查询CAT140029JWI-GT3供应商

Voltage Supervisor with I2C Serial

CMOS EEPROM

CAT140xx

FEATURES

Precision Power Supply Voltage Monitor

5V, 3.3V, 3V & 2.5V systems

7 threshold voltage options

Active High or Low Reset

Valid reset guaranteed at V

Supports Standard and Fast I

= 1 V

CC

2

C Protocol

16-Byte Page Write Buffer

Low power CMOS technology

1,000,000 Program/Erase cycles

100 year data retention

Industrial temperature range

RoHS-compliant 8-pin SOIC package

For Ordering Information details, see page 14.

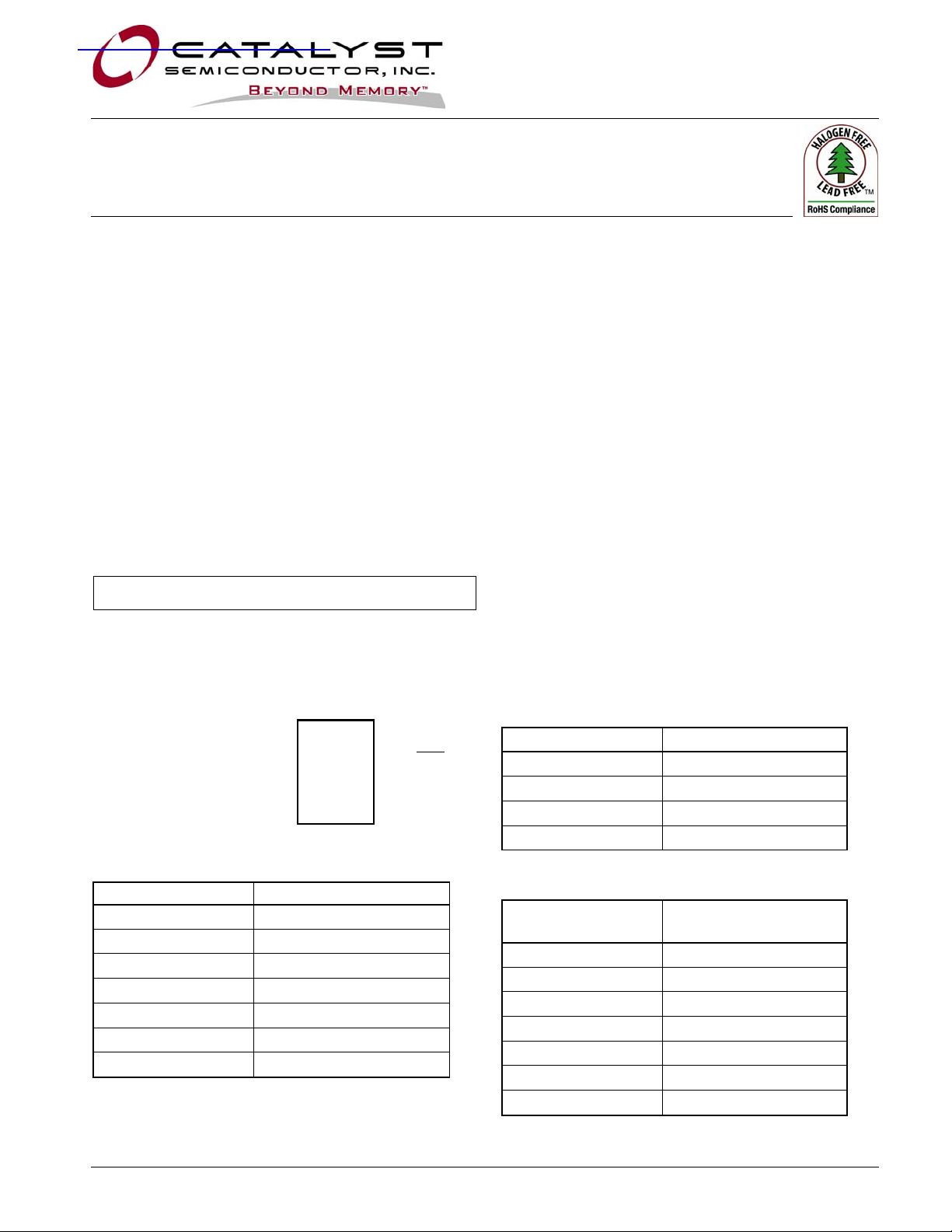

PIN CONFIGURATION

SOIC (W)

CAT14016 / 08 / 04 / 02

8

NC / NC / NC / A

NC / NC / A

NC /

1A1

A2A2A

///

V

0

2

SS

1

2

3

4

V

7

RST/RST

6

SCL

5

SDA

CC

PIN FUNCTION

Pin Name Function

A0, A1, A2 Device Address Inputs

SDA Serial Data Input/Output

SCL Serial Clock Input

¯¯¯¯

RST/RST

VCC Power Supply

VSS Ground

NC No Connect

Reset Output

DESCRIPTION

The CAT140xx (see table below) are memory and

supervisory solutions for microcontroller based systems. A

CMOS serial EEPROM memory and a system power

supervisor with brown-out protection are integrated

together. Memory interface is via both the standard

(100kHz) as well as fast (400kHz) I

The CAT140xx provides a precision V

2

C protocol.

sense circuit

CC

with two reset output options: CMOS active low output

or CMOS active high. The RESET output is active

whenever V

is below the reset threshold or falls

CC

below the reset threshold voltage.

The power supply monitor and reset circuit protect

system controllers during power up/down and against

brownout conditions. Seven reset threshold voltages

support 5V, 3.3V, 3V and 2.5V systems. If power

supply voltages are out of tolerance reset signals

become active, preventing the system microcontroller,

ASIC or peripherals from operating. Reset signals

become inactive typically 240ms after the supply

voltage exceeds the reset threshold level.

