Page 1

SPECIALTY WHEEL TRACTORS

SPECIALTY WHEEL TRACTORS

We’re up to

The Challenge

SPECIALTY SERIES

45 TO 240 PTO HP

Page 2

Serious Machinery

for serious applications

Governmental and industrial applications call for

one tough machine... whether the job is mowing

roadside ditches, powering a broom or towing a

scraper. Fortunately, Challenger

line of wheel tractors that are up to the challenge.

Choose from more than 20 different specialized

models that range from 45 to 240 PTO horsepower.

Select a special “BRU” or “BRM” model that

integrates a customized MT400B or MT500B

Series tractor with a Little & Company mower for

a complete brush control system. Or pick a highhorsepower MT665B model with an all-inclusive

scraper package. Take your machine to the next

level, with innovative options like a municipal cab

and puncture-resistant Michelin, Nokia or Trelleborg

tires on roadside mowing models.

2

®

offers a special

Single-Point Support

If your company or agency owns or leases

®

Caterpillar

commands more respect for its integrity, in-field

service and parts support than the Cat

network. The same philosophy applies to

Challenger equipment, thanks to a partnership

between AGCO Corporation and Caterpillar.

It all began in March 2002, when AGCO

Corporation acquired the highly respected

Challenger line of track tractors from Caterpillar Inc.

and began expanding it into a full line of serious

equipment. Today, the Challenger brand includes a

complete line of wheel and track tractors from 23

to 570 engine horsepower, as well as a family of

hay equipment and combines.

Your Cat dealer now offers a single point of

contact for all your equipment needs, no matter

the application. And that translates into less

downtime and greater productivity.

equipment, you know that nobody

®

dealer

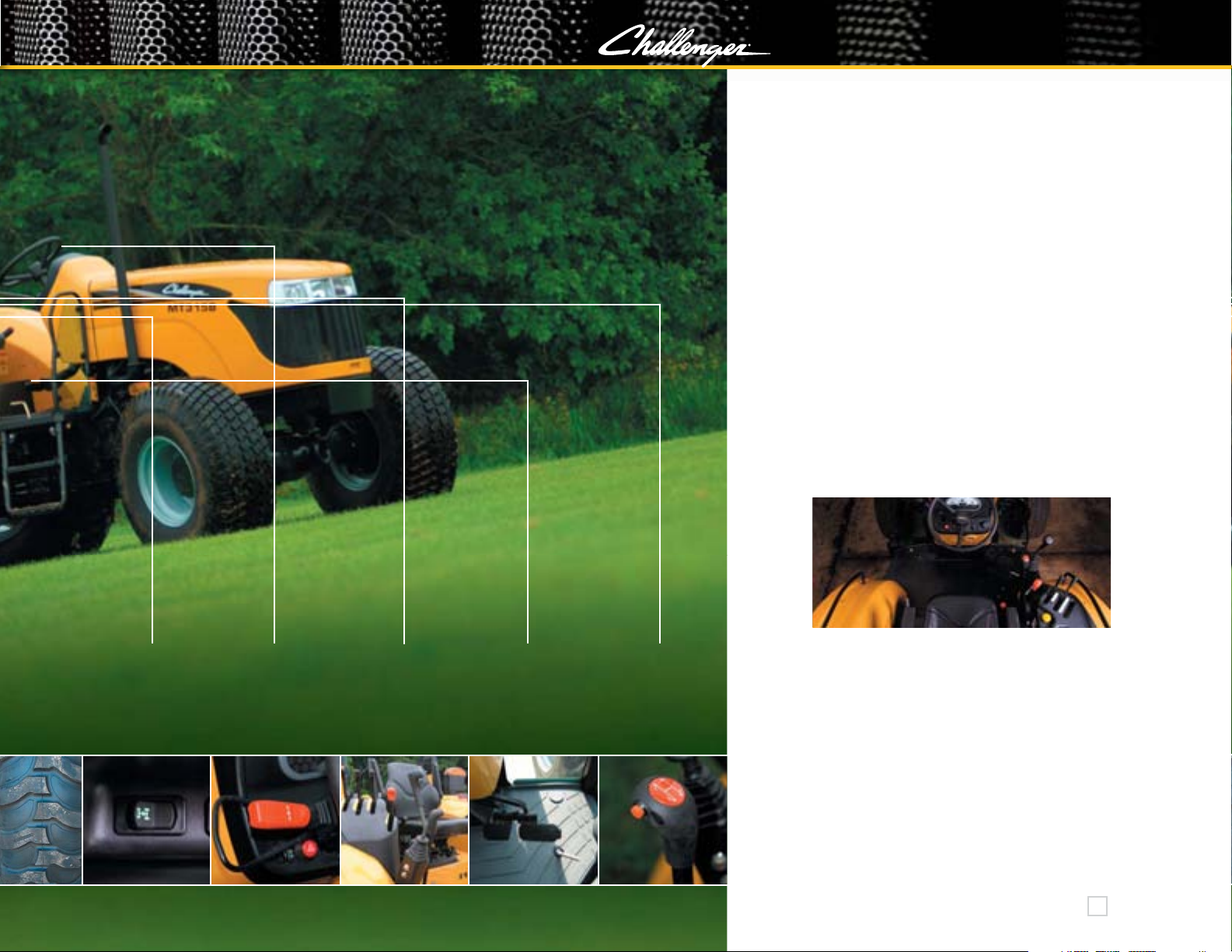

Electro-hydraulically

actuated differential

lock offers on-the-go

engagement for maximum

productivity.

Category I/II 3-point

hitch and SAE swinging

drawbar offers compatibility

with all implements.

Hitch Valves Ag Tires “Turf” TiresDifferential Lock Switch

The 15-8 total gpm (60 lpm)

hydraulic system with two

standard valves provides

outstanding flow for loaders

and towed implements.

A wide variety of wheels

and tires, including R4

industrial and low-pressure

“turf” tires, let you match

the MT300B Series to

the job.

Page 3

SPECIALTY WHEEL TRACTORS

MT300B

light utility tractors

New to the Challenger line-up, the MT300B Series is a true

middleweight champ that can handle highway mowing and loader work

with equal ease. Available in four horsepower ranges, the MT300B

tractors are powered by a powerful 3.3-liter, 3-cylinder diesel engine

that is also turbocharged for maximum performance and fuel efficiency.

Adaptable Transmission

Despite its compact, maneuverable size, the MT300B comes

with a standard 12FX12R shuttle transmission for an equal

number of gears in both forward and reverse. Reverse speeds are

15 percent slower than forward speeds for shorter cycle times and

increased productivity.

Four-wheel braking on

all-wheel-drive models

activates at speeds greater

than 8.5 mph, a feature

normally only available on

larger tractors.

R4 Tires 4-Wheel Drive Switch Shuttle Lever GearshiftBrake PedalsJoystick

Power shuttle allows

even smoother shifting and

the ability to Shift forward

and reverse without the use

of a clutch pedal.

Optional factory installed

hydraulic joystick and two

mid-mounted valves offer

integrated ergonomics and

superb loader control.

Hydraulically actuated,

oil-cooled multi-disc brakes

provide optimum efficiency

and safety, yet require

minimal maintenance.

The Power Shuttle

transmission provides the

added convenience of

a push-button gearshift

without the use of the clutch

pedal. (Push, shift and go.)

Whether you choose the comfortable, open platform, or the roomy, ergonomic

cab, the MT300B Series offers the kind of operator comfort that results in

greater productivity.

Responsive PTO

Although a 540 rpm PTO is standard on all MT300B models, those

who use this versatile tractor for mowing and PTO applications

might want to consider the optional 540/540E PTO. In light-duty

applications, this economy minded option allows the operator to

attain rated 540 rpm PTO speed at only 1,648 engine rpm. You’ll not

only save on fuel costs, but minimize operator fatigue and improve

productivity by reducing noise levels.

We’re up to

The Challenge

3

Page 4

Challenger Integrated

mowing systems

RMS

Roadside Management System

Never before has a tractor manufacturer taken

the initiative to provide customers with a complete

brush management solution, much less designed

the tractor and mower as a single unit. However,

that has changed with the introduction of six new

Challenger

Now, through your local Cat dealer, you can

attain single-source price bids, service, parts

support and warranty protection. Most importantly,

you receive a unit that has been built as an

integral package, so you’re assured of

reliability, performance and adherence to the

design parameters of both the tractor and

mowing system.

®

BRM and BRU models.

MT400B Series Tractors

Thanks to the excellent visibility, easy

maneuverability and exceptional power-to-weight

ratio, MT400B Series tractors—which serve as

the base unit for all MT400BRU and MT400BRM

models—are especially well suited for jobs

like roadside mowing and brush management.

Standard features on all models include:

• Rugged 4-cylinder, 4.4-liter (268 cu. in.)

• AutoPower™ IV 16F/16R transmission

®

Caterpillar

reliability and performance.

offers four clutchless powershifts in four

ranges for improved tractor and operator

performance as well as a power shuttle

for reduced cycle times.

diesel engine for legendary

• Total hydraulic flow of 34.8 gpm puts the MT400B

up to 123 percent ahead of most competitors.

• Optional creeper transmission provides operating

speeds down to 0.12 mph (0.2 kph) for even

greater adaptability.

