Page 1

SERVICE MANUAL

ELECTRONIC CASH REGISTER

SE-S300/S2000

SE-C300/C2000

TE-900/1500

TK-950/1550

PCR-T48S/T470/T480/T470L/T480L/

T220S/T2100/T2200/T2100L/T2200L

(EX-292/EX-293/EX-592/EX-593)

FEB. 2008

SE-S2000M

Ver.1 : Mar. 2007

Page 2

CONTENTS

PAGE

1. SPECIFICATIONS ...................................................................................................... 1

2. MACHINE INITIALIZATION ....................................................................................... 4

3. DISASSEMBLY .......................................................................................................... 9

4. BLOCK DIAGRAM ...................................................................................................17

5. DIAGNOSTIC OPERATION .....................................................................................18

6. ERROR CODE LIST ................................................................................................. 39

7. PCB LAYOUT ...........................................................................................................41

8. CIRCUIT DIAGRAMS ............................................................................................... 43

9. PARTS LIST .............................................................................................................52

Page 3

1. SPECIFICATIONS

1-1. Electrical specifications

• Power consumption

In operation

Display off

• Memory protection Back-up battery

Back-up period

Battery life

• Clock & Calendar Accuracy

Auto calendar

120 V 230 V 240 V

Max.

0.4 A

Max.

0.05 A

Two new size AA alkaline batteries

1 year (25 °C)

Replace the battery every 1 year.

Within ± 30 sec. per month (25 °C)

Effective until 2099 A.D.

0.26 A

0.04 A

1-2. Environmental specifications

• Operating temperature 0 °C ~ 40 °C

• Operating humidity 10 % ~ 90 %

• Storage temperature -25 °C ~ 65 °C

• Storage humidity 10 % ~ 95 %

• Drop Durability Durable through dropping one end of the unit from 3 cm in height.

1-3. Main components

• CPU Name

Number of control bit

• SRAM Name

Capacity

• FROM Name

Capacity

• Thermal printer Name

Print method

Head specification

Total dot number

Dot pitch

Paper supply method

Print wide

Roll diam

Type

• Roll paper Type

Size

Roll diam

Thickness

uPD70F3733GJ-UEN-A

32 bit

CY62146EV30LL-45ZSXIT

4 Mbit

S29JL032H70TFI020

32 Mbit

FTP-628MCL518 (Receipt)

FTP-628MCL518 (Journal)

Thermal dot line printing

384 dots/dot line

Lenght 8 dots/mm

Wide 8 dots/mm

57.5 ± 0.5 mm

Heat-sensitive paper

Heat-sensitive paper

57.5 ± 0.5 mm

Φ 80 mm or less

0.06 ~ 0.85 mm

0.26 A

0.04 A

— 1 —

Page 4

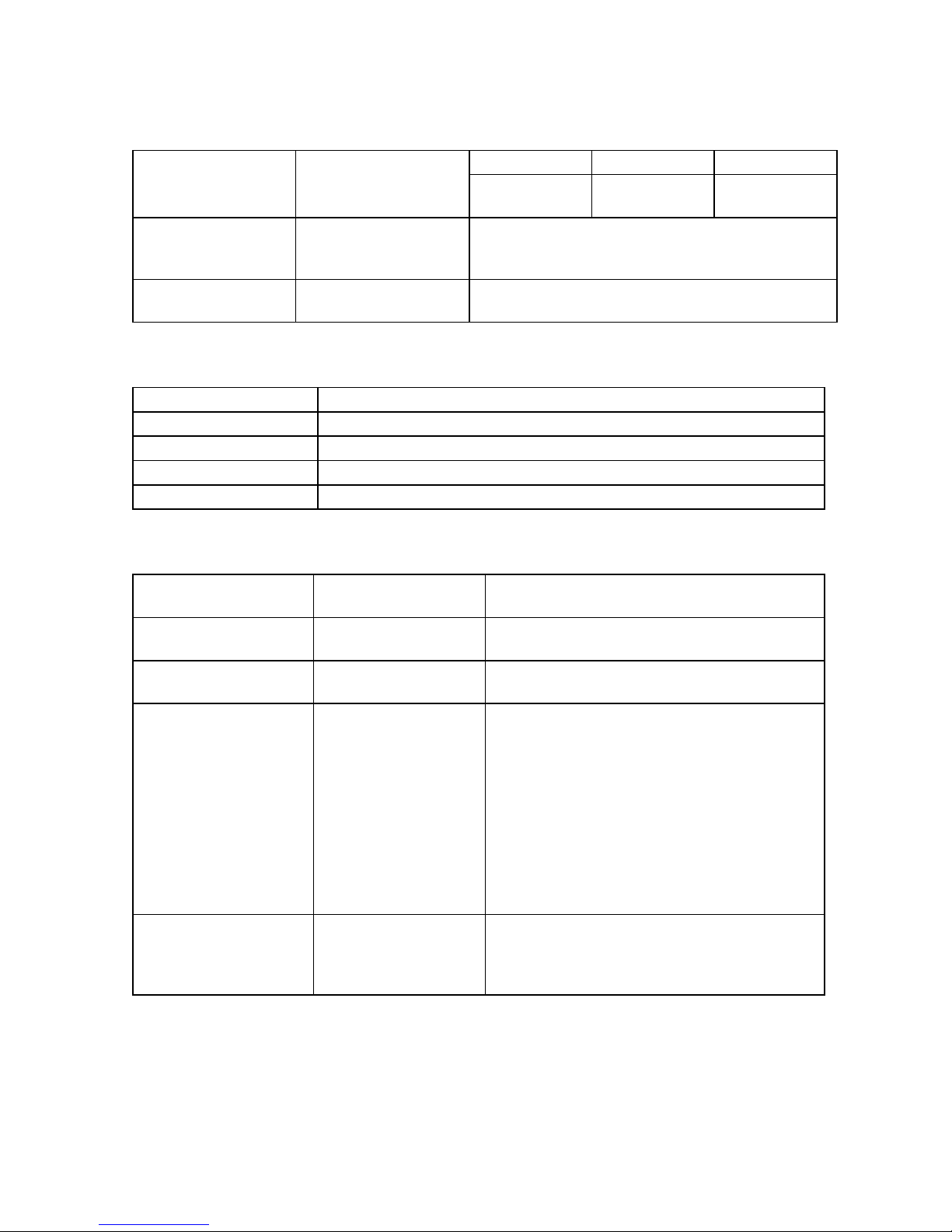

1-4. Drawer List

Type Drawer Name Specification Europe UK U.S.A. Canada Others

SE-S300

S DL-1842 D-21K2C-D53RM-17*

M DL-2800 D-24K2C-B84RM-9*

SE-S2000

M DL-2800 D-24K2C-B84RM-9*

M DL-2803 D-24K2C-B84SRM-9*

SE-C300

M DL-2806 D-24K2C-B84SRM-4*

M DL-2807 D-24K2C-B84RM-4*

SE-C2000

M DL-2806 D-24K2C-B84SRM-4*

M DL-2807 D-24K2C-B84RM-4*

TE-900

S DL-1332 D-21K2C-D54RM-4*

TE-1500

M DL-2433 D-24K2C-B55SRM-4*

TK-950

S DL-1332 D-21K2C-D54RM-4*

TK-1550

M DL-2433 D-24K2C-B55SRM-4*

PCR-T48S

S DL-1332 D-21K2C-D54RM-4*

PCR-T220S

M DL-2433 D-24K2C-B55SRM-4*

PCR-T470

S DL-1332 D-21K2C-D54RM-4*

PCR-T470L

M DL-2802 D-24K2C-A84RM-4*

PCR-T480

S DL-1331 D-21K2C-D54RM-17*

PCR-T480L

M DL-2801 D-24K2C-A84RM-9*

PCR-T2100

M DL-2433 D-24K2C-B55SRM-4*

PCR-T2100L

M DL-2805 D-24K2C-A84SRM-4*

PCR-T2200

M DL-2432 D-24K2C-B55SRM-9*

PCR-T2200L

M DL-2804 D-24K2C-A84SRM-9*

— 2 —

Page 5

1-5. Option List

DEVICE NAME MODEL NOTE Applicable

Roll paper TRP-5880T Common

Waterproof cover WT-89 SE-S300/S2000,

TE-900/1500, PCR series

Waterproof cover WT-90 SE-C300/C2000,

TK-950/1550

Sheet cover WT-91 SE-C300/C2000,

TK-950/1550

PC cable PRL-CB-2 Common

External memory RAC-12B 4MB (Thermal pop) Common

External memory RAC-14B 16MB (Electronic journal) Common

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED

BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING

TO THE INSTRUCTIONS

— 3 —

Page 6

2. Initialization

Initializing the cash register

• Automatic initialization

Use the following procedure to initialize the cash register before using it for first time after you purchase it.

1. Install the two memory backup batteries (see page 10 of the User’s Manual).

2. Plug the cash register into a wall outlet.

• At this time, "00000000" appears on the display and the printer operates for a minite. Initialization is complete

when the Printer stops operating.

CAUTION!

Automatic initialization (which clears all sales and programming data stored in the register’s memory) is performed

whenever all power (both the backup batteries and power through power cord) is cut form the cash register

and then restored. The program data stored in the flash memory is restored.

Remember...

Main power cut by:

•

Unplugging the cash register

• Power failure

Backup power cut off by:

+

• Removing the batteries

• Dead or low batteries

Automatic initialization when

the main power is restored

+

and the mode switch is set to

any position besides OFF.

• Manual initialization

Use the following procedure to initialize the cash register and clear all transaction data and program data

from its memory.

1. Insert the mode key marked “PGM” into the mode switch.

2. Turn the mode switch to the OFF position.

3. SE-S300/SE-C300:

While holding down the

SE-S2000/SE-C2000:

While holding down the

4. SE-S300/SE-C300:

Release the

FEED

key.

SE-S2000/SE-C2000:

JOURNAL

Release the

FEED

key.

5. Enter A B 0 0 and press the

FEED

key, turn the mode switch to the PGM position.

JOURNAL

FEED

key, turn the mode switch to the PGM position.

SUB

key.

TOTAL

A. Language selection

This specification defines the

language to use for the date in

receipt/journal printing.

English

French

Spanish

German

0

1

2

4

B. Area / monetary mode

This specification defines the area

and the decimal position.

U.S.

Canada

German

Two decimal place

No decimal place

— 4 —

2

9

4

1

3

C. Department number

This specification defines the

number of deparment keys.

Always

SE-S300

SE-C300/

SE-C2000

SE-S2000

2 5

7 2

3 0

Page 7

Clearing a machine lock up

If you make a mistake in operation, the cash register may lock up to avoid damage to programs and preset

data.

Should it happens, you can use the following procedure to clear the lock up without losing any data.

1. Power off the register.

2. Insert the PGM key in the mode switch.

3. SE-S300/SE-C300:

Press down and hold

SE-S2000/SE-C2000:

Press down and hold

4. SE-S300/SE-C300:

The display shows INIT (on alpha-display), then release

SE-S2000/SE-C2000:

The display shows INIT (on alpha-display), then release

SUB

5. Press

TOTAL

. A receipt is issued.

FEED

, and turn the mode switch to PGM mode.

RECEIPT

FEED

, and turn the mode switch to PGM mode.

FEED

RECEIPT

FEED

.

.

— 5 —

Page 8

2. Initialization

Load IPL data

•

When you replace a main PCB with a spare parts, load the IPL data to ECR as the following steps;

1. Required materials

RS232C cross cable which is using CV10

Memory pack RAC-12B

RAC_TOOL software

IPL data file

*Please contact CASIO sales division to get the above materials.

PC with RS232C COM port

Windows 2000 / XP / Vista

2. System configuration

SE series ECR

3. Steps to load IPL data

3-1. Write the IPL data to the RAC-12B from the PC. (Make a special RAC for IPL.)

1) Remove power cord of ECR from AC outlet.

2) Connect the ECR (COM1 port) and PC with the RS232C cross cable.

3) Insert RAC-12B in to the ECR.

RS232C Cross Cable

PC with RS232C COM port

Windows 2000/XP/Vista

RAC-12B

— 6 —

Page 9

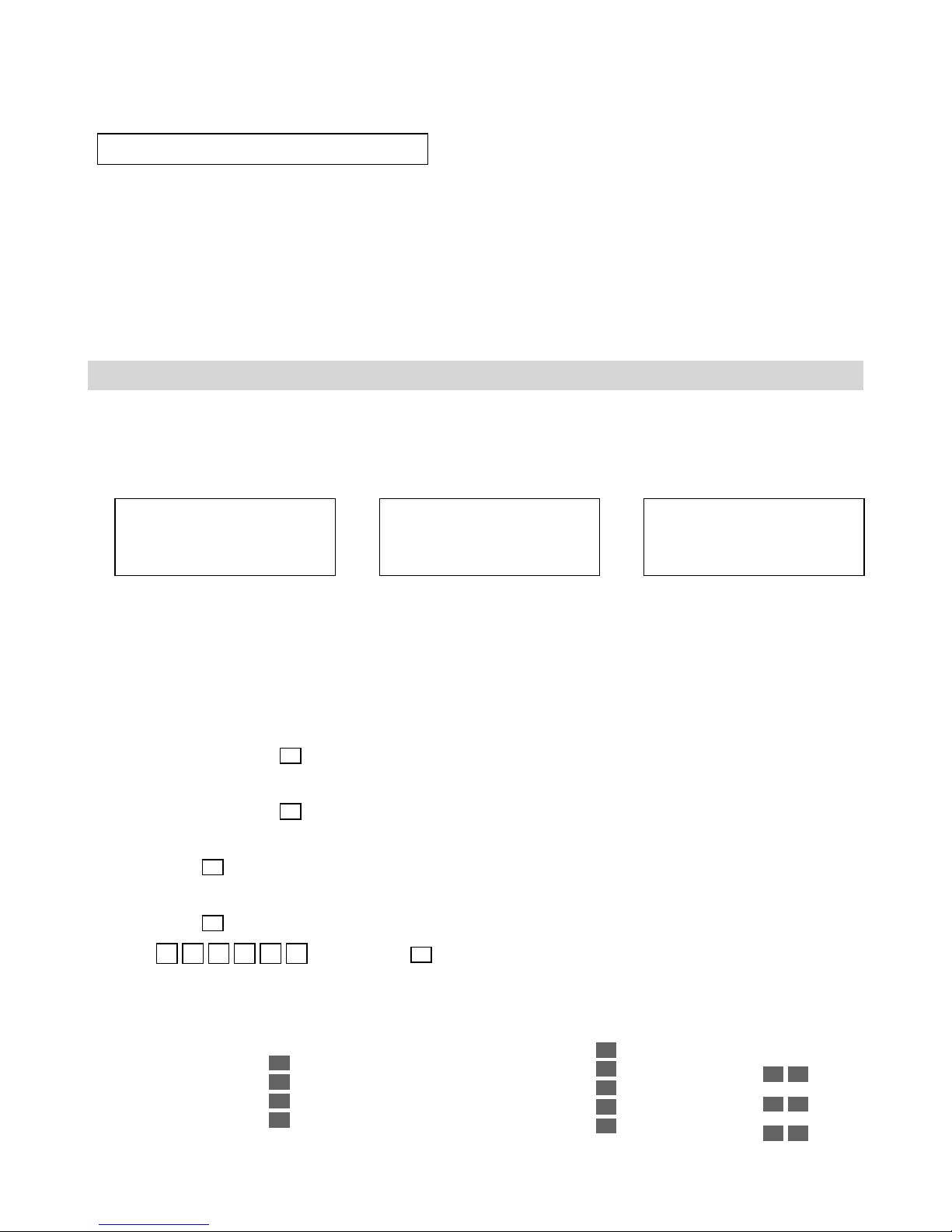

4) Plug in the power cord of ECR to the AC outlet and start up the diag software. (See Page 18)

5) Make double-click RAC_TOOL.exe to run the software.

* RAC_TOOL.exe, FILE969.HAD, and LogoConv.dll (3 files) must be stored at same folder.

6) Select the appropriate COM port according to your configuration.

7) Select “Send RAC File” and choose the IPL file. The file name should be XXX.rac. (Do not send now)

8) Make sure the ECR is in the diag mode, then enter 914 and press "Sub Total" key.

9) The ECR will display “CLEARING RAC” and number will be counted up until 63.

10) The display will be changed to “WAITING RAC”.

When the display is changed to “WAITING RAC”, start sending the file on PC within 30 second.

11) The ECR will display “WRITING RAC” and counter will be displayed every 64Kbytes data are received.

— 7 —

Page 10

12) The following transmission progress will be shown on the PC.

R A C 9 1 4

R A C I P L O K

E N D 9 1 4

13) The following receipt will be issued when all the data has been received.

(ECR will be terminated automatically if data is not receiving 5 second or more)

This process will take approximately 20 minutes to send IPL data to the RAC-12B.

