Page 1

Garage Opener

• Please read this manual and the enclosed safety materials carefully!

• Fasten the manual near the garage door after installation.

• The door WILL NOT CLOSE unless the Protector System® is connected

and properly aligned.

• Periodic checks of the garage door opener are required to ensure

safe operation.

Owner’s Manual

B500 • B503 • B510

Belt Drive

Garage Door Opener

FOR RESIDENTIAL USE ONLY

PRE-PROGRAMMED REMOTE CONTROL

INCLUDED

TO WATCH VIDEOS GO TO:

tinyurl.com/lgh5x3h

• The model number label is located on the left side panel of your

garage door opener.

• This garage door opener is compatible with MyQ® and

Security+2.0® accessories.

• DO NOT install on a one-piece door if using devices or features

providing unattended close. Unattended devices and features are

to be used ONLY with sectional doors.

Contents

Preparation ......................................2-5

Assembly ....................................... 6-10

Installation .................................. 11-28

Install the Door Control ............ 21-22

Install the Protector System® .... 23-26

Power ......................................27-28

Adjustments .................................29-31

Operation ..........................................32

Features .......................................33

Using your Garage Door Opener .....34

Multi-Function Control Panel .... 34-35

Remote Control and

Keyless Entry ........................... 35-36

Homelink® ...................................36

To Erase the Memory .....................36

To Open the Door Manually ...........37

Maintenance .....................................38

Troubleshooting ........................... 39-40

Accessories ........................................41

Warranty ...........................................42

Repair Parts .................................43-44

www.chamberlain.com

www.mychamberlain.com

Page 2

Torsion

Spring

Extension

Spring

OR

Preparation

Safety Symbol and Signal Word Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated,

maintained and tested in strict accordance with the instructions and warnings contained in this manual.

Whenyou see these Safety Symbols and Signal Words on

the following pages, they wi ll alert you to the possibil ity of

Mechanical

serious injury or death i f you do not comply wi th the

warnings that accompany them.The hazard may come

from something mechanical or from electric shock. Read

Electrical

the warnings carefully.

Whenyou see this Signal Word on the followi ng pages, it

will alert you to the possibility of damage to your garage

door and/or the garage door opener if you do not comply

with the cautionary statements that accompany it. Read

themcarefully.

WARN ING: This product can expose you to chemicals i ncluding lead, which are known to the State of

California to causecancer or birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov

Unattended Operation

The Timer-to-Cl ose (TTC) feature, the MyQ®Smartphone Control app, and MyQ®Garage Door and Gate Monitor

are examples of unattended close and are to be used ON LY with sectional doors. Any device or feature that allows the

door to close without being in the li ne of si ght of the door is consideredunattended close. The T imer-to-Close (TTC)

feature, the MyQ®Smartphone Control, and any other MyQ®devices are to be used ONLY with sectional doors.

Check the Door

To prevent possible SERIOUSINJURYor DEATH :

l ALWAYScall a trained door systems technician if garage door binds, sticks, or is out of balance. An

unbalanced garage door may NOT reverse when r equired.

l NEVER try to loosen, move or adjust garage door, door springs, cables, pulleys, brackets or their hardware,

ALLof w hich are under EXTR EME tension.

l Disable ALLlocks and r emoveALLropes connected to garage door BEFORE installation and operating

garage door opener to avoid entanglement.

l DO NOT install on a one-piece door if using devices or features providing unattended close. Unattended

devices and features are to be used ONLY with sectional doors.

To prevent damage to garage door and opener:

l ALWAYSdisable locks BEFORE installing and operating the opener.

l ONLY operate garage door opener at 120V, 60Hz to avoid malfunction and damage.

Before you begin:

1. Disable locks and remove any r opes connectedto the garage door.

2. Lift the door halfway up. R elease the door. If balanced, it should stay in place,

supportedentirely by its springs.

3. Raise and lower the door to check for binding or sticki ng. If your door binds,

sticks, or is out of balance, call a traineddoor systems technician.

4. Check the seal on the bottomof the door. Any gap between the floor and the

bottom of the door must not exceed 1/4 inch (6 mm). Otherwise, the safety

reversal system may not work properly.

5. The opener should be installed above the center of the door. If there is a torsion

spring or center bearing plate in the way of the header bracket, it may be

installed w ithin 4feet (1.2m) to the left or right of the door center. See page 12.

2

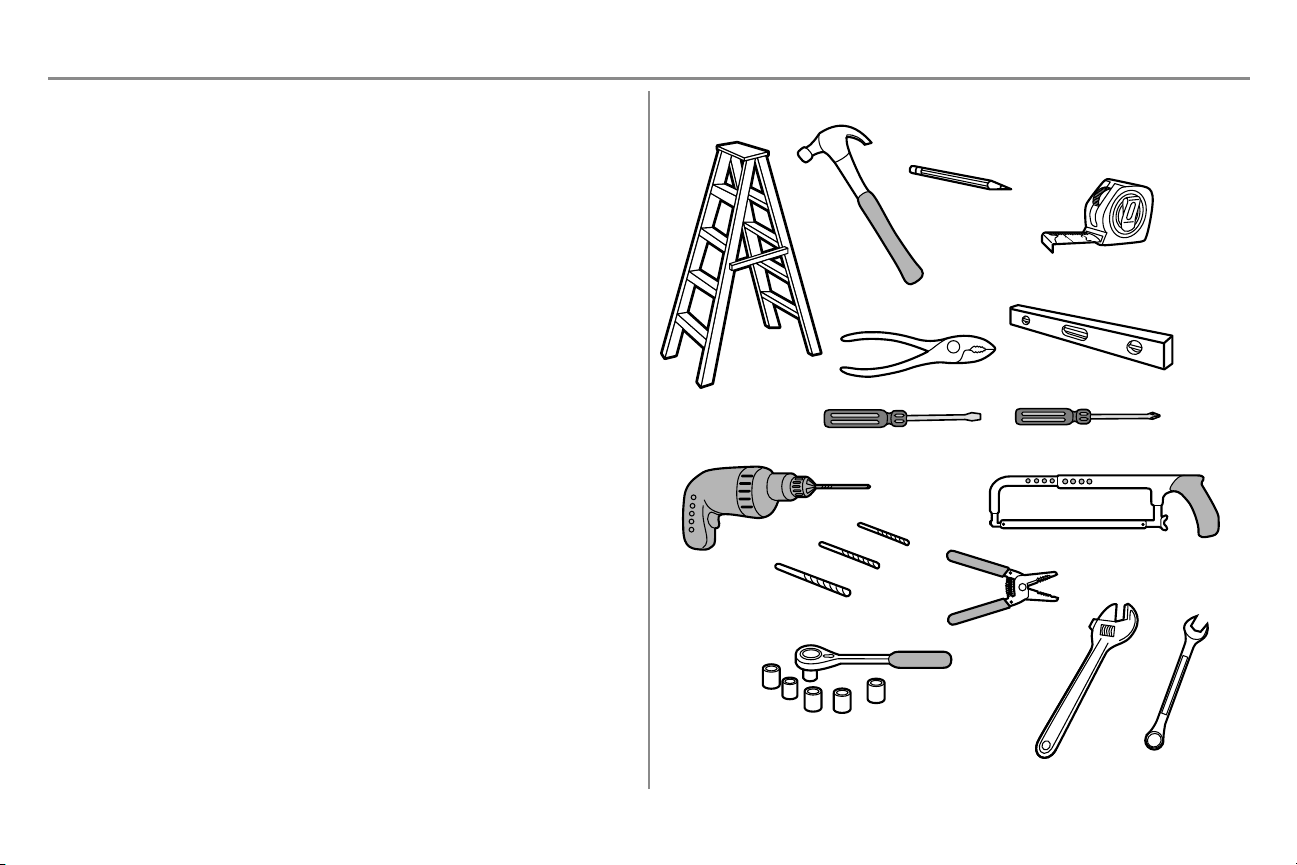

Page 3

3/16

7/16

1/2

5/32

5/16

5/8

9/16

1/4

7/16

Preparation

Additional Items You May Need:

Survey your garage area to see if you w ill needany of the following items:

n (2) 2X4 PIECES OF WOOD

May be used to fasten the header bracket to the structural supports. Also used to position the garage door

opener during installation and for testing the safety reversi ng sensors.

n SUPPORT BR ACKET AND FASTENIN G H ARDWARE

Must be used if you have a finished ceiling in your garage.

n EXTENSION BRACK ETS (MODEL 041A5281-1) OR WOOD B LOCKS

Dependingupon garage construction, extension brackets or wood blocks may be neededto install the

safety reversing sensor.

n FASTENIN G H ARDWARE

Alternate floor mounting of the safety r eversing sensor will require hardware not provided.

n DOOR REINFORC EMENT

Required if you have a lightweight steel, aluminum,fiberglass or glass panel door.

n RAIL EXTENSION K IT

Required if your garage door is more than 7 feet (2.13m) high.

Tools Needed

3

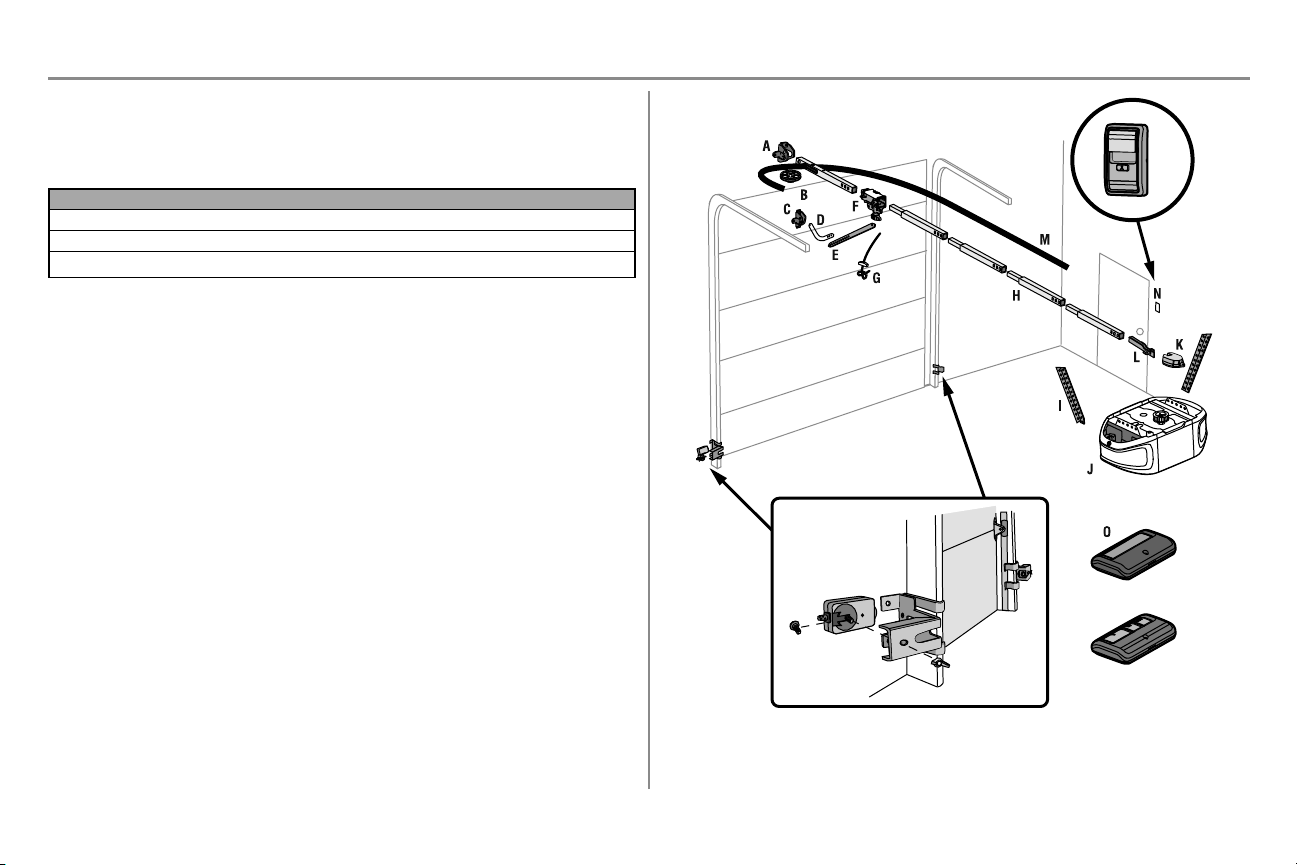

Page 4

OR

P

Preparation

Carton Inventory

Save the cartonand packing material until the installation and adjustment is complete. Instructions for the accessories

will be attachedto the accessory andare not i ncluded in this manual. The images throughout this manual are for

reference only and your product may look different.

Model Power Doo r C ont rol Remot e Control Wireless Keypad

B500 Med Lift Power System™ Multi-Function 1-button(2)

B503 Med Lift Power System™ Multi-Function 3-button(2)

B510 Med Lift Power System™ Multi-Function 3-button(2)

A. Header bracket

B. Pulley

C. D oor bracket

D. C urved door arm

E. Straight door arm (Packaged inside front rail section)

F. T rolley

NOTE: Be sure to assemble the trolley before sliding onto rail.

