ESTATE SERIES

MASTER / SLAVE SYSTEMS

MODEL SL 1000-B3, SW 2000-B3 & BG 3000-B3

SLIDE, SWING, AND BARRIER GATE OPERATORS

MODEL SL 1000-B3

B3

MODEL BG 3000-B3

MODEL SW 2000-B3

TABLE OF CONTENTS

SAFETY SUMMARY ............................................................................................................................1

BASIC INSTALLATION HINTS AND RULES ...................................................................................... 2

PART 1 MASTER/SLAVE OPERATION............................................................................................ 3

A. WHAT IS MASTER/SLAVE OPERATION?...............................................................................................3

B. MASTER/SLAVE GATE CONFIGURATIONS...........................................................................................3

C. MASTER/SLAVE INSTALLATION DETAILS ............................................................................................3

PART 2 MASTER/SLAVE LAYOUTS AND WIRING ....................................................................... 10

A. PHOTO-SENSOR INSTALLATION FOR BIPARTING GATE CONFIGURATION ..................................10

B. PHOTO-SENSOR INSTALLATION FOR TRAP/TANDEM GATE CONFIGURATION ...........................12

C. CONNECTING INPUT WIRING ..............................................................................................................13

D. MASTER/SLAVE INTERCONNECTION.................................................................................................14

E. MASTER/SLAVE WIRING.......................................................................................................................15

F. SWITCH S1 MASTER SLAVE CONFIGURATIONS AND GATE CONTROLS SETTINGS:...................15

G. SYSTEM LAYOUTS AND CONTROL WIRING ......................................................................................16

H. TROUBLESHOOTING ............................................................................................................................30

FCC REQUIREMENTS....................................................................................................................... 31

NOTICE TO CANADIAN USERS ....................................................................................................... 32

