water supply line fitted with a 3/4" male garden hose

fitting (supplied by others). Make sure the water supply line is flushed out before making

connection to the machine.

Figure 2.4.1

Water Connections

Model UH-200B, UH-200

(UH-200B shown)

6 ft. [1829mm] flexible fill hose

3/4" PRV, pressure reducing valve

3/4" line strainer

3/4" Water shutoff Valve

3/4" I.D. copper water supply line

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

9

Page 22

Part 2: INSTALLATION

2.4.2 (Water Connections) Models UH-100B, UH-100, UL-100

Refer to the Table below for minimum water supply requirements.

Model Temperature Pressure*

UH-100B with

40°F/22°C Booster 140°F/60°C 25-95 PSI (173-656 kPa)

UH-100B-70 with

70°F/39°C Booster 110°F/43°C 25-95 PSI (173-656 kPa)

UH-100 without

Booster 180°F/82°C 25-95 PSI (173-656 kPa)

UL-100 140°F/60°C 25-95 PSI (173-656 kPa)

*Incoming water supply pressure should be tested with a pressure gauge

(supplied by others) at the dishwasher water supply connection. Incoming water supply

pressure must be able to maintain a minimum flowing pressure of 25 PSI [173 kPa].

1. The fill solenoid valve mounted in the machine (supplied by Champion) is equipped

with a flow control that will accommodate the min./max. incoming line pressures

listed above. A PRV, pressure reducing valve, is not required.

2. If incoming line pressure is below 25 PSI [173 kPa], the customer must make the necessary provisions to increase the incoming line pressure

minimum of 25 PSI [173 kPa].

3. The fill solenoid valve is equipped with a built-in line strainer. A separate line strainer

is not shipped with this machine.

4. A 3/4" manual shutoff valve (supplied by others) should be installed in the water supply

line. The valve must be the same size as or larger than the water supply line. The shutoff

valve allows for servicing of the machine.

5. The dishwasher is supplied with a 1/2" I.D., 6 ft. [1829mm], reinforced flexible hose.

The hose is fitted with a 3/4" female garden hose fitting.

Minimum Minimum-Maximum

Incoming Water Supply Incoming Water Supply

at the dishwasher to the required

CAUTION:

!

The reinforced fill hose supplied with the dishwasher is designed for high pressure and

high temperature application and should never be replaced with common garden hose.

6. Connect a 3/4" I.D. minimum copper water supply line fitted with a 3/4" male garden hose

fitting (supplied by others). Make sure the water supply line is flushed out before making

connection to the machine. The installation of a pressure gauge (supplied by others) is

recommended, but not required, in the 3/4" supply line after the shutoff valve.

Figure 2.4.2

Water Connections

Model UH-100B, UH-100, UL-100

(UH-100B shown)

