SENSUS Digital Data Logger -

Users Handbook

Digital Data Logger

Users Handbook

April 2002

SENSUS

HB3290-01

COPYRIGHT

The copyright in this document which contains proprietary information is vested in

CASELLA CEL LIMITED. The contents of this document must not be used for purposes

other than that for which it has been supplied or reproduced or disclosed wholly or in

part without the prior written permission of

CASELLA CEL LIMITED

CASELLA CEL

Regent House

Wolseley Road

Kempston

Bedford

MK42 7JY U.K.

Phone: +44 (0) 1234 844 100

Fax: +44 (0) 1234 841 490

E-mail info@casellagroup.com

Web: www.casellagroup.com

CASELLA USA

17 Old Nashua Road #15

Amherst

NH 03031

U.S.A.

Toll Free: +1 800 366 2966

Fax: +1 603 672 8053

e-mail: info@casellausa.com

Web: www.casellausa.com

.

SENSUS Digital Data Logger -

Users Handbook

Page 2 of 44

SENSUS Digital Data Logger -

Users Handbook

Warnings

WARNINGS !

The SENSUS Logger contains no user serviceable

components. If an electrical fault is suspected the

instrument must be returned to Casella CEL Ltd for repair.

The Logger should not be dropped or subjected to

mechanical shock. Failure to comply will render the

warranty invalid.

The warranty DOES NOT extend to cleaning or general

servicing of the instrument.

Page 3 of 44

Getting Started

SENSUS Digital Data Logger -

Users Handbook

GETTING STARTED

The easiest way to get the Sensus Logger up and running

is to transfer a new profile from the PC application

software Online Pro. With just a few mouse clicks the

Sensus Logger can be tailored to match the sensors used

and begin recording data within minutes.

Page 4 of 44

SENSUS Digital Data Logger -

Users Handbook

Contents

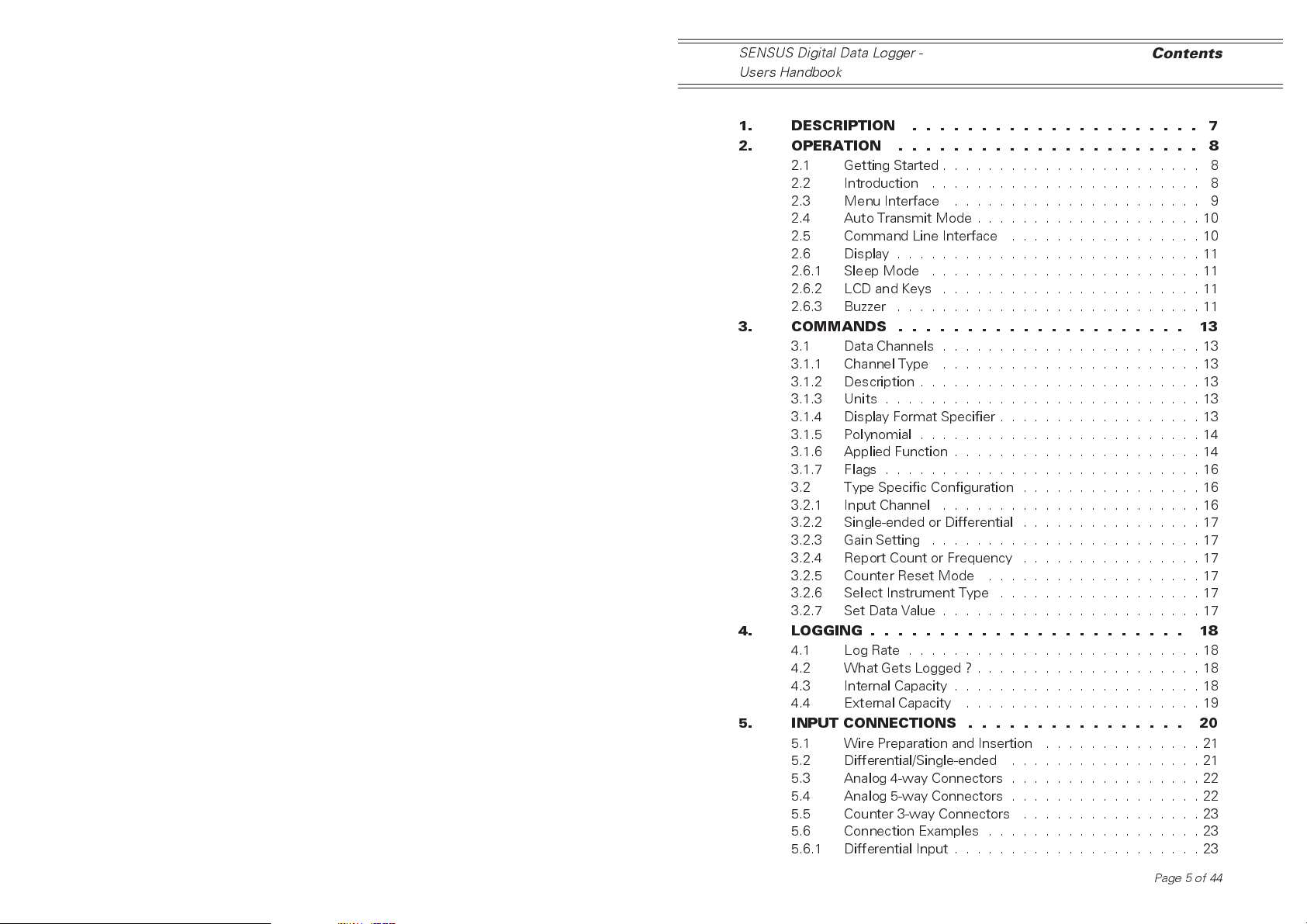

TABLE OF CONTENTS ...........Page

1. DESCRIPTION ..................... 7

2. OPERATION ...................... 8

2.1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Menu Interface . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Auto Transmit Mode . . . . . . . . . . . . . . . . . . . . 10

2.5 Command Line Interface . . . . . . . . . . . . . . . . . 10

2.6 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6.1 Sleep Mode . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6.2 LCD and Keys . . . . . . . . . . . . . . . . . . . . . . . 11

2.6.3 Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. COMMANDS ..................... 13

3.1 Data Channels . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Channel Type . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.4 Display Format Specifier . . . . . . . . . . . . . . . . . . 13

3.1.5 Polynomial . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.6 Applied Function . . . . . . . . . . . . . . . . . . . . . . 14

3.1.7 Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Type Specific Configuration . . . . . . . . . . . . . . . . 16

3.2.1 Input Channel . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.2 Single-ended or Differential . . . . . . . . . . . . . . . . 17

3.2.3 Gain Setting . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.4 Report Count or Frequency . . . . . . . . . . . . . . . . 17

3.2.5 Counter Reset Mode . . . . . . . . . . . . . . . . . . . 17

3.2.6 Select Instrument Type . . . . . . . . . . . . . . . . . . 17

3.2.7 Set Data Value . . . . . . . . . . . . . . . . . . . . . . . 17

4. LOGGING ....................... 18

4.1 Log Rate . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 What Gets Logged ? . . . . . . . . . . . . . . . . . . . . 18

4.3 Internal Capacity . . . . . . . . . . . . . . . . . . . . . . 18

4.4 External Capacity . . . . . . . . . . . . . . . . . . . . . 19

5. INPUT CONNECTIONS ................ 20

5.1 Wire Preparation and Insertion . . . . . . . . . . . . . . 21

5.2 Differential/Single-ended . . . . . . . . . . . . . . . . . 21

5.3 Analog 4-way Connectors . . . . . . . . . . . . . . . . . 22

5.4 Analog 5-way Connectors . . . . . . . . . . . . . . . . . 22

5.5 Counter 3-way Connectors . . . . . . . . . . . . . . . . 23

5.6 Connection Examples . . . . . . . . . . . . . . . . . . . 23

5.6.1 Differential Input . . . . . . . . . . . . . . . . . . . . . . 23

Page 5 of 44

Contents

SENSUS Digital Data Logger -

Users Handbook

TABLE OF CONTENTS (Continued) .... Page

5.6.2 Single-ended Inputs . . . . . . . . . . . . . . . . . . . 23

5.6.3 4 to 20 mA Current . . . . . . . . . . . . . . . . . . . . 24

5.6.4 4-Wire Resistive . . . . . . . . . . . . . . . . . . . . . 24

5.6.5 Counter.......................... 24

6. COMMUNICATIONS ................. 25

6.1 RS 232 Command . . . . . . . . . . . . . . . . . . . . 25

6.2 SleepMode ....................... 26

6.3 RS 232 Instrument . . . . . . . . . . . . . . . . . . . . 26

6.4 RS 485 Command Alternate . . . . . . . . . . . . . . . 27

6.5 Modems ......................... 27

7. COMPACTFLASH CARDS ............. 28

8. ALARMS ....................... 30

8.1 IDText .......................... 30

8.2 Input Channel . . . . . . . . . . . . . . . . . . . . . . 30

8.3 TestMode ........................ 30

8.4 Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.5 Action . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.6 On/Off Delays . . . . . . . . . . . . . . . . . . . . . . 31

