Page 1

SERVICE MANUAL

ELECTRONIC CASH REGISTER

V-R200

(EX-843)

JUL. 2016

Ver.3 : Jun. 2017

Page 2

V-R200 / VER.1

CONTENTS

IMPORTANT NOTICE ....................................................................................... P. 1

PRODUCT SPECIFICATIONS .......................................................................... P. 8

DIAGNOSTIC OPERATION ............................................................................. P. 12

DISASSEMBLY/ASSEMBLY ........................................................................... P. 33

CIRCUIT DIAGRAM .........................................................................................P. 59

EXPLODED VIEW/PARTS LIST ...................................................................... P. 63

Page 3

V-R200 / VER.1

– 1 –

IMPORTANT NOTICE

1.

Safety Precautions ................................................................................... P. 2

2.

Precautions for Use ................................................................................. P. 3

3.

Information

3-1. Basic Operation .................................................................................................... P. 5

3-2. SD/SDHC memory card ........................................................................................ P. 7

Repair Information

When the main PCB is replaced with a spare part one.

• Since an OS is already installed on the spare part main PCB, update the OS to an appropriate

version as required.

Refer to: Diagnostic operation

2. UPDATING the OS

• Write the serial number.

Refer to: Diagnostic operation

1-6. Checking and Registering the Serial Number

When the IOC PCB is replaced with a spare part one.

• Firmware is already installed on it.

• The fi rmware version is confi rmed at power on and, if necessary, it is automatically updated.

• UUID setting is not required.

When the CASE ASSY/FRONT is replaced with a spare part one.

• Carry out the touch panel calibration.

Refer to: Diagnostic operation

1-4. Touch panel calibration

To carry out the Diagnostic operation, a dedicated application is needed to be installed

beforehand.

NOTE: After completion of the test, make sure to uninstall the test application.

Page 4

V-R200 / VER.1

– 2 –

1.

Safety Precautions

*

Caution

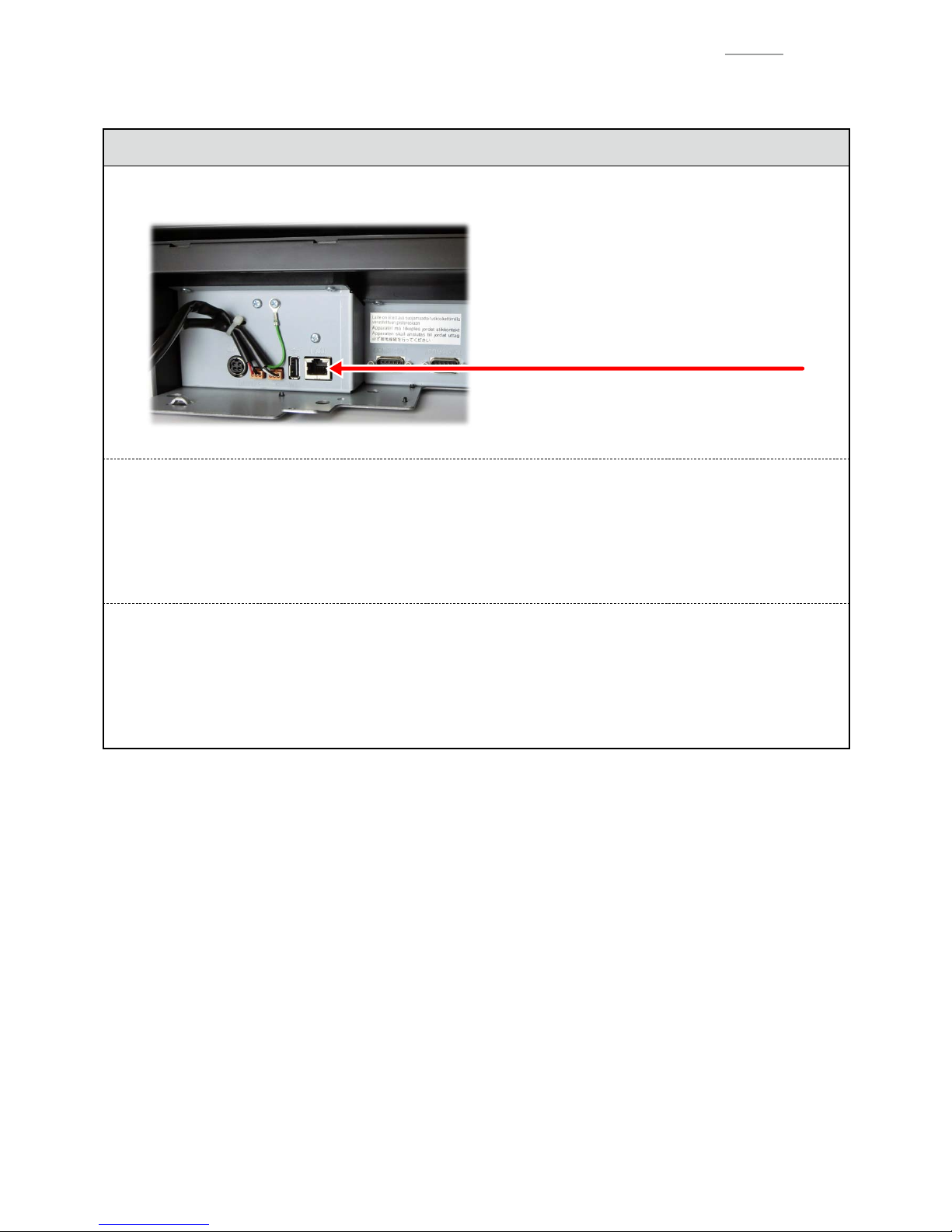

LAN Conenector

Ethernet (LAN) Connector:

Not used to a telecommunication network

To Prevent malfunctions caused by the weak batteries, charge the memory

protection batteries for over 6-hours.

1. Before installation, initialize the terminal and leave it power on over 6-hours.

2. After the terminal is repaired or checked, you must leave it power on over 6-hours.

BATTERIES HANDLING PRECAUTIONS

1. Do not use old and new batteries mixed together, or batteries at different charge levels.

This may cause leakage of battery fl uid and heat generation.

2. Load a set of three new batteries at being care of their polarity.

Page 5

V-R200 / VER.1

– 3 –

2.

Precautions for Use

Read the following items thoroughly and use this product properly. CASIO bears no responsibility whatsoever

for malfunction or damage caused by handling not following below contents. Please note that it will also result in

charged repair, and actual cost required for repair will be charged, even if it is within the warranty period.

Installation Location

Do not place in a hot or dusty location, or in any location exposed to oily smoke or water. Never store or leave in

following locations. This could erase the memory and cause a malfunction or result in deformation of the case.

0

Temperature of 0 °C or lower

0

Inside vehicles in summer

0

Close to air conditioner

0

Under direct sunlight

0

Temperature of 40 °C or higher

Avoid using this product in following locations.

0

Outdoor

0

Close to equipment that will become hot such as range, electrical heater, etc.

0

Location exposed to water or steam

0

Location with severe change in environment such as temperature, humidity, etc.

0

Location where corrosive gas or saline matter is generated

0

Location where dirt or dust is generated

0

Location with vibration

0

Location prone to static electricity

Other

0

Prepare separate AC power supply from the power line for motor, ice maker, microwave oven, etc., which may

generate noise.

0

Do not touch the power switch with wet hands. This may result in electrical shock.

0

Wipe thoroughly with dry cloth, etc., when there is any water droplet on the device.

0

Do not use any volatile chemical such as thinner, benzine, cosmetics, etc., for cleaning. Wipe with dry soft cloth

when this product gets dirty. The display section may be scratched when scuffed strongly with a cloth.

0

When the capacity of the internal memory protection battery is insuffi cient ant there is no power supply available

due to a power outage, malfunction or other reason, the memory content might be erased.

0

Contact the dealer or the CASIO service representative around 5 years after purchase to replace the battery (this

time depends on how the product is used).

Page 6

V-R200 / VER.1

– 4 –

Take Advance Notice of the Following

0

The content of this manual may be changed without prior notice due to improvement or specifi cation change of

the product.

0

Please note that CASIO bears no responsibility for damage, loss of profi t, or any claim from third party due to

loss or change of data caused by usage, malfunction, or repair of this product.

0

The copyright for this manual and all rights related to the software described in this manual are the property of

CASIO Computer Co., Ltd. The unauthorized reproduction of this manual in whole or part is prohibited without

the written permission of CASIO.

0

The screen or illustration used in this manual may be different from the actual product. The keys and icons are

described in simplifi ed manner.

0

Weld Line

The line on the exterior of the product is called “weld line”, which is created at the time of plastic forming, and it is

not a crack or a scratch. This will not interrupt the usage.

Trademark Registration

SD, SDHC, microSD and microSDHC are trademarks of SD-3C, LLC.

Page 7

V-R200 / VER.1

– 5 –

3.

Information

3-1. Basic Operation

(1) General information

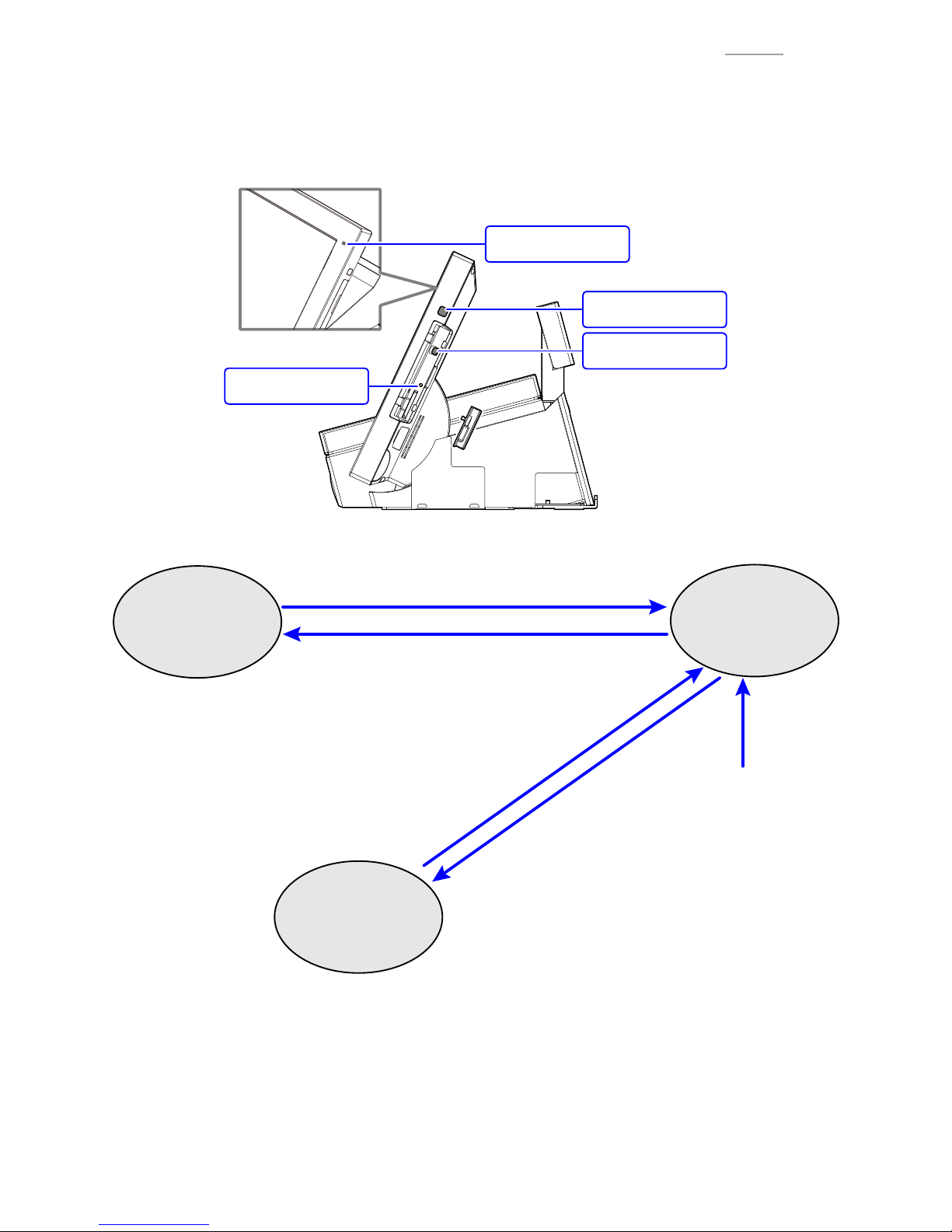

Fig. 1

Maintenance switch

Power switch

Power lamp

Reset switch

Fig. 2

• The power switch is pressed.

• When touching the touch panel.

• An alarm occurs.

• The reset switch is pressed.

¨ Reboot without shutdown

• The power switch is pressed.

• No operation is done for a certain period of time.

• The power switch is pressed.

• The reset switch is pressed.

¨ Reboot without shutdown

• The power switch is held down more than 5 sec.,

then choose "Power off".

• The maintenance switch is held down more than 5 sec.

OFF state

Power lamp: OFF

ON state

Power lamp: Green

Sleep state

Power lamp: Orange

NOTE: Power lamp: Red (Insuffi

cient capacity of the internal memory backup battery)

Do not shutdown the power supplied to the product or unplug the power cord.

NOTE: After taking out a product from carton box, connect AC adaptor to the product then leave it more than

6hours to charge internal memory buck up battery for full charge.