6 ft. [1829mm] flexible fill hose

Pressure Gauge

3/4" Water shutoff Valve

3/4" I.D. copper water supply line

10

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 23

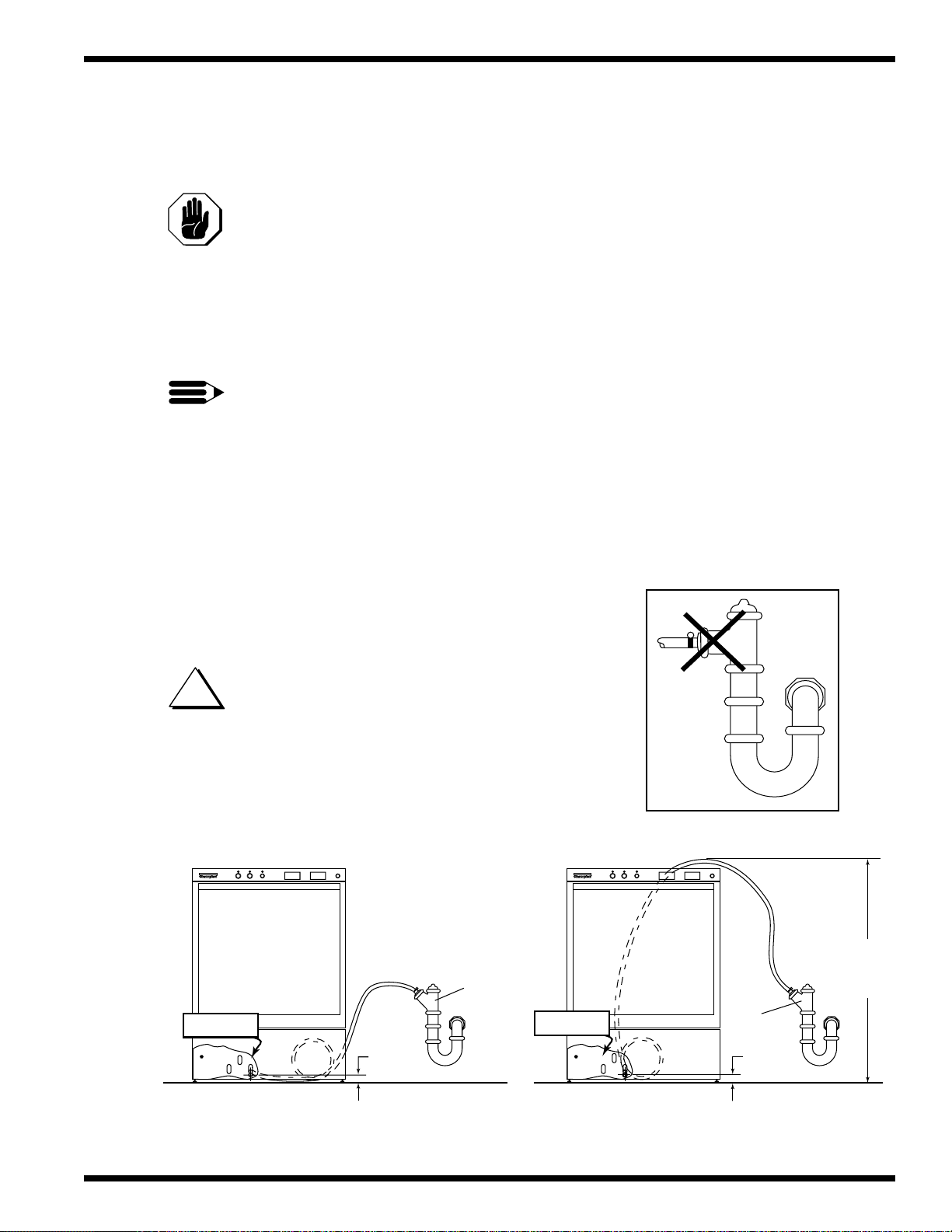

Part 2: INSTALLATION

2.5 Drain Connections

The following instructions apply to all dishwasher models.

Refer to Fig. 2.5.3 below.

WARNING:

The installation of this unit must conform to local codes or, in the absence of

local codes, to all National Codes governing plumbing, sanitation, safety and

good trade practices.

!! ATTENTION INSTALLER !!

All dishwashers are fitted with 6 ft. [1829mm], 5/8" I.D. flexible reinforced drain hoses

located at the rear of the machine.

Make sure drain hose does not kink, resulting in a water flow restriction.

NOTE:

Your plumbing installation must allow the machine to be pulled out for repair.

1. The dishwasher drain hose may be routed to an indirect floor drain (not shown), or

connected directly to a sink drain (see Fig. 2.5.3). The installer must follow all local

plumbing, sanitary, and safety codes where applicable. Local codes may vary from the

recommended connections shown in Fig. 2.5.3 below.

2. Connect the 5/8" I.D. flexible reinforced drain hose supplied to a 1-1/2" wye (Y) drain

fitting. Use a 5/8" hose adapter (supplied by others).

3. Do not reduce the diameter of the drain hose connection

or add additional length to the drain hose.

4. Do not connect the drain hose to a 90° drain fitting.

Do not

use a 90°

fitting

CAUTION:

!

The drain must have a minimum flow capacity

of 15 US gal. per min [54 liters per minute], and

12.5 Imperial gallons per minute.

5. The maximum height of the drain or the drain hose should

not exceed 3 ft. [915mm].

1-1/2"

"Y"

Fitting

cut away

to show rear

1-5/8"

[42mm]

Figure 2.5.3

Recommended Direct Drain Connections

for All Models

cut away

to show rear

1-1/2"

"Y"

Fitting

1-5/8"

[42mm]

Max. Drain

Height

3 ft.

[915mm]

