Page 1

INFINITI(极限)

Operation Manual

FY-33VC

Thank you very much for purchasing CHALLENGER

In order to use CHALLENGER correctly and safely and understand this product’s capability,

please read thi s manual carefully.

The manual includes equipment structure, description, technical parameters, operation manual,

safety information, application of software, etc.

This manual is subject to change without notice.

Contents herein contained are believed to be correct, however, please contact us if you find

any error or something not clear enough.

Copyright 2004 Fei Yeung Union. All rights reserved.

Version 1.0

November 15, 2004

Page 2

FY –33VC Operation manual

- 2 -

Page 3

FY –33VC Operation manual

- 3 -

INDEX

CHAPTER 1 SAFETY INFORMATI ON

1.1 Important Safety Information

1.2 Caution When Using Printer

1.3 Guide When Using Ink Cartridge

1.4 Choosing Printer Installation Place

1.5 Warning, Caution and Attention

CHAPTER 2 TECHNICAL PARAMETERS

CHAPTER 3 EQUIPMENT ASSEMBL Y AND ADJUSTMENT

3.1 Assemble Printer

3.2 Attention before Turning on FY-33VC

3.3 Port of printer

3.4 Connect with power

CHAPTER 4 EQUIPMENT STRUCTURE AND ACCESSORIES

CHAPTER 5 USAGE AND MAINTAINS OF PRINTER

5.1 USAGE OF XAAR PRINTER

5.2 MAINTAINS OF PRINTER

CHAPTER 6 BASIC PANEL OPERATION

6.1 Menu Structure of Control Panel

6.2 Function Description in Details

6.3 Printing Steps

CHAPTER 7 DESCRIPTION OF INK SUPPLY, CLEANING SYSTEM AND BOARD

7.1

Ink Supply and Cleaning System

7.2 Assistant Board

CHAPTER 8 INK SUPPLY SYSTEM

8.1 Summary

8.2 System Diagram

8.3 Function Description

8.4 Operation Description

8.5 Intelligent Detection Function

CHAPTER 9 CLEANING SYSTEM

9.1 Summary

9.2 System Diagram

9.3 Work Principle

9.4 Operation Description

CHAPTER 10 HEATING SYSTEM

10.1 Summary

10.2 System Diagram

10.3 Function Description

10.4 Working Process and Characteristics

CHAPTER 11 SOFTWARE OPERATION

11.1 Installation

11.2 Application Of Printer Driver

11.3 Operation of RIP

Page 4

FY –33VC Operation manual

- 4 -

Chapter 1

Safety information

1.1 Important Safety Information

Before use your CHALLENGER FY-33VC InkJet Digital Printer, please read following safety information.

Pay attention to the cautions on the Printer.

• Do not block the hole on the cover.

• Do not insert any object into the Printer groove. Don’t let any kind of liquid splash into Printer.

• Only use the power supply according to the label. You may choose either AC 110V or 220V for

different countries and regions.

• Connect all the equipment to a properly grounded socket. Avoid the socket in the same circuit with

copy machine or air conditioner.

• Avoid to using the socket controlled by the wall switch or by auto timer.

• Please keep Printer away from the latent source of electromagnetic disturbance. For example,

loudspeaker or wireless phone.

• If you use additional cable, please make sure that total amperage of the equipment connecting with

cable shall not exceed the amperage of the power supply. Moreover, the amperage of all

equipment connecting with wall socket does not exceed the amperage of the wall socket.

• Do not use damaged Electrical Power wire.

• Do not repair Printer by yourself.

• Shut off the power and ask experienced technician for help, if the following situations occur:

Power cable or plug is damaged.

Liquid splashes into printer.

Printer falls down or broken.

Printer cannot work properly or change in property.

1.2 Caution When Using Printer

• Don’t use your hand to move print head; otherwise the printer will be damaged.

• Always use power switch to turn On/off the printer. Before shutting down the Printer, do not pull out

Power Supply wire or Data Wire.

• Before moving the printer, please make sure the print head is fixed at original position.

1.3 Guide When Using Ink Cartridge

• Keep ink away from childr en. Do not let the children drink or touch.

• If ink spills on the skin, please wash with soap and water. If ink splashes into eye, please wash with

water immediately

• Do not shake the ink cartridge in case ink leak is caused.

• After using for a certain period (generally 3 months), you should take off the ink cartridge, clean it

and dry it.

• Please keep surrounding clean when you replace a new ink container. It helps you improve printing

quality.

Page 5

FY –33VC Operation manual

- 5 -

1.4 Choosing Printer Installation Place

• Put printer at a horizontal and stable place with enough space; otherwise, the Printer may not work

properly.

• Don’t leave Printer at a place where temperature and humidity change severely. Avoid direct sunlight,

strong light or heat.

• Avoid shaking or vibrating.

• Keep sufficient room around printer for air circulation.

• Place printer nearby the wall socket, so that it is easy to connect or disconnect the power supply

1.5 Warning, Caution and Attention

Warning

Must obey in order to ensure personal safety.

Caution

Must obey in order to protect the machine.

Attention

Contain some important and useful information about operation.