Page 8

V-R200 / VER.1

– 6 –

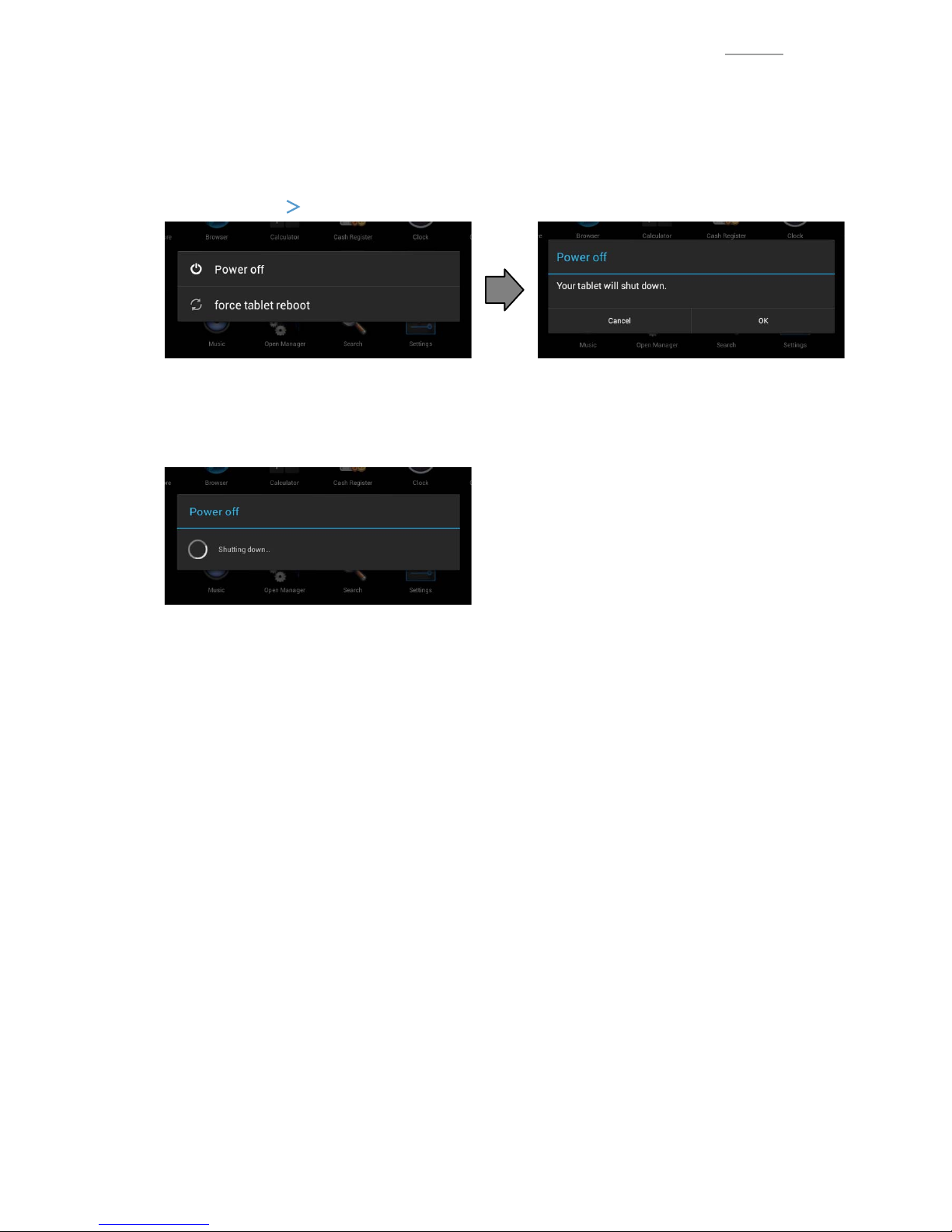

(2) Shutdown procedure

There are two ways to shut down.

0Shutting down by the power switch

Press and hold the power switch until “Power off” / “force tablet reboot” appears.

Select “Power off”

“OK”.

Fig. 3 Fig. 4

0Shutting down by the maintenance switch

Press and hold the maintenance switch until “Pwer off” appears.

Fig. 5

Page 9

V-R200 / VER.1

– 7 –

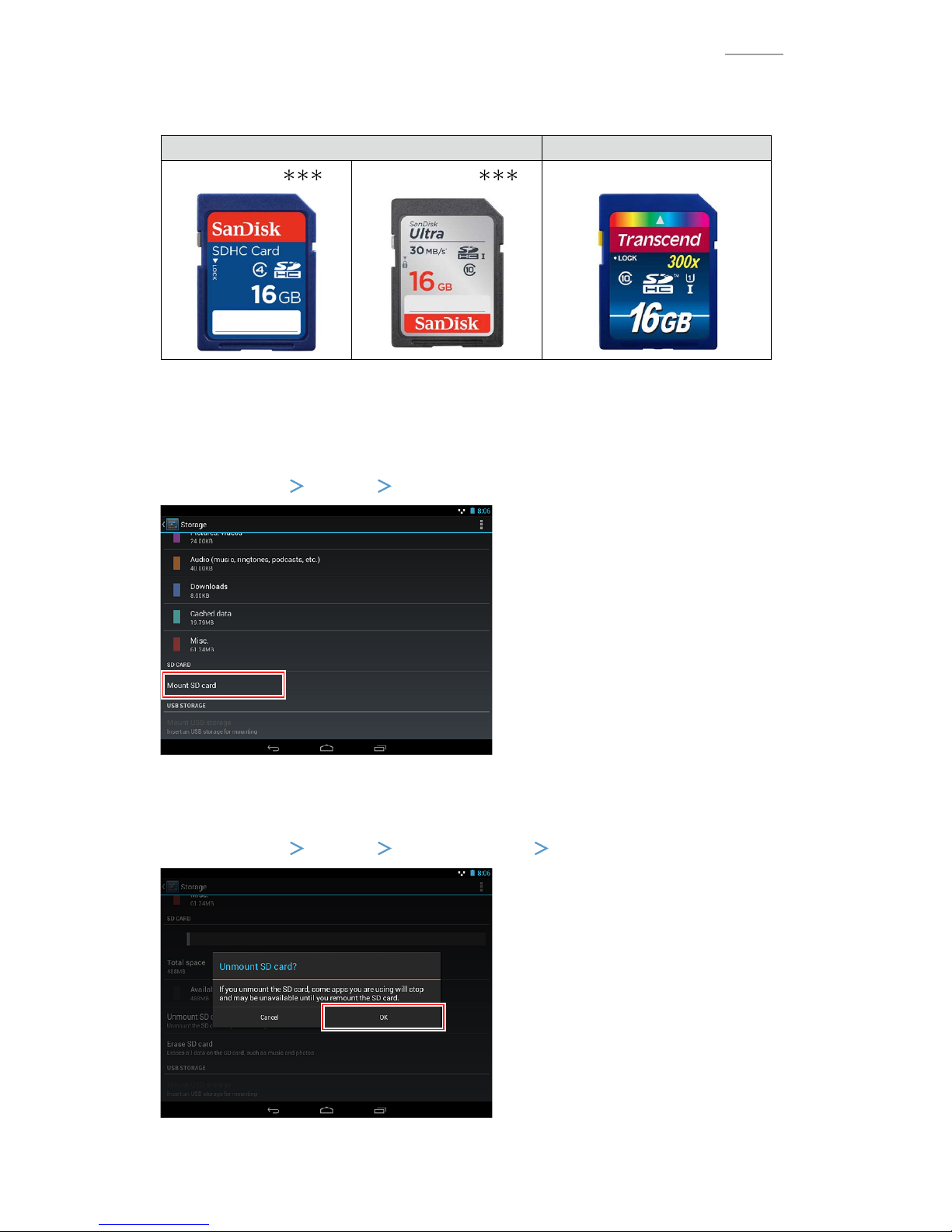

3-2. SD/SDHC memory card

(1) Recommended SD/SDHC memory card

SanDisk Corporation Transcend Information, Inc.

SDSDB-016-

SDSDUL-016-

TS16GSDU1

Fig. 6

(2) Mounting the SD/SDHC memory card

SD/SDHC memory card is automatically mounted when it is inserted. If it has been unmounted due to

incorrect operation, mount it again.

Select “Settings”

“Storage”

“Mount SD card”.

Fig. 7

(3) Unmounting the SD/SDHC memory card

Select “Settings”

“Storage”

“Unmount SD card”

“OK”.

Fig. 8

Page 10

– 8 –

V-R200 / VER.1

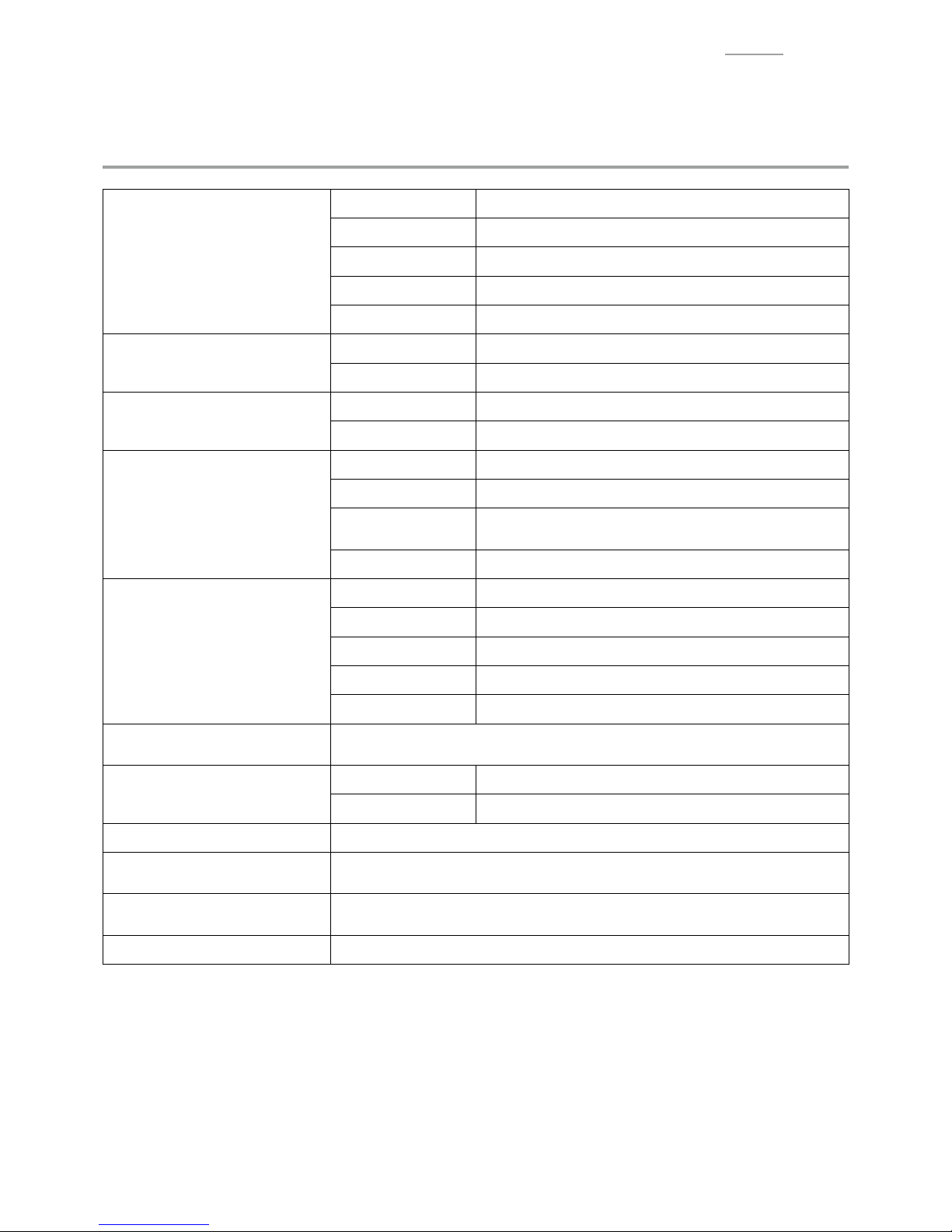

PRODUCT SPECIFICATIONS

YSpecifi cations List

Main display

Type 10.4 SVGA color TFT LCD

Resolution 800 × 600

Color *1 Max. 16.77 million colors

Backlight White LED

Other Power tilt function (15° to 75°)

Touch panel

Method 4-wire resistive fi lm

Size 10.4 inch

Sub display

Resolution 32 × 160 dot (20 single-byte characters, 2 lines)

Backlight 2 colors (emerald green, white)

Printer

Print method Thermal printer

Print speed *1 Max. 120 mm/sec.

Paper roll

Thermal recording paper, width 58 mm or 80 mm,

external diameter 80 mm or smaller

Paper cut-off Automatic cutter

Memory protection *2

Battery Nickel-metal hydride rechargeable battery

Memory holding *3 Approximately 1 hour (used at 25 °C)

Battery life *4 5 years (used at 25 °C)

Charge time Full charge in 6 hours (used at 25 °C)

Time holding Approximately 30 days (used at 25 °C)

Power supply/

power consumption

120 V ac ±10 V 50/60 Hz 0.64 A (Operating) 0.2A (Standby)

220 V to 240 V ac ±10 V 50/60 Hz 0.36 A (Operating) 0.11A (Standby)

External interface

Side of display SD/SDHC memory card slot x 1

Back of the device COM port x 3, LAN port x 1, USB port x 1, DC jack x 1

Water proof performance IP53 level (main display only) *5

Temperature/humidity

(when in use)

0°C to 40°C/20% to 85% RH

External dimensions

W 395 mm x D 237 mm x H 229 mm

(With maximum tilt angle) (Not including protruding parts)

Weight Approximately 4.0 kg

*1: These fi gures indicate the performance level of the hardware. The actual colours and speed vary depending on

the application in use.

*2: The internal battery is a consumable item. Contact the dealer or the CASIO service representative around

5 years after purchase to replace the battery (this time depends on how the product is used). Memory protection

may not operate properly if the battery becomes depleted.

*3: After 1 hour of disconnect power, the product will shut itself down. To turn the power ON, press the power

switch after power recovery.

*4: With a battery usage frequency of once per month.

*5: The specifi cations here are test values, and are not guaranteed values.

