Page 1

TM

OWNER’S MANUAL MODEL CB24

BEDIENUNGSANLEITUNG MODELL CB24

Serial # Arm 1

Seriennummer Arm 1

Serial # Arm 2

Seriennummer Arm 2

Serial # Box

Seriennummer Box

Installation Date

Installationsdatum

Konformitätserklärung

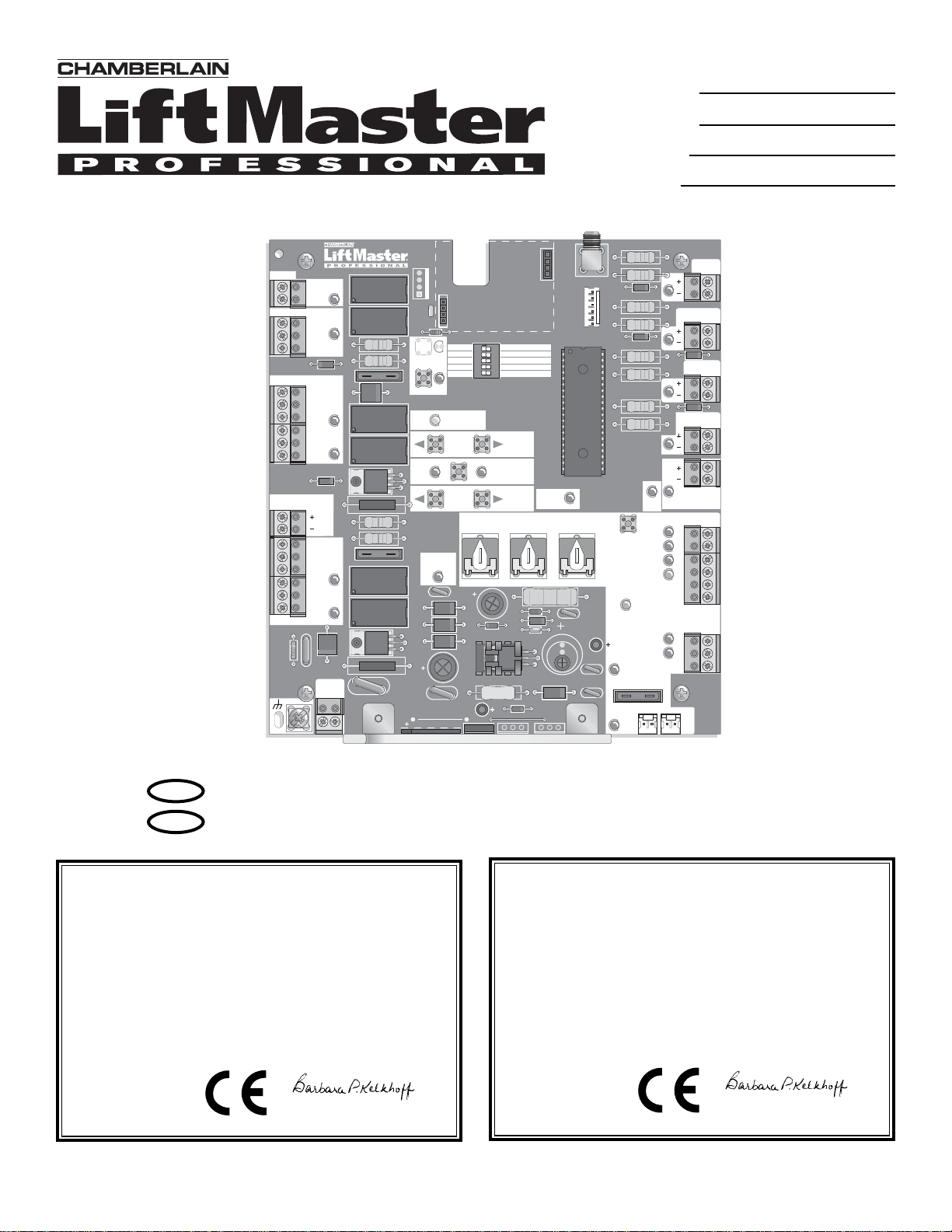

Electronic Control Model CB24

erfüllt die Anforderungen der geltenden

Abschitte der Normenvorschriften EN300220-3 • EN55014 • EN61000-3 • EN60555,

EN60335-1 • ETS 300 683 • EN60335-1: 2002 • EN60335-2-103: 2003 • EN55014-1:

2000 + A1 + A2 • EN55014-2: 2001 • EN61000-3-2: 2000 • EN61000-3-3: 1995 + A1 • EN

301 489-3, V1.3.1 • EN 300 220-3 V1.1.1 • EN 13241-1

sowie die Bestimmungen und sämtliche Ergänzungen

der EU-Vorschriften ..................................................73/23/EEC, 89/336EEC, 1999/5/EG

Einschlußerklärung

Die Steuerung, erfüllt die Bestimmungen der EU-Vorschrift 89/393/EEC und ihre

Ergänzungen, wenn sie gemäß den Anleitungen des Herstellers installiert und gewartet

wird und wenn sie mit einem Tor verwendet wird, das ebenfalls gemäß

Herstelleranleitungen installiert wurde und gewartet wird.

Die Unterzeichnende erklärt hiermit, dass das vorstehend

angegebenne Gerät sowie sämtliches im Handbuch aufgeführtes

Zubehör den oben genannten Vorschriften und Normen entspricht.

The Chamberlain Group, Inc

Elmhurst, IL 60126, USA

May, 2005

B. P. Kelkhoff

Manager, Test and Regulatory

Declaration of Conformity

Electronic Control Model CB24

are in conformity to the applicable

sections of StandardsEN300220-3 • EN55014 • EN61000-3 • EN60555, EN60335-1 • ETS

300 683 • EN60335-1: 2002 • EN60335-2-103: 2003 • EN55014-1: 2000 + A1 + A2 •

EN55014-2: 2001 • EN61000-3-2: 2000 • EN61000-3-3: 1995 + A1 • EN 301 489-3,

V1.3.1 • EN 300 220-3 V1.1.1 • EN 13241-1

per the provisions & all amendments

of the EU Directives ..................................................73/23/EEC, 89/336EEC, 1999/5/EG

Declaration of Incorporation

Electronic Control, when installed and maintained according to all the Manufacturer’s

instructions in combination with a Gate, which has also been installed and maintained

according to all the Manufacturer’s instructions, meets the provisions of EU Directive

89/392/EEC and all amendments.

I, the undersigned, hereby declare that the equipment

specified above and any accessory listed in the manual

conforms to the above Directives and Standards.

The Chamberlain Group, Inc

Elmhurst, IL 60126, USA

May, 2005

B. P. Kelkhoff

Manager, Test and Regulatory

Chamberlain GmbH • Alfred-Nobel-Str. 4 • D-66793 Saarwellingen

GB

D

TM

ALARM

MAGLOCK

GATE 1

ACCESSORY

POWER

GATE 2

J4

P2

D6

TIMER

RUNNING

D1

D4

D2

P1

TIMER TO

CLOSE

F7

C13

J18

U4

F6

F2

J19

K6

NO

C

NO

C

NC

Z1

10A 32V

BRN

GRN

WHT

YEL

BLU

RED

Z12

R9

24V

BRN

GRN

WHT

YEL

BLU

RED

D15

R196

C2R4

24 VAC/

SOLAR

INPUT

F3

D1

Ø

K1

Ø

10A 32V

MOV2

J1

K5

L1

S8

1

R2

LEARN

SINGLE

XMITTER

R1

2

K2

DIAGNOSTIC

SET

Q9

OPEN

LIMIT

Ø

1

R1

R1

ØØ

F4

ACCESSORY

OVLD

K4

F5

D21

K3

D8

D22

Q22

C11

MOV1

JMPR2

DB1

Ø

14GPØ89ØE

Ø

14LGØ89ØE

Ø

14SKØ89ØE

O

N

1 2 3 4 5

OFF

ON

OFF

NO

NO

FORCE

MIN MAX OFF MAX OFF MAX

C12

C64

SAVE

ON

MAGLOCK

DUAL

MODE

NC

EDGE

PHOTO

NC

S1

GATE 1

SET

LEARN

CLOSE

LIMITS

LIMIT

GATE 2

BIPART

DELAY

R35

D9

D27

Z3

Z4

U3

R9

JMPR1

U2

BUTTON

C4

SINGLE

Ø

7

R2

R224

SINGLE BUTTON

CHGR

OVLD

F1 2

FUSE

OPEN

Z2

Ø

R227

0

A 32V

R223

Z22

R92

R91

R94

R93

COM

OVLD

OPEN

RESET

STOP

POWER

SHADOW

INTERRUPT

24V

OVLD

BATT 1BATT 2

COM

COM

COM

CLOSE

EDGE

OPEN EDGE/

PHOTO

OPEN

PHOTO

CLOSE

PHOTO

SWITCHED

ACCESSORY

POWER

CONTROL

INPUTS

LOOP

INPUTS

Z9

Z8

Page 2

SPECIFICATIONS

Carton Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Control Board Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

WARNINGS

Safety Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Warnings and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Suggested Entrapment Protection Device Locations . . . . . . . . . .4

WIRING

Control Box Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Earth Ground Rod Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring Of Motor To Control Board . . . . . . . . . . . . . . . . . . . . . . . .9

BASIC CONTROL BOARD SETUP

Set Dip Switch for Gate Type . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Install Radio Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Programming Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Wire Stop Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Optional Control Devices . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

Force and Timer to Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Program Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

OPERATION and MAINTENANCE

First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

WIRING DIAGRAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

REPAIR PARTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your gate and/or the gate

operator if you do not comply with the cautionary statements that

accompany it. Read them carefully.

Mechanical

Electrical

TABLE OF CONTENTS

• BEFORE attempting to install, operate or maintain the operator,

you must read and fully understand this manual and follow all

safety instructions.

• These instructions are intended to highlight certain safety

related issues. These instructions are not intended to be

comprehensive. Because each application is unique, it is the

responsibility of the purchaser, designer, installer and end user

to ensure that the total gate system is safe for its intended use.

