Page 1

150-255 hp

MT500D

Smart Machines. Serious Results.

Page 2

YOUR VERSATILE

SKILLED WORKHORSE

Five new models in the Challenger MT500D Series with power

ranging from 150-255hp deliver users optimum performance

and efficiency with straight-forward automation.

Combined with their light, but immensely strong

design, the MT500D Series tractors are built to provide

exceptional productivity and economy in a wide range

of tasks from heavy draft applications through to delicate

top work.

All are powered by the very latest, most advanced six

cylinder AGCO POWER™ engines. Developed specifically

for agriculture and to run on high sulphur diesel, they

are proven to deliver outstanding power and torque at

low engine speeds for industry-leading fuel efficiency.

The engines also generate up to 25hp extra power with

Engine Power Management (EPM).

The robust AutoPower VI™ transmission provides

superior, clutch-free changing of 24 speeds in both

directions. A wide range of automatic modes, with lever

and pedal operation, enhance efficiency and the driving

experience. For specialist work there are creep and

super-creep options providing speeds down to 1km/hr.

A completely new cab structure offers high levels

of space, comfort and visibility. Inside operators will find

the new Tractor Management Center™ offers superb,

straight-forward and easy to use controls.

Two levels of specifications allow customers to tailor

their MT500D tractor to match their budget and

requirements. For those looking for cost effective power

and performance there are the Essential models,

while Efficient versions provide higher levels of comfort,

control and extra features.

2 2

Page 3

Models MT525D MT545D MT565D MT585D MT595D

Engine Performance

Rated ISO engine Hp @ 2 100rpm (kW) 140 (103) 165 (121) 185 (136) 220 (162) 240 (177)

Maximum ISO engine Hp @ 1 950rpm (kW) 150 (110) 175 (129) 200 (147) 235 (173) 255 (187)

Maximum engine Hp with EPM Boost (kW) 175 (129) 200 (147) 220 (162) 260 (191) 280 (206)

Maximum ISO engine torque (Nm) @1 500 engine rpm 660 740 880 1,030 1,049

Maximum engine torque with EPM Boost (Nm) 745 840 980 1,120 1,145

3

Page 4

4

Page 5

The MT500D Series are equipped with high displacement, 6.6 litre

and 7.4 litre capacity engines that develop exceptional levels of power

and torque across a wide speed range for optimum economy.

AGCO POWER™ is one of Europe’s leading manufacturers

that is respected throughout the world, building an

enviable reputation for its robust construction, durable,

reliable engines.

The engines are designed and built exclusively to

provide the uncompromising performance that precisely

matches the fluctuating loads and exacting demands in

agricultural work. They deliver superb power, strong torque

and exceptional economy – in tests producing a specific

fuel consumption figure as low as 192g/kWh.

Maximum power (ISO) is delivered at a low 1,950rpm,

while the maximum torque is generated at an economical

1,500rpm. Low operating speeds reduce fuel consumption,

cut wear levels, reduce noise and extend working time

between services.

Durability is built in. Thick engine block side walls along

with cylinder mid-supports significantly reduce vibration,

wear and noise. Wet cylinder liners improve cooling and

extend engine service life.

Superb access for maintenance is provided by the onepiece lifting bonnet. The air filter is easily reached from

the ground, with auto air cleaning provided by a vortex

system, with a wide 150mm gap between radiators for

great access for cleaning.

Outstanding fuel economy, torque and power

1200

1100

1000

900

Torque (Nm)

