Page 1

Challenger

MT525B-535B-545B-555B-

565B-575B Series

Agricultural Tractors

AGCO - SA - Beauvais - France - RC B562 104 539 January 2005

N° 3378697M1

Issue 1

Challenger MT500B EU

English

Page 2

Page 3

OPERATOR INSTRUCTION BOOK

CONTENTS

Chapter 1

TRACTOR IDENTIFICATION

Chapter 2

INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

Chapter 3

INSTRUMENTS AND CONTROLS

Chapter 4

OPERATION

1

2

3

4

Chapter 5

MAINTENANCE AND ADJUSTMENTS

Chapter 6

SPECIFICATIONS

Chapter 7

ACCESSORIES AND OPTIONS

Chapter 8

TROUBLESHOOTING

Appendix

CONVERSION TABLES

Index

5

6

7

8

Challenger MT500B EU

Page 4

Page 5

Chapter 1

1 . TRACTOR IDENTIFICATION

1

TRACTOR IDENTIFICATION

Challenger MT500B EU

1.1

Page 6

Page 7

1 . TRACTOR IDENTIFICATION

CONTENTS

1.1 - SERIAL NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5

1

Challenger MT500B EU

1.3

Page 8

1 . TRACTOR IDENTIFICATION

1.4

Challenger MT500B EU

Page 9

1 . TRACTOR IDENTIFICATION

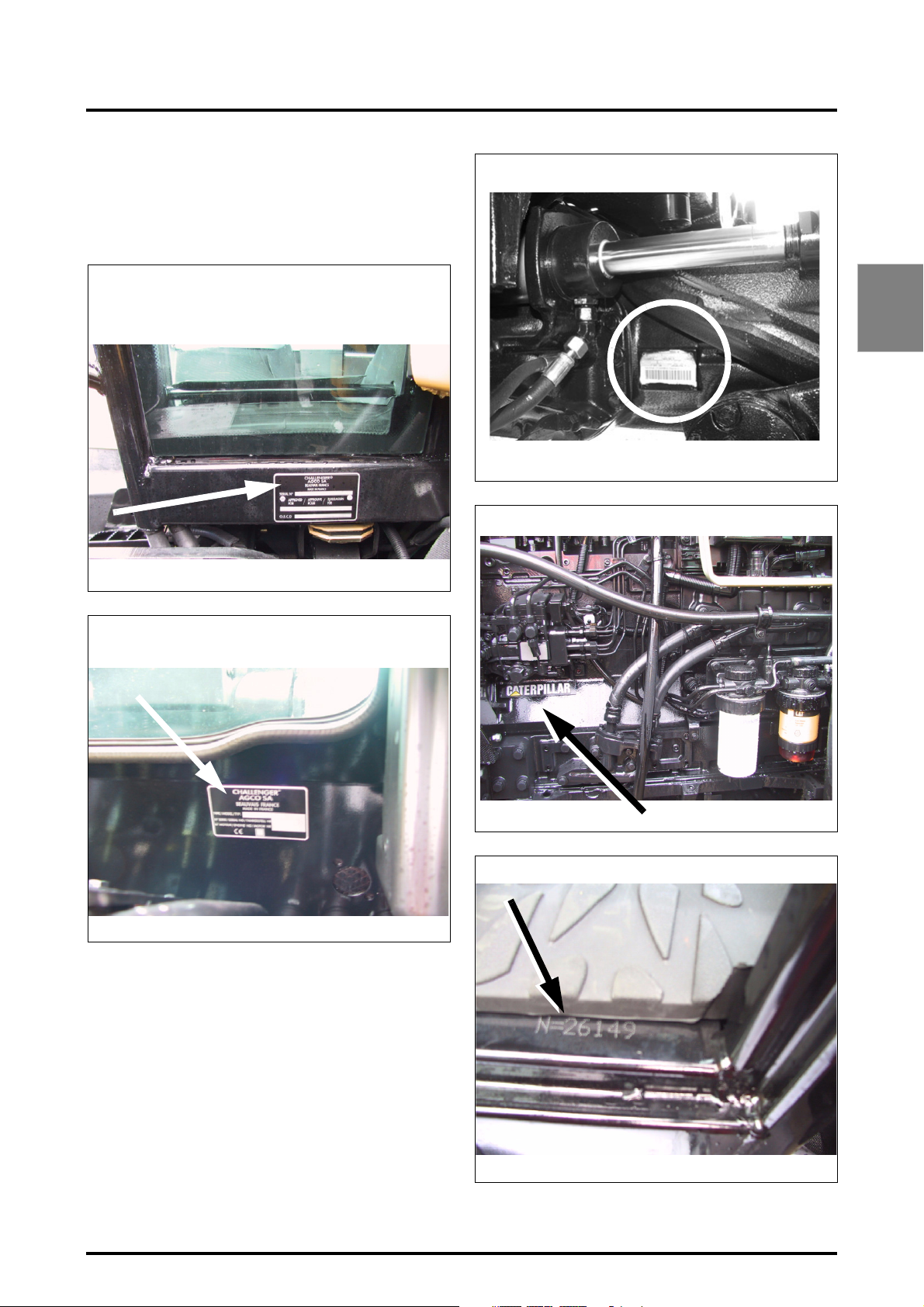

1.1 - SERIAL NUMBERS

IMPORTANT: WHEN CONTACTING YOUR DEALER OR

AGENT, ALWAYS INDICATE YOUR TRACTOR SERIAL

NUMBER.

Registration plate (according to country)

CE -013- 01-0 5

Fig. 1

Front axle Serial number

1

Z2-095

Fig. 3

"CAT" engine serial number

Name plate with serial number (according to country).

CE-014-01-05

Fig. 2

MT0041103

Cab serial number

Fig. 4

Challenger MT500B EU

CE -012- 01-0 5

Fig. 5

1.5

Page 10

1 . TRACTOR IDENTIFICATION

MODEL:..............................................................................

............................................................................................

SERIAL NUMBER:..............................................................

............................................................................................

ENGINE SERIAL NUMBER:................................................

............................................................................................

OWNER NAME AND ADDRESS (if applicable):

............................................................................................

............................................................................................

............................................................................................

............................................................................................

DEALER: ............................................................................

............................................................................................

............................................................................................

STREET: .............................................................................

TOWN:................................................................................

STATE:................................................................................

ZIP CODE:...........................................................................

DEALER CODE: .................................................................

............................................................................................

TRACTOR RECEIVED FROM:

(tick one of the following)

................ FACTORY

................ OTHER DEALER (transfer)

1.6

Challenger MT500B EU

Page 11

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

Chapter 2

2

INTRODUCTION - SAFETY INSTRUCTIONS AND

WARRANTY

Challenger MT500B EU

2.1

Page 12

Page 13

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

CONTENTS

2.1 - NOTE TO THE USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5

2.2 - THIS BOOK MUST ALWAYS BE KEPT WITH THE TRACTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5

2.3 - WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5

2.4 - SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5

2.5 - SAFETY - ALERT SYMBOLS AND TERMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.6

2.6 - TRACTOR AND IMPLEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.6

2.7 - MAXIMUM TRAVEL SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.6

2.8 - INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.7

2.9 - NOTE TO THE OPERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.7

2.10 - DANGER, WARNING AND CAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.7

2.11 - DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.7

2.12 - SAFETY PROCEDURE TO FOLLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

2.12.1 For proper operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

2.12.2 Observe the following instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

2.13 - PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

2.13.1 Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

2.13.2 Damage to the ROPS cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

2.14 - PREPARING FOR SAFE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

2.14.1 Know your equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.8

2.14.2 Protect yourself . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.9

2.14.3 Use all available protective and safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.9

2.14.4 Equipment check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.10

2.14.5 Clean the tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.10

2.14.6 Protect the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.11

2.15 - SERVICING THE TRACTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.11

2

2.16 - STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.11

2.16.1 Warn personnel before starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.11

2.16.2 Get on and off the tractor safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.11

2.16.3 Safe start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.11

2.16.4 Follow recommended start-up procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.12

2.16.5 Controls test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.12

2.16.6 Starting fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.12

2.17 - WORKING SAFELY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.12

2.17.1 Make the right moves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.12

2.17.2 Safety instructions to be observed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.12

2.17.3 Safety of bystanders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.13

2.17.4 Risk of overturning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.13

2.17.5 To avoid side overturns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.14

2.17.6 To avoid rear overturns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.14

2.17.7 Other risks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.15

2.17.8 Implements and attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.16

2.17.9 Tractor Towing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.16

2.17.10 Road use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.17

2.17.11 Highway code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.17

Challenger MT500B EU

2.3

Page 14

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.18 - SAFETY - AFTER OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.17

2.19 - DESCRIPTION OF DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.18

2.4

Challenger MT500B EU

Page 15

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.1 - NOTE TO THE USER

The purpose of the contents of the present Book (text and

illustrations) is to help the user to better master tractor operation and maintenance.

Every vehicle part must be maintained to a certain level in

order to remain in perfect operating condition. The utmost

has been done to include all settings and adjustments for

use in all possible operating conditions. However, special

attention is required in certain cases.

Please read this Operator Instruction Book very carefully in

order to familiarise yourself with all the operating settings,

adjustments and procedures before using the tractor. Always remember that this machine has been designed and

tested to work effectively in most operating conditions and

that its operation depends on the maintenance it receives.

Ask the dealer if certain cases require special attention. His

Spare Parts and Service team will be pleased to help and to

answer any questions relating to the operation and maintenance of the machine.

2.2 - THIS BOOK MUST ALWAYS BE KEPT

WITH THE TRACTOR

The present book includes all information available about

the product at the time of publication. The manufacturer reserves the right to modify it at any time.

WARNING: In some illustrations in this Book,

safety guards and protective panels have

been removed for the sake of clarity. Never

use the tractor if these elements are not in

place. If safety guards and protective panels have been

removed for repair purposes, they MUST be refitted

before use.

2

2.3 - WARRANTY

The warranty that applies to this tractor can be found on the

purchase order and warranty conditions card given by the

dealer at the time of purchase.

As set out by the terms and conditions listed on the purchase order form signed by the buyer and dealer, the vehicle buyer is responsible for all inspections and for

transporting the vehicle to and from the dealer.

2.4 - SAFETY

Driver safety is one of the major concerns taken into account when designing and tuning the new tractor. The designers have included as many safety systems as possible.

In spite of these precautions, each year a number of accidents happen which could have been avoided by a few seconds consideration and greater care when using

agricultural machines and implements.

For this reason you are strongly advised to carefully read

and strictly apply the safety instructions set out in this

Book.

Challenger MT500B EU

2.5

Page 16

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.5 - SAFETY - ALERT SYMBOLS AND TERMS

This Safety Alert Symbol means CAUTION!

BE ALERT! YOUR SAFETY DEPENDS ON IT!

SAFETY is essential! Why?

• ACCIDENTS DISABLE AND KILL

• ACCIDENTS ARE COSTLY

• ACCIDENTS CAN BE AVOIDED

2.6 - TRACTOR AND IMPLEMENTS

The tractor is a source of power - Mechanical - Hydraulic

• On its own, the tractor is of little practical value. Only

when used in conjunction with an implement or other

attachment does it become a working unit.

• This Operator Instruction Book is compiled to cover the

safe working practices when the tractor runs under normal conditions.

• It does not cover all operation and safety instructions

relevant to all known implements and attachments that

may be fitted at the time of tractor delivery or later.

• It is essential that operators use and understand the rel-

evant instruction books of such implements and attachments.

The safety alert symbol identifies important

safety messages on machines, safety signs, in

manuals, or elsewhere. When you see this

symbol, be alert to the risk of personal injury or

death. Follow the instructions in the safety

message.

2.7 - MAXIMUM TRAVEL SPEEDS

DANGER: Road use of agricultural tractors is

subject to speed restrictions depending on

the bulkiness of the equipment and weight of

the transported load. Consult the regulatory

texts in force in the relevant countries.