MEMORY SIZE SELECTOR

Product Memory density

14002 2-Kbit

14004 4-Kbit

14008 8-Kbit

14016 16-Kbit

THRESHOLD SUFFIX SELECTOR

Nominal Threshold

Voltage

4.63V L

4.38V M

4.00V J

3.08V T

2.93V S

2.63V R

2.32V Z

Threshold Suffix

Designation

© 2006 Catalyst Semiconductor, Inc. 1 Doc. No. 1117 Rev. A

Characteristics subject to change without notice

CAT140xx

T

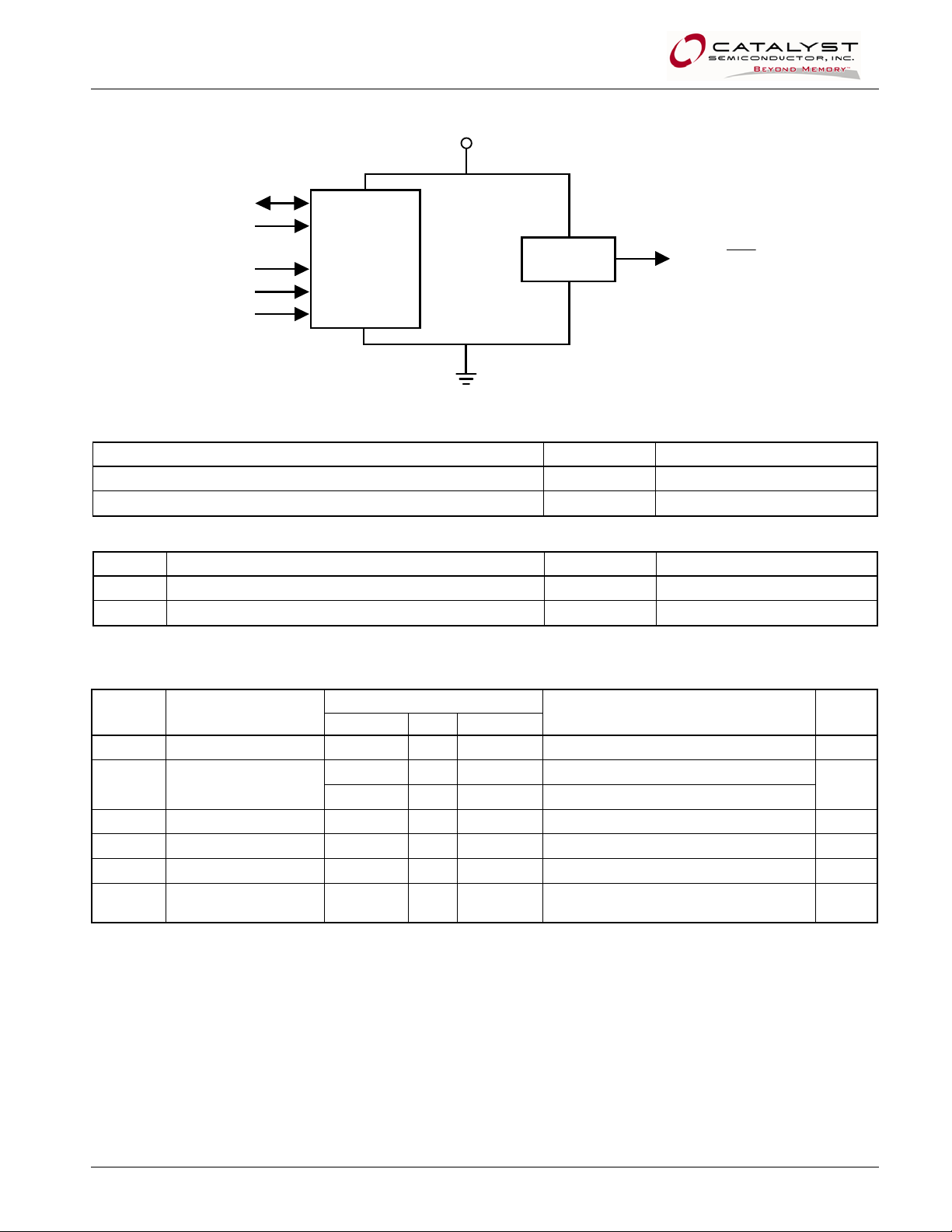

BLOCK DIAGRAM

SDA

SCL

A0

A1

A2

EEPROM

V

CC

V

SS

VOLTAGE

DETECTOR

RST or RS

ABSOLUTE MAXIMUM RATINGS

(1)

Parameters Ratings Units

Storage Temperature -65 to +150 °C

Voltage on Any Pin with Respect to Ground

RELIABILITY CHARACTERISTICS

(3)

(2)

-0.5 to +6.5 V

Symbol Parameter Min Units

(4)

NEND

Endurance 1,000,000 Program/ Erase Cycles

TDR Data Retention 100 Years

D.C. OPERATING CHARACTERISTICS

V

= +2.5V to +5.5V unless otherwise specified.

CC

Limits

Symbol Parameter

Min. Typ. Max.

Test Condition Units

ICC Supply Current 1 Read or Write at 400kHz mA

ISB Standby Current

10 22 V

8 17 V

< 5.5V; All I/O Pins at VSS or VCC

CC

< 3.6V; All I/O Pins at VSS or VCC

CC

IL I/O Pin Leakage 2 Pin at GND or VCC μA

VIL Input Low Voltage -0.5 VCC x 0.3 V

V

VOL Output Low Voltage

Input High Voltage VCC x 0.7 VCC + 0.5 V

IH

SDA

0.4

≥ 2.5 V, IOL = 3.0 mA

V

CC

μA

V

Notes:

(1) Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions outside of those listed in the operational sections of this

specification is not implied. Exposure to any absolute maximum rating for extended periods may affect device performance and reliability.