Page 6

FY –33VC Operation manual

- 6 -

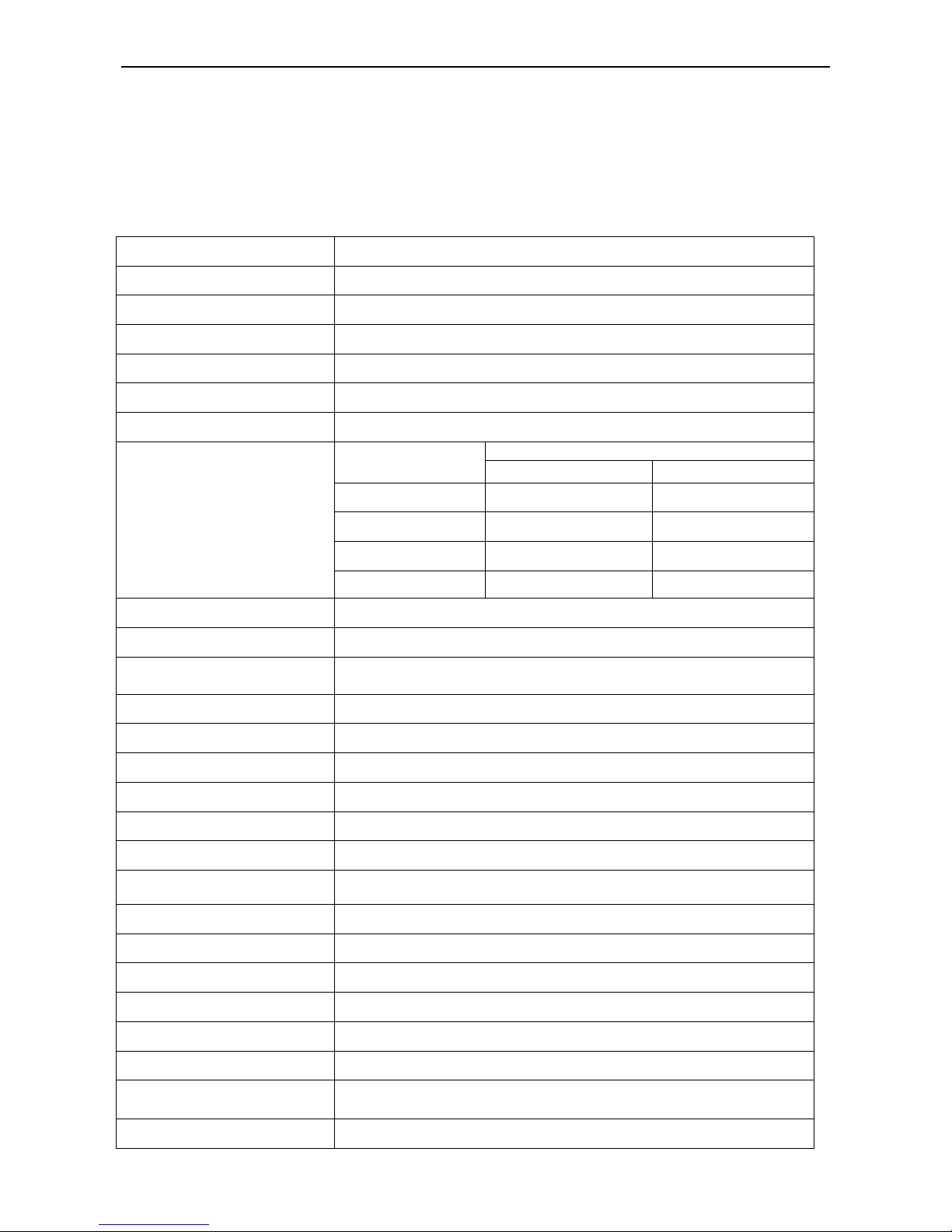

Chapter 2

Technical Parameters

Figure2-1 Printer Outlook

Product Model FY-33VC

Print Technique Xaar 126 piezo head, 12 heads inside

Resolution

200dpi、400dpi

Color Quality Photo effect including 2 levels: Basic and High Quality

Max Media Width 3300mm

Max Printing Width 3250mm

Min Printing Size A4 or 21omm

Output (m²/h)

Mode

Level 10 Level 11

200dpi 2pass

40.85 47.36

200dpi 3pass

32.11 34.41

200dpi 4pass

24.92 25.42

Output (m²/h)

400dpi

24.92 25.42

Display LCD display with 8 key panel, self-diagnosis available

Ink Type

Solvent-base ink:C, M, Y, K

Ink Supply Mode

300ml/min auto ink supply by electric pump,volume of main tank

1000ml/color

Ink Inspection System Auto/manual ink supply, low ink detector

Printing Driver Support many RIP drivers

Operation Platforms Multi-operation platforms (Window2000, XP, etc.)

Media Type Flex, vinyl, window film, polyester, etc.

Media Transmission Roll media or sheet media (bigger than A4 or 210mm)

Media Processing Auto feeding and take-up system, weight less than 40kg/roll

Print head Height 2mm-4mm above media adjustable

Pre-heater & Dry System Auto heating after electrifying, the tiptop temperature is abou t 40°C

Clamp Manual adjustment media width

Print head Cleaning System Auto positive pressure cleaning

Safety System Inside safety lock with auto shutting down function

Print Interface

USB2.0 interface (

Window2000、NT、XP etc)

Noise

Printing status≤70dB/waiting status≤40dB (ISO7779)

Printer Size ( including ink

tank) / Net Weight

L 4610mm×W 875mm×H 1,250 mm / 550 kg

Package Size / Weight

L 4700mm×W 890mm×H 1,420 mm / 720 kg

Page 7

FY –33VC Operation manual

- 7 -

Input Voltage

AC 100 - 240 V, 50HZ/60HZ

(Heating voltage can be set to be manual setup by an engineer;

Controlling voltage is auto setup.)

Voltage for the Feeding and

Cleaning System

AC 220V, 50HZ/60HZ(AC 110V optional)

Power(AC 220V applied)

Control:≤ 3A

Heating:≤ 5A

Feeding、cleaning:≤ 5A

Working Environment

Temperature:20°C - 28°C

The parameters above are subject to change without notice.

Page 8

FY –33VC Operation manual

- 8 -

Chapter 3

Equipment Assembly and Adjustment

3.1 Assemble Printer

The whole packaging equipment is easy to assembly.

1. Please assemble supporter to a horizontal, clean and proper work area, tighten all screws on the

supporter to insure safety and stability;

2. Put main ink bottles to main ink bottle frame on the right side. Make sure to connect ink pipe to

correct ink holes;

Figure 3-1 Main ink bottles

3. Fixing Xaar print head 126 on supporter;

Figure 3-2 Print head frame

1—Up screw 2—Left screw 3—Right screw

Ink hole

1

2

3

Page 9

FY –33VC Operation manual

- 9 -

Figure 3-3 Print head frame

1—Up screw 2—Left screw 3—Right screw

Method: Loosen Up and Left Screw, then remove Right Screw

Insert Xaar print head 126 downwards

Put on Right Screw and tighten all three screws

★

After assembling the print head, clip cirques, which is prepared in spare parts tank, on the

plugs of In and Out tube to prevent the plugs jumped out.

4. Please connect all power cables correctly;

5. Install Rip software on the computer.

3.2 Attention before Turning on FY-33VC

1. In order to clean print head easily, please prepare following items:

• Flush solution

• Non-woven fabric.

2. In order to inspect temperature and humidity of printing environment, please prepare relative

measurers. Requirement for environment:

• Temperature: 20°C - 28°C

• Humidity: 40% - 70%

3. Power supply

• You may select AC 110V or 220V for different countries or regions.

• Control power supply: AC 100 - 240V 50/60HZ

• Heating power supply: AC 100 / 240V 50/60HZ (AC 100 V optional)

• Feeding power supply: AC 100 / 240V 50/60HZ (AC 100 V optional)

• Cleaning power supply: AC 100 / 240V 50/60HZ (AC 100 V optional)

• Please choose the type of power shown on the printer in case of damage to the printer.

• Make sure the printer is well grounded.

• It is better to use UPS stable-voltage power.

2

3

Page 10

FY –33VC Operation manual

- 10 -

4. Requirement for computer

In order to avoid problems caused by computer, please choose high quality computer or brand

computer such as DELL or IBM, etc.

3.3 Port of Printer

USB 2.0

Connect printer’s USB and computer’s USB directly.

Find driver for USB at UsbInstalFile/Try Setup under printer’s driver.

3.4 Connect With Power

1, After all the parts installed, move printer to its working area and clean up the package.

2, Connect power cables, including power for printer and heater, printing data cable. Protective

switch only works for heater’s power. Usually this switch should be at status of On (switch on

above, far from red point)

3, After finishing, turn on power. The Auto-ink-supply-system runs to pump ink from main ink

bottles to Sub ink bottles.

4, Feed in media and printer enters waiting status.

5, Then go in test printing. Observe ink drop. If not good, clean print head again.