G. Emergency r elease rope and handle

H. R ail (1 front and 4 center sections)

I. Hanging brackets (2) ( Packagedinside the fr ont rail section)

J. Garagedoor opener (motor unit)

K. Sprocket cover and scr ews

L. “U ” bracket

M. Belt

N. D oor control

O. Remote control

P. The Prot ector System

Safety reversi ng sensors wi th 2 conductor white and white/black wire attached: Sending Sensor (1),

Receiving Sensor (1), and Safety Sensor Brackets (2)

NOT SH OWN

Wireless Keypad

White and red/white wire

Owner's manual

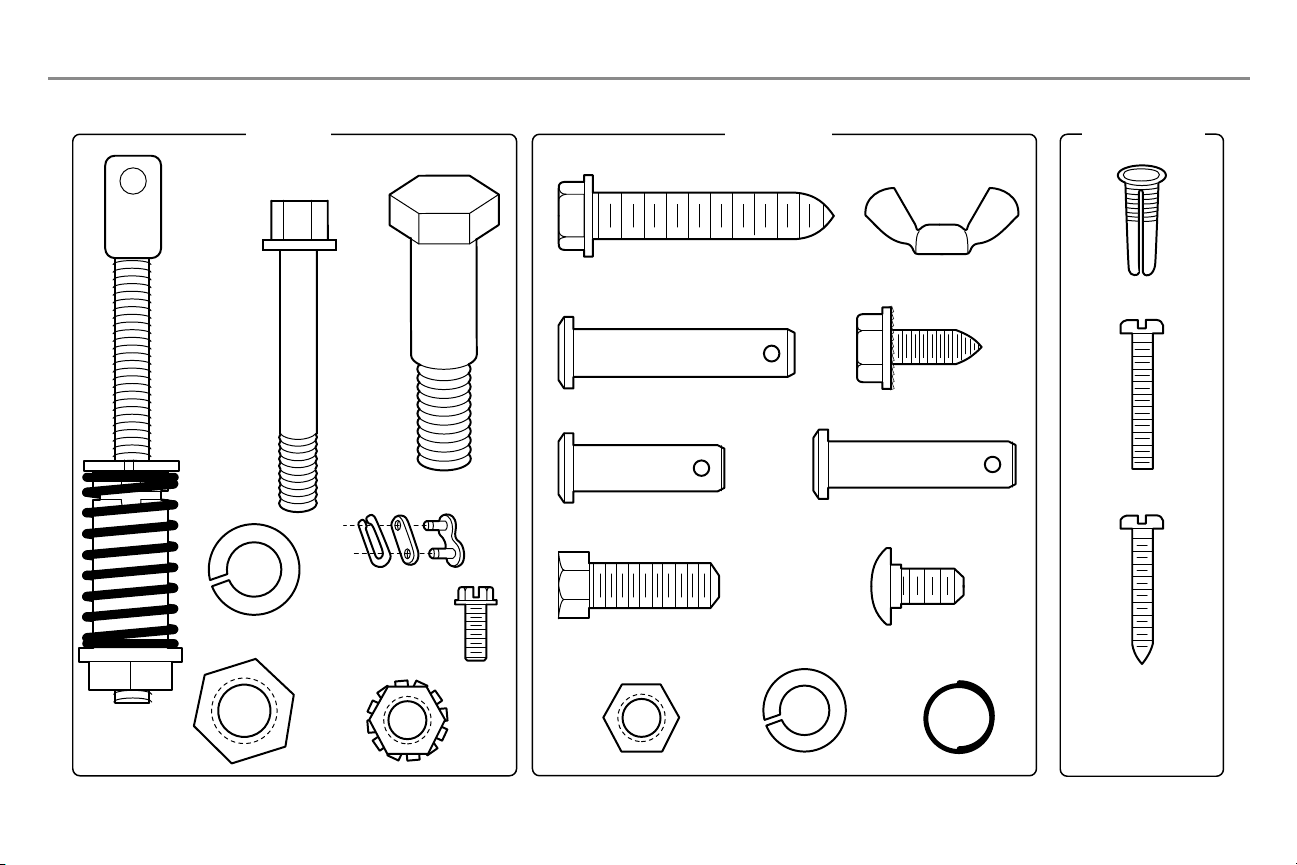

Hardware

®

ü

4

Page 5

ASSEMBLY INSTALLATION

DOOR CONTROL

Insulated Staples

(Not

Shown)

Clevis Pin 5/16"x1-1/2"

Ring

Fastener (3)

Hex Bolt 5/16"-18x7/8" (4)

Self-Threading Screw

1/4"-14x5/8" (2)

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Carriage Bolt

1/4"-20x1/2" (2)

Wing Nut

1/4"-20 (2)

Lag Screw 5/16"-9x1-5/8" (4)

Screw 6ABx1" (2)

Drywall Anchors (2)

Screw 6-32x1" (2)

Hex Screw #8x3/8" (2)

(packed with the

sprocket cover)

Bolt

1/4"-20x1-3/4"

Lock Nut

1/4"-20

Bolt

Nut 3/8"

Lock Washer 3/8"

Master Link

Threaded

Shaft with

Spring

Trolley Nut

Lock Washer

5/16"-18 (4)

Nut

5/16"-18 (4)

Preparation

Hardware

5

Page 6

Assembly

Wear Pads

Front Rail Section

(TO DOOR)

“U” Bracket

(TO MOTOR UNIT)

Trolley

Rail Tab

On Top

Slide to stops

on top and sides

of “U” bracket

Screwdriver

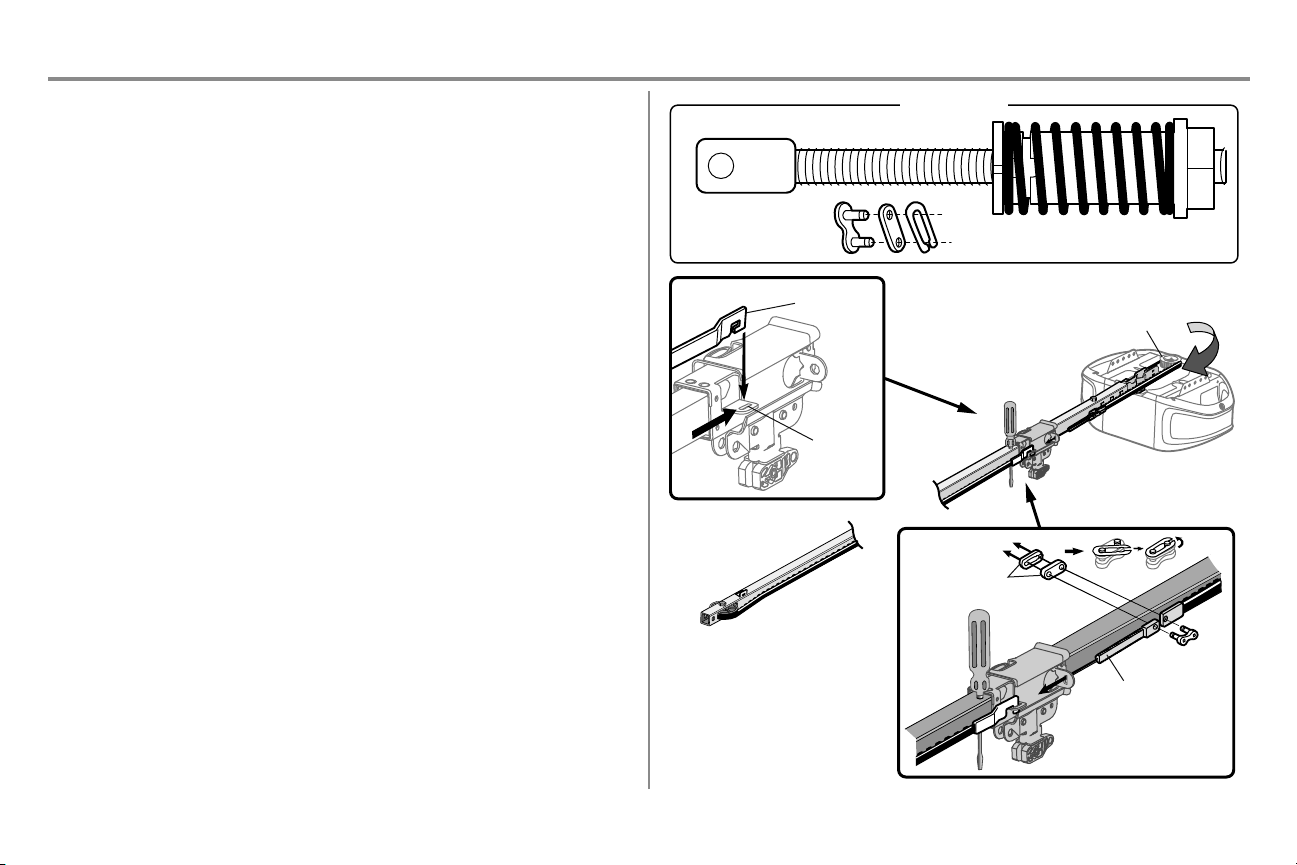

STEP 1 Assemble the rail and install the trolley

To prevent INJURY from pinching, keephands and fingers away from the joints while assembling the r ail.

To avoid installation difficulties, do not run t he garage d oor op ener until instructed t o do so.

The front rail has a cut out “w indow” at the door end. The rail tab MUST be on top of the r ail when assembled.

1. Remove the straight door arm and hangingbracket packaged inside the front r ail and set aside for

Installation Step 5 and 9. NOTE: To prevent INJURY w hile unpacking the rail carefully remove the straight

door arm stored w ithin the rail section.

2. Align the rail sections on a flat surface as shown and slide the tapered ends intothe larger ones. Tabs

along the side will lock into place.

3. Place the motor unit on packing material to protect the cover, and rest the back end of the rail on top. For

convenience, put a support under the frontend of the rail.

4. As a temporary stop, insert a screwdriver into the hole in the second r ail section fr om the motor unit, as

shown.

5. Check to be sure there are 4 plastic w ear pads inside the inner trolley. If they became loose during

shipping, check all packing material. Snap them back into position as shown.

6. Slide the trolley assembly toward the screwdriver as shown.

7. Slide the rail onto the “U” bracket, until it reaches all the stops on the top and sides of the “U ” bracket.

6

Page 7

Assembly

Bolt

1/4"-20x1-3/4"

Lock Nut

1/4"-20

HARDWARE

“U” Bracket

Cover Protection

Bolt Hole

Bolt

Lock Nut

Bolts (Mounted in the

garage door opener)

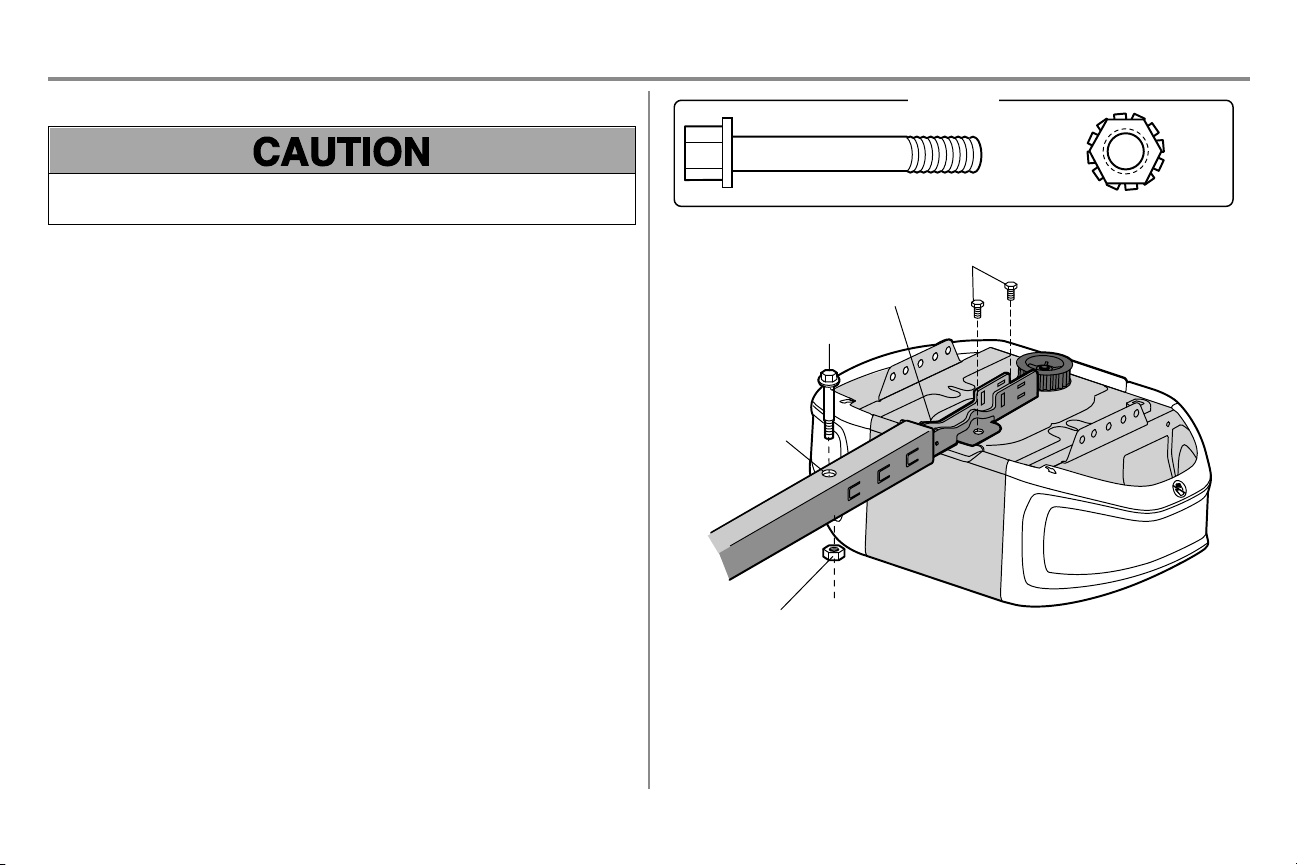

STEP 2 Fasten the rail to the motor unit

To avoid SERIOU S damageto garage door opener, use ONLY those bolts/fasteners mounted in the top of the

opener.