Rev E Doc 01-20201

TABLE OF FIGURES

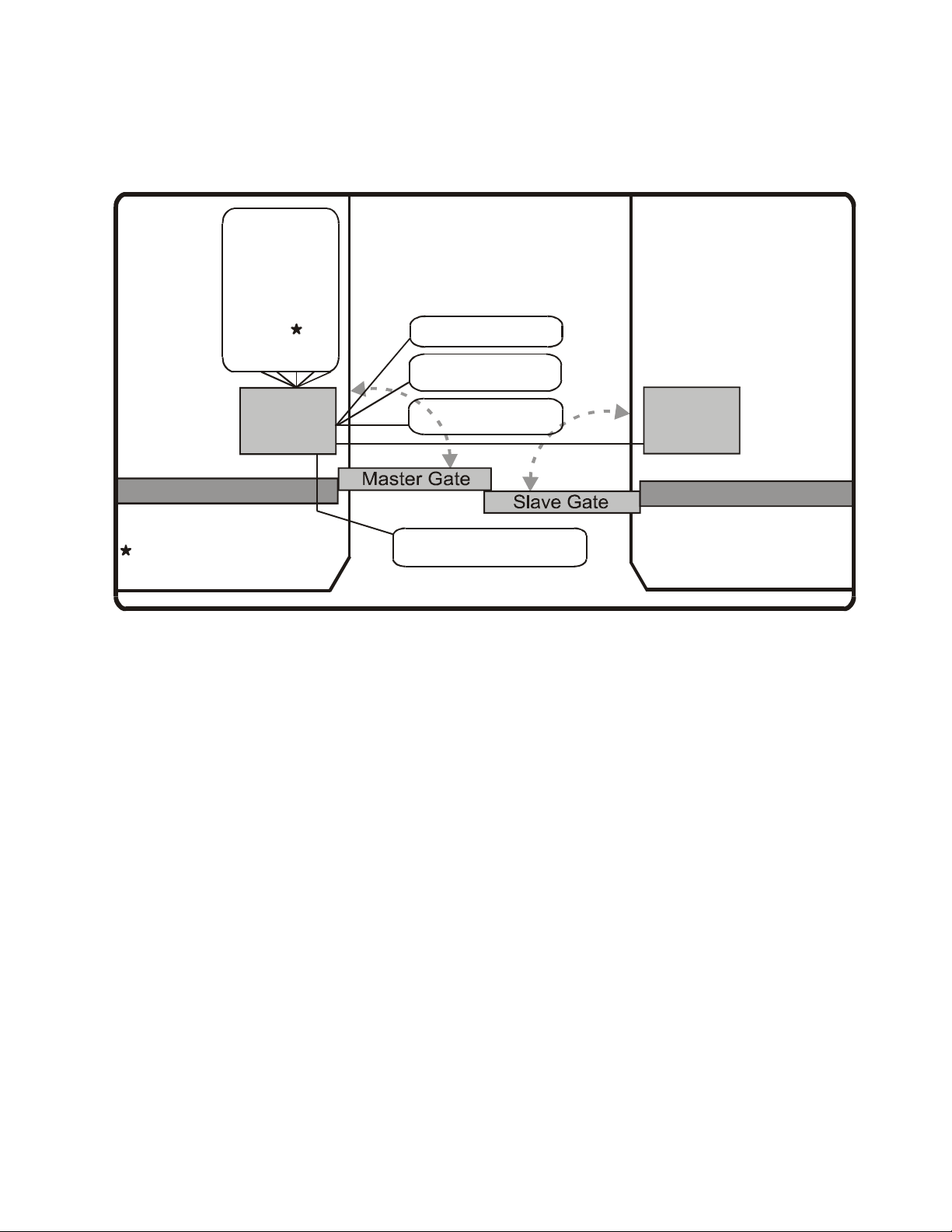

Figure 1. Master/Slave Gate Configurations........................................................................................................3

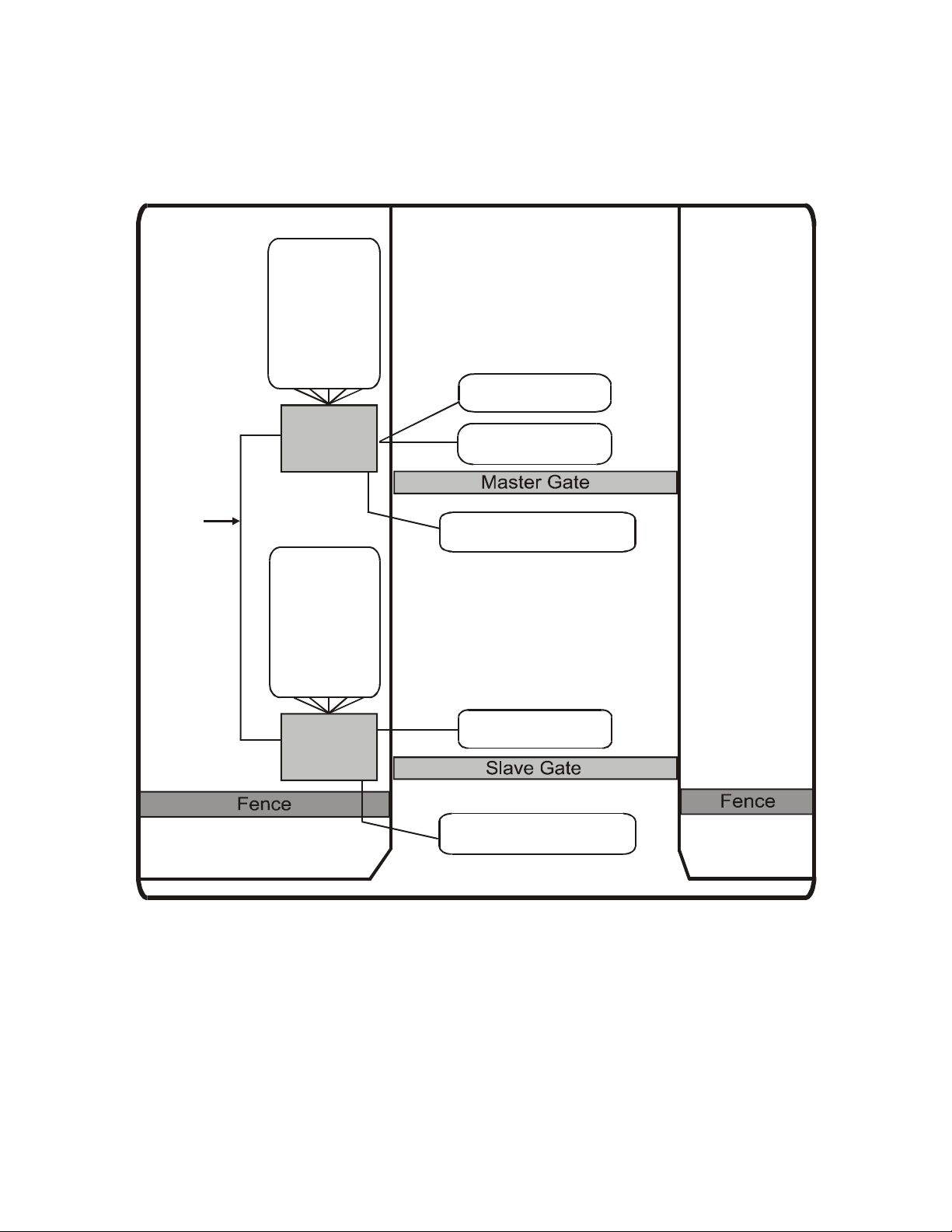

Figure 2. Typical Bi-Parting Gate Installation. .....................................................................................................4

Figure 3. Typical Bi-Parting Latch Gate Installation.............................................................................................5