RMS

Roadside Management System

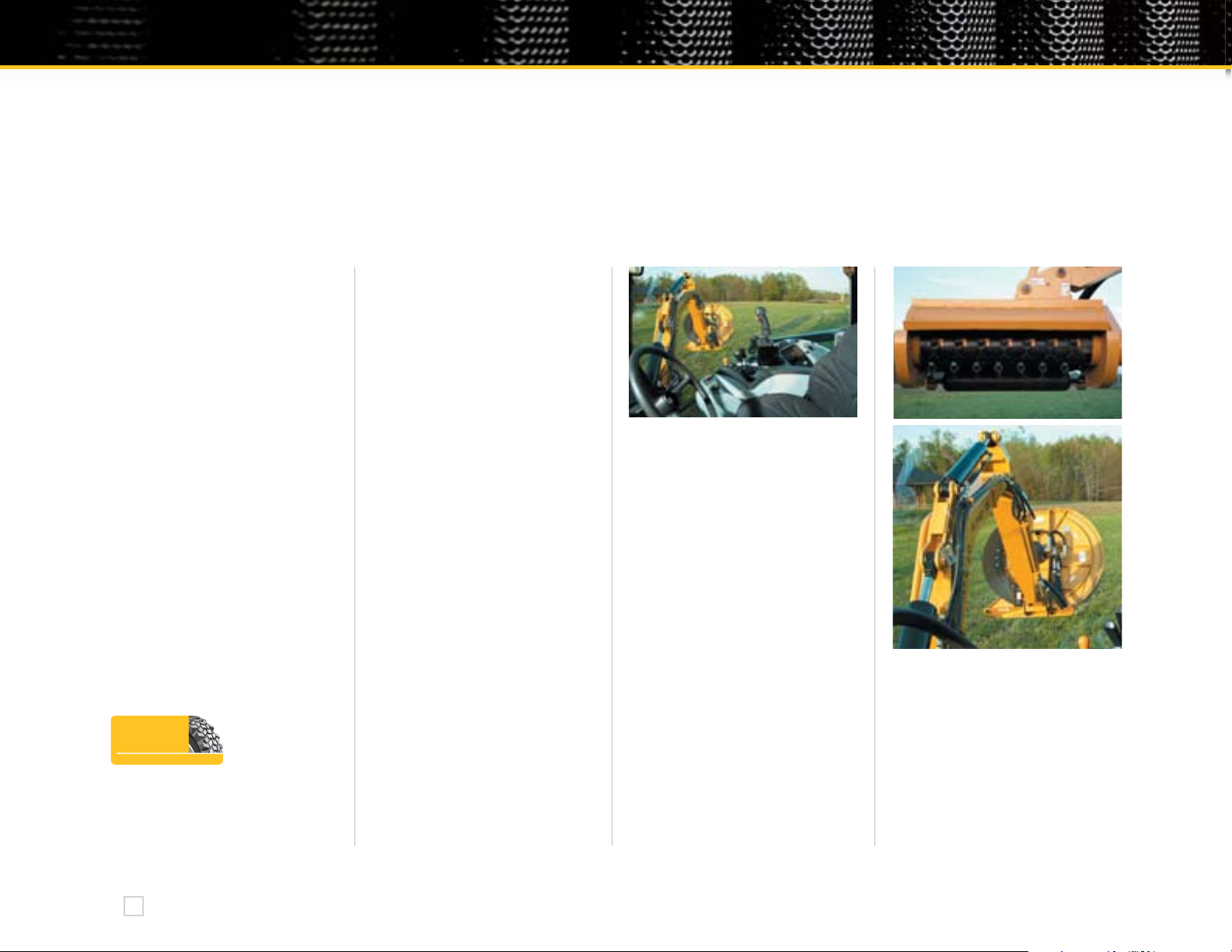

MT400BRU Mowing Systems

Ideal for roadside mowing and brush management,

MT400BRU models couple the rugged performance

of a Little & Company two-piece boom with your

choice of a PowerAxe flail head or rotary head in

a 4- or 5-foot (1.22 - 1.52 m.) width.

• Support and stability come from the 1/2-inch

(12.7 mm) thick steel Powerplate frame designed

into the tractor. Equipped with top and bottom

cross bracing, as well as vertical and horizontal

bracing, it allows external forces to pass

through the frame, and not the tractor chassis,

ensuring durability and longer service life from

all components.

• Articulated, two-piece Dynamx booms are

fabricated from 100,000-psi yield strength and

130,000 psi tensile strength ASTM A514 steel

with internal reinforcement, which minimizes

twisting and flexing in the toughest conditions.

An isolation-mounted cab, compete with heating and

air conditioning, front windshield wiper/washer and an

adjustable steering column is standard on all MT400BR,

MT400BRU and MT400BRM models. For additional

comfort, an air-suspended seat is optional.

• A minimum 130 degrees of horizontal swing

with breakaway protection in both forward and

reverse directions.

• Boom movement provides a horizontal reach

of 22 feet (6.7 m) out; a minimum of 17 feet

(5.2 m) up, and 10 feet (3.1 m) down from the

centerline of the tractor for unmatched flexibility.

• A 40-gpm PTO-driven hydraulic pump

coupled to a powerful 50-horsepower hydraulic

drive motor ensures plenty of power to drive

the flail or rotary head. Oil is provided by a

self-contained hydraulic system that includes

its own 35-gallon (132.5 litre) reservoir and

filter system. This allows the tractor hydraulics

to operate boom movement without hesitation

or stalling.

• MT445BRU - 72 PTO hp (52.2 kW) at 1000 RPM

• MT455BRU - 82 PTO hp (59.7 kW) at 1000 RPM

• MT465BRU - 95 PTO hp (67.1 kW) at 1000

RPM

4

Page 5

Just once, I’d like

“

to find a tractor and

mower that’s designed

as a unit, instead of a

pieced-together outfit.

It’d be nice, too, if one

dealer serviced and

SPECIALTY WHEEL TRACTORS

warranted the whole

package.

”

We’re up to

The Challenge

5

Page 6

MT500B

series tractors

Today’s fast-paced municipal and commercial

workload often calls for a mid-sized tractor with the

guts to handle the tough jobs, the comfort to enhance

operator productivity and the technology to improve

efficiency – all of this can be found in the MT500B.

Whether it serves as the base unit for an MT500BRM,

or as the power unit for your batwing mower or loader

operation, an MT500B offers everything you need.

AutoPower VI

Six powershift ratios on the standard AutoPower™ VI

transmission allow the operator to shift under full load

within four mechanical robotized selected ranges for

a total of 24 speeds in both forward and reverse. A

rotary-dial Autodrive controller also provides automatic

shifting based on the load and the desired engine

speed. With the right speed for any situation, you’ll

cover more ground in less time and with less fuel.

Maximum road speed can even be achieved

between 1,600 & 1,880 rpm for improved fuel

economy and reduced noise levels.

MT400BRM & MT500BRM

Boom Mowers

RMS

Roadside Management System

Whether your needs call for the raw power of the

95 PTO HP MT465BRM or the performance of an

MT500BRM model, Challenger has the answer to

your brush-control assignment.

Choose any one of three available models and

acquire the strength of a fully integrated Little

& Company brushcutter system. Similar to the

MT400BRU system, but built even heavier, the

BRM boasts features that aren’t even available on

many competitive units.

• The 5/8-inch (15.9 mm) thick steel Powerplate

frame, which includes both vertical and horizontal

bracing, provides a solid foundation without

restricting access to daily and preventative

maintenance. Equally important, the Powerplate

allows external forces to pass through the frame,

and not the tractor chassis, ensuring durability

and a longer service life from all components.

• The articulated, two-piece Dynamx booms are

fabricated from 100,000-psi yield strength and

130,000 psi tensile strength ASTM A514 steel

with internal reinforcement to prevent twisting and

flexing, even in the toughest conditions.

• Minimum 140 degree swing breakaway

protection from obstacles in both forward and

reverse directions.

• Three boom lengths offer mowing reaches

from 20 to 25 feet (6.1 to 7.6 m) to specifically

match your local requirements.

• Boom reach provides a minimum of 19 feet up

and 10 feet down from the centerline of the

tractor for peak productivity with each pass.

• Booms retract the cutting head to within 24

inches of tractor tires for tight roadside conditions.