1. Insert a 1/4"-20 x 1-3/4" bolt into the cover protection bolt hole on the back end of the rail as shown. Tighten

securely with a 1/4"-20 lock nut. D O NOT overtighten.

2. Remove the bolts from the top of the motor unit.

3. Use the carton to support the front end of the rail .

4. Place the “U ” bracket, flat side down onto the motor unit and align the bracket holes w ith the bolt holes.

5. Fasten the “ U” bracket with the previously removed bolts; D O N OT use any power tools. The use of power

tools may permanently damage the garage door opener.

7

Page 8

Assembly

Rail

Idler Pulley

Grease Inside

Pulley

Bolt

Belt

Lock Washer

Nut

Bolt

Nut 3/8" Lock Washer 3/8"

HARDWARE

Trolley Connector

Rail Tab

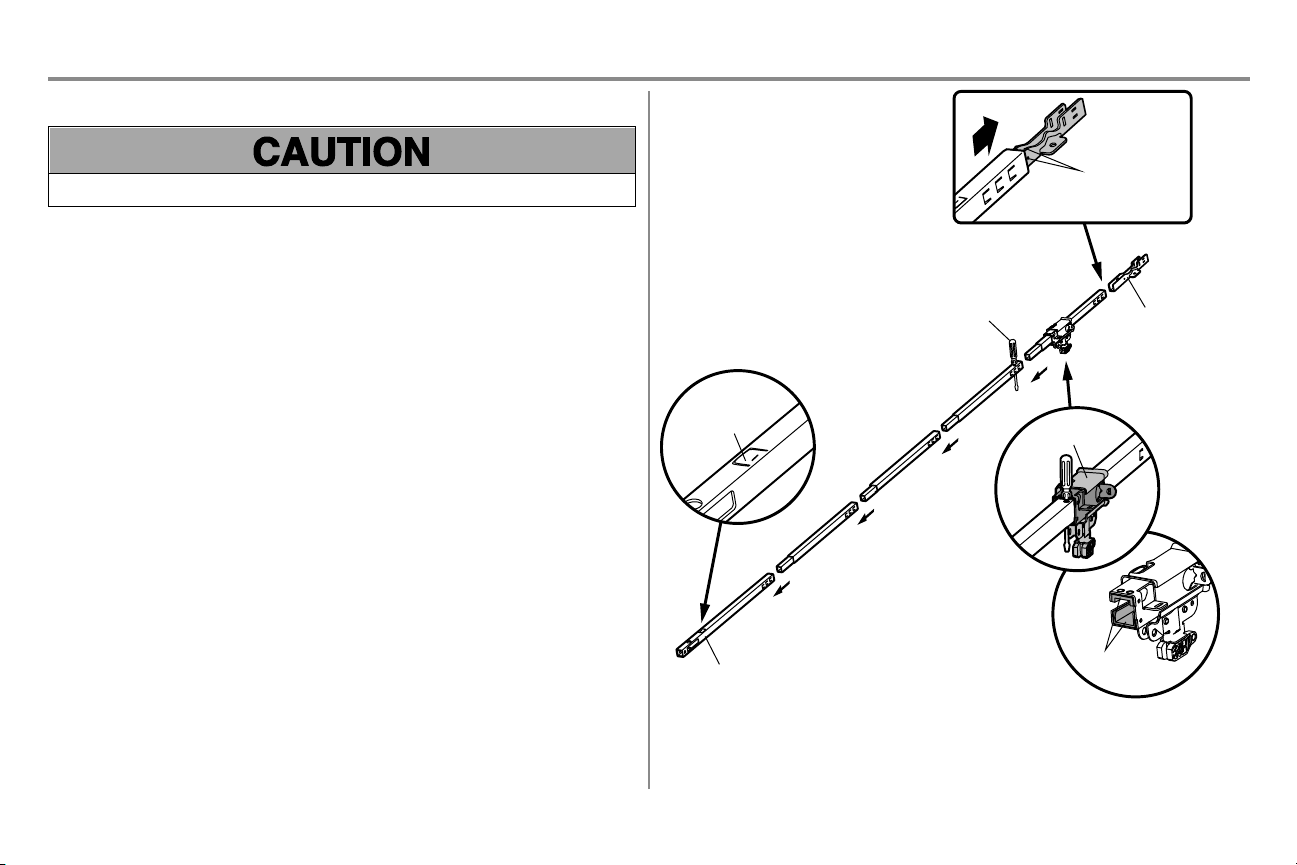

STEP 3 Install the idler pulley

1. Lay the belt beside the rail, as shown. Grasp the end with the hooked trolley connector and pass

approximately 12" (30 cm) of belt through the w indow. Keep the r ibbed side toward the rail, and allow it to

hanguntil Assembly Step 4.

2. Remove the tape from the idler pulley. The inside center should be pre-greased. If dry, regrease to ensure

proper operation.

3. Place the idler pulley intothe window as shown.

4. Insert the idler bolt from the top through the rail and pulley. Tightenwith a 3/8" lock washer and nut

underneath the rail until the lock washer is compressed.

5. Rotate the pulley to be sure it spins freely.

6. Locate the rail tab. The rail tab is between the idler bolt and the trolley in the front rail section. Use a

flathead screwdriver and lift the rail tab until the tab is vertical (90º).

8

Page 9

Assembly

HARDWARE

Master Link

Figure 3

Threaded Shaft with Spring Trolley Nut

Threaded Shaft

Master Link

Sprocket

Figure 2

Figure 1

Trolley

Connector

Retaining

Slot

STEP 4 Install the belt

1. Pull the belt around the idler pulley and toward the trolley. The ribbed si de must contact the pulley.

2. Hook the troll ey connector into the retaining sl ot on the tr olley as shown ( Figure 1).

3. With the trolley against the screwdriver, dispense the remainder of the belt along the rail lengthtoward the

motor unit and around the sprocket (Figure 2). The sprocket teeth must engage the belt.

4. Check to make sure the belt i s not twisted.Connect the trolley threaded shaft wi th the master link(Figure

3).

l Push pins of master link bar through holes i n end of belt and trolley threaded shaft.

l Push master link cap over pins and past pin notches.

l Slide the closed end of the clip-on spring over one of the pins. Push the open end of the clip-on spring

ontothe other pin.

5. Remove the spring trolley nut from the threaded shaft.

6. Insert the trolley threaded shaft through the hole in the troll ey.

9

Page 10

Assembly

Spring

Trolley Nut

Nut Ring Slot

Nut RingNut Ring

AFTER

1-1/4" (3.18 cm)

BEFORE

1" (2.5 cm)

Hex Screw #8x3/8"

(Packed with the sprocket cover)

HARDWARE

Hex Screw #8x3/8"

Sprocket Cover

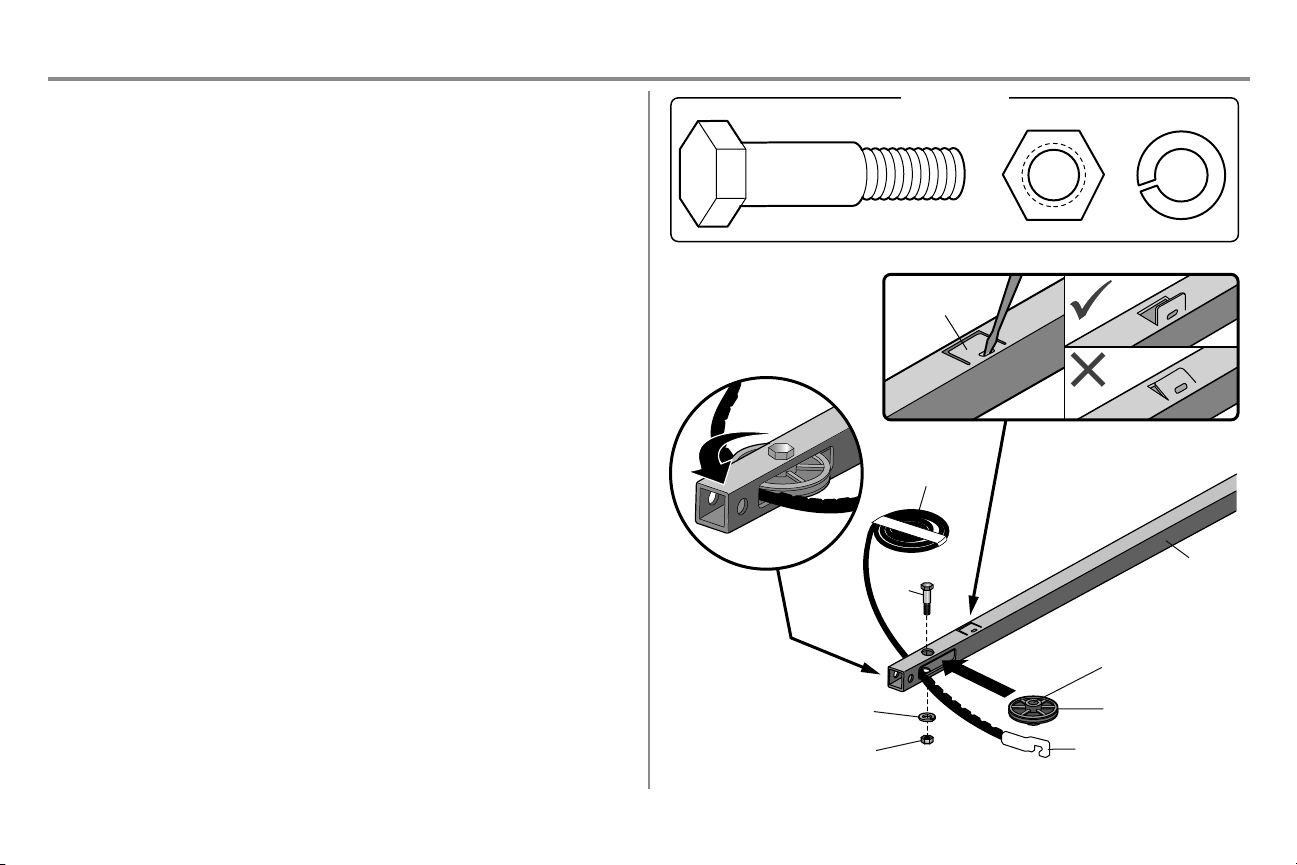

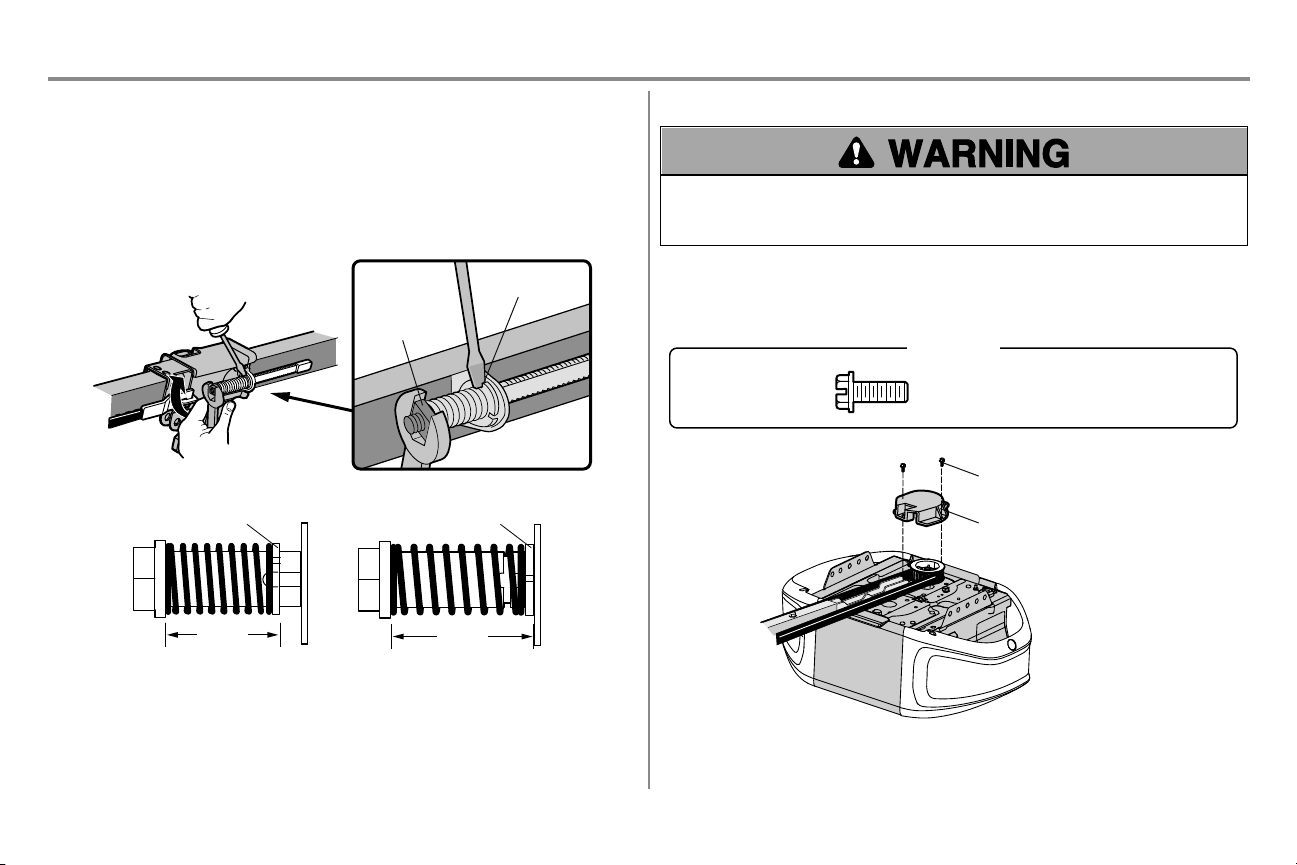

STEP 5 Tighten the belt

1. By hand, thread the spring trolley nut on the threadedshaft until i t is finger tight against the trolley. Do not

use any tools. Remove the screwdriver.