Page 11

FY –33VC Operation manual

- 11 -

Chapter 4

Equipment Structure and Accessory

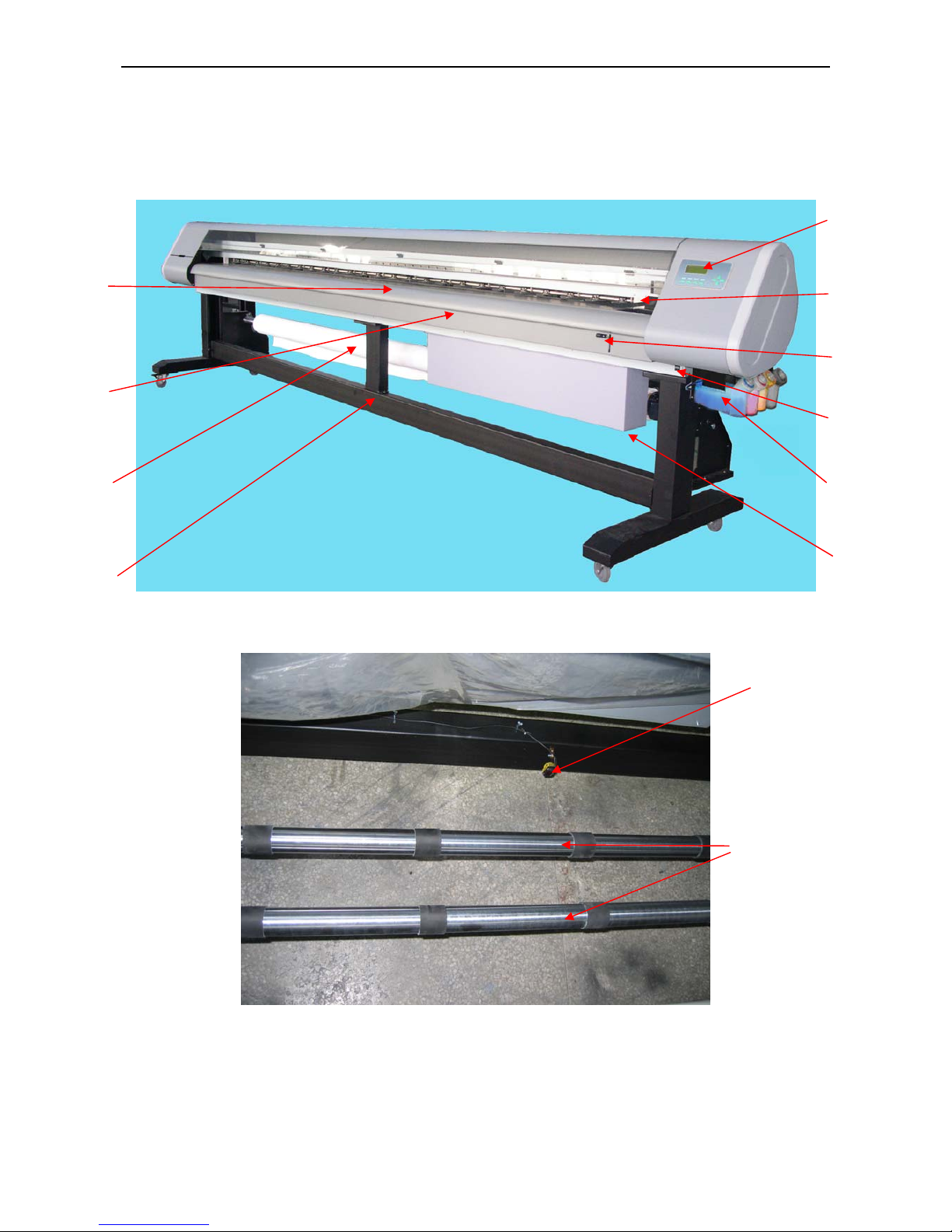

Figure 4-1 Front View

Figure 4-2 Media feeding system

6

1

5

4

8

9

3

7

2

10

11

13

Page 12

FY –33VC Operation manual

- 12 -

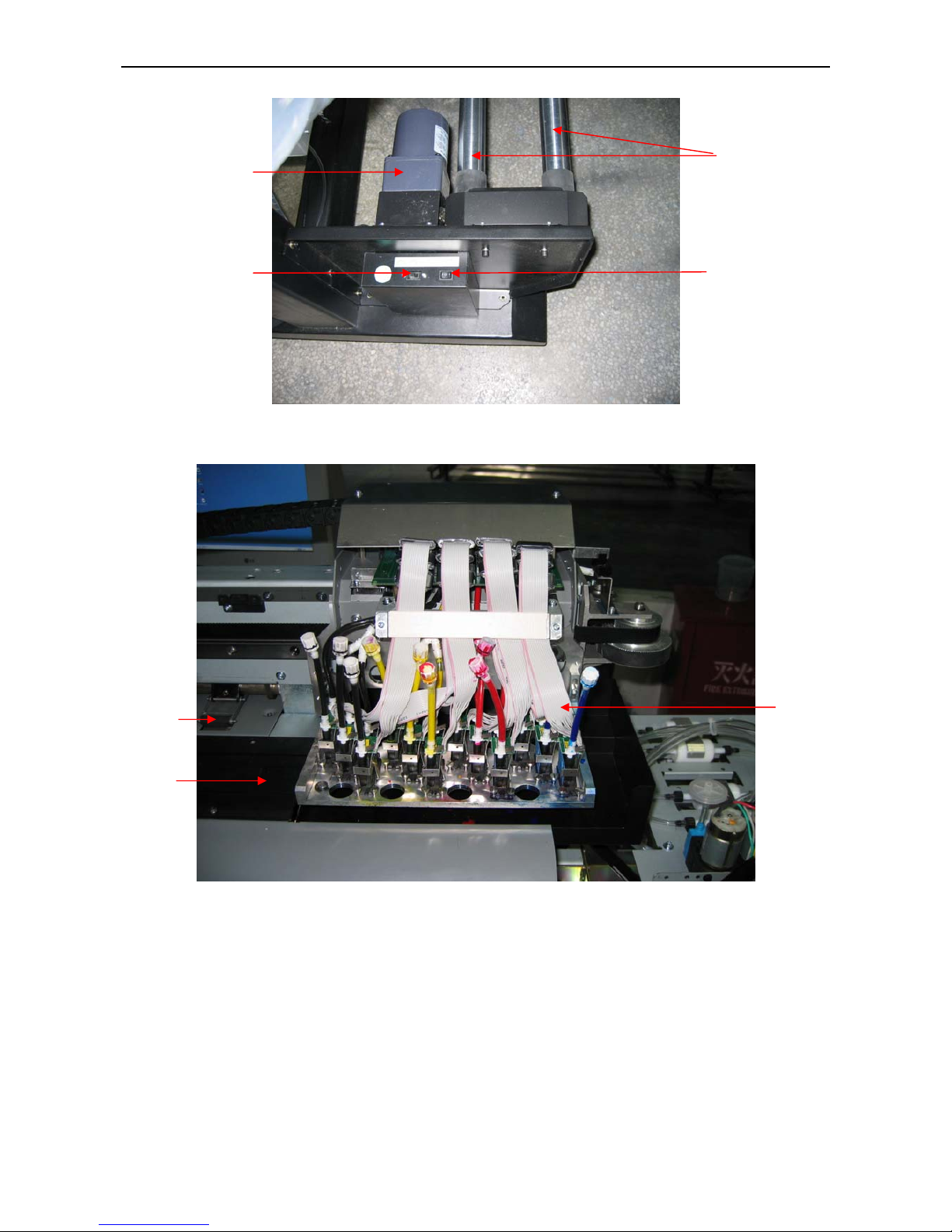

Figure 4-3 Media feeding system

Figure 4-4 Print head Unit

13

15

12

14

1

16

3

Page 13

FY –33VC Operation manual

- 13 -

Figure 4-5 Power and cable socket

Figure 4-6 Ink pumping, filter and valves

22

20

19

21

24

25

23

Page 14

FY –33VC Operation manual

- 14 -

Figure 4-7 Assistant ink tanks

Figure 4-8 Cleaning operation panel

1. Print head:8 piezo print heads

2. Media:A wide range of media available

3. Printing Platform:Platform for printing

4. Power Switch:Turn on/off printer

5. Press Roller Control Pole:Control press roller up / down for media feeding

6. LCD Control Panel:Set up and execute function and mode

7. Heating board:Heat media to dry the ink on the media

27

28

32

31

30

Page 15

FY –33VC Operation manual

- 15 -

8. Electric tank: Used to settle circle board

9. Main Ink tanks:Total C, M, Y, K 4 colors, 1000ml/color

10 Waste Ink Tank: Collect the waste ink during cleaning

11. Media Auto-feeding sensor: Control media feeding motor running

12. Media feeding motor:Roller driver

13. Media Feeding Roller: Hold media for printing

14. Media Feeding System Switch:Make media feeding roller turn forward or backward

15. Media Feeding Manually/Automatically Switch:Manually control or automatically control or shut down

media feeding motor.

16. Press Roller:Press media and make media smoothly

17. Clamp:Manually adjust media width

18. Flash Protector Frame:Prevent ink splash

19. Print Interface:USB2.0 interface or connect to data card in computer

20. Power Socket:Provide power for printer

21. Heating Power Socket: Provide power for heater

22. Heater Protective switch:Prevent electric leakage of heating board

23. Ink pump: provide ink to sub ink tank

24. Ink filter: Filtrate impurity in ink.

25. Valve: Automatically control the air route

26. Air pump: Compress air as positive cleaning the print head.

27. Assistant ink tank: Store ink.

28. Safety tank: Store air. Prevent ink leak out while float switch inside sub ink tank is broken.

29. Tube clamp: manually control the air route

30. Reset button: Stop alarming of ink lacking in assistant ink tank

31. Positive clean button: Control starting and process of positive pressure clean

32. Lighten: Lighten for checking the print head status

Page 16

FY –33VC Operation manual

- 16 -

Chapter 5

Usage and Maintains of print head

5.1 Usage of Xaar Printer

1—Print head 2—In tube 3—Out tube 4—Cap 5—Fitting

Figure 5-1 Print head

1、Flush humectants out of print head

To moisturize print head, lots of humectants are injected into the head before it is used. The humectants

must be flushed out for the first using. Before fix the head on the print head frame, do the steps as follows:

Joint a filter on the In-tube of the head, and then joint an injector--which fills with flush solution--on the filter.

Inject 10-20 ml flush solution to the head to eject the humectants inside. Then fill the head with flush

solution to dissolve the humectants completely within 5-10 minutes. Finally, flush the head with about 30ml

flush solution to eliminate the humectants completely.

Make sure to operate on a stable and clean platform.

Cautions:

1. Clean platform for convenient operation;

2. Don’t touch the surface of head and socket with hand;