Page 11

– 9 –

V-R200 / VER.1

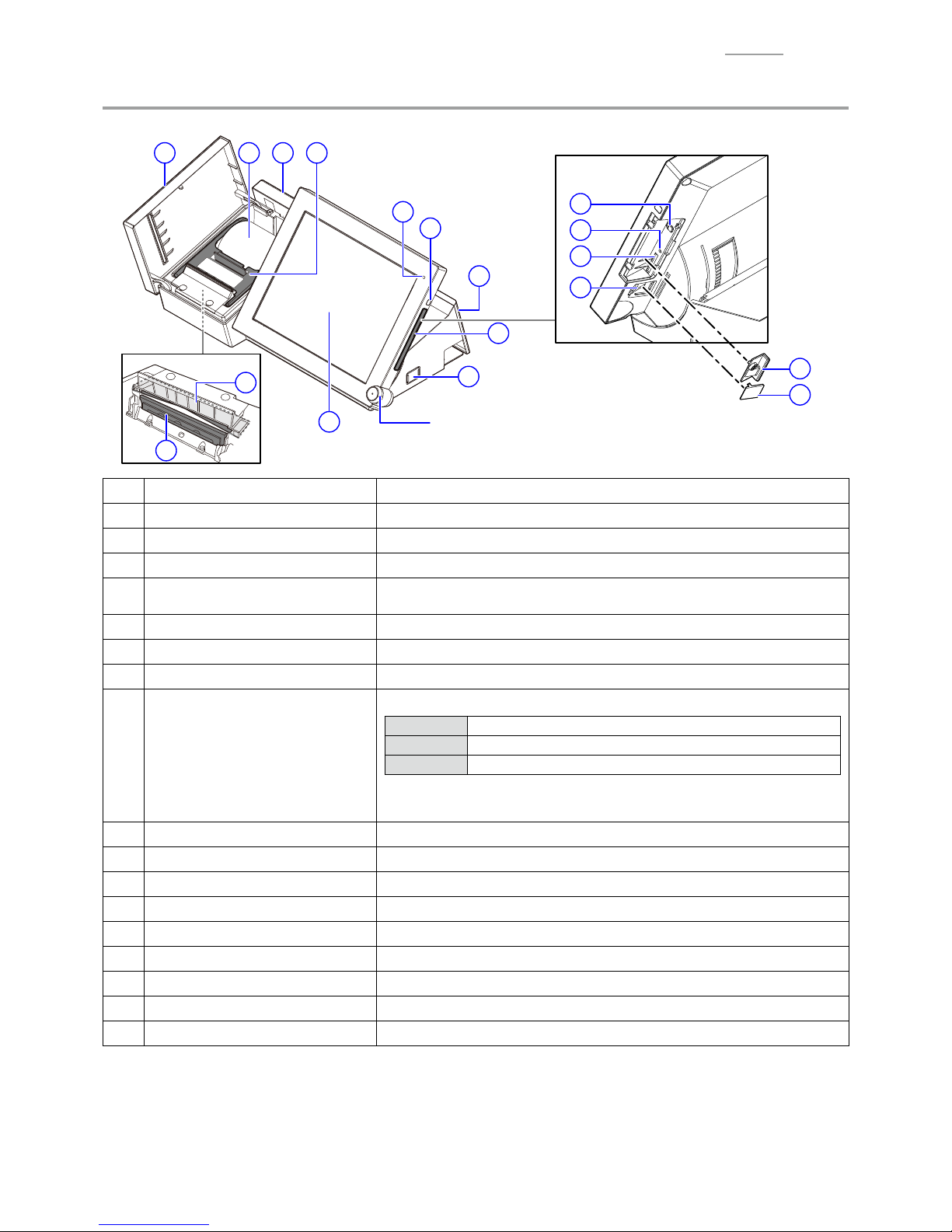

YParts Names and Functions

15

12

13

14

Dallas key

For operators to sign on and off. (Factory option)

Front

1

2

11 10 4

6

18

16

17

5

8

9

7

3

1 Printer cover Open this replacing the paper roll. Keep closed during normal use.

2 Printer head Prints the receipts.

3 Auto cutter block The customer receipt is cut automatically when it is issued.

4 Paper holder Open this when replacing the paper roll.

5

Main display and touch screen

panel

Display each menu. Used for data input.

6 Side cover Cover for SD/SDHC memory card slot.

7 Connector cover Open when connecting the power supply or various devices.

8 Power switch Turn the power ON. Switch the ON and OFF of the main display.

9 Power lamp

Display the status of the power supply.

Green Starting

Orange Main display OFF

Red Insuffi cient internal memory protection battery capacity

NOTE: When the power lamp is red, do not shut down the power or

remove the power plug.

10 Sub display Displays information for customers.

11 Paper roll Insert the roll of paper used for receipts, etc.

12 SD/SDHC memory card slot Insert the SD or the SDHC memory card.

13 Card cover Cover for the SD/SDHC memory card slot (screw lock).

14 Boot cover Boot cover

15 Boot switch Boot device setting *User operation prohibited.

16 Reset switch Reboot without shutdown *User operation prohibited.

17 Maintenance switch Shutdown (by a long press) *User operation prohibited.

18 Tilt switch Adjusts the angle of the main display.

NOTE 1: Do not put your fi ngers in the Auto cutter unit while the receipts are being cut. This may result in

injury.

NOTE 2: Before removing the power plug or turning the breaker off for moving or cleaning the product, for

example, make sure to shut down the power by pressing and holding the power switch. The data

may be damaged or the product may be broken if the above procedure is not done properly.

Page 12

– 10 –

V-R200 / VER.1

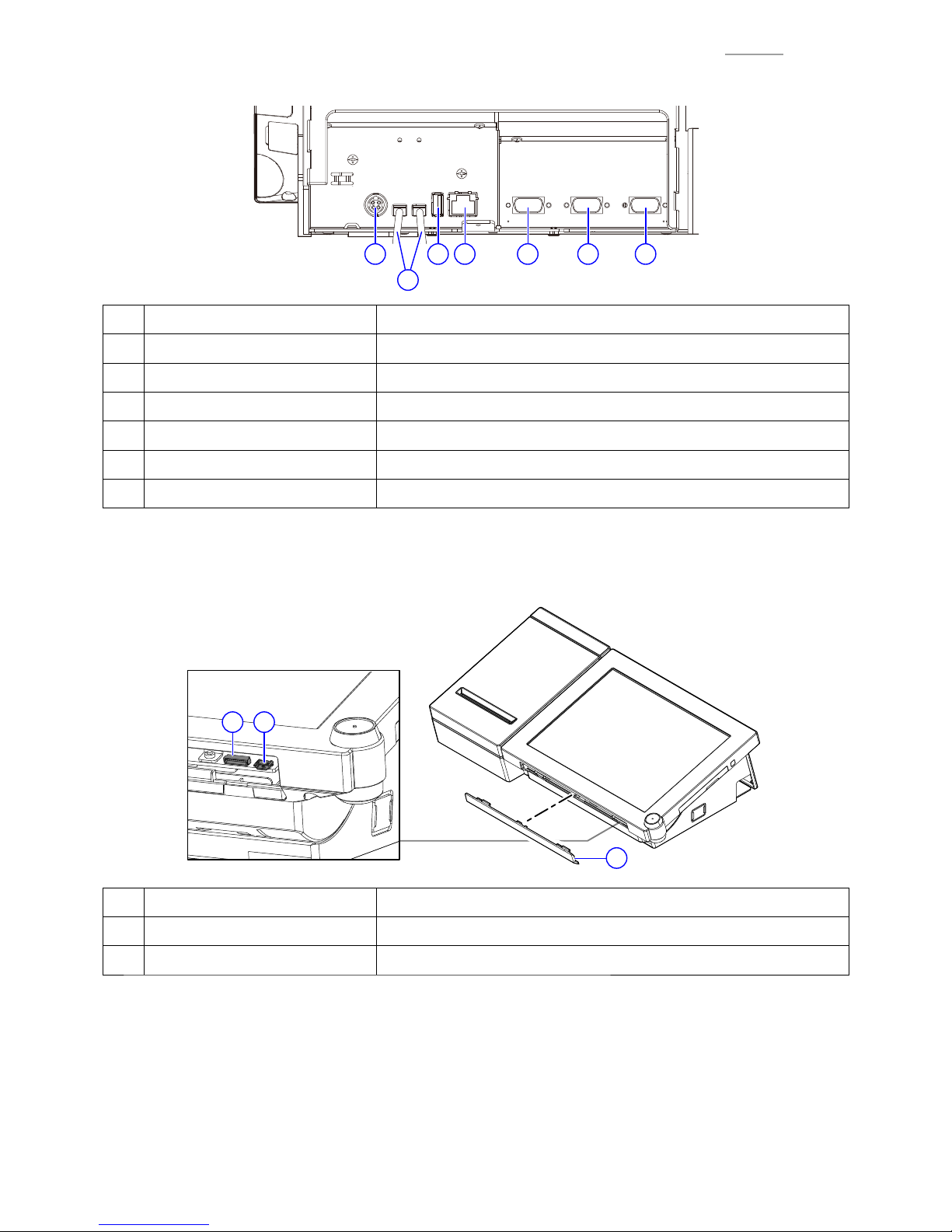

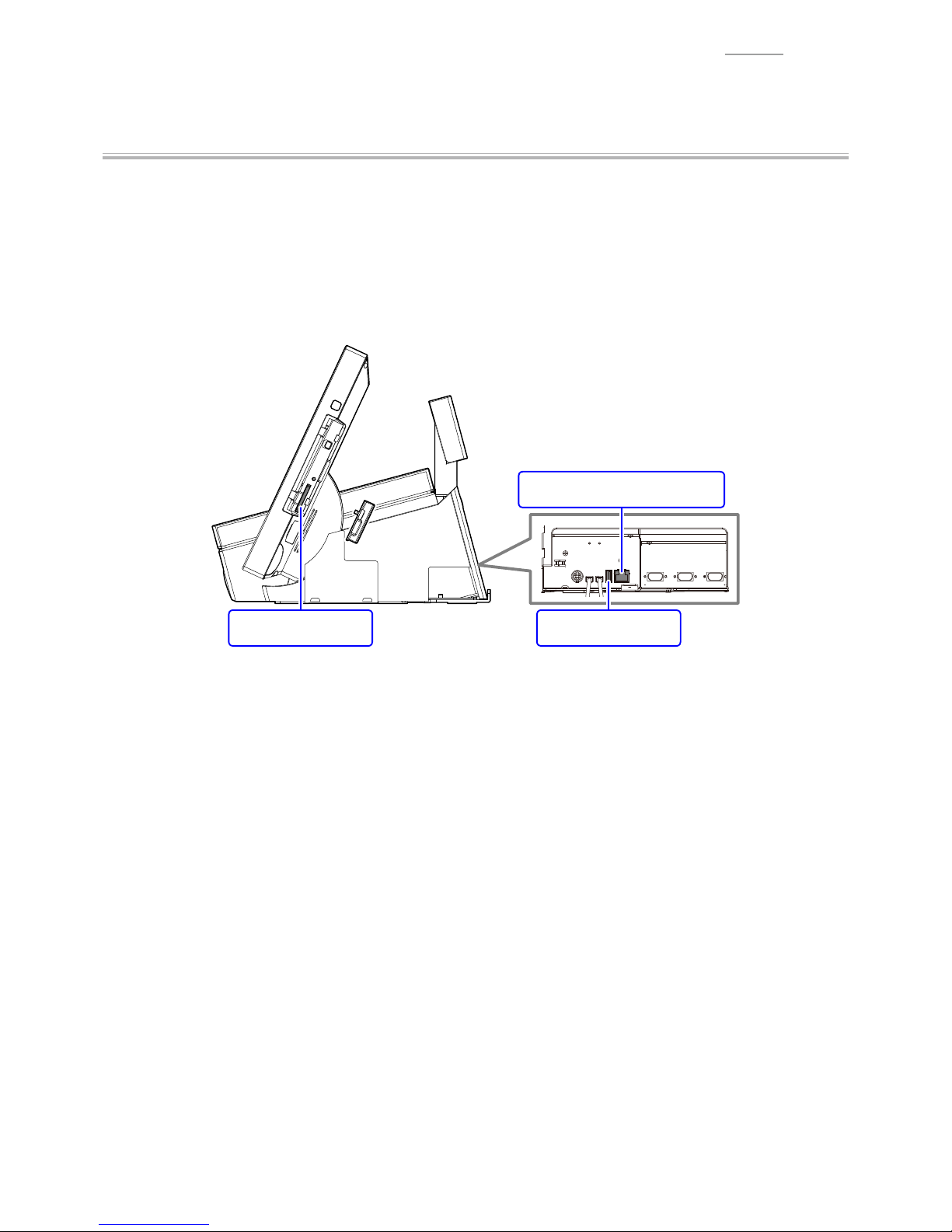

Rear

19181715

16

20 21

15 DC jack Connect the AC adaptor.

16 Drawer connecting cable Cable for connecting to the drawer.

17 USB port Connect the USB device. *1

18 LAN port Connects with external devices via a hub. *1

19 COM3 port Connect device such as printer, etc. *1

20 COM2 port Connect device such as printer, etc. *1

21 COM1 port Connect device such as printer, etc. *1

*1: Use the recommended product. For detailed information, contact your sales outlet.

Front

22

23 24

22 Sheet cover Connector cover

23 Serial console connector Connector for development (not used )

24 microUSB port Connector for development (not used )

