Page 1

16

Motor Grader

Engine Moldboard

Model Cat

Emissions U.S. EPA Tier 4 Final/EU Stage V/

Base Power (1st gear) – Net 216 kW 290 hp

Optimized VHP Range – Net 216-259 kW 290-348 hp

®

C13

Japan2014 (Tier 4 Final)

Tier 3/Stage IIIA/Japan 2006 (Tier3)

Equivalent emissions – depending on

emission ofspecic country

Tier 2/Stage II/Japan 2001 (Tier 2)

Equivalent Emission Standards –

depending on emission standards

ofspeci c country

Width 4.9 m 16 ft

Weight

Operating Weight, Typically Equipped 32 411 kg 71,454 lb

Page 2

Introduction

Enabling you to build and maintain

haul roads to maximize mine-site

productivity and lower your owning

and operating cost.

Contents

Structures and Drawbar-Circle-Moldboard .....4

Engine ...................................................................6

Emission Technology ..........................................7

Power Train ..........................................................8

Operator Station................................................10

Hydraulics ..........................................................12

Integrated Technologies ..................................13

Safety ..................................................................14

Serviceability .....................................................16

Work Tools and Attachments ..........................18

Sustainability .....................................................19

Customer Support.............................................19

Speci cations ....................................................20

Standard Equipment.........................................24

Optional Equipment...........................................26

Notes...................................................................27

2

Page 3

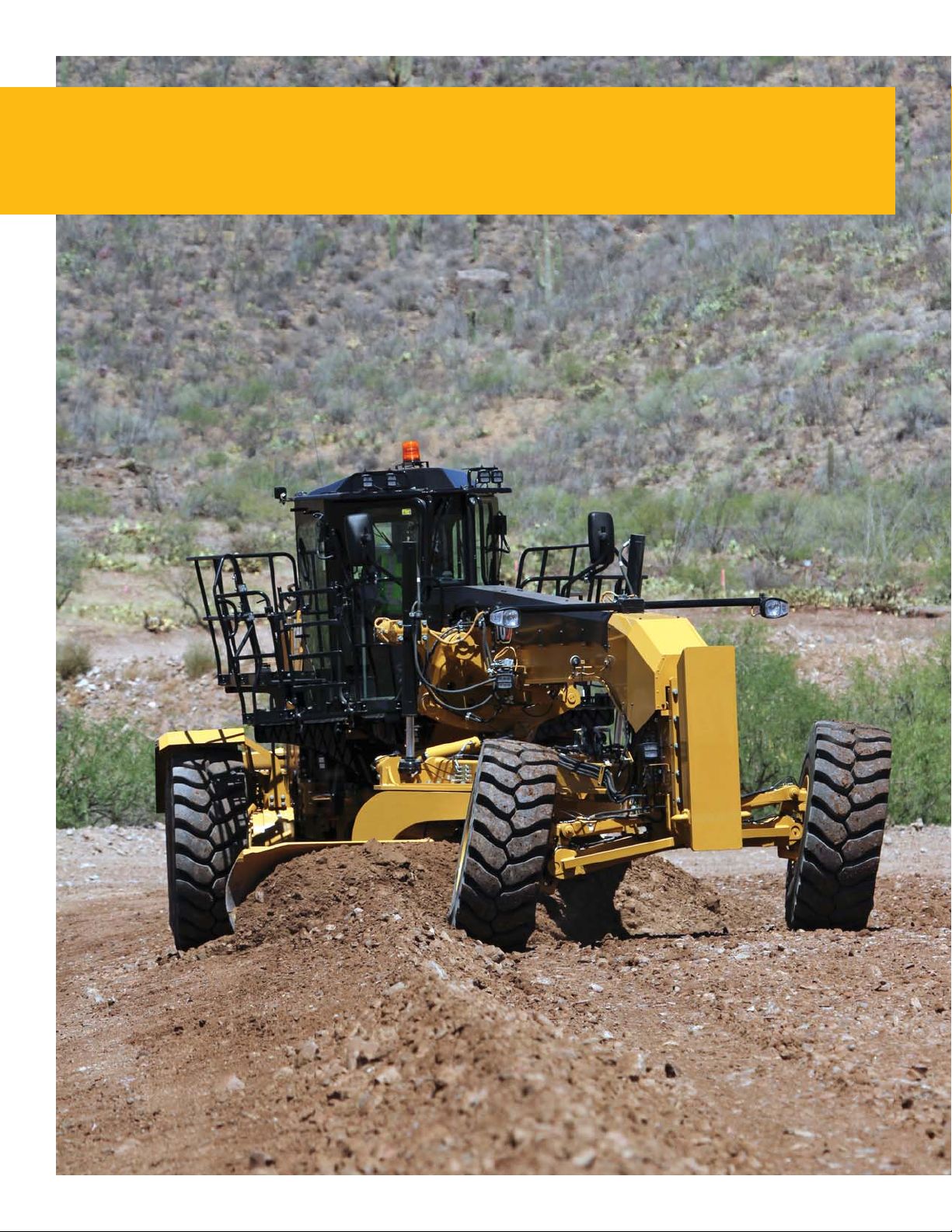

Good road conditions are key to extending truck life, reducing maintenance, lowering

fuel costs and reducing tire damage. As a result, cycle times are improved and more ore

is produced at a lower cost.

The 16 includes features that optimize operating cost reduction, uptime and performance

improvements as well as enhanced safety for your mining operations.

3

Page 4

Structures and Drawbar-Circle-Moldboard

Engineered for maximum production and service life.

4

Page 5

Structure Strength – Built to Last

The 16’s design to the front frame, hitch area and rear frame provides

performance and durability in heavy duty applications.

• Front Frame Structure – Continuous top and bottom plate construction

provides consistency and strength. The Center Shift Section is made

ofheavy duty steel casting which improves stress distribution to this

high load area of the mainframe for enhanced durability.

• Rear Frame Structure – Is lengthened to provide easy service access

to components in the engine enclosure as well as to improve machine

balance. It also utilizes two bumper castings and thick hitch plates for

improved durability. A mechanical locking pin prevents frame articulation

to ensure safety when servicing or transporting the machine.