3. Clean the filter with flush solution;

4. Connect a tube on the exit of the head to prevent ink flowing into the socket;

5. Don’t touch the surface of head with other objects;

6. Be careful to distinguish In tube and Out tube of the head;

7. Eject flush solution from the nozzles with strength no more than 0.3 kg. (It is better to hold the

injector with single hand and push it with the same thumb.)

2、Extrude air from the print head

After fixing the head on the head frame (be cautious of the in tube and out tube). Remove the Cap from

4

5

3

2

1

Page 17

FY –33VC Operation manual

- 17 -

the Out tube; positive-pressure clean to fill the head with ink till ink streams out from nozzles. During the

process air is extruded completely from the head.

3、Moisturize print head surface

After extruding air from the head, cover the Cap on the Out tube. Positive-pressure clean again until ink

streams out of the nozzles, then scrub the head surface with a dry clean stick to form a protecting layer of ink

on the head surface. The ink on the surface will stream into the nozzles because of negative pressure.

Notes: Never scrub the head surface when head surface is dry, for that will orient air into the nozzles and

shape bubbles in the pipelines and affect the printing quality.

4、Test printing

Design some color blocks as 20x20cm with some image operating software, and set color luminance as

100%, 50% and 10%. Print the color blocks under test mode and check the print result. If the print result is

normal which means no ink-break and no ink spots on the mediums, the printer can work normally.

Figure 5-2 color blocks for test printing

5.2 Cleanness and maintenance of the print head

1. Ink replacing

Flush the print head with the original ink first, and then flush it again with new flush solution, which matchs

the new ink.

2. Print head cleaning

If low quality printing takes place, a positive-pressure cleaning is proper for the head. After positive pressure

cleaning, scrub the head surface with a dry clean stick to stop ink streaming from the nozzles. Be sure not to use a

stick with flush solution to scrub the head surface, otherwise, the flush solution will be siphoned into the nozzles.

3. Moisturize print head

Use wet keeping frame to moisturize the head if the printers is left unused. Put a clean non-woven fabric on

the sponge of wet keeping frame and drop some flush solution on it because the sponge usually has dust on it. If

no wet keeping frame, adhere a clean non-woven fabric with some flush solution on the print head and wrap it

with a fresh keeping polyester film.

Page 18

FY –33VC Operation manual

- 18 -

Chapter 6

Basic Panel Operation

6.1 Menu Structure of Control Panel

Figure 6-1 Control Panel

Function Keys

1. Direction (Arrow) Key

2. Function Key

1) ONLINE:Switch between online and offline mode; Press for 3-4 seconds for a pause during pringing

2) ESC:Back to the upper menu

3) ENTER:Confirm the command and execute it

4) FUNC:In self-diagnosis mode when offline; Shortcut to the cleaning position in Clean Pos mode.

3. Basic Operation

After the printer is power on, X motor self-tests first and then Y motor. After self-testing, carriage goes

back to the original position. You will see the following information displayed on the LCD screen:

• Mark

/// CHALLENGER

with machine model

• Version

• Then back to basic operation menu.

The machine is in normal conditions if shown as below.

Figure 6-2 Main Menu

Denotation of the menu:

“+” stands for containing submenu. “– ” stands for containing no submenu.