2.6

Challenger MT500B EU

Page 17

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.8 - INTRODUCTION

The present Safety chapter sets out certain typical situations that may be encountered during normal tractor operation and maintenance, and suggests solutions to remedy

them. This chapter DOES NOT replace the other safety instructions in the other chapters of this book.

Other precautions must be taken depending on the equipment used and the working conditions on the site or in the

maintenance area. The manufacturer is unable to directly

control the use, operation, checking, lubrication and maintenance of the tractor. The DRIVER is therefore responsible for applying the safety measures relevant to all these

operations.

NOTE: This Book is intended for distribution in North

America; it is possible that some default equipment or

attachments mentioned are not available in the country

where the tractor is used. Please consult your dealer for

further information on this subject.

Only use approved attachments and equipment.

2.9 - NOTE TO THE OPERATOR

It is YOUR responsibility to read and understand the Safety

chapter in this book before starting your tractor. You must

follow these safety instructions that take you step by step

through your working day.

In reading this section, you will note that illustrations have

been used to highlight certain situations. Each item illustrated is numbered and the same number appears in the

text, in parentheses. This number is placed at the end of

the written text that refers to the item illustrated.

Remember that YOU are the key to safety. Good safety

practices not only protect you, but also bystanders. Study

the features in this book with care and make them a working part of your safety program.

Keep in mind that this safety section is written only for this

type of machine. Also study the usual protective measures

taken when working and in particular -

CAUTION: This signal, displayed with the

word CAUTION, indicates a potentially hazardous situation that, if not avoided, may

result in MINOR INJURY.

IMPORTANT: Indicates a special instruction or procedure that, if not strictly observed may cause damage to,

or destruction of the machine, the process, or the surroundings.

NOTE: The word NOTE indicates additional information

about a subject or procedure for more efficient or convenient operation or repair.

2

2.11 - DECALS

WARNING: DO NOT remove or obscure DANGER, WARNING, CAUTION or Instruction

Decals.

Replace any Danger, Warning, Caution or Instruction Decals that are not readable or are missing. Replacement decals are available from your Dealer in the event of loss or

damage. The actual location of these Safety Signs is illustrated at the end of this chapter.

If a used tractor has been purchased, refer to the illustrations at the end of this book to ensure that all the safety

signs are in the correct position and are readable.

REMEMBER THAT SAFETY DEPENDS ON YOU. YOU

CAN PREVENT SERIOUS INJURY OR DEATH.

2.10 - DANGER, WARNING AND CAUTION

Whenever you see the words and symbols shown below,

used in this book and on decals, you MUST apply their instructions as they relate to personal safety.

DANGER: This signal, displayed with the

word DANGER, indicates an imminently hazardous situation that, if not avoided, may

result in DEATH OR VERY SERIOUS INJURY.

WARNING: This signal, displayed with the

word WARNING, indicates a potentially hazardous situation that, if not avoided, may

result in DEATH OR SERIOUS INJURY.

Challenger MT500B EU

2.7

Page 18

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.12 - SAFETY PROCEDURE TO FOLLOW

2.12.1 - For proper operation

For proper operation of an agricultural tractor, you must be

a qualified and approved operator. To be qualified you must

understand the written instructions supplied in this manual,

have training, and know the safety rules and regulations for

the job.

Some regulations specify that no one under the age of 16

years, for example, may operate power machinery. This includes tractors. It is your responsibility to know what these

regulations are, and respect them, in the operating area or

situation.

These will include, but are not limited to, the following instructions for safe tractor operation.

WARNING: The operator must not drink alcohol or take any medication that may affect his

concentration or coordination. If taking medi-

cation, whether prescribed or not, the operator must seek medical advice as regards his ability to

safely operate machinery.

2.12.2 - Observe the following instructions

• DO NOT ALLOW children or unqualified persons to

operate your tractor. Keep others away from the working area.

• Always wear your seat belt securely fastened.

• Where possible, avoid operating the tractor near

ditches, embankments and holes. Reduce speed when

turning, crossing slopes, and on rough, slippery, or

muddy surfaces.

• Stay off slopes too steep for safe operation.

• Watch where you are going, especially at row ends, on

roads, and around trees.

• Passenger seat is only intended for short periods of use

• Do not allow children in the passenger seat.

• DO NOT PERMIT others to ride on the tractor or the

implement unless an approved passenger seat is fitted.

• Only hitch attachments and implements to the drawbar

and hitch points recommended, and never above the

centre line of the rear axle.

• Operate the tractor smoothly - no jerky turns, starts or

stops. When the tractor is stopped, apply the parking

brake securely. Lower the implement and remove the

ignition key.

• DO NOT MODIFY OR REMOVE any part of the equip-

ment and DO NOT USE attachments unless they are

properly matched to your tractor.

2.13 - PROTECTION

2.13.1 - Cab

The ROPS (Roll Over Protective Structure) cab has been

designed for this tractor series and meets all the safety and

sound legal requirements.

The ROPS cab conforms to the various international safety

standards. The ROPS cab must NEVER be drilled or modified to install attachments or implements. Welding on cab

components IS NOT PERMITTED. DO NOT attach chains

or ropes to the main frame of the cab for pulling purposes.

If additional controls or displays are to be added to the operator’s area contact your dealer for information.

The ROPS cab together with the seat belt is effective in reducing injuries during overturn accidents. Wearing the seat

belt is an important part of this protection.

• Always wear your seat belt adjusted snugly.

• Check the seat belt for damage. A damaged seat belt

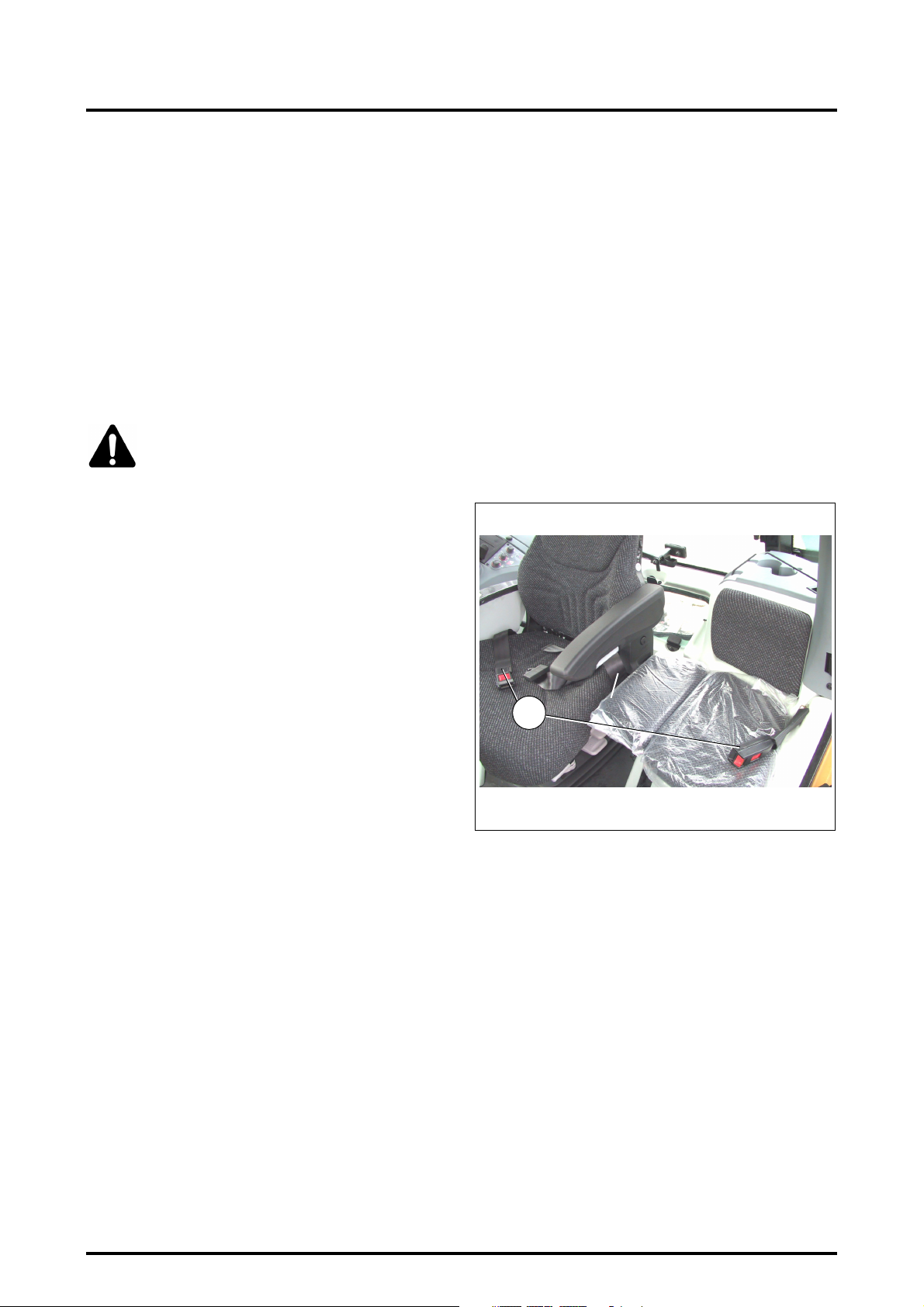

must be replaced (Fig. 1).

1

MT-0011103

2.13.2 - Damage to the ROPS cab

If the ROPS cab has been damaged as a result of tractor

rollover or incident, it must be replaced, NOT repaired.

DO NOT use the tractor with a damaged ROPS cab.

Fig. 1

2.14 - PREPARING FOR SAFE OPERATION

2.14.1 - Know your equipment

It is important to know the tractor and operation of all its accessories, implements and additional equipment. It is also

important to know how to use all the controls, gauges and

dials, as well as the rated load capacity, speed range, braking and steering characteristics, turning radius, and operating clearances.

Remember that rain, snow, ice, loose gravel, soft ground,

etc. can change the performance of your tractor.

Under poor conditions, slow down and be extra careful,

and engage four-wheel drive if fitted.

2.8

Challenger MT500B EU

Page 19

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

Study the DANGER, WARNING and CAUTION safety

symbols on your tractor and the information signs also.

READ THIS OPERATOR INSTRUCTION BOOK CAREFULLY BEFORE STARTING THE ENGINE.

STUDY IT BEFORE YOU START WORK (Fig. 2).

Z2-530-05-03

Fig. 2

DO NOT wear loose clothing, jewellery or other items and

tie up long hair which could catch on controls or other parts

of the equipment.

Z2-531-05-03

Learn where fire extinguishers and first-aid or emergency

equipment is kept and where to get help in a hurry. Make

sure you know how to use this equipment (Fig. 4).

Fig. 3

2

IF THERE IS SOMETHING IN THE BOOK YOU DON’T UNDERSTAND, ASK SOMEONE (for example your equipment

dealer) TO EXPLAIN IT TO YOU.

This book covers general safety practice for agricultural

tractors. It must always be kept with the tractor. For extra

copies contact your Dealer.

2.14.2 - Protect yourself

Wear all protective clothing and equipment provided or

which is appropriate for certain working conditions. Do not

take any risks (Fig. 3).

For example, you may need:

• A safety helmet.

• Goggles, or a face shield.

• Hearing protection.

• Respirator or filter mask.

• Inclement weather clothing.

• Reflective clothing.

• Heavy gloves (neoprene for chemicals, leather for rough

work).

• Safety shoes.

Fig. 4

2.14.3 - Use all available protective and safety devices

Ensure that all protective devices, guards and safety signals are fitted as required and are in a good condition.

To help keep you and others around you safe, your tractor

should be equipped with:

• ROPS cab and safety belt

• PTO guard

• Back rear-view mirror

• SMV warning triangle

• Additional lights and decals

Depending on the work to be carried out, the following ac-

cessories may also be required:

Challenger MT500B EU

2.9

Page 20

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

• Fire extinguisher

• Backup alarm

• Any other suitable protective devices

Make sure all required equipment is in place and in good

working order. DO NOT remove or disconnect any safety

devices.