Page 13

– 11 –

V-R200 / VER.1

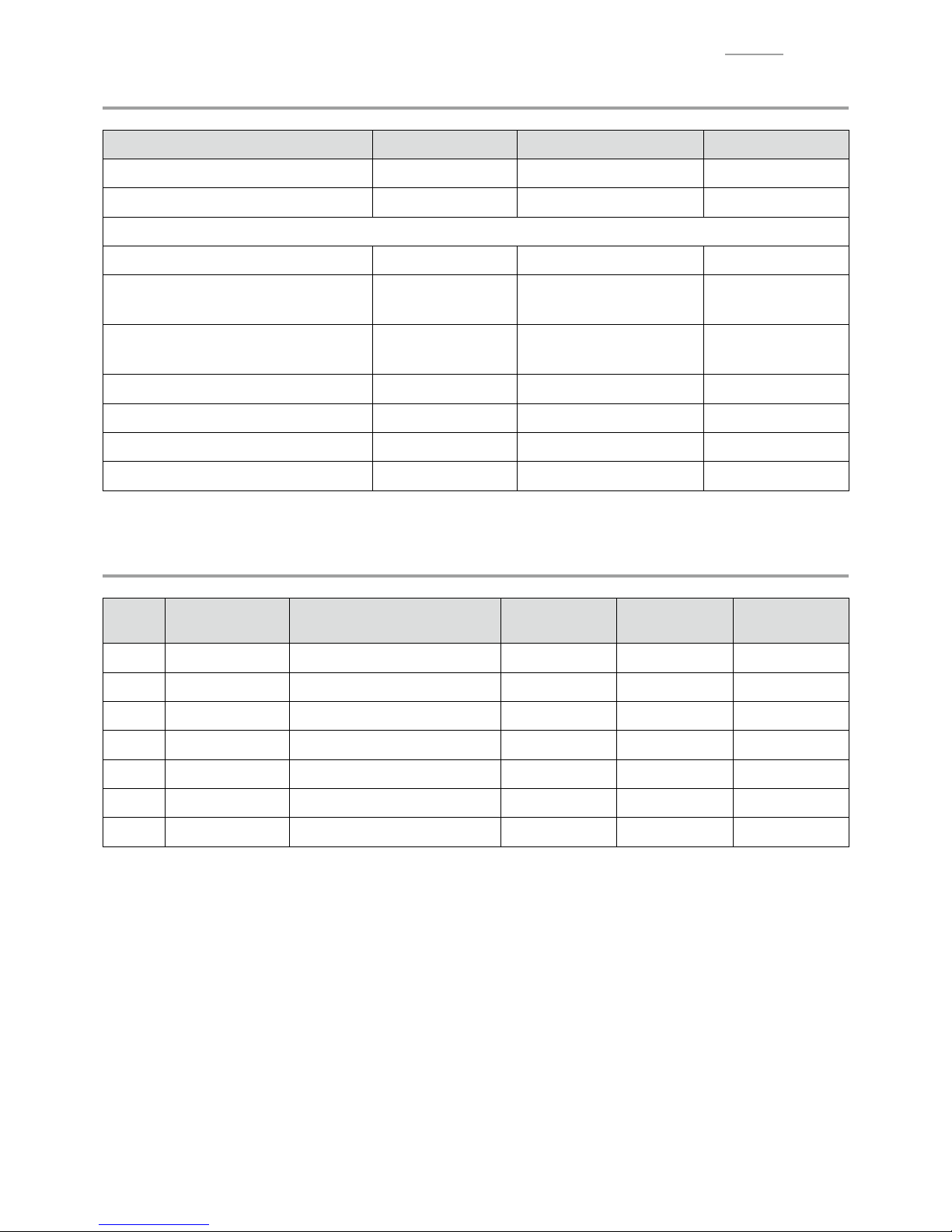

YOption List

Device name Model Specifi cation Note

Remote printer (RS-232C port) UP-370B EX-PRT-UNIT-11B

Remote printer (RS-232C / LAN port) UP-400B EX-PRT-UNIT-10B

Customer display

with original stand VA-B70DE-BK EX-DP-UNIT-17B-BK Height 170 mm

with extension pole kit A

VA-B70DE-BK +

VA-B73PK-BK

EX-DP-UNIT-17B-BK +

EX-DP-PL-1A-BK

Height 350 mm

with extension pole kit B

VA-B70DE-BK +

VA-B73LPK-BK

EX-DP-UNIT-17B-BK +

EX-DP-PL-1B-BK

Height 500 mm

Customer display serial cable QT-6061CB-B EX-DP-CB-4C Length 0.4 m

Customer display serial cable QT-6062CB-B EX-DP-CB-4D Length 5.0 m

Customer display serial cable VA-B63CB EX-DP-CB-5A Length 1.5 m

Magnetic card reader VA-A46MCR EX-MCR-PCG-14D

YDrawer List

Type Model Specifi cation EU / UK DI

US /

CANADA

M DL-2814 D-26P1C-B84RM-4

M DL-2815 D-26P1C-B84SRM-4

M DL-2436 D-26P1C-B55SRM-4

M DL-2822 D-26P1C-B84RM-1

M DL-2823 D-26P1C-B84SRM-1

L DL-3624 D-11P1H-B65SR-4

L DL-3625 D-11P1H-B65R-4

Page 14

– 12 –

V-R200 / VER.2

DIAGNOSTIC OPERATION

1.

HARDWARE TEST

1-1. List of test items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 13

1-2. Installing the Test Application

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 14

1-3. About the Test Application

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 15

1-4. Touch panel calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 16

1-5. Test Method

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 17

1-6. Checking and Registering the Serial Number

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 29

1-7. Uninstalling the Test Application

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 30

2.

UPDATING the OS

2-1. Checking the Version

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 31

2-2. Updating Method

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 31

Repair Information

When the main PCB is replaced with a spare part one.

• Since an OS is already installed on the spare part main PCB, update the OS to an appropriate

version as required.

Refer to: Diagnostic operation

2. UPDATING the OS

• Write the serial number.

Refer to: Diagnostic operation

1-6. Checking and Registering the Serial Number

When the IOC PCB is replaced with a spare part one.

• Firmware is already installed on it.

• The fi rmware version is confi rmed at power on and, if necessary, it is automatically updated.

• UUID setting is not required.

When the CASE ASSY/FRONT is replaced with a spare part one.

• Carry out the touch panel calibration.

Refer to: Diagnostic operation

1-4. Touch panel calibration

To carry out the Diagnostic operation, a dedicated application is needed to be installed

beforehand.

NOTE: After completion of the test, make sure to uninstall the test application.

Page 15

– 13 –

V-R200 / VER.2

1.

HARDWARE TEST

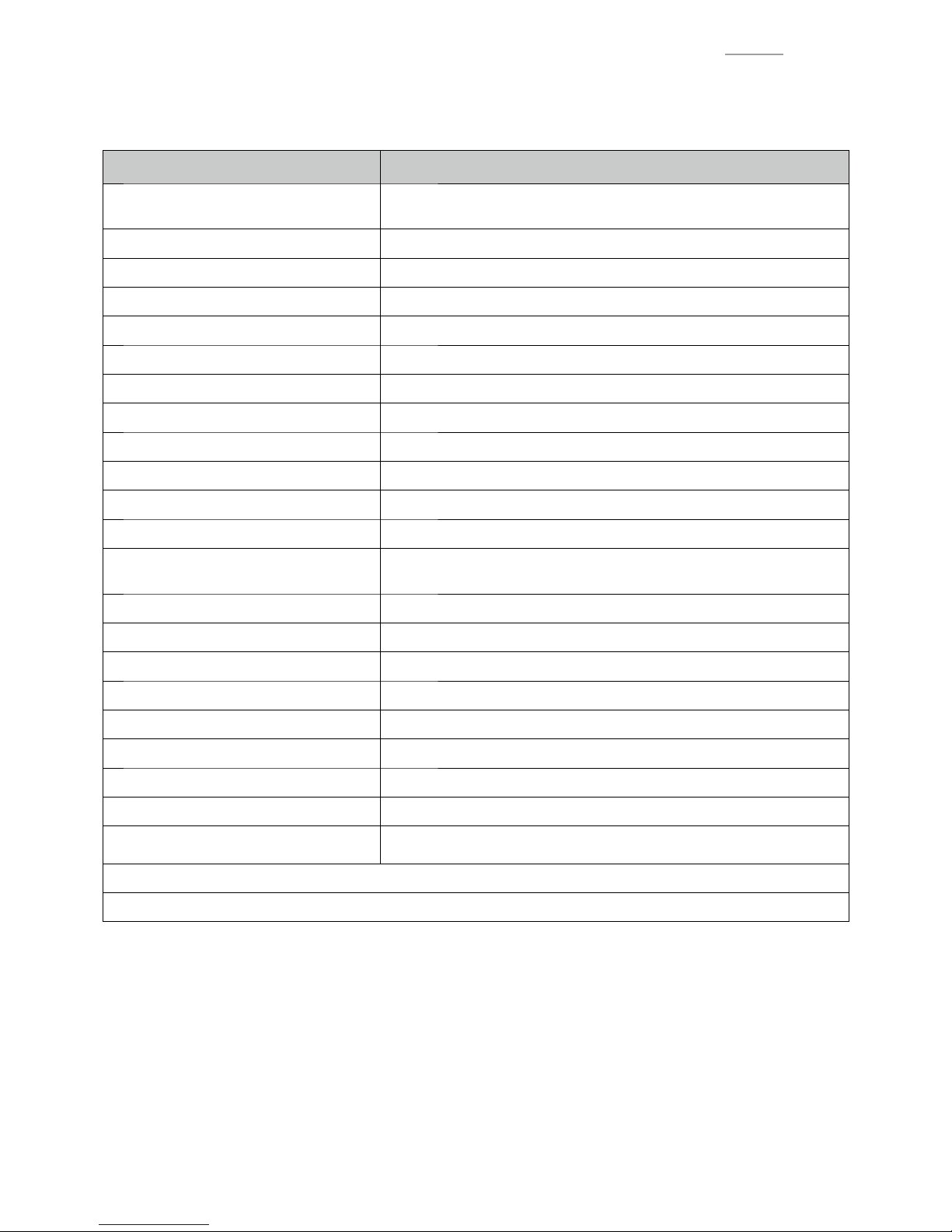

1-1. List of test items

Test items Remarks

1-2. Installing the Test Application

To be prepared

Flash memory (USB memory or SD card),

Test application “FuncTest843_0100000003.apk”

1-3. About the Test Application

1-4. Touch panel calibration

1-5. Test Method

Preparation Before Testing

Button

Touch Panel

LCD

Backlight

USB Storage To be prepared USB memory

Internal Storage

SD Card To be prepared SD card

Ethernet To be prepared

LAN cable

* Environment where DHCP connection is available.

Mac Address

COM 1, COM 2, COM 3 To be prepared Loop-back connector

Dallas Key To be prepared Dallas key

Drawer 1, Drawer 2 To be prepared Drawer

MCR To be prepared Magnetic card for testing

Speaker

Customer Display

Receipt Printer To be prepared Paper roll

Auto-Run

The tests from “Button” to “Receipt Printer” are automatically done in

succession.

1-6. Checking and Registering the Serial Number

1-7. Uninstalling the Test Application

Page 16

– 14 –

V-R200 / VER.2

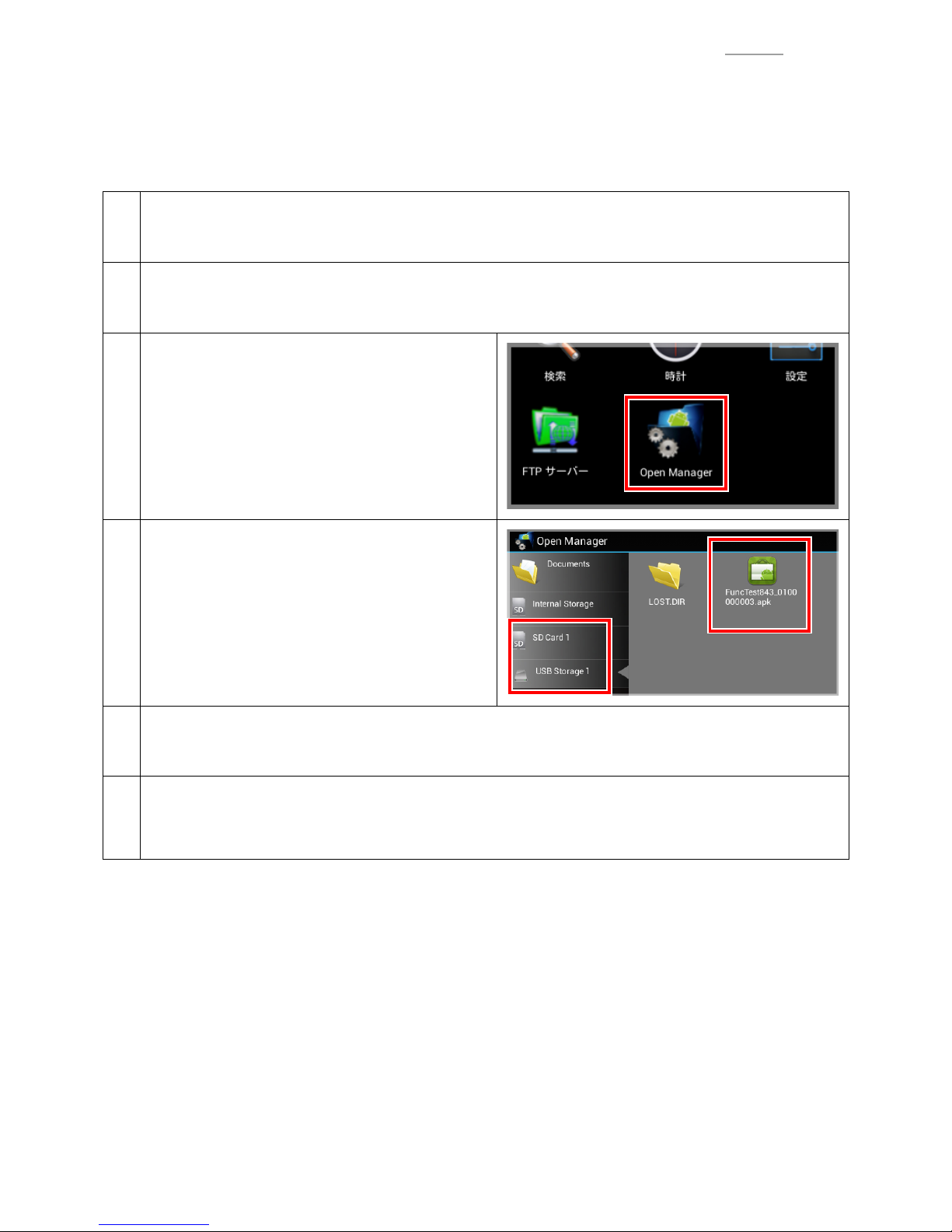

1-2.

Installing the Test Application

To be prepared

0Flash memory (USB memory or SD card)

0Test application “FuncTest843_0100000003.apk”

1

Store the test application “FuncTest843_0100000003.apk” to the root directory of the fl ash memory (USB

memory or SD card).

2

Tap “Settings” I “Security”, and check the “Unknown sources” box.

3

Insert a fl

ash memory and tap “Open Manager”.

4

Tap “SD Card 1 OR USB Storage 1” I

“FuncT

est843_0100000003.apk”.

O R

O R

5

T

ap “Next” I “Install”.

After completion of installation, tap either “Done” or “Open”.

6

Remove the fl ash

memory.

Tap “Settings” I “Storage”, unmount the fl

ash memory to allow safe removal, and then remove it.

Page 17

– 15 –

V-R200 / VER.2

1-3.

About the Test Application

The test application runs.

Function Description Refer to

Red frame

Test items

TIPS: “CF Bench” is excluded from the test item.

1-5. Test Method

Set Serial Number

Checking and registering the serial number

TIPS: Carry out when the main PCB is replaced with a

new one.

1-6. Checking and

Registering the Serial

Number

Set MAC Address Not used

SDK Not used

Firmware Update

Updating the fi rmware

TIPS: This item is not used here.

TouchPanel Calibration

Touch panel calibration

TIPS: Carry out this item depending on the situation.

Auto-Run Continuous execution of the test items

Output Result Printing the test results and outputting the result fi le

Settings Launching the Android settings screen

Exit Closing the test application

Test result “OK” Test result “NG”

To interrupt the test item being tested, tap the part indicated by the red frame at the bottom of the screen.

Tap the black belt portion, to display marks.