Figure 4. Typical Trap Gate Installation...............................................................................................................6

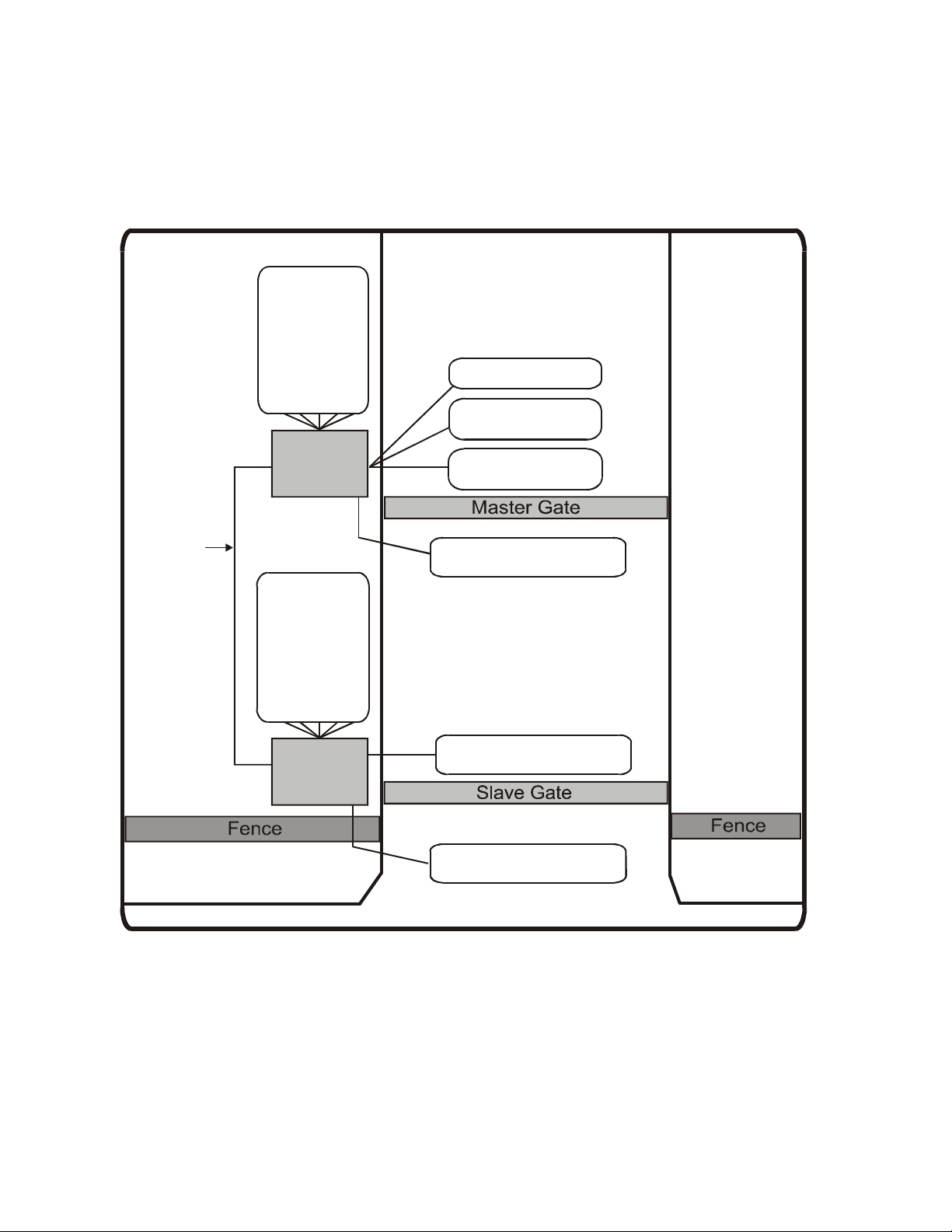

Figure 5. Typical Tandem Gate Installation. ........................................................................................................8

Figure 6. Biparting Slide Gate Photo-Sensor Layout.........................................................................................10

Figure 7. Biparting Swing Gates Photo-Sensor Layout. ....................................................................................11

Figure 8. Biparting Barrier Gates Photo-Sensor Layout. ...................................................................................12

Figure 9. Control Board Wiring. .........................................................................................................................13

Figure 10. Master Slave Connection and Switch S1 Location...........................................................................15

Figure 11. Switch S1 Settings for Master/Slave Systems..................................................................................16

Figure 12. Bi-Part, Bi-Directional Gate System. ................................................................................................17

Figure 13. Bi-Part, Uni-Directional Gate System (Swing gate, if used, opens in)..............................................17

Figure 14. Bi-Part, Uni-Directional Gate System (Swing gate opens out). ........................................................18