2.14.4 - Equipment check

Before you begin your working day, take time to check your

tractor and ensure that all systems are in good operating

condition.

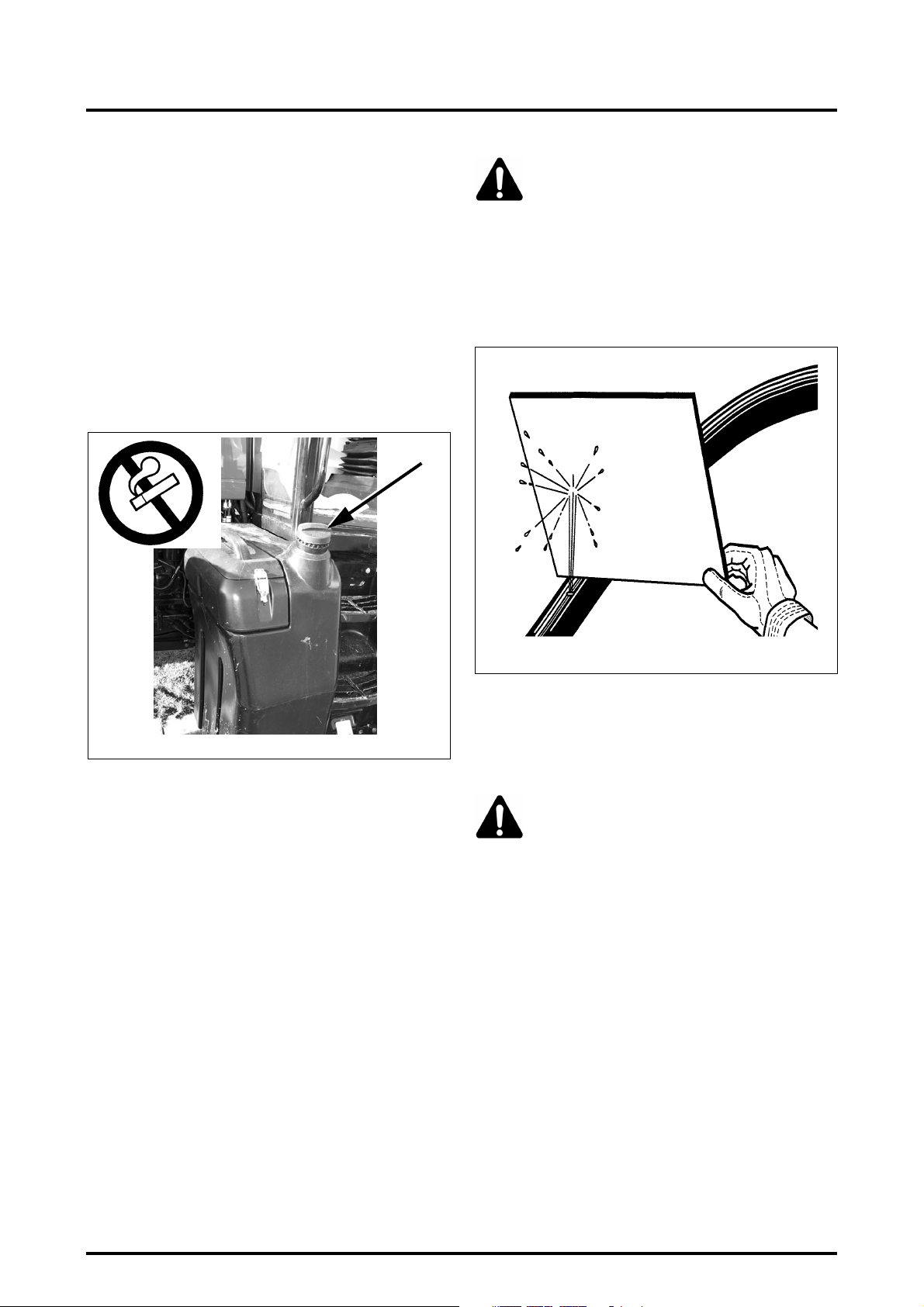

• DO NOT SMOKE while refuelling the tractor. Keep any

type of naked flame away (Fig. 5).

• Stop the engine and wait for it to cool before refuelling.

WARNING: Diesel fuel or hydraulic fluid under

pressure can penetrate the skin or eyes and

cause serious personal injury, blindness or

death.

Fluid leaks, under pressure, may not be visible. Use a

piece of cardboard or wood to detect leaks. DO NOT

USE YOUR BARE HANDS. Wear safety goggles for eye

protection. If any fluid is injected into the skin, it MUST

be surgically removed within a few hours by a doctor

familiar with this type of injury (Fig. 6).

Z2-532-05-03

• Check for loose, broken, missing, or damaged parts.

Have everything put into good repair. Make certain all

safety devices are in place.

• Check the seat belt for damage. A damaged seat belt

must be replaced.

• Check that all implements and equipment are correctly

fitted and that the tractor and implement PTO ratios

(rpm) are respected.

• Check the condition and pressure of tyres (absence of

cuts and bulges). Replace worn or damaged tyres.

Check the hand and foot brake operation. Adjust if necessary.

• Check the oil level. Add some oil if necessary.

• Perform all servicing procedures outlined in the Maintenance and Adjustments chapter in this book.

• Check that the PTO shaft locking devices are latched.

• Check that the tractor PTO shield and shaft guards are in

place and operating properly.

• Check the tractor and implement hydraulic system.

Have any leaks or damaged parts repaired or replaced.

Fig. 5

D-58 42A

Before applying pressure to the fuel or hydraulic system,

be sure all connections are tight and that lines, pipes, and

hoses are not damaged. Before disconnecting fuel or hydraulic lines, be sure to relieve all pressure.

Make sure that all hydraulic lines are correctly installed and

not crossed.

WARNING: Liquid cooling systems build up

pressure as the engine gets hot. Before

removing the radiator cap, stop the engine

and let the system cool.

• Check the engine cooling system and add coolant as

required.

2.14.5 - Clean the tractor

• Keep work surfaces and engine compartments clean.

• Before cleaning the machine, always lower implements

to the ground, place transmission in neutral, engage the

parking brake, stop the engine and remove the ignition

key.

• Clean footsteps, pedals and floor. Remove grease or oil.

Brush away dust or mud. In winter, scrape away snow

and ice. Remember - slippery surfaces are hazardous.

• Remove or put away implements, buckets, chains and

hooks.

Fig. 6

2.10

Challenger MT500B EU

Page 21

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.14.6 - Protect the environment

• It is illegal to pollute drains, water courses or soil. Use

authorized waste disposal facilities, including civic

amenity sites and garages providing facilities for disposal of used oil. If in doubt, contact your local authority

for advice.

2.15 - SERVICING THE TRACTOR

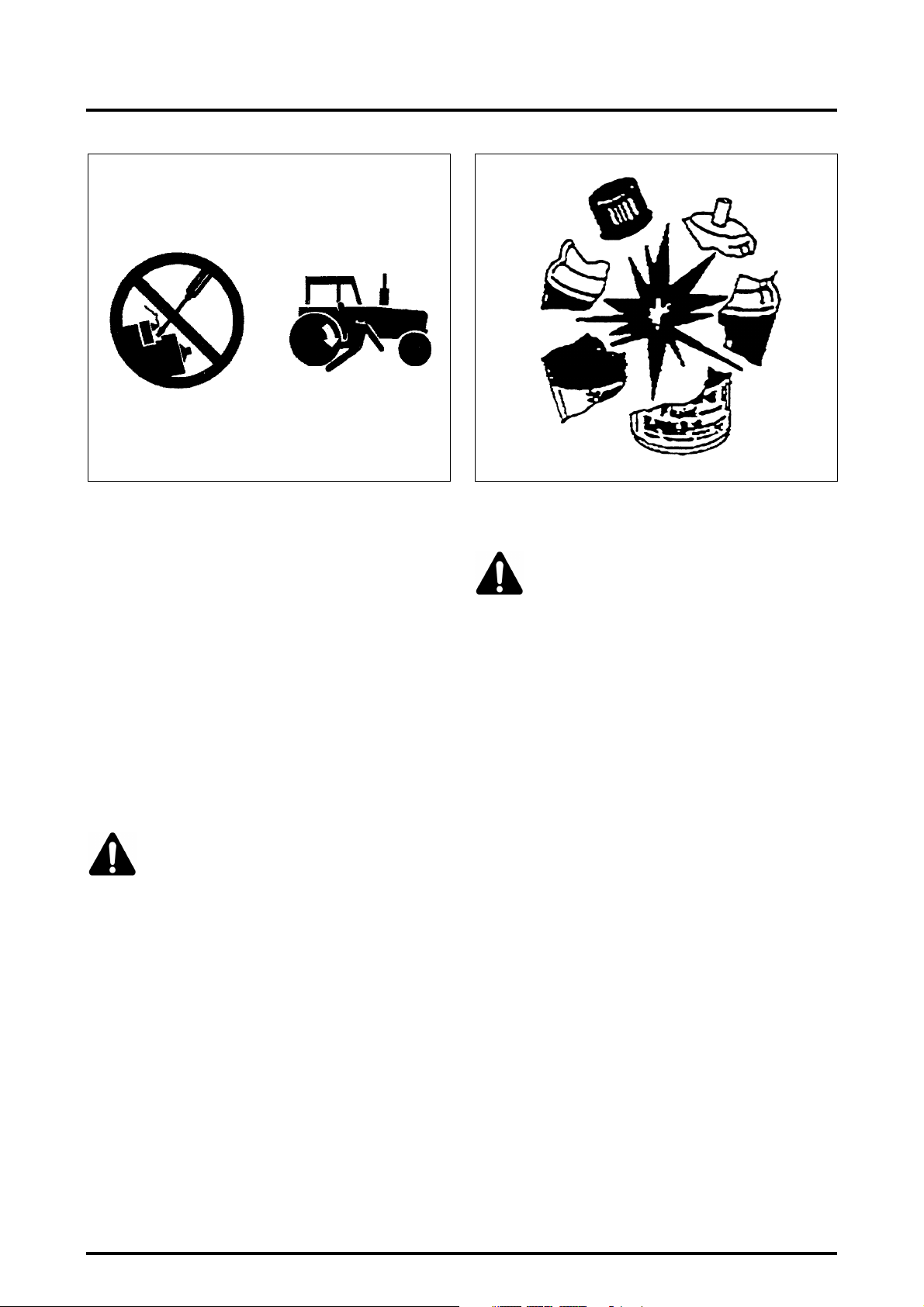

• DO NOT SERVICE the tractor while the engine is running or hot, or if the tractor is in motion (Fig. 7).

2.16 - STARTING

2.16.1 - Warn personnel before starting

Before starting, walk completely around the tractor and any

attached equipment. Make sure that no one is under it, on

it, or close to it. Tell other workers or people nearby that the

tractor is about to start. Do not start the tractor while there

are people near the tractor, tools or trailed implements.

Ensure that all bystanders, particularly children, are a suitable distance away before starting the engine.

2.16.2 - Get on and off the tractor safely

Always use "three point contact" with the machine, and

face the machine when you get on it. (Three point contact

means both hands and one foot or one hand and both feet

are in contact with the machine at all times when getting

on and off).

Clean your shoes and wipe your hands before getting on.

Use handrails, grab handles, ladders or footsteps (as provided) when getting on and off.

DO NOT use control levers as a hand hold and never step

on pedals when getting on and off.

DO NOT attempt to get on or off a moving tractor. DO NOT

jump off a tractor other than in an emergency.

2

Z2-534-05-03

Fig. 7

• Before making adjustments to or servicing the electrical

system, disconnect the battery cables, negative (-) cable

first.

• To prevent fires or explosions keep open flame away

from the battery or cold weather starting aids. To prevent sparks which could cause explosions use jumper

cables according to instructions.