(2) The DC input voltage on any pin should not be lower than -0.5 V or higher than V

undershoot to no less than -1.5 V or overshoot to no more than V

(3) These parameters are tested initially and after a design or process change that affects the parameter according to appropriate AEC-Q100

and JEDEC test methods.

(4) Page Mode, V

Doc. No. 1117 Rev. A 2 © 2006 Catalyst Semiconductor, Inc.

= 5 V, 25°C

CC

+ 1.5 V, for periods of less than 20 ns.

CC

+ 0.5 V. During transitions, the voltage on any pin may

CC

Characteristics subject to change without notice

CAT140xx

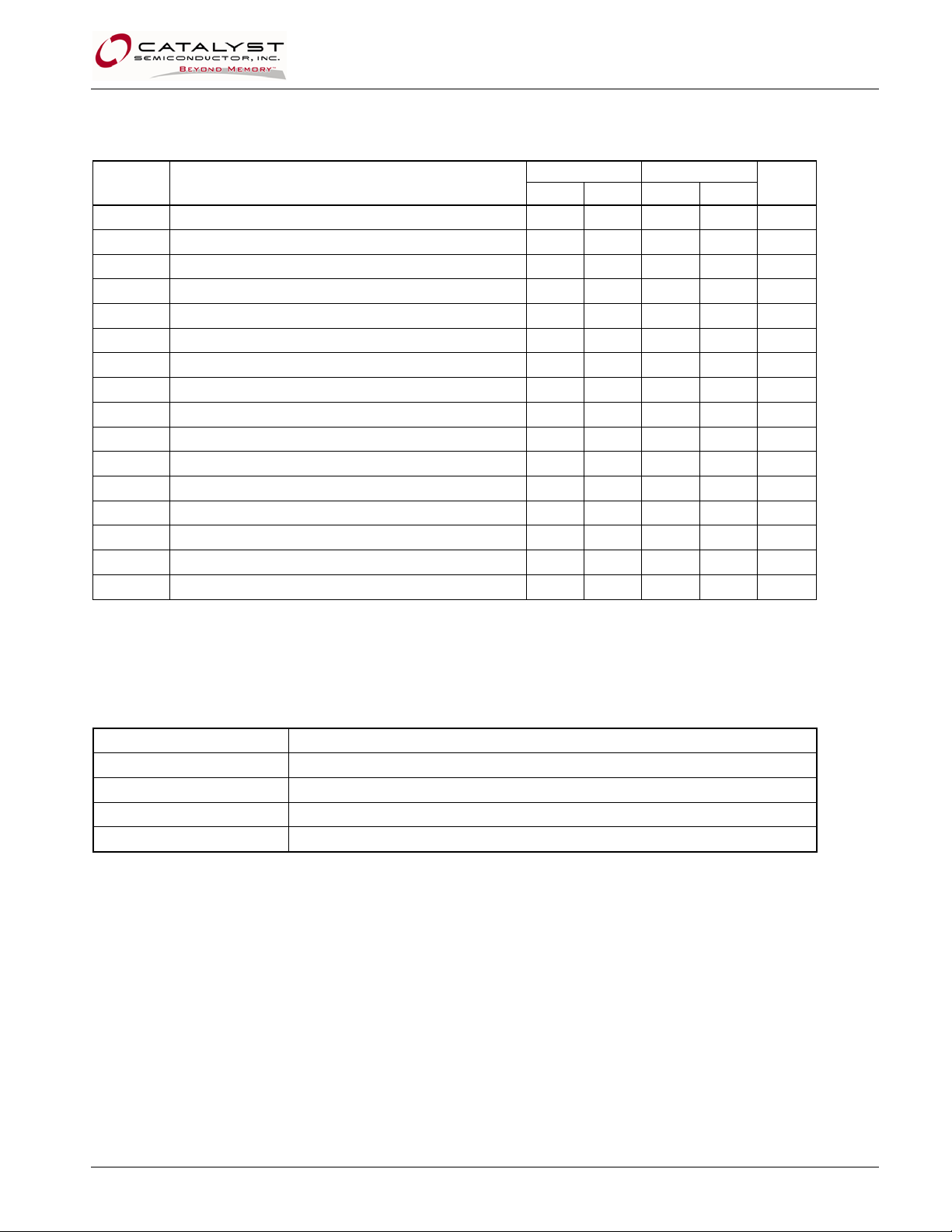

A.C. CHARACTERISTICS (MEMORY)

V

= 2.5V to 5.5V, TA = -40°C to 85°C, unless otherwise specified.

CC

Symbol Parameter

F

Clock Frequency 100 400 kHz

SCL

t

START Condition Hold Time 4 0.6 µs

HD:STA

t

Low Period of SCL Clock 4.7 1.3 µs

LOW

t

High Period of SCL Clock 4 0.6 µs

HIGH

t

START Condition Setup Time 4.7 0.6 µs

SU:STA

t

Data In Hold Time 0 0 µs

HD:DAT

t

Data In Setup Time 250 100 ns

SU:DAT

(2)

t

SDA and SCL Rise Time 1000 300 ns

R

(2)

t

SDA and SCL Fall Time 300 300 ns

F

t

STOP Condition Setup Time 4 0.6 µs

SU:STO

t

Bus Free Time Between STOP and START 4.7 1.3 µs

BUF

(1)

Standard Fast

Min Max Min Max

Units

tAA SCL Low to Data Out Valid 3.5 0.9 µs

tDH Data Out Hold Time 100 100 ns

(2)

T

Noise Pulse Filtered at SCL and SDA Inputs 100 100 ns

i

tWR Write Cycle Time 5 5 ms

(2, 3)

t

Power-up to Ready Mode 1 1 ms

PU

Notes:

(1) Test conditions according to “A.C. Test Conditions” table.