8.7 On/Off Values . . . . . . . . . . . . . . . . . . . . . . 31

8.8 Output Channel . . . . . . . . . . . . . . . . . . . . . 31

8.9 Digital Output . . . . . . . . . . . . . . . . . . . . . . 32

8.10 FastLogMode...................... 32

8.11 Modem.......................... 32

8.12 Phone Number . . . . . . . . . . . . . . . . . . . . . . 32

8.13 SMS Phone Numbers . . . . . . . . . . . . . . . . . . 32

8.14 Channel List . . . . . . . . . . . . . . . . . . . . . . . 32

8.15 Alarm Flags . . . . . . . . . . . . . . . . . . . . . . . . 33

9. ANALOG OUTPUT .................. 34

10. INTEGRATED SENSORS ............... 35

10.1 Temperature . . . . . . . . . . . . . . . . . . . . . . . 35

10.2 Barometric Pressure . . . . . . . . . . . . . . . . . . . 35

11. POWER SUPPLIES .................. 37

11.1 Solar Power . . . . . . . . . . . . . . . . . . . . . . . 37

11.2 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 37

12. SERVICING ...................... 38

13. SPECIFICATION ................... 39

13.1 Channel Information . . . . . . . . . . . . . . . . . . . 39

13.2 Display and Keypad . . . . . . . . . . . . . . . . . . . 42

13.3 General.......................... 42

Page 6 of 44

SENSUS Digital Data Logger -

Users Handbook

Description

1. DESCRIPTION

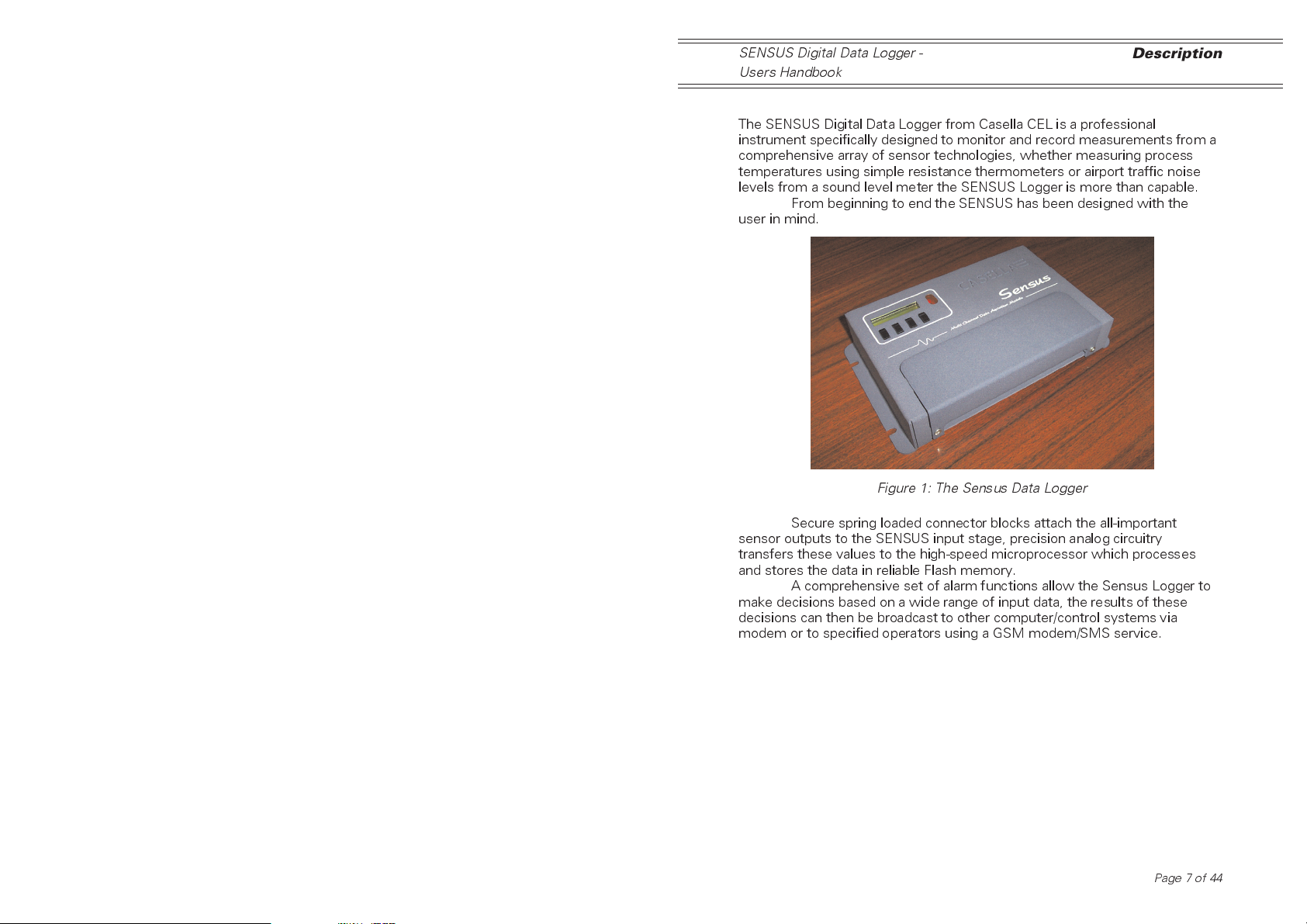

The SENSUS Digital Data Logger from Casella CEL is a professional

instrument specifically designed to monitor and record measurements from a

comprehensive array of sensor technologies, whether measuring process

temperatures using simple resistance thermometers or airport traffic noise

levels from a sound level meter the SENSUS Logger is more than capable.

From beginning to end the SENSUS has been designed with the

user in mind.

Figure 1: The Sensus Data Logger

Secure spring loaded connector blocks attach the all-important

sensor outputs to the SENSUS input stage, precision analog circuitry

transfers these values to the high-speed microprocessor which processes

and stores the data in reliable Flash memory.

A comprehensive set of alarm functions allow the Sensus Logger to

make decisions based on a wide range of input data, the results of these

decisions can then be broadcast to other computer/control systems via

modem or to specified operators using a GSM modem/SMS service.

Page 7 of 44

Operation

SENSUS Digital Data Logger -

Users Handbook

2. OPERATION

2.1 Getting Started

The easiest way to get the Sensus Logger up and running is to transfer a

new profile from the PC application Online Pro. With just a few mouse clicks

the Sensus Logger can be tailored to match the sensors used and begin

recording data within minutes.

2.2 Introduction

The Sensus is designed to start processing/logging data as soon as power is

applied to it and to continue to do so until power is removed. This means that

should power to the logger be interrupted for any reason, the unit will recover

and continue collecting data when power is restored without any user

intervention.

When the Sensus Logger is powered-up, it re-configures itself

automatically, based upon a set of operating parameters held in its internal

profile. Once the contents of the profile have been processed the logger

begins its task of collecting/logging data.

Most aspects of the loggers operation can be changed by the user,

either via the menu system or via the command line interface. Both of these

configuration tools are accessible via the RS232 command interface.

The factory default setting for the RS232 command interface is 9600

baud, 8 data bits, 1 stop bit, no parity and no handshake. The configuration

tools can be accessed manually using any terminal interface program, (such

as Hyperterm, as supplied with the WindowsTM operating system).

The menu system is more useful for manual reconfiguration where

a few parameters are to be changed or a new sensor added. The command

line interface is of more use where an automatic configuration is needed and

it is this approach that is used by the Online Pro application to provide

automated configuration. The menu system is activated by default but it can

switch between the two as and when required.

While the Sensus Logger is running it is at all times performing a

series of tasks in the background.

Sensor scanning: This task is performed at regular intervals

determined by the period set in the

profile. Each time it runs fresh data is

collected from the attached sensors, this

data is in turn processed to provide the

values logged by the system and used in

alarm comparisons.

Logging: Again, this task is performed at an interval

defined in the profile. While running, all

data values marked to be logged are

moved to a holding buffer then written

either to the internal memory or to

external CompactFlash card.

Alarms: At fixed intervals current data values are

compared against active alarm channels

Page 8 of 44

SENSUS Digital Data Logger -

Users Handbook

and alarm states and actions are updated

at this time.

Operation

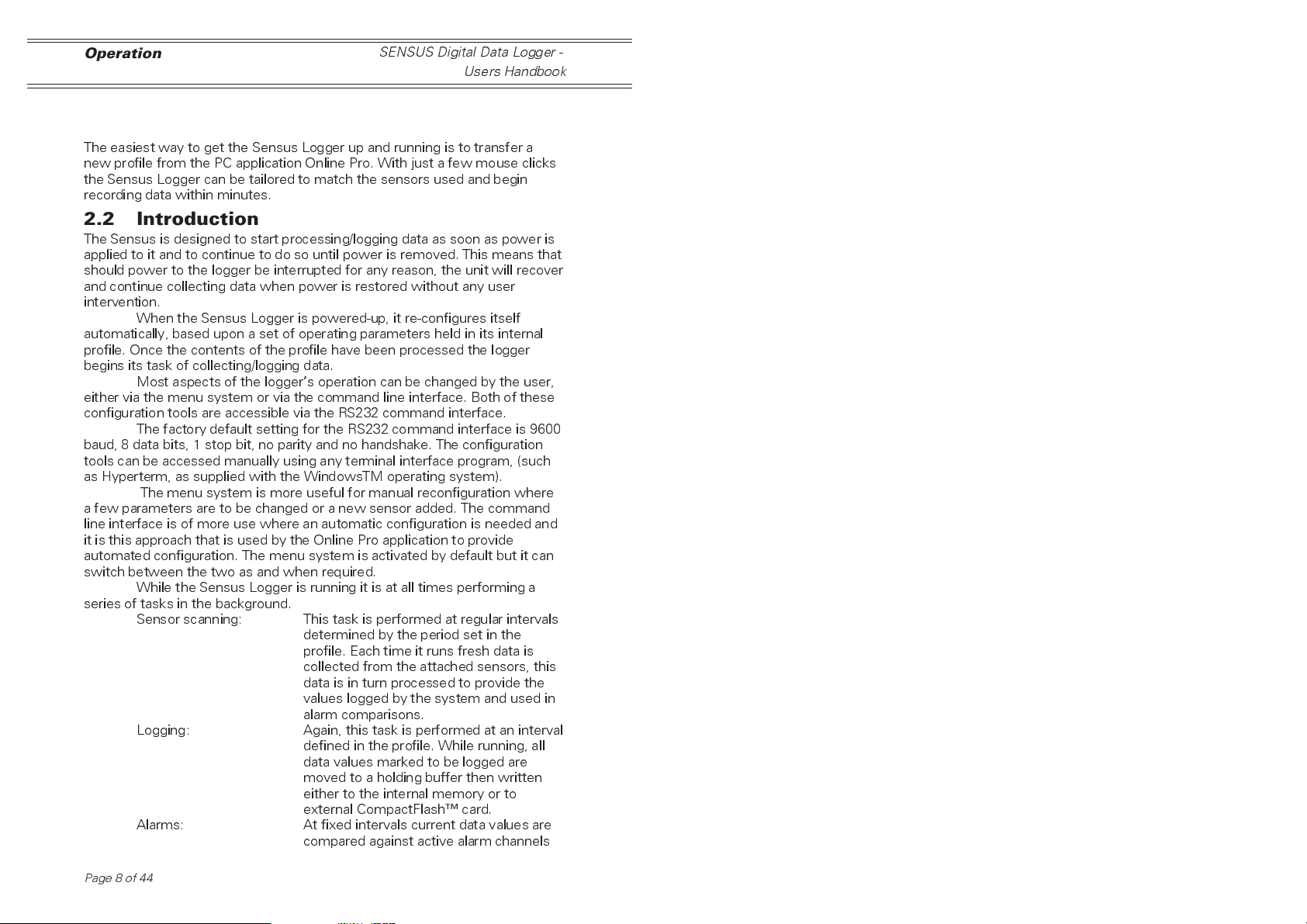

2.3 Menu Interface

This interface is the default selection when the Sensus Logger is switched

on. The clear and easy to follow structure allows the user to redefine most

aspects of the loggers configuration with ease.

When navigating around the menu system the following rules apply.

Action Result

Pressing the Escape key This cancels the current operation and

causes the menu system to step back a

level without making any changes.

This can be done at any prompt.

Pressing the Backspace key

Deletes the last character entered from

the input buffer.

The Logger responds with Backspace-

Space-Backspace to remove character

from display.

Type a menu option number and press the Enter key

Executes the function associated with

that menu option number.

Typing text All typed text should be in lowercase

except where the text is contained in

quotes , here mixed case text can be

used.

All prompts limit the amount of text that

can be entered by the user, when this

limit is reached further characters are

ignored.

Typing an empty string Where a blank string needs to be entered

(for example, to clear the loggers ID text)

this can be achieved by typing a pair of

double quotes without any spaces

between ( ).

To read a value Select the menu option number for that

value, the menu system always prints the

current value before the prompt to

change it.

Once displayed press the Escape key.

To change a value Select the menu option number for that

value and when prompted for a new

value type it in and press the Enter key.

Continuous output Where the menu system is continuously

outputting values (data display option)

pressing the Escape key will terminate

the option and return control to the parent

menu.

Page 9 of 44

Operation

No activity If the menu system detects no user

activity for more than 60 seconds then it

will automatically terminate the current

option and return control to the parent

menu.

This ensures the menu system will return

to a safe state if communication should

fail. The only exception to this is where

the user has selected continuous output.

SENSUS Digital Data Logger -

Users Handbook

2.4 Auto Transmit Mode

A special feature of the menu interface, is the availability of an Auto Transmit

mode, for use where data must be sent by the Sensus at regular intervals

without further user intervention.