Figure 15. Bi-Part, Bi-Directional Gate System. ................................................................................................18

Figure 16. Bi-Part Latch, Uni-Direction Gate System (Swing gate, if used, opens in).......................................19

Figure 17. Bi-Part Latch, Uni-Directional Gate System (Swing gate opens out). ..............................................19

Figure 19. Bi-Directional Trap Gate System (Swing gate opens out). ...............................................................21

Figure 20. Uni-Directional Trap Gate System (internal Swing gate, if used, opens in)......................................22

Figure 21. Uni-Directional Trap Gate System (internal Swing gate opens out). ................................................23

Figure 22. Uni-Directional Trap Gate System (external Swing gate, if used, opens in).....................................24

Figure 23. Uni-Directional Trap Gate System (external Swing gate opens out). ...............................................25

Figure 24. Bi-Directional Tandem Gate System (Swing gate, if used, opens in)...............................................26

Figure 25. Bi-Directional Tandem Gate System (Swing gate opens out). ..........................................................27

Figure 26. Uni-Directional Tandem Gate System (Swing gate, if used, opens in).............................................28

Figure 27. Uni-Directional Tandem Gate System (Swing gate opens out). .......................................................29

Rev E Doc 01-20201

SAFETY SUMMARY

It is important for everyone involved in the installation and operation of the LiftMaster models SL 1000,

SW 2000, and BG 3000 Master/Slave systems to read the following warnings.

WARNING!

• A vehicle gate is a large, heavy object that is moved by an electric motor. A moving gate can

cause serious injury or death! The safety and well-being of others depends on the installation

of a safe system.

• READ AND FOLLOW ALL INSTRUCTIONS. Improper installation of a gate operator can result

in a dangerous system. SAVE THESE INSTRUCTIONS

• The entrance is for vehicles only. Pedestrians must use separate entrance.

• Gate operators can present serious hazards to persons in the immediate area when not

controlled in a safe manner. Choose one or more controls which together will allow complete

control of the gate. Most importantly, the gate must be able to be stopped at all times in case

of emergency, and the emergency control should be conveniently located, clearly marked, and

visible.

• All controls must be kept out of reach of small children. Serious injury or death can result

from children playing with the controls.

• Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF

THE MOVING GATE.

• All controls should be located so the person operating them can see the full area of gate

movement.

• Use the emergency release only when the gate is not moving.

• KEEP GATES PROPERLY MAINTAINED. Read the Installation and Operation manual. Have a

qualified person make repairs to gate hardware.

• Test the gate operator safety features monthly. The gate MUST reverse on contact with a rigid

object or stop when an object activates the non-contact sensors.

• After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and

retest the gate operator properly can increase the risk of damage, injury or death.

• Gate operators and associated control equipment should be installed by qualified

professional installers who should observe the following safe installation procedures:

1. Power should always be disconnected whenever installing, wiring, or servicing a gate

operator. Moving chains and belts in gate operators can catch clothing or fingers and

cause severe injury.

2. Installation of wiring should comply with all local building and electrical codes.

3. All manual gate locks should be disabled to avoid damage to the gate or gate operator

should the lock become engaged after the operator is installed.

4. All operator controls and safety equipment should be tested at the conclusion of

installation to be sure they are functioning properly.

5. The operation of the gate controls and safety equipment should be reviewed with the

owner and/or end user of the automated gate system. They should also be informed of the

need to maintain control and safety equipment on a regular basis. Safety equipment

should be checked monthly to ensure it is working properly. All installation manuals and

safety information should be left with the owner.

6. Moving gates have pinch points and entrapment zones which can be extremely dangerous

to pedestrians, especially small children.

Rev E Doc 01-20201 1 of 33

BASIC INSTALLATION HINTS AND RULES

READ THIS SECTION CAREFULLY BEFORE BEGINNING YOUR INSTALLATION

1. UNDERSTAND THE SYSTEM AND INSTALLATION SITE THOROUGHLY. The B3 series are

flexible and reliable gate operator systems, but the quality of service depends directly on the quality

of installation. Please read these instructions and the Installation and Operation instructions for

each gate operator carefully. Study the applicable diagrams before planning your installation. In

particular, understand any site characteristics that may affect the system installation.

WARNING

2. INSTALL PERMANENT WIRING. U.L. specifications require the B3 Series Master/Slave systems

to be permanently wired. Refer to your local wiring code for specific information.

WARNING: Damage caused by faulty wiring is not covered by warranty.

3. GROUND THE SYSTEM. The system contains parts which may be damaged by static discharge.

A proper earth ground connected to the housing will significantly reduce the chances of damage or

improper operation. The shielding in the cables specified for all remote sensors and controls should

also be connected to earth ground at the controller end of the cable only.

