Page 1

QAD#IM6010 RevD 11.01.19

ELECTRIC ACTUATOR HQ006

INSTALLATION AND OPERATION

MANUAL

www.challengervalves.com.au

Page 2

QAD#IM6010 RevD 11.01.19

CONTENTS

COMPANY OVERVIEW

INTRODUCTION

PRODUCT IDENTIFICATION

GENERAL INFORMATION AND FEATURES

INSTALLATION INSTRUCTION

OPERATION INSTRUCTIONS

MAINTENANCE

TROUBLE SHOOTING

DIMENSIONS FOR ACTUATOR

HEAD OFFICE

3 Glenn Street, Shepparton

Victoria 3630

P: 03 5822 1533

F: 03 5822 2277

E: sales@challengervalves.com.au

www.challengervalves.com.au

Page 3

QAD#IM6010 RevD 11.01.19

COMPANY OVERVIEW

INTRODUCTION

Challenger Valves is a leading manufacturer, supplier and distributor of valving and actuation, providing products and soluti ons to

the water, mining, irrigation and general industries. We stock a wide range of products in various materials including ductile iron,

stainless steel, brass and uPVC to handle a wide range of industrial applications.

The companies’ head office is located in Shepparton, north of Melbourne in central Victoria, with a 2400m² purpose built faci lity,

which includes production, storage and testing. The commitment by the directors to re-invest profits back into the company

demonstrates Challenger’s commitment to it’s customers, employees and long term investment in the Australian market.

Challenger operate branches in Brisbane, Melbourne, Sydney, Perth and Newcastle, supporting an Australia wide distributor

network.

HISTORY

Challenger Valves and Actuators were established in 1984 and provide high quality product lines of performance and reliability,

backed by a professional team delivering superior service and cost effective solutions to our clients.

QUALITY

Challenger Valves provide in house testing and distributes a range of products that meet or exceed the highest Australian and

International Standards, many of which carry the coveted Australian Standard Mark. Customer testaments are available on

request.

OH&S

Challenger Valves management team are committed to ensuring the health, safety and welfare of it’s employees, visitors and

contractors by adhering to all statutory requirements.

NATIONAL CODE OF PRACTICE

Challenger is a compliant participant in the National Code of Practice for the Building and Construction Industry, details available

upon request.

3

Page 4

QAD#IM6010 RevD 11.01.19

HQ 006 INTRODUCTION

This installation and operating manual explains how to install, operate and maintain HQ-006 electric actuators.

Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury and damage to the

equipment. User must read these instructions before installation, operating, or maintenance.

DANGER: Refers to personal safety. Alerts the user to potential danger or harm. The hazard or unsafe practice will result

in severe injury or death.

WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow warning notices could result in

personal injury or death.

CAUTION: Directs the user’s attention to general precautions that, if not followed could result in personal injury and/or equipment

damage.

Note: Highlights information critical to the user’s understanding of the actuators’ installation and operation.

PRODUCT IDENTIFICATION

The actuator name plate is located on the top cover of the actuator.

The name plate contains the following:

HQ logo (trade mark)

Electrical power supply

Model

Type

Rated current

Operating time (seconds)

Serial No.

Option

Initial Inspection

Upon receipt of the actuator, inspect the condition of the product and ensure the name plate matches the order sheet or your

requirements, also check for any damage that may have occurred during shipment. If the wrong product has been shipped

immediately or is damaged report to the coordinator.

Storage

Actuators must be stored in a clean, cool and dry area. The unit shall be stored with the cover fastened and the conduit ope nings

sealed. Storage must be off the floor, covered with a seal dust protector.

When actuators are stored outdoors, they must be stored off the ground, high enough to prevent being immersed in water or

buried in snow.