When enabled, the Sensus will wait at the main menu prompt for a

specified period of inactivity. When this occurs, the current data values are

collected and transmitted over the command interface together with an 8-bit

checksum value. This data collection and transmission sequence is repeated

at a specified rate until command activity is detected, at which time, the main

menu regains control of the interface.

2.5 Command Line Interface

This interface can be activated at any time from an option in the top-level

menu of the menu interface. Once activated the menu system is suspended

until the command line interface is closed, which is achieved by pressing the

Escape key when at the command line prompt.

The command line interface represents itself by displaying a single

greater- than character (>), this is the command line prompt.

Commands are entered in lowercase (except for quoted text which

can have mixed cases). Each command consists of two parts, the command

name and its parameters. The parameters are separated from the command

name by enclosing them in round brackets ( () ).

Typing a question mark ( ? ) allows the user to search for likely

commands followed by some portion of the command name, some

command search examples are given here:

Search pattern Result

>?date setdate

>?rate setscanrate

setfastscanrate

setlograte

setfastlograte

Some examples of command formats are given below.

Command Function

>setloggeridtext(Test field 1) Set the loggers id text to

Test field 1"

>setchandesc(1,Cabinet humidity) Set the channel description

for data channel 1 to

Cabinet humidity

Page10of44

SENSUS Digital Data Logger -

Users Handbook

>setchanpolynomial(1,0.0,1.23) Set the scaling polynomial

for data channel 1 to

C=0.0, X1=1.23

As with other prompts, if the logger detects no user activity for 60 seconds,

then the command line interface terminates and control returns to the menu

interface, top level.

Operation

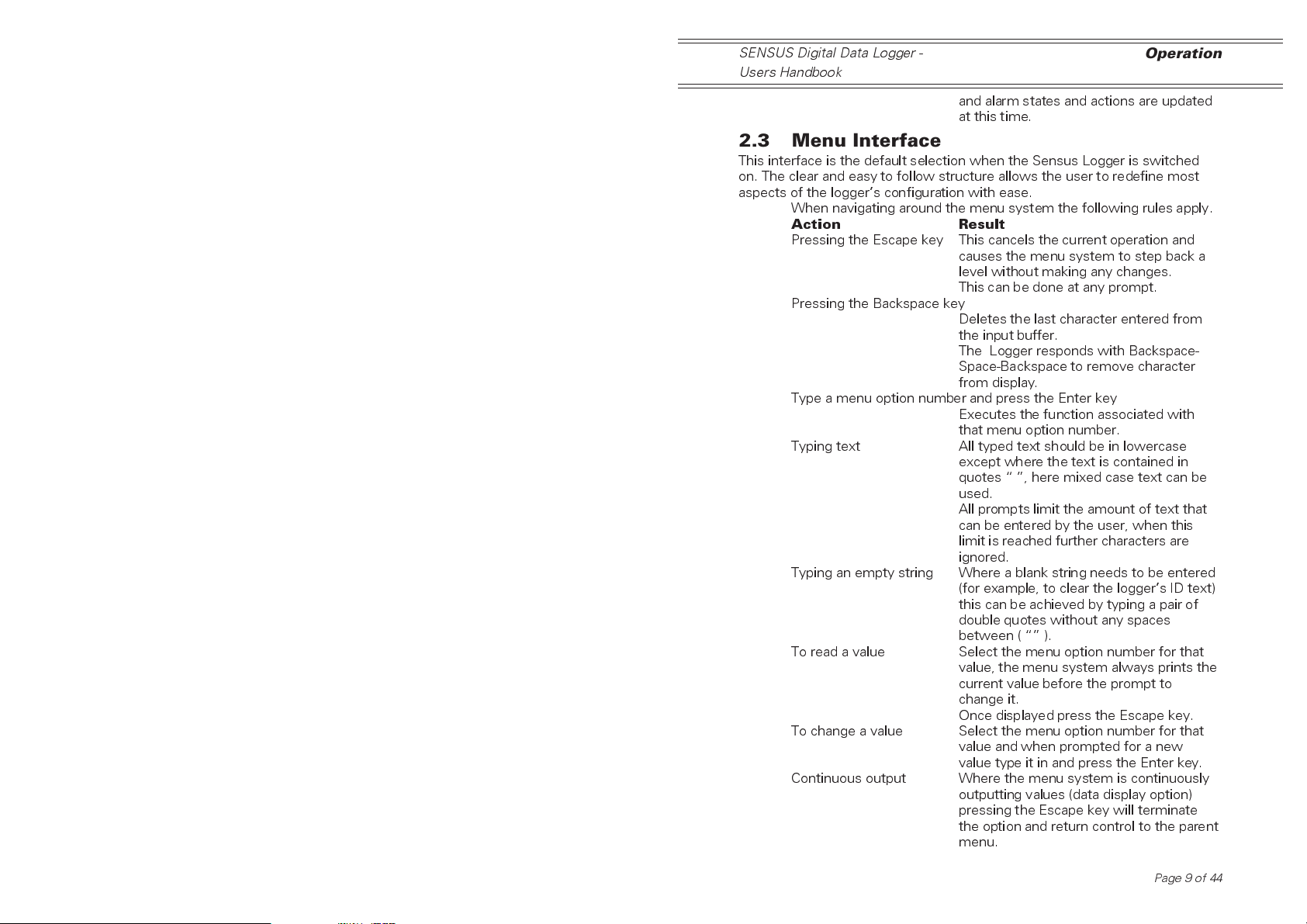

2.6 Display

The Sensus Logger supports a

2-line by 20-character LCD

module, 4 keys and a buzzer.

The display provides

information about the internal

status of several of the key

functions of the logger, these

include date/time, active channels

and logging summary.

2.6.1 Sleep Mode

The LCD will always show

something, unless the logging

period has been set to one minute

or more, whereupon an internal

power-save function comes into effect and the LCD becomes blank,

switching on again only as data is logged.

Should the LCD be blank, it can be reactivated immediately (without

having to wait for a log cycle) by pressing any one of the front panel keys.

Key 1 Key 2 Key 3 Key 4

2.6.2 LCD and Keys

The LCD incorporates a back light that is lit for a few seconds on every key

press.

Keys 1 and 4, (the two end keys, see Figure 2) are used to scroll

between the available status screens. This is indicated by the up and down

arrows depicted on the LCD above the corresponding keys. Where further

information is available for viewing, left and right arrows will be added above

keys 2 and 3. Use these keys to display any additional information for the

option. At any time key 1 or key 4 can be used to move to the next/previous

status screen.

Should a selection become necessary, the annotation for key 2 will

change to N (indicating No) and for key 3 to Y (indicating Yes). Figure 3

shows the Sensus menu structure.

2.6.3 Buzzer

The buzzer gives the user an audible indication that a key press has been

recognised. In addition, the buzzer can be assigned to one or more of the

alarm channels, to give an audible indication when the alarm becomes active.

13:45:00

22/12/2001

01096

Figure 2: The layout of the LCD

and keypad.

Page 11 of 44

Operation

13:30:00, 15/12/2001

13:30:00, 15/12/2001

Last record:

Last record:

SENSUS Digital Data Logger -

Users Handbook

02018

995.0 mbar

Ch: 07,

...

Figure 3: Menu Structure of the Sensus data logger

13:45:00

Page12of44

installed in the Casella Nomad weather station

Switching off

N

Y

Switch off ?

22/12/2001

Power control

Supply: 13.6 V

o

Temp.: +22.7 C

80-XXXXXXA-22

System information

03:10:00, 30/06/2001

03:10:00, 30/06/2001

First record

First record

254

254

Int. record count:

Ext. record count:

Logging information

See note 1

(Run)

Enabled (paused)

(Pause)

Enabled

Logging control

(Run)

Disabled (paused)

(Pause)

Disabled

See note 2

Ch:...

...

Ch:...

1.3 m/s

Ch: 02,

0.0 mm

Ch: 01,

Data values

See note 3

CF card ? version ?

CF card ? serial ?

CF card present

CF card detected

CF slot empty

CF card error

CF card full

CF card ? unknown ?

CF card *BUSY*

If a CF card is present in the slot when this option is selected, then the six screens will display information relating to the data stored on the card.

Notes 1.

If there is no card present, the screens will display information relating to data stored internally in the Sensus logger.

If logging is currently enabled, then the top two screens will be shown. When logging is NOT enabled, the bottom two will be shown.

The CF display screens change automatically, depending on the current state of the CF card installed (if any). Apart from inserting or removing a

CF card, the user has no control over which of these screens is displayed.

2.

3.

SENSUS Digital Data Logger -

Users Handbook

Commands

3. COMMANDS

A full and detailed description of all the commands available on the Sensus

Logger is beyond the scope of this handbook. When this information is

essential to your particular application, please contact Casella CEL and

request a copy of the document: Sensus - A Programmers Guide (HB3291).

3.1 Data Channels

The configuration information stored in a data channel controls how input

data is collected, processed and stored by the logger.

3.1.1 Channel Type

The channel type allocated to a data channel controls where the channel will

go in order to obtain real world measurements.

Allowable channel types are detailed below.

Data Channel Type Function

Analog Readings are taken from analog input

signals (differential or single-ended).

Counter Readings are taken from digital counter

inputs.

Data Readings are taken from other data

channels.

Instrument Readings taken from RS232 Inst. interface

Passive This data channel type does not obtain

readings itself, rather it waits to be

updated from other sources (for example

alarms).

Parameter Allows values held in the loggers

parameter space (system variables) to be

processed just like other data.

Options and settings that differ depending on the channel type selected will

be explained in greater detail in Section 2.2, Type Specific Configuration. The

following paragraphs describe options that are common to all channel types.

3.1.2 Description

The text allocated to the data channels description tells the user the physical

property actually being measured by the channel. The text is used to identify

the channel contents in alarm messages and other outputs.

3.1.3 Units

This text identifies the measuring units used when presenting data for the

channel. This is used in alarm messages, logging to CompactFlash cards

and LCD messages.