* Please keep the special RAC memory pack for IPL, otherwise you need to do the above process again.

3-2. Send the IPL data from RAC to ECR.

1) Pull out AC cord from wall outlet.

2) Insert the RAC-12B which has the IPL data to the ECR.

3) Press and hold “Journal” feed key and plug in AC cord to the wall outlet.

4) Wait few second and release Journal feed key.

“BT-INIT” should be displayed on the ECR.

5) Enter 44449999 and press "Sub Total" key, then enter 30 and press "Sub Total" key.

6) Back light will be turned off and start loading IPL data from RAC.

7) When the loading is completed, "INIT 0000000000" will be displayed.

8) Enter 99990000 and press "Sub Total" key, then "DIAG 1" will be displayed.

9) Enter your locale code and press "Sub Total" key, then locale code will be printed.

* Locale code is as follows;

Europe: No need to enter the locale code. Skip 8) - 11), go to 12).

U.S.A. and Canada: 200016

Others: 600016

10) Turn the MODE KEY is “OFF”. Then while holding down the “JFEED” button, turn MODE KEY to “PGM”.

11) Release “JFEED” button, then "INIT 0000000000" will be displayed.

12) Enter your INIT code and press "Sub Total" key, then the information will be printed.

* INIT code is as follows;

Model Name INIT Code

SE-C300 / SE-C2000 17200

SE-S2000 13040

SE-S300 12540

TE-1500 23040

TE-900 22540

TK-950 / TK-1550 27200

PCR-T2100 / PCR-T2200 / PCR-T220S 23000

PCR-T2100L / PCR-T2200L 93000

PCR-T470 / PCR-T480 / PCR-T48S 22500

PCR-T470L / PCR-T480L 92500

— 8 —

Page 11

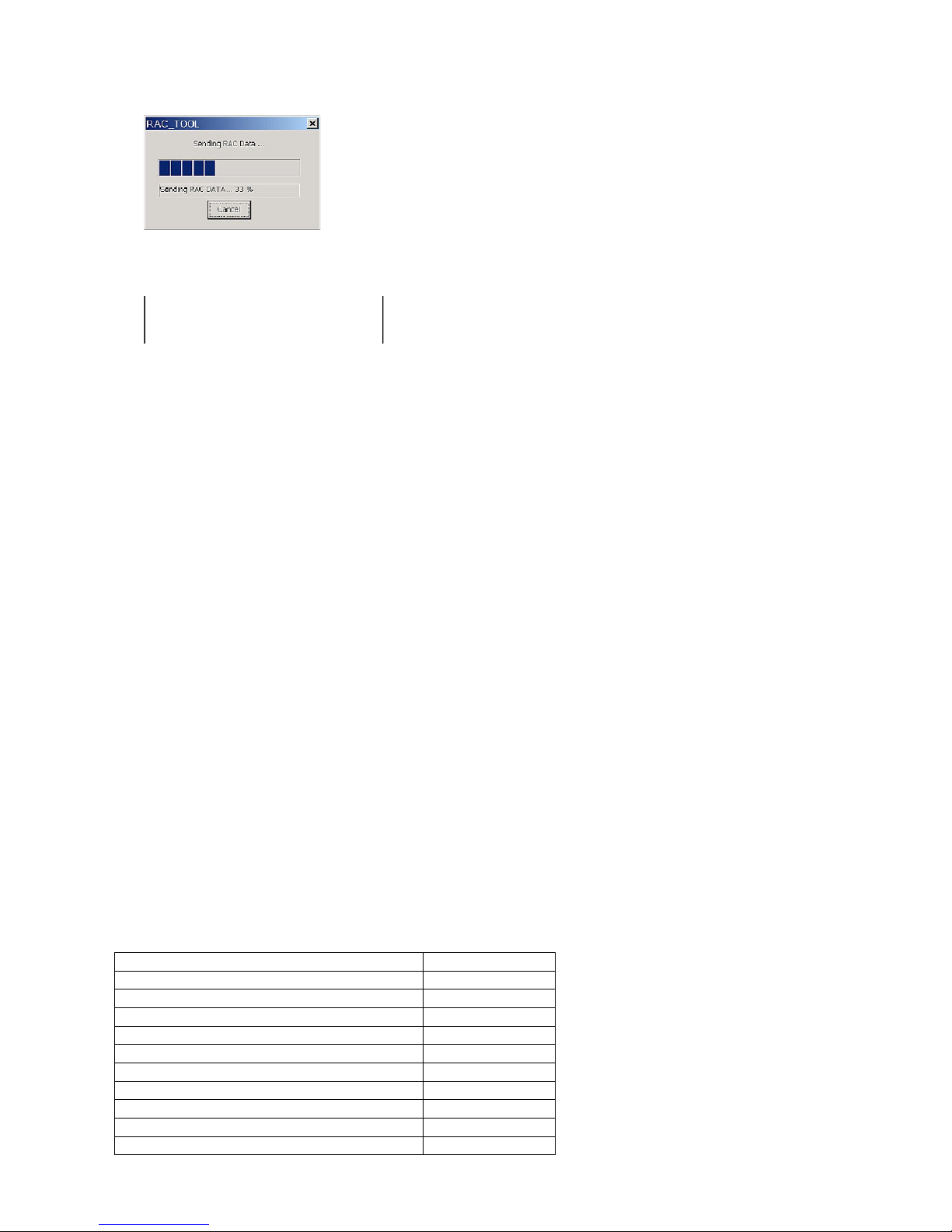

3. DISASSEMBLY

Removing the upper case block

■

1. Remove the Printer cover.

2. Remove two Roll paper and theTake-up reel.

3. Remove the battery cover and disengage the battery.

Take-up reel

Printer cover

4. Remove 3 screws.

Screw

Screws

— 9 —

Page 12

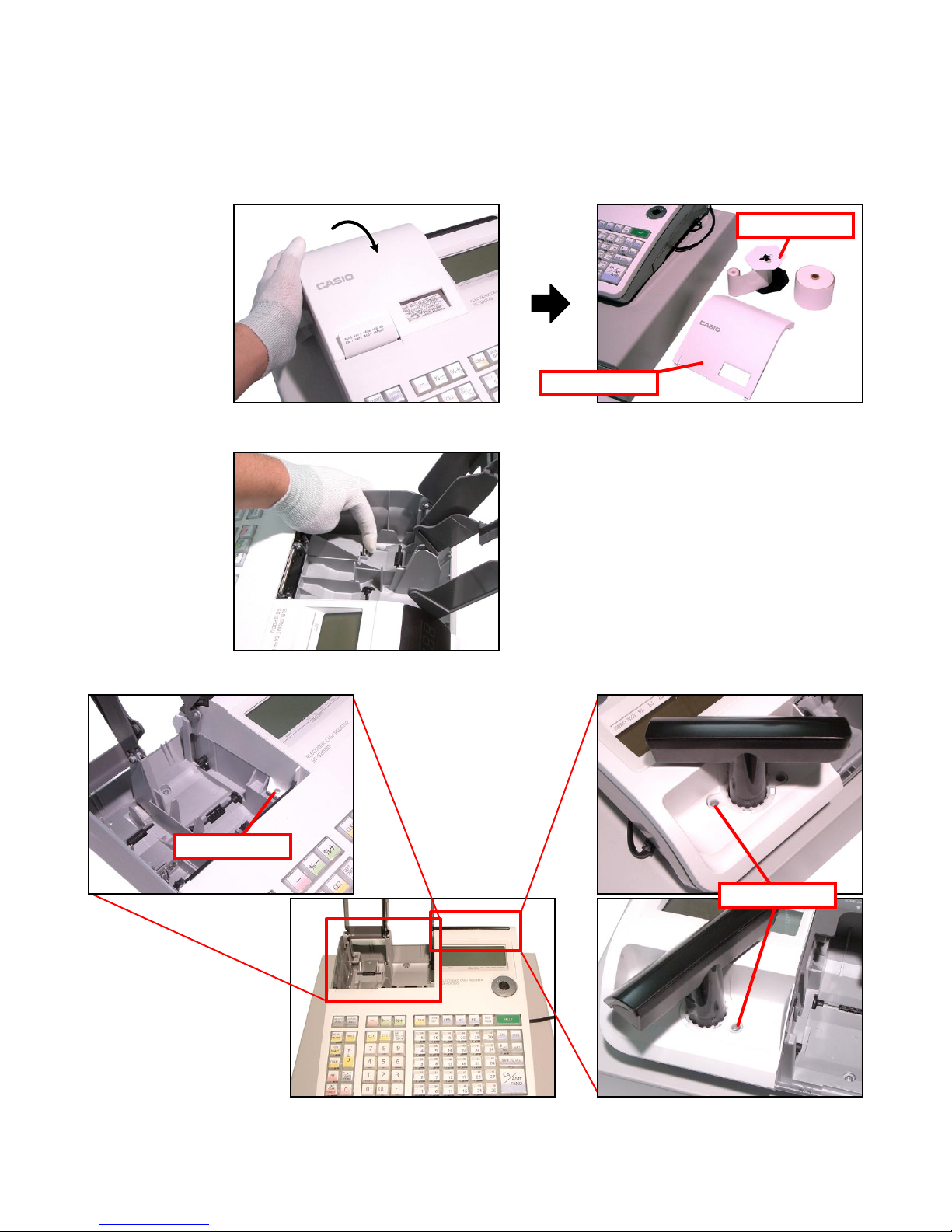

5. Lift the upper case block and then remove 3 FPCs.

Hooks Hooks

Hooks

FPC (KEY)

FPC (Pop-up displasy)

Assembling Point:

Be sure to insert the FPC securely by holding it with both hands or, if holding it with one hand,

holding by its center.

— 10 —

Page 13

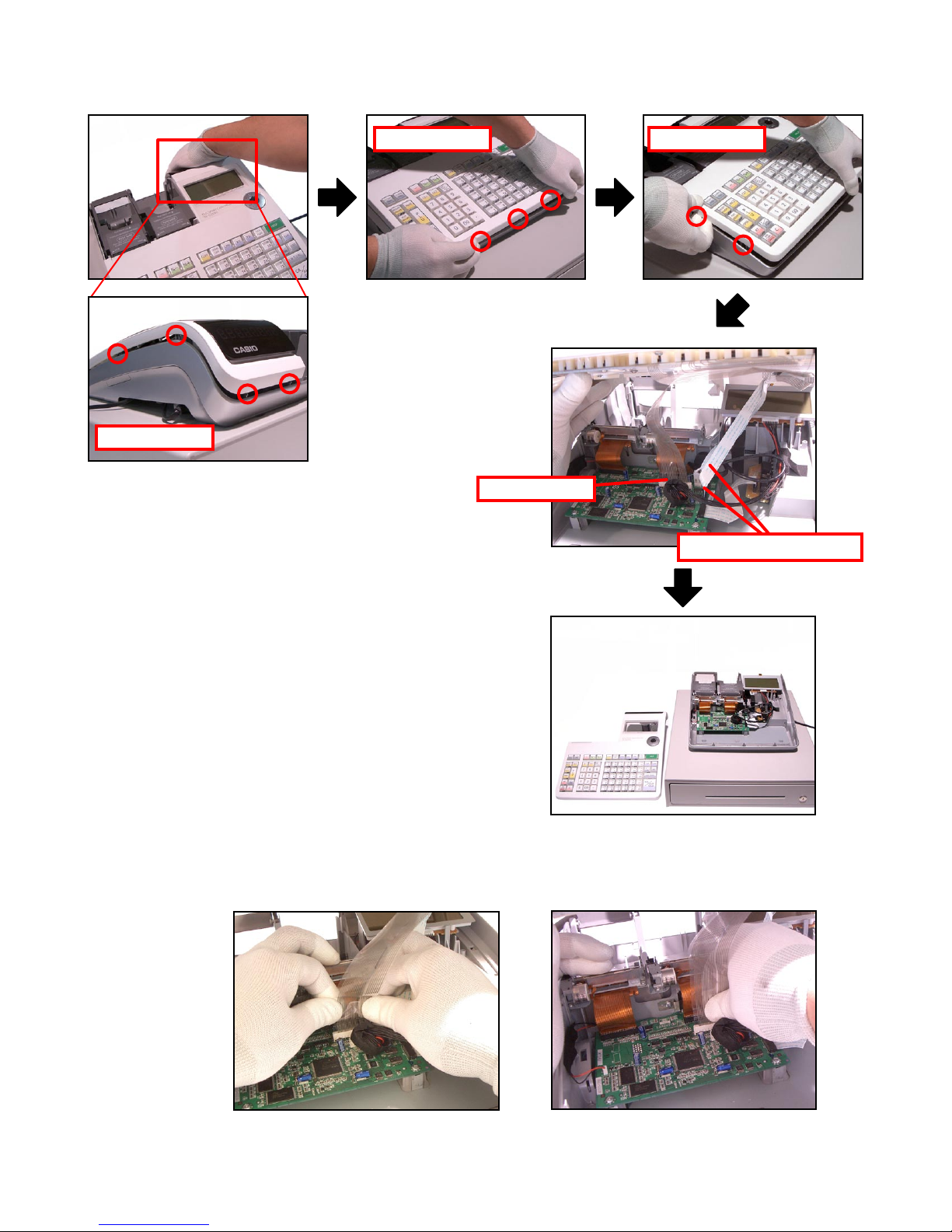

■ Upper case block disassembly

(KEY BOARD ASS'Y, MODE SW ASS'Y, POP-UP DISPLAY BLOCK)

1. Remove the FPC.

2. Remove 8 screws and then the KEY BOARD ASS’Y.

Assembling Point:

Secure the FPC (Mode key, Pop-up Display).