•

Save These Instructions

IMPORTANT NOTE

01-G0665F18

SAFETY PRECAUTIONS FOR SWING and ORNAME NTAL “GRILL TYPE GATES”

To pr ev ent SERIOUS INJU RY or DEAT H from a moving gate:

• Entrapment protection devices MUST be installed to protect

anyone who may come near a moving gate.

• Locate entrapment protection devices to protect in BOTH the open

and close gate cycles.

• Locate entrapment protection devices to protect between moving

gate and RIGID objects, such as posts.

• A swinging gate shall NOT open into public access ways

INSTALLATION

We recommend to use E-locks/Maglock against vandilism and if gate

is installed where strong winds may appear.

2

Page 3

LY N3 00 -2 4 W in g G at e O pe ra t or 2 4V ol t/ 2 50 kg /2 .5 m

LY N4 00 -2 4 W in g G at e O pe ra t or 2 4V ol t/ 2 50 kg /4 .0 m

SCS300-24 Wing Gate Operator 24Volt/250kg/3.0m

LA400-JB40 Extensioncable Kit 12m (page 6)

600206-24 Solar Panel 24 Volt

041ASWG-0479 Post bracket for round posts/piece

50-19503 Post bracket for gates opening to outside

(push to open)/piece

Battery Charger Supply . . . . . . . . . . . . . . . . . . . . . . . . .26Vac, 29VA

Solar Panel Supply (Optional) . . . . . . . . . . . . .27.4V, 9W (Minimum)

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-20

o

C to + 55oC

Battery 12V/7AH . . . . . . . . . . . . . . . . . . . . . . . . . . . .-15

o

C to + 55oC

Electronic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IP44

Main Supply (Control) Dedicated

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230V~240V/50~60Hz

Absorbed Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.75 Watts

Protection Fuse Gate 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATC 10A

Protection Fuse Gate 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATC 10A

Protection Fuse Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATC 20A

CARTON INVENTORY

3

CB24K KIT

1x PVC – Box

1x CB24-Logic Board (pre-mount)

1x Charge transformer (pre-mount)

2x 12Volt Batteries & wires (pre-mount)

1x 771E IR-sensor

CB24R KIT

1x PVC – Box

1x CB24-Logic Board (pre-mount)

1x Run transformer (pre-mount)

1x IR-sensor (771E)

CAK-1 COMMON ACCESSORY KIT

1x RF module 433.92MHz

2x Transmitter 3-channel 94335E

1x Key switch

1x Flashing Light (FLA24-2)

1x Antenna

INVENTORY & SPECIFICATIONS

SAFETY INSTALLATION INFORMATION

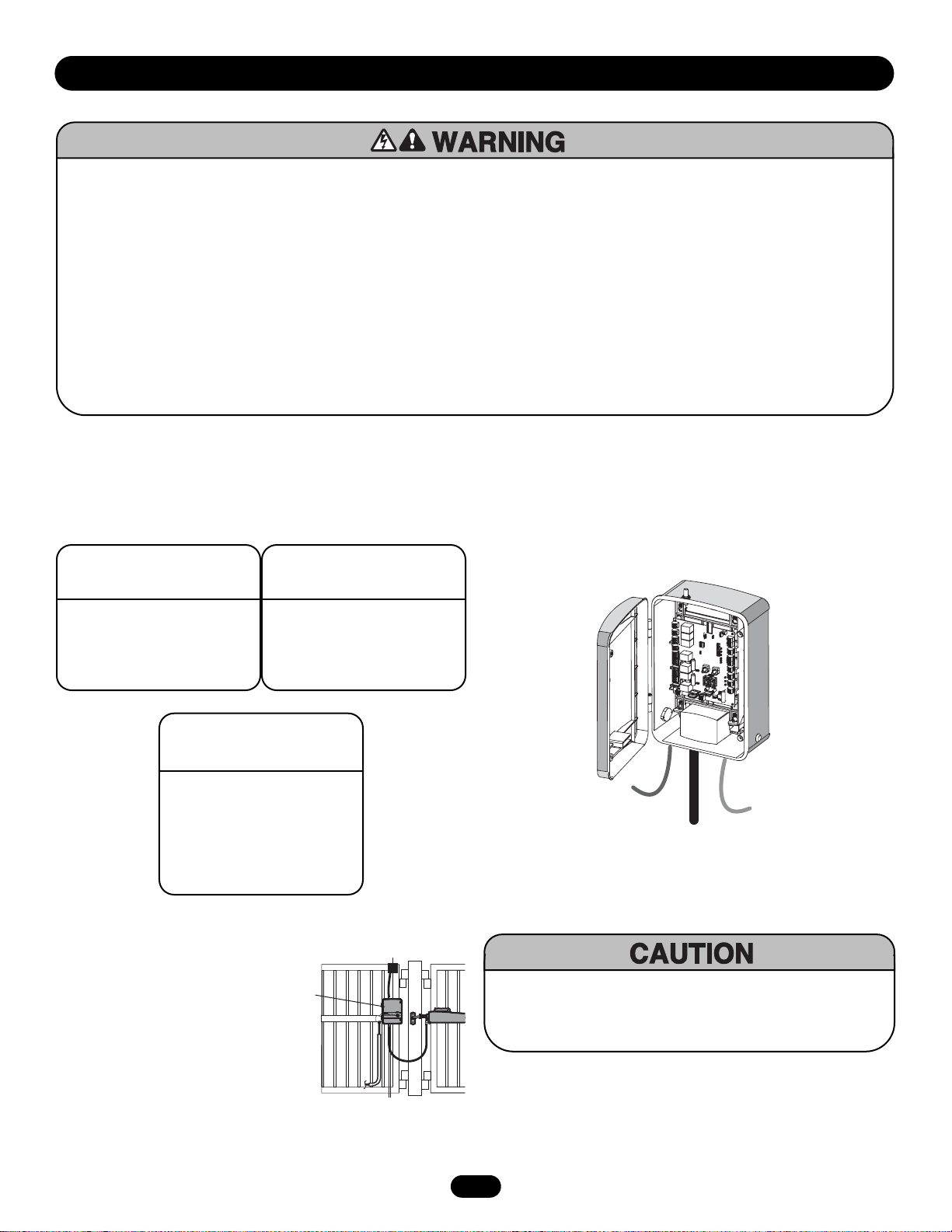

Warning - To reduce the risk of SEVERE INJURY or DEATH from an incorrect installation:

1. Vehicular gate systems provide convenience and security. Gate systems are comprised of many component parts. The gate operator is only one

component. Each gate system is specifically designed for an individual application.

2. Gate operating system designers, installers and users must take into account the possible hazards associated with each individual application.

Improperly designed, installed or maintained systems can create risks for the user as well as the bystander. Gate systems design and installation

must reduce public exposure to potential hazards.

3. A gate operator can create high levels of force in its function as a component part of a gate system. Therefore, safety features must be

incorporated into every design. Specific safety features include:

• Gate Edges • Guards for exposed rollers • Photoelectric Sensors

• Screen Mesh • Vertical Posts • Instructional and Precautionary Signage

4. Install the gate operator only when:

a. The operator is appropriate for the construction and the usage class of the gate.

b. All openings of a horizontal swing gate are guarded or screened from the bottom of the gate to a minimum of

4' (1.2 m) above the ground to prevent a 2 1/4" (6 cm) diameter sphere from passing through the openings anywhere in the gate, and in that

portion of the adjacent fence that the gate covers in the open position.

c. All exposed pinch points are eliminated or guarded, and guarding is supplied for exposed rollers.

5. The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access opening.

6. The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when opening and closing

to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

7. The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

8. Controls must be far enough from the gate so that the user is prevented from coming in contact with the gate while operating the controls.

9. Controls intended to be used to reset an operator after 2 sequential activations of the entrapment protection device or devices must be located in

the line of sight of the gate, or easily accessible controls shall have a security feature to prevent unauthorized use.

10. All warning signs must be installed where visible, on each side of the gate.

11. For a gate operator utilizing a non-contact sensor:

a. Reference owner’s manual regarding placement of non-contact sensor for each type of application.

b. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the sensor while the gate is still moving.

c. One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter reachable by a

moving gate or barrier.

12. For a gate operator utilizing a contact sensor such as an edge sensor:

a. A hard wired contact sensor shall be located and its wiring arranged so the communication between the sensor and the gate operator is not

subject to mechanical damage.

b. A wireless contact sensor such as the one that transmits radio frequency (RF) signals to the gate operator for entrapment protection functions

shall be located where the transmission of the signals are not obstructed or impeded by building structures, natural landscaping or similar

obstruction. A wireless contact sensor shall function under the intended end-use conditions.

c. One or more contact sensors shall be located at the leading edge, trailing edge and post mounted both inside and outside of a vehicular

horizontal slide gate.

d. One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

e. One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the bottom edge of a

swing gate is greater than 6" (15 cm) above the ground at any point in its arc of travel, one or more contact sensors shall be located on the

bottom edge.