Optimized Machine Balance

The 16 is designed to optimize machine balance and performance at

your site. With optimized combination of weight and balance the 16

delivers improved traction and the ability to keep ground speed especially

when carrying a large load on the board. Operators will nd that the

machine will be able to take corners better with improved turning.

Easy Maintenance for More Uptime

A series of shims, patented top-adjust wear strips and wear inserts

areeasy to add or replace. This keeps drawbar-circle-moldboard

components factory-tight for higher quality work, and saves you service

time and costs. An adjustable circle drive reduces service time and

reduces wear by keeping components tight.

5

Page 6

Engine

Consistent power and reliability for

maximumproductivity.

Engine

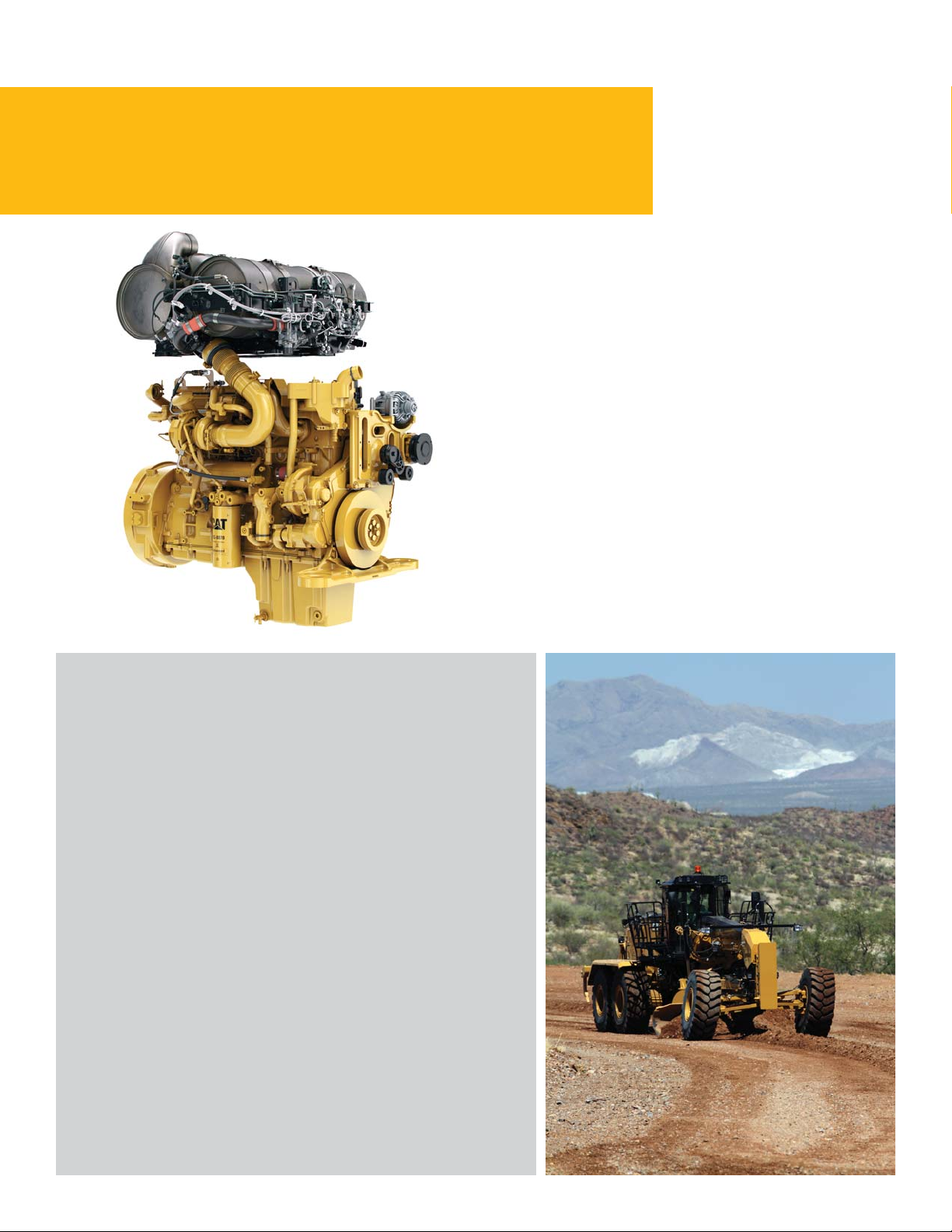

The Cat C13 engine gives you the performance to maintain

consistent grading speeds for maximum productivity. Superior

torque and lugging capability pulls through sudden, short-term

load increases.

Standard optimized variable horse power (VHP) is designed

toprovide the ideal amount of power in all gears toefciently

perform diverse motor grader applications while protecting

structure and drive train components.

Engine Economy (ECO) Mode

ECO Mode improves fuel economy by reducing high idle engine speed

while maintaining machine power. ECO Mode controls the high engine

idle speed (capped at 1,900 rpm in working gears) to ensure the engine

is performing as efciently as possible with respect to fuel consumption.

ECO Mode could provide signicant fuel consumption savings

especially in operations that are typically run at light to moderate

loads, high idle and gear usage between 3R to 5F.

Consistent Power to the Ground

This standard, automatically enabled feature changes the engine

power levels in real-time to offset cooling fan losses, resulting in

consistent power to the ground independent of ambient temperatures

and machine workloads. As a result the operator will get the best

performance from the machine all the time.

6

Page 7

Emission Technology

Providing you reliable, integrated solutions.

Emission Regulations

Emissions reduction technology is designed so regeneration

runs in the background while you work. It delivers the same

power and torque needed for optimal performance. The C13

engine variation with Tier 4 Final/EU Stage V/Japan 2014

(Tier4 Final) emission standards includes:

• Diesel Particulate Filter (DPF)

The Diesel Particulate Filter can provide a particulate

reduction of greater than 90%. It lters soot from the

exhaust. Soot is then removed through the regeneration

process automatically or manually.