2. Insert a flathead screwdriver tip into one of the nut r ing slots and brace it firmly against the trolley.

3. Tighten the spring trolley nut w ith an adjustable wrench or a 7/16" openendwrench about a quarter turn

until the spring releases and snaps the nut ring against the troll ey. This sets the spring to optimum belt

tension.

STEP 6 Install the sprocket cover

To avoid possible SERIOUS INJURY to finger fr om moving garage door opener:

l ALWAYSkeep handclear of sprocket while operating opener.

l Securely attach sprocket cover BEFORE operating.

1. Position the sprocket cover over the sprocket as shown and fasten to the mountingplate with 8x3/8" hex

screws provided.

You have n ow finished assembling your garage doo r o pener. Please read the following warnings before

proceeding t o the installation section.

10

Page 11

Installation

Change 5. to say "Where possible, i nstall the door opener 7 feet (2.13 m) or more above the floor." per regulatory Bill Carrey.

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTALLATION WARN INGS AND INSTRUCTIONS.

2. Install garage door opener ON LY on properly balanced and lubricated garage door. An improperly balanced

door may N OT reverse whenrequired and could result in SEVERE INJU RY or DEATH.

3. ALL repairs to cables, spring assemblies and other hardware MUST be made by a tr ained door systems

technician BEFORE installing opener.

4. Disable ALL locks and r emoveALL ropes connected to garage door BEFORE installing opener to avoid

entanglement.

5. Where possible, install the door opener 7 feet (2.13 m) or more above the floor.

6. Mountthe emergency release w ithin reach, but at least 6 feet (1.83m) above the floor and avoiding contact

with vehicles to avoid accidental r elease.

7. NEVER connect garage door opener to power source until instructed to do so.

8. NEVER w ear w atches, rings or loose clothing while installing or servicing opener. They could be caughtin

garage door or opener mechanisms.

Step 11. changed" manual" to "emergency" label. Per Bill C. regulatory. Updated in 114A5010MDR. Updated in

114A4862,114A5051. - LTB

9. Install wall-mounted garage door control:

l within sight of the garage door.

l out of reach of small children at a minimum height of 5feet (1.5m) above floors, landings, steps or any

other adjacent walking surface.

l away from ALL moving parts of the door.

10. Place entrapmentwarning l abel on wall next to garage door control.

11. Place emergency r elease/safety r everse test label in plain view on inside of garage door.

12. Upon completion of installation, test safety reversal system. Door MUST reverse on contact with a 1-1/2"

(3.8cm) high object (or a 2x4 laid flat) on the floor.

13. To avoid SERIOU S PERSONAL INJURY or DEATH from electrocution, disconnect ALL electric power

BEFORE performing ANY service or maintenance.

14. DO NOT install on a one-piece door if using devices or features providing unattendedclose. U nattended

devices and features are to be used ONLY with sectional doors.

11

Page 12

Installation

Header Wall

Vertical Centerline of Garage Door

2x4

Structural

Supports

Level

(Optional)

Unfinished

Ceiling

2x4

OPTIONAL CEILING MOUNT

FOR HEADER BRACKET

Sectional door with curved track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door with horizontal track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door without track:

jamb hardware

Header Wall

8" (20 cm)

Highest

Point of

Travel

Door

Jamb

Hardware

One-piece door without track:

pivot hardware

Header Wall

8" (20 cm)

Highest

Point of

Travel

Door

Pivot

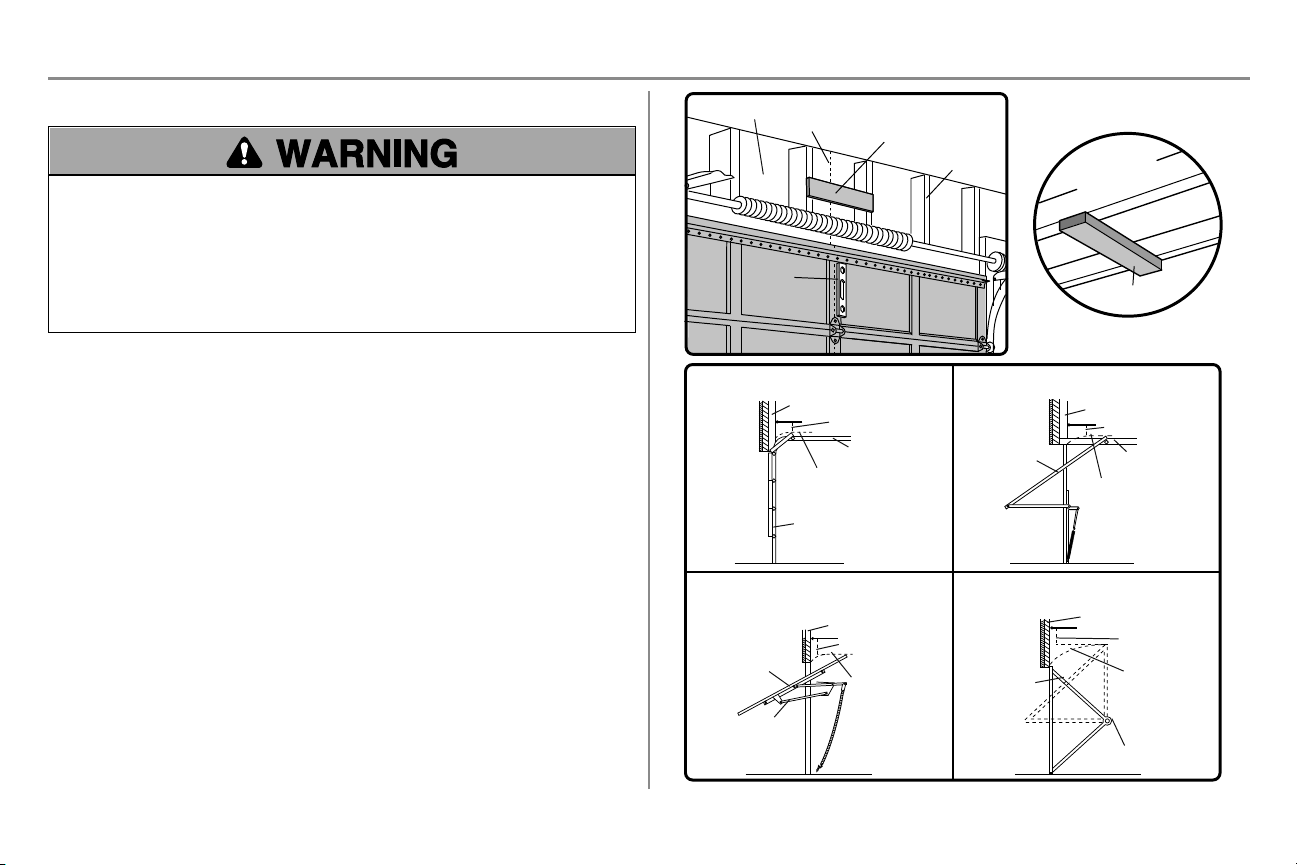

STEP 1 Determine the header bracket location

To prevent possible SERIOUS IN JUR Y or D EATH:

l Header bracket MUST be R IGIDLY fastened to str uctural support on header wall or ceiling, otherwise

garage door might NOT reverse whenrequired. DO NOT install header bracket over dryw all.

l Concrete anchors MUST be used if mountingheader bracket or 2x4 into masonry.

l NEVER try to loosen, move or adjust garage door, springs, cables, pulleys, brackets, or their hardware, ALL

of which are under EXTR EME tension.

l ALWAYScall a trained door systems technician if garage door binds, sticks, or is out of balance. An

unbalanced garage door might N OT reverse whenrequired.

Installation procedures vary according to garage door types. Follow the instructions which apply to your door.

1. Close the door and mark the inside vertical centerline of the garage door.

2. Extend the line onto the header wall above the door.Youcan fasten the header bracket within 4 feet ( 1.22 m)

of the left or right of the door center only if a torsion spring or center bearing plate is i n the w ay; or you can

attach it to the ceil ing (see page 13) w hen clearance is minimal. (It may be mounted on the w all upside

down if necessary, to gain approximately 1/2" (1 cm). If you needto install the header bracket on a 2x4 ( on

wall or ceiling), use lag screws (not provided) to securely fasten the 2x4 to structural supports as shown

here and on page 13.

3. Open your door to the highest point of travel as shown. Dr aw an intersecting horizontal line on the header

l 2" ( 5 cm) above the high point for sectional door and one-piece door w ith track.

l 8" ( 20 cm) above the high point for one-piece door without track.

This height will provide travel clearance for the top edge of the door. NOTE: If the total number of inches exceeds the

height available in your garage, use the maximumheight possible, or refer to page13 for ceiling installation.

wall 2" ( 5 cm) above the high point:

12

Page 13

Installation

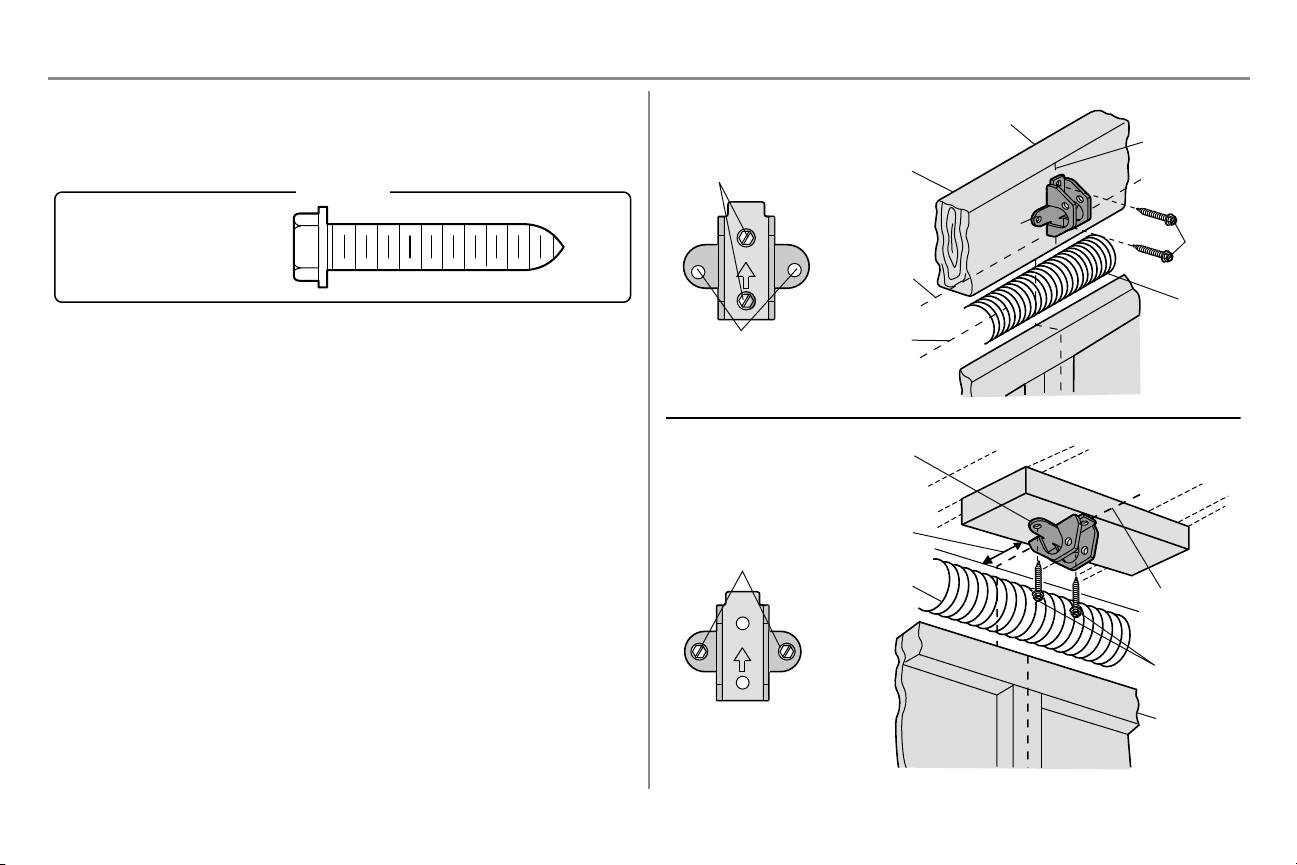

Lag Screw 5/16"-9x1-5/8"

HARDWARE

UP

Wall Mounting

Holes

WALL INSTALLATION

CEILING INSTALLATION

Optional Mounting

Holes

Vertical

Centerline of

Garage Door

Header Wall

Header

Bracket

2x4

Structural

Support

Door

Spring

Garage Door

Highest Point

of Garage

Door Travel

Horizontal

Line

Lag

Screw

UP

Header Wall

Ceiling Mounting

Holes

Finished Ceiling

Vertical

Centerline of

Garage Door

Header

Bracket

6" (15 cm)

Maximum

Door Spring

Garage Door

Lag Screw

STEP 2 Install the header bracket

You can attach the header bracket either to the w all above the garage door, or to the ceiling. Follow the instructions

which wi ll work best for your particular r equirements. D o not install t he header bracket over drywall. If installing

into masonry, use concrete anchors (not pro vided).