Page 4

4

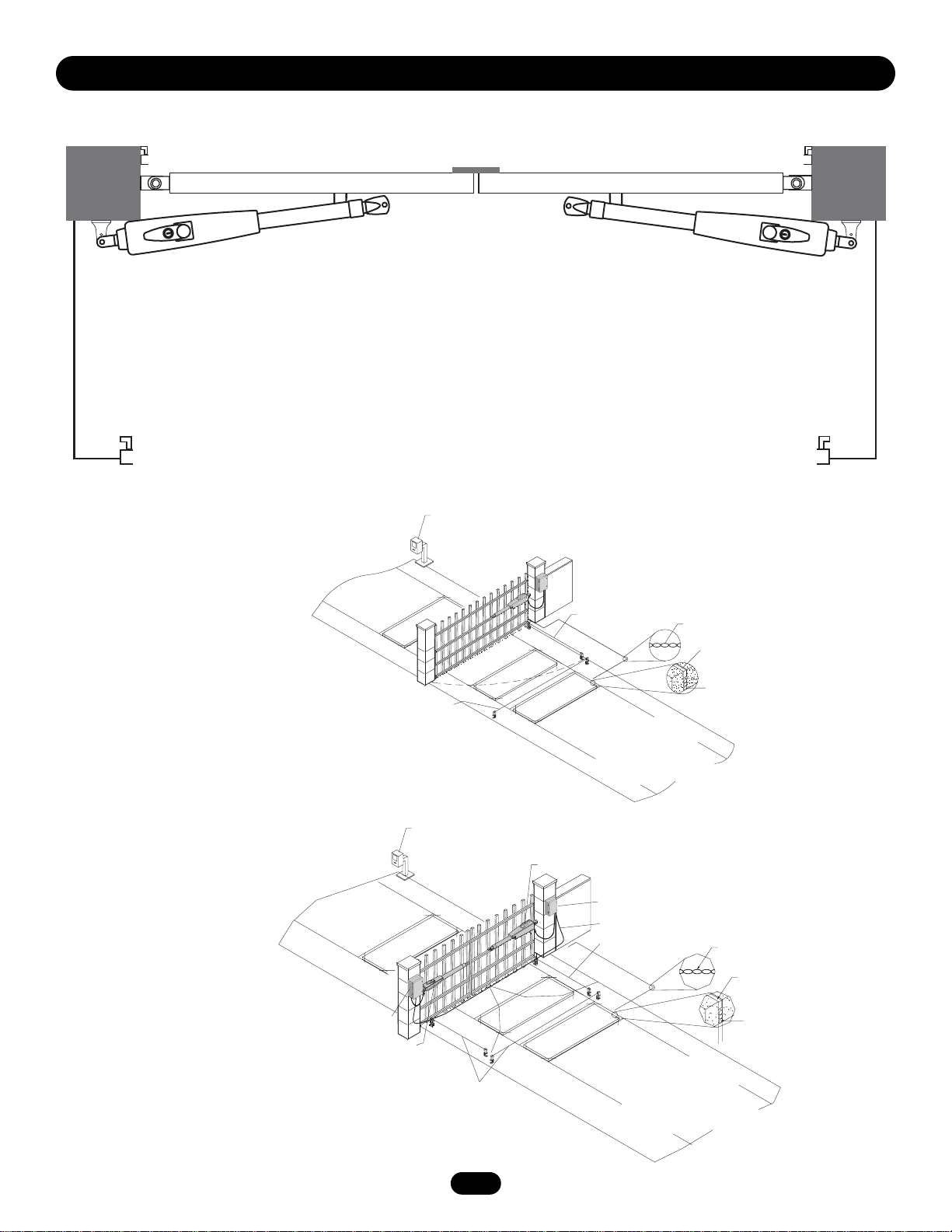

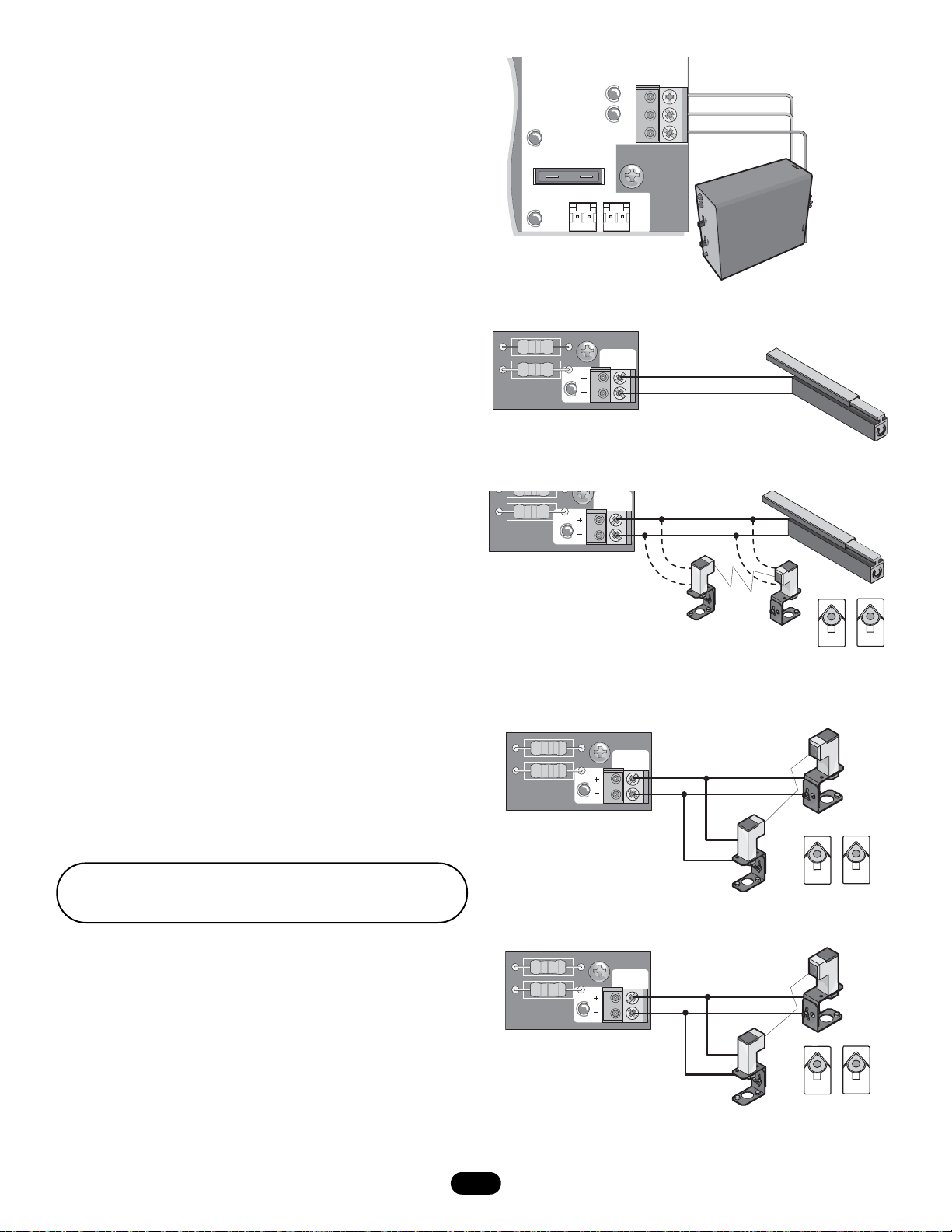

SUGGESTED ENTRAPMENT PROTECTION DEVICE LOCATIONS

SINGLE SWING GATE SYSTEM

DUAL SWING GATE SYSTEM

MAIN PROTECTION, WITH 2 PAIR OF PHOTOCELLS

Other options:

Complex or Parking Lot

1. Telephone Entry System

2. Photo Eye for Open Cycle

3. Run Twisted Wire* from Loop

to Operator

4. Seal Loops*

5. Loop Copper Wire

6. Interrup Loop

7. Shadow Loop

Complex or Parking Lot

1. Telephone Entry System

2. Gate 2

3. Junction Box

4. Extension Cable

5. Photo Eye for Open Cycle

6. Run Twisted Wire* from Loop

to Operator

7. Seal Loops

8. Loop Copper Wire

9. Interrupt Loop

10. Shadow Loop

11. Control Box

12. Gate 1

INSTALL ALL EQUIPMENT IN COMPLIANCE WITH EN60335-2-103, EN13241-1.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Primary Photocell For Closing

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Photocell For Opening

1

6

1

9

11

12

2

7

2

5

6

2

3

4

5

10

9

3

4

5

6

7

8

Page 5

5

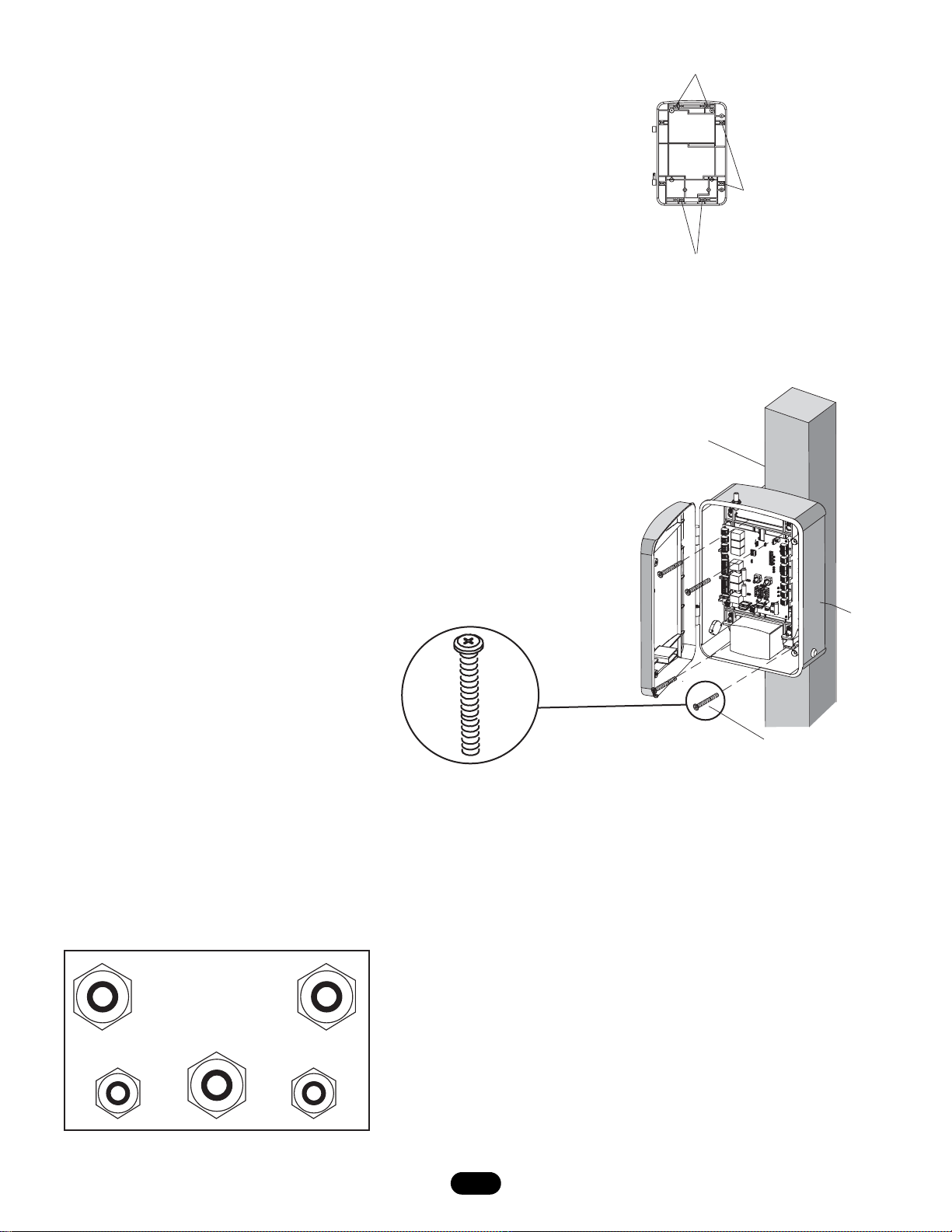

CONTROL BOX MOUNTING

1. Determine the spacing required for mounting and select the

proper holes to be used for mounting (Figure 1).