800

700

600

500

1000 1200

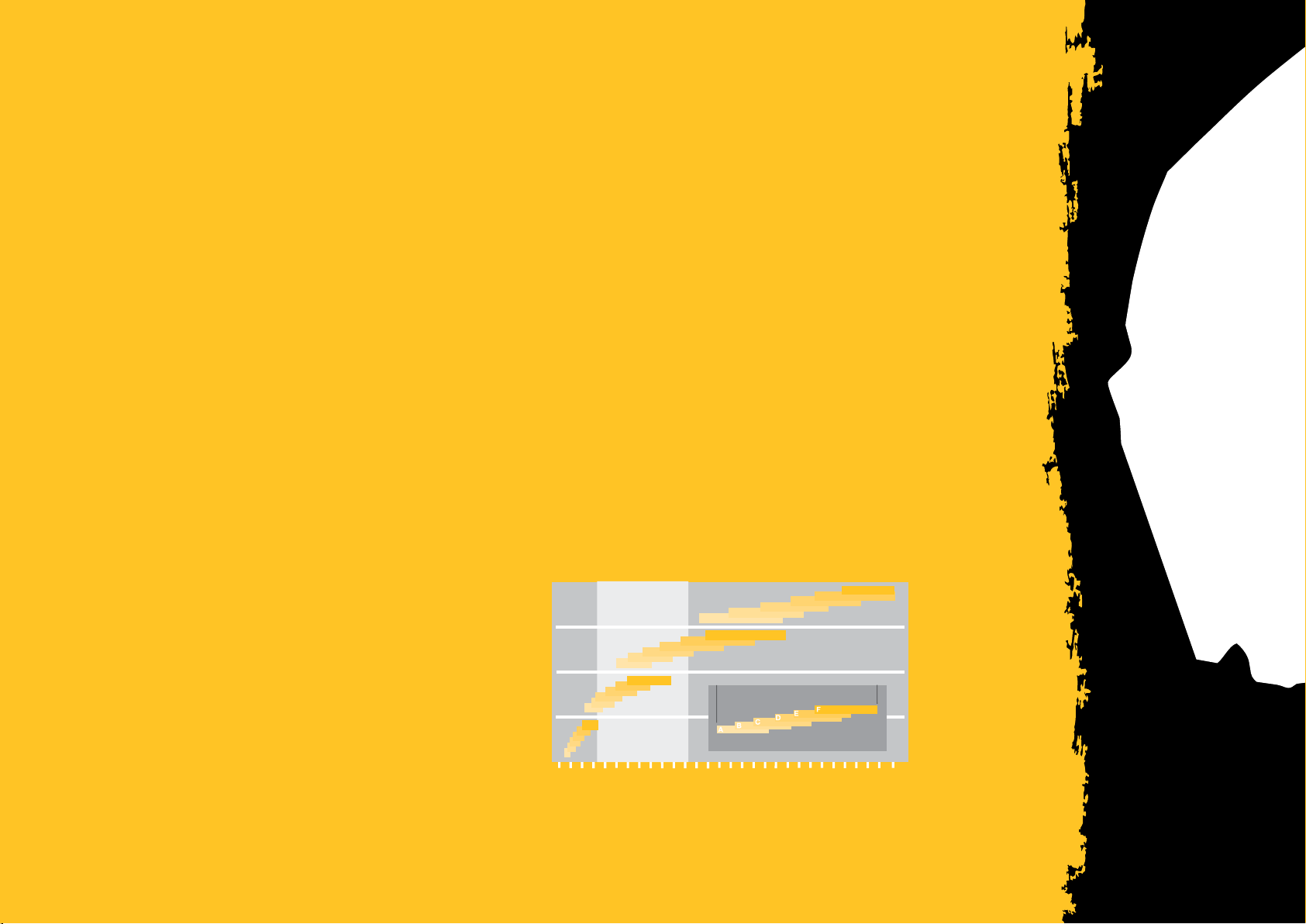

This curve clearly shows how maximum torque

is maintained between 1200 and 1500 rpm,

with steep torque rise as engine rpm falls between

2100 and 1500 rpm for greater torque ability

and constant PTO speed.

1600

1300 1500

1400

1100

18001700 1900

2100

2000

230

Optimum fuel economyTorque reserve

220

210

Specific fuel consumption (sfc)

200

190

180

1000 1200 1400 1600 1800 2000 2200

Engine rpm Engine rpmEngine rpm

Challenger’s electronic engine management system

broadens the operating range within which the

tractor is operating at optimum fuel efficiency.

Power (PS)

1000 1200 1400 1600 1800 2000 2200

This curve clearly shows high power, with

‘constant power’ maintained down to 1570 rpm.