• When making repairs or adjustments it is recommended

that you consult your Dealer, and have the work carried

out by trained personnel.

• The implement and/or tractor must be supported on

suitable blocks or stands, NOT a hydraulic jack.

• Check all nuts and bolts periodically for tightness, especially wheel hub and rim nuts. Tighten to the prescribed

torque values.

2.16.3 - Safe start-up

WARNING: Before starting the engine make

sure there is plenty of ventilation. DO NOT

operate the engine in a closed building. The

exhaust fumes may cause asphyxiation.

Always start the engine from the driver’s seat with all the

transmission levers and the PTO lever in neutral.

Make sure that the tractor dual brake pedals are locked together at all times unless you are making turns in the field

which require independent use of the brakes. Make sure

the brakes are properly adjusted so that both brakes engage at the same time.

Adjust the seat, fasten the seat belt (as specified in the

book), apply the handbrake and put all controls in neutral

before starting up.

DANGER: Start the engine, with the ignition

key, from the driver’s seat only. DO NOT

ATTEMPT to start the engine by shorting

across the starter terminals. The machine will

start in gear if the neutral start circuit is bypassed. This

could cause serious injury or death to anyone in the

vicinity of the tractor (Fig. 8).

Challenger MT500B EU

2.11

Page 22

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

Z2-535-05-03

Fig. 8

2.16.4 - Follow recommended start-up procedures

Follow the start-up procedures recommended in the Operation chapter of this Operator instruction Book. This chapter includes normal starting, cold starting, and the use of

starting fluids.

2.16.5 - Controls test

After starting, check all gauges and lights again. Make sure

everything is functioning correctly. If the tractor does not

respond correctly when each control is operated, DO NOT

USE the machine until the fault is remedied.

Ensure that the starter solenoid cover is always in position.

2.16.6 - Starting fluid

WARNING: It is very important that you read

and follow the starter fluid instructions before

using it. DO NOT use aerosol cans of starter

fluid on tractors with the thermostat connected to the electrical system. Ether combined with

thermostat can cause an explosion with damage to

engine, personal injury, or both.

Handle starting fluid correctly. Starting fluid must only be

used in conjunction with an ether-start aid fitted as original

equipment by the manufacturer or installed by a Dealer as

an accessory. In cases of tractors being fitted with glow

plugs or a thermostat, these must be removed prior to the

installation of an ether-start aid (Fig. 9).

If aerosol cans of starting fluid are to be used the thermostat must be disconnected. Remove the wire from the

thermostat which will be found on the manifold. Tape the

end of the wire to prevent an electrical short circuit.

WC1952

Fig. 9

2.17 - WORKING SAFELY

WARNING: An unbalanced tractor could overturn and cause injury or death.

Make sure front frame counterweights, wheel

weights and wheel ballast are used as recommended by the manufacturer. DO NOT add extra counterweights to compensate for an overloaded tractor; it

is recommended to reduce the load. Keep all parts of

your body inside the cab while operating the tractor.

2.17.1 - Make the right moves

Ensure that the tractor is ready for the work to be carried

out. Make sure you know the tractor nominal load capacities and never exceed them. Be certain that any attachments or implements you intend to use DO NOT EXCEED

the load rating of your tractor. Be sure the tractor and implement PTO speed match.

Keep in mind that tractors normally operate on uneven, unpaved, and often bumpy or sloping surfaces. Operating

conditions can reduce the amount of weight you should

carry or pull.

2.17.2 - Safety instructions to be observed

• Operate the controls smoothly - don’t jerk the steering

wheel or other controls.

• NEVER get on or off a moving tractor. Keep a firm grip

on the steering wheel at all times, with the thumbs clear

of the spokes when driving the tractor.

• Make sure you have adequate clearance in all directions

for the tractor and implement.

• DO NOT play with a tractor or equipment. Use only for

intended purpose.

• DO NOT attempt to work the controls except from the

driver’s seat.

2.12

Challenger MT500B EU

Page 23

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

• Before getting off, always disengage the PTO, lower all

attachments and implements to the ground, set the

tractor to neutral, activate the Park Lock, stop the

engine and remove the ignition key.

NOTE: DO NOT TOUCH, lean on, or reach through any

implement mechanism or permit others to do so.

Stay alert! If a part breaks, loosens or does not operate

correctly, stop work, switch off the engine, check the machine and carry out any necessary adjustments or repairs

before resuming work.

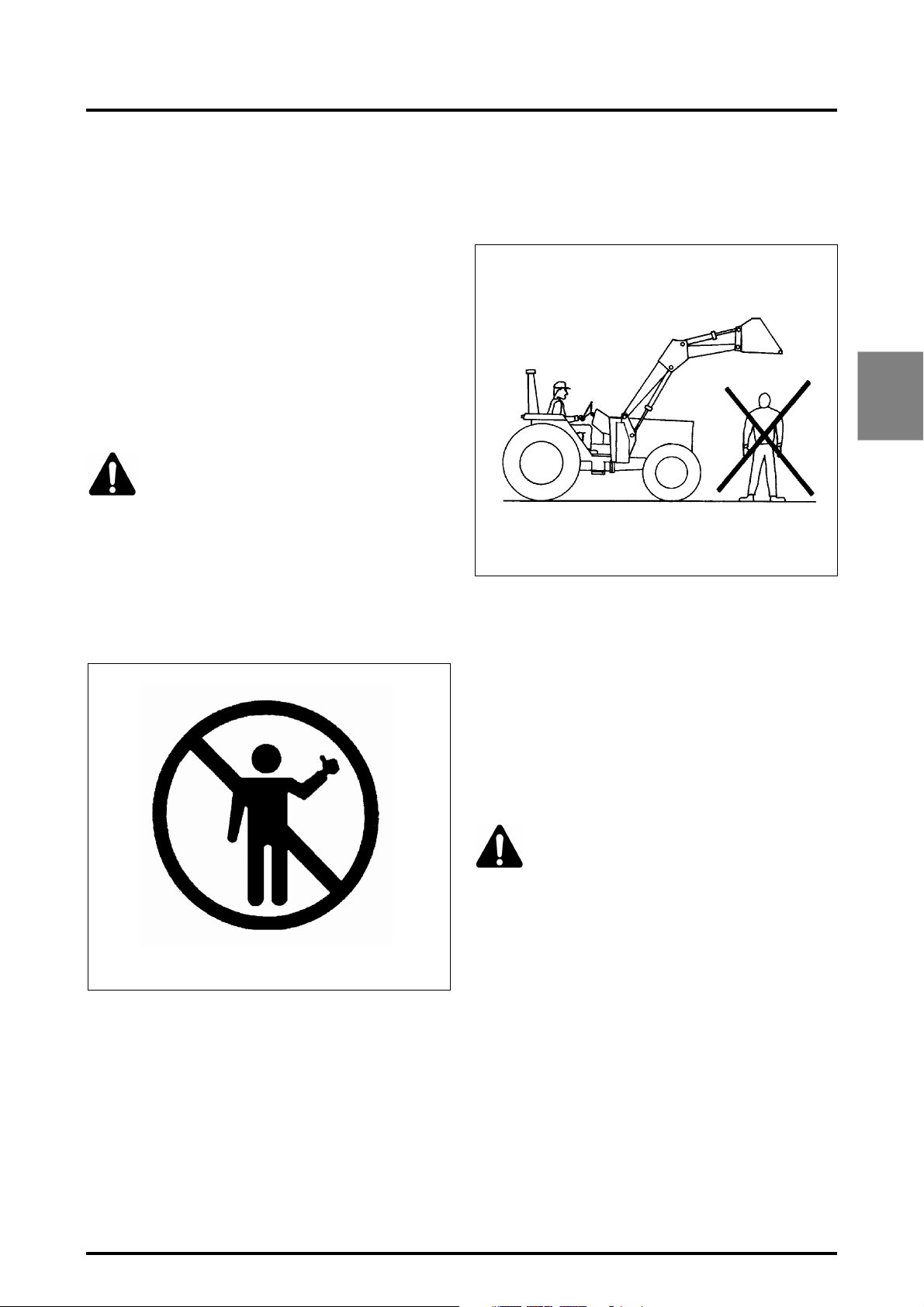

2.17.3 - Safety of bystanders

Watch out for others. DO NOT allow inexperienced or unqualified people to operate the tractor. They may cause injury to themselves or to others.

WARNING: A tractor is a personal piece of

machinery. Do not allow others to drive the

tractor or to use the implement (Fig. 10). DO

NOT ALLOW another person to get on the

implements or any other equipment, including trailers,

except in the case of harvesters specially designed for

this purpose (for the harvest itself and not for transport

purposes). Space should be provided on such equipment so that this type of transport can be carried out

in complete safety. DO NOT ALLOW children on the

tractor.

• DO NOT LIFT a load over anyone.

• Keep others away from the working area. DO NOT

ALLOW others to stand beside or walk beneath a raised

implement (Fig. 11).

2

S-1125

Fig. 11

• DO NOT lift objects that do not fit safely into the

bucket. Obtain the correct equipment.

• When using a loader, avoid sudden stops, starts, turns,

or change of direction. Keep loads close to the ground

when transporting.

• DO NOT stand (or allow anyone else to stand) in front

of, under, or behind loaded or loading equipment. DO

NOT DRIVE a tractor up to someone standing in front of

a fixed object.

• Keep others away from universal joints, hitches, drawbars, lift arms, PTO shafts, cylinders, belts, pulleys, and

other moving parts. Keep all shields and guards in place.

WARNING: DO NOT STAND, or allow anyone

else to stand, between the tractor and implement unless the engine is turned off and the

parking brake is engaged, the transmission

control lever is in neutral, and all attachments or implements are lowered to the ground.

Z2-536-05-03

Fig. 10

• Be certain you can control both speed and steering

before moving. Move slowly until you are sure that

everything is operating properly. After starting, recheck

the steering, right and left. Be certain you have full

steering and brake control. If differential is locked, DO

NOT operate at high speed or turn the tractor until the

differential lock is disengaged.