2. Knockout plastic from holes using screw driver.

Insert the strain reliefs (Figure 3).

3. Place box up against the mounting surface. Insert the screws

through the mounting holes in back and secure in place

(Figure 2).

STRAIN RELIEF

(1) Screw Spacing 101.6mm (4”)

(2) Screw Spacing 152.4mm (6”)

(3) Screw Spacing 63.5mm (2-1/2”)

(1) Mounting Post

(2) E-Box

(3) Mounting Screws (4 pieces)

1

Figure1

2

3

1

Figure 2

Figure 3

2

3

Page 6

230Vac POWER WIRE

(STRANDED COPPER WIRE)

NOTE: Calculated using NEC guidelines. Local codes and conditions must be reviewed for suitability of wire installation.

To r educe the r isk of SEVER E INJURY or DE ATH:

• ANY maintenance to the operator or in the area near the

operator MUST not be performed until disconnecting the

electrical power and locking-out the power via the operator

power switch. Upon completion of maintenance the area MUST

be cleared and secured, at that time the unit may be returned

to service.

• Disconnecting power at the fuse box BEFORE proceeding.

Operator MUST be properly grounded and connected in

accordance with local electrical codes.

NOTE: The operator

should be on a separate fused line of adequate capacity.

• ALL electrical connections MUST be made by a qualified

individual.

• DO NOT install any wiring or attempt to run the operator

without consulting the wiring diagram. We recommend that

you Install an optional reversing edge BEFORE proceeding with

the control station installation.

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

• BEFORE installing power wiring or control stations be sure to

follow all specifications and warnings described below. Failure

to do so may result in SEVERE INJURY to persons and/or

damage to operator.

Wire Gauge

0.75/1.5mm

2

1.5mm

2

Length

50m

100m

WIRING

6

EARTH GROUND ROD INSTALLATION

Attach ground wire to control

box.

System must be grounded. In case no ground wire is available

a ground rod must be installed. Follow the local applicable

standards of EN or IEC.

1

All power wiring should be on a dedicated circuit and well protected.

24Vac TRANSFORMER

(STRANDED COPPER WIRE)

Wire Gauge

0.75/1.5mm

2

1.5mm

2

Length

50m

100m

LA400-JB40 MOTOR

EXTENSION CABLE KIT

(OPTIONAL)

Kit Contains:

(1) 12m cable with terminals

(1) Junction box IP65

(2) Strain reliefs PG 13,5

(1) Mounting hardware

(1) Control Box

1

3

2

Page 7

7

MOV2

24 VAC/

SOLAR

INPUT

J4

BATT 2

BATT 1

BATTERY WITH CHARGE TRANSFORMER

The main source of power are the batteries. The batteries

can be charged in circuit by using a charging transformer

or solar panels.

CONTROL WIRING

POWER IN

The 24Vac input can accept a charging transformer or the run

transformer. Ideally the charge transformer is installed at the

house and a low voltage line is used to the control board at the

gate.

The run transformer is installed in the control box.

SOLAR PANELS

Optional solar panels may be used to charge the batteries. Solar

Panels must be a minimum of 27.4V, 9W output.

To r educe the r isk of FIRE or I NJURY to perso ns use only

Chamberlain parts for replacement batteries.

BATTERY WITH RUN TRANSFORMER

The main source of power is the transformer.

The batteries may or may not be used. Batteries

if installed function as back-up to open the gate

in case of a power outage.

Transfor mer must be re moved fr om the backside of the control board if batteries are installed.

GROUND

ALARM

MAGLOCK

GATE 1

ACCESSORY

POWER

GATE 2

J4

GREEN/YELLOW

J19

NO

C

NO

C

NC

Z1

BRN

GRN

WHT

YEL

BLU

RED

BRN

GRN

WHT

YEL

BLU

RED

C2R4

K6

10A 32V

Ø

D1

Z12

R9

Ø

24V

10A 32V

D15

R196

24 VAC/

SOLAR

INPUT

MOV2

J1

K5

L1

S8

1

OFF

R2

OFF

LEARN

SINGLE

XMITTER

R1

NO

NO

2

F3

K2

DIAGNOSTIC

SET

K1

Q9

OPEN

LIMIT

Ø

1

ØØ

F4

ACCESSORY

OVLD

K4

MIN MAX OFF MAX OFF MAX

F5

D21

K3

D8

D22

Q22

C11

MOV1

C64

JMPR2

DB1

FORCE

C12

U2

R1

R1

P2

Ø

14GPØ89ØE

Ø

14LGØ89ØE

Ø

14SKØ89ØE

O

N

1 2 3 4 5

ON

SAVE

ON

MAGLOCK

DUAL

MODE

NC

EDGE

NC

PHOTO

S1

GATE 1

SET

LEARN

CLOSE

LIMITS

LIMIT

TIMER

GATE 2

RUNNING

BIPART

TIMER TO

DELAY

CLOSE

R35

D9

D27

Z3

F7

Z4

U3

D4

R9

D1

JMPR1

D2

D6

R223

P1

Ø

7

R2

Z2

R227

J18

R224

U4

SINGLE

BUTTON

SINGLE BUTTON

C13

C4

CHGR

OVLD

F6

F2

Ø

F1 2

FUSE

OPEN

Ø

Z22

R92

R91

R94

R93

POWER

SHADOW

INTERRUPT

A 32V

CLOSE

EDGE

OPEN EDGE/

PHOTO

Z9

OPEN

PHOTO

Z8

CLOSE

PHOTO

24V

SWITCHED

ACCESSORY

COM

OVLD

POWER

OVLD

CONTROL

INPUTS

OPEN

RESET

STOP

COM

COM

LOOP

INPUTS

COM

BATT 1BATT 2

(Optional)

150VA

TORROID

TRANSFORMER

USE DEDICATED CIRCUIT

OR

Page 8

8

Z22

R91

CLOSE

EDGE

R94

R92

R93

L1

R1

R2

Z1

K5

Ø

14GPØ89ØE

Ø

14LGØ89ØE

Ø

14SKØ89ØE

K6

K2

F3

10A 32V

D1

Ø

OPEN EDGE/

PHOTO

OPEN

PHOTO

CLOSE

PHOT

O

J18

R227

R2

Ø

7

Z2

Ø

R223

P1

Z9

Z8

F2

F6

D4

D2

R9

C64

JMPR1

R224

U4

P2

J1

J19

SINGLE

BUTTON

CONTROL

INPUTS

FORCE

BIPART

DELAY

TIMER TO

CLOSE

MIN MAX OFF MAX OFF MAX

OPEN

SINGLE BUTTON

RESET

STOP

SHADOW

S1

INTERRUPT

CHGR

OVLD

COM

COM

COM

FUSE

OPEN

LOOP

INPUTS

POWER

BATT 1BATT 2

F1 2

0

A 32V

R35

D9

Z3

Z4

U3

D1

D27

F5

C11

C13

C12

D15

C2R4

R1

Ø

1

R1

ØØ

R9

Ø

Q9

K1

R196

Q22

D8

K3

K4

D21

D22

C4

ACCESSORY

OVLD

D6

JMPR2

MOV1

MOV2

DB1

U2

Z12

24 VAC/

SOLAR

INPUT

GATE 2

ACCESSORY

POWER

MAGLOCK

ALARM

GATE 1

C

C

NC

NO

NO

GRN

WHT

YEL

BLU

RED

BRN

GRN

WHT

YEL

BLU

RED

BRN

F4

10A 32V

F7

24V

24V

COM

OVLD

OVLD

SWITCHED

ACCESSORY

POWER

TIMER

RUNNING

GATE 2

SET

OPEN

LIMIT

SET

CLOSE

LIMIT

LEARN

LIMITS

DIAGNOSTIC

GATE 1

J4

SAVE

MAGLOCK

MODE

EDGE

PHOTO

OFF

OFF

SINGLE

NO

NO

ON

ON

DUAL

NC

NC

LEARN

XMITTER

S8

1 2 3 4 5

O

N

2

1

14

13

12

20

11*

10

2

LED A

3

5

4

6*

22

7

8

18

17

19

1

9 23 24 25 15

16

LED P

LED Q

LED R

LED S

LED T

LED U

21

26

LED C

LED D

LED E

LED F

LED G

LED H

LED I

LED J

LED K

LED L

LED M

LED N

LED O

LED B

LED V

LED W

LED X

LED Y

LED Z

27

BASIC CONTROL BOARD SETUP

ITEM DESCRIPTION FUNCTION

1Connector P1 Antenna Input

2Connector P6 Close Edge

3Connector P8 Open Edge/Photo

4Connector P7 Open Photo

5Connector P9 Close Photo

6Connector P12 Switched Accessory Power

7Connector P10 Control Inputs

8Connector P11 Loop Inputs

9Connector P5 24Vac/Solar Input

10 Connector P16 Gate 2

11 Connector P13 Accessory Power

12 Connector P17 Gate 1

13 Connector P14 Maglock/Solenoid

14 Connector P15 Alarm

15 Connector Battery 1

16 Connector Battery 2

18 Pushbutton Learn Xmitter - Program Remote

Button 1 To Open Gate 1

Button 2 To Open Gate 1 and Gate 2

19 Pushbuttons Gate 1 - Jog Learn Limit

20 Pushbutton Learn Limits

21 Pushbuttons Gate 2 - Jog Learn Limit

22 Pushbutton Single Button

23 Potentiometer Force

24 Potentiometer BiPart Delay

25 Potentiometer Timer To Close

26 Connector Earth

27 Radio Socket Radio Module

*Maximum 300 mA combined output

LED DESCRIPTION

RED LED should be “Off” or indicate a fault to resolve (Example: Photocell activated or

shortened wire).