FPC

Screws

3. Remove 15 screws and then disassemble the KEY BOARD ASS'Y.

Screws

— 11 —

Page 14

4. Remove the screw and then the MODE SW ASS’Y.

Screw

5. Remove the hook and then remove the STROBE ASSY

Hooks

6. Remove the hook and then remove the STROBE ASSY.

7. Remove two FPCs and then remove the Rear Display Board.

— 12 —

Page 15

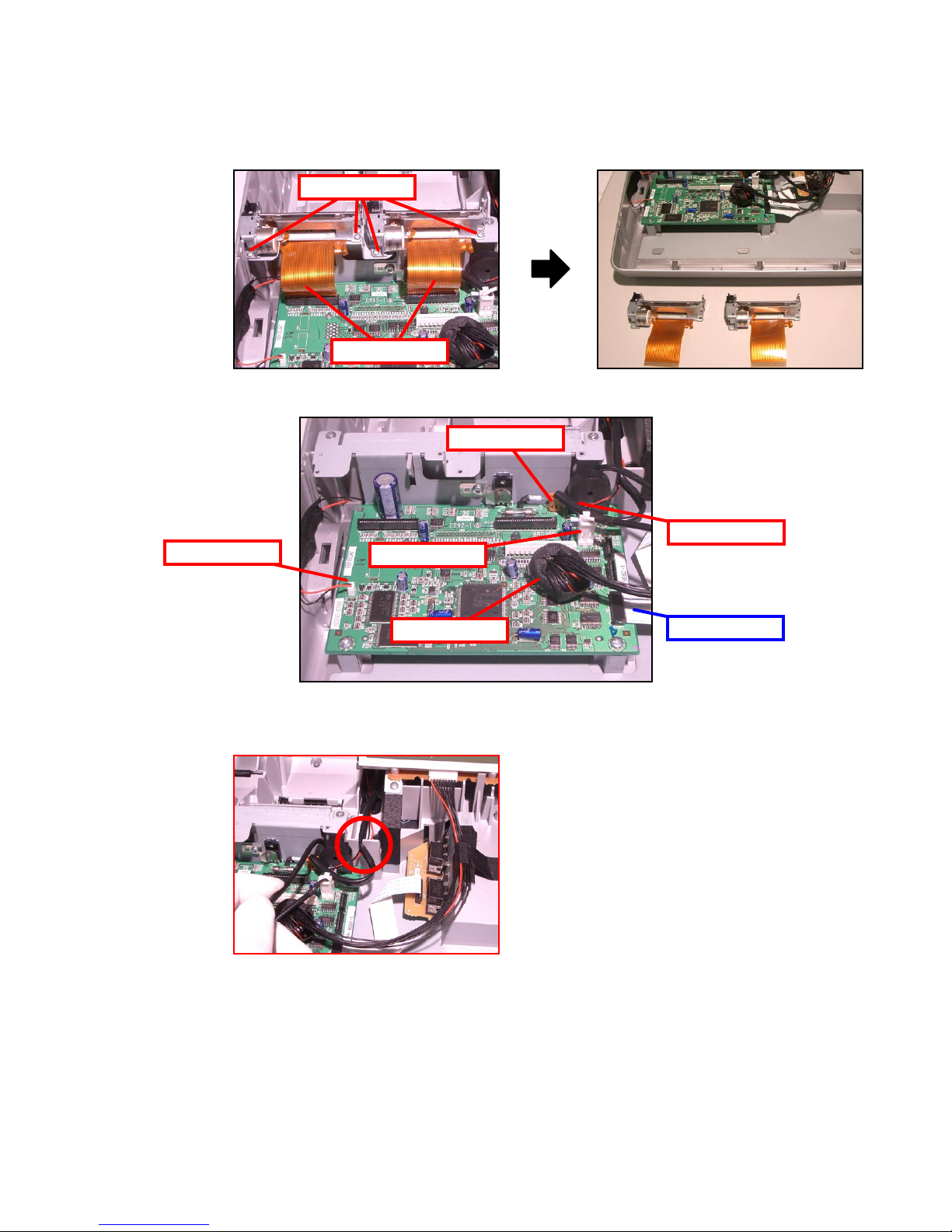

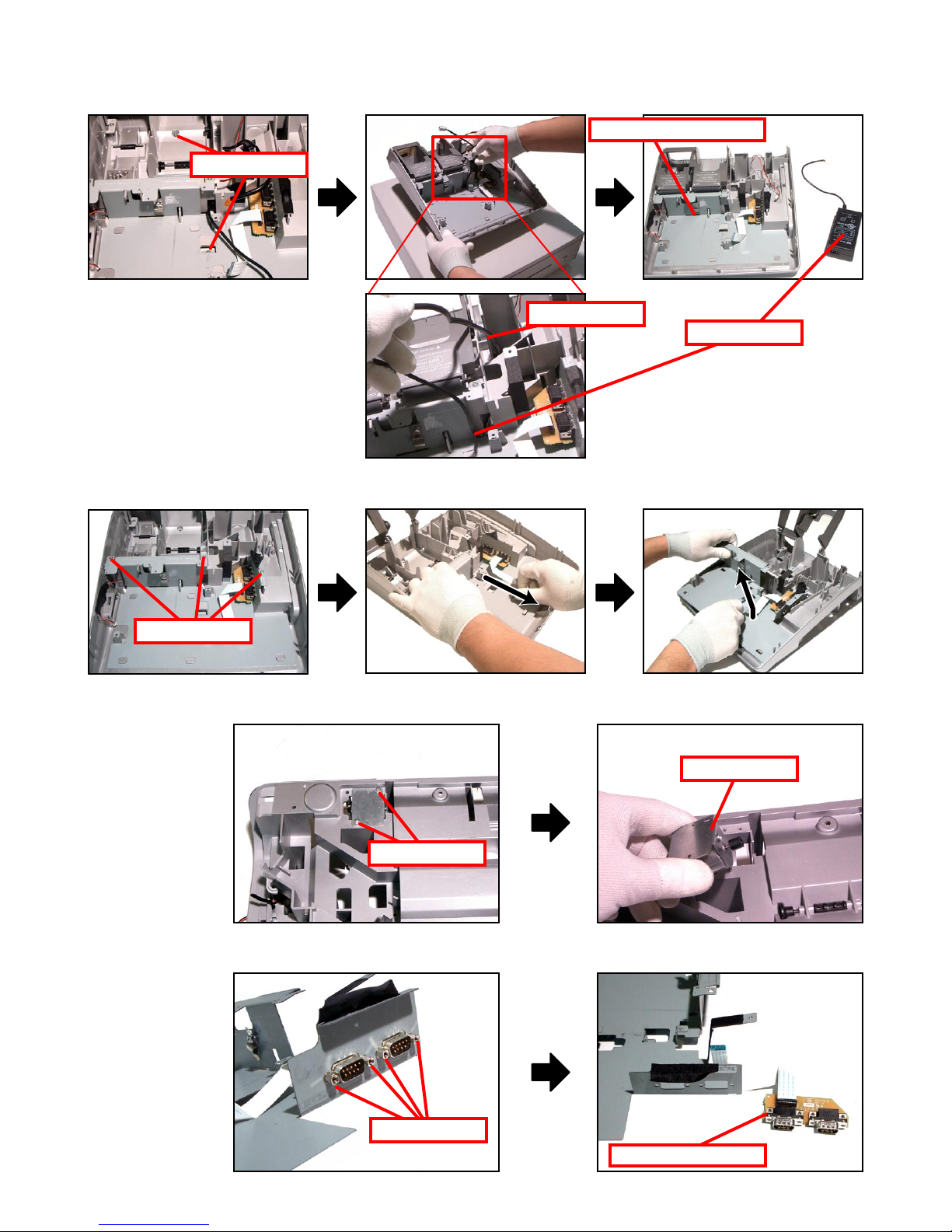

■ Lower case block disassembly (Printer unit, MAIN PCB, LCD unit, E292-COM PCB)

1. Remove 4 screws.

2. Remove 2 FPCs and then 2 Printer units.

Screws

FPCs

3. Remove the FPC and 5 connectors.

Drawer

Motor

Battery

Power

LCD

Assembling Point:

Run the power cable and the motor wires through the groove on the case.

COM Port

— 13 —

Page 16

4. Remove 3 screws.

Screws

5. Loosen the screw and change the orientation of the plate.

6. Remove the main PCB.

7. Remove a screw.

Screw

— 14 —

Page 17

8. Remove the hook and then remove the LCD ASSY.

9. Remove 2 screws and then the LCD and E292LCD-E2 PCB.

Screws

10. Unsolder to remove 3 lead wires.

11. Remove the FPC and then the E292LCD-E2 PCB.

Lead wires

FPC

— 15 —

Page 18

12. Remove 2 screws and then the Lower case unit ans AC Adaptor.

Screws

13. Remove 3 screws and then the Lower case unit ans AC Adaptor.

Lower case unit

Drawer

AC Adaptor

Screws

14. Remove 2 screws and then the Motor assy.

Screws

15. Remove 4 screws and then the E292-COM PCB.

Motor assy

Screws

E292-COM PCB

— 16 —

Page 19

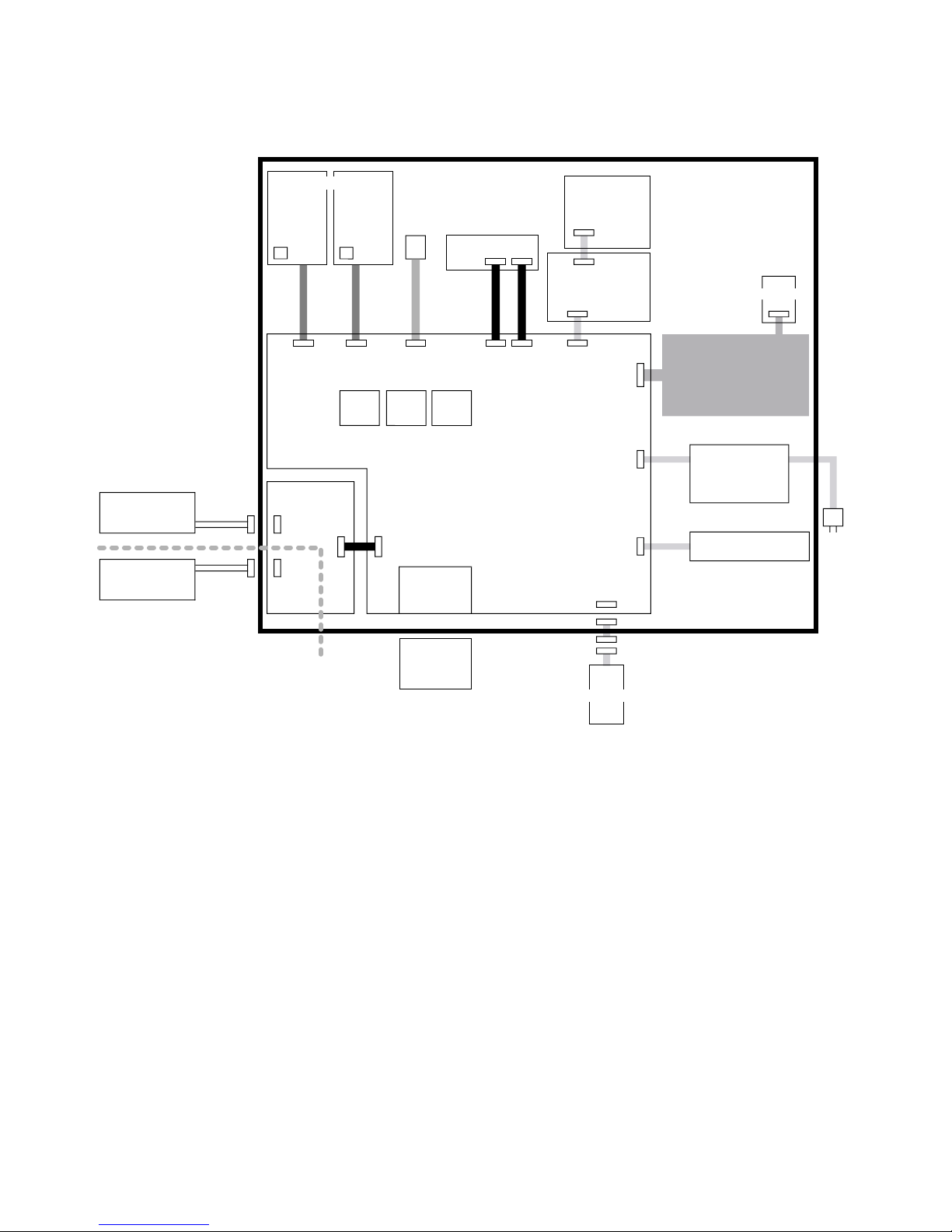

4. BLOCK DIAGRAM

DRAWER UNIT

DRW I/F

RAC12 socket

RAC12

32Mbi

t

PWB : E292-1

PWB : E292-COM

POWER SUPPLY UNIT

AC

cord

AC Adaptor

S01224A

Optional PC or

Optional Hand

Held Scanner

Optional Hand

Held Scanner

+5V supply

+5V suppl

y

COM1

Feed Motor

Feed Motor

PWB:E283-E22

Thermal PRN UNIT

Receipt

Journal

Winder Motor

MODE KEY

PWB:E274-E3

PWB:E292LCD-E2-

1

LCD UNI

T

32Mbit

FROM

CPU

4Mbit

COM2

SRAM

Two AA size alkaline batteries

SE-S300/SE-S2000/TE-900/

TE-1500/PCR series (STROKE KEY)

or

SE-C300/SE-C2000/

TK-950/TK-1550 (COMBINATION KEY)

SE-S2000/SE-C2000/TE-1500/TK-1550/

PCR-T220S/2100/2100L/2200/2200L

— 17 —

Page 20

5. DIAGNOSTIC OPERATION

RPT

AMOUNT

T1 T2 T3 T4

TOTAL CHANGE

INIT

RPT

AMOUNT

T1 T2 T3 T4

TOTAL CHANGE

INIT

,,

B o o t V e r : 4 4 9 9 A

A p l i V e r : 4 5 0 1 A C

AGQA

BAFQA

RPT

AMOUNT

T1 T2 T3 T4

TOTAL CHANGE

DIAG

E S C

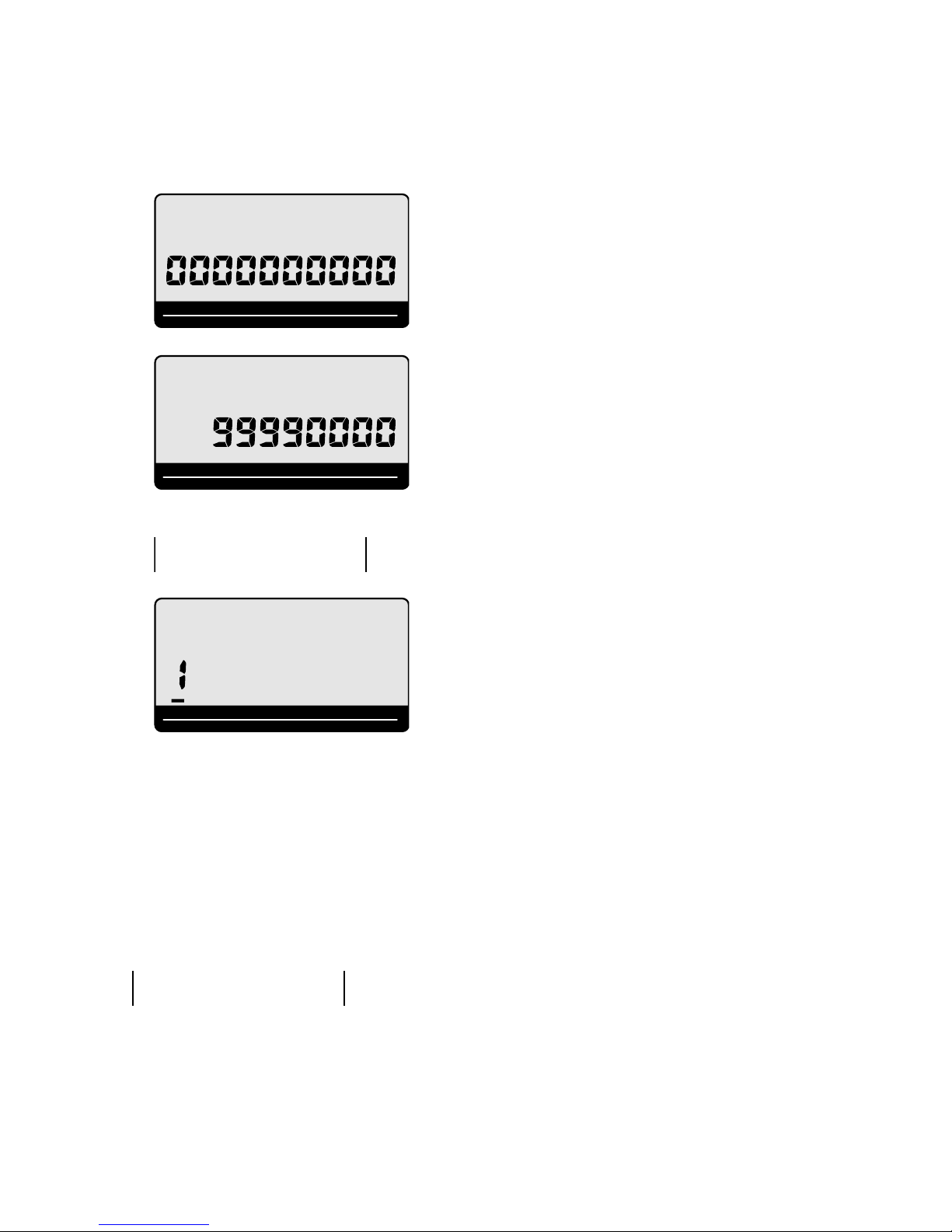

5-1. To start the diagnostic program

1. First, be sure that MODE KEY is “OFF”. While holding down the “JFEED” button, turn MODE KEY to “PGM”.

When the “JFEED” button is released, the main display indicates as illustrated below.

2. Enter “99990000” and then press the “SUB TOTAL” button.

3. After DIAG version is printed out, DIAG mode starts.

5-2. Notes for the DIAG

• To perform the continuous check, follow the direction for each test, and input numbers except 0. Input

numbers 1-9 as the command how many times to perform the test for the operation in each page to

perform continuous check. Note that you can only choose one time check or continuous check.

[Others]

• ESC value is printed as follows if the test ended by force. Press the “C” key or turn off the power to end

the test while performing continuous check. The result of ending by force is not printed in each test.

