Page 1

Smart Garage Opener

• Please read this manual and the enclosed safety materials carefully!

• Fasten the manual near the garage door after installation.

• The door WILL NOT CLOSE unless the Protector System® is connected

and properly aligned.

• Periodic checks of the garage door opener are required to ensure

safe operation.

Owner’s Manual

B980

Belt Drive

Garage Door Opener

FOR RESIDENTIAL USE ONLY

PRE-PROGRAMMED REMOTE CONTROL

INCLUDED

TO WATCH VIDEOS GO TO:

tinyurl.com/lgh5x3h

• The model number label is located on the left side panel of your

garage door opener.

• This garage door opener is compatible with MyQ® and

Security+b2.0® accessories.

• DO NOT install on a one-piece door if using devices or features

providing unattended close. Unattended devices and features are

to be used ONLY with sectional doors.

Contents

Preparation ......................................2-5

Assembly .........................................6-9

Installation .................................. 10-28

Install the Door Control ............20-21

Install the Protector System® ....22-25

Install the Automatic Door Lock ......26

Connect power ..............................27

Adjustments .................................29-31

Battery Backup ..................................32

MyQ® Smartphone Control .................33

Operation .....................................34-38

Using your Garage Door Opener ..... 35

To Open the Door Manually ...........35

Smart Control Panel® ............... 36-37

Remote Control .............................37

To Erase the Memory .....................38

Maintenance .....................................39

Troubleshooting ........................... 40-41

Accessories ........................................42

Warranty ...........................................43

Automatic Garage Door Opener

Safety & Maintenance Guide .......... 44-45

Repair Parts ................................. 46-47

www.chamberlain.com

www.mychamberlain.com

Page 2

Torsion

Spring

Extension

Spring

OR

Preparation

Safety Symbol and Signal Word Review

This garagedoor opener has been designedandtestedto offer safeservice provided it is installed, operated,

maintained and tested in strict accordancewith theinstructions and warnings containedin this manual.

Whenyou see these Safety Symbols and Signal Words on

the followingpages, they will alert you to the possibility of

Mechanical

serious injury or death if youdo not comply with the

warnings that accompany them.The hazard may come

from somethingmechanical or from electric shock. Read

Electrical

the warnings carefully.

Whenyou see this Signal Word onthe followingpages, it

will alert you to thepossibility of damageto your garage

door and/or the garage door opener if you do notcomply

with thecautionary statements that accompany it. Read

themcarefully.

WARNING: This product can expose youto chemicals including lead, which are known to the State of

California to cause cancer or birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov

Unattended Operation

The Timer-to-Close (TTC) feature, the MyQ®SmartphoneControl app, and MyQ®Garage Door andGate Monitor

are examples of unattendedclose and are to be used ONLY with sectional doors. Anydevice or feature that allows the

door to close without being in the line of sightof the door is considered unattended close. TheTimer-to-Close (TTC)

feature, the MyQ®SmartphoneControl, and any other MyQ®devices are to be usedONLY with sectional doors.

Check the Door

To preventpossible SERIOUSINJURYor DEATH:

l ALWAYScall a trained door systems technician if garage door binds, sticks, or is out ofbalance. An

unbalanced garage door may NOT reverse whenrequired.

l NEVER try to loosen, move or adjust garage door, door springs, cables, pulleys, brackets or their hardware,

ALLof which are under EXTREME tension.

l DisableALLlocks and removeALLropes connected to garage door BEFORE installationandoperating

garagedoor opener to avoid entanglement.

l DO NOT install ona one-piece door if usingdevices or features providingunattended close.Unattended

devices and features are to be used ONLY with sectional doors.

To preventdamageto garage door and opener:

l ALWAYSdisable locks BEFORE installing and operating the opener.

l ONLY operate garage door opener at 120V, 60Hz toavoid malfunction and damage.

Before you begin:

1. Disable locks andremove any ropes connectedto the garage door.

2. Lift the door halfway up. R elease the door. Ifbalanced, it should stay in place,

supportedentirely byits springs.

3. Raise andlower thedoor to check for bindingor sticking. If your door binds,

sticks, or is out ofbalance,call a trained door systems technician.

4. Check theseal on the bottomof the door. Any gap between the floor andthe

bottom of the door must not exceed 1/4 inch (6 mm). Otherwise, the safety

reversal system may not work properly.

5. The opener should beinstalled above the center ofthe door. If there is a torsion

spring or center bearing plate in the way of the header bracket, it may be

installed within 4feet (1.2 m) to the leftor right of the door center. See page 11.

2

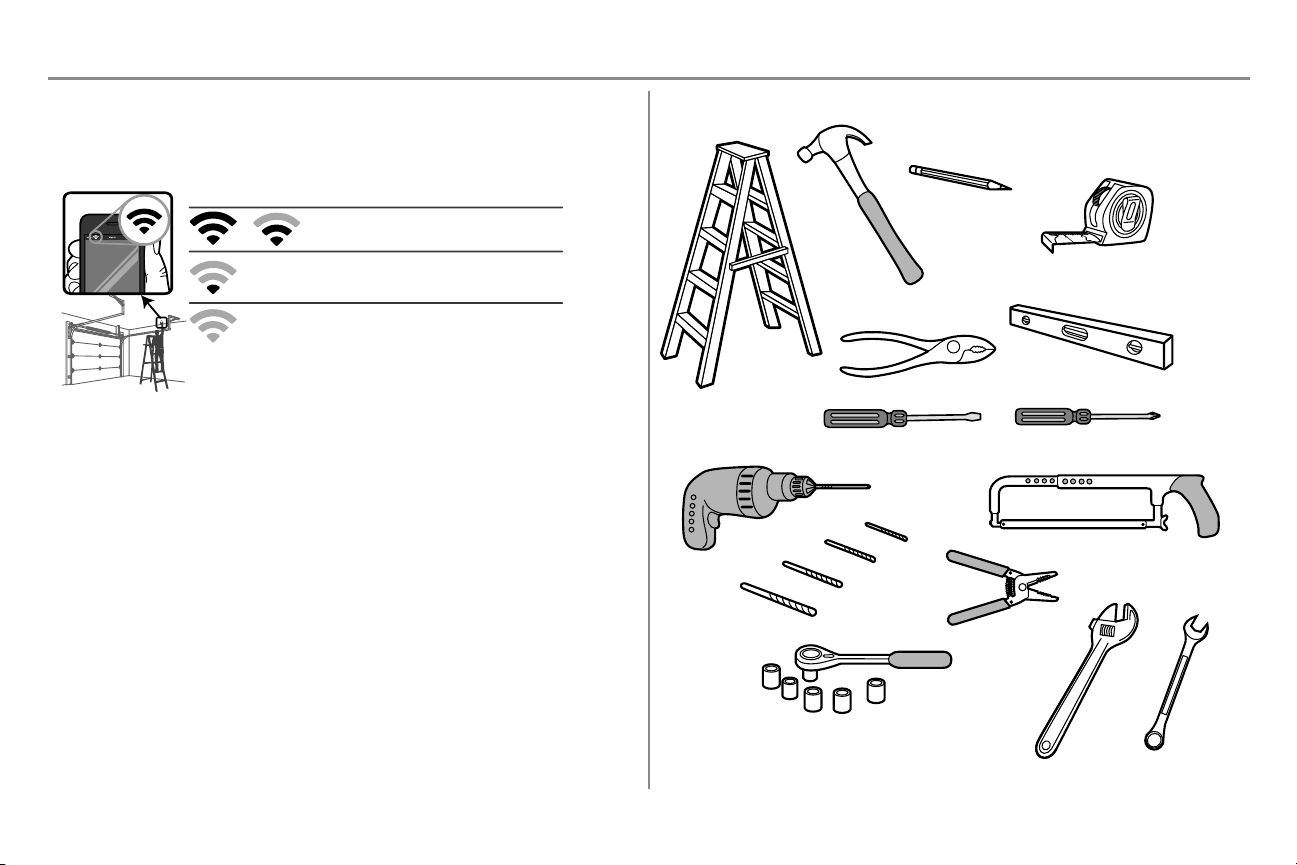

Page 3

Wi-Fi signal is weak.

The garage door opener will likely connect to your Wi-Fi

network. If not, try one of the options below

.

No Wi-Fi signal. Try one of the following:

• Move your router closer to the garage door opener to

minimize interference from walls and other objects

• Buy a Wi-Fi range extender

• Buy a Chamberlain MyQ® Internet Gateway (CIGBU) see page 41

Check Signal Strength. If you see:

Wi-Fi signal is strong. You’re all set!

Install your new garage door opener.

Visit wifihelp.chamberlain.com for more details

3/16

7/16

1/2

5/32

5/16

3/4

5/8

9/16

1/4

7/16

Preparation

Before You Connect with Your Smartphone

Monitor andcontrol your garagedoor from anywhere usingthe MyQ®app.Youwill need a router with Wi-Fi anda

smartphone or other mobile device. Make sure your mobile device is connectedto your Wi-Fi network. Hold your

mobile device in the place where your garagedoor opener will be installedandcheck the Wi-Fi signal strength.

See MyQ®SmartphoneControl page 33 to connect your garagedoor opener to your Wi-Fi network.

AdditionalItems You May Need:

Survey your garage area to see if you will need any of thefollowing items:

l (2) 2X4Piecesof wood : May be used to fasten the header bracket to the structural supports. Also used to

position the garage door opener during installation and for testingthesafety reversing sensors.

l Support bracket and fastening hardware: Must be usedif you havea finished ceiling in your garage.

l Extension brackets (MODEL 041A5281-1) or wood blocks: Depending upongarageconstruction,

extensionbrackets or woodblocks may beneeded to install the safety reversing sensor.

l Fastening hardware: Alternatefloor mountingof the safety reversing sensor will require hardware not

provided.

l Door reinforcement: Required if you have a lightweight steel, aluminum,fiberglass or glass panel door.

l Rail extension kit: Required if your garagedoor is more than 7 feet(2.13 m) high.

Tools Needed

3

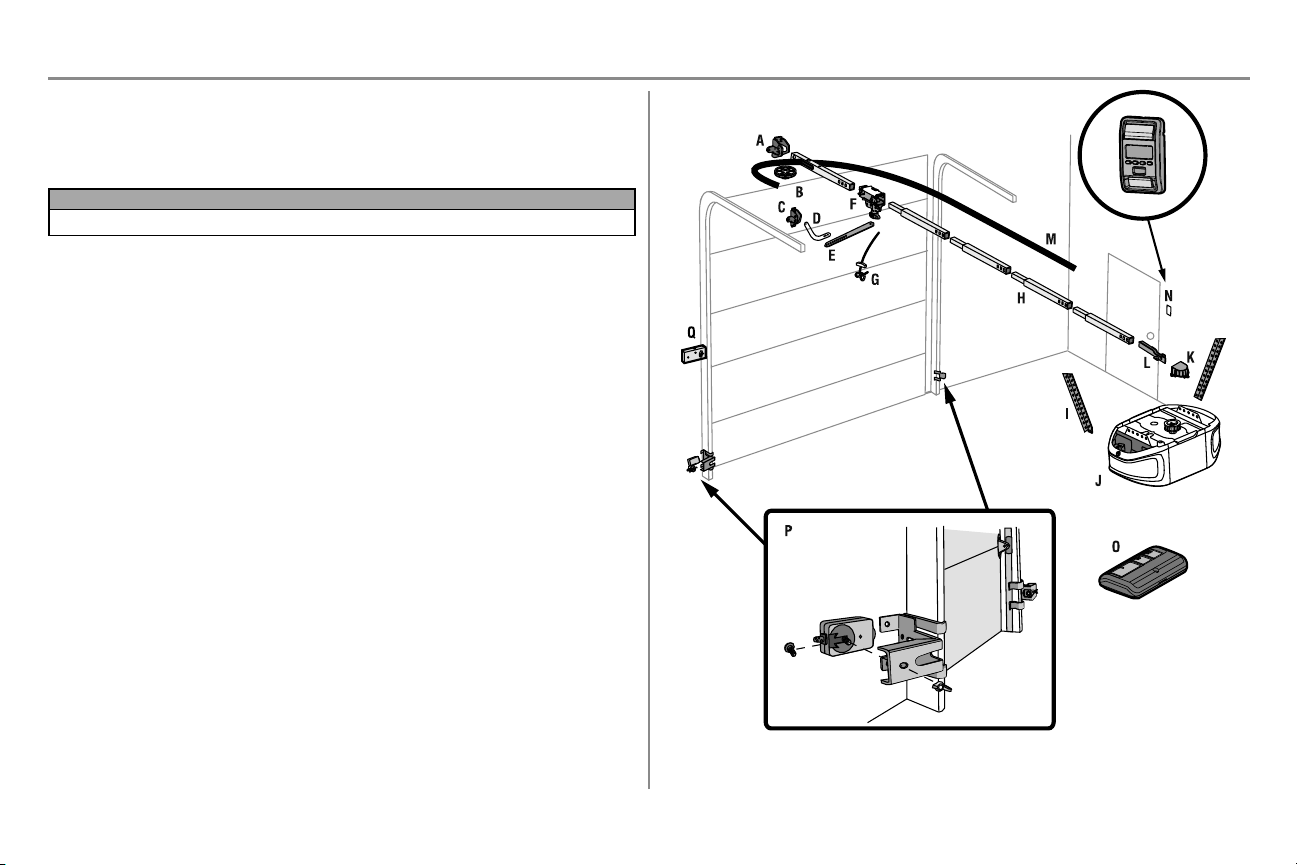

Page 4

Preparation

CartonInventory

Save the cartonandpacking material until theinstallation and adjustmentis complete. Instructions for the accessories

will beattached to the accessory and are not includedin this manual. Theimagesthroughout this manual are for

reference only andyour product may look different.

Model Power Door Control Remote Control Wireless Keypad

B980 Max Lift Power System™

A. Header bracket

B. Pulley

C. Door bracket

D. Curved door arm

E. Straight door arm

(Packaged inside frontrail section)

F. Trolley

NOTE: Be sure to assemble the trolley before sliding onto rail.