FloorFloor

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

11

Page 24

Part 2: INSTALLATION

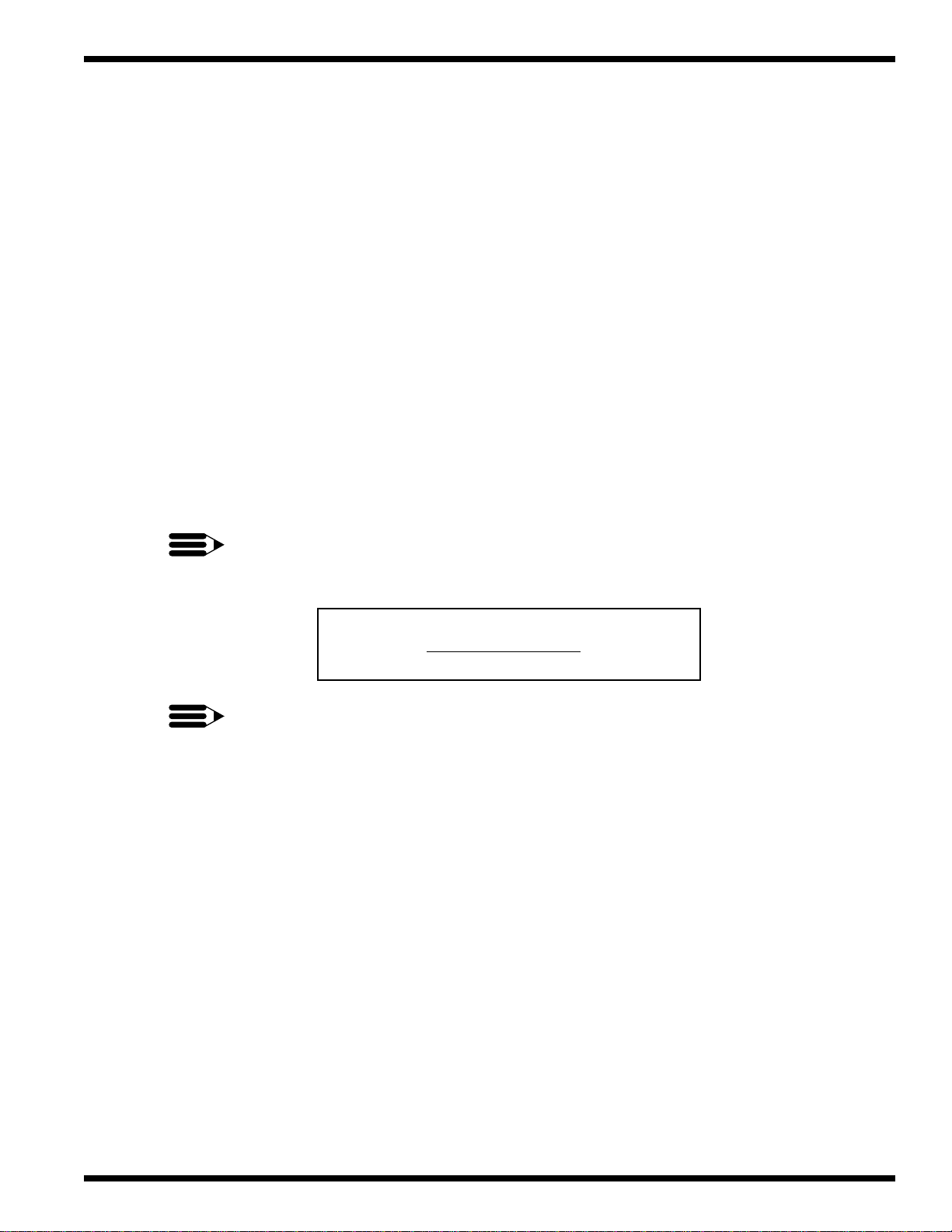

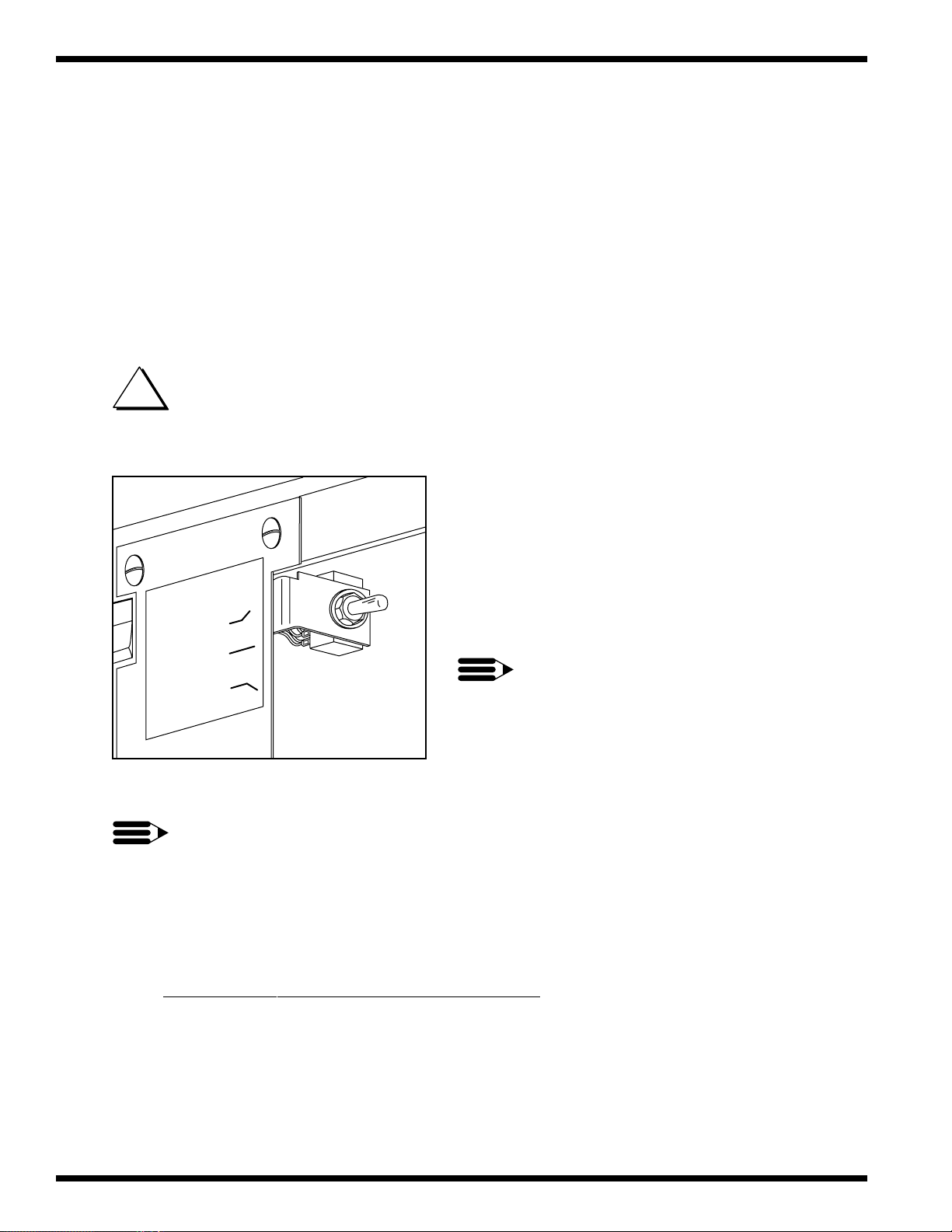

2.6 Installation and Service Switch (Model UH-200B, UH-100B Only)

The following instructions apply to Models UH-200B and UH-100B which are equipped

with a Champion built-in booster.

The Booster Installation and Service Switch is provided to fill the built-in booster tank with

water prior to placing the dishwasher in service for the first time. It can also be used by service

technicians to interrupt 120VAC control power to service the machine.

!! ATTENTION INSTALLER !!

CAUTION:

!

Failure to fill the booster before operating the dishwasher will cause damage to the

booster heater components and will void the machine warranty.

Figure 2.6.1

Installation and Service Switch

Models UH-200B and UH-100B Only

BOOSTER INSTALLATION

AND SERVICE SWITCH

ON

OFF

BOOSTER FILL

NOTE:

Switch is located behind the lower front

panel on the left front of the dishwasher.