Challenger MT500B EU

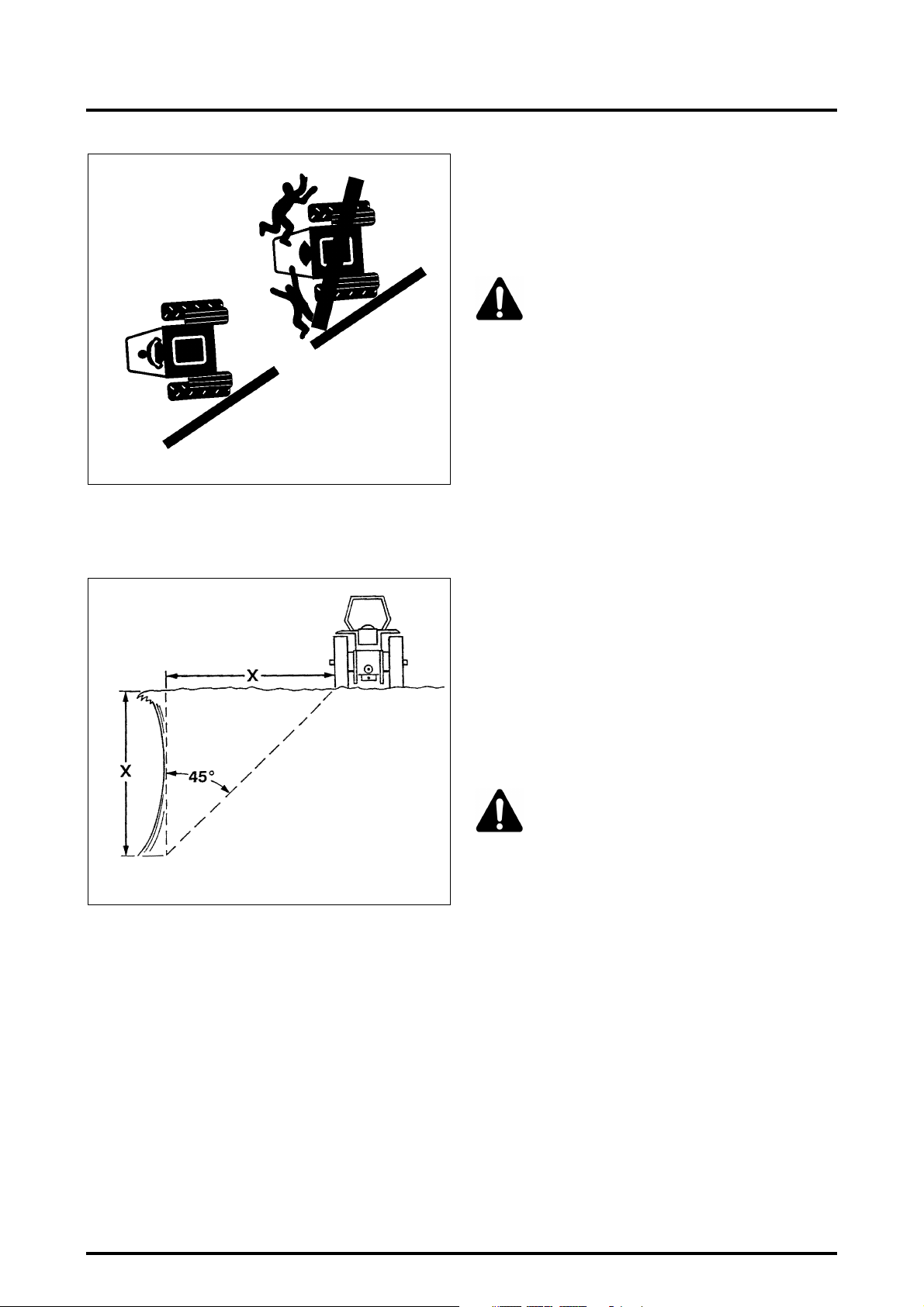

2.17.4 - Risk of overturning

In the event of an overturn with a tractor fitted with a cab,

hold the steering wheel firmly and do not attempt to leave

the seat until the tractor has come to a standstill (Fig. 12).

If the doors of the cab are obstructed, leave through the

rear window or roof hatch.

2.13

Page 24

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

• When driving down a slope, use the gas control to slow

the tractor engine and choose the same gear ratio as

used when climbing a slope. Shift into gear before you

start downhill.

• Engage four-wheel drive (if fitted), this will give fourwheel braking.

WARNING: DO NOT disengage the clutch or

attempt to shift gear after you have started

downhill.

• The tractor is less likely to turn over if you drive up or

down a steep slope rather than driving across it.

• Avoid steep slopes whenever possible. If this is not possible, avoid holes and dips when driving downhill. Avoid

stumps, stones, bumps and raised areas when driving

uphill. Keep the tractor behind the shear line when

Z2-538-05-03

Fig. 12

Fig. 13: Do not operate near the edge of ditches or banks.

The distance from the edge should always be equal to or

greater than the height of the bank, to prevent it from collapsing.

working close to ditches or banks. (Fig. 13). Avoid

ditches, banks and riversides which might give way.

• When you must drive on a steep slope, avoid turning at

the top of the slope. Slow down and turn in a wide turning circle. Drive straight on uphill or downhill slopes, and

never drive across them. Keep the heavier end of the

tractor facing towards the top of the slope when driving

up and down it.

• If a tractor fitted with lateral implements is used on a

steep slope, the implement must always face up the

slope. Do not raise implements. Keep them as low to

the ground as possible when crossing a slope.

• When towing a load at transport speed, lock the drawbar in the centre position and use a safety chain.

• DO NOT use your tractor to round up farm animals.

S-1031

Fig. 13

2.17.5 - To avoid side overturns

• Set the wheel track at the widest setting suitable for the

work being done.

• Lock the brake pedals together before driving at transport speeds.

• Reduce speed to match operating conditions. If the tractor is equipped with a front-end loader, carry the bucket

and load as low as possible.

• Make wide slow turns at reduced speed. Don’t let your

tractor bounce. You may lose steering control.

• Don’t pull a load too heavy for your tractor. It could run

down the slope or the tractor could jackknife around a

towed load.

• Don’t brake suddenly. Apply brakes smoothly and gradually.

2.17.6 - To avoid rear overturns

WARNING: Hitching to the rear axle, or any

other point above the swinging drawbar, can

cause a rear overturn.

• DO NOT PULL anything using the top link connection,

or from any point on the rear axle or above. Always use

a manufacturer approved drawbar, and only use a drawbar pin of the correct size and that can be locked in

place.

• High hitching can cause rear overturn, which may cause

serious injury or death. Hitch loads to the drawbar only.

• Only use a three-point linkage drawbar when stays are

fitted to keep it in the down position.

• Use front counterweights to increase tractor stability

when towing a heavy load or to counterbalance a heavy

rear mounted implement.

• Start forward slowly and gradually increase your speed.

DO NOT reverse or release the clutch. If the tractor is

attached to a heavy load or immovable object, improper

clutching may cause rear overturn.

• If the front end of the tractor starts to lift, reduce your

speed and, if necessary, disengage the clutch.

2.14

Challenger MT500B EU

Page 25

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

• If your tractor is bogged down in mud or frozen to the

ground, DO NOT attempt to drive forward. The tractor

can rotate around its rear wheels and overturn. Lift any

attached implement and attempt to BACK OUT. If this

is not possible, tow it out with another vehicle.

• If you get stuck in a ditch, BACK OUT, if possible. If you

must go forward, do so slowly and carefully.

• A bare tractor or tractor with rear mounted attachments

should be backed up the slope in reverse and travel forward downhill.

• A tractor with a loaded front-end bucket should be

backed down the slope and travel forward uphill. Keep

the loader bucket as low as possible.

• Always keep the tractor in gear when going downhill.

DO NOT PERMIT the tractor to coast with clutch disengaged or transmission in neutral.

DANGER

2

Z2-541-05-03

Fig. 15

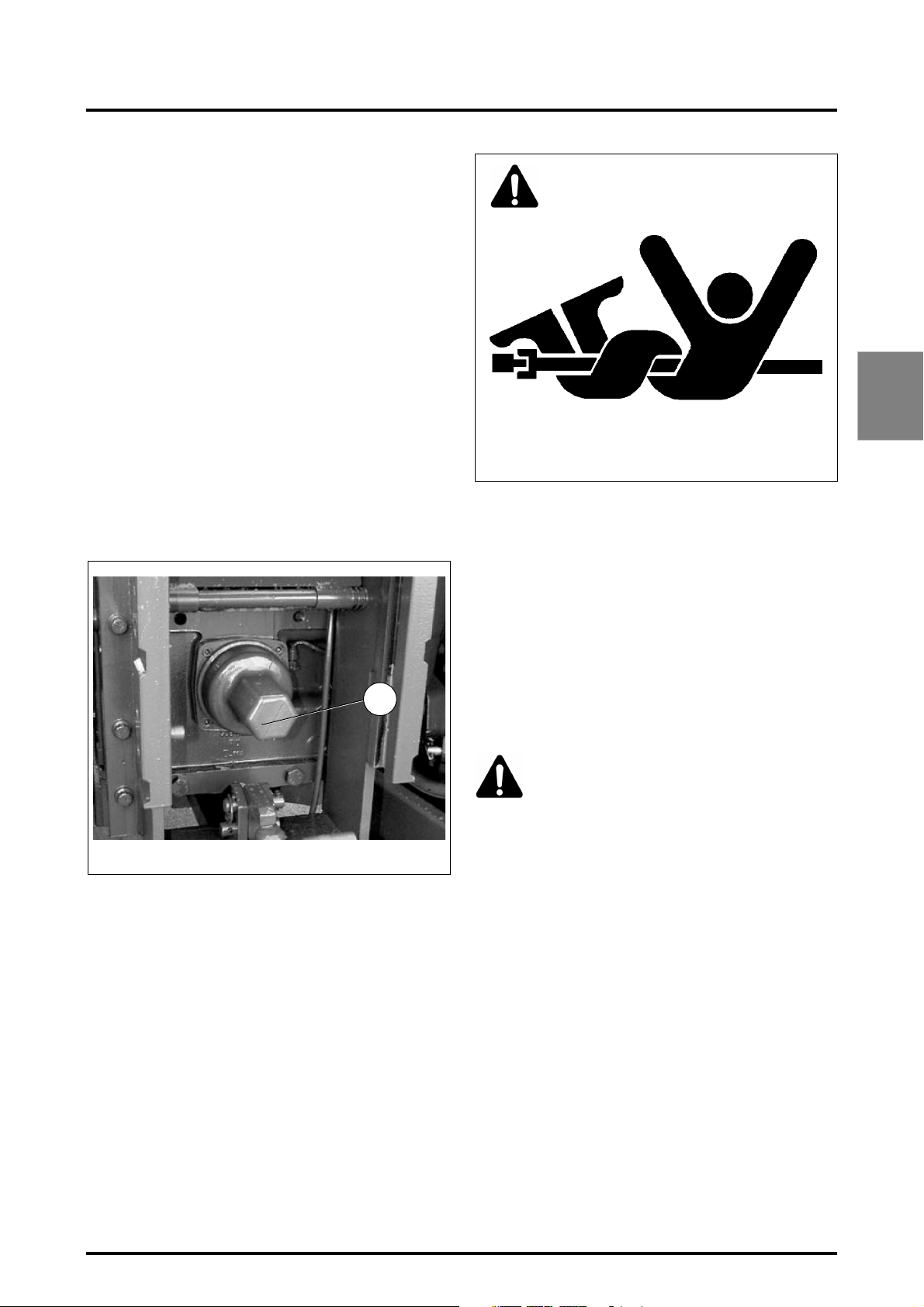

2.17.7 - Other risks

• Ensure that the PTO shield (1) is in place when the PTO

driveline is not in use (Fig. 14).

1

Z2-540-05-03

• Before attaching, detaching, cleaning or adjusting PTO

driven implements, disengage the PTO, stop the

engine, remove the ignition key, and make sure that the

PTO transmission shaft has stopped.

• Ensure that all the PTO transmission shaft guards and

shields are in place and check the presence of all safety

decals (Fig. 15).

Fig. 14

• Be sure everyone is clear of your machine before engaging the PTO. For stationary PTO operation, always place

transmission control lever in neutral, engage parking

brake, and chock both tractor and implement wheels.

• When operating mobile PTO driven equipment, DO

NOT leave the tractor seat until the PTO drive is disengaged, the transmission is in neutral, the parking brake

is engaged, the engine shut off and the ignition key

removed.

• DO NOT use PTO adapters, reducers or extensions as

they extend the PTO coupler and universal joint out

beyond the protection offered by the PTO shield.

• The deployment of drawbars and lift rods must not

allow the threads to show.

DANGER: DO NOT attempt to unplug the

hydraulic connections, or adjust an implement with the engine running or the PTO

drive in operation. To do so may result in seri-

ous injury or death.

• When using chemicals, carefully follow the chemical

manufacturer’s instructions for use, storage and disposal. Also follow the chemical application equipment

manufacturer’s instructions.

• When operating under poor visibility conditions, or in the

dark, use your tractor work headlights and reduce your

ground speed (DO NOT use your work headlights when

travelling on a roadway because rear pointed white

lights are illegal except when reversing and may confuse following drivers).

• Operate your tractor with tyres of suitable width, consistent with the particular task you are performing. To

adjust tyre width, see chapter Maintenance and Adjustments.

• Reduce your speed when operating over rough or slippery ground and when foliage restricts your view of hazards.

• DO NOT make sharp turns at high speed.

Challenger MT500B EU

2.15

Page 26

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.17.8 - Implements and attachments

WARNING: A front-end loader (bucket or

forks) must be equipped with a suitable holding device to prevent the load (bales, fence

posts, rolls of fence, wire etc.) from rolling

down the lift arms into the driver’s compartment and

crushing the driver when the loader is raised. Inadequately secured objects could also fall and injure

bystanders.