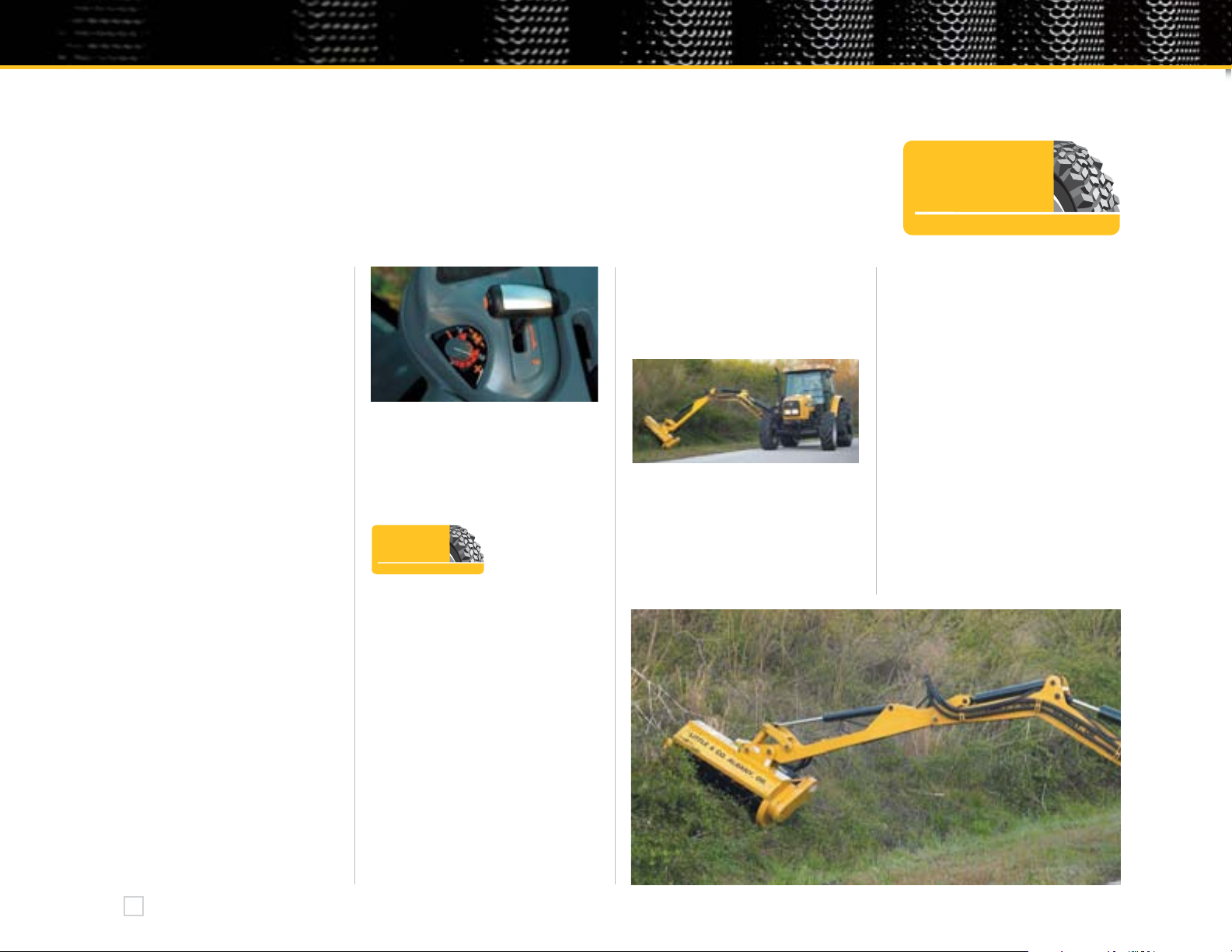

A single, primary grade, electronic joystick linked to an

electronic proportional four-way hydraulic spool valve,

provides simultaneous control of multiple boom functions.

• A patented, quick-change system permits simple

and efficient flail blade changes in the field,

reducing downtime and saving road travel back to

the shop.

• The electronic joystick is equipped with an on/off

switch to enable lockout for transport. The boom

electronics also utilize a separate circuit breaker.

• A 52 gpm PTO-driven hydraulic pump linked to

a powerful hydraulic drive motor provides a

minimum of 60-horsepower to drive the flail or

rotary head. Oil is supplied by a self-contained

hydraulic system that includes its own 55-gallon

(208 litre) reservoir and filter system. This allows

the tractor hydraulics to operate boom movement

without hesitation or stalling.

Three High-Performance Choices

• MT465BRM - 95 PTO hp (67.1 kW) at 1000 RPM

• MT525BRM - 105 PTO hp (70.8 kW) at 1000 RPM

• MT535BRM - 110 PTO hp (78.3 kW) at 1000 RPM

Take your choice of a PowerAxe flail head or rotary head

on all MT400BRM and MT500BRM systems. Each is also

available in a 4- or 5-foot cutting width.

• Rotary head deck and side skirts and flail head

cowling are constructed of 1/4” (6.4 mm)

T-l steel for increased stability and a longer

service life. Cowling side plates are 3/8”

(9.5mm) steel.

• Flail models have 18 or 24 mounting stations,

which accept various cutting blades with the

ability to cut tree limbs, brush and heavy grass.

6

Page 7

SPECIALTY WHEEL TRACTORS

A choice between the AUtoPower™

VI or TechStar™ CVT lets you

decide which transmission is best

for your application.

TechStar™ CVT AutoPower™ VI

Largest cab available on a

tractor under 130 horsepower.

Six-cylinder, electronically

fuel-injected Caterpillar®

engines, recognized around

the world for durability

and reliability.

EngineCab 2WD 4WD Suspension

2WD or AWD only. Optional front axle suspension

system & 31 mph.

7

Page 8

RMS

roadside management system

MT400BR/MT500BR Tractors

Custom Design Your Own System

For those who wish to mount their own roadside

mowing system on an MT400B or MT500B tractor,

Challenger offers five different “BR” models. Each is

shipped without rear hydraulics or the rear

3-point hitch typically found on tractors.

Like their counterparts, however, each model is

available with a choice of transmissions and 2WD

or all-wheel-drive. A bank of three hydraulic remotes

is also available as a supplement to the swinging

drawbar, for those who plan to tow a batwing mower

or other towed implement.

Five Adaptable Models

• MT445BR - 72 PTO hp (52.2 kW) at 1000 RPM

• MT455BR - 82 PTO hp (59.7 kW) at 1000 RPM

• MT465BR - 95 PTO hp (67.1 kW) at 1000 RPM

• MT525BR - 105 PTO hp (70.8 kW) at 1000 RPM

• MT535BR - 110 PTO hp (78.3 kW) at 1000 RPM

As an option for adverse operating conditions, all

MT400B and MT500B models can be ordered with

welded steel rims and a choice of tires, including

Michelin, Trelleborg or Nokia puncture-resistant

selections, depending upon the tractor model.

8

Page 9

SPECIALTY WHEEL TRACTORS

Municipal

viseo cab

A must for the serious roadside mower operator, the new

Viseo municipal cab, offers a level of protection and visibility

that is unmatched by anyone in the industry. Available only

from Challenger on the MT525B and MT535B, it utilizes a

one-piece, impact-resistant Plexiglas panel in place of the “B”

post, window glass and side door on the right side of the cab.

For all weather convenience, a wiper and sunshade are included

as standard equipment.

We’re up to

The Challenge

9

Page 10

MT600B

series tractors

TechStar CVT

Whether you acquire the TechStar™ CVT (continuously variable

transmission) as standard equipment on an MT665B, or specify it as

an option on an MT500BR or MT500BRM model, you won’t find a

better power train on any machine. The TechStar™ CVT is backed by

more than a decade of research, development and production.

One pass with a TechStar-equipped MT500B or MT600B model and

you’ll quickly appreciate the infinite speed control that allows you to

attain the optimum speed for the job.

Two continuously variable speed ranges provide working speed

selections from 0 to 17 mph (0-28 kph) and transport speeds from

0 to 25 mph (0-40 kph) with the standard front axle and 0 to 32 mph

(0-50 kph) with the optional front-axle suspension system.

MT665B Special Application Tractor

Rated at 240 PTO horsepower (180 kW), the Challenger MT665B

features exceptional power, excellent efficiency and the most innovative

technology in the industry. That also makes it an ideal tractor for

scraper and industrial applications... particularly when it’s equipped

with Challenger’s new “Special Application” package, which includes:

pneumatic cab suspension, 2 roof mounted beacons and extra weights

to assist traction for the 710/70R38 and 600/65R28 tires.

Perhaps the best feature of the MT665B scraper tractor, though, is the

standard-equipment TechStar CVT (continuously variable transmission).

When coupled with the Challenger Endurance diesel engine and its

electronic engine management system, the TechStar CVT provides a

virtually unlimited combination of engine speeds and ground speeds

from 60 feet per hour to 25 mph (32 mph with the suspended front

axle). Pull a scraper at exactly the right speed for slope and soil

conditions. Then take advantage of the rapid transport.

Stepless Speed Control....How It Works

By using both its mechanical and hydrostatic capabilities at the same

time, the TechStar CVT not only operates more efficiently, but it does

so without preset gear limits.

With stepless variable speed, you have access to the power

reserves, as well as the speed choices, normally hidden in the areas

between gears.

Say, for example, you choose to pull a 30’ chisel at 6.4 mph instead

of the 5.7 mph gear limit on a competitive powershift. The difference

in speed adds up to an extra 36 acres in a 14-hour day. And that’s

just one operation on one day.

Think of the possibilities with applications like crop spraying, where

a constant ground speed is critical for accuracy. Or harvesting with

PTO-drive equipment, where it’s important to keep engine speed at

a steady level.

With the Challenger MT600B and the TechStar CVT, the operator can

control precise ground speed, engine speed and/or PTO speed as

each takes precedence.

10

Page 11

The 8.4-liter (512 cu. in.), 6-cylinder

Challenger “Endurance” diesel used in

the MT665B is Tier III compliant and

was designed from inception to provide

the highest level of performance and

reliability when coupled with the

TechStar CVT.

Four valves per cylinder, along with a

turbocharger and aftercooler ensure

Tier III compliance, while providing

continuous power and up to 40

percent torque backup.

• Electronic Engine Management

(EEM)ensures quick and precise

response to throttle movement.

The EEM system also allows the

operator to program or recall two

specific engine speeds with the

touch of a button.

• The single-piece cast-iron block

provides maximum strength and

serves as a load-bearing frame

component, contributing to a

shorter turning radius.