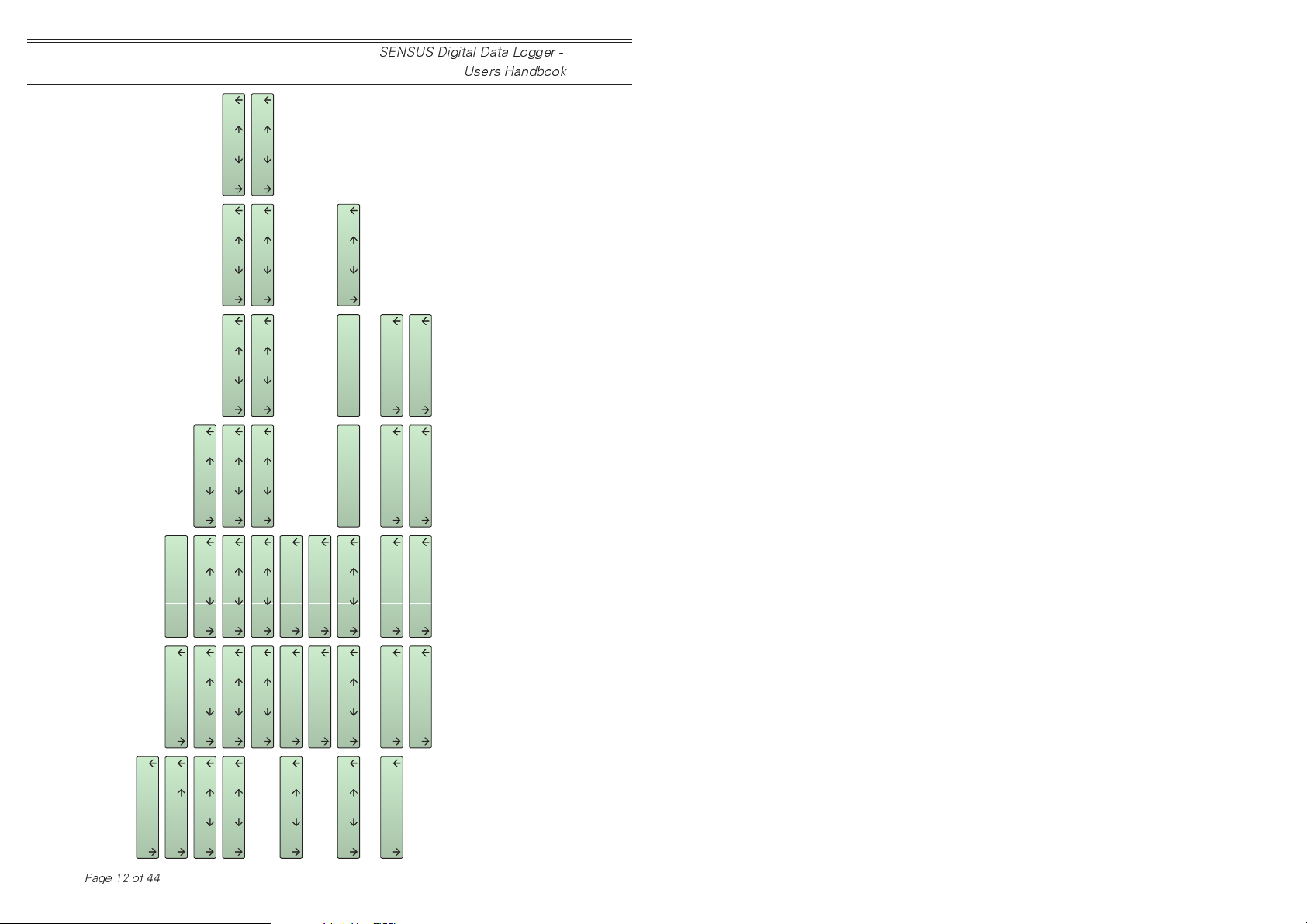

3.1.4 Display Format Specifier

The text allocated to this parameter controls how data values for the channel

are presented to the user. This specifier controls whether a value is signed,

the field width and the number of decimal places. Character positions are

indicated by the hash ( # ) or zero ( 0 ) characters. Some format specifier

examples are given below.

Page 13 of 44

Commands

Format Specifier Result

####.# 12.3 (Blank fill, sign optional)

1234.5

-1234.5

-1.2

+####.# +12.3 (Blank fill, sign mandatory)

+1234.5

-1234.5

-1.2

0000.0 0012.3 (Zero fill, sign optional)

1234.5

-1234.5

-0001.2

+0000.0 +0012.3 (Zero fill, sign mandatory)

+1234.5

-1234.5

-0001.2

This determines only how data is presented to the user, data is still

processed and logged with full precision.

SENSUS Digital Data Logger -

Users Handbook

3.1.5 Polynomial

The factors assigned to this polynomial dictate how data values are

scaled/converted from raw voltage/count values to real physical quantities.

Each data channel has room for an 8-term polynomial, one constant and 7

X-terms.

The format for the polynomial is as follows:

C, X-term, X2-term, X3-term, X4-term, X5-term, X6-term, X7-term

The polynomial is calculated as follows:

y=P0+xP1+x2P2+x3P3 + x4P4 + x5P5+x6P6 + x7P7

Where: y = the result

x = the input value

P0 = X-term

Pn = Xn-term (where n = 1 to 7)

Define only those terms required by the conversion in question, all additional

unnecessary terms add to the processing time required for this channel.

3.1.6 Applied Function

The applied function property allows for further processing to be applied to

data values far beyond the scope of simple scaling. Functions exist that allow

averaging, min/max hold and crosswind calculation.

A list of available functions together with examples is given in Table 1 below.

Page14of44

SENSUS Digital Data Logger -

Users Handbook

Table 1: Available Functions

Commands

Function

Name

none none() None Input channel No additional

minhold minhold() None 1. Input Channel Holds most

maxhold maxhold() None 1.Input Channel Holds most

rollingavg rollingavg(60) 1.Averaging

vectoravg vectoravg(60) 1.Averaging

degreeday degreeday(30,gain) 1.Limit value

windto windto() None 1.Input Channel Convert input

crosswind crosswind() None 1.Wind speed

vapour vapour() None 1.Air

Example Parameters Input

Channels

period in

seconds

period in

seconds

2.

gain

-

accumulate

when value is

above limit

loss

-

accumulate

when value is

below limit

1.Input Channel Calculates

1.Input Channel Calculates

1.Input Channel Calculate solar

channel

2.Wind

direction

channel

3.Bearing

channel

temperature

2.Humidity

Result

processing is

performed,

output value

equals input

value

negative value

until reset

positive value

until reset

rolling average

over given

interval

vector average

over given

interval

gain (loss)

based on

percentage of

time (over 24

hours) that the

value exceeds

(is below) limit

value of

wind

from

direction

to output value

of

wind to

direction

Calculate cross

wind

component for

wind speed

using direction

and bearing

values

Calculate the

saturated

vapour

pressure for

the air

temperature

and humidity

values

Page 15 of 44

Commands

SENSUS Digital Data Logger -

Users Handbook

Function

Name

dewpoint() dewpoint() None 1.Vapour

sum() sum() None 1 to 4 input

Example Parameters Input

Channels

pressure

channels

Result

Calculate the

dew point for

the saturated

vapour

pressure value

Calculate the

sum of the

specified input

values

3.1.7 Flags

The flags setting controls yes/no (enable/disable) type options for the data

channel. Current options are given below.

Option Flag Set to Enabled Set to Disabled

Channel Channel is active

and processing

data. Channel data

can be included in

reports and further

processing.

Logging Channel data

should be included

in log events

Function Reset The function

associated with

this channel will

reset any running

calculation the next

time it is updated

(for example,

forced reset of

maximum hold)

Channel is inactive,

data is not updated

and is not included

in any reports.

Channel data is

ignored by log

events

No action

3.2 Type Specific Configuration

This option gives access to settings, which differ depending on the channel

type selected.

3.2.1 Input Channel

Where a channel must obtain data values from an input source (analog input

or other data channel) the number associated with that source is set here.

For

analog

For single-ended types this can be positive for the positive input channel, or

negative for the negative input channel. For differential input channels, the

value is always positive. The allowable range is from 1 to the maximum

number of analog channels.

For

digital

to be used. The allowable range is 1 to 4.

Page16of44

type channels, this is the number of the analog input.

type channels, this is the number of the counter channel

SENSUS Digital Data Logger -

Users Handbook

For

data

type channels, this is the channel number of another data

channel whose data values will be further processed by this channel. The

allowable range is 1 to the maximum number of data channels.

For

parameter

whose value is to be further processed by the channel. The allowable range

is1to100.

type channels, this is the number of the parameter

Commands

3.2.2 Single-ended or Differential

This option applies only to analog type channels and determines whether the

associated analog channel will be read as a single-ended voltage input or as a

differential input. It should be set to match how the sensor is connected.

3.2.3 Gain Setting

Again only for analog type channels, it sets the gain to be applied to the input

analog signal before the logger converts it. The allowable options are shown

below.

Analog Gain Option Action

x1 Leave analog signal untouched,

full scale ±2.5 V.

x10 Multiply analog signal by a factor

of 10, full scale ±250 mV.

x100 Multiply analog signal by a factor

of 100, full scale ±25 mV.

3.2.4 Report Count or Frequency

This applies only to counter type channels and determines whether the

channel result will represent the pulse count for the measurement period or

the equivalent frequency value.

3.2.5 Counter Reset Mode

Again only for counter type channels, it sets when the count value is to be

reset. The allowable options are shown below.

Counter Reset Option Action

Reset on scan Reset the counter every time it is read in

the scan event.

Reset on log Reset the counter every time the log

event occurs.

Reset at midnight Reset the counter only at midnight

(for daily accumulated values).

3.2.6 Select Instrument Type

This option is only for instrument type channels and specifies the type of

instrument attached to the logger. It configures how the logger will talk to

the instrument and which data values it is to extract.

3.2.7 Set Data Value

Purely for passive type data channels which do not actively gather data from

other sources but merely presents data for other channels to read. This

option allows the data value held to be updated.

Page 17 of 44

Logging

SENSUS Digital Data Logger -

Users Handbook

4. LOGGING

By default, the Sensus logs data to its internal record store at an interval

specified by the user. If the logger detects the presence of a compatible

CompactFlash card, it automatically uses this instead. When the card is

removed, the logger reverts to using its internal store. For information on the

use of CompactFlash cards please refer to Section 8 on CompactFlash.

4.1 Log Rate

The logger operates with two logging rates, one normal rate and one fast

rate. Switching between these two rates is handled automatically by the

alarm system. For further information please refer to Section 12 on Alarms.

Both logging rates can be set to any value between 5 seconds and

24 hours.

4.2 What Gets Logged ?

Any data channel that has its log active flag set will be included when the

next log event occurs. Logging globally can be disabled/enabled by changing

the log active flag held in the logging configuration. This allows logging to

be suspended temporarily without changing all the channel flags.

4.3 Internal Capacity

The Sensus Logger has 512 kBytes of internal Flash storage available to hold

logged information. This store is updated in a first-in-first-out manner so that

the earliest records are always being replaced with the newest ones. While

this means the logger will never stop recording data, only a set period of time

will remain available for collection at any time.

The number of records held and the period of time covered by the

internal store depend on both the number of channels being logged and the

logging interval.

The following equations let the user calculate the record capacity

and the store duration.

524288

74+=()

Channels x

Re cord Capacity x Logging Interval Store Duration=

These equations should be used only as a guideline as the logging interval

may change during operation, especially if the fast mode option has been

enabled in the alarms.

Some example internal result capacities are shown in Table 2.

Page18of44

Re

cord Capacity

SENSUS Digital Data Logger -

Users Handbook

Table 2: Internal Store Capacity (512 kB)

Logging

Number of

Channels

1 1 47662 33 days

1 10 47662 33 days

1 60 47662 5.4 years

7 1 14979 10 days

7 10 14979 104 days

7 60 14979 1.7 years

24 1 5090 3.5 days

24 10 5090 35 days

24 60 5090 212 days

Logging Interval

(mins)

Record Capacity Storage Capacity

4.4 External Capacity

When logging to external media such as CompactFlash cards, the store is

updated with data being added to the card until it becomes full. Logging will

then stop until the card has been replaced with an empty one.

The following equations let the user calculate the record capacity

and the store duration for external media.

(.)

Capacity in MB x x

74+

Re cord Capacity x Logging Interval Store Duration=

Again, these equations should be used only as a guideline, for the

same reasons as given for the internal store and also because of the

approximation that only 95% of the cards capacity is available for actual data

storage. Some example CompactFlash result capacities are given in Table 3.