ELECTRIC ACTUATOR

QUARTERTURN ELECTRIC ACTUATORS

POWER: TORQUE:

OPERATION TIME: SEC TYPE:

RATED CURRENT: A OPTION:

SERIAL NUMBER:

Name Plate

4

Page 5

QAD#IM6010 RevD 11.01.19

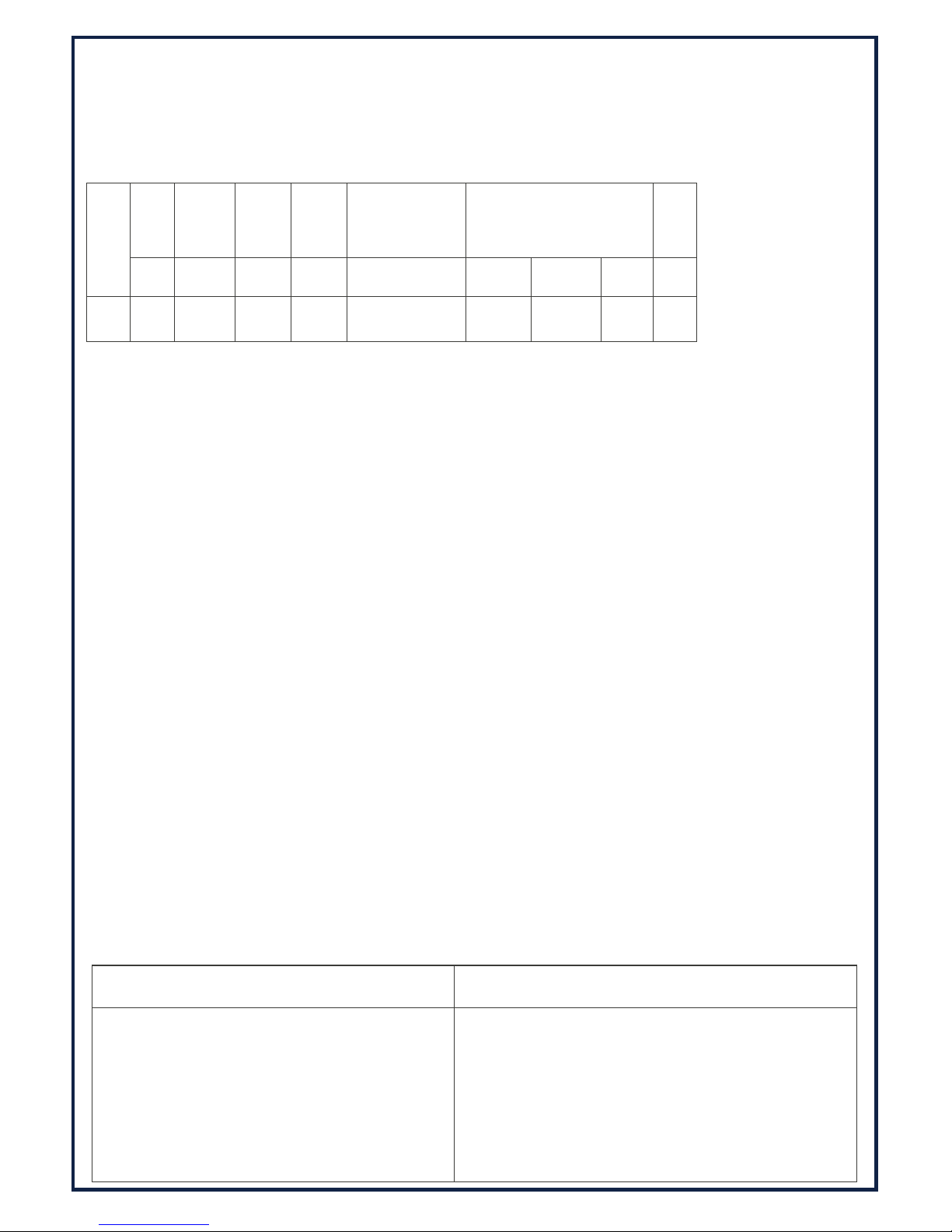

GENERAL INFORMATION AND FEATURES

HQ series electric actuators are designed to provide reliable and efficient operation of 90 degree quarter turn valves , damp ers,

etc.

Performance

HQ006 Standard Technical Data (optional)

Enclosure Rated Weatherproof IP67

Enclosure High grade aluminium alloy, corrosion coated

Power Supply 110/220 VAC 1 Ph, 24 VAC - 24VDC 50/60Hz

Motor Reversible motor

Limit Switches 2 x open/close SPDT, 250 VAC 10A rating

Auxiliary Limit Switches 2 x open/close SPDT, 250 VAC 10A rating

Indicator Continuous position indicator

Manual Manual Override Nut

Space Heater 2W

Conduit Entries 2 x PG 13.5

Lubrication Grease moly EP

Ambient Temperature -20ºC + 70ºC

External Coating Dry powder polyester

HQ Option Technical Data (optional)

PIU Potenometer unit (0 1K Ω)

PCU Proporonal control unit (input, output 0 10 VDC or 4 20mA DC)

CPT Current posion transmier (output 4 20mA DC)

Duty Cycle

Duty cycle is rated IEC60034 - S4 50% / S2 30 min

Exceeding the actuators rated duty cycle may cause thermal overload.