To be effective, the ground connection must be made by running 12 AWG copper wire to a good

ground point (e.g., an electrical panel, a metallic cold water pipe that runs into the earth, or a

grounding rod at least 10 feet in length that is driven into the earth) within 12 feet of the system.

Even if you have a good ground, you should try to discharge any static before handling the circuit

boards.

WARNING: Damage caused by static discharge and lightning is not covered by warranty.

4. PROVIDE POWER FROM A DEDICATED SOURCE. The outlet into which you connect the Gate

Operators should be wired to its own circuit breaker. This will reduce the line noise introduced into

system power and minimize the risk of having other equipment interrupt system operation. In a

Master/Slave system, Master and Slave must each have separate circuits.

5. DO NOT OVERLOAD THE TERMINAL BLOCKS. The operator’s terminal blocks are removable

and the pins are soldered into the boards. To connect the wires, remove the “head” from the

correct terminals and open the screws. Insert the wire into the correct opening on the front and

tighten the screw until the wire is held firmly. When you have made all connections for a given

“head”, plug it back onto the pins designated for that terminal block.

Stranded wire must be between 16 and 24 AWG. Solid wire must be between 18 and 24 AWG.

This is the total thickness measurement so, if you are putting two wires in, the combined thickness

must fall within this range. NEVER try to insert more than two wires per terminal.

6. ENSURE GOOD CONNECTIONS. A light tug on the wire will tell you if the connection is secure.

When reconnecting system components, make sure all pins are straight on chips, connectors, and

terminal block heads.

7. READ MARKINGS CAREFULLY. The connection points are marked on the boards clearly.

Before making any connection, be sure to read the marking and check it against the corresponding

figure in these instructions so that you understand the connection you are making.

8. TRAIN YOUR CUSTOMERS THOROUGHLY. Although customer responsibility is limited to proper

installation, the quality of service is determined by the care of system set up. Ensure that the

customer has a copy of this manual to guide them. It will save you and them lots of inconvenience

and aggravation later.

Rev E Doc 01-20201 2 of 33

PART 1

MASTER/SLAVE OPERATION

A. WHAT IS MASTER/SLAVE OPERATION?

The easy way to understand master/slave operation is by the computer terms “smart” and “dumb”.

• “Smart” machines are controlled by a computer or dedicated microprocessor, such as microwave

ovens and new-style washing machines.

• “Dumb” machines are controlled by simple electronic or physical mechanisms, like old-style washing

machines with their cams and timers.

When your installation requires using two gates together, they can be controlled either by the “dumb”

method of wiring them in parallel and using limit cams and reclose timers for control (see the Installation

and Operation manual for the individual gate operator), or the “smart” method of enabling the

Master/Slave programming built into the gate operators.

LiftMaster gate operators are capable of handling any gate combination you’re likely to need, and we

strongly recommend using the “smart” method for the following reasons:

1. Synchronization: Gate actions (opening, closing, etc.) are synchronized in Master/Slave

operation.

2. Added safety: A fault in one unit affects both units, providing added safety to the system.

3. Reduced wiring: Inputs (radio, exit loops, etc.) need be wired to only one unit in some

Master/Slave configurations.

4. Simplified gate setting: Gate controls (Anti-Tailgate, Reclose Timer, etc.) only need to be

set in one unit in some Master/Slave configurations.

Let’s take a quick look at some Master/Slave gate configurations, cover the wiring and setup procedures,

then go into the details of each type to help plan your installation.