— 18 —

Page 21

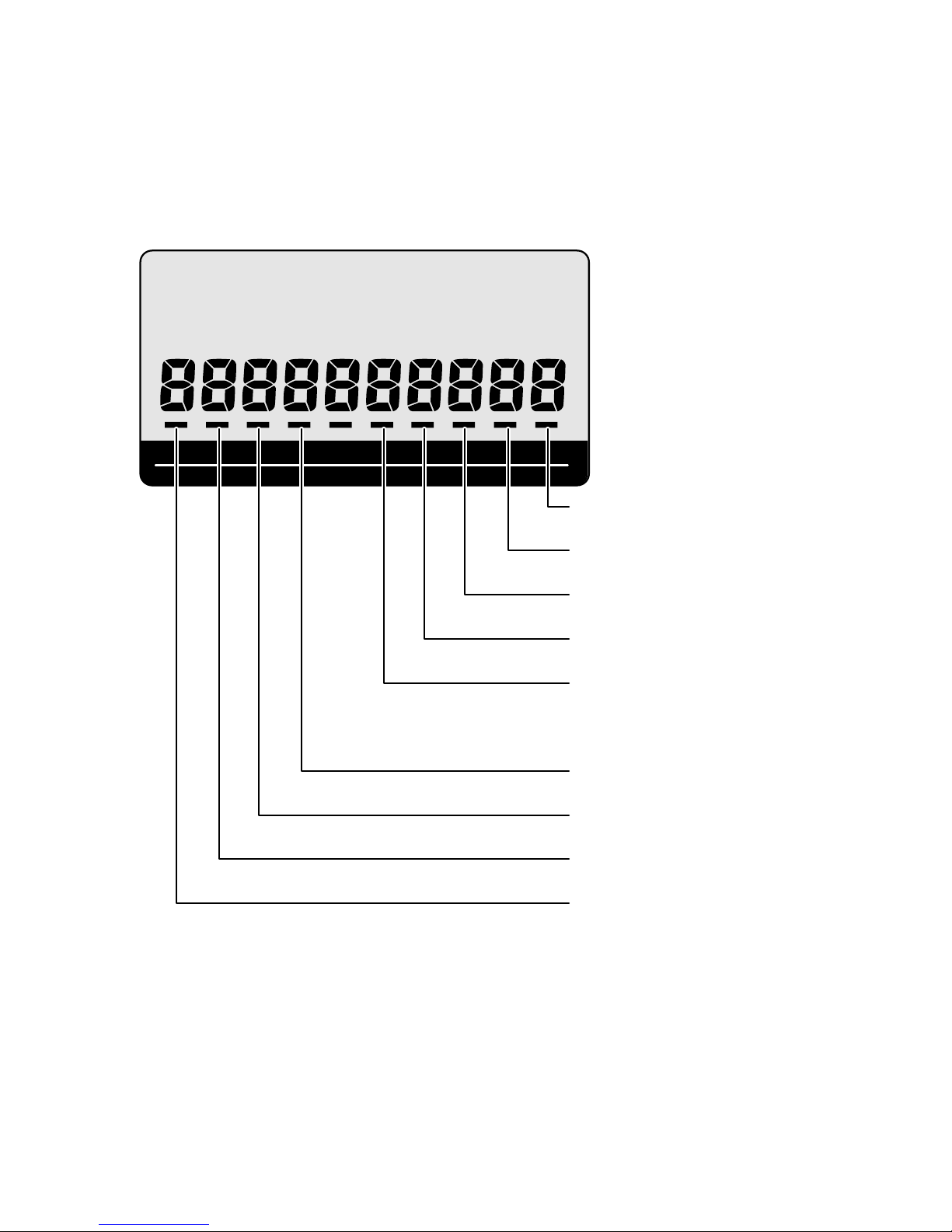

5-3. Displaying the status of the device

RPT

AMOUNT

T1 T2 T3 T4

TOTAL CHANGE

DIAG

Drawer sensor

OFF:Close ON:Open

Printer type

OFF:Reciept ON:Reciept and Journal

KEY type

OFF:Stroke ON:Combination

Memory protection batteris

OFF:Normal ON:Low Battery

Reciept head sensor

OFF:Head down ON:Head up

Journal head sensor

OFF:Head down ON:Head up

Reciept paper sensor

OFF:Paper available ON:No Paper

Journal paper sensor

OFF:Paper available ON:No Paper

RAC detect

OFF:Uninsertion ON:Insertion

[Function]

Changing to status mode or pressing the “C” key when the device is in the command input wait state

during test program startup displays the device status.

[DISPLAY]

The figure below shows the relative display positions for the status information.

— 19 —

Page 22

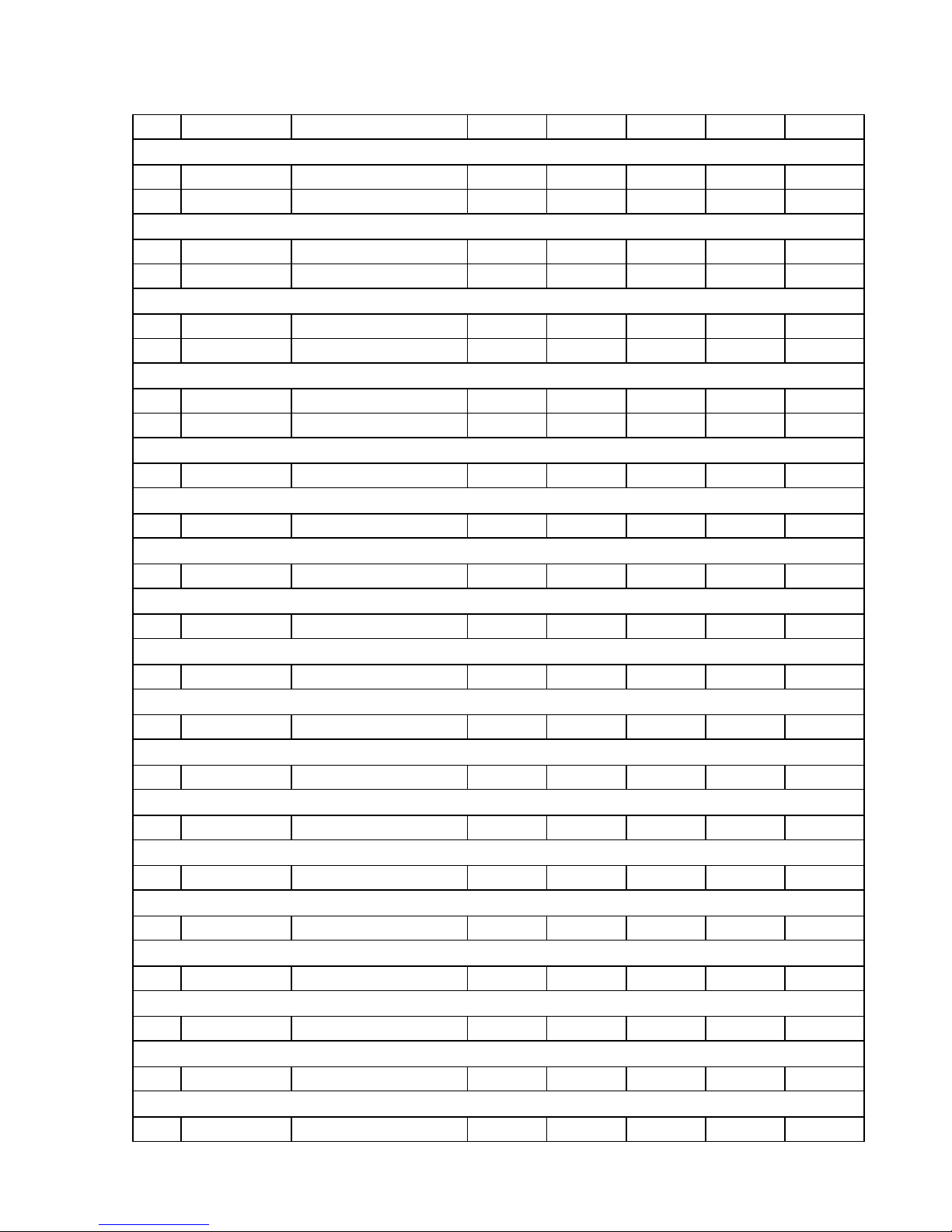

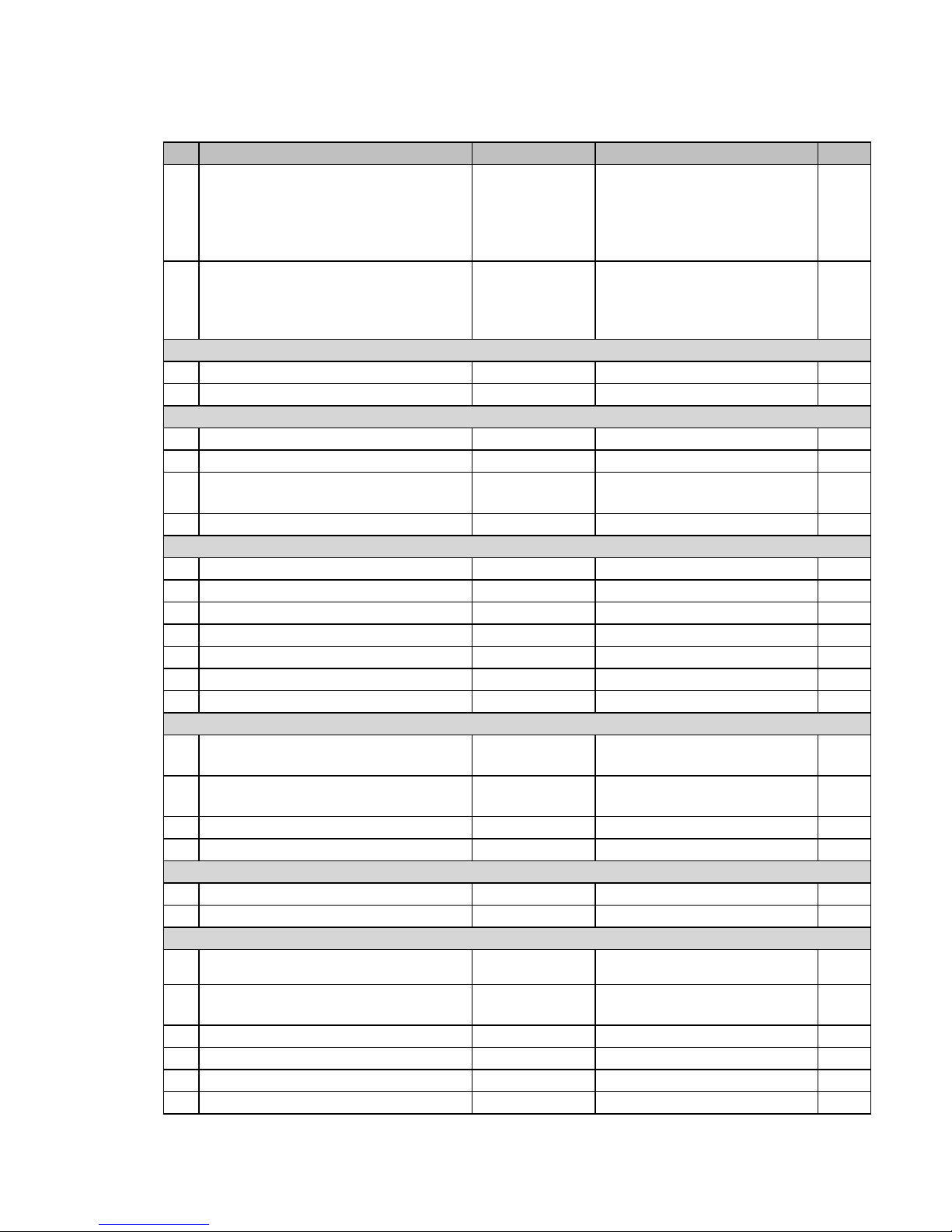

5-4. Check item

The following test can be checked in the diagnostic test.

No Device to be checked Operation Note Page

1 BATCH TEST 1 1 Test Device :

2 BATCH TEST 2 2 Test Device :

RAM TEST

3 RAM WRITE/READ TEST n011 22

4 RAM READ ONLY TEST n111 22

FLASH ROM TEST

5 FLASH ROM CLEAR TEST n212 23

6 FLASH ROM WRITE/READ TEST n012 23

7 FLASH ROM CLEAR & WRITE/READ

TEST

8 FLASH ROM PROECT AREA CLEAR 0216 25

DISPLAY TEST

9 DISPLAY TEST n21 25

10 DISPLAY TEST (REPEAT) 521 26

11 7 SEGMENT DISPLAY TEST 221 26

12 LCD BACKLIGHT TEST c0121 27

13

DISPLAY PATTERN TEST

14

LCD CONTRAST ADJUSTMENT TEST

15

LCD BIT MAP TEST

PRINT TEST

16 INTERNAL PRINTER CHARACTER

PRINT TEST

17 INTERNAL PRINTER GRAPHIC

PATTERN PRINT TEST

18

INTERNAL PRINTER DOT RATE TEST

19 INTERNAL PRINTER PRINT TEST 435 33

RS232C TEST

20 RS232C PORT TEST xn04d 33

21 RS232C PORT BATCH TEST 40 34

TIME/DRAWER/BUZZER/KEY/OBR TEST

22 TIME SETTING

23 TIME DISPLAY 070

24 DRAWER OPEN TEST n091 36

25 BUZZER TEST n092 36

26 KEY DISPLAY TEST 94 37

27 OBR TEST 95 38

RAM READ/WRITE test,

Watch, buzzer test and drawer

open test are performed

continuously.

Display test and LCD

backlight test are performed

continuously.

n312 24

n321 27

421 28

621 29

acn03d 30

P1P1P1P2P2P2n13d

pn33d 32

hhmmss0070

yymmdd0170

170

21

21

31

35

35

— 20 —

Page 23

5-5. Operation of each test

B A T C H 1

R A M W R O

K

B B B B B B B B B B B B B B B B

D A T E 0 5

T I M E 2 3

D R W O

K

E N D 1

03-95:

13/21/

BBBBBBBB

B A T C H 2

D I S P O K

D I S P M A I N O K

D I S P 7 S E G O K

B A C K L I G H T

O K

E N D 2

[ 1 ] BATCH TEST 1

[Function]

RAM READ/WRITE test, Watch, buzzer test and drawer open test are performed continuously.

[Operation]

Operation : 1 SUB TOTAL

The following tests are performed automatically.

(1) RAM test: WRITE/READ area test.

(2) Test print

(3) Time setting: Set the following data.

Arranged data: 2005 December 31,23:59'30

(4) Buzzer: Ring once the one shot buzzer.

No print or display in this test.

(5) Drawer open: Drawer 1 opens only.

(6) Receipt issuance

[Print]

*Test print is also done on the journal side.

*If no journal printers are available, “BBBBBBBBBBBBBBBBBBBBBBBB” is printed out on the receipt.

[ 2 ] BATCH TEST 2

[Function]

Display test and LCD backlight test are performed continuously.

[Operation]

Operation : 2 SUB TOTAL

The following tests are performed automatically.

(1) Display test: Press any key to go to the next screen.

(2) LCD pattern test

(3) 7 segment test

(4) LCD backlight test Press any key to switch ON/OFF.

[Print]

— 21 —

Page 24

[ 3 ] RAM WRITE/READ TEST

R A M 1 1

R A M W R O

K

E N D 1

1

R A M 1 1 1

R A M R D O

K

E N D 1 1 1

[Function]

Data on the RAM is written, and tests are performed to check if the data has been written properly.

The data to be written should be a one-byte data, which is the sum of the fourth, the third, and the

second digits from the last of the address. After writing is completed, the data is read and checked

whether it is identical to the original. The test will not be performed, however, in the area where

performing this test affects the operation. Memory used in HANDLER (static area). Memory used in

DIAG (stack, static areas). Code, however, will be performed from FLASH ROM.

[Operation]

Operation : n 0 1 1 SUB TOTAL

n: 0 = One time check (can be omitted)

not 0 = Continuous check (To stop the test, press “C” key)

[Display]

A counter is displayed in the 7 segments to indicate that RAM check is in progress.

[Print]

The following is printed when all areas for RAM are tested.

[ 4 ] RAM READ ONLY TEST

[Function]

Read only test for RAM (read, write, verify) is performed.

Note that write test (n011) must be performed right before this test.

[Operation]

Operation : n 1 1 1 SUB TOTAL

n: 0 = One time check (can be omitted)

not 0 = Continuous check (To stop the test, press “C” key)

[Display]

A counter is displayed in the 7 segments to indicate that RAM check is in progress.

[Print]

The following is printed when all areas for RAM are tested.

— 22 —

Page 25

[ 5 ] FLASH ROM CLEAR TEST

R O M 2 1 2

F L A S

H C L R O K

E N D 2 1 2

R O M 1 2

F L A S H W R O

K

E N D 1

2

[Function]

After this test, be sure to perform [6] FLASH ROM WRITE/READ test before conducting other tests. If

other tests are performed without having conducted FLASH ROM WRITE/READ test and the program

is damaged, proper operation cannot be guaranteed. Please perform IPL again.

[Operation]

Operation : n 2 1 2 SUB TOTAL

n: 0 = One time check (can be omitted)

not 0 = Continuous check (To stop the test, press “C” key)

[Display]

A counter is displayed in the 7 segments to indicate that RAM check is in progress.

[Print]

The following is printed when all areas for RAM are tested.

[ 6 ] FLASH ROM WRITE/READ TEST

[Function]

[5] FLASH ROM CEAR test must have been performed immediately before this test. The test is

performed in the user area.

[Operation]

Operation : n 0 1 2 SUB TOTAL

n: 0 = One time check (can be omitted)

not 0 = Continuous check (To stop the test, press “C” key)

[Display]

A counter is displayed in the 7 segments to indicate that RAM check is in progress.

[Print]

The following is printed when all areas for RAM are tested.

— 23 —

Page 26

[ 7 ] FLASH ROM CLEAR & WRITE/READ TEST

R O M 3 1 2

F L A S H O

K

E N D 3 1 2

L O C A L E 2 1 6

L O C A L E C L R O

K

E N D 2 1 6

[Function]

After CLEAR function clears the memory, WRITE test is performed.