NOTE:

Perform the following procedure after all plumbing and electrical connections have been

made. Make sure the interior of the machine is clean and free of debris.

1. Remove screws holding lower front panel. Lift panel up, forward and off.

2. Push and hold the switch in the BOOSTER FILL position until you hear water

entering the wash tank of the machine.

DO NOT FILL THE WASH TANK WITH WATER.

3. Release the switch.

4. Push the switch up to the ON position.

5. Booster fill is complete.

12

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 25

Part 2: INSTALLATION

2.7 Electrical Connections (Single Phase)

2.7.1 Models UH-200B, UH-100B Only

WARNING:

The installation of electrical supplies and controls must conform to local codes or, in the

absence of local codes, the National Electrical Code and good trade practices.

WARNING:

When working on the dishwasher, disconnect the electrical service and place a red tag

at the disconnect switch to indicate work is being done on that circuit.

!! ATTENTION INSTALLER !!

Use flexible conduit to connect incoming power to the dishwasher to allow the machine to be

pulled out 5 ft. [1524mm] for servicing. A service loop is recommended. Service enters at the

right rear corner of the machine. The main connection block is located on the right side of the

dishwasher. See Section 1.4, page 4.

1.

A qualified electrician must compare the electrical power supply with the machine

electrical specifications stamped on the MACHINE ELECTRICAL CONNECTION

PLATE before connecting to the incoming service through a fused disconnect switch or

circuit breaker (supplied by others). The plate is located near the main terminal block.

CAUTION:

!

DO NOT CONNECT models UH-200B or UH-100B to a 120VAC circuit

or to a 208-240VAC (2 wire system) utilizing two power wires plus a ground.

2. Models UH-200B and UH-100B utilize a 208-240VAC (3 wire plus ground system)

consisting of three power wires which includes a current carrying neutral wire.

A fourth wire for machine ground also must be provided.

Refer to the diagram and table below for UH-200B and UH-100B power requirements.

120V

208-240/60/1

208-240V

L1 L2 N

Voltage

Hz

Phase Machine FLA Machine FLA

208/60/1 44.4 50/50 58.9 60/60

120V

40°F/22°C Rise Booster

G

Min. Wire Amp/

Max. Fuse Size

3 Wire Plus Ground System

Diagram

70°F/39°C Rise Booster

Min. Wire Amp/

Max. Fuse Size

220/60/1 46.4 50/50 61.7 70/70

230/60/1 48.1 50/50 64.0 70/70

240/60/1 49.8 50/50 66.4 70/70

Single Phase Power Requirements

Models UH-200B and UH-100B Only

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

13

Page 26

Part 2: INSTALLATION

2.7 Electrical Connections (Single Phase) Cont.

2.7.2 Models UH-200, UH-100, UL-100 Only

WARNING:

The installation of electrical supplies and controls must conform to local codes or, in the

absence of local codes, the National Electrical Code and good trade practices.

WARNING:

When working on the dishwasher, disconnect the electrical service and place a red tag

at the disconnect switch to indicate work is being done on that circuit.

!! ATTENTION INSTALLER !!

Use flexible conduit or cable to connect incoming power to the dishwasher to allow the machine

to be pulled out 5 ft. [1524mm] for servicing. A service loop is recommended. Service enters at

the right rear corner of the machine. The main connection block is located on the right side of the

dishwasher. See Section 1.4, page 4.

1.

A qualified electrician must compare the electrical power supply with the machine

electrical specifications stamped on the MACHINE ELECTRICAL CONNECTION

PLATE before connecting to the incoming service through a fused disconnect switch or

circuit breaker (supplied by others). The plate is located near the main terminal block.

2. Models UH-200, UH-100 and UL-100 utilize a 120VAC power supply.

Power cord and plug are supplied by others.

Voltage Machine

Hz FLA

Phase

120/60/1 23.4 25/25

Voltage Machine

Hz FLA

Phase

120/60/1 19.3 25/25

Voltage Machine

Hz FLA

Phase

120/60/1 12.5 15/15

Min. Wire

Ampacity/

Max. Fuse Size

Min. Wire

Ampacity/

Max. Fuse Size

Min. Wire

Ampacity/

Max. Fuse Size

Single Phase Power Requirements

Models UH-200 Only

Single Phase Power Requirements

Models UH-100 Only

Single Phase Power Requirements

Models UL-100 Only

14

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 27

Part 2: INSTALLATION

2.8 Electrical Connections (Three Phase)

2.8.1 Models UH-200B, UH-100B Only

WARNING:

The installation of electrical supplies and controls must conform to local codes or, in the

absence of local codes, the National Electrical Code and good trade practices.

WARNING:

When working on the dishwasher, disconnect the electrical service and place a red tag

at the disconnect switch to indicate work is being done on that circuit.

!! ATTENTION INSTALLER !!

Use flexible conduit to connect incoming power to the dishwasher to allow the machine to be

pulled out 5 ft. [1524mm] for servicing. A service loop is recommended. Service enters at the

right rear corner of the machine. The main connection block is located on the right side of the

dishwasher. See Section 1.4, page 4.

1.

A qualified electrician must compare the electrical power supply with the machine

electrical specifications stamped on the MACHINE ELECTRICAL CONNECTION

PLATE before connecting to the incoming service through a fused disconnect switch or

circuit breaker (supplied by others). The plate is located near the main terminal block.

2. Models UH-200B and UH-100B utilize a 208-240VAC (4 wire plus ground system)

consisting of four power wires which includes a current carrying neutral wire.