• Selective Catalytic Reduction (SCR)

The Selective Catalytic Reduction system can provide

aNOxreduction of greater than 90%. SCR operation is

transparent tothe operator during operation. The urea

solution, DieselExhaust Fluid (DEF), is pumped from the

DEFtank andis sprayed into the exhaust stream. The DEF

reacts withthe SCRcatalyst to reduce NOx.

• Diesel Exhaust Fluid (DEF)

Diesel Exhaust Fluid is a liquid that is injected into the

exhaust system of engines equipped with Selective Catalytic

Reduction (SCR) systems. Diesel Exhaust Fluid that meets

ISO 22241 specications is required.

• Ground Level Diesel Exhaust Fluid (DEF) Fill

DEF ll allows the DEF tank to be lled from ground level.

This removes the burden of climbing onto and off of

themachine to ll the DEF tank and allows the DEF tank

tobelled at the same time the fuel tank is being lled.

7

Page 8

Power Train

We designed the 16 to give you efciency and longevity in your most

demanding applications.

• Standard Automatic Differential Lock unlocks the differential during a turn and

re-locks when straight for easier operation and improved power train protection.

• Advanced Productivity Electronic Control System (APECS) transmission

isakey contributor to improved speed shift performance. Theoperator will

notice enhanced comfort during shifting resulting in anincreased level of

operator productivity.

• Eight forward and six reverse gears are specically designed to give you

awide operating range for maximum productivity.

• Engine Over-Speed Protection prevents downshifting until an acceptable

safetravel speed has been established.

Front and Rear Axles

The sealed spindle keeps front axle bearings lubricated and protected from

contaminants. The Cat “Live Spindle” design places the larger tapered roller

bearing on the outside, where the load is greater, extending bearing life.

A bolt-on modular rear axle improves serviceability and contamination control

with easy access to differential components.

Hydraulic Brakes

Additional brake capacity is achieved by increased brake disc diameter and

piston area resulting in increased dynamic braketorque.

Manual standard brake wear indicator allows brake wear to be measured

during maintenance work without removal of the brake pods and supports

better maintenance planning.

8

Page 9

Power Train

Maximum power to the ground.

Front axle steering cylinder has been designed to enhance durability

and hydraulic hoses have been routed to improvereliability.

An optional front guard is available to help protect the front axlefrom

rocks or other debris that could damage the axle oritscomponents.

9

Page 10

Operator Station

Designed for your comfort, convenience,

andproductivity.

10

Ease of Operation

Two electro-hydraulic joysticks require up to 78% less hand and wrist

movement than conventional lever controls for greatly enhanced operator

comfort and efciency. The intuitive control pattern allows both new and

experienced operators to quickly become productive. Electronically

adjustable control pods help position joysticks for optimal comfort,

visibility and proper operation.

With the touch of a button, the articulation return-to-center feature

automatically returns the machine to a straight frame position from

anyangle.

You can choose the blade lift modulation mode that best ts your

application or operating style: Fine, Normal or Coarse.

Electronic throttle control provides easy, precise and consistent throttle

operation. An automatic/manual mode switch offers exibility for different

applications and operator preferences.

Page 11

Visibility

Good visibility is key to your safety and efciency. The large windows and

enhanced design of the rear frame provides exceptional visibility and additional

clearance between moldboard and rear tires. A standard rear vision camera is

available to enhance your sight lines to the rear of the machine.

Comfort and Control

Experience the most spacious, comfortable cab in the industry. Revolutionary

joystick controls replace levers, so hand and arm movement is reduced by 78%,

helping to reduce operator fatigue.

The multi-color/touch screen Information Display is the operator’s gateway

tomonitoring machine performance, a convenient way of modifying machine

parameters to tailor performance to the current task and access the service

information for initial troubleshooting.

The keypad allows activation and deactivation of different functions in the machine

with one touch and indicates whether a function is active or not through light

emitting diode (LED) lights.

Standard Cat Comfort Series suspension seat has six way adjustment control for

optimal support and comfort. Seat side bolsters restrain side-to-side movement,

especially when working on side slopes. Multiple isolation mounts signicantly

reduce sound and vibration for a more relaxed work environment. Optional heated

and ventilated seat provides enhanced comfort for operators in extreme

weatherconditions.

The high capacity Heating, Ventilation and Air Conditioning (HVAC) system

dehumidies and pressurizes the cab, circulates fresh air, seals out dust and

keepswindows clear.

Additional storage space for common used cabin items is included inside the cab.

Optional Bluetooth and satellite radio are available.

11

Page 12

Hydraulics

Advanced machine controls with precise

andpredictable movements.

Load Sensing Hydraulics (PPPC)

A proven load-sensing system and advanced Proportional

Priority Pressure-Compensating (PPPC) electro-hydraulic

valves give you superior implement control and enhanced

machineperformance. Continuously matching hydraulic

ow/pressure to power demands creates less heat and

reducespower consumption.

• Consistent, Predictable Movement – PPPC valves have different

ow rates for the head and rod ends of the cylinder, so you

can count on consistent, predictable implement response.

• Balanced Flow – Hydraulic ow is proportioned to give you

condence that all implements will operate simultaneously

without slowing the engine or speed of some implements.

Blade Float

Allows the blade to move freely under its own weight. By oating both

cylinders, the blade can follow the contours of the haul road. Floating only one

cylinder permits the toe of the blade to follow a hard surface while the operator

controls the slope with the other lift cylinder. An optional Variable Down Pressure

feature allows you to select the amount of down force when the blade is in

oat. This helps you extend cutting edge life and is effective for removing snow

and mud from a road surface.

Independent Oil Supply

Large, separate hydraulic oil supplies prevent cross-contamination and provide

proper oil cooling, which reduces heat build-up and extends component life.

Cat XT™ hose allows high pressures for maximum power and reduced downtime.

12

Page 13

Integrated Technologies

Monitor, manage, and enhance

jobsiteoperations.