[Operation]

Operation : n 3 1 2 SUB TOTAL

n: 0 = One time check (can be omitted)

not 0 = Continuous check (To stop the test, press “C” key)

[Display]

A counter is displayed in the 7 segments to indicate that RAM check is in progress.

[Print]

The following is printed when all areas for RAM are tested.

[ 8 ] FLASH ROM PROTECT AREA CLEAR

[Function]

The area with LOCAL/CONTRAST setting is cleared.

[Operation]

Operation : 0 2 1 6 SUB TOTAL

[Print]

— 24 —

Page 27

[ 9 ] DISPLAY TEST

Command input Pattern 1 Pattern 2 END

Press Any key Press Any key

RPT

AMOUNT

T1 T2 T3 T4

TOTAL CHANGE

RPT

AMOUNT

T1 T2 T3 T4

TOTAL CHANGE

Pattern 1 Pattern 2

ABCDEFGHIJKLMOP

QRSTUVWXYZabcdef

D I S P 2 1

D I S P O K

N D 2 1

[Function]

The test of LCD/7 segment display and transaction display is performed as shown below.

[Operation]

Operation : n 2 1 SUB TOTAL

n: 0 = One time check (can be omitted)

not 0 = Continuous check (To stop the test, press “C” key)

[Print]

— 25 —

Page 28

[ 10 ] DISPLAY TEST (REPEAT)

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 1

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 2 Pattern 3

D I S P 5 2 1

D I S P O K

N D 5 2

1

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

D I S P 2 2 1

D I S P 7 S E G O K

N D 2 2

1

[Function]

The test of LCD/7 segment display and transaction display is performed as shown below.

[Operation]

Operation : 5 2 1 SUB TOTAL

To stop the test, press “C” key

[Print]

[ 11 ] 7 SEGMENT DISPLAY TEST

[Function]

The test of 7 segment display is performed as shown below.

[Operation]

Operation : 2 2 1 SUB TOTAL

To stop the test, press “C” key

[Print]

— 26 —

Page 29

[ 12 ] LCD BACKLIGHT TEST

D I S P 1 2 1

D I S P L I G H T O

K

N D 1 2

1

Command input

Pattern 1 Pattern 4

END

Press Any key Press Any key

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 3

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 1

ABCDEFGHIJKLMOP

QRSTUVWXYZabcdef

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 2

ABCDEFGHIJKLMOP

QRSTUVWXYZabcdef

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 4

D I S P 3 2 1

D I S P M A I N O K

N D 3 2

1

[Function]

LCD Backlight is turned ON/OFF.

[Operation]

Operation : c 0 1 2 1 SUB TOTAL

c: 0 = Press any button to turn “OFF” -> “ON”

1 = Backlight OFF

2 = Backlight ON

[Print]

[ 13 ] DISPLAY PATTERN TEST

[Function]

Performs an LCD display pattern test.

The test displays the 4 patterns shown below.

In run-once mode, press any key to end the test. In unlimited-run mode, set the mode to OFF to end

the test.

[Operation]

Operation : n 3 2 1 SUB TOTAL

n: 0 = One time check (can be omitted)

not 0 = Continuous check (To stop the test, press “C” key)

[Print]

— 27 —

Page 30

[ 14 ] LCD CONTRAST ADJUSTMENT TEST

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

ABCDEFGHIJKLMOP

QRSTUVWXYZabcdef

D I S P 4 2 1

L C D C O N T R A S T E S C

E N D 4 2 1

L C D C O N T R A S T N G

L C D C O N T R A S T O V R

L C D C O N T R A S T E S C

[Function]

Adjusts the LCD contrast and writes the adjustment to the FLASH ROM.

Up to 16 adjustments can be written to the FLASH ROM. If more than 16 adjustments are written, an

error occurs.

The contrast value when adjustment begins is the value written during the previous adjustment ("22" if

no data has been written). After the adjustment, pressing the “#1” key updates the stored adjustment

value.

[Operation]

Operation : 4 2 1 SUB TOTAL

“RECEIPT ON/OFF” button: Current contrast + 1 (dark)

“PRICE” button: Current contrast - 1 (light)

“#1” button: Confirm contrast (writes the value to FLASH ROM). Exits the adjustment sequence.

To stop the test, press “C” key.

[DISPLAY]

[Print]

XX is the adjustment value.

Printed when an error occurs.

Printed if more than 16 adjustments have been written.

Printed if you exited the sequence without setting an adjustment value.

[Operation]

Up to 16 adjustments can be written to the FLASH. If more than 16 adjustments are written, an error

occurs. In such cases, perform the following command to clear the area.

Operation : 1 0 4 2 1 SUB TOTAL

— 28 —

Page 31

[ 15 ] LCD BIT MAP TEST

Command input Pattern 1 Pattern 4 END

Press Any key Press Any key

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 3

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 1

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 2

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

Pattern 4

D I S P 6 2 1

L C D B I T M A P O

K

N D 6 2

1

[Function]

Performs an LCD display pattern test.

[Operation]

Operation : 6 2 1 SUB TOTAL

To stop the test, press “C” key.

[Print]

— 29 —

Page 32

[ 16 ] INTERNAL PRINTER CHARACTER PRINT TEST

B B B B B B B B B B B B B B B B

[FUNCTION]

This test will check the characters in the receipt/journal of the internal printer.

[Operation]

Operation : a c n 0 3 d SUB TOTAL

a: 0 = normal print out

1 = reduced size print out

c : 0 = prints character’ B’

1 = prints all characters

n : 0 = One time check

not 0 = Continuous check (To stop the test, press “C” key)

d : 3 = Recipet

4 = Journal

5 = Recipet and Journal

[Print]

1. Prints character’ B’

2. Prints all characters

Refer to the figure in the next page for the characters to be printed.

The printing order is in the order of the character code. The characters from 0x20(SP) to 0xFD(•) are

printed.

A space is printed for a code without the printing character.

A character which cannot be printed is a character within the range of the code 0x00 to 0x1F and

0xFB to 0xFF.

— 30 —

Page 33

[ 17 ] INTERNAL PRINTER GRAPHIC PATTERN PRINT TEST

Print pattern image

Print pattern image

Print pattern image

[FUNCTION]

This test will check the graphic patterns in the receipt/journal of the internal printer.

The graphic patterns and the print images are as follows;

Graphic pattern 1

Graphic pattern 2

Graphic pattern 1

Graphic pattern 2

:

: repeat (for 28 Dot line )

[Operation]

Operation : P1 P1 P1 P2 P2 P2 n 1 3 d SUB TOTAL

P1: 0 = Graphic patter 1 (change 8 bit into a decimal number and input it)

P2: 0 = Graphic patter 2 (change 8 bit into a decimal number and input it)

n: 0 = One time check

not 0 = Continuous check (To stop the test, press “C” key)

d : 3 = Recipet

4 = Journal

5 = Recipet and Journal

* Print patterns and commands

(1) Receipt, 25% pattern, continuous

Operation : 0 8 5 0 0 0 1 1 3 3 SUB TOTAL

The display unit of the print pattern image in the right is as follows;

Horizontal: dot

Vertical: do line

(2) Receipt, 50% pattern, continuous

Operation : 0 8 5 1 7 0 1 1 3 3 SUB TOTAL

The display unit of the print pattern image in the right is as follows;

Horizontal: dot

Vertical: do line

(3) Receipt, 100% pattern, continuous

Operation : 2 5 5 2 5 5 1 1 3 3 SUB TOTAL

The display unit of the print pattern image in the right is as follows;

Horizontal : dot

Vertical : do line

— 31 —

Page 34

[ 18 ] INTERNAL PRINTER DOT RATE TEST

(1) 3 dot lines

The first 3 dot lines in the 1/2 line ( 14 dot lines) out of one line are printed in all dots.

3 dot lines (printed in all dots)

11

dot lines (no printing)

3 dot lines (printed in all dots)

11

dot lines (no printing)

(2) 5 dot lines

The first 5 dot lines in the 1/2 line ( 14 dot lines) out of one line are printed in all dots.

5 dot lines (printed in all dots)

9 dot lines (no printing)

5 dot lines (printed in all dots)

9 dot lines (no printing)

(3) 7 dot lines

The first 7 dot lines in the 1/2 line ( 14 dot lines) out of one line are printed in all dots.

7 dot lines (printed in all dots)

7 dot lines (no printing)

7 dot lines (printed in all dots)

7 dot lines (no printing)

Printing image of 1/2 line

(14 dot lines)

Printing image of 1/2 line

(14 dot lines)

printing image of 1 line

(28 dot lines)

Printing image of 1/2 line

(14 dot lines)

Printing image of 1/2 line

(14 dot lines)

printing image of 1 line

(28 dot lines)

Printing image of 1/2 line

(14 dot lines)

Printing image of 1/2 line

(14 dot lines)

printing image of 1 line

(28 dot lines)

[FUNCTION]

This test will check the printing of the receipt/journal according to the following specifications.

The printing specification is reflected in 1/2 line and the only specified number of dot lines are printed

in all dots from the 1 dot line.

Note that 1/2 line is printed two times because the printing unit is one line.

[Operation]

Operation : p n 3 3 d SUB TOTAL

p: 0= 3 dot line

1 = 5 dot line

2 = 7 dot line

n: 0 = One time check

not 0 = Continuous check (To stop the test, press “C” key)

d : 3 = Recipet

4 = Journal

5 = Recipet and Journal

[Print]

— 32 —

Page 35

[ 19 ] INTERNAL PRINTER PRINT TEST

P R T 4 3 5

N D 4 3

5

COM1 30041

RTS1=1 --> CTS1=1 OK

DTR1=1 --> DSR1=1 OK

RTS1=0 --> CTS1=0 OK

DTR1=0 --> DSR1=0 OK

TxD --> RxD OK

END 30041

[FUNCTION]

Print out is performed on the internal printer receipt/journal in the following format. This test is

performed once. The number of the tests to be performed cannot be changed.

[Operation]

Operation : 4 3 5 SUB TOTAL

[Print]

Prints 3 lines from character code 0X30 to 0X8.

[ 20 ] RS232C PORT TEST

[FUNCTION]

This is the RS232C test.

The loop back test for RS232C port is performed by making the connection shown in the figure.

Refer to [ 22 ] RS232C PORT BATCH TEST the figure for RS232C port connection.

[Operation]

Operation : x n 0 4 d SUB TOTAL

x: Baud rate selection

0=2400 bps, 1=4800 bps, 2=9600 bps, 3=19.2 kbps, 4=38.4 kbps, 5=56 kbps, 6=Invalid, 7=115.2

kbps

n: 0 = One time check (can be omitted)

not 0 = Continuous check (To stop the test, press “C” key)

d: 1 = COM1 (UART1)

2 = COM2 (UART0)

[Print]

— 33 —

Page 36

[ 21 ] RS232C PORT BATCH TEST

COM BATCH

Figure : RS232C port connection

outputs "1" R "0" from the output terminal and checks the input terminal.

TxD

RxD

RTS

CTS

DTR

DSR

COM1/2

COM BATCH 40

RTS1=1 --> CTS1=1 OK

DTR1=1 --> DSR1=1 OK

RTS1=0 --> CTS1=0 OK

DTR1=0 --> DSR1=0 OK

TxD --> RxD OK

RTS2=1 --> CTS2=1 OK

RTS2=0 --> CTS2=0 OK

DTR2=0 --> DSR2=0 OK

TxD --> RxD OK

END 40

COM1

COM2

[Function]

This is the RS232C port batch test.

When performing this test, fix loop back connectors to all COM ports.

By the setting below, the loop back batch test is performed once from COM1 through COM2.

[Operation]

Operation : 4 0 SUB TOTAL

Baud rate: COM1: 19.2 kbps, COM 2: 9600 bps

Check time: one time

[Print]

— 34 —

Page 37

[ 22 ] TIME SETTING

RPT

AMOUNT

T1 T2 T3 T4

TOTAL CHANGE

06/01/01

05-49 ss

[ 23 ] TIME DISPLAY

[Function]

This sets the time and date.

When setting the time, the time and date will be displayed without inputting the fixed value.

[Operation]

(1) Date and time setting

Operation : h h m m s s 0 0 7 0 SUB TOTAL

hh: hour

mm: minutes

ss: second

Operation : y y m m d d 0 1 7 0 SUB TOTAL

yy: year

mm: month

dd: day

(2) Date and time display

Operation (time): 0 7 0 SUB TOTAL

Operation (date): 1 7 0 SUB TOTAL

Pressing

“C” key

displays the date and time in order. Pressing

the test.

[LCD]

“C” key

while the time is displayed ends

— 35 —

Page 38

[ 24 ] DRAWER OPEN TEST

D R W 9 1

D R W O

K

E N D 9

1

B U Z Z 9 2

E N D 9

2

[Function]

This test checks whether the drawer opens or not..

[Operation]

Operation : n 0 9 1 SUB TOTAL

n: 0 = One time check

not 0 = Continuous check (To stop the test, press “C” key)

[Print]

[ 25 ] BUZZER TEST

[FUNCTION]

This test checks whether the buzzer sounds or not.

One time check causes one shot buzzer to sound once, while infinite time check causes the buzzer to

sound for 500 msec. When the infinite time check is performed, press “C” key to stop the intermittent

buzzer.

[Operation]

Operation : n 0 9 2 SUB TOTAL

n: 0 = One time check

not 0 = Continuous check (To stop the test, press “C” key)

[Print]

— 36 —

Page 39

[ 26 ] KEY DISPLAY TEST

089 082

087

088 081

086

085 078

084

C

079

076 073 070

075 072 069

007 008 009

004 005 006

001 002 003

000 011 012

067 060 053

066 059 052

065 058 051

064 057 050

063 056 049

062 055

024 018

023 015

046 039 032

025

045 038

044 037

043 036

042 035

041 034048

014

013

089 082

087

088 081

086

085 078

084

C

079

076 073 070

075 072 069

007 008 009

004 005 006

001 002 003

000 011 012

067 060 053

066 059 052

065 058 051

064 057 050

063 056 049

062 055

024 018

023 015

046 039 032

025

045 038

044 037

043 036

042 035

041 034

031

030

029

028

027048

014

013

C 037 034

007 008 009

004 005 006

001 002 003

000 011 012

031 024 019

030 023 018

041 039 036

040 038 035

033 026 021

049

032 025 020

029 022 015

028 014=017

027 013

113

11

2

057

048 056

065 073

064 072

081 089

080 088

097 105

096 104

047 111

11

0

055

046 054

063 071

062 070

079 087

078 086

095 103

094 102

045 109

108

053

044 052

061 069

060 068

077 085

076 084

093 101

092 100

043 107

106

051

042 050

059 067

058 066

075 083

074 082

091 099

090 098

RPT

AMOUNT

T1 T2 T3 T4

TOTALCHANGE

11:STROKE KEY

10:COMBI KEY

KEY CODE

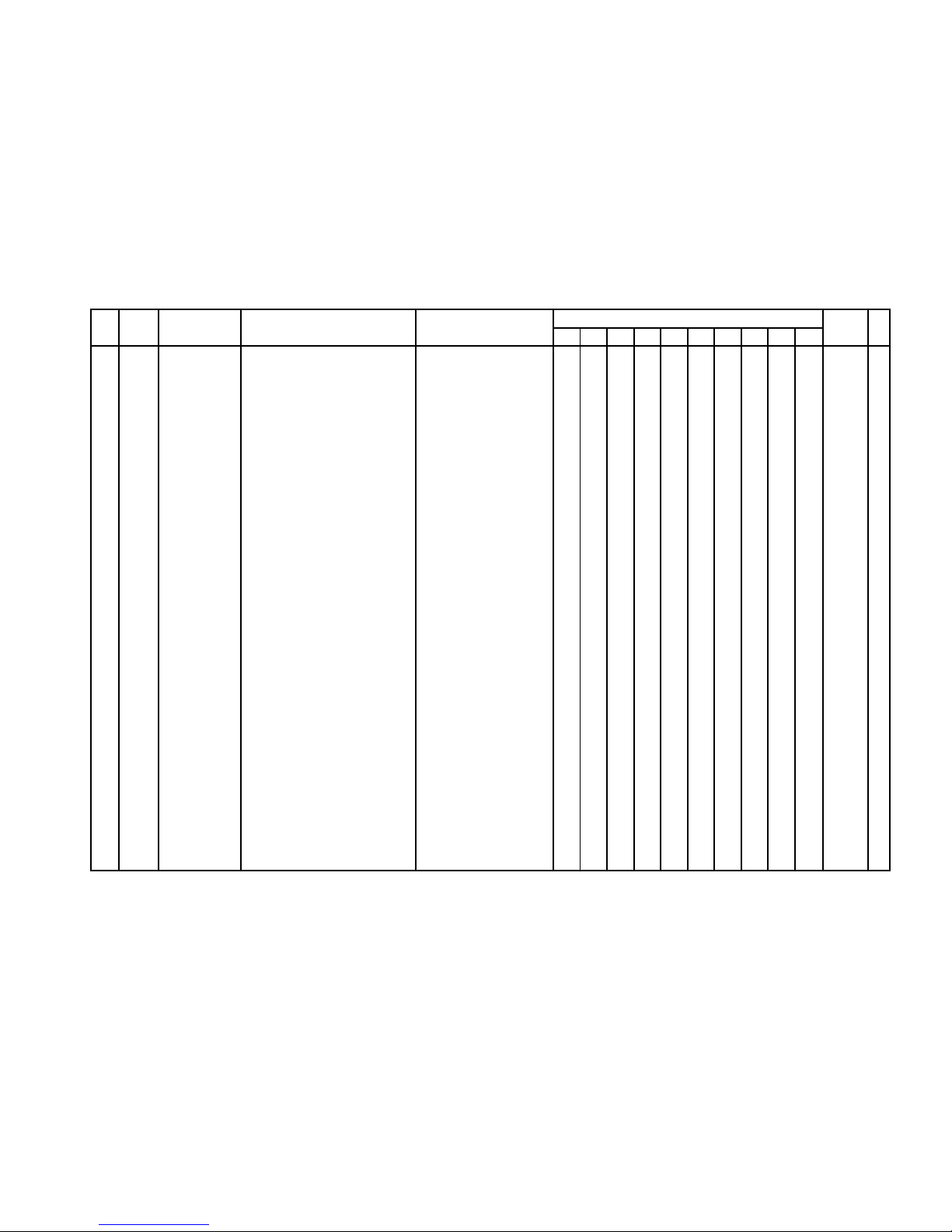

[FUNCTION]

The hard key code of a key is displayed every time any key except “C” key is pressed.