A fifth wire for machine ground also must be provided.

CAUTION:

!

Before connecting power to the machine check that the voltage between the power

wire chosen and the current carrying neutral does not exceed 120VAC ± 15VAC.

Refer to the diagram and table below for UH-200B and UH-100B power requirements.

208-240V

G

120V

208-240V

L1 L2 L3N

208-240V

4 Wire Plus Ground System

208-240/60/3

Diagram

Voltage

Hz

Phase Machine FLA Machine FLA

208/60/3 32.0 35/35 40.3 45/45

220/60/3 33.2 35/35 42.0 45/45

230/60/3 34.3 35/35 43.5 45/45

240/60/3 35.4 40/40 45.0 50/50

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

40°F/22°C Rise Booster

Min. Wire Amp/

Max. Fuse Size

Three Phase Power Requirements

Models UH-200B and UH-100B Only

70°F/39°C Rise Booster

Min. Wire Amp/

Max. Fuse Size

15

Page 28

Part 2: INSTALLATION

2.9 Chemical Connections

2.9.1 General (All Models)

!! ATTENTION DISHWASHER OWNER !!

Your dishwasher is designed to work best with liquid commercial dishwashing chemicals.

Detergents must be a commercial non-foaming liquid. Champion strongly recommends that

you contact a qualified chemical supplier to supply these products and to setup your machine for

the first time.

Your machine was shipped with the chemical dispensing adjustments set at their minimum

settings, because of variations in chemical products. As a result of these variations, Champion

is not able to advise you on the proper dispenser settings for any particular product nor can we

recommend one supplier over another. You may wish to consult your equipment dealer or your

Champion authorized service agent for help in contacting a chemical supplier in your area.

NOTE:

Residential automatic dishwashing detergents and rinse aids found in most grocery

stores are designed to work in machines with cycles of 15 minutes or longer.

Your Champion dishwasher cycle is complete in less than 3 minutes.

Champion does not recommend the use of residential automatic detergents and

rinse aid products. These products may accumulate in your machine and produce

poor washing results.

CAUTION:

!

Never use residential non-automatic dishwashing detergents such as JOY™ or

DAWN™, or any other liquid designed for the handwashing of wares, in your machine.

Extreme foaming inside your Champion dishwasher will cause operation problems.

NOTE:

FOR MODEL UL-100 ONLY

The UL-100 model is a low temperature dishwasher utilizing a chemical sanitizing final

rinse. Use a sodium hypochlorite (Chlorine) based sanitizer at a minimum

concentration of 50 PPM in the final rinse. Use chlorine test papers to verify and

monitor the 50 PPM chlorine level. (Consult local authority in Canada for proper

concentration).

Some metals, including silver, aluminum, and pewter, are attacked by

sodium hypochlorite (chlorine sanitizer). Avoid washing these metals

in a UL-100 model dishwasher.

16

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 29

2.9.1 General (All Models) Cont.

NOTE:

The detergent and rinse aid chemical dispensing pumps are optional equipment on

Models UH-200B, UH-200, UH-100B, and UH-100 dishwashers. The pumps may

have been specified when the dishwasher was ordered and installed at the factory.

The following instructions assume that your dishwasher was delivered to your

installation site with the dispensing pumps installed and explains the procedures for

placing the chemical dispensing system in service for the first time.

If optional pump(s) are not installed, Refer to Section 2.10, Installing Optional

Chemical Pumps, to install the chemical pump(s) before proceeding with

Sections 2.9.2 through 2.9.4.

Three chemical dispensing pumps (detergent, rinse aid, and sanitizer) are standard

on the UL-100 model.

Part 2: INSTALLATION

!! ATTENTION CHEMICAL SUPPLIER !!

WARNING:

The instructions contained in Sections 2.9.2 through 2.9.4 require adjustments to the

Fill/Chemical Dispenser Circuit Board located inside the top mounted slide-out

control cabinet. When working on the dishwasher, disconnect the electrical service and

place a red tag at the disconnect switch to indicate work is being done on that circuit.

NOTE:

Refer to Part 7, Solid State Circuit Board Set-up and Repair, Section 7.3.5, page 66,

Fill/Chemical Dispenser Board, before making any adjustments to the dispenser

board settings.

.

Perform the following steps in preparation for making dispenser pump adjustments.