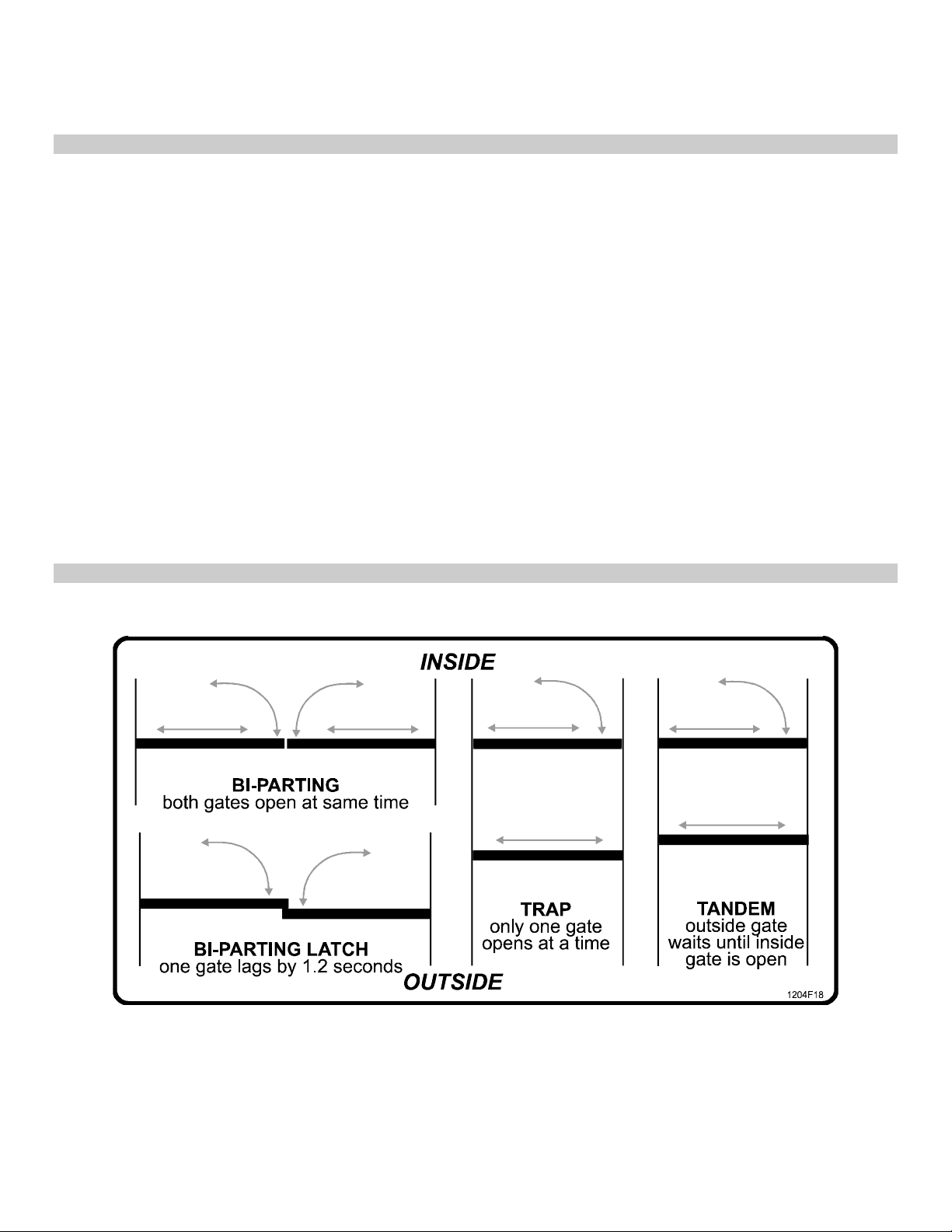

B. MASTER/SLAVE GATE CONFIGURATIONS

LiftMaster models SL 1000-B3 (slide gate), SW 2000-B3 (swing gate), and BG 3000-B3 (barrier gate)

can be teamed as Master/Slave systems in the following configurations:

Figure 1. Master/Slave Gate Configurations.

• In the Master/Slave configuration, one Master unit controls one Slave unit.

• Master and Slave units communicate at 9600 baud via a 4-wire interconnection cable.

Rev E Doc 01-20201 3 of 33

C. MASTER/SLAVE INSTALLATION DETAILS

1. BI-PARTING GATE DETAILS

The simple Bi-Parting Gate is typically used in low traffic residential sites due to its ease of use. The BiParting configuration can consist of any combination of models SL 1000-B3 (slide gate),

SW 2000-B3 (swing gate), and BG 3000-B3 (barrier gate).

ADDITIONAL

INPUTS:

Radio

Cycle

Interrupt Bar

Photo-Sensors

Fire

MagLock

Manual Inputs

COMPLEX

Exit Loop

Inside Interrupt

Loop

Operator

Fence

Gate

Master

Shadow Loop

(swing gates only)

Master/Slave Cable

Master Gate

Slave Gate

Gate

Operator

Slave

Fence

Outside Interrupt

Connect MagLock to one unit only.