The hard key code is arranged as follows.

[Operation] [LCD]

Operation : 9 4 SUB TOTAL

To stop the test, press “C” ke

[Location of the key code]

STROKE KEY (SE-S300/SE-S2000)

STROKE KEY (SE-S300/SE-S2000)

COMBI KEY (SC-S300/SE-C2000)

— 37 —

Page 40

[ 27 ] OBR TEST

O B R 9 5

O B R O

K

O

E N D 9 5

B R E R R * * * * * * * *

[Function]

This is a scanner test. The test enters the wait mode for the scanner input, and waits only for scanner.

The test determines the result between OK and NG by comparing the fixed data and the read data.

* The fixed barcode is as follows.

[Operation]

SE-S2000/SE-C2000: COM2

SE-S300/SE-C300: COM1

Operation : 9 5 CA/AMT TEND

To stop the test, press “C” key

[Print]

When an error occurs, the read data is printed.

— 38 —

Page 41

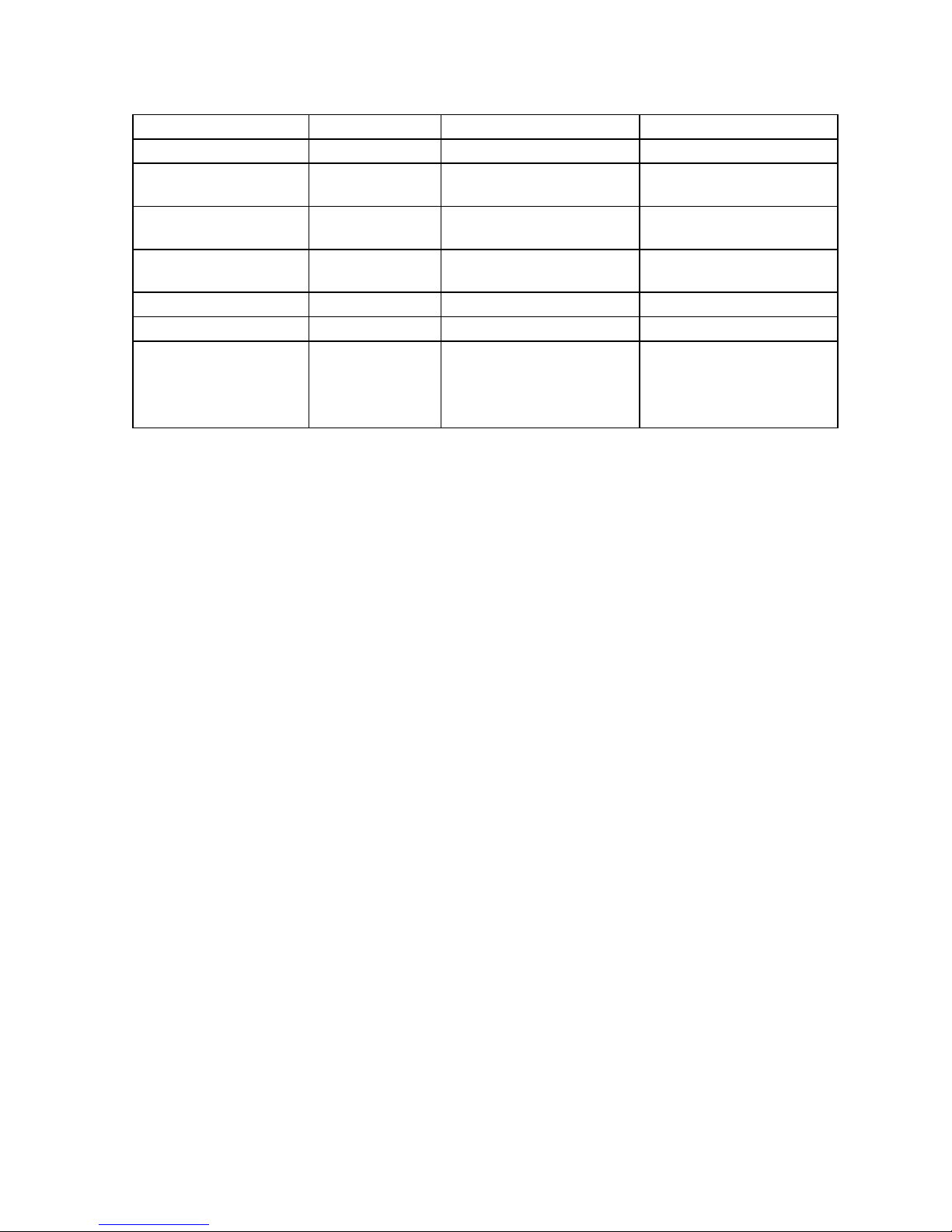

6. ERROR CODE LIST

This section describes what to do when you have problems with operation.

When an error occurs

Errors are indicated by an error codes. When this happens, you can usually find out what the problem is

as illustrated below.

Press C and check the appropriate section of this manual for the operation you want to perform.

Error

code

E001 Wrong mode Mode switch position changed before

E003 Wrong operator The signed on clerk differs from the

E004 Error INIT/FC Initialization or unit lock clear

E008 Please sign on Registration without entering a clerk

E010 Close the drawer The drawer is left open longer than the

E011 Close the drawer Attempt to register while the cash

E016 Change back to REG

E017 Enter CHK/TBL

E018 Enter Table number Attempt made to register an item

E019 Enter number of

E021 No DEPT Link No department linked PLU is

E026 Enter condiment/

E029 In the tender opera-

E031 Press ST key Finalization of a transaction attempted

E033 Enter tendered amount Finalize operation attempted without

E035 Change amount

E036 Remove money from

E037 Digit or amount

E038 Perform money

Message Meaning Action

finalization.

clerk performed the tracking check

registration.

operation in progress.

number.

program time (drawer open alarm).

drawer is open.

Two consecutive transactions

mode

number

customers

preparation PLU

tion

exceeds limit

the drawer

limitation over

declaration

attempted in the refund mode.

Attempt made to register an item

without inputting a check number.

without inputting a table number.

Finalize operation attempted without

entering the number of customer.

registered.

No condiment/preparation PLU is

registered.

Item registration is prohibited, while

partial tender.

without confirming the subtotal.

entering amount tender.

Change amount exceeds preset limit. Input amount tendered again.

Contents of the drawer exceed

programmed limit.

High amount lock out/low digit lock out

error

Read/reset operation without declaring

cash in drawer.

This error appears only when this

function is activated.

Return the mode switch to its original

setting and finalize the operation.

Input correct check number or assign

the proper clerk number.

Complete operation.

Enter a clerk number.

Close the drawer.

Shut the cash drawer.

Switch to another mode and then

back to the RF mode for the next

transaction.

Input a check number.

Input a table number.

Enter the number of customer.

Correct the program.

Register condiment/preparation PLU.

Finalize the transaction.

Press <SUBTOTAL>.

Enter the amount tendered.

Perform paidout operation.

Enter correct amount.

Perform money declaration.

— 39 —

Page 42

Error

code

E040 Issue guest receipt Attempt to register a new transaction

Message Meaning Action

Issue a guest receipt.

without issuing a guest receipt.

E046 REG buffer full Registration buffer full. Finalize the transaction.

E049 CHECK memory full Check tracking index memory full. Finalize and close the check number

currently used.

E050 DETAIL memory full Check tracking detail memory full. Finalize and close the check number

currently used.

E051 CHK/TBL No. is occu-

pied

E053 CHK/TBL No. is not

opened

Attempt to made use <New Check>

to open a new check using a number

that is already used for an existing

check in check tracking memory.

Attempt made to use <Old Check>

reopen a new check using a number

that is not used for an existing check

in check tracking memory.

Finalize and close the check that is

currently under the number that you

want to use or use a different check

number.

Use the correct check number (if you

want to reopen a check that already

exists in check tracking memory) or

use <New Check> to open a new

check.

E075 Negative balance

cannot be finalized

E101 PLU maintenance file

full. Press <#2> to exit

E103 PLU Code is not exist.

Attempt to finalize a transaction when

balance is less than or equal to zero.

Scanning PLU direct maintenance/

Register item(s) until the balance

becomes positive amount.

Terminate the maintenance.

batch maintenance file becomes full.

PLU code is not existed in the file. Enter proper PLU code.

Input the PLU Code

E105 PLU file full Scanning PLU file full Modify the designated item.

E106 Item exists in the PLU

FILE

E112 Close the journal

The designated item has already

existed in the scanning PLU file.

The journal platen arm is opened. Close the journal platen arm.

platen arm

E114 Close the receipt

The receipt platen arm is opened. Close the receipt platen arm.

platen arm

E139 Negative balance is

not allowed

Attempt to register <–> or <CPN>

when the balance becomes negative.

Enter proper minus/coupon amount.

E146 Arrangement file full Arrangement file is full. Set the arrangement properly.

E200 Insert RAC RAC is set. Set RAC.

E201 Illegal Format Illegally formatted RAC Format the RAC.

E202 File not found The designated file is not found in the

Enter proper file name.

RAC.

E205 File already exist. Can not write, because designated file

Check the operation and retry.

has already been in the RAC.

— 40 —

Page 43

7. PCB LAYOUT

MAIN PCB (E292-1 PCB)

(TOP VIEW)

— 41 —

Page 44

MAIN PCB (E292-1 PCB)

(BOTTOM VIEW)

— 42 —

Page 45

8. CIRCUIT DIAGRAMS

SE-S300/SE-S2000/SE-C300/SE-C2000

PCR-T48S/PCR-T470/PCR-T480/PCR-T470L/PCR-T480L

PCR-T220S/PCR-T2100/PCR-T2200/PCR-T2100L/PCR-T2200L

1. MAIN PCB CIRCUIT

1-1. MAIN PCB CIRCUIT 1/5 (PW,PWD,COM) ........................................................................44

1-2. MAIN PCB CIRCUIT 2/5 (CPU) .........................................................................................45

1-3. MAIN PCB CIRCUIT 3/5 (ROM,RAM,SIO) ........................................................................46

1-2. MAIN PCB CIRCUIT 4/5 (LCD,KEY,LED) .......................................................................... 47

1-3. MAIN PCB CIRCUIT 5/5 (PRT) ..........................................................................................48

SE series

TE series / TK series

TE-900/TE-1500/TK-950/TK-1550

PCR series

(EX-292/EX-293/EX-592/EX-593)

2. COM PCB CIRCUIT ...................................................................................................................49

3. DISPLAY PCB CIRCUIT ............................................................................................................50

4. REAR DISPLAY PCB CIRCUIT .................................................................................................51

— 43 —

Page 46

— 44 —

E292-1

Model

NameBoard No. Drawing No.

MAIN BOARD 1/5 (PW, PWD, COM)

RJE502513D201CASIO COMPUTER CO.,LTD. SE-S300/S2000/C300/C2000

SE-S300 and SE-C300: not used

SE-S300: not used

Page 47

— 45 —

SW1, R234, C112: not used

E292-1

Model

NameBoard No. Drawing No.

MAIN BOARD 2/5 (CPU)

RJE502513D201CASIO COMPUTER CO.,LTD. SE-S300/S2000/C300/C2000

Page 48

— 46 —

E292-1

Model

NameBoard No. Drawing No.

MAIN BOARD 3/5 (ROM, RAM, SIO)

RJE502513D201CASIO COMPUTER CO.,LTD. SE-S300/S2000/C300/C2000

R233: not used

Page 49

— 47 —

E292-1

Model

NameBoard No. Drawing No.

MAIN BOARD 4/5 (LCD, KEY, LED)

RJE502513D201CASIO COMPUTER CO.,LTD. SE-S300/S2000/C300/C2000

Page 50

— 48 —

E292-1

Model

NameBoard No. Drawing No.

MAIN BOARD 5/5 (PRT)

RJE502513D201CASIO COMPUTER CO.,LTD. SE-S300/S2000/C300/C2000

R219,220,221,222:SE-S2000 not used

SE-S300: not used

SE-S300: not used

IC22,C75,R184:SE-S300 not used

SE-S300: not used

SE-S300: not used

R223,224,225,226,227,228:SE-S2000 not used

R173:SE-S300 not used

SE-S300/C300 only

SE-S2000: not used

SE-S2000/C2000 only

SE-S300: not used

Page 51

— 49 —

E283-E22

Model

NameBoard No. Drawing No.

CON BOARDCASIO COMPUTER CO.,LTD. SE-S300/S2000/C300/C2000

SE-S2000/SE-C2000 only

Page 52

— 50 —

E292LCD-E2-1 A

Model

NameBoard No. Drawing No.

DISPLAY-BOARD RJE******D302CASIO COMPUTER CO.,LTD. SE-S300/S2000/C300/C2000

VCC

VCC

V3.0

V3.0

V3.0

VCC

VCC

-9.5V

VLCD

D1

RB161M-20TRD1RB161M-20TR

VSS

1

VIN2VO

3

NC

4

IC2

S-817A30ANB

IC2

S-817A30ANB

R1410K R1410K

J7 0J7 0

J10 0J10 0

TP16TP16

TP7TP7

VR

1

V5

2

V4

3

V3

4

V2

5

V1

6

VOUT

7

NC1

8

VSS

9

NC2

10

VDD

11

SI

12

SCL

13

A0

14

/RESET

15

/CS1B

16

CN2

IMSA-9632S-16Y917

CN2

IMSA-9632S-16Y917

*2 0*2 0

C510u C510u

TP12TP12

R3510K R3510K

C21uC2

1u

J3 0J3 0

C230.1u C230.1u

R6 2MFR6 2MF

C14100p C14100p

1A

1

1B

2

1Y

3

2A

4

2B

5

2Y

6

3A

9

3B

10

3Y

8

4A

12

4B

13

4Y

11

GND7VCC

14

IC3

SN74LV08APWR

IC3

SN74LV08APWR

R51MF R51MF

J9 0J9 0

R7 1.5MFR7 1.5MF

J2 0J2 0

1 2

L1

CDRH3D16NP-220NC

L1

CDRH3D16NP-220NC

C30

0.022u

C30

0.022u

C28

22p

C28

22p

TP8TP8

*3 0*3 0

C29

0.1u

C29

0.1u

R1210K R1210K

TP11TP11

C12100p C12100p

R1010K R1010K

R1310K R1310K

R111K R111K

D2 RB751V-40D2 RB751V-40

C3

10uC310u

R21 300R21 300

R1

68.1K

F

R1

68.1K

F

TP24TP24

PA-GPA-G

TP15TP15

C250.1u C250.1u

TP4TP4

2

13

Q1

DTA115EUAQ1DTA115EUA

TP2TP2

J60 J60

J1 0J1 0

*4 0*4 0

TP9TP9

R16 300R16 300

R18 300R18 300

C101uC10

1u

R4510K R4510K

R15 300R15 300

R17 300R17 300

R2

9.09K

F

R2

9.09K

F

C21 0.1uC21 0.1u

PA-WPA-W

TP17TP17

C15100p C15100p

TP23TP23

2

31

Q2

DTD113ZKQ2DTD113ZK

TP18TP18

J8 0J8 0

*5 0*5 0

SW

1

GND

2

FB

3

SDREF

4

D

5

Vin

6

IC1

LT3462A

IC1

LT3462A

C26

33u/10V

C26

33u/10V

TP10TP10

C91u C91u

TP22TP22

C81u C81u

R8 510KR8 510K

C71u C71u

R24 300R24 300

GND1

1

RESET

2

VCC

3

/CS_1B

4

AD

5

/LED_ON

6

S_DATA

7

S_CLK

8

GND2

9

CN3

A2001WR2-9P

CN3

A2001WR2-9P

A_White

1

A_Geen

2

NC

3

Cathode

4

CN1

BM04B-SRSS

CN1

BM04B-SRSS

C19100p C19100p

C13100p C13100p

TP3TP3

OUT4IN B

1

IN A

2

GND3Vcc

5

IC4

SN74LVC1G08DCKR

IC4

SN74LVC1G08DCKR

C18100p C18100p

TP5TP5

R22 300R22 300

R20 300R20 300

C20100p C20100p

J5 0J5 0

C17100p C17100p

C24 0.1uC24 0.1u

C61u C61u

TP14TP14

TP19TP19

PA-BPA-B

C1 1uC1 1u

R9 510KR9 510K

C16100p C16100p

*1 0*1 0

TP6TP6

C22

100u/10V

C22

100u/10V

C11100p C11100p

TP21TP21

R19 300R19 300R23 300R23 300

J4 0J4 0

TP20TP20

C4

33u/10VC433u/10V

TP13TP13

Page 53

— 51 —

E283-E22

Model

NameBoard No. Drawing No.