OPTION A - WALL INSTALLATION

1. Center the bracket on the vertical centerline w ith the bottom edge of the bracket on the horizontal line as

shown ( with the arrow pointing toward the ceiling).

2. Mark the vertical set of bracket holes. D ril l 3/16" pilot holes and fasten the bracket securely to a structural

OPTION B - CEILING INSTALLATION

1. Extend the vertical centerline onto the ceiling as shown.

2. Center the bracket on the vertical mark, no more than 6" (15 cm) from the wall. Make sure the arr ow is

3. Mark the side holes. D rill 3/16" pilot holes and fasten bracket securely to a structural support wi th the

support with the hardware provided.

pointing away from the w all. The bracket can be mounted flush against the ceili ng when clearance is

minimal.

hardware provided.

13

Page 14

Installation

HARDWARE

Clevis Pin

5/16"x1-1/2"

Ring Fastener

Clevis Pin

Ring Fastener

Connected Disconnected

One-piece door

without tracks

2x4 2x4

All other

door types

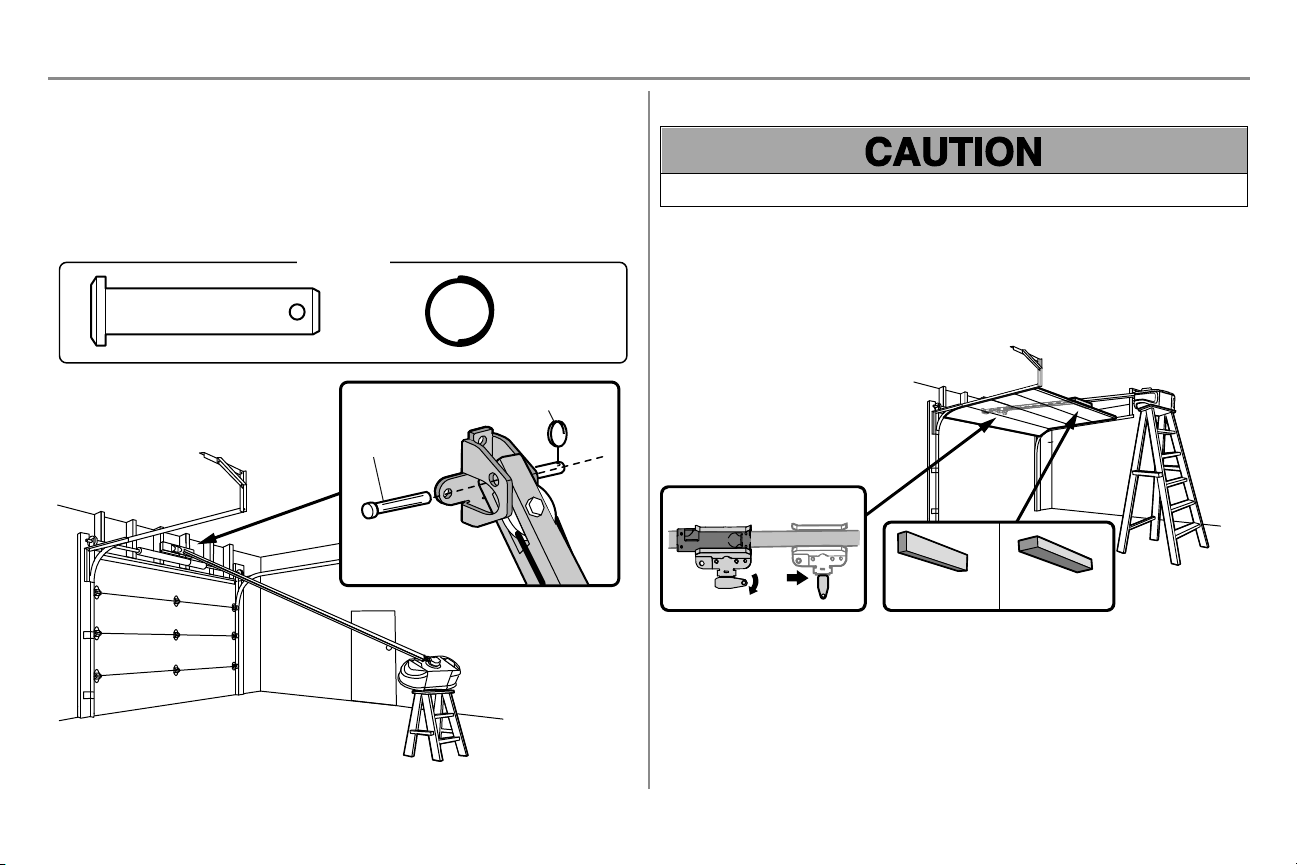

STEP 3 Attach the rail to the header bracket

1. Position the opener on the garage floor below the header bracket. Use packing material as a protective

base.

NOTE: If the door spring is in the w ay, you will need help. Have someone hold the opener securely on a

temporary support to allow the rail to clear the spring.

2. Position the rail bracket against the header bracket.

3. Align the bracket holes and join with a clevis pin as shown.

4. Insert a ring fastener to secure.

STEP 4 Position the garage door opener

To prevent damage to garage door, rest garage door opener r ail on 2x4 placed on top section of door.

1. Remove the packing material and l ift the garage door opener onto a ladder.

2. Fully open the door and place a 2x4 (laid flat) under the r ail. For one-piece doors w ithout tracks, lay the

2x4 on it's side.

NOTE: A 2x4 is ideal for setting the distancebetweenthe rail and the door. If the ladder is not tall enough you will

needhelp at this point. If the door hits the trolley whenit is r aised, pull the trolley r elease arm down to disconnect the

inner and outer trolley. Slide the outer trolley toward the garage door opener. The tr olley can remain disconnected

until instructed.

14

Page 15

Installation

Finished Ceiling

Lag Screw

1

2

3

Not

Provided

Not Provided

Not Provided

Hex Bolt

Nut

Lock

Washer

4 5

6

Lag Screw

Finished Ceiling

EXAMPLES

Unfinished Ceiling

HARDWARE

Hex Bolt

5/16"- 18x7/8"

Nut

5/16"-18

Lock Washer

5/16"-18

Lag Screw

5/16"-9x1-5/8"

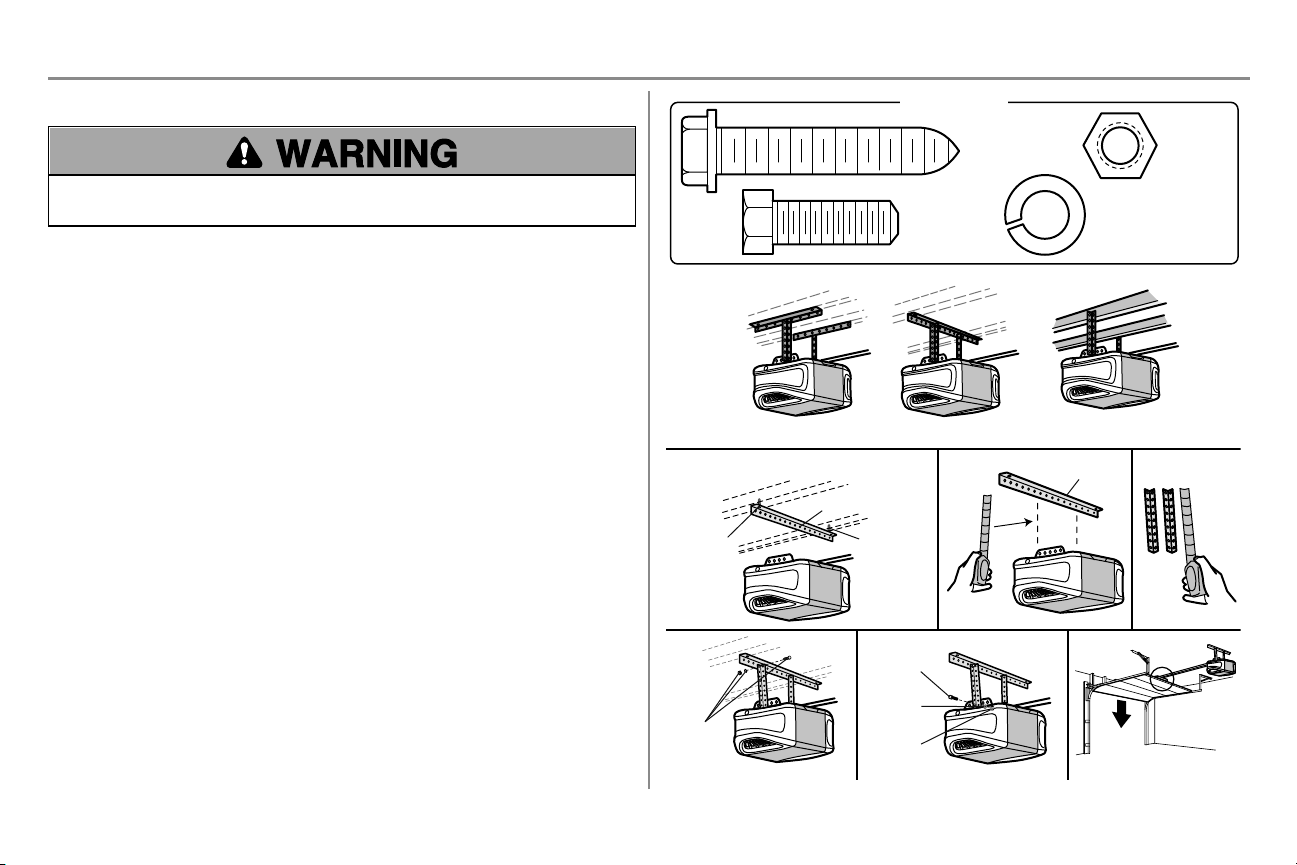

STEP 5 Hang the garage door opener

To avoid possible SERIOUS INJURY from a falling garage door opener, fasten it SECU RELY to structural

supports of the garage. Concrete anchors MUST be used if installi ng ANY brackets into masonry.

Hanging the garage door opener will vary dependingon your garage. Below are three example installations. Your

installation may be different. For ALL installations the garage door opener MUST be connectedto structural supports.

The instructions il lustrate one of the examples below.

1. On finished ceilings, use the lag screws to attach a support bracket (not provided) to the structural

supports before installing the garage door opener.

2. Make sure the garage door opener is aligned w ith the header bracket. Measure the distance from each side

of the garage door opener to the support bracket.

3. Cut both pieces of the hanging bracket to required lengths.

4. Attach the end of each hanging bracket to the support bracket with appropriate hardware (not provided).

5. Attach the garage door opener to the hanging brackets wi th the hex bolts, lock washers, and nuts.

6. Remove the 2x4 and manually close the door. If the door hits the rail, raise the header bracket.

15

Page 16

Installation

or

or

STEP 6 Install the Light Bulbs

To prevent possible OVERHEATING of the end panel or light socket:

l Use ONLY A19 incandescent (100W maximum) or compact fluorescent (26W maximum) light bulbs.

l DO NOT use incandescent bulbs larger than 100W.

l DO NOT use compact fluorescent light bulbs l arger than 26W (100W equivalent).

l DO NOT use halogen bulbs.

l DO NOT use short neck or specialty light bulbs.

1. Pull on the top sides of the l ight lens and rotate the light lens down.

2. Insert an A19 incandescent (100W maximum) or compact fluorescent (26W, 100W equivalent) light bulb

into the light socket.

3. Rotate the lens up to close.

NOTE: Do not use halogen, short neck, or specialty light bulbs as these may overheat the end panel or light socket.

Do not use LED bulbs as they may reduce the rangeor performance of your remote controls.

STEP 7 Attach the emergency release rope and handle

To prevent possible SERIOUS IN JUR Y or D EATH froma falling garage door:

l If possible, use emergency r elease handle to disengage trolley ONLY when garage door is C LOSED. Weak

or broken springs or unbalanceddoor could result in an open door falling rapidly and/or unexpectedly.

l NEVER use emergency release handle unless garage doorway is clear of persons and obstructions.

l NEVER use handle to pull door open or closed. If rope knot becomes untied, you could fall.

1. Insert one end of the emergency r elease rope through the handle. Make sure that “N OTICE” is ri ght side

up. Secure w ith an overhand knot at l east 1" (2.5 cm) from the end of the r ope to prevent slipping.

2. Insert the other end of the emergency release rope through the hole in the trolley release arm. Mount the

emergency release w ithin reach, but at least 6 feet (1.83m) above floor, avoiding contact w ith vehicles to

prevent accidental release and secure with an overhand knot.

NOTE: If it is necessary to cut the emergency release rope, seal the cut end wi th a match or lighter to prevent

unraveling. Ensure the emergency release rope and handle are above the top of all vehicles to avoid entanglement.

16

Page 17

Installation

FIGURE 1

FIGURE 3 FIGURE 4

FIGURE 2

Vertical

Reinforcement

Vertical

Centerline

of Garage Door

UP

Door Bracket

Vertical Reinforcement

Vertical Reinforcement

Horizontal Reinforcement

Vertical Centerline

of Garage Door

Hardware

(not provided)

Door Bracket

UP

Vertical

Centerline

of Garage Door

UP

Vertical Centerline of

Garage Door

Hardware

(not provided)

UP

Inside Edge of Door or

Reinforcement Board

Self-Threading Screw

Self-Threading

Screw

HARDWARE

Self-Threading Screw

1/4"-14x5/8"

STEP 8 Install the door bracket

Fiberglass, aluminum or lightweight steel garage doors WILL R EQUIRE reinforcement BEFORE installation of

door bracket. Contact the garage door manufacturer or installi ng dealer for opener r einforcement instructions or

reinforcement kit. Failure to r einforce the top section as required according to the door manufacturer may void the

door warranty.