1048576 0 95

()

Channels x

Re

=

cord Capacity

Table 3: External Store Capacity (16 MB)

Number of

Channels

1 1 1448941 2.7 years

1 10 1448941 27 years

1 60 1448941 165 years

7 1 455381 316 days

7 10 455381 8.6 years

7 60 455381 51 years

24 1 154741 107 days

24 10 154741 2.9 years

24 60 154741 17 years

Logging Interval

(mins)

Record Capacity Storage Capacity

Page 19 of 44

Input Connections

SENSUS Digital Data Logger -

Users Handbook

5. INPUT CONNECTIONS

Removing the connector cover plate gives access to the input connector

array. The connector array consists of 3, 4 and 5-way detachable connector

blocks to which sensor outputs are wired. The combination of spring-clamp

technology and plug-in modules allow for rapid and secure attachment of a

variety of sensors.

Figure 4: The logger with cover removed

Channel numbering starts from the left-side, bottom-row and

alternates between the bottom and top row, from left to right. In addition the

pins of each connector are numbered from left to right.

4

+A

3

+A

+Vsw

+Vsw

0V

V

0

6

8

V

+A

+A

0

8

6

+Vsw

-A

-A

7

5

-A

-A

5

+A

+Vsw

0V

7

+A

2

V

+A

0V

0

4

2

+Vsw

-A

-A

AN2 AN4 AN6 AN8 AN10 AN12 CNT2 CNT4 AN.OUT

AN1 AN3 AN5 AN7 AN9 AN11 CNT1 CNT3 ALARMS

3

1

-A

-A

1

V

V

0

0

+Vsw

+A

I2

+Vsw

I1

+Vsw

V

0

0V

0

1

0

+A

1

-A

9

-A

9

+A

I4

+Vsw

I3

+Vsw

0V

0V

2

1

2

I6

+A

1

-A

1

1

1

-A

1

+A

+Vsw

I5

+Vsw

0V

0V

+V

0V

C2

C1

V

0

+V

2

A

+V

VSS

1

A

C4

1

L

C3

2

A

L

0V

+V

A

CTS

RXD

0V

RS232 SOLAR

CHARGER BATT

0V

TXD

V

0

DTR

G

+CH

G

+CH

-SP

0V

Figure 5: The connector cover label

A copy of this connector/pin assignment diagram is located on the

reverse of the connector cover plate for reference in the field.

Page20of44

+SP

RS485

0V

-A

-B

G

G

+CH

+CH

01072

SENSUS Digital Data Logger -

Users Handbook

5.1 Wire Preparation and Insertion

To insert a wire into a spring terminal,

first strip back the insulation leaving

10 mm of bare wire exposed as

shown in Figure 6.

01083

Use a small

i

screwdriver to

ii

depress the

iii

orange clamp

iiii

while inserting

iiiii

the stripped

iiiiii

end of the

iiiiiii

conductor

01084

Figure 7: Depressed clamp

while inserting wire

Using a small flat headed screw-

driver (or similar) fully depress the

orange plunger located above the

hole into which the wire is to be

inserted and insert the wire into the

hole as far as it will go, as shown in

Figure 7.

Figure 6: Stripped wire

Remove the

i

screwdriver to

ii

iii

iiii

iiiii

Stripped

10 mm

Conductori

release the

clamp and

grip the

conductor

Logging

Release the orange plunger and the

wire is held captive by the connector

(Figure 8).

A gentle tug on the wire will

confirm that it is held firmly.

01085

Figure 8: Wire firmly clamped

5.2 Differential/Single-ended

Each analog connector has available 2-inputs that must be connected as a

pair where a differential signal is to be measured. Alternatively, they can be

wired to 2 independent single-ended signals and measured separately.

When the logger is configured to read 2 independent signals in this

way, the polarity inversion of the negative input is automatically compensated

before the readings are processed further.

Page 21 of 44

Logging

5.3 Analog 4-way Connectors

SENSUS Digital Data Logger -

Users Handbook

The first 3 connectors of each row of

the connector array are intended

specifically for analog channels. They

have the following pin assignments.

Figure 9: 4-way connector

4-way connectors - AN1 to AN6

0 V Analog signal ground reference,

-Ax Differential connection negative input,

+Ax Differential connection positive input,

+Vsw 13.8 V switched supply for sensor

excitation. This excitation voltage is

common to all analog sensor connectors.

5.4 Analog 5-way Connectors

The next 3 connectors of each row of

the connector array are also intended

specifically for analog channels. They

have the following pin assignments:

0V

-Ax

+Ax

+Vsw

01073

0V

-Ax

+Ax

+Vsw

ly

5-way connectors - AN7 to AN12

0 V Analog signal ground reference,

-Ax Differential connection negative input,

+Ax Differential connection positive input,

+Vsw 13.8 V switched supply for sensor

Iy 200 µA sensor excitation (this excitation

Page22of44

01074

Figure 10: 5-way connector

excitation. This excitation voltage is

common to all analog sensor connectors.

current can be switched between each of

these 5-way connectors).

SENSUS Digital Data Logger -

Input Connections

Users Handbook

5.5 Counter 3-way Connectors

The next 2 connectors of each row of

the connector array are dedicated to

counter channels. They have the

following pin assignments.

01075

Figure 11: 3-way connector

3-way connectors - CNT1 to CNT4

0 V Analog signal ground reference,

Cx Counter input,

+V Permanent 13.8 V supply for sensor

excitation This excitation voltage is

common to all counter sensor connectors.

5.6 Connection Examples

The following set of figures show wiring schemes for some of the more

common input configurations:

0V

Cx

+V

5.6.1 Differential Input

5.6.2 Single-ended Inputs

01076

Figure 12: Differential connection to

4-way analog

01088

Figure 13: 2-single-ended signals

connected to 4-way analog

Page 23 of 44

?

?

?

?

?

?

?

?

Input Connections

SENSUS Digital Data Logger -

Users Handbook

5.6.3 4 to 20 mA

Current

5.6.4 4-Wire Resistive

PRTD

5.6.5 Counter

?

?

?

?

100R

01089

Figure 14: Signal connected for

4to20mAinput

R

01090

Figure 15: 4-wire PRTD connected to

current excitation with differential

measurement (5-way analog)

?

Page24of44

01091

Figure 16: Counter connected to

3-way counter

SENSUS Digital Data Logger -

Users Handbook

Communications

6. COMMUNICATIONS

The Sensus Logger is fitted with several communications interfaces, two RS

232 and one RS 485. These interfaces allow both control of the logger via

different media and data to be logged from other instruments with similar

interfaces.

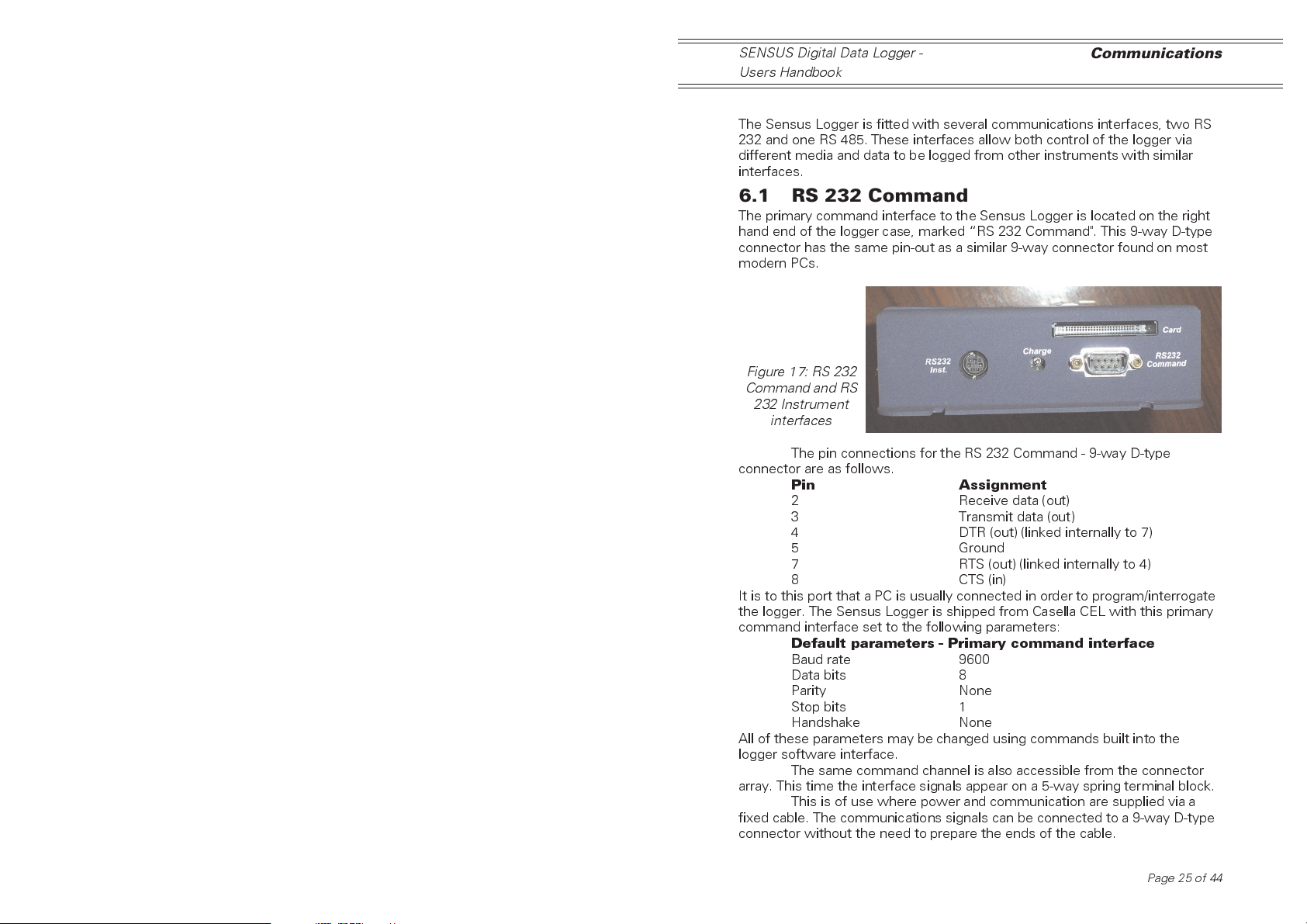

6.1 RS 232 Command

The primary command interface to the Sensus Logger is located on the right

hand end of the logger case, marked RS 232 Command". This 9-way D-type

connector has the same pin-out as a similar 9-way connector found on most

modern PCs.

Figure 17: RS 232

Command and RS

232 Instrument

interfaces

The pin connections for the RS 232 Command - 9-way D-type

connector are as follows.

Pin Assignment

2 Receive data (out)

3 Transmit data (out)

4 DTR (out) (linked internally to 7)

5 Ground

7 RTS (out) (linked internally to 4)

8 CTS (in)

It is to this port that a PC is usually connected in order to program/interrogate

the logger. The Sensus Logger is shipped from Casella CEL with this primary

command interface set to the following parameters:

Default parameters - Primary command interface

Baud rate 9600

Data bits 8

Parity None

Stop bits 1

Handshake None

All of these parameters may be changed using commands built into the

logger software interface.

The same command channel is also accessible from the connector

array. This time the interface signals appear on a 5-way spring terminal block.

This is of use where power and communication are supplied via a

fixed cable. The communications signals can be connected to a 9-way D-type

connector without the need to prepare the ends of the cable.

