Challenger MT315B, MT325B, MT335B, MT345B, MT445B User Manual

...

SPECIALTY WHEEL TRACTORS

SPECIALTY WHEEL TRACTORS

We’re up to

The Challenge

SPECIALTY SERIES

45 TO 240 PTO HP

Serious Machinery

for serious applications

Governmental and industrial applications call for

one tough machine... whether the job is mowing

roadside ditches, powering a broom or towing a

scraper. Fortunately, Challenger

line of wheel tractors that are up to the challenge.

Choose from more than 20 different specialized

models that range from 45 to 240 PTO horsepower.

Select a special “BRU” or “BRM” model that

integrates a customized MT400B or MT500B

Series tractor with a Little & Company mower for

a complete brush control system. Or pick a highhorsepower MT665B model with an all-inclusive

scraper package. Take your machine to the next

level, with innovative options like a municipal cab

and puncture-resistant Michelin, Nokia or Trelleborg

tires on roadside mowing models.

2

®

offers a special

Single-Point Support

If your company or agency owns or leases

®

Caterpillar

commands more respect for its integrity, in-field

service and parts support than the Cat

network. The same philosophy applies to

Challenger equipment, thanks to a partnership

between AGCO Corporation and Caterpillar.

It all began in March 2002, when AGCO

Corporation acquired the highly respected

Challenger line of track tractors from Caterpillar Inc.

and began expanding it into a full line of serious

equipment. Today, the Challenger brand includes a

complete line of wheel and track tractors from 23

to 570 engine horsepower, as well as a family of

hay equipment and combines.

Your Cat dealer now offers a single point of

contact for all your equipment needs, no matter

the application. And that translates into less

downtime and greater productivity.