In this case, press ×/Ø key to circularly display these four menus up and down. When there’s a “+” after

Function Key

LCD

Direction Key

FY-33VC Ver 4.43

MENU -> 1.Moving System +

2.Clean Tools +

3.Adjustment +

OFFLINE 4.Options +

Page 19

FY –33VC Operation manual

- 19 -

the menu arrow (that is the first line on menu), press ENTER key, and submenu will be displayed. For

example, when the arrow point to “1.Moving system”, press ENTER key, and it will display on the LCD

screen as follows:

6.2 Function Description in Details

Main Menu Submenu Description

X-Move

After pressing ENTER, “MOVE” flashes on LCD. Move the media

by pressing key ×/ Ø. After media moves to the proper position,

press “ENTER”.

Media

Detect

After pressing ENTER, print head will traverse along the Y-rail

only once to detect media, and then stop in front of the beginning

of media. If LCD displays “ERROR”, please check if media or

sensor is installed or not. (Now this function is not available)

Clean POS

Press ENTER to execute. LCD displays the setting value “XXXX”,

unit in mm. Press “FUNC” to move the head quickly to the setting

position. If it does not reach the cleaning position exactly, adjust by

pressing Õ Ö. Then press ENTER to save this value.

Use this function to clean print head. Enter this menu, LCD

displays value “XXXX”. Press FUNC, print head moves to the

setting position automatically. If press Ø at the moment, print head

will purge automatically.

Moving

System

Print POS

After pressing ENTER, value “XXXX” flashes on the LCD. Press

Õ

Öto move the print head right or left. After moving to the proper

position, press ENTER to save the value. Later image printing or

test printing will start from this position.

CLEAN

ALL

After you press ENTER, print head moves to the cleaning area to

clean with positive pressure automatically, and then back to the

original position.

Purge Ⅱ

After you press ENTER, “JET” flashes on the LCD. Print head jets

ink to prevent from jams. “JET” disappears after jetting finishes.

Press ENTER again if you want to repeat. In this mode, ink amount

jetted is normal. Ink amount can be modified on the option “Purge

Quantity” under “Option” menu.

Clean Tools

Purge Ⅲ

After you press ENTER, “JET” flashes on the LCD. Print head jets

ink to prevent from jams. “JET” disappears after jetting finishes.

Press ENTER again if you want to repeat. In this mode, ink amount

jetted is large. Ink amount can be modified on the option “Purge

Quantity” under “Option” menu.

MENU →

M1

OFFINE

1.X-Move -

2. Media Detect -

3.Clean POS -

4.Print POS

-

“M1” stands for the submenu of the first main menu.

In this case, press ESC key, and it will go back to main

menu. Press ×/Ø key to circularly display these four

menus up and down. When there’s a “–” after the menu

arrow (that is the first line on menu), press ENTER key

to execute operation. Press ESC key to exit.

Page 20

FY –33VC Operation manual

- 20 -

JAM TEST

Press ENTER to execute test printing. (It is same to press FUN on

the OFFLINE mode.)

Moving

Test

After pressing ENTER, LCD displays as below:

Follow guide for operation. Printer is under simulate-printing mode

without ink jetting. It is just for a test purpose.

Print Speed

Horizontal speed has 12 shifts ranging from 0 to 11. After you

press ENTER, it displays as follow:

Press ×Ø to adjust the value. Printing quality drops while print

speed rise.

BID adjust

This function is used to adjust the print head, in order to prevent

overlapping under BID printing. After pressing ENTER, LCD

displays as below:

Press

×Øto add or deduct 1,and pressÕÖto add or deduct 20. It is

necessary to use the FY-33VC driver software at the same time.

Please refer to the software instructions in the following chapter.

Adjustment

Rectangle

This function is to adjust the feeding rectangle in Y direction. After

you press ENTER, LCD displays as follow:

Press×Øto add or deduct 1,and pressÕÖto add or deduct 20.

Note: This function is invalid for FY-33VC. Adjust the feeding

compensation in the software that is more convenient.

Purge

Times

Set for print head to purge automatically after printing several

lines. No purge when the value is 0.

Options

Purge

Quantity

Set the amount of purge after cleaning, and amount of PURGE

Ⅲ in M2 when cleaning manually.

Note: The value cannot be set too large. Otherwise it may affect

the print quality.

MENU -> Moving Test

M3-1 Press <FUNC> to run

test and Press <ESC>

OFFLINE to stop

MENU -> Print Speed

M3-2 XXXX

Default is 4

OFFLINE

MENU -> BID Adjust

M3-3 XXXX

OFFLINE

MENU -> Rectangle Adjust

M3-4 XXXX

OFFLINE

Page 21

FY –33VC Operation manual

- 21 -

Paper

Detect

Check whether the media is exhausted. 0 means detecting;1 means

automatically detecting The function is not available so far, so you

must set 0.

Fan

Velocity

Used to set suction value to media. Set the velocity between 0 and

255, and the normal value around 128.

6.3 Printing Steps

On normal condition, the steps are as follows:

1. Power on the printer

2. Turn on the computer

Note:It is recommended to turn on the printer before computer. Otherwise the connection

may fail.

3. Install media, put down the press bar to press on media.

4. Clean the head and start the self-diagnosis till no nozzle clogging.

5. Press ONLINE.

Offline mode Online mode

6. Trim the pattern for printing, and save it in computer.

7. Open CHALLENGER RIP.

8. Create new file.

9. Read the pattern for printing.

10. Adjust the position, size, property, and resolution of the pattern.

11. Printer setting

1) Select File/Printer setting. Below dialogue box shows:

2) Select the type of printer as “FeiYeung Printer” and the model as “FY-33VC”.

3) Click the “Printer setting”. Set the relevant value in the following dialogue box.

MENU -> 1.Moving System +

2.Clean Tools +

3.Adjustment +

OFFLINE 4.Options +

ONLINE

MODE

Page 22

FY –33VC Operation manual

- 22 -

a. Select the printing resolution.

b. Select BID or single direction printing. BID has higher efficiency than single

direction.

4) Click“color tune”to activate following dialogue box.

Note: Details of the functions above and others referred to the CHALLENGER RIP

Manual

12. Click “Printing Project” to print.

13. LCD displays as below when printing:

14. If clogging appears during the printing,press ONLINE for a longer time (3s) to pause printing

for print head cleaning. After cleaning, press ONLINE to go on printing.

(

Cleaning procedure:

To avoid the nozzle clogging during printing, you can press ONLINE key for a pause. Press Õ key to

make the print head move to leftmost cleaning position and do the cleaning operation by selecting

“Ink”button on Cleaning operation board. Press Ø key to make the print head jet ink automatically;

Press × key to let the print head execute positive pressure cleaning automatically. When cleaning

finishes, press ENTER key to continue printing. Press Ö key to drive the print head to original position.

Press ESC key to cancel the printing. Do not switch mode from ONLINE to OFFLINE until “printing

cancel” shows up on computer. )

15. Press ONLINE when the printing is all finished. Then the printer is under the Offline mode.

Note: To cancel printing operation, usually do in RIP. If you want to cancel printing directly

on the printer, press ONLINE button after the menu “printing cancel” appears in software.