(2) Tested initially and after a design or process change that affects this parameter.

is the delay between the time VCC is stable and the device is ready to accept commands.

(3) t

PU

A.C. TEST CONDITIONS

Input Levels 0.2 x V

Input Rise and Fall Times

50 ns

≤

to 0.8 x VCC

CC

Input Reference Levels 0.3 x VCC, 0.7 x VCC

Output Reference Levels 0.5 x VCC

Output Load Current Source: IOL = 3 mA; CL = 100 pF

© 2006 Catalyst Semiconductor, Inc. 3 Doc. No. 1117 Rev. A

Characteristics subject to change without notice

CAT140xx

ELECTRICAL CHARACTERISTICS (SUPERVISORY FUNCTION)

V

= Full range, TA = -40ºC to +85ºC unless otherwise noted. Typical values at TA = +25ºC and VCC = 5V for

CC

L/M/J versions, V

Symbol Parameter Threshold Conditions Min Typ Max Units

V

TH

Reset Threshold Voltage

Symbol Parameter Conditions Min Typ

Reset Threshold Tempco 30 ppm/ºC

t

V

RPD

= 3.3V for T/S versions, VCC = 3V for R version and VCC = 2.5V for Z version.

CC

TA = +25ºC 4.56 4.63 4.70

T

= -40ºC to +85ºC 4.50 4.75

A

TA = +25ºC 4.31 4.38 4.45

T

= -40ºC to +85ºC 4.25 4.50

A

TA = +25ºC 3.93 4.00 4.06

T

= -40ºC to +85ºC 3.89 4.10

A

TA = +25ºC 3.04 3.08 3.11

T

= -40ºC to +85ºC 3.00 3.15

A

TA = +25ºC 2.89 2.93 2.96

T

= -40ºC to +85ºC 2.85 3.00

A

TA = +25ºC 2.59 2.63 2.66

T

= -40ºC to +85ºC 2.55 2.70

A

TA = +25ºC 2.28 2.32 2.35

T

= -40ºC to +85ºC 2.25 2.38

A

= VTH to (VTH -100mV) 20 µs

to Reset Delay

CC

L

M

J

T

S

R

Z

(2)

V

CC

(1)

Max Units

V

t

Reset Active Timeout Period TA = -40ºC to +85ºC 140 240 460 ms

PURST

¯¯¯¯¯¯

RESET

Output Voltage Low

(Push-pull, active LOW,

CAT140xx9)

V

OL

¯¯¯¯¯¯

RESET

V

(Push-pull, active LOW,

OH

Output Voltage High

CAT140xx9)

RESET Output Voltage Low

V

OL

(Push-pull, active HIGH,

CAT140xx1)

RESET Output Voltage High

VOH

(Push-pull, active HIGH,

CAT140xx1)

Notes:

(1) Production testing done at T

(2) RESET

output for the CAT140xx9; RESET output for the CAT140xx1.

VCC = VTH min, I

= 1.2 mA

SINK

R/S/T/Z

VCC = VTH min, I

= 3.2 mA

SINK

J/L/M

> 1.0V, I

V

CC

VCC = VTH max, I

= 50µA 0.3

SINK

= -500µA

SOURCE

R/S/T/Z

= VTH max, I

V

CC

SOURCE

= -800µA

J/L/M

VCC > VTH max, I

= 1.2mA

SINK

R/S/T/Z

> VTH max, I

V

CC

= 3.2mA

SINK

J/L/M

1.8V < V

I

SOURCE

= +25ºC; limits over temperature guaranteed by design only.

A

≤ VTH min,

CC

= -150µA

0.3

0.4

0.8V

CC

V

V

- 1.5

V

CC

0.3

V

0.4

0.8VCC V

Doc. No. 1117 Rev. A 4 © 2006 Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

CAT140xx

g

g

N

R

PIN DESCRIPTION

RESET/RESET

This output is available in two versions: CMOS

Active Low (CAT140xx9) and CMOS Active High

(CAT140xx1). Both versions are push-pull outputs

for high efficiency.

SDA: SERIAL DATA ADDRESS

The Serial Data I/O pin receives input data and

transmits data stored in EEPROM. In transmit mode,

this pin is open drain. Data is acquired on the

positive edge, and is delivered on the negative edge

of SCL.

SCL: SERIAL CLOCK

The Serial Clock input pin accepts the Serial Clock

generated by the Master.

A0, A1, A2: Device Address Inputs

The Address inputs set the device address when

cascading multiple devices. When not driven, these

pins are pulled LOW internally.

¯¯¯¯¯¯

: RESET OUTPUT

and remains asserted for at least 140ms (t

PURST

) after

the power supply voltage has risen above the threshold.

Reset output timing is shown in Figure 1.

The CAT140xx devices protect μPs against brownout

failure. Short duration V

transients of 4μsec or less

CC

and 100mV amplitude typically do not generate a Reset

pulse.