equipment, you know that nobody

®

dealer

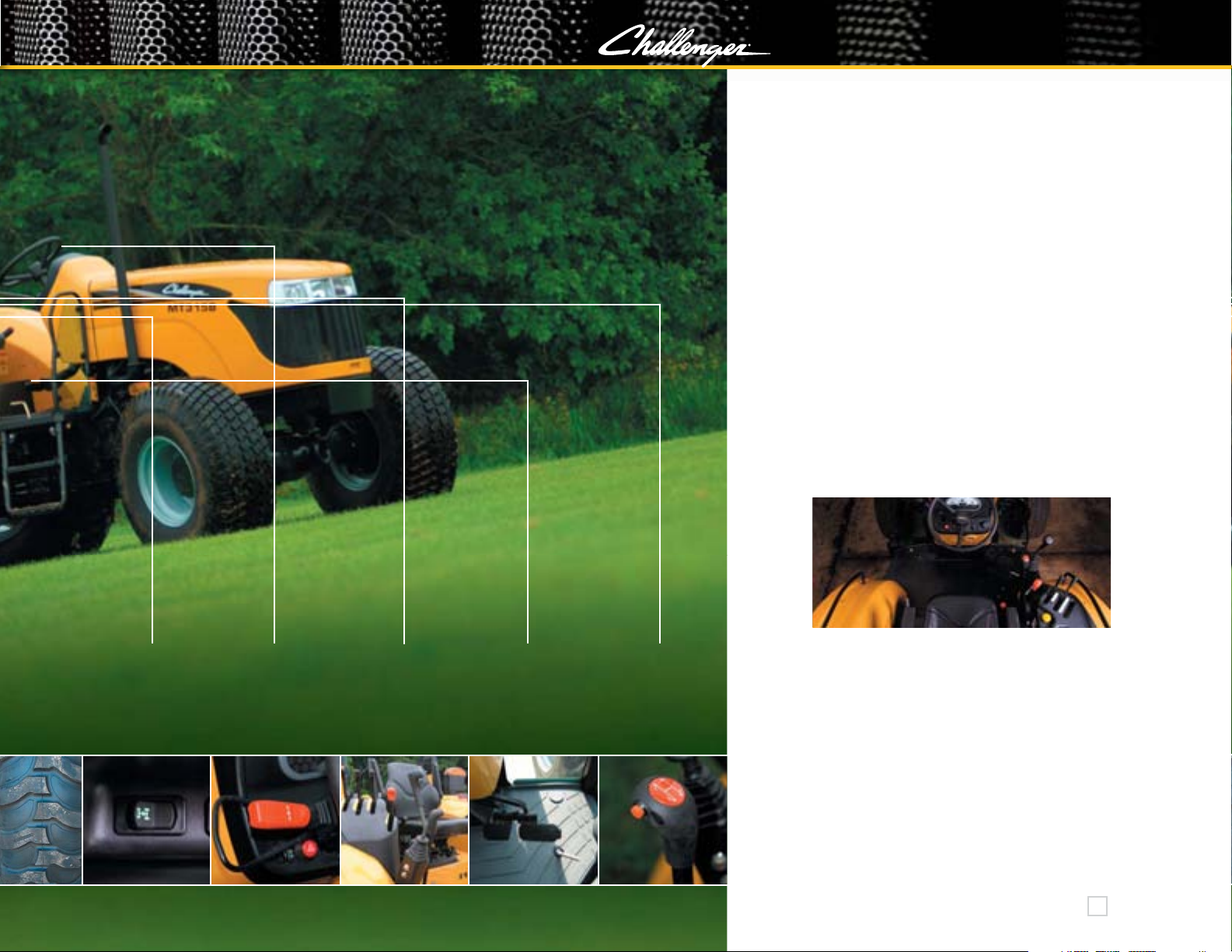

Electro-hydraulically

actuated differential

lock offers on-the-go

engagement for maximum

productivity.

Category I/II 3-point

hitch and SAE swinging

drawbar offers compatibility

with all implements.

Hitch Valves Ag Tires “Turf” TiresDifferential Lock Switch

The 15-8 total gpm (60 lpm)

hydraulic system with two

standard valves provides

outstanding flow for loaders

and towed implements.

A wide variety of wheels

and tires, including R4

industrial and low-pressure

“turf” tires, let you match

the MT300B Series to

the job.

SPECIALTY WHEEL TRACTORS

MT300B

light utility tractors

New to the Challenger line-up, the MT300B Series is a true

middleweight champ that can handle highway mowing and loader work

with equal ease. Available in four horsepower ranges, the MT300B

tractors are powered by a powerful 3.3-liter, 3-cylinder diesel engine

that is also turbocharged for maximum performance and fuel efficiency.

Adaptable Transmission

Despite its compact, maneuverable size, the MT300B comes

with a standard 12FX12R shuttle transmission for an equal

number of gears in both forward and reverse. Reverse speeds are

15 percent slower than forward speeds for shorter cycle times and

increased productivity.

Four-wheel braking on

all-wheel-drive models

activates at speeds greater

than 8.5 mph, a feature

normally only available on

larger tractors.

R4 Tires 4-Wheel Drive Switch Shuttle Lever GearshiftBrake PedalsJoystick

Power shuttle allows

even smoother shifting and

the ability to Shift forward

and reverse without the use

of a clutch pedal.

Optional factory installed

hydraulic joystick and two

mid-mounted valves offer

integrated ergonomics and

superb loader control.

Hydraulically actuated,

oil-cooled multi-disc brakes

provide optimum efficiency

and safety, yet require

minimal maintenance.

The Power Shuttle

transmission provides the

added convenience of

a push-button gearshift

without the use of the clutch

pedal. (Push, shift and go.)

Whether you choose the comfortable, open platform, or the roomy, ergonomic

cab, the MT300B Series offers the kind of operator comfort that results in

greater productivity.

Responsive PTO

Although a 540 rpm PTO is standard on all MT300B models, those

who use this versatile tractor for mowing and PTO applications

might want to consider the optional 540/540E PTO. In light-duty

applications, this economy minded option allows the operator to

attain rated 540 rpm PTO speed at only 1,648 engine rpm. You’ll not

only save on fuel costs, but minimize operator fatigue and improve

productivity by reducing noise levels.