Total lines

Finished lines

RIP ready lines

PRINT PROJECT

LINE:TOTAL:XXXX

FINSH:XXXX

RIP READY:XXXX

Page 23

FY –33VC Operation manual

- 23 -

Chapter 7

Description of Ink Supply, Cleaning system and board

7.1 Ink Supply and Cleaning System

Figure 7-1 Ink Supply and Cleaning System ( Right Side)

1. Main Tank C 2. Main Tank M 3. Main Tank Y 4. Main Tank K

Figure 7-2 Ink Supply and Cleaning System(Seen from Back)

1. Ink Filter C 2. Ink Filter M 3. Ink Filter Y 4. Ink Filter K 5. Solenoid E-valve 6. Air Filter

7. Air Pump 8. Ink pump K 9. Ink pump Y 10. Ink pump M 11. Ink pump C

1 2 3 4

1 2 3 4 5

6 7 8 9 10 11

Page 24

FY –33VC Operation manual

- 24 -

Figure 7-3 Ink Supply and Cleaning System(Seen from Back)

1. Sub Tank C 2. Sub Tank M 3. Safety Tank 4. Sub Tank Y 5. Sub Tank K

6. Floating Switch (in sub-tank) 7. Ink in Tube 8. Ink out Tube 9.Air Tube 10.clamp

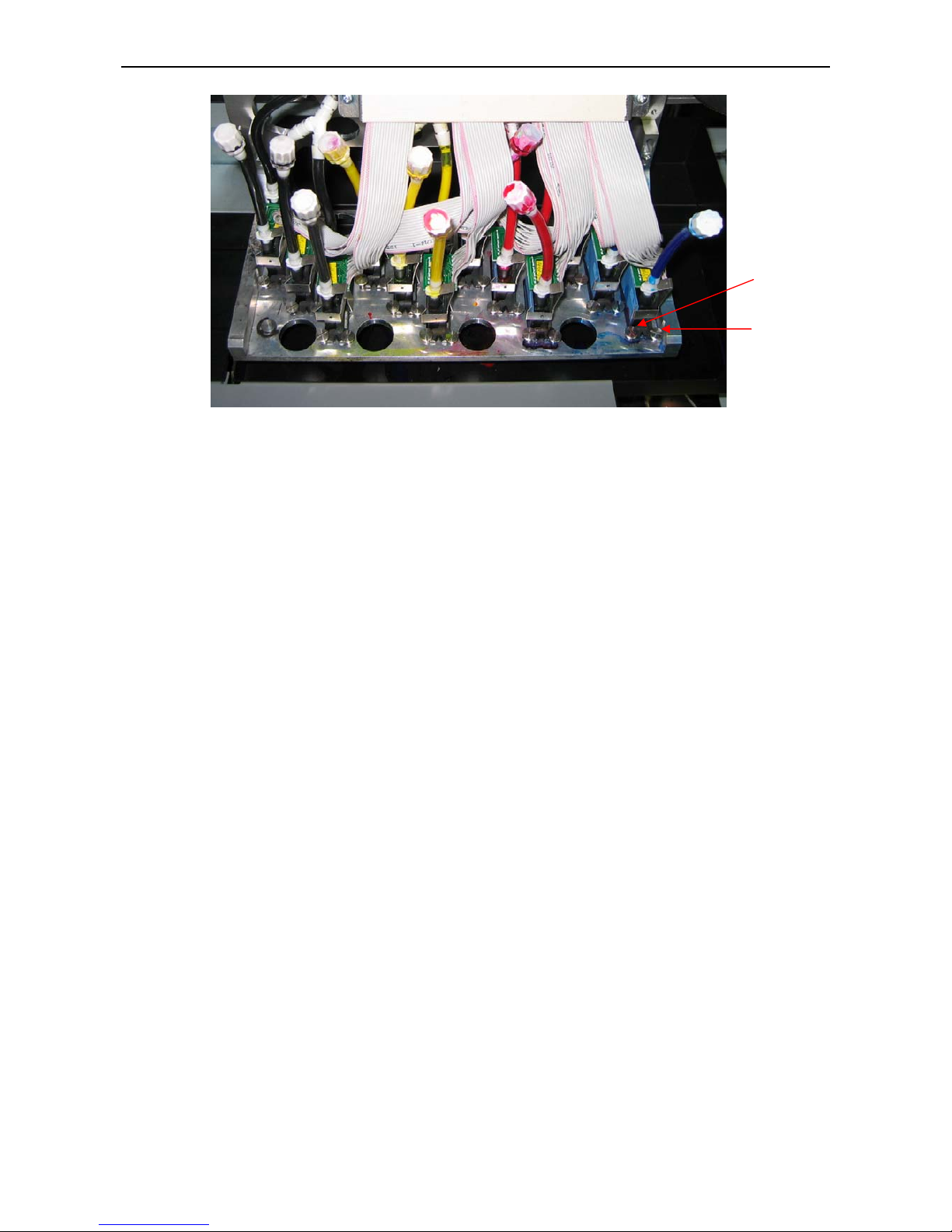

Figure 7-4 Ink Supply and Cleaning System(Seen from Front)

7.2 Assistant Board and Cleaning Operation board

Assistant Board has many functions. It can control ink supply, cleaning and heating.

Tube connector cap

Printhead

Ink in tube

1 2 3 4 5

9

10

7

8

6

Data lines

Ink out tube

Printhead board

Page 25

FY –33VC Operation manual

- 25 -

1—Reset 2—Positive pressure clean 3--Light

Ink Supply and Cleaning Operation Board is connected to assistant board for ink supplement and print head

cleaning. Press “Restoration” and “Cleaning” to execute.

1 2 3

Page 26

FY –33VC Operation manual

- 26 -

Chapter 8

Ink Supply System

8.1 Summary

This ink supply system can control automatically several pumps at the same time and provides protect

function. Isolated ink supply system is easy for operation.

8.2 System Diagram

Figure 8-1 Ink Supply System Diagram

8.3 Function Description

1. This system work automatically and control several pumps to supply ink simultaneously. When

printer is power on, ink pump starts automatically to pump ink to assistant ink tanks from main ink

tanks.

2. With perfect alarm and protection function. If any problem occurred in any pump, it will alarm and

indicate which one is in trouble and the troubled one will not affect others.

3. Ink filter switches get signals through serial ports.

4. It is easy to connect it to other systems. All floating switches signals can be input by serial port or

parallel port.

5. Main controller consists of micro CPU, which can check signals using software to filter out the false

ones, which is helpful to make system work more reliably.

6. The ink-pumping limit is controlled by intelligent control system of main control board; in case that

the electric circuit will cause ink supply shortage.

8.4 Operation Description

Note: please read descriptions carefully for ink supply system, cleaning system and Ink

Pump

Main Tank

Filter

Sub-tank

Floating Switch

Ink tube

Print head

Ink Control Board

Output:

Speaker

Pump light

Ink light

Input:

Signal for floating switch

Interface signal

Manual ink supply button

Power Supply

Page 27

FY –33VC Operation manual

- 27 -

Control system before starting the following operations.

1. As soon as the printer’s connected with power, system detects floating switch signal automatically,

and then ink will be filled into sub-tank.