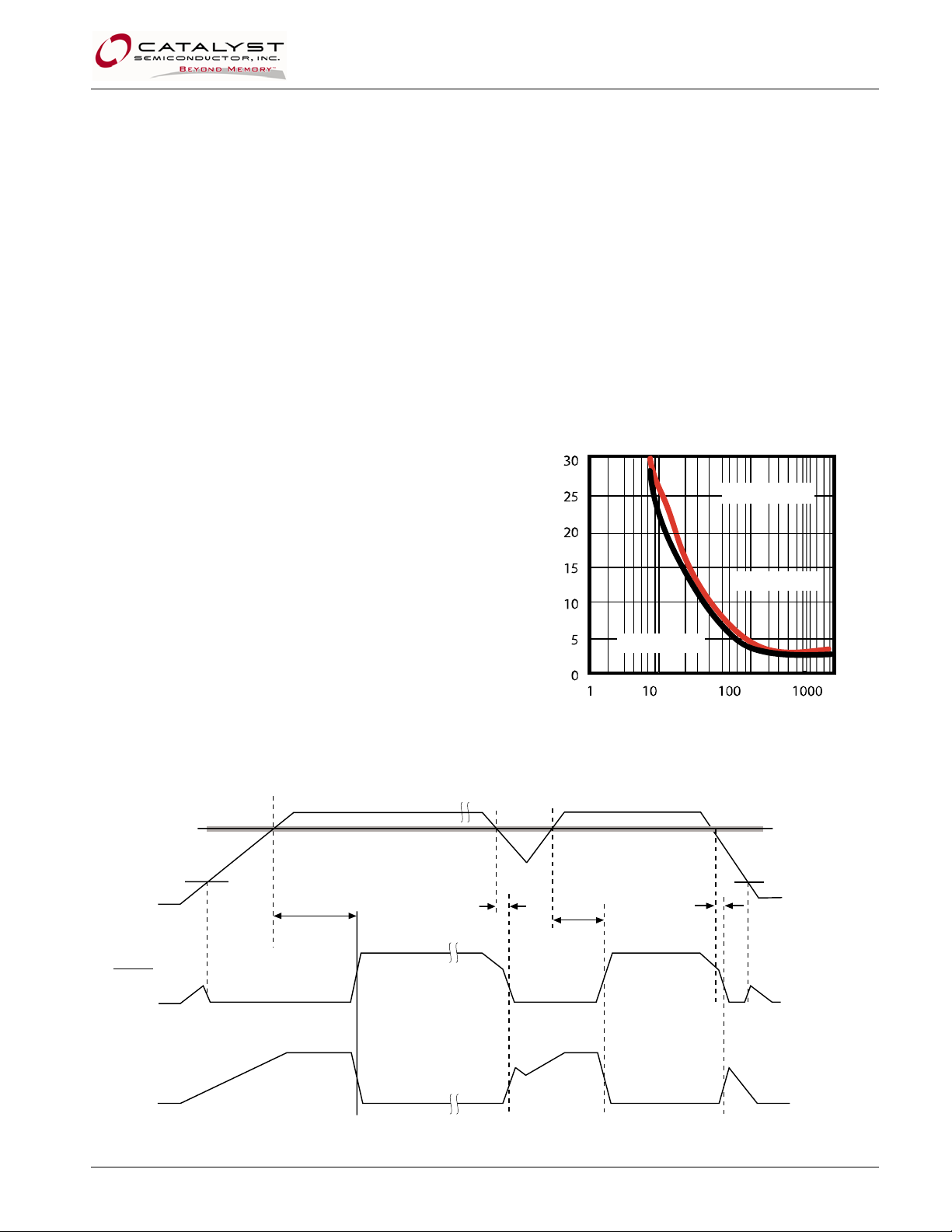

Figure 2 shows the maximum pulse duration of negativegoing V

transients that do not cause a reset condition.

CC

As the amplitude of the transient goes further below the

threshold (increasing V

duration decreases. In this test, the V

- VCC), the maximum pulse

TH

starts from

CC

an initial voltage of 0.5V above the threshold and

drops below it by the amplitude of the overdrive voltage

- VCC).

(V

TH

= 25ºC

T

AMB

ATION [µs]

DEVICE OPERATION

The CAT140xx products combine the accurate

voltage monitoring capabilities of a standalone

voltage supervisor with the high quality and reliability

of standard EEPROMs from Catalyst Semiconductor.

RESET CONTROLLER DESCRIPTION

The reset signal is asserted LOW for the CAT140xx9

and HIGH for the CAT140xx1 when the power

supply voltage falls below the threshold trip voltage

V

CC

V

RVALID

TH

t

PURST

t

RPD

V

RESE T

T DU

CAT140xxZ

CAT1 40xxM

TRANSIE

RESET OVERDRIVE VTH - VCC [mV]

Figure 2. Maximum Transient Duration Without

Causing a Reset Pulse vs. Overdrive Voltage

t

t

PURST

RPD

CAT140xx9

RESE T

ure 1. RESET Output Timin

Fi

CAT140xx1

© 2006 Catalyst Semiconductor, Inc. 5 Doc. No. 1117 Rev. A

Characteristics subject to change without notice

CAT140xx

EMBEDDED EEPROM OPERATION

The CAT140xx supports the Inter-Integrated Circuit

2

C) Bus data transmission protocol, which defines a

(I

device that sends data to the bus as a transmitter and

a device receiving data as a receiver. Data flow is

controlled by a Master device, which generates the

serial clock and all START and STOP conditions. The

CAT140xx acts as a Slave device. Master and Slave

alternate as either transmitter or receiver.

I2C BUS PROTOCOL

The I2C bus consists of two ‘wires’, SCL and SDA.

The two wires are connected to the V

pull-up resistors. Master and Slave devices connect to

the 2-wire bus via their respective SCL and SDA pins.

The transmitting device pulls down the SDA line to

‘transmit’ a ‘0’ and releases it to ‘transmit’ a ‘1’.

Data transfer may be initiated only when the bus is not

busy (see A.C. Characteristics).

During data transfer, the SDA line must remain stable

while the SCL line is HIGH. An SDA transition while

SCL is HIGH will be interpreted as a START or STOP

condition (Figure 3). The START condition precedes

all commands. It consists of a HIGH to LOW transition

on SDA while SCL is HIGH. The START acts as a

‘wake-up’ call to all receivers. Absent a START, a

Slave will not respond to commands. The STOP

condition completes all commands. It consists of a

LOW to HIGH transition on SDA while SCL is HIGH.

