CATALYST CAT5116 Service Manual

W

查询CAT5116RIMSOP供应商

CAT5116

Log-Taper, 100-Tap Digitally Programmable Potentiometer (DPP™)

FEATURES

APPLICATIONS

O

L

A

H

L

E

A

CAT5116

N

E

G

F

R

E

E

E

R

D

F

E

TM

■ 100-position, log-taper potentiometer

■ Non-volatile EEPROM wiper storage

■ 10nA ultra-low standby current

■ Single-supply operation: 2.5V - 5.5V

■ Increment Up/Down serial interface

■ Resistance value: 32k

ΩΩ

Ω

ΩΩ

■ Ava i la b le i n 8-pin MSOP, TSSOP, SOIC and DIP packages

DESCRIPTION

The CAT5116 is a log-taper single digitally

programmable potentiometer (DPP™) designed as a

electronic replacement for mechanical potentiometers

and trim pots.

Ideal for automated adjustments on high volume

production lines, DPP ICs are well suited for

applications where equipment requiring periodic

adjustment is either difficult to access or located in a

hazardous or remote environment.

The CAT5116 contains a 100-tap series resistor array

connected between two terminals RH and RL. An up/

down counter and decoder that are controlled by three

input pins, determines which tap is connected to the

wiper, RW.

■ Automated product calibration

■ Remote control adjustments

■ Offset, gain and zero control

■ Audio volume control

■ Sensor adjustment

■ Motor controls and feedback systems

■ Programmable analog functions

automatically reinstated when power is returned. The

wiper can be adjusted to test new system values without

effecting the stored setting.

Wiper-control of the CAT5116 is accomplished with

three input control pins, CS, U/D, and INC. The INC

input increments the wiper in the direction which is

determined by the logic state of the U/D input. The CS

input is used to select the device and also store the

wiper position prior to power down.

The digitally programmable potentiometer can be

used as a three-terminal resistive divider or as a

two-terminal variable resistor.