2. When ink channel lacks of ink, system will start the pump automatically; and indicator lighten. After

the floating switch senses the ink, the pump will continue to work for a little period and then stop;

and the indicator light extinguishes.

3. When ink in assistant tanks is used out or other reasons cause some pump running overtime, the

system will alarm (voice a straight buzz) and force to stop the pump automatically. Press “restore”

button on cleaning operation board to cancel the alarm, and system goes back to auto-ink-supply

process.

4. When waste ink tank is full, system will alarm as intermission buzz. (Only one waste tank is

equipped, so this function is invalid at the moment)

5. When safety tank is full, system will alarm as short buzz.

Figure 8-2 Cleaning Operation Board

1—Restoration button 2—Cleaning Button 3—Flush solution Button (opt for 5 main ink tanks)

4—Illuming button

8.5 Intelligent Detection Function

Intelligent detection function for ink supply system is implemented by collecting floating switch signal

with high frequency. By using concept of probability, the signal is regarded as effective if probability of

floating switch signals is higher than a set value (for example, 80%). Therefore, wrong act of floating switch

can affect the system’s stability much less and accor dingly system’s anti-disturbance improves.

1 2 3

Page 28

FY –33VC Operation manual

- 28 -

Chapter 9

Cleaning System

9.1 Summary

This type of printer use cleaning methods as positive pressure cleaning, you execute cleaning before

printing, during printing or idle for a long time.

9.2 System Diagram

Figure 9-1 Cleaning System Diagram

9.3 Function Description of Positive Pressure Cleaning

When you press “clean” button on the Cleaning Operation Board, the cleaning signal will be transfer to

air pump; air pump starts running and transfers air pressure to valve; the air pressure raises in air tank and

is transferred to assistant ink tanks through air channels. With pressure got from the air pump, ink will be

purged through the head and ink channel, so as to clean them.

Figure 9-2 cleaning operation board

1—Reset 2—Clean 3--Light

Air Filter

Air Pump

A

ir Filter

Valve

Ink

pump

Output:

Pump light

Input:

Data Signal

Pressure Signal

A

ssistant Board

Power

Main Tank

Ink Filter

Assistant

Ink Tank

Floating Switch

Ink

channel

Print head

1

2

3

Page 29

FY –33VC Operation manual

- 29 -

9.4 Operation Description

Move print head to cleaning position, Press “Ink” button on Cleaning Operation Board to launch positive

pressure cleaning. Release the button to stop cleaning. Turn on Illuming Switch to lighten and check the ink

drop.

You have two choices to clean two channels or all four channels of color s. If choose cleaning two

channels, clamp the other two air route to cut off the air. Cleaning of the two ink channels won’t operate

without air pressure.

Page 30

FY –33VC Operation manual

- 30 -

Chapter 10

HEATING SYSTEM

10.1 Summary

This heating system can adjust temperature based on different PVC material and surrounding. It can

adjust the temperature automatically to keep temperature constant. Customer can have satisfactory

printing effect.

10.2 System Diagram

Figure 10-1 System Diagram

10.3 Function Description

1、To keep the front and rear heating boards in auto constant temperature.

2、 With advanced protective functions to avoid over-heating, leakage, etc. The line will be cut off

automatically if a certain line’s temperature is over 70° C. As soon as the temperature lowers, it will

resume heating. Over heating will not occur when the entire input signal is cut off.

3、 The system can work independently and can be easily transplanted. It is easy to convert input

voltage from AC110V to 220V.

4、 The heating system is controlled by advanced intelligent microprocessor; it has features of heating

up quickly, controlling temperature accurately and saving energy.

5、Inner heaters are used. It is easy to install, with no extra space needed and longer lifetime.

10.4 Working Process and Characteristics

1. The temperature of front and rear heater is already set in the factory. User cannot amend it.

2. Heating power supply is independent from control power supply. Please turn on the heating power

before turning on the power for the printer. Once the power is on, the system heats up

automatically to set temperature and keeps the temperature at the set value. Without turning on

▽

Front heating board

Temp-switch signal

D

Heating signal

Cleaning Operation Board

Solid

relay

Back Heating Board

Page 31

FY –33VC Operation manual

- 31 -

power for printer, the heating system will not work. However, there is still AC 220V inside machine.

3. Temperature detector lies about 50cm to the right physical printing original position. Print media

should cover this region when printing.

4. After printing, make sure to turn off the two powers.

Page 32

FY –33VC Operation manual

- 32 -

Chapter 11

Software Operation

11.1 Installation

1. Installation of Challenger RIP Software: see the RIP User’s Manu al for details.

a) Insert RIP CD into computer’s CD-ROM

b) Run setup.exe

c) Follow the instruction to finish the installation

2. Installation of printer driver

a) Insert installation CD of FY series printer into CD-ROM

b) Run setup.exe under directory of Try Setup.CHL V5.0T

c) Follow the instruction to finish the installation

Note:Please use the default directory for the installation.

11.2 Application Of Printer Driver

Note:The FY series printer driver program is only for engineer to adjust the print head,and not

necessary for normal operation.

11.2.1 Enter TRY

1. Click Start\Program\Try, enter Try system.

2. Open TRY

Page 33

FY –33VC Operation manual

- 33 -

3. First, choose the type of printer. Click “Printer” menu , choose the item of

FY-3212C/FY-3212C+/FY-33VC.

4. Then open “File” to adjust some settings.

Page 34

FY –33VC Operation manual

- 34 -

In these menus, most important is print setting.

11.2.2 Print Setting

This function is to set the printing parameter, print mode, uni-direction, BID and the color of ink.

Note: Usually the four colors should all be selected. Only when the engineer adjusts the

position of head, one certain color is chosen to modify the printing parameter.

Print Mode:

There are 7 modes for choosing: Test mode, 200 2Pass, 200 4-2Pass, 200 3Pass, 200 6-3Pass, 200

4Pass, 400 DPI

Explanation:

Test mode: Just 200 1Pass. 200dpi of horizontal resolution and print once at feeding

direction

200 2Pass: 200dpi of horizontal resolution and print twice at feeding direction. Ink volume

is twice of 200 1Pass, but printing speed is just 1/2.

200 4-2Pass: print quarter under half of 200dpi for horizontal resolution and involving twice

at feeding direction. Ink volume is twice of 200 1Pass, but printing speed is

just 1/2.

200 3Pass: 200dpi of horizontal resolution and price thrice at feeding direction. Ink

volume is 3 times of 200 1Pass but printing speed is 1/3 of 200 1Pass.

200 6-3Pass: print six times under half of 200dpi for horizontal resolution and involving

twice at feeding direction. Ink volume is twice of 200 1Pass, but printing

speed is just 1/2 of 200 3Pass.

200 4Pass: 200dpi of horizontal resolution and print 4 times at feeding direction. Ink

volume is 4 times of 200 1Pass and printing speed is 1/4 of 200 1Pass.

400 DPI: Just 400 4-2Pass. 200dpi of horizontal resolution and print 4 times, so

horizontal printing resolution is 400dpi. Printing twice at feeding direction. Ink

volume is 4 times of 200 1Pass and printing speed is 1/2 of 400 2Pass.