Page 25 of 44

Commuications

SENSUS Digital Data Logger -

Users Handbook

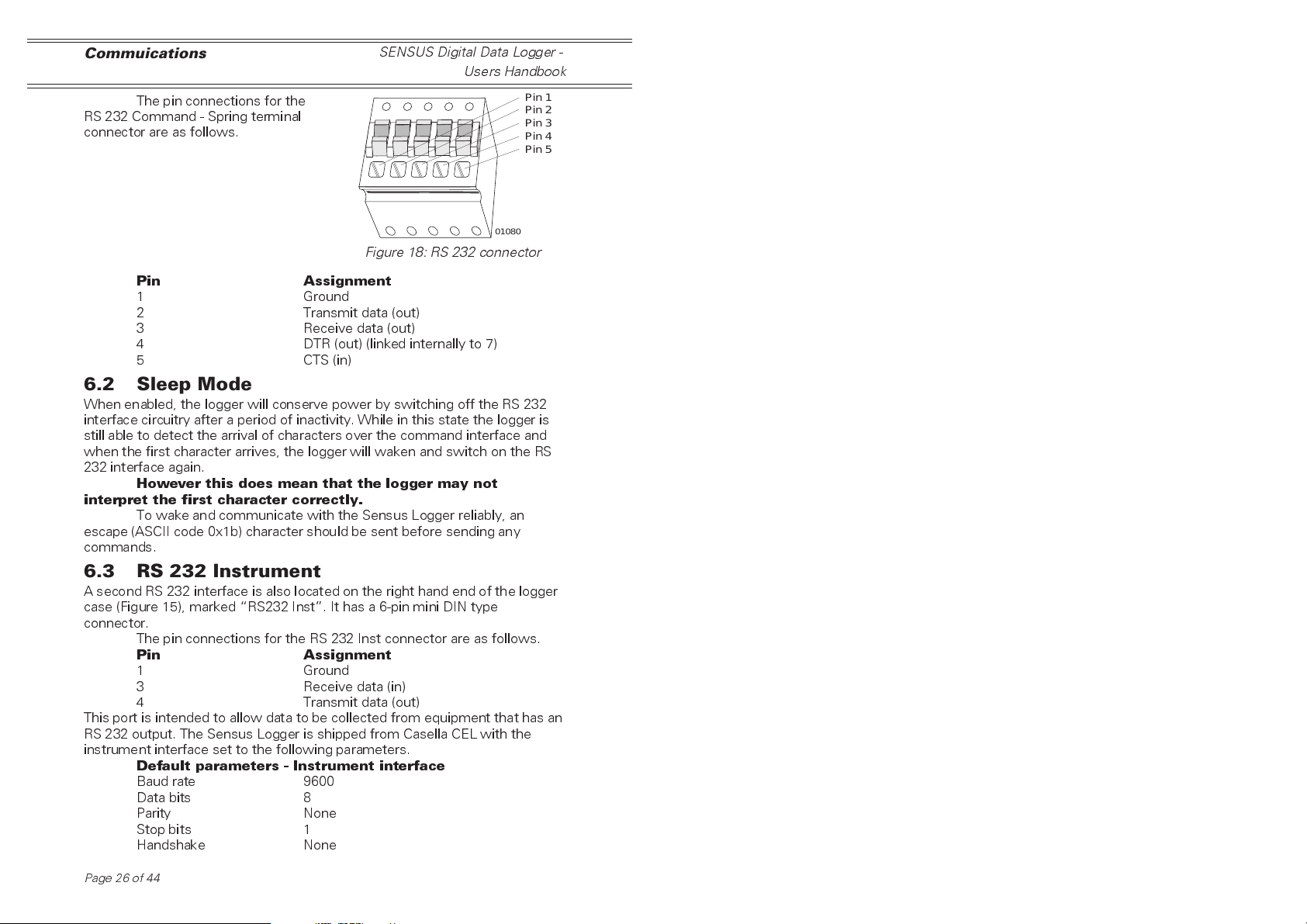

The pin connections for the

RS 232 Command - Spring terminal

connector are as follows.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

01080

Figure 18: RS 232 connector

Pin Assignment

1 Ground

2 Transmit data (out)

3 Receive data (out)

4 DTR (out) (linked internally to 7)

5 CTS (in)

6.2 Sleep Mode

When enabled, the logger will conserve power by switching off the RS 232

interface circuitry after a period of inactivity. While in this state the logger is

still able to detect the arrival of characters over the command interface and

when the first character arrives, the logger will waken and switch on the RS

232 interface again.

However this does mean that the logger may not

interpret the first character correctly.

To wake and communicate with the Sensus Logger reliably, an

escape (ASCII code 0x1b) character should be sent before sending any

commands.

6.3 RS 232 Instrument

A second RS 232 interface is also located on the right hand end of the logger

case (Figure 15), marked RS232 Inst. It has a 6-pin mini DIN type

connector.

The pin connections for the RS 232 Inst connector are as follows.

Pin Assignment

1 Ground

3 Receive data (in)

4 Transmit data (out)

This port is intended to allow data to be collected from equipment that has an

RS 232 output. The Sensus Logger is shipped from Casella CEL with the

instrument interface set to the following parameters.

Default parameters - Instrument interface

Baud rate 9600

Data bits 8

Parity None

Stop bits 1

Handshake None

Page26of44

SENSUS Digital Data Logger -

Users Handbook

All of these parameters may be changed using commands built into the

logger software interface.

Communications

6.4 RS 485 Command Alternate

The Sensus Logger also has an RS 485

interface accessible from the connector array

(Figure 19). The signals are available from a

2-way spring terminal block.

This interface can be used as an

alternate to the primary command interface

(RS232) where longer distances exist.

The pin connections for the RS 485

alternate command interface connector are as

follows.

Figure 19: RS 485 interface

Pin Assignment

1 A (-)

2 B (+)

The Sensus Logger is shipped from Casella CEL with this instrument

interface set to the following parameters.

Default parameters - RS485 alternate command interface

Baud rate 9600

Data bits 8

Parity None

Stop bits 1

Handshake None

All of these parameters may be changed using commands built into the

logger software interface.

Pin 1

Pin 2

01081

6.5 Modems

The Sensus Logger is pre-configured with a generic set of command/

response strings suitable for most Hayes-compatible modems. If the modem

used differs from this standard, these strings will need to be altered to match

the new configuration.

In addition, all command/response time-out values are also

configurable for those instances where the default values are insufficient for

the equipment used.

Page 27 of 44

CompactFlash Cards

SENSUS Digital Data Logger -

Users Handbook

7. COMPACTFLASH™ CARDS

CompactFlash memory cards are

lightweight, small form factor,

removable data storage devices

built around reliable Flash storage

technology.

The Sensus Loggers

integrated CompactFlash slot

allows its storage capacity to be

increased and in addition provides

a compact and reliable method of

transporting data from site for

analysis. The slot is located on the

right-hand side of the unit directly

above the primary RS 232 9-way D-Type port as shown in Figure 20.

The unit has been designed to recognise CompactFlash ATA cards

and treat them as IDE hard disk drives, thereby simplifying the process of

data transfer to PCs. The same card can be connected to a suitably equipped

PC and the files transferred without the need for specialist software.

The current technical specification for suitable CompactFlashTM

cards is outlined below.

Operating voltage 3.3 V DC

Temperature range -20 to +70oC

Physical size CompactFlash CF Type 1

Capacity 4 MB to 256 MB

A card can hold data from only one logger at any time, irrespective of the

capacity of the card or the amount of data it holds. When a logger writes data

to the card, it also writes an electronic signature uniquely identifying this

logger. From then on (or until the card is erased) the card can be used only

with this particular logger.

The electronic signature also identifies the logger configuration used

to create any data on the card. If the configuration has changed since the

card was last used, then the signature will not be accepted as this could

result in a misinterpretation of the stored data later on. This ensures the

integrity of the data until off-loaded to a PC.

Before use, all cards must be formatted on a suitable PC.

The logger automatically checks the type of card, signature and

configuration every time a new card is inserted. The correct orientation for

inserting the card is shown in Figure 21.

Having accepted the card as suitable for data storage, the logger

transfers any stored data to the card. In addition while the card remains

inserted all new data will be logged to the card, rather than stored internally.

The card can be removed any time the logger is not actively writing

new data to it. During these periods, the LCD shows a card busy message

and the card should not be removed.

Figure 20: The CompactFlash slot and

RS 232 Command port

Note: capacity is limited by file system,

only FAT12 and FAT16 are supported.

Page28of44

SENSUS Digital Data Logger -

Users Handbook

CompactFlash Cards

Once removed, the

card can be inserted into a

suitably equipped PC and the

data and control files copied

in exactly the same way as

any other disk drive.

Narrow Slot

Connector

Wide Slot

Figure 21: Correct orientation for

inserting a CompactFlash card

01095

Page 29 of 44

Alarms

SENSUS Digital Data Logger -

Users Handbook

8. ALARMS

The Sensus Logger includes a comprehensive set of rules that can be used

individually or in combination to detect alarm conditions. These alarm

conditions can then cause one or more actions to be taken by the logger.

These actions include an audible warning, external alarm triggering, changing

the logging rate and remote message transmission via modem and SMS.

Each of the 16 alarm channels can be programmed in isolation or

combined for greater flexibility. The following sections describe how each

parameter of these alarms work and how it can be programmed

8.1 ID Text

Each alarm can be allocated a piece of descriptive text, which gets

transmitted during remote message and SMS alarm conditions. This text can

be used to identify the particular alarm causing the transmission when more

than one alarm is active on the logger.

In addition, each remote message is also prefixed with the loggers own ID

text and ID number allowing immediate or automatic identification of the

alarm source at the receiving end.

8.2 Input Channel

Each alarm channel monitors a single input data source and processes the

value of this data against its own set of rules. The data source can be any

one of the available data channels, analog, counter or calculated. Irrespective

of channel type, the alarms work solely on its current value.

8.3 Test Mode

This describes the logical comparison to be applied by the alarm to its

selected data value. The logical result of this comparison will determine

whether the alarm condition is active or not.

The available test modes are listed below.

Alarm Test mode

Mode Result,

none Alarm always returns false,

eq Alarm true if data value equals limit value,

neq Alarm true if data value not equal to limit

value,

gt Alarm true if data value greater than limit

value,

lt Alarm true if data value less than limit

value,

lt or gt Alarm true if data value less than first

limit value or greater than second limit

value,

gt and lt Alarm true if data value greater than first

limit value and less than second limit

value.

Page30of44

SENSUS Digital Data Logger -

Users Handbook

Alarms

8.4 Limits

Each alarm channel can compare its data value to either one or two limit

values depending on the test mode selected. For test modes that require

only a single limit value, the data is compared against the first limit value

allocated to the channel. For two limits, it is compared against both.

Both the data and limit values are held in floating-point format, so

some care should be exercised when using the eq test mode as the values

may not be exactly equal (displayed values are usually truncated after a few

decimal places).

8.5 Action

Alarms can be used either in isolation or combined with others for more

complex situations. The action parameter for an alarm defines how it

interacts with the next defined alarm channel. Available action modes are

listed below.

Alarm Action Mode

Mode Result,

none Alarm is acting in isolation,

or Alarm result should be logically ord with

the result of the next defined alarm,

and Alarm result should be logically andd

with the result of the next defined alarm.

Any single alarm, or the last alarm in a logical chain, should have its

action mode set to none. Only those alarms with an action mode none will

actually trigger an alarm event.