Type of duty according to VDE 0530 / IEC 60034-1

Type

Max

output

torque

Operating

Time (sec)

Duty

cycle IEC

34 - 1

Mounting

size

Power 1 Phase Weight Rated current (A) 50/60Hz 1 Phase

Kgf.m 50/60HZ S4(%) ISO 5210 AC,DC 110V AC 220V AC 24V DC Kg

HQ006 6 12/14 50

F03, F05,

F07

AC110V, 220V,

DC24V, 24 VAC

0.4A/0.39A 0.02A/0.19A 0.4A 3

Short - time duty S2 Intermittent duty S4

The operation time at a constant load is short, so that thermal equilibrium is not reached. The pause is long enough

for the machine to cool down to ambient temperature. The

duration of the short - time operation is limited to 15 min

(10 min, 30 min).

The duty is a sequence of identical cycles which consist of starting

time, operation time with constant load and rest period. The rest

period allows the machine to cool down so that so that thermal

equilibrium is not reached. The relative on-time at S4-25% or S450% is limited to 25% and 50% respectively

5

Page 6

QAD#IM6010 RevD 11.01.19

Heater

Condensation in the actuator is possible due to wide fluctuation of the ambient temperature. The heater integrated in the co ntrol

unit prevents this in general.

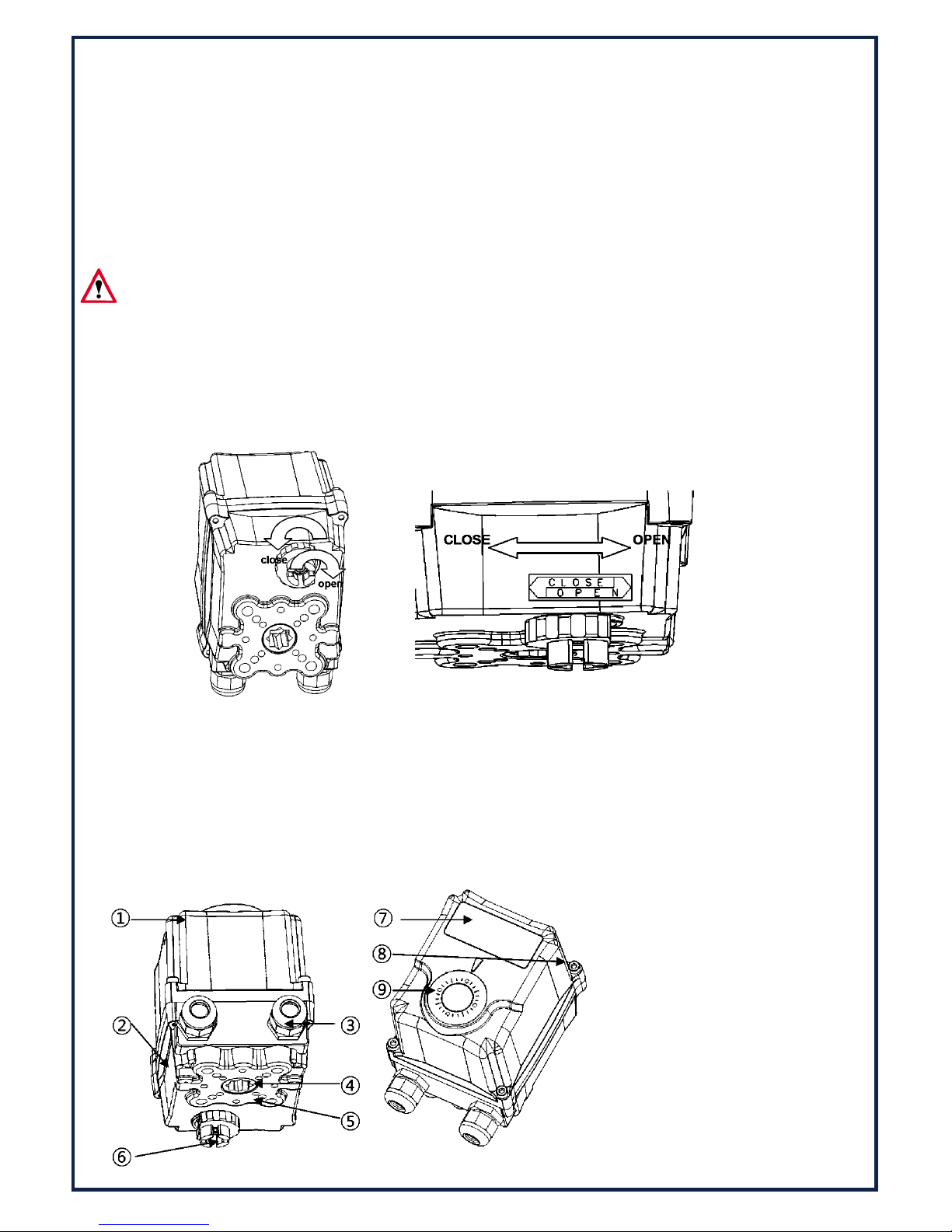

Manual Hand Wheel and Lever

HQ actuators are provided with a manual operation system.

The HQ006 actuator comes standard with a manual override nut.

This is located on the bottom of the unit, and can be easily operated with a 5M wrench.

Turn the hand wheel until the valve reaches the required position

Turn clockwise to open and counter clockwise to close

When nut becomes tight DO NOT FORCE further as this will cause serious damage to the gearing.

CAUTION: The manual nut is to facilitate the setting up of the actuator drive to the valve shaft at time of assembly or to drive the

valve to a fail safe position in the event of power failure. It is NOT designed to free up a jammed valve. Using the manual nut

when the valve is tight or jammed will damage the gears and void any warranty.

To free up a tight or jammed valve you must remove the actuator from the valve, using a spanner directly on the valve shaft, rotate

until it turns freely.