The wiper setting, stored in nonvolatile memory, is not

lost when the device is powered down and is

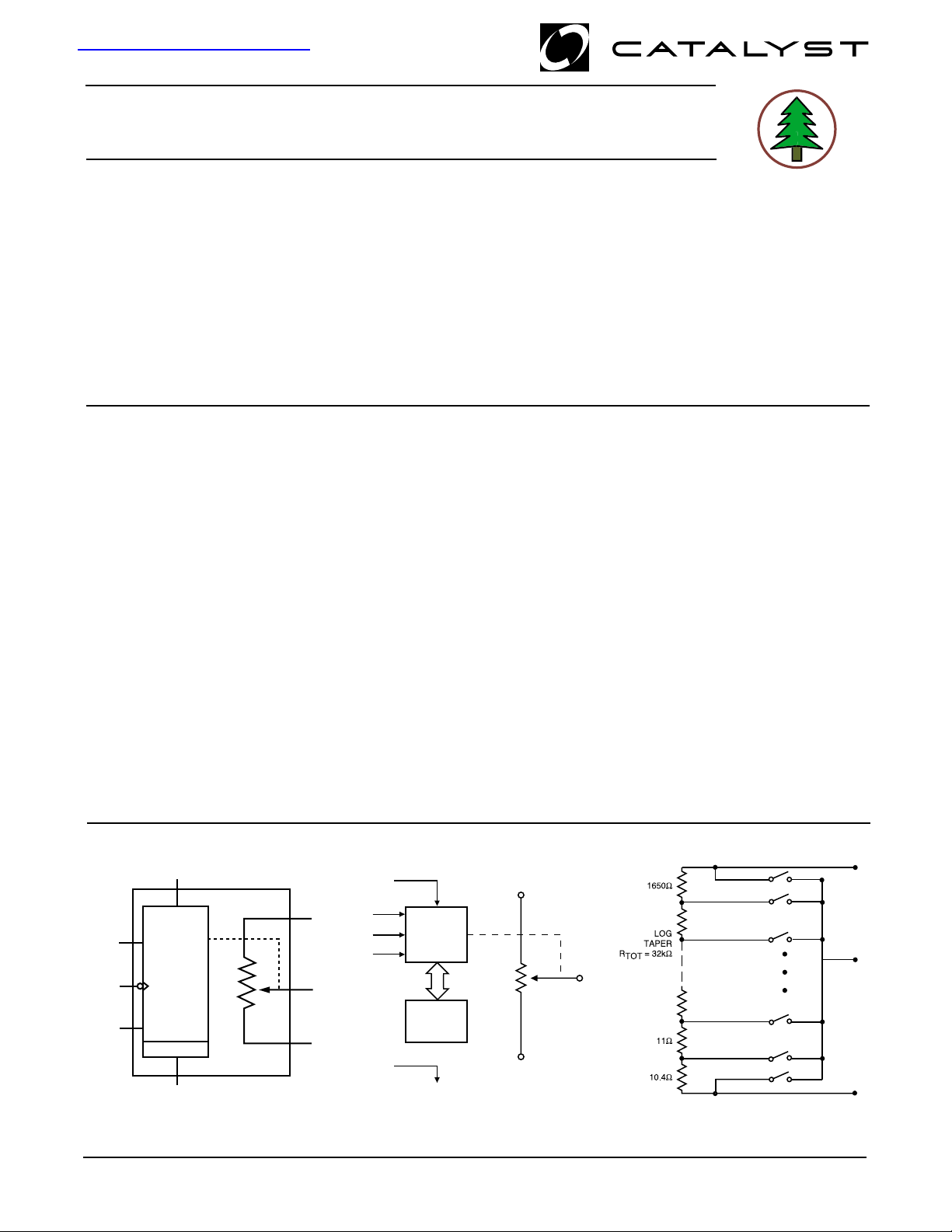

FUNCTIONAL DIAGRAM

V

CC

UP/DOWN

U/D

CONTROL

INCREMENT

INC

CHIP SELECT

CS

© 2004 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

AND

MEMORY

POR

GND

GENERAL BLOCK DIAGRAM POTENTIOMETER SCHEMATIC

R

H

R

W

R

L

U/D

INC

CS

V

CC

GND

INTERFACE

&

WIPER

CONTROL

EEPROM

Potentiometer

R = 32kΩ

1

1

R

R

H

R

R

L

Doc. No. 2118, Rev. J

Doc. No. 2118, Rev. J

H

R

W

R

L

CAT5116

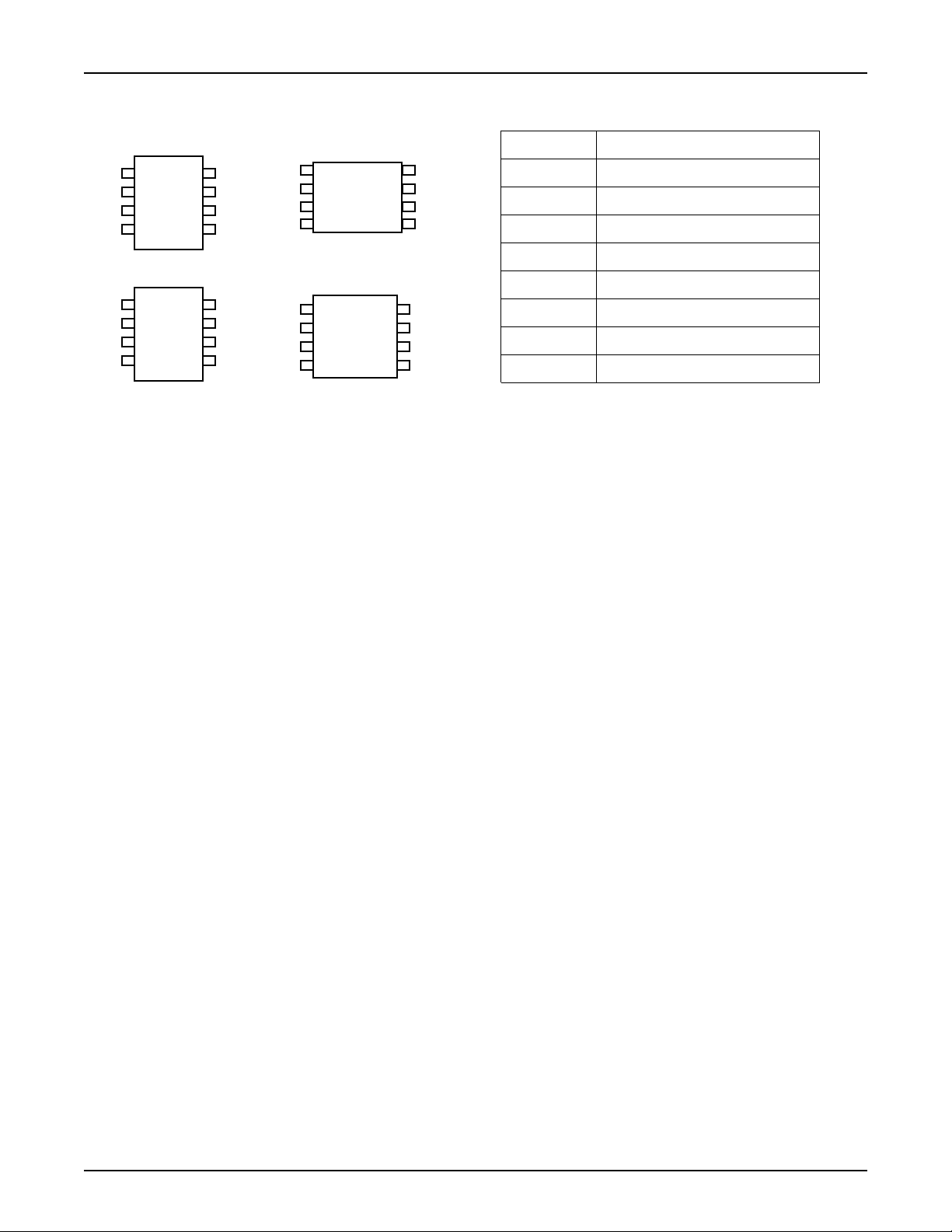

PIN CONFIGURATION

DIP Package (P, L)

1

INC

2

U/D

3

R

H

GND

4

SOIC Package (S, V)

1

INC

2

U/D

3

R

H

GND

4

8

V

CC

7

CS

6

R

L

5

R

W

8

V

CC

7

CS

6

R

L

5

R

W

TSSOP Package (U, Y)

1

CS

V

CC

INC

U/D

2

3

4

MSOP Package (R, Z)

1

INC

2

U/D

3

R

H

GND

4

8

R

L

7

R

W

6

GND

5

R

H

8

V

CC

7

CS

6

R

L

5

R

W

PIN DESCRIPTIONS

INCINC

INC: Increment Control Input

INCINC

The INC input moves the wiper in the up or down

direction determined by the condition of the U/D input.

DD

U/

D: Up/Down Control Input

DD

The U/D input controls the direction of the wiper

movement. When in a high state and CS is low, any highto-low transition on INC will cause the wiper to move one

increment toward the RH terminal. When in a low state

and CS is low, any high-to-low transition on INC will

cause the wiper to move one increment towards the

RL terminal.

PIN FUNCTIONS

Pin Name Function

INC Increment Control

U/D Up/Down Control

R

H

GND Ground

R

W

R

L

CS Chip Select

V

CC

CSCS

CS: Chip Select

CSCS

The chip select input is used to activate the control input

of the CAT5116 and is active low. When in a high

state, activity on the INC and U/D inputs will not

affect or change the position of the wiper.

