CellarPro 4200VSX User Manual

Control the Elements

Owner’s Manual –

3200VSi / 3200VSx / 4200VSi / 4200VSx

C O N G R A T U L A T I O N S !

Thank you for purchasing a new CellarPro cooling system.

Please take a minute to read through this Owner’s Manual before you unpack,

install and turn on your Cooling Unit.

If you have any questions about your new cooling unit, it is likely that you will find the

answers in this Owner’s Manual. We also have more information on our website,

including the latest version of the Owner’s Manual, at

www.cellarpro.com/customerservice .

If you still have questions, please don’t hesitate to contact your dealer or CellarPro

directly. We can be reached during normal business hours at 1.877.726.8496. You also

may contact us anytime via email at info@cellarpro.com.

Contact Information:

CellarPro Cooling Systems

531 Mercantile Drive

Cotati, CA 94931

877.726.8496

Email: info@cellarprocoolingsystems.com

Website: www.cellarprocoolingsystems.com

Serial Number*________________________

*We recommend that you take a minute to fill-in your CellarPro serial number above.

The serial number has seven-digits and can be found on the printed label on the left

side of your cooling unit.

Don’t forget to register your cooling unit warranty at www.cellarpro.com/register

Table of Contents

I. Specifications 4

II. Installation Instructions 10

III. Operating Instructions 19

IV. Troubleshooting 30

V. Limited Warranty 32

3

I. Specifications

Specs and Cut Sheets

Model Dimensions (inches)

3200/4200VSi

3200/4200VSi*

3200/4200VSx

* With optional duct hood

W x D x H

14.1 x 25.1 x 19.6

(incl.drain)

14.5 x 29.3 x 19.7

(incl. duct hood & drain)

14.5 x 27.6 x 19.7

(incl. exterior case & drain)