• Three-point hitch and side mounted implements make a

much larger arc when turning than towed equipment-.

Make certain to maintain sufficient clearance for turning.

Use only manufacturer approved equipment.

• When using attachments or implements with the trac-

tor, be sure to read and understand the instructions in

the Operator Instruction Book for that attachment or

implement and follow its safety instructions. Use only

manufacturer approved attachments and implements.

• DO NOT overload a towed attachment or equipment.

Use proper counterweights to maintain tractor stability.

Hitch loads to the drawbar only.

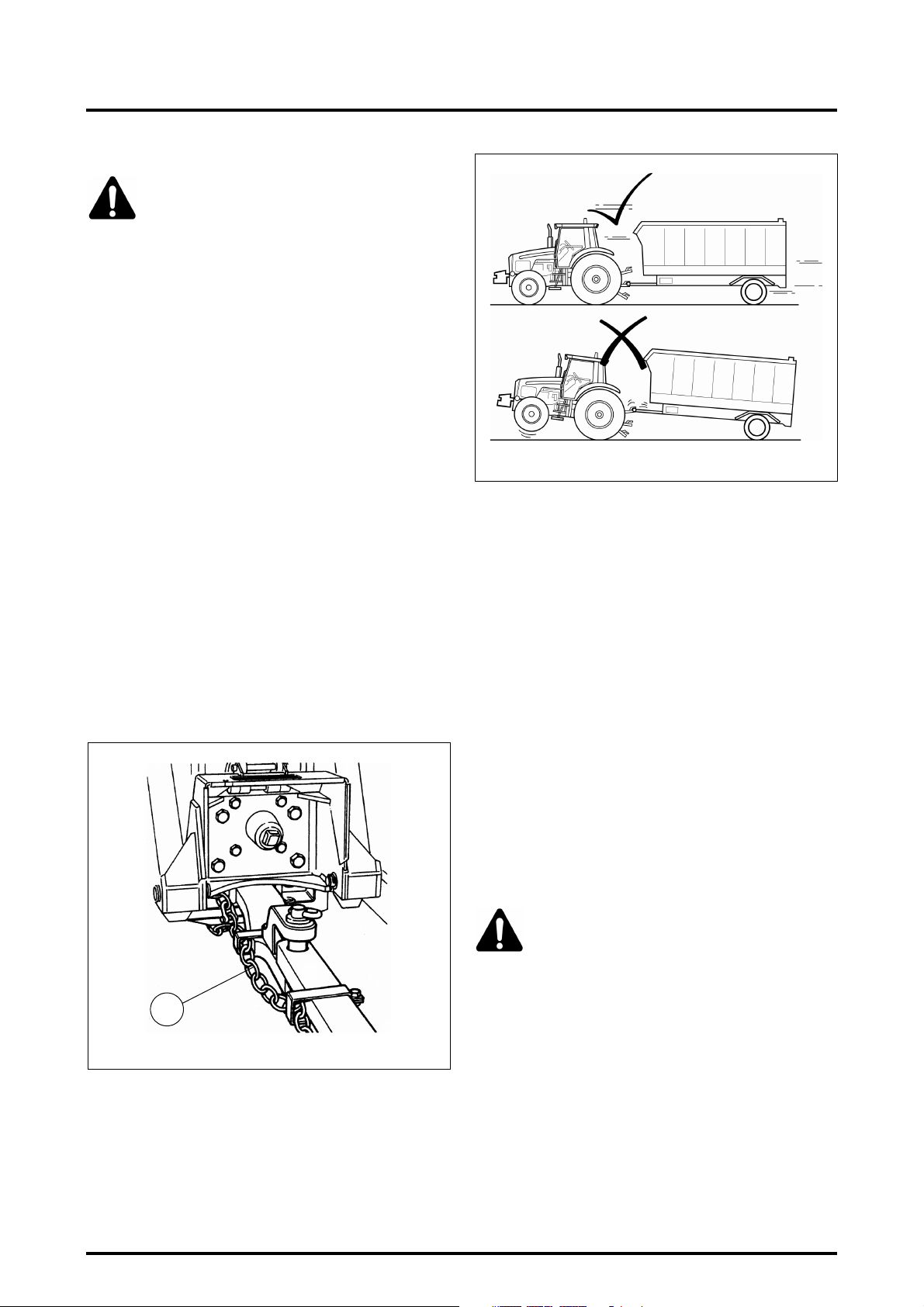

• A transport chain (1) will help control drawn equipment

should it be accidentally separated from the drawbar

while transporting. Using the appropriate adapter parts,

attach the chain to the tractor’s safety chain anchor or

any other specified anchor point. Provide only enough

slack in the chain to permit turning. Contact your dealer

for a chain of equal or greater strength than the weight

of the trailed implement (Fig. 16).

• Ensure that all trailed implements are fitted with a

safety chain linking the tractor to the implement, if

required by law (Fig. 16).

Z2-543-05-03

2.17.8.1 - Safety measures when towing

• For towed equipment WITHOUT brakes, DO NOT tow

equipment:

- at speeds over 32 kph (20 mph), or

- when, fully loaded, its weight exceeds 1t5 (3,300 lb)

and is 1.5 times heavier than the tractor.

• For towed equipment WITH BRAKES, DO NOT tow

equipment:

- at speeds over 40 kph (25 mph), or

- when, fully loaded, its weight exceeds 4.5 times the

weight of the tractor.

NOTE: The tractor requires correct trailer braking system installed and connected to the equipment.

Fig. 17

1

Z2-542-05-03

Fig. 16

• Pull only from the approved drawbars. Towing or attaching to other locations may cause the tractor to overturn

(Fig. 17).

Stopping distance increases with speed and weight of

towed loads, and on hills and slopes. Towed loads with or

without brakes that are too heavy for the tractor or are

towed too fast can cause loss of control. Consider the total

weight of the equipment and its load.

2.17.9 - Tractor Towing

WARNING: Towing: the following instructions must be followed when towing:

If the engine is not running:

• Maximum towing speed: 10 kph.

• Maximum towing distance: 8 km.

If the engine is running:

• Towing speed is identical to that of a trailer without

brakes at the speed authorised by legislation in force in

the country concerned.

2.16

Challenger MT500B EU

Page 27

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.17.10 - Road use

Take the following precautions before using the tractor on

a public road.

• Respect national laws and local regulations in force

relating to tractor use.

• Lock the brake pedals together.

• Place all implements in transport position and lock.

• Place all implements into their narrowest transport configuration.

• Disengage the PTO and differential lock.

• Make sure any required clearance flags or hazard warning lights are in place and in working order.

• Clean off all reflectors and road lights, front and rear,

and be certain they are in working order.

• Ensure that the tractor and equipment are fitted with

emergency warning triangles and other markings recommended to improve visibility when driving on roads,

unless otherwise indicated (Fig. 18).

• Beware of blind intersections. Slow down until you have

a clear view.

• DO NOT attempt to pass at any intersection.

• Slow down for turns and curves.

• Make wide, gentle turns.

• Signal your intent to slow, stop or turn.

• Shift to a lower gear before going up or down hills.

• Keep tractor in gear. Do not coast with the clutch disengaged or transmission in neutral.

• Stay out of the path of oncoming traffic.

• Drive in your correct lane keeping as near to the curb as

possible.

• If traffic builds up behind you, pull off the road and let it

go by.

• Drive carefully. Anticipate what other drivers might do.

• When towing a load, start braking sooner than normal

and slow down gradually.

• Watch out for overhead obstructions.

• Make sure load does not obscure hazard warning or

transport lights.

2.18 - SAFETY - AFTER OPERATION

Whenever stopping, bring the tractor to a complete halt,

apply the parking brake, disengage the PTO, place the

PowerShuttle lever in neutral position, lower the implement to the ground, stop the engine and remove the ignition key BEFORE leaving the seat.

2

Z2-544-05-03

Fig. 18

2.17.11 - Highway code

When operating your tractor on a public road the following

precautions must be taken.

WARNING: NEVER allow any persons to ride

on the tractor or on the towed equipment.

• Know the road you are going to travel.

• Turn on flashing warning lights when travelling on roads,

day or night, unless prohibited by law.

• Take care when towing a load at transport speeds,

especially if the towed equipment is NOT fitted with

brakes.

• Observe all local or national regulations regarding the

road speed of your tractor.

• Use extreme caution when transporting on snow-covered or slippery roads.

• Wait for traffic to clear before entering a public road.

DANGER: PowerShuttle control: Before leaving the seat it is mandatory to move the PowerShuttle control to NEUTRAL position.

Remove ignition key if the tractor is to be left

unattended.

IMPORTANT: Electromechanic ParkLock control: Move

lever to locked position (symbol: closed padlock) to

engage ParkLock before stopping the engine.

Challenger MT500B EU

2.17

Page 28

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

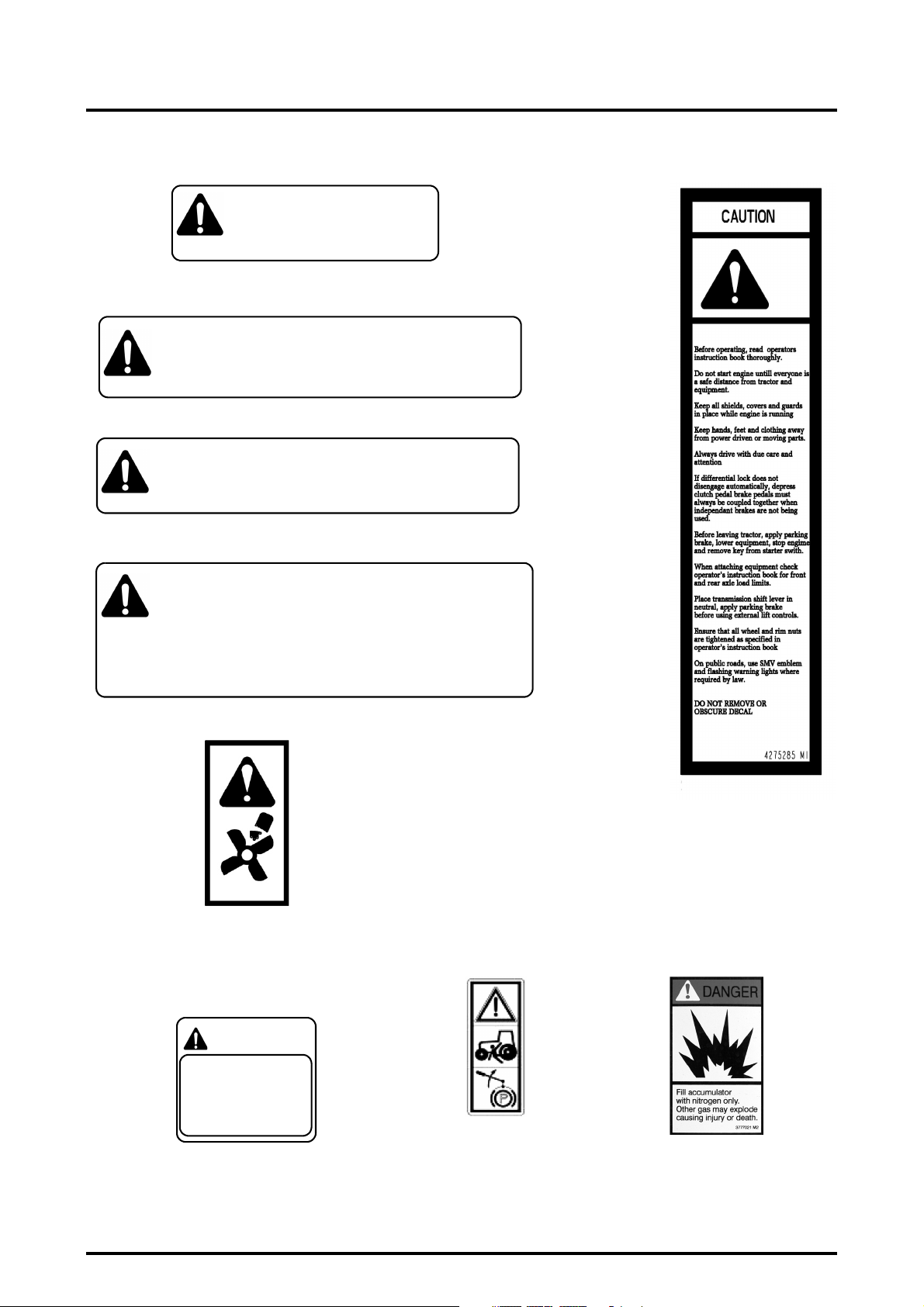

2.19 - DESCRIPTION OF DECALS

High pressure steam and hot water.