Constant Power

55

Page 6

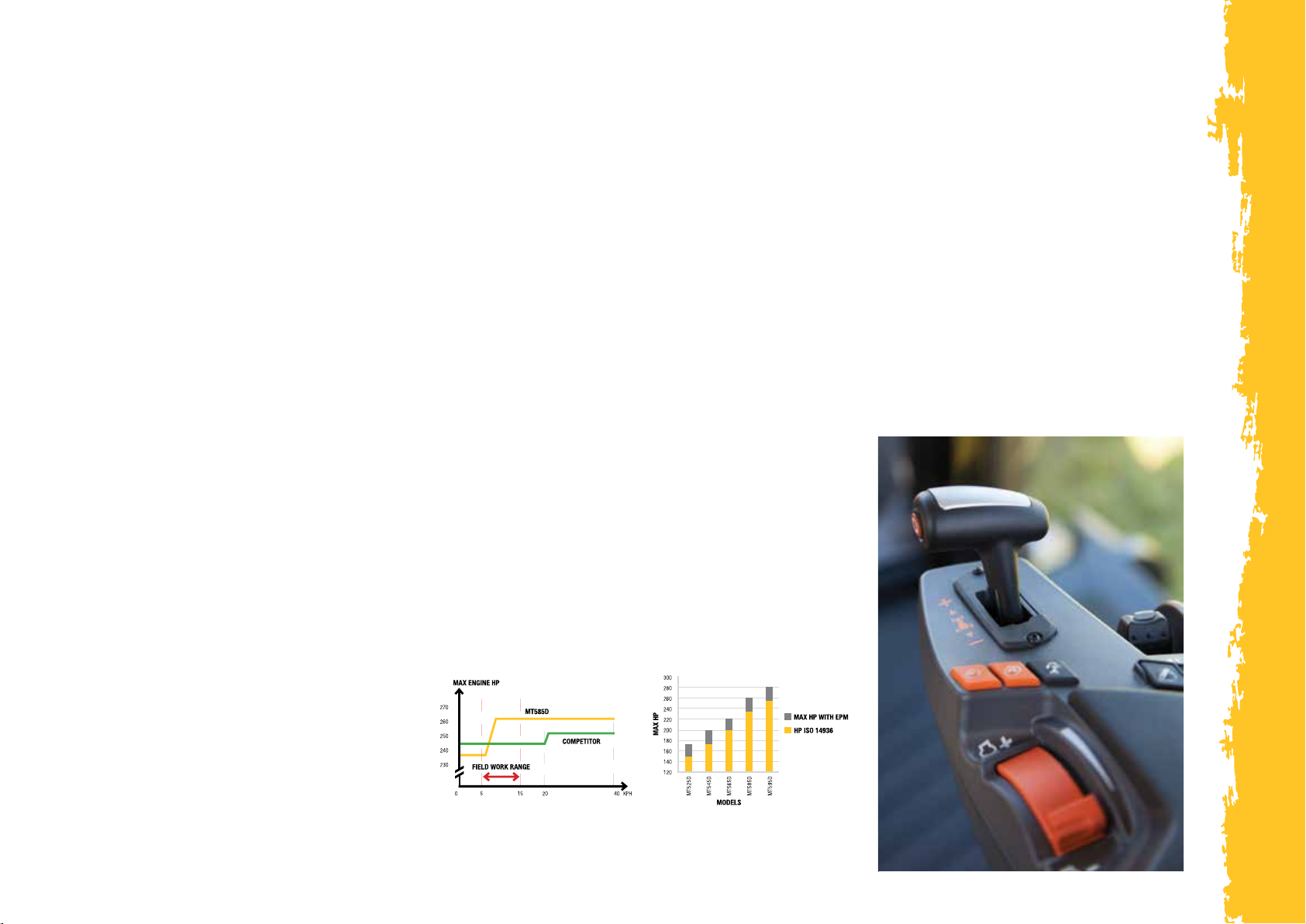

Models MT525D MT545D MT565D MT585D MT595D

Max HP 150 175 200 235 255

Max HP with EPM 175 200 220 260 280

6

Page 7

ECONOMY

AND CONTROL

Developed specially for operation with high sulphur diesel,

the AGCO POWER™ engine’s superior design makes the

best use of every drop of fuel.

Ultimate efficiency starts with Challenger’s Electronic

Engine Management (EEM) system, which controls the

high pressure, common rail fuel injection system and

delivers a precise and immediate response to match

varying load demands.

Four valves/cylinder improve gas exchange with the

crossflow cylinder head ensuring optimum combustion.

A viscous fan drive responds quickly to changing engine

temperatures, providing effective cooling with minimum

power loss.