3200VSi / 4200VSi Cut Sheet

Weight

Running Compressor

Amps

115

9.2 – 3200

123

11.5 – 4200

123

4

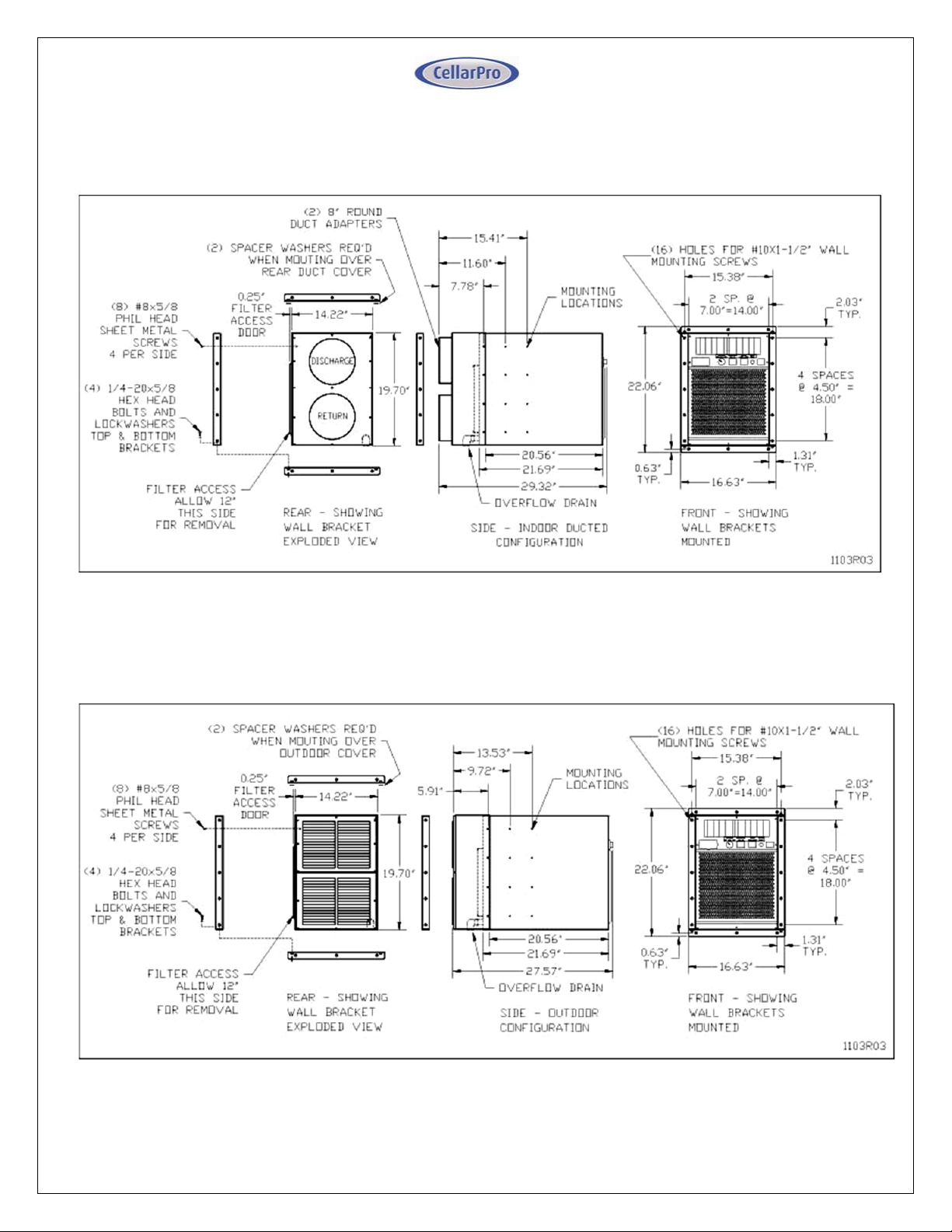

3200VSi / 4200VSi (with Rear Duct Hood) - Cut Sheet

3200VSx / 4200VSx Cut Sheet

5

Placement

CellarPro 3200 and 4200 Series cooling units are designed to be installed THROUGH THE

WALL, so that the rear and the front of the cooling unit DO NOT SHARE THE SAME AIR

SPACE.

The rear of the cooling unit must be installed in a space that is at least as large as the wine

cellar unless the rear intake and exhaust are ducted. Both the front and the rear of the

cooling unit require a minimum clearance of 8 inches.

These units also can be placed completely INSIDE or OUTSIDE the cellar when used in

combination with our duct kits.

Ambient Environment

3200VSi / 4200VSi - designed for internal use only (ie sheltered from outdoor

weather), the rear of the unit can be exposed to temperature conditions ranging

from 40 to 115°F.

3200VSx / 4200VSx – designed for external use, the rear of the unit can be

exposed to temperature conditions ranging from 40 to 115°F. Refer to the

Installation section for additional requirements for outdoor exposures.

PLEASE NOTE: With our (optional) crankcase heater, all of our cooling units can

be used in environments down to 20°F, and with our (optional) low ambient kit, all of

our cooling units can be used in environments down to -20°F.

CellarPro cooling units are not designed to heat the cellar space, so if

temperatures inside the cellar drop below proper wine storage temperatures, the

cooling unit cannot create heat inside the cellar.

Insulation

CellarPro cooling units are

designed to be installed

inside wine cellars that have

proper insulation, moisture

barriers and an airtight seal

from the environment

outside the cellar. Interior

walls and floor should

have a minimum of R-11

insulation, and a vapor barrier

on the warm side of the

insulation. The ceiling should

6

have a minimum of R-19 insulation and a vapor barrier on the warm side of the

insulation. Doors also should be insulated and tightly sealed with weather

stripping around the perimeter of the door. Surface-mounted

fixtures are recommended over recessed lighting, which can allow air to leak

into the cellar.

It is important that all walls, joints, doors and windows, electrical outlets

and/or switches, pipes, vents and light fixtures be sealed to prevent air and

moisture from entering the cellar. If there is a leak in the cellar, the cooling unit will

build up excess condensation.

CellarPro 3200 and 4200 cooling units are equipped with a condensate

management system, which includes a stainless steel pan, a thermostaticallycontrolled electric heating element, and an overflow drain at the rear of the

cooling unit.

We strongly recommend that the overflow drain line (shipped loose with the

cooling unit) be connected to the overflow drain (as shown in the installation

section), and that the cooling unit be mounted to tilt slightly backwards, so that

any overflow condensate is channeled safely to the overflow drain line. In addition,

we recommend turning on the electric heating element to burn off excess

condensate that accumulates in the stainless steel pan during the initial cooling of

the cellar and during high run-times, as well as in high-humidity environments.