Cat Product Link™ Elite

Product Link is deeply integrated into your machine, helping you take the guesswork out of equipment management. Easy access to

timely information like machine location, hours, fuel usage, idle time and event codes via the online VisionLink® user interface can help

you effectively manage your eet and lower operating costs.

Product Link licensing not available in all areas. Please consult your Cat dealer for availability.

Cat GRADE

Cat GRADE with Cross Slope is a standard, fully integrated, factory installed grade control system that helps your operator more easily

maintain desired cross slope by automatically controlling one side of the blade. The system is job-ready from day one, and scalable for

the future with upgrade kits that provide additional 2D and/or 3D control features.

Cat MineStar™ System

Cat MineStar helps you manage everything from material tracking to sophisticated real-time eet management, machine health

systems, autonomous equipment systems and more. The capability sets – Fleet, Terrain, Detect, Health and Command – can be used

incombination or individually to allow your operation the exibility and scalability it needs to be more productive, efcient and safe.

For more information visit cat.com

13

Page 14

Safety

Focused on keeping everyone safe.

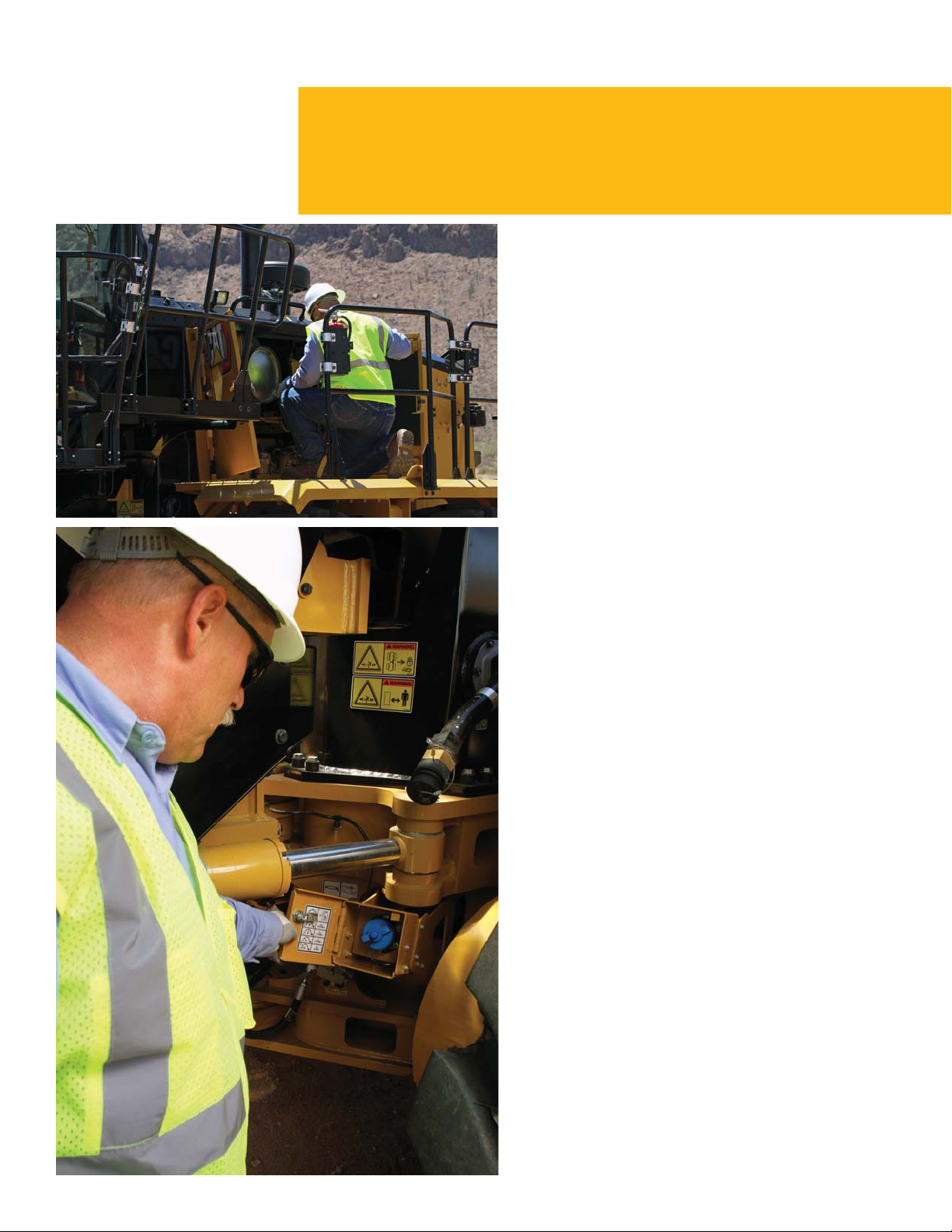

Access Platform – Optional

The access platform provides a full second access path to the

engine compartment and cab of the machine. This arrangement

includes ladder, walkways, handrails and access to the cab

from both the left and right side of the machine.

Service Access Platform – Optional

This service access conguration provides ladders, walkways

and handrails for enhanced fall protection access to the

engine compartment from both sides of the machine. In this

type of conguration the operator accesses the cab through

the regular ladders installed to the sides of the cab.

14

Access to Tandem

Two strategically placed grab handles and a non-slip step are

provided on the back right side of the engine compartment

foraccess to tandem walkways, particularly when fenders

are installed.

Page 15

Speed Sensitive Steering

Makes steering less sensitive as ground speed increases for

greater operator condence and control.

Secondary Steering System

Automatically engages an electric hydraulic pump in case of a drop

in steering pressure so the operator can safely steer the machine

toa stop.

Light Emitting Diode (LED) Enclosure Service

Lights – Optional

The enclosure lights provide better visibility to eld technicians

formachine services and maintenance as well as operator’s walk

around performed at night. A set of two LED 4×4 lights are offered

asan optional feature in the interior of the engine compartment.

Seat Belt Indication

Provides visual and audible alert to the operator when the seat belt is

not used, codes generated are recorded in VisionLink or VIMS™ PC.