We’re up to

The Challenge

3

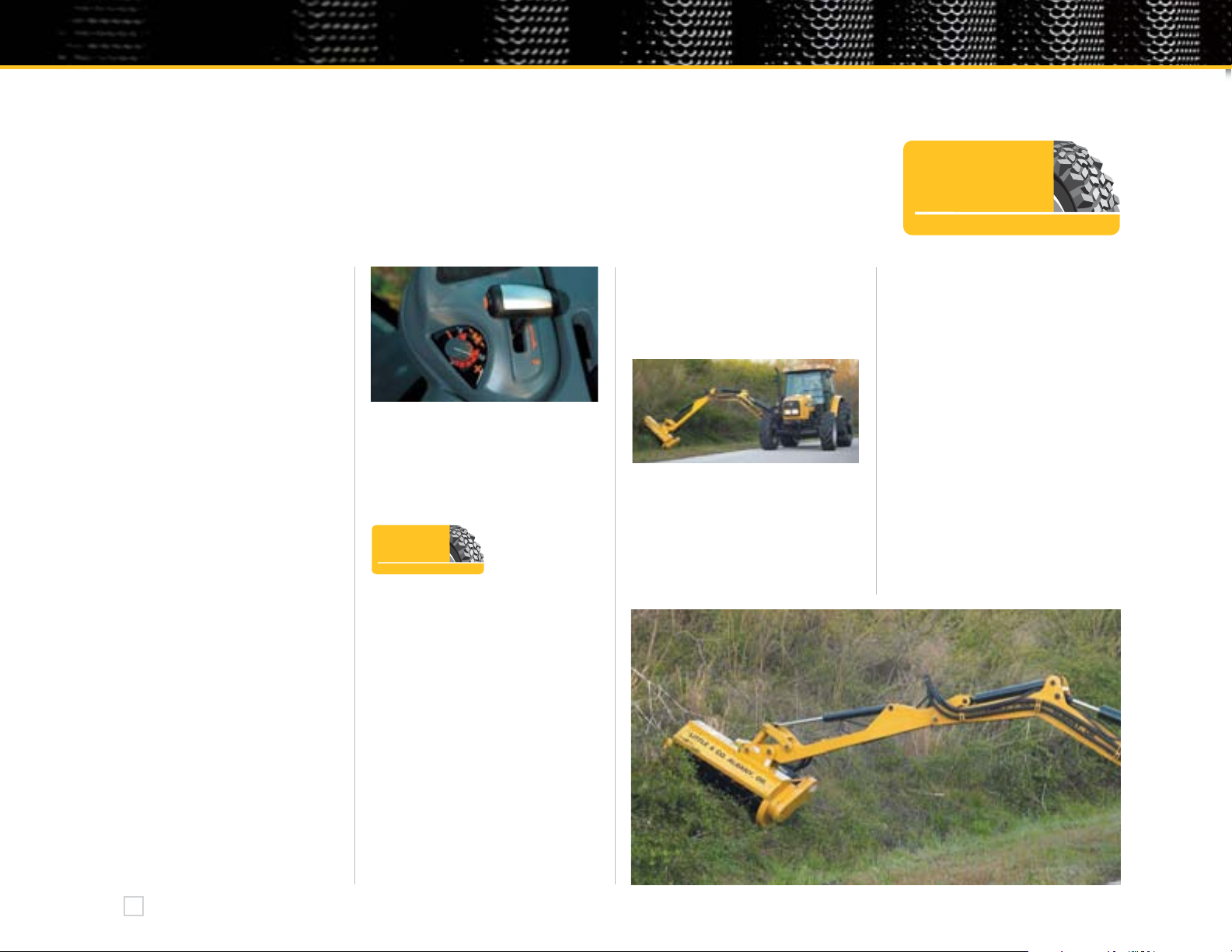

Challenger Integrated

mowing systems

RMS

Roadside Management System

Never before has a tractor manufacturer taken

the initiative to provide customers with a complete

brush management solution, much less designed

the tractor and mower as a single unit. However,

that has changed with the introduction of six new

Challenger

Now, through your local Cat dealer, you can

attain single-source price bids, service, parts

support and warranty protection. Most importantly,

you receive a unit that has been built as an

integral package, so you’re assured of

reliability, performance and adherence to the

design parameters of both the tractor and

mowing system.

®

BRM and BRU models.

MT400B Series Tractors

Thanks to the excellent visibility, easy

maneuverability and exceptional power-to-weight

ratio, MT400B Series tractors—which serve as

the base unit for all MT400BRU and MT400BRM

models—are especially well suited for jobs

like roadside mowing and brush management.

Standard features on all models include:

• Rugged 4-cylinder, 4.4-liter (268 cu. in.)

• AutoPower™ IV 16F/16R transmission

®

Caterpillar

reliability and performance.

offers four clutchless powershifts in four

ranges for improved tractor and operator

performance as well as a power shuttle

for reduced cycle times.

diesel engine for legendary

• Total hydraulic flow of 34.8 gpm puts the MT400B

up to 123 percent ahead of most competitors.

• Optional creeper transmission provides operating

speeds down to 0.12 mph (0.2 kph) for even

greater adaptability.

RMS

Roadside Management System

MT400BRU Mowing Systems

Ideal for roadside mowing and brush management,

MT400BRU models couple the rugged performance

of a Little & Company two-piece boom with your

choice of a PowerAxe flail head or rotary head in

a 4- or 5-foot (1.22 - 1.52 m.) width.

• Support and stability come from the 1/2-inch

(12.7 mm) thick steel Powerplate frame designed

into the tractor. Equipped with top and bottom

cross bracing, as well as vertical and horizontal

bracing, it allows external forces to pass

through the frame, and not the tractor chassis,

ensuring durability and longer service life from

all components.