GREEN LED should be “On” to indicate “OK”.

ITEM DESCRIPTION

LED A Red Edge for closing

LED B Red Edge/photo for opening

LED C Red Photo for opening

LED D Red Photo for closing

LED E Red Accessory current overload

LED F Red COM overload

LED G Red Timer to close run indicator

LED H Red Open gate command

LED I Red Open gate command

LED J Red Reset Function button

LED K Green Stop Button

LED L Green Logic board general power

LED M Green Shadow loop

LED N Green Interrupt loop

LED O Red Charger Overload

LED P Red Battery fuse open

LED Q Red Accessory overload

LED R Red Gate 2 Limit indicator

LED S Red Gate 2 Limit indicator

LED T Red Gate 1 Limit indicator

LED U Red Gate 1 Limit indicator

LED V Red E-Lock/Maglock relay indicator

LED W Red Alarm/Flashing light relay indicator

LED X Green Diagnostic (see troubleshooting section)

LED Y Red Transmitter learn indicators

LED Z Red Open/Close programming indicator

Page 9

S1

SAVE

MAGLOCK

MODE

EDGE

PHOTO

OFF

OFF

SINGLE

NO

NO

ON

ON

DUAL

NC

NC

1 2 3 4 5

O

N

SET DIP SWITCH FOR GATE TYPE

1. The Save switch must be set to the OFF position prior to

setting or changing the switches.

2. Set switch to Single for single gate installation. For Dual

(Gate 1 and 2) installation set switch on Dual.

3. Set the Save switch to ON to save the setting.

NOTE: When setting switches S2-5 the save switch must be in

the off position prior to setting or changing switches for the

change to be saved.

WIRING OF MOTOR 1 & 2 INTO THE CONTROL BOARD

Connect gate that opens first to terminal “Gate 1”, the other to

terminal “Gate 2”.

NOTE: Connect color correctly. Watch out if you use splitter

boxes.

9

ALARM

MAGLOCK

GATE 1

ACCESSORY

POWER

GATE 2

P2

LEARN

LIMITS

R35

JMPR1

SAVE

MAGLOCK

MODE

EDGE

PHOTO

BIPART

DELAY

D9

Z3

Z4

P1

TIMER

RUNNING

TIMER TO

CLOSE

F7

C13

U3

D4

D1

D2

D6

J19

NO

C

NO

C

NC

Z1

BRN

GRN

WHT

YEL

BLU

RED

Z12

BRN

GRN

WHT

YEL

BLU

RED

C2R4

J4

K6

K5

L1

S8

1

R2

LEARN

XMITTER

10A 32V

R9

24V

D15

R196

24 VAC/

SOLAR

INPUT

R1

2

F3

Ø

D1

K2

SET

K1

Q9

OPEN

10A 32V

LIMIT

Ø

1

R1

R1

ØØ

F4

ACCESSORY

OVLD

K4

F5

D21

K3

D8

D22

Q22

MOV1

JMPR2

DB1

Ø

MOV2

Ø

14GPØ89ØE

Ø

14LGØ89ØE

Ø

14SKØ89ØE

J1

O

N

1 2 3 4 5

OFF

ON

OFF

ON

SINGLE

DUAL

NO

NC

NO

NC

S1

DIAGNOSTIC

GATE 1

SET

CLOSE

LIMIT

GATE 2

FORCE

MIN MAX OFF MAX OFF MAX

C12

D27

C11

R9

C64

U2

R223

CLOSE

Z22

R92

R91

R94

R93

OVLD

RESET

POWER

SHADOW

INTERRUPT

24V

COM

OVLD

OPEN

STOP

COM

COM

COM

BATT 1BATT 2

EDGE

OPEN EDGE/

PHOTO

Z9

OPEN

PHOTO

Z8

CLOSE

PHOTO

SWITCHED

ACCESSORY

POWER

CONTROL

INPUTS

SINGLE

LOOP

INPUTS

OFF

OFF

SINGLE

NO

NO

OFF

OFF

NO

NO

O

N

1 2 3 4 5

O

N

1 2 3 4 5

ON

ON

DUAL

NC

NC

ON

ON

DUAL

NC

NC

Ø

7

R2

Z2

Ø

R227

J18

R224

U4

SINGLE

BUTTON

SINGLE BUTTON

C4

CHGR

OVLD

F6

F2

F1 20A 32V

FUSE

OPEN

1 Brown

2 Green

3 White

4 Yellow

5 Blue

6 Red

Page 10

10

COM

COM

CONTROL

INPUTS

OPEN

SINGLE BUTTON

RESET

STOP

POWER

WIRE STOP BUTTON (OPTIONAL)

A jumper wire is factory installed between the stop and common input.Stop (N/C) - Stop only (does not reset alarm)

PROGRAMMING REMOTE

1.Press LEARN XMITTER button (LED will light up).

2.Press remote button, the LED will flash, alarm output will

activate twice.

3. Repeat steps 1 and 2 until all remotes are programmed

(50 remotes maximum total).

NOTE: For highest level of security, we recommend the Rolling

Code line of products.

XMITTER button 1 will open Gate 1 only.

XMITTER button 2 will open both gates with one command

from the remote control.

COMPATIBLE REMOTES - 433MHz

Billion Code Remotes Rolling CodesRemotes

4330E 94330E

4333E 94333E

4335E 94335E

4332E (1 x Dip)

Keypads Rolling Codes Keypad

747E 9747E

L

i

f

t

M

a

s

t

e

r

L1

R1

R2

Z1

K5

Ø

14GPØ89ØE

Ø

14LGØ89ØE

Ø

14SKØ89ØE

K6

K2

F3

10A 32V

D1

Ø

P1

P2

J1

J19

S1

Q9

K1

Z12

MAGLOCK

ALARM

GATE 1

C

C

NC

NO

NO

GRN

WHT

YEL

BLU

RED

BRN

SET

OPEN

LIMIT

SET

CLOSE

LIMIT

LEARN

LIMITS

DIAGNOSTIC

GATE 1

SAVE

MAGLOCK

MODE

EDGE

PHOTO

OFF

OFF

SINGLE

NO

NO

ON

ON

DUAL

NC

NC

1 2 3 4 5

O

N

LEARN

XMITTER

2

1

LEARN

XMITTER

2

1

INSTALL PLUG-IN RADIO RECEIVER MODULE

DELETE REMOTE

1.Press LEARN XMITTER button (LED will light up) and

hold until LED is off.

Transmit ter Memor y is era sed.

ALARM

MAGLOCK

Z1

GATE 1

ACCESSORY

POWER

GATE 2

J4

NO

C

NO

C

NC

10A 32V

BRN

GRN

WHT

YEL

BLU

RED

Z12

R9

24V

BRN

GRN

WHT

YEL

BLU

RED

D15

R196

C2R4

24 VAC/

SOLAR

INPUT

P2

R35

JMPR1

D9

Z3

Z4

BIPART

DELAY

SAVE

MAGLOCK

MODE

EDGE

PHOTO

U3

D1

D6

TIMER

RUNNING

D4

TIMER TO

D2

CLOSE

F7

P1

C13

J19

K6

K5

L1

S8

1

R2

LEARN

XMITTER

R1

2

F3

D1

Ø

K2

SET

K1

Q9

OPEN

Ø

LIMIT

R1

Ø

1

ØØ

R1

F4

ACCESSORY

10A 32V

OVLD

K4

F5

D21

K3

D8

D22

Q22

MOV2

MOV1

JMPR2

DB1

Ø

14GPØ89ØE

Ø

14LGØ89ØE

Ø

14SKØ89ØE

J1

O

N

1 2 3 4 5

OFF

ON

OFF

ON

SINGLE

DUAL

NO

NC

NO

NC

S1

DIAGNOSTIC

GATE 1

SET

LEARN

CLOSE

LIMITS

LIMIT

GATE 2

FORCE

MIN MAX OFF MAX OFF MAX

C12

D27

C11

R9

C64

U2

R223

CLOSE

Z22

R92

R91

R94

R93

COM

OVLD

RESET

POWER

SHADOW

INTERRUPT

EDGE

OPEN EDGE/

PHOTO

Z9

OPEN

PHOTO

Z8

CLOSE

PHOTO

24V

SWITCHED

ACCESSORY

OVLD

POWER

CONTROL

INPUTS

OPEN

STOP

COM

COM

LOOP

INPUTS

COM

BATT 1BATT 2

Ø

7

R2

Ø

Z2

R227

J18

R224

U4

SINGLE

BUTTON

SINGLE BUTTON

C4

CHGR

OVLD

F6

F2

F1 20A 32V

FUSE

OPEN

Page 11

11

COM

COM

CONTROL

INPUTS

OPEN

SINGLE BUTTON

RESET

STOP

POWER

OPTIONAL CONTROL DEVICES

SBC (Single Button Control) Input (N/O)

This input will command the gate to OPEN ! STOP ! CLOSE !

STOP in sequence.

Reset Control Input (N/O) - This input will NOT stop the gate.

This input is NOT active.