Page 18

– 16 –

V-R200 / VER.2

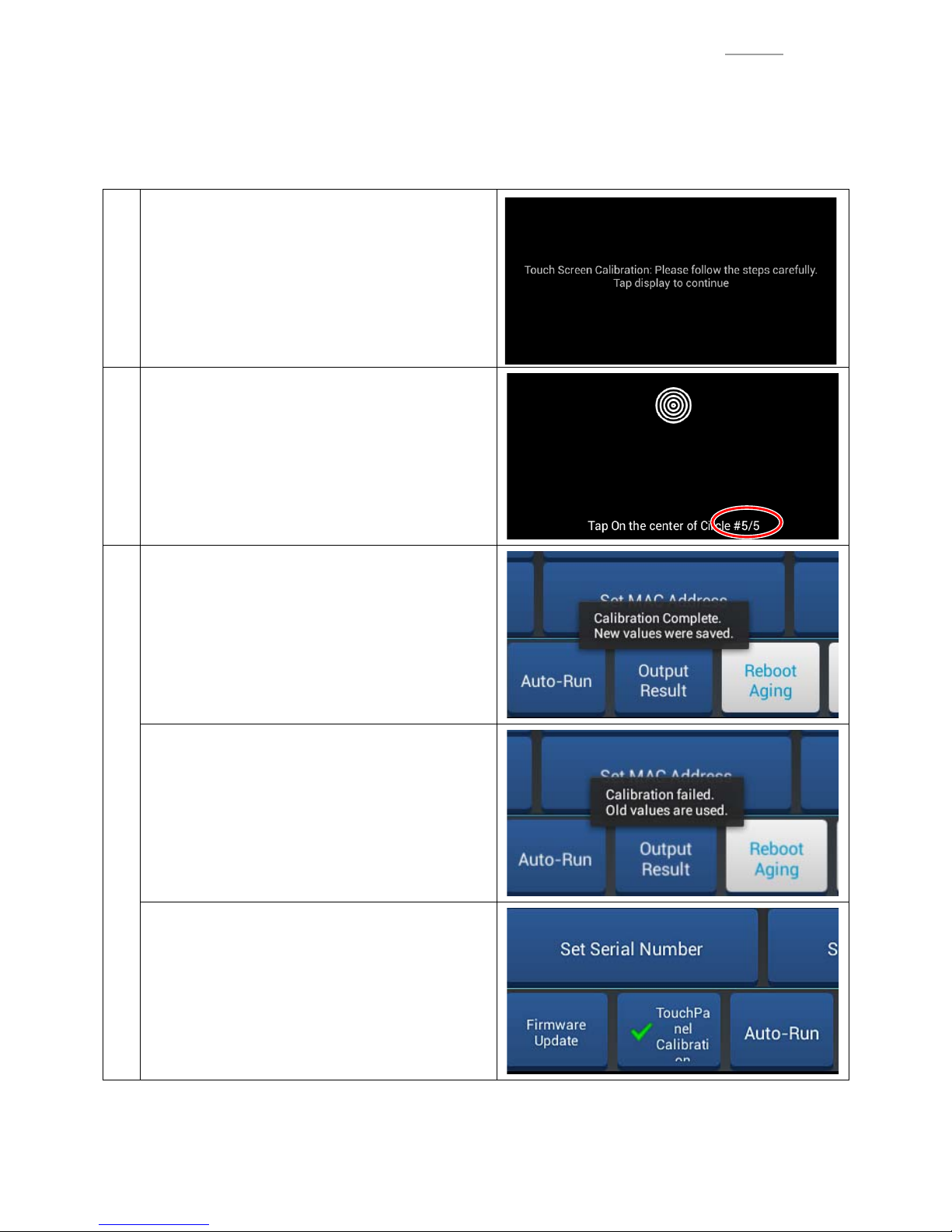

1-4. Touch panel calibration

0When the F case “CASE ASSY/FRONT” is replaced with a new one, be sure to carry out the touch panel

calibration.

TIPS: Same operation as Touch Screen Calibration in Settings mode.

1

Tap “TouchPanel Calibration”.

Tap the screen, following the onscreen instructions.

2

When tapping the last screen (#5/5), the screen

returns to the menu screen.

3

When the calibration ends successfully.

• A success message is displayed for several

seconds.

• The set values are saved.

When the calibration fails.

• A failure message is displayed for several seconds.

• The set values are not saved.

Regardless of the calibration result (either success

or failure), test result “OK” is displayed.

TIPS: When the test result is displayed, the letters

“TouchPanel Calibration” are misaligned.

Page 19

– 17 –

V-R200 / VER.2

1-5.

Test Method

Preparation Before Testing

Prepare the necessary items referring to “1-1. List of test items”.

Before testing, set the following items to the product.

0Set the paper roll.

0Insert the USB memory and SD card.

0Connect the LAN cable (DHCP).

USB memorySD card

For LAN (DHCP) connection

Page 20

– 18 –

V-R200 / VER.2

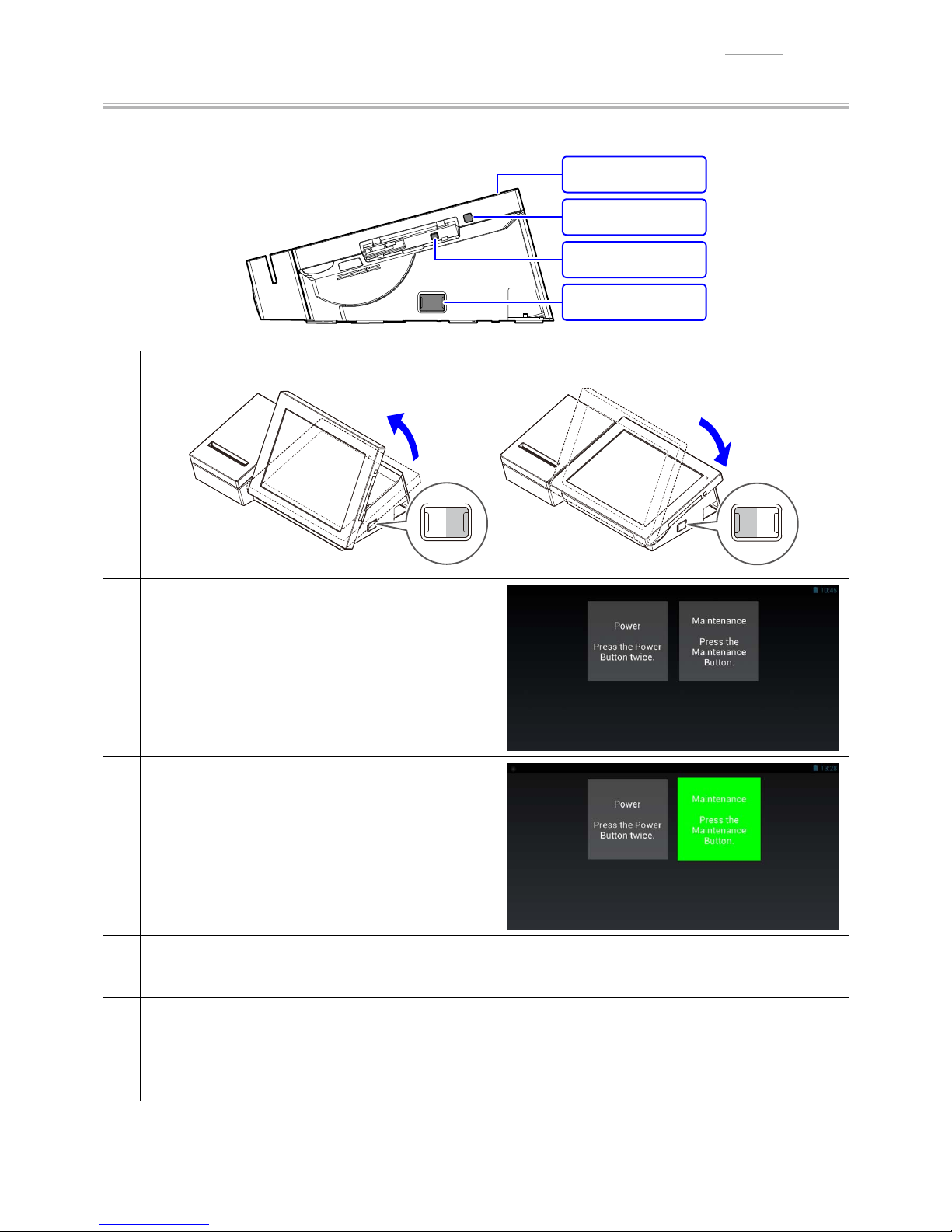

Button

0Test the tilt switch, power switch and maintenance switch.

Power switch

Maintenance switch

Power lamp

Tilt switch

1

Operate the tilt switch to check that the angle of the main display changes accordingly.

TILT

DOWN UP

TILT

DOWN UP

2

Tap “Button” I tap any place on the screen.

3

Press the maintenance switch.

Automatic judgment is done and the test result

appears.

4

Press the power switch. Sleep state

(Screen: Blank, Power lamp: Orange)

5

Tap any place on the screen.

Automatic judgment is done and the test result

appears. Then, the display returns to the menu

screen.

Page 21

– 19 –

V-R200 / VER.2

Touch Panel

0Carry out a handwriting test.

1

Tap “Touch Panel” I tap any place on the screen.

Since the screen turns to white, handwrite anything

with your fi nger

tip.

When you lift your fi nger from the screen, the

judgment screen appears.

2

Tap the test result to return to the menu screen.

LCD

0Check that there are no missing dots on the screen.

1

Tap “LCD” I tap any place on the screen.

The screen turns to white.

2

Tap any place on the screen.

The screen turns to black.

3

Tap any place on the screen.

Tap the test result to return to the menu screen.

Page 22

– 20 –

V-R200 / VER.2

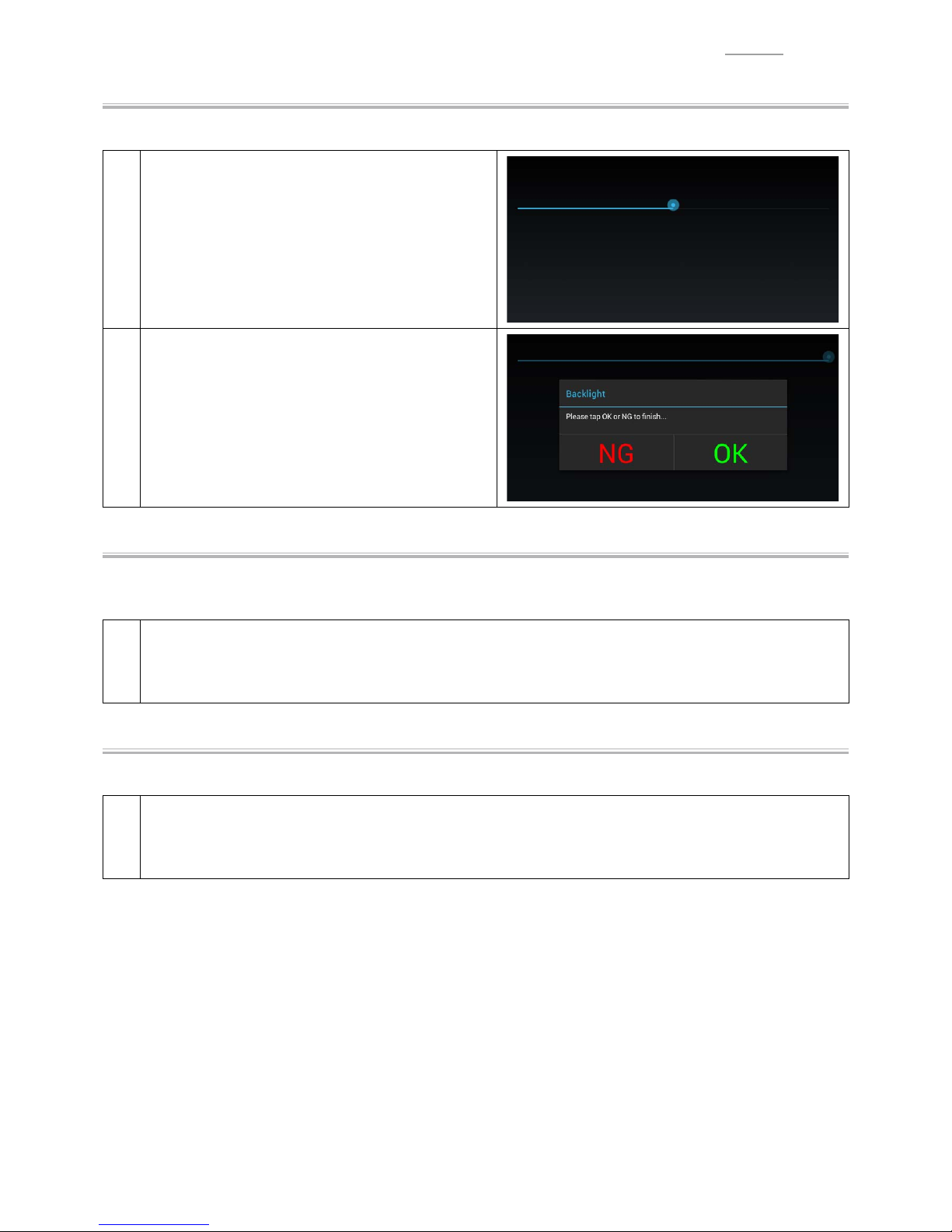

Backlight

0Check that the intensity of the backlight is adjustable.

1

Tap “Backlight” I tap any place on the screen.

Move the slider and check that the brightness of the

screen changes accordingly

.

When you lift your fi nger from the screen, the

judgment screen appears.

2

Tap the test result to return to the menu screen.

USB Storage

0Carry out the USB storage test.

0Make sure that the USB memory is already inserted.

1

Tap “USB Storage”.

Automatic judgment is done and the test result appears on the menu screen.

Internal Storage

0Carry out the Internal storage test.

1

Tap “Internal Storage”.

Automatic judgment is done and the test result appears on the menu screen.

Page 23

– 21 –

V-R200 / VER.2

SD Card

0Carry out the SD card test.

0Make sure that the SD card is already inserted.

1

Tap “SD Card”.

Automatic judgment is done and the test result appears on the menu screen.

Ethernet

0Make sure that the LAN cable (DHCP) is already connected.

0Once success of this test, if you need to test again, perform reboot, then test again.

1

Tap “Ethernet”

Automatic judgment is done and the test result

appears on the menu screen.

NOTE: If LAN cable is not connected or Ethernet

is set to off in Stteings mode, right screen

appears.

MAC Address

0Carry out the MAC address test.

1

Tap “MAC Address”.

Automatic judgment is done and the test result appears on the menu screen.

Page 24

– 22 –

V-R200 / VER.2

COM 1, COM 2, COM 3

0Carry out the COM port communication test.

0Information of the loop back tool.

Pin assignment on the register side (male) Pin Signal name Connection information

51

69

1 DCD

2 RxD

3 TxD

4 DTR

5 GND

6 DSR

7RTS

8 CTS

9RI

1

Connect the loop-back connector to the COM port to be tested.