G. Emergency releaserope and handle

H. Rail (1 frontand4 center sections)

I. Hanging brackets (2)

(Packaged inside thefront rail section)

J. Garage door opener (motor unit)

K. Sprocket cover and screws

L. “U” bracket

M. Belt

N. Door Control

O. Remote control

P. The Protector System

Safetyreversing sensors with 2conductor white and white/black wire attached: Sending Sensor (1),

ReceivingSensor (1), and Safety Sensor Brackets (2)

Q. Automatic GarageDoor Lock

NOT SHOWN

Wireless keypad

White and red/white wire

Owner's manual

Hardware

Smart Control Panel

®

®

3-button(2)

ü

4

Page 5

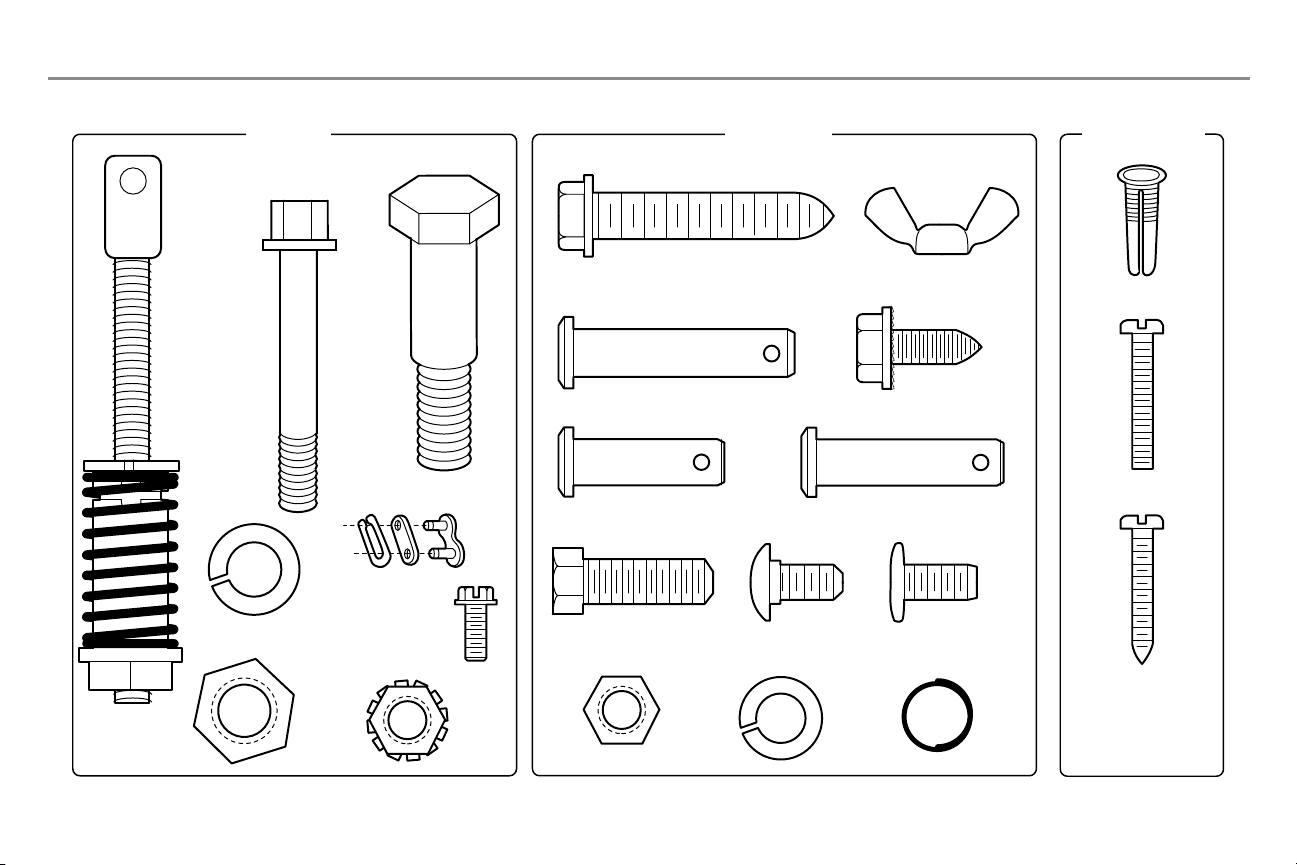

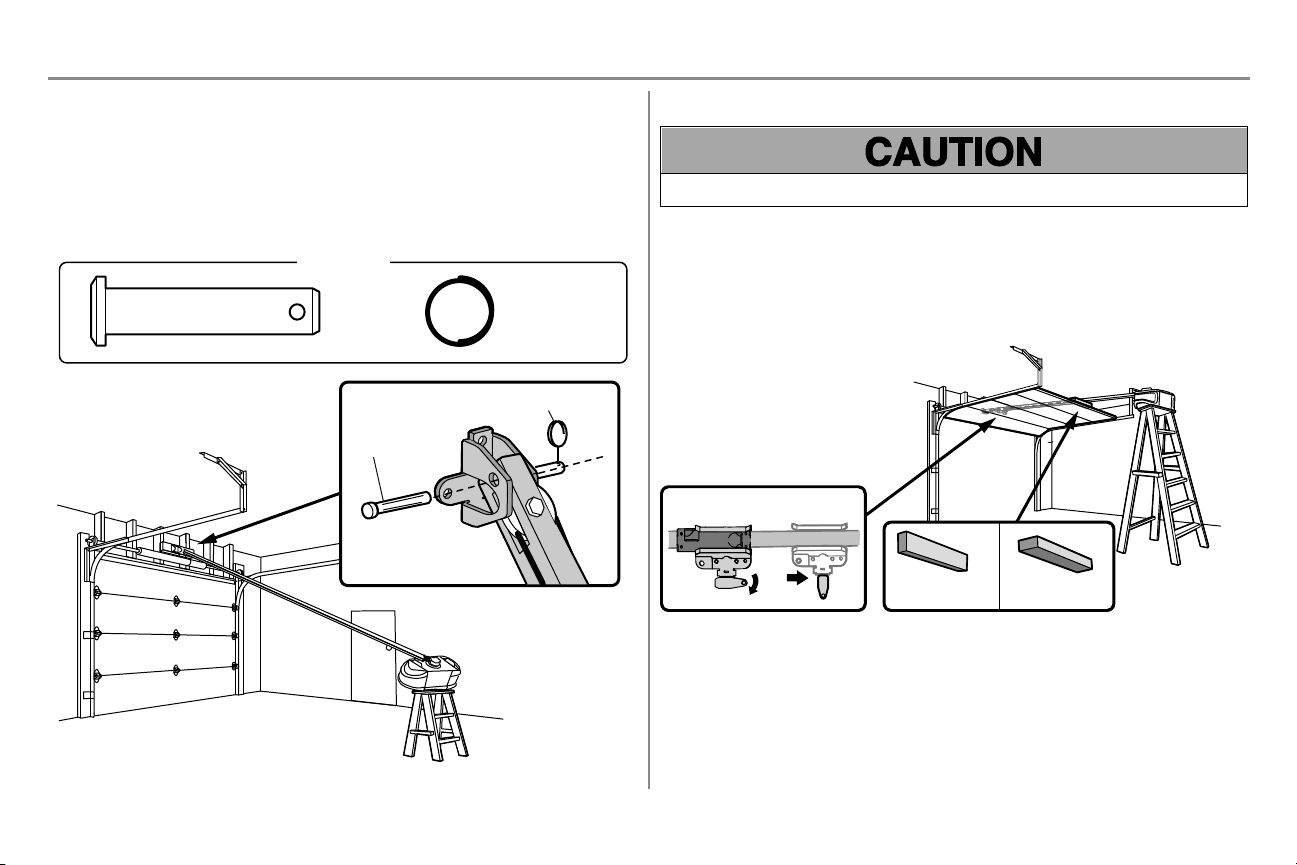

ASSEMBLY INSTALLATION

DOOR CONTROL

Insulated Staples

(N

ot Shown)

Clevis Pin 5/16"x1-1/2"

Ring

Fastener (3)

Hex Bolt 5/16"-18x7/8" (4)

Self-Threading Screw

1/4"-14x5/8" (2)

Clevis Pin 5/16"x1"

Clevis Pin 5/16"x1-1/4"

Carriage Bolt

1/4"-20x1/2" (2)

Screw

1/4"-20x1/2" (2)

Wing Nut

1/4"-20 (2)

Lag Screw 5/16"-9x1-5/8" (4)

Screw 6ABx1" (2)

Drywall Anchors (2)

Screw 6-32x1" (2)

Hex Screw #8x3/8" (3)

(packed with the

sprocket cover)

Bolt

1/4"-20x1-3/4"

Lock Nut

1/4"-20

Bolt

Nut 3/8"

Lock Washer 3/8"

Master Link

Threaded

Shaft with

Spring

Trolley Nut

Lock Washer

5/16"-18 (4)

Nut

5/16"-18 (4)

Preparation

Hardware

5

Page 6

Assembly

Wear Pads

Front Rail Section

(TO DOOR)

“U” Bracket

(TO MOTOR UNIT)