• Stepless variable speed provide

access to the power reserves, as

well as the speed choices, normally

hidden in the areas between gears

on powershift units.

• Achieve precise ground speed,

engine speed and/or PTO speed as

each takes precedence.

• A separate oil reservoir isolates the

transmission from the hydraulic

remotes, minimizing the chance

for contamination.

• All tractor movements can be

controlled with the operators left

hand leaving the right hand free

to operate the boom mower

or other machinery.

Extra wheel weights

F600/65R28 and

R710/70R38 tire

package

lbs./459 kg) and up to 16

suitcase weights

SPECIALTY WHEEL TRACTORS

Rear window washer/wiperPneumatic cab suspensionFront belly weight (1,012

Two roof-mounted

rotating beacons

Engine CVT Weights Tires Weights Cab Suspension Wiper Beacons

11

Page 12

All-Day

comfort

Designed by ergonomic specialists, with the help of user

focus groups, the MT600B cab offers the best comfort, control

and ease of use in the industry.

• An industry-leading 71 dB(A) maximum interior sound level

helps the operator concentrate on the job.

• The VRS semi-active operator’s seat allows continuous realtime automatic damping force adjustments based on terrain

inputs. The comfortable ride, combined with the quieter

environment, helps keep the operator fresh and alert through

long days for improved safety, performance and productivity.

• A multi-function armrest, attached to the seat, puts all

frequently used controls at the operator’s fingertips.

• An ergonomically designed right-hand control console

groups all controls by function for quick response.

• 61 square feet (5.67 square meters) of glass provides

excellent visibility in all directions.

• The slim-profile dash features improved forward ground

visibility and provides both analog and LCD displays.

Computerized Assistance

An in-cab Power Performance display allows the operator to

monitor all tractor operations and pre-setup to 21 tractor

and implement functions for efficient operator performance.

Using the Trailed Implement Control (TIC) the operator can

control scraper depth automatically by presetting the maximum

wheel slip and allowing the tractor to adjust the blade height.

As a result, engine performance remains at peak levels and

scraper cuts are always gradual and even, improving cycle

times and ensuring single-pass accuracy.

12

Page 13

SPECIALTY WHEEL TRACTORS

World-Class

commitment

When you purchase a Challenger® special application

tractor, you’re buying a lot more than a piece of

machinery. You’re purchasing the Challenger commitment

to quality and service.

Take a close look at a Challenger tractor or mowing system

and you’ll realize that it’s built to the highest standards of

quality in terms of components and construction, as well

as fit and finish.

But Challenger’s commitment to the customer goes far

beyond steel and rubber.

Complete Warranty Coverage

Whether you purchase a tractor or a complete system,

you are assured of full grille-to-drawbar warranty

protection for two years or 2,000 hours, whichever comes

first. That includes the frame and booms on the BRM and

BRU mowing systems, making it the best protection in

the industry.

New ProTech Protection

Unlike any other offering in the industry, Challenger’s

new ProTech Service and Support Program includes a

valuable 4-year/4,000-hour Extended Service Contract

at no additional cost. In each case, the Extended Service

Contract is provided through Cat

fully transferable.

®

insurance and is

We’re up to

The Challenge

13

Page 14

SPECIFICATIONS MT300B

MODEL MT315B MT325B MT335B MT345B

ENGINE

PTO HP 45 55 65 75

Gross HP 58 68 78 91

Engine Challenger Challenger Challenger Challenger

No. of Cylinders 3 3 3 3

Displacement (in

Aspiration Turbo Turbo Turbo Turbo/Aftercooled

Rated RPM 2,150 2,150 2,150 2,150

Fuel Tank Capacity (US Gal) 29 (109.7) 29 (109.7) 29 (109.7) 29 (109.7)

Bore (in / mm) 4.13 / 105 4.13 / 105 4.13 / 105 4.13 / 105

Stroke (in / mm) 5.0 / 127 5.0 / 127 5.0 / 127 5.0 / 127

TRANSMISSION

Base (Synchro Shuttle) 12x12 (0.3-18.6 mph) 12x12 (0.3-18.6 mph) 12x12 (0.3-18.6 mph) 12x12 (0.3-18.6 mph)

Optional (Power Shuttle) 12x12 (0.3-18.6 mph) 12x12 (0.3-18.6 mph) 12x12 (0.3-18.6 mph) 12x12 (0.3-18.6 mph)

POWER TAKE-OFF (PTO)

Engagement Electro Hydraulic Electro Hydraulic Electro Hydraulic Electro Hydraulic

Standard 540 Ind. 540 Ind. 540 Ind. 540 Ind.

Optional 540/540E Ind. 540/540E Ind. 540/540E Ind. 540/540E Ind.

DIFFERENTIAL LOCK

Type Electro Hydraulic Electro Hydraulic Electro Hydraulic Electro Hydraulic

FRONT AXLE ENGAGEMENT

Type Electro Hydraulic Electro Hydraulic Electro Hydraulic Electro Hydraulic

HYDRAULICS

Max Flow to Remotes GPM (l/min.) 15.8 (60) 15.8 (60) 15.8 (60) 15.8 (60)

Total Flow 22.4 (84.8) 22.4 (84.8) 22.4 (84.8) 22.4 (84.8)

Maximum Hydraulic Pressure psi (bar) 2755 (190) 2755 (190) 2755 (190) 2755 (190)

3 Point Hitch Cat I/II Cat I/II Cat I/II Cat I/II

3 Point Hitch Controls Position & Draft Position & Draft Position & Draft Position & Draft

Lift Capacity @ Link Ends lbs (kg) 5500 (2500) 5500 (2500) 5500 (2500) 5500 (2500)

Auxiliary Valves 2 Valves SA/DA Standard / 3rd Valve Optional / Mid-Mount Joystick with 2 Valves Optional

STEERING

Type Hydrostatic Power Hydrostatic Power Hydrostatic Power Hydrostatic Power

BRAKES

Type Hydraulic Oil Cooled Disc Hydraulic Oil Cooled Disc Hydraulic Oil Cooled Disc Hydraulic Oil Cooled Disc

ELECTRICAL SYSTEM

Altemator (AMP) 80 80 80 80

Battery/CCA 12V/675 12V/675 12V/675 12V/675

OPERATOR STATION

Brake/Clutch Pedals Pendant Pendant Pendant Pendant

Gearshift Lever - Main & Range R.H. Side R.H. Side R.H. Side R.H. Side

Gearshift Lever - Shuttle L.H. Side/Column L.H. Side/Column L.H. Side/Column L.H. Side/Column

OPERATOR STATION NON CAB

Floor Type Platform Platform Platform Platform

2 Post Folding ROPS Standard Standard Standard Standard

CAB VERSION

Floor Type Platform Platform Platform Platform

Tilt & Telescopic Steering Wheel Standard Standard Standard Standard

Sound Level DBA 78 78 78 78

DIMENSIONS IN (16.9-30 REAR TIRE)

Wheelbase 2wd & 4wd 82.7 82.7 82.7 82.7

Maximum Length (2wd/4wd) 126/132.3 126/132.3 126/132.3 148

Overall Height (ROPS/Cab) 101/101.4 101/101.4 101/101.4 105/102.5

Minimum Width 72.8 72.8 72.8 76

Weight Platform 2wd/4wd (lbs) 5291/5732 5291/5732 5291/5732 5291/5732

Weight Cab with AC 2wd/4wd (lbs) 6614/7716 6614/7716 6614/7716 6614/7716

3

/litres) 201/3.3 201/3.3 201/3.3 201/3.3

Page 15

SPECIFICATIONS MT400B

MODEL MT445B MT455B MT465B

ENGINE Caterpillar 3054C / Perkins 1104C-44T Caterpillar 3054C / Perkins 1104C-44T Caterpillar 3054C / Perkins 1104C-44T

Gross Eng HP (Kw) @ 2000 rpm 91.7 (68.38) 103.2 (76.95) 123.12 (91.81)

PTO HP @ 2000 rpm (Rated PTO Speed) 72 (53.96) Nebraska Test 82 (61.14) Nebraska Test 95 (70.84) Nebraska Test

Rated PTO HP (Kw) @ 2200 rpm 70 (52.19) 80 (59.65) 90 (67.11)

Type Wastegate Turbocharge Wastegate Turbocharge Wastegate Turbocharge Air-to-Ait Intercooled

Displacement CID (L) 268.0 (4.4) 268.0 (4.4) 268.0 (4.4)

Number of Cylinders 4 4 4

Bore in. (mm) 4.13 (105) 4.13 (105) 4.13 (105)

Stroke in. (mm) 5.00 (127) 5.00 (127) 5.00 (127)

Alternator Std (optional) 80 AMP (120 AMP) 80 AMP (120 AMP) 80 AMP (120 AMP)

TRANSMISSION & CLUTCH AutoPowerTM IV Semi-Powershift AutoPowerTM IV Semi-Powershift AutoPowerTM IV Semi-Powershift

Type 16 x 16 Power Shuttle w/4-Speed Powershift 16 x 16 Power Shuttle w/4-Speed Powershift 16 x 16 Power Shuttle w/4-Speed Powershift

Option w / 8-Creeper Gears 24 x 24 Power Shuttle w/4-Speed Powershift 24 x 24 Power Shuttle w/4-Speed Powershift 24 x 24 Power Shuttle w/4-Speed Powershift