As well as outstanding control and economy,

the Engine Power Management (EPM) provides

an automatic power boost of up to 25hp (depending

on model). Available at working speeds above 6km/hr

this delivers the extra power and torque you need

to keep going in the field and on the road.

Power boost is also available automatically

whenever the PTO is engaged, providing the power

when it’s needed most to further boost efficiency.

Operators can pre-set, store and activate two

different engine speeds at the touch of a button.

These can also be set and operated manually

or stored and replayed automatically by the

One-Touch™ headland management system.

Engine power boost comparison MT500D engine power

7

Page 8

EFFORTLESS

TRANSMISSION CONTROL

The Challenger AutoPower VI™ robotised, semi-powershift transmission provides

industry-leading, clutchless operation and control for all MT500D Series tractors.

With AutoPower VI™ there’s no need to use the clutch

to change speeds or direction. Six speeds in four gears

can be changed, under load, at the flick of a lever.

There are ten speeds in the main working range, and top

speeds* of 40km/hr and 40km/hr ECO and 50km/hr (option)

are achieved at low engine speeds (1,600rpm), for optimum

economy for haulage duties and transport. (*Top speed

depends on markets and legislation).

Renowned for its superb reliability, the AGCO-built transmission

employs a straight-forward design for ease of operation with

top economy. It uses just three clutch packs to change all the

speeds and ranges, which significantly reduces power losses

compared with other, more complex, transmissions.

AutoPower VI™ blends sophisticated features with

simple and straight-forward control. The power direction

lever, mounted conveniently to the left of the steering wheel,

combines three functions allowing operators to use it to

declutch, switch direction and change speeds.

It’s even possible to set how the shuttle responds via the

TMC dash display, with separate settings for how smoothly

the tractor pulls away in both forwards and reverse.