2

Start the test by tapping the COM port to which the

loop-back connector is connected.

When the test result is “OK”.

3

The COM port tile being tested turns to green, and

COM1: test result appears on menu screen.

COM2&3: judgement screen appears, then tap “OK” to return to menu screen.

When the test result is “NG”.

4

The COM port tile being tested turns to red, and the display returns to the menu screen.

Page 25

– 23 –

V-R200 / VER.2

Dallas Key

0For Dallas key model only

0Carry out the recognition test of Dallas key.

1

Tap “Dallas Key”.

2

Set the Dallas key.

When the Dallas key is recognized normally, the

light green tile appears.

3

Remove the Dallas key.

Another light green tile appears and the display returns to the menu screen.

Page 26

– 24 –

V-R200 / VER.2

Drawer 1, Drawer 2

0DAWER 1: Longer cable, DAWER 2: Shorter cable

Drawer 2

Drawer 1

0The check method and test procedure differ depending on the drawer type.

Model name Check item

Without drawer detecting switch

DL-2814

DL-2822

Drawer opening operation only

With drawer detecting switch

DL-2436

DL-2815

DL-2823

Drawer opening operation and closing operation

1

Tap “Drawer 1” I tap any place on the screen.

For models without drawer detecting switch

2

Tap “Drawer Open”.

The drawer opens, the drawer status is displayed,

and then the judgment screen appears.

TIPS:

Although the tile “Drawer status open” is red, there

is nothing wrong with it.

The test result is “OK” if the tile “Drawer Open”

is green and the opened drawer can be closed

correctly.

Tap “OK” to return to the menu screen.

Page 27

– 25 –

V-R200 / VER.2

For models with drawer detecting switch

3

Tap “Drawer Open”.

The drawer opens and the drawer status is

displayed.

4

Close the drawer.

The drawer status is displayed, and then the

judgment screen appears.

Tap the test result to return to the menu screen.

Page 28

– 26 –

V-R200 / VER.2

MCR

0For MCR model only

0Carry out the magnetic card reading test.

1

Tap “MCR”.

2

Slide the magnetic card for testing.

When the test result is “OK”.

3

When the magnetic card is correctly scanned, a large green circle appears, and then the display

automatically returns to the menu screen.

When the test result is “NG”.

4

Slide the magnetic card for testing again. if the magnetic card is correctly scanned, a large green circle

appears, and then the display automatically returns to the menu screen.

If the test results end up with failure, tap “

” to display the judgment screen.

Tap the test result to return to the menu screen.

Page 29

– 27 –

V-R200 / VER.2

Speaker

0Carry out the speaker output test.

1

Tap “Speaker” I tap any place on the screen.

Check that an alarm sound is heard.

T

ap the test result to return to the menu screen.

Customer Display

0Carry out the sub display test.

1

Tap “Customer Display” I tap any place on the

screen.

Check that the backlight of the sub display changes

in the order of “None (colorless)” → “White” →

“Green” → “Emerald green”.

T

ap the test result to return to the menu screen.

Receipt Printer

0Carry out the character printing, paper feed and paper cutting tests.

1

Tap “Receipt Printer” I tap any place on the

screen.

T

est printing is done and the judgment screen

appears.

Tap the test result to return to the menu screen.

Page 30

– 28 –

V-R200 / VER.2

Auto-Run

0The following items are tested in succession.

Test items Judgment Remarks

Button Auto

Touch Panel Manual

LCD Manual

Backlight Manual

USB Storage Auto To be prepared USB memory

Internal Storage Auto

SD Card Auto To be prepared SD card

CF Bench Skip * Skip this test item as test is not required.

Ethernet Auto To be prepared

LAN cable

* Environment where DHCP connection is available.

Mac Address Auto

COM 1, COM 2, COM 3 Manual To be prepared Loop-back connector

Dallas Key Manual To be prepared Dallas key

Drawer 1, Drawer 2 Manual To be prepared Drawer

MCR Manual To be prepared Magnetic card for testing

Speaker Manual

Customer Display Manual

Receipt Printer Manual To be prepared Paper roll

TIPS: By holding down “Auto-Run” or “Output Result”, you can choose the tests as your requirement.

Page 31

– 29 –

V-R200 / VER.2

1-6.

Checking and Registering the Serial Number

0Carry out check and registration of the product serial number.

1

Tap “Set Serial Number”.

Enter the serial number and tap the “Enter key”.

2

Tap “Set Serial No.”.

3

Tap “

” to display the judgment screen.

Tap the test result to return to the menu screen.

Page 32

– 30 –

V-R200 / VER.2

1-7.

Uninstalling the Test Application

1

Tap “Settings” I “Apps” I “Function Tester”.

2

Tap “Uninstall” I “OK”.

Page 33

– 31 –

V-R200 / VER.2

2.

UPDATING THE OS

2-1. Checking the Version

Select “Settings”

I

“About tablet”, and check the “Build number”.

The OS version is displayed in the following red

rectangular box.

Example:

1.0.0_ 1005

2-2. Updating Method

Preparation

1. Prepare the data with the version you want to update.

Example : V-R200_5059-AAUDAC-ota_update-1.0.0_1011-signed.zip

NOTE : Do not uncompress or change the fi le name.

2. Create a “V-R200Update” folder in the root directory of the SD card, and copy the prepared compressed fi le

to that folder.

Procedure

1. Set the SD card.

2. Tap “Settings”

I

“About tablet”

I

“System Update”.

Page 34

– 32 –

V-R200 / VER.2

3. Confi rm the display content and tap “Execute” twice.

4. After completion of the update, restart begins.

Page 35

V-R200 / VER.1

– 33 –

DISASSEMBLY/ASSEMBLY

YImportant .................................................................................................................... P. 34

YScrews ........................................................................................................................ P. 35

A. Replacing the Main PCB ........................................................................................... P. 36

B. Replacing the LCD Unit ............................................................................................ P. 41

C. Replacing the IOC ASSY ........................................................................................... P. 44

D. Replacing the Sub Display ....................................................................................... P. 47

E. Replacing the Motor .................................................................................................. P. 49

F. Replacing the Printer ................................................................................................ P. 50

G. Replacing the Cable

G-1. IOC PCB - E843-PR PCB ................................................................................... P. 52

G-2. IOC PCB - Main PCB ......................................................................................... P. 55

H. Other Parts

H-1. REAR CASE ....................................................................................................... P. 57

H-2. CASE ASSY/FRONT .......................................................................................... P. 57

H-3. CHASSIS/BOTTOM ............................................................................................ P. 58

H-4. CHASSIS/LCD ................................................................................................... P. 58

Page 36

V-R200 / VER.1

– 34 –

YImportant

• Please note that the product on this manual may appear to be different from the actual one according

to the changes such as engineering design change.

• In order to prevent static electricity and avoid leaving grease from the hand, wear conductive gloves,

fi nger cots, or anti-static band when assembling/disassembling the product.

• Do not use metal tweezers. Be sure to use plastic tweezers with fl at tips.

(Anti-static tweezers are recommended)

• When replacing the MCR, refer to “V-R7000/V-R7100 Installation Manual”.

• The disassembly procedure explained here is based on the model “V-R7100-BD” that is equipped with

Dallas key.

MCR

Dallas key

Page 37

V-R200 / VER.1

– 35 –

YScrews

There are several kinds of screws. Be sure to use the

correct type of screws when reassembling.

It is advisable to sort the screws as shown on the right

after removing them.

S1

( φ : 3mm, L: 10mm)

S2

( φ : 3mm, L: 5mm)

S3

( φ : 3mm, L: 8mm)

10 mm

3 mm

5 mm

3 mm

8 mm

3 mm

S4

( φ : 3mm, L: 8mm)

S5

( φ : 3mm, L: 5mm)

S6B (S6)

( φ : 3mm, L: 8mm)

8 mm

3 mm

5 mm

2 mm

8 mm

3 mm

S7

( φ : 3mm, L: 8mm)

S8

( φ : 2.5mm, L: 6.2mm)

S9

( φ : 2mm, L: 6mm)

8 mm

3 mm

6.2 mm

2.5 mm

6 mm

2 mm

S10

( φ : 3mm, L: 10mm)

10 mm

3 mm

Page 38

V-R200 / VER.1

– 36 –

A. Replacing the Main PCB

Supplementary explanation

When the main PCB is replaced with a spare part one.

• Since an OS is already installed on the spare part main PCB, update the OS to an appropriate

version as required.

Refer to: Diagnostic operation

2. UPDATING the OS

• Write the serial number.

Refer to: Diagnostic operation

1-6. Checking and Registering the Serial Number

A-1. Removal of the DISPLAY-ASSY

(1) Undo two screws.

Screw (S1)

(2) Remove the DISPLAY-ASSY.

Page 39

V-R200 / VER.1

– 37 –

(3) Remove one cable tie.

(4) Undo one screw and remove two ground wires.

(5) Disconnect three connectors. (Four connectors for the model “V-R200-BD” (Dallas key built in model)).

Connector 3

Screw (S2) Ground wire 2Cable tie

Connector 1

V-R200-BD (Dallas key built in model) only

Note on reassembling

0Put the lead wires of the speaker in the case.

A-2. Remove the following parts.

(1) COVER/SHEET (Screw (S8) 1)

(2) COVER/BATTERY (Screw (S3)

2)

(3) COVER/CONNECTOR (COVER-USB)

(4) COVER/SD (Screw (S8)

1)

(3)

(COVER/USB)

(4)

COVER/SD (S8)

(1)

COVER/SHEET (S8)

(2)

COVER/BATTERY (S3)

(3)

COVER/CONNECTOR

Page 40

V-R200 / VER.1

– 38 –

A-3. Undo fi ve screws and remove the REAR CASE.

Screw (S6) 5

REAR CASE

H-1

Note on reassembling

0Assemble the REAR CASE in the order indicated by the numbers below.

1

2

3

4

Page 41

V-R200 / VER.1

– 39 –

A-4. Undo four screws and remove the CHASSIS/HNG.

Screw (S2) 4

CHASSIS/HNG

Note on reassembling

0Fix the lead wires of the battery with tape.

Tape

Note on reassembling

V-R200-BD (Dallas key built in model)

0Fix the ferrite core with double-sided tape, and then fi x its lead wires and the lead wires of the battery together

with tape.

CUSHION/DLS Tape

Page 42

V-R200 / VER.1

– 40 –

A-5. Removal of the main PCB (PCB ASSY/E843-1)

(1) Unlock the connector lock and disconnect the FPC.

(2) Disconnect four connectors.

(3) Undo four screws.

(4) Replace the main PCB (PCB ASSY/E843-1) with a new one.

(1) FPC

(2) Connectors

(2) Connector

Ground wire

(3) Screw (S2) 4

(4)

PCB ASSY/E843-1

Note on reassembling

0In this stage, the two places shown below are not fastened with screws yet.

A-6. Assemble the parts in the reverse order of the disassembly procedure.

Page 43

V-R200 / VER.1

– 41 –

B. Replacing the LCD Unit

Supplementary explanation

When the CASE ASSY/FRONT is replaced with a spare part one.

• Carry out the touch panel calibration.

Refer to: Diagnostic operation

1-4. Touch panel calibration

Model with no Dallas key

B-1. Remove the REAR CASE.

Reference Procedure: A-1 to A-3

B-2. Removal of the CHASSIS/LCD

(4) Screw (S4) 5

(3) Connector

(1) Tape (

15 50)

(1) Tape (

15 50)

NOTE: There is a connector under the tape. Peel

off the tape without giving a load to the

connector.

(3) Connectors

(1) Tape (

15 30)

NOTE: Peel off the tape without giving a load to

the FPC.

(2) FPC

(1) Peel off tape (3 pcs.).

(2) Unlock the connector lock and disconnect the FPC.

(3) Disconnect three connectors.

(4) Undo fi ve screws.

(5) Remove the CHASSIS/LCD block.

(5) CHASSIS/LCD

block

Note on reassembling

Ground wire

When attaching the ground wire, make sure that the

wire does not protrude from the CHASSIS/LCD.

Page 44

V-R200 / VER.1

– 42 –

Dallas key built in model

B-1. Remove the CHASSIS/HNG.

Reference Procedure: A-1 to A-4

B-2. Remove the CHASSIS/LCD.

(1) Peel off tape (3 pcs.).

(2) Unlock the connector lock and disconnect the FPC.

(3) Disconnect three connectors.

(4) Peel off the tape that is fi xing the lead wires from the Dallas key.

(5) Remove the Dallas key’s ferrite core that is fi xed with double-sided tape.

(6) Undo fi ve screws.

(7) Remove the CHASSIS/LCD block.

(6) Screw (S4) 5

(1) Tape (

15 50)

NOTE: There is a connector under the tape. Peel

off the tape without giving a load to the

connector.

(3) Connector

(1) Tape (

15 30)

NOTE: Peel off the tape without giving a load to

the FPC.

(7) CHASSIS/LCD

block

(3) Connector

(2) FPC

(1)

Tape (

15 50)

(4) Tape(5) Ferrite core

Note on reassembling

Ground wire

When attaching the ground wire, make sure that the

wire does not protrude from the CHASSIS/LCD.

Page 45

V-R200 / VER.1

– 43 –

B-3. Remove the LCD unit (LCD UNIT).

CASE ASSY/FRONT

H-3

LCD UNIT

Note on reassembling

0Attach the four cushions to the new LCD UNIT.

NOTE: Attach them in the order indicated by the numbers below.

1

2

3 4

CUSHION/LCD

1234

0Make sure that no dirt or dust is on the touch panel surface and LCD surface.

B-4. Assemble the parts in the reverse order of the disassembly procedure.

Page 46

V-R200 / VER.1

– 44 –

C. Replacing the IOC ASSY

Supplementary explanation

When the IOC PCB is replaced with a spare part one.

• Firmware is already installed on it.

• The fi rmware version is confi rmed at power on and, if necessary, it is automatically updated.

• UUID setting is not required.

C-1. Undo 11 screws and remove the CHASSIS/BOTTOM.

NOTE: There are two types of screws (S2 × 6, S7 × 4).

Screw (S2) 7

Screw (S7) 4

CHASSIS/BOTTOM

H-4

Page 47

V-R200 / VER.1

– 45 –

C-2. Remove the following parts.

(1) Connector 4 (Model with no Dallas key)

Connector 5 (Dallas key built in model)

(2) Printer FFC

(3) Tape, Ferrite core, Sub Display FFC

(4) Scrwe

12

NOTE: There are two types of screws (S2 × 8, S7 × 4).