Trolley

Rail Tab

On Top

Slide to stops

on top and sides

of “U” bracket

Screwdriver

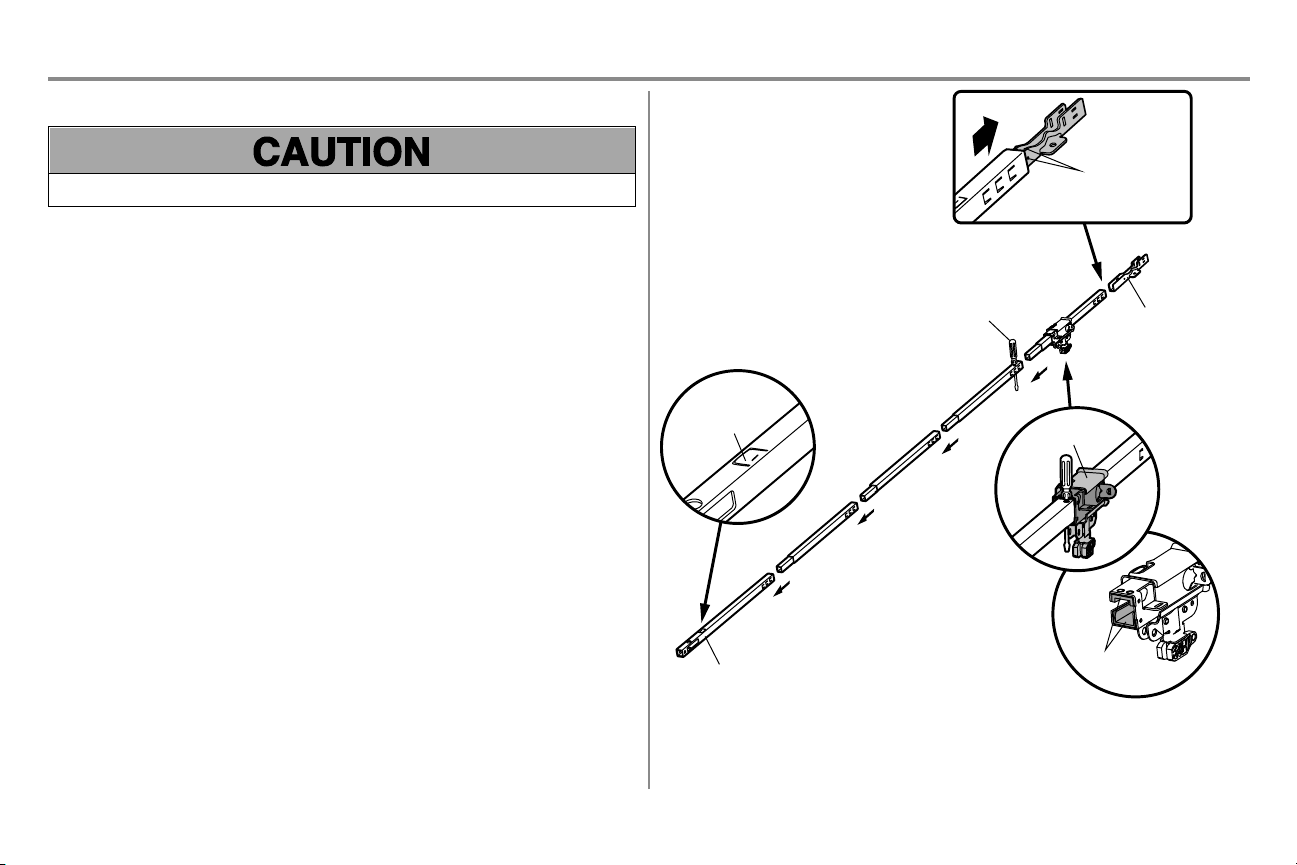

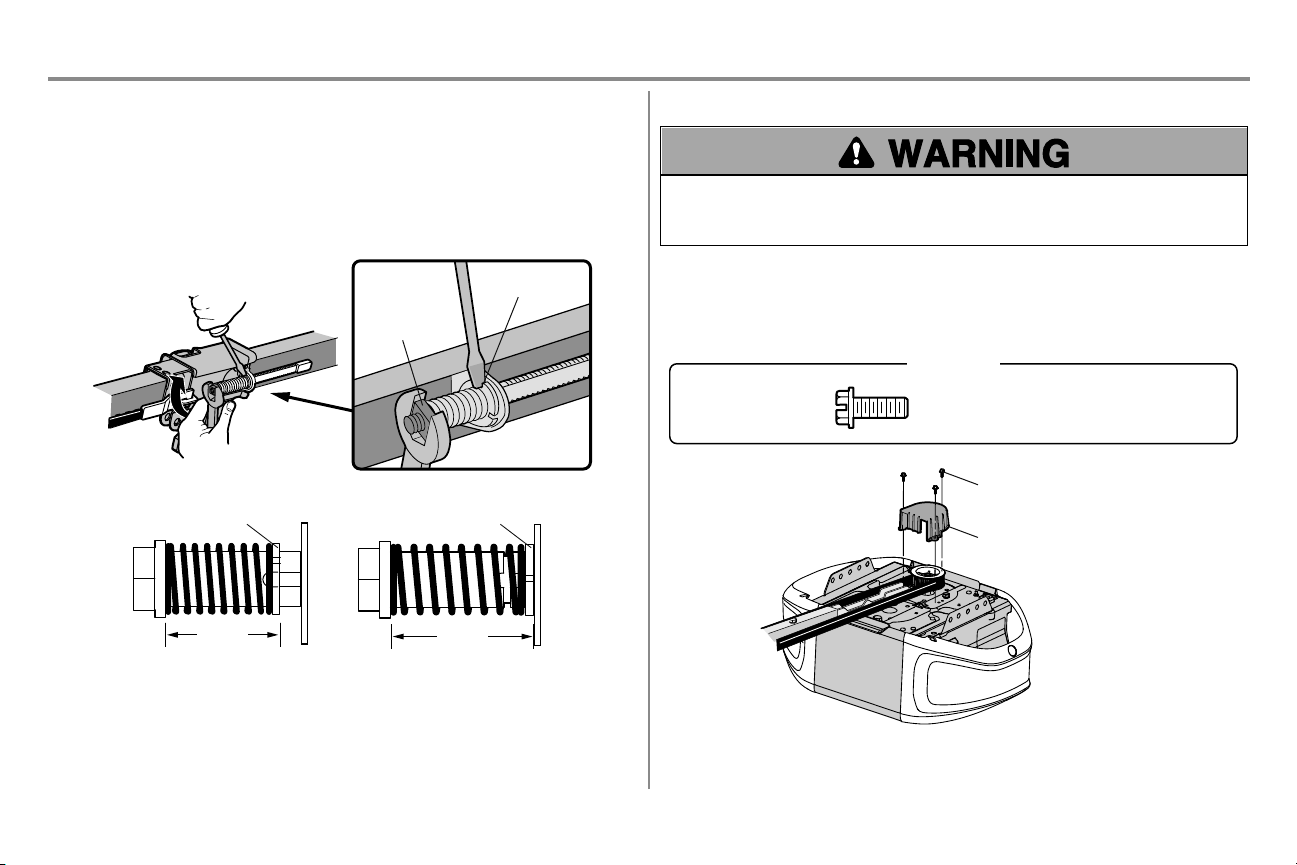

STEP 1 Assemble the rail and install the trolley

To preventINJURY frompinching,keep hands and fingers away fromthejoints while assembling the rail.

To avoid installation difficulties, do not run the garage door opener until instructed to do so.

The frontrail has a cut out “w indow” at the door end. The rail tab MUST be on top of therail when assembled.

1. Remove the straightdoor arm andhanging bracket packagedinside the frontrail andset asidefor

Installation Step 5 and 9. NOTE: To prevent INJURY while unpacking the r ail carefully removethe straight

door arm stored within the rail section.

2. Align the rail sectionson a flatsurface as shown and slide the tapered ends intothe larger ones.Tabs

alongthe side will lock into place.

3. Place the motor unit onpacking material toprotect the cover, andrest the back endofthe rail on top. For

convenience, put a support under the frontendof the rail.

4. As atemporary stop,insert a screwdriver into the hole in the second rail section from the motor unit, as

shown.

5. Check tobe sure there are 4plastic wear pads inside the inner trolley. If they becameloose during

shipping, check all packing material. Snap themback intoposition as shown.

6. Slide the trolley assembly toward the screwdriver as shown.

7. Slide the rail onto the “U” bracket, until it reachesall thestops on the top and sides of the “U” bracket.

6

Page 7

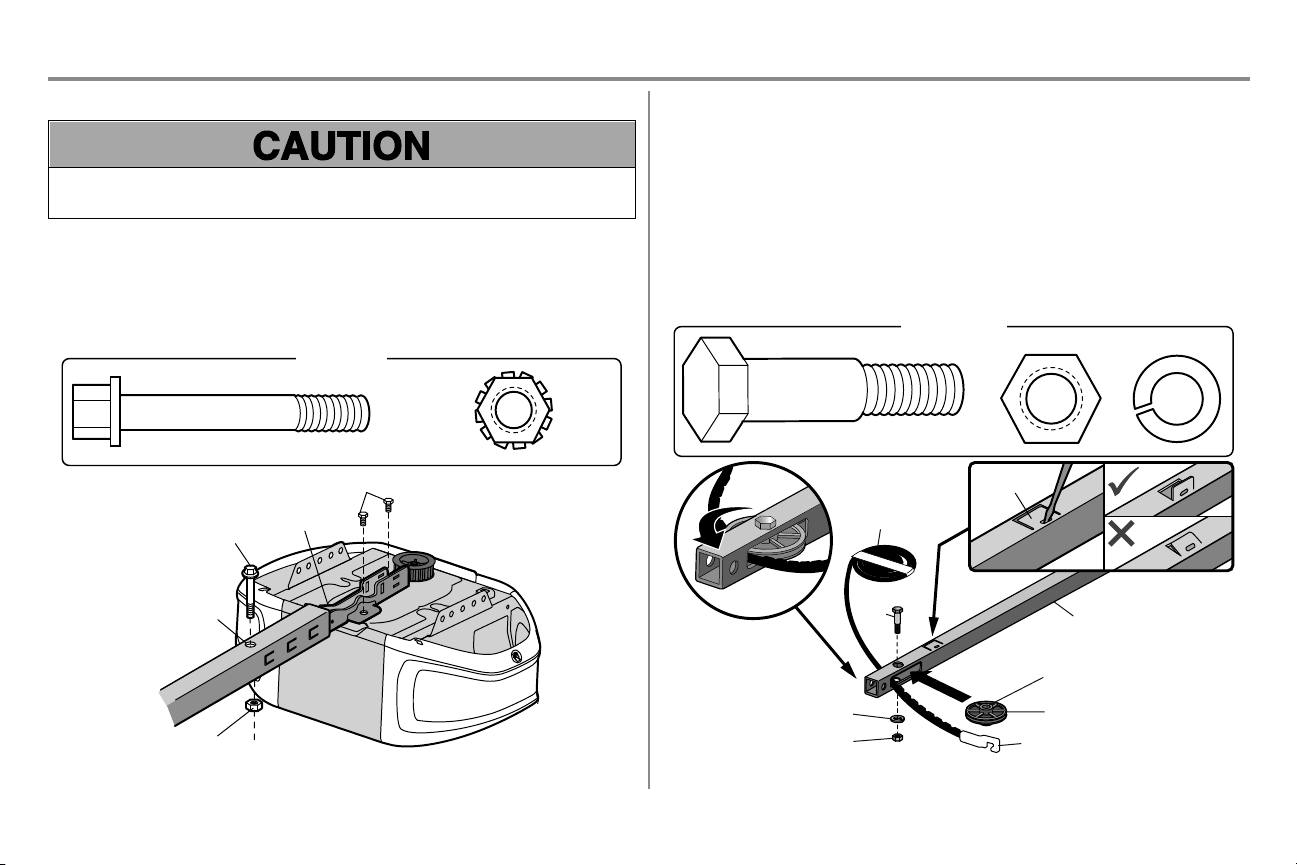

Assembly

Bolt

1/4"-20x1-3/4"

Lock Nut

1/4"-20

HARDWARE

“U” Bracket

Cover Protection

Bolt Hole

Bolt

Lock Nut

Bolts (Mounted in the garage door opener)

Rail

Idler Pulley

Grease Inside Pulley

Bolt

Belt

Lock Washer

Nut

Bolt

Nut 3/8" Lock Washer 3/8"

HARDWARE

Trolley Connector

Rail Tab

STEP 2 Fasten the rail to the motor unit

To avoid SERIOUS damageto garage door opener, use ONLY those bolts/fasteners mountedin the top of the

opener.

1. Insert a 1/4"-20 x 1-3/4" bolt intothe cover protectionbolt hole on theback end of the rail as shown. Tighten

securely with a1/4"-20 lock nut. DO NOT overtighten.

2. Remove the bolts from the top of the motor unit.

3. Use thecarton to support the frontendof the rail.

4. Place the “U” bracket, flat side down onto the motor unit andalign the bracket holes with the bolt holes.

5. Fasten the “U” bracket with the previously removed bolts; D O NOT useany power tools. Theuse of power

tools may permanently damage the garage door opener.

STEP 3 Install the idler pulley

1. Lay the belt besidetherail, as shown. Grasp theendwith thehooked trolley connector and pass

approximately 12" (30 cm) of belt through the window. Keep the ribbed side toward the rail, and allow it to

hanguntil Assembly Step4.

2. Remove the tape from the idler pulley. The inside center should bepre-greased. If dry, regreaseto ensure

proper operation.

3. Place the idler pulley into the window as shown.

4. Insert the idler bolt from the top through the rail and pulley. Tightenwith a 3/8" lock washer and nut

underneaththe rail until thelock washer is compressed.

5. Rotate the pulley to be sure it spins freely.

6. Locatetherail tab. The rail tabis between the idler bolt andthetrolley in the frontrail section. Use a

flathead screwdriver and lift the rail tabuntil thetab is vertical (90º).

7

Page 8

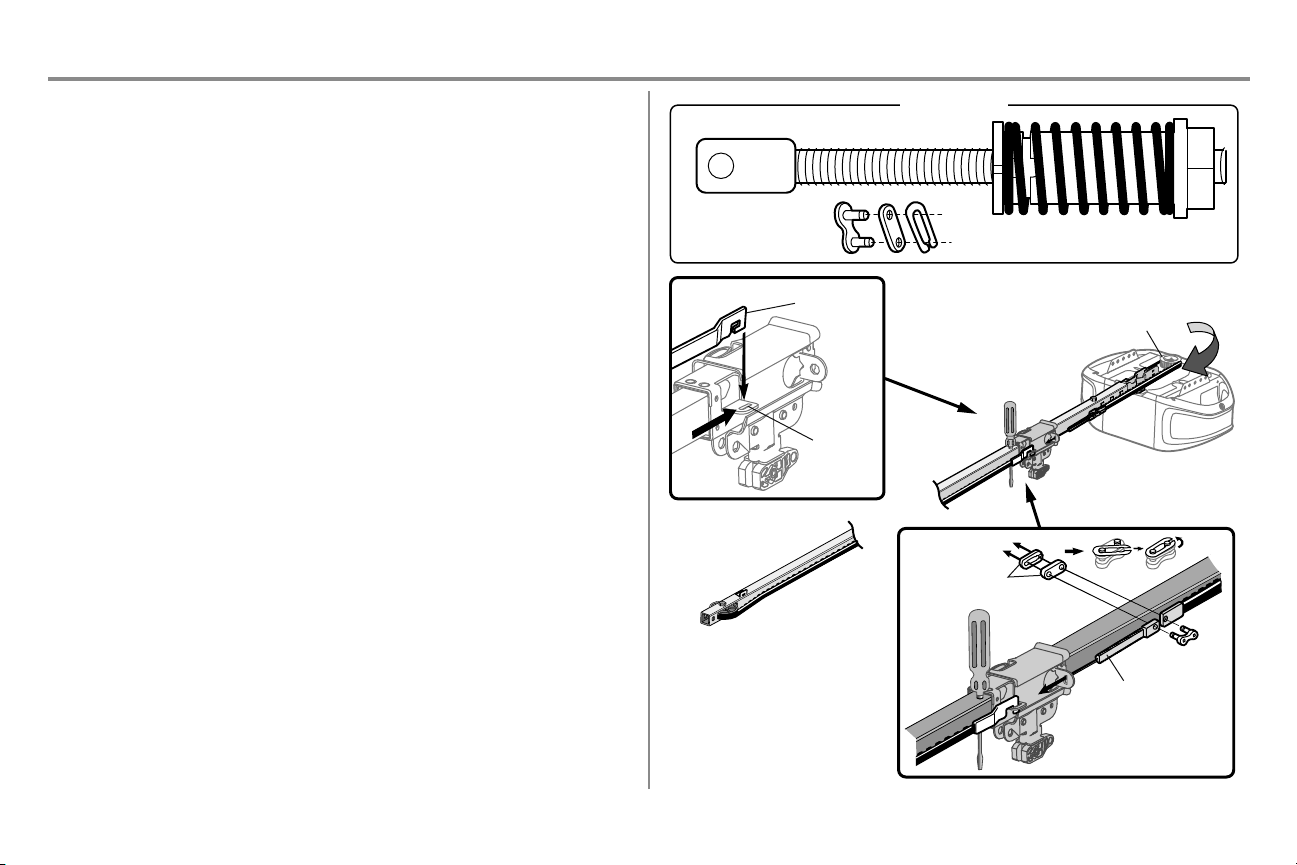

Assembly

HARDWARE

Master Link

Figure 3

Threaded Shaft with Spring Trolley Nut

Threaded Shaft

Master Link

Sprocket

Figure 2

Figure 1

Trolley

Connector

Retaining

Slot

STEP 4 Install the belt

1. Pull thebelt around the idler pulley and toward thetrolley. The ribbedside must contact the pulley.

2. Hook thetrolley connector intothe retaining slot on the trolley as shown (Figure 1).

3. With the trolley against the screwdriver, dispense the remainder of thebelt along the rail lengthtoward the

motor unit and around the sprocket (Figure 2). Thesprocket teeth must engagethe belt.

4. Check tomake sure thebelt is not twisted.Connect the trolley threaded shaft with the master link(Figure

3).

l Push pins ofmaster link bar throughholes in end of belt and trolley threadedshaft.

l Push master link capover pins andpast pin notches.

l Slide the closed end of the clip-on spring over oneof the pins. Pushthe openendof the clip-on spring

ontotheother pin.