Open (N/O) - Opens only or reverses a closing gate

Open Input and Exit Loop

These terminals are intended for use as a general open control.

Accessories such as telephone entry systems, radio receivers

(open only applications), exit loop detectors, keypads and 7-day

timers may be wired to this input.

EXIT LOOP

OPEN

COMMON

AND/OR

PRESEN

RELAY 2

625 X

CE

SENS

FREQ

FREQ

Sarasota

625X

MADE IN USA

ALARM

MAGLOCK

GATE 1

ACCESSORY

POWER

GATE 2

SINGLE

BUTTON

COMMON

AND/OR

J19

K6

NO

C

NO

C

NC

Z1

10A 32V

BRN

D1

Ø

GRN

WHT

YEL

BLU

RED

Z12

R9

Ø

24V

BRN

GRN

10A 32V

WHT

YEL

BLU

RED

D15

R196

C2R4

24 VAC/

SOLAR

INPUT

MOV2

J4

K5

1

R2

LEARN

XMITTER

R1

2

F3

K2

SET

K1

Q9

OPEN

LIMIT

R1

Ø

1

R1

ØØ

F4

K4

K3

Q22

J1

L1

S8

OFF

OFF

SINGLE

NO

NO

DIAGNOSTIC

FORCE

ACCESSORY

OVLD

MIN MAX OFF MAX OFF MAX

F5

D21

D8

C12

D22

C11

MOV1

C64

JMPR2

U2

DB1

P2

Ø

14GPØ89ØE

14LGØ89ØE

Ø

Ø

14SKØ89ØE

O

N

1 2 3 4 5

ON

SAVE

ON

MAGLOCK

DUAL

MODE

NC

EDGE

NC

PHOTO

S1

GATE 1

SET

LEARN

CLOSE

LIMITS

LIMIT

TIMER

GATE 2

RUNNING

BIPART

TIMER TO

DELAY

CLOSE

R35

D9

D27

Z3

F7

Z4

U3

D4

R9

D1

JMPR1

D2

D6

R223

P1

R2

7

Ø

Z2

R227

J18

R224

U4

SINGLE

BUTTON

SINGLE BUTTON

C13

C4

CHGR

OVLD

F6

F2

F1 20A 32V

FUSE

OPEN

Ø

Z22

R92

R91

R94

R93

POWER

SHADOW

INTERRUPT

CLOSE

EDGE

OPEN EDGE/

PHOTO

Z9

OPEN

PHOTO

Z8

CLOSE

PHOTO

24V

SWITCHED

ACCESSORY

COM

OVLD

POWER

OVLD

CONTROL

INPUTS

OPEN

RESET

STOP

COM

COM

LOOP

INPUTS

COM

BATT 1BATT 2

Page 12

12

PHOTO/EDGE INPUTS (P6-7-8 and 9) (see page 13)

Terminal P 6 – C lose Edge

This input will reverse a closing gate. It will disable the Timer-toClose if that feature has been enabled. Activating this input while

the gate is opening will have no effect.

Terminal P 8 – O pen Edge or Ph oto Eye

If an Open Edge device or a Retro-Reflective Photo Eye has been

connected to Terminal P8, then this input will reverse an opening

gate for 2 seconds then stop. Activating this input with an Open

Edge device or a Retro-Reflective Photo Eye connected to

Terminal P 8 w hile the ga te is closi ng will have n o effect.

If a Chamberlain Pulsing Photo Eye has been connected to

Terminal P 8, then this i nput will p ause an open ing gate un til the

obstruction has been removed. Upon removing the obstruction,

the gate will continue to open. Activating this input with a

Chamberlain Pulsing Photo Eye connected to Terminal P8 while

the gate is closing will have no effect.

Terminal P 7 – O pen Photo Ey e

This input will pause an opening gate until the obstruction has

been removed. Upon removing the obstruction, the gate will

continue to open. Activating this input while the gate is closing

will have no effect.

Terminal P 9 – C lose Phot o E ye

This input will reverse a closing gate to the open limit. Activating

this input while the gate is opening will have no effect. The Timerto-Close will not reactivate at the open limit.

NOTE: Make sure the positive (+) and negative (-) wires are

wired correctly.

LOOP INPUTS (P11) (see page 13)

Shadow Loop Input Terminal and Common

This input protects cars by preventing the gate from moving off

of the open or close limit when the shadow loop input is active.

Interrupt Loop Input Terminal and Common

This input functions to reverse a closing gate to the open limit.

Latching this input will reset the timer to close.

CLOSE

EDGE

OPEN EDGE

PHOTO

or

771E

OPEN

PHOTO

or

771E

CLOSE

PHOTO

or

771E

See page 15 for Dip-Switch settings.

Unused safety inputs may require a wire bridge (JUMPER)

F1 20A 32V

FUSE

OPEN

CHGR

OVLD

SHADOW

INTERRUPT

BATT 1BATT 2

COM

LOOP

INPUTS

SHADOW LOOP

INTERRUPT LOOP

COMMON LOOP

PR

ES

E

NCE

RE

L

AY

Sarasota

2

625X

SEN

S

625 X

FRE

FRE

Q

Q

MADE IN USA

Page 13

13

MAGLOCK/ALARM/FLASHING LIGHT

Flashing Light

(optional)

Siren

(optional)

Maglock

When enabled, the maglock output is activated (energized) while the gate

is in motion.

E-Lock

(optional)

Maglock

(optional)

ALARM

MAGLOCK

GATE 1

ACCESSORY

POWER

GATE 2

J4

P2

U3

D1

D6

TIMER

RUNNING

TIMER TO

D4

D2

P1

CLOSE

F7

C13

J18

U4

J19

10A 32V

R9

R196

K6

J1

K5

L1

1

R2

LEARN

SINGLE

XMITTER

R1

2

F3

D1

Ø

K2

DIAGNOSTIC

SET

K1

Q9

OPEN

LIMIT

Ø

Ø

1

R1

R1

ØØ

F4

K4

K3

Q22

ACCESSORY

OVLD

F5

D21

D8

D22

MOV1

JMPR2

DB1

10A 32V

MOV2

NO

C

NO

C

NC

Z1

BRN

GRN

WHT

YEL

BLU

RED

Z12

24V

BRN

GRN

WHT

YEL

BLU

RED

D15

C2R4

24 VAC/

SOLAR

INPUT

Ø

14GPØ89ØE

Ø

14LGØ89ØE

Ø

14SKØ89ØE

O

N

1 2 3 4 5

OFF

ON

OFF

NO

NO

SAVE

ON

MAGLOCK

DUAL

MODE

EDGE

NC

PHOTO

NC

S1

GATE 1

SET

LEARN

CLOSE

LIMITS

LIMIT

GATE 2

BIPART

DELAY

FORCE

MIN MAX OFF MAX OFF MAX

R35

D9

C12

D27

Z3

Z4

C11

R9

C64

JMPR1

U2

F6

F2

SINGLE

BUTTON

C4

R2

Ø

7

Ø

Z2

R227

R224

SINGLE BUTTON

CHGR

OVLD

F1 20A 32V

FUSE

OPEN

R223

Z22

R92

R91

R94

R93

COM

OVLD

OPEN

RESET

STOP

POWER

SHADOW

INTERRUPT

24V

OVLD

BATT 1BATT 2

COM

COM

COM

CLOSE

EDGE

OPEN EDGE/

PHOTO

OPEN

PHOTO

CLOSE

PHOTO

SWITCHED

ACCESSORY

POWER

CONTROL

INPUTS

LOOP

INPUTS

Z9

Z8

Accessory

Power

Auxillary Output Power for Optional Devices

(2) +24VDC Outputs (P13 and P12) have

been provided for optional devices

Maximum 300mA combined output

The switched output should be used only if the gate is

powered by a solar panel to reduce the energy consumption

during stand by.

Page 14

FORCE

GATE 2

SET

OPEN

LIMIT

SET

CLOSE

LIMIT

LEARN

LIMITS

DIAGNOSTIC

GATE 1

14

TIMER TO CLOSE ENABLE

Set the TIMER TO CLOSE to

desired setting. The range is 0 to

180 seconds, 0 seconds is OFF.

FORCE CONTROL

Set the sensitivity such that the unit will

complete a full cycle of gate travel but will

reverse off an obstruction without applying

an unreasonable amount of force.

BIP

ART DELAY

Set the BIPART DELAY to desired

setting. The range is 0 to 8

seconds, 0 seconds is OFF.

FORCE AND TIMER TO CLOSE

PROGRAM LIMITS

1. Turn BiPart switch to desired setting. Set to “Off” for single

gate applications.

2. Press the “LEARN LIMITS” button.

3. The “SET OPEN LIMIT” LED will blink.

4. Use any of the “Gate 1” buttons to move Gate 1 to the

desired open position. Repeat if Gate 2 is present using “Gate

2” buttons.

5. Press the “LEARN LIMITS” button to set the Open Limit for

gate(s).

6. The “SET OPEN LIMIT” LED will turn off. The “SET CLOSE

LIMIT” LED will blink.

7. Use the “Gate 1” buttons to move Gate 1 to the desired close

position. Repeat if Gate 2 is present using “Gate 2” buttons.

8. Press the “LEARN LIMITS” button to set the close limit for

gate(s).

9. The “SET CLOSE LIMIT” LED will turn off. The limits are set.

10 Using programmed remote or single button input (SBC) run

the gate(s) from the close limit to the open limit. After

reaching the open limit, run the gate(s) to the close limit.

This will learn the force in the open and close direction.

11. If the learned force is not high enough, manually

adjust the force control as described above.

NOTE: Any following SBC or Remote inputs will move the gate

.

The “Save” Dip switch must be set to OFF to allow programming.

After completion set the “Save” switch back to on.

INSTALL ALL EQUIPMENT IN COMPLIANCE WITH EN60335-2-103, EN13241-1.