Fan Speeds

Your fan speed setting will need to be on “High” under the following conditions:

- As the thermal load of the wine cellar increases

- As ambient temperatures increase

- As the static load from ducting (if any) increases due to factors including the

length of the duct run, turns, vent grills and/or reducers

Ventilation

Adequate ventilation is critically important for the proper operation of your

CellarPro cooling unit.

OUTSIDE THE CELLAR

(At the rear of the cooling unit)

Condenser Air Exhaust. CellarPro 3200 and 4200 Series cooling units create

significant hot air which must be exhausted into an appropriately-sized space

in order for the heat to dissipate. If the space is constrained and/or too small,

7

the heat will not dissipate. In this event, the cooling unit will be forced to recirculate its hot air exhaust and/or the static pressure will back up the cooling

unit. If this happens, the cooling unit’s ability to create cold air inside the cellar

will be compromised.

Condenser Air Intake. The condenser coils require access to cool air in order

for the cooling unit to produce cold air. In addition, the cooling unit must be

installed so that, after its installation, the condenser coils are accessible for

periodic cleaning or replacing of the filter.

The rear of the cooling unit must be installed in a space that is at least as large as the

wine cellar unless the rear intake and exhaust are ducted. Both the front and the rear

of the cooling unit require a minimum clearance of 8 inches.

Ducting. CellarPro 3200 and 4200 units allow the condenser air intake and

exhaust each to be ducted up to 50 equivalent feet with 8” diameter ducting, or

100 equivalent feet with our auxiliary fan and 8” diameter ducting. We offer two

rear duct kits (sold separately) that attach to the rear of the cooling unit.

INSIDE THE CELLAR

(At the front of the cooling unit)

Evaporator Air Intake. CellarPro cooling units should be mounted at the

highest point inside wine cellars, so that warm air – which rises – will be the first to

pass over the evaporator coils, which are located behind the grill on the face of

the cooling unit. When the warm air passes across the evaporator coils, heat is

removed the air, and the resulting cold air is exhausted into the cellar. To ensure

proper airflow, minimum clearance of 12” is required in front of the cooling unit.

Evaporator Air Exhaust. Cold air is exhausted at the top front of the cooling

unit. Because CellarPro cooling units are located at the highest point inside

wine cellars, the cold air exhaust eventually will drop to the bottom of the cellar.

To ensure proper airflow and reduce temperature stratification inside the cellar,

the space in front of the cold air discharge should be clear of any obstructions,

including wine bottles, wine racks, etc.

Ducting. CellarPro 3200 and 4200 units allow the evaporator air intake and

exhaust each to be ducted up to 50 equivalent feet with 8” diameter ducting.

We offer a front duct kit (sold separately) that attaches to the front of the

cooling unit.

We also offer a remote control panel kit that can be installed remotely (up to 10

feet) from the cooling unit, either inside or outside the cellar, and a bottle probe

(10 foot cord) that can be plugged into the cooling unit.

8

Power Requirements

CellarPro cooling systems should be plugged into a dedicated non-GFI outlet

connected to a 15-amp circuit. The cooling unit uses approximately 11.5 (4200)

and 9.2 (3200) amps during its “on” cycle.

A number of variables, including the minimum set point, the temperature in the

ambient environment, the insulation of the cellar, and the thermal mass inside

the cellar, will affect the cooling unit’s runtime. It is normal for the cooling unit

to run up to 75 percent of the time in order to maintain proper conditions inside

the cellar.

Select a power receptacle (Front or Rear) and plug the provided power cord into

that receptacle. Plug the other end of the power cord into a dedicated 15 amp

circuit. A surge-protected circuit is recommended. Set the power selector

switch to energize the appropriate receptacle used (Front or Rear).

The power cord provided for the model 3200VSi and 4200VSi is approved for

indoor use only, while the power cord for model 3200VSx and 4200VSx may be

used both for indoor or outdoor applications.

9

II. Installation Instructions

TEST THE UNIT BEFORE INSTALLING IT

1. Remove the unit from the box. SAVE THE BOX AND PACKING

MATERIALS.

2. Plug in the power cord and let the unit run on a hard, flat surface for no

more than 5 minutes.

3. Check to make sure that both fans (one in the front and one at the rear of

the cooling unit) are blowing.