5. Remove the spring trolley nut fromthe threadedshaft.

6. Insert the trolley threaded shaft through the hole in the trolley.

8

Page 9

Assembly

Spring

Trolley Nut

Nut Ring Slot

Nut RingNut Ring

AFTER

1-1/4" (3.18 cm)

BEFORE

1" (2.5 cm)

Hex Screw #8x3/8"

(Packed with the sprocket cover)

HARDWARE

Hex Screw

Sprocket Cover

STEP 5 Tighten the belt

1. By hand,thread the springtrolley nut on the threaded shaft until it is finger tightagainstthe trolley. Do not

use any tools. R emovethe screwdriver.

2. Insert a flathead screwdriver tip intooneof the nut ring slots and brace it firmly against the trolley.

3. Tighten the spring trolley nut with an adjustable wrench or a 7/16" open end wrench abouta quarter turn

until the spring releases and snaps the nut ring against the trolley. This sets the spring to optimumbelt

tension.

STEP 6 Install the sprocket cover

To avoid possible SERIOUS INJURY to finger frommoving garage door opener:

l ALWAYSkeephandclear ofsprocket while operating opener.

l Securely attach sprocketcover BEFORE operating.

1. Position the sprocket cover over thesprocket as shown and fasten to the mountingplatewith 8x3/8" hex

screws provided.

You have now finished assembling your garagedoor opener. Please read the following warnings before

proceeding to the installation section.

9

Page 10

Installation

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTALLATION WARNINGS AND INSTRUCTIONS.

2. Install garage door opener ONLY on properly balancedandlubricated garage door. Animproperly balanced

door may NOT reverse whenrequired and could result in SEVERE INJUR Y or DEATH.

3. ALL repairs to cables, spring assemblies andother hardware MUST bemade by a trained door systems

technician BEFORE installing opener.

4. Disable ALL locks and remove ALL ropes connectedtogaragedoor BEFORE installing opener to avoid

entanglement.

5. Where possible, install the door opener 7 feet(2.13 m) or more above the floor.

6. Mount the emergency release within reach, but atleast 6 feet (1.83m) above the floor andavoiding contact

with vehicles to avoid accidental release.

7. NEVER connectgaragedoor opener to power source until instructed to doso.

8. NEVER wear watches, rings or loose clothing while installing or servicing opener. They could be caught in

garagedoor or opener mechanisms.

9. Install wall-mountedgaragedoor control:

l within sight of the garage door.

l out of reachof small children ata minimum heightof 5feet (1.5m) above floors, landings, steps or any

other adjacent walking surface.

l away fromALLmoving parts ofthe door.

10. Place entrapment warning label onwall next to garage door control.

11. Place emergency release/safety reverse test label in plain view oninside of garage door.

12. Upon completion of installation,test safety reversal system.Door MUST reverse on contact with a 1-1/2"

(3.8cm) high object (or a 2x4 laid flat) on thefloor.

13. To avoid SERIOUS PERSONAL INJURY or DEATH from electrocution,disconnect ALL electric and battery

power BEFORE performing ANY service or maintenance.

14. DO NOT install ona one-piece door if using devices or features providingunattended close.Unattended

devices and features are to be used ONLY with sectional doors.

10

Page 11

Installation

Header Wall

Vertical Centerline of Garage Door

2x4

Structural

Supports

Level

(Optional)

Unfinished

Ceiling

2x4

OPTIONAL CEILING MOUNT

FOR HEADER BRACKET

Sectional door with curved track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door with horizontal track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door without track:

jamb hardware

Header Wall

8" (20

cm)

Highest

Point of

Travel

Door

Jamb

Hardware

One-piece door without track:

pivot hardware

Header Wall

8" (20

cm)

Highest

Point of

Travel

Door

Pivot

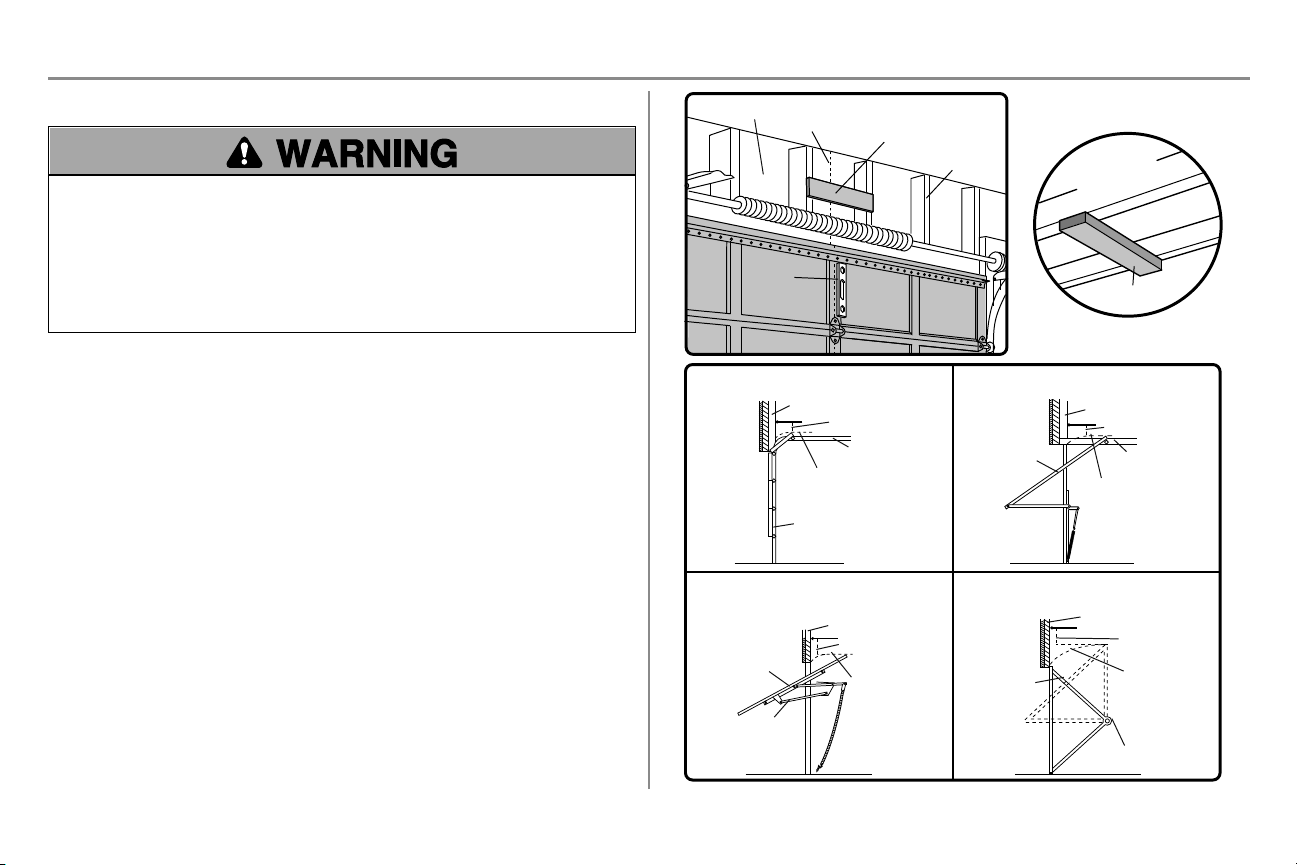

STEP 1 Determine the header bracket location

To preventpossible SERIOUS INJURY or DEATH:

l Header bracket MUST beRIGIDLY fastened to structural support on header wall or ceiling, otherwise

garagedoor might NOT reverse whenrequired. DO NOT install header bracket over drywall.

l Concrete anchors MUST beusedif mountingheader bracketor 2x4into masonry.

l NEVER try to loosen, move or adjust garage door, springs, cables, pulleys, brackets, or their hardware, ALL

of which are under EXTREME tension.

l ALWAYScall a trained door systems technician if garage door binds, sticks, or is out ofbalance. An

unbalanced garage door might NOT reverse whenrequired.

Installation procedures vary accordingto garage door types. Follow theinstructions which apply to your door.

1. Close thedoor and mark theinside vertical centerlineof the garage door.

2. Extendthe line onto the header wall above the door.You can fasten the header bracket within 4 feet (1.22m)

of the left or right of the door center only if a torsion spring or center bearing plate is in the way; or you can

attachit totheceiling (see page 12) whenclearance is minimal. (It may bemountedonthe wall upside

down if necessary, to gainapproximately 1/2" (1 cm). If you need to install the header bracket on a 2x4(on

wall or ceiling), uselag screws (not provided) tosecurely fastenthe2x4 to structural supports as shown

here and on page 12.

3. Open your door tothehighest point of travel as shown. Draw anintersecting horizontal line on the header

wall 2" (5 cm) abovethehigh point:

l 2" (5 cm) abovethe high point for sectional door andone-piece door with track.

l 8" (20 cm) abovethehigh point for one-piece door withouttrack.

This heightwill providetravel clearance for thetopedgeofthe door. N OTE: If the total number of inches exceeds the

height available in your garage, use themaximum height possible, or refer to page 12 for ceiling installation.

11

Page 12

Installation

Lag Screw 5/16"-9x1-5/8"

HARDWARE

UP

Wall Mounting

Holes

WALL INSTALLATION

CEILING INSTALLATION

Optional Mounting

Holes

Vertical

Centerline of

Garage Door

Header Wall

Header

Bracket

2x4

Structural

Support

Door

Spring

Garage Door

Highest Point

of Garage

Door Travel

Horizontal

Line

Lag

Screw

UP

Header Wall

Ceiling Mounting

Holes

Finished Ceiling

Vertical

Centerline of

Garage Door

Header

Bracket

6" (15 cm)

Maximum

Door Spring

Garage Door

Lag Screw

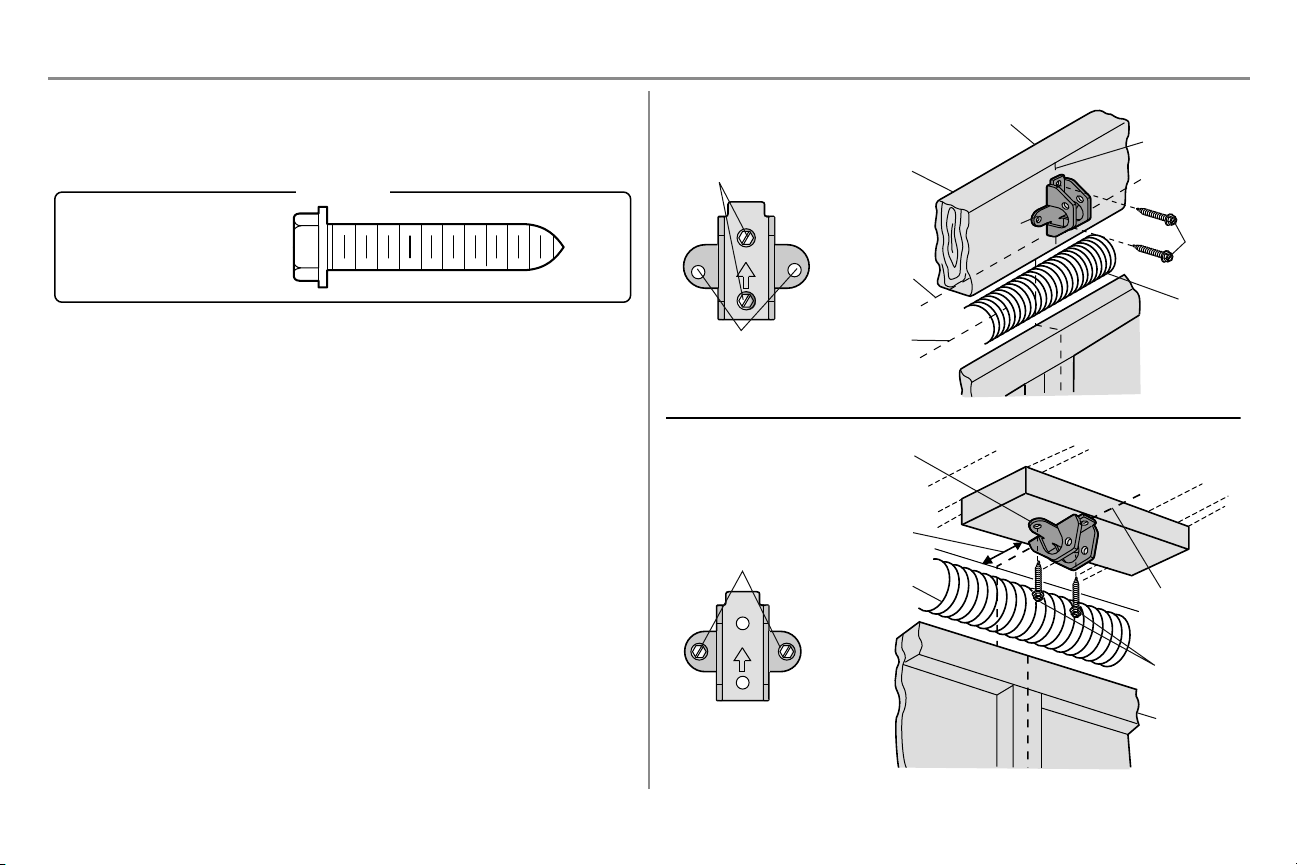

STEP 2 Install the header bracket

You can attach the header bracket either tothewall abovethe garage door, or to the ceiling. Follow the instructions

which will work best for your particular requirements. Do not install the header bracket over drywall. If installing

into masonry, use concrete anchors (not provided).

OPTIONA - WALLINSTALLATION

1. Center the bracket onthe vertical centerlinewith thebottom edgeof the bracket onthe horizontal line as

shown (with thearrow pointingtoward the ceiling).

2. Mark the vertical set of bracket holes. Drill 3/16" pilot holes and fasten the bracket securely to a structural

support with the hardware provided.