(3) Tape, Ferrite core, Sub Display FFC

• Tape (15

50)

NOTE: Peel off the tape without giving a load to the FFC

and connector.

(1) Connector 4(2) Printer FFC

Screw (S2) 8

Screw (S7) 4

(1) Connector 1

V-R200-BD (Dallas key built in model) only

Ground wire 2

C-3. Remove the IOC ASSY.

C-4. Disconnect the connectors.

IOC ASSY

Connector

Page 48

V-R200 / VER.1

– 46 –

C-5. Remove the following parts.

(1) Cable tie 1

(2) Scrwe

1

(3) Cable

2

C-6. Replace the IOC ASSY with a new one.

IOC ASSY

(1) Cable tie

(3) CABLE/DRW1

(3) CABLE/DRW2

(2) Screw + Ground wire

Note on reassembling

0Drawer cables

DRW1 Connector

• DRW1-CABLE-SUBASSY (Longer cable)

• Earth terminal fastening screw (S2)

• Tie the cables with a cable tie.

DRW2 Connector

• DRW2-CABLE-SUBASSY

(Shorter cable)

C-7. Assemble the parts in the reverse order of the disassembly procedure.

Page 49

V-R200 / VER.1

– 47 –

D. Replacing the Sub Display

D-1. Remove the CHASSIS/BOTTOM.

Reference Procedure: C-1

D-2. Peel off tape (2 pcs.) and disconnect the FFC.

CLOTH-TEPE (10 30)

CLOTH-TEPE (15 50)

NOTE: Peel off the tape without giving a load to the connector.

Ferrite core

FFC

D-3. Release hooks and remove the sub display (DISPLAY ASSY/REAR).

DISPLAY ASSY/REAR

Hooks

Note on replacing

0Form the FFC into shape by using the following jig.

3

33 mm

29 mm

22 mm

Page 50

V-R200 / VER.1

– 48 –

12

34

5

D-4. Assemble the parts in the reverse order of the disassembly procedure.

Page 51

V-R200 / VER.1

– 49 –

E. Replacing the Motor

E-1. Remove the IOC ASSY.

Reference Procedure: C-1 to C-3

E-2. Undo two screws and remove the MOTOR SUPPORT.

E-3. Undo two screws and replace the motor (GEAR ASSY) with a new one.

MOTOR SUPPORT

GEAR ASSY

Screw (S11) 2 Screw (S4) 2

E-4. Assemble the parts in the reverse order of the disassembly procedure.

Page 52

V-R200 / VER.1

– 50 –

F. Replacing the Printer

F-1. Undo two screws and remove the PLATE/BLIND.

Screw (S7) 2

PLATE/BLIND

F-2. Unlock the connector lock and disconnect two FPCs.

FPC

F-3. Remove the SHEET/BLIND.

NOTE: Be careful not to put a scratch on the MASK/PRINTER, when removing the SHEET/BLIND.

F-4. Undo two screws and remove the PLATE/BLIND.

MASK/PRINTER

Screw (S4) 2

SHEET/BLIND

Page 53

V-R200 / VER.1

– 51 –

F-5. Undo two screws and remove the PRINTER.

PRINTER

Screw (S5) 2

F-6. Undo two screws and remove the PLATEN.

PLATEN

Screw (S2) 2

F-7. Assemble the parts in the reverse order of the disassembly procedure.

Page 54

V-R200 / VER.1

– 52 –

G. Replacing the Cable

G-1. IOC PCB - E843-PR PCB

FFC-JOINER-E840PR

Note on replacing

0Form the FFC into shape by using the following jigs.

1

33 mm

13 mm

33 mm

2

33 mm

19 mm

48 mm

79 mm

3

33 mm

29 mm

22 mm

Page 55

V-R200 / VER.1

– 53 –

12

34

5

8 mm

67

89

Page 56

V-R200 / VER.1

– 54 –

10

11 1 2

13

Page 57

V-R200 / VER.1

– 55 –

G-2. IOC PCB - Main PCB

0Remove the IOC ASSY. 0Remove the DISPLAY-ASSY.

Reference Procedure: C-1 to C-3 Reference Procedure: A-1

Ferrite core

0Remove the ferrite core.

0Remove the CABLE MASK.

0Replace the cables.

FG-CABLE-SUBASSY

IOC-CABLE-SUBASSY

CABLE MASK

USB-CABLE-SUBASSY

Page 58

V-R200 / VER.1

– 56 –

Note on replacing

0Bundle the three or four cables with tube.

175 ± 5 mm

110 ± 5 mm

130 ± 5 mm

80 ± 5 mm

CABLE-SUBASSY/IOC

CABLE-SUBASSY/USB

CABLE-SUBASSY/DASR

* V-R200-BD only

CABLE-SUBASSY/FG

Connector (female)Connector (male)

Tube (70mm, 10 mm)

Note on reassembling

0Fix the cables with tape.

FILAMENT-TEPE (15 40)

NOTE: Align the border between black and white of the

USB-CABLE-SUBASSY with the boss.

NOTE: Fold back the lead wires of the motor at the rib.

Page 59

V-R200 / VER.1

– 57 –

H. Other Parts

Supplementary explanation

• For the parts other than the replaced parts, reuse the original ones.

H-1. REAR CASE BLOCK

SPEAKER

Screw (S7) 2

Screw (S6)

CASE/REAR

COVER/BOOT

BLIND/DALLAS

Screw (S9) 2

H-2. CASE ASSY/FRONT

LENS/LED

Screw (S10) 3

PCB ASSY/E843-E61

CASE ASSY/FRONT

Page 60

V-R200 / VER.1

– 58 –

H-3. CHASSIS/BOTTOM

PAD/RUBBER/E843

PAD/RUBBER 3

BLIND/CN

CHASSIS/BOTTOM

H-4. CHASSIS/LCD

BATTERY-ASSY 3

BOX/BAT

SHEET/BAT

CHASSIS/LCD

Page 61

V-R200 / VER.1

– 59 –

CIRCUIT DIAGRAM

YBlock Diagram

SD Card

Slot

Power

Switch

E843-PR

Feed Motor

Thermal Printer Unit

RJ45

E843-E63

Rear LCD

160x32 Full dots

10.4 inch

Touch Panel

10.4 inch TFT-LCD

AC 100-240 V

E843-IOC

Tilt

Motor

MCR*

COM1

Off

Switch

Reset

Switch

USB

Hub

LVDS

CPU DDR

TP

Control

Charger

eMMC

NAND

Debag

10-pin

USB

Client

Power

USB

PHY

PMIC

E843-E61

E843-1

Status

LED

LED

Battery × 3

Speaker

Dallas

Key

Power

USB-A

E843-E22

COM2

COM3

Tilt

Switch

(Up)

Tilt

Switch

(Down)

AC Adaptor

Drawer*

Drawer*

* Optional

* Optional

IOCLAN

ETH

Cutter Motor

CN14

(3 pin)

CN11

(10 pin)

CN8

(10 pin)

CN1

(2 pin)

CN7

(3 pin)

CN6

(2 pin)

CN2

(8 pin)

CN15

(4 pin)

CN3

(9 pin)

CN18

(32 pin)

CN502

(2 pin)

CN13

(4 pin)

CN6

(6 pin)

CN2

(20 pin)

CN3

(4 pin)

CN5

(5 pin)

CN9

(2 pin)

Page 62

V-R200 / VER.1

– 60 –

YPCB

E843-1 PCB

0.3TH

Thermal Via

123

456

12

43

123

456

12

43

1(G)

2(S)

3(D)

1(G)

2(S)

3(D)

IG

O

1(G)

2(S)

3(D)

212121

21

23456

1

12

Top entry

Top entry

12

312

12

12

12

43214321432143

21

43

21

IG

O

12123456 7811019

13

15

1617

14

65

60

18

19

30

3148

49

707172

73

6667 68

69

62

64

65

63

61

1

C20

IC20

R219

IC26

C33

C34

C35

C36

R222

IC31

R225

IC32

R226

IC34

R228

R229

IC38

R232

P100

R234

C48

IC40

P101

C49

P102P103

P104P105P106P107

C50

C200

P108

C51

C201

P109

C53

C205

C55

C206

C56

C57

P110

C58

C59

P111P112P113

P114

P115

P116

P117

C60

P118

C61

P119

C62

C63

Q10

C64

Q11

C65

Q12

C66

C67

C217

Q14

C218

P120

C68

Q15

C219

P121

C69

P122P123

Q18

P124

Q19

C220

P128

C70

C221

P129

C71

C222

C72

C73

C224

C74

C75

C225

C76

C77

C227

C78

C228

P130

C79

C229

P131

P132

P133

P134

P135

P136

P137

C80

C230

P138

C81

P139

C82

C232

C83

C84

C85

C86

C87

C88

P140

C89

P141

P142

P143

P144

R278

R279

P147

P148

C91

C92

C93

R280

R282

R283

R284

P150

P151

R285

R286

P153

R289

R290

R291

R295

D3D4D5

R299

D6

ZZZ1

C279

ZZZ2

ZZZ3

ZZZ4 ZZZ5

ZZZ6

C282

C283

C284

C285

C286

SW1

SW2 SW3

C291

C294

C296

C298

TH1

R101

CN11

R102

R103

CN13

R104

CN14

R105

R106 R107

R108

R109

D12 D14

R302

R110

D18

R111

D19

R305

R112

R306

R113

R308

R114

R115

R116

R117

D20

R119

D21

D25

R120

L2L3L4L5L6

R126

R127

L7

L8L9

R132

R137

L10

L12

C100

L16

C103C104

C107

R144

C109

R145

R146

C300

C302

C303

L23

C110

C304

IC2

C112

C307

P10

C308

C115

P11

C309

C116

IC6

P12

C117

P13

C118

P14

C119

P15

R155

P16 P17P18

C310

P19

C311

C312C313

C120

R10

C121

R11

C316

C122

R12

C317

C123

R13

C124

R14

P20

P1

R15

P21

FU1

P22

P2

R16

P23

C127

P3

P24

C128

P4

P25

C129

P5

R19

P6

P26

P7

P27

R167

P28

P8

R168

P29

P9

R169

C322

R20

C130

R21

C131 C132

R22

R23

P30

C134

R24

R170

P31

Q1

R25

R171

C136

P32

Q2

R26

R172

R27

P33

C137

R173

C138

R28

P34

R174

R29

P35

C139

R175

P36

R176

P37

R177

P38

R178

P39

R179

C140

R31

C142

P40

R180

P41

R181

P42

R182

P43

R183

P44

R184

R5

P45

R185

P46

R6

R186

R7

P47

R8

P48

R9

P49

C152

C153

P50

C154

R190

P51

C155

R191

P52

C156

P53

R47

C157

P54

R48

R49

P55

P56P57

P58

R52

R53

P68

P69

R60

P70

P71

P72

P73

P74

R68

P75

R69

P76P77P78P79

R71

R72

R73

P80

P81

R76

P82

R77

P83

R78

P84

R79

P85P86P87

P88P89

R80

R81

R82

R83

R84

P90

R85

P91

R86

P92

R87

P93

C197

R88

P94

C198

R89

P95

C199

P96

P97

P98

CN1

P99

CN2

CN3

5NC4NC

R91

CN6

R92

CN7

R93

CN8

R94

CN9

C11

C12

C13

C14

C15

C16

IC10

IC11

IC12 IC13

IC14

CN11

CN13

CN14

+

CN1

CN2

CN3

CN4

CN5

CN6

CN7

CN8

CN9

E843-1

C

G

12

43

123

456

8765

1234

1(G)

2(S)

3(D)

1(G)

2(S)

3(D)

3

12

IG

O

IG

O

IG

O

21

21

21

12

12

12

12

58

145814

5

8

14

5

8

14

581458

14

58

14

8765

1234

IG

O

IG

O

IG

O

1(G)

2(S)

3(D)

IG

O

1(G)

2(S)

3(D)

1

43

2

43

12

IC18

IC19

C21

C22

C23

C24

R210

C25

C26

R212R213

C27

C28

C29

R215

IC21

R216

R217

IC23

IC24

IC25

IC27

C30

IC28

C31

IC29

C32

R220

R221

R223

C37

R224

IC30

C38

C39

R227

IC35

IC36

IC37

C40

C41

C42

C43

C44

R230

C45

R231

C46

R233

C47

IC41

R235

IC42

R236

R237

R238

R239

C52

C202

C203

C54

C204

R241

R242

C207

R243

C208

R244

C209

R245R246

R247R248

R249

C210

C212

C213

C214

R250

C215

R251

C216

R252

Q13

R253

R254

R255

Q16

R256

Q17

R257

R258

R259

C223

R260

Q20

R261

Q21

Q22

C226

R262

R263

R264

R265

R266

R267

R268

C231

C233

C234

R270

C235

R271

C236

C237

R273

C238

R274

C239

P145

C90

C240

C241

C242

C243

C244

C94

C245

C95

C246

C96

C97

C247

C98

C248

C1

C99

C249

C2

C3

C4

C5

C6

C7

C8

C250

C9

C251

C252

C253

C254

C255

C256

R292

C257

R293

C258

R294

D1

C259

D2

R296

R297

R298

D7

D8

C260

D9

C261

C262

C263

C264

C265

C266

C267

C268

C269

C270

C271

C272

C273

C274

C275

C276

C277

C278

ZZZ7

C292

C293

C295

C297

C299

R100

CN10

CN12

D10

D11

D13

R300

D15

R301

D16

D17

R303

R307

R309

R118

D22

D23

D24

R121

L1

R122

R123

R124

R125

R128

R129

RM1 RM2RM3 RM4

RM5 RM6

RM7

R130

R131

R133

R134

R135

R136

R138

L11

R139

L13

L14

C101

L15

C102

L17

R140

L18

R141

C105

L19

R142

C106

R143

C108

L20

R148

C301

L21

R149

L22

C111

IC1

C305 C306

C113

IC3

IC4

C114

R150

R151

R152

IC7

R153

IC8

R154

IC9

R156

R157

R158

R159

C314C315

C318

R160

C319

C125

R161

C126

R162

R17

R163

R18

R164

R165

R166

C320

C321

C133

C135

Q3 Q4

Q5

Q6

Q7

Q8

R30

C141

R32

R33

C143

C144

R34

R35

R1

C145

R2

R36

C146

C147

R3

R37

C148

R4

R38

C149

R39

R187

R188

R189

R40

C150

C151

R41

R42

R43

R44

R45

R46

R192

R193

C158

R194

C159

R195

R196

R197

R198

R50

C160

R51

C161

C162

C163

C164

C165

R56

C166

R57

C167

R58

C168

R59

C169

C170

R61

C171

R62

C172

R63

C173

R64

C174

R65

C175

R66

C176

R67

C177

C178

C179

R70

C180

C181

C182

C183

C184

C185

C186

C187

C188

C190

C191

C192

C193

C194

C195

C196

R90

X1

R95

R96

X2

R97

R98

R99

C10

R200

R201

R202

R203

C17

R204

C18

R205

C19

R206

R208

IC15

R209

IC16

IC17

Page 63

V-R200 / VER.1

– 61 –

E843-IOC PCB

E843-PR PCB

Page 64

V-R200 / VER.1

– 62 –

E843-E22 PCB

E843-E61 PCB

E843-E63 PCB

Page 65

– 63 –

V-R200 / VER.2

EXPLODED VIEW/PARTS LIST

MODEL : V-R200

(EX-843)

1.