• Articulated, two-piece Dynamx booms are

fabricated from 100,000-psi yield strength and

130,000 psi tensile strength ASTM A514 steel

with internal reinforcement, which minimizes

twisting and flexing in the toughest conditions.

An isolation-mounted cab, compete with heating and

air conditioning, front windshield wiper/washer and an

adjustable steering column is standard on all MT400BR,

MT400BRU and MT400BRM models. For additional

comfort, an air-suspended seat is optional.

• A minimum 130 degrees of horizontal swing

with breakaway protection in both forward and

reverse directions.

• Boom movement provides a horizontal reach

of 22 feet (6.7 m) out; a minimum of 17 feet

(5.2 m) up, and 10 feet (3.1 m) down from the

centerline of the tractor for unmatched flexibility.

• A 40-gpm PTO-driven hydraulic pump

coupled to a powerful 50-horsepower hydraulic

drive motor ensures plenty of power to drive

the flail or rotary head. Oil is provided by a

self-contained hydraulic system that includes

its own 35-gallon (132.5 litre) reservoir and

filter system. This allows the tractor hydraulics

to operate boom movement without hesitation

or stalling.

• MT445BRU - 72 PTO hp (52.2 kW) at 1000 RPM

• MT455BRU - 82 PTO hp (59.7 kW) at 1000 RPM

• MT465BRU - 95 PTO hp (67.1 kW) at 1000

RPM

4

Just once, I’d like

“

to find a tractor and

mower that’s designed

as a unit, instead of a

pieced-together outfit.

It’d be nice, too, if one

dealer serviced and

SPECIALTY WHEEL TRACTORS

warranted the whole

package.

”

We’re up to

The Challenge

5

MT500B

series tractors

Today’s fast-paced municipal and commercial

workload often calls for a mid-sized tractor with the

guts to handle the tough jobs, the comfort to enhance

operator productivity and the technology to improve

efficiency – all of this can be found in the MT500B.

Whether it serves as the base unit for an MT500BRM,

or as the power unit for your batwing mower or loader

operation, an MT500B offers everything you need.

AutoPower VI

Six powershift ratios on the standard AutoPower™ VI

transmission allow the operator to shift under full load

within four mechanical robotized selected ranges for

a total of 24 speeds in both forward and reverse. A

rotary-dial Autodrive controller also provides automatic

shifting based on the load and the desired engine

speed. With the right speed for any situation, you’ll

cover more ground in less time and with less fuel.

Maximum road speed can even be achieved

between 1,600 & 1,880 rpm for improved fuel

economy and reduced noise levels.