Remove cap carefully.

CAUTION

DO NOT REMOVE OR OBSCURE DECAL

3596029 M1

Located on top of the bonnet (access to

radiator cap)

CAUTION

Disconnect the negative cables from

all batteries before starting work on

the tractor.

CAUTION

Before removing a battery, disconnect the negative cables before the

positive cables.

DO NOT REMOVE OR OBSCURE DECAL

Located on the battery cover

Keep all shields, covers and guards fastened

in place while engine is running.

WARNING

CAUTION

Beware hot parts.

DO NOT REMOVE OR OBSCURE DECAL

Located on the right- and left-hand sides of the bonnet

CAUTION

Always disengage the PTO and stop the

engine before attaching or detaching a

PTO shaft or before working on an implement towed by the PTO. Always fit

the PTO guard when the PTO is not in

use.

Do not stand between tractor and equipment when operating controls.

Tow only with MF approved tractor drawbar or hitch.

WARNING

3596045 M1

3596037 M1

Located at the rear of the tractor

4271915M1

Located to the left

and right of the

radiator

CAUTION

TO AVOID POSSIBLE TRACTOR OVERTURN, TOW ONLY

FROM THE DRAWBAR OR

LOWER LINKS OF THREE

POINT HITCH.

539613 M1

Located on the

fenders to the rear of

the cab

DO NOT REMOVE OR OBSCURE DECAL

3581564 M1

3782489 M1

Located on the RH

inner column of the

cab

Located on the RH

inner column of the cab

3777021M2

Located on the accumulator

2.18

Challenger MT500B EU

Page 29

2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

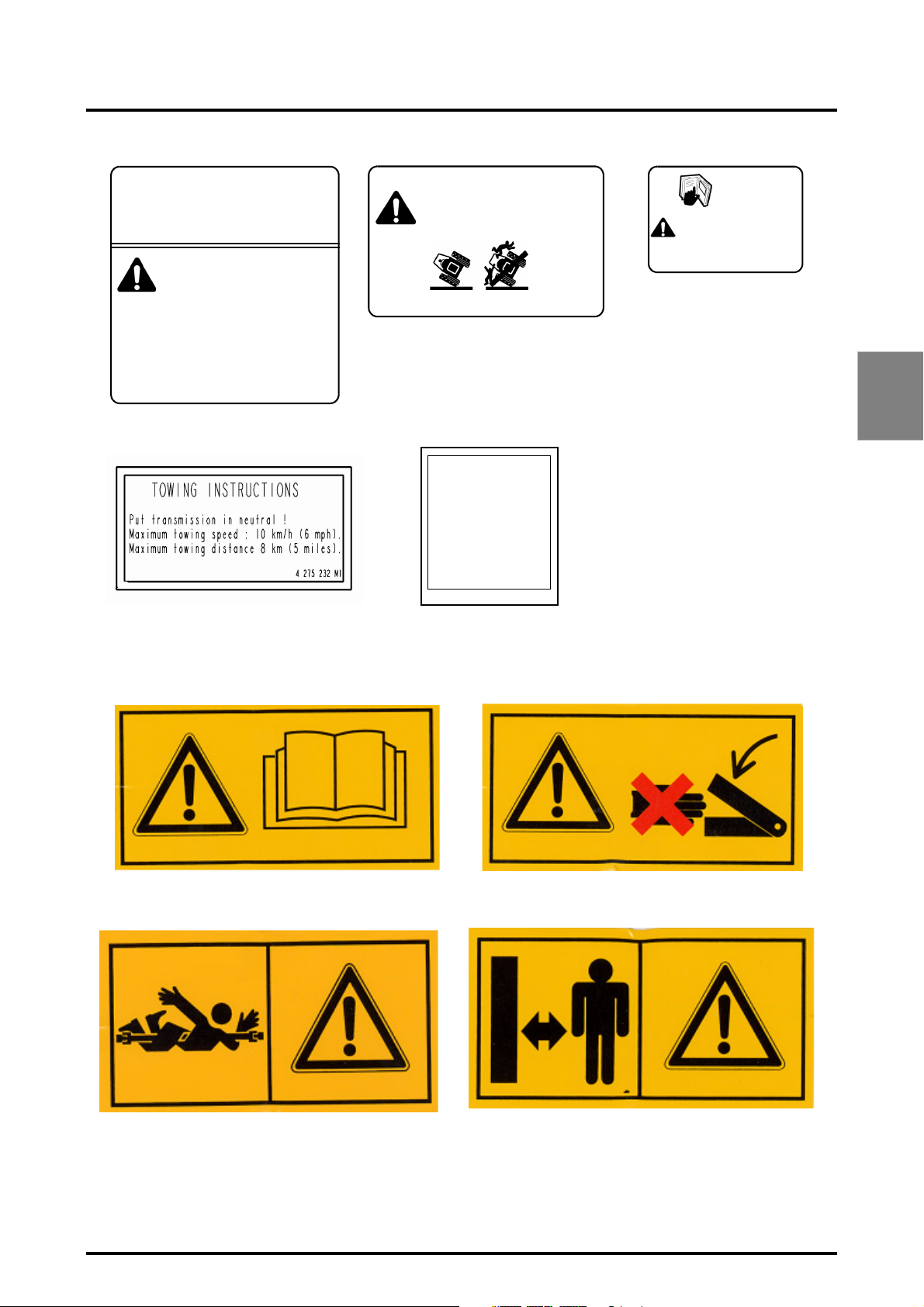

CAUTION

Before working on the tractor or removing this cover, disconnect negative cables to all batteries.

WARNING

Do not short across starter terminals to

start engine.

Only start the tractor when sat in the

seat.

Start engine only with ignition key, ensuring that transmission and PTO are in neutral with handbrake applied.

DO NOT REMOVE OR OBSCURE DECAL

3596467 M1

Located on the starter motor

Located on the inner side of the right-

hand door

WARNING

If tractor is overturning, hold onto the steering wheel.

Do not leave seat.

DO NOT REMOVE OR OBSCURE DECAL

3580313 M1

Located at the rear of the passenger seat

Do not stop the

engine while the

tractor is running.

3783395M1

Located on the inner side of the right-

hand door

IT IS IMPERATIVE TO USE

THE TRANSMISSION OIL

RECOMMENDED IN THE OPERATOR INSTRUCTION

BOOK.

3713698 M1

Located on the fenders

to the rear of the cab

2

Front linkage decals and front PTO decals

WARNING: Read the Operator Instruction Book

before starting work.

DANGER: Keep a safe distance from the rotating

PTO.

DANGER: Avoid being caught by moving parts

DANGER: Keep a safe distance from moving parts.

DANGER:

Challenger MT500B EU

2.19

Page 30

Page 31

3 . INSTRUMENTS AND CONTROLS

Chapter 3

3

INSTRUMENTS AND CONTROLS

Challenger MT500B EU

3.1

Page 32

Page 33

3 . INSTRUMENTS AND CONTROLS

CONTENTS

3.1 - INSTRUMENT PANEL (FIG. 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.5

3.2 - INDICATOR LIGHTS PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.8

3.2.1 Control indicator lights for functions in use (Fig. 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.8

3.2.2 Failure and parking brake control indicator lights (Fig. 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.8

3.3 - CONTROL DISPLAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.9

3.4 - DOT MATRIX SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.10

3.5 - PEDALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.10

3.6 - RIGHT-HAND CONSOLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.11

3.7 - LEFT-HAND CONSOLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.13

3.8 - SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.13

3.8.1 Description (Fig. 19). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.13

3.8.2 Operation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.14

3.9 - STEERING WHEEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.15

3

3.10 - UPPER CONSOLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.16

3.10.1 Air conditioning system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.17

3.10.2 Manual air conditioning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.17

3.10.3 Automatic air conditioning system (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.17

3.11 - SUN VISOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.19

3.12 - ROOF HATCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.19

3.13 - BODY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.20

Challenger MT500B EU

3.3

Page 34

3 . INSTRUMENTS AND CONTROLS

3.4

Challenger MT500B EU

Page 35

3 . INSTRUMENTS AND CONTROLS

.

INSTRUMENT PANEL

8

5

3

2

3

9

6

7

Z3A-1500-11-04

3.1 - INSTRUMENT PANEL (FIG. 1)

1. Start switch (see details in Fig. 3).

2. Control unit (see details in Fig. 4).

This assembly is comprised of the steering change,

windscreen wiper, front and rear windscreen washer

and horn indicator functions.

3. Steering wheel adjustment (see details in Fig. 23).

4. DOT MATRIX controls (see details in Fig. 10).

5. Parameter display selector (Ref. 21, Fig. 2).

6. Main light switch.

7. Hazard warning lights and control switch.

8. Direction of travel and PowerShuttle control lever.

9. Electromechanical brake control (ParkLock).

4

1

Fig. 1

Challenger MT500B EU

3.5

Page 36

3 . INSTRUMENTS AND CONTROLS

2

INSTRUMENT PANEL

19

AUTO

AUTO

21

Z3A-993-08-04

17

15

14

1

10

5

0

S

1

..

..

v

S

2

.

.

v

.

.

12

RPM x 100

10

15

20

25

11

18

2

540

750

100 0

13

AAB

AAB

KPH

KPH

MPH

MPH

RPM

RPM

20

21

16

Fig. 2

3

2

1

Z2-005

4

5

Fig. 3

Start switch details (Fig. 3):

1. Stop.

2. Contact position for electrical equipment to be

used when the engine is not running.

3. Contact position for electrical equipment used

when the engine is running.

4. Preheating (wait for instrument panel indicator

lights to switch off)

5. Start.

NOTE: The tractor runs with the key in position (3); to

fully disconnect all electrical equipment, the key must

be moved back through the accessory position (2) to

the stop position (1).

Legend:

1. Windscreen wiper

-0. Stop

- J. Intermittent

- I. Speed 1

- II. Speed 2

2. Left-hand direction indicator

3. Right-hand direction indicator

4. Horn

5. Headlights flash

6. Headlights

7. Rear and front windscreen washer

1

5

3

Z2-18 7-B

2

7

4

6

Fig. 4

3.6

Challenger MT500B EU

Page 37

Instrument panel (Fig. 2)

10. Tachometer.

The tachometer shows the engine speed in hundreds

of revolutions per minute.

11. Fuel gauge.

12. Engine coolant temperature gauge.

Stop the engine if the needle moves into the red zone.

13. Right-hand direction indicator light (green).

14. Left-hand direction indicator light (green).

15. Failure control indicator lights panel.

See details (Fig. 7)

16. Headlight indicator light (blue).

17. Direction indicator light for the first trailer (green).

18. Direction indicator light for the second trailer (green).

19. Control indicator lights for functions in use (see

details in Fig. 5).

20. Failure and parking brake control indicator lights (see

details in Fig. 6).

If one of the indicator lights remains lit after the engine

has started or during normal use, stop the engine and

investigate the cause of the problem.

21. Digital display

Displays the speed engaged (forward / reverse), A/B

memory (electronic injection engine), Hare / Tortoise

range.