OPTIONB - CEILING INSTALLATION

1. Extendthe vertical centerlineontotheceilingas shown.

2. Center the bracket onthe vertical mark, nomore than 6" (15 cm) from the wall. Make sure thearrow is

3. Mark the sideholes. Drill 3/16" pilot holes and fasten bracket securely to a structural support with the

pointingaway fromthewall. The bracket can be mounted flush against the ceiling whenclearance is

minimal.

hardware provided.

12

Page 13

Installation

HARDWARE

Clevis Pin

5/16"x1-1/2"

Ring Fastener

Clevis Pin

Ring Fastener

Connected Disconnected

One-piece door

without tracks

2x4 2x4

All other

door types

STEP 3 Attach the rail to the header bracket

1. Position the opener on thegaragefloor below the header bracket. Use packing material asa protective

base.

NOTE: If thedoor spring is in the way, you w ill need help. Have someone hold the opener securely on a

temporary support to allow the rail to clear the spring.

2. Position the rail bracket against the header bracket.

3. Align the bracket holes and join with a clevis pin as shown.

4. Insert a ring fastener tosecure.

STEP 4 Positionthe garage door opener

To preventdamageto garage door, rest garage door opener rail on2x4 placed on top sectionof door.

1. Remove the packing material and lift the garage door opener onto a ladder.

2. Fully openthe door and place a 2x4 (laid flat) under the rail. For one-piece doors without tracks, lay the

2x4 on it's side.

NOTE: A 2x4 is ideal for setting the distance between the r ail andthe door. If the ladder is not tall enough you will

needhelp at this point. If the door hits the trolley when it is r aised, pull the trolley release arm down to disconnect the

inner and outer trolley. Slide the outer trolley toward thegaragedoor opener. The trolley can remain disconnected

until instructed.

13

Page 14

Installation

Finished Ceiling

Lag Screw

1

2

3

Not

Provided

Not Provided

Not Provided

Hex Bolt

Nut

Lock

Washer

4 5

6

Lag Screw

Finished Ceiling

EXAMPLES

Unfinished Ceiling

HARDWARE

Hex Bolt

5/16"- 18x7/8"

Nut

5/16"-18

Lock Washer

5/16"-18

Lag Screw

5/16"-9x1-5/8"

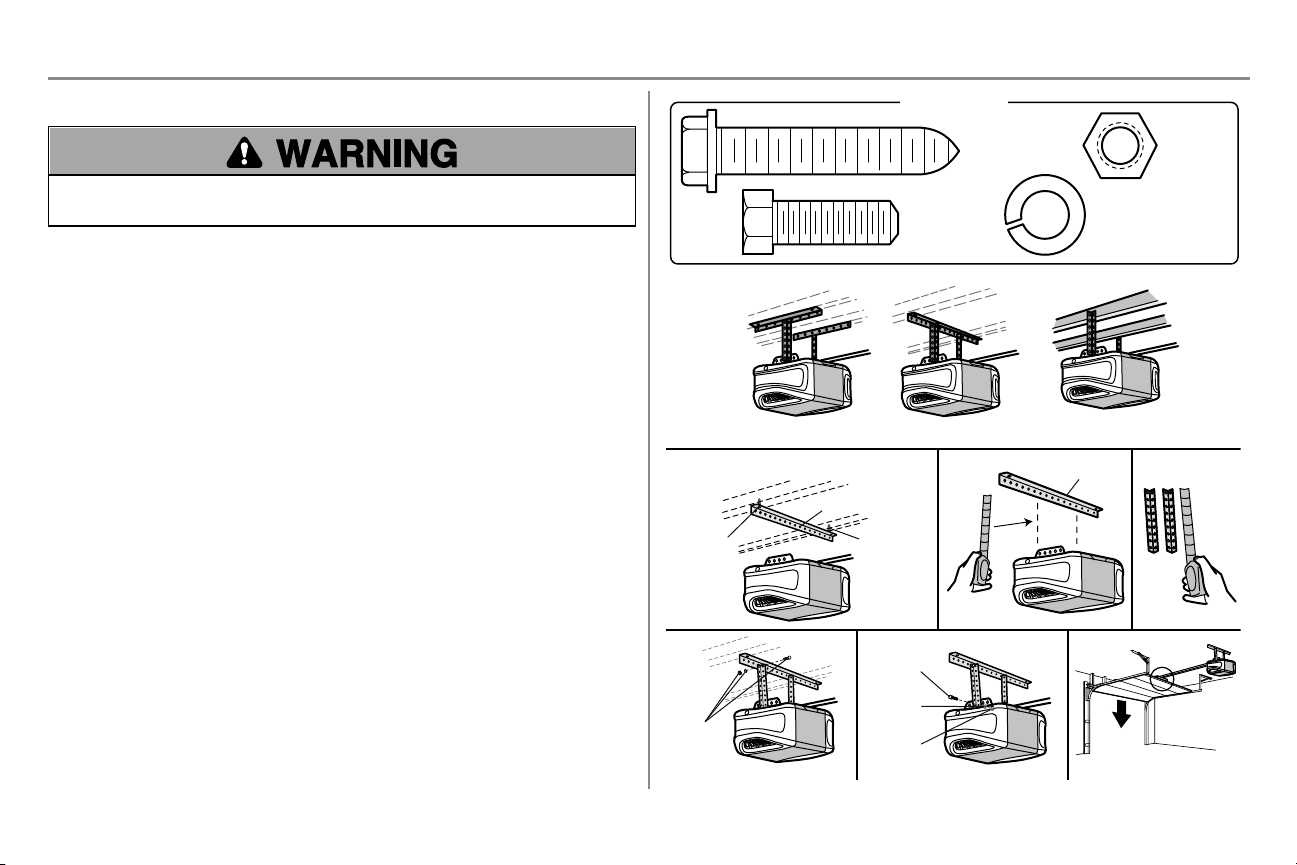

STEP 5 Hang the garage door opener

To avoid possible SERIOUS INJURY from afalling garage door opener, fasten it SECURELY to structural

supports of the garage. Concreteanchors MUST beusedif installing ANY brackets into masonry.

Hanging the garage door opener will vary depending on your garage.Below are three example installations. Your

installation may bedifferent.For ALLinstallations the garage door opener MUST be connectedto structural supports.

The instructions illustrate one of theexamples below.

1. On finishedceilings, usethe lag screws to attach a support bracket (not provided) to thestructural

supports before installing the garage door opener.

2. Make sure thegaragedoor opener is aligned with the header bracket.Measure thedistancefrom each side

of the garage door opener to the support bracket.

3. Cut both pieces ofthehanging bracketto required lengths.

4. Attach the end of each hangingbracket to thesupport bracket with appropriate hardware (not provided).

5. Attach the garage door opener to thehanging brackets with thehex bolts, lock washers, andnuts.

6. Remove the 2x4 and manually close the door. Ifthe door hits the rail, raise the header bracket.

14

Page 15

Installation

or

or

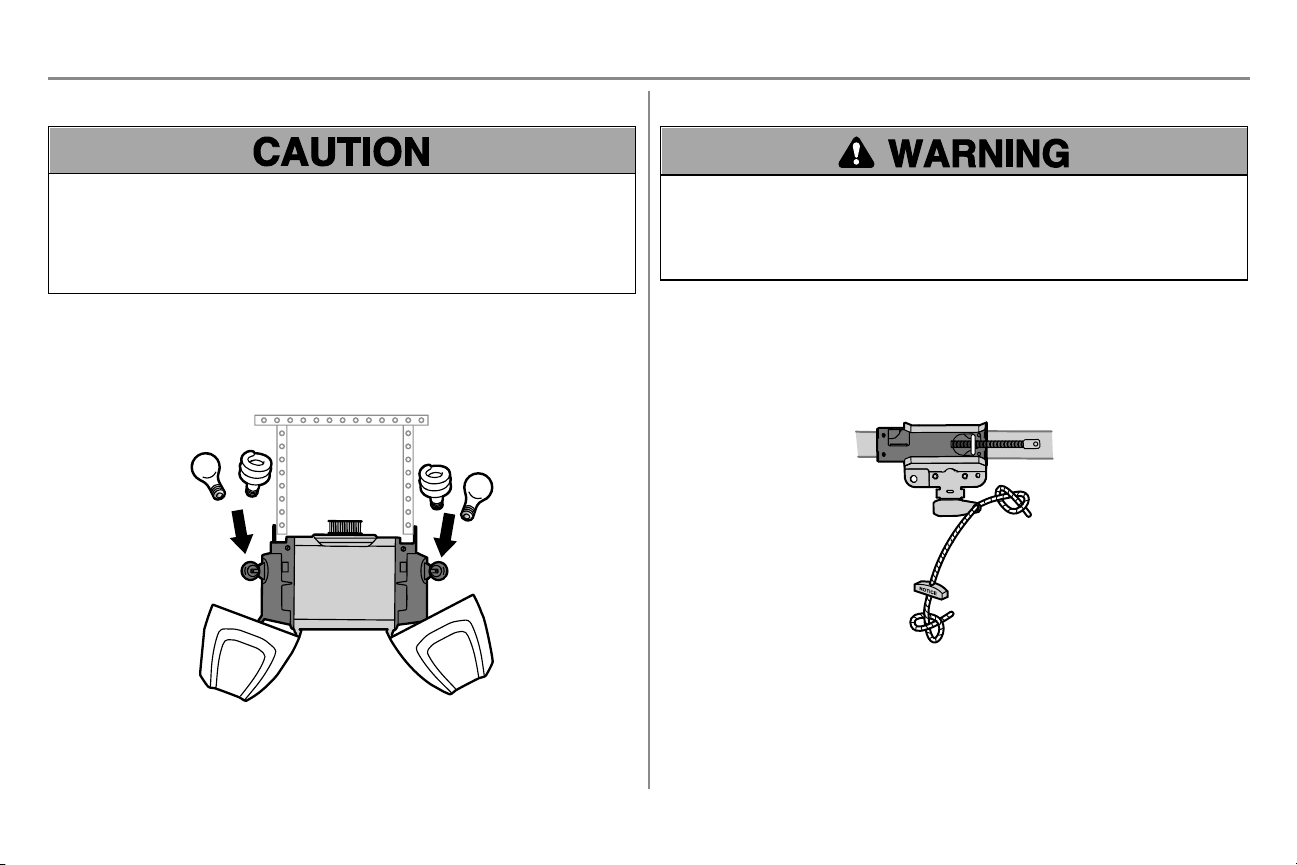

STEP 6 Install the Light Bulbs

To preventpossible OVERHEATING of the end panel or lightsocket:

l Use ONLY A19 incandescent (100W maximum) or compactfluorescent (26W maximum) lightbulbs.

l DO NOT use incandescent bulbs larger than 100W.

l DO NOT use compact fluorescent light bulbs larger than 26W (100Wequivalent).

l DO NOT use halogenbulbs.

l DO NOT use short neck or specialty light bulbs.

1. Pull onthetop sides ofthe lightlens and rotatethelight lens down.

2. Insert an A19incandescent (100W maximum) or compact fluorescent (26W, 100W equivalent) light bulb

into the light socket.

3. Rotate the lens upto close.

NOTE: Do not use halogen,short neck, or specialty light bulbs as these may overheat the end panel or light socket.

Do not use LED bulbs as they may reducethe range or performance of your remote controls.

STEP 7 Attach the emergency release rope andhandle

To preventpossible SERIOUS INJURY or DEATH from afalling garage door:

l If possible, useemergency release handleto disengagetrolley ONLY whengaragedoor is CLOSED. Weak

or brokensprings or unbalanceddoor could result in an open door falling rapidly and/or unexpectedly.

l NEVER use emergency release handle unless garage doorway is clear of persons and obstructions.

l NEVER use handle to pull door open or closed. If ropeknot becomes untied, you could fall.

1. Insert one end of theemergency release rope through the handle. Make sure that “NOTICE” is rightside

up. Secure with an overhand knot at least 1" (2.5 cm) from the end of the ropeto prevent slipping.

2. Insert the other end of theemergency release rope through the hole in the trolley release arm. Mount the

emergency release within reach, but at least 6 feet (1.83 m) abovefloor, avoiding contact with vehicles to

prevent accidental releaseand secure with an overhand knot.

NOTE: If it is necessary to cut the emergency release rope, seal the cut end with a match or lighter toprevent

unraveling. Ensure the emergency release rope and handle are above the top of all vehicles to avoid entanglement.

15

Page 16

Installation

FIGURE 1

FIGURE 3 FIGURE 4

FIGURE 2

Vertical

Reinforcement

Vertical

Centerline

of Garage Door

UP

Door Bracket

Vertical Reinforcement

Vertical Reinforcement

Horizontal Reinforcement

Vertical Centerline

of Garage Door

Hardware

(not provided)

Door Bracket

UP

Vertical

Centerline

of Garage Door

UP

Vertical Centerline of

Garage Door

Hardware

(not provided)

UP

Inside Edge of Door or

Reinforcement Board

Self-Threading Screw

Self-Threading

Screw

HARDWARE

Self-Threading Screw

1/4"-14x5/8"

STEP 8 Install the door bracket

Fiberglass, aluminum or lightweight steel garagedoors WILL REQUIRE reinforcementBEFORE installation of

door bracket. Contactthe garage door manufacturer or installing dealer for opener reinforcement instructions or

reinforcementkit. Failure toreinforce the top sectionas required according tothedoor manufacturer may void the

door warranty.

A horizontal and vertical reinforcement is needed for lightweight garage doors (fiberglass, aluminum, steel, doors with

glass panel, etc.) (not provided). A horizontal reinforcement brace should be longenough to be secured to two or three

vertical supports. A vertical reinforcement brace shouldcover theheight of thetoppanel. Contactthe garage door

manufacturer or installingdealer for opener reinforcement instructions or reinforcementkit.

NOTE: Many door reinforcement kits provide for direct attachment of the clevis pin and door arm. In this case you will

not need the door bracket; proceedto the next step.

OPTIONA - SECTIONALDOORS

1. Center the door bracket on the previously marked vertical centerlineused for theheader bracket

installation. Notecorrect UP placement,as stampedinside the bracket.