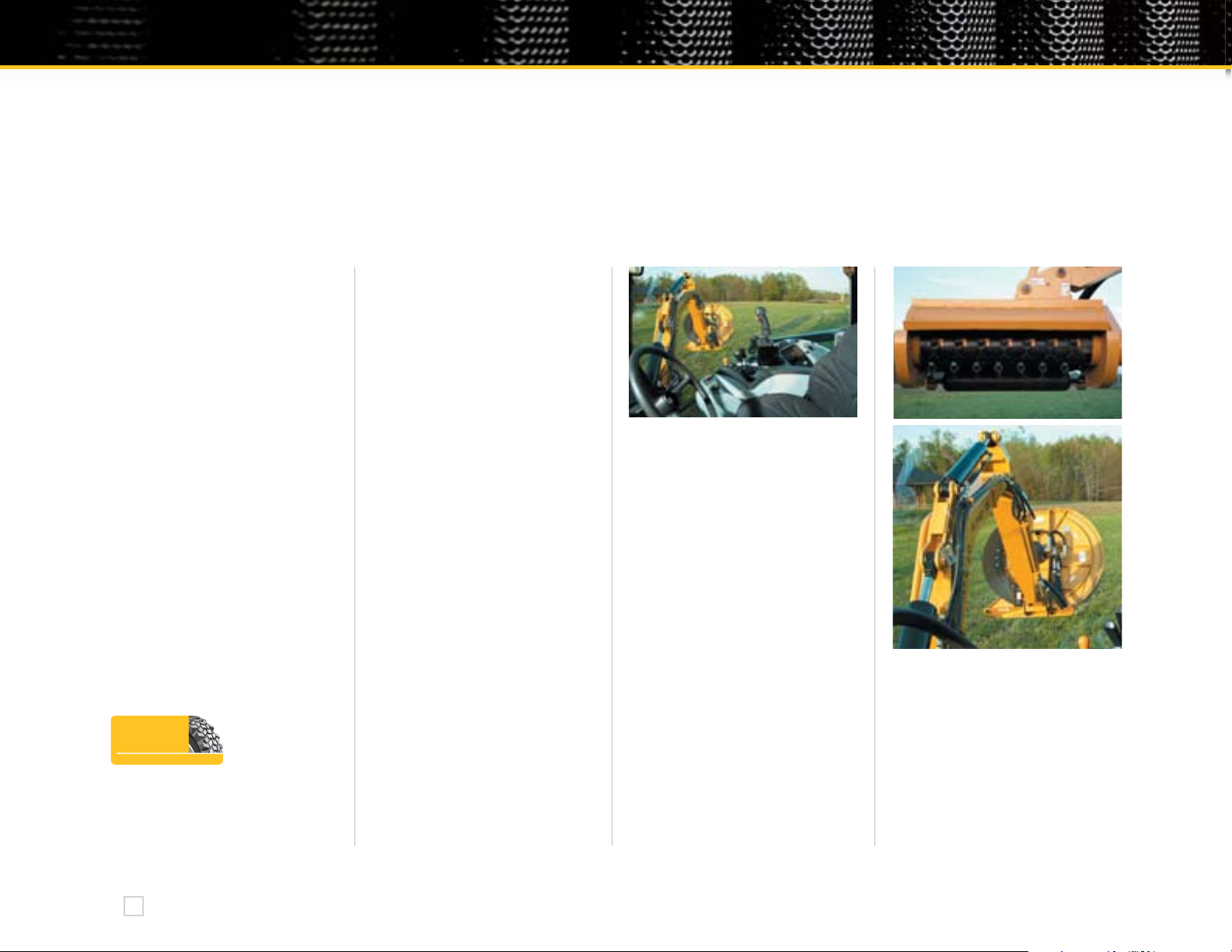

MT400BRM & MT500BRM

Boom Mowers

RMS

Roadside Management System

Whether your needs call for the raw power of the

95 PTO HP MT465BRM or the performance of an

MT500BRM model, Challenger has the answer to

your brush-control assignment.

Choose any one of three available models and

acquire the strength of a fully integrated Little

& Company brushcutter system. Similar to the

MT400BRU system, but built even heavier, the

BRM boasts features that aren’t even available on

many competitive units.

• The 5/8-inch (15.9 mm) thick steel Powerplate

frame, which includes both vertical and horizontal

bracing, provides a solid foundation without

restricting access to daily and preventative

maintenance. Equally important, the Powerplate

allows external forces to pass through the frame,

and not the tractor chassis, ensuring durability

and a longer service life from all components.

• The articulated, two-piece Dynamx booms are

fabricated from 100,000-psi yield strength and

130,000 psi tensile strength ASTM A514 steel

with internal reinforcement to prevent twisting and

flexing, even in the toughest conditions.

• Minimum 140 degree swing breakaway

protection from obstacles in both forward and

reverse directions.

• Three boom lengths offer mowing reaches

from 20 to 25 feet (6.1 to 7.6 m) to specifically

match your local requirements.

• Boom reach provides a minimum of 19 feet up

and 10 feet down from the centerline of the

tractor for peak productivity with each pass.

• Booms retract the cutting head to within 24

inches of tractor tires for tight roadside conditions.

A single, primary grade, electronic joystick linked to an

electronic proportional four-way hydraulic spool valve,

provides simultaneous control of multiple boom functions.

• A patented, quick-change system permits simple

and efficient flail blade changes in the field,

reducing downtime and saving road travel back to

the shop.

• The electronic joystick is equipped with an on/off

switch to enable lockout for transport. The boom

electronics also utilize a separate circuit breaker.

• A 52 gpm PTO-driven hydraulic pump linked to

a powerful hydraulic drive motor provides a

minimum of 60-horsepower to drive the flail or

rotary head. Oil is supplied by a self-contained

hydraulic system that includes its own 55-gallon

(208 litre) reservoir and filter system. This allows

the tractor hydraulics to operate boom movement

without hesitation or stalling.

Three High-Performance Choices

• MT465BRM - 95 PTO hp (67.1 kW) at 1000 RPM

• MT525BRM - 105 PTO hp (70.8 kW) at 1000 RPM

• MT535BRM - 110 PTO hp (78.3 kW) at 1000 RPM

Take your choice of a PowerAxe flail head or rotary head

on all MT400BRM and MT500BRM systems. Each is also

available in a 4- or 5-foot cutting width.

• Rotary head deck and side skirts and flail head

cowling are constructed of 1/4” (6.4 mm)

T-l steel for increased stability and a longer

service life. Cowling side plates are 3/8”

(9.5mm) steel.

• Flail models have 18 or 24 mounting stations,

which accept various cutting blades with the

ability to cut tree limbs, brush and heavy grass.

6

Loading...

Loading...