MIN MAX OFF MAX OFF MAX

ALARM

MAGLOCK

GATE 1

ACCESSORY

POWER

GATE 2

NO

C

NO

C

NC

Z1

BRN

GRN

WHT

YEL

BLU

RED

BRN

GRN

WHT

YEL

BLU

RED

C2R4

J4

K6

K5

1

R2

XMITTER

10A 32V

Z12

24V

D15

R196

24 VAC/

SOLAR

INPUT

R1

2

F3

Ø

D1

K2

K1

Q9

OPEN

10A 32V

LIMIT

Ø

1

R1

R1

ØØ

F4

K4

K3

Q22

R9

Ø

MOV2

J19

J1

L1

OFF

OFF

LEARN

SINGLE

NO

NO

S1

DIAGNOSTIC

SET

FORCE

ACCESSORY

OVLD

MIN MAX OFF MAX OFF MAX

F5

D21

D8

C12

D22

C11

MOV1

C64

JMPR2

U2

DB1

O

N

1 2 3 4 5

SET

CLOSE

LIMIT

P2

Ø

14GPØ89ØE

Ø

14LGØ89ØE

Ø

14SKØ89ØE

ON

SAVE

ON

MAGLOCK

DUAL

MODE

NC

EDGE

NC

PHOTO

GATE 1

LEARN

LIMITS

TIMER

GATE 2

RUNNING

BIPART

TIMER TO

DELAY

CLOSE

R35

D9

D27

Z3

F7

Z4

U3

D4

R9

D1

JMPR1

D2

D6

R223

P1

R2

Ø

7

Z2

Ø

R227

J18

R224

U4

SINGLE

BUTTON

SINGLE BUTTON

C13

C4

CHGR

OVLD

F6

F2

F1 2

0

A 32V

FUSE

OPEN

Z22

R92

R91

R94

R93

OVLD

RESET

POWER

SHADOW

INTERRUPT

CLOSE

EDGE

OPEN EDGE/

PHOTO

Z9

OPEN

PHOTO

Z8

CLOSE

PHOTO

24V

SWITCHED

ACCESSORY

COM

OVLD

POWER

CONTROL

INPUTS

OPEN

STOP

COM

COM

LOOP

INPUTS

COM

BATT 1BATT 2

Page 15

COM

OVLD

S1

SAVE

MAGLOCK

MODE

EDGE

PHOTO

OFF

OFF

SINGLE

NO

NO

ON

ON

DUAL

NC

NC

1 2 3 4 5

O

N

DIP SWITCH SETTINGS

SAVE SWITCH S1-1

This switch (S1-1) is used to save the settings for

switches 2 thru 5 and the limits of the gate.

NOTE: When setting switches S2-5 the save switch

must be in the off position prior to setting or changing

switches for the change to be saved.

MAG DELAY ENABLE

This switch (S1-2) enables the Mag Lock/E-Lock feature.

On an open command there will be a .5 second delay

before the motor starts, to allow the Mag Lock/E-Lock to

release.

MODE DUAL/SINGLE

This switch (S1-3) sets the mode as Dual or Single

(See Programming section for mode).

SAFETY INPUTS

Swing gates allow four safety inputs. A DIP switch is

required for determining between N/O and N/C edges and

N/O and N/C eyes.

EDGE INPUT (SAFETY EDGE)

Set switch (S1-4) to the following settings:

N/O Edge (Active Close) = 8.2K, 10K Edge, N/O dry

contact edge

N/C Edge (Active Open) = N/C dry contact edge

NOTE: Monitored Edges should be set in the N/O

position, as the activation condition is shorting the

terminals. Unused inputs in N/C mode require a wire

bridge (JUMPER).

PHOTO-EYE INPUT (PHOTOCELL)

This switch (S1-5) differentiates between N/O and N/C

dry contact photoelectric eye inputs.

NOTE: Pulsing Chamberlain photoelectric eyes will

automatically learn in N/C mode. Unused inputs in N/C

mode require a wire bridge (JUMPER).

15

ALARM

MAGLOCK

GATE 1

ACCESSORY

POWER

P2

GATE 1

LEARN

LIMITS

GATE 2

SAVE

MAGLOCK

MODE

EDGE

PHOTO

TIMER

RUNNING

P1

J19

NO

C

NO

C

NC

Z1

BRN

GRN

WHT

YEL

BLU

RED

K6

K5

L1

S8

1

R2

LEARN

XMITTER

10A 32V

Z12

R1

2

F3

Ø

D1

K2

SET

K1

Q9

OPEN

Ø

R9

LIMIT

J1

OFF

OFF

SINGLE

NO

NO

DIAGNOSTIC

S1

O

N

1 2 3 4 5

SET

CLOSE

LIMIT

Ø

Ø

Ø

ON

ON

DUAL

NC

NC

14GPØ89ØE

14LGØ89ØE

14SKØ89ØE

R223

Ø

7

R2

Z2

Ø

R227

J18

R224

Z22

U4

R92

R91

R94

R93

24V

OVLD

CLOSE

EDGE

OPEN EDGE/

PHOTO

Z9

OPEN

PHOTO

Z8

CLOSE

PHOTO

SWITCHED

ACCESSORY

POWER

MAG DELAY

SAVE

OFF

OFF

OFF

OFF

O

N

1 2 3 4 5

O

N

1 2 3 4 5

O

N

1 2 3 4 5

SAVE

ON

O

N

1 2 3 4 5

ON

MAG DELAY

ON

OFF

OFF

SINGLE

NO

NO

OFF

OFF

SINGLE

EDGE NO

OFF

OFF

SINGLE

PHOTOEYE NO

O

N

1 2 3 4 5

N

N

O

1 2 3 4 5

O

1 2 3 4 5

O

N

1 2 3 4 5

ON

ON

DUAL

NC

ON

ON

DUAL

NC

ON

ON

DUAL

NC

NC

Page 16

16

External entrapment

protection systems

●

Check for proper operation

Gate warning signs

●

Make sure they are present

Manual disconnect

●

Check and operate

Gate

●

Inspect for wear or damage

Accessories

●

Check all for proper operation

Electrical

●

Inspect all wire connections

Frame bolts

●

Check for tightness

Total unit

●

Inspect for wear or damage

6 MONTHS

MONTHLY

3 MONTHS

WEEKLY

12 MONTHS

6 MONTHS

TASK

CHECK AT LEAST ONCE EVERY

Complete Check Out

NOTES:

1. Disconnect power before servicing.

2. Severe or high cycle usage will require more frequent maintenance checks.

3. Inspection and service should always be performed anytime a malfunction is observed or suspected.

4. When servicing, please do some “house cleaning” of the operator and the area around the operator. Pick up any debris in the area.

Clean the operator as needed.

5. It is suggested that while at the site voltage readings be taken at the operator. Using a Digital Voltmeter, verify that the incoming

voltage to the operator it is within ten percent of the operators rating.

DESCRIPTION

To r educe the r isk of SEVER E INJURY or DE ATH:

• Disconnect ALL power BEFORE performing ANY

maintenance.

• ALL maintenance MUST be performed by a LiftMaster

professional.

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. NEVER let children operate or play with gate controls.

Keep the remote control away from children.

3. ALWAYS keep people and objects away from the gate.

NO ONE SHOULD CROSS THE PATH OF THE MOVING

GATE.

4. Test the gate operator monthly. The gate MUST reverse

on contact with a rigid object or stop when an object

activates the non-contact sensors. After adjusting the

force or the limit of travel, retest the gate operator.

Failure to adjust and retest the gate operator properly

can increase the risk of INJURY or DEATH.

5. Use the emergency release ONLY when the gate is not

moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the

owner’s manual. Have a qualified service person make

repairs to gate hardware.

7. The entrance is for vehicles ONLY. Pedestrians MUST

use separate entrance.

8.

SAVE THESE INSTRUCTIONS.

OPERATION and MAINTENANCE

MAINTENANCE

MONTH

DAILY

●

COMMERCIAL USE 50+ CYCLES/DAY (350+ PER WEEK

RESIDENTIAL USE 1-50 CYCLES/DAY (350 PER WEEK)

Page 17

17

WIRING DIAGRAM

To p rotect ag ainst fir e and elect rocuti on:

• DISCONNECT power BEFORE installing or servicing

operator.

• Replace ONLY with fuse of same type and rating.

D6

JMPR2

DB1

Siren

T

(optional)

Flashing Light

E-Lock

(optional)

Maglock

(optional)

GATE 1

(Opens First)

GATE 2

GROUND

(Optional)

GREEN/YELLOW

150VA

TORROID

TRANSFORMER

BRN

GRN

WHT

YE L

BLU

RED

BRN

GRN

WHT

YE L

BLU

RED

ALARM

MAGLOCK

GATE 1

ACCESSORY

POWER

GATE 2

J4

P2

BIPART

DELAY

SAVE

MAGLOCK

MODE

EDGE

PHOTO

U3

D1

D6

TIMER

RUNNING

D4

TIMER TO

D2

CLOSE

F7

P1

C13

J19

D15

24 VAC/

SOLAR

INPUT

YELLOW

10A 32V

R196

K6

J1

K5

L1

1

R2

LEARN

XMITTER

R1

2

F3

ÿ

D1

K2

SET

K1

Q9

OPEN

10A 32V

LIMIT

R1

ÿ

1

R1

ÿÿ

F4

ACCESSORY

OVLD

K4

F5

D21

K3

D8

D22

Q22

MOV1

JMPR2

DB1

R9

ÿ

MOV2

O

N

1 2 3 4 5

OFF

ON

OFF

SINGLE

DIAGNOSTIC

ON

DUAL

NO

NC

NO

NC

S1

GATE 1

SET

LEARN

CLOSE

LIMITS

LIMIT

GATE 2

FORCE

MIN MAX OFF MAX OFF MAX

R35

D9

C12

D27

Z3

Z4

C11

R9

C64

JMPR1

U2

BLUE

SECONDARY

NO

C

NO

C

NC

Z1

BRN

GRN

WHT

YEL

BLU

RED

Z12

24V

BRN

GRN

WHT

YEL

BLU

RED

C2R4

J18

U4

F6

F2

BLACK

C4

SINGLE

BUTTON

ÿ

7

R2

R224

SINGLE BUTTON

F1 20A 32V

FUSE

OPEN

CHGR

OVLD

RED

Z2

ÿ

R227

R223

Z22

R92

R91

R94

R93

OVLD

RESET

POWER

SHADOW

INTERRUPT

CLOSE

EDGE

OPEN EDGE/

PHOTO

Z9

OPEN

PHOTO

Z8

CLOSE

PHOTO

24V

SWITCHED

ACCESSORY

COM

OVLD

POWER

CONTROL

INPUTS

OPEN

STOP

COM

COM

LOOP

INPUTS

COM

BATT 1BATT 2

BLACK

OR OR

EDGE EDGE EDGE

OR OR

EDGE

EDGE

PULSING PHOTO

OR OR

PHOTO

PHOTO

PULSING PHOTO

OR OR

PHOTO

PHOTO

24VDC OUTPUT

SWITCHED OFF

IN LOW POWER MODE

OPEN (EXIT LOOP)

SINGLE BUTTON

RESET

STOP

COMMON (+24VDC)

COMMON (+24VDC)

SHADOW LOOP

INTERRUPT LOOP

COMMON (+24VDC)

RED

EDGE

PULSING PHO

OR

GREEN/YELLOW

CHARGE TRANSFORMER

PRIMARY

Page 18

18

OPERATOR IS DEAD

When power is supplied to

the control board, no LED

turns ON.