8.6 On/Off Delays

The resultant alarm condition can be filtered with respect to time by defining

on/off delays for the alarm channel. These delays are expressed in seconds

and can be set to any value between 0 and 65535 (approximately 18 hours).

A value of zero means the change of alarm condition will be

processed immediately it occurs. Any other value means the alarm condition

must remain steady in that state for the specified period of time before the

change of condition is processed. Any change of alarm condition within the

specified time period will cause the delay time to be counted again.

8.7 On/Off Values

Each alarm channel can be allocated a pair of data values that it can pass on

to a data channel whenever the alarm changes state. This allows alarm states

to be logged, displayed, used to control the actions of other alarms and affect

the processing of other data values.

8.8 Output Channel

This defines the data channel into which the on/off values are to be written

when the alarm changes state. This should be the channel number of a

passive type channel, as all other channel types automatically collect their

data values during the scan process. To disable this feature, refer to the

section on alarm flags.

Page 31 of 44

Alarms

SENSUS Digital Data Logger -

Users Handbook

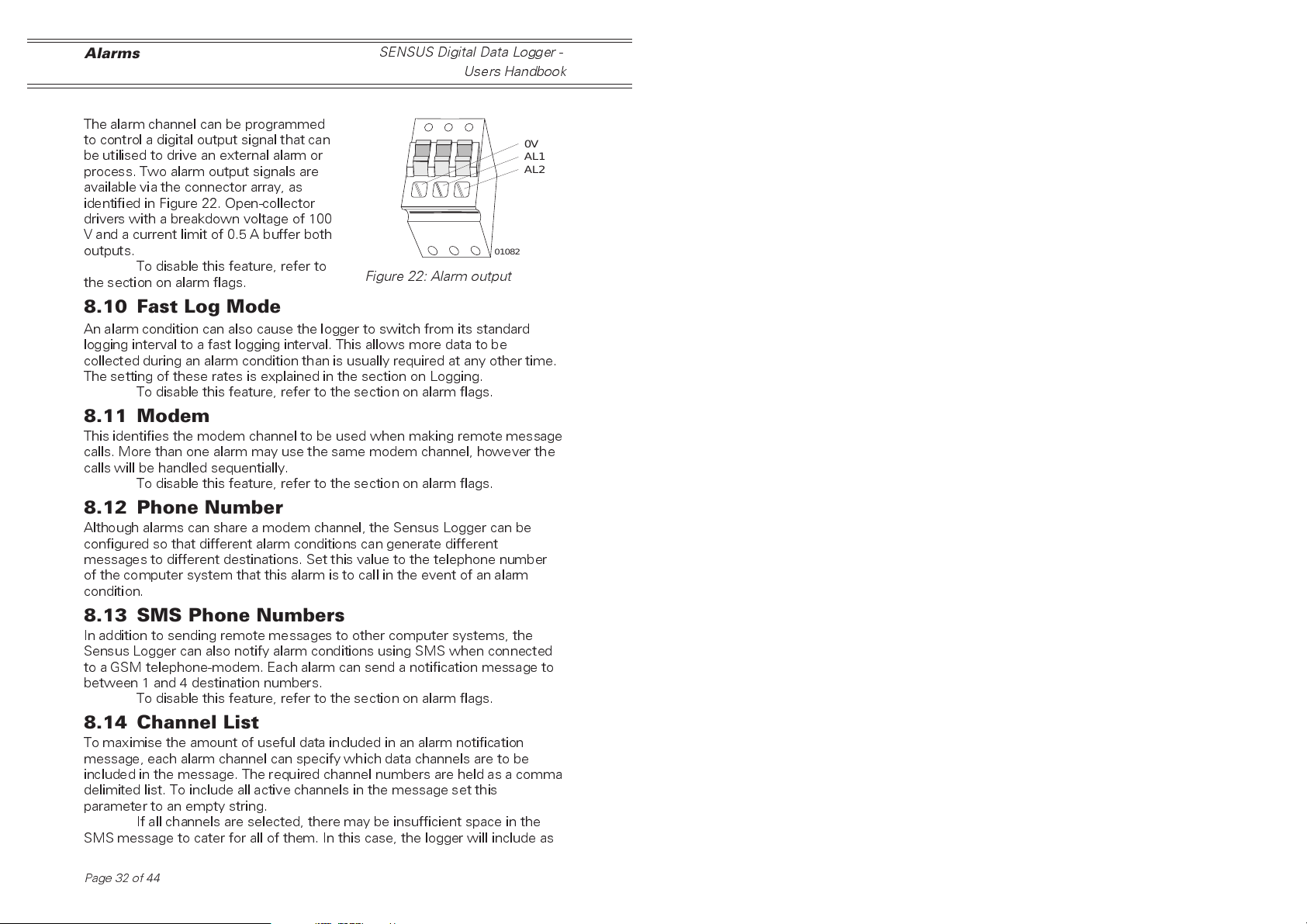

8.9 Digital Output

The alarm channel can be programmed

to control a digital output signal that can

be utilised to drive an external alarm or

process. Two alarm output signals are

available via the connector array, as

identified in Figure 22. Open-collector

drivers with a breakdown voltage of 100

V and a current limit of 0.5 A buffer both

outputs.

To disable this feature, refer to

the section on alarm flags.

Figure 22: Alarm output

0V

AL1

AL2

01082

8.10 Fast Log Mode

An alarm condition can also cause the logger to switch from its standard

logging interval to a fast logging interval. This allows more data to be

collected during an alarm condition than is usually required at any other time.

The setting of these rates is explained in the section on Logging.

To disable this feature, refer to the section on alarm flags.

8.11 Modem

This identifies the modem channel to be used when making remote message

calls. More than one alarm may use the same modem channel, however the

calls will be handled sequentially.

To disable this feature, refer to the section on alarm flags.

8.12 Phone Number

Although alarms can share a modem channel, the Sensus Logger can be

configured so that different alarm conditions can generate different

messages to different destinations. Set this value to the telephone number

of the computer system that this alarm is to call in the event of an alarm

condition.

8.13 SMS Phone Numbers

In addition to sending remote messages to other computer systems, the

Sensus Logger can also notify alarm conditions using SMS when connected

to a GSM telephone-modem. Each alarm can send a notification message to

between 1 and 4 destination numbers.

To disable this feature, refer to the section on alarm flags.

8.14 Channel List

To maximise the amount of useful data included in an alarm notification

message, each alarm channel can specify which data channels are to be

included in the message. The required channel numbers are held as a comma

delimited list. To include all active channels in the message set this

parameter to an empty string.

If all channels are selected, there may be insufficient space in the

SMS message to cater for all of them. In this case, the logger will include as

Page32of44

SENSUS Digital Data Logger -

Users Handbook

many as it can in the available space and ignore the rest. Data values are

formatted according to the pre-set display format string. To maximise the

number of channels included in the message, the display format should be

set with the minimum number of decimal places required to display the data

values correctly.

Alarms

8.15 Alarm Flags

Rather than removing the details associated with unused alarm options, each

option can be individually enabled/disabled using the relevant alarm flag. If an

option does not appear to be working, then check that the relevant flag has

been enabled before checking other settings.

Page 33 of 44

Analog Output

9. ANALOG OUTPUT

The Sensus Logger provides two analog

signals derived from internal PWM (pulse

width modulation) circuitry. These signals

can be accessed from the connector array as

shown in Figure 22.

These PWM outputs directly mimic

the value contained in a specified data

channel. As the data value changes, the

PWM output also changes to match it.

The following points should be

noted about these PWM outputs.

¤

The data value is interpreted as meaning volts, that is a data value of

0.5 will generate a voltage of 0.5 V.

¤

Only a positive signal can be generated by the PWM circuitry and

this is limited to between 0 and 5 V.

Data values below zero will be limited to zero and those above 5 will

be limited to 5 V.

¤

The resolution of the PWM output is fixed at 10-bits (0 to 1023)

giving a voltage resolution of 4.88 mV.

¤

While the PWM outputs are updated every 50 ms, the data channel

it mimics is updated at most only once a second.

¤

Excessive loading of the PWM output may result in reduced

amplitude and possibly oscillation.

Depending on the length of cable, an external buffer may be required.

SENSUS Digital Data Logger -

Users Handbook

0V

A1

A2

01092

Figure 23: The PWM

connector

Page34of44

SENSUS Digital Data Logger -

Users Handbook

Integrated Sensors

10. INTEGRATED SENSORS

The Sensus has the capacity to house two integrated sensors within the

logger case. Temperature measurement is installed as standard and

barometric pressure is available as an option.

10.1 Temperature

The temperature sensor is integrated into the design of the logger circuit

board and therefore is available at all times. The value from this sensor is

read every 10 seconds and held within the loggers parameter space for use

by the system.

The current value can be read from the System information status

screen on the LCD.

This value can also be accessed for logging and alarm comparison by

defining a parameter type data channel, then setting the input channel

number to point to the associated parameter number, in this case parameter

number 59.

The temperature is presented as degrees Celsius but by assigning a

different polynomial to the data channel the final readings can be set to other

measurement scales, see below.

Temperature Polynomials

Scale required Polynomial (C,M)

Degrees Celsius 0,1

Degrees Fahrenheit 32,1.8

Degrees Kelvin 273.15,0

10.2 Barometric Pressure

The optional barometric pressure sensor and its associated circuitry are

housed on a small PCB which can be installed piggy-back fashion on the

loggers main PCB within the loggers case (Figure 24).

When installed the signal

from the sensor replaces any

signal fed into analog channel

+A1. The corresponding negative

input -A1 is still available and can

be used for another single-ended

input source.

Once installed analog

channel +A1 can be switched

between the pressure signal and

any signal fed in on pin +A1 of

the connector array by moving

the position of a link (PL2) on the

loggers main PCB.

Figure 23 shows the

location of this link on the main

PCB. The PL2 link settings are

detailed below.

Barometer Circuit

Figure 24: Location of pressure PCB

PL2 Link

Page 35 of 44

Integrated Sensors

SENSUS Digital Data Logger -

Users Handbook

Jumper position Signal available on

analog channel +A1

Pins 1 - 2 (jumper to left) Barometric pressure

Pins 2 - 3 (jumper to right) Analog input +A1

By using a link to select the signal source for analog channel +A1,

the analog input can be reclaimed for an external signal without the need to

remove the barometric pressure sensor assembly.

The output from the pressure sensor is scaled at 1 mV per mbar.

Therefore in order to scale the data channel to show mbar, a polynomial of

0,1000 needs to be assigned (this scales the default reading of Volts to mbar).

Page36of44

SENSUS Digital Data Logger -

Users Handbook

11. POWER SUPPLIES

11.1 Solar Power

The Sensus Logger incorporates a solar

power regulator as standard. This

regulator is designed to operate in

conjunction with a nominal 12 V (30 W)

panel with a short circuit current of no

more than 2 A.

The solar panel should be wired

to the connector identified in Figure 25.

The pin assignments for the

solar panel connector are as follows.

Pin Assignment

1 Solar panel negative terminal,

2 Solar panel positive terminal.

11.2 Battery

The Sensus Logger incorporates a 12 V

lead-acid battery charger as standard.

This charger is designed to operate in

conjunction with a nominal 12 V lead-acid

battery and supplies a maximum charge

current of 0.5 A.

The lead-acid battery should be

wired to the connector identified in

Figure 26.