Potentiometer High Terminal

Potentiometer Wiper Terminal

Potentiometer Low Terminal

Supply Voltage

R

High End Potentiometer Terminal

H:

RH is the high end terminal of the potentiometer. It is not

required that this terminal be connected to a potential

greater than the RL terminal. Voltage applied to the R

terminal cannot exceed the supply voltage, VCC or go

below ground, GND.

RW: Wiper Potentiometer Terminal

RW is the wiper terminal of the potentiometer. Its position

on the resistor array is controlled by the control inputs, INC,

U/D and CS. Voltage applied to the RW terminal cannot

exceed the supply voltage, V

or go below ground, GND.

CC

RL: Low End Potentiometer Terminal

RL is the low end terminal of the potentiometer. It is not

required that this terminal be connected to a potential

less than the RH terminal. Voltage applied to the R

terminal cannot exceed the supply voltage, VCC or go

below ground, GND. RL and RH are electrically

interchangeable.

Doc. No. 2118, Rev. J

H

L

2

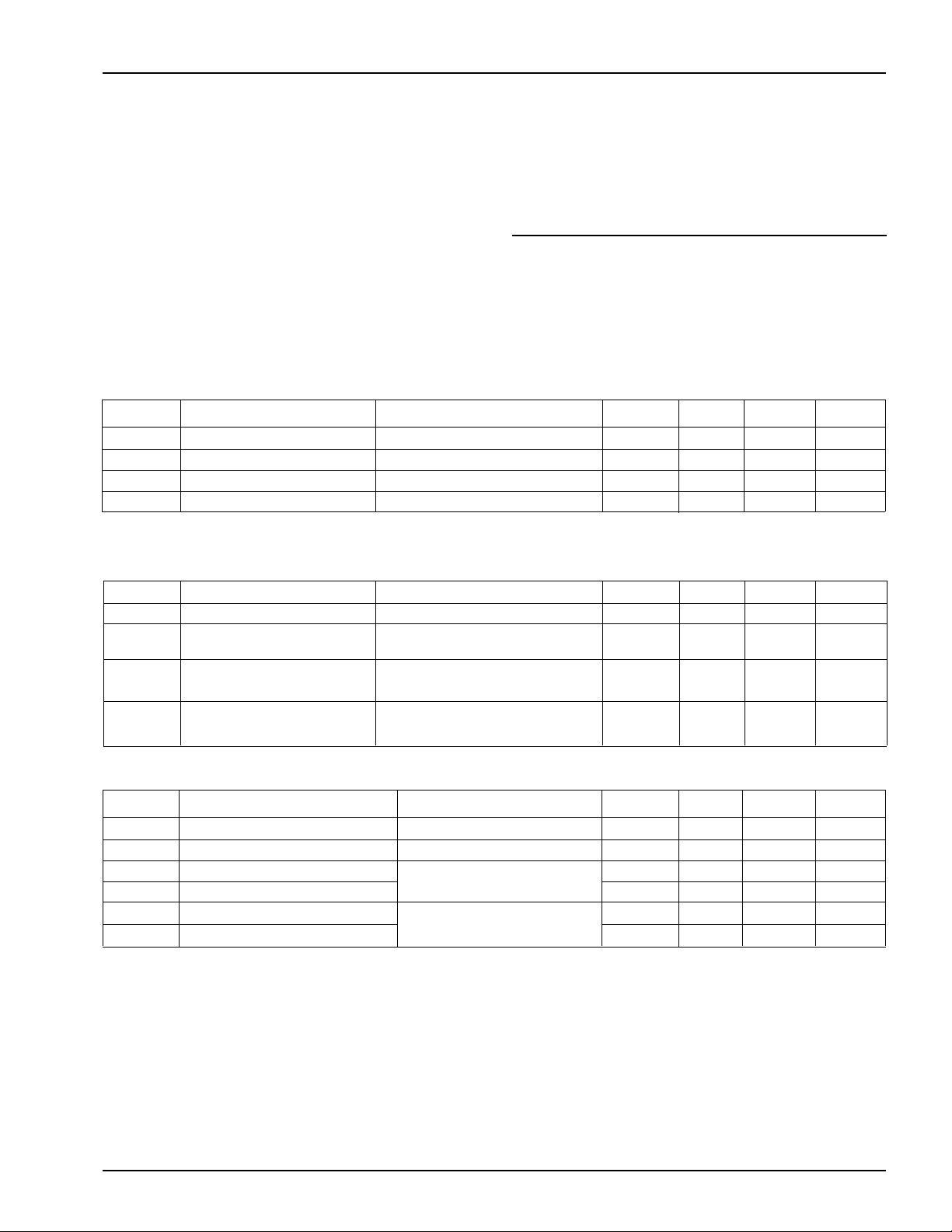

ABSOLUTE MAXIMUM RATINGS

CAT5116

Supply Voltage

V

to GND ....................................... -0.5V to +7V

CC

Inputs

CS to GND ........................ -0.5V to VCC to +0.5V

Operating Ambient Temperature ........-40°C to +85°C

Junction Temperature (10 secs)..................... +150°C

Storage Temperature...................................... +150°C

Lead Soltering (10 sec max)........................... +300°C

INC to GND ....................... -0.5V to VCC to +0.5V

U/D to GND ....................... -0.5V to VCC to +0.5V

RH to GND ......................... -0.5V to VCC to +0.5V

RL to GND ......................... -0.5V to VCC to +0.5V

RW to GND ........................ -0.5V to VCC to +0.5V

*Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Absolute Maximum