Option w / 16-Creeper Gears 32 x 32 Power Shuttle w/4-Speed Powershift 32 x 32 Power Shuttle w/4-Speed Powershift 32 x 32 Power Shuttle w/4-Speed Powershift

Clutch AutoPowerTM IV Powershift 2-Multi-Wet Clutch Packs 2-Multi-Wet Clutch Packs 2-Multi-Wet Clutch Packs

Clutch Lubrication & Brakes 8.075 GPM (30.57 LPM) Open-Center Hyd 8.075 GPM (30.57 LPM) Open-Center Hyd 8.075 GPM (30.57 LPM) Open-Center Hyd

Clutch Lubrication & Brakes & Charge Pump 43.6 GPM (165 LPM) Closed PFC 43.6 GPM (165 LPM) Closed PFC 43.6 GPM (165 LPM) Closed PFC

***Optional Mechanical 16 x 16 Mechanical Shuttle w/2-Speed Powershift 16 x 16 Mechanical Shuttle w/2-Speed Powershift 16 x 16 Mechanical Shuttle w/2-Speed Powershift

Clutch Mechanical Shuttle 1-cerimetallic 13” Dry Paddle 1-cerimetallic 13” Dry Paddle 1-cerimetallic 13” Dry Paddle

REAR AXLE Heavy-Duty Flange Heavy-Duty Flange Heavy-Duty Flange

Planetary Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard

Permissible Static Load Limit 34,943 Lbs (15,850 Kg) 34,943 Lbs (15,850 Kg) 34,943 Lbs (15,850 Kg)

Brakes Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled

Differential Lock Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement

FRONT AXLE 2WD / 4WD 2WD / 4WD 2WD / 4WD

Type 2WD Box in Box Design Box in Box Design Box in Box Design

Type 4WD Center Pivot Center Pivot Center Pivot

Maximum Turning Angle 55 degrees 55 degrees 55 degrees

Steering Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic

Permissible Static Load Limit 2WD 9,590 Lbs (4,350 Kg) 9,590 Lbs (4,350 Kg) 9,590 Lbs (4,350 Kg)

Permissible Static Load Limit 4WD 16,534 Lbs (7,500 Kg) 16,534 Lbs (7,500 Kg) 22,046 Lbs (10,000 Kg)

POWER TAKE - OFF (PTO) Independent Independent Independent

Speeds 540 / 1000 540 / 1000 540 / 1000

Speeds Optional 540 / 540E / 1000 / 1000E 540 / 540E / 1000 / 1000E 540 / 540E / 1000 / 1000E

Control Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic

Clutch Multi-Wet Clutch Pack Multi-Wet Clutch Pack Multi-Wet Clutch Pack

HYDRAULIC SYSTEM Open Center or (Closed, Load Sensing PFC Cab only) Open Center or (Closed, Load Sensing PFC Cab only) Open Center or (Closed, Load Sensing PFC Cab only)

Max Flow to Remotes GPM 26.4 Open Center / 29 Closed PFC 26.4 Open Center / 29 Closed PFC 26.4 Open Center / 29 Closed PFC

No. of Remotes Std 2 2 2

No. of Remotes Optional up to 4 up to 4 up to 4

Max Pressure PSI (Bar) 2,900 (200) 2,900 (200) 2,900 (200)

Max Flow Power Steering GPM 11.09 Open Center / 43.6 Closed PFC 11.09 Open Center / 43.6 Closed PFC 11.09 Open Center / 43.6 Closed PFC

3-POINT HITCH Electronic (ELC) Electronic (ELC) Electronic (ELC)

Control Mouse Wheel, Rocker Switch, Draft Knobs, Fenders Mouse Wheel, Rocker Switch, Draft Knobs, Fenders Mouse Wheel, Rocker Switch, Draft Knobs, Fenders

Electronic Draft Control Top Link Sensing Top Link Sensing Top Link Sensing

Rate of Drop Electronic Control Electronic Control Electronic Control

Speed Control Electronic Control Electronic Control Electronic Control

Telescopic Stabilizers Standard Standard Standard

Telescopic Draft Link Ends Standard Standard Standard

Lift Capacity @ 24 in Behind Ball Ends 7,285 Lbs (3,304 Kg) Nebraska Test 7,285 Lbs (3,304 Kg) Nebraska Test 7,285 Lbs (3,304 Kg) Nebraska Test

Capacities

Fuel Tank Gal (L) 40 (150) Optional 53 (241) 40 (150) Optional 53 (241) 40 (150) Optional 53 (241)

Cooliing System Gal (L) 4.4 (16.6) 4.4 (16.6) 4.4 (16.6)

Transmission Hydraulic System Gal (L) 19.5 (73.8) 19.5 (73.8) 19.5 (73.8)

Engine Crankcase Qt (L) 8.0 (7.5) 8.0 (7.5) 8.0 (7.5)

DIMENSIONS

Wheelbase in (mm) 97.0 (2,464) 97.0 (2,464) 100.4 (2550)

Unballasted Weight Lbs (Kg) 2WD Cab 8,631 (3,915) 8,631 (3,915) 9,171 (4,160)

Unballasted Weight Lbs (Kg) 4WD Cab 8,929 (4,050) 8,929 (4,050) 9,976 (4,525)

Tire Sizes Used For Specifi cations 480/70R38 R /340/85R28 F /10.00-16 F 480/70R38 R /340/85R28 F /10.00-16 F 480/70R38 R /340/85R28 F /10.00-16 F

SPECIALTY WHEEL TRACTORS

15

Page 16

SPECIFICATIONS MT500B

MODEL MT525B Auto PowerTM VI MT525B TechStar CVT MT535B Auto PowerTM VI MT535B TechStar CVT MT545B Auto PowerTM VI MT545B TechStar CVT

ENGINE

Gross Eng HP (Kw) @ 2000 rpm 138.6 (103.54) 134.4 (100.22) @ 2034 145.2 (108.27) @ 2000 148.2 (110.51) @ 2000 155 (115.58) 157 (117.07) @ 2034

PTO HP @ 2000 rpm (Rated PTO Speed)

Rated PTO HP (Kw) @ 2200 rpm 95 (70.84) 95 (70.84) 105 (78.29) 105 (78.29) 115 (85.75) 115 (85.75)

Type Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled

Displacement CID (L) 365.0 (6.0) 365.0 (6.0) 365.0 (6.0) 365.0 (6.0) 365.0 (6.0) 365.0 (6.0)

Number of Cylinders 6 6 6 6 6 6

Bore in. (mm) 3.94 (100) 3.94 (100) 3.94 (100) 3.94 (100) 3.94 (100) 3.94 (100)

Stroke in. (mm) 5.00 (127) 5.00 (127) 5.00 (127) 5.00 (127) 5.00 (127) 5.00 (127)

Alternator Std (optional) 120 AMP 120 AMP 120 AMP 120 AMP 120 AMP 120 AMP

TRANSMISSION AutoPower

Type

Option w / 8-Creeper Gears 32 x 32 Power Shuttle w/6-Speed Powershift 60 FPH-32 MPH (50 KPH) Continuously Variable 32 x 32 Power Shuttle w/6-Speed Powershift 60 FPH-32 MPH (50 KPH) Continuously Variable 32 x 32 Power Shuttle w/6-Speed Powershift 60 FPH-32 MPH (50 KPH) Continuously Variable

REAR AXLE Heavy-Duty Flange Bar Axle Bar Axle Bar Axle Bar Axle Bar Axle

Planetary Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard

Permissible Static Load Limit 34,943 Lbs (15,850 Kg) 34,943 Lbs (15,850 Kg) 52,414 Lbs (23,775 Kg) 52,414 Lbs (23,775 Kg) 52,414 Lbs (23,775 Kg) 52,414 Lbs (23,775 Kg)

Brakes Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled

Differential Lock Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement

FRONT AXLE 2WD / 4WD 4WD only 2WD / 4WD 4WD only 2WD / 4WD 4WD only

Type 2WD Box in Box Design N/A Box in Box Design N/A Box in Box Design N/A

Type 4WD Center Pivot Center Pivot Center Pivot Center Pivot Center Pivot Center Pivot

Maximum Turning Angle 55 degrees 55 degrees 55 degrees 55 degrees 55 degrees 55 degrees

4WD Suspension Option Hydraulic Hydraulic Hydraulic Hydraulic Hydraulic Hydraulic

Steering Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic

Permissible Static Load Limit 2WD N/A N/A N/A N/A N/A N/A

Permissible Static Load Limit 4WD 36,493 Lbs (16,553 Kg) 41,336 Lbs (18750 Kg) 36,493 Lbs (16,553 Kg) 41,336 Lbs (18750 Kg) 41,336 Lbs (18,750 Kg) 41,336 Lbs (18,750 Kg)

POWER TAKE - OFF (PTO) Independent Independent Independent Independent Independent Independent

Speeds 540 / 1000 540 / 540E / 1000 540 / 1000 540 / 540E / 1000 540 / 1000 540 / 540E / 1000

Speeds Optional 540 / 540E / 1000 / 1000E No Option 540 / 540E / 1000 / 1000E No Option 540 / 540E / 1000 / 1000E No Option

Control Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic

HYDRAULIC SYSTEM Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC)

Max Flow to Remotes GPM (LPM) 29 (110) 29 (110) 29 (110) 29 (110) 29 (110) 29 (110)

No. of Remotes Std 2 2 2 2 2 2

No. of Remotes Optional up to 5 up to 4 up to 5 up to 4 up to 5 up to 4

Max Pressure PSI (Bar) 2,900 (200) 2,900 (200) 2,900 (200) 2,900 (200) 2,900 (200) 2,900 (200)

Total Flow, Steering, cooling, charge etc.