START

The START condition precedes all commands.

It consists of a HIGH to LOW transition on SDA while

SCL is HIGH. The START acts as a ‘wake-up’ call to

all receivers. Absent a START, a Slave will not

respond to commands.

supply via

CC

STOP

The STOP condition completes all commands.

It consists of a LOW to HIGH transition on SDA while

SCL is HIGH. The STOP starts the internal Write cycle

(when following a Write command) or sends the

Slave into standby mode (when following a Read

command).

Device Addressing

The Master initiates data transfer by creating a

START condition on the bus. The Master then

broadcasts an 8-bit serial Slave address. For normal

Read/Write operations, the first 4 bits of the Slave

address are fixed at 1010 (Ah). The next 3 bits are

used as programmable address bits when cascading

multiple devices and/or as internal address bits. The

last bit of the slave address, R/W, specifies whether a

Read (1) or Write (0) operation is to be performed.

The 3 address space extension bits are assigned as

illustrated in Figure 4. A

state of the external address pins, and a

, A1 and A0 must match the

2

, a9 and a8

10

are internal address bits.

Acknowledge

After processing the Slave address, the Slave

responds with an acknowledge (ACK) by pulling down

the SDA line during the 9

th

clock cycle (Figure 5). The

Slave will also acknowledge the address byte and

every data byte presented in Write mode. In Read

mode the Slave shifts out a data byte, and then

releases the SDA line during the 9

th

clock cycle. As

long as the Master acknowledges the data, the Slave

will continue transmitting. The Master terminates the

session by not acknowledging the last data byte

(NoACK) and by issuing a STOP condition. Bus timing

is illustrated in Figure 6.

Doc. No. 1117 Rev. A 6 © 2006 Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

Figure 3. START/STOP Conditions

SCL

SDA

CAT140xx

CONDITION

Figure 4. Slave Address Bits

101 0A2A

101 0A2A

101 0A

101 0a

Figure 5. Acknowledge Timing

BUS RELEASE DEL AY (TRANSMITTER) BUS RELEASE DELAY (RECEIVER)

SCL FROM

MASTER

DATA OUTPUT

FROM TRANSMITTER

START

STOP

CONDITION

A0R/W CAT14002

1

a8R/W CAT14004

1

2a9

10a9

189

a8R/W CAT14008

a8R/W CAT14016

DATA OUTPUT

FROM RECEIVER

START

ACK DELAY (≤ tAA)

ACK SETUP (≥ t

SU:DAT

)

Figure 6. Bus Timing

t

AA

t

HIGH

t

HD:DAT

t

LOW

SCL

t

SU:STA

SDA IN

SDA OUT

© 2006 Catalyst Semiconductor, Inc. 7 Doc. No. 1117 Rev. A

Characteristics subject to change without notice

t

F

t

LOW

t

HD:STA

t

DH

t

R

t

SU:DAT

t

SU:STO

t

BUF

CAT140xx

WRITE OPERATIONS

Byte Write

In Byte Write mode, the Master sends the START

condition and the Slave address with the R/W bit set

to zero to the Slave. After the Slave generates an

acknowledge, the Master sends the byte address that

is to be written into the address pointer of the

CAT140xx. After receiving another acknowledge from

the Slave, the Master transmits the data byte to be

written into the addressed memory location. The

CAT140xx device will acknowledge the data byte and

the Master generates the STOP condition, at which

time the device begins its internal Write cycle to

nonvolatile memory (Figure 7). While this internal

cycle is in progress (t

stated and the CAT140xx will not respond to any

request from the Master device (Figure 8).

Page Write

The CAT140xx writes up to 16 bytes of data in a

single write cycle, using the Page Write operation

(Figure 9). The Page Write operation is initiated in the

same manner as the Byte Write operation, however

instead of terminating after the data byte is

transmitted, the Master is allowed to send up to fifteen

additional bytes. After each byte has been transmitted

the CAT140xx will respond with an acknowledge and

internally increments the four low order address bits.

The high order bits that define the page address

remain unchanged. If the Master transmits more than

sixteen bytes prior to sending the STOP condition, the

address counter ‘wraps around’ to the beginning of

page and previously transmitted data will be

overwritten. Once all sixteen bytes are received and

the STOP condition has been sent by the Master, the

internal Write cycle begins. At this point all received

data is written to the CAT140xx in a single write cycle.

), the SDA output will be tri-

WR

Acknowledge Polling

The acknowledge (ACK) polling routine can be used

to take advantage of the typical write cycle time.

Once the stop condition is issued to indicate the end

of the host’s write operation, the CAT140xx initiates

the internal write cycle. The ACK polling can be

initiated immediately. This involves issuing the start

condition followed by the slave address for a write

operation. If the CAT140xx is still busy with the write

operation, NoACK will be returned. If the CAT140xx

has completed the internal write operation, an ACK

will be returned and the host can then proceed with

the next read or write operation.

Doc. No. 1117 Rev. A 8 © 2006 Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

Figure 7. Byte Write Sequence

CAT140xx

BUS ACTIVITY:

MASTER

SLAVE

Figure 8. Write Cycle Timing

SCL

SDA

Byte n

S

T

A

R

T

S

SLAVE

ADDRESS

ACK8th Bit

ADDRESS

A

C

K

STOP

CONDITION

BYTE

a7⎟a

DATA

BYTE

0

d7÷d

0

S

T

O

P

P

A

C

K

ADDRESS

t

WR

A

C

K

START

CONDITION

Figure 9. Page Write Timing

BUS ACTIVITY:

MASTER

SLAVE

S

T

A

R

T

S

n = 1

P ≤ 15

SLAVE

ADDRESS

A

C

K

ADDRESS

BYTE

DATA

BYTE

n

DATA

BYTE

n+1

DATA

BYTE

n+P

S

T

O

P

P

A

C

K

A

C

K

A

C

K

A

C

K

© 2006 Catalyst Semiconductor, Inc. 9 Doc. No. 1117 Rev. A

Characteristics subject to change without notice

CAT140xx

READ OPERATIONS

Immediate Read

Upon receiving a Slave address with the R/W bit set

to ‘1’, the CAT140xx will interpret this as a request for

data residing at the current byte address in memory.