Additionally, the machine is pre-wired so customer will be able to

easily install a beacon on top of the cab which will serve as an

external indicator of the seat belt usage.

Fire Suppression Ready System – Optional

Provides the 16 with the required provisions and brackets to mount

a re suppression system. It allows the customer to install are

suppression system faster without compromising other machine

components.

Other Standard Safety Features

• Rearview camera

• Operator not present monitoring system

• Hydraulic lockout

• Laminated front window glass

• Ground-level electrical disconnect switch

• Ground-level engine shutoff switch

• Glare reducing paint for night operation

15

Page 16

Serviceability

Reduce service time to increase your uptime.

16

High mechanical availability is one of your top concerns. The 16

helps increase uptime by making our machine easier to repair and

maintain. Major components are modular in design, so most can

be removed and reinstalled without disturbing other components.

Page 17

Fluid Level Monitoring Strategy

Helps prevent critical components from damage when low uid levels are

present. All information is available via the Information Display within the cab,

and diagnostic codes are logged.

• Ok-to-Start strategy provides electronic uid level verication at startup

onthe coolant, engine and hydraulic oil.

• Critically Low Fluid Level Monitoring System monitors the coolant, engine oil,

hydraulic uid and trans-axle oil during regular operation.

Long Life Service Intervals

Key service intervals*:

• 2× engine air lter life.

• 1,000 hours for hydraulic main and pilot lters as well as the transmission lter.

• 2,000 hours for transmission and rear axle.

*When SOSSM sampling and Cat branded lters are used.

Modular Cooling Package

The modular cooling package makes for simple removal and installation of

components on the cooling system which reduces service time. The radiator

also uses a bar plate design which is durable, rugged, and able to handle the

most demanding applications. Additionally, clean out access doors provide

easy clean out of the cores as needed.

Serviceability Enhancements

• French style engine enclosure doors – without post

• Easy access to the engine valve cover and injectors

• Optimized lter and SOS port placement

• Rear axle modular design

• Metallic fuel and shunt tanks

• Brake wear indication

• Gen 2 Electro-Hydraulic (EH) steering – optimized warning strategy

• In-chassis – nal drive removal

• Transmission and axle – cold and hot dipstick uid marks

• Platform door for ground level access to cab air lter

• Electronic Technician (Cat ET)

• VIMS – optimizes machine availability and component life

• Automatic lubrication system – optional

17

Page 18

Work Tools and Attachments

Provide exibility to match the machine to your job.

Moldboard Options

A 4.9 m (16 ft) moldboard is standard on the 16.

Ground Engaging Tools (GET)

A variety of tools are available from Cat Work Tools, including cutting edges, grader bits and

endbits, all designed for maximum service life and productivity.

Rear Ripper/Scarifier

Made to penetrate tough material fast and rip thoroughly for easier movement with the moldboard.

The ripper includes three shanks with the ability to add four more for additional versatility.

18

Page 19

Sustainability

Thinking generations ahead.

Sustainable Development for Caterpillar means leveraging technology

and innovation to increase efciency and productivity with less impact

on the environment. This helps customers by enabling their businesses

to become more productive by providing products, services and

solutions that use resources more efciently. The 16 offers anumber

ofsustainable benets:

• Fuel saving features like Engine Economy (ECO) Mode help decrease

overall fuel consumption.

• Major components on Cat Motor Graders are designed to be rebuilt.

The Cat Certied Rebuild program conserves natural resources by

delivering a cost effective second and even third life for our machines.

• Standard Cat GRADE with Cross Slope improves operator productivity,

as well as saving fuel and wear and tear on the machine. The need for

grade checking crews on the ground is eliminated which increases

sitesafety.

Customer Support

Your Cat dealer knows

how tokeep yourmining

machinesmoving.

From helping you choose the right machine to

knowledgeable ongoing support, Catdealers provide

you with unmatched sales and service.

• Preventive maintenance programs and guaranteed

maintenancecontracts.

• Best-in-class parts availability.

• Operator training to help boost your prots.

• Genuine Cat Remanufactured parts.

19

Page 20

16 Motor Grader Specifications

Engine

Engine Model Cat C13 VHP

Base Power (1st gear) – Net 216 kW 290 hp

Base Power (1st gear) – Net (metric) 294 hp

VHP Range – Net 216-259 kW 290-348 hp

VHP Range – Net (metric) 294-353 hp

Displacement 12.5 L 763 in

Bore 130 mm 5.1 in

Stroke 157 mm 6.2 in

Torque Rise

Tier 4/Stage V/Japan 2014 (Tier 4) 43%

Tier 3/Stage IIIA/Japan 2006 39%

(Tier3) Equivalent

Tier 2/Stage II/Japan 2001 (Tier 2) 39%

Equivalent

Maximum Torque ISO 9249

Tier 4/Stage V/Japan 2014 (Tier 4) 1771 Nm 1,306 lbf-ft

Tier 3/Stage IIIA/Japan 2006 1721 Nm 1,270 lbf-ft

(Tier3) Equivalent

Tier 2/Stage II/Japan 2001 (Tier 2) 1721 Nm 1,270 lbf-ft

Equivalent

Speed @ Rated Power 2,000 rpm

Number of Cylinders 6

Derating Altitude

Tier 4/Stage V/Japan 2014 (Tier 4) 3810 m 12,500 ft

Tier 3/Stage IIIA/Japan 2006 3711 m 12,176 ft

(Tier3) Equivalent

Tier 2/Stage II/Japan 2001 (Tier 2) 3954 m 12,973 ft

Equivalent

Standard – Fan Speed

Maximum 1,450 rpm

Minimum 550 rpm

Standard – Ambient Capability 50° C 122° F

• Notes: The 16 is offered with three variations of the C13 engine.

One emits U.S. EPA Tier 4 Final/EU Stage V/Japan 2014 (Tier 4

Final) emissions and is required for higher regulated countries.