3-POINT HITCH Electronic (ELC) Electronic (ELC) Electronic (ELC) Electronic (ELC) Electronic (ELC) Electronic (ELC)

Control

Electronic Draft Control Lower Link Sensing Lower Link Sensing Lower Link Sensing Lower Link Sensing Lower Link Sensing Lower Link Sensing

Rate of Drop Electronic Control Electronic Control Electronic Control Electronic Control Electronic Control Electronic Control

Speed Control Electronic Control Electronic Control Electronic Control Electronic Control Electronic Control Electronic Control

Telescopic Stabilizers Standard Standard Standard Standard Standard Standard

Telescopic Draft Link Ends Standard Standard Standard Standard Standard Standard

Lift Capacity @ 24 in Behind Ball Ends 7,152 Lbs (3,244 Kg) Nebraska Test 10915 Lbs (4,950 Kg) Nebraska Test 7,152 Lbs (3,244 Kg) Nebraska Test 10915 Lbs (4,950 Kg) Nebraska Test 7,152 Lbs (3,244 Kg) Nebraska Test 10915 Lbs (4,950 Kg) Nebraska Test

CAB

Sound Level 71dBa 71dBa 71dBa 71dBa 71dBa 71dBa

Municipality Cab (5 Post Cab) Optional Optional Optional Optional Optional Optional

CAPACITIES

Fuel Tank Gal (L) 71.3 (270) 71.3 (270) 71.3 (270) 71.3 (270) 71.3 (270) 71.3 (270)

Cooliing System Gal (L) 7.5 (28.4) 7.5 (28.4) 7.5 (28.4) 7.5 (28.4) 7.5 (28.4) 7.5 (28.4)

Transmission Hydraulic System Gal (L) 18.7 (71) 26.4 (100) 18.7 (71) 26.4 (100) 18.7 (71) 26.4 (100)

Engine Crankcase Qt (L) 15.3 (14.5) 15.3 (14.5) 15.3 (14.5) 15.3 (14.5) 15.3 (14.5) 15.3 (14.5)

Tech Star CVT Transmission Gal (L) Not Available 14.8 (56) Not Available 14.8 (56) Not Available 14.8 (56)

DIMENSIONS

Wheelbase in (mm) 109.4 (2,780) 109.4 (2,780) 109.4 (2,780) 109.4 (2,780) 109.4 (2,780) 109.4 (2,780)

Overall Height 115 (2930) 115 (2930) 115 (2930) 115 (2930) 115 (2930) 115 (2930)

Unballasted Weight Lbs (Kg) 2WD Cab 10,956 (4,970) Not Available 10,956 (4,970) Not Available 10,956 (4,970) Not Available

Unballasted Weight Lbs (Kg) 4WD Cab 12,181 (5,525) 13,084 (5,935) 12,181 (5,525) 13,084 (5,935) 12,181 (5,525) 13,084 (5,935)

Tire Sizes Used For Specifi cations 460/85R38 R /380/85R28 F /14.00-16 F 460/85R38 R /380/85R28 F 460/85R38 R /380/85R28 F /14.00-16 F 460/85R38 R /380/85R28 F 460/85R38 R /380/85R28 F /14.00-16 F 460/85R38 R /380/85R28 F

Caterpillar 3056C / Perkins 1106C-E 60TA Caterpillar 3056C / Perkins 1106C-E 60TA Caterpillar 3056C / Perkins 1106C-E 60TA Caterpillar 3056C / Perkins 1106C-E 60TA Caterpillar 3056C / Perkins 1106C-E 60TA Caterpillar 3056C / Perkins 1106C-E 60TA

105 (78.29) Nebraska Test 102 (76.06) Nebraska Test @ 2034 110 (82.02) Nebraska Test 110 (82.02) Nebraska Test @ 2034 120 (89.48) Nebraska Test 120 (89.48) Nebraska Test @ 2034

TM

VI Semi-Powershift TechStar CVT w / Creeper Std AutoPowerTM VI Semi-Powershift TechStar CVT w / Creeper Std AutoPowerTM VI Semi-Powershift TechStar CVT w / Creeper Std

24 x 24 Power Shuttle w/6-Speed Powershift 60 FPH-25 MPH (40 KPH) Continuously Variable 24 x 24 Power Shuttle w/6-Speed Powershift 60 FPH-25 MPH (40 KPH) Continuously Variable 24 x 24 Power Shuttle w/6-Speed Powershift 60 FPH-25 MPH (40 KPH) Continuously Variable

78.83 GPM (190 LPM) Closed (PFC) 52.8 GPM (190 LPM) Closed (PFC) 78.83 GPM (190 LPM) Closed (PFC) 52.8 GPM (190 LPM) Closed (PFC) 78.83 GPM (190 LPM) Closed (PFC) 52.8 GPM (190 LPM) Closed (PFC)

Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders

Page 17

SPECIALTY WHEEL TRACTORS

MODEL MT555B Auto PowerTM VI MT555B TechStar CVT MT565B Auto PowerTM VI MT565B TechStar CVT MT575B Auto PowerTM VI MT575B TechStar CVT

ENGINE

Gross Eng HP (Kw) @ 2000 rpm 180 (134) @ 2000 180 (134) @ 2000 190 (141) @ 2000 190 (141) @ 2000 203 (151) @ 2000 203 (151) @ 2000

PTO HP @ 2000 rpm (Rated PTO Speed)

Rated PTO HP (Kw) @ 2200 rpm 130 (96.94) 130 (96.94) 145 (108) 145 (108) 160 (119) 160 (119)

Type Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled Turbocharge Air-to-Air Intercooled

Displacement CID (L) 402 (6.6) 402 (6.6) 402 (6.6) 402 (6.6) 402 (6.6) 402 (6.6)

Number of Cylinders 6 6 6 6 6 6

Bore in. (mm) 4.13 (105) 4.13 (105) 4.13 (105) 4.13 (105) 4.13 (105) 4.13 (105)

Stroke in. (mm) 5.00 (127) 5.00 (127) 5.00 (127) 5.00 (127) 5.00 (127) 5.00 (127)

Alternator Std (optional) 120 AMP 120 AMP 120 AMP 120 AMP 120 AMP 120 AMP

TRANSMISSION AutoPower

Type

Option w / 8-Creeper Gears 32 x 32 Power Shuttle w/6-Speed Powershift 60 FPH-32 MPH (50 KPH) Continuously Variable 32 x 32 Power Shuttle w/6-Speed Powershift 60 FPH-32 MPH (50 KPH) Continuously Variable 32 x 32 Power Shuttle w/6-Speed Powershift 60 FPH-32 MPH (50 KPH) Continuously Variable

REAR AXLE Bar Axle Bar Axle Bar Axle Bar Axle Bar Axle Bar Axle

Planetary Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard Heavy-Duty Inboard

Permissible Static Load Limit 52,414 Lbs (23,775 Kg) 52,414 Lbs (23,775 Kg) 52,414 Lbs (23,775 Kg) 52,414 Lbs (23,775 Kg) 52,414 Lbs (23,775 Kg) 52,414 Lbs (23,775 Kg)

Brakes Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled Hydraulic Multi-Wet Disk, Oil Cooled

Differential Lock Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement Electro-Hydraulic Engagement

FRONT AXLE 2WD / 4WD 4WD only 2WD / 4WD 4WD only 2WD / 4WD 4WD only

Type 2WD Box in Box Design N/A Box in Box Design N/A Box in Box Design N/A

Type 4WD Center Pivot Center Pivot Center Pivot Center Pivot Center Pivot Center Pivot

Maximum Turning Angle 55 degrees 55 degrees 55 degrees 55 degrees 55 degrees 55 degrees

4WD Suspension Option Hydraulic Hydraulic Hydraulic Hydraulic Hydraulic Hydraulic

Steering Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic Hydrostatic Power, Tilt and Telescopic

Permissible Static Load Limit 2WD N/A N/A N/A N/A N/A N/A

Permissible Static Load Limit 4WD 41,336 Lbs (18,750 Kg) 41,336 Lbs (18,750 Kg) 41,336 Lbs (18,750 Kg) 41,336 Lbs (18,750 Kg) 41,336 Lbs (18,750 Kg) 41,336 Lbs (18,750 Kg)

POWER TAKE - OFF (PTO) Independent Independent Independent Independent Independent Independent

Speeds 540 / 1000 540 / 540E / 1000 540 / 1000 540 / 540E / 1000 540 / 1000 540 / 540E / 1000

Speeds Optional 540 / 540E / 1000 / 1000E No Option 540 / 540E / 1000 / 1000E No Option 540 / 540E / 1000 / 1000E No Option

Control Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic Electro-Hydraulic

HYDRAULIC SYSTEM Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC) Closed, Pressure / Load Sensing (PFC)

Max Flow to Remotes GPM (LPM) 29 (110) 29 (110) 29 (110) 29 (110) 29 (110) 29 (110)

No. of Remotes Std 4 4 4 4 4 4

No. of Remotes Optional up to 5 up to 4 up to 5 up to 4 up to 5 up to 4

Max Pressure PSI (Bar) 2,900 (200) 2,900 (200) 2,900 (200) 2,900 (200) 2,900 (200) 2,900 (200)

Total Flow, Steering, cooling, charge ect..