11.2.3 Printer Parameter Setting

Pressing “Printing parameter setting”, it shows warning as below:

Page 35

FY –33VC Operation manual

- 35 -

After pressing “Yes”, you can see the dialogue box:

Note: Press “load parameter” first to read the original data before adjusting.

Meaning of this dialogue box:

1. Parameter of nozzle installation:

Adjust the head position and overlapping of four colors.

Page 36

FY –33VC Operation manual

- 36 -

A. Look head C1 as datum mark, its horizontal and vertical value is 0. The value is A (0, 0).

B. The vertical gap between head C2 and head C1 is ensured by mechanical precision. The value of

horizontal gap is B. (In above figure is 255)

C. The vertical gap between head C3 and head C1 is ensured by mechanical precision. The value of

horizontal gap is C. (In above figure is 510)

D. The vertical gap between head M1 and head C1 is 0 in above figure. The value of horizontal gap is D. (In

above figure is 765)

E. The vertical gap between head M2 and head C1 is ensured by mechanical precision. The value of

horizontal gap is E. (In above figure is 1020)

F. The vertical gap between head M3 and head C1 is ensured by mechanical precision. The value of

horizontal gap is F. (In above figure is 1276)

G. The vertical gap between head Y1 and head C1 is 0 in above figure. The value of horizontal gap is G. (In

above figure is 1531)

H. The vertical gap between head Y2 and head C1 is ensured by mechanical precision. The value of

horizontal gap is H. (In above figure is 1786)

I. The vertical gap between head Y3 and head C1 is ensured by mechanical precision. The value of

horizontal gap is I. (In above figure is 2041)

J. The vertical gap between head K1 and head C1 is 5 in above figure. The value of horizontal gap is J. (In

above figure is 2296)

Head 2 Head 5 Head 8 Head 11

Head 1 Head 4 Head 7 Head 10

Head 0 Head 3 Head 6 Head 9

Printhead driving board

Clean position Original

Feed

L K J I H G F E D C B A(0,0)

Head 0-K3 Head 3-Y3 Head 6-M3 Head 9-C3

Vertical gap

Hor. gap

Head 1-K2 Head 4-Y2 Head 7-M2 Head 10-C2

Head 2-K1 Head 5-Y1 Head 8-M1 Head 11-C1

Page 37

FY –33VC Operation manual

- 37 -

K. The vertical gap between head K2 and head C1 is ensured by mechanical precision. The value of

horizontal gap is K. (In above figure is 2551)

L. The vertical gap between head K3 and head C1 is ensured by mechanical precision. The value of

horizontal gap is L. (In above figure is 2806)

2. BID Rectangle: To adjust the BID rectangle tolerance value. Generally, modify BID rectangle value first

in

BID adjust.

If the difference is not big, adjust here.

3. Ignore horizontal and vertical deviation: No adjustment. Only for inspect printer status.

4. Feed Compensate:Used to adjust the feeding on the Y direction. The amount of feeding is different

with different Pass.

5. COM port:Set the serial port.

6. Load parameter:Load the parameter saved in printer.

7. Input parameter: Save the parameter in printer.

8. Curve of head voltage:

(1)Press “Curve of head voltage”. The dialogue box appears.

1) Viscosity file:Open viscosity file of ink. This curve shows the relationship between viscosity and

temperature. For FY-3212C, open the file

Xaar126.Ink.

2) Read Curve:Open the voltage control file. The curve shows the relationship between voltage and

temperature. For FY-3212C, open the file

Xaar126.Crv.

Note: Different ink has different read curves. Please use the ink recommended by us and

use the corresponding curve. If you want to use other brand ink, please contact us.

3) Save Curve:Save the voltage control file.

4) Control Curve:Control and adjust the EF value of head voltage for each color.

5) Upload:Save data to printer.

6) Download:Read relevant data from printer.

Users can also select “All”, and then press “Download”. All the relevant data of four colors will be

loaded.

Based on the different properties and status of ink, users can select different viscosity file and voltage

control file.

Page 38

FY –33VC Operation manual

- 38 -

EF value setting:

Each Xaar126 head has its own EF value. Manufacture always provides a standard EF value, which is

captured under standard condition. Users input this value at column Voltage. Usually, the printing effect is

good. The value is marked on the head. It is also saved in the chip of print head driver. User can download it

directly.

If the voltage is too high, it produces the satellites and ink supply is easy to break;If the voltage is

too low, the printing line is not straight and easy to have an angle. Besides, ink volume is small and output

color is light. Therefore, every head has its optimal EF value. When adjusting, you can adjust the EF value

one by one. Usually user needn’t to adjust EF value.

Warning:Do not change these values at will. It may cause printout overlapping or dimness.

11.3 Equipment adjustment:

Steps:

11.3.1 Enter TRY

11.3.2 Print head adjustment

Select Open/File, load the file

C:\try\SmallGrid126.group

SmallGrid126.group

In “Print setting”, select 200 1Pass,single direction, color “C”. Press printing

, and print color “C”.

The line should be vertical on the vertical direction. If not, adjust the angle of head.

Effect of vertical line Adjusting the angle head

Adjust head installation angle

After the line is straight, check the accordance of lines printed by C1 and C2 heads. If not, adjust the C2

head backward or forward.

After adjusting the head of color “C”, do the same adjustment to the other heads. During adjustment,

do not change “Printer parameter setting”.

Feeding direction

Start position

Head moving

Page 39

FY –33VC Operation manual

- 39 -

11.3.3 Feed Compensate adjustment

Select Open/File, load the file

C:\try\SmallGrid126.gro.

In “Print setup”, select test mode,single

direction, color “C”. Press printing key

, and print with color “C”. Adjust the value in

Print setup \

Important setup \ Feed Compensate”

until the grid becomes perfect, and then save the value. If there is

space in printout, reduce the value; if overlap , add.

The rest passes can be adjusted in the same way.

11.3.4 Four colors overlapping adjustment

Take “C” for datum line and adjust another color together with “C”. Adjust M, Y, K one by one and print

at 200 1Pass, single direction. See below:

Following above guide to adjust “Head nozzle installation parameter” in “Printer parameter setting”, and

input values in the blank behind the distance coefficient. The prior is X, and the latter is Y.

Note: usually printer’s horizontal and vertical distance are finished adjusting when deliver. User needn’t

adjust. Only when after long transportation and CMYK cannot ov erlap, user can go to this function to adjust.

11.3.5 BID adjustment:

Follow below steps:

1. In the control panel, set a common value for

Adjustment\Speed

,e.g. highest 11.

2. Press ONLINE.

3. Use FY-3212C software to open the adjustment file

BID_test.group

.

BID_test.group

4. Press printing key

to print.

5. Check the printout whether every line is straight. Then input the value in

Adjustment \ BID

adjust.

6. If some of them are straight while others not, you can input the value in dialog “Important

Setup\BiComp” for each print head.

Note: Different speed has its own BID rectangle value.

11.4 Basic operation of RIP

Refer to CHALLENGER RIP Manual. Please close the printer driver software before

opening RIP.

Reduce value X

Add value Y

C(datum line)

M、Y、K

C、M、Y、K overlap

no adjustment

Loading...

Loading...