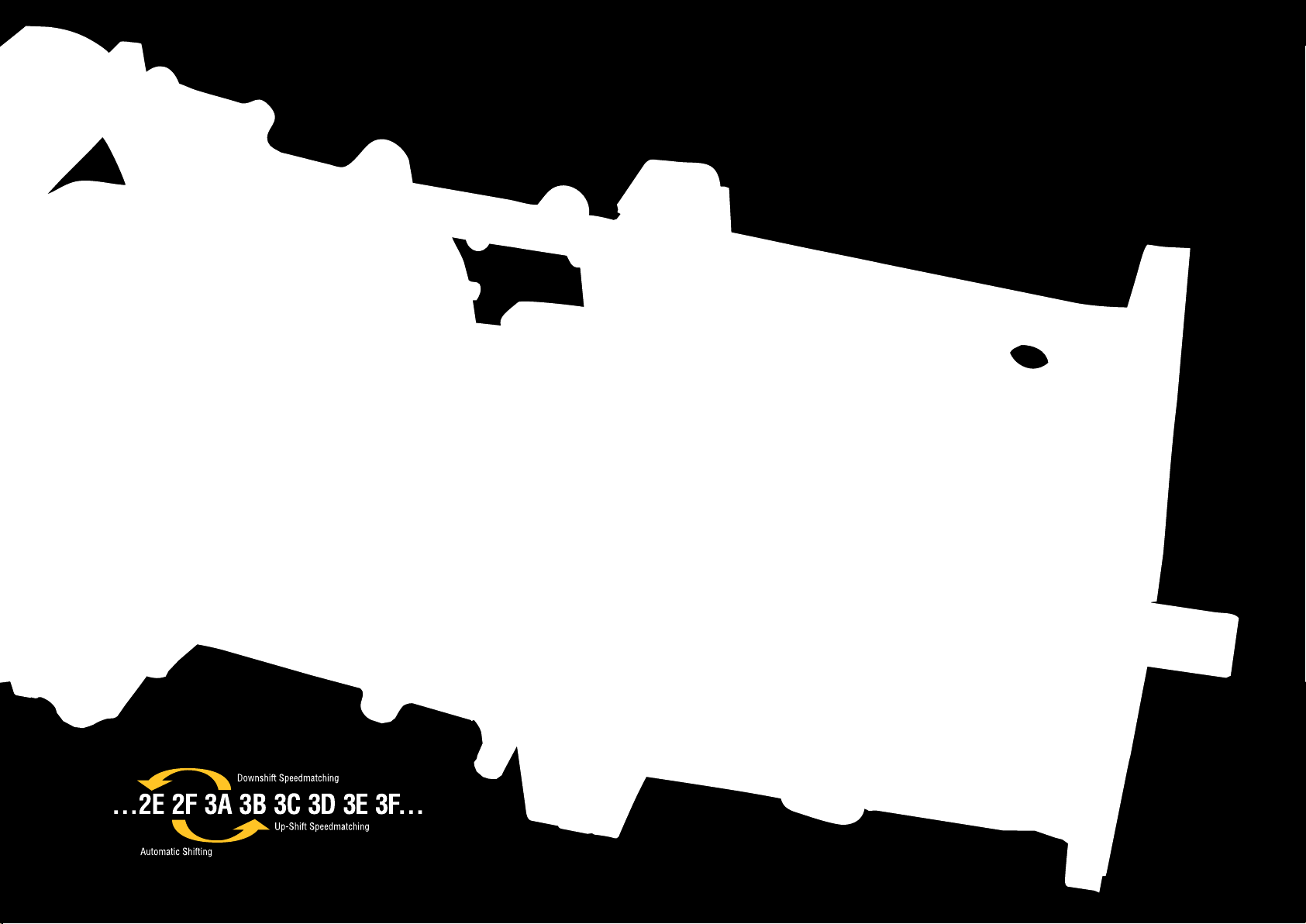

Speed matching automatically selects the best powershift

speed when changing ranges to suit the actual speed

and load.

4Field work range

3

Range

2

1

05 15 40

AutoPower VI speed chart.

1400 2100

Speed in Km/h

8

Page 9

Speedmatching

9

Page 10

10

Page 11

EASY AND

EFFECTIvE AuTOMATION

With AutoPower VI™ operators can choose to control the transmission using

the best method to suit their needs or the operation. Completely clutchless changes

SIMPLE, MULTI FUNCTION,

LEFT-HAND POWER DIRECTION LEVER

1. NEUTRAL

2. DE-CLUTCH

3. FORWARD DRIVE

4. REVERSE DRIVE

5. CHANGE UP RATIO

6. CHANGE DOWN RATIO

2

6

6

4

2

5

3

are made under load resulting in smooth, effortless operation and high efficiency.

In road mode all the ranges and powershift speeds are changed seamlessly.

This ensures the tractors always operate at optimum efficiency in the maximum

torque band and is perfect high efficiency transport operations.

FIELD MODE

The six powershift speeds change seamlessly, while ranges

can be changed, under load and without the clutch, by simply

pressing a button on the T-handle or multi-function joystick

levers to maintain high performance in heavy draft work.

CRuISE CONTROL

Two pre-set gears – SV1 and SV2 – can be saved and

automatically selected at the touch of a button. Powershift steps

are changed in field mode, while range changes are also made

automatically in road mode.

DRIvINg MODES FuRThER ENhANCE CONTROL

With AutoPower VI™ operators can also choose to use either

hand levers or the foot pedal to control the transmission.

In lever mode moving the power direction lever, T-handle

or multi function joystick forwards or back will increase or

decrease the speed, also changing the powershift speeds

and ranges, depending on whether it in field or road mode.

In pedal mode all the operator needs to do is simply adjust

the foot or hand throttle and the system responds accordingly.

It increases or decreases the speed, while also changing the

powershift speeds and, in road mode, also the ranges.

5

1

11

Page 12

BuILT ON

STRONg FOuNDATIONS

An exceptionally strong, but lightweight, chassis plays

a key role in creating the Challenger MT500D Series’

exceptional power to weight ratio, which increases

output while saving fuel.

A pair of robust chassis rails, specially contoured for tight turning, extend from

the front axle mount right back to the mounting plate behind the engine, with a long

wheelbase that increases traction and further improves efficiency.

The rails provide a strong and rigid support for mounting a front-end loader, front

linkage and other attachments.

The clever front linkage design allows equipment to be closely coupled to the tractor

and offers lift capacities up to 4t. As well as increasing stability it also permits both

a front linkage and loader to be fitted at the same time.

12

Page 13

Offering +/- 11° of oscillation and

a 55° steering angle, the standard,

mechanically driven front axle combines

superb manoeuvrability with high traction.

It can be engaged manually, under load,

at the touch of a button or set to engage

and disengage automatically, according

to speed and steering angle.