REAR-DISPLAY-BOARD RJE502391D307CASIO COMPUTER CO.,LTD. SE-S300/S2000/C300/C2000

HDSP-521G

D4

HDSP-521G

D3

f1

b2

a2

f2

DI2

DI1

b1a1g1

e1

DP2c2g2d2e2

DP1c1d1

181716151413121110

123456789

f1

b2

a2

f2

DI2

DI1

b1a1g1

e1

DP2c2g2d2e2

DP1c1d1

181716151413121110

123456789

HDSP-521G

D2

f1

b2

a2

f2

DI2

DI1

b1a1g1

e1

DP2c2g2d2e2

DP1c1d1

181716151413121110

123456789

HDSP-521G

D1

f1

b2

a2

f2

DI2

DI1

b1a1g1

e1

DP2c2g2d2e2

DP1c1d1

181716151413121110

123456789

DG3

DG2

SB1

SF1

SA1

SD1

SE1

SC1

SG1

DG3

DG2

SB1

SF1

SA1

SD1

SE1

SC1

SG1

1

2

3

4

5

6

7

8

9

CN1

IMSA-9610S-09B-TC

SDP1

SB0

SF0

SA0

SC0

SD0

SDP0

SE0

SG0

DG0

DG1

STR

SDP1

SB0

SF0

SA0

SC0

SD0

SDP0

SE0

SG0

DG0

DG1

STR

1

2

3

4

5

6

7

8

9

10

11

12

CN2

IMSA-9610S-12B-TC

DG0

DG1

D6D7HLMP-S501

HLMP-S501

Page 54

9. PARTS LIST

SE series

SE-S300/SE-S2000/SE-C300/SE-C2000

TE series / TK series

TE-900/TE-1500/TK-950/TK-1550

PCR series

PCR-T48S/PCR-T470/PCR-T480/PCR-T470L/PCR-T480L

PCR-T220S/PCR-T2100/PCR-T2200/PCR-T2100L/PCR-T2200L

(EX-292/EX-293/EX-592/EX-593)

EXPLODED VIEW

BODY ............................................................................................................53

BUTTON BLOCK (STROKE) ........................................................................54

BUTTON BLOCK (COMBINATION) .............................................................55

PARTS LIST

SE series ...........................................................................................................56

SE-S300/SE-S2000/SE-C300/SE-C2000

TE series / TK series .........................................................................................60

TE-900/TE-1500/TK-950/TK-1550

PCR series ........................................................................................................64

PCR-T48S/PCR-T470/PCR-T480/PCR-T470L/PCR-T480L

PCR-T220S/PCR-T2100/PCR-T2200/PCR-T2100L/PCR-T2200L

DRAWER

DRAWER S type .............................................................................................68

DL-1331/DL-1332/DL-1842

DRAWER M type ............................................................................................70

NOTES :

1. Price and specifications are subject to change withput prior notice.

2.

As for spare parts order and supply, refer to the “GUIDEBOOK for Spare Parts Supply”, published separately.

3. The numbers in item column corespond to the same numbers in drawing.

4. CASIO does not supply the spare parts without parts code.

5. Remarks

Q'ty: Quantity used per unit

RANK: A = Essential

B = Stock recommended

C = Less recommended

X = No stock recommended

DL-2800/DL-2801/DL-2802/DL-2803/DL-2804/DL-2805/DL-2806/DL-2807/DL-2432/DL-2433

— 52 —

Page 55

EXPLODED VIEW (BODY)

1

77

2

84

76

84

76

3

4

63

99

90

78

74

73

75

81

82

80

85

89

91

86

83

88

79

87

69

70

72

98

64

65

66

5

6 7

8

67

71

91

91

94

96

93

95

92

92

91

94

92

68

68

101

102

103

100

SE-S2000/SE-C2000/TE-1500/TK-1550/

PCR-T220S/2100/2100L/2200/2200L

SE-S300/SE-C300/

TE-900/TK-950/

PCR-T48S/470/470L/480/480L

— 53 —

Page 56

BUTTON BLOCK (STROKE) SE-S300/SE-S2000/TE-900/TE-1500/PCR series

9

24

23

22

10 21to

28

29

30

27

34

33

32

31

26

25

— 54 —

Page 57

BUTTON BLOCK (COMBINATION) SE-C300/SE-C2000/TK-950/TK-1550

35

52

54

59

4736

~

4736

~

48

48

50

49

51

53

55

57

56

58 58

60

61

62

— 55 —

Page 58

1 SE-S300

1 2 3 4

1.MAIN PCB BLOCK

1 10306296 PCB ASSY/E292-1 TK-RJE502623*001 1 1 A

1 10306297 PCB ASSY/E292-1 TK-RJE502623*002 1 1 A

C5,C29,C45,C48,

C60,C61,C103

10216488 AL CAPACITOR RE3-16V101ME3# 7 7 7 7 A

IC11 10003984 IC/MOS SN74LV00APWR 1 1 1 1 A

IC12,IC16 10005659 IC/MOS SN74LV08APWR 2 2 2 2 A

IC3 10007179 IC/MOS SN74LV10APWR 1 1 1 1 A

IC9,IC10 10275578 IC/MOS SN74LVC374APWR 2 2 2 2 A

IC30 10100704 IC/MOS SN74LVC2G04DCKR 1 1 1 1 A

D2,D4 10157825 DIODE RB520G-30T2R 2 2 2 2 A

Q2 10028955 FET 2SK3018T106 1 1 1 1 A

IC17 10116986 IC SN74AHCT1G08DCKR 1 1 1 1 A

IC23 10214145 IC BA2903F-E2 1 1 A

IC22,IC23 10214145 IC BA2903F-E2 2 2 A

IC2 10241776 IC BA50BC0T 1 1 1 1 A

IC25 10278149 IC BD7050EFV-E2 1 1 A

IC24,IC25 10278149 IC BD7050EFV-E2 2 2 A

IC6 10295605 IC MAX3243ECPWR 1 1 A

IC5,IC6 10295605 IC MAX3243ECPWR 2 2 A

IC18 10275575 IC RV5C348A-E2-FB 1 1 1 1 A

IC13 10132445 IC SN74LVC1G00DCKR 1 1 1 1 A

IC29 10184975 IC SN74LVC2G74DCUR 1 1 1 1 A

IC21,IC26,IC27 10005721 IC SN74LV244APWR 3 3 A

IC1 10251631 IC XC6108N10AMR 1 1 1 1 A

IC7 10275826 IC XC61CN2402MR 1 1 1 1 A

IC4 10275573 IC XC6215B332MR 1 1 1 1 A

IC15 10256784 LSI CY62146EV30LL45ZST 1 1 1 1 A

IC14 10194558 LSI S29JL032H70TFI020 1 1 1 1 A

IC8 10299661 LSI UPD70F3733GJUENABB 1 1 1 1 A

D1,D5,D7-D22 10009218 DIODE 1SS400TE61 18 18 18 18 B

Q5 10275630 MOSFET/CHIP RTF010P02TL 1 1 1 1 B

Q13 10275631 MOSFET/CHIP RTF025N03TL 1 1 1 1 B

D6,D23 23902058 DIODE/CHIP 1SR154-400TE25 2 2 2 2 B

D3 10275792 DIODE/CHIP RB160M-30TR 1 1 1 1 B

Q8-Q10,Q12 10120138 TRANSISTOR 2SA2018-TL 4 4 4 4 B

Q3,Q6,Q7,Q11 25902697 TRANSISTOR/DIGITAL DTC114EETL 4 4 4 4 B

C102 10204411 CAPACITOR/ELECTROLYTIC RE3-16V332MI6# 1 1 1 1 B

Q1 22501601 TRANSISTOR 2SC4617TLQ 1 1 1 1 B

Q4 10288938 TRANSISTOR RHP030N03 1 1 1 1 B

Q14 10241779 TRANSISTOR RSS090P03TB 1 1 1 1 B

FU1 10225980 FUSE 230.600MXP 1 1 1 1 A

SP1 10241792 BUZZER AW1S22TEP-251Z 1 1 1 1 C

IC19,IC20 10295606 IC/MONOLITHIC ULN2003ADR 2 2 2 2 A

2.MAIN DISPLAY BLOCK

2 10306298 PCB ASSY/E292LCD-E2-1 TK-RJE502626*001 1 1 1 1 A

3 10288659 LCD UNIT JIC-MSGF10360-06 1 1 1 1 A

IC1 10294213 IC LT3462AES6#TRPBF 1 1 1 1 A

IC2 10197366 IC S-817A30ANB-CUTT2G 1 1 1 1 A

IC3 10005659 CMOS IC SN74LV08APWR 1 1 1 1 A

IC4 10207634 IC SN74LVC1G08DCKR 1 1 1 1 A

Q1 10127459 TRANSISTOR/DIGITAL DTA115EUAT106 1 1 1 1 C

Q2 22592781 TRANSISTOR/DIGITAL DTD113ZKT146 1 1 1 1 C

CN2 10204342 CONNECTOR IMSA-9632S-16Y917 1 1 1 1 C

CN3 10273693 CONNECTOR A2001WR2-9P 1 1 1 1 C

R

Price

code

SpecificationN Item Code No. Parts Name

Q

Remarks

2 SE-S2000

3 SE-C300

4 SE-C2000

— 56 —

Page 59

1 SE-S300

1 2 3 4

3.CUSTOMER DISPLAY BLOCK

4 10272394 CASE/REAR DISPLAY RJE502341-001V01 1 1 1 1 C

5 10272398 PANEL/REAR DISPLAY RJE502347-001V01 1 1 1 1 C

6 10275915 CABLE/FFC JOINER E441341-011V01 1 1 1 1 C

7 10275916 CABLE/FFC JOINER E441341-012V01 1 1 1 1 C

8 10275677 PCB ASSY/E283-E22 RJE502385*001V01 1 1 1 1 A

D1,D2,D3,D4 10072597 LED/7SEG HDSP-521G 4 4 4 4 B

4.BUTTON BLOCK (STROKE)

9 10291844 FLAME/KEY RJE502288-001V02 1 1 X

10 10295298 BUTTON/1 RJE501915-037V01 1 1 X

11 10295299 BUTTON/2 RJE501915-038V01 1 1 X

12 10295300 BUTTON/3 RJE501915-039V01 1 1 X

13 10295301 BUTTON/4 RJE501915-040V01 1 1 X

14 10295302 BUTTON/5 RJE501915-041V01 1 1 X

15 10295303 BUTTON/6 RJE501915-042V01 1 1 X

16 10295304 BUTTON/7 RJE501915-043V01 1 1 X

17 10295325 BUTTON/8 RJE501915-044V01 1 1 X

18 10295326 BUTTON/9 RJE501915-045V01 1 1 X

19 10300642 BUTTON/0 RJE501915-046V02 1 1 X

20 10300643 BUTTON/. RJE501915-047V02 1 1 X

21 10300644 BUTTON/00 RJE501915-048V02 1 1 X

22 10241195 CAP/S E341251-002V02 51 56 A

23 10241196 CAP/L RJE500370-002V02 3 3 A

24 10274307 CAP/LLL RJE500374-002V02 1 1 A

25 10072609 KEYTOP/S E341250-1 63 68 A

26 10233587 KEYTOP/L RJE500369-004V02 3 3 A

27 10235021 KEYTOP/LLL RJE500372-003V02 1 1 A

28 10166869 RUBBER/CONTACT RJE501209-001V01 67 72 B

29 10072611 SPRING/COMPRESS E441298-1 4 4 C

30 10072612 SPRING/COMPRESS E441298-2 6 6 C

31 10276423 SHEET/COMMON RJE502283-001V01 1 1 B

32 10276424 SPACER RJE502284-001V01 1 1 C

33 10276422 SHEET/FPC RJE502282-001V01 1 1 B

34 10274354 CHASSIS/BUTTON RJE502285-001V01 1 1 C

5.BUTTON BLOCK (COMBINATION)