If the torque required to move the valve is greater than the rated output torque of the actuator the unit will not operate.

HQ006

Note: The override engagement lever returns automatically to auto position when the actuator is operated electrically.

Lubrication

HQ is a totally enclosed unit with a permanently lubricated gear train (Moly EP Grease). Once installed lubrication should n ot be

required. However, periodic preventative maintenance will extend the operating life of the actuator.

External Parts

1. Top Cover

2. Body

3. Cable Entry (PG 13.5) x2

4. Drive Shaft

5. Mounting Base (F03, F05, F07)

6. Manual Override Nut

7. Name Plate

8. Cover Bolt (captive design)

9. Indicator

6

External Parts

Page 7

QAD#IM6010 RevD 11.01.19

Internal Parts for Standard Models

Internal Parts - HQ006 Series

1. Motor

2. Indicator

3. Open Limit Switch

4. Additional Open Limit Switch

5. Close Limit Switch

6. Additional Close Limit Switch

7. Potentiometer Unit

8. Terminal

9. Heater

10. Capacitor

INSTALLATION INSTRUCTION

Pre-Installation (for use in General Services)

Verify the actuators name plate to ensure correct model number, force, operating speed, voltage and enclosure type before ins tallation and use.

It is important to verify that the output force of the actuator is appropriate for the force requirements of the valve and th at the

actuator duty cycle is appropriate for the intended application.

WARNING: Read this installation and maintenance manual carefully and completely before attempting to install , operate or

trouble shoot the HKC actuator.

Actuator Mounting

Note:

Prior to mounting the part-turn actuator it must be checked for damage.

Damaged parts must be replaced by original spare parts.

Mounting is most effectively carried out with the valve shafting pointing vertically upwards, however mounting is also possib le in

any other position.

The HQ series actuators are supplied with a Union Joint and nut which is removable for ease of machining.

CAUTION:

Do not attempt to work on your HKC actuator without first shutting off Incoming power.

Do not attach ropes or hooks to the hand wheel for the purpose of lifting by hoist.