Ratings are limited values applied individually while other parameters are within specified operating conditions, and functional

operation at any of these conditions is NOT implied. Device

performance and reliability may be impaired by exposure to

absolute rating conditions for extended periods of time.

RELIABILITY CHARACTERISTICS

Symbol Parameter Test Method Min Typ Max Units

(1)

V

ZAP

(1)(2)

I

LTH

T

DR

N

END

DC ELECTRICAL CHARACTERISTICS: V

Power Supply

Symbol Parameter Conditions Min Typ Max Units

V

CC

(3)

I

CC1

I

CC2

ISB

1

ESD Susceptibility MIL-STD-883, Test Method 3015 2000 Volts

Latch-Up JEDEC Standard 17 100 mA

Data Retention MIL-STD-883, Test Method 1008 100 Years

Endurance MIL-STD-883, Test Method 1003 1,000,000 Stores

= 2.5V to 5.5V unless otherwise specified.

CC

Operating Voltage Range 2.5 5.5 V

Supply Current (Increment) VCC = 5.5V, f = 1MHz, IW=0 100 µA

VCC = 5.5V, f = 250kHz, IW=0 50

Supply Current (Write) Programming, VCC = 5.5V 1 mA

VCC = 3V 500 µA

Supply Current (Standby) CS=VCC-0.3V 0.01 1 µA

U/D, INC=VCC-0.3V or GND

Logic Inputs

Symbol Parameter Conditions Min Typ Max Units

I

IH

I

IL

V

IH1

V

IL1

V

IH2

V

IL2

NOTES: (1) This parameter is tested initially and after a design or process change that affects the parameter.

Input Leakage Current VIN = V

CC

10 µA

Input Leakage Current VIN = 0V -10 µA

TTL High Level Input Voltage 4.5V ≤ VCC ≤ 5.5V 2 V

CC

TTL Low Level Input Voltage 0 0.8 V

CMOS High Level Input Voltage 2.5V ≤ VCC ≤ 5.5V VCC x 0.7 VCC + 0.3 V

CMOS Low Level Input Voltage -0.3 VCC x 0.2 V

(2) Latch-up protection is provided for stresses up to 100mA on address and data pins from –1V to VCC + 1V

(3) IW=source or sink

3

Doc. No. 2118, Rev. J

V

Loading...

Loading...