A horizontal and vertical r einforcement is needed for l ightweight garage doors (fiberglass, aluminum, steel, doors with

glass panel, etc.) (not provided). A horizontal r einforcement brace should be l ong enough to be secured to two or three

vertical supports. A vertical reinforcement brace should cover the height of the top panel. Contact the garage door

manufacturer or installing dealer for opener reinforcement instructions or reinforcement kit.

NOTE: Many door reinforcement kits provide for direct attachment of the clevis pin and door arm. In this case you wil l

not need the door bracket; proceed to the next step.

OPTION A - SECTIONALDOORS

1. Center the door bracket on the previously marked vertical centerline used for the header bracket

installation. Note correct UP placement,as stamped inside the bracket.

2. Position the top edge of the bracket 2"-4" (5-10cm) below the top edge of the door, OR directly below any

structural support across the top of the door.

3. Mark, drill holes and install as follows, depending on your door’s construction.

Metal or light weight doors using a vertical angle iron brace between the door panel support and the door

bracket:

l Drill 3/16" fastening holes. Secure the door bracket using the tw o 1/4"-14x5/8" self-threading screws.

(Figure1)

l Alternately, use two 5/16"-18x2" bolts, lock washers and nuts (not provided). ( Figure2)

Metal, insulated or light weight factory reinforced do ors:

l Drill 3/16" fastening holes. Secure the door bracket using the self-threading screws. ( Figure3)

Wood doors:

l Use top and bottom or side to side door bracket holes. Drill 5/16" holes through the door and secure

bracket w ith 5/16"-18x2" carriage bolts, lock w ashers and nuts (not provided). ( Figure4)

NOTE: The 1/4"-14x5/8" self-threading scr ews are not intendedfor use on wood doors.

17

Page 18

Installation

HARDWARE

Self-Threading Screw

1/4"-14x5/8"

For a door with no exposed

framing, or for the optional

installation, use lag screws

5/16"x1-1/2" (not provided)

to fasten the door bracket.

Vertical

Centerline

of Garage

Door

Optional

Placement

of Door

Bracket

Door Bracket

Header Bracket

Header Wall

2x4 Support

(Finished Ceiling)

Door

Bracket

Top of Door

(Inside Garage)

Top Edge of

Door

Optional

Placement

Optional

Placement

Top Edge

of Door

Top of Door

(Inside Garage)

Door

Bracket

Hardware

(not provided)

Hardware

(not provided)

Metal Door Wood Door

Self-Threading Screw

STEP 8 Install the door bracket (continued)

OPTION B - ONE-PIECE DOORS

1. Center the door bracket on the top of the door, in line with the header bracket as shown.

2. Mark either the left and r ight, or the top and bottom holes.

Metal Doors:

l Drill 3/16" pilot holes and fasten the bracket w ith the self-threading screws provided.

Wood D oors:

l Drill 5/16" holes and use 5/16"-18x2" carriage bolts, lock w ashers and nuts (not provided) or 5/16"x1-1/2"

lag screws (not provided) depending on your installation needs.

NOTE: The door bracket may be installed on the top edgeof the door if required for your installation.(Refer to the

dotted line optional placementdrawing.)

18

Page 19

Installation

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut 5/16"-18

Lock Washer

5/16" -18

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Ring Fastener

Lock Washer

Nut

Hex Bolt

Clevis Pin

5/16"x1-1/4"

Ring Fastener

Clevis Pin 5/16"x1"

Straight

Door Arm

(Groove

facing out)

Curved

Door Arm

STEP 9 Connect the door arm to the trolley

Installation will vary according to the garage door type. Follow the instructions which apply to your door.

OPTION A - SECTIONALDOORS

IMPORTAN T: The groove on the straight door arm MUST face away from the curved door arm.

1. Close the door. D isconnect the tr olley by pulling the emergency release handle.

2. Attach the straight door arm to the outer trolley using the clevis pin. Secure w ith the ring fastener.

3. Attach the curved door arm to the door bracket using the clevis pin. Secure with the r ing fastener.

4. Bring arm sections together. F ind two pairs of holes that line up and join sections. Select holes as far apart

as possible to increase door arm rigidity and attach using the bolts, nuts, and lock washers.

5. Pull the emergency release handle toward the garage door opener until the trolley release arm is

horizontal. The trolley will re-engage automatically w hen the garage door opener is activated.

NOTE: If the holes in the curved door arm and the str aight door arm do not align, reverse the straight door arm, select

two holes (as far apart as possible) and attach using bolts, nuts, and lock w ashers. If the straight door arm is hanging

down too far, you may cut 6 inches (15 cm) from the solid end.

19

Page 20

Installation

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut 5/16"-18

Lock Washer

5/16" -18

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Ring Fastener

One-Piece Door without Track

One-Piece Door with Track

Ring Fastener

Ring Fastener

Ring Fastener

Nut

Nut

Ring Fastener

Lock Washer

Lock Washer

Clevis Pin 5/16"x1-1/4"

Clevis Pin

5/16"x1-1/4"

Hex Bolts

Hex Bolts

Clevis Pin

5/16"x1"

Clevis Pin

5/16"x1"

Straight Door Arm

(Groove facing out)

Curved Door Arm

STEP 9 Connect the door arm to the trolley (continued)

OPTION B - ONE-PIECE DOORS

IMPORTAN T: The groove on the straight door arm MUST face away from the curved door arm.

1. Close the door. D isconnect the tr olley by pulling the emergency release handle.

2. Fasten the straight door arm and the curved door arm together to the longest possible length (with a 2 or 3

hole overlap) using the bolts, nuts, and lock washers.

3. Attach the straight door arm to the door bracket using the clevis pin. Secure with the ring fastener.

4. Attach the curved door arm to the trolley using the clevis pin. Secure with the ring fastener.

5. Pull the emergency release handle toward the garage door opener until the trolley release arm is

horizontal.

20

Page 21

Installation

Screw

6AB

x1"

(2)

Drywall

Anchors (2)

Screw

6-32x1" (2)

HARDWARE

7/16" (11 mm)

Wall

1

2 3

DRYWALL

GANG BOX

6AB x 1"

6-32 x 1"

Drywall Anchor

4-5

6

6-32 x 1"

GANG BOX

8

DRYWALL

6AB x 1"

Drywall Anchor

7

STEP 10 Install the door control

To prevent possible SERIOUS IN JUR Y or D EATH fromelectrocution:

l Be sure power is NOT connected BEFORE installing door control.

l Connect door control ONLY to 12 VOLT l ow voltage wires.

To prevent possible SERIOUS IN JUR Y or D EATH froma closing garage door:

l Install door control wi thin sightof garage door, out of reach of small chil dren at a minimum height of 5feet

(1.5m) above floors, landings, steps or any other adjacent walking surface, and away from ALL moving parts

of door.

l NEVER permit children to operate or play with door control push buttons or remote control transmitters.

l Activate door ONLY when it can be seen cl early, is properly adjusted, and there are no obstructions to door

travel.

l ALWAYSkeep garage door in sight until completely closed. NEVER permit anyone to cr oss path of closing

garage door.

INTRODUCTION

Compatible with MyQ®enabled accessories, see page41. Your garage door opener is compatible with up to 2 MyQ

door controls. NOTE: Older Chamberlain door controls and third party products are not compatible.

Install the door control within sight of the door at a minimum height of 5 feet (1.5 m) above floors, landings, steps or

any other adjacent w alking surface, where small children cannot reach, and away from the moving parts of the door.

For gang box installations it is not necessary to drill holes or install the drywall anchors. Use the existing holes in the

gangbox.

NOTE: Your product may look different than the illustrations.

1. Strip 7/16 inch (11 mm) of insulation from one end of the wire and separate the wires.

2. Connect one w ire to each of the two scr ews on the back of the door control. The wires can be connected to

either screw. If your garage is pre-wired for the door control choose any two wir es to connect, note which

wir es are used so the correct w ires are connected to the garage door opener in a l ater step.

3. Mark the location of the bottom mounting hole and drill a 5/32 inch hole.

4. Install the bottomscrew, allowing 1/8 inch (3 mm) to protrude fr om the wall.

5. Position the bottomhole of the door control over the screw and sli de down into place.

6. Lift the push bar up and mark the top hole.

7. Remove the door control from the wall and drill a 5/32 inch hole for the top screw.

8. Position the bottomhole of the door control over the screw and sli de down into place. Attach the top screw.

®

21

Page 22

Installation

RED

WHITE

WHITE

GREY

7/16" (11 mm)

2

3

1

HARDWARE

Insulated Staple (Not Shown)

Staple

STEP 11 Wire the door control to the garage door opener

1. Run the white and red/white wire from the door control to the garage door opener. Attach the wire to the

wall and ceiling w ith the staple (not applicable for gang box or pre-wired installations). Do not pierce the

wir e with the staple as this may cause a short or an open circuit.

2. Strip 7/16 inch (11 mm) of insulation from the end of the w ire near the garage door opener.

3. Connect the w ire to the red and white terminals on the garage door opener. If your garage is pre-wir ed

make sure you use the same wires that are connectedto the door control. To insert or release wires from

the terminal, push i n the tab w ith screwdri ver tip.

STEP 12 Attach the warning labels

1. Attach the entrapment w arning label on the w all near the door control with tacks or staples.

2. Attach the manual release/safety reverse test label in a visible location on the inside of the garage door.

22

Page 23

Installation

Safety Reversing Sensor

6" (15 cm) max.

above floor

Invisible Light Beam

Protection Area

Facing the door from inside the garage

Carriage Bolt

1/4"-20 x 1/2"

Wing Nut

1/4"-20

HARDWARE

No more

than 6 inches

(15 cm)

Carriage Bolt

Wing Nut

1

2

3

STEP 13 Install the Protector System

®

Be sure power is NOT connected to the garage door opener BEFOR E installing the safety reversing sensor.

To prevent SERIOUS INJURY or D EATH from closing garage door:

l Corr ectly connect and align the safety reversing sensor. This required safety device MUST N OT be

disabled.

l Install the safety reversing sensor so beam is NO HIGHER than 6" (15 cm) above garage floor.

IMPORTAN T INFORMATION ABOUT TH E SA FETY REVERSING SENSORS

The safety reversing sensors must b e connected and aligned correctly befo re the garage doo r o pener will

move in the down direction.

The sending sensor (with an amber LED) transmits an invisi ble li ght beamto the receiving sensor (w ith a green

LED). If an obstruction breaks the light beamwhile the door is closing, the door w ill stop and reverse to the full open

position, and the garage door opener lights will flash 10 times.

NOTE: For energy efficiency the garage door opener w ill enter sleep mode whenthe door is fully closed. The sleep

modeshuts the garage door opener down until activated. The sleep mode is sequenced with the garage door opener

light bulb; as the light bulb turns off the sensor LEDs w ill turn off and w henever the garage door opener lights turn on

the sensor LEDs will light.The garage door opener will not go into the sleep mode until the garage door opener has

completed 5 cycles upon power up.

When installing th e safety reversing sensors check th e following:

l Sensors are installed inside the garage, one on either side of the door.

l Sensors are facing each other wi th the lenses aligned and the r eceiving sensor lens does not receive direct

sunlight.

l Sensors are no more than 6 inches (15 cm) above the floor and the light beam is unobstructed.

The safety reversi ng sensors can be attachedto the door tr ack, the w all, or the floor. The sensors should be no more

than6 inches (15 cm) above the floor. If the door track w ill not support the sensor bracket a w all installation is

recommended.Choose one of the following installations.

OPTION A - DOOR TRACKINSTALLATION

1. Slide the curved arms of the sensor bracket around the edge of the door track. Snap into place so that the

sensor bracket is flush against the track.

2. Slide the carr iage bolt into the slot on each sensor.

3. Insert the bolt through the hole in the sensor bracket and attach with the wing nut. The lenses on both

sensors should point toward each other. Make sure the lens is not obstructed by the sensor bracket.

23

Page 24

Installation

Lens

Carriage

Bolt

(Not provided)

No more than

6 inches (15 cm)

1 2

(Not provided)

Wing Nut

3 4

(Not provided)

I

e

l

l

1 2

Carriage Bolt

Wing Nut

3 4

STEP 13 Install the Protector System®(continued)

OPTION B - WALL INSTALLATION

If additional clearance is neededan extension bracket ( not provided) or wood blocks can be used. Make sure each

bracket has the same amountof clearance so they will align correctly.

1. Position the sensor bracket against the wall with the curved arms facing the door. Make sure there is

enough clearance for the beamto be unobstructed. Mark holes.

2. Dr ill 3/16 inch pilot holes for each sensor bracket and attach the sensor brackets to the wall using lag

screws ( not provided).

3. Slide the carr iage bolt into the slot on each sensor.

4. Insert the bolt through the hole in the sensor bracket and attach with the wing nut. The lenses on both

sensors should point toward each other. Make sure the lens is not obstructed by the sensor bracket.

OPTION C - FLOOR INSTALLATION

Use an extension bracket (not provided) or wood block to raise the sensor bracket if needed.

1. Carefully measure the position of bothsensor brackets so they will be the same distance from the wall and

unobstructed.

2. Attach the sensor brackets to the floor using concrete anchors (not provided).

3. Slide the carr iage bolt into the slot on each sensor.

4. Insert the bolt through the hole in the sensor bracket and attach with the wing nut. The lenses on both

sensors should point toward each other. Make sure the lens is not obstructed by the sensor bracket.