4. Check that the cooling unit is discharging cold air from the front (it should

be approximately 10 - 12° F colder than the temperature on the digital

display)

5. Please note: The cooling system is programmed with a 3-Minute Delay

at Startup to protect its internal components

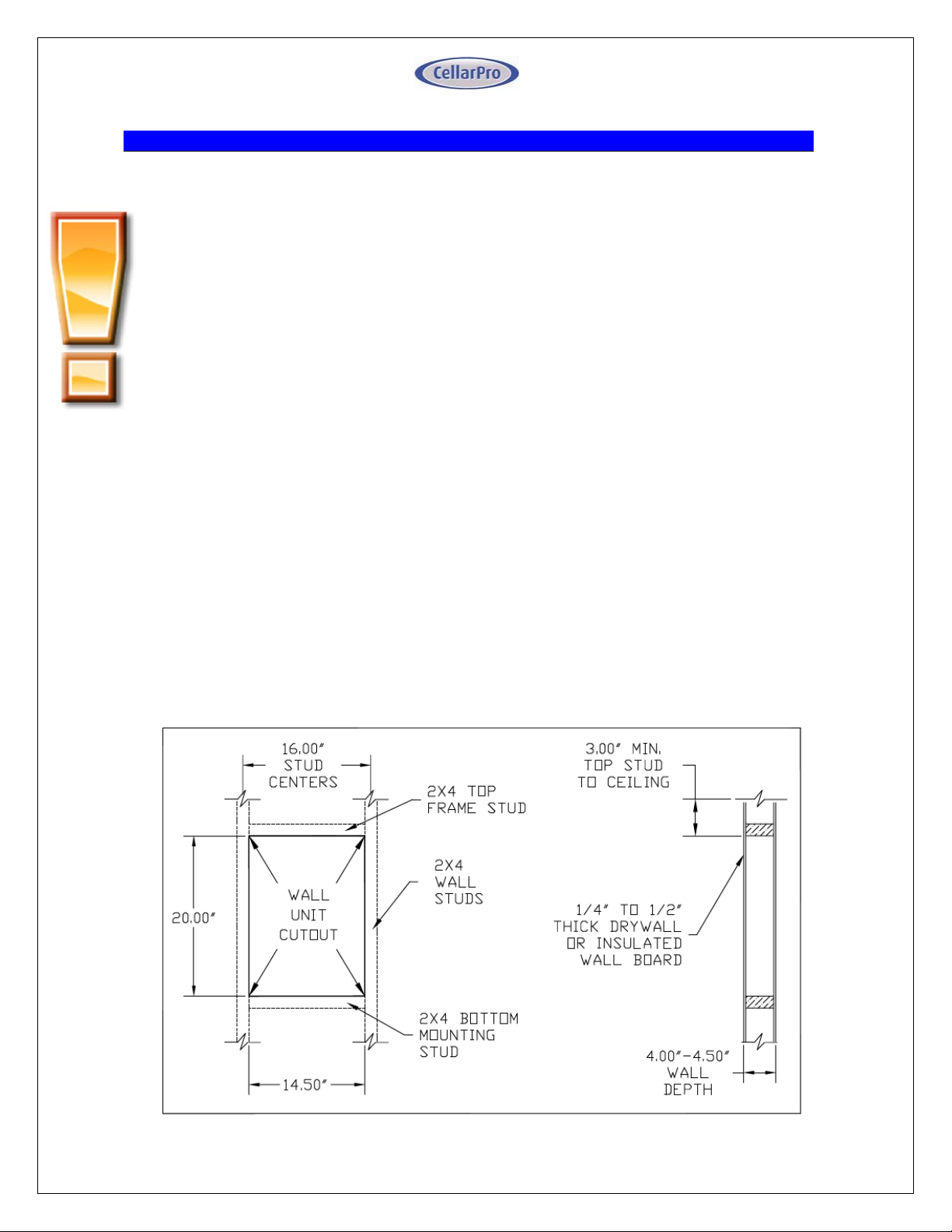

Cut a hole in the wall that is 1/4 inch larger than the dimensions (W x

H) of the cooling unit, and create a frame to support the rear of the

cooling unit. The rear of the cooling unit should be supported by the wall

through which it is installed. Horizontal 2 x 4 inch braces should be installed

between the studs below and above the cooling unit. If the studs in the wall

must be cut to accommodate the width of the cooling unit, vertical braces also

should be installed on either side of the cooling unit.

3200 / 4200 Frame and Cut-Out Diagram

10

Loading...

Loading...