The other options are capable of emitting Tier 2/Stage II/Japan

2001 (Tier 2) or Tier 3/Stage IIIA/Japan 2006 (Tier 3) equivalent

emissions and are available for lesser or non-regulated countries,

depending on the emission standards of the speci c country.

• Power as declared per ISO 14396 Tier 4 Final/Stage V/Japan2014

(Tier 4 Final) 272 kW (365 hp) Tier 3/Stage IIIA/Japan 2006

(Tier3) or Tier 2/Stage II/Japan 2001 (Tier 2) equivalent emissions

267 kW (359 hp) at 2,000 rpm rated speed.

• Net power is measured per ISO 9249 at rated speed of 2,000 rpm

and includes an engine equipped with fan, air cleaner, muf er and

alternator.

• On Tier 4/Stage V/Japan 2014 (Tier 4) machines, Ultra Low Sulfur

Diesel (ULSD) and low ash oil are required.

• On Tier 4/Stage V/Japan 2014 (Tier 4) machines, Diesel Exhaust

Fluid (DEF) that meets ISO 22241 specications is required.

3

Variable Power Tier 4 Final/Stage V/Japan 2014

(Tier 4 Final), Tier 3/Stage IIIA/Japan 2006 (Tier 3)

orTier 2/Stage II/Japan 2001 (Tier 2)

Gear Net kW Net HP Metric HP

Forward

1st 216 290 294

2nd 216 290 294

3rd 222 298 302

4th 227 304 309

5th 232 311 315

6th 239 320 325

7th 244 328 332

8th 259 348 353

Reverse

1st 216 290 294

2nd 216 290 294

3rd–6th 222 298 302

Power Train

Forward/Reverse Gears 8 Forward/6 Reverse

Transmission Direct drive, power shift,

countershaft

Brakes

Service Oil-actuated, oil disc

Dynamic Brake Torque per Wheel 36 701 Nm 27,069.27 lbf-ft

Parking Spring applied,

hydraulically released

Secondary Oil-actuated, oil-disc

Hydraulic System

Circuit Type Electro-hydraulic load

sensing, closed center

Pump Type Variable piston

Pump Output* 280 L/min 74 gal/min

Maximum System Pressure 24 750 kPa 3,590 psi

Standby Pressure 5900 kPa 856 psi

• Pump output measured at 2,150 rpm.

20

Page 21

16 Motor Grader Specifications

Operating Specifications Frame

Top Speed Circle

Forward 51.7 km/h 32.1 mph Diameter 1822 mm 71.7 in

Reverse 40.8 km/h 25.4 mph Blade Beam Thickness 50 mm 2 in

Turning Radius (outside front tires) 9.3 m 30 ft 6 in Drawbar

Steering Range – Left/Right 47.5° Height 203 mm 8 in

Articulation Angle – Left /Right 20° Width 76 mm 3 in

Forward Front Frame Structure

1st 4.5 km/h 2.8 mph Height 460 mm 18.1 in

2nd 6.1 km/h 3.8 mph Width 356 mm 14.0 in

3rd 8.9 km/h 5.5 mph Thickness 14 mm 0.6 in

4th 12.3 km/h 7.6 mph Front Axle

5th 19.0 km/h 11.8 mph Height to Center 670 mm 26.4 in

6th 25.8 km/h 16.0 mph Wheel Lean 18° Left/17° Right

7th 35.5 km/h 22.0 mph Total Oscillation per Side 35°

8th

Reverse

1st 3.6 km/h 2.2 mph

2nd 6.6 km/h 4.1 mph

3rd 9.7 km/h 6.0 mph

4th 15.0 km/h 9.3 mph

5th 28.0 km/h 17.4 mph

6th 40.8 km/h 25.3 mph

• Calculated with no slip and 23.5 R25 L-3 tires.

Service Refill

Fuel Capacity 496 L 131 gal

DEF Tank

Cooling System

Hydraulic System

Total 146 L 38.6 gal

Tank 70 L 18.5 gal

Engine Oil 36 L 9.5 gal

Transmission/Differential/Final Drives 98.5 L 34 gal

Tandem Housing (each) 129 L 34 gal

Front Wheel Spindle Bearing Housing 0.9 L 0.24 gal

Circle Drive Housing 10 L 2.6 gal

51.7 km/h 32.1 mph

16 L

70 L

4.2 gal

18.5 gal

Tandems

Height 648 mm 25.5 in

Width 236 mm 9.3 in

Sidewall Thickness

Inner 22 mm 0.9 in

Outer 22 mm 0.9 in

Drive Chain Pitch 63.5 mm 2.5 in

Wheel Axle Spacing 1841 mm 72.5 in

Tandem Oscillation

Front Up 15°

Front Down 25°

Moldboard

Width 4.9 m 16 ft

Height 787 mm

Thickness 25 mm 1 in

Arc Radius 413 mm 16.3 in

Throat Clearance 126 mm 5 in

Cutting Edge

Width 203 mm 8 in

Thickness 25 mm 1 in

End Bit

Width 152 mm 6 in

Thickness 19 mm 0.75 in

Blade Pull*

Base GVW 18 615 kg 41,039 lb

Maximum GVW 23 985 kg 52,878 lb

Down Force

Base GVW 13 945 kg 30,743 lb

Maximum GVW 19 895 kg 43,861 lb

• Blade pull calculated at 0.9 traction coefcient, which is equal

toideal no-slip conditions, and Gross Machine Weight.