24

Page 25

Installation

Staple

7/16" (11 mm)

WHITE

WHITE

GREY

RED

1

2

3

HARDWARE

Insulated Staple (Not Shown)

STEP 14 Wire the Safety Reversing Sensors

If your garage already has w ires installed for the safety r eversing sensors, proceed to page 26.

OPTION A - INSTALLATION WITHOUT PRE-WIRING

1. Run the wire from both sensors to the garage door opener. Attach the wir e to the wall and ceiling with the

staples.

2. Strip 7/16 inch (11 mm) of insulation from each set of wires. Separatethe wir es. Twist the w hite wi res

together. Twist the w hite/black wires together.

3. Insert the white wires into the w hite terminal on the garage door opener. Insert the white/black wi res into

the grey terminal on the garage door opener. To insert or r emove the wires from the terminal, push in the

tab with a screwdriver tip.

25

Page 26

Installation

Safety reversing

sensor wires

Pre-installed

wires

White

White/Black

Yellow (for example)

Purple (for example)

Wire nuts (not provided)

Pre-installed wires

Safety reversing

sensor wires

1

3

4

7/16" (11 mm)

2

Purple

Yellow

5

7/16" (11 mm)

Yellow

Purple

To insert or remove the wires from the terminal,

push in the tab with a screwdriver tip.

STEP 14 Wire the Safety Reversing Sensors (continued)

OPTION B - PRE-WIRED INSTALLATION

1. Cut the end of the safety reversing sensor wi re, making sure there is enough wire to reach the pre-installed

wir es from the wall.

2. Separate the safety reversing sensor wi res and strip 7/16 inch (11 mm) of insulation from each end.

Choose two of the pre-installed wir es and strip 7/16 inch (11 mm) of insulation from each end. Make sure

that you choose the samecolor pre-installed wir es for each sensor.

3. Connect the pre-installed w ires to the sensor wires with wi re nuts making sure the colors correspond for

each sensor. For example, the white wire w ould connect to the yellow w ire and the w hite/black wire would

connect to the purple wire.

4. At the garage door opener, strip 7/16 inch (11 mm) of insulation fr om each end of the wir es previously

chosen for the safety r eversing sensors. Tw ist the li ke-colored wires together.

5. Insert the wires connected to the white safety sensor wires to the white terminal on the garage door opener.

Insert the w ires that are connectedto the white/black safety sensor wi res to the grey terminal on the garage

door opener.

26

Page 27

Installation

Ground Tab

Green Ground Screw

Ground Wire

White Wire

Black Wire

STEP 15 Connect power

To prevent possible SERIOUS IN JUR Y or D EATH fromelectrocution or fire:

l Be sure power is NOT connected to the opener, and disconnect power to cir cuit BEFORE removing cover to

establish permanentwiring connection.

l Garage door installation and wiring MUST be in compliance with ALL l ocal electrical and building codes.

l NEVER use an extension cord, 2-wire adapter, or change plug in ANY way to make it fit outlet. Be sure the

opener is grounded.

To avoid installation difficulties, do not run t he opener at this time.

To r educe the risk of electric shock, your garage door opener has a grounding type plug with a third grounding pin.

This plug w ill only fit into a grounding type outlet. If the plug doesn’t fit into the outlet you have, contact a qualified

electrician to install the proper outlet.

THER E A RE TWO OPTIONS FOR CON NECT ING POWER:

OPTION A - TYPICAL WIRING

1. Plug in the garage door opener into a grounded outlet.

2. DO N OT run garage door opener at this time.

OPTION B - PERMANENTWIRING

If permanent wiring is requ ired b y your local code, refer to the following procedure. To make a p ermanent

connection thro ugh t he 7/8 inch ho le in the top of the motor un it (according to local code):

1. Remove the motor unit cover screws and set the cover aside.

2. Remove the attached 3-prong cord.

3. Connect the black ( line) wire to the screw on the brass terminal; the white (neutral) wire to the screw on

the silver terminal; and the ground wire to the greengroundscrew. The opener must b e gro unded.

4. Reinstall the cover.

27

Page 28

Installation

Green LED

Amber LED

Wing Nut

SENDING SENSOR

RECEIVING SENSOR

(invisible light beam)

If the receiving sensor is in direct

sunlight, switch it with sending sensor so

it is on the opposite side of the door.

RED

WHITE

GREY

3

2

1

1

2

STEP 16 Aligning the safety reversing sensors

The door will no t close if t he sensors have n ot been installed and aligned correctly.

Whenthe light beam is obstructed or misaligned whil e the door is cl osing, the door will reverse and the garage door

opener lights will flash ten times. If the door is already open,it w ill not close.

1. Check to make sure the LEDs in both sensors are glowing steadily. T he LEDs in both sensors will glow

steadily i f they are alignedandwired correctly.

The sensors can be aligned by loosening the wing nuts, aligningthe sensors, and tightening the wing nuts.

IF THE AMBER LED ON THE SENDING SENSOR IS N OT GLOWING:

1. Make sure there is power to the garage door opener.

2. Make sure the sensor wire is not shorted/broken.

3. Make sure the sensor has beenwir ed correctly: w hite wires to w hite terminal and white/black wires to

grey terminal.

IF THE GREEN L ED ON THE RECEIVING SENSOR IS N OT GLOWING:

1. Make sure the sensor wire is not shorted/broken.

2. Make sure the sensors are aligned.

STEP 17 Ensure the door control is wired correctly

If the door control has been installed and wired corr ectly, the command LED on the Multi-Function Control Panel will

blink.

28

Page 29

Adjustments

UP (Open)

DOWN (Close)

Correct

Incorrect

UP Button

Adjustment Button

DOWN Button

PROGRAMMING BUTTONS

Introduction

Withouta properly installed safety reversal system, persons (particularly small children) could be SERIOUSLY

INJURED or KILLED by a closing garage door.

l Incorrect adjustment of garage door travel limits w ill interfere wi th proper operation of safety r eversal

system.

l After ANY adjustments are made, the safety reversal system MUST be tested. Door MUST reverse on

contact with 1-1/2" ( 3.8 cm) high object (or 2x4 laid flat) on floor.

To prevent damage to vehicles, be sure fully open door provides adequate clearance.

Your garage door opener is designed with electronic controls to make setup and adjustments easy. The adjustments

allow you to program w here the door wi ll stop in the open (U P) and close (D OWN) position. The electronic controls

sense the amountof force required to open and close the door. T he force is adjusted automatically w hen you program

the travel.

NOTE: If anything interferes with the door’s upward travel it will stop. If anything interferes with the door’s downward

travel, it will reverse.

One-Piece Doors Only

Whensetting the UP travel for a one-piece door ensure that the door does not slant backwards when fully open (UP).

If the door is sl anted backwards this w ill cause unnecessary bucking and/or jerking whenthe door is opening or

closing.

ProgrammingButtons

The programming buttons are located on the left side panel of the garage door opener and are used to program the

travel. While programming, the UP and D OWN buttons can be used to move the door as needed.

29

Page 30

Adjustments

UP Button

Adjustment Button

DOWN Button

PROGRAMMING BUTTONS

1 2

3

4 5

6 7

STEP 1 Program the Travel

Withouta properly installed safety reversal system, persons (particularly small children) could be SERIOUSLY

INJURED or KILLED by a closing garage door.

l Incorrect adjustment of garage door travel limits w ill interfere wi th proper operation of safety r eversal

system.

l After ANY adjustments are made, the safety reversal system MUST be tested. Door MUST reverse on

contact with 1-1/2" ( 3.8 cm) high object (or 2x4 laid flat) on floor.

While programming, the UP and DOWN buttons can be used to move the door as needed.

1. Press and hold the AdjustmentButton until the UP Button begins to flash and/or a beep is heard.

2. Press and hold the UP Button until the door i s in the desired U P position.

3. Once the door is in the desired U P position press and release the Adjustment Button. The garage door

opener lights will flash twice and the D OWN Button will begin to flash. IMPORTAN T NOTE: For one-

piece door installations refer to page 29.

4. Press and hold the DOWN button until the door is in the desir ed DOWN position.

5. Once the door is in the desired D OWN position press and release the AdjustmentButton. The garage door

opener lights will flash twice and the U P Button will begin to flash.

6. Press and r elease the UP Button. When the door travels to the programmed UP position, the D OWN Button

will begin to flash.

7. Press and r elease the DOWN Button. The door will travel to the programmedD OWN position.

Programmingis complete.

* If the garage door opener lights are flashing 5 times during the steps for Program the Travel, the programming has

timed out. If the garage door opener lights are flashing 10 times during the steps for Program the Travel, the safety

reversing sensors are misaligned or obstructed (refer to page 28). When the sensors are aligned and unobstructed,

cycle the door through a complete up and down cycle using the remote control or the UP and DOWN buttons.

Programmingis complete.If you are unable to operate the door up and down, repeat the steps for Programming the

Travel.

To w atch a video, go to tinyurl.com/lkwbnhj

30

Page 31

Adjustments

1 2

1

2

STEP 2 Test the Safety Reversal System

Withouta properly installed safety reversal system, persons (particularly small children) could be SERIOUSLY

INJURED or KILLED by a closing garage door.

l Safety reversal system MUST be tested every month.

l After ANY adjustments are made, the safety reversal system MUST be tested. Door MUST reverse on

contact with 1-1/2" ( 3.8 cm) high object (or 2x4 laid flat) on the floor.

The second paragraph contained instructions that are no longer correct and was replaced with the list of steps if the

test fails. Per regulatory and Lisa R. Change is being madeto the commonsnippet.It has not beenimplemented in any

documents yet. MDR

Addedl ast sentence to snippet per Lisa. MDR

1. With the door fully open, place a 1-1/2inch (3.8 cm) board (or a 2x4 l aid flat) on the floor, centered under

the garage door.

2. Press the r emote control push button to close the door. The door MUST reverse w hen it makes contact

with the board.

If the door stops but does not reverse:

1. Review the installation instructions provided to insure all steps were followed;

2. Repeat Program the Travel (see Adjustment Step 1);

3. Repeat the Safety R eversal test.

If the test continues to fail, call a trained door systems technician.

STEP 3 Test the Protector System

Withouta properly installed safety reversing sensor, persons (particularly small children) could be SERIOUSLY

INJURED or KILLED by a closing garage door.

1. Open the door. Place the garage door opener carton in the path of the door.

2. Press the r emote control push button to close the door. The door will not move more than an inch (2.5 cm),

and the garage door opener lights will flash 10 times.

The garage door opener wi ll not close from a remote control if the LED in either safety reversing sensor is off (alerting

you to the fact that the sensor is misaligned or obstructed). If the garage door opener closes the door when the safety

reversing sensor is obstructed (andthe sensors are no more than 6inches [15 cm] above the floor), call for a trained

door systems technician.

®

31

Page 32

Operation

Changed"Important Installation Instructions to "Important Safety Instructions". For 114a5010 MDR

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL WARNIN GS AND INSTR UCTIONS.

2. ALWAYS keep remote controls out of reach of children. NEVER permit children to operate or play with garage

door control push buttons or remote controls.

3. ONLY activate garage door when it can be seenclearly, it is properly adjusted, and there are no obstructions

to door travel.

4. ALWAYS keep garage door in sight and away from people and objects until completely closed. NO ONE

SHOULD C ROSS THE PATH OF THE MOVING DOOR.

5. NO ON E SH OULD GO UNDER A STOPPED, PARTIALLY OPENED D OOR.

6. If possible, use emergency r elease handle to disengage trolley ONLY when garage door is C LOSED. U se

caution when using this release with the door open.Weak or broken springs or unbalanced door could result in

an open door falling rapidly and/or unexpectedly and incr easing the ri sk of SEVERE INJURY or D EATH.

7. NEVER use emergency release handle unless garage doorway is clear of persons and obstructions.

8. NEVER use handle to pull garage door open or closed. If rope knot becomes untied, you could fall.

9. After ANY adjustments are made, the safety reversal system MUST be tested.

10. Safety reversal system MUST be tested every month. Garage door MUST reverse on contact with 1-1/2"

(3.8 cm) high object (or a 2x4 laid flat) on the floor. Failure to adjust the garage door opener properly

increases the risk of SEVERE INJURY or D EATH.

11. ALWAYS KEEP GARAGE DOOR PROPERLY BALANCED (see page 2). An improperly balanced door

may NOT reverse whenrequired and could result in SEVERE INJU RY or DEATH.

12. ALL repairs to cables, spring assemblies and other hardware, ALL of which are under EXTREME tension,

MUST be made by a traineddoor systems technician.

13. ALWAYS disconnect electric power to garage door opener BEFORE making ANY repairs or r emoving

covers.

14. This operator system is equippedwith an unattended operation feature. The door could move

unexpectedly. N O ON E SH OULD C ROSS THE PATH OF THE MOVING DOOR.

15. DO NOT install on a one-piece door if using devices or features providing unattendedclose. U nattended

devices and features are to be used ONLY with sectional doors.

16. SAVE THESE INSTRUCTIONS.

32

Page 33

Operation

Features

Your garage door opener is equipped with features to provide you with greater control over your garage door

operation.

®

MyQ

MyQ®technology uses a 900MHz signal to provide two-w ay communication between the garage door opener and

MyQ®enabled accessories. Your garage door opener is compatible with up to 8 MyQ®accessories. For Smartphone

App control of your garage door opener and other MyQ®accessories, Chamberlain's MyQ®InternetGateway (model

CIGBU) is required.