7

Page 8

QAD#IM6010 RevD 11.01.19

ACTUATOR MOUNTING DETAILS

*Direct mounting / ISO (ISO standard) *Bracket Mounting

F03, F05, F07

HQ006: ISO5211 F03/F05 and F07

Star Adapter 14mm - 11 mm

11mm - 9mm

Square Adapter 14mm - 11 mm

11mm - 9mm

Danger: HAZARDOUS VOLTAGE (Make sure all power is disconnected prior to mounting)

Limit Switch Setting

Rotate the actuator hand wheel manually to closed position

Using hex wrench, loosen the set screw on the CLOSE limit switch cam

Rotate the CLOSE cam towards CW limit switch lever until the switch “clicks” Tighten the set screw with hex wrench

Rotate the actuator hand wheel manually to open position

Using hex wrench, loosen the set screw in the “open” limit switch cam

Rotate to “open” cam towards CCW limit switch lever until the switch “clicks” (fig 2)

Tighten set screw with hex wrench

Danger: HAZARDOUS VOLTAGE (Make sure all power is disconnected before prior to mounting)

8

Page 9

QAD#IM6010 RevD 11.01.19

Close Cam Setting

Close Limit Switch

Close limit Switch Cam (clockwise)

2mm Hexagon socket screw Key

OPERATION INSTRUCTION

Electrical Connections and Preliminary Test

Loosen the screws on the actuator cover and lift it off

Make sure that the power supply voltage is in accordance with the data on the actuator name plate

Connect wires according to the enclosed wiring diagram

Move the valve manually to a half-open position, operate and electrical opening and check that the motor rotates in the right

direction

Standard units are counter-clockwise to open set

Test the actuator and check the limit switches work correctly

Check all the cable glands are correctly tightened, applicable cable glands should be selected to be meet the applications

condition. Over the grade IP67 of cable gland recommended in potentially explosive atmospheres.

Mount cover and tighten cover bolts

9

Page 10

QAD#IM6010 RevD 11.01.19

Wiring Diagrams for Standard Models - 240V AC

HQ006 240V AC

PCU Type

Wiring Diagram

Number HQ-150-B

HQ006 240V AC

On/Off type

Wiring Diagram

Number HQ-110-A

10

Page 11

QAD#IM6010 RevD 11.01.19

DC Wiring Diagram - 24V DC

On/Off type

Wiring Diagram

Number HQ-840-B

11

Wiring Diagrams for Standard Models - 24V

AC Wiring Diagram - 24V AC

On/Off type

Wiring Diagram Number HQ-740-B

Page 12

QAD#IM6010 RevD 11.01.19

TORQUE AND LIMIT SWITCH OPERATION

SWITCH CLOSE INTERMEDIATE OPEN

CLS 1-2

CLS 1-3

OLS 1-2

OLS 1-3

ACLS 1-2

ACLS 1-3

AOLS 1-2

AOLS 1-3

SYMBOL DESCRIPTION RATING

CLS CLOSE LIMIT SWITCH 250 VAC

OLS OPEN LIMIT SWITCH 250 VAC

ACLS AUX. CLOSE LIMIT SWITCH 250 VAC

AOLS AUX. OPEN LIMIT SWITCH 250 VAC

* EACH ACTUTAOR SHOULD BE POWERED THROUGH IT’S

INDIVIDUAL SWITCH OR RELAY CONTACTS TO PREVENT FEED

BETWEEN TWO OR MORE ACTUATORS

DRAW B.R.LEE CHECK

DESIGN S.K.KANG APPR S.M.

PART NAME 1 PH WIRING DIAGRAM PCU

DWG.NO HQ-250-

HQ-006 ISSU. DEPT. HADR DATE: 2011

APPLICATION HKC - H K C CO. LTD

HQ 006-2

AC OPERATION DIP SWITCH 1 DOWN - DIP SWITCH 2 UP

HQ 006-2

DC OPERATION DIP SWITCH 1 UP - DIP SWITCH 2 DOWN

12

PCU Wiring Diagram 24V DC

Wiring Diagram Number HQ-850-c

NOTE:

The HQ006 24V Unit requires the relay panel to be programmed ot suit either AC or DC operation.

Use the below photos to set Dip Switches to suit.

Page 13

QAD#IM6010 RevD 11.01.19

Tools

1 Metric Allen Key (Hex Wrench)

1 Screw Driver

1 Metric Spanner

1 Wrench 200mm

1 Wrench 300mm

1 Wire Stripper Long Nose

1 Multi Meter (AC, DC, Resistance)

1 DC Signal Generator (4 -20mA): PCU Board Opon

1mA Meter (0 25mA): PCU & CPT Board Option

MAINTENANCE

Caution: Turn off all power services before attempting to perform a service on the actuator. POTENTIAL HIGH PRESSURE

VESSEL. Before removing or disassembling the actuator ensure the valve or other actuated devices are isolated and not under

pressure.