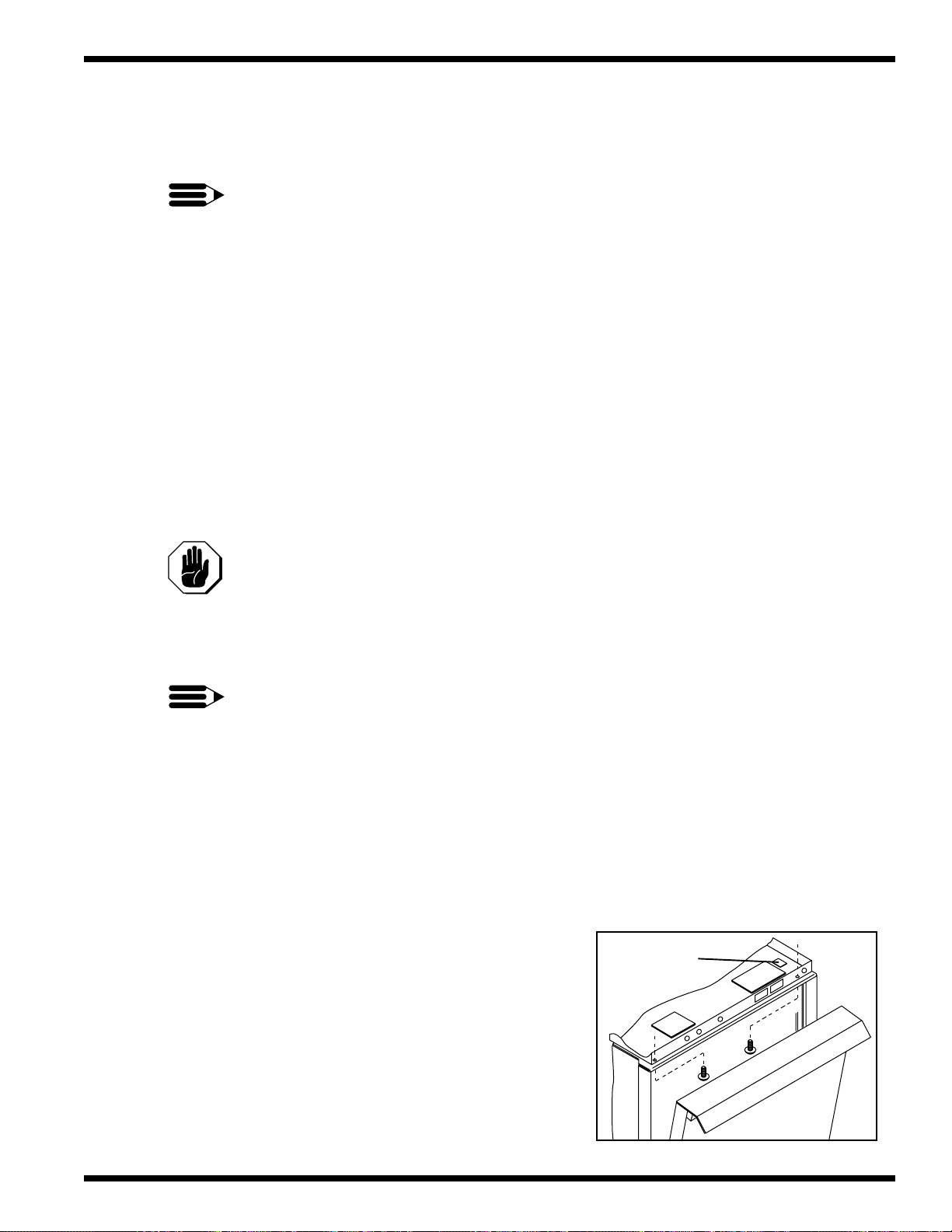

1. Loosen – do not remove – the (2) retaining screws at the bottom of the lower front access

panel. Lift the lower panel up and forward to remove.

2. Check for chemical dispensing pump(s) located at the front of the machine base.

3. Refer to Fig. 2.9.1.

Open the dishwasher door.

4. Locate the two screws, one in each corner

of the top hood, that retain the slide-out

control cabinet.

5. Remove the screws and pull the slide-out

cabinet forward to gain access to the

Fill/Chemical Dispenser Circuit Board.

(continued on next page)

FILL/CHEMICAL

DISPENSER

BOARD

Figure 2.9.1

Control Cabinet

Retaining Screws

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

17

Page 30

Part 2: INSTALLATION

Floor

cut away

to show rear

Route chemical tubing

through rear access

hole above fill and

drain hose access

Max.

6 ft.

[1829mm]

2.9 Chemical Connections (Cont.)

2.9.1 General (All Models) Cont.

!! ATTENTION CHEMICAL SUPPLIER !! (continued from previous page)

6. Refer to Fig. 2.9.2 showing the Fill/Chemical Dispenser Circuit Board.

7. There are (4) adjustable potentiometers.

• Fill- 2 to 40 seconds

• Detergent- 1 to 30 seconds

• Sanitizer- 1 to 30 seconds

• Rinse aid- 1 to 30 seconds

8. Two dots on one end of the potentiometer

serve as the dial pointer.

9. Turn CW to increase time setting.

5

4

3

6

7

28

91

5

6

010

DOTS ON END

POTENTIOMETER

OF

4

7

3

28

91

010

FILL DETERGENT SANITIZER RINSE

5

4

6

4

7

3

3

28

28

91

010

010

5

6

4

7

3

28

91

010

5

6

7

91

AID

NOTE:

The graduated numbers

(0-10) around the potentiometers

Fill/Chemical Dispenser Circuit Board

Figure 2.9.2

DO NOT correspond to time settings.

Use them for position reference only,

not an actual time setting indication.

Refer to Sections 2.9.2 through 2.9.4 for specific adjustments and chemical

priming instructions for your model dishwasher.

10. Refer to Fig. 2.9.3. showing the recommended chemical bottle placement.

Bottles may be placed on either side of the dishwasher.

11. Bottles must be placed no farther than

6 ft. [1829mm] from the machine.

12. I.D. tags identify chemical tubing.

13. Pick-up tubes are inserted directly

in chemical bottles.

I.D.TAG

INSERT PICK-UP

IN BOTTLE

TUBE

18

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Chemical Bottle Placement

Figure 2.9.3

Page 31

Part 2: INSTALLATION

Rinse aid

injection point

Final rinse

manifold

2.9.2 Models UH-200B, UH-200 (Chemical Adjust and Prime)

The following chemical adjustment information applies to UH-200B and UH-200 only.

Refer to Section 2.9.1, page 18, for a description of the dispenser adjust potentiometers.

1. The data below will assist in adjusting the time settings for the dispenser pumps:

• The wash tank holds 3.6 US gal. [13.6 liters] of water.

• Initial fill receives three doses of detergent from the detergent pump.

• Detergent is injected in the wash tank through a fitting at the rear of the wash tank.