OPERATOR DOES NOT RUN

Unit does not respond to a

Radio command.

OPERATOR DOES NOT RUN

Unit does not respond to

SBC command.

MOTOR DOES NOT RUN

Relays ‘click’ when Radio

or SBC signal is given, but

the operator does not

move.

GATE STOPS AND

REVERSES RIGHT AFTER

IT STARTS MOVING

GATE STOPS RUNNING

RIGHT AFTER IT STARTS

MOVING (BATTERY RUN)

GATE OPENS BUT DOES

NOT CLOSE

GATE LOSES LIMITS

1) Battery fuse is blown. ➤ Replace battery fuse. Use only 20A, ATC style fuse.

2) Battery or Run Transformer

➤ Check battery and transformer connections.

connection is loose.

3) Dead battery.

➤ Measure voltage across battery > 23V.

4) Bad control board.

➤ Replace control board.

1) Low battery.

➤ Measure voltage across battery >23V.

2) SBC button connection loose.

➤ Check SBC and COM connections to ensure they are secure.

3) STOP button connection loose.

➤ Check STOP button connections (STOP and COM) to make sure they

STOP LED is OFF. are secure.

4) Obstruction is blocking the photoelectric

➤ Check gate area to ensure photoelectric eyes are not blocked.

eyes in the direction of movement.

5) The safety edge is damaged

➤ Check gate area to ensure safety edge is not resting on an obstruction.

or on an obstruction.

➤ Check safety edge wiring and connections.

6) Interrupt loop is obstructed.

➤ Check gate area to ensure path is unobstructed.

7) Bad control board.

➤ Replace control board.

8) Motor fuse is blown.

➤ Replace motor fuse. Use only 10A, ATC style fuse.

9)Indicator light blinks.

➤ Reset system by achieving the Stop/Reset with a wire bridge momentarily.

10)Release lever opened.

➤ Reconnect arm.

1) Bad motor. ➤ Replace motor.

2) Cable wiring between control and

➤ Fix wiring or connect arm.

operator arm disconnected or loose.

3) Bad control board.

➤ Replace control board.

4) Batteries not connected.

➤ Connect batteries.

1) A fault has occurred. ➤ Check gate for obstructions.

2) Force set too low.

➤ Adjust FORCE setting until gate completes a full open/close cycle

without reversing. The force setting may need to be adjusted in cold

weather, as the gate will not move as freely.

1) Battery voltage low or near low ➤ Charge batteries. If problem persists, they may be near the end of their

voltage cut-off. LED blinks 11x. life. Replace batteries.

NOTE: Replace both batteries at the same time.

2) A fault has occurred. ➤ Check gate for obstructions.

➤ Check motor terminals.

1) An input is continuously activated. ➤ Verify that all inputs are functioning properly.

2) Entry system output is connected to

➤ Verify Entry system connections and operation.

the Open input, and is “stuck” opening.

➤ Disconnect devices or Led if gate closes. Reconnect devices after one

by one.

FAULT POSSIBLE CAUSE FIX

TROUBLESHOOTING

1) After a day the programming is lost or ➤ Make sure the “SAVE” Dip-switch is back to “ON” after programming.

different.

1)Low battery.

➤ Measure voltage across battery > 23V.

2)Radio (remote) not programmed.

➤ See Programming Remote section for programming instructions.

3)STOP button connection loose.

➤ Check STOP button connections (STOP and COM) to make sure they

STOP LED is OFF. are secure.

4)There is an obstruction blocking

➤ Check gate area to ensure photoelectric eyes are not blocked.

photoelectric eyes in direction

of movement.

5)Safety edge is damaged or on an

➤ Check gate area to ensure safety edge is not resting on an obstruction.

obstruction. Check safety edge wiring and connections.

6)Interrupt loop is obstructed.

➤ Check gate area to ensure path is unobstructed.

7)Bad control board.

➤ Replace control board.

8)Motor fuse is blown.

➤ Replace motor fuse. Use only 10A, ATC style fuse.

9)Release lever opened.

➤ Reconnect arm.

Page 19

19

GATE RUNS TOO SLOW

GATE DOES NOT CLOSE

AUTOMATICALLY

GATE WON’T STAY OPEN

WHEN USING FIRE INPUT

Fire Input switch should

be a constant contact

key switch connected to

Open Loop input

(Open only).

INTERRUPT LOOP DOES

NOT ACT PROPERLY

EXIT LOOP (FREE EXIT)

DOES NOT OPEN GATE

MAGLOCK DOES NOT

WORK

Maglock does not hold

gates locked

STATUS INDICATOR LED

BLINKS

# OF BLINKS (1-11) AND

THEIR MEANING

PHOTO LED’S ON BOARD

INDICATE PROBLEM BUT

PHOTOCELLS AND WIRING

ARE OK

1) Open and Close Limits are set too ➤ If the Open and Close Limits are set within the ramp down distance of

close together. each other, the gate will run at slow speed all the time.

2) The gate is starting within the ramp

➤ Gate will run slow to limits if motion is started within the ramp-down

down distance from the Open or distance from the limit.

Close Limit.

1) Verify that the TTC is turned OFF. ➤ Verify that the TTC (Timer To Close) is ON and set.

2) Gate opened by an obstruction reversal.

➤ Check gate area to ensure path is unobstructed.

3) The Interrupt Loop is obstructed.

4) Obstructed close photoelectric eye or edge.

5) The Open input is "stuck".

➤ Check the Open Loop area to ensure all obstructions are removed. If an

external opening device or entry or entry system is attached, check for

proper operation of that system.

1) Fire Input switch is a momentary ➤ Make sure the Fire Input switch is constant contact. If it is not, replace

contact. with a constant contact switch.

1) Bad loop sensor or loop detector. ➤ Replace loop sensor or loop detector.

2) Bad connection between loop sensor,

➤ Check connections to make sure they are secure.

loop detector, and the control board.

1) Bad loop sensor or detector. ➤ Replace loop sensor or loop detector.

2) Bad connection between the loop

➤ Check connections to make sure they are secure.

sensor, loop detector, and the

control board.

3) The Shadow Loop is obstructed.

➤ Check the gate area to make sure all obstructions are removed.

4) An Open photoelectric eye or safety

➤ Check the gate area to make sure all obstructions are removed.

edge is obstructed.

1) Bad connection between the Maglock, ➤ Check connections between the Maglock, its power supply, and

its power supply, and the control board. the control board to make sure they are secure.

2) Bad Maglock or Maglock power supply.

➤ Replace Maglock or Maglock power supply.

3) Large gap between gates.

➤ Reduce the gap between the gates.

4) Bad control board.

➤ Replace the control board.

FAULT POSSIBLE CAUSE FIX

TROUBLESHOOTING

1) No stop switch connected 6) Force reversal 11) Battery low or bad

2) Gate 1 arm disengaged 7) Processor Reset

3) Gate 2 arm disengaged 8) ROM check failed

4) Both gate arms disengaged 9) RAM check failed

5) RPM reversal 10) EEPROM check failed

1) Dip switch setting incorrect NO/NC ➤ Set Dip switch correctly

for Photo/Edge.

➤ Set program “Save” switch to OFF

2) Photocell still bad or misaligned

➤ Check LED’s of Photocells if LED is constant.

➤ Detach Photocells and jumper output “Dip to NC” to see if it works.

➤ Switch to OFF or cycle switch with a pause (2-3 seconds)

Page 20

Refer to the parts lists below for replacement parts available for your operator. If optional modifications and/or accessories are included

with your operator, certain components may be added or removed from these lists.

E-BOX ASSEMBLY

ITEM PART # DESCRIPTION QTY

1K79-12815Control Board 1

2K75-15480Control Box & Cover

with Gasket 1

3K75-30764Control Board Bracket1

4 K74-19499 Antenna 1

5600190Battery 2

6K74-30763Charge Transformer1

K21-30749 Run Transformer 1

Not Shown K74-30941 ATC Fuse Kit Includes

20 Amp (1), 10 Amp (2)

REPAIR PARTS

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

• PART NUMBER

• PART NAME

• MODEL NUMBER

ADDRESS ORDERS TO:

Email: info@chamberlain.com

www.liftmaster.com

HOW TO ORDER REPAIR PARTS

INSTALLATION AND SERVICE INFORMATION

IS AS NEAR AS YOUR TELEPHONE SIMPLY DIAL:

Int. Service (+49) 6838/907 172

für Service 06838/907 172

for service (+44) 0845 602 4285

pour service 03 87 95 39 28

voor service 020 684 7978

INT

D

GB

F

NL

© 2005, Chamberlain GmbH, Inc

01-32640B All Rights Reserved

2

3

1

6

5

4

Loading...

Loading...