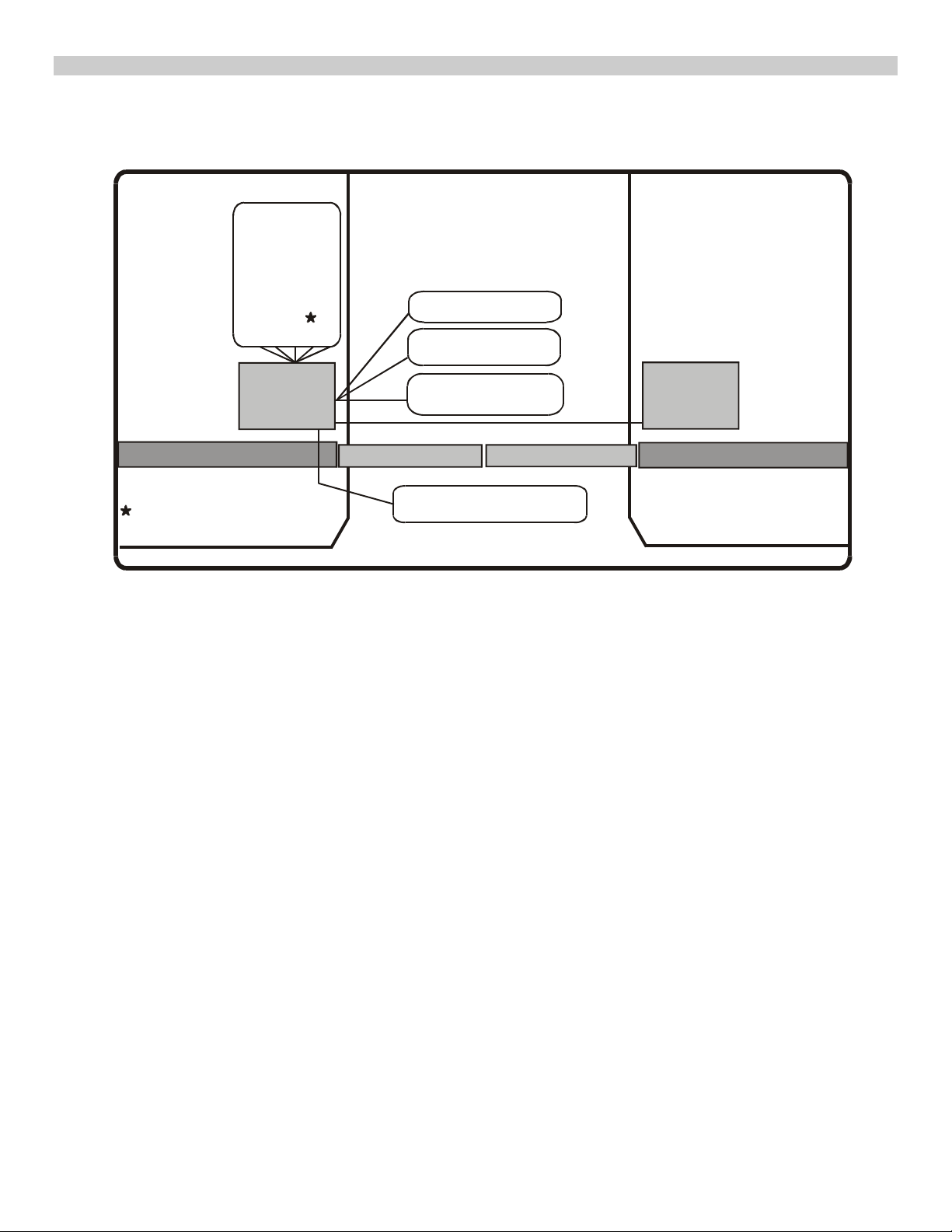

Figure 2. Typical Bi-Parting Gate Installation.

HOW IT WORKS:

• The gates in a Bi-Parting configuration are mirror images of each other and act identically.

• A Fault in one unit affects both units (see Troubleshooting/Maintenance for Fault List in the

Installation and Operation manual for the individual gate).

• A Continuous open input in either unit opens the gates and holds them open.

There are 3 different ways to close the gates (entering or exiting):

1. Reclose Timer: When the Reclose Timer expires, gates close automatically.

2. ATG (Anti-Tailgate) and Interrupt Loop: With ATG ON, clearing the Inside Interrupt Loop closes the

gates. NOTE: For safety reasons, ATG does not function with gate type SWING or LINEAR.

3. Alternate Action: With ATG and TIMER OFF, a Radio or CYCLE command will close fully-open

gates.

INPUT CONNECTIONS: Refer to Part 2, Master/Slave Layout and Wiring, for more details.

• Inputs can be connected to either gate.

Loop

STREET

1384F2

Rev E Doc 01-20201 4 of 33

2. BI-PARTING LATCH GATE DETAILS

The Bi-Parting Latch Gate is typically used in low traffic residential sites due to ease of use and added

security of magnetic locking. The Bi-Parting Latch configuration can consist of any combination of

models SL 1000-B3 (slide gate), SW 2000-B3 (swing gate), and BG 3000-B3 (barrier gate).

ADDITIONAL

INPUTS:

Radio

Cycle

Interrupt Bar

Photo Sensors

Fire

MagLock

Manual Inputs

COMPLEX

Exit Loop

Inside Interrupt

Loop

Gate

Operator

Master

Shadow Loop

Master/Slave Cable

Gate

Operator

Slave

Fence

Connect MagLock to one unit only.

Outside Interrupt

Loop

STREET

Fence

1384F3

Figure 3. Typical Bi-Parting Latch Gate Installation.

HOW IT WORKS:

• The Master moves first during opening and the Slave first during closing, with a 2 second delay

between them to prevent gate intercollision and to ensure proper latching. When the gates are fully

closed, the outer edge of the Master gate rests on the outer edge of the Slave gate.