The OptiRide front axle suspension

option permits higher road speeds and,

by keeping the tyres in better contact with

the soil, can increase traction by up to

20%. It also enhances operator comfort

and, coupled with the OptiRide cab

suspension, can cut vibration by 50%.

The Challenger MT500D’s sturdy rear axles are built to

handle the heaviest loads and strongest torque. A robust

and reliable flanged axle is fitted to the three models up

to 200hp. There is also option to mount a bar axle,

which is standard on the two most powerful tractors.

All models have true four-wheel differential locking with

manual push-button or automatic control that disengages

at steering angles above 7° and reactivates below 5°.

13

Page 14

An exceptionally strong three-point linkage coupled with a powerful hydraulic system

and versatile PTO make the most of the MT500D Series tractors’ pulling power.

An advanced closed-centre load sensing (CCLS) system delivers 110 litres/min (150 litres/

min option) at 200 bar for an almost instant response to handle the demands of the most

sophisticated implements. Providing flow on demand saves fuel and power.

Standard on the three tractors above 200hp, CCLS can also

be specified for the MT525D and MT545D models. For these

tractors, less than 200hp, there is also an Open Centre system

providing a choice of 100 litres/min or 57 litres/min option,

both generating a pressure of 200 bar.

With up to four rear spool valves and two on the front,

the MT500D Series is equipped to easily operate the widest

range of implements with high hydraulic demands.

Front- and rear-mounted combinations are handled simply

and easily by AGCO’s exclusive Dual Control system - an option

on the Efficient models. This automatically raises and lowers

the implements at pre-set distances. This eases the load on

the operator and increases output.

Another unique feature, Trailed Implement Control (TIC),

monitors wheelslip to provide draft control for trailed and semimounted machines. Both systems can be incorporated into the

One-Touch™ sequence for completely automated operation.

14

Heavy loads are handled with ease by the robust linkage,

providing lift capacities up to 8,100kg on the MT525D and

MT545D models and 9,300kg on the tractors above 200hp.

The TMC terminal, which is an option on Efficient models,

offers simple finger-tip operation and control for the Electronic

Linkage Control (ELC). This provides a comprehensive range

of settings, which can all be included into the One-Touch™

headland management system, which relieves the operator

of many repetitive tasks on the turn.

A wide range of PTO speeds are available to suit all machines

and applications with an Economy option allowing engine

speeds to be cut by 18%. The optional front PTO further

increases versatility.

Page 15

15

Page 16

hIghEST quALITY

COMFORTABLE wORkpLACE

The quiet, cool and comfortable MT500D panoramic cab is equipped to the highest

specification with easy to use controls allowing operators to make the most of the

tractors’ performance potential.

A new cab structure, with optional OptiRide mechanical

suspension, offers great visibility through its curved front

windscreen and is equipped with a new slim, Instrument

Panel and adjustable steering column.

The standard Air-Ride, suspended seat swivels 10°

to the left and 20° to the right, while the optional SemiActive seat offers even greater comfort. Air conditioning

is standard.

The new Tractor Management Center™ (TMC) and Right

Hand Pillar give operators complete control with all levers

and switches falling to hand easily.

Efficient specification tractors come equipped with the

TMC Armrest, which includes a T handle transmission

control lever at the front, fingertip spool valve buttons to

the side along with the linkage controls. Further buttons

operate the transmission, engine and One-Touch™

headland management system.

A new Multi Function Lever option sits next to the

transmission lever on the TMC Armrest. The obvious

choice for loader work, it not only operates the spool

valves or the loader, but also has buttons to change

direction and gears.

The colour touch-screen TMC display option for Efficient

models, allows operators to monitor and control a vast

range of functions. These include engine performance,

hydraulics, transmission settings, linkage controls,

efficiency and cost monitoring as well operating the

One-Touch™ system and Dual Control and TIC options.

On Essential specification tractors the transmission’s

T-handle is mounted to the side console, along with the

spool valve levers and other controls.

Essential Cab

Efficient Cab

16

Page 17

17

Page 18

1818

Page 19

™

AuTOguIDE

BOOSTS EFFICIENCY

Challenger’s AutoGuide™ automatic steering is a genuine output enhancing option

that increases productivity while saving fuel, labour and machine wear.