31 in

21

Page 22

16 Motor Grader Specifications

Blade Range

Circle Centershift

Right 560 mm 22 in

Left 690 mm 27.2 in

Moldboard Sideshift

Right 790 mm 31.1 in

Left 740 mm 29.1 in

Maximum Blade Position Angle 65°

Blade Tip Range

Forward 40°

Backward 5°

Maximum Shoulder Reach

OutsideofTires

Right

Left

Maximum Lift above Ground 400 mm 15.7 in

Maximum Depth of Cut 470 mm 18.5 in

2311 mm

2311 mm

91 in

91 in

Ripper

Ripping Depth – Maximum 452 mm 17.8 in

Ripper Shank Holders 7

Shank Holder Spacing

Minimum 445 mm 17.5 in

Maximum 500 mm 20 in

Penetration Force 13 749 kg 30,311 lb

Pryout Force 19 822 kg 43,700 lb

Machine Length Increase, 1610 mm 63.4 in

BeamRaised

Weights Tier 4/Stage V/Japan 2014 (Tier 4 Final)*

Gross Vehicle Weight –

TypicallyEquipped

Total 32 411 kg 71,454 lb

Front Axle 8733 kg 19,253 lb

Rear Axle 23 678 kg 52,201 lb

Gross Vehicle Weight – Base**

Total 28 816 kg 63,528 lb

Front Axle 8134 kg 17,932 lb

Rear Axle 20 682 kg 45,596 lb

Gross Vehicle Weight –

MaximumTested

Total 38 500 kg 84,877 lb

Front Axle 11 850 kg 26,125 lb

Rear Axle 26 650 kg 58,753 lb

*

*For machines not equipped with Tier 4 Final emission engine,

act 150 kg (331 lb) from the rear axle weight and total weight.

subtr

**Base operating weight calculated on standard machine con guration

with 23.5 R25 tires, full fuel tank operator and ROPS cab.

Standards

ROPS/FOPS ISO 3471:2008/

ISO 3449:2005

Steering ISO 5010:2007

Brakes ISO 3450:2011

Sound ISO 6394:2008/

ISO 6395:2008/

ISO 6396:2008

• The dynamic spectator sound power level is 109 dB(A) for

StageVcerti ed congurations and 109 dB(A) for Tier 2/StageII/

Japan 2001 (Tier 2) and Tier 3/Stage IIIA/Japan 2006 (Tier 3)

equivalent emission standard machines when measured according

to the dynamic test procedures that are specied in ISO 6395:2008.

The measurement was conducted at 70% of the maximum engine

cooling fan speed. The machine was equipped with a sound

suppression system.

• The dynamic operator sound pressure level is 71 dB(A) for

StageVcerti ed congurations and 72 dB(A) for Tier 2/StageII/

Japan 2001 (Tier 2) and Tier 3/Stage IIIA/Japan 2006 (Tier 3)

equivalent emission standard machines when measured according

to the dynamic test procedures that are specied in ISO 6396:2008.

The measurement was conducted at 70% of the maximum engine

cooling fan speed, with the cab doors and the cab windows closed.

The cab was properly installed and maintained. The machine was

equipped with a sound suppression system.

22

Page 23

16 Motor Grader Specifications

Dimensions

All dimensions are approximate, based on standard machine conguration with 23.5R25 tires.

1

10

9

8

11

12

13 6

Height – Top of Cab 3719 mm 146.4 in

1

Height – Front Axle Center 733 mm 28.9 in

2

Length – Between Tandem Axles 1841 mm 72.5 in

3

Length – Front Axle to Moldboard 3066 mm 120.7 in

4

Length – Front Axle to Mid Tandem 7365 mm 290 in

5

Length – Front Tire to Rear of Machine (includes tow hitch) 10 593 mm 417 in

6

Length – Counterweight to Ripper 12 051 mm 474.4 in

7

Ground Clearance at Rear Axle 396 mm 15.6 in

8

Height to Top of Cylinders 3088 mm 121.6 in

9

Height to Exhaust Stack 3557 mm 140 in

10

Width – Tire Center Lines 2703 mm 106.4 in

11

Width – Outside Rear Tires 3411 mm 134.3 in

12

Width – Outside Front Tires 3411 mm 134.3 in

13

7

5

43

16

2

Optional Tire Arrangements

Common tire options for the 16.

Wheel Group Tires

19.5×25 MP 23.5R25 Bridgestone VKT 2 Star

19.5×25 MP 23.5R25 Bridgestone VKT 1 Star

19.5×25 MP 23.5R25 Bridgestone VJT 1 Star

19.5×25 MP 23.5R25 Michelin XHA 2 Star

19.5×25 MP 23.5R25 Michelin XLDD 2 Star L5

*Factory options may vary based on availability.

23

Page 24

16 Standard Equipment

Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

OPERATOR ENVIRONMENT

• Adjustable Electric Arm rest

• Adjustable wrist rest

• Air conditioner with heater

• Articulation, automatic Return-to-Center

• Centershift pin indicator

• Coat hook

• Cup holder

• Display, digital speed and gear

• Doors, left and right side with wiper

• Gauges (analog) inside the cab (includes fuel,

articulation, engine coolant temp, engine

rpm, and hydraulic oil temp)

• Gauges, machine level

• Information display touch screen

• Joystick gear selection

• Joystick hydraulic controls for implements,

steering, transmission

• Ladders, cab, left and right side

• Lights, left and right side lights

• Lights, night time cab

• Meter, hour, digital

• Mirror, inside rearview, wide angle

• Power port, 12V

• Radio ready, entertainment

• ROPS cab, sound suppressed, less than

73dB(A) ISO 6394 (70% fan speed)

• Seat, cloth-covered, comfort air suspension

• Storage compartments

• Throttle control, electronic

POWER TRAIN

• Air cleaner, dual stage dry type radial seal

with service indicator through messenger

and automatic dust ejector

• Air-to-air after cooler (ATAAC)

• Auto Diff Lock

• Belt, serpentine, automatic tensioner

• Brake wear indication

• Brakes, oil disc, four-wheel, hydraulic

• Consistent Power to ground

• Critically Low Fluid Level

MonitoringSystem

• Differential, lock/unlock

• Drain, engine oil, high speed

• Electronic over speed protection

• Engine ECO Mode: Tier 4 Final/StageV/

Japan 2014 (Tier 4 Final) and Tier 2/

StageII/Japan 2001 (Tier 2) equivalent

emissions

• Engine, compression brake

• Ether starting aid

• Fuel tank, fast ll, ground level

• Fuel-water separator

• Hydraulic Demand Fan

• Mufer, under hood (Tier 2/Stage II/

Japan2001 (Tier 2) and Tier 3/Stage IIIA/

Japan 2006 (Tier 3)

• OK-to-Start

• Optimized VHP

• Parking brake – multi disc, sealed, oil-cooled

• Priming pump, fuel

• Rear axle, modular

• Sediment drain, fuel tank

• Three variations of the C13 engine.