MAIN UNIT ......................................................................................................... P.64

2.

DISPLAY-ASSY.................................................................................................. P.66

3.

CABLES ............................................................................................................. P.68

4.

ACCESSORIES ................................................................................................. P.70

NOTES :

1. Price and specifi cations are subject to change without prior notice.

2. As for spare parts order and supply, refer to the “GUIDEBOOK for Spare Parts Supply”, published

separately.

3. The numbers in item column correspond to the same numbers in drawing.

4. CASIO does not supply the spare parts without parts code.

5. Refer to the latest “Parts Price Code” at “PARTS FINDER” on the Casio Service WEB site

(https://www.servicecasio.com).

6. Remarks

Q’ty: Quantity used per unit

RANK: A = Essential

B = Stock recommended

C = Less recommended

X = No stock recommended

7. We recommend to purchase screws locally.

e.g. SCREW (38)

Diameter: 3 mm, Length: 8 mm

NUT (4X0.7)

Diameter:4 mm, Thickness: 0.7 mm

Page 66

– 64 –

V-R200 / VER.2

1.

MAIN UNIT

EXPLODED VIEW

5

S5

1214

13

3

S4

S2

4

1-5

1-6

1-1

1-4

1-2

1-3

6

10

7

S2

S1

DISPLAY-ASSY

2

1

S10

S4

S2

8

9

11

S2

Page 67

– 65 –

V-R200 / VER.2

PARTS LIST

1: V-R200-BD 2: V-R200-BD-WE 3: V-R200-U 4: V-R200-U-WE 5: V-R200-C

12345

MAIN UNIT

N 1 10540722 CASE ASSY/UPPER/BK RJE504576*001V01 1 1 1 C

N 1 10540723 CASE ASSY/UPPER/WE RJE504576*002V01 1 1 C

S1

SCREW (3x10) S-PADSMA-3X10Z3 22222X

N 1-1 10540717 COVER/PRINTER/BK RJE504693*001V01 1 1 1 C

N 1-1 10540718 COVER/PRINTER/WE RJE504693*002V01 1 1 C

N 1-2 10529377 ARM/PLATEN RJE504567-001V01 11111C

N 1-3 10465445 LEVER/EJECT RJE504177-001V01 11111C

N 1-4 10540724 LABEL/PUSH RJE503907-003V01 11111X

N 1-5 10529371 MASK/PRINTER RJE504584-001V01 11111C

S4

SCREW (3x8) S-BDPT-3X8Z3 22222X

1-6 10413753 GEAR ASSY TK-RJE503868*001 11111B

S4

SCREW (3x8) S-BDPT-3X8Z3 22222X

S10

SCREW (3x10) S-BDPT-3X10Z3 22222X

N 2 10525695 PRINTER/THERMAL CAPD347J-E 11111Awith Cutter

S2

SCREW (3x5) S-BDMA-3X5Z3 22222X

S5

SCREW (2x5) S-PAMA-2X5Z3 22222X

N 3 10525699 SHEET/BLIND RJE504607-001V01 22222A

N 4 10540719 DISPLAY ASSY/REAR/BK RJE504575*001V01 1 1 1 C

N 4 10540720 DISPLAY ASSY/REAR/WE RJE504575*002V01 1 1 C

N 5 10529378 COVER/IF/BK RJE504555-001V01 1 1 1 X

N 5 10529379 COVER/IF/WE RJE504555-002V01 1 1 X

S2

SCREW (3x5) S-BDMA-3X5Z3 11111X

6 10406965 SW SUBASSY/TILT RJE503884*001V01 1 1 1 B

6 10436482 SW SUBASSY/TILT RJE503884*002V01 1 1 B

N 7 10540726 PCB ASSY/E843-E63 RJE504582*001V01 11111B

N 8 10540725 PCB ASSY/E843-PR RJE504579*001V01 11111B

S2

SCREW (3x5) S-BDMA-3X5Z3 11111X

N 9 10540721

PCB ASSY/E843-IOC

W/CHASSIS

RJE504692*001V01 11111A

S2

SCREW (3x5) S-BDMA-3X5Z3 88888X

S7

SCREW (3x8) S-BD-PT-3X8Z3 44444X

N 10 10529382 CHASSIS/BOTTOM RJE504541-001V01 11111X

S2

SCREW (3x5) S-BDMA3X5-Z3 77777X

S7

SCREW (3x8) S-BD-PT-3X8Z3 44444X

N 11 10529384 PLATE/BLIND RJE504583-001V01 11111X

S7

SCREW (3x8) S-BD-PT-3X8Z3 22222X

12 10414065 PAD/RUBBER RJE503879-001V02 33333X

N 13 10540737 PAD/RUBBER/E843 RJE504592-001V03 11111X

14 10413634 BLIND/CN RJE503920-001V01 11111X

R RemarksN Item Code No. Parts Name Specification

Qt'y

Page 68

– 66 –

V-R200 / VER.2

2.

DISPLAY-ASSY

EXPLODED VIEW

Screws

16

22

21

25

20

26

24

23

33

18

34

29

17

d

30

32

35

S3

S9

S7

S8

S8

31

27

S6

29

S9

39

19

c

a

b

bd c a

Dallas key model

Dallas key model

Dallas key model

37

38

36

15

Dallas key model

Page 69

– 67 –

V-R200 / VER.2

PARTS LIST

1: V-R200-BD 2: V-R200-BD-WE 3: V-R200-U 4: V-R200-U-WE 5: V-R200-C

12345

R RemarksN Item Code No. Parts Name Specification

Qt'y

DISPLAY-ASSY

N 15 10537626 CASE ASSY/FRONT/BK RJE504694*001 TK 1 1 A Including Touch Panel

N 15 10537627 CASE ASSY/FRONT/WE RJE504694*002 TK 1 A Including Touch Panel

N 15 10537628 CASE ASSY/FRONT/BK/DLS RJE504694*003 TK 1 A Including Touch Panel

N 15 10537629 CASE ASSY/FRONT/WE/DLS RJE504694*004 TK 1 A Including Touch Panel

16 10416295 LENS/LED RJE503847-001V02 11111C

N 17 10540727 PCB ASSY/E843-E61 RJE504581*001V01 11111B

S9

SCREW (2x6) S-BDPT-2X6Z3 33333X

N 18 10517415 LCD UNIT G104STN01.0 11111A

N 19 10544514 CUSHION/LCD RJE504664-001V01 11111A

N 20 10529356 CHASSIS/LCD RJE504536-001V01 11111X

S4

SCREW (3x8) S-BDPT-3X8Z3 55555X

21 10409528 BOX/BAT RJE503893*001V01 11111C

22 10409546 SHEET/BAT RJE503903-001V01 11111X

N 23 10540716 PCB ASSY/E843-1 RJE504603*001 TK 11111A

S2

SCREW (3x5) S-BDMA-3X5Z3 55555X

N 24 10529357 CHASSIS/HNG RJE504535-001V01 11111X

S2

SCREW (3x5) S-BDMA-3X5Z3 44444X

25 10413757 BATTERY-ASSY TK-RJE503905*001 33333B

N 26 10530397 CASE/REAR/BK RJE503837-003V04 1 1 1 X

S6B

SCREW (3x8) S-BDPT-3X8B3 5 5 5 X

N 26 10540735 CASE/REAR/WE RJE503837-004V04 1 1 X

S6

SCREW (3x8) S-BDPT-3X8NI 5 5 X

27 10409533 BLIND/DALLAS/BK RJE503838-003V01 1 1 X

27 10436469 BLIND/DALLAS/WE RJE503838-004V01 1 X

27 10409514 COVER/DALLAS/BK RJE503839-001V01 1 X

27 10476663 COVER/DALLAS/WE RJE503839-002V01 1 X

N 28 10540728 COVER/SHEET/BK RJE503841-003V02 1 1 1 C

N 28 10540729 COVER/SHEET/WE RJE503841-004V02 1 1 C

S8

10409505 SCREW (2.5x6.2) RJE503894-001V01 11111X

N 29 10540730 SPACER/SC RJE504668-001V01 22222X

30 10409516 SPEAKER 2828CP08P1-21(GP) 11111C

S9

SCREW (2x6) S-BDPT-2X6Z3 22222X

S7

SCREW (3x8) S-BD-PT-3X8Z3 22222X

N 31 10540736 COVER/BATTERY RJE503908-002V01 11111X

S3

SCREW (3x8) S-BDMA-3X8Z3 22222X

N 32 10529360 COVER/SD/BK RJE504548-001V01 1 1 1 C

N 32 10529361 COVER/SD/WE RJE504548-002V01 1 1 C

S8

SCREW (2.5x6.2) RJE503894-001V01 11111X

N 33 10540731 COVER/CONNECTOR/BK RJE503840-003V02 1 1 1 C

N 33 10540732 COVER/CONNECTOR/WE RJE503840-004V02 1 1 C

N 34 10540733 COVER/USB/BK RJE503864-003V02 1 1 1 C

N 34 10540734 COVER/USB/WE RJE503864-004V02 1 1 C

N 35 10529358 COVER/BOOT/BK RJE504544-001V01 1 1 1 C

N 35 10529359 COVER/BOOT/WE RJE504544-002V01 1 1 C

36 10322440 ASSY/DALLAS TK-RJE502827*001 1 1 B

37 10409543 SPACER/DALLAS RJE503900-001V01 1 1 X

38 10448859 FERRlTE CORE GTR-20-10-10 1 1 X

N 39 10544519 CUSHION/DLS RJE504590-001V01 1 1 X

Page 70

– 68 –

V-R200 / VER.2

3.

CABLES

EXPLODED VIEW

Item 40 (CABLE-SUBASSY/DRAWER)

E843-IOC PCB

CN5

Drawer

Item 41 (CABLE-SUBASSY/DRAWER)

E843-IOC PCB

CN4

Drawer

Item 42 (CABLE/FFC JOINER)

E843-IOC PCB

CN18

E843-PR PCB

CN501

Item 43 (CABLE-SUBASSY/PRN)

E843-IOC PCB

CN502

E843-PR PCB

CN502

Item 44 (CABLE-SUBASSY/FG)

E843-IOC PCB

E843-1 PCB

Item 45 (CABLE-SUBASSY/USB)

E843-IOC PCB

CN15

E843-1 PCB

CN13

Item 46 (CABLE-SUBASSY/IOC)

E843-IOC PCB

CN8

E843-1 PCB

CN11

Page 71

– 69 –

V-R200 / VER.2

Item 47 (CABLE-SUBASSY/BL)

E843-1 PCB

CN5

LCD UNIT

Item 48 (CABLE-SUBASSY/LCD)

E843-1 PCB

CN2

LCD UNIT

Item 49 (CABLE-SUBASSY/DASR)

E843-IOC PCB

CN1

DALLAS ASSY

PARTS LIST

1: V-R200-BD 2: V-R200-BD-WE 3: V-R200-U 4: V-R200-U-WE 5: V-R200-C

12345

R RemarksN Item Code No. Parts Name Specification

Qt'y

CABLES

40 10476620 CABLE-SUBASSY/DRAWER RJE503863*001V04 11111CDRW1 (Length: 900 mm)

41 10412270 CABLE-SUBASSY/DRAWER RJE502394*002V02 11111CDRW2 (Length: 250 mm)

42 10406971 CABLE/FFC JOINER E441341-017V03 11111C

N 43 10544516 CABLE-SUBASSY/PRN RJE504534*001V01 11111C

N 44 10436476 CABLE-SUBASSY/FG RJE503921*001V01 11111C

N 45 10544517 CABLE-SUBASSY/USB RJE504532*001V01 11111C

N 46 10544518 CABLE-SUBASSY/IOC RJE504533*001V01 11111C

N 47 10413625 CABLE-SUBASSY/BL RJE503726*001V02 11111C

N 48 10409550 CABLE-SUBASSY/LCD RJE503739*001V01 11111C

N 49 10544515 CABLE-SUBASSY/DASR RJE504586*001V01 1 1 C

Page 72

– 70 –

V-R200 / VER.2

4.

ACCESSORIES

EXPLODED VIEW

50

51

52

53

4754

55

PARTS LIST

1: V-R200-BD 2: V-R200-BD-WE 3: V-R200-U 4: V-R200-U-WE 5: V-R200-C

12345

R RemarksN Item Code No. Parts Name Specification

Qt'y

ACCESSORIES

50 10331637 SUBASSY/TRAY-BK RJE503185*001V01 1 1 1 C Multi-purpose tray (Black)

50 10436522 SUBASSY/TRAY-WE RJE503185*002V01 1 1 C Multi-purpose tray (White)

N 51 10540740 SUBASSY/POP TRAY RJE504570*001V01 1 1 1 C Pop tray (Black)

N 51 10540741 SUBASSY/POP TRAY RJE504570*002V01 1 1 C Pop tray (White)

N 52 10540742 AC adaptor EM1-240400M3 11111AAC adaptor

N 53 10540743 CORD/POWER 991-91993 1 X Power cord (US only)

N 54 10540744 PLATE/MAGNET-BK RJE504571*002V01 1 1 1 C Magnetic plate (Black)

N 54 10540745 PLATE/MAGNET-WE RJE504571*001V01 1 1 C Magnetic plate (White)

N 55 10529376 SPACER (58mm) RJE504547-001V01 11111C

Spacer

(58 mm for printer paper)

Page 73

CASIO COMPUTER CO., LTD.

Overseas CS Department

TOKYO, JAPAN

© 2016 – 2017 CASIO COMPUTER CO., LTD.

Ver.2 : Apr. 2017

EXPLODED VIEW/PARTS LIST (Ver.2)

• Correction of the EXPLODED VIEW (P66)

Ver.3 : Jun. 2017

DIAGNOSTIC OPERATION (Ver.2)

• Correction of the CHECKING THE VERSION (P31)

Loading...

Loading...