3-POINT HITCH Electronic (ELC) Electronic (ELC) Electronic (ELC) Electronic (ELC) Electronic (ELC) Electronic (ELC)

Control

Electronic Draft Control Lower Link Sensing Lower Link Sensing Lower Link Sensing Lower Link Sensing Lower Link Sensing Lower Link Sensing

Rate of Drop Electronic Control Electronic Control Electronic Control Electronic Control Electronic Control Electronic Control

Speed Control Electronic Control Electronic Control Electronic Control Electronic Control Electronic Control Electronic Control

Telescopic Stabilizers Standard Standard Standard Standard Standard Standard

Telescopic Draft Link Ends Standard Standard Standard Standard Standard Standard

Lift Capacity @ 24 in Behind Ball Ends 14700 Lbs (6668 kg) 13700 Lbs (6214 kg) 14700 Lbs (6668 kg) 13700 Lbs (6214 kg) 14700 Lbs (6668 kg) 13700 Lbs (6214 kg)

CAB

Sound Level 71dBa 71dBa 71dBa 71dBa 71dBa 71dBa

Municipality Cab (5 Post Cab) Optional Optional Optional Optional Optional Optional

CAPACITIES

Fuel Tank Gal (L) 100 (380) 100 (380) 100 (380) 100 (380) 100 (380) 100 (380)\

Cooliing System Gal (L) 6.73 (25.5) 6.73 (25.5) 6.73 (25.5) 6.73 (25.5) 6.73 (25.5) 6.73 (25.5)

Transmission Hydraulic System Gal (L) 37.5 (142) 26.4 (100) 37.5 (142) 26.4 (100) 37.5 (142) 26.4 (100)

Engine Crankcase Qt (L) 22 (20.8) 22 (20.8) 22 (20.8) 22 (20.8) 22 (20.8) 22 (20.8)

Tech Star CVT Transmission Gal (L) Not Available 14.8 (56) Not Available 14.8 (56) Not Available 14.8 (56)

DIMENSIONS

Wheelbase in (mm) 112.1 (2,848) 112.1 (2,848) 112.1 (2,848) 112.1 (2,848) 112.1 (2,848) 112.1 (2,848)

Overall Height 119 (3024) 119 (3024) 119 (3024) 119 (3024) 119 (3024) 119 (3024)

Unballasted Weight Lbs (Kg) 2WD Cab 14,028 (6,363) Not Available 14,028 (6,363) Not Available 14,028 (6,363) Not Available

Unballasted Weight Lbs (Kg) 4WD Cab 14,528 (6,590) 15,060 (6,830) 14,528 (6,590) 15,060 (6,830) 14,528 (6,590) 15,060 (6,830)

Tire Sizes Used For Specifi cations 460/85R38 R /380/85R28 F /14.00-16 F 460/85R38 R /380/85R28 F 460/85R38 R /380/85R28 F /14.00-16 F 460/85R38 R /380/85R28 F 460/85R38 R /380/85R28 F /14.00-16 F 460/85R38 R /380/85R28 F

Caterpillar C6.6 / Perkins 1106D-E 66TA Caterpillar C6.6 / Perkins 1106D-E 66TA Caterpillar C6.6 / Perkins 1106D-E 66TA Caterpillar C6.6 / Perkins 1106D-E 66TA Caterpillar C6.6 / Perkins 1106D-E 66TA Caterpillar C6.6 / Perkins 1106D-E 66TA

144 (107) 144 (107) 175 (130) 175 (130) 190 (141) 190 (141)

TM

VI Semi-Powershift TechStar CVT w / Creeper Std AutoPowerTM VI Semi-Powershift TechStar CVT w / Creeper Std AutoPowerTM VI Semi-Powershift TechStar CVT w / Creeper Std

24 x 24 Power Shuttle w/6-Speed Powershift 60 FPH-25 MPH (40 KPH) Continuously Variable 24 x 24 Power Shuttle w/6-Speed Powershift 60 FPH-25 MPH (40 KPH) Continuously Variable 24 x 24 Power Shuttle w/6-Speed Powershift 60 FPH-25 MPH (40 KPH) Continuously Variable

78.83 GPM (190 LPM) Closed (PFC) 52.8 GPM (190 LPM) Closed (PFC) 78.83 GPM (190 LPM) Closed (PFC) 52.8 GPM (190 LPM) Closed (PFC) 78.83 GPM (190 LPM) Closed (PFC) 52.8 GPM (190 LPM) Closed (PFC)

Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders Armrest Rocker Switch, Draft Knobs, Fenders

Page 18

SPECIFICATIONS MT600B

MODEL MT635B MT645B MT655B MT665B

ENGINE

Model Endurance 74ETA Endurance 74ETA Endurance 84ETA Endurance 84ETA

PTO HP 180 (134 kW) 200 (149 kW) 220 (164 kW) 240 (180 kW)

Type In-line, liquid-cooled diesel In-line, liquid-cooled diesel In-line, liquid-cooled diesel In-line, liquid-cooled diesel

# Cylinders/Valves 6/24 6/24 6/24 6/24

Displacement (CID/L) 451/7.4 451/7.4 512/8.4 512/8.4

Rated Speed 2,200 2,200 2,200 2,200

Aspiration Turbocharged and aftercooled Turbocharged and aftercooled Turbocharged and aftercooled Turbocharged and aftercooled

Bore (in/mm) 4.3/108 4.3/108 4.4/111 4.4/111

Stroke (in/mm) 5.3/136 5.3/136 5.7/145 5. 7/145

FUEL SYSTEM Bosch radial-piston pump - Bosch radial-piston pump - Bosch radial-piston pump - Bosch radial-piston pump -

electronically controlled electronically controlled electronically controlled electronically controlled

TRANSMISSION

Type TechStar CVT TechStar CVT TechStar CVT TechStar CVT

Speed Range (mph/kph) 0.01 to 25 mph (0.03 to 40 kph) 0.01 to 25 mph (0.03 to 40 kph) 0.01 to 25 mph (0.03 to 40 kph) 0.01 to 25 mph (0.03 to 40 kph)

Option 01 - 32 MPH (50 KPH) Continuously Variable 01 - 32 MPH (50 KPH) Continuously Variable 01 - 32 MPH (50 KPH) Continuously Variable 01 - 32 MPH (50 KPH) Continuously Variable

AXLES

Front (standard) AG210 High pivot MFD AG210 High pivot MFD AG280 High pivot MFD AG280 High pivot MFD

Rear Bar Axle (in/mm) 118/3,000 – 4.33/110 dia. 118/3,000 – 4.33/110 dia. 118/3,000 – 4.33/110 dia. 118/3,000 – 4.33/110 dia.

Tread Width-18.4 tires (in/mm) 60 to 88/1,524 to 2,235 60 to 88/1,524 to 2,235 60 to 88/1,524 to 2,235 60 to 88/1,524 to 2,235

DIFFERENTIAL LOCK Electrohydraulic front & rear Electrohydraulic front & rear Electrohydraulic front & rear Electrohydraulic front & rear

BRAKES

Rear Hydraulic wet multi-disc Hydraulic wet multi-disc Hydraulic wet multi-disc Hydraulic wet multi-disc

Front Wet brakes on cardan shaft Wet brakes on cardan shaft Wet brakes on cardan shaft Wet brakes on cardan shaft

INDEPENDENT PTO

Type Electronically controlled Electronically controlled Electronically controlled Electronically controlled

Speed 540/1,000 rpm or 540/1,000 rpm or 540/1,000 rpm or 540/1,000 rpm or

(Optional) 540 Economy/1,000 rpm 540 Economy/1,000 rpm 540 Economy/1,000 rpm 540 Economy/1,000 rpm

ELECTRICAL SYSTEM

Alternator 150 amp. 150 amp. 150 amp. 150 amp.

Batteries (2) 775 cca 12-V (2) 775 cca 12-V (2) 775 cca 12-V (2) 775 cca 12-V

Block Heater (Optional) 1,000 watt coolant heater 1,000 watt coolant heater 1,000 watt coolant heater 1,000 watt coolant heater

HYDRAULIC SYSTEM

Type Pressure/fl ow compensated Pressure/fl ow compensated Pressure/fl ow compensated Pressure/fl ow compensated

# Remotes (std/opt.) 4/up to 6 4/up to 6 4/up to 6 4/up to 6

Max. Pressure (PSI/BAR) 2,900/200 2,900/200 2,900/200 2,900/200

Max. Flow (gpm/lpm), at remotes 39/147 39/147 39/147 39/147

3-POINT HITCH

Control Electronic Electronic Electronic Electronic

Draft Sensing Lower link Lower link Lower link Lower link

Rear Hitch Cat. 3, adjustable linkage Cat. 3, adjustable linkage Cat. 3, adjustable linkage Cat. 3, adjustable linkage

Lift Capacity @ 24” (lbs/kg) 15,600/7,078 15,600/7,078 15,600/7,078 15,600/7078

Front Hitch (Optional) Cat. 2 Cat 2 Cat. 2 Cat. 2

Lift Capacity (lbs/kg) 7,700/3,500 or 12,100/5,500 7,700/3,500 or 12,100/5,500 7,700/3,500 or 12,100/5,500 7,700/3,500 or 12,100/5,500

STEERING Full power hydrostatic Full power hydrostatic Full power hydrostatic Full power hydrostatic

CAPACITIES

Fuel Tank (gal/L) 159/600 159/600 159/600 159/600

Cooling System (gal/L) 8.9/34 8.9/34 8.9/34 8.9/34

Engine Crankcase (qt/L) 20/19 20/19 20/19 20/19

Hydraulic System (gal/L) 26.4/100 26.4/100 26.4/100 26.4/100

TechStar CVT (gal/L) 17.7/67 17.7/67 17.7/67 17.7/67

DIMENSIONS

Wheelbase (in/mm) 121/3,075 121/3,075 121/3,075 121/3,075

Minimum Width (in/mm) 118/3,000 118/3,000 118/3,000 118/3,000

Height Top of Cab (in/mm) 123.6/3,140 123.6/3,140 123.6/3,140 123.6/3,140

Overall Length (in/mm) 206/5,240 206/5,240 206/5,240 206/5,240

Axle Clearance (in/mm) 22.44/570 22.44/570 22.44/570 22.44/570

Shipping Weight (lbs/kg) 18,308/8,304 18,308/8,304 19,550/8,868 19,550/8,868

Shipping weight is with pressed steel, single rear wheels.