Oneemits U.S. EPA Tier 4 Final/EU StageV/

Japan 2014 (Tier4 Final) emissions and

is required for sale in higher regulated

countries. The other options are capable

of meeting Tier 2/Stage II/Japan 2001

(Tier 2) or Tier 3/Stage IIIA/Japan 2006

(Tier 3) equivalent emission standards and

are available for lesser or non-regulated

countries, depending on the emission

standards of the speci c country.

• Transmission, 8F/6R, power shift

• VIMS no telematics

ELECTRICAL

• Alternator, 150 ampere, sealed

• Batteries, maintenance free, heavy duty,

1,400 CCA

• Breaker panel

• Electrical system, 24V

• Lights: brake, reversing, roof-mounted

roading, stop and tail (LED), work front

• Product Link

• Starter, electric, heavy duty

SAFETY

• Alarm, back up

• Ground level engine shutdown

• Hammer (emergency exit)

• Horn, electric

• Lockout, hydraulic implement for roading

• Operator not present monitoring System

• Paint, glare reducing – top of front frame,

rear enclosure an ripper cylinders

• Rearview camera

• Seat belt indicator

• Seat belt, retractable 76 mm (3 in)

• Secondary steering

• Windows, laminated glass

– Fixed front with intermittent wiper

– Door with intermittent wipers (2)

• Windows: tempered

– Left and right side wipers

– Rear with intermittent wiper

Continued on next page

24

Page 25

Standard Equipment (Continued)

Standard equipment may vary. Consult your Cat dealer for details.

16 Standard Equipment

OTHER STANDARD EQUIPMENT

• 3-Bolt blade Bracket

• Attachment Ready Option (ARO)

• Accumulators, blade lift

• Brake accumulators, dual certi ed

• Cat GRADE with Cross Slope

• CD ROM Parts Book

• Clutch, circle drive slip

• Cutting edges, curved DH-2 steel

– 203 mm × 25 mm (8 in × 1 in)

– 19 mm (

• Doors (four), engine compartment,

(twoleft, two right hand) locking

• Doors, two service, left and right side

• Drawbar – six shoe with replaceable

wearstrips

• End bits, 16 mm (

19mm (34 in) mounting bolts

• Fast ll fuel, 567.8 L/min (150 gpm)

• Fluid check

• Frame, articulated, with safety lock

• Hydraulics, load-sensing

• Metallic Fuel tank, 496 L (131 gal)

• Metallic DCM wear strips

• Modular cooling package

• Moldboard

– 4880 mm × 787 mm × 25 mm

(16 ft × 31 in × 1 in)

– Hydraulic side shift and tip

• Radiator, two cleanout access doors

• Rear bumper

• Rear tandem access steps and hand bars

• SOS ports: engine, hydraulic,

transmission, coolant

• Tandem walkway

• Top adjust circle wear strips

• Tow hitch (not available with ripper)

3

4 in) mounting bolts

5

8 in) DH-2 steel,

TIRES, RIMS, AND WHEELS

• A partial allowance for tires on 597mm

× 609.6mm (23.5 in × 24in) multi-piece

rims is included in the base machine price

andweight

FLUIDS

• Extended Life Coolant to –35° C (–31° F)

WORK TOOLS/G.E.T.

• 4.9 m (16 ft) blade with curved cutting edge

203 mm × 25 mm (8 in×1 in)

25

Page 26

16 Optional Equipment

Optional Equipment

Optional equipment may vary. Consult your Cat dealer for details.

OPERATOR ENVIRONMENT

• Air horn

• Comfort package

• Heated door

• Mirrors high visibility

• Mirrors, outside heated 24V

• Mirrors, outside mounted

• Seat heated

• Seat heated/ventilated

• Windows cleaning platform and ladders

left-right hand side

POWER TRAIN

• Transmission, autoshift

GUARDS

• Debris guard

• Front axle cylinder guard

• Rear fenders

• Sound suppression, engine enclosure

andtransmission

• Transmission guard

ELECTRICAL

• Light, LED, warning strobe

• Lights front LED

• Lights, front headlights high

• Lights, front headlights low

• Mounting, for warning light

• Service lights

• Working lights halogen

• Working lights LED

SAFETY

• Additional monitor for rearview camera

• Enhanced access platform

• Fire suppression ready

• Machine Security System Key

• Service access platform

OTHER ATTACHMENTS

• Auto-lube, Centro-matic

• Auto-lube, ripper enhancement

• Control, blade, variable oat

• Heater, engine coolant, 120V

• Heater, engine coolant, 240V

• Hydraulic arrangements with additional

hydraulic valves Base+1

• Hydraulic arrangements with additional

hydraulic valves Base+5

• Product Link Elite dual

• Rim, 495.3 mm × 635 mm (19.5 in × 25 in)

MP(spare)

• Weather, Cold Plus package

WORK TOOLS/G.E.T.

• 4.9 m (16 ft) blade with at cutting edge

254 mm × 35 mm (10in × 1

• Push block, counterweight

• Ripper, rear

• Tooth, ripper

FLUIDS

• Coolant, –51° C (–60° F)

3

8 in)

26

Page 27

Notes

27

Page 28

For more complete information on Cat products, dealer services, andindustry solutions, visit us on the web

atwww.cat.com

© 2020 Caterpillar

All rights reserved

AEHQ7496-02 (01-2020)

Replaces AEHQ7496-01

Build Number: 15A

(Global excluding Japan)

Materials and specications are subject to change without notice. Featured machines in photos may include

additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Yellow,” the “Power Edge”

and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks

ofCaterpillar and may not be used without permission.

VisionLink is a trademark of Trimble Navigation Limited, registered in the United States and in other countries.

Loading...

Loading...