• A fault in one unit affects both units (see Troubleshooting/Maintenance for Fault List in the

Installation and Operation manual for the individual gate operator).

• A continuous open input in either unit opens the gates and holds them open.

There are 3 different ways to close the gates (entering or exiting):

1. Reclose Timer: When the Reclose Timer expires, gates close automatically.

2. ATG (Anti-Tailgate) and Interrupt Loop: With ATG ON, clearing the Inside Interrupt Loop closes the

gates. NOTE: For safety reasons, ATG does not function with gate type SWING or LINEAR.

3. Alternate Action: With ATG and TIMER OFF, a RADIO or CYCLE command will close the fully

open gates.

INPUT CONNECTIONS: Refer to Part 2, Master/Slave Layout and Wiring, for more details.

• Inputs can be connected to either unit.

Rev E Doc 01-20201 5 of 33

3. TRAP GATE DETAILS

The Trap gate is typically used in secured sites for screening incoming and/or outgoing traffic. In the

Trap configuration, only one gate opens at a time, “trapping” the vehicle between gates. Due to ease of

use, Slide Gates are the most popular for the Trap configuration. The Trap configuration can consist of

any LiftMaster model for the Master, and a model SL 1000-B3 (slide gate), or BG 3000-B3 (barrier gate)

for the Slave. NOTE: The SW 2000-B3 (swing gate) may not be used for the Slave gate.

ADDITIONAL

INPUTS:

Radio

Cycle

Interrupt Bar

Photo-Sensors

Fire

MagLock

Manual Inputs

COMPLEX

Inside Interrupt

Loop

Gate

Operator

Master

Shadow Loop

(swing gate only)

Master/

Slave

Cable

ADDTIONAL

INPUTS:

Radio

Cycle

Interrupt Bar

Photo-Sensors

Fire

MagLock

Manual Inputs

Outside Interrupt

Loop

Gate

Operator

Inside Interrupt

Loop

Slave

Outside Interrupt

Loop

STREET

Figure 4. Typical Trap Gate Installation.

HOW IT WORKS

• In normal operation, one gate must completely close before the other opens, so only one gate is

open at a time. As soon as one gate closes, the second gate automatically opens. If the second

gate does not open within 10 seconds, the first gate reopens to let the vehicle exit the trap area.

• ATG (Anti-Tailgate) is always active for both Master and Slave units. Each gate closes as soon as its

Inside Interrupt loop clears.

• Faults and Manual Input Commands in one unit affect both units.

• A continuous FIRE or Manual OPEN input in either unit opens the gates and holds them open.

• If a vehicle stalls between the gates and they close, they can be opened by a CYCLE or RADIO

command, or by driving over the Slave unit Inside Interrupt Loop (gate to SLIDE or BARRIER only).

1384F4

Rev E Doc 01-20201 6 of 33

There are 2 different ways to close the gate (entering or exiting):

1. Reclose Timer: When the Reclose Timer expires, gate closes automatically (Master or Slave).

2. Interrupt Loop: clearing the Inside Interrupt Loops cause the gates to close (Master or Slave).

NOTE: To ensure gate closure, set Reclose Timer = ON in both Master and Slave units.

INPUT CONNECTIONS: Refer to Part 2 Master/Slave Layout and Wiring, for more details

• Master and Slave units require their own separate inputs.

• If Radio inputs are used in both units, each requires its own transmitter and entry code.

Rev E Doc 01-20201 7 of 33

4. TANDEM GATE DETAILS

The Tandem gate is typically used in high traffic situations where some control of incoming and/or

outgoing traffic is required. The outside gate (slave) is usually a less expensive fast moving

barrier gate (or light slide gate) which protects the more expensive and less mobile Slide or Swing

inside gate (master). The outside gate does this by stopping the vehicle until the inside gate is

completely open. The Tandem configuration can consist of any LiftMaster model for Master, and

a model SL 1000-B3 (slide gate), or BG 3000-B3 (barrier gate) for Slave. NOTE: The SW 2000B3 (swing gate) may not be used for Slave.

ADDTIONAL

INPUTS:

Radio

Cycle

Interrupt Bar

Photo-Sensors

Fire

MagLock

Manual Inputs

COMPLEX

Exit Loop

Inside Interrupt

Loop

Gate

Operator

Master

Shadow Loop

(swing gate only)

Master/

Slave

Cable

ADDITIONAL

INPUTS:

Radio

Cycle

Interrupt Bar

Photo-Sensors

Fire

MagLock

Manual Inputs

Gate

Operator

Slave

Figure 5. Typical Tandem Gate Installation.

Outside Interrupt

Loop

Inside Interrupt

Loop

Outside Interrupt

Loop

STREET

1384F5

Rev E Doc 01-20201 8 of 33

Loading...

Loading...