Maintenance under normal conditions at six month intervals, however when conditions are more severe, more frequent

inspections may be advisable.

Ensure valve actuator alignment

Ensure wiring is insulated, connected and terminated properly

Ensure all screws are present and tight

Ensure cleanliness of internal electrical devices

Ensure conduit connections are installed properly and are dry

Check internal devices for condensation

Check power to internal heater

Check enclosure O-ring seals and verify the O-ring is not pinched between flange

Verify declutch mechanism

Visually inspect during open /close cycle

Inspect identification labels for ware and replace if necessary

Warning: Treat cover with care. Gap surfaces must not be damaged or dirtied in any way. Do not jam cover during fitting.

13

Page 14

QAD#IM6010 RevD 11.01.19

TROUBLE SHOOTING

The following instructions are offered for the most common difficulties encountered during installation and start up.

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Motor not running Open in control unit Refer to appropriate wiring diagram and check for continuity

Insulation resistance breakdown in motor Perform megger test

No power available to actuator Tripped circuit breaker Reset circuit breaker

Manual override nut hard to turn Valve stem improperly lubricated.

Actuator lubricant has broken down

Lubricate with grease

Clean out old grease and replace with recommended lubricant

Valve packing gland too tight Loosen gland nuts as necessary

Jammed valve Refer to valve maintenance.

IMPORTANT: Do not un-jam valve using the manual override.

Remove actuator from valve and un-jam valve.

Valve only opens or closes partially with motor Limit switch improperly set Check setting and reset if necessary

Stripped gearing Replace as necessary Manual override nut will not operate valve

Broken hand wheel shaft Replace as necessary

Broken valve stem Repair or replace as necessary

Motor runs but will not operate valve Stripped gearing Replace as necessary

Actuator does not respond

Verify the line voltage to the actuator

Check that the voltage matches the rating on the actuator nameplate

Check internal wiring against actuator wiring diagram

Check limit switch cams

Actuator is receiving power but does not operate

Verify the line voltage to the actuator

Check actuator force to see if it’s greater than the valve force

Check limit switches and cams

Check that the force switches have not tripped

Check mechanical travel stop adjustment

Verify the actuator against valve rotation (standard units are anti-clockwise open)

Check internal wiring

Check for corrosion and condensation

Verify coupler/bracket are correctly installed and is not causing binding

Actuator runs erratically

Check ambient temperature

Verify that the duty cycle has not been exceeded

Check the position of manual override lever

Optional Equipment

Potentiometer Current Position Transmitter

Check resistance value

Check potentiometer gear for jamming

Check zero and span calibration

Check board for damage

Current Position Transmitter

Verify input signal

Check dip switch configuration

Check Board for damage

14

Page 15

QAD#IM6010 RevD 11.01.19

DIMENSIONS FOR ACTUATOR

HQ006

HQ006 On/Off Type

125.5

103.6

Cable Entry: PG 13.5

Indicator

M5 Bolt Hexagon Socket Head Cap Screws

Enclosure: IP67

Torque: 6Kg.m

Operation Time: 13sec

Position Switch: 4 SPDT Switch

Cable Entry: PG 13.5 x 2

Mounting Flange: F03, F05, F07

acc to DIN/ISO5211

147.5

126.4

105.4

132.3

14

Ø 70/F07 ISO 4 - M8TAP DP12

Ø 50/F05 ISO 4 - M6TAP DP12

Ø 36/F03 ISO 4 - M5TAP DP12

Hand wheel 1

M6 Hexagon socket head cap

Hand wheel 2

15

Page 16

QAD#IM6010 RevD 11.01.19

HQ006 PCU TYPE

103.6

125.5

Cable Entry: PG 13.5

14

Handwheel

Ø70/F7ISO 4-M8TAP DP12

Ø6.8 DRILL DP14

Ø50/F5ISO 4-M6TAP DP12

Ø5 DRILL DP14

Ø36/F3ISO 8-M5TAP DP12

Ø4.2 DRILL DP14

133

108

126.4

212.4

147.5

148

16

Page 17

QAD#IM6010 RevD 11.01.19

www.challengervalves.com.au

HEAD OFFICE AND WAREHOUSE

3 Glenn Street

Shepparton Victoria 3630

P: 1800 120 751

Email:

sales@challengervalves.com.au

Loading...

Loading...