2. Position the top edge of the bracket 2"-4" (5-10cm) below the top edge of thedoor, OR directly below any

structural support across the topof thedoor.

3. Mark, drill holes and install as follows, dependingon your door’s construction.

Metal or light weight doors using a vertical angle iron bracebetween the door panel support and the door

bracket:

l Drill 3/16" fastening holes. Secure thedoor bracket using thetwo 1/4"-14x5/8" self-threadingscrews.

(Figure1)

l Alternately, use two 5/16"-18x2" bolts, lock washers and nuts (not provided). (Figure2)

Metal,insulated or light weight factory reinforced doors:

l Drill 3/16" fastening holes. Secure thedoor bracket using theself-threadingscrews. (Figure3)

Wood doors:

l Use topandbottom or side to side door bracket holes. Drill 5/16" holes through the door and secure

bracket with 5/16"-18x2" carriage bolts, lock washers and nuts (not provided). (Figure4)

NOTE: The 1/4"-14x5/8" self-threading screws are not intended for use on wood doors.

16

Page 17

Installation

HARDWARE

Self-Threading Screw

1/4"-14x5/8"

For a door with no exposed

framing, or for the optional

installation, use lag screws

5/16"x1-1/2" (not provided)

to fasten the door bracket.

Vertical

Centerline

of Garage

Door

Optional

Placement

of Door

Bracket

Door Bracket

Header Bracket

Header Wall

2x4 Support

(Finished Ceiling)

Door

Bracket

Top of Door

(Inside Garage)

Top Edge of

Door

Optional

Placement

Optional

Placement

Top Edge

of Door

Top of Door

(Inside Garage)

Door

Bracket

Hardware

(not provided)

Hardware

(not provided)

Metal Door Wood Door

Self-Threading Screw

STEP 8 Install the door bracket (continued)

OPTIONB - ONE-PIECE DOORS

1. Center the door bracket on the top of thedoor, in line with the header bracket as shown.

2. Mark either theleft and right,or the topandbottomholes.

Metal Doors:

l Drill 3/16" pilot holes and fasten the bracket with the self-threading screws provided.

Wood Doors:

l Drill 5/16" holes and use 5/16"-18x2" carriage bolts, lock washers and nuts (not provided) or 5/16"x1-1/2"

lag screws (not provided) depending on your installationneeds.

NOTE: The door bracket may be installed on the top edge of the door if required for your installation. (R efer to the

dotted line optional placement drawing.)

17

Page 18

Installation

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut 5/16"-18

Lock Washer

5/16" -18

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Ring Fastener

Lock Washer

Nut

Hex Bolt

Clevis Pin

5/16"x1-1/4"

Ring Fastener

Clevis Pin 5/16"x1"

Straight

Door Arm

(Groove

facing out)

Curved

Door Arm

STEP 9 Connect the door arm to the trolley

Installation will vary according to the garage door type.Follow the instructions which apply to your door.

OPTIONA - SECTIONALDOORS

IMPORTANT: The grooveon the straightdoor arm MUST face away from the curveddoor arm.

1. Close thedoor. Disconnectthe trolley by pulling the emergency releasehandle.

2. Attach the straightdoor arm totheouter trolley using theclevis pin. Secure with the ring fastener.

3. Attach the curveddoor arm tothe door bracket using the clevis pin. Secure w ith the ring fastener.

4. Bring arm sections together. Find two pairs of holes that lineup and join sections. Select holes as far apart

as possible to increase door arm rigidity and attach usingthe bolts, nuts, and lock washers.

5. Pull theemergency release handletoward the garage door opener until the trolley releasearm is

horizontal. The trolley will re-engageautomatically when the garage door opener is activated.

NOTE: If theholes in thecurved door arm and the straightdoor arm donot align, reverse the straight door arm, select

two holes ( as far apart as possible) and attach using bolts, nuts, and lock washers. If the str aight door arm is hanging

down too far, you may cut 6 inches (15 cm) from the solid end.

18

Page 19

Installation

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut 5/16"-18

Lock Washer

5/16" -18

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Ring Fastener

One-Piece Door without Track

One-Piece Door with Track

Ring Fastener

Ring Fastener

Ring Fastener

Nut

Nut

Ring Fastener

Lock Washer

Lock Washer

Clevis Pin 5/16"x1-1/4"

Clevis Pin

5/16"x1-1/4"

Hex Bolts

Hex Bolts

Clevis Pin

5/16"x1"

Clevis Pin

5/16"x1"

Straight Door Arm

(Groove facing out)

Curved Door Arm

STEP 9 Connect the door arm to the trolley (continued)

OPTIONB - ONE-PIECE DOORS

IMPORTANT: The grooveon the straightdoor arm MUST face away from the curveddoor arm.

1. Close thedoor. Disconnectthe trolley by pulling the emergency releasehandle.

2. Fasten the straight door arm andthecurved door arm together tothe longest possible length (with a2 or 3

hole overlap) using the bolts, nuts, and lock w ashers.

3. Attach the straightdoor arm tothedoor bracket using the clevis pin.Secure with the ring fastener.

4. Attach the curveddoor arm tothe trolley using the clevis pin. Secure with the ring fastener.

5. Pull theemergency release handletoward the garage door opener until the trolley releasearm is

horizontal.

19

Page 20

Installation

Screw

6AB

x1"

(2)

Drywall

Anchors

(2)

Screw

6-32x1"

(2)

HARDWARE

7/16" (11 mm)

Wall

1

2 3

4-5 6

8

7

DRYWALL

GANG BOX

6ABx1"

6-32x1"

Drywall Anchor

DRYWALL GANG BOX

6ABx1"

6-32x1"

Drywall Anchor

STEP 10 Install the door control

To preventpossible SERIOUS INJURY or DEATH from electrocution:

l Be sure power is NOT connectedBEFORE installing door control.

l Connect door control ONLY to 12 VOLT low voltage wires.

To preventpossible SERIOUS INJURY or DEATH from aclosing garage door:

l Install door control within sightof garage door, out ofreach of small children ata minimum height of 5feet

(1.5m) above floors, landings, steps or any other adjacent walking surface, and away from ALL moving parts

of door.

l NEVER permit children to operate or play with door control push buttons or remotecontrol transmitters.

l Activate door ONLY whenit canbe seen clearly, is properly adjusted,andthere are noobstructions to door

travel.

l ALWAYSkeepgaragedoor in sight until completely closed.NEVER permit anyone to cross path of closing

garagedoor.

INTRODUCTION

Older Chamberlain door controls andthird party products are notcompatible. Install thedoor control within sight of the

door at aminimumheight of 5feet(1.5 m) abovefloors, landings, steps or any other adjacent walking surface, where

small children cannot reach, and away fromthemoving parts ofthedoor. For gangbox installations it is not necessary

to drill holesor install the drywall anchors. Use the existing holes in the gang box.

NOTE: Your product may look different than the illustrations.

1. Strip 7/16 inch (11 mm) ofinsulation from one end of the wire andseparatethewires.

2. Connect one wire toeach of the two screws onthe back of thedoor control. The wires canbe connectedto

either screw. If your garage is pre-wired for the door control choose any two wires toconnect,notewhich

wires are used so thecorrect wires are connected to the garage door opener in a later step.

3. Mark the location ofthebottom mounting hole and drill a 5/32inch hole.

4. Install the bottomscrew, allowing 1/8 inch (3 mm) to protrude from thewall.

5. Position the bottom hole of thedoor control over the screw and slide down intoplace.

6. Lift the push bar upandmark the tophole.

7. Remove the door control from the wall and drill a 5/32inch hole for the top screw.

8. Position the bottom hole of thedoor control over the screw and slide down intoplace. Attach the top screw.

20

Page 21

Installation

RED

WHITE

WHITE

GREY

7/16" (11 mm)

2

3

1

HARDWARE

Insulated Staple (Not Shown)

Staple

STEP 11 Wire the door control to the garage door opener

1. Run the white and red/whitewire fromthedoor control to the garage door opener. Attach the wire tothe

wall and ceilingwith thestaple (not applicable for gangbox or pre-wired installations). Do not pierce the

wire with the staple as this may causea short or an open circuit.

2. Strip 7/16 inch (11 mm) ofinsulation from the end of thewire near the garage door opener.

3. Connect the wire tothe red and white terminals onthegaragedoor opener. If your garage is pre-wired

makesure youuse the same wires thatare connectedto the door control. To insert or release wires from

the terminal, push in the tab with screwdriver tip.

STEP 12 Attach the warning labels

1. Attach the entrapment warning label on thewall near the door control with tacks or staples.

2. Attach the manual release/safety reverse test label in a visible location ontheinside of thegaragedoor.

21

Page 22

Installation

Safety Reversing Sensor

6" (15

cm) max. above floor

Invisible Light Beam

Protection Area

Facing the door from inside the garage

Carriage Bolt

1/4"-20 x 1/2"

Wing Nut

1/4"-20

HARDWARE

No more

than 6 inches

(15 cm)

Carriage Bolt

Wing Nut

1

2

3

STEP 13 Install the Protector System

®

Be sure power is NOT connectedto the garage door opener BEFORE installing the safety reversing sensor.

To preventSERIOUS INJURY or DEATH fromclosing garage door:

l Correctly connect and align thesafety reversing sensor. This required safety device MUST NOT be

disabled.

l Install the safety reversing sensor so beamis NO HIGHER than 6" (15 cm) above garage floor.

IMPORTANT INFORMATION ABOUT THE SAFETY REVERSING SENSORS

The safety reversing sensors must be connected and aligned correctly before the garage door opener will

move in the down direction.

The sending sensor (with an amber LED) transmits aninvisible lightbeamto thereceiving sensor (w ith a green

LED). If an obstruction breaks the lightbeamwhile thedoor is closing, the door will stop and reverse to thefull open

position, and the garage door opener lightswill flash 10 times.

NOTE: For energy efficiency the garage door opener will enter sleep mode when the door is fully closed. The sleep

modeshuts the garage door opener down until activated. The sleep mode is sequenced with the garage door opener

light bulb; as the light bulb turns offthe sensor LEDs w ill turn off andw henever thegaragedoor opener lights turn on

the sensor LEDs will light. The garage door opener will not go into thesleep modeuntil the garage door opener has

completed 5 cycles upon power up.

When installing the safety reversing sensors checkthe following:

l Sensors are installed inside the garage, one on either side of thedoor.

l Sensors are facing each other with the lenses alignedandthereceivingsensor lens does not receive direct

sunlight.

l Sensors are no more than 6 inches (15 cm) above the floor and the light beamis unobstructed.

The safety reversing sensors can beattached to the door track, the wall, or the floor. The sensors should be no more

than6 inches (15 cm) abovethefloor. If thedoor track will notsupport thesensor bracket a wall installation is

recommended. Chooseoneof the following installations.

OPTIONA - DOOR TRACKINSTALLATION

1. Slide the curvedarms ofthesensor bracket around the edge of the door track. Snap into place so that the

sensor bracket is flush against the track.

2. Slide the carriage bolt intotheslot oneachsensor.

3. Insert the bolt through the hole in the sensor bracket and attach with the wing nut. The lenses on both

sensors should point toward eachother. Make sure the lens is not obstructed by thesensor bracket.

22

Page 23

Installation

Lens

Carriage

Bolt

(Not provided)

No more than

6 inches (15 cm)

1 2

(Not provided)

Wing Nut

3 4

(Not provided)

I

e

l

l

1 2

Carriage Bolt

Wing Nut

3 4

STEP 13 Install the Protector System®(continued)

OPTIONB - WALLINSTALLATION

If additional clearanceis neededan extension bracket (not provided) or woodblocks canbe used. Make sure each

bracket has thesameamount of clearanceso they will align correctly.

1. Position the sensor bracket against the wall with the curved arms facingthedoor. Make sure there is

enough clearance for the beamto be unobstructed. Mark holes.

2. Drill 3/16inch pilot holes for each sensor bracket and attach the sensor brackets to thewall using lag

screws (not provided).

3. Slide the carriage bolt intotheslot oneachsensor.

4. Insert the bolt through the hole in the sensor bracket and attach with the wing nut. The lenses on both

sensors should point toward eachother. Make sure the lens is not obstructed by thesensor bracket.

OPTIONC - FLOORINSTALLATION

Use anextensionbracket (not provided) or woodblock to raise the sensor bracket if needed.

1. Carefully measure the position of bothsensor brackets so they will be the same distance fromthe wall and

unobstructed.

2. Attach the sensor brackets to thefloor using concreteanchors (notprovided).

3. Slide the carriage bolt intotheslot oneachsensor.

4. Insert the bolt through the hole in the sensor bracket and attach with the wing nut. The lenses on both

sensors should point toward eachother. Make sure the lens is not obstructed by thesensor bracket.

23

Page 24

Installation

Staple

7/16" (11 mm)

WHITE

WHITE

GREY

RED

1

2

3

HARDWARE

Insulated Staple (Not Shown)

STEP 14 Wire the Safety Reversing Sensors

If your garagealready has wires installed for the safety reversing sensors, proceed to page 25.

OPTIONA - INSTALLATION WITHOUTPRE-WIRING

1. Run the wire from both sensors to the garage door opener. Attach the wire tothe wall and ceiling with the

staples.

2. Strip 7/16 inch (11 mm) ofinsulation from each set ofwires. Separate the wires. Twist the white wires

together. Twist thewhite/black wires together.

3. Insert the white wires intothe white terminal on the garage door opener. Insert thewhite/black wires into

the grey terminal onthegaragedoor opener. To insert or remove the wires from the terminal, pushin the

tab with a screwdriver tip.

24

Page 25

Installation

Safety reversing

sensor wires

Pre-installed

wires

White

White/Black

Yellow (for example)

Purple (for example)

Wire nuts (not provided)

Pre-installed wires

Safety reversing

sensor wires

1

3

4

7/16" (11 mm)

2

Purple

Yellow

5

7/16" (11 mm)

Yellow

Purple

To insert or remove the wires from the terminal,

push in the tab with a screwdriver tip.