• Detergent is injected during the first 1 to 16 seconds of the wash cycle.

• The final rinse utilizes 1.1 US gal [4.2 liters] of water per rack.

• Rinse aid is injected into the final rinse manifold. The manifold is located

in the top left rear corner of the dishwasher.

• Rinse aid is injected during the last 11 seconds of the final rinse cycle.

Dispenser pump output rates:

• Detergent- 69 ml/min.

• Rinse aid- 35 ml/min.

Detergent time adjustment- Turn the POT CW to increase run time from the beginning

of the wash cycle.

Rinse aid time adjustment- The final rinse cycle is 11 seconds. Turning the POT CW

moves the pump start point backward from the end of the rinse cycle.

2. The following describes the operation of the chemical prime button.

Refer to Fig. 2.9.4 below.

• The POWER button must be pushed ON to operate the prime button.

• The PRIME button is enabled whenever the temperature display is active.

• The PRIME button operates both dispensing pumps at the same time.

WASH

Champion

POWER

START

EXTENDED

WASH

Figure 2.9.4

UH-200B, UH-200 Touchpad/Display

RINSE

160 F

TEMPERATURE

PRESSURE

PRIME

To prime the detergent and rinse aid pumps:

3. Insert pick-up tubes in the chemical bottles.

4. Push POWER button ON.

Machine fills. Temperature is displayed.

5. Open dishwasher door and observe detergent

injection point on rear wall of machine.

6. Push and hold PRIME button until detergent is

observed entering the machine.

7. Push and hold the PRIME button and observe

chemical flowing at the rinse aid injection point

located in the final rinse manifold.

8. Priming is complete.

Figure 2.9.5

Rinse aid injection point

Models UH-200B, UH-200

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

19

Page 32

Part 2: INSTALLATION

2.9.3 Models UH-100B, UH-100 (Chemical Adjust and Prime)

The following chemical adjustment information applies to UH-100B and UH-100 only.

Refer to Section 2.9.1, page 18, for a description of the dispenser adjust potentiometers.

1. The data below will assist in adjusting the time settings for the dispenser pumps:

• The wash tank holds 1.8 US gal. [6.8 liters] of water.

• Proper fill water level is even with the bottom of the round scrap screen.

• Detergent and rinse aid enter the wash tank through the fill chute on the left side of the

machine.

• Detergent is injected during the first 1 to 16 seconds of the wash cycle.

• The final rinse utilizes 1.8 US gal [6.8 liters] of water per rack.

• Rinse aid is injected as the fill/rinse valve adds water during the final rinse.

Dispenser pump output rates:

• Detergent- 69 ml/min.

• Rinse aid- 69 ml/min.

Detergent time adjustment- Turn the POT CW to increase run time from the beginning

of the wash cycle.

Rinse aid time adjustment- The final rinse cycle is 15 seconds. Turning the POT CW

moves the pump start point backward from the time the fill valve closes for the final rinse.

2. The following describes the operation of the chemical prime buttons.

Refer to Fig. 2.9.6 below.

• The POWER button must be pushed ON to operate the prime button.

• The PRIME button is enabled whenever the temperature display is active.

• The PRIME button operates both dispensing pumps at the same time.

Champion

POWER START

EXTENDED

WASH

Figure 2.9.6

UH-100B, UH-100 Touchpad/Display

160 F

TEMPERATURE

To prime the detergent and rinse aid pumps:

3. Insert pick-up tubes in the chemical bottles.

4. Push POWER button ON.

Machine fills. Temperature is displayed.

5. Open dishwasher door and observe

fill chute on left inside of machine.

6. Push and hold PRIME button until detergent and rinse aid

are observed entering the interior of the machine.

Rinse aid is usually blue in color, hold PRIME button

until the colored liquid is detected.

7. Priming is complete.

PRIME

Figure 2.9.7

Fill Chute

Models UH-100B, UH-100, UL-100

20

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 33

Part 2: INSTALLATION

2.9.4 Models UL-100 (Chemical Adjust and Prime)

The following chemical adjustment information applies to UL-100 only.

Refer to Section 2.9.1, page 18, for a description of the dispenser adjust potentiometers.

1. The data below will assist in adjusting the time settings for the dispenser pumps:

• The wash tank holds 2.5 US gal. [10 liters] of water.

• Proper fill water level is even with the top of the handle on the round scrap screen.

• Detergent, rinse aid and sanitizer enter the wash tank through the fill chute on the left

side of the machine.

• Detergent is injected during the first 1 to 18 seconds of the wash cycle.

• The final rinse utilizes 2.3 US gal [8.7 liters] of water per rack.

• Rinse aid is injected as the fill/rinse valve adds water during the final rinse.

Dispenser pump output rates:

• Detergent- 69 ml/min. • Sanitizer- 69 ml/min

• Rinse aid- 69 ml/min.

Detergent time adjustment- Turn the POT CW to increase run time from the beginning

of the wash cycle.

Rinse aid time adjustment- The final rinse cycle is 15 seconds. Turning the POT CW

moves the pump start point backward from the time the fill valve closes for the final rinse.

2. The following describes the operation of the chemical prime buttons.

Refer to Fig. 2.9.8 below.

• The POWER button must be pushed ON to operate the prime buttons.

• The PRIME buttons are enabled whenever the temperature display is active.

• The PRIME buttons operate their respective dispenser pumps independently.

Champion

POWER START

EXTENDED

WASH

Figure 2.9.8

UL-100 Touchpad/Display

To prime the dispensing pumps:

3. Insert pick-up tubes in their respective chemical

bottles.

4. Push POWER button ON.

Machine fills. Temperature is displayed.