Efficient specification MT500D tractors can, as an option,

be supplied ready for AutoGuide™ installation or equipped with

the system as a factory-fit option.

AutoGuide™ employs the unique and most advanced Topcon

Paradigm, G3 multiple-constellation receiver chip, which allows

the AGI-3 receiver to track and pick-up signals from all visible

satellites – GPS, GLONASS and Galileo.

The ability to employ multiple satellite constellations improves signal

stability and increases positioning reliability and accuracy. State of

the art inertia sensors further improve precision and fine-tune the

steering by detecting the tractor’s working angle and direction of travel.

The advanced Topcon AGI-3 antenna comes with sub-metre and

decimetre accuracy as standard and is suitable for use with a wide

range of differential signals (DGPS), from the cost-effective

OmniStar VBS to the accurate OmniStar HP.

For ultimate precision, to within 2cm, is the optional RTK radio

module, which is a simple ‘snap-in’ fit into the AGI-3 antenna.

This module is able to receive correction signals from a mobile or

fixed base station, as well as from a GSM correction signal, also

offering 2cm accuracy wherever GSM coverage is available

AuTOguIDE™ ADvANTAgES

The Operator

• Relieves boredom, stress and fatigue through what

can often be long working days and nights

• Provides operators with time to optimise the performance

of machine and implement, and to monitor screen

settings and gauges

• Enables less experienced operators to achieve higher

workrates and greater productivity

• Allows the operator to work efciently in poor visibility

The machine

• Cuts overlaps and misses

• Saves fuel, labour and wear

• Increased application accuracy saves seed, fertiliser and pesticides

• Boosts output by ensuring full working width is employed

• Faster headland turns from automatic navigation

• Higher work quality from ability to closely monitor implement

19

Page 20

™

AgCOMMAND

MANAgES OpERATIONS

All MT500D tractors come ready for fitting the AGCOMMAND™ telemetry

option that provides customers with a cost-effective, easy to use data

recording and fleet management system.

Users are able to employ the system to boost machine and

operator efficiency, locate, track, as well as plan maintenance

and create comprehensive records. Users can cut the risk

of equipment theft by setting alarms to alert managers if

machines enter or leave pre-defined boundaries.

AGCOMMAND™ offers enormous management benefits by

constantly monitoring machine operations and transmitting data

back to a secure website via the mobile ‘phone network. There is no

need to install any additional software, with users able view their

records from any computer connected to the internet. With the

owner’s permission, dealers are also able to monitor service needs.

Data from AGCOMMAND™ is easy to view and manage on

a special, secure webpage that shows the location on Google

Maps™. Users can choose to see the whole fleet or locate

individual machines, current working status as well as check staff.

The system organises the information and can show an

Instant Report Card, which indicates the machine’s actual

position, engine hours, current speed, direction and whether

it is working.

A range of ready-prepared reports help users to quickly

create records to analyse, manage and control costs. Users can

also create their own reports. If provided with the machine’s

working width, AGCOMMAND™ will also deliver information

on the area worked by the field, day or in any given period.

20

Page 21

FEATURES AND BENEFITS

NEAR REAL TIME ACCESS

AGCOMMAND Standard Plus collects and transmits data

providing accurate and precise information regarding machine

performance and location optimising machine utilisation

and efficiency

F

ULLY AUTOMATIC DATA COLLECTING AND TRANSFER

AGCOMMAND Standard Plus requires no operator input,

operator can concentrate on the task in hand maximising in

performance whilst the da

UNIVERSAL INSTALLATION

AGCOMMAND Standard Plus is not limited to AGCO branded

machines and vehicles

A

LARMS

AGCOMMAND GEO-fences allow the customer to monitor

machine position and check that the machine is working in

the correct loca

to be planned and actioned with a minimum impact to

machine productivity

MAINTENANCE

AGCOMMAND allows the requirements for machine maintenance

to be directly monitored and managed by the customer or

passed over to the dealer

tion. Service alarms allow routine maintenance

ta is continuously transferred

the

field

M

APS

AGCOMMAND provides maps showing a machines working

y - historic locations, area worked, travel patterns, etc.,

histor

allowing productivity to be measured in speci

a specific length of time

OMPARISONS

C

AGCOMMAND allows the direct comparison of the performance

and efficiency of up to five machines in the same fleet working

in any location or application

R

EPORTS

AGCOMMAND allows a number of reports to be genera

ranging from individual

report allowing productivity to be studied and maximised

AGCOMMAND A

For those customers wishing to receive minute-by-minute

updates plus an abundance of extra information to assist their

business with data capture

field reports up to a full season efficiency

DVANCED

fic fields or over

ted,

AGCOMMAND Application for iPad and iPhone is now available

on Apple store, to follow your fleet from anywhere.