Page 19

SPECIFICATIONS LITTLE MOWER

SPECIALTY WHEEL TRACTORS

MODEL 000219-CHBM 000221-CHBM 000223-CHBM 000221-UTBM 000048-CHFL 000060-CHFL

ENGINE DESCRIPTION

000203-CHPFB PowerPlate Frame, MT525B X X X X X

000203-CHPFBR PowerPlate Frame, MT525B,RMS X X X X X

000203-CHPFBCVT PowerPlate Frame, MT525BCVT X X X X X

000204-CHPFB PowerPlate Frame, MT535B X X X X X

000204-CHPFBR PowerPlate Frame, MT535BR X X X X X

000206-UTPF

000207-UTPF PowerPlate Frame pkg, 465B UTILITY BOOM X

SPECS

Boom Reach Out Dependant on head selection 20’ - 22’ 22’ - 24’ 23’ - 25’ 20’ - 22’

Boom Reach Up Dependant on head selection 17’ 18’ 19’ 17’

Boom Reach Down Dependant on head selection 10’ 10’ 10’ 10’

swing angle 140° 140° 140° 130°

Swing Cylinder Rotar y Actuated Rotary Actuated Rotary Actuated Welded Cyl

Operator Controls Single, proportional controller for all functions 3-axis Joystick 3-axis Joystick 3-axis Joystick 3-axis Joystick

BreakAway Protection Hydraulic/Adj Hydraulic/Adj Hydraulic/Adj Hydraulic/Adj

Pivot Height From ground to Base Pin of Boom 40” 40” 40” 41”

Hydraulic seal type ORFS ORFS ORFS JIC

Hydraulics Warranty Parker® Leak Free Guaranty© Hose and Fitting set X X X

Pin Bushings All joints are greasable Hardened steel Hardened steel Hardened steel Hardened steel

Pins Machined, Heat Treated, AISI 8620 X X X X

Boom Hose Interface Coupling system between Frame and Boom Dual Plane Swivel Dual Plane Swivel Dual Plane Swivel Dual Plane Swivel

Hardware Grade 8, plated Grade 8, plated Grade 8, plated Grade 8, plated Grade 8, plated Grade 8, plated

Skin Steel Wear Surface Steel Grade 1/4” A514 1/4” A514 1/4” A514 3/16” A514 3/16” A514 3/16” A514

Warranty Years/Hours, Material and Workmanship 2/2000 2/2000 2/2000 1/1000 2/2000 2/2000

Hyd fl ow/pressure GPM / PSI 45/1850 45/1850

Hyd Pump/Drive Cast Steel, High Volume, Gear Pump 3”/PTO Coupled 3”/PTO Coupled

Hyd Motor/Drive Cast Steel, High Pressure, Gear Motors 2”/Sync Belt 2”/Sync Belt

Blade Option NW1, NW2, NW8-5 NW1, NW2, NW8-5

Grass Shaft Option Flail Heads Only Yes Yes

Blade Tip Speed ft/min 9650 9650

Spindle/ Stubs One piece construction, material spec AISI 4340 AISI 4340

Blade Carrier Material ASTM A514 ASTM A514

Cut Width 48” 62”

PowerPlate Frame pkg, 455B 2WD UTILITY BOOM X

MODEL 000148-CHRO 000061-CHRO 000448-UTFL 000460-UTFL 000448-UTRO 000461-UTRO

ENGINE DESCRIPTION

000203-CHPFB PowerPlate Frame, MT525B X X

000203-CHPFBR PowerPlate Frame, MT525B,RMS X X

000203-CHPFBCVT PowerPlate Frame, MT525BCVT X X

000204-CHPFB PowerPlate Frame, MT535B X X

000204-CHPFBR PowerPlate Frame, MT535BR X X

000206-UTPF PowerPlate Frame pkg, 455B 2WD UTILITY BOOM X X X X

000207-UTPF PowerPlate Frame pkg, 465B UTILITY BOOM X X X X

SPECS

Hardware Grade 8, plated Grade 8, plated Grade 8, plated Grade 8, plated Grade 8, plated Grade 8, plated

Skin Steel Wear Surface Steel Grade 3/16” A514 3/16” A514 3/16” A514 3/16” A514 3/16” A514 3/16” A514

Warranty Years/Hours, Material and Workmanship 2/2000 2/2000 1/1000 1/1000 1/1000 1/1000

Hyd fl ow/pressure GPM / PSI 45/1850 45/1850 40/2300 40/2300 40/2300 40/2300

Hyd Pump/Drive Cast Steel, High Volume, Gear Pump 3”/PTO Coupled 3”/PTO Coupled 2.37”/ PTO direct 2.37”/ PTO direct 2.37”/ PTO direct 2.37”/ PTO direct

Hyd Motor/Drive Cast Steel, High Pressure, Gear Motors 2”/Direct 2”/Direct 1.5”/Sync Belt 1.5”/Sync Belt 1.75”/Direct 1.75”/Direct

Blade Option Disc, Bar, FreeFlow Disc, Bar, FreeFlow NW1, NW2, NW8-5 NW1, NW2, NW8-5 BladeBar BladeBar

Grass Shaft Option Flail Heads Only Yes Yes

Blade Tip Speed ft/min 18800 23500 12500 12500 17500 21900

Spindle/ Stubs One piece construction, material spec AISI 4142 AISI 4142 AISI 4340 AISI 4340 AISI 4142 AISI 4142

Blade Carrier Material ASTM A514 ASTM A514 ASTM A514 ASTM A514 ASTM A514 ASTM A514

Cut Width 48” 60” 48” 62” 48” 60”

RMS

Roadside Management System

Page 20

SPECIALTY WHEEL TRACTORS

Cat dealers and service

world-renowned dealers, world-class service

In addition to bringing new thinking to machines, the

Challenger team brings a whole new concept to sales and

service through Cat dealers. It may be our biggest

difference and our greatest strength. And it may be the

reason your operation could become more profi table with

Challenger equipment.

When you buy Challenger equipment you get the backing

and support of the legendary network of Cat dealers.

People who have been keeping contractors, construction,

mining, landscaping, roadwork and just about every

heavy-machine demand undertaking in the world, up and

running…365 days a year, day and night. People who don’t take

downtime lightly. That’s why we’re already creating Challenger

brand loyalists—because every Challenger machine is backed

by the same support. In fact, Cat dealers are second to none in

on-location service.

© 2007 AGCO Corporation. AGCO® is a registered trademark and TechStarTM CVT are registered trademarks of AGCO Corporation. Caterpillar®, Cat® and Challenger® are registered trademarks of Caterpillar Inc.

AGCO Corporation has a corporate policy of continuous product improvement and development; therefore, specifi cations are subject to change without any advance notice. AGCO Corporation is not responsible

for differences between the specifi cations or illustrations contained in this publication and the actual equipment. Equipment produced by other manufacturers is shown in photographs in this brochure for the

purpose of illustration only and is not intended as an endorsement of that particular equipment or its suitability. All rights reserved. AGCO Corporation, 4205 River Green Parkway, Duluth, GA 30096

CHSW_B (02) 10 PD 15515/02/2007

With more mobile service trucks loaded with more diagnostic

equipment than most repair shops, and better-trained

technicians who work as hard at preventing problems as they

do at repairing them.

Combine it all with our 24-hour-a-day parts network and

you have the absolute gold standard in service. And it’s all at

work, ready to maximize your productivity and uptime.

Plus, Cat dealers have a rock-solid commitment to

agriculture. This partnership solidifi es their confi dence in the

Challenger product by putting their name behind the sales force

and service network. Combining Serious Machinery with the

Serious Dealers of Caterpillar is shifting the way things have

always been done. A shift we’re certain you’ll agree will soon

be the standard to beat.

Visit us at: www.challengerag.com

At AGC0 Finance, we understand that

financing is as much a part of your purchase

decision as the features and benefits of the

product. So we’re committed to providing the

best means of acquiring the equipment you

need, while allowing you to preserve other

credit lines of operating capital.

We offer flexible payment schedules,

flexible terms, quality service, competitive

rates, comprehensive financing and leasing

options, and virtually unlimited resources.

All are available under one roof, at your

authorized Caterpillar dealership.

Loading...

Loading...