5. Open dishwasher door and observe

fill chute on left inside of machine.

6. Push and hold each PRIME button in succession

• Detergent

• Rinse aid

• Sanitizer

7. Observe that each chemical enters the machine.

8. Priming is complete.

140 F

TEMPERATURE

PRIME

DETERGENT SANITIZER

RINSE AID

4-2

Figure 2.9.9

Fill Chute Discharge

Models UH-100B, UH-100, UL-100

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

21

Page 34

Part 2: INSTALLATION

2.10 Installing Optional Chemical Pumps

Perform the following steps to install the optional detergent and rinse aid pumps for

the models in Sections 2.10.1 and 2.10.2

WARNING:

When working on the dishwasher, disconnect the electric service and place a red tag at

the disconnect switch to indicate work is being done on that circuit.

2.10.1 Models UH-200B, UH-200

Refer to Fig. 2.10.1 at right.

The illustration shows the typical

installation of the detergent and

rinse aid pumps. Pump kits contain

the necessary parts for field installation

and are available from your authorized

Champion parts supplier.

Signal connection

points: 2A Max @

120VAC

• The detergent pump is a peristaltic

pump enclosed in a black housing.

• The rinse aid pump is a peristaltic

pump enclosed in a black housing..

Route tubing

UH-200B, UH-200 Chemical Pumps

Figure 2.10.1

Rinse aid

To install the detergent pump:

1. Remove the lower front access panel.

2. Mount the pump on the machine base with two screws.

3. Route the detergent tubing out the rear of the machine through the access hole located

above and between the fill and drain hoses.

4. Pump rotation is clockwise. The supply tube connects on the left side of the pump

the discharge tubing connects on the right side of the pump.

5. Remove the 1/8" plug at the rear of the machine and replace with the 90° detergent fitting.

Apply teflon tape to the fitting threads to ensure a watertight seal.

Detergent

4-16

4-9

(continued of next page)

22

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 35

Part 2: INSTALLATION

2.10.1 Models UH-200B, UH-200

(continued from previous page)

To install the detergent pump (continued):

6. Connect the detergent tubing from the outlet of the pump to the 90° fitting

7. Connect the pump motor wires to the harness wires supplied in the installation kit.

8. Refer to Fig. 2.10.2 below.

Connect the wiring harness to the 10 pin terminal block located on the lower right side of

the machine. Connect the #2 harness wire to the Common (#2) terminal on the block.

Connect the #24 wire to the Detergent #24 terminal on the block.

9. Refer to Section 2.9.2, page 19, for pump priming and adjustment procedures.

10. Check all connections for leaks.

11. Installation is complete.

4-10 H04

Common

Hot

PUMP

MOTOR

Harness #2

Harness # x

# x =

Detergent #24

Rinse aid #25

Sanitizer #26

To

Terminal

Block

!!ATTENTION INSTALLER!!

If you are installing pumps not

supplied by Champion then the

chemical connection points are

limited to 2 AMP maximum.

2 AMP maximum amp load per pump;

6 AMP total amp load.

4

66

54 54

24

25

26

2

2

4

24

25

26

2

22

2

24

25

26

2

2

2

DET

R/A

SANI

COM

COM

COM

Figure 2.10.2

Chemical Pump Connection Terminal Block

(Lower right side of machine base)

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

23

Page 36

Part 2: INSTALLATION

2.10 Installing Optional Chemical Pumps (Cont.)

2.10.1 Models UH-200B, UH-200

To install the rinse aid pump:

1. Remove the lower front access panel.

2. Mount the pump on the machine base with two screws.

3. Route the rinse aid tubing out the rear of the machine through the access hole located

above and between the fill and drain hoses.

4. Pump rotation is clockwise. The supply tube connects on the left side of the pump;

the discharge tubing connects on the right side of the pump.

5. Remove the 1/8" plug located in the final rinse manifold.

6. Install the rinse aid check valve. Apply teflon tape to the valve threads to ensure a seal.

7. Route the rinse aid tubing to the rinse manifold and connect to the check valve.

8. Connect the pump motor wires to the harness wires supplied in the kit with wire nuts.

9. Refer to Fig. 2.10.2 on page 23.

Connect the wiring harness to the 10 pin terminal block located on the lower right side of

the machine. Connect the #2 harness wire to the Common (#2) terminal on the block.

Connect the #25 wire to the rinse aid #25 terminal on the block.

10. Refer to Section 2.9.2, page 19, for pump priming and adjustment procedures.

11. Check all connections for leaks.

12. Installation is complete.

4-16

4-5 4-6

24

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4-4

Page 37

Part 2: INSTALLATION

2.10.2 Models UH-100B, UH-100

Chemical discharge tubes were installed at the factory and stowed in the base of the machine.

Installation of the optional detergent pump and/or the rinse aid pump requires mounting

the pump, connecting all tubing to the pump(s) and making the electrical connections.

WARNING:

When working on the dishwasher, disconnect the electric service and place a red tag at

the disconnect switch to indicate work is being done on that circuit.

Refer to Fig. 2.10.3 at right.

The illustration shows the typical

installation of the detergent and

rinse aid pumps. Pump kits contain

the necessary parts for field installation

and are available from your authorized

Champion parts supplier.

Signal connection

points: 2A Max @

120VAC

• The detergent pump is a peristaltic

pump enclosed in a black housing.

Route tubing

• The rinse aid pump is a peristaltic

pump enclosed in a black housing.

UH-100B, UH-100 Chemical Pumps

To install the detergent pump:

1. Remove the lower front access panel.

2. Mount the pump on the machine base with two screws.