212223

Page 22

Page 23

Quick to fit and easy to operate, the rugged and versatile Challenger ML Series

front-end loaders are the perfect partner for the MT500D Series tractors.

A wide range of high lift capacities and heights allows customers to choose

exactly the right ML Series loader to handle every task. All come with a third

hydraulic service and are equipped with parallel linkages to keep the load

level to further ease operation.

The loader’s robust subframe is designed specifically for Challenger tractors,

combining superb balance, visibility and manoeuvrability with easy fitting.

A unique mounting system locks the loader frame securely to the tractor,

creating a solid, integrated combination, while the standard Soft Drive system

reduces shock loads on the tractor, operator and loader.

Loader operation has never been easier thanks to the range of novel and

useful features on the MT500D Series that make materials handling tasks

simple, easy and comfortable for operators.

The standard left-hand power direction lever and the AutoPower VI™

transmission’s fully clutchless shifting make for effortless manoeuvring.

The new MultiFunction joystick option on Efficient models, not only operates

all the loader functions, but also includes push-button control of the reverse

shuttle well as gear changing.

The ML Series Lock & Go system makes it quick and simple to mount the

ML Series loader to Challenger tractors, using integral parking stands and

a locking wheel on each side. For fast, clean hydraulic hook-ups is the MC4

Multi-Coupler option, which connects all the hoses, under pressure as well

as the electrics in one simple movement. The SelectoFix option works in the

same way for connecting the hoses to the implement tool carrier.

MODEL LINES

MT525D MT545D MT565D MT585D MT595D

ML66

ML68

ML76

ML78

ML88

MODEL Sp

Max lift height* 4,25 m

Max lift capacity**

* to pivot pin, may vary depending on tractor configuration

** at max lift height, 800 mm from pivot pin

4 4

4 4

4 4 4 4 4

- -

- - -

ECIFICATIONS

ML66 ML68 ML76 ML78 ML88

2120 kg 2450 kg 2120 kg 2430 kg 2770 kg

4,25 m 4,50 m 4,50 m 4,95 m

- - -

- - -

4 4 4

4 4

Page 24

ML SERIES LOADER IMpLEMENTS

The right tools for the job. Purpose-designed to suit Challenger ML Series Loaders,

this complete range of implements provides the widest choice available.

Developed through a rigorous R&D programme, those versatile and high quality

imlplements will suit the widest range of tasks like bale handling, grain loading,

cattle feeding, etc...

Please contact your dealer for a complete list of implements.

24

Page 25

25

Page 26

26

Page 27

2

Models MT525D MT545D MT565D MT585D MT595D

Engine Performance

Rated ISO engine Hp @ 2 100rpm (kW) 140 (103) 165 (121) 185 (136) 220 (162) 240 (177)

Maximum ISO engine Hp @ 1 950rpm (kW) 150 (110) 175 (129) 200 (147) 235 (173) 255 (187)

Maximum engine Hp with EPM Boost (kW) 175 (129) 200 (147) 220 (162) 260 (191) 280 (206)

Maximum ISO engine torque (Nm) @1 500 engine rpm 660 740 880 1,030 1,049

Maximum engine torque with EPM Boost (Nm) 745 840 980 1,120 1,145

Page 28

MT500D

Smart Machines. Serious Results.

Every effort has been made to ensure that the information contained in this publication is as accurate and current as possible.

However, inaccuracies, errors or omissions may occur and details of the specifications may be changed at any time without

notice. Therefore, all specifications should be confirmed with your Challenger Dealer or Distributor prior to any purchase.

Visit the Challenger Site: www.challenger-ag.com or for Challenger Merchandise: www.challengerstore.com

Cat®, Caterpillar® and Challenger® are registered trademarks of Caterpillar Inc. and are used under licence by AGCO.

© AGCO Limited. 2012 A-A-15388

Loading...

Loading...