The pin assignments for the 12

V lead-acid battery connector are as

follows.

Pin Assignment

1 Battery negative terminal,

2 Battery positive terminal.

Power Supplies

Pin 1

Pin 2

01081

Figure 25: Solar power connector

Pin 1

Pin 2

01081

Figure 26: Battery connector

Page 37 of 44

Servicing

SENSUS Digital Data Logger -

Users Handbook

12. SERVICING

Casella CELs in house service department offers a comprehensive range of

repair and calibration services, designed to effect a fast and efficient back-up

for all our products. The Service Department is operated under the scope of

our BSI registration for products manufactured by us. We will however,

undertake the repair of other manufacturers equipment. For further

information please contact our service department at our Bedford

headquarters. We will be happy to provide quotations for individual repairs or

provide annual maintenance under contract.

We recommend factory service by technicians trained and equipped

to repair your instrumentation. Should you wish factory repair assistance,

send your equipment in a package equivalent to the original packaging. Insure

to full value and ship pre-paid. Include a letter giving full details with your

packing list.

Send to: Casella CEL Ltd

(Service Department)

Regent House

Wolseley Road

Kempston

Beds MK42 7JY

United Kingdom

For service outside the United Kingdom, please return to our appointed

distributor.

Page38of44

SENSUS Digital Data Logger -

Users Handbook

13. SPECIFICATION

13.1 Channel Information

Analog Channels:

12 differential analogue channels, each programmable as 2

independent single-ended channels, to give 12/24 from the main

connector panel.

4 differential analogue channels, each programmable as 2

independent single-ended channels, to give 4/8 from the expansion

port.

Numbers of differential and single-ended channels can be freely

mixed, up to the maximum number of channels available (16/32)

Input voltage ranges (measured resolution):

±2.5 V (±150 µV)

±250 mV (±24 µV)

±25 mV (±15 µV)

16-bit analogue to digital converter approx 20 ms per sample.

Switched (multiplexed) 13.8 V supply for sensor excitation.

Switched (multiplexed) 200 µA current source for sensor excitation.

Resistance measurements up to 12 kΩ. Suitable for 100 R PRTD

temperature sensors to 0.1% resolution.

Thermocouple interface under development.

Counter channels:

4 counter channels.

2 high speed and 2 medium speed.

Each channel can measure either accumulated count or frequency.

Input range:

Pulse count: 32-bit count, over scan period, logging

period or 24 hours.

Frequency: In excess of 100 kHz (high speed counter),

3 kHz (medium speed).

Inputs are 5 V logic compatible into Schmitt buffers (for slow edged

signals).

Medium speed counters continue to function when logger is in

power save (sleep) mode, high speed counters only function when

logger in full power mode.

Digital Channels:

Available via analogue channels (number of channels determined by

available analogue channels)

Specification

Page 39 of 44

Specification

Programmable threshold

Programmable data value (0/1, -1/+l)

SENSUS Digital Data Logger -

Users Handbook

Instrument Channel:

The unit has a single channel available to accept digital data

(via RS-232) from external instruments, including CEL sound level

meters. (Other instruments on request, development fee).

Passive Channels:

Software derived channels, which hold values entered via the user

command interface.

Can record manual readings and values from external automated

equipment.

Note: The number of passive channels available depends on the number of

unassigned data channels.

Data Channels:

64 data channels under software control to read:

Analogue

Digital

Pulse counter

Frequency

Instrument

Passive

Other data channels

Alarms

Data channels allow further manipulation of the available data before

it is logged or displayed. Each channel includes:

Description (Free text, Air temperature)

Units (Free text, Degrees C)

Display format (How the number is represented) Signed, fixed width,

leading zeros.

Eight-term polynomial (For scale, offset and linearisation of raw data)

Y = C + M1 *X + M2*X^2 ...+ M7*X^7

Data process function: including minimum hold, maximum hold,

average, vector average.

Analog Outputs:

2 analogue outputs derived from PWM (pulse width modulation)

signals. Any of the data channels can act as a source for the output

value.

Output voltage (0 to 5 V)

Resolution (10-bit : 1 in 1024)

Update period (50 mS)

Page40of44

SENSUS Digital Data Logger -

Users Handbook

Alarm Output Channels:

4 alarm output channels

2 available from the main connector panel 2 via expansion port

Primary channels (main connector):

These have open-collector outputs, suitable to drive relays on external

equipment.

Secondary channels (expansion port):

These are 5 V logic outputs, which require additional buffering

between them and any external equipment.

Alarm Channels:

16 alarm channels, each of which is capable of activating any of the

alarm output channels.

Each alarm channel can be programmed to act individually or in

combination with other alarms to cater for complex alarm conditions.

Each channel includes:

Identity

conditions) Sounder (used to notify alarm condition) Test mode

(Identifies the type of comparison to make)

EQ data equal to limit value

NEQ data not equal to limit value

GT data greater than limit value

LT data less than limit value

LT or GT data less than first limit or greater than

GT and LT data greater than first limit and less than

Action

NONE alarm is independent from any others

OR alarm result is ord with result of

AND alarm result is anded with result of

Fast mode

data logging rates, in the presence of an alarm condition.

State delays

allocated to it, thereby no action is taken until the alarm state has

been steady for the specified time.

Data values

get transferred to a specified data channel when the alarms state

changes.

(Free text, used when notifying external equipment of alarm

(Identifies how alarms interact)

alarm can trigger a change in both the channel scan and

where each change of alarm state can have a delay

that can be assigned for alarm-on and alarm-off; these

Specification

second limit value

second limit

next alarm

next alarm

Page 41 of 44

Specification

The condition of alarm can then be tied into further processing.

Modem

where each channel can initiate a dial-out via an attached

modem, each time the alarm becomes true.

Communication Channels:

The unit has the following communication options:

RS-232 (2 channels) Instrument interface (1 off)

Command interface (1 off)

RS-485 (1 channel) Command interface

13.2 Display and Keypad

2 line x 20 alpha-numeric display, allows status readout, operated

via 4 button keypad.

Only certain controller aspects of the unit can be interrogated via

this interface. The unit cannot be programmed from the keypad.

13.3 General

On-board clock-calendar with accuracy better than 1 minute per

month.

Code upgrade-in-the-field via RS-232 based Flash memory interface.

Operating Temperature -25 to 70oC, non condensing.

Current consumption 21 mA (normal), 5.5 mA (standby).

In-built solar panel regulator and lead-acid battery charger; requires

panel and battery.

Transient suppression and EMC filtering included.

Remote access menu interface for user interaction/configuration.

Remote access command line interface for rapid (automatic)

configuration

Integrated Sensors:

The logger has provision to measure both temperature and

barometric pressure from sensors integrated on to the main PCB.

Remote Control

IrDA port for future developments.

RS 485 instrument network (up to 5 km).

Logging Capacity - Internal

512 kB of Flash storage

SENSUS Digital Data Logger -

Users Handbook

Capacity

(kB)

512 7 1 14980 10 days

512 7 60 14980 624 days

512 24 60 5090 212 days

Page42of44

Number of

channels

Interval

(Minutes)

Data sets Duration

SENSUS Digital Data Logger -

Users Handbook

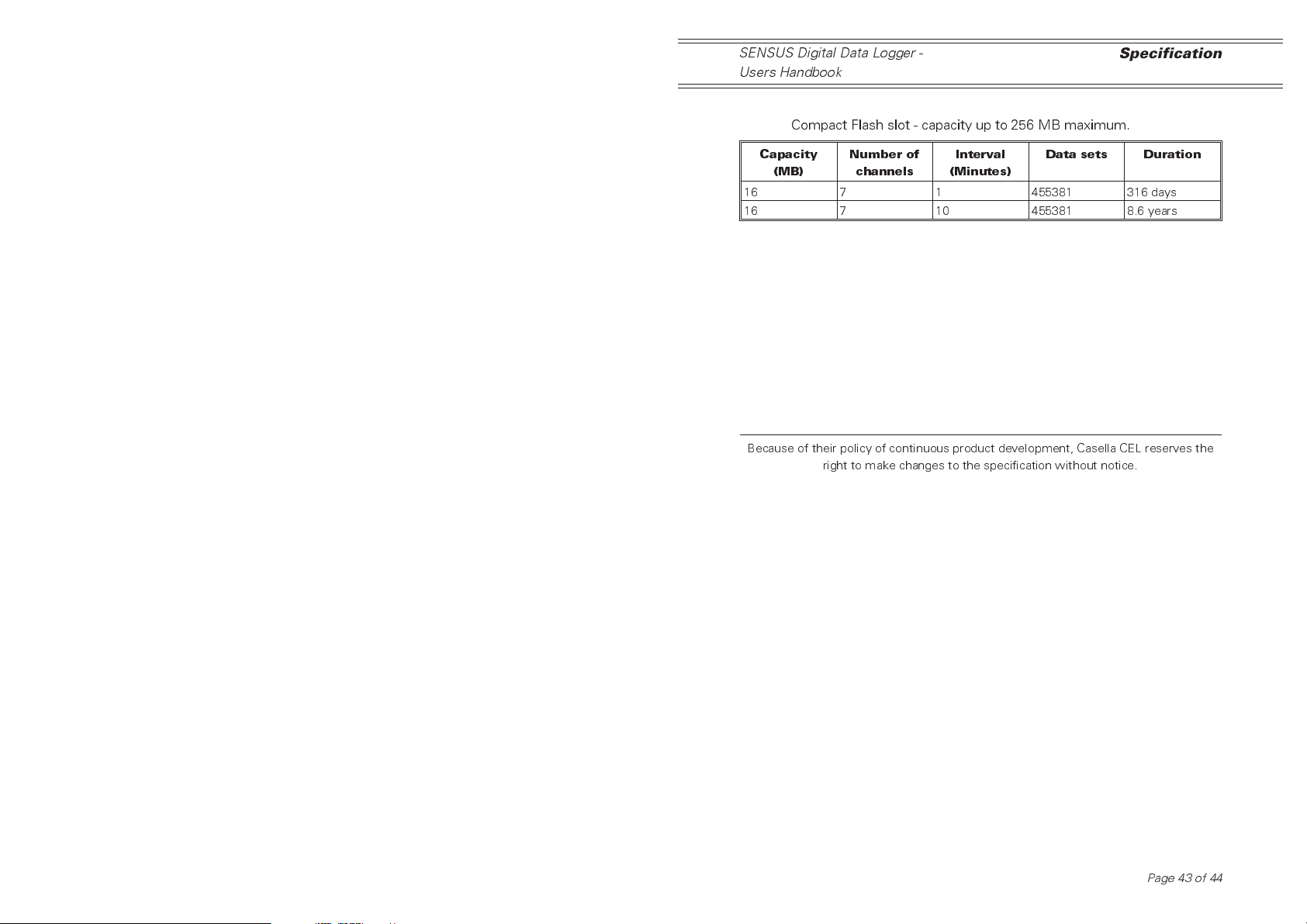

Logging Capacity - External:

Compact Flash slot - capacity up to 256 MB maximum.

Specification

Capacity

(MB)

16 7 1 455381 316 days

16 7 10 455381 8.6 years

Because of their policy of continuous product development, Casella CEL reserves the

Number of

channels

right to make changes to the specification without notice.

Interval

(Minutes)

Data sets Duration

Page 43 of 44

Specification

SENSUS Digital Data Logger -

Users Handbook

Page44of44

Loading...

Loading...