22. DOT MATRIX screen (see details in Fig. 10).

3 . INSTRUMENTS AND CONTROLS

3

Challenger MT500B EU

3.7

Page 38

3 . INSTRUMENTS AND CONTROLS

3.2 - INDICATOR LIGHTS PANEL

3.2.1 - Control indicator lights for functions in

use (Fig. 5)

Green and orange control indicator lights display and monitor the functioning of attachments and implements.

1. Front power take-off (yellow).

Z3A-1139-10-04

21

3 4

2. Not used

3. High pressure transmission oil filter clogging indicator

light (yellow).

4. 4WD engaged indicator light (green).

5. Differential lock indicator light (yellow).

6. Power take-off engaged (yellow).

5

6

Fig. 5

3.2.2 - Failure and parking brake control indicator lights (Fig. 6)

Red control indicator lights signal problems of varying importance. They light up when the ignition key is turned in

the start switch and usually go out once the engine is running.

Z3A-1140-10-04

87

9 10

If they light up when the engine is running normally,

stop the engine at once and investigate the cause of the

problem.

7. Auxiliary hydraulics oil temperature indicator light

(red).

8. 15 micron auxiliary hydraulics oil filter clogging indicator light (yellow).

11 12

Fig. 6

9. Parking brake indicator light (red)

10. Grid heater indicator light (red).

11. Inlet air temperature indicator light (red).

This indicator light is switched on when the ignition

key is in "auxiliary" position. It switches off when the

engine starts running. If the indicator light comes on

3.8

when the engine is running, stop the engine and investigate the cause of the problem immediately.

12. Air filter clogging indicator light (yellow).

Challenger MT500B EU

Page 39

Failure control indicator lights

3 . INSTRUMENTS AND CONTROLS

13

Z3A-1138-10-04

14

15 16

17 18

Fig. 7

13. Trailer air brake pressure indicator light (if fitted) (red).

14. Engine oil pressure indicator light (red).

This indicator light is switched on when the ignition

key is in "auxiliary" position. It switches off when the

engine starts running. If the indicator light comes on

when the engine is running, stop the engine and investigate the cause of the problem immediately.

Check for low oil level or consult your dealer.

15. Coolant temperature indicator light (red).

16. Auxiliary hydraulics oil pressure indicator light (red).

If this indicator light comes on when the engine is running, check

auxiliary hydraulics oil

the

(see chapter 4 - Using the DOT MATRIX). If this indicator light

stays on, consult your dealer.

17. Gearbox oil pressure indicator light (red).

If this warning light illuminates during operation, consult your agent or dealer.

18. Alternator charge indicator light (red).

level on the DOT MATRIX screen

6

A

1000

540

ECO

Z3A-1137-12-04a

5

1

7

A

2

B

KPH

RPM

8

RPM

KPH

MPH

4

RPM

3

Fig. 8

3

5

3.3 - CONTROL DISPLAY

Fig. 8 - This control screen allows the different parameter

displays to be monitored:

1. Forward / neutral / reverse liquid crystal display.

2. Reverse shuttle sensitivity indicator.

3. Selected symbol display: rear PTO/engine speed/forward ground speed:

All parameters that can be displayed in the lower part

of the screen can be selected by pressing button 5

(Fig. 9) located on the instrument panel.

4. Digital display: rear PTO speed, engine speed, ground

speed, hours worked.

NOTE: To reinitialise hours worked, select the relevant

parameter and hold the switch 5 (Fig. 8) down for

approximately 5 seconds to reset the display.

5. Power take-off automation.

6. Front axle automatic control.

7. A/B speed (engine with electronic fuel injection) memorisation status.

8. Hare / Tortoise range engagement indicator lights.

Z3A-1511-11-04

Fig. 9

Challenger MT500B EU

3.9

Page 40

3 . INSTRUMENTS AND CONTROLS

3.4 - DOT MATRIX SCREEN

Fig. 10 - This control screen allows the different parameter

displays to be monitored:

1. Programmed engine speed A

2. Programmed engine speed B

3. Programmed engine speed indicator

4. Engine underspeed supervisor

5. Forward shuttle speed value display

6. Reverse shuttle speed value display

7. Mode display (pedal, lever, etc.)

8. Selected mode speed display

9. SV1 speed regulator display

10. SV2 speed regulator display

11. Control unit to access DOT MATRIX menus

12. Up scrolling key

13. Down scrolling key

14. Left-hand adjustment key

15. Right-hand adjustment key

16. Validation key

17. Cancel key

1

2

1055 800

3.5 - PEDALS

(Fig. 11)

1. Clutch pedal.

This is fitted with a safety start switch. Fully depress

the clutch pedal before operating the ignition key.

NOTE: Do not keep the clutch pedal pressed fully or half

down.

2. Brake pedals.

The two brake pedals can either be used separately or

locked together using latch 3.

3. Brake pedals locking latch.

4. Foot throttle.

Use of the foot throttle enables a momentary increase

in the engine speed set by the hand throttle lever.

CAUTION: When travelling on the road only

the foot throttle should be used, and the hand

throttle lever should be brought to the idle

position so that engine braking can be opera-

tional.

Check that A/B memorised speed is not activated.

4

AUTO

3

A/B

Z2-602-05-03-A

3.2

0.2

12

14

S

v

S

v

1

2

9

35.0

10

3.2

7

3

8

1

2

4

5

6

25.3

Z2-410-05-03-A

11

16

15

Fig. 11

Z2-409-05-03

3.10

17

13

Fig. 10

Challenger MT500B EU

Page 41

3 . INSTRUMENTS AND CONTROLS

5

CE -001- 01-05

14

10

13

29

30

12

11

15

16

20

19

18

17

3

7

6

8

4

3

2

1

23

23

9

22

21

24

25

Z2-478-05-03

3.6 - RIGHT-HAND CONSOLE

1. Hand throttle lever

2. Engine underspeed supervisor

3. Lever or pedal mode button

4. Hare / Tortoise range button

5. SV1 speed regulator display knob

6. SV2 speed regulator display knob

7. Electronic linkage controls

8. First Auxiliary Spool valve lever

9. Second Auxiliary Spool valve lever

10. Third Auxiliary Spool valve lever

11. 4WD switch

12. Differential lock switch

13. A/B speed switch

14. +/- engine speed switch after selecting A/B speed

15. Suspended front axle switch

28

26

16. Cab suspension switch

17. Neutral PTO switch

18. 540 rpm PTO control button

19. 540E (Economy) PTO control switch.

20. 1000 rpm PTO control switch

21. 540/540E Economy or 1000 rpm rear PTO ON/OFF

22. Rear power take-off selector switch in automatic mode

23. Multi-function armrest

24. Hydraulic spool valve control Joystick (optional)

25. Height / depth setting knob

26. Lift / Lower selector switch with “neutral” position

27. SV1 speed regulator control knob

28. SV2 speed regulator control knob

29. Spool valve hydraulic flow rate memory or cancel but-

27

31

switch

ton.

Fig. 12

Challenger MT500B EU

3.11

Page 42

3 . INSTRUMENTS AND CONTROLS

30. Spool valve control ON/OFF button.

31. Quick soil engagement button

32. Datatronic 2 onboard computer.

32

Z2-614-07-03

33. Datatronic 3 onboard computer.

Fig. 13

Adjusting the clock: to change the time press buttons B or C to select the information (hr or min.) to

be changed.

Temperature control: Press button A to select the

outside temperature display. To change from °Celsius to °Fahrenheit press button A for approximately 5 seconds.

Z2-413-05-03

7

A

B

4

34

Z3A-743-07-04

5

1

2

C

6

3

Fig. 15

33

Z3A-772-07-04

34. Work headlights / digital clock / temperature sensor

control and indicator lights

Work headlights: Press the key(s) 1 to 6 (Fig. 15) to

operate de desired function(s). The corresponding indicator light will come on:

1. Front work headlights

2. Work headlights on footsteps and handrails

3. Work headlights on fenders

4. Work headlights on front of roof

5. Flashing beacon (optional).

6. Work headlights at rear of roof

7. Digital clock and temperature sensor:

Press button A to select and change the time or

temperature display.

Fig. 14

35. Power socket for connection of accessories (Fig. 16).

Maximum available power 12 volts

15/30 - + Permanently live (25 A).

82 - + Only live with ignition key ON (5 A).

31 "-" negative.

3.12

Challenger MT500B EU

Page 43

3 . INSTRUMENTS AND CONTROLS

35

37

36

Z2-415-05-03

36. Diagnostics connector.

37. Cigar lighter.

Fig. 16

3.7 - LEFT-HAND CONSOLE

(Fig. 17, Fig. 18)

38. Cigarette lighter type connector.

39. Electrical control for external rear-view mirrors

(optional).

40. Rear windscreen wiper.

41. Rear view mirror defrosting control (optional).

X3 A-2 010-10 -0 4

3.8 - SEAT

MT-0101103

42

44

43

Z2-417-05-03

Fig. 18

3

6

7

9

40

39

38

Z2-613-05-03

42. Passenger seat (optional).

43. Storage compartment.

44. Can carrier.

41

Fig. 17

3

1011

3.8.1 - Description (Fig. 19)

1. Weight adjustment

2. Height adjustment

3. Fore / aft adjustment

4. Backrest angle adjustment

5. Swivel adjustment

6. Adjustable backrest extension

7. Lumbar support adjustment

8. Fore / aft isolator control

9. Armrest angle adjustment

10. Seat pan angle adjustment

11. Seat depth adjustment

4

5

1

2

8

Fig. 19

Challenger MT500B EU

3.13

Page 44

3 . INSTRUMENTS AND CONTROLS

3.8.2 - Operation:

WARNING: Never adjust seat when tractor is

moving.

1.Weight adjustment:

Automatic pneumatic seat

The seat is adjusted for the driver's weight by briefly

pulling the weight and seat height automatic actuator

lever (1) while the driver is sitting on the seat.

Semi-automatic pneumatic seat

The seat should be adjusted for the driver’s weight

with the driver sitting on the seat. The adjustment is

made by pulling out or pushing in the actuator lever (1)

until the green mark is visible in the weight-and-height

indicator (10).

Manual adjustment seat

The seat should be adjusted when the driver is not

seated by turning the actuator lever (or adjustment

thumb wheel) provided for this purpose. The indicator

displays the weight which has been set

NOTE: To prevent damage to the health, the setting for

the driver's weight must be checked and adjusted as

necessary before the vehicle is driven.

2. Height adjustment:

Automatic pneumatic seat

The seat height can be set automatically and continu-

ously.

The seat height can be altered by either pulling out or

pushing in the actuator lever of the automatic weight

and height actuator lever (ref. 2). If the adjustment

reaches the top or bottom endstop, the height is

adjusted automatically in order to guarantee a minimum spring travel.

8. Fore/aft isolator:

Under certain driving conditions (for example with a

trailer attached), it is useful to activate the fore / aft isolator. This means that shock impacts in the driving

direction can be better absorbed by the driver seat:

- Position 1 = fore / aft isolator on

- Position 2 = fore / aft isolator off.

9. Armrest angle adjustment:

The armrests can be folded up if required and the

height individually adjusted.

To adjust the armrest height (arrows) the plastic cover

must be removed by pressing together the inner clips

and pulling off the cover at the same time.

The cover is refitted in the same way in reverse order.

2

1

8

MT-0281103

v721a

NOTE: In order to avoid damage, do not operate compressor for more than 1 minute.

Manual adjustment seat

The seat height can be set automatically and is adjusta-

ble in several steps. The seat can be raised as required

until it clicks into position. If the seat is raised higher

than the last notch (end of travel), it returns to its lowest position.

3. Fore / aft adjustment:

The locking lever must latch into the desired position.

It should not be possible to move the driver seat into

another position when it is locked.

4. Backrest angle adjustment.

5. Swivel adjustment:

Pull the lever until you feel resistance which allows

you to turn the seat 20° to the left and 10° to the right.

Lockable every 10°.

If you pull more strongly to overcome the resistance

the swivel is unlocked and you can turn freely. For

locking push back lever again.

The locking lever must latch audibly into place. The