TIMER-TO-CLOSE (DO NOT enable on one-piece doors)

The Timer-to-Cl ose feature is not available on all door controls. Below is a list of door controls w ith the Timer-toClose feature:

041A7305-1 Smart Control Panel and 041A7327-1 Motion Detecting Control Panel

The Timer-to-Cl ose feature automatically closes the garage door after a specified time period. D O NOT enable TTC

if operating a one-piece do or. TTC is to be used ONLY with sectional doors. F actory default is set to off. The

garage door opener will beep and the li ghts will flash before closing the door. The TTC feature will deactivate if the

garage door encounters an obstruction twice; or the safety reversi ng sensors are incorrectly installed. The garage

door will reverse open and WILL NOT close until the obstructions are clear or the safety reversing sensors are

correctly installed. When the obstruction has beencleared or the safety reversing sensors have been aligned, the door

will close when the garage door opener is activated. TTC WILL NOT work i f the garage door opener is operating by

battery power or if the safety reversi ng sensors are misaligned. This feature is N OT intendedto be the primary

method of closing the door. A keylessentry should be installed in the event of an accidental lock out when

using this feature.

REMOTE CONTROLS ANDDOOR CONTROLS (MyQ®)

Your garage door opener has already been programmed at the factory to operate with your remote control, which

changes with each use, randomly accessing over 100 billi on new codes. Compatible with MyQ®enabled accessories,

see page 41.

NOTE: Older Chamberlain r emote controls, door controls, and third party products are not compatible.

MyQ®Accessories

Remote Controls Up to 8

Door Controls

Keyless Entries Up to 1

MEMORY CA PACITY

Up to 2 MyQ®door controls

THE PROTECTOR SYSTEM®(SAFETY REVERSING SENSORS)

Whenproperly connected and aligned, the safety reversi ng sensors wi ll detect an obstruction in the path of the

infrared beam. If an obstruction breaks the infrared beamwhile the door is closing, the door will stop and reverse to

full open position, and the opener lights will flash 10 times. If the door is fully open, and the safety reversi ng sensors

are not installed, or are misaligned, the door will not close from a remote control. However, you can close the door if

you hold the button on the door control or keyless entry until the door is fully closed. The safety reversi ng sensors do

not effect the opening cycle.

ENERGY CONSERVATION

For energy efficiency the garage door opener will enter sleep mode when the door is fully closed. The sleep mode

shuts the garage door opener down until activated. The sleep mode is sequenced with the garage door opener light

bulb; as the light bulb turns off the sensor LEDs w ill turn off and w henever the garage door opener lights turn on the

sensor LEDs w ill l ight. The garage door opener will not go into the sleep modeuntil the garage door opener has

completed 5 cycles upon power up.

LIGHTS

The garage door opener light bulbs will turn on whenthe opener is initially plugged in; power is r estored after

interruption, or whenthe garage door opener is activated. The lights will turn off automatically after 4-1/2 minutes. An

incandescent A19 light bulb (100 w att maximum) or for maximum energy efficiency a 26W (100W equivalent) compact

fluorescent light (CF L) bulb may be used. NOT E: Do not use halogen, short neck, or specialty light bulbs as these

may overheat the end panel or light socket. Do not use LED bulbs as they may reduce the r angeor performance of

your remote controls.

Light Feature

The garage door opener is equipped with an added feature; the lights will turn on whensomeone enters through the

opengaragedoor and the safety reversi ng sensor infrared beamis broken. For added control over the light bulbs on

your garage door opener, see page 34.

33

Page 34

Operation

Push Bar

LIGHT Button

LOCK Button

Command LED

LEARN Button

Using your Garage Door Opener

The garage door opener can be activated through a w all-mounteddoor control, remote control, wireless keyless entry

or MyQ®accessory.

Whenthe door is closed and the garage door opener is activatedthedoor will open. If the door senses an obstruction

or is interrupted while opening the door will stop. When the door is in any position other than closed and the garage

door opener is activatedthe door will close. If the garage door opener senses an obstruction while closing, the door

will reverse. If the obstruction interr upts the sensor beam the garage door opener lights will blink 10 times. However,

you can close the door if you hold the button on the door control or keyless entry until the door is fully closed.

The safety reversi ng sensors do not affect the openingcycle. The safety reversing sensor must be connected and

aligned correctly before the garage door opener w ill move in the down dir ection.

Multi-Function Control Panel

SYNCHRONIZE THE DOOR CONTROL

To synchronize the door control to the garage door opener, press the push bar until the garage door opener activates

(it may take up to 3 presses). T est the door control by pressing the push bar, each press of the push bar will activate

the garage door opener.

MULTI-FUNCTION CONTROL PANEL FEATURES

PUSH BAR

Press the push bar to openor close the door.

LIGHTS

Light Button

Press the LIGHT button to turn the garage door opener lights on or off. When the l ights are turned on they will stay on

until the LIGHT button is pressed again, or until the garage door opener is activated. Once the garage door opener is

activated the lights wil l turn off after the specified period of time (the factory settingis 4-1/2 minutes). The LIGHT

button will not control the lights whenthe door is in motion.

To change th e amount of time the garage door o pener lights will stay on:

Press and hold the LOCK button ( approximately 10 seconds) until the garage door opener lights flash. T he time

interval is indicated by the number times the garage door opener flashes:

l 1 flash is 1-1/2minutes

l 2 flashes is 2-1/2 minutes

l 3 flashes is 3-1/2 minutes

l 4 flashes is 4-1/2 minutes

To cycle through the time intervals repeat the step above.

Light Feature

The lights wi ll turn on whensomeone enters through the open garage door and the safety r eversing sensor i nfrared

beami s broken.

l Deactivate: Press and hold the LIGHT button (approximately 10 seconds) until the garage door opener

lights turn on, then off again.

l Activate: Start wi th the garage door opener lights on. Press and hold the LIGHT button (approximately 10

seconds) until the garage door opener lights turn off, then on again.

If the commandLED is continuously blinking, the LOCK feature needs to be deactivated.

34

Page 35

Operation

Push Bar

LIGHT Button

LOCK Button

Command LED

LEARN Button

The command LED

will flash once.

The command LED will

flash once again.

1

2

OR

PIN

? ? ? ?

3

Multi-Function Control Panel (continued)

LOCK

The LOCK feature is designed to prevent activation of the garage door opener from r emote controls w hile still allowing

activation from the door control and keyless entry. This feature is useful for added peace of mind when the home is

empty (i.e. vacation).

l Activate: Press and hold the LOCK button for 2 seconds. The command LED wi ll flash as long as the lock

feature is activated and your handheld remote control w ill not operateyour door at this time.

l Deactivate: Press and hold the LOCK buttonagain for 2 seconds. The command LED will stop flashing

and normal operation wi ll resume.

PROGRAM

Any compatible remote controls, wireless keyless entry, or MyQ®accessories can be programmedto the garage door

opener by pressing the Learn button.

Remote Control and Keyless Entry*

Pre-prog rammed remote cont rol included, no n eed to program t he remote.

To add or reprogram a remote control, follow the instructions below. Older Chamberlain remote controls are N OT

compatible, see page41 for compatible accessories.

PROGRAM USING THE DOOR CONTROL

1. Press the LEARN buttonon the door control to enter Programming Mode.

2. Press the LEARN buttonagain, the LED will flash once.

3. Remote C ont rol: Press the button on the r emote control that you wish to operate your garage door.

KeylessEntry: Enter a 4-digit personal identification number (PIN) of your choice on the keyless entry

keypad. Then press the EN TER button.

The garage door opener lights will flash ( or two clicks will be heard) whenthe code has been programmed.

* N ot included w ith all models.

35

Page 36

Operation

LEARN LED

LEARN

Button

“click”

“click”

1-2 3

PIN

Remote Control (continued)

PROGRAM USING THE LEARN BUTTON

1. Locate the Learn Button.

2. Press and immediately release the Learn button.The Learn LED w ill glow steady for 30 seconds. Within 30

seconds...

3. Remote C ont rol: Press and hold the buttonon the remote control that you w ish to use.

KeylessEntry: Enter a 4-digit personal identification number (PIN) of your choice on the keyless entry

keypad. Then press and hold the ENTER button.

Release the button when the garage door opener li ghts blink or two clicks are heard. When replacing the light lens

cover, ensure the antennawires are hanging straight down.

To w atch a video, go to tinyurl.com/lcsf6xt

HomeLink

If your vehicle is equipped with HomeLink, a Compatibility BridgeTM(not included) may be necessary for certain

vehicles. Visit bridge.chamberlain.com to find out i f a Bridgeis needed.

®

To Erase the Memory

ERASE ALL REMOTE CONTROLS AND KEYLESS ENTRIES

1. Press and hold the LEARN button on garage door opener until the learn LED goes out (approximately 6

seconds). All remote control and keyless entry codes are now erased. Reprogram any accessory you wish

to use.

ERASE ALL DEVICES (IncludingMyQ®enabledaccessories)

1. Press and hold the LEARN button on garage door opener until the learn LED goes out (approximately 6

seconds).

2. Immediately press and hold the LEARN buttonagain until the learn LED goes out. All codes are now

erased. Reprogram any accessory you wish to use.

36

Page 37

Operation

To Open the Door Manually

To prevent possible SERIOUS IN JUR Y or D EATH froma falling garage door:

l If possible, use emergency r elease handle to disengage trolley ONLY when garage door is C LOSED. Weak

or broken springs or unbalanceddoor could result in an open door falling rapidly and/or unexpectedly.

l NEVER use emergency release handle unless garage doorway is clear of persons and obstructions.

l NEVER use handle to pull door open or closed. If rope knot becomes untied, you could fall.

DISCONNECTTHE TROLLEY

1. The door should be fully closed if possible.

2. Pull down on the emergency release handle so the trolley release arm snaps to the vertical position. The

door can now be raised and lowered as oftenas necessary.

TO RE-CONNECT THE TROLLEY

1. Pull the emergency release handle toward the garage door opener so the trolley release arm snaps to the

horizontal position. The trolley w ill reconnect on the next UP or DOWN operation, either manually or by

using the door control or remote control.

37

Page 38

Maintenance

1

2

3

Maintenance Schedule

EVERY MONTH

l Manually operate door. If it is unbalanced or binding, call a trained door systems technician.

l Check to be sure door opens and closes fully. Adjust if necessary, see page 29.

l Test the safety reversal system. Adjust if necessary, see page 31.

EVERY YEA R

l Oil door rollers, bearings and hinges. The garage door opener does not r equire additional lubrication. Do not

grease the door tracks.

NOTIC E: This device complies with Part 15 of the FCC rules and Industry Canada’s license-exemptRSSs.

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

This device must be installed to ensure a minimum 20 cm (8 in.) distance is maintainedbetween users/bystanders

and device.

This device has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of

the FCC rules and Industry Canada ICES standard. These limits are designed to provide r easonable protection

against harmful interference i n a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance w ith the i nstructions, may cause harmful interference

to radio communications. H owever, there is no guarantee that interferencewill not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determinedby

turning the equipment off and on, the user is encouraged to try to corr ect the interference by one or more of the

following measures:

l Reorient or relocate the r eceiving antenna.

l Increase the separation between the equipmentandreceiver.

l Connect the equipment intoan outlet on a cir cuit differentfrom that to w hich the receiver i s connected.

l Consult the dealer or an experienced radio/TV technician for help.

The Remote Control Battery

To prevent possible SERIOUS IN JUR Y or D EATH:

l NEVER allow small chil dren near batteries.

l If battery is swallowed, immediately notify doctor.

To r educe risk of fire, explosion or chemical burn:

l Replace ON LY with 3V CR2032 coin batteries.

l DO NOT recharge, disassemble, heat above 212°F ( 100°C) or incinerate.

The 3V CR 2032Lithiumbattery should produce power for up to 3

years. If the battery is low, the r emotecontrol’s LED will not flash

when the button is pressed.

To r eplace battery, pry openthecase fir st in the middle (1), then at

each side (2 and 3) wi th the visor clip. Replace the batteries with only

3V CR2032 coin cell batteries. Insert battery positive side up. Dispose

of old batteries properly.

38

Page 39

Troubleshooting

Diagnostic Chart

Your garage door opener is programmed with self-diagnostic capabilities. The U P and D OWN arrows on the garage door opener flash the diagnostic codes.

DIAGNOSTICCODE SYMPTOM SOLUTION

Up Arrow

Flash(es)

1 1

1 2

1 3

1 4

1 5

1 6

2 1-5

3 2

Down Arrow

Flash(es)

The garage door opener wi ll not close and the light bulbs flash. Safety reversi ng sensors are not installed, connected, or w ires may be cut. Inspect sensor w ires for a disconnected

or cut w ire.

The garage door opener wi ll not close and the light bulbs flash. There i s a short or reversed wire for the safety r eversing sensors. Inspect safety sensor wir e at all staple and

connectionpoints, replace w ire or correct as needed.

The door control will not function. The wires for the door control are shorted or the door control is faulty. Inspect door control w ires at all staple and

connectionpoints, replace w ire or correct as needed.

The garage door opener wi ll not close and the light bulbs flash. Safety reversi ng sensors are misaligned or were momentarily obstructed.Realign both sensors to ensure both LEDs

are steady and not flickering. Make sure nothing is hanging or mounted on the door that would interrupt the sensor’s

pathwhile closing.

Door moves 6-8" ( 15-20 cm) stops or reverses. Manually open and close the door. C heck for binding or obstructions, such as a broken spring or door lock, correct as

needed. Check wiring connections at travel module and at the l ogic board. R eplace travel module if necessary.

No movement, only a single click. Manually open and close the door. C heck for binding or obstructions, such as a broken spring or door lock, correct as

needed. Replace logic board if necessary.

Opener hums for 1-2 seconds no movement. Manually open and close the door. C heck for binding or obstructions, such as a broken spring or door lock, correct as