STEP 14 Wire the Safety Reversing Sensors (continued)

OPTIONB - PRE-WIREDINSTALLATION

1. Cut theend ofthesafety reversing sensor wire, making sure there is enough wire to reach the pre-installed

wires fromthe wall.

2. Separatethesafety reversing sensor wires and strip 7/16 inch (11 mm) of insulationfrom each end.

Choose two of the pre-installed wires and strip 7/16 inch (11 mm) of insulation from each end. Make sure

thatyou choose the samecolor pre-installed wires for each sensor.

3. Connect the pre-installed wires to the sensor wires with wire nuts making sure the colors correspondfor

each sensor. For example, the white wire would connect to the yellow wire andthewhite/black w ire would

connectto the purple wire.

4. At the garage door opener, strip 7/16 inch (11 mm) ofinsulation from each end of the wires previously

chosenfor thesafety reversing sensors. Twist thelike-colored wires together.

5. Insert the wires connected to the white safety sensor wires to the white terminal onthegaragedoor opener.

Insert the wires thatare connectedto the white/black safety sensor wires tothe grey terminal on the garage

door opener.

25

Page 26

Installation

1

2

3

4

5

Approx. 3"

(7.6 cm)

Lock

Terminals

STEP 15 Install the Automatic Garage Door Lock

For use on Residential Garages with an Entry Door Only. Install On Sectional Doors with Torsion

Assemblies Only. Up to two locks canbe installed per compatible garage door opener.

To preventpossible SERIOUS INJURY or DEATH from aclosing gate or door:

l Automatic GarageDoor Lock MUST be installed per theowner’s manual.

l Be sure to DISCONNECT ALLELECTRIC AND BATTERY POWER to the garage door opener BEFORE

installing thegaragedoor lock.

l The door MUST be in the fully opened or closed position BEFORE installing the garage door lock.

l Be sure to DISASSEMBLEandREMOVE any manual door locks that might be currently installed.

UNPLUG THE GARAGE DOOR OPENER AND DISCONNECT THE BATTERY (IF APPLICABLE) BEFORE

PROCEEDING. REMOVE ANY MANUAL LOCKS FROM THE GARAGE DOOR.

1. Attach template(provided) totrack. TIP: The second roller from the bottomis ideal for most installations.

2. Drill holes as markedon template. Use a 3/4" stepdrill bit todrill holes as marked on the template.

OR

If not usinga step drill bit, pre-drill with a smaller drill bit toassure proper placement of the 3/4" hole.

3. Fasten automatic garage door lock to theoutsideof the garage door track with the 1/4"-20x1/2" screws.

4. Run wire (provided) from automatic garage door lock to garagedoor opener. Use insulated staples (not

provided) tosecure wire in several places. N OTE: If you are going to cut the wire you will need to

reconnect wire using a wire nut. D o not tape the ends together. The lock is polarized and requires you

reconnect black to black and white to white wi res.

5. Plug the connector intooneof the lock terminals onthegaragedoor opener. NOT E: To install a second

automatic garage door lock, repeat installation steps on the opposite side of the garage door.

26

Page 27

Installation

Ground Tab

Green Ground Screw

Ground Wire

White Wire

Black Wire

STEP 16 Connect power

To preventpossible SERIOUS INJURY or DEATH from electrocutionor fire:

l Be sure power is NOT connectedto the opener, and disconnect power to circuit BEFORE removingcover to

establish permanentwiring connection.

l Garage door installation and wiring MUST be in compliance with ALL local electrical and building codes.

l NEVER use an extension cord, 2-wire adapter, or change plug in ANY way tomake it fit outlet. Be sure the

opener is grounded.

To avoid installation difficulties, do not run the opener at this time.

To reducethe risk ofelectric shock, your garagedoor opener has agroundingtypeplug with a third grounding pin.

This plug will only fit into a grounding type outlet. If theplug doesn’t fit intothe outlet you have, contact a qualified

electrician to install the proper outlet.

THERE ARE TWO OPTIONS FOR CONNECTING POWER:

OPTIONA - TYPICAL WIRING

1. Plug in the garage door opener intoa groundedoutlet.

2. DO NOT run garage door opener at this time.

OPTIONB - PERMANENT WIRING

If permanent wiring isrequired by your local code, refer to the following procedure. To make a permanent

connection through the 7/8 inch hole in the top of the motor unit (according to local code):

1. Remove the motor unit cover screws and set the cover aside.

2. Remove the attached3-prong cord.

3. Connect the black (line) wire tothe screw onthebrass terminal; the white (neutral) wire to thescrew on

the silver terminal; and the ground wire tothegreen ground screw. The opener must be grounded.

4. Reinstall the cover.

27

Page 28

Installation

Green LED

Amber LED

Wing Nut

SENDING SENSOR

RECEIVING SENSOR

(invisible light beam)

If the receiving sensor is in direct

sunlight, switch it with sending sensor so

it is on the opposite side of the door.

RED

WHITE

GREY

3

2

1

1

2

STEP 17 Aligning the safety reversing sensors

The door will not closeif the sensors have not been installed and aligned correctly.

Whenthelight beam is obstructed or misalignedwhile thedoor is closing,thedoor will reverse andthegaragedoor

opener lights will flash ten times. Ifthe door is already open,it will not close.

1. Check tomake sure theLEDs in both sensors are glowingsteadily. The LEDs in both sensors will glow

steadily if they are aligned and wired correctly.

The sensors can be aligned by looseningthewing nuts, aligningthesensors, and tighteningthe wingnuts.

IF THE AMBER LED ON THE SENDING SENSOR IS NOT GLOWING:

1. Make sure there is power to the garage door opener.

2. Make sure thesensor wire is not shorted/broken.

3. Make sure thesensor has been wired correctly: white wires to white terminal and white/black wires to

grey terminal.

IF THE GREEN LED ON THE RECEIVING SENSOR IS NOT GLOWING:

1. Make sure thesensor wire is not shorted/broken.

2. Make sure thesensors are aligned.

STEP 18 Ensure the door control is wired correctly

If the door control has been installed and wired correctly, a messagewill display on the Smart C ontrol Panel screen.

28

Page 29

Adjustments

UP (Open)

DOWN (Close)

Correct

Incorrect

UP Button

Adjustment

Button

DOWN Button

Actual product may differ from image shown.

PROGRAMMING

BUTTONS

Introduction

Withouta properly installed safety reversal system,persons (particularly small children) couldbe SERIOUSLY

INJURED or KILLED by a closing garage door.

l Incorrect adjustmentof garage door travel limits will interfere with proper operation of safety reversal

system.

l After ANY adjustments are made, the safety reversal system MUST betested.Door MUST reverse on

contactwith1-1/2" (3.8 cm) highobject (or 2x4 laid flat) on floor.

To preventdamageto vehicles, be sure fully opendoor provides adequate clearance.

Your garage door opener is designedwith electronic controls to make setup and adjustments easy. The adjustments

allow you to programwhere the door will stop in theopen(UP) and close (DOWN) position. The electronic controls

sense the amountof force required to open and close the door. The force is adjusted automatically when youprogram

the travel.

NOTE: If anything interferes with the door’s upward travel it will stop. If anything interferes with thedoor’s downward

travel, it will reverse.

One-Piece Doors Only

Whensettingthe UP travel for a one-piece door ensure that the door does not slant backwards when fully open(UP).

If the door is slanted backwards this will causeunnecessary bucking and/or jerking whenthedoor is opening or

closing.

ProgrammingButtons

The programming buttons are located on the left side panel of the garage door opener and are usedto program the

travel. While programming,the UP andDOWN buttons can beused to move the door as needed.

29

Page 30

Adjustments

UP Button

Adjustment

Button

DOWN Button

Actual product may differ from image shown.

PROGRAMMING

BUTTONS

1 2

3

4

5

6 7

STEP 1 Program the Travel

Withouta properly installed safety reversal system,persons (particularly small children) couldbe SERIOUSLY

INJURED or KILLED by a closing garage door.

l Incorrect adjustmentof garage door travel limits will interfere with proper operation of safety reversal

system.

l After ANY adjustments are made, the safety reversal system MUST betested.Door MUST reverse on

contactwith1-1/2" (3.8 cm) highobject (or 2x4 laid flat) on floor.

While programming, the UP and DOWN buttons can beusedto move the door as needed.

1. Press andhold the AdjustmentButton until theUP Button begins to flashand/or a beepis heard.

2. Press andhold the UP Buttonuntil thedoor is in the desiredUP position.

3. Once the door is in the desiredUP position press andrelease the Adjustment Button. Thegaragedoor

opener lights will flash twice and the DOWN Button will begin to flash. IMPORTANT NOTE: For one-

piece door installations refer to page 29.

4. Press andhold the DOWN button until thedoor is in the desired DOWN position.

5. Once the door is in the desiredDOWN position press and release the AdjustmentButton. The garage door

opener lights will flash twice and the UP Button will beginto flash.

6. Press andrelease the UP Button. Whenthe door travels to theprogrammed UP position, the DOWN Button

will begin to flash.

7. Press andrelease the DOWN Button.The door will travel to the programmedDOWN position.

Programmingis complete.

* If thegaragedoor opener lights are flashing5 times during the steps for Program the Travel, the programming has

timedout.If the garage door opener lights are flashing10 times during the steps for Program the Travel, the safety

reversingsensors are misaligned or obstructed (refer to page 28). When the sensors are alignedandunobstructed,

cycle thedoor through a completeup and down cycle using the remote control or the UP and DOWN buttons.

Programmingis complete. If youare unable to operate the door upanddown, repeat the steps for Programming the

Travel.

To watch a video,go to tinyurl.com/lkwbnhj

30

Page 31

Adjustments

1 2

1

2

STEP 2 Test the Safety Reversal System

Withouta properly installed safety reversal system,persons (particularly small children) couldbe SERIOUSLY

INJURED or KILLED by a closing garage door.

l Safetyreversal system MUST be tested every month.

l After ANY adjustments are made, the safety reversal system MUST betested.Door MUST reverse on

contactwith1-1/2" (3.8 cm) highobject (or 2x4 laid flat) on the floor.

1. With the door fully open,place a 1-1/2inch (3.8 cm) board (or a 2x4 laid flat) on the floor, centered under

the garagedoor.

2. Press theremotecontrol push buttonto close the door. Thedoor MUST reverse when it makes contact

with theboard.

If the door stops but does not reverse:

1. Review the installationinstructions providedto insure all steps were followed;

2. Repeat Program the Travel (see Adjustment Step 1);

3. Repeat the Safety Reversal test.

If the test continues to fail, call a traineddoor systems technician.

STEP 3 Test the Protector System

Withouta properly installed safety reversing sensor, persons (particularly small children) could be SERIOUSLY

INJURED or KILLED by a closing garage door.

1. Open the door. Place the garage door opener cartonin the path of the door.

2. Press theremotecontrol push buttonto close the door. Thedoor will not move more than an inch (2.5 cm),

andthe garage door opener lights will flash 10 times.

The garage door opener will not close froma remote control if the LED in either safetyreversing sensor is off (alerting

you to the factthatthe sensor is misalignedor obstructed). If the garage door opener closes the door whenthe safety

reversingsensor is obstructed (andthe sensors are no more than 6inches [15 cm]abovethefloor), call for a trained

door systems technician.

®

31

Page 32

Battery Backup

Battery Status LED

1 2

3

STEP 1 Install the Battery

To reducethe risk ofFIRE or INJURY to persons:

l Disconnect ALL electric andbattery power BEFORE performing ANY service or maintenance.

l Use ONLY Chamberlain part # 41A6357-1 for replacementbattery.

l DO NOT dispose of battery in fire. Battery may explode. Check with local codes for disposal instructions.

ALWAYSwear protective gloves and eye protection whenchanging the battery or working around the battery

compartment.

The battery backup allows access in andoutof your garage, even whenthe power is out. The battery does not have to

be fully charged to operate the garage door opener. When the garage door opener is operating on battery power, it will

run slower andthebattery status LED will glow solid orange, a beep will soundapproximately every 2 seconds. The

following features are unavailable whenoperatingonbattery power:

l Garage Door Opener Lights

l Unattended close devices andfeatures (e.g.MyQ

1. Unplug the garage door opener.

2. Open the lightlens on the right side panel of thegarage door opener. Use a Phillips head screwdriver to

remove the battery cover on thegaragedoor opener.

3. Partially insert thebattery into the battery compartment with the terminals facing out.

4. Connect red (+) and black (-) wires from the garage door opener to thecorresponding terminals onthe

battery.

5. Replace the battery cover.

®

SmartphoneControl andTimer-to-Close)

6. Plug in the garage door opener.

7. Wait for thegreen Battery Status LED to start flashing before proceeding to test thebattery.

STEP 2 Test the Battery

1. Unplug the garage door opener. Thebattery status LED will either glow solid orange indicating opener is

operatingon battery power or will flash indicatinglow battery power. NOTE:Make sure the garage door

opener is unplugged.

2. Open and close thedoor using the remote control or door control. The garage door opener may run slower

if the battery is not fully charged.The battery will take 24 hours tofully charge.

3. Plug in the garage door opener. Verify the battery status LED is flashing green, indicatingthebattery is

charging.

Charge the Battery

The battery chargeswhen the garage door opener is plugged into a 120Vac electrical outlet that has power and

requires 24hours to fully charge.A fully charged battery supplies 12Vdc to thegaragedoor opener for oneto two days

of normal operation duringan electrical power outage. After theelectrical power has been restored,thebattery will

recharge within 24 hours. Thebattery will last approximately 1 to 2 years with normal usage. Instructions for

replacement are provided with the battery. To obtain maximumbattery life and prevent damage, disconnect the battery

when the garage door opener is unplugged for anextended period of time,such as a summer or winter home.

NOTE: When the garage door opener is in battery backup mode the garage door opener lights, Timer-to-Close, and

Remote Close features are unavailable.

In battery backup mode, the Automatic GarageDoor Lock will unlock when the garage door is opened, and will remain

disabled until power is restored.