35 10291843 FLAME/KEY RJE502272-002V02 1 1 X

36 10300645 BUTTON/1 RJE501915-049V02 1 1 X

37 10300646 BUTTON/2 RJE501915-050V02 1 1 X

38 10300647 BUTTON/3 RJE501915-051V02 1 1 X

39 10300649 BUTTON/4 RJE501915-052V02 1 1 X

40 10300650 BUTTON/5 RJE501915-053V02 1 1 X

41 10300651 BUTTON/6 RJE501915-054V02 1 1 X

42 10300652 BUTTON/7 RJE501915-055V02 1 1 X

43 10300653 BUTTON/8 RJE501915-056V02 1 1 X

44 10300654 BUTTON/9 RJE501915-057V02 1 1 X

45 10300655 BUTTON/0 RJE501915-058V02 1 1 X

46 10300656 BUTTON/. RJE501915-059V02 1 1 X

47 10299891 BUTTON/00 RJE501915-060V02 1 1 X

48 10241195 CAP/S E341251-002V02 26 26 A

49 10241196 CAP/L RJE500370-002V02 2 2 A

50 10088889 KEYTOP/S E341250-2 38 38 A

51 10241194 KEYTOP/L RJE500369-002V02 2 2 A

52 10276644 RUBBER/CONTACT RJE502275-001V01 1 1 B

53 10072611 SPRING/COMPRESS E441298-1 2 2 C

54 10276639 SHEET/COMMON RJE502268-001V01 1 1 C

N RemarksItem Code No. Parts Name Specification

Q

Price

code

R

2 SE-S2000

3 SE-C300

4 SE-C2000

— 57 —

Page 60

1 SE-S300

1 2 3 4

55 10276640 SPACER RJE502269-001V01 1 1 C

56 10276638 SHEET/FPC RJE502267-001V01 1 1 B

57 10276642 CHASSIS/BUTTON RJE502270-001V01 1 1 C

58 10166869 RUBBER/CONTACT RJE501209-001V01 40 B

59 10276641 SPACER RJE502269-002V01 1 1 C

60 10276643 CHASSIS/BUTTON RJE502271-001V01 1 1 C

61 10276743 SHEET/NO SLIP RJE502277-001V01 1 1 B

62 10276740 COVER/SHEET RJE502435-001V01 1 1 B

6.UPPER CASE BLOCK

63 10294951 CASE/UPPER RJE502348-005V01 1 C

63 10294958 CASE/UPPER RJE502348-007V01 1 C

63 10294885 CASE/UPPER RJE502348-009V01 1 C

63 10294894 CASE/UPPER RJE502348-010V01 1 C

64 10269751 BUSH/REAR DISPLAY RJE502265-001V01 1 1 C

64 10276416 BUSH/REAR DISPLAY RJE502265-002V01 1 1 C

65 10072504 SWITCH ASSY/MODE KEY E341249*1 1 1 1 1 B

66 10291888 COVER/MK RJE502607-001V01 1 1 1 1 C

67 10242021 CUSHION/LCD RJE500743-003V01 2 2 2 2 X

68 10242022 CUSHION/LCD RJE500743-004V01 2 2 2 2 X

69 10236319 CUTTER/PAPER E441364-003V02 1 1 1 1 C

70 10284497 TAPE/ADHESIVE RJE502542-002V01 1 1 1 1 X

71 10284495 TAPE/ADHESIVE RJE502542-003V01 2 2 2 2 X

72 10291886 PANEL/DISPLAY RJE502606-001V01 1 C

72 10294959 PANEL/DISPLAY RJE502606-004V01 1 C

72 10294886 PANEL/DISPLAY RJE502606-007V01 1 C

72 10294887 PANEL/DISPLAY RJE502606-009V01 1 C

7.LOWER CASE BLOCK

73 10291880 CASE/LOWER RJE502598-001V01 1 C

73 10291881 CASE/LOWER RJE502598-002V01 1 C

73 10291882 CASE/LOWER RJE502598-003V01 1 C

73 10291883 CASE/LOWER RJE502598-004V01 1 C

74 10142488 ROLLER/RP RJE500850-001V01 1 1 1 1 B

75 10236328 ROLLER/RP RJE500121-001V02 1 1 B

76 10291407 CABLE/FFC JOINER E441341-014V02 1 1 1 1 B

77 10292223 HOLDER/IC RJE502611-001V01 1 1 1 1 C

78 10276594 PIVOT RJE502342-001V01 1 C

78 10276595 PIVOT RJE502342-002V01 1 C

79 10282328 CABLE RJE502396*001V02 1 1 1 1 B

80 63452238 SPRING/BATTERY A42606B-1 1 1 1 1 C

81 10294939 SPRING/BATTERY RJE502620-001V01 1 1 1 1 C

82 10294940 SPRING/BATTERY RJE502622-001V01 1 1 1 1 C

83 10282081 CABLE/BATTERY RJE502392*001V02 1 1 1 1 C

84 10306299 PCB ASSY/E292-COM TK-RJE502628*001 1 A

84 10306300 PCB ASSY/E292-COM TK-RJE502628*002 1 1 A

85 10291846 COVER/CONNECTOR RJE502339-001V02 1 1 C

85 10291847 COVER/CONNECTOR RJE502339-002V02 1 1 C

86 10291884 COVER/BATTERY RJE502601-001V01 1 1 C

86 10291885 COVER/BATTERY RJE502601-002V01 1 1 C

87 10248009 CORE/FERRITE TR-22-14-6.5 1 1 1 1 X

88 10292218 COVER/CONNECTOR/RAC RJE502602-001V01 1 1 C

88 10292219 COVER/CONNECTOR/RAC RJE502602-002V01 1 1 C

8.MOTOR BLOCK

89 10234746 RUBBER/WINDER RJE502008-001V01 1 1 1 1 C

90 10282326 CONNECTOR ASSY/MOTOR RJE502393*001V02 1 1 1 1 C

91 10264935 MOTOR WRF-370C-13380 1 1 1 1 B

Item Code No. Parts Name RemarksSpecification

Q

Price

code

RN

2 SE-S2000

3 SE-C300

4 SE-C2000

— 58 —

Page 61

1 SE-S300

1 2 3 4

9.PRINTER BLOCK

92 10272412 PRINTER/THERMAL FTP-628MCL518#67 1 2 1 2 A

93 10262839 STOPPER RJE502189-001V01 1 2 1 2 C

94 10287458 ARM/PLATEN J RJE502343-001V02 1 1 1 1 C

95 10272396 ARM/PLATEN R RJE502344-001V01 1 1 C

96 10298675 PULLY/WIND RJE501880-001V02 1 1 1 1 A

97 10285007 SPOOL/PAPER RJE502545-001V01 1 1 1 1 A

98 10294917 COVER/PRINTER RJE502345-006V01 1 1 C

98 10294923 COVER/PRINTER RJE502345-007V01 1 1 C

10.OTHERS

99 10276596 AC ADAPTOR SO1224A 1 1 1 1 C

100 10254924 KEY SET/MODE SW RJE500074*002V03 1 1 1 1 C

101 10300534 CORD/POWER 2166H10C3 C USA

102 30008016 CORE/FERRITE TFC-23-11-14 1 1 1 1 X

103 10127255 CUSHION RJE500743-001V01 1 1 1 1 X

RemarksN Item Code No. Parts Name Specification

Q

Price

code

R

2 SE-S2000

3 SE-C300

4 SE-C2000

— 59 —

Page 62

1 TE-900

1 2 3 4

1.MAIN PCB BLOCK

1 10306296 PCB ASSY/E292-1 TK-RJE502623*001 1 1 A

1 10306297 PCB ASSY/E292-1 TK-RJE502623*002 1 1 A

C5,C29,C45,C48,

C60,C61,C103

10216488 AL CAPACITOR RE3-16V101ME3# 7 7 7 7 A

IC11 10003984 IC/MOS SN74LV00APWR 1 1 1 1 A

IC12,IC16 10005659 IC/MOS SN74LV08APWR 2 2 2 2 A

IC3 10007179 IC/MOS SN74LV10APWR 1 1 1 1 A

IC9,IC10 10275578 IC/MOS SN74LVC374APWR 2 2 2 2 A

IC30 10100704 IC/MOS SN74LVC2G04DCKR 1 1 1 1 A

D2,D4 10157825 DIODE RB520G-30T2R 2 2 2 2 A

Q2 10028955 FET 2SK3018T106 1 1 1 1 A

IC17 10116986 IC SN74AHCT1G08DCKR 1 1 1 1 A

IC23 10214145 IC BA2903F-E2 1 1 A

IC22,IC23 10214145 IC BA2903F-E2 2 2 A

IC2 10241776 IC BA50BC0T 1 1 1 1 A

IC25 10278149 IC BD7050EFV-E2 1 1 A

IC24,IC25 10278149 IC BD7050EFV-E2 2 2 A

IC6 10295605 IC MAX3243ECPWR 1 1 A

IC5,IC6 10295605 IC MAX3243ECPWR 2 2 A

IC18 10275575 IC RV5C348A-E2-FB 1 1 1 1 A

IC13 10132445 IC SN74LVC1G00DCKR 1 1 1 1 A

IC29 10184975 IC SN74LVC2G74DCUR 1 1 1 1 A

IC21,IC26,IC27 10005721 IC SN74LV244APWR 3 3 A

IC1 10251631 IC XC6108N10AMR 1 1 1 1 A

IC7 10275826 IC XC61CN2402MR 1 1 1 1 A

IC4 10275573 IC XC6215B332MR 1 1 1 1 A

IC15 10256784 LSI CY62146EV30LL45ZST 1 1 1 1 A

IC14 10194558 LSI S29JL032H70TFI020 1 1 1 1 A

IC8 10299661 LSI UPD70F3733GJUENABB 1 1 1 1 A

D1,D5,D7-D22 10009218 DIODE 1SS400TE61 18 18 18 18 B

Q5 10275630 MOSFET/CHIP RTF010P02TL 1 1 1 1 B

Q13 10275631 MOSFET/CHIP RTF025N03TL 1 1 1 1 B

D6,D23 23902058 DIODE/CHIP 1SR154-400TE25 2 2 2 2 B

D3 10275792 DIODE/CHIP RB160M-30TR 1 1 1 1 B

Q8-Q10,Q12 10120138 TRANSISTOR 2SA2018-TL 4 4 4 4 B

Q3,Q6,Q7,Q11 25902697 TRANSISTOR/DIGITAL DTC114EETL 4 4 4 4 B

C102 10204411 CAPACITOR/ELECTROLYTIC RE3-16V332MI6# 1 1 1 1 B

Q1 22501601 TRANSISTOR 2SC4617TLQ 1 1 1 1 B

Q4 10288938 TRANSISTOR RHP030N03 1 1 1 1 B

Q14 10241779 TRANSISTOR RSS090P03TB 1 1 1 1 B

FU1 10225980 FUSE 230.600MXP 1 1 1 1 A

SP1 10241792 BUZZER AW1S22TEP-251Z 1 1 1 1 C

IC19,IC20 10295606 IC/MONOLITHIC ULN2003ADR 2 2 2 2 A

2.MAIN DISPLAY BLOCK

2 10306298 PCB ASSY/E292LCD-E2-1 TK-RJE502626*001 1 1 1 1 A

3 10288659 LCD UNIT JIC-MSGF10360-06 1 1 1 1 A

IC1 10294213 IC LT3462AES6#TRPBF 1 1 1 1 A

IC2 10197366 IC S-817A30ANB-CUTT2G 1 1 1 1 A

IC3 10005659 CMOS IC SN74LV08APWR 1 1 1 1 A

IC4 10207634 IC SN74LVC1G08DCKR 1 1 1 1 A

Q1 10127459 TRANSISTOR/DIGITAL DTA115EUAT106 1 1 1 1 C

Q2 22592781 TRANSISTOR/DIGITAL DTD113ZKT146 1 1 1 1 C

CN2 10204342 CONNECTOR IMSA-9632S-16Y917 1 1 1 1 C

CN3 10273693 CONNECTOR A2001WR2-9P 1 1 1 1 C

SpecificationN Item Code No. Parts Name

Q

R Remarks

Price

code

2 TE-1500

3 TK-950

4 TK-1550

— 60 —

Page 63

1 TE-900

1 2 3 4

3.CUSTOMER DISPLAY BLOCK

4 10272394 CASE/REAR DISPLAY RJE502341-001V01 1 1 1 1 C

5 10272398 PANEL/REAR DISPLAY RJE502347-001V01 1 1 1 1 C

6 10275915 CABLE/FFC JOINER E441341-011V01 1 1 1 1 C

7 10275916 CABLE/FFC JOINER E441341-012V01 1 1 1 1 C

8 10275677 PCB ASSY/E283-E22 RJE502385*001V01 1 1 1 1 A

D1,D2,D3,D4 10072597 LED/7SEG HDSP-521G 4 4 4 4 B

4.BUTTON BLOCK (STROKE)

9 10291845 FLAME/KEY RJE502288-002V02 1 1 X

10 10300645 BUTTON/1 RJE501915-049V02 1 1 X

11 10300646 BUTTON/2 RJE501915-050V02 1 1 X

12 10300647 BUTTON/3 RJE501915-051V02 1 1 X

13 10300649 BUTTON/4 RJE501915-052V02 1 1 X

14 10300650 BUTTON/5 RJE501915-053V02 1 1 X

15 10300651 BUTTON/6 RJE501915-054V02 1 1 X

16 10300652 BUTTON/7 RJE501915-055V02 1 1 X

17 10300653 BUTTON/8 RJE501915-056V02 1 1 X

18 10300654 BUTTON/9 RJE501915-057V02 1 1 X

19 10300655 BUTTON/0 RJE501915-058V02 1 1 X

20 10300656 BUTTON/. RJE501915-059V02 1 1 X

21 10299891 BUTTON/00 RJE501915-060V02 1 1 X

22 10241195 CAP/S E341251-002V02 51 58 A

23 10241196 CAP/L RJE500370-002V02 3 2 A

24 10274307 CAP/LLL RJE500374-002V02 1 1 A

25 10088889 KEYTOP/S E341250-2 63 70 A

26 10241194 KEYTOP/L RJE500369-002V02 3 2 A

27 10276421 KEYTOP/LLL RJE500372-002V02 1 1 A

28 10166869 RUBBER/CONTACT RJE501209-001V01 67 73 B

29 10072611 SPRING/COMPRESS E441298-1 4 3 C

30 10072612 SPRING/COMPRESS E441298-2 6 6 C

31 10276423 SHEET/COMMON RJE502283-001V01 1 1 B

32 10276424 SPACER RJE502284-001V01 1 1 C

33 10276422 SHEET/FPC RJE502282-001V01 1 1 B

34 10274354 CHASSIS/BUTTON RJE502285-001V01 1 1 C

5.BUTTON BLOCK (COMBINATION)

35 10291843 FLAME/KEY RJE502272-002V02 1 1 X

36 10300645 BUTTON/1 RJE501915-049V02 1 1 X

37 10300646 BUTTON/2 RJE501915-050V02 1 1 X

38 10300647 BUTTON/3 RJE501915-051V02 1 1 X

39 10300649 BUTTON/4 RJE501915-052V02 1 1 X

40 10300650 BUTTON/5 RJE501915-053V02 1 1 X

41 10300651 BUTTON/6 RJE501915-054V02 1 1 X

42 10300652 BUTTON/7 RJE501915-055V02 1 1 X

43 10300653 BUTTON/8 RJE501915-056V02 1 1 X

44 10300654 BUTTON/9 RJE501915-057V02 1 1 X

45 10300655 BUTTON/0 RJE501915-058V02 1 1 X

46 10300656 BUTTON/. RJE501915-059V02 1 1 X

47 10299891 BUTTON/00 RJE501915-060V02 1 1 X

48 10241195 CAP/S E341251-002V02 26 26 A

49 10241196 CAP/L RJE500370-002V02 2 2 A

50 10088889 KEYTOP/S E341250-2 38 38 A

51 10241194 KEYTOP/L RJE500369-002V02 2 2 A

52 10276644 RUBBER/CONTACT RJE502275-001V01 1 1 B

53 10072611 SPRING/COMPRESS E441298-1 2 2 C

N Item Code No. Parts Name Specification

Price

code

R Remarks

Q

2 TE-1500

3 TK-950

4 TK-1550

— 61 —

Page 64

1 TE-900

1 2 3 4

54 10276639 SHEET/COMMON RJE502268-001V01 1 1 C

55 10276640 SPACER RJE502269-001V01 1 1 C

56 10276638 SHEET/FPC RJE502267-001V01 1 1 B

57 10276642 CHASSIS/BUTTON RJE502270-001V01 1 1 C

58 10166869 RUBBER/CONTACT RJE501209-001V01 40 40 B

59 10276641 SPACER RJE502269-002V01 1 1 C

60 10276643 CHASSIS/BUTTON RJE502271-001V01 1 1 C

61 10276743 SHEET/NO SLIP RJE502277-001V01 1 1 B

62 10276740 COVER/SHEET RJE502435-001V01 1 1 B

6.UPPER CASE BLOCK

63 10294954 CASE/UPPER RJE502348-006V01 1 C

63 10294882 CASE/UPPER RJE502348-008V01 1 C

63 10294885 CASE/UPPER RJE502348-009V01 1 C

63 10294894 CASE/UPPER RJE502348-010V01 1 C

64 10276416 BUSH/REAR DISPLAY RJE502265-002V01 1 1 1 1 C

65 10072504 SWITCH ASSY/MODE KEY E341249*1 1 1 1 1 B

66 10291888 COVER/MK RJE502607-001V01 1 1 1 1 C

67 10242021 CUSHION/LCD RJE500743-003V01 2 2 2 2 X

68 10242022 CUSHION/LCD RJE500743-004V01 2 2 2 2 X

69 10236319 CUTTER/PAPER E441364-003V02 1 1 1 1 C

70 10284497 TAPE/ADHESIVE RJE502542-002V01 1 1 1 1 X

71 10284495 TAPE/ADHESIVE RJE502542-003V01 2 2 2 2 X

72 10295911 PANEL/DISPLAY RJE502606-011V01 1 C

72 10295913 PANEL/DISPLAY RJE502606-012V01 1 C

72 10295914 PANEL/DISPLAY RJE502606-013V01 1 C

72 10295916 PANEL/DISPLAY RJE502606-014V01 1 C

7.LOWER CASE BLOCK

73 10291881 CASE/LOWER RJE502598-002V01 1 1 C

73 10291883 CASE/LOWER RJE502598-004V01 1 1 C

74 10142488 ROLLER/RP RJE500850-001V01 1 1 1 1 B

75 10236328 ROLLER/RP RJE500121-001V02 1 1 B

76 10291407 CABLE/FFC JOINER E441341-014V02 1 1 1 1 B

77 10292223 HOLDER/IC RJE502611-001V01 1 1 1 1 C

78 10276595 PIVOT RJE502342-002V01 1 1 C

79 10282328 CABLE RJE502396*001V02 1 1 1 1 B

80 63452238 SPRING/BATTERY A42606B-1 1 1 1 1 C

81 10294939 SPRING/BATTERY RJE502620-001V01 1 1 1 1 C

82 10294940 SPRING/BATTERY RJE502622-001V01 1 1 1 1 C

83 10282081 CABLE/BATTERY RJE502392*001V02 1 1 1 1 C

84 10306299 PCB ASSY/E292-COM TK-RJE502628*001 1 1 A

84 10306300 PCB ASSY/E292-COM TK-RJE502628*002 1 1 A

85 10291847 COVER/CONNECTOR RJE502339-002V02 1 1 1 1 C

86 10291885 COVER/BATTERY RJE502601-002V01 1 1 1 1 C

87 10248009 CORE/FERRITE TR-22-14-6.5 1 1 1 1 X

88 10292219 COVER/CONNECTOR/RAC RJE502602-002V01 1 1 1 1 C

8.MOTOR BLOCK

89 10234746 RUBBER/WINDER RJE502008-001V01 1 1 1 1 C

90 10282326 CONNECTOR ASSY/MOTOR RJE502393*001V02 1 1 1 1 C

91 10264935 MOTOR WRF-370C-13380 1 1 1 1 B

N Item Code No. Parts Name Specification

Price

code

R Remarks

Q

2 TE-1500

3 TK-950