The CAT140xx will acknowledge the Slave address,

will immediately shift out the data residing at the

current address, and will then wait for the Master to

respond. If the Master does not acknowledge the data

(NoACK) and then follows up with a STOP condition

(Figure 10), the CAT140xx returns to Standby mode.

Selective Read

Selective Read operations allow the Master device to

select at random any memory location for a read

operation. The Master device first performs a ‘dummy’

write operation by sending the START condition, slave

address and byte address of the location it wishes to

read. After the CAT140xx acknowledges the byte

address, the Master device resends the START

condition and the slave address, this time with the R/W

bit set to one. The CAT140xx then responds with its

acknowledge and sends the requested data byte. The

Master device does not acknowledge the data (NoACK)

but will generate a STOP condition (Figure 11).

Sequential Read

If during a Read session, the Master acknowledges

st

data byte, then the CAT140xx will continue

the 1

transmitting data residing at subsequent locations until

the Master responds with a NoACK, followed by a

STOP (Figure 12). In contrast to Page Write, during

Sequential Read the address count will automatically

increment to and then wrap-around at end of memory

(rather than end of page).

POWER-ON RESET (POR)

Each CAT140xx incorporates Power-On Reset (POR)

circuitry which protects the internal logic against

powering up in the wrong state.

A CAT140xx device will power up into Standby mode

after V

down into Reset mode when V

exceeds the POR trigger level and will power

CC

drops below the

CC

POR trigger level. This bi-directional POR feature

protects the device against ‘brown-out’ failure follo–

wing a temporary loss of power.

Delivery State

The CAT140xx is shipped erased, i.e., all bytes are FFh.

© 2006 Catalyst Semiconductor, Inc. 10 Doc. No. 1117 Rev. A

Characteristics subject to change without notice

Figure 10. Immediate Read Sequence and Timing

BUS ACTIVITY:

MASTER

S

T

A

R

T

SLAVE

ADDRESS

CAT140xx

N

O

S

T

A

C

O

P

K

P

SCL

S

SLAVE

A

C

K

DATA

BYTE

89

SDA 8th Bit

Figure 11. Selective Read Sequence

BUS ACTIVITY:

MASTER

S

T

A

R

SLAVE

T

ADDRESS

BYTEADDRESS

S

T

A

R

T

SLAVE

ADDRESS

STOPNO ACKDATA OUT

N

O

S

T

A

O

C

P

K

S

SLAVE

Figure 12. Sequential Read Sequence

BUS ACTIVITY:

MASTER

SLAVE

SLAVE

ADDRESS

A

C

K

DATA

BYTE

n

n+x

P

N

O

S

A

T

C

O

K

P

P

S

A

C

K

A

C

K

DATA

BYTE

n+1

A

C

K

A

C

K

DATA

BYTE

n+2

A

C

K

A

C

K

DATA

BYTE

DATA

BYTE

© 2006 Catalyst Semiconductor, Inc. 11 Doc. No. 1117 Rev. A

Characteristics subject to change without notice

CAT140xx

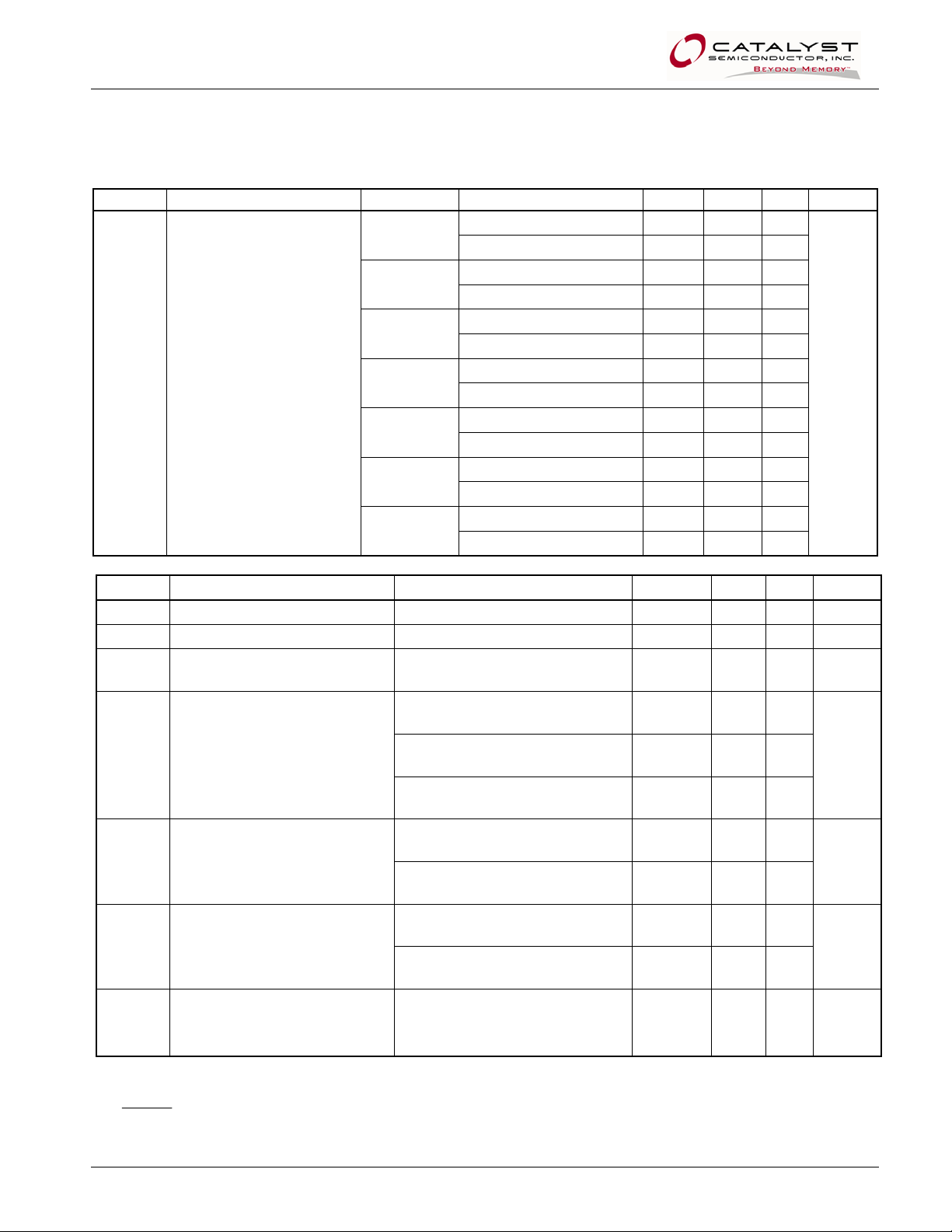

PACKAGE OUTLINES

8-LEAD 150 MIL SOIC (W)

E1

E

D

e

A1

b

SYMBOL

A1

A

b

MIN

0.10

1.35

0.33

NOM

C

D

E

E1

4.80

5.80

3.80

e 1.27 BSC

h

L

0.25

0.40

q1 0° 8°

For current Tape and Reel information, download the PDF file from:

http://www.catsemi.com/documents/tapeandreel.pdf.

Notes:

(1) All dimensions are in millimeters.

(2) Complies with JEDEC specification MS-012 dimensions.

h x 45

C

A

q1

L

MAX

0.25

1.75

0.51

0.250.19

5.00

6.20

4.00

0.50

1.27

Doc. No. 1117 Rev. A 12 © 2006 Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

–

ORDERING INFORMATION

CAT140xx

Prefix

Device # Suffix

CAT 14002 9 S W I

Company ID

Temperature Range

I = Industrial (-40ºC to 85ºC)

Product Type with

Memory Density

02 – 2K-bits

04 – 4K-bits

08 – 8K-bits

16

16K-bits

Reset Threshold Voltage

L: 4.50V – 4.75V

M: 4.25V – 4.50V

J: 3.89V – 4.10V

T: 3.00V – 3.15V

S: 2.85V – 3.00V

R: 2.55V – 2.70V

Z: 2.25V – 2.38V

Package

W: SOIC

- G T3

Lead Finish

G: NiPdAu (PPF)

Tape & Reel

T: Tape & Reel

3: 3000 units / Reel

Supervisor Output Type

9: CMOS Active Low

1: CMOS Active High

Notes:

(1) All packages are RoHS-compliant (Lead-free, Halogen-free).

(2) The standard lead finish is NiPdAu pre-plated (PPF) lead frames.

(3) The device used in the above example is a CAT140029SWI-GT3 (2Kb EEPROM, with Active Low CMOS output, with a reset threshold between

2.85V - 3.00V, in an SOIC, Industrial Temperature, NiPdAu, Tape and Reel.

(4) For additional package and temperature options, please contact your nearest Catalyst Semiconductor Sales office.

© 2006 Catalyst Semiconductor, Inc. 13 Doc. No. 1117 Rev. A

Characteristics subject to change without notice

REVISION HISTORY

Date Rev. Reason

11/09/06 A Initial Issue

Copyrights, Trademarks and Patents

Trademarks and registered trademarks of Catalyst Semiconductor include each of the following:

Beyond Memory™, DPP™, EZDim™, MiniPot™, and Quad-Mode™

Catalyst Semiconductor has been issued U.S. and foreign patents and has patent applications pending that protect its product s.

CATALYST SEMICONDUCTOR MAKES NO WARRANTY, REPRESENTATION OR GUARANTEE, EXPRESS OR IMPLIED, REGARDING THE SUITABILITY OF ITS

PRODUCTS FOR ANY PARTICULAR PURPOSE, NOR THAT THE USE OF ITS PRODUCTS WILL NOT INFRINGE ITS INTELLECTUAL PROPERTY RIGHTS OR THE

RIGHTS OF THIRD PARTIES WITH RESPECT TO ANY PARTICULAR USE OR APPLICATION AND SPECIFICALLY DISCLAIMS ANY AND ALL LIABILITY ARISING

OUT OF ANY SUCH USE OR APPLICATION, INCLUDING BUT NOT LIMITED TO, CONSEQUENTIAL OR INCIDENTAL DAMAGES.

Catalyst Semiconductor products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Catalyst Semiconductor product could create a situation where personal

injury or death may occur.

Catalyst Semiconductor reserves the right to make changes to or discontinue any product or service described herein without notice. Products with data sheets labeled

"Advance Information" or "Preliminary" and other products described herein may not be in production or offered for sale.

Catalyst Semiconductor advises customers to obtain the current version of the relevant product information before placing orders. Circuit diagrams illustrate typical

semiconductor applications and may not be complete.

Catalyst Semiconductor, Inc.

Corporate Headquarters

2975 Stender Way

Santa Clara, CA 95054

Phone: 408.542.1000 Document No: 1117

Fax: 408.542.1200 Revision: A

www.catsemi.com Issue date: 11/09/06

Loading...

Loading...