32

Page 33

MyQ®Smartphone Control

“beep”

LED

Learn

Button

Google Play

App Store

or

Get Connected

…and control your garage door opener with the MyQ®App.

You will need:

l A smartphoneor tablet

l Broadband Internet connection

l A strongWi-Fi signal (2.4 Ghz, 802.11b/g/n required) in the garage, see page3

l Password for your homenetwork

®

l MyQ

serial number locatedonthe garage door opener

1. ACTIVATE "Wi-FiLEARN"MODE

Press andrelease the yellow LEARN buttononthe garage door opener 3 times.The garage door opener will beep

once and a blue light will flash. You have 20 minutes to complete the connectionprocess.

2. CONNECTTO THE MyQ®Wi-FiNETWORK

On your mobile device, go toSettings > Wi-Fi, andselect the network with the "MyQ-" prefix.

3. CONNECTTHEGARAGE DOOR OPENER TO YOURHOME Wi-FiNETWORK

Launch the web browser (such as Safari or Chrome) onyour mobile device andgo to "setup.myqdevice.com". Follow

the on-screenprompts to addthegaragedoor opener to your home Wi-Fi network.

4. SETUP YOURMyQ®ACCOUNT

Download the MyQ®appfrom the App StoreSMor Google Play™ store. Signup for your MyQ®accountandaddthe

MyQ®serial number to your account.

Congratulations you've successfully completed the setup. Enjoy MyQ®Smartphone Control!

In addition to controlling your garagedoor opener you cancontrol your houselighting with additional MyQ

accessories, see page42.

NOTES:

The MyQ®Smartphone Control WILL NOT work if the garage door opener is operating on battery power.

To erase the Wi-Fi settings, see page 38.

®

To learn more go towifihelp.chamberlain.com.

33

Page 34

Operation

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS.

2. ALWAYSkeep remote controls outof reach ofchildren. NEVER permit children to operate or play with garage

door control pushbuttons or remote controls.

3. ONLY activategaragedoor whenit canbe seen clearly, it is properly adjusted, and there are no obstructions

to door travel.

4. ALWAYSkeep garage door in sight and away from people and objects until completely closed. NO ONE

SHOULD CROSS THE PATH OF THE MOVING DOOR.

5. NO ONE SHOULD GO UNDER A STOPPED, PARTIALLY OPENED DOOR.

6. If possible, use emergency release handle to disengagetrolley ONLY whengaragedoor is CLOSED. Use

cautionwhen using this releasewith thedoor open.Weak or broken springs or unbalanceddoor could result in

an opendoor falling rapidly and/or unexpectedly and increasing the risk ofSEVERE INJURY or DEATH.

7. NEVER use emergency releasehandle unless garagedoorway is clear ofpersons and obstructions.

8. NEVER use handle to pull garagedoor open or closed. If ropeknot becomesuntied,you could fall.

9. After ANY adjustments are made,thesafety reversal system MUST betested.

10. Safety reversal system MUST be tested every month. Garage door MUST reverse oncontact with 1-1/2"

(3.8 cm) high object (or a 2x4 laid flat) on thefloor. Failure to adjustthe garage door opener properly

increases therisk of SEVERE INJURY or DEATH .

11. ALWAYS KEEP GARAGE DOOR PROPERLY BALANCED (seepage2). An improperly balanceddoor

may NOT reverse whenrequired and could result in SEVERE INJURY or DEATH.

12. ALLrepairs to cables, spring assemblies and other hardware, ALL of which are under EXTREMEtension,

MUST bemade by a trained door systems technician.

13. ALWAYS disconnect electric and battery power to garage door opener BEFORE making ANY repairs or

removing covers.

14. This operator systemis equippedwith anunattended operation feature. The door could move

unexpectedly. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

15. DO NOT install ona one-piece door if using devices or features providingunattended close.Unattended

devices and features are to be used ONLY with sectional doors.

16. SAVE THESE INSTRUCTIONS.

34

Page 35

Operation

Manual

release

Using your Garage Door Opener

l The garage door opener can beactivatedwith a wall-mounted door control, remotecontrol, wireless

keyless entry, MyQ®SmartphoneControl appor MyQ®Garage Door Monitor. When the door is closed and

the garagedoor opener is activated the door will open.If the door senses an obstruction or is interrupted

while opening the door will stop. When the door is in any positionother than closed and the garage door

opener is activatedthe door will close. Ifthe garage door opener senses anobstruction while closing, the

door will reverse. If the obstruction interrupts the sensor beamthe garage door opener lights will blink 10

times. If the door is fully open, and the safety reversing sensors are not installed, or are misaligned,the

door will notclose froma remote control, TTC, or the MyQ®SmartphoneControl app. However, youcan

close the door by holding the buttonon the door control or the ENTER button on the keyless entry until the

door is fully closed.

l The garage door opener lightbulbs will turn on whenthe opener is initially plugged in; power is restored

after interruption, or when the garage door opener is activated. The lights will turn off automatically after 41/2 minutes.The lights will turn on whensomeone enters through the opengaragedoor and the safety

reversingsensor infrared beamis obstructed, see page 36. Use an incandescent A19 lightbulb (100W

maximum) or for maximumenergy efficiency a 26W (100W equivalent) compact fluorescent light (CFL)

bulb. NOTE: Do not use halogen, short neck, or specialty light bulbs as these may overheat the end panel

or light socket. D o not use LED bulbs as they may reduce the range or performance of your remote

controls.

To Open the Door Manually

To preventpossible SERIOUS INJURY or DEATH from afalling garage door:

l If possible, useemergency release handleto disengagetrolley ONLY whengaragedoor is CLOSED. Weak

or brokensprings or unbalanceddoor could result in an open door falling rapidly and/or unexpectedly.

l NEVER use emergency release handle unless garage doorway is clear of persons and obstructions.

l NEVER use handle to pull door open or closed. If ropeknot becomes untied, you could fall.

TO MANUALLYDISENGAGE AUTOMATICGARAGE DOORLOCK

1. The door shouldbe fully closed if possible.

2. Disengagethe automatic garage door lock by slidingthe manual releaseto the

openposition.

3. Pull theemergency release handledown and back (toward thegaragedoor

opener). The garage door canthenbe raisedandlowered manually as

necessary.

4. To reconnect the trolley, pull the emergency release handle straight down. The

trolley will reconnect on thenextUP or DOWN operation.

NOTE: The automatic garage door lock w ill re-engage when garage door opener

operationresumes.

DISCONNECTTHETROLLEY

1. The door shouldbe fully closed if possible.

2. Pull down on the emergency releasehandle so the trolley release arm snaps to

the vertical position. The door cannow be raised and lowered as often as

necessary.

TO RE-CONNECTTHE TROLLEY

1. Pull theemergency release handletoward the garage door opener so the

trolley release arm snapsto the horizontal position. The trolley will reconnect

on the next UP or DOWN operation,either manually or by using the door

control or remote control.

35

Page 36

Operation

Push Bar

LIGHT Button

Motion Sensor

Navigation Buttons

Screen

Smart Control Panel

SYNCHRONIZE THE DOOR CONTROL: To synchronize thedoor control to the garage door opener, press the

push bar until thegaragedoor opener activates (it may take upto 3 presses). Test the door control by pressing the

push bar; each press of thepushbar will activate the garage door opener.

PUSH BAR: Press thepush bar toopen or close the door.

LIGHT BUTTON: Press theLIGHT buttonto turn thegarage door opener lights on or off. When the lights are turned

on they will stay on until theLIGHT button is pressed again, or until the garage door opener is activated. Once the

garagedoor opener is activated the lights will turn off after thespecified period oftime (the factory default is 4-1/2

minutes). The LIGHT buttonwill not control thelights whenthe door is in motion.The Light Feature will turn onthe

light on thegaragedoor opener whensomeoneenters through the open garage door and the safety reversing sensor

infrared beam is obstructed.

MOTION SENSOR: The motion sensor automatically turns on the garage door opener lights when motion is detected.

The lights come on for the set period of time, and then shutoff.If using thegaragedoor opener light as awork light

disable the motion sensor, otherwise the lights may turn off automatically if youare beyond the rangeofthe motion

sensor.

NAVIGATION AND SCREEN: The screen displays the time, temperature, and current battery charge(if applicable)

until the menubutton is pressed, and then it will display the menu options. If there is a problemwith thegaragedoors

opener the screen will display an error code(diagnostic code, see page 40). Thefeatures onthedoor control can be

programmed through a series ofmenus on the screen.Use thenavigationbuttons to scroll throughthe menus and

makeselections.

®

MENUOPTIONS

CLOCK SETUP: Set the time; choose 12 or 24 hour clock andshow/hideclock.

TEMPERATURE: Display the temperature in Fahrenheit or Celsius and show/hidethetemperature.

LANGUAGE: SelectEnglish, Spanish or French.

CONTRAST ADJUST: Adjust thescreen contrast.

LIGHT SETTINGS:

To change the amount of timethelights stay on:

1. Select LIGHT SETTINGS fromthe menu.

2. Select LIGHT TIME.

3. Select the timeinterval.

To turn the Light Feature on or off (Factory default is On):

1. Select LIGHT SETTINGS fromthe menu.

2. Select AUTOMATIC LIGHTS.

3. Select ENTRY SENSOR.

To turn the motion sensor onor off:

1. Select LIGHT SETTINGS fromthe menu.

2. Select AUTOMATIC LIGHTS.

3. Select MOTION SENSOR.

LOCK: Prevents the garage door opener from being activated by remotecontrols while still allowing activationfrom

the door control andkeyless entry.

To turn the LOCK feature ON or OFF:

1. Select LOCK from the menu.WhentheLOCK feature is on, a message displays on the screen.

36

Page 37

Operation

1

2 3

OR

PIN

? ?

? ?

4

Press

to continue.

Press

to continue.

MENUOPTIONS (CONTINUED)

TIMER-TO-CLOSE (TTC) (Factory default is set to off): The Timer-to-Close feature automatically closes the

door after aspecified time period and can beadjusted using thedoor control. DO NOT enable TTC if operating a onepiece door. TTC is to be used ONLY with sectional doors. The garage door opener will beepandthe lights will flash

before closing the door. The TTC feature will deactivateif the garage door encounters an obstruction twice; or the

safety reversing sensors are incorrectly installed. Thegaragedoor will reverse open and WILL NOT close until the

obstructions are clear or the safety reversing sensors are correctly installed. When the obstruction has been cleared

or thesafety reversing sensors have been aligned, the door will close when the garage door opener is activated. TTC

WILLNOT work if thegaragedoor opener is operating by battery power or if thesafety reversing sensors are

misaligned.This feature is NOT intendedto be the primary methodof closing the door. A keyless entry should be

installed in the event of anaccidental lock out whenusing this feature.

To turn TTC onor off or to setthe TTC timeinterval:

1. Select TTC from the menu.

2. Select a timeinterval of1, 5, 10minutes or a customsettingup to 99 minutes. Once the TTC has beenset

andthe door is open, a message will display on the screen with the selected time interval.

To temporarily suspend the TTC feature select HOLD. Select REL to resume normal TTC operation.

PROGRAM: Any compatibleremotecontrol, wireless keyless entry, or MyQ®devices canbe programmedto the

garagedoor using the PROGRAM option fromthemenu.

Remote Control and Keyless Entry

Pre-programmed remote control included, no need to program the remote.

To add or reprogram aremotecontrol, follow the instructions below. Older Chamberlain remote controls are NOT

compatible, see page 42 for compatible accessories.

PROGRAMUSINGTHE DOOR CONTROL

1. Press thenavigationbutton below "MENU" to view the Features menu.

2. Use thenavigationbuttons to scroll to "PROGRAM".

3. Select "REMOTE" or "KEYPAD" to programfrom the program menu.

4. Remote Control: Press thebutton on the remote control that you wish tooperateyour garage door.

KeylessEntry: Enter a 4-digit personal identification number (PIN) of your choice on the keyless entry

keypad.Then press theENTER button.

The garage door opener lights will flash (or two clicks will beheard) whenthe code has been programmed. Repeat

the steps for programmingadditional remote controls or keyless entry devices. If programming is unsuccessful, repeat

the steps usingthe learn buttonon the garage door opener.

To watch a video,go to tinyurl.com/lcsf6xt

37

Page 38

Operation

LEARN Button

Adjustment Button

To Erase the Memory

ERASE ALL REMOTE CONTROLS AND KEYLESS ENTRIES

1. Press andhold the LEARN buttonongaragedoor opener until thelearn LED goes out (approximately 6

seconds). All remote control andkeyless entry codes are now erased.Reprogram any accessory youwish

to use.

ERASE ALL REMOTE CONTROLS,KEYLESS ENTRIES ANDMyQ®DEVICES FROM GARAGE

DOOR OPENER

1. Press andhold the LEARN buttonongaragedoor opener until thelearn LED goes out (approximately 6

seconds).

2. Immediately press and hold the LEARN buttonagainuntil the learn LED goes out. All codes are now

erased. Reprogram any accessory youwish to use.

ERASE THE CONNECTIONFROMGARAGE DOOR OPENER TO HOMEWi-FiNETWORK

1. Press andhold the black adjustmentbuttonon thegaragedoor opener until 3 beeps are heard

(Approximately 6 seconds).

ERASE A MyQ®ACCOUNT

1. Go to www.mychamberlain.comto access your MyQ®account.

2. Go to "Account" section.

3. Click "Delete Account".

Go to wifihelp.chamberlain.com for more details.

38

Page 39

Maintenance

1

2

3

Maintenance Schedule

EVERY MONTH

l Manually operate door. If it is unbalancedor binding, call a traineddoor systems technician.

l Check tobe sure door opens and closes fully. Adjust if necessary, see page29.

l Test the safety reversal system.Adjust if necessary, seepage31.

EVERY YEAR

l Oil door rollers, bearings and hinges. Thegaragedoor opener does not require additional